Sony WMGX-410 Service manual

WM-GX410

SERVICE MANUAL

Ver 1.0 2004. 03

Model Name Using Simillar Mechanism NEW

Tape Transport Mechanism Type MT-WMGX410-175

SPECIFICATIONS

Canadian Model

AEP Model

E Model

Chinese Model

Tourist Model

Frequency range

Area* FM (MHz) AM(kHz)

AEP, E, Chinese 7.5 - 108 531 - 1 602

Canada, Tourist 87.5 - 108 530 - 1 710

Frequency response Playback: 40 - 15 000 Hz

Recording: 100 - 8 000 Hz

Input Microphone (MIC) jack

Output Headphones (i) jack

Load impedance 8 - 300 Ω

Power requirements 3 V DC: batteries R6 (size AA) x 2

External DC 3V power sources

Power output Speaker 500 mW + 500 mW

(JEITA*)

Dimensions (w/h/d) Approx. 112.0x 82.5 x 35.0 mm

(4 1/2 x 3 1/4 x 1 7/16 inches), excl.

projecting parts and controls

Mass Approx. 200 g (7.1oz)

(main unit only)

Supplied accessories Stereo headphones or earphones (1)

Sony dry battery R6P(SR) (2)

(“Sony World Model” only)

Design and specifications are subject to change without notice.

Battery life* (Approx. hours)

Sony alkaline LR6(SG)** Sony

R6P(SR)

(using headphones/earphones)

playback 24 6

radio 48 15

mic recording 20 4.5

radio recording 12 3

(using the speakers)

playback 10 2.5

radio 17.5 5

radio recording 6.5 1

*Measured value by the standard of JEIT A (Japan Electronics and

Information T echnology Industries Association). (Using a Sony

HF series cassette tape)

** When using Sony LR6 (SG) alkaline dry batteries (producedin

Japan).

Note

The battery life may be shorter depending on the operating ondition,

the surrounding temperature and battery type.

9-877-585-01

2004C02-1

© 2004.03

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

WM-GX410

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

TABLE OF CONTENTS

Specifications ............................................................................ 1

