Sony XCG-C30, XCG-C32, XCG-C130, XCG-C30C, XCG-C32C Technical Manual

...

Digital Video

Camera Module

C-189-100-11 (1)

Technical Manual

XCG-C30/C32/C130

XCG-C30C/C32C/C130C

© 2015 Sony Corporation

Table of Contents

Overview

Features .................................................................. 3

Typical CCD Phenomena ...................................... 4

System Components .............................................. 5

Connection ............................................................. 6

Location and Function of Parts and

Operation ............................................................... 7

Front/Top/Bottom ............................................... 7

Using a tripod ..................................................... 7

Rear .................................................................... 8

Connecting the cables ........................................ 9

Controlling the camera from the host device ..... 9

When mounting the camera ............................. 10

Heat dissipation of the camera ......................... 11

The electrolytic capacitor during the PoE

operation ......................................................... 11

Connections

Network Settings ................................................. 12

Using Persistent IP ........................................... 12

Using DHCP .................................................... 12

Using LLA ....................................................... 12

Packet Size ....................................................... 12

Packet Delay ..................................................... 12

Network connection speed .................................. 13

Trigger Signal Input ............................................ 14

Trigger signal polarity ...................................... 14

GPIO Connector .................................................. 15

Frame Rate ...........................................................25

Auto frame rate .................................................25

Specifying frame rate ........................................25

Displaying frame rate .......................................25

Fastest frame rate for partial scanning ..............26

Timing Chart ........................................................28

Trigger latency ..................................................28

Sensor Readout (Sensor Output) ........................29

White Balance ......................................................30

LUT .......................................................................30

Binarization ......................................................30

5-point interpolation .........................................30

Arbitrary setting ................................................31

Save LUT ..........................................................31

Color Matrix Conversion ....................................31

3 × 3 filter ..............................................................32

Test Chart Output ................................................32

GPIO .....................................................................33

GPI ....................................................................33

GPO ..................................................................33

Pulse Train Generator .........................................35

Status LED ............................................................35

Temperature Readout Function .........................35

Sensitivity Control ...............................................35

User Set .................................................................35

User set memory ...............................................35

User ID ..................................................................36

Saving and Startup ..............................................36

Camera Information ............................................36

Restart ...................................................................36

Switching a CCD Driving Clock .........................36

Command List ......................................................37

Functions

Partial Scan .......................................................... 16

Binning ................................................................. 16

Output format ...................................................... 17

Gain ...................................................................... 17

Analog gain ...................................................... 17

Auto gain (AGC) .............................................. 17

Shutter (Exposure) .............................................. 18

Configuring the setting ..................................... 18

Auto exposure (AE) ......................................... 18

Combination of Continuous AGC and Continuous

AE ......................................................................... 18

Trigger Control .................................................... 19

Free run/trigger mode ....................................... 19

Special trigger .................................................. 20

Trigger source .................................................. 21

Trigger inhibition ............................................. 21

Trigger shift ...................................................... 22

Trigger delay .................................................... 23

Trigger counter ................................................. 23

Trigger range limit ........................................... 23

Trigger control .................................................. 24

Specifications

Specifications ........................................................45

Spectral Sensitivity Characteristics (Typical

Values) ...................................................................46

Dimensions ............................................................48

2

Table of Contents

Overview

Before operating the unit, please read this manual

thoroughly and retain for future reference.

Partial scan (during DC IN power supply

only)

The camera module can limit the number of video

output lines to achieve high frame rates, enabling highspeed image processing.

Overview

This unit is a digital video camera module that adopts

the 1000BASE-T/100BASE-TX interface.

Features

GigE Vision compliant

This unit supports GigE Vision Ver.2.0/Ver.1.2, and the

versions are switchable by changing the settings.

High image quality

All cameras feature a progressive scan CCD for highresolution images. Both cameras produce stable output

images, by adopting the proven CCD.

By adopting square pixels, images can be processed

using the original aspect ratio without a converting

procedure.

The following models and their CCDs are shown below.

Model name Pixel count

XCG-C30/C32/C30C/

C32C

XCG-C130/C130C 1,300,000-pixel CCD,

330,000-pixel CCD, compatible

with VGA

compatible with SXGA

Body fixing

The screw holes to install the camera module are located

under the front panel (the CCD reference plane).

Installing the camera module on the front panel

minimizes deviation of the optical axis.

LUT (Look Up Table)

You can switch to OFF or ON. When set to ON, you can

select from five preset values, such as inversion,

binarization, settable five-point approximations, etc.

Switching an Output Bit Length

You can select 8-bit output, 10-bit output, or 12-bit

output.

For color models, you can also select an output of RGB

24-bit, YUV 24-bit, or YUV 16-bit.

Binning (during DC IN power supply/

black and white camera only)

Sensitivity can be doubled by combining two pixels

aligned vertically, you can achieve a standard output

frame rate between 1.8x and 2x. Sensitivity can be

doubled by combining two pixels align horizontally.

You can set horizontal and vertical binning at the same

time.

Various settings

Sending a command from the host device allows various

settings, including the following.

•Gain

•Shutter

• Partial scan (during DC IN power supply only)

• Trigger control

• LUT (Look Up Table)

• Output: 8/10/12-bit, RGB 24-bit, YUV 24-bit

(YUV444), or YUV 16-bit (YUV422)

Electronic shutter function

Set anywhere from 1/100,000 sec to 2 sec in 1 µs

increments. If you do not prioritize the image quality,

you can set it up to 60 sec during operation.

External trigger shutter function

By synchronizing with an external trigger signal, any

shutter timing can be used.

White balance control (color camera

only)

You can adjust the R and B level against G level to adjust

the white balance. This unit is also equipped with the

one-push white balance function, by which the camera

can automatically adjust the white balance.

Note

The CCD is driven at high speed during a Partial scan or

Binning operation. In this situation, if intense light is

input to the camera, the peripheral areas of the video

image may be affected. In such a situation, adjust the

amout of light using the iris.

Features

3

CCD used in XCG-C130/C130C

Typical CCD Phenomena

The following effects on the monitor screen are

Overview

characteristic of CCD cameras. They do not indicate any

fault with the camera module.

Smear

This occurs when shooting a very bright object such as

electric lighting, the sun, or a strong reflection.

This phenomenon is caused by an electric charge

induced by infrared radiation deep in the photosensor. It

appears as a vertical smear, since the CCD imaging

element uses an interline transfer system.

Vertical aliasing

When you shoot vertical stripes or lines, they may

appear jagged.

Under the following operating conditions, because the

construction of the CCD of this camera is different from

the CCDs used in other cameras, the brightness level

near the pedestal may increase, or white dots described

above may become pronounced, degrading the image

quality.

