Page 1

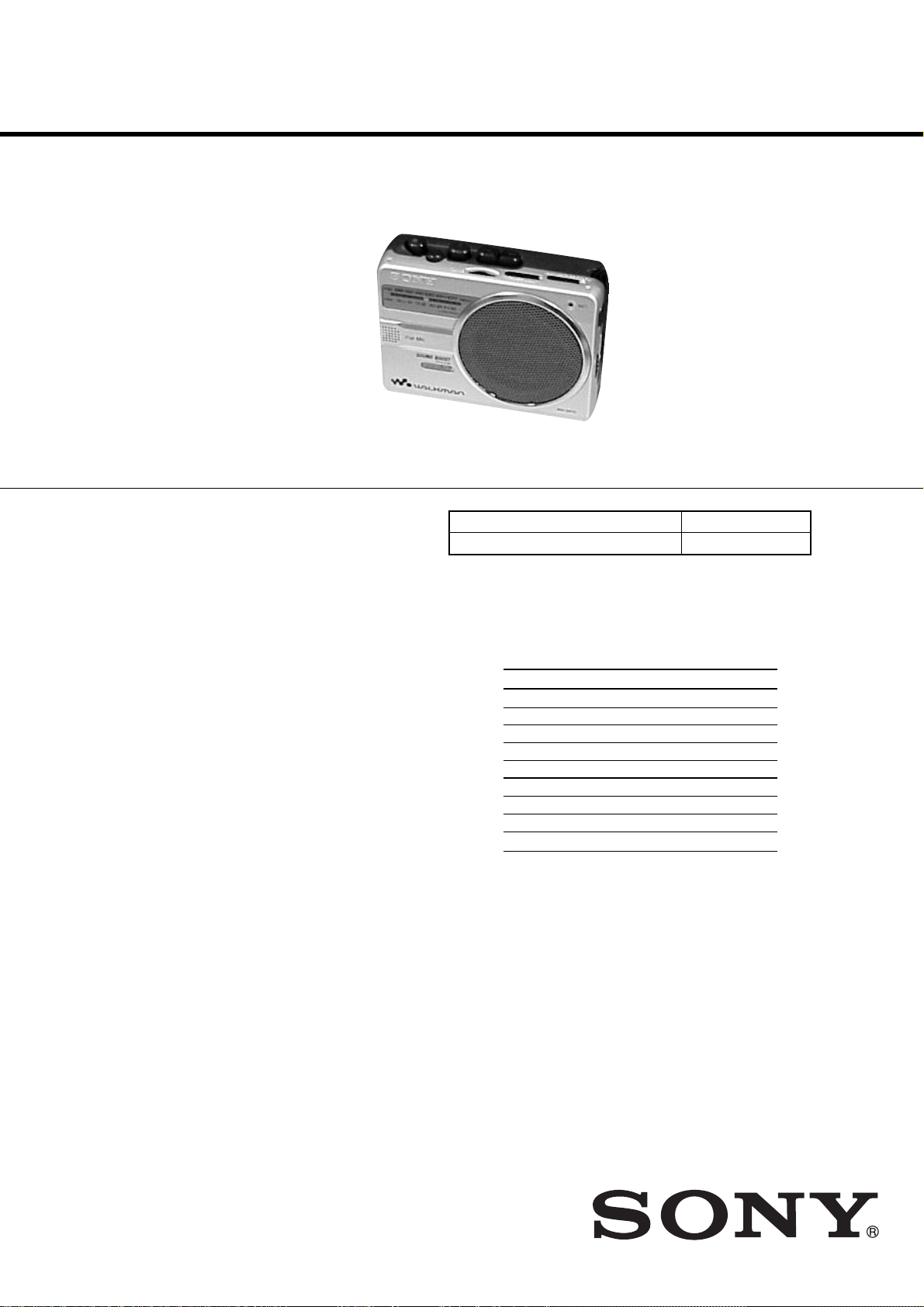

WM-SR10

SERVICE MANUAL

Ver 1.1 2003. 05

Model Name Using Similar Mechanism WM-GX221

Tape Transport Mechanism Type MT-WMGX221-175

SPECIFICATIONS

E Model

Frequency range

FM: 87.5 - 108 MHz (Saudi Arabia)

87.6 - 107.9 MHz (Other countries)

AM: 526.5 - 1 606.5 kHz (Saudi Arabia)

531 - 1 602 kHz (Other countries)

Frequency response Playback: 40 - 15 000 Hz

Input Microphone (MIC) jack

Output Headphones (i) jack, Load impedance 8 - 300 Ω

Speaker

Power requirement 3V DC

Dimensions

Approx. 112.0 × 82.5 × 37.5 mm (4

(w/h/d), excl. projecting parts and controls

Mass Approx. 187 g (6.6 oz) (main unit only)

Supplied accessory

Stereo headphones or Stereo earphones (1)

Design and specifications are subject to change without

notice.

Recording: 100 - 8 000 Hz

Approx. 5 cm (2 in.) dia.

Batteries R6 (AA) x 2

External DC 3 V power sources

1

⁄2 × 3 1⁄4 × 1 1⁄2 inches)

Battery life* (approximate hours)

Sony alkaline LR6(SG)**Sony R6P(SR)

(using headphones/earphones)

Tape playback 24 7

Radio reception 48 15

Mic recording 20 4.5

Radio recording 12 3

(using the speaker)

Tape playback 15 4.5

Radio reception 26 6

Radio recording 11.5 3

* Measured value by the standard of JEITA (Japan Electronics and

Information Technology Industries Association).

(Using a Sony HF series cassette tape)

** When using LR6 (SG) Sony “STAMINA” alkaline dry batteries

(produced in Japan).

Note

The battery life may be shorter depending on the operating

condition, the surrounding temperature and battery type.

9-874-215-02

2003E16-1

© 2003.05

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

WM-SR10

TABLE OF CONTENTS

1. SERVICE NOTE ............................................................... 3

2. GENERAL .......................................................................... 4

3. DISASSEMBLY

3-1. Front Cabinet Assy.......................................................... 5

3-2. MAIN Board ................................................................... 6

3-3. Mechanism Deck (MT-WMGX221-175) ....................... 6

3-4. Belt (CAP), M601, HRP901, HE901 .............................. 7

3-5. Cassette Holder Sub Assy ...............................................7

4. MECHANICAL ADJUSTMENT .................................. 8

5. ELECTRICAL ADJUSTMENT .................................... 8

6. DIAGRAMS ...................................................................... 10

6-1. Block Diagram – Tuner Section –................................. 11

6-2. Block Diagram – Main Section – ................................. 12

6-3. Printed Wiring Boards .................................................. 13

6-4. Schematic Diagram – MAIN Board (1/2) –.................. 14

6-5. Schematic Diagram – MAIN Board (2/2) –.................. 15

6-6. IC Block Diagrams ....................................................... 16

7. EXPLODED VIEWS

7-1. Overall Section ............................................................. 17

7-2. Cabinet (Front) Section ................................................. 18

7-3. Mechanism Deck Section-1 (MT-WMGX221-175) ..... 19

7-4. Mechanism Deck Section-2 (MT-WMGX221-175) ..... 20

8. ELECTRICAL PARTS LIST .......................................21

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

Page 3

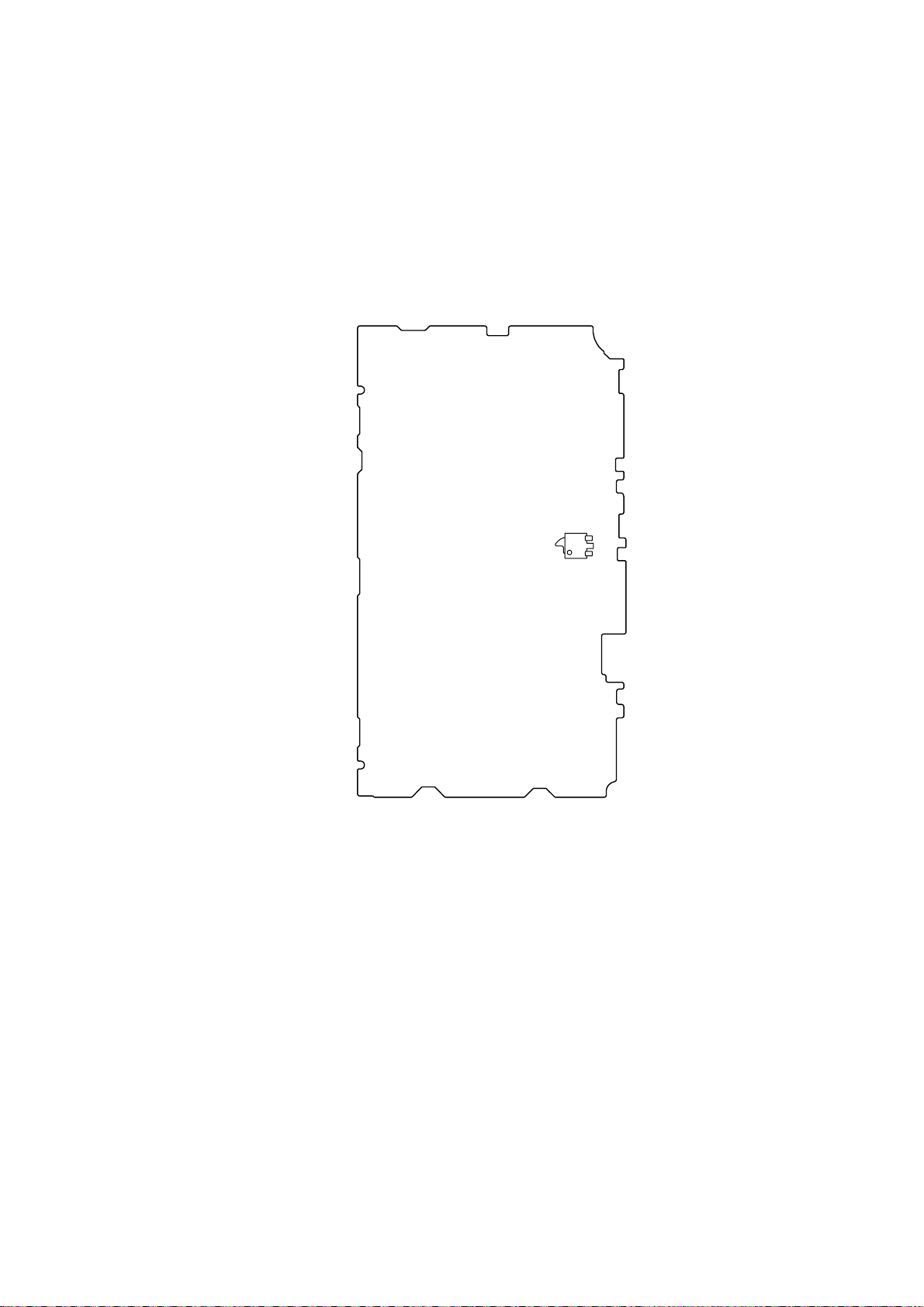

SECTION 1

SERVICE NOTE

In this set, record/play mode is detected using the switch S704 (TAPE POWER).