1. GENERAL

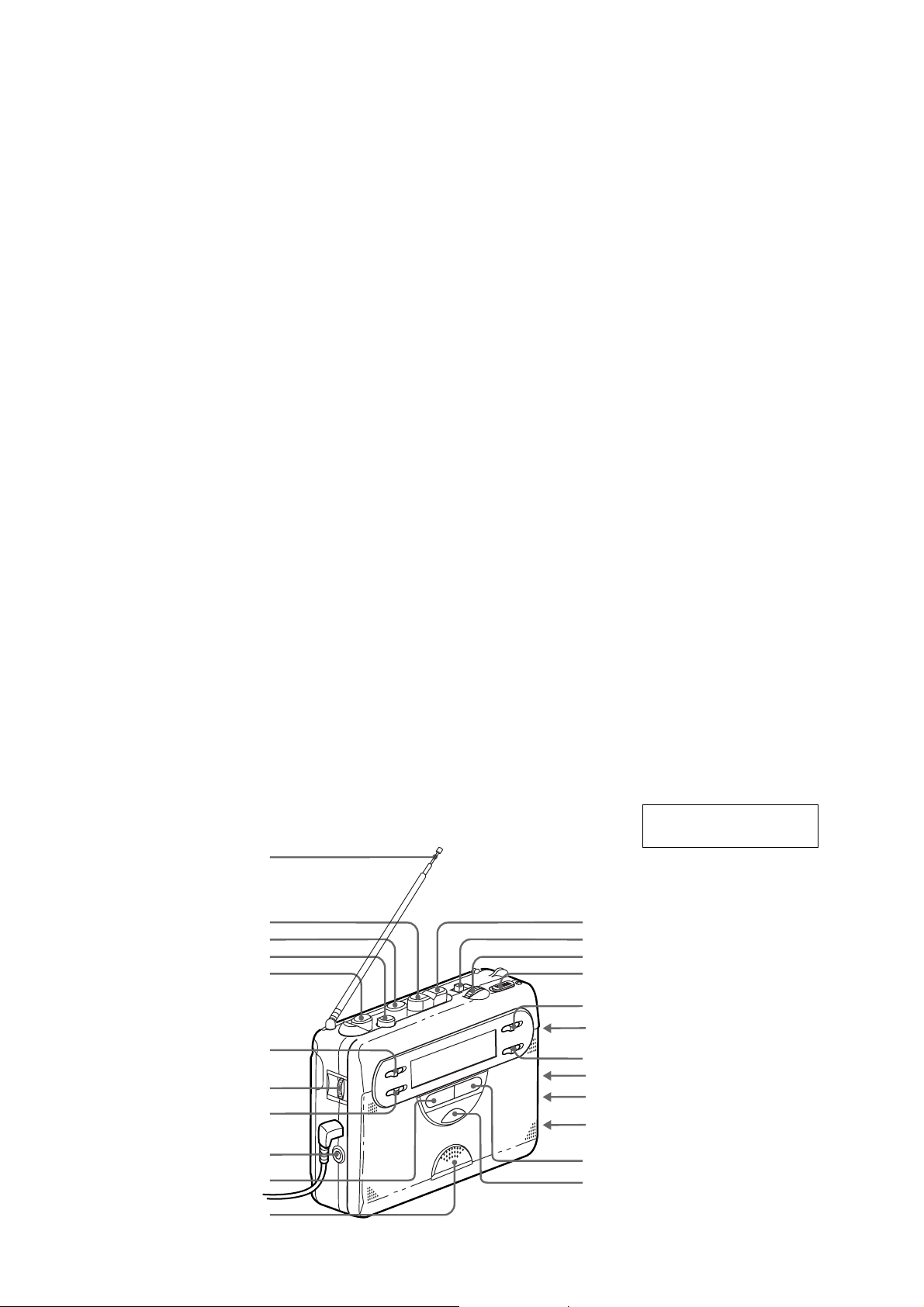

Location of Parts and Controls ........................................2

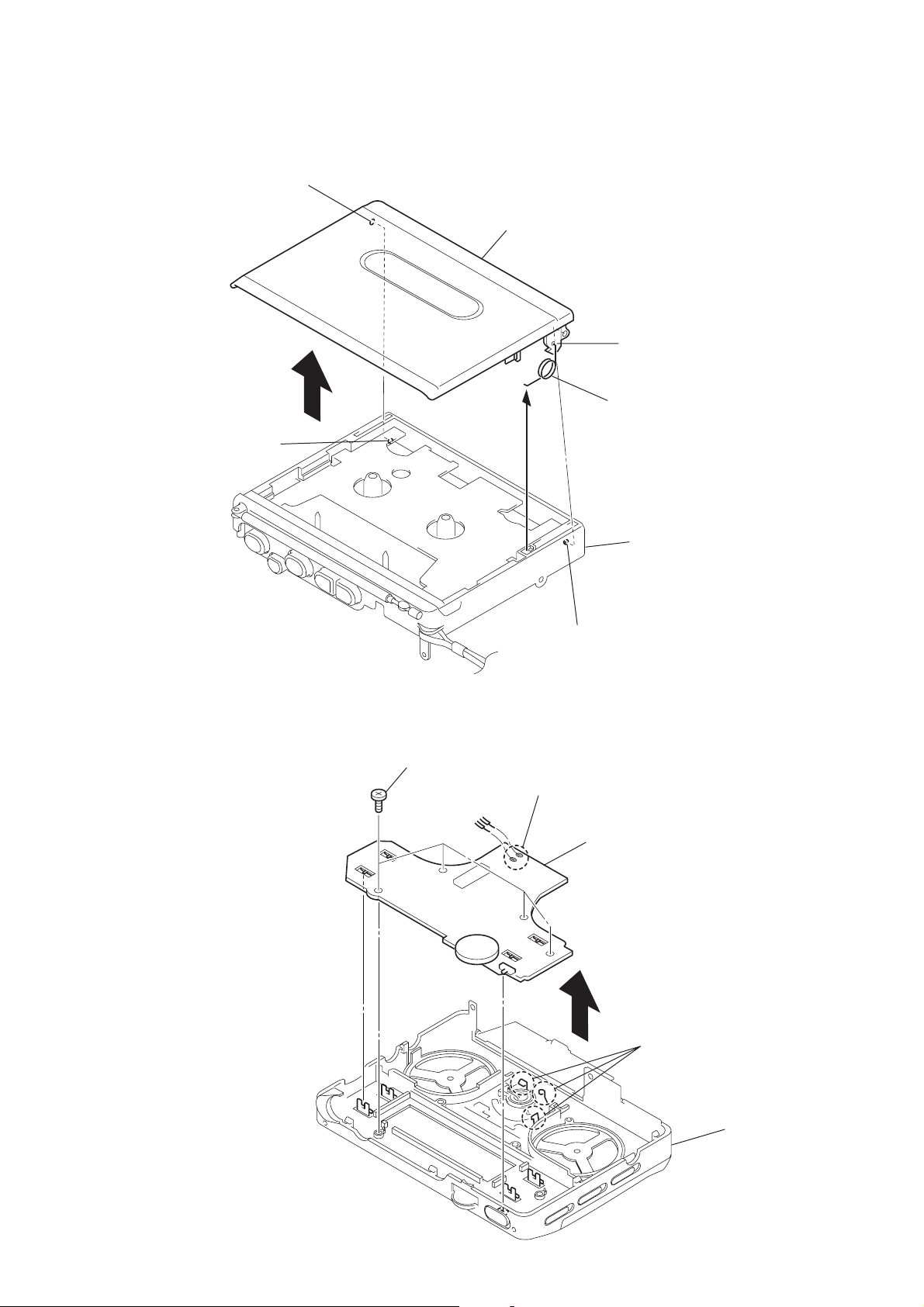

2. DISASSEMBLY

2-1. Disassembly Flow .................................................... 3

2-2. Cabinet (Center), cabinet Front Assy....................... 3

2-3. Main Board .............................................................. 4

2-4. Mechanism Deck (MT-WMFX410-175) ................. 4

2-5. Cassette Holder Sub Assy ........................................ 5

2-6. Sub Board................................................................. 5

