Sony XCG-CG160,XCG-CG160C,XCG-CG510C,XCG-CG510,XCG-CG240,XCG-CG240C Technical Manual

Digital Video

Camera Module

C-283-100-12 (1)

Technical Manual

XCG-CG160/CG160C

XCG-CG240/CG240C

XCG-CG510/CG510C

© 2015 Sony Corporation

Table of Contents

Overview

Features ...................................................................3

Phenomena Specific to Image Sensors .................4

System Components ...............................................5

Connection ..............................................................6

Location and Function of Parts and

Operation ................................................................7

Front/Top/Bottom ...............................................7

Using a tripod .....................................................7

Rear .....................................................................8

Connecting the cables .........................................8

When mounting the camera ................................9

Connections

Network Settings ..................................................10

Using Persistent IP ............................................10

Using DHCP .....................................................10

Using LLA ........................................................10

Packet Size ........................................................10

Packet Delay .....................................................10

Network connection speed ...................................11

Trigger Signal Input ............................................12

Trigger signal polarity ......................................12

GPIO Connector ..................................................13

Functions

Partial Scan ..........................................................15

Binning (XCG-CG160 only) ................................15

Drive mode ............................................................16

Multi ROI (XCG-CG160/CG160C only) ...........17

Output format ......................................................18

Image flip (Same level as output format) ...........20

Gain .......................................................................20

Manual gain ......................................................20

Auto gain (AGC) ..............................................20

Area gain ...........................................................21

Shutter (Exposure) ...............................................21

Configuring the setting .....................................21

Auto exposure (AE) ..........................................22

Combination of Continuous AGC and Continuous

AE ..........................................................................22

Trigger Control ....................................................23

Free run/trigger mode / PTP (IEEE1588) .........23

Special trigger ...................................................26

Burst trigger ......................................................27

FreeSetSequence ...............................................28

Trigger source ...................................................30

Trigger inhibition ..............................................30

Trigger delay .....................................................30

Trigger counter .................................................30

Trigger range limit ............................................31

Frame Rate ........................................................... 32

Auto frame rate ................................................ 32

Specifying frame rate ....................................... 32

Displaying frame rate ....................................... 32

Fastest frame rate for partial scanning ............. 33

Frame counter ...................................................... 35

Timing Chart ....................................................... 35

Trigger latency/Exposure time ......................... 35

Trigger Overlap ................................................ 36

Memory shot .................................................... 36

White Balance ...................................................... 38

LUT ....................................................................... 38

Binarization ...................................................... 38

5-point interpolation ......................................... 38

Arbitrary setting ............................................... 39

Save LUT ......................................................... 39

Color Matrix Conversion .................................... 39

3 × 3 filter ............................................................. 40

Test Chart Output ............................................... 40

GPIO ..................................................................... 41

GPI ................................................................... 41

GPO .................................................................. 41

Status LED ........................................................... 43

Temperature Readout Function ......................... 43

Defect Correction ................................................. 43

Shading Correction ............................................. 44

User Set .................................................................46

User set memory .............................................. 46

User ID .................................................................. 46

Saving and Startup .............................................. 46

Camera Information ........................................... 46

Restart .................................................................. 46

Command List ..................................................... 47

Specifications

Specifications ........................................................ 56

Spectral Sensitivity Characteristics (Typical

Values) .................................................................. 58

Dimensions ........................................................... 59

2

Overview

Before operating the unit, please read this manual

thoroughly and retain for future reference.

• Output: 8/10/12-bit, RGB 24-bit, YUV 24-bit

(YUV444), or YUV 16-bit (YUV422)

• Pixel defect correction function

• Shading correction function

• Area gain function

This unit is a digital video camera module that adopts

the 1000BASE-T/100BASE-TX interface.

This operating instruction of the digital video camera

module covers:

• XCG-CG160/CG240/CG510 (monochrome models)

• XCG-CG160C/CG240C/CG510C (color models)

In this document, we refer to “Digital Video Camera

Module” as “the unit”, “XCG-CG160/CG240/CG510”

as “Monochrome camera”, and “XCG-CG160C/

CG240C/CG510C” as “Color camera”.

Features

GigE Vision compliant

This unit supports GigE Vision Ver.2.0/Ver.1.2, and the

versions are switchable by changing the settings.

IEEE1588 compliant

This precision clock synchronization via network

protocol conforms to the defined IEEE1588 standard.

This unit can synchronize the exposures of multiple

cameras via an Ethernet cable.

External trigger shutter function

By synchronizing with an external trigger signal, any

shutter timing can be used.

Partial scan

The camera module can limit the number of video

output lines to achieve high frame rates, enabling highspeed image processing.

Body fixing

The screw holes to install the camera module are located

under the front panel (the image sensor reference plane).

Installing the camera module on the front panel

minimizes deviation of the optical axis.

LUT (Look Up Table)

You can switch to OFF or ON. When set to ON, you can

select from five preset values, such as inversion,

binarization, settable five-point approximations, etc.

Switching an Output Bit Length

You can select 8-bit output, 10-bit output, or 12-bit

output.

For color models, you can also select an output of RGB

24-bit, YUV 24-bit (YUV444), or YUV 16-bit

(YUV422).

High image quality

This unit produces stable output images, by adopting the

latest CMOS image sensors with a global shutter

function.

By adopting the square pixel image sensor, images can

be processed using the original aspect ratio without a

converting procedure.

The following models and resolutions of their image

sensors are shown below.

Model name Pixel number

XCG-CG160/CG160C 1,580,000-pixel

XCG-CG240/CG240C 2,350,000-pixel

XCG-CG510/CG510C 5,070,000-pixel

Various settings

Sending a command from the host device allows various

settings, including the following.

•Gain

•Shutter

• Partial scan

• Trigger control

• LUT (Look Up Table)

White balance control (color camera

only)

You can adjust the R and B level against G level to adjust

the white balance. This unit is also equipped with the

one-push white balance function, by which the camera

can automatically adjust the white balance.

Area gain function

You can set the gains between 0 to 32 times for a

preference position (up to 16 positions). If the set area is

duplicated, the low-numbered area takes priority.

Equipped with temperature sensor

This unit can readout the temperature inside of the

camera from the temperature sensor installed on the

module board. If the update interval of the temperature

sensor value is set to other than 0, the temperature

information can be sent to a PC application as event

data.

Defect correction function

This unit is equipped with the function that reduces the

sensor defect, and it can be switched On/Off.

3

Shading correction function

This unit is equipped with the function that corrects the

shadings caused by a light source and lens, and it can be

switched On/Off.

Phenomena Specific to Image Sensors

Binning function (XCG-CG160 only)

Adding 2 pixels in the vertical and horizontal directions

achieves higher sensitivity and frame rate.

Note

The following phenomena that may occur in images are

specific to image sensors.

They do not indicate a malfunction.

White flecks

Although the image sensors are produced with highprecision technologies, fine white flecks may be

generated on the screen in rare cases, caused by cosmic

rays, etc.

This is related to the principle of image sensors and is

not a malfunction.

The white flecks especially tend to be seen in the

following cases:

• when operating at a high environmental temperature

• when you have raised the gain (sensitivity)

• when using the slow shutter

Aliasing

When fine patterns, stripes, or lines are shot, they may

appear jagged or flicker.

