Page 1

WM-PA1

SERVICE MANUAL

SPECIFICATIONS

Radio Section

FM :87.6 – 108MHz

AM :530 – 1,710kHz

E Model

Model Name Using Similar Machanism WM-FX123

T ape Transport Mechanism T ype MF-WMFX103-48CY

Power Requirements

3V DC Batteries AA (R6) x 2

External DC 3V power sources

Battery Life

(approximate hours when using the batteries specified below)

Battery Playback Radio

Sony Alkaline LR6 (SG) 16 hours 48 hours

Sony R6P (SR) 4.5 hours 16 hours

Dimensions

94.2x 119.0 x 36.0 mm

Mass

260g incl. batteries and tape

Supplied Accessories

• Stereo headphones (1)

• Belt clip (1)

Design and specifications are subject to change without notice.

MICROFILM

RADIO CASSETTE PLAYER

Page 2

TABLE OF CONTENTS

mark

mark

CF2

X2

Specifications ........................................................................... 1

1. GENERAL

Location and Function of Controls .................................... 2

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

2. DISASSEMBLY

2-1. Cabinet (Rear) Removal ............................................. 3

2-2. Cabinet (Front) Removal ............................................ 3

2-3. Main Board, Mechanism Deck Removal ................... 4

2-4. Cassette Holder Sub Assy Removal ........................... 4

2-5. Switch board Removal ............................................... 5

2-6. Dial Pointer Setting .................................................... 5

3. ADJUSTMENTS

3-1. Mechanical Adjustment .............................................. 6

3-2. Electrical Adjustment ................................................. 6

4. DIAGRAMS

4-1. Block Diagram............................................................ 8

4-2. Printed Wiring Boards .............................................. 10

4-3. Schematic Diagram................................................... 15

5. EXPLODED VIEWS

5-1. Cabinet and Board Section ....................................... 19

5-2. Mechanism Deck Section ......................................... 20

6. ELECTRICAL P ARTS LIST ................................21

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

• HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF2 and X2.

Y ou must used same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must changed two pieces together