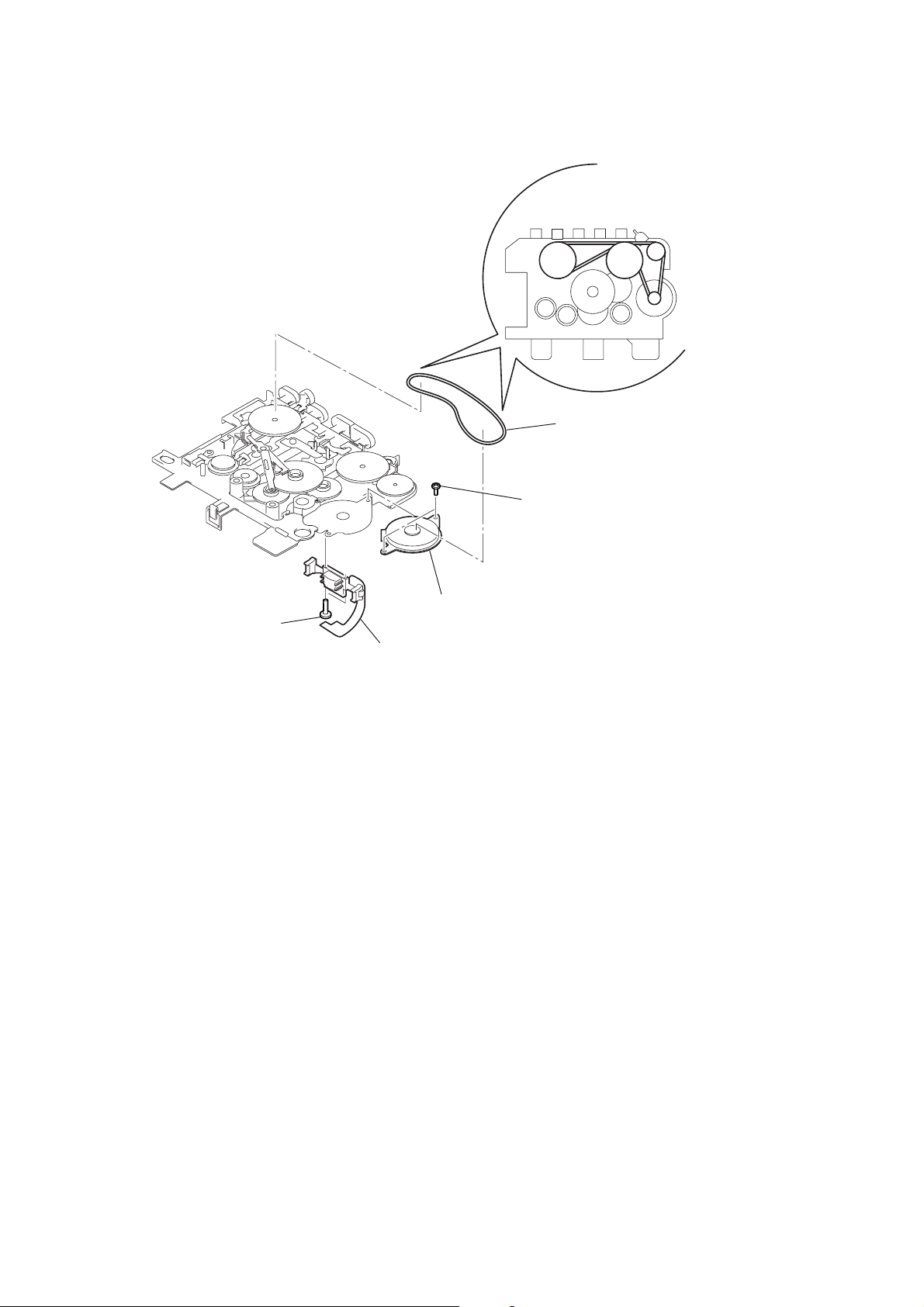

2-7. Rec/PB/ Erase head (HRPE301), Belt (AR),

Capstan/Reel Motor (M601) ................................... 6

3. ADJUSTMENTS

3-1. Mechanical Adjustments.......................................... 7

3-2. Electrical Adjustments ............................................. 7

SECTION 1

GENERAL

Antenna

4. DIAGRAMS

4-1.IC Pin Function Descriptions .................................... 10

4-2. Block Diagrams –Tape Section– .............................. 11

4-3. Block Diagrams –Tuner Section– ............................ 12

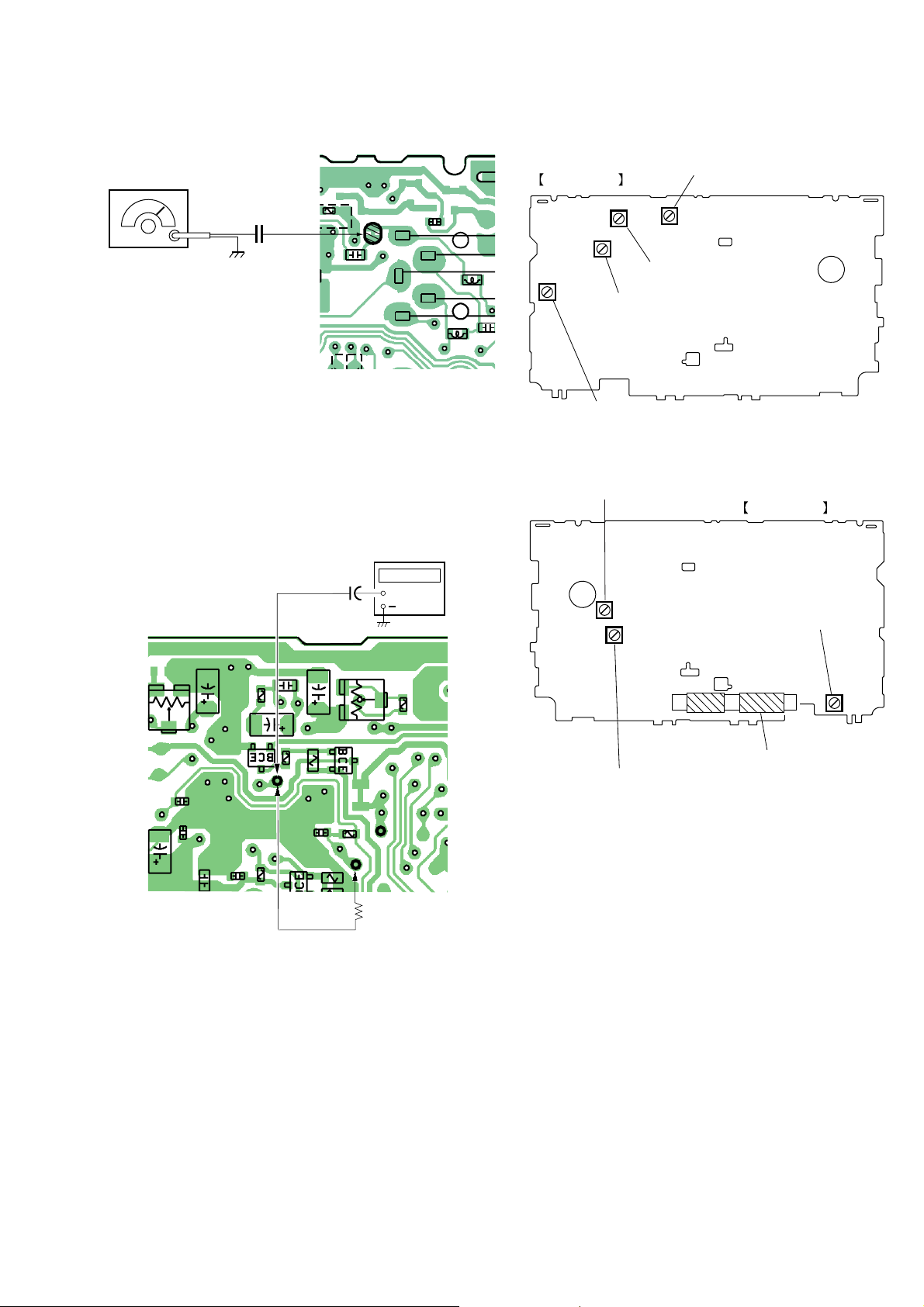

4-4. Printed Wiring Board –Main Section (Side A)– ...... 13

Printed Wiring Board –Main Section (Side B)–.......14

4-5. Schematic Diagram –Main Section (1/2)–............... 15

4-6. Schematic Diagram –Main Section (2/2)–............... 16

4-7. Printed Wiring Board –Sub Section (Side A)–.........17

4-8. Printed Wiring Board –Sub Section (Side B)–......... 18

4-9. Schematic Diagram –Sub Section–.......................... 19