4

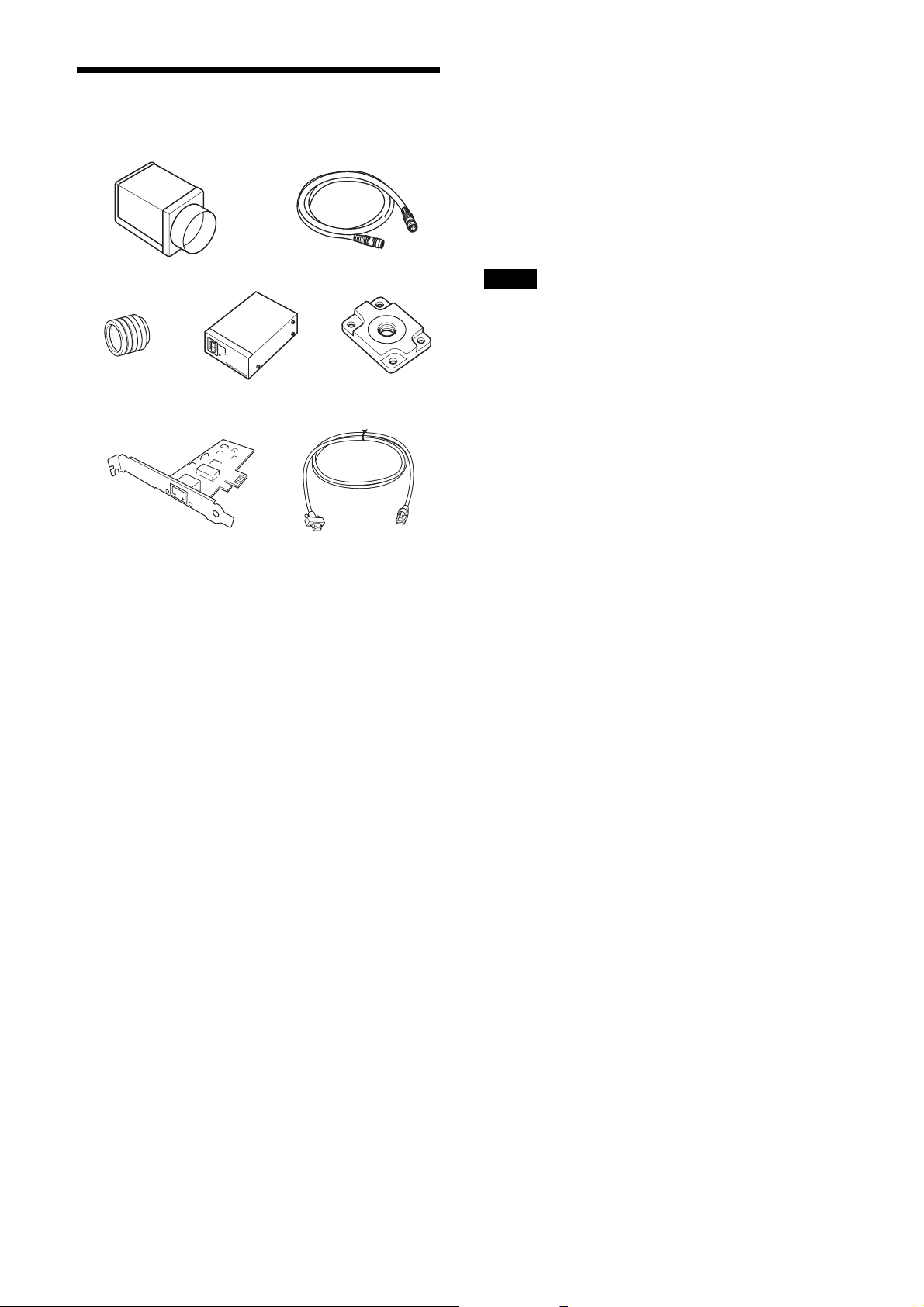

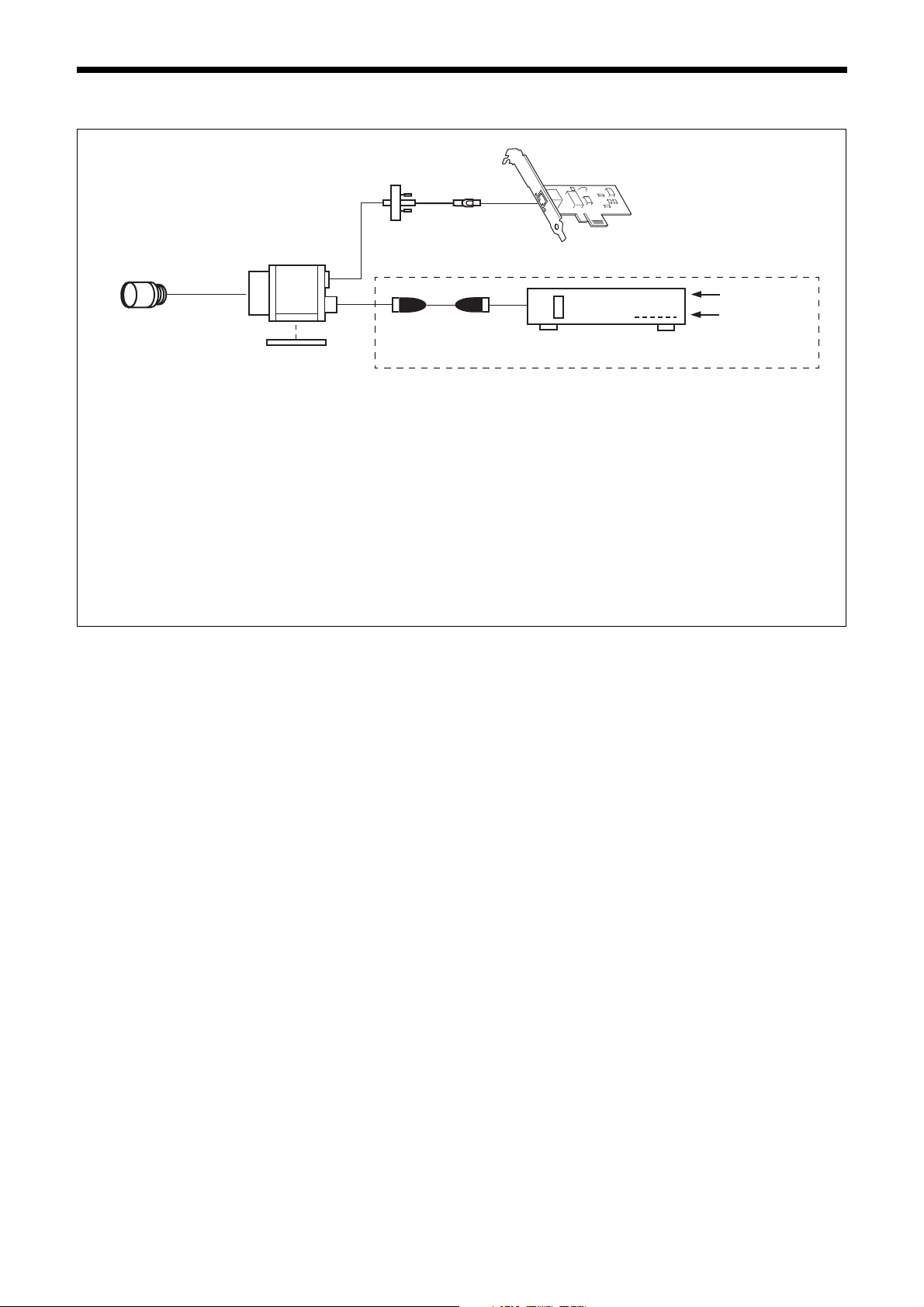

System Components

a

cd e

fg

b

g LAN cable

This cable connects to the RJ45 connector on the rear

panel of the camera module.

Image/control signals are transmitted via this cable. Use

a LAN cable (CAT5e or higher standard) that supports

1000BASE-T (or allows 100BASE-TX when it is used).

Depending on the attributes of the LAN cable, images

may become less clear and the camera module may

become unstable. Be sure to use a LAN cable that has

sufficient noise reduction.

Note

When you connect the LAN cable of the unit to

peripheral device, use a shielded-type cable to prevent

malfunction due to radiation noise.

The video camera module system comprises the

following optional products (available separately).

a Video Camera Module

This is a small-size, high image-quality video camera

module that uses CMOS image sensors with a global

shutter function.

b Camera cable

This is attached to the DC IN connector of the camera

module and is used for power supply and exchange of

trigger signals.

For purchasing the cable, consult the dealer.

c C-mount lens

Use a suitable lens to fit the camera pixel count.

d DC-700/700CE camera adaptor

This is connected to the camera module to enable power

supply from ordinary AC power source.

e VCT-333I tripod adaptor

This attaches to the bottom of the camera module to fix

the camera module to a tripod.

f Camera module interface board

Install the board in the expansion slot of the host device

(ex: computer). Use a board that is appropriate for your

system and that supports 1000BASE-T (or allows

100BASE-TX when it is used) and jumbo packets.

5

Connection

LAN cable

Camera module

C-mount lens

Camera cable

Tripod adaptor

VCT-333I

Power supply

You can supply power to the camera module using the following methods.

Using the RJ45 connector

This unit supports PoE (IEEE802.3af standard). By using a PoE-compatible LAN cable and camera module interface board or hub,

you can power, control, and output images from the camera using one LAN cable.

Using the DC IN connector

You can supply power via the DC IN connector using the power adapter.

Use DC-700/700CE which is the stable power source free from ripple or noise.

If the HUB supports PoE, the items within the dashed line are not necessary.

Camera module interface board

AC

TRIG

Camera adaptor

DC-700/700CE

Heat dissipation

For heat dissipation, refer to When mounting the camera (see page 9).