S704 is mounted on the MAIN board. If MAIN board is removed, it becomes impossible to detect

record/play mode.

Where MAIN board is removed, when you measure operation and voltage of each part of the mechanism

deck, please turn on S704.

– MAIN Board (SIDE A) —

WM-SR10

S704

3

Page 4

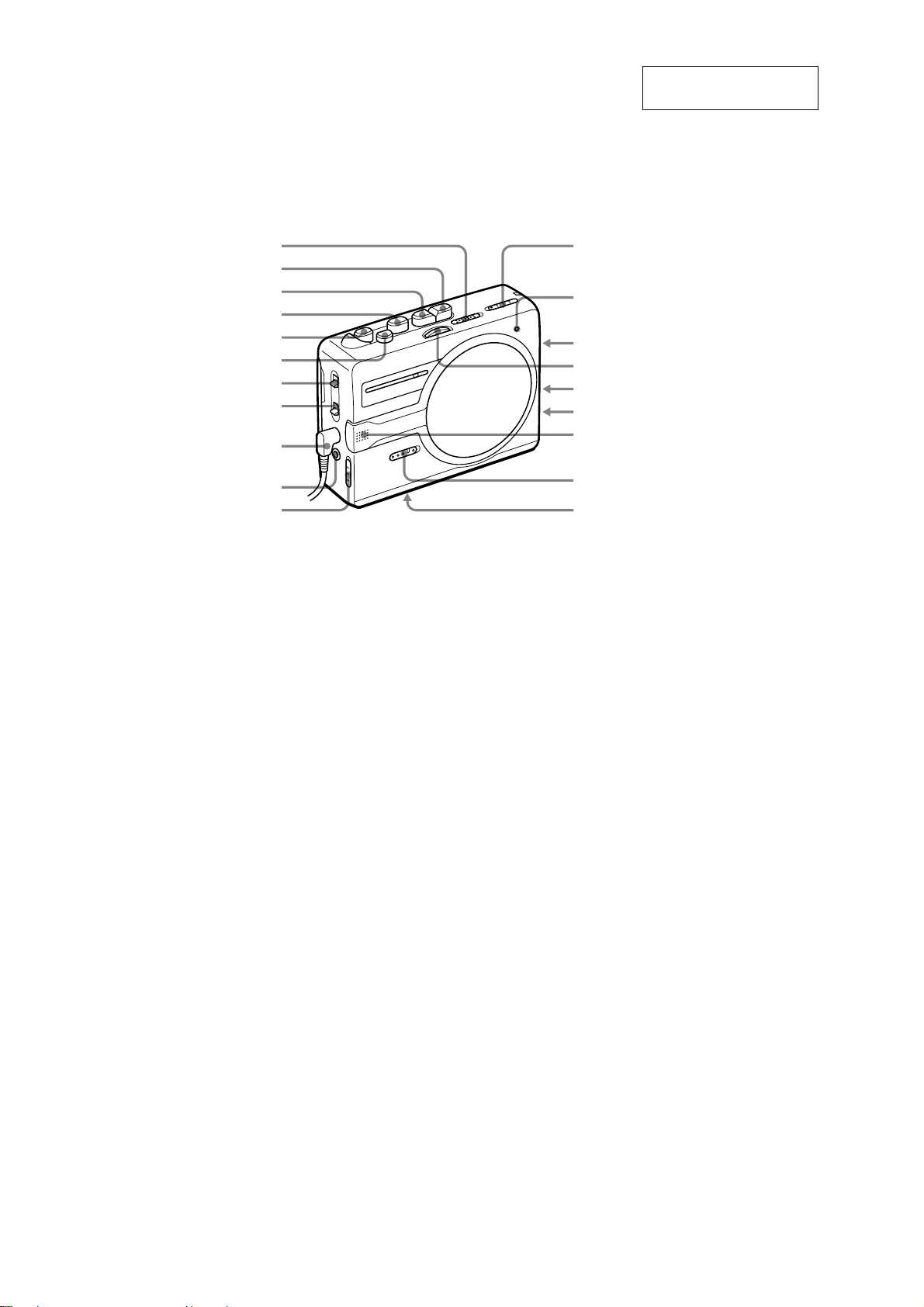

WM-SR10

• LOCATION OF CONTROLS

SECTION 2

GENERAL

This section is extracted

from instruction manual.

PAUSE

MFF/CUE

mREW/REVIEW

NPLAY**

zREC

xSTOP

ISS

FM ST/MONO

i

MIC (PLUG IN POWER)**

AVLS

* There is a tactile dot beside VOL on the main unit to show the direction to turn up the volume.

** The button/jack has a tactile dot.

(RADIO OFF) TAPE/

AM/FM

BATT indicator

VOL*

TUNING

SPEAKER/ i

DC IN 3 V

Built-in microphone

SOUND BOOST

Battery compartment

4

Page 5

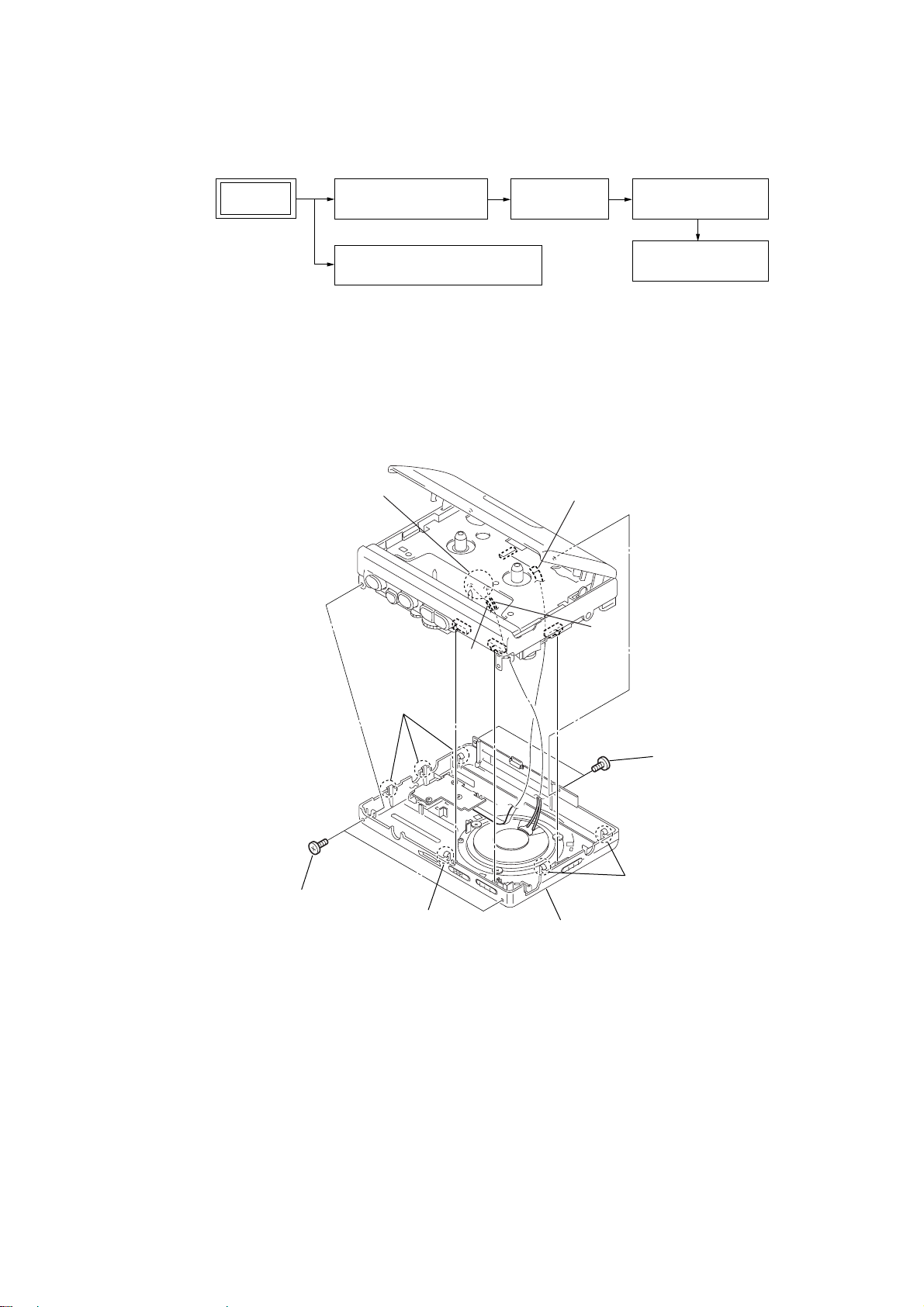

Note : Disassemble the unit in the order as shown below.

WM-SR10

SECTION 3

DISASSEMBLY

SET

FRONT CABINET ASSY MAIN BOARD

CASSETTE HOLDER SUB ASSY

Note : Follow the disassembly procedure in the numerical order given.

3-1. Front Cabinet Assy

7

Remove soldering

from the two points.

6

flexible flat cable

(CN701)

RED

MECHANISM DECK

(MT-WMGX221-175)

BELT (CAP), M601,

HRP901, HE901

2

two screws

(M1.4) (EG)

3

three claws

4

claw

WHT

8

front cabinet assy

1

5

two claws

two screws

(TP 1.7

×

3.7)