4-10.IC Block Diagrams..................................................20

5. EXPLODED VIEWS

5-1. Cabinet (Rear) Section ............................................. 22

5-2. Cassette Lid Section................................................. 23

5-3. Mechanism Section-1 (MT-WMGX410-175)..........24

5-4. Mechanism Section-2 (MT-WMGX410-175)..........25

6. ELECTRICAL PARTS LIST .................................. 26

This section is extracted

from instruction manual.

FF/CUEREW/REVIEW

PLAY**

STOP

REC

HOLD

VOL*

REC TIME/PLAY MODE

MIC (PLUG IN POWER)**

FM

Flat Mic

* There is a tactile dot beside VOL on the main unit to show the direction to turn

up the volume.

2

** The button or jack has a tactile dot.

DIR

TUNING/ENTER

PAUSE

TUNE MODE

FM MODE•MONO/ST

FM MODE•LOCAL/DX

SOUND BOOST

AVLS

ISS

DC IN 3V

AM

RADIO OFF

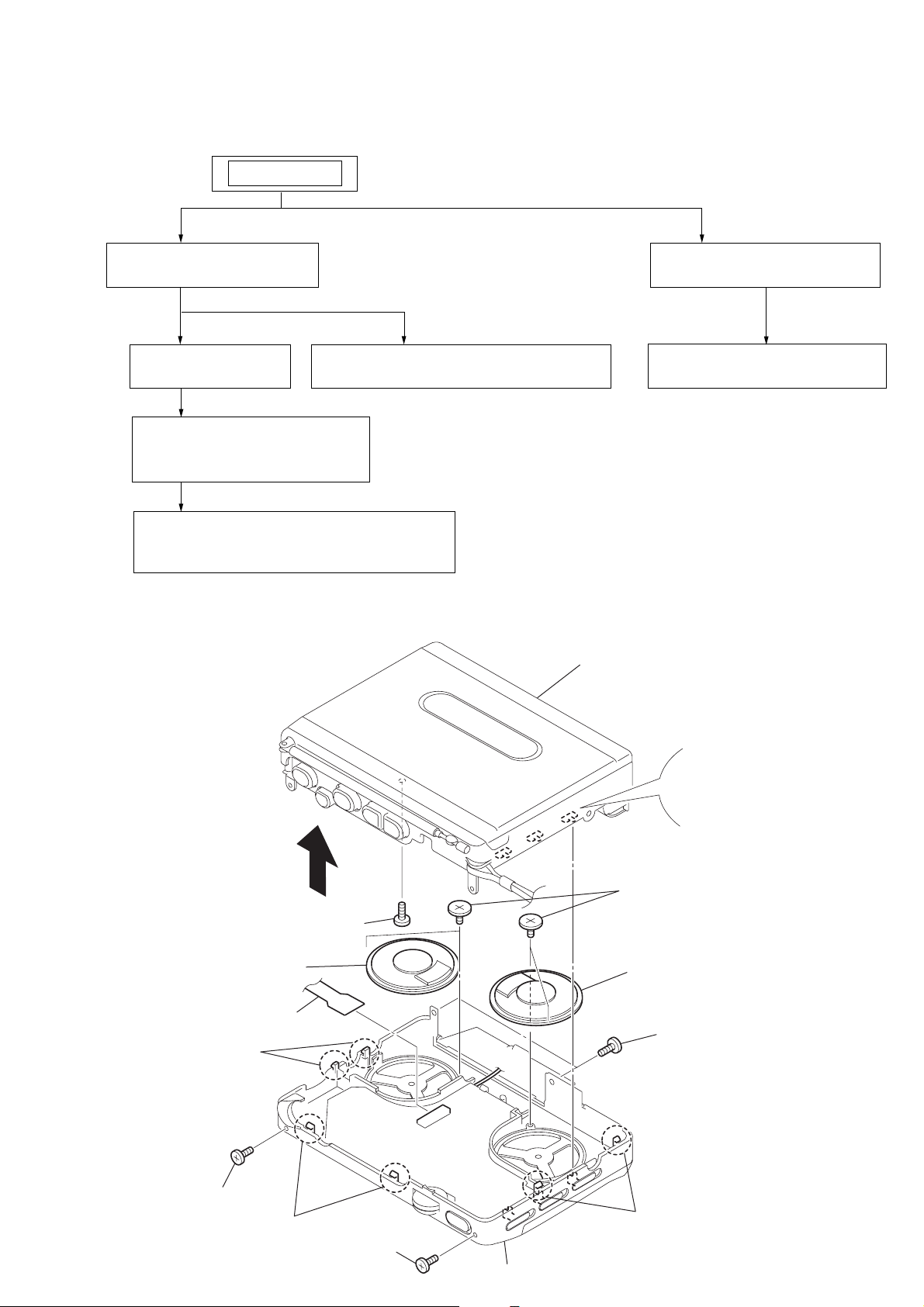

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

WM-GX410

SECTION 2

DISASSEMBLY

2-2. CABINET (CENTER)