• When used in a hot environment

• When the gain is increased

• When the exposure time is long (0.1 second or longer)

In these situations, decrease the environmental

temperature, or adjust the light source or lens aperture,

and change the camera gain or exposure time.

Note on laser beams

Laser beams may damage a CCD. You are cautioned

that the surface of a CCD should not be exposed to

laser beam radiation in an environment where a laser

beam device is used.

Blemishes

A CCD image sensor consists of an array of individual

sensor elements (pixels). A malfunctioning sensor

element will cause a single pixel blemish in the picture

(This is generally not a problem.).

White speckles

While CCD image pickup device is made by an accurate

technique, imperceptible speckless may rarely come up

on the screen due to cosmic rays and so on. This is

connected to the principle of CCD image pickup device,

not a malfunction. And the white speckless are easy to

come up in the following conditions.

• Using the camera in high temperature

• When turning up the gain

Note

If strong light enters a wide area of the screen, the screen

may become dark. This is not a malfunction.

If this occurs, avoid strong light or adjust the lens iris to

reduce the light amount.

4

Typical CCD Phenomena

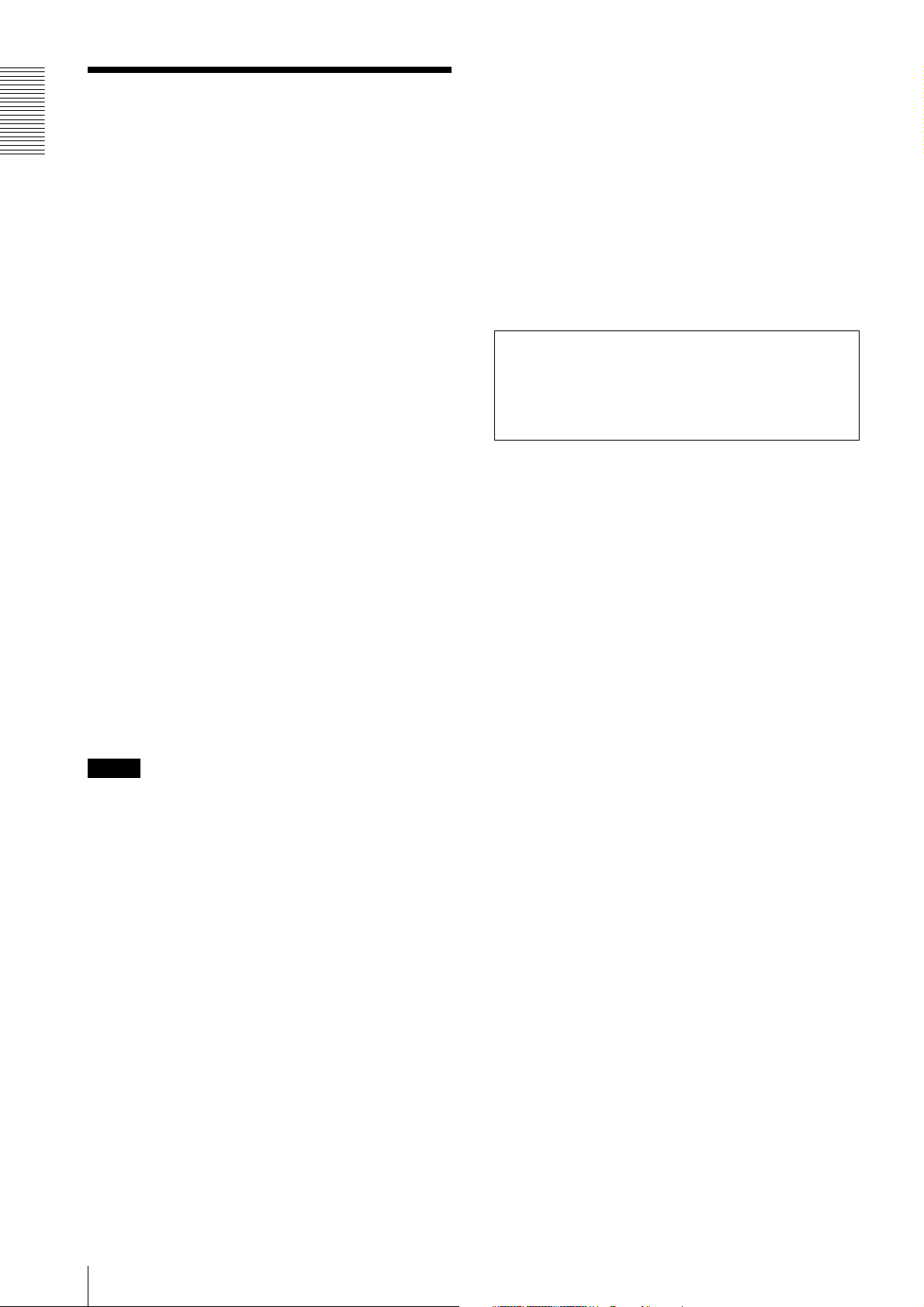

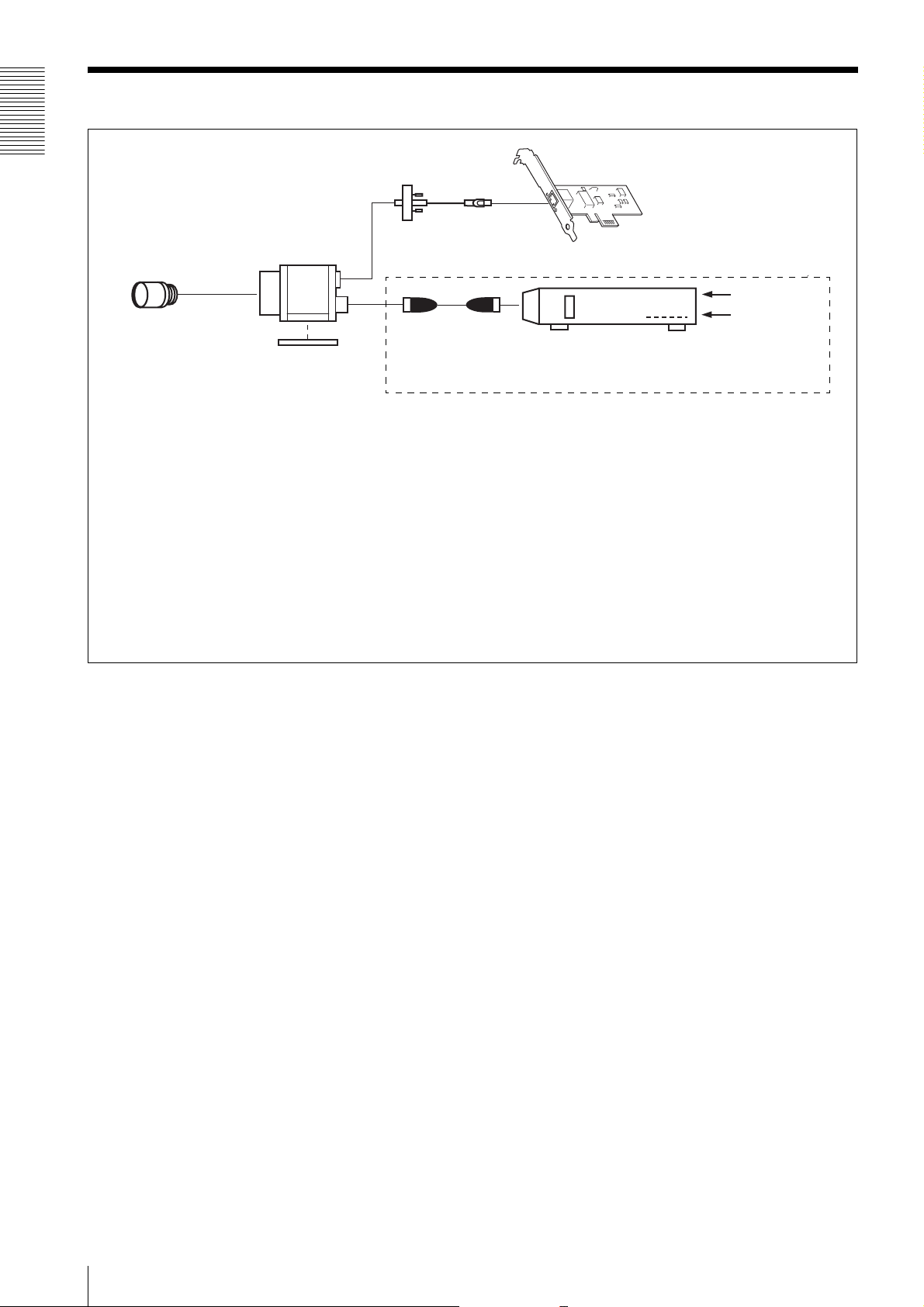

System Components

a

cd e

fg

b

g LAN cable

This cable connects to the RJ45 connector on the rear

panel of the camera module.

Image/control signals are transmitted via this cable. Use

a LAN cable (CAT5e or higher standard) that supports

1000BASE-T (or allows 100BASE-TX when it is used).

Depending on the attributes of the LAN cable, images

may become less clear and the camera module may

become unstable. Be sure to use a LAN cable that has

sufficient noise reduction.

Note

When you connect the LAN cable of the unit to

peripheral device, use a shielded-type cable to prevent

malfunction due to radiation noise.

Overview