5

Page 6

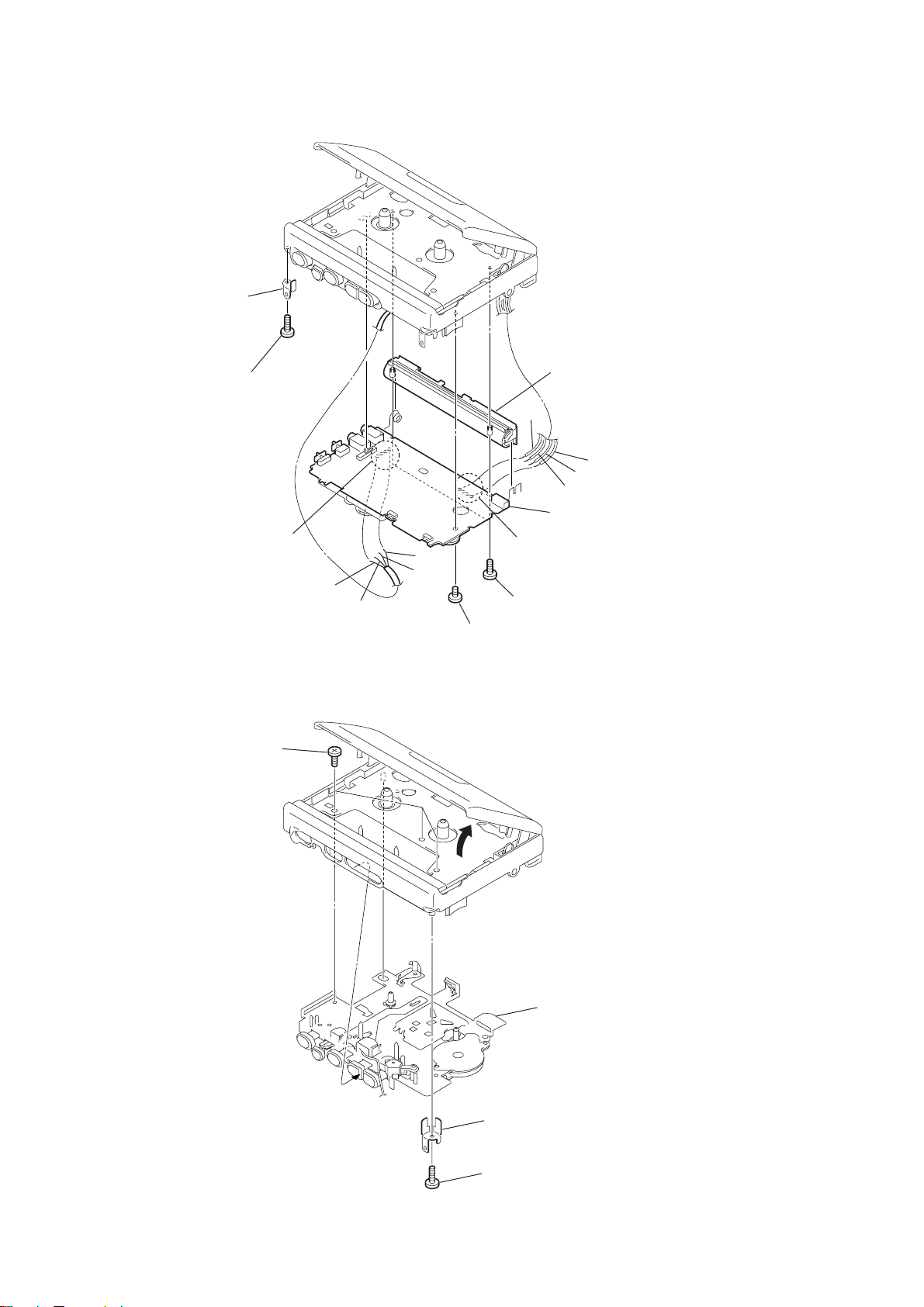

WM-SR10

3-2. MAIN Board

2

plate connector (L)

1

screw

(TP B1.7

3

Remove soldering

from the four points.

×

4)

RED

BLU

GND

WHT

5

8

ORG

BLK

7

4

Remove soldering

from the four points.

6

two screws

(TP B1.7

screw

×

3)

(M1.4

joint cover

RED

WHT

MAIN board

×

4)

3-3. Mechanism Deck (MT-WMGX221-175)

2

three screws

(IB LOCK)

1

4

plate connector (R)

5

mechanism deck

(MT-WMGX221-175)

3

screw

(TP B1.7 × 4)

6

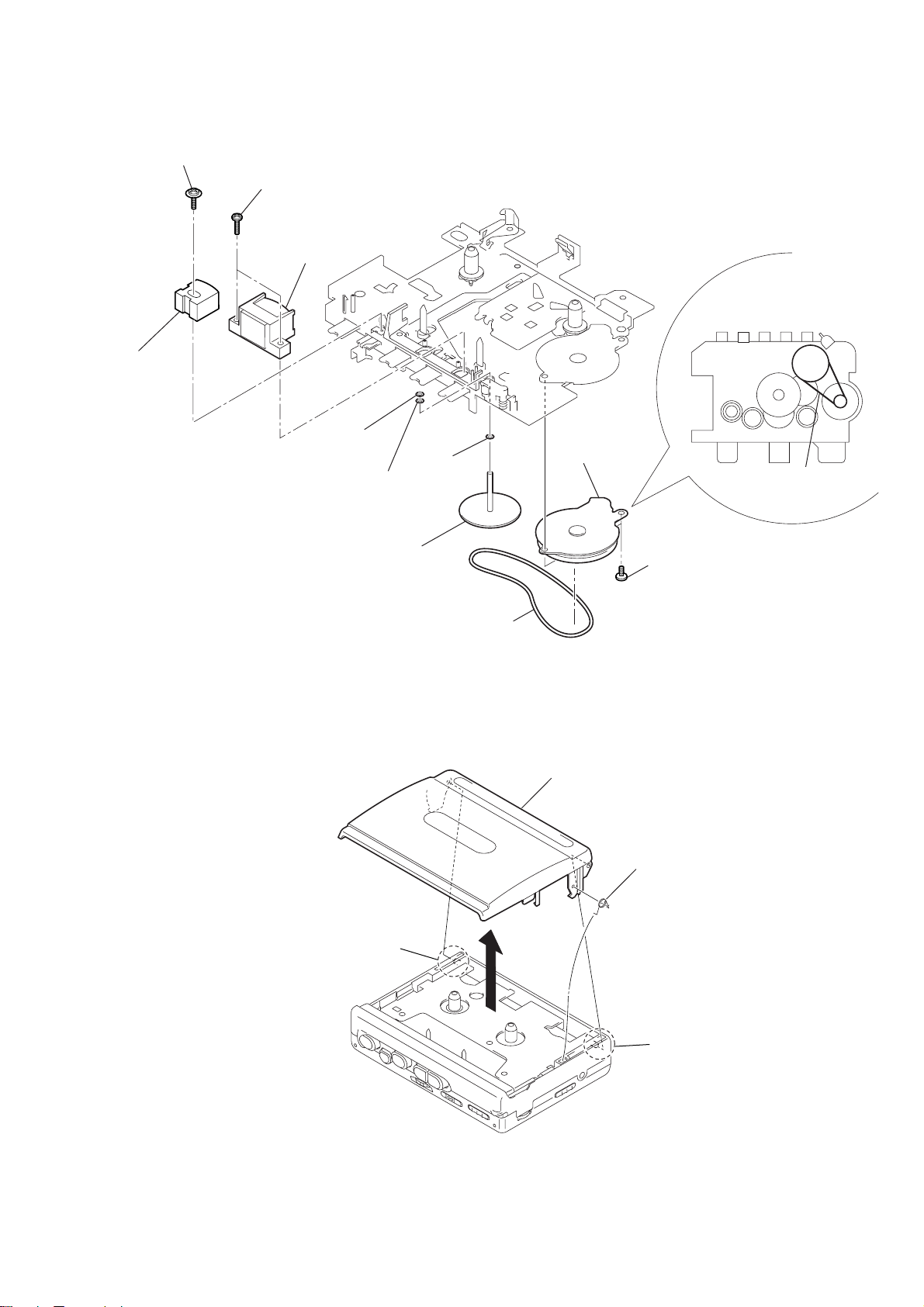

Page 7

3-4. Belt (CAP), M601, HRP901, HE901

)

screw

0

8

two screws

9

HRP901

(REC/PB head)

HE901

qa

(erase head)

4

washer

(stopper N)

5

washer

7

washer

M601

3

(capstan/reel

motor)

WM-SR10

z

Attaching belt (CAP).

belt (CAP)

capstan fly assy (AR)

6

3-5. Cassette Holder Sub Assy

2

boss

1

belt (CAP)

3

two screws (M1.4)

2

5

cassette holder sub assy

4

spring (torsion

1

boss

7

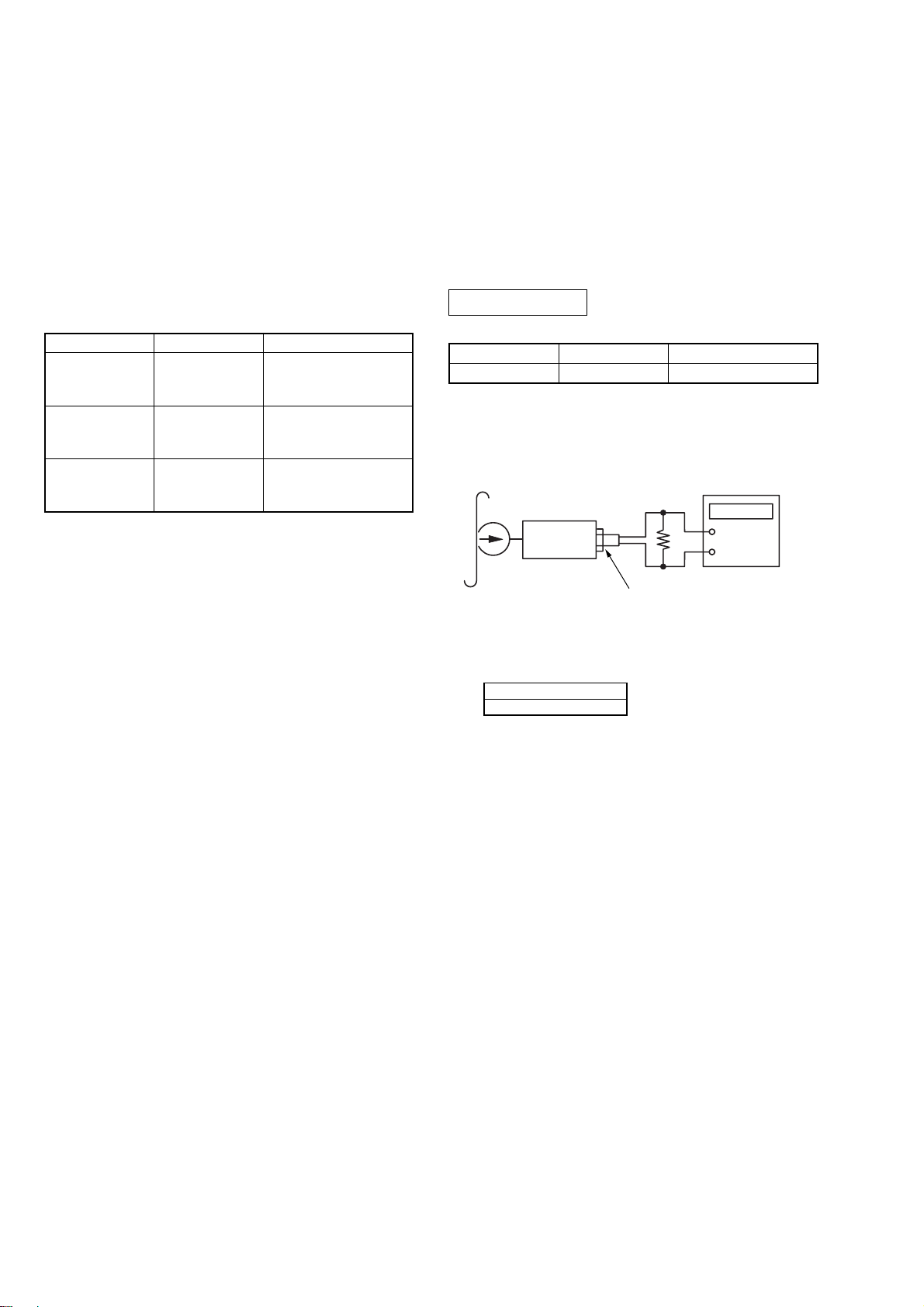

Page 8

WM-SR10

r

SECTION 4

MECHANICAL ADJUSTMENT

SECTION 5

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring a head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Torque Measurement