since it's supply two pieces in one package as a spare parts

Mark Center Frequency

red 10.70MHz

blue 10.67MHz

orange 10.73MHz

black 10.64MHz

white 10.76MHz

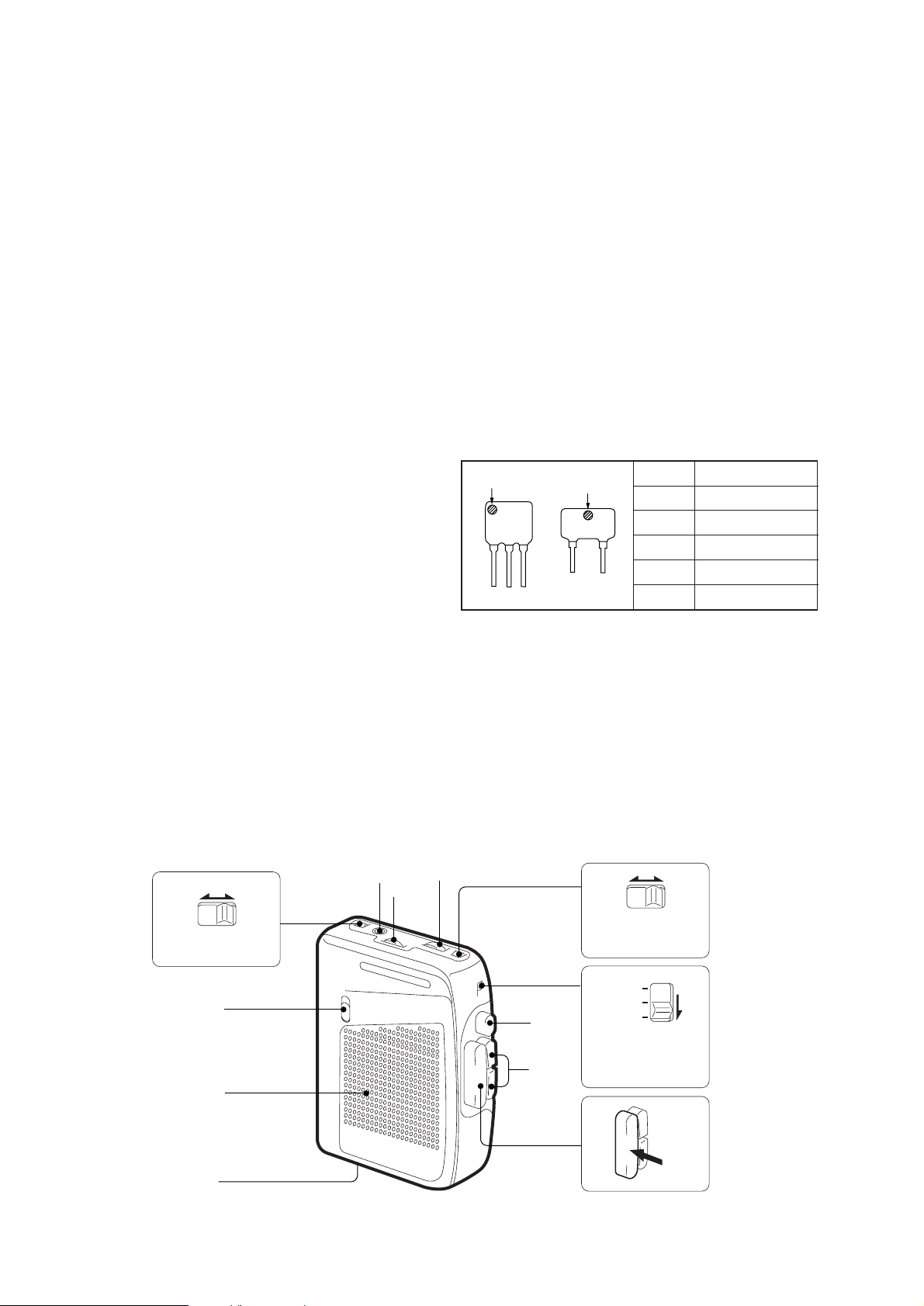

LOCATION AND FUNCTION OF CONTROLS

••

NORM LIMIT

AVLS

SPEAKER

SWITCH

SPEAKER

DC IN 3V

SECTION 1

GENERAL

VOLUME

2

TUNING

p

0 )

••

NORM CrO

METAL

DX LOCAL

FM AM TAPE

(RADIO OFF)