The video camera module system comprises the

following optional products (available separately).

a Video Camera Module

This is a small-size, high image-quality video camera

module that uses a progressive scan CCD image sensor.

b Camera cable

This is attached to the DC IN connector of the camera

module and is used for power supply and exchange of

trigger signals.

For purchasing the cable, consult the dealer.

c C-mount lens

Use a suitable lens to fit the camera pixel count.

d DC-700/700CE camera adaptor

This is connected to the camera module to enable power

supply from ordinary AC power source.

e VCT-333I tripod adaptor

This attaches to the bottom of the camera module to fix

the camera module to a tripod.

f Camera module interface board (Network

interface card)

Install the board in the expansion slot of the host device

(ex: computer). Use a board that is appropriate for your

system and that supports 1000BASE-T (or allows

100BASE-TX when it is used) and jumbo packets.

System Components

5

Connection

Overview

LAN cable

Camera module

C-mount lens

Camera cable

Tripod adaptor

VCT-333I

If the HUB supports PoE, the items within the dashed line are not necessary.

Power supply

You can supply power to the camera module using the following methods.

Using the RJ45 connector

This unit supports PoE (IEEE802.3af standard). By using a PoE-compatible LAN cable and camera module interface board or hub,

you can power, control, and output images from the camera using one LAN cable.

When you operate this unit using PoE, heat dissipation is required depending on the usage environment because the inside of the

camera becomes hot.

For heat dissipation, refer to the User's Guide.

Camera module interface board

AC

TRIG

Camera adaptor

DC-700/700CE

(adopt EIAJ compliant 12-pin

connector pin assignments)

Using the DC IN connector

You can supply power via the DC IN connector using the power adapter.

Use DC-700/700CE which is the stable power source free from ripple or noise.