Mode

FWD

FWD

Back Tension

FF, REW

Torque Meter

CQ-102D

CQ-102D

CQ-201B

Meter Reading

19.6 to 39.2 mN•m

(20 to 40 g•cm)

(0.28 to 0.56 oz•inch)

0.49 to 4.9 mN•m

(0.5 to 5.0g•cm)

(0.0069 to 0.069 oz•inch)

More than 49 mN•m

(More than 50 g•cm)

(More than 0.69 oz•inch)

PRECAUTION

1. Specified voltage: 2.5 V (DC)

2. Switch and control position

VOL : MAX

SPEAKER : OFF

AVLS : NORM

SOUND BOOST : OFF

PAUSE : OFF

ISS : 1

FM MODE : FM ST

TAPE SECTION

Set

Signal

3 kHz, 0 dB

2

jack (J301)

16

Ω

Tape

WS-48A

Tape Speed Adjustment

Procedure:

Test tape

WS-48A

(3kHz, 0dB)

1. Enter the FWD playback mode.

2. Adjust RV601 so that the value of the frequency counter reading

becomes 3,000 Hz.

Specification value:

Frequency counter

2,985 Hz – 3,015 Hz

3. Check that the frequency deviation at the beginning and ending

of a tape is within 1.5 % (45 Hz).

Used for

Ta pe Speed Adjustment

+

–

Frequency counte

Adjustment Location : MAIN Board (see page 9)

8

Page 9

WM-SR10

r

TUNER SECTION

0dB=1µV

[AM]

BAND : AM

AM RF signal

generator

30% amplitude modulation by 400 Hz

signal.

Output level : as low as possible

Put the lead-wire

antenna close to

the set.

[FM]

BAND : FM

FM RF signal

generator

0.01µF

75kHz frequency deviation by 1kHz signal.

Output level : as low as possible

to ANT (FM IN)

•Repeat the procedures in each adjustment several times.

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 505 kHz (516.5 kHz)

CT1-4 1,680 kHz (1,631.5 kHz)

( ) : EA MODEL

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 621 kHz

CT1-1 1,404 kHz

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 455 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 86.0 MHz (87.35 MHz)

CT1-3 109.5 MHz (108.25 MHz)

( ) : EA MODEL

set

2

jack (J301)

Adjustment Parts Location :

[MAIN Board] — SIDE A —

CT1-3 : FM frequency

coverage adjustment

CT1-3

CT1-2

Ω

16

+

–

level mete

CT1-4 : AM frequency

CT1-4

CT1-1

coverage adjustment

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.0 MHz (87.35 MHz)

CT1-2 109.5 MHz (108.25 MHz)

•Abbreviation

EA : Saudi Arabia model

[MAIN Board] — SIDE B —

RV601 : Tape speed adjustment

L4 : AM frequency

coverage adjustment

L3 : FM frequency

coverage adjustment

RV601

L1

L4

( ) : EA MODEL

T1 : AM IF

adjustment

T1

L3

L2

CT1-2 : FM tracking

adjustment

CT1-1 : AM tracking

adjustment

L1 : AM tracking

adjustment

L2 : FM tracking

adjustment

9

Page 10

WM-SR10

SECTION 6

DIAGRAMS

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. p: pF.

50 WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/

• C : panel designation.

• A : B+ Line.

• H : adjustment for repair.

•Total current is measured with no cassette installed.

•Power voltage is dc 3 V and fed with regulated dc power supply

from external power voltage jack (J401).

•Voltages and waveforms are dc with respect to ground under nosignal (detuned) conditions.

no mark : FM

(): PB

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM

E : PB

d : REC

N : MIC INPUT

•Abbreviation

9E : E model without the indication of the country of origin.

EA : Saudi Arabia model

4

W or less unless otherwise specified.

Note on Printed Wiring Board:

• Y : parts extracted from the conductor side.

a

•

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Par ts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

: Through hole.

• WAVEFORMS

1

T551 (REC mode)

21

µ

10 V/DIV, 10 µs/DIV 1 V/DIV,

s

42 Vp-p

2

IC301 r; (VOUT)

(PB mode)

4.4 ms

2 ms

/DIV

2.7 Vp-p

10

Page 11

6-1. Block Diagram – Tuner Section –

WM-SR10

• SIGNAL PATH

: FM

X2

10.7MHz

12

QUAD

FM

DET

LEVEL

DET

AM

DET

AGC

FM

MUTE

TUN

LED

TUN LED

BUFFER

ST

LED

ST LED

11

AF

AMP

LP1

MO-ST

151610

MPX-IN

DIVIDER/

VCO

DECODER

AMP

SWITCH

S1

FM ST MONO

DET-OUT

AF

18 17

PD1

PD2

LP2

BAND

L OUT

R OUT

14

13

FM

RF AMP

AM

RF AMP

IC1

FM-RF OUT

CT1-3, L3

FM FREQUENCY

COVERAGE

FM/AM

MIX AMP

FM/AM

OSC

FM OSC

AM OSC

2123

20

MIX

CT1-4, L4

AM FREQUENCY

COVERAGE

CF2

4 8

AM IF

10.7MHz

T1

CF1

455kHz

FM

IF IN

FM

IF AMP

AM

IF IN

7

AM

IF AMP

FM/AM RF AMP, FM/AM MIX AMP,

FM/AM OSC, FM/AM IF AMP, DET, MPX

ANT

A

C2

L1

AM

FERRITE BAR

ANTENNA

CT1-1, L1

AM TRACKING

CP1

B.P.F.

CT1-1 CV1-1

L2

FM RF

CT1-2, L2

FM TRACKING

FM-RF

IN

1

AM-RF

IN

24

CT1-2 CV1-2

: AM

TU L, TU R

B

L3

FM OSC

CV1

TUNING

CT1-3 CV1-3

L4

AM OSC

Q33, 34

CT1-4CV1-4

AM

D

FM

E

D33

BAND SELECT

SWITCH

Q30, 32

MUTING

CONTROL

TUNER MUTING

JR3

C

R5

TU VCC

1111

Page 12

WM-SR10

6-2. Block Diagram – Main Section –

TU L, TU R

B

J501

(PLUG IN POWER)

MIC

MIC501

FLAT MIC

TUNER MUTING

C

21

19

MIC

IN (L)

MIC

IN (R)

IC501 (1/2)

MIC AMP, ALC

ALC

ALC

MIC

AMP

MIC

AMP

MIC

OUT (L)

MIC

OUT (R)

TU L TU R

16

17

IC501 (2/2)

REC/PB AMP

BUF

IN (L)

Q706

14

BUF

IN (R)

13

+

+

MUTING

MODE

CONTROL

CIRCUIT

PB AMP

REC AMP

PB AMP

REC AMP

OUT (L)

REC

OUT (L)

OUT (R)

REC

OUT (R)

LINE SW

REC SW

PW SW

PB

8

2

PB

9

3

15

11

12

TU B+

PB/REC

REC VCC

MAIN VCC

S304

AVLS

NORM

LIMIT

Q252

PRE AMP

4

3

2

BYPASS

IC151

POWER AMP

–

+

SHUT DOWN

1

–

+

5

8

Q717,718

CONTROL

Q714

MUTING

+

MUTING

D234

SP251

(SPEAKER)

HRP901

(REC/PB)

L-CH

R-CH

HE901

(ERASE)

BATT B+

M601

(CAPSTAN/REEL)

S301 (3/4)

(REC/PB)

REC PB

MAIN VCC

COM

WV

Q551

ISS

SWITCH

U

S301 (1/4)

(REC/PB)

REC PB

S301 (2/4)

(REC/PB)

REC PB

VREF

T551

BIAS OSC

3

S551

2

ISS

1

PRE AMP, POWER AMP, MEGA-BASS

FWDIN (L)

9

10

REVIN (L)

FWDIN (R)

11

12

REVIN (R)

VREF

13

Q553

REC

BIAS OSC

OUT

37

UOUT

39

VOUT

40

WOUT

41

IC301 (1/2)

EQ

AMP

EQ

AMP

MAIN VCC

PB/REC

COMPARATOR

CONTROL

MOTOR

CIRCUIT

MUTING

PRE-OUT (L)

PRE-NF (L)

PRE-NF (R)

PRE-OUT (R)

S301 (4/4)

(REC/PB)

REC PB

+

VSP

–

SPEED

DRIVE

IN+

5

6

8

7

35

36

SWITCH &

LOGIC

CIRCUIT

EQ

EQ

OSC

CIRCUIT

OSC

47

TH601

+

S303

SOUND BOOST

OFF

ON

34

M-VREF

BIAS

REFERENCE

VOLTAGE

IC301 (2/2)

CAPSTAN/REEL

MOTOR DRIVE

+

LOW

BOOST

L.B-SW

32

TAPE SPEED

RV601

S/S

3

30

MIX-IN (R)

29

MAIN VCC

MIX-IN (L)

Q702

MIX 1

+

–

MIX 2

–

+

–

+

VREF

POWER MUTE

SWITCH

Q703, 711

START/STOP

CONTROL SWITCH

PB/REC PAUSE

NF

Q707

DET

MIX-OUT (L)

MIX-OUT (R)

POWER

MUTE

21

S702

PAUSE

L

R

CONTROL

24

25

SYSTEM

15

D35

D32

PB/REC

MAIN VCC

OFF

ON

Q302

AVLS

SWITCH

Q704

PRE MUTE

SWITCH

H/P MUTE

MUTING

MAIN VCC

PB/REC

MAIN VCC

Q705

H/P MUTE

SWITCH

D701

Q722

MUTING

CONTROL

Q720

MUTING

CONTROL

Q31, 709

MUTING

CONTROL

Q719

MUTING

CONTROL

RV301

VOL

PB/REC

TU B+

MAIN VCC

H/P MUTE

22

SPEAKER

POWER

IN (L)

S701 (2/2)S701 (1/2)

i

POWER

AMP

BATT B+

POWER

OUT (L)

Q710

SWITCH

16

TU B+

PB/REC

(HEADPHONE)

J301

MUTING

i

+

AMP

AMP

POWER

OUT (R)

20

POWER

OUT (COM)

18

Q401, 403

RIPPLE

FILTER

Q402

SWITCH

D302

D401

BATT

D301

BATT B+

S703

(FUNCTION)

FM

AM

TAPE

(RADIO OFF)

ANT

A

• SIGNAL PATH

: TUNER (FM/AM)

: TAPE PLAY

: TAPE REC

: MIC INPUT

DRY BATTERY

SIZE ‘‘AA’’

(IEC DESIGNATION R6)

2PCS. 3V

–

J401

DC IN 3V

+

MUTING

TU VCC

REC VCC

PB/REC

MIC B+

REC VCC

MAIN VCC

TU B+

(ON at FF/REW/PLAY modes.)