(Page 3)

2-3. MAIN BOARD

(Page 4)

2-5. CASSETTE HOLDER SUB ASSY

(Page 5)

2-4. MECHANISM DECK

(MT-WMFX410-175)

(Page 4)

2-7. REC/PB/ERASE HEAD (HRPE301),

BELT (AR), CAPSTAN/REEL MOTOR

(M601) (Page 6)

Note: Follow the disassembly procedure in the numerical order given.

2-2. CABINET (CENTER), CABINET FRONT ASSY

2-2. CABINET FRONT ASSY

(Page 3)

2-6. SUB BOARD

(Page 5)

cabinet (center)

8

screw (M1.4 toothed lock)

SP401

7

fiexible board (CN301)

5

two claws

2

screw (M1.4)

4

two claws

6

2

screw (M1.4)

Note on installation

Align three switches and

three knobs

9

four screws (tapping B2.0)

SP402

1

two screws

3

two claws

cabinet front assy

3

WM-GX410

)

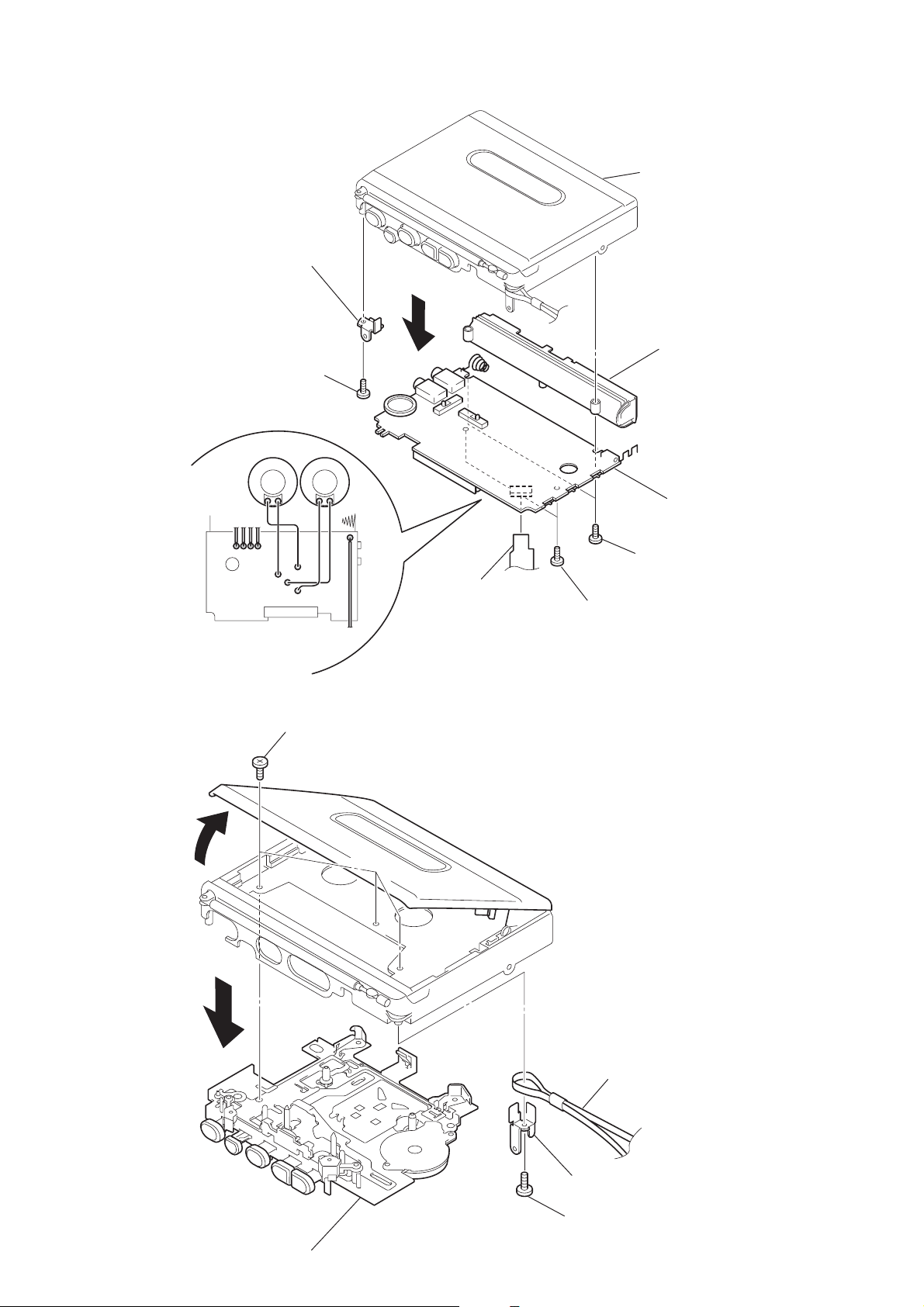

2-3. MAIN BOARD

2

remove nine soldering

6

plate connector (L)

5

screw

7

cabinet (center)

8

joint cover

MAIN board

2-4. MECHANISM DECK (MT-WMFX410-175)

2

three screws (IB lock)

1

6

1

flexible board

(CN305)

4

two screws

3

two screws (M1.4 toothed lock)

5

hand strap

4

plate, connector (R

3

screw

mechanism deck (MT-WMGX410-175)