6

Connection

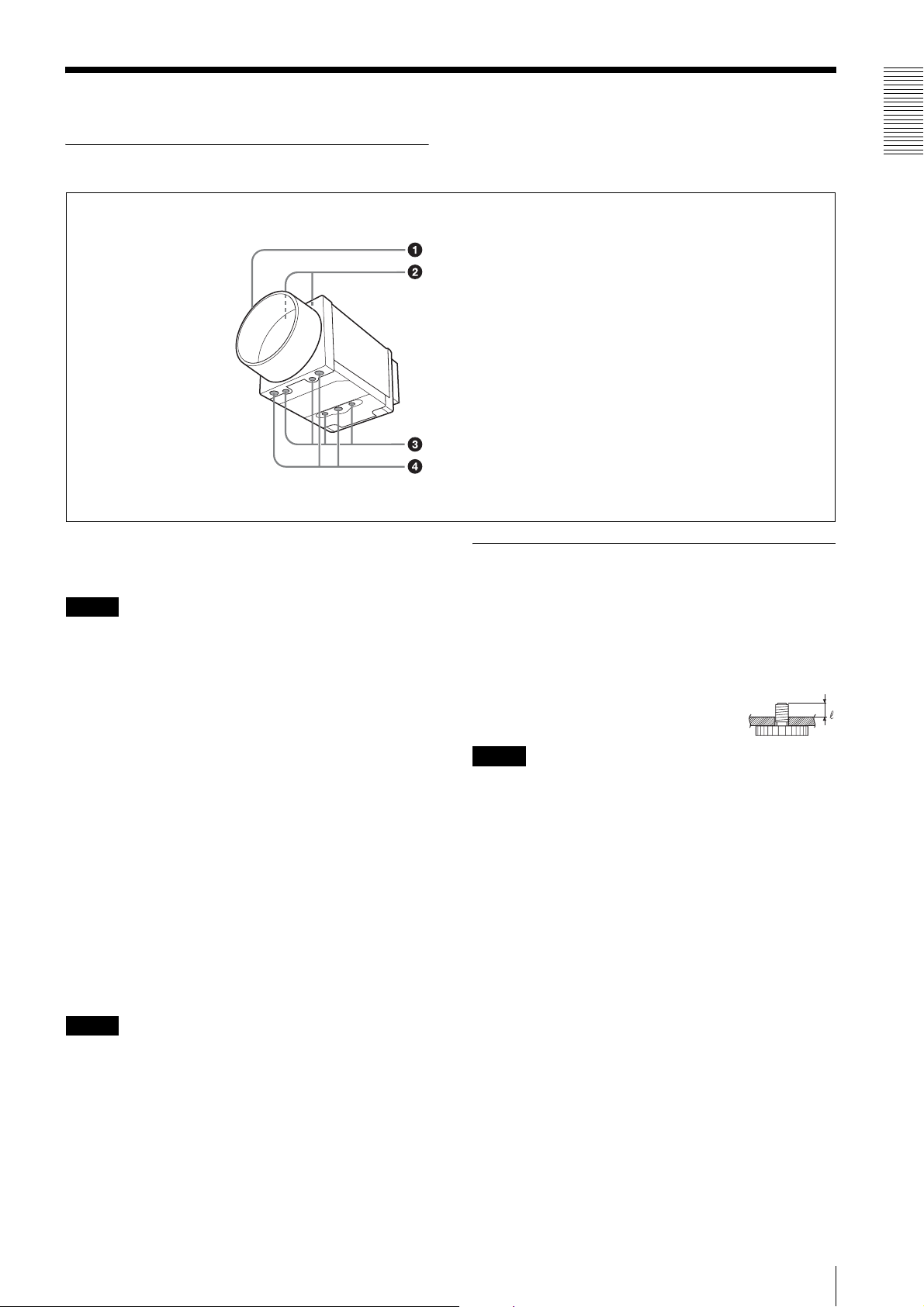

Location and Function of Parts and Operation

Front/Top/Bottom

a Lens mount (C-mount)

Attach any C-mount lens or other optical equipment.

Note

The lens must not project more than 10 mm (13/32 inch)

from the lens mount.

When you use the camera with the lens attached, the

resolution of the image output from the camera may

differ according to the performance of the lens. Note it

when you select a lens.

The performance of a lens may change according to the

aperture level.

If the resolution is not enough, adjust the aperture level.

b Guide screw holes (Top)

Overview

Lens mount (C-mount)

Guide screw holes (Top)

Guide screw holes/Tripod screw holes (bottom)

Reference screw holes (bottom)

Using a tripod

To use the tripod, install the tripod adaptor VCT-333I

(not supplied) on the camera module.

Use a tripod screw with a protrusion (4) extending from

the installation surface, as follows, and tighten it, using

a screwdriver. Be sure that the protrusion (4) does not

exceed 5.5 mm (0.2 in.) in length.

Length 4.5 to 5.5 mm

Length 0.18 to 0.22 inches

Note

If you install a tripod adapter (not supplied), use the

screws provided.

c Guide screw holes/Tripod screw holes (bottom)

When using a tripod, use these four screw holes to attach

a VCT-333I tripod adaptor.

d Reference screw holes (bottom)

These precision screw holes are for locking the camera

module. Locking the camera module into these holes

secures the optical axis alignment.

Note

Refer to XCG-C30 Demensions in page 48 for about the

position/size of the Guide hole and the Reference hole.

Location and Function of Parts and Operation

7

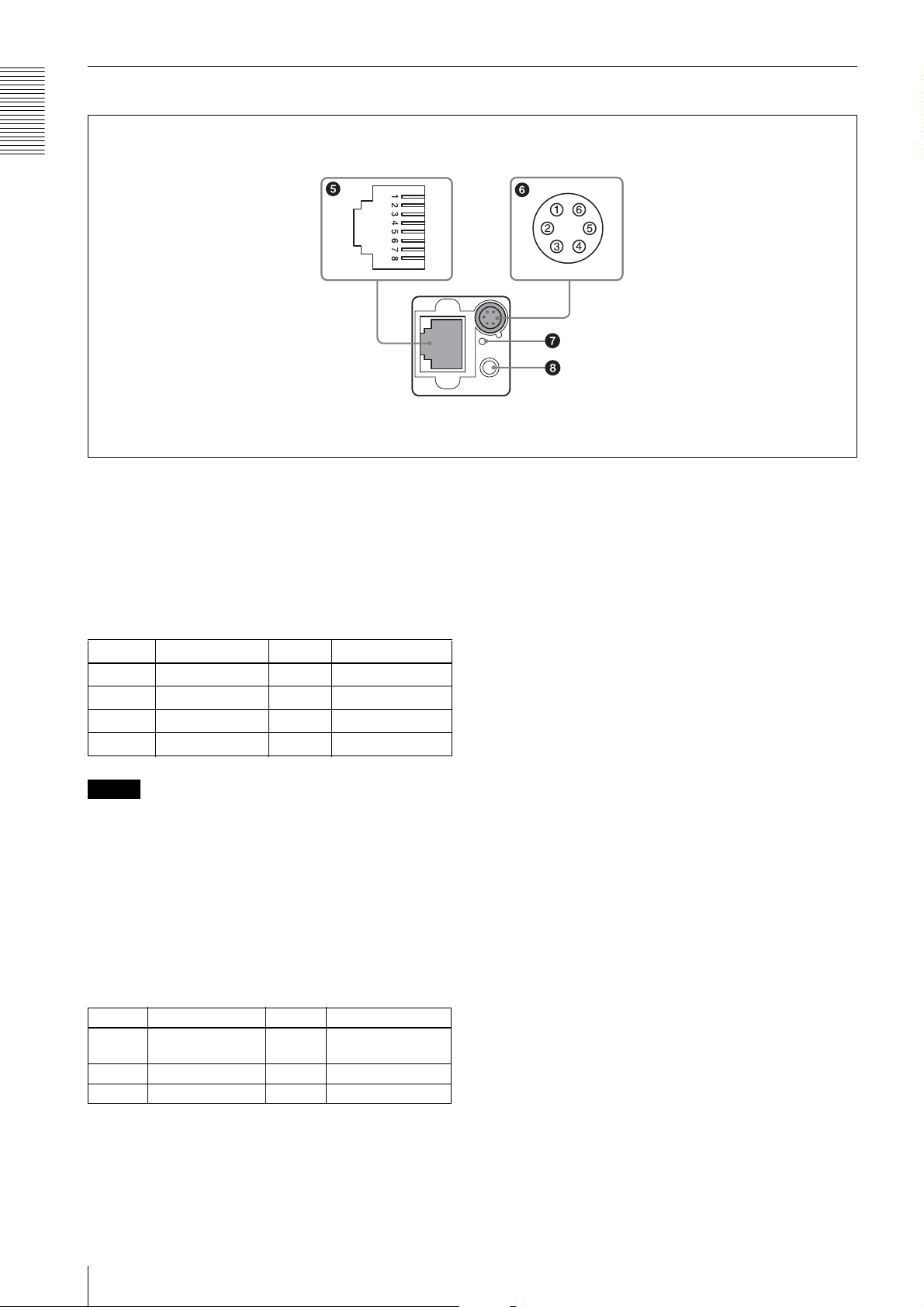

Rear

Overview

e RJ45 connector

You can connect a LAN cable to this connector to

control the camera module from a host device to output

image to a host device. By using a PoE-compatible LAN

cable and camera module interface board or hub, you

can supply power using the LAN cable.