POWER

IN (R)

23

VREF

S704

(TAPE POWER)

POWER

POWER

Q712, 713

B+ SWITCH

Q701,715

B+ SWITCH

Q501, 502

B+ SWITCH

AM

D

FM

E

1212

Page 13

WM-SR10

6-3. Printed Wiring Boards

A

B

IC301

C

• : Uses unleaded solder.

S703

TAPE

(RADIO OFF)

SP251

(SPEAKER)

BATT

IC151

WHT

–1 –2

RED

RED

WHT

BLK

ORG

/REEL MOTOR

COM

W

V

U

WHT

BLK

D

E

F

G

IC1

(ERASE)

• Semiconductor Location

CV1

TUNING

IC501

Ref. No. Location

D32 B-8

D33 D-3

D34 A-4

D35 A-8

D234 C-8

D301 A-4

RED

BLU

WHT

BLK

D302 D-8

D401 A-6

D701 D-1

CF2

IC1 F-3

IC151 B-7

CF1

X2

IC301 C-2

IC501 E-9

Q30 D-2

Q31 C-3

Q32 C-3

Q33 C-3

Q34 D-3

Q252 B-7

Q302 B-3

MONO

S1

FM ST

Q401 A-1

Q402 A-2

Ref. No. Location

Q403 A-1

Q501 E-1

Q502 E-1

Q551 F-1

Q553 E-1

Q701 D-1

Q702 C-6

Q703 C-1

Q704 D-1

Q705 B-2

Q706 E-9

Q707 B-8

Q709 C-8

Q710 D-1

Q711 C-1

Q712 D-8

Q713 D-8

Q714 C-7

Q715 D-1

Q717 C-7

Q718 C-7

Q719 D-8

Q720 C-8

Q722 D-8

12

3456789101112 13

1313

Page 14

WM-SR10

6-4. Schematic Diagram – MAIN Board (1/2) –

Q501

C503

0.1 B

C502

0.1 B

UN5114-TX

Q502

XP1214

47

R505

C504

2.2k

R504

2.2k

C505

0.01 B

4V (A)

10V (B)

22

1M

R507

C508

TA8155FN(ER)

F

1

47

C510

C509

2.2k

2.2k

R508

R509

C514

1F

47k

R506

B

0.01

C507

IC501

1k

R503

10V (B)

2.2k

R501

2.2k

R502

L

MIC

R

MIC

FB501

FB

1K

FB502

FB 1K

FB503

J501

FB 1K

MIC

MONO

• Refer to page 16 for IC Block Diagram.

B

B

F

C515

C513

1

C512

2200p

2200p

10k

R510

220k

R511

C516

4V (A)

B

C511

22

470p

10k

C521

R516

REC

VCC

R716

10k

C519

R515

10k

0.1 F

R514

10k

C520

0.47 F

F

C517

0.1

F

0.47

C518

R512

220k

R513

10k

1F

Q701

XP1215

R717

F

2.2

C522

0

2SB1679

Q706

XP1215

0

0

J10

J9

F

F

0.47

0.47

C28

C27

B

47k

470p

R517

C523

Q715

S1

CH

UJ

4

C3

1000p

B

C32

1000p

B

C40

1000p

SL

FB2

1K FB

CP1

TP3

FM

FM BPF

IN

C2

1000p

BP1

C33

2200p

SL

-1

1p

C7

TP8

AM RF

J7 C14

0 4.7

C38

100p

10p

L1

SL

R465

AM ANT

R459

470

2.2k

CT1

SML-210LT-T86

L2

CV1

C9

TP1

TU

GND

D401

-2

-2

FM RF

CV1

CT1

C10

AM IFT

C11

0.47 B

C37

100p SL

MA111

D301

D302

1

-1

3

2

L3

FM OSC

C12

R3

0

T1

MA111

S703

-3

-3

CN701

6 PIN

L4

CV1

CT1

AM OSC

C5

6p

IC1

TA2111FN(EL)

B

SL

C17

C39

0.047

1000p

C15

C13

470

4V (A)

R2

1k

R9

5

-4

-4

CV1

C18

CT1

C30

0.22

CF1

455kHz BPF

CF2

10.7MHz BPF

CN702

6PIN

C560

0.1 B

F

MONO STEREO

1000p

B

C501

0.22

S304

0

10k

R5

JR3

TP6

MIC501

F

47k

100k

25V

R6

R10

0.1

C23

TP2

TU

VCC

D34

MA111

1

F

10.7MHz

C29C22

0.1

16V

F

X2

C26

UN5214-TX

10V (B)

47

C24

4700p

Q33

C25

4700p

TP5

TU

TP4

R

TU

L

100k

100k

R7

R8

Q712

R719

2SB1679

47k

R718

10k

Q713

2SA1162-YG-TE85L

R34

1k

2.2k

R31

Q34

DTC114YUA

R30

100k

0

C35

2F

FB1

10

R11

R724

1M

C707

C34

R32

2F

1M

R33

100k

Q32

MA111

2SA1162-YG

-TE85L

D33

Q30

DTA114TUA

R64

1M

220

R713

22k0.01 B

Q720

DTA114TUA

R725

2F

R257C250

100k

C251

C153

0.1 F

R250

D234

R258

Q710

XP4215-TX

R259C252 100k0.022 B

4V EC

0

S701(2/2)

IC151

LM4871MM

MA111

SP-MUTE

220k

C253

0.47

R711

R712

10k

10k

R706

220k

R255

470k

Q714

UN5215-TX

R252

470k

Q717, 718

Q718

DTA115TUA

B

C210

0.1

Q717

DTA114TUA

R708

1M

C705

B

R707

220k

2F

C710

2F

R254

22k

SP251

10k

R256

C21

50V

B

TP7

DET

OUT

S303

1414

Page 15

WM-SR10

6-5. Schematic Diagram – MAIN Board (2/2) –

C103

470p B

C101

S301(3/4)

C316

1000p B

C506

1F

R551

S551

47

C551

Q551

XP1501

CH

C552

470p

B

0.01

1k

R552

47k

R553

• Refer to page 10 for Waveforms. • Refer to page 16 for IC Block Diagrams.

C203

470p B

B

10k

B

10k

C102

2200p

R101

S301(1/4) S301(2/4)

F

1

B

470p

C104

CH

C553

220p

B

47k

C554

0.01

R554

C202

R201

2200p

F

1

C201

PB

REC

B

C205

4700p

R206

R213

2.2k

B

C301

1000p

B

470p

C204

T551

BIAS-OSC

B

C555

2200p

1k

R555

R560 100

47

R556

R557

2SD596-T1DV4

4.7k

R559

10k

C557

0.022 B

C556

10V (B)

47

F

F

1

1

C207

C107

R204 R104

10k 10k

1k

4V (A)

C206

22

Q553

C558

BIAS OFF

4700p

R103R203

22k22k

R105R205

R212

2.2M

B

R558

10

1M1M

R112

2.2M

S301(4/4)

R722

1M

R723

100k

Q722

DTA114TUA

C709

12F

Q703

XP1215

1k

R605

R601

22k

D701

DAN202U

PAUSE

R603

47k

C601

0.01 B

Q704

XP4315

EC

4V

C319

Q711

UN5116

B

C105

4700p

1k

R106

R113

2.2k

4V (A)

C106

22

220

R703

REF

Q702

UN5214-TX

R602

4.7k

V

MIX-IN

R

MIX-IN

L

R610

MAIN

0

R115

0

R607

10k

3900PPM

3.3K

0

R303

10k

1000p B

1F

1F

2SA1162-YG

Q252

RV601

0.1 B

4.7k

0.022

22k

C307

V

REF

B

R215

BOOST

Q705

UN5215-TX

RV301

10k/10k

C263

0.22 16V B

C318

10 10V

R315

100k

0.1 B

S701(1/2)

C303

100p

CH

R302

100k

C317

22

6.3V

C304

2.2 F

C305

1F

H/P

MUTE

R304

1k

C315

1k

R263

Q719

DTA114TUA

C706

R702

100k

AVLS

S702

MA111

D32

MA111

D35

C703

F

C701

0.01

10k

R264

Q707

UN5214-TX

10K/47K

C264

0.01 F

B

0.01

B

B

B

B

0.1

0.1

0.1

0.22

C603

C605

C604

C602

IC301

LB8115W-NA-TLM

2.2

R305

F

1

C308

B

F

F

0.1

0.1

10V (B)

1000p

22

C311

C309

C312

C310

10V (B)

22

C313

B

0.22

C607

C606

2.2 B

R604

100k

TH601

R606

1k

R608

R613

C108

1000p B

C208

C306

Q302

XP4501-TX

R207

100

R107

100

C109

R208

2.2k

2.2k

R108

R260

100k

B

B

B

0.47

SL

1000p

1000p

C314

100p

C211

C111

C405

C209

1k

R160

100k

R265

B

C400

0.1

470k

2.2k

R261

R262

VCC

4V

C404

220

Q31

DTA114TUA

R710

1M

2F

R62

C36

1M

2F

R63

100k

Q403

2SB1679

10k

4.7k

R402

Q401

XP1501

1k

R401

XP1214

C401

Q402

R705

1M

Q709

XP4315

R210

1k

R405

2.2k

R403

B

1000p

R704

R110

470k

220k

C402

10V (B)

R406

R404

22

1M

C708

2F

1k

HP/R

10

R209

10

R109

HP/L

0

R309

HP/COM

TAPE-SW

1

R609

1

+B

4V

C403

220

GND

FB201

FB 1K

FB101

FB 1K

FB301

FB 1K

S704

J401

M601

J301

1515

Page 16

WM-SR10

6-6. IC Block Diagrams

AM-RF IN

23

24

FM

RF

VCC1

FM-RF OUT

21

22

FM OSC

FM MIX

1

FM-RF IN

FM OSC

2

GND

AM OSC

AM MIX

3 4

LPF3

AM OSC

20

MIX

IC1 TA2111FN (EL)

DET-OUT

AFC

1819

FM

IF

FM

MUTE

AM DET

FM DET

FM

AM

AGC

5

6 7

AGC

VCC2

IF

AM IF IN

IF

8

FM IF IN

LEVEL

DET

9

17

AF

GND2

MPX-IN

16

DIVIDE

TUNE

LP1 MO-ST

L OUT

LP2 BAND

VCO

LED

10 11 12

TUN-LED

13

1415

DECODE

ST

LED

ST-IND

R OUT

ST/MO

FM/AM

QUAD

SHUTDOWN

BYPASS

+IN

IC151 LM4871MM

VO2

1

2

3

-IN

4

BIAS

VDD/2

AV=-1

8

GND

7

VDD

6

VO1

5

COM

PRE-GND

PRE-OUT (L)

PRE-NF (L)

PRE-OUT (R)

PRE-NF (R)

FWDIN (L)

REVIN (L)

FWDIN (R)

REVIN (R)

S/S

IC301 LB8115W-NA-TLM IC501 TA8155FN (ER)

M-VCC

OSCUBVB

48 47 46 45 44 43 42 41 40 39 38 37

1

REF

VOLTAGE

2

RI

BIAS

3

4

5

6

7

8

9

10

11

12

REF

OSC

CURRENT

DET

WB

FWD/

REV

OPERATION

DET

SYS

CONT

DR

MPGND

WOUT

VOUT

PRE DRIVER

OPERATION LOGIC

PULSE DET

REF VOLTAGE

FOR SPEED CONTROL

DET

–

+

UOUT

SPEED

FC

FREQ

CARC.