2

/

PLAY

– 2 –

Page 3

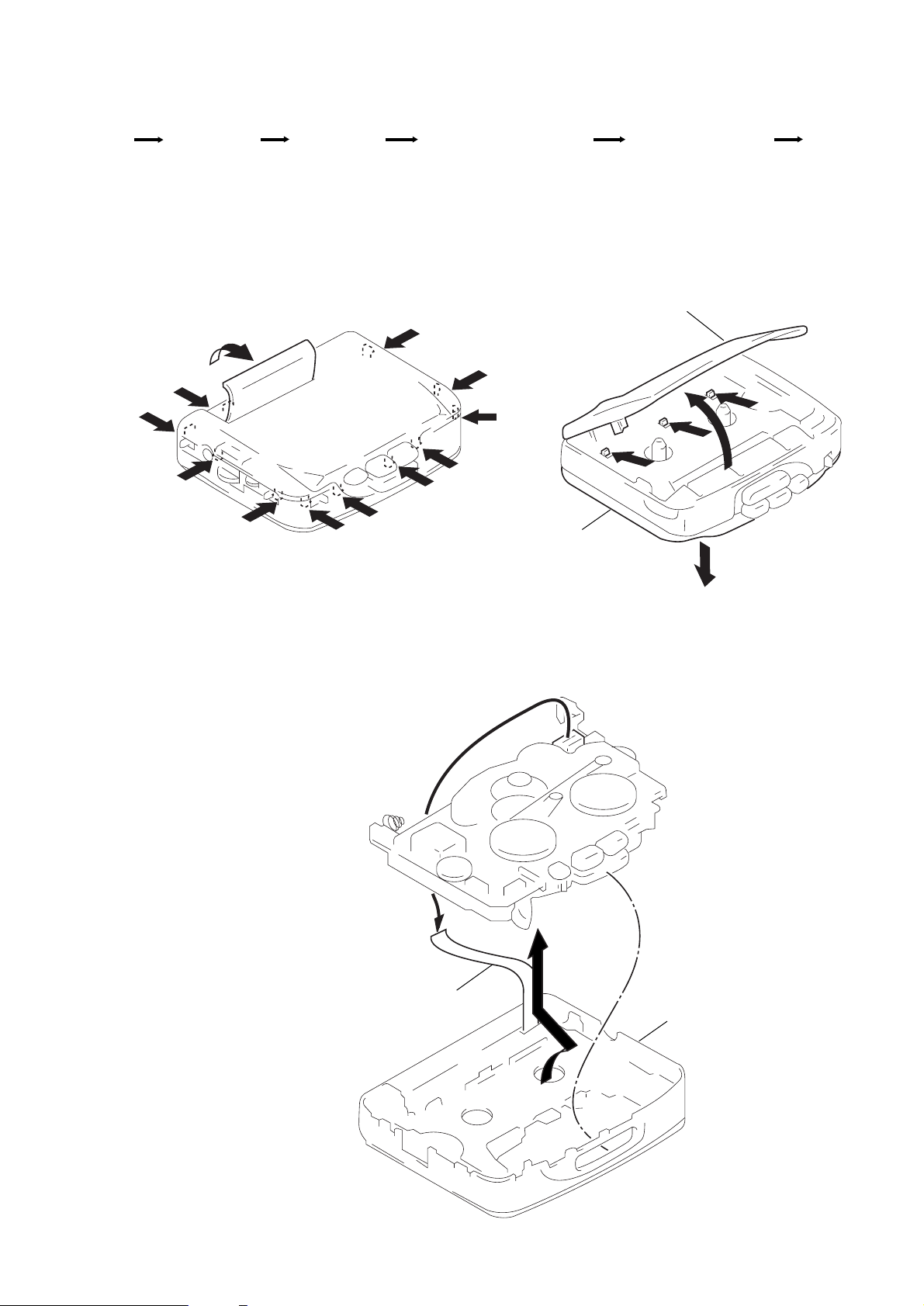

SECTION 2

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Set

Cabinet (Rear)

Cabinet (Front)

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR) REMOVAL

1

Main board, Mechanism deck

4

Cassette holder sub assy Switch board

Cassette holder sub assy

2

2

3

3

2-2. CABINET (FRONT) REMOVAL

7

7

7

4

7

7

Cabinet (Rear)

6

6

6

5

8

1

Flexible board

2

Cabinet (Front)

– 3 –

Page 4

2-3. MAIN BOARD, MECHANISM DECK REMOVAL

k

y

2

Head flexible board

3

Claw

2-4. CASSETTE HOLDER SUB ASSY REMOVAL

4

1

Remove solder

Main board

Mechanism dec

3

Claws

Cabinet (Front)

3

Flexible board

1

2

Cassette holder sub ass

4

NOTE FOR INSTALLATION

The torsion spring will be removed together with the cassette lid that preform the following for installation.

r

TORSION SPRING

1

Attach the torsion spring

as shown in the figure

3

Lift the torsion spring in the arrow

direction and hook it properly

2

Insert the torsion spring

in the hole as shown in the figure.

– 4 –

Page 5

1

Screws

(1.7x3) tapping

Retainer, Speaker

Speaker

Cassette holder sub assy

Switch board

y

)

r

t

SECTION 3

S302

(MD POWER)

S304 - 1

S304

FM

AM

TAPE

RADIO

OFF

RV601

TAPE

SPEED

DC IN 3V

ADJUSTMENTS

WM-P A1

SECTION 4

DIAGRAMS

2-5. SWITCH BOARD REMOVAL

2-6. DIAL POINTER SETTING

2

Align pointer with arrow marked

side as shown in Fig. 1 and then

fit to groove in the order of

a

and b.