(Refer to Fig.

5 above for the pin assignment of the

connector.)

Pin No. Signal Pin No. Signal

1TP3 + 5TP1 –

2TP3 – 6TP2 –

3TP2 + 7TP4 +

4TP1 + 8TP4 –

Note

For safety, do not connect the connector for peripheral

device wiring that might have excessive voltage to this

port. Follow the instructions for this port.

f DC IN (DC power input) connector (6-pin)

You can connect a camera cable to input the +12 V DC

power supply. The pin configuration of this connector is

as follows.

(Refer to Fig.

6 above for the pin assignment of the

connector.)

g Reset switch

This reformats the network settings.

h Status LED (Green)

When power is on, this LED lights up.

Pin No. Signal Pin No. Signal

1 DC input (10.5 V

to 15 V)

2 GPI1 (ISO +) 5 GPI1 (ISO –)

3 GPI2/GPO2 6 GND

8

Location and Function of Parts and Operation

4 GPI3/GPO3

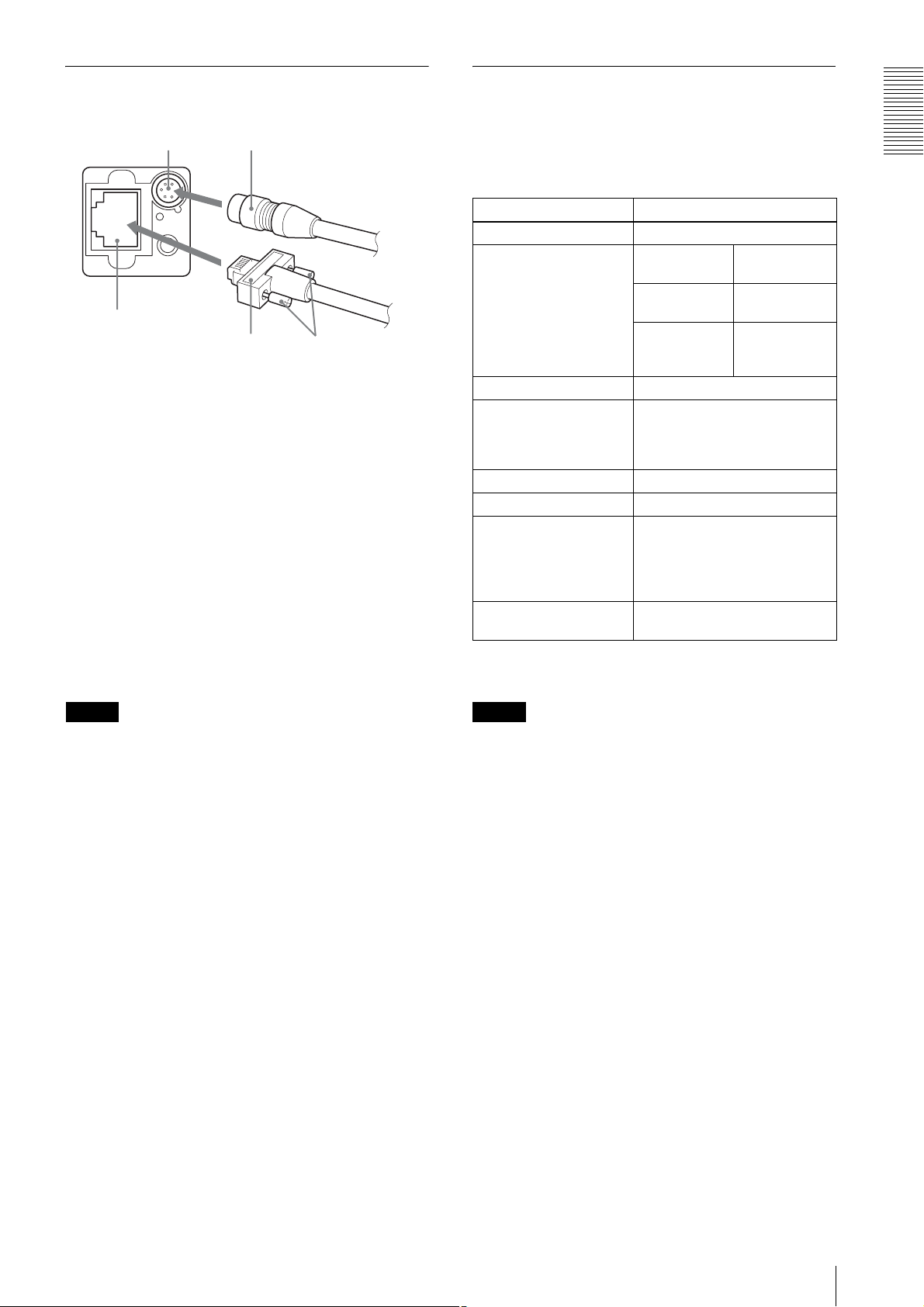

Connecting the cables

Controlling the camera from the host device

Connect the camera cable to the DC IN connector and

connect the LAN cable to the RJ45 connector

respectively. If you use a camera module interface board

or a hub with support for PoE, you can operate the

camera even if you do not connect the camera cable to

the DC IN connector. When you connect the LAN cable

with fastening screws, turn the two screws on the

connector to secure the cable tightly.

1 DC IN connector 2 RJ45 connector

3 Camera cable 4 LAN cable

5 Fastening screws

Connect the other end of the camera cable to the DC700/700CE and the other end of the LAN cable to the

camera module interface board or a hub.

You can control the camera from host devices such as a

computer. The following table shows the major control

functions.

Control functions Description

Operating mode Free run/Trigger

Shutter speed* Free run 1/100,000 sec to

2 sec

Trigger edge

detection

Trigger pulse

width detection

Gain 0 dB to 18 dB

Partial Scan (during DC

IN power supply only)

LUT (Look Up Table) OFF/ON (Mode: 5 types)

External trigger input DC IN connector

Video output switch Monochrome model: Mono 8/10/

Binning (during DC IN

power supply only)

Variable, 2-line increments (the

number of settable lines is 32 or

more/the recommended setting is

120 lines or more)

12-bit

Color model: Raw 8/10/12-bit,

RGB 24-bit, YUV 24-bit, YUV

16-bit

2×1, 1×2, 2×2

1/100,000 sec t o

2 sec

Setting by

trigger pulse

width

*If you do not prioritize the image quality, you can set

the shutter speed up to 60 sec during operation.