4

2-5. CASSETTE HOLDER SUB ASSY

n

y

1

remove from projection

cassette holder sub assy

2

remove from projectio

WM-GX410

projection

2-6. SUB BOARD

3

2

four screws

4

spring, torstion

cabinet (center)

projection

1

remove two soldering

sub board

Note on installation

Align five switches and

five knobs

4

3

three claws

cabinet front ass

5

WM-GX410

2-7. REC/PB/ERASE HEAD (HRPE301), BELT (AR), CAPSTAN/REEL MOTOR (M601)

Attaching belt (AR)

3

belt (AR)

1

two screws (M1.4)

4

two screws (M1.4)

5

M601 (CAPSTAN/REEL motor)

2

HRPE301 (REC/PB/ERASE head)

6

r

SECTION 3

R607

R601

RV602: Tape Speed Adjustment

(4.8cm/s)

RV601: Tape Speed Adjustment

(2.4cm/s)

RV601

RV602

[MAIN BOARD] (SIDE B)

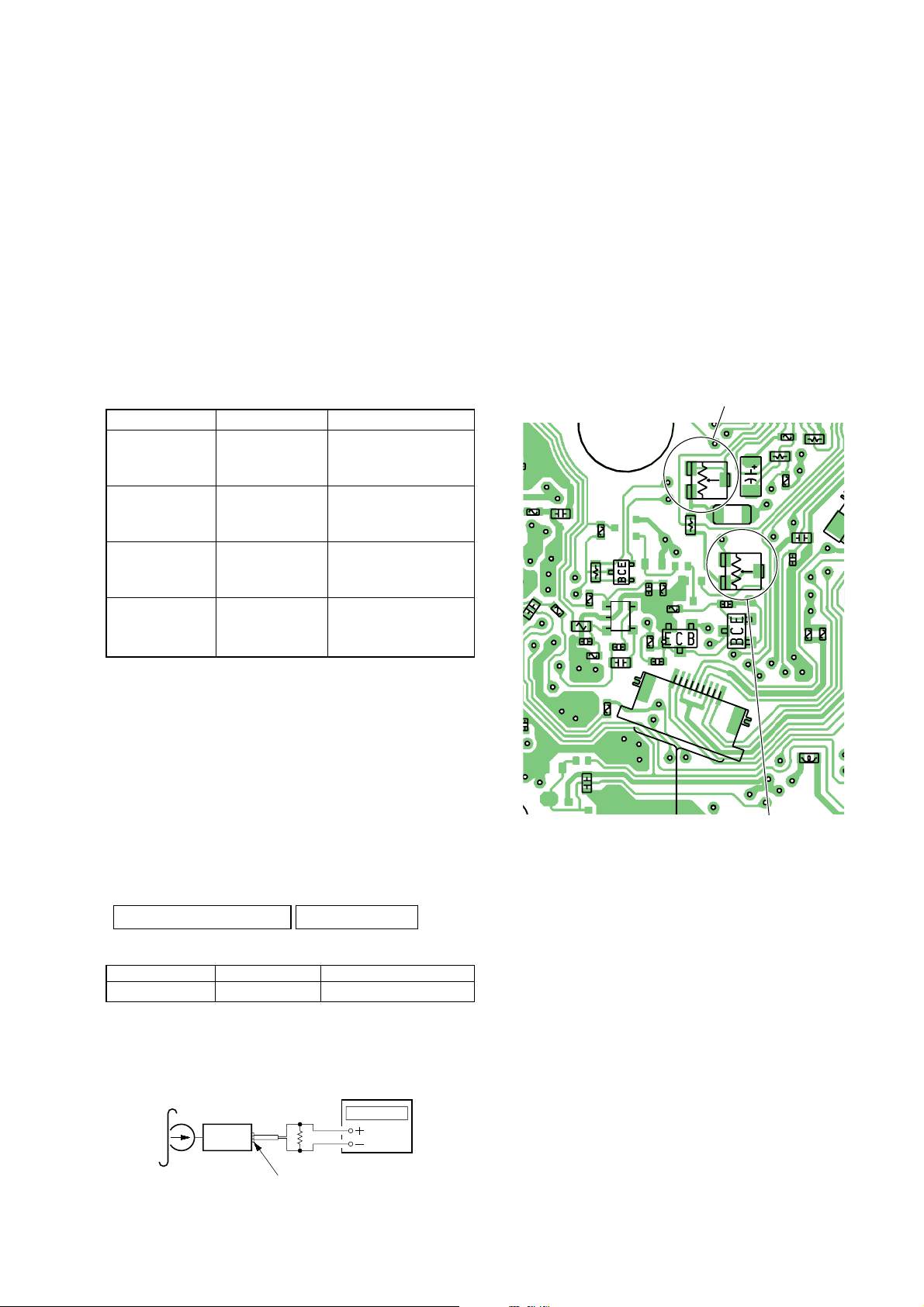

ADJUSTMENTS

WM-GX410

3-1. MECHANICAL ADJUSTMENTS

1. Clean the following parts with a denatured alcohol-moistened

2. Demagnetize the record/playback/erase head with a head

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

5. The adjustments should be performed with the rated power

6. Power supply voltage : 3V DC.

Torque Measurement

Forward/Reverse CQ-102C (20 to 40 g • cm)

Back Tension

Back Tension

Fast Forward

and Rewind

3-2. ELECTRICAL ADJUSTMENTS

Note:

1. Supplied voltage: 3 V (DC)

2. Switch and control position

PRECAUTION

swab :

record/playback/erase head pinch roller

capstan rubber belts

demagnetizer.

the parts adjusted.

supply voltage unless otherwise noted.