OUT

LOW

BOOST

36

VSP

35

IN

34

M-VREF

33

M-GND

32

L. B-SW

31

DET-OUT

30

MIX-IN (L)

29

MIX-IN (R)

28

H.PIN (L)

27

H.PIN (R)

26

LP.2

25

MIX-OUT (R)

ALC

DET

ALC

ALC

RADIO / TAPE

24

23

22

21

20

19

18

17

16

15

14

ALC

VCC

MIC NF (L)

MIC IN (L)

GND

MIC IN (R)

MIC NF (R)

MIC OUT (R)

MIC OUT (L)

LINE SW

BUF IN (L)

VREF

1

2

3

4

5

6

7

8

9

10

11

REC AMP

VREF

PB AMP

PB AMP

REC / PB

VCC (REC)

REC OUT (L)

REC OUT (R)

PB IN (L)

+

PB IN (R)

PB NF (L)

PB OUT (L)

PB OUT (R)

PB NF (R)

REC SW

R.F

13 14 15

VREF

R.P-REF

16

17

(L)

SYSTEM

POWER-OUT

VREF

18 19 20 21 22 23 24

(R)

VCC

(COM)

POWER-GND

POWER-OUT

POWER-MUTE

POWER-OUT

(L)

POWER-IN

(L)

(R)

MIX-OUT

POWER-IN

PW SW

12

PW SW

13

BUF IN (R)

1616

Page 17

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

7-1. Overall Section

SECTION 7

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Accessories are given in the last of this parts

list.

23

WM-SR10

•Abbreviation

9E : E model without the indication of the

country of origin.

EA : Saudi Arabia model

19

21

20

18

a

7

MT-WMGX221-175

15

14

13

12

11

17

10

16

7

19

* 9

22

27

25

28

a

3

cabinet (front) section

L1

2

1

8

#1

26

7

6

5

4

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-244-967-01 KNOB (TUNING)

2 3-237-136-01 GEAR (B)

3 3-225-996-11 SCREW (M1.4)(EG),PRECISION PAN

4 3-244-968-01 POINTER

5 3-244-969-01 HOLDER (GEAR)

6 3-345-648-95 SCREW (M1.4), TOOTHED LOCK

7 3-318-203-61 SCREW (B1.7X4), TAPPING

8 3-237-135-01 GEAR (A)

* 9 A-3178-901-A MAIN BOARD, COMPLETE (EXCEPT EA)

* 9 A-3178-905-A MAIN BOARD, COMPLETE (EA)

10 3-375-114-81 SCREW

11 3-234-569-01 BUTTON (FF)

12 3-234-570-01 BUTTON (REW)

13 3-234-568-01 BUTTON (PLAY)

14 3-235-589-01 BUTTON (STOP)

15 3-235-588-01 BUTTON (REC)

16 3-245-464-01 PLATE, CONNECTOR (R)

17 3-242-657-01 CUSHION

18 3-245-463-01 PLATE, CONNECTOR (L)

19 3-242-657-11 CUSHION

20 3-237-121-21 CABINET (CENTER)

21 3-939-590-16 SCREW (IB LOCK)

22 3-237-140-01 SPRING (TORSION)

23 X-3382-585-1 HOLDER SUB ASSY. CASSETTE (9E)

23 X-3382-599-1 HOLDER SUB ASSY CASSETTE (EXCEPT 9E)

25 3-237-139-01 COVER, JOINT

26 3-559-407-01 CUSHION, STOPPER

27 3-328-319-41 HAND STRAP

28 3-318-382-41 SCREW (1.7X3.7), TAPPING

L1 1-456-156-11 ANTENNA, FERRITE-ROD (EXCEPT EA)

L1 1-456-156-21 ANTENNA, FERRITE-ROD (EA)

#1 7-627-552-07 SCREW,PRECISION +P 1.7X2.5

17

Page 18

WM-SR10

Ver 1.1 2003.05

7-2. Cabinet (Front) Section

62

MIC501

57

53

56

54

58

59

60

not

supplied

55

61

63

SP251

64

65

66

67

68

52

51

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-244-961-01 RING (SPEAKER)

52 3-244-970-01 GRILLE (SPEAKER)

53 3-244-963-01 WINDOW (DIAL) (EXCEPT EA)

53 3-244-963-11 WINDOW (DIAL) (EA)

54 3-244-966-01 KNOB (PAUSE)

55 3-244-965-01 KNOB (FUNCTION)

56 3-237-130-01 KNOB (AVLS)

57 3-237-128-01 CUSHION (MIC)

58 1-823-821-11 WIRE (MIC+)(WHT)

59 1-823-821-21 WIRE (MIC-)(BLK)

61 1-824-629-21 CABLE, FLEXIBLE FLAT 6P

62 3-248-626-01 SCREW, TAPPING (B2.0)

63 1-823-820-11 WIRE (SPEAKER)

64 3-237-125-01 LID, BATTERY CASE

65 3-244-964-01 KNOB (SOUND)

66 3-244-959-01 CABINET (FRONT)

67 3-237-129-01 KNOB (SP/HP)

68 3-022-581-01 PLATE, LIGHT GUIDE

MIC501 1-542-481-11 MICROPHONE, ELECTRET CAP(FLAT MIC)

SP251 1-825-222-11 SPEAKER

60 3-318-382-41 SCREW (1.7X3.7), TAPPING

18

Page 19

7-3. Mechanism Deck Section - 1

(MT-WMGX221-175)

z

A (Included in Ref. No.151)

113

108

WM-SR10

HE901

111

109

not

supplied

HRP901

107

106

104

105

102

M601

101

112

not

supplied

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 3-704-197-01 SCREW (M1.4), SPECIAL HEAD

102 3-234-857-01 BELT (CAP)

104 X-3379-877-1 FLY ASSY (AR), CAPSTAN

105 3-386-694-01 WASHER

106 3-029-278-01 WASHER

107 3-029-275-01 WASHER (STOPPER N)

108 3-703-816-73 SCREW (M1.4), SPECIAL HEAD

109 3-234-861-01 GUIDE (ARO), TAPE

111 3-703-816-23 SCREW (M1.4X2.5), SPECIAL HEAD

112 X-3379-882-1 PINCH (N) ASSY, ARM

113 3-703-925-21 SCREW (M1.4)

HE901 1-500-232-13 HEAD, MAGNETIC (ERASE)

HRP901 1-500-718-11 HEAD,MAGNETIC(RECORD/PLAYBACK)

M601 1-763-772-11 MOTOR, DC (CAPSTAN/REEL)

19

Page 20

WM-SR10

7-4. Mechanism Deck Section - 2

(MT-WMGX221-175)

164

156

155

154

153

152

157

160

159

161

162

151

(Including A)

166

172

165

169

170

z

171

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 X-3381-206-1 CHASSIS ASSY (ARO)

152 3-225-385-01 GEAR (B)

153 3-229-063-01 SPRING (UD) (R), COMPRESSION

154 3-019-778-01 SLEEVE (MS)

155 3-728-091-01 WASHER, STOPPER

156 3-225-427-01 WASHER, LEVER

157 3-225-384-01 GEAR (A)

159 3-225-395-01 LEVER (REW ROTARY)

160 X-3380-677-1 LEVER (E DETECTION) ASSY

161 3-229-064-01 WASHER, STOPPER

162 3-225-393-01 LEVER (SHUT/OFF)

164 3-321-813-71 WASHER, COTTER POLYETHYLENE

165 X-3379-881-1 CLUTCH ASSY (AR)

166 3-315-384-31 WASHER, STOPPER

169 3-225-388-01 GEAR (D)

170 3-225-394-01 LEVER (FF ROTARY)

171 3-225-444-01 SPRING (FR ROTARY), TENSION

172 3-344-901-01 WASHER, STOPPER

20

Page 21

WM-SR10

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-3178-901-A MAIN BOARD, COMPLETE (EXCEPT EA)

* A-3178-905-A MAIN BOARD, COMPLETE (EA)

**********************************

3-237-149-01 TERMINAL (-), BATTERY

3-237-150-01 TERMINAL (+), BATTERY

< CAPACITOR >

C2 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C3 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C5 1-162-937-11 CERAMIC CHIP 6PF 0.5PF 50V

C7 1-162-905-11 CERAMIC CHIP 1PF 0.25PF 50V

C9 1-162-997-11 CERAMIC CHIP 10PF 0.5PF 50V

C10 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C10 1-164-726-11 CERAMIC CHIP 9PF 0.50PF 50V (EA)

C11 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C12 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C12 1-162-997-11 CERAMIC CHIP 10PF 50V (EA)

C13 1-164-434-11 CERAMIC CHIP 8PF 0.5PF 50V

C13 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V (EA)

C14 1-135-151-21 TANTALUM CHIP 4.7uF 20% 4V

C15 1-162-909-11 CERAMIC CHIP 4PF 0.25PF 50V

C15 1-162-913-11 CERAMIC CHIP 8PF 50V (EA)

C17 1-165-176-11 CERAMIC CHIP 0.047uF 10.00% 16V

C18 1-162-908-11 CERAMIC CHIP 3PF 0.25PF 50V

C18 1-162-907-11 CERAMIC CHIP 2PF 0.25PF 50V (EA)

C21 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C22 1-115-156-11 CERAMIC CHIP 1uF 10V

C23 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C24 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C25 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C26 1-137-934-91 TANTAL. CHIP 47uF 20% 10V

C27 1-113-619-11 CERAMIC CHIP 0.47uF 10V

C28 1-113-619-11 CERAMIC CHIP 0.47uF 10V

C29 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C30 1-165-128-11 CERAMIC CHIP 0.22uF 16V

C32 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C33 1-164-676-11 CERAMIC CHIP 2200PF 5.00% 16V