Overview

Note

Do not supply power to the camera cable and LAN cable

at the same time.

Note

Make sure to supply power to the camera module and

confirm that the camera module is operating before

inputting a trigger signal. If you input trigger signal to a

camera module without the power supplied, this may

cause a malfunction of the camera module.

Do not exit the application software of the host device

before completing the image transmission from the

camera. This may cause a malfunction on the camera.

Location and Function of Parts and Operation

9

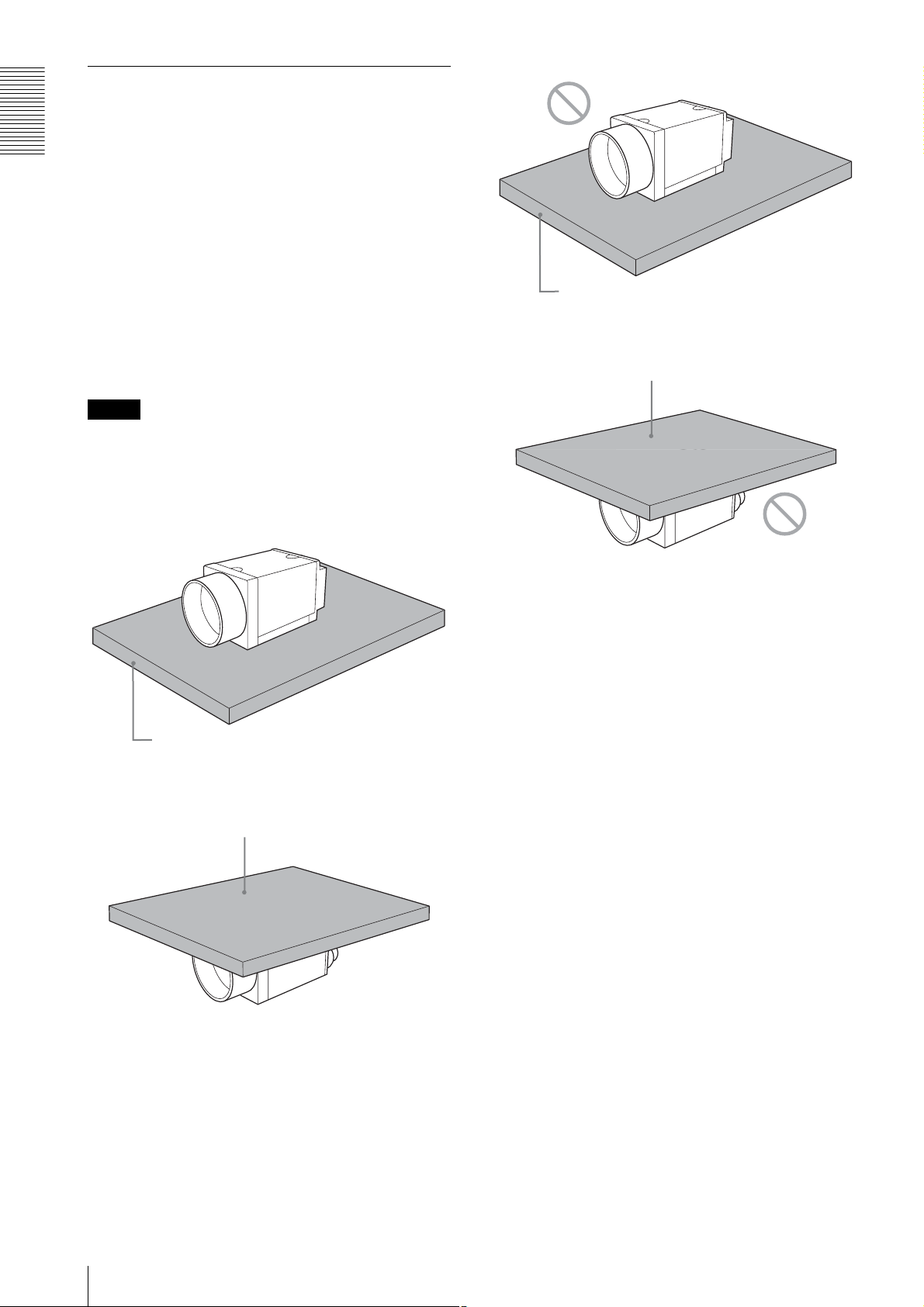

When mounting the camera

When you operate this unit in the following conditions,

heat dissipation is required depending on the usage

Overview

environment because the inside of the camera becomes

hot.

• when using PoE system

• when the partial scan is set to less than 120 lines

during the power is supplied through DC IN

To promote heat dissipation from the unit and maintain

performance, mount the camera to a metallic heat

dissipation plate.

Dimension of the heat dissipation plate: 180 mm ×

110 mm × 5 mm or more (Thermal conductivity:

16.3 W/m·K or more)

For heat dissipation, refer to the User's Guide.

Notes

• When mounting the camera to the heat dissipation

plate, secure the camera tightly by using the reference

screw holes (see page 7) and screws.

• Do not mount the camera to a plate made of a material

such as wood or resin that prevents heat dissipation.

Plate that prevents heat dissipation

(made of wood, resin, etc.)

Plate that prevents heat dissipation

(made of wood, resin, etc.)

Metallic heat dissipation plate

Metallic heat dissipation plate

10

Location and Function of Parts and Operation

Heat dissipation of the camera

The electrolytic capacitor during

• Use this camera in an environment that the read value

of the temperature sensor is 68°C (154.4°F) or less

during PoE mode.

• The read value of the temperature sensor becomes

high if the temperature around the camera is high.

When the read value is higher than 68°C (154.4°F),

mount a heat dissipation plate to the camera.

• If you use a larger heat dissipation plate, it is possible

to lower the read value of the temperature sensor.

The read value of the temperature sensor can be

obtained by the following formula:

Read value of temperature sensor =

Temperature around the camera + Temperature inside

the camera

The relation between the heat dissipation plate area

and the temperature inside the camera is shown in the

following graph:

(The heat dissipation differs depending on the

material.)

35/95

the PoE operation

This unit has an electrolytic capacitor.

This electrolytic capacitor is not powered on during the

DC IN operation. It is powered on during the PoE

operation.

When the power is supplied by PoE, the electrolytic

capacitor is designed to work for more than 3 years

without any problems even if it is operated for 24 hours

under an environment at a temperature of 40°C (104°F).

Also, if the operating time is 8 hours per day, the life

expectancy is 3 times the above mentioned period.

Periodic inspections are recommended if it is used for a

long time.

◆ Contact a Sony sales representative for more

information about inspections.