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch roller

capstan rubber belt

2. Demagnetize the playback head using a head demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage (2.5V) unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

FWD

CQ-102C

20 – 42 g • cm

(0.28 – 0.58 oz• inch)

FWD less than 2 g • cm

back tension (less than 0.03 oz• inch)

FF, REW CQ-201B

more than 60g • cm

(more than 0.83 oz• inch)

Tape Pulling Force Measurement

Mode Torque Meter Meter Reading

FWD CQ-403A

more than 40 g

(more than 1.42 oz)

3-2. ELECTRICAL ADJUSTMENTS

PRECAUTION

• Specified voltage : 2.5V.

• Switch and control position

TAPE switch : NORM

VOLUME control : maximum

AVLS switch : NORM

T APE SECTION

Test T ape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure :

test tape

WS-48A

(3kHz, 0dB)

set

Play back WS-48A (tape center part) and adjust RV601 so that

the frequency counter reading becomes 3,000 ± 15Hz.

Frequency difference the beginning and the end of the tape

should be within 1.5%.

Adjustment Location :

frequency counter

16

Ω

J302 (phones)

+

–

TUNER SECTION

AM Section

BAND : AM

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM Section

BAND : FM

LOCAL/DX switch : DX

FM RF signal

generator

22.5kHz frequency deviation by

400Hz signal.

Output level : as low as possible

set

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

Put the lead-wire

antenna close to

the set.

Ω

16

J302 (phones)

µ

0.01 F

level mete

+

–

(ANT TAP

(GND)

AM IF ALIGNMENT

Adjust for a maximum reading on level meter.

T1 1,000kHz

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 505kHz

CT1–4 1,750kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 620kHz

CT1–1 1,400kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 86.0MHz

CT1–3 109.5MHz

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.0MHz

CT1–2 109.5MHz

4-1. BLOCK DIAGRAM

Ferrite-rod antenna sub assy

Main board

a

Pointer

3

Ferrite-rod antenna sub ass

[MAIN BOARD] (Side A)

Adjustment Location :

b

Pointer

Fig. 1

Knob (tune)

1

Rotate tune knob fully to arrow direction.

– 5 – – 6 – – 8 –– 7 – – 9 –

Align point

A

(A=B)

B

Align point

RV601

CT1–4 : AM Frequency Coverage Adjustment

CT1–3 : FM Frequency Coverage Adjustment

T1 : AM IF Alignment

L4 : AM Frequency Coverage Adjustmen

L3 : FM Frequency Coverage Adjustment

L2 : FM Tracking Adjustment

CT1–2 : FM Tracking Adjustment

CT1–1 : AM Tracking Adjustment

L1 : AM Tracking Adjustment

• Signal path.

: FM

: PB

Page 6

4-3. SCHEMATIC DIAGRAM

STEREO

DECODER

SWHYS

ST

LED

TU

LED

FM

DET

VCO

PHASE

COM

PHASE

COM

FREQ.

DIVIDER

FM/AM

MONO SW

FM

IF

L

DET

AM

IF

PRE

AF

AM

OSC

FM

OSC

AM

MIX

FM

MIX

FM

RF

AM

RF

AM

DET

AM

AGC

1

24 23 22 21 20 18 17 16 15 14 13

2 3 4 5 6 7 8 9 10 11 12

19

AM RF INFM RF IN

GND1

FM MIX

AM MIX

AGC

VCC2

AM IF IN

FM IF IN

GND2

TUN LED

ST LED

QUAD

FM RF OUT

VCC1

FM OSC

AM OSC

DET OUT

MPX IN

LPF1

LPF2

VCO

L OUT

R OUT

r

IC BLOCK DIAGRAM

IC1 TA8122AF

WM-PA1

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• : B+ Line.

• : adjustment for repair.

• Power voltage is dc 3V and fed with regulated dc power

supply from external power voltage jack (J301).

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

( ) : AM

< > : PLAY

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Signal path.