C34 1-164-346-11 CERAMIC CHIP 1uF 16V

C35 1-164-346-11 CERAMIC CHIP 1uF 16V

C36 1-164-346-11 CERAMIC CHIP 1uF 16V

C37 1-164-918-11 CERAMIC CHIP 100PF 5.00% 16V

C38 1-164-918-11 CERAMIC CHIP 100PF 5.00% 16V

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

C39 1-164-357-11 CERAMIC CHIP 0.001uF 5.00% 50V

C40 1-164-357-11 CERAMIC CHIP 0.001uF 5.00% 50V

C101 1-115-156-11 CERAMIC CHIP 1uF 10V

C102 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C103 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C104 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C105 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C106 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C107 1-115-156-11 CERAMIC CHIP 1uF 10V

C108 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C109 1-115-156-11 CERAMIC CHIP 1uF 10V

C111 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C153 1-113-690-11 ELECT CHIP 220uF 20.00% 4V

(EXCEPT EA)

(EXCEPT EA)

(EXCEPT EA)

(EXCEPT EA)

(EXCEPT EA)

C201 1-115-156-11 CERAMIC CHIP 1uF 10V

C202 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C203 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C204 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C205 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C206 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C207 1-115-156-11 CERAMIC CHIP 1uF 10V

C208 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C209 1-115-156-11 CERAMIC CHIP 1uF 10V

C210 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C211 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C250 1-162-970-11 CERAMIC CHIP 0.01uF 10.00% 25V

C251 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C252 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C253 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C263 1-127-715-91 CERAMIC CHIP 0.22uF 10% 16V

C264 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C301 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C303 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C304 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C305 1-115-156-11 CERAMIC CHIP 1uF 10V

C306 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C307 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C308 1-115-156-11 CERAMIC CHIP 1uF 10V

C309 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C310 1-104-852-11 TANTAL. CHIP 22uF 20.00% 10V

C311 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C312 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C313 1-104-852-11 TANTAL. CHIP 22uF 20.00% 10V

C314 1-117-863-11 CERAMIC CHIP 0.47uF 10.00% 6.3V

C315 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C316 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C317 1-119-750-11 TANTAL. CHIP 22uF 20.00% 6.3V

C318 1-104-851-11 TANTAL. CHIP 10uF 20.00% 10V

When indicating parts by reference number,

please include the board name.

• CAPACITORS:

uF: µF

• COILS

uH: µH

•Abbreviation

9E : E model without the indication of the

country of origin.

EA : Saudi Arabia model

MAIN

21

Page 22

WM-SR10

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C319 1-113-690-11 ELECT CHIP 220uF 20.00% 4V

C400 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C401 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

CN701 1-691-344-11 CONNECTOR, FFC/FPC (ZIF) 6P

< CONNECTOR >

C402 1-104-852-11 TANTAL. CHIP 22uF 20.00% 10V

C403 1-124-434-00 ELECT 220uF 20.00% 4V

C404 1-124-434-00 ELECT 220uF 20.00% 4V

C405 1-162-953-11 CERAMIC CHIP 100PF 5% 50V

C502 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C503 1-137-934-91 TANTAL. CHIP 47uF 20% 10V

C504 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C505 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C506 1-115-156-11 CERAMIC CHIP 1uF 10V

C507 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C508 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C509 1-137-934-91 TANTAL. CHIP 47uF 20% 10V

C510 1-115-156-11 CERAMIC CHIP 1uF 10V

C511 1-104-847-11 TANTAL. CHIP 22uF 20.00% 4V

C512 1-115-156-11 CERAMIC CHIP 1uF 10V

C513 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C514 1-115-156-11 CERAMIC CHIP 1uF 10V

C515 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C516 1-115-156-11 CERAMIC CHIP 1uF 10V

C517 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C518 1-113-619-11 CERAMIC CHIP 0.47uF 10V

C519 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C520 1-113-619-11 CERAMIC CHIP 0.47uF 10V

C521 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C522 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C523 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C551 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C552 1-164-315-11 CERAMIC CHIP 470PF 5.00% 50V

C553 1-164-230-11 CERAMIC CHIP 220PF 5.00% 50V

C554 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C555 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C556 1-137-934-91 TANTAL. CHIP 47uF 20% 10V

C557 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C558 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C601 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

< FILTER >

CP1 1-236-711-21 FILTER, BAND PASS

< VARIABLE CAPACITOR >

CV1 1-141-624-21 CAP, VAR(TUNING)

< DIODE >

D32 8-719-404-50 DIODE MA111-TX

D33 8-719-404-50 DIODE MA111-TX

D34 8-719-404-50 DIODE MA111-TX

D35 8-719-404-50 DIODE MA111-TX

D234 8-719-404-50 DIODE MA111-TX

D301 8-719-404-50 DIODE MA111-TX

D302 8-719-404-50 DIODE MA111-TX

D401 8-719-059-96 DIODE SML-210LT-T86 (BATT)

D701 8-719-941-86 DIODE DAN202UT106

< FERRITE BEAD >

FB1 1-216-864-11 METAL CHIP 0 5% 1/10W

FB2 1-414-385-21 FERRITE 0UH

FB101 1-500-329-21 FERRITE 0UH

FB201 1-500-329-21 FERRITE 0UH

FB301 1-500-329-21 FERRITE 0UH

FB501 1-500-329-21 FERRITE 0UH

FB502 1-500-329-21 FERRITE 0UH

FB503 1-500-329-21 FERRITE 0UH

< IC >

IC1 6-701-564-01 IC TA2111FN(EL)

IC151 6-703-214-01 IC LM4871MM

IC301 8-759-665-91 IC LB8115W-NA-TLM

IC501 8-759-062-63 IC TA8155FN(ER)

< JUMPER RESISTOR >

C602 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C603 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C604 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C605 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

C606 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C607 1-125-838-11 CERAMIC CHIP 2.2uF 10% 6.3V

C701 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C703 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C705 1-164-346-11 CERAMIC CHIP 1uF 16V

C706 1-164-346-11 CERAMIC CHIP 1uF 16V

C707 1-164-346-11 CERAMIC CHIP 1uF 16V

C708 1-164-346-11 CERAMIC CHIP 1uF 16V

C709 1-164-346-11 CERAMIC CHIP 1uF 16V

C710 1-164-346-11 CERAMIC CHIP 1uF 16V

< FILTER >

CF1 1-578-677-11 FILTER, CRYSTAL

CF2 1-795-533-71 FILTER ASSY, CERAMIC

22

J7 1-216-295-91 SHORT CHIP 0

J9 1-216-864-11 METAL CHIP 0 5% 1/10W

J10 1-216-864-11 METAL CHIP 0 5% 1/10W

< JACK >

J301 1-816-213-11 JACK (i)

J401 1-794-615-11 JACK,DC (POLARITY UNIFIED TYPE)(DC IN 3V)

J501 1-766-847-51 JACK (MIC(PLUG IN POWER))

< JUMPER RESISTOR >

JR3 1-216-864-11 METAL CHIP 0 5% 1/10W

< COIL >

L1 1-456-156-11 ANTENNA, FERRITE-ROD (AM)(EXCEPT EA)

L1 1-456-156-21 ANTENNA, FERRITE-ROD (AM)(EA)

L2 1-456-243-21 COIL (FM RF)(EXCEPT EA)

L2 1-456-245-21 COIL (FM RF)(EA)

L3 1-456-244-21 COIL (FM OSC)(EXCEPT EA)

Page 23

WM-SR10

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

L3 1-460-066-22 COIL (FM OSC)(EA)

L4 1-428-874-21 COIL (AM OSC)(EXCEPT EA)

L4 1-428-875-21 COIL (AM OSC)(EA)

< TRANSISTOR >

Q30 8-729-028-74 TRANSISTOR DTA114TUA-T106

Q31 8-729-028-74 TRANSISTOR DTA114TUA-T106

Q32 8-729-230-47 TRANSISTOR 2SA1162-YG-TE85L

Q33 8-729-230-47 TRANSISTOR 2SA1162-YG-TE85L

Q34 8-729-028-99 TRANSISTOR DTC114YUA-T106

Q252 8-729-216-22 TRANSISTOR 2SA1162-YG-TE85L

Q302 8-729-427-72 TRANSISTOR XP4501-TXE

Q401 8-729-429-44 TRANSISTOR XP1501-TXE

Q402 8-729-426-31 TRANSISTOR XP1214-TXE

Q403 8-729-054-79 TRANSISTOR 2SB167900LSO

Q501 8-729-402-96 TRANSISTOR UN5114-TX

Q502 8-729-426-31 TRANSISTOR XP1214-TXE

Q551 8-729-429-44 TRANSISTOR XP1501-TXE

Q553 8-729-141-75 TRANSISTOR 2SD596-T1DV4

Q701 8-729-426-36 TRANSISTOR XP1215-TXE

Q702 8-729-402-93 TRANSISTOR UN5214-TX

Q703 8-729-426-36 TRANSISTOR XP1215-TXE

Q704 8-729-425-46 TRANSISTOR XP4315-TXE

Q705 8-729-420-50 TRANSISTOR UN5215-(TX)

Q706 8-729-426-36 TRANSISTOR XP1215-TXE

Q707 8-729-402-93 TRANSISTOR UN5214-TX

Q709 8-729-425-46 TRANSISTOR XP4315-TXE

Q710 8-729-427-51 TRANSISTOR XP4215-TXE

Q711 8-729-924-04 TRANSISTOR UN5116-TX

Q712 8-729-054-79 TRANSISTOR 2SB167900LSO

Q713 8-729-402-93 TRANSISTOR UN5214-TX

Q714 8-729-420-50 TRANSISTOR UN5215-(TX)

Q715 8-729-054-79 TRANSISTOR 2SB167900LSO

Q717 8-729-028-74 TRANSISTOR DTA114TUA-T106

Q718 8-729-028-78 TRANSISTOR DTA115TUA-T106

Q719 8-729-028-74 TRANSISTOR DTA114TUA-T106

Q720 8-729-028-74 TRANSISTOR DTA114TUA-T106

Q722 8-729-028-74 TRANSISTOR DTA114TUA-T106

< RESISTOR >

R2 1-216-821-11 METAL CHIP 1K 5% 1/10W

R3 1-216-864-11 METAL CHIP 0 5% 1/10W

R5 1-216-833-11 METAL CHIP 10K 5% 1/10W

R6 1-216-845-11 METAL CHIP 100K 5% 1/10W

R7 1-216-845-11 METAL CHIP 100K 5% 1/10W

R8 1-216-845-11 METAL CHIP 100K 5% 1/10W

R9 1-216-817-11 METAL CHIP 470 5% 1/10W

R10 1-216-841-11 METAL CHIP 47K 5% 1/10W

R11 1-216-797-11 METAL CHIP 10 5% 1/10W

R30 1-216-845-11 METAL CHIP 100K 5% 1/10W

R31 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R32 1-216-857-11 METAL CHIP 1M 5% 1/10W