Overview

30/86

SUS

25/77

Temperature inside the camera (˚C/˚F)

20/68

0

Heat dissipation plate area (cm2) *Thickness: 0.5 cm (7/32 inches)

50 100 150

Fe

Al

200

Location and Function of Parts and Operation

11

Connections

Connections

Network Settings

For the camera to be connected to a network, the

following address data must be properly specified:

• IP address

• Subnet mask

• Default gateway

The camera provides the following three methods for the

address data setting:

• Using Persistent IP

• Using DHCP

• Using Link Local Address (LLA)

Using Persistent IP

Use this method when the IP address to be assigned to

the camera has been specified in advance. When using

the persistent IP, subnet mask and default gateway

settings are also required. When using persistent IP

forwarding on a router, default gateway settings are also

required.

Packet Delay

The delay amount to be inserted between packets can be

set when sending them to a network. By increasing the

packet delay, you can reduce the network bandwidth that

the camera uses for sending packets. However, as the

amount of data sent in a certain time is decreased with

increased delay, the frame rate of output images of the

camera may be consequently decreased.

Using DHCP

The camera is equipped with a function to automatically

obtain an IP address by communicating with a DHCP

server on a network. When using the DHCP method for

IP address setting, the subnet mask and default gateway

values automatically obtained from the DHCP server are

also used.

Using LLA

If neither Persistent IP nor DHCP is used, or if an IP

address cannot be obtained from the DHCP server, the

IP address is determined by LLA. The IP address

determined by LLA will be 169.254.XXX.YYY, with

XXX and YYY automatically specified.

In addition, the following network settings can be

changed.

• Packet size

• Packet delay

Packet Size

The amount of image data per packet can be set in bytes.

To permit the camera to operate properly, set the packet

size to a value less than the MTU of the network device

connected to the camera. Set the largest value in the

networks including the hub.

12

Network Settings

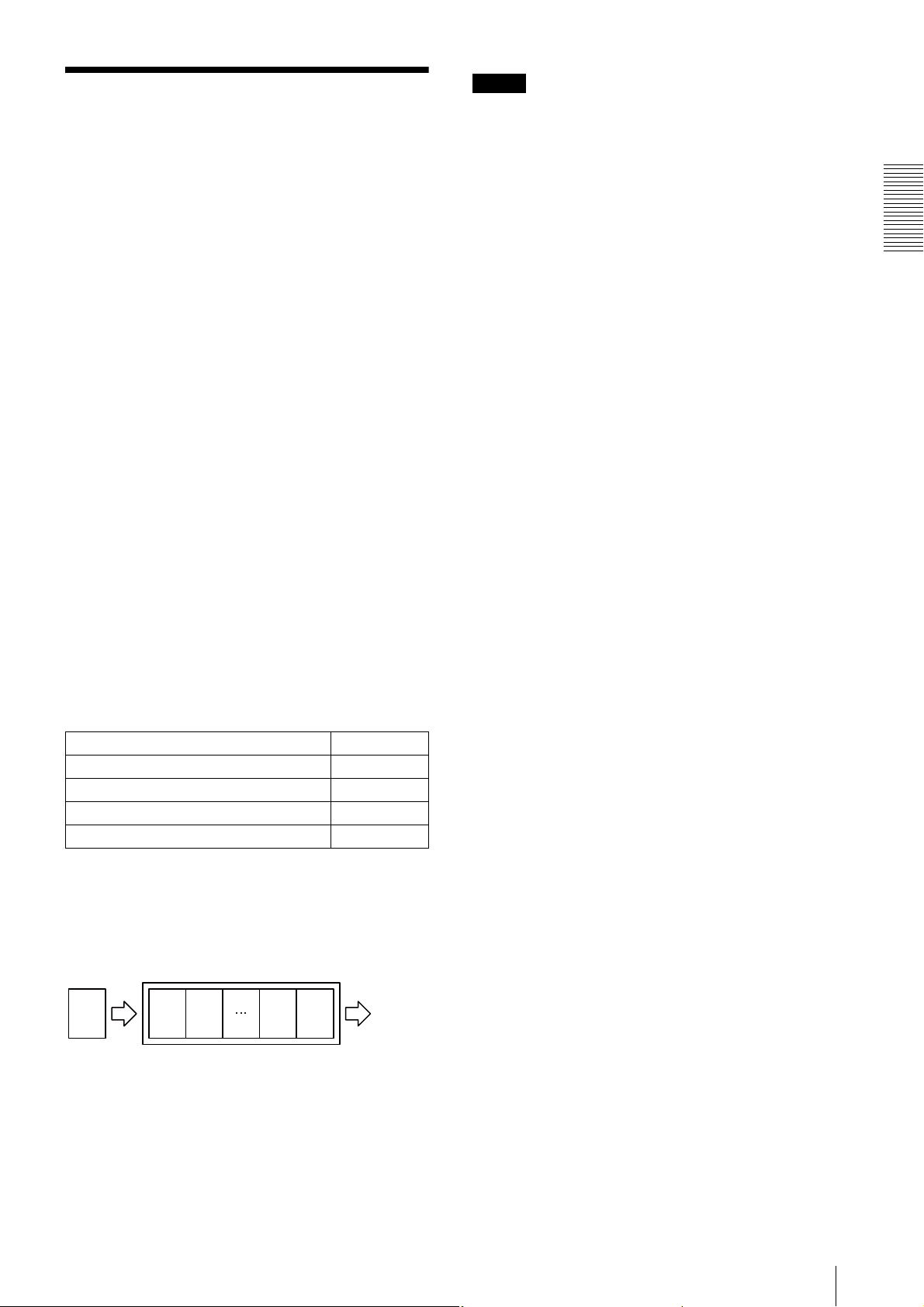

Network connection speed

This unit supports the connection with 1000Base-T

(1 Gbps) or 100Base-TX (100 Mbps).

When you connect the unit to the network, negotiate the

communication speed with the connected equipment

and start communication at a higher speed of that both

equipment are compatible with.

When using the unit with 100Base-TX connection, the

frame rate to be output is limited, because the output

data band width from the camera becomes narrow

compared to the 1000Base-T connection.

The camera has a buffer to store multiple images and all

of the shot images are stored once in the buffer.

The stored images are output from the camera in order

starting from the oldest image in the buffer.

Therefore, if the frame rate during shooting is faster than

the frame rate that can be output from the camera, the

image data will always be stored in the buffer, and the

time interval from shooting to image output becomes

large.

To avoid this situation, it is required to set the shooting

frame rate to the proper value when using 100Base-TX

connection.

The data rate of images is obtained by the following

formula:

Notes

• Any persistent IP address can be entered, but the

camera may become unable to be detected, depending

on the IP address setting. If this occurs, use a tool for

issuing ForceIP and set a persistent IP address again.

• When setting the parameters (Width, Height, and

PixelFormat) for calculating the payload size, stop

camera image output beforehand.