: FM

: PB

– 15 – – 16 – – 18 –– 17 –

Page 7

NOTE :

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

5-1. CABINET AND BOARD SECTION

12

11

SP1

SECTION 5

EXPLODED VIEWS

• The mechanical parts with no reference

number in the exploded views are not

supplied.

• Accessories and packing materials are given

in the last of this parts list.

13

14

15

16

L1

19

10

9

17

18

20

22

8

7

7

5

6

4

3

2

21

1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 X-3374-460-1 CABINET (REAR) SUB ASSY

2 3-910-896-01 GROUND, MOTOR

3 3-933-647-01 BUTTON (STOP)

4 3-933-644-01 BUTTON (FF)

5 3-933-643-01 BUTTON (REW)

6 3-933-646-01 BUTTON (PLAY)

7 3-318-382-01 SCREW (1.7X3), TAPPING

8 3-017-324-01 RETAINER, SPEAKER

9 1-667-057-11 FLEXIBLE BOARD

* 10 1-667-779-11 SWITCH BOARD

11 X-3374-461-1 HOLDER SUB ASSY, CASSETTE

12 3-017-323-01 KNOB (SW)

13 3-018-931-01 SPRING, TORSION

14 3-937-353-01 CABINET (FRONT) (CF-O)

15 3-364-675-01 SPRING (CASSETTE)

16 3-933-678-01 POINTER

17 3-933-642-01 TERMINAL (+), BATTERY

18 3-933-675-01 GEAR (TUNE)

19 3-910-902-12 KNOB (TUNE)

20 A-3016-981-A MAIN BOARD, COMPLETE

21 3-937-356-01 LID, BATT

22 3-910-895-01 TERMINAL (–), BATTERY

L1 X-3371-847-1 ANTENNA SUB ASSY, FERRITE-ROD

SP1 1-505-794-11 SPEAKER

– 19 –

Page 8

5-2. MECHANISM DECK SECTION (MF-WMFX103-48CY)

60

51

59

61

58

HP901

62

not

supplied

52

not

supplied

53

54

55

M901

57

56

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 X-3367-902-1 ARM (N) ASSY, PINCH

52 3-364-328-01 SPRING, COMPRESSION

53 3-910-635-01 SCREW

54 3-910-647-01 LEVER (PR/O), PLAY

55 X-3368-729-1 CHASSIS ASSY

56 3-354-868-01 BELT

57 3-352-758-21 SCREW (M1.7), TOOTHED LOCK

58 3-909-727-01 GEAR (REVERSE)

59 3-364-320-01 GEAR (S REEL)

60 3-910-640-01 GEAR (T REEL)

61 3-321-483-11 RING, RETAINING

62 X-3367-905-1 CLUTCH ASSY

HP901 1-500-115-11 HEAD, MAGNETIC (PLAYBACK)

M901 1-698-353-11 MOTOR, DC (REEL, CAPSTAN)

– 20 –

Page 9

SECTION 6

ELECTRICAL PARTS LIST

NOTE :

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms

METAL : Metal-film resistor

METAL OXIDE :Metal oxide-film resistor

F : nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3016-981-A MAIN BOARD, COMPLETE

*********************

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• SEMICONDUCTORS

In each case, u : µ , for example :

uA.... : µ A.... , uPA.... : µ PA....

uPB.... : µ PB.... , uPC.... : µ PC....

uPD.... : µ PD....

• CAPACITORS

uF : µ F

• COILS

uH : µ H

C308 1-126-157-11 ELECT 10uF 20% 16V

C309 1-163-038-91 CERAMIC CHIP 0.1uF 25V

When indicating parts by reference number, please include the board.