6

Location and Function of Parts and Operation

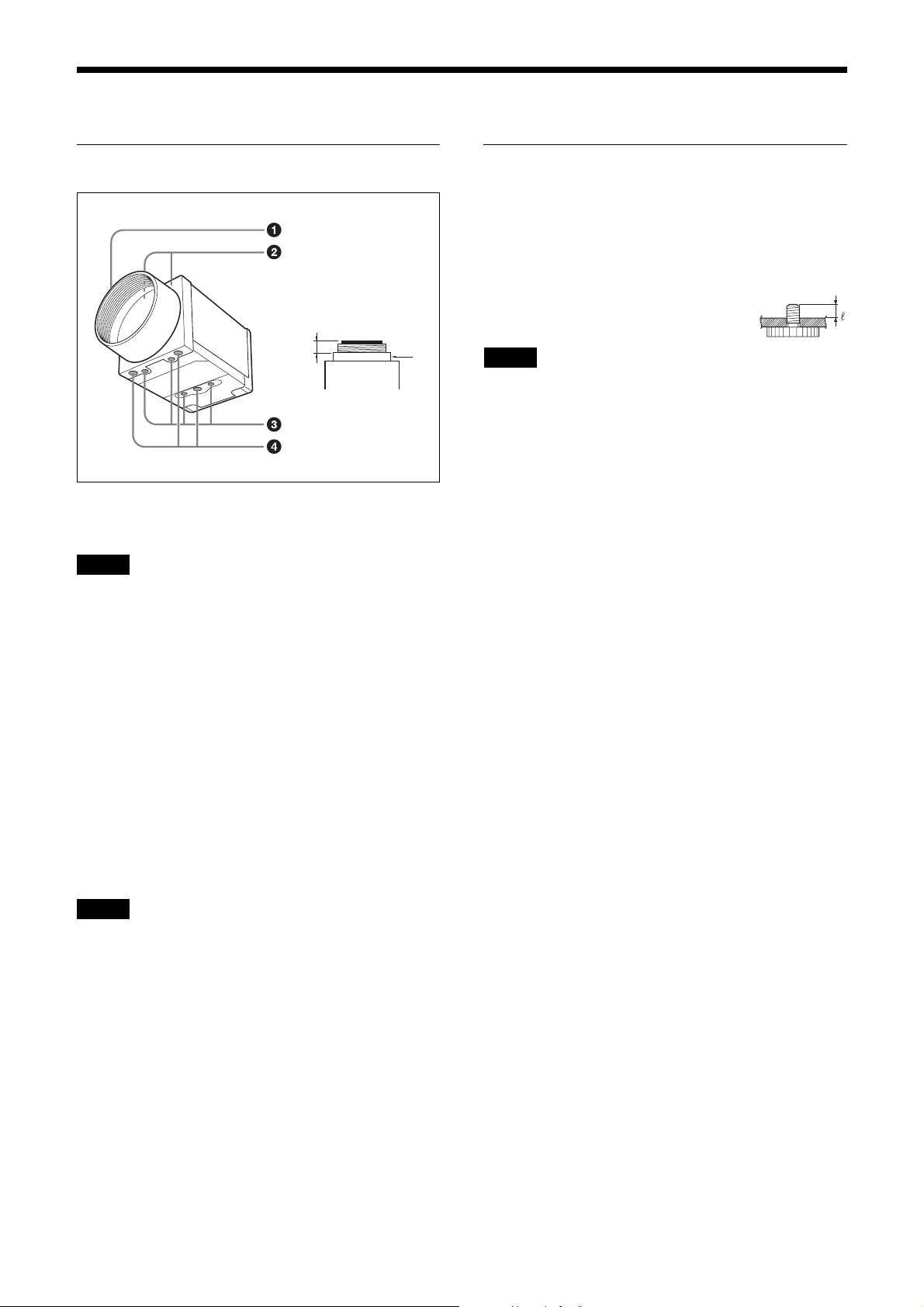

Front/Top/Bottom

a

a Lens mount (C-mount)

Attach any C-mount lens or other optical equipment.

Note

Use a C-mount lens with a protrusion (a) extending from

the lens mount face (b) of 10 mm (13/32 inch) or less.

The performance of a lens may change according to the

aperture level.

If the resolution is not enough, adjust the aperture level.

b

Using a tripod

To use the tripod, install the tripod adaptor VCT-333I

(not supplied) on the camera module.

Use a tripod screw with a protrusion (4) extending from

the installation surface, as follows, and tighten it, using

a screwdriver. Be sure that the protrusion (4) does not

exceed 5.5 mm (0.2 in.) in length.

Length 4.5 to 5.5 mm

Length 0.18 to 0.22 inches

Note

If you install a tripod adapter (not supplied), use the

screws provided.

b Guide screw holes (Top)

c Guide screw holes/Tripod screw holes (bottom)

When using a tripod, use these four screw holes to attach

a VCT-333I tripod adaptor.

d Reference screw holes (bottom)

These precision screw holes are for locking the camera

module. Locking the camera module into these holes

secures the optical axis alignment.

Note

Refer to XCG-CG240 Demensions in page 59 for about

the position/size of the Guide hole and the Reference

hole.

7

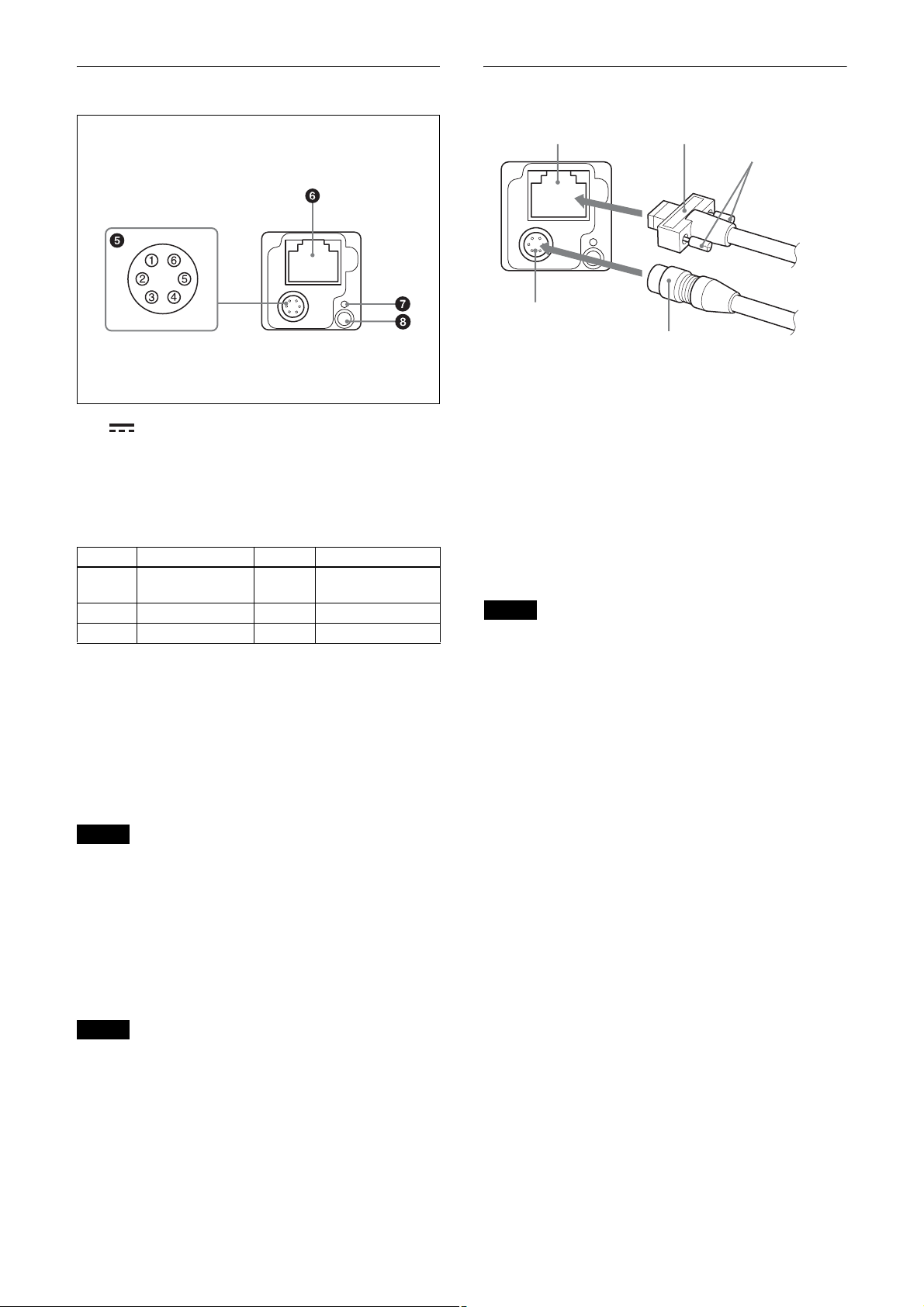

Rear

Connecting the cables

e (DC power input) connector (6-pin)

You can connect a camera cable to input the +12 V DC

power supply. The pin configuration of this connector is

as follows.

