Sony WMGX-400 Service manual

WM-GX400

SERVICE MANUAL

Ver 1.0 2001.03

SPECIFICATIONS

Canadian Model

AEP Model

E Model

Chinese Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-WMGX400-175

Frequency range

Area* FM (MHz) AM (kHz)

AEP, E, Chineses model 87.5 - 108 531 - 1 602

US, Canadian model 87.5 - 108 530 - 1 710

Tourist model 76 - 90 531 - 1 710

* E: European and other countries, U: Canada, and Central and

South America, J: Japan.

Frequency response Playback: 40 - 15,000 Hz

Recording: 100 - 8,000 Hz

Input Microphone (MIC) jack

Output Headphones (i) jack

Load impedance 8 - 300 ohms

Power requirements 3 V DC batteries R6 (size AA) × 2

External DC 3V power sources

Dimensions (w/h/d) Approx. 112.5 × 87.0 × 39.0 mm

(14 1/2 × 3 1/2 × 1 9/16 inches), excl.

projecting parts and controls

Mass Approx. 190 g (6.8oz) (main unit only)

Supplied accessories Stereo headphones or earphones (1)

Stereo microphone (1)

Sony dry battery R6P(SR) (2) (“Sony

World Model” only)

Design and specifications are subject to change without notice.

Battery life (Approx. hours) (EIAJ*)

Sony alkaline LR6 (SG)** Sony R6P (SR)

(using headphones/earphones)

playback 24 6

radio 48 15

mic recording 20 4.5

radio recording 12 3

(using the speakers)

playback 13 3

radio 23 6

radio recording 8.5 1.5

* Measured value by the standard of EIAJ (Electronic Industries

Association of Japan) (using a Sony HF series cassette tape).

** When using Sony LR6 (SG) “STAMINA” alkaline dry

batteries (produced in Japan).

Note

• The battery life may be shorter depending on the operating

condition, the surrounding temperature and battery type.

9-873-087-11

2001C0200-1

© 2001.3

RADIO CASSETTE-CORDER

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

WM-GX400

TABLE OF CONTENTS

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Specifications ........................................................................... 1

1. GENERAL

Location of Parts and Controls .......................................... 2

2. DISASSEMBLY

2-1. Cabinet (Front)Cabinet (Rear),

"Lid, Cassette ASSY" ............................................... 3

2-2. Main Board ................................................................. 4

2-3. Mechanism Deck ........................................................ 4

2-4. HRPE301 (REC/PB/ERASE head),

M601 (Capstan/reel motor), Belt (AR) ....................... 5

2-5. Display Board ............................................................. 5

3. ADJUSTMENTS

3-1. Mechanical Adjustments............................................. 6

3-2. Electrical Adjustments ................................................ 6

4. DIAGRAMS

4-1. Explanation of IC Terminals ....................................... 7

4-2. Block Diagrams –Tape Section– ................................ 8

4-3. Block Diagrams –Tuner Section– ............................... 9

4-4. Printed Wiring Board –Main Section (Side A)– ....... 10

4-5. Printed Wiring Board –Main Section (Side B)– ....... 11

4-6. Schematic Diagram –Main Section (1/2)– ............... 12

4-7. Schematic Diagram –Main Section (2/2)– ............... 13

4-8. Printed Wiring Board –Display Section (Side A)– ... 14

4-9. Printed Wiring Board –Display Section (Side B)– ... 15

4-10. Schematic Diagram –Display Section– .................. 16

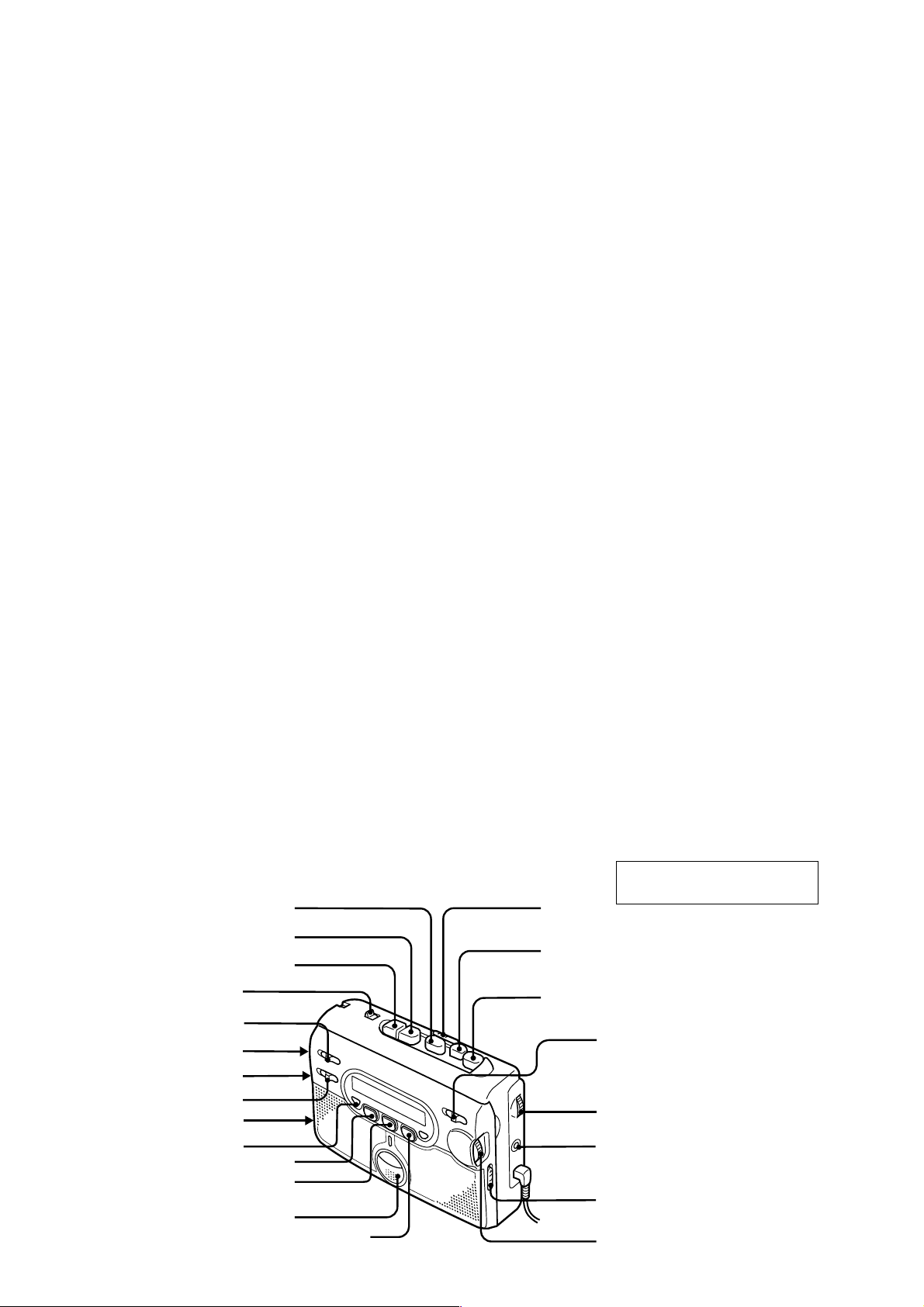

Location of parts and controls

Y PLAY

REW/REVIEW

FF/CUE

DIR

REC TIME

AVLS

ISS

SPEAKER

DC IN 3V

ENTER

built-in microphone

FM

AM

SECTION 1

GENERAL

OFF

5. EXPLODED VIEWS

5-1. Cabinet (Rear) Section .............................................. 20

5-2. Cassette Lid Section ................................................. 21

5-3. Mechanism Section-1 (MT-WMGX400-175) .......... 22

5-4. Mechanism Section-2 (MT-WMGX400-175) .......... 23

6. ELECTRICAL PARTS LIST ................................ 24

This section is extracted from

instruction manual.

PAUSE

x STOP

z REC

TUNING MODE

VOL

MIC (PLUG IN POWER)

i

FM MODE

FM MODE

TUNING

z

ST/MONO

(or/ou/oder)

z

DX/LOCAL

2

SECTION 2

DISASSEMBLY