MAIN

3-910-895-01 TERMINAL (–), BATTERY

3-933-642-01 TERMINAL (+), BATTERY

< CAPACITOR >

C1 1-163-083-00 CERAMIC CHIP 1PF 50V

C2 1-163-099-00 CERAMIC CHIP 18PF 5% 50V

C3 1-163-101-00 CERAMIC CHIP 22PF 5% 50V

C4 1-163-089-00 CERAMIC CHIP 6PF 50V

C5 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C6 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

C7 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C8 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C9 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C10 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C11 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C12 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C14 1-126-153-11 ELECT 22uF 20% 6.3V

C15 1-163-078-11 CERAMIC CHIP 0.033uF 10% 25V

C16 1-163-063-91 CERAMIC CHIP 0.022uF 10% 50V

C17 1-126-154-11 ELECT 47uF 20% 6.3V

C18 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C19 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C24 1-164-234-11 CERAMIC CHIP 1uF 10V

C101 1-163-007-11 CERAMIC CHIP 680PF 10% 50V

C102 1-126-153-11 ELECT 22uF 20% 6.3V

C103 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C104 1-164-234-11 CERAMIC CHIP 1uF 10V

C105 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C106 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C310 1-164-234-11 CERAMIC CHIP 1uF 10V

C311 1-164-234-11 CERAMIC CHIP 1uF 10V

C312 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C313 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C314 1-163-117-00 CERAMIC CHIP 100PF 10% 50V

C401 1-163-117-00 CERAMIC CHIP 100PF 10% 50V

C402 1-163-021-91 CERAMIC CHIP 0.01uF 5% 50V

C403 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C404 1-164-234-11 CERAMIC CHIP 1uF 10V

C405 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C406 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C407 1-126-157-11 ELECT 10uF 20% 16V

C408 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C409 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C410 1-126-176-11 ELECT 220uF 20% 4V

C411 1-164-234-11 CERAMIC CHIP 1uF 10V

C412 1-164-234-11 CERAMIC CHIP 1uF 10V

C413 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C601 1-126-154-11 ELECT 47uF 20% 6.3V

C602 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C603 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C604 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C605 1-164-005-11 CERAMIC CHIP 0.47uF 25V

< FILTER >

CF1 1-527-870-00 FILTER

CF2 1-578-672-71 FILTER, CRYSTAL

< CONNECTOR >

C201 1-163-007-11 CERAMIC CHIP 680PF 10% 50V

C202 1-126-153-11 ELECT 22uF 20% 6.3V

C203 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C204 1-164-234-11 CERAMIC CHIP 1uF 10V

C205 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C206 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C301 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C302 1-126-153-11 ELECT 22uF 20% 6.3V

C303 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C304 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C305 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C306 1-126-176-11 ELECT 220uF 20% 4V

C307 1-164-505-11 CERAMIC CHIP 2.2uF 16V

CN301 1-569-252-21 HOUSING, CONNECTOR (FPC) 5P

CN401 1-565-289-11 HOUSING, CONNECTOR 7P

< TRIMMER >

CT1 1-141-567-11 CAP, VAR (TUNING)

< VARIABLE CAPACITOR >

CV1 1-141-567-11 CAP, VAR (TUNING)

< IC >

IC1 8-759-230-39 IC TA8122AF

IC301 8-759-497-06 MM1316AFBE

– 21 –

Page 10

WM-PA1

MAIN SWITCH

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

IC401 8-759-702-02 IC NJM062M

< JACK >

J301 1-750-061-11 JACK,DC(POLARITY UNIFIED TYPE)(DC IN 3V)

J302 1-565-287-11 JACK (2)

R410 1-216-001-00 METAL CHIP 10 5% 1/10W

R411 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R601 1-217-905-11 METAL GLAZE 1.5 5% 1/10W

R602 1-216-298-00 METAL CHIP 2.2 5% 1/10W

R603 1-216-043-91 METAL GLAZE 560 5% 1/10W

< JUMPER RESISTOR >

JC1 1-216-295-00 METAL CHIP 0 5% 1/10W

JC4 1-216-295-00 METAL CHIP 0 5% 1/10W

JC5 1-216-295-00 METAL CHIP 0 5% 1/10W

< COIL >

L1 X-3371-847-1 ANTENNA SUB ASSY, FERRITE-ROD

L2 1-460-120-11 COIL (WITH CORE)

L3 1-403-696-11 COIL (WITH CORE)

L4 1-406-408-11 COIL (OSC)