(Refer to Fig.

6 above for the pin assignment of the

connector.)

Pin No. Signal Pin No. Signal

1 DC input (10.5 V

to 15 V)

2 GPI1 (ISO +) 5 ISO –

3 GPI2/GPO2 6 GND

4 GPI3/GPO3

(GPO3 (ISO +)*)

*XCG-CG160/CG160C only

Connect the camera cable (5) to the DC IN connector

(2) and connect the LAN cable (3) to the RJ45

connector (1) respectively. If you use a camera module

interface board or a hub that supports PoE, you can

operate the camera even if you do not connect the

camera cable to the DC IN connector. When you connect

the LAN cable with fastening screws, turn the two

screws (4) on the connector to secure the cable tightly.

Connect the other end of the camera cable to the DC700/700CE and the other end of the LAN cable to the

camera module interface board or a hub.

Note

Do not supply power to the camera cable and LAN cable

at the same time.

f RJ45 connector

You can connect a LAN cable to this connector to

control the camera module from a host device to output

image to a host device. By using a PoE-compatible LAN

cable and camera module interface board or hub, you

can supply power using the LAN cable.

Note

For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to this

port. Follow the instructions for this port.

g Reset switch

The camera can be reset to the factory setting by

pressing the reset switch for more than 3 seconds while

the power is turned on.

Notes

• All the setting items will be deleted.

• Formatting is performed after operation.

Do not turn off the power for 1 minute after the LED

lights again.

h Status LED (Green)

Displays the unit status.

For details, see “Status LED” (page 43).

8

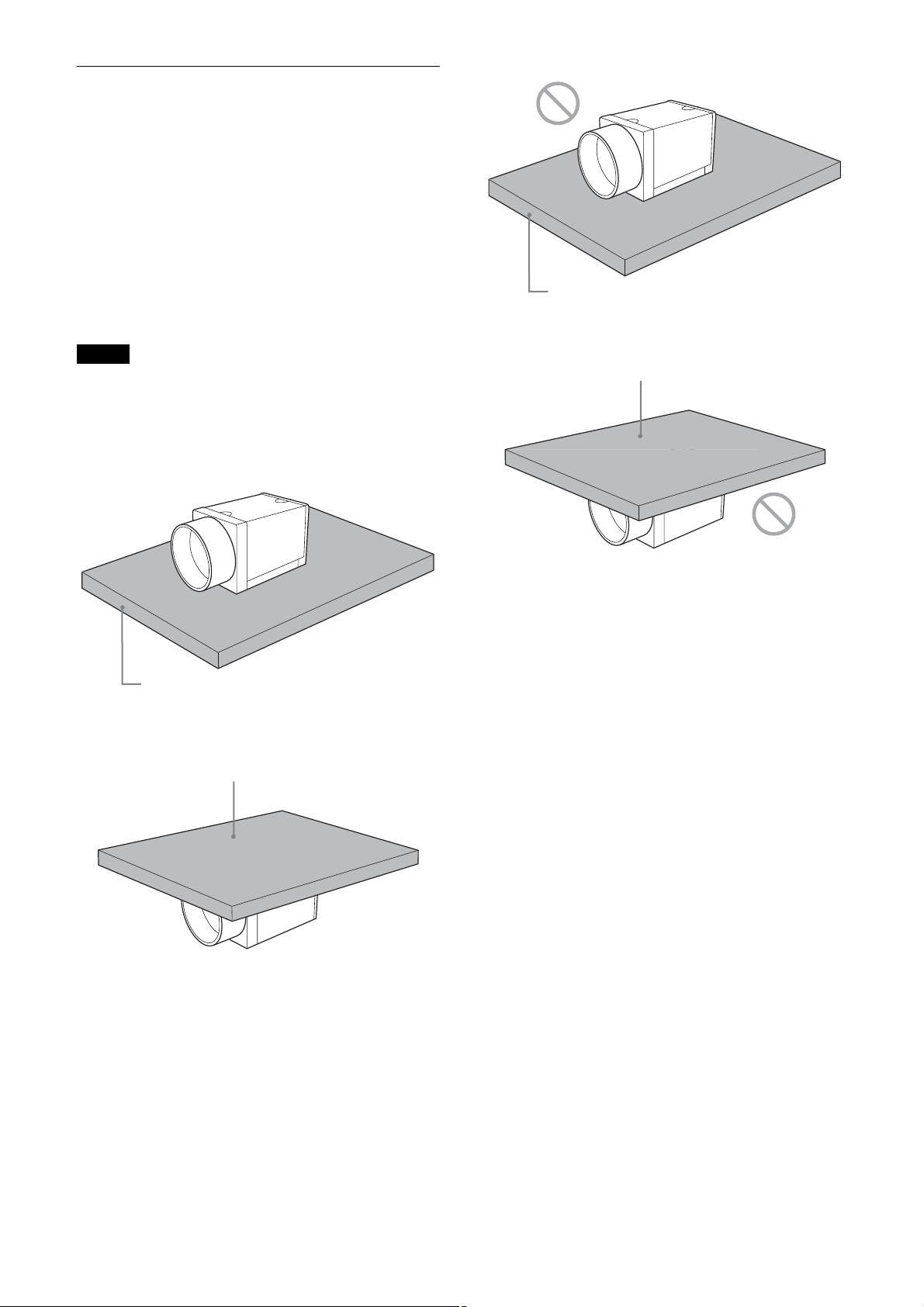

When mounting the camera

When the value read from temperature sensor is above

75 °C (167 °F), heat dissipation is required.

* For CG160/CG160C, in addition to the above

condition, use in environments where the difference

with the ambient temperature is 34°C or less.

To promote heat dissipation from the unit and maintain

performance, mount the camera to a metallic heat

dissipation plate.

Dimension of the heat dissipation plate: 160 mm ×

130 mm × t5 mm or more (Thermal conductivity:

16.3 W/m·K or more)

Plate that prevents heat dissipation

(made of wood, resin, etc.)

Notes

• When mounting the camera to the heat dissipation

plate, secure the camera tightly by using the reference

screw holes (see page 7) and screws.

• Do not mount the camera to a plate made of a material

such as wood or resin that prevents heat dissipation.

Metallic heat dissipation plate

Metallic heat dissipation plate

Plate that prevents heat dissipation

(made of wood, resin, etc.)

9

Connections

Network Settings

For the camera to be connected to a network, the

following address data must be properly specified:

• IP address

• Subnet mask

• Default gateway

The camera provides the following three methods for the

address data setting:

• Using Persistent IP

• Using DHCP

• Using Link Local Address (LLA)

Using Persistent IP

Use this method when the IP address to be assigned to

the camera has been specified in advance. When you use

a fixed IP, setting of subnet mask is necessary. To use

beyond the router, you need to set the default gateway as

well.

Packet Delay

The delay amount to be inserted between packets can be

set when sending them to a network. By increasing the

packet delay, you can reduce the network bandwidth that

the camera uses for sending packets. However, as the

amount of data sent in a certain time is decreased with

increased delay, the frame rate of output images of the

camera may be consequently decreased.

Using DHCP

The camera is equipped with a function to automatically

obtain an IP address by communicating with a DHCP

server on a network. When using the DHCP method for

IP address setting, the subnet mask and default gateway

values automatically obtained from the DHCP server are

also used.

Using LLA

If neither Persistent IP nor DHCP is used, or if an IP

address cannot be obtained from the DHCP server, the

IP address is determined by LLA. The IP address

determined by LLA will be 169.254.XXX.YYY, with

XXX and YYY automatically specified.

Packet Size

The amount of image data per packet can be set in bytes.

To permit the camera to operate properly, set the packet

size to a value less than the MTU of the network device

connected to the camera. Set the largest value in the

networks including the hub.

10

Network connection speed

This unit supports the connection with 1000Base-T

(1 Gbps) or 100Base-TX (100 Mbps).