Mode Torque Meter Meter Reading

1.97 to 3.92 mN • m

(0.28 to 0.55 oz• inch)

Forward

CQ-102C (0.5 to 5.0 g • cm)

Reverse

CQ-102RC (0.5 to 5.0 g • cm)

CQ-201B (50 g • cm)

0.05 to 0.49 mN • m

(0.007 to 0.07 oz• inch)

0.05 to 0.49 mN • m

(0.007 to 0.07 oz• inch)

more than 4.90 mN • m

(0.7 oz• inch)

VOLUME control : output level < > :AEP

FM -20dBm <-30dBm>

AM-30dBm <-40dBm>

AVLS switch : NORM

REC TIME/PLAY MODE switch : NORMAL

ISS switch : 1

1. Set REC TIME switch (S706) to NORMAL (4.8cm/s).

2. Play back the center portion of tape in REVmode, adjust R V602

so that the reading on the frequency counter becomes 3,000 Hz.

3. Set REC TIME switch (S706) to DOUBLE (2.4cm/s).

4. Play back the center portion of tape in REVmode, adjust R V601

so that the reading on the frequency counter becomes 1,500 Hz.

Specifications:

NORMAL (4.8cm/s) : 2,985Hz - 3,015Hz

DOUBLE (2.4cm/s) : 1,493Hz - 1,507Hz

5. Confirm the frequency difference between the beginning and

the end of tape should be 1.5%.

NORMAL (4.8cm/s) : 45Hz

DOUBLE (2.4cm/s) : 22.5Hz

4

RV602

C606

R605

R609

06

R423

R340

C339

R341

C221

R344

R354

R338

B

E

B

C336

C337

Q342

Q335

C

C

R337

C338

R339

C333

R606

R336

Q336

RV601

C332

TH601

C70

Q334

C410

R309

R3

9

C86

R335

CN303

1

FB303

C340

Adjustment Location: Main board (See page 9)

TAPE DECK SECTION 0 dB = 0.775 V

Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure:

test tape

WS-48A

(3kHz, 0dB)

frequency counte

16Ω

set

i headphone jack (J401)

7

WM-GX410

)

)

TP333

(LPF)

TP8

TP3

Q308

C43

R313

Q307

R3

C71

C17

R6

R312

C16

C8

C12

R18

Q3

RV1

C31

R22

r

±

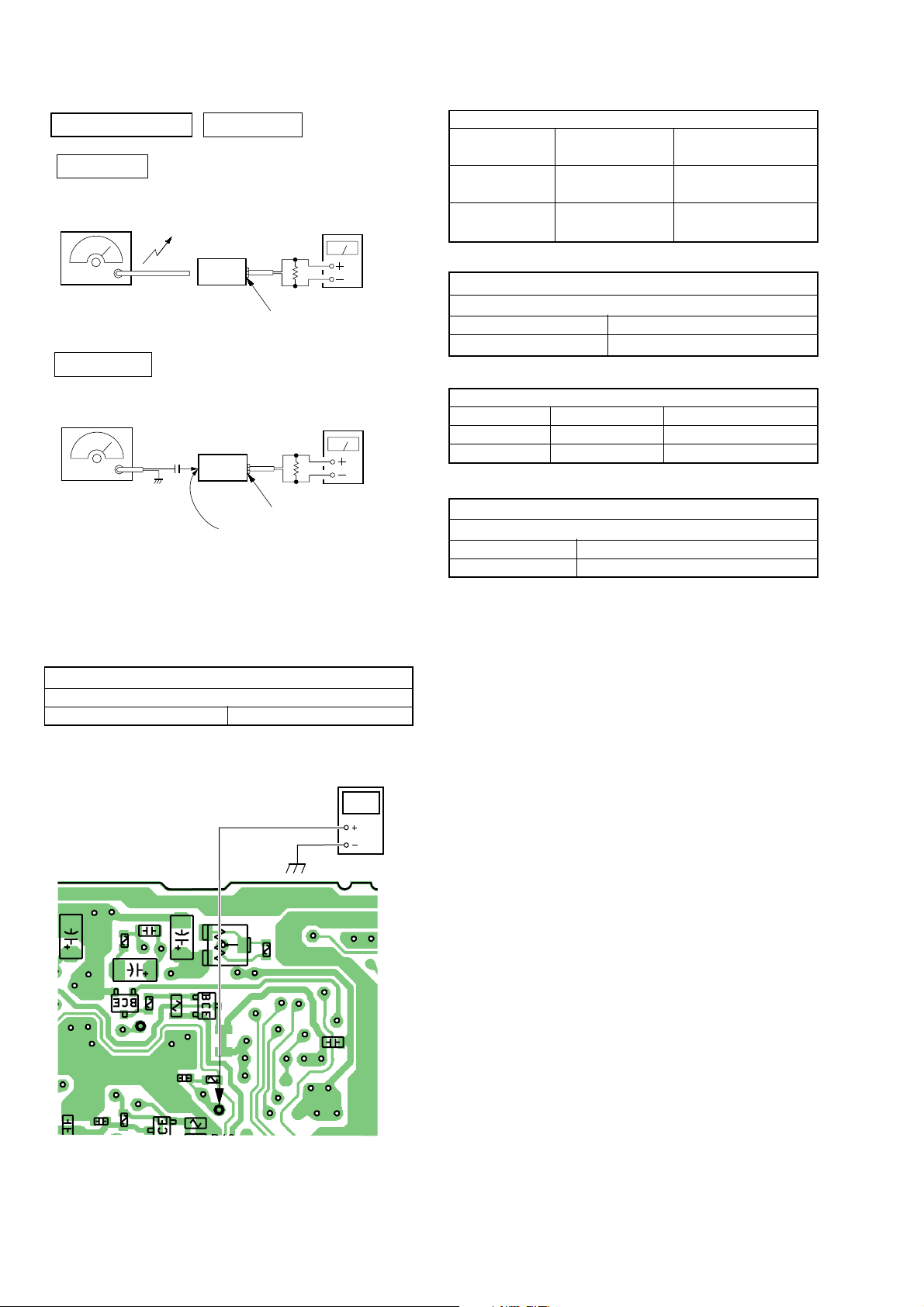

TUNER SECTION 0 dB = 1 µV

AM Section

FUNCTION switch: AM

AM RF SSG

30% amplitude modulation by

400Hz signal.