L101 1-500-245-11 INDUCTOR

L201 1-500-245-11 INDUCTOR

L301 1-412-006-31 INDUCTOR CHIP 10uH

< TRANSISTOR >

Q2 8-729-216-22 TRANSISTOR 2SA1162-G

Q301 8-729-402-13 TRANSISTOR XN1501

Q302 8-729-216-22 TRANSISTOR 2SA1162-G

Q401 8-729-216-22 TRANSISTOR 2SA1162-G

Q402 8-729-207-73 TRANSISTOR RN2407

Q403 8-729-230-49 TRANSISTOR 2SC2712-YG

< RESISTOR >

R1 1-216-009-00 METAL CHIP 22 5% 1/10W

R2 1-216-081-00 METAL CHIP 22K 5% 1/10W

R3 1-216-077-00 METAL CHIP 15K 5% 1/10W

R4 1-216-077-00 METAL CHIP 15K 5% 1/10W

R5 1-216-037-00 METAL CHIP 330 5% 1/10W

R6 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R7 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R101 1-216-006-11 METAL GLAZE 16 5% 1/10W

R102 1-216-077-00 METAL CHIP 15K 5% 1/10W

R201 1-216-006-11 METAL GLAZE 16 5% 1/10W

R202 1-216-077-00 METAL CHIP 15K 5% 1/10W

R301 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R302 1-216-073-00 METAL CHIP 10K 5% 1/10W

R304 1-216-308-00 METAL CHIP 4.7 5% 1/10W

R305 1-216-081-00 METAL CHIP 22K 5% 1/10W

R306 1-216-073-00 METAL CHIP 10K 5% 1/10W

R322 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R401 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R402 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R403 1-216-113-00 METAL CHIP 470K 5% 1/10W

R404 1-216-049-91 METAL CHIP 1K 5% 1/10W

R405 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R406 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R407 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R408 1-216-089-91 METAL GLAZE 47K 5% 1/10W

< VARIABLE RESISTOR >

RV301 1-225-578-11 RES, VAR, CARBON (∑ VOLUME)

RV601 1-225-252-11 RES, ADJ, CARBON 470 (TAPE SPEED)

< SWITCH >

S302 1-571-986-11 SWITCH, LEAF (MD POWER)

S303 1-692-298-11 SWITCH, SLIDE (LOCAL/DX, NORM/METAL)

S304 1-692-299-11 SWITCH, SLIDE (FM, AM, TAPE RADIO OFF)

S305 1-692-898-11 SWITCH, SLIDE (AVLS)

< TRANSFORMER >

T1 1-404-949-11 TRANSFORMER, IF

< THERMISTOR >

TH601 1-809-279-11 THERMISTOR, POSITIVE

TH602 1-810-764-11 THERMISTOR, POSITIVE

< FILTER >

X1 1-577-091-11 OSCILLATOR, CRYSTAL

X2 1-578-672-71 FILTER, CRYSTAL

************************************************************

* 1-667-779-11 SWITCH BOARD

*************

1-667-057-11 FLEXIBLE BOARD

< SWITCH >

S401 1-572-922-11 SWITCH, SLIDE (SPEAKER)

************************************************************

MISCELLANEOUS

**************

9 1-667-057-11 FLEXIBLE BOARD

HP901 1-500-115-11 HEAD, MAGNETIC (PLAYBACK)

L1 X-3371-847-1 ANTENNA SUB ASSY, FERRITE-ROD

M901 1-698-353-11 MOTOR, DC (REEL, CAPSTAN)

SP1 1-505-794-11 SPEAKER

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

3-861-236-21 MANUAL, INSTRUCTION (SPANISH,

PORTUGUESE)

8-953-130-90 HEADPHONE MDR-E801//K SET

X-3372-629-1 CLIP ASSY, BELT

R409 1-216-089-91 METAL GLAZE 47K 5% 1/10W

Sony Corporation

9-923-266-11

Personal A&V Products Company

– 22 –

Printed in Singapore © 1997.10

97J027025-1

Published by Quality Engineering Dept.

(Shibaura)

Loading...

Loading...