When you connect the unit to the network, negotiate the

communication speed with the connected equipment

and start communication at a higher speed of that both

equipment are compatible with.

When using the unit with 100Base-TX connection, the

frame rate to be output is limited, because the output

data band width from the camera becomes narrow

compared to the 1000Base-T connection.

The camera has a buffer to store multiple images and all

of the shot images are stored once in the buffer.

The stored images are output from the camera in order

starting from the oldest image in the buffer.

Therefore, if the frame rate during shooting is faster than

the frame rate that can be output from the camera, the

image data will always be stored in the buffer, and the

time interval from shooting to image output becomes

large.

To avoid this situation, it is required to set the shooting

frame rate to the proper value when using 100Base-TX

connection.

The data rate of images is obtained by the following

formula:

Notes

• Any persistent IP address can be entered, but the

camera may become unable to be detected, depending

on the IP address setting. If this occurs, use a tool for

issuing ForceIP and set a persistent IP address again.

• When setting the parameters (Width, Height, and

PixelFormat) for calculating the payload size, stop

camera image output beforehand.

Data rate = Width

× Height × BPP × FPS

Width: Width of image

Height: Height of image

BPP: The number of bits per pixel depends on the

PixelFormat setting

Mono8/BayerRG8 8-bit

Mono10Packed/BayerRG10Packed 12-bit

Mono12Packed/BayerRG12Packed 12-bit

RGB8Packed/BRG8Packed/YUV8_UYV 24-bit

YUV422_8/YUV422_8_UYVY 16-bit

FPS: Frame rate [frame/sec]

It is possible to minimize delay by using the camera at a

frame rate where the data rate becomes low with a

margin against 100 Mbps.

Buffer

Image

sensor

Image nImage

n

Image 2Image

1

Image

output

11

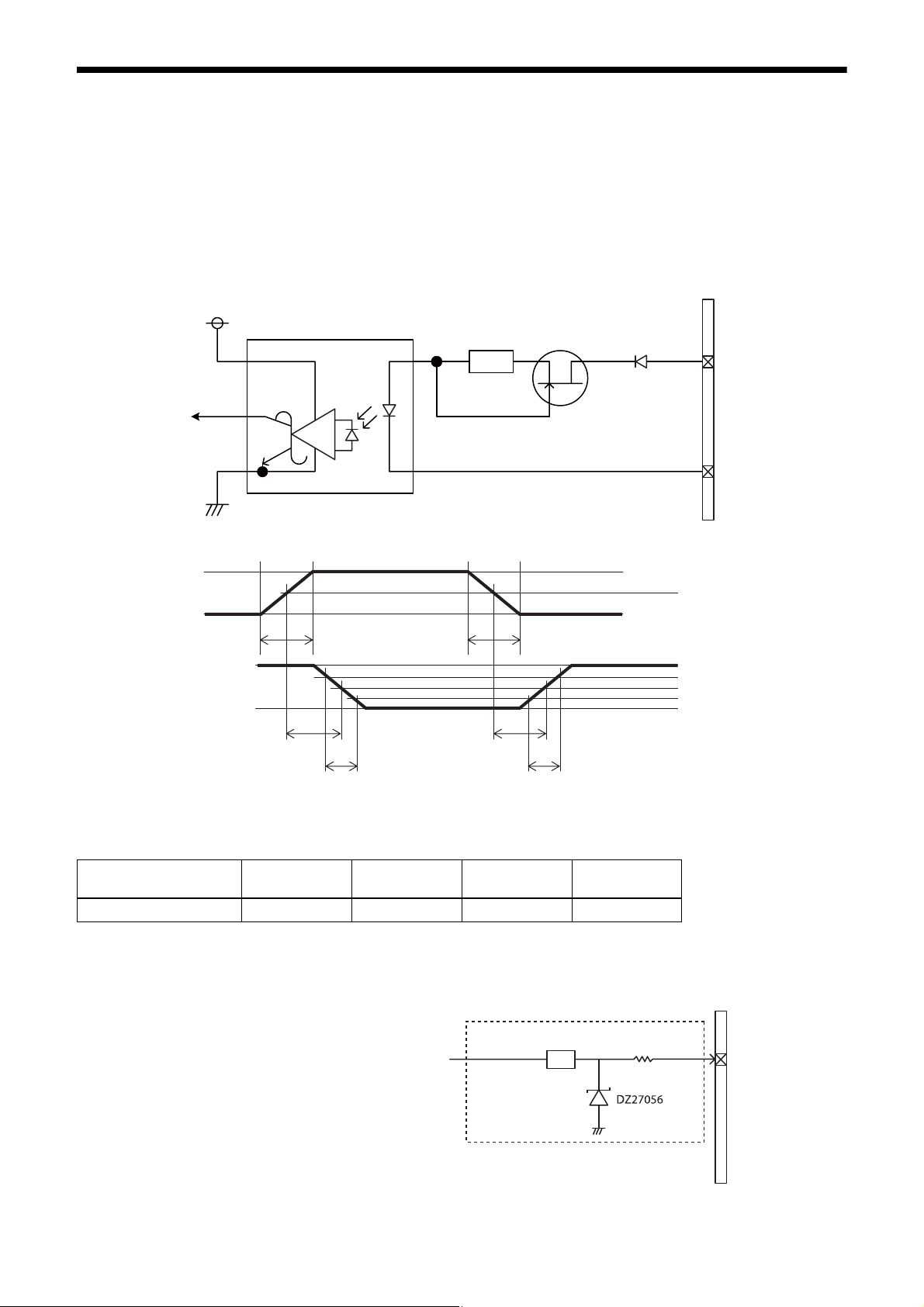

Trigger Signal Input

Trigger signals can be input via the 2nd, 3rd, 4th pins of the DC IN connector, or the software command. Switchover of

the trigger signal can be changed via the TriggerSource register.

Trigger signal polarity

Positive refers to a trigger signal polarity activated while rising from Low to Hi, or during the Hi interval. Negative refers

to a trigger signal polarity activated while falling from Hi to Low, or during the Low interval.

Register Parameter Setting

TriggerActivation FallingEdge (0)

RisingEdge (1) Positive

DC IN connector specifications

2.0 µs or less

Negative

5 to 24 V (DC IN connector 2nd pin)

3.5 to 5.5 V (DC IN connector 3rd

and 4th pins*)

0 to 0.4 V

2.0 µs or less

10 µs to 2 s

1 frame time or more

Trigger input polarity = Negative

5 to 24 V (DC IN connector 2nd pin)

3.5 to 5.5 V (DC IN connector 3rd

and 4th pins*)

0 to 0.4 V

2.0 µs or less

10 µs to 2 s

2.0 µs or less

1 frame time or more

Trigger input polarity = Positive

* XCG-CG160/C160C: Unavailable. Dedicated to output.

Note

• When inputting a trigger signal to the camera using the DC-700/CE, use DC 5 V or less at the logical high level.

• Make sure to supply power to the camera module and confirm that the camera module is operating before inputting a

trigger signal. If you input trigger signal to a camera module without the power supplied, this may cause a malfunction

of the camera module.