Connections

Data rate = Width

× Height × BPP × FPS

Width: Width of image

Height: Height of image

BPP: The number of bits per pixel depends on the

PixelFormat setting

Mono8/BayerRG8 8-bit

Mono10Packed/BayerRG10Packed 12-bit

Mono12Packed/BayerRG12Packed 12-bit

RGB8Packed/BRG8Packed/YUV8_UYV 24-bit

YUV422_8/YUV422_8_UYVY 16-bit

FPS: Frame rate [frame/sec]

It is possible to minimize delay by using the camera at a

frame rate where the data rate becomes low with a

margin against 100 Mbps.

Buffer

CCD

Image nImage

n

Image 2Image

1

Image

output

Network connection speed

13

Connections

Trigger Signal Input

Trigger signals can be input via the 2nd, 3rd, 4th pins of the DC IN connector, or the software command. Switchover of

the trigger signal can be changed via the TriggerSource register.

Register Parameter Setting

TriggerSource Line1 (0)

Line2 (1) DC IN connector 3rd pin (GPI2) *

Line3 (2) DC IN connector 4th pin (GPI3) *

Software (4) Software (TriggerSoftware register)

* The 3rd and 4th pins of DC IN connector are available only when the input/output switching setting is set to input.

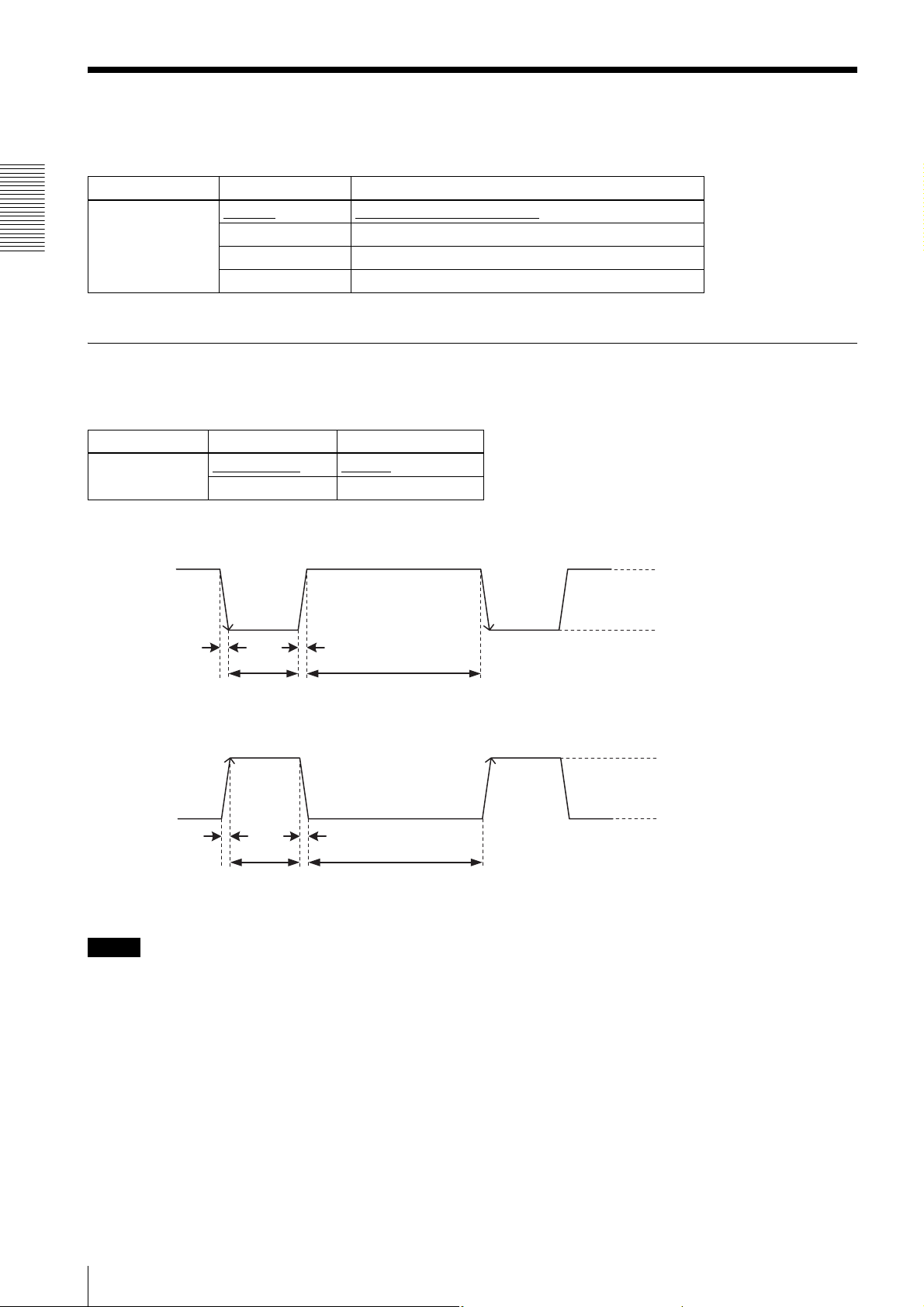

Trigger signal polarity

Positive refers to a trigger signal polarity activated while rising from Low to Hi, or during the Hi interval. Negative refers

to a trigger signal polarity activated while falling from Hi to Low, or during the Low interval.

Register Parameter Setting

TriggerActivation FallingEdge (0)

RisingEdge (1) Positive

DC IN connector specifications

DC IN connector 2nd pin (GPI1)

Negative

5 to 24 V (DC IN connector 2nd pin)

3.5 to 5.5 V (DC IN connector 3rd

and 4th pins)

0 to 0.4V

2.0µs or less

10µs to 2s

2.0µs or less

100µs or more

Trigger input polarity = Negative

5 to 24 V (DC IN connector 2nd pin)

3.5 to 5.5 V (DC IN connector 3rd

and 4th pins)

0 to 0.4V

2.0µs or less

10µs to 2s

2.0µs or less

100µs or more

Trigger input polarity = Positive

Note

When inputting a trigger signal to the camera using the DC-700/CE, use DC 5 V or less at the logical high level.

14

Trigger Signal Input

GPIO Connector

The 2nd DC IN connector is the GPI connector and the 3rd and 4th are connectors that can set to either GPI or GPO.

The trigger reset pin is the DC IN connector 2nd pin (GPI1). If you are connecting an external device to the GPI or GPO

connector, refer to the circuit specifications below.

GPI circuit specifications

5V

HCPL-M611

GPIO circuit specifications

GPI2/GPO2

180

MMBF4393LT1G

DC IN connector

DA2710100L

DC IN connector

#3

Connections

#2

#5

GPI3/GPO3

As GPI2/GPO2

#4

GPIO Connector

15

Loading...

Loading...