R33 1-216-845-11 METAL CHIP 100K 5% 1/10W

R34 1-216-821-11 METAL CHIP 1K 5% 1/10W

R62 1-216-857-11 METAL CHIP 1M 5% 1/10W

R63 1-216-845-11 METAL CHIP 100K 5% 1/10W

R64 1-216-857-11 METAL CHIP 1M 5% 1/10W

R101 1-216-833-11 METAL CHIP 10K 5% 1/10W

R103 1-216-837-11 METAL CHIP 22K 5% 1/10W

R104 1-216-833-11 METAL CHIP 10K 5% 1/10W

R105 1-216-857-11 METAL CHIP 1M 5% 1/10W

R106 1-216-821-11 METAL CHIP 1K 5% 1/10W

R107 1-216-809-11 METAL CHIP 100 5% 1/10W

R108 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R109 1-216-797-11 METAL CHIP 10 5% 1/10W

R110 1-216-821-11 METAL CHIP 1K 5% 1/10W

R112 1-216-861-11 METAL CHIP 2.2M 5% 1/10W

R113 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R115 1-216-864-11 METAL CHIP 0 5% 1/10W

R160 1-216-845-11 METAL CHIP 100K 5% 1/10W

R201 1-216-833-11 METAL CHIP 10K 5% 1/10W

R203 1-216-837-11 METAL CHIP 22K 5% 1/10W

R204 1-216-833-11 METAL CHIP 10K 5% 1/10W

R205 1-216-857-11 METAL CHIP 1M 5% 1/10W

R206 1-216-821-11 METAL CHIP 1K 5% 1/10W

R207 1-216-809-11 METAL CHIP 100 5% 1/10W

R208 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R209 1-216-797-11 METAL CHIP 10 5% 1/10W

R210 1-216-821-11 METAL CHIP 1K 5% 1/10W

R212 1-216-861-11 METAL CHIP 2.2M 5% 1/10W

R213 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R215 1-216-864-11 METAL CHIP 0 5% 1/10W

R250 1-216-864-11 METAL CHIP 0 5% 1/10W

R252 1-216-853-11 METAL CHIP 470K 5% 1/10W

R254 1-216-837-11 METAL CHIP 22K 5% 1/10W

R255 1-216-853-11 METAL CHIP 470K 5% 1/10W

R256 1-216-833-11 METAL CHIP 10K 5% 1/10W

R257 1-216-837-11 METAL CHIP 22K 5% 1/10W

R258 1-216-849-11 METAL CHIP 220K 5% 1/10W

R259 1-216-845-11 METAL CHIP 100K 5% 1/10W

R260 1-216-845-11 METAL CHIP 100K 5% 1/10W

R261 1-216-853-11 METAL CHIP 470K 5% 1/10W

R262 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R263 1-216-821-11 METAL CHIP 1K 5% 1/10W

R264 1-216-833-11 METAL CHIP 10K 5% 1/10W

R265 1-216-821-11 METAL CHIP 1K 5% 1/10W

R302 1-216-845-11 METAL CHIP 100K 5% 1/10W

R303 1-216-837-11 METAL CHIP 22K 5% 1/10W

R304 1-216-821-11 METAL CHIP 1K 5% 1/10W

R305 1-216-789-11 METAL CHIP 2.2 5% 1/10W

R309 1-216-864-11 METAL CHIP 0 5% 1/10W

R315 1-216-845-11 METAL CHIP 100K 5% 1/10W

R401 1-216-821-11 METAL CHIP 1K 5% 1/10W

R402 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R403 1-216-833-11 METAL CHIP 10K 5% 1/10W

R404 1-216-849-11 METAL CHIP 220K 5% 1/10W

R405 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R406 1-216-853-11 METAL CHIP 470K 5% 1/10W

R459 1-216-817-11 METAL CHIP 470 5% 1/10W

R465 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R501 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R502 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R503 1-216-821-11 METAL CHIP 1K 5% 1/10W

R504 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R505 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

23

Page 24

WM-SR10

MAIN SUB

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R506 1-216-841-11 METAL CHIP 47K 5% 1/10W

R507 1-216-857-11 METAL CHIP 1M 5% 1/10W

R508 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R509 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R510 1-216-849-11 METAL CHIP 220K 5% 1/10W

R511 1-216-833-11 METAL CHIP 10K 5% 1/10W

R512 1-216-849-11 METAL CHIP 220K 5% 1/10W

R513 1-216-833-11 METAL CHIP 10K 5% 1/10W

R514 1-216-833-11 METAL CHIP 10K 5% 1/10W

R515 1-216-833-11 METAL CHIP 10K 5% 1/10W

R516 1-216-833-11 METAL CHIP 10K 5% 1/10W

R517 1-216-841-11 METAL CHIP 47K 5% 1/10W

R551 1-216-805-11 METAL CHIP 47 5% 1/10W

R552 1-216-821-11 METAL CHIP 1K 5% 1/10W

R553 1-216-841-11 METAL CHIP 47K 5% 1/10W

S1 1-771-350-31 SWITCH, SLIDE (FM ST/MONO)

S301 1-786-499-11 SWITCH, SLIDE (REC/PB)

S551 1-762-391-21 SWITCH, SLIDE (ISS)

S701 1-571-277-51 SWITCH, SLIDE (i/SPEAKER)

S702 1-572-922-11 SWITCH, SLIDE (PAUSE.)

S703 1-692-605-31 SWITCH, SLIDE (FM/AM/TAPE(RADIO OFF))

S704 1-771-040-21 SWITCH, PUSH (TAPE POWER)

T1 1-428-876-21 COIL (AM IFT)

T551 1-433-286-23 TRANSFORMER, BIAS OSCILLATION

< SWITCH >

< TRANSFORMER >

< THERMISTOR >

R554 1-216-841-11 METAL CHIP 47K 5% 1/10W

R555 1-216-821-11 METAL CHIP 1K 5% 1/10W

R556 1-216-805-11 METAL CHIP 47 5% 1/10W

R557 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R558 1-216-797-11 METAL CHIP 10 5% 1/10W

R559 1-216-833-11 METAL CHIP 10K 5% 1/10W

R560 1-216-809-11 METAL CHIP 100 5% 1/10W

R601 1-216-821-11 METAL CHIP 1K 5% 1/10W

R602 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R603 1-216-841-11 METAL CHIP 47K 5% 1/10W

R604 1-216-845-11 METAL CHIP 100K 5% 1/10W

R605 1-216-837-11 METAL CHIP 22K 5% 1/10W

R606 1-216-821-11 METAL CHIP 1K 5% 1/10W

R607 1-216-833-11 METAL CHIP 10K 5% 1/10W

R608 1-216-864-11 METAL CHIP 0 5% 1/10W

R609 1-218-446-11 METAL CHIP 1 5% 1/10W

R610 1-218-446-11 METAL CHIP 1 5% 1/10W

R613 1-216-833-11 METAL CHIP 10K 5% 1/10W

R702 1-216-845-11 METAL CHIP 100K 5% 1/10W

R703 1-216-813-11 METAL CHIP 220 5% 1/10W

R704 1-216-857-11 METAL CHIP 1M 5% 1/10W

R705 1-216-857-11 METAL CHIP 1M 5% 1/10W

R706 1-216-849-11 METAL CHIP 220K 5% 1/10W

R707 1-216-849-11 METAL CHIP 220K 5% 1/10W

R708 1-216-857-11 METAL CHIP 1M 5% 1/10W

R710 1-216-857-11 METAL CHIP 1M 5% 1/10W

R711 1-216-833-11 METAL CHIP 10K 5% 1/10W

R712 1-216-833-11 METAL CHIP 10K 5% 1/10W

R713 1-216-813-11 METAL CHIP 220 5% 1/10W

R716 1-216-833-11 METAL CHIP 10K 5% 1/10W

R717 1-216-864-11 METAL CHIP 0 5% 1/10W

R718 1-216-833-11 METAL CHIP 10K 5% 1/10W

R719 1-216-841-11 METAL CHIP 47K 5% 1/10W

R722 1-216-857-11 METAL CHIP 1M 5% 1/10W

R723 1-216-845-11 METAL CHIP 100K 5% 1/10W

TH601 1-810-794-11 THERMISTOR, POSITIVE

< VIBRATOR >

X2 1-795-533-71 FILTER ASSY, CERAMIC (10.7MHz)

**************************************************************

SUB BOARD

**********

< CAPACITOR >

C501 1-115-467-11 CERAMIC CHIP 0.22uF 10.00% 10V

C560 1-107-826-11 CERAMIC CHIP 0.1uF 10.00% 16V

< CONNECTOR >

CN702 1-691-344-11 CONNECTOR, FFC/FPC (ZIF) 6P

< SWITCH >

S303 1-572-922-11 SWITCH, SLIDE (SOUND BOOST)

S304 1-572-922-11 SWITCH, SLIDE (AVLS)

**************************************************************

MISCELLANEOUS

**************

58 1-823-821-11 WIRE (MIC+)(WHT)

59 1-823-821-21 WIRE (MIC-)(BLK)

61 1-824-629-21 CABLE, FLEXIBLE FLAT 6P

63 1-823-820-11 WIRE (SPEAKER)

HE901 1-500-232-13 HEAD, MAGNETIC(ERASE)

HRP901 1-500-718-11 HEAD,MAGNETIC(RECORD/PLAYBACK)

M601 1-763-772-11 MOTOR, DC(CAPSTAN/REEL)

MIC501 1-542-481-11 MICROPHONE, ELECTRET CAP(FLAT MIC)

SP251 1-825-222-11 SPEAKER

**************************************************************

ACCESSORIES

************

R724 1-216-857-11 METAL CHIP 1M 5% 1/10W

R725 1-216-845-11 METAL CHIP 100K 5% 1/10W

< VARIABLE RESISTOR >

RV301 1-227-449-21 RES, VAR, MAIN CARBON 10K/10K (VOL )

RV601 1-238-663-11 RES, ADJ, CARBON 4.7K

24

∑

3-245-900-11 MANUAL, INSTRUCTION

(ENGLISH, TRADITIONAL CHINESE,

KOREAN, ARABIC)(EXCEPT 9E)

3-245-900-21 MANUAL, INSTRUCTION

(ENGLISH, TRADITIONAL CHINESE,

KOREAN, ARABIC)(9E)

8-954-008-93 RECEIVER,EAR MDR-E808LP/C1 SET

Page 25

MEMO

WM-SR10

25

Page 26

WM-SR10

REVISION HISTORY

Clicking the version allows you to jump to the revised page.

Also, clicking the version at the upper right on the revised page allows you to jump to the next revised

page.

Ver. Date Description of Revision

1.0 2002. 10 New

1.1 2003. 05 Correction of Ref, No.64 (SPM-03008)

26

Loading...

Loading...