12

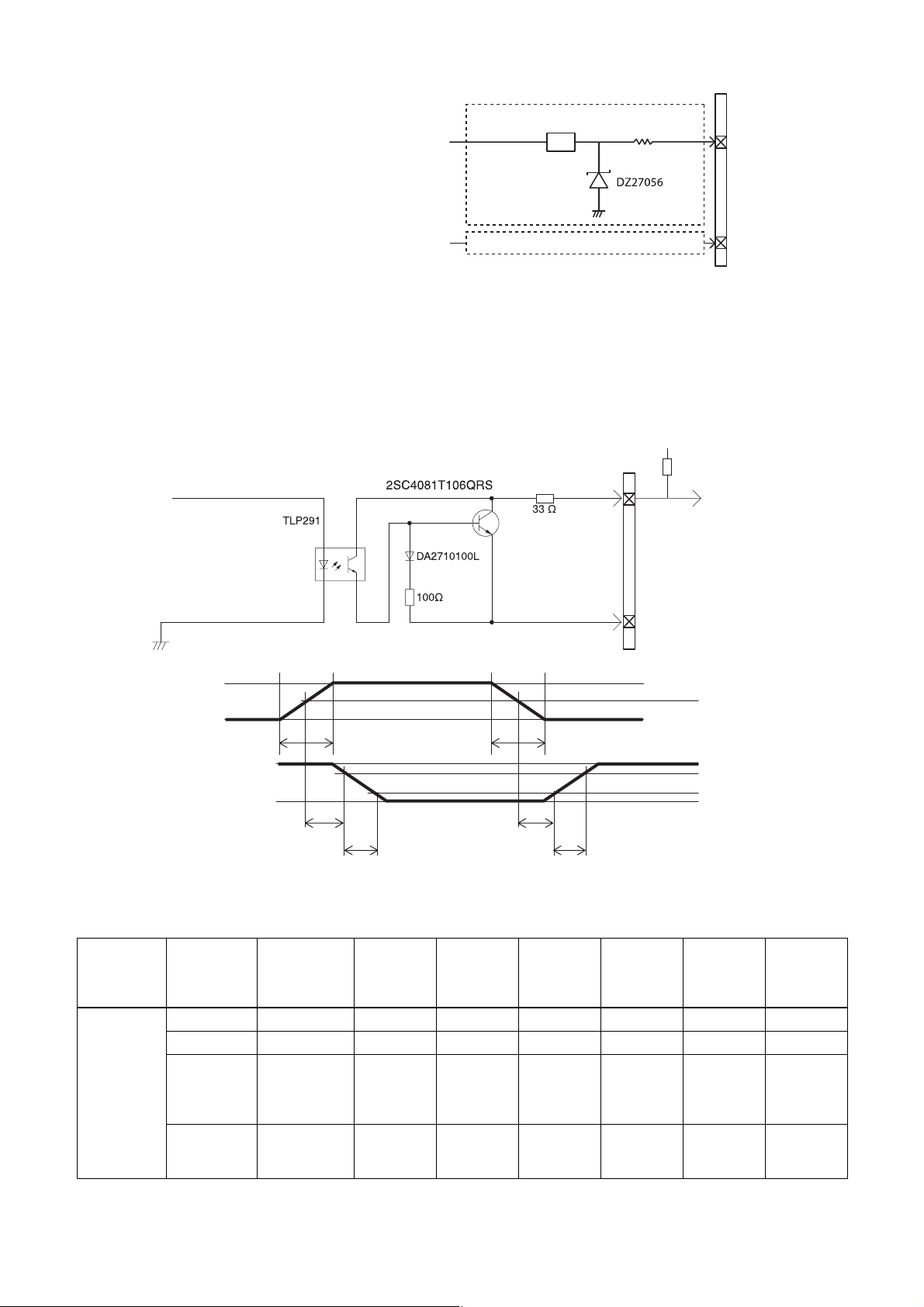

GPIO Connector

The DC IN connector #2 is the GPI connector. #3 and #4 connectors can be set as GPI/GPO.* The trigger reset pin is

the DC IN connector 2nd pin (GPI1). If you are connecting an external device to the GPI or GPO connector, refer to the

circuit specifications below.

* #4 is GPO connector only for XCG-CG160/CG160C.

GPI circuit specifications

DC IN connector

3.3V

ACPL-M60

GPI1

Input level Low: 0 to 0.4 V, High: 5 to 24 V

180

MMBF4393LT1G

#2

DA2710100L

#5

5 V

0 V

*

3.3 V

0 V

TDF

FT

* Rising the input signal as soon as possible.

Example

Input voltage

[V]

5.0 167 297 192 358

TDF

[ns]

GPIO circuit specifications

XCG-CG160/CG160C

FT

[ns]

*

TDR

TDR

[ns]

RT

RT

[ns]

50%

90%

50%

10%

DC IN connector

GPI2/GPO2

13

SN74LVC1T45

180 Ω

#3

XCG-CG240/CG240C

XCG-CG510/CG510C

DC IN connector

GPO circuit specifications

XCG-CG160/CG160C

GPO3

GPI2/GPO2

GPI3/GPO3

SN74LVC1T45

As GPI2/GPO2

Input level Low: 0 to 0.4 V, High: 3.5 to 5.5 V

Output level 0 to 3.3 V

180 Ω

External power source

(3.3 V to 24 V)

DC IN

connector

#4

Pull up resistance

#3

#4

#5

3.3 V

50%

0 V

3.3 V

0.9 V

TDF

FT

TDR

RT

90%

10%

Example

When connecting to an external power supply, be sure to use a pull-up resistor for a current limit of less than 50 mA.

Normal

temperature

Supply

voltage of

the output

[V]

3.3 470 Ω 5.07 0.75 0.49 24 35 0.916

5.0 820 Ω 4.98 0.73 0.63 28 46 0.909

12.0 Two

24.0 Eight 8200 Ω

Pull-up

resistor

(Use 1/16 W)

2200 Ω

resistors in

parallel

resistors in

parallel

Current

[mA]

TDF

[µs]

FT

[µs]

TDR

[µs]

RT

[µs]

Output

voltage

9.87 0.71 1.05 36 64 1.112

21.85 0.73 1.45 45 76 1.571

[V]

14

Functions

Binning (XCG-CG160 only)

Partial Scan

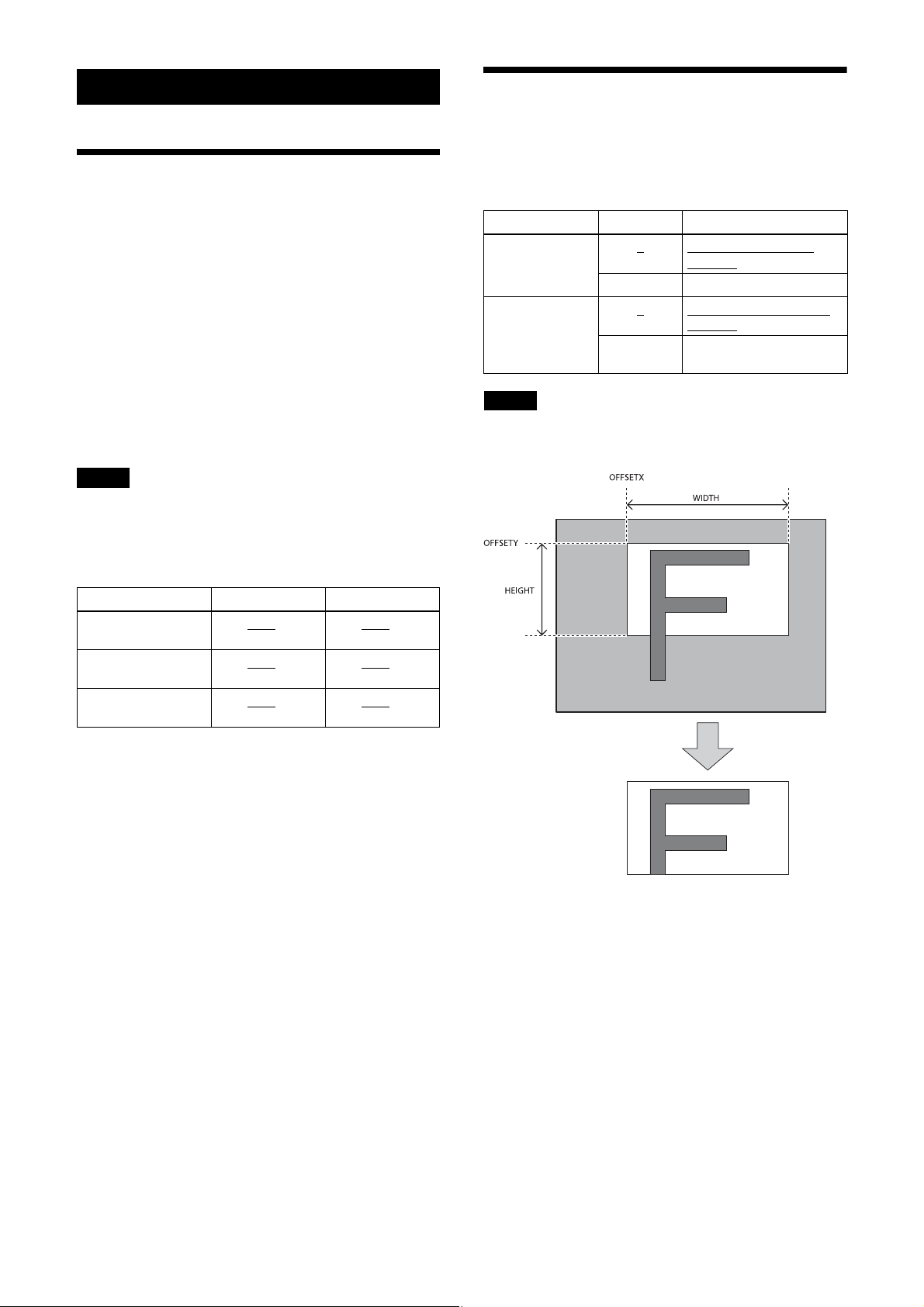

Only the area selected from the effective pixel area can

be read out. Adding 2 pixels of vertical and horizontal

directions achieves higher sensitivity and frame rate.

The area size is selected by the Height and Width

registers, and the read beginning point is selected by the

OffsetX and OffsetY registers. Reducing Height

increases the frame rate, but changing the Width register

does not change the frame rate. Partial scan can be set

with or without a trigger.

OffsetX and OffsetY relate to Width and Height as

follows:

OffsetX + Width

OffsetY + Height

Note

Since the shutter setting has priority, use a shutter speed

high enough to enable partial scan at a higher frame rate.

Configurable range

XCG-CG160/

CG160C

XCG-CG240/

CG240C

XCG-CG510/

CG510C

≤ Width (maximum value)

≤ Height (maximum value)

Width Height

16 to 1440

16 to 1920

16 to 2448

to 1456 16 to 1080 to 1088

to 1936 16 to 1200 to 1216

to 2464 16 to 2048 to 2056

Adding 2 pixels in the vertical and horizontal directions

achieves higher sensitivity and frame rate.

Register Parameter Setting

BinningVertical 1

2 Vertical binning is available

BinningHorizontal 1

2 Horizontal binning is

Note

Vertical binning is not

available

Horizontal binning is not

available

available

To fasten the frame rate on binning, use the shutter in a

sufficiently high speed.

Configurable values

The values of OFFSETX, OFFSETY, WIDTH and

HEIGHT increase or decrease in steps of 4.

Partial scan

15

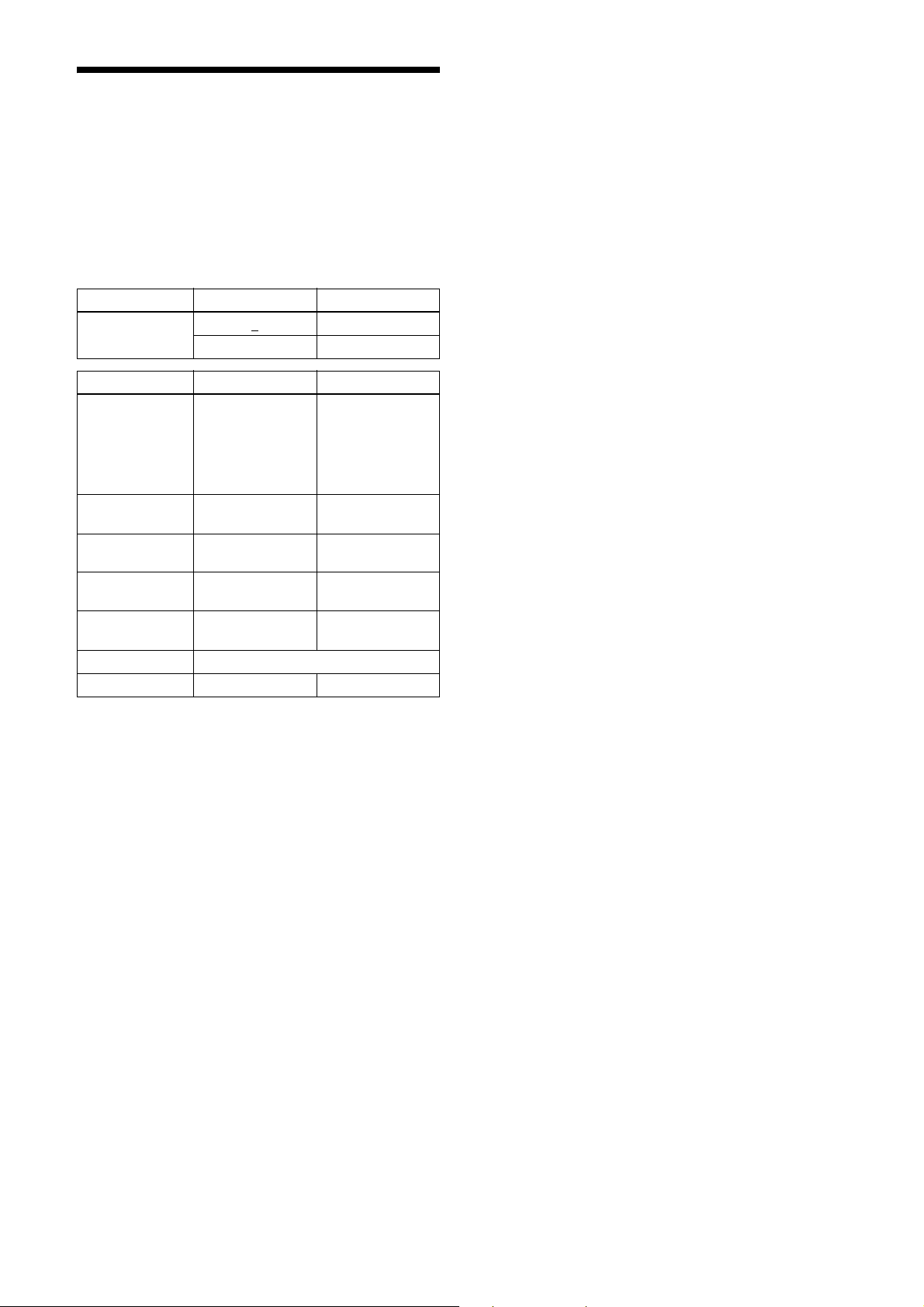

Drive mode

“Mode 0” which prioritizes the frame rate is set by

default.

The frame rate upper limit of “Mode 0” is higher

than“Mode 1,” but the usable functions are limited.

When correcting the defects/shadings in “Mode 0.”

After detecting and saving the defects/shadings in

“Mode 1,” return to “Mode 0” and use them.

Reboot the unit to reflect the changes of the drive mode.

command parameter Setting

DRIVE_MODE 0

1Mode 1

DRIVE_MODE Mode 0 Mode 1

Maximum frame

rate

Defect detection

function

Defect correction

function

Shading detection

function

Shading correction

function

Output format See the “Output format” function.

Free set sequence z –

75 fps (XCGCG160/CG160C)

41 fps (XCGCG240/CG240C)

23 fps (XCGCG510/CG510C)

– z

zz

– z

zz

Mode 0

50 fps (XCGCG160/CG160C)

32 fps (XCGCG240/CG240C)

15 fps (XCGCG510/CG510C)