Output level : as low as possible

Put the lead-wire

antenna close to

the set.

set

level meter

Ω

16

i

headphone jack (J401

FM Section

FUNCTION switch: FM

FM RF SSG

0.01

µ

F

set

30% amplitude

modulation by

1kHz signal.

Deviation : 75kHz

Output level : as low

as possible

main board

TAP66

• Repeat the procedures in each adjustment several times, and

the frequency coverage and tracking adjustments should be

finally done by the trimmer capacitors.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

RV2 999 kHz <1,000kHz>

level meter

Ω

16

i

headphone jack (J401

(side B)

no mark : 9kHz step

< > : 10kHz step

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust parts Frequency

L7

Confirmation

AM TRACKING ADJUSTMENT

<530kHz>

531kHz

<1,710kHz>

1,602kHz

Reading on digtal

voltmeter

1.1 ± 0.4V

5.0 ± 0.6V

Adjustment for a maximum reading on level meter.

L3 <620 kHz> 621 kHz

CT1 <1,400 kHz> 1,404 kHz

FM FREQUENCY COVERAGE CONFIRMATION

Frequency display Reading on digtal voltmeter

Confirmation 87.5 MHz Standard value : 4.2 ± 0.5 V

Confirmation 108 MHz 9.1 ± 0.5 V

FM TRACKING ADJUSTMENT

Adjustment for a maximum reading on level meter.

L4 87.5 MHz

Confirmation 108 MHz

Adjustment Location: Main board (See page 9)

[MAIN BOARD] (SIDE A)

8

TP (LPF)

digital voltmete

(DC range)

WM-GX410

TP(LPF)

TP8

Q308

C43

R313

Q307

R3

C56

C17

R6

C89

R312

C16

C8

C12

R18

Q3

RV1

C31

RV2

C49

R22

P

2

FM VCO Adjustment

Procedure:

FM RF SSG

0.01

µ

Carrier frequency : 98MHz

Deviation : None

Output level : 562

µ

TAP66

F

(ANT)

V (55dB)

[MAIN BOARD] (SIDE B)

ND

C905

CND

908

4

-3

C920

C40

S302

REC

t

PB

-4

TAP66

TAP66

FB306

FB305

C35

1. Connect the resistor 10kΩ between TP8 and TP(LPF).

2. Connect the frequency counter to TP8 (IC8 7 pin).

3. Set FUNCTION switch to FM.

4. Tune the set in 98MHz.

5. Adjust RV1 so that the reading on the frequency counter becomes 76 kHz.

Specifications: 75 kHz - 77 kHz

frequency

counter

µ

F

1

+

TP8

(IC1 7 pin)

+

Adjustment Location:

MAIN BOARD (SIDE A)

T

RV2 : AM IF adjustment

L4 : FM Tracking Adjustment

C5

L7 : AM Frequency

coverage

adjustment

RV602 : Tape Speed Adjustment (4.8cm/s)

RV1 : FM VCO adjustment

MAIN BOARD (SIDE B)

CT1 :

AM T rac king Adjustment

[MAIN BOARD]

(SIDE A)

Adjustment Location: Main board (See page 9)

10k

L3 : AM Tracking Adjustment

RV601: Tape Speed Adjustment (2.4cm/s)

Ω

9

WM-GX410

SECTION 4

DIAGRAMS

4-1. IC Pin Function Descriptions IC701 (SYSTEM CONTROL/LCD DRIVE) LC723483 W-9C33-E

Pin No. Pin name I/O Description

1 XOUT O Connected to 75kHz Crystal oscillator

2 TEST 2 I For Test (Connected to GND)

3 MECHA REC I REC mode signal input

4 to 6 PA3 to 1 I Control key inputs

7 KO2 O Key source signal output

8 KO1 O Key source signal output

9 REC CTRL O REC control signal output L: REC

10 AMP ON O Power amplifier on/off control signal output

11 SD I SD input

12 COMP I COMP input

13 PUSH I Tuning dial (S701) common switch signal input

14 MECHA TAPE I Tape on/off detection signal input

15 RADIO ON O Radio on/off control signal output

16 BAND O Band select signal output

17 TUNING-B I Tuning dial (S701) B phase signal input

18 TUNING-A I Tuning dial (S701) A phase signal input

19 MUTE O Mute signal output

20 BEEP O Beep signal output

21 BACK UP VOLTAGE I Back-up voltage detection signal input

22 BATT LEVEL I Battery voltage detection signal input

23 VERSION I Destination select signal input

24 GND — Ground terminal

25 TUNER MODE INPUT I Tuning mode select switch (S707) signal input

26 2X INPUT I Tape speed select switch (S706) signal input

27 PAUSE I Pause switch (S702) signal input

28 HOLD I HOLD switch (S705) signal input

29 SHUTDOWN O Not used (open)

30 MOTOR BRAKE O Motor brake control signal output

31 MOTOR CTL O Motor control signal output

32 to 44 S13 to S1 O LCD driver segment output terminal

45 to 48 COM4 to 1 O LCD driver common output terminal

49 TU O Output for tuning voltage generator

50 to 53 DBR4 to 1 I For LCD power supply booster

54 RESET I System reset signal input

55 HCTR NC — Not used (open)

56 VDD — Power supply terminal

57 FM IN I FM VCO input

58 AM IN I AM VCO input

59 GND — Ground terminal

60 E0 O Tuning signal (PWM) output

61 AIN I LPF amplifier input

62 AOUT O LPF amplifier output

63 TEST 1 I For test (connected to ground)

64 XIN I Connected to 75kHz Crystal oscillator

10

Loading...

Loading...