z Usable function – Not usable function

16

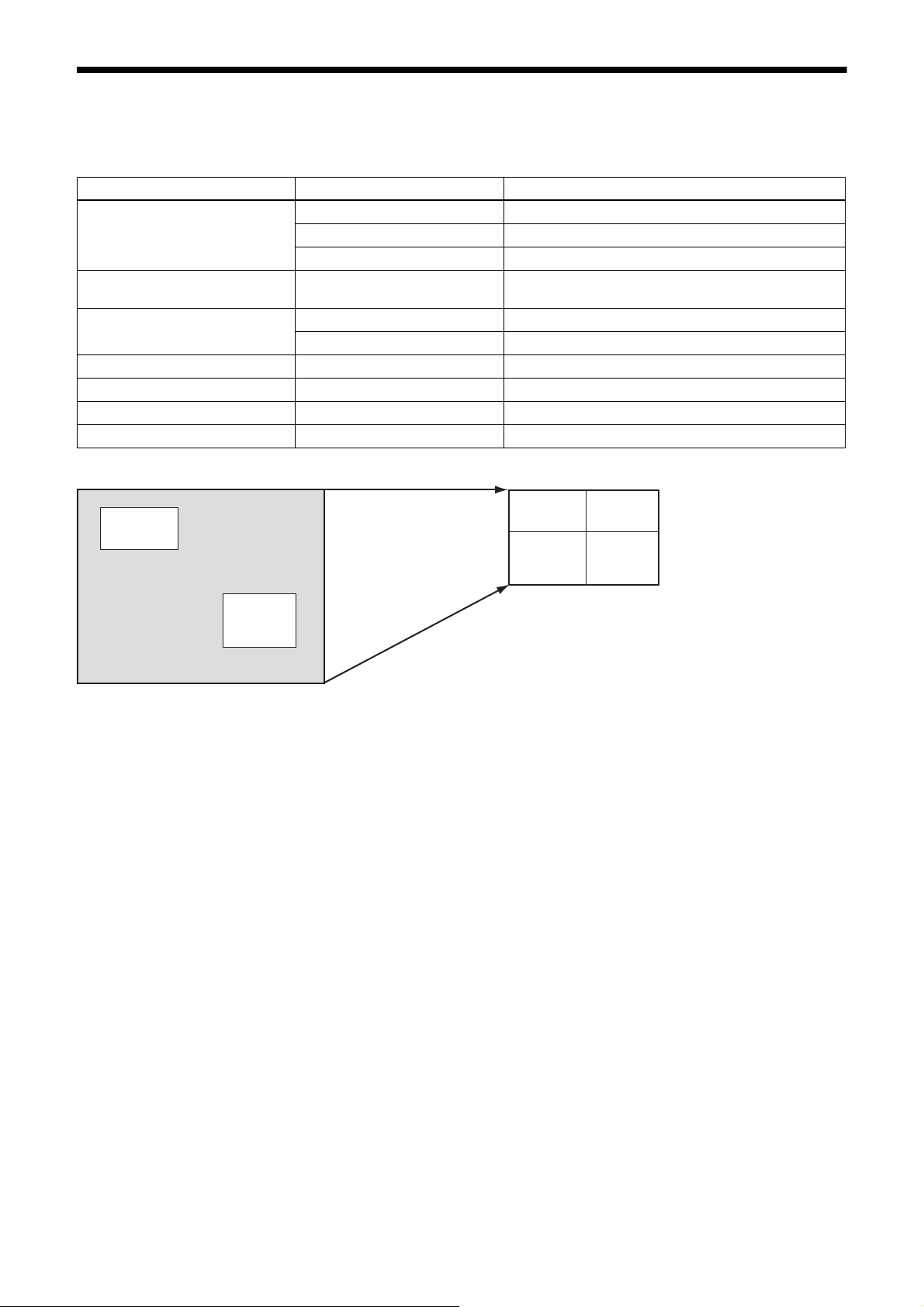

Multi ROI (XCG-CG160/CG160C only)

Af

You can set and read two arbitrary rectangular areas from the effective pixel area.

By reading only necessary parts, you can shorten the time it takes to read.

Register Parameter Setting

MultiROIMode 0 (Off) All areas Off

1 (On) All areas On

2 Highlight

MultiROISelect 0 to 1 Designates the number of the area the parameter is to be

changed.

MultiROIEnable 0 (Off) The area designated in MultiROISelect is Off.

1 (On) The area designated in MultiROISelect is On.

MultiROIWidth 4 to 1456 Horizontal size of the area

MultiROIHeight 4 to 1088 Vertical size of the area

MultiROIOffsetX 0 to 1452 Horizontal position of the area

MultiROIOffsetY 0 to 1084 Vertical position of the area

Before reading the part

䋰

ter reading the part

䋰

䋱

䋱

17

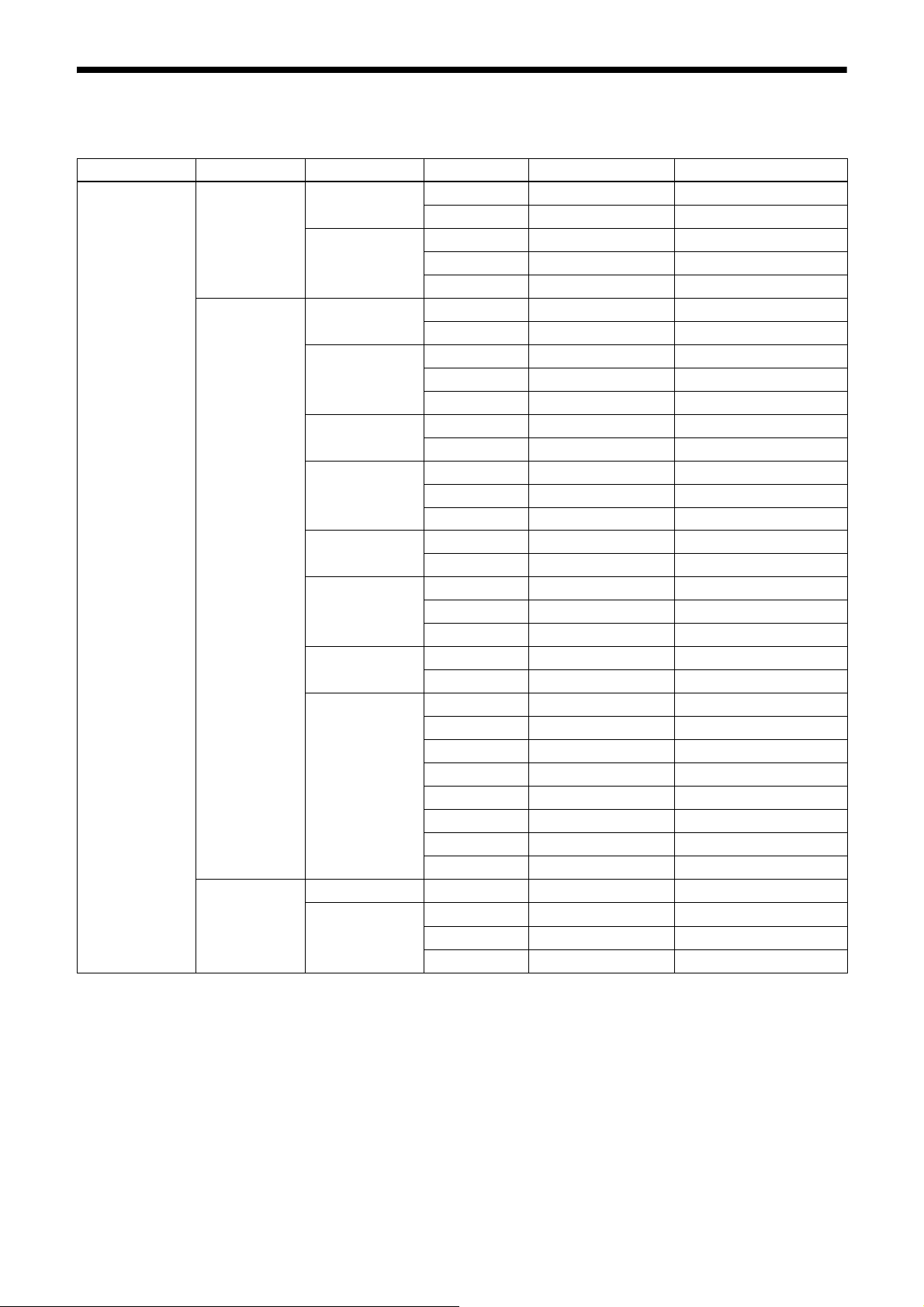

Output format

The settable pixel formats are as follows:

Register Model Drive mode ReverseX/Y Parameter Setting

PixelFormat XCG-CG240 Mode0 * 0x01080001 Mono8

* 0x010C0004 Mono10Packed

Mode1 * 0x01080001 Mono8

* 0x010C0004 Mono10Packed

* 0x010C0006 Mono12Packed

XCG-CG240C Mode0 0 0x0108000B BayerBG8

0 0x010C0029 BayerBG10Packed

Mode1 0 0x0108000B BayerBG8

0 0x010C0029 BayerBG10Packed

0 0x010C002D BayerBG12Packed

Mode0 1 0x01080008 BayerGR8

1 0x010C0026 BayerGR10Packed

Mode1 1 0x01080008 BayerGR8

1 0x010C0026 BayerGR10Packed

1 0x010C002A BayerGR12Packed

Mode0 2 0x0108000A BayerGB8

2 0x010C0028 BayerGB10Packed

Mode1 2 0x0108000A BayerGB8

2 0x010C0028 BayerGB10Packed

2 0x010C002C BayerGB12Packed

Mode0 3 0x01080009 BayerRG8

3 0x010C0027 BayerRG10Packed

Mode1 3 0x01080009 BayerRG8

3 0x010C0027 BayerRG10Packed

3 0x010C002B BayerRG12Packed

* 0x02180014 RGB8Packed

* 0x02180015 BGR8Packed

* 0x02180020 YUV8_UYV(YUV444)

* 0x0210001F YUV422_8_UYVY

* 0x02100032 YUV422_8

XCG-CG160/

CG510

Mode0 * 0x01080001 Mono8

Mode1 * 0x01080001 Mono8

* 0x010C0004 Mono10Packed

* 0x010C0006 Mono12Packed

*: optional

* Selectable setting format varies between drive modes.

* Modes for ReverseX/Y are limited for the color camera, as some setting formats fix the pixel array.

18

Loading...

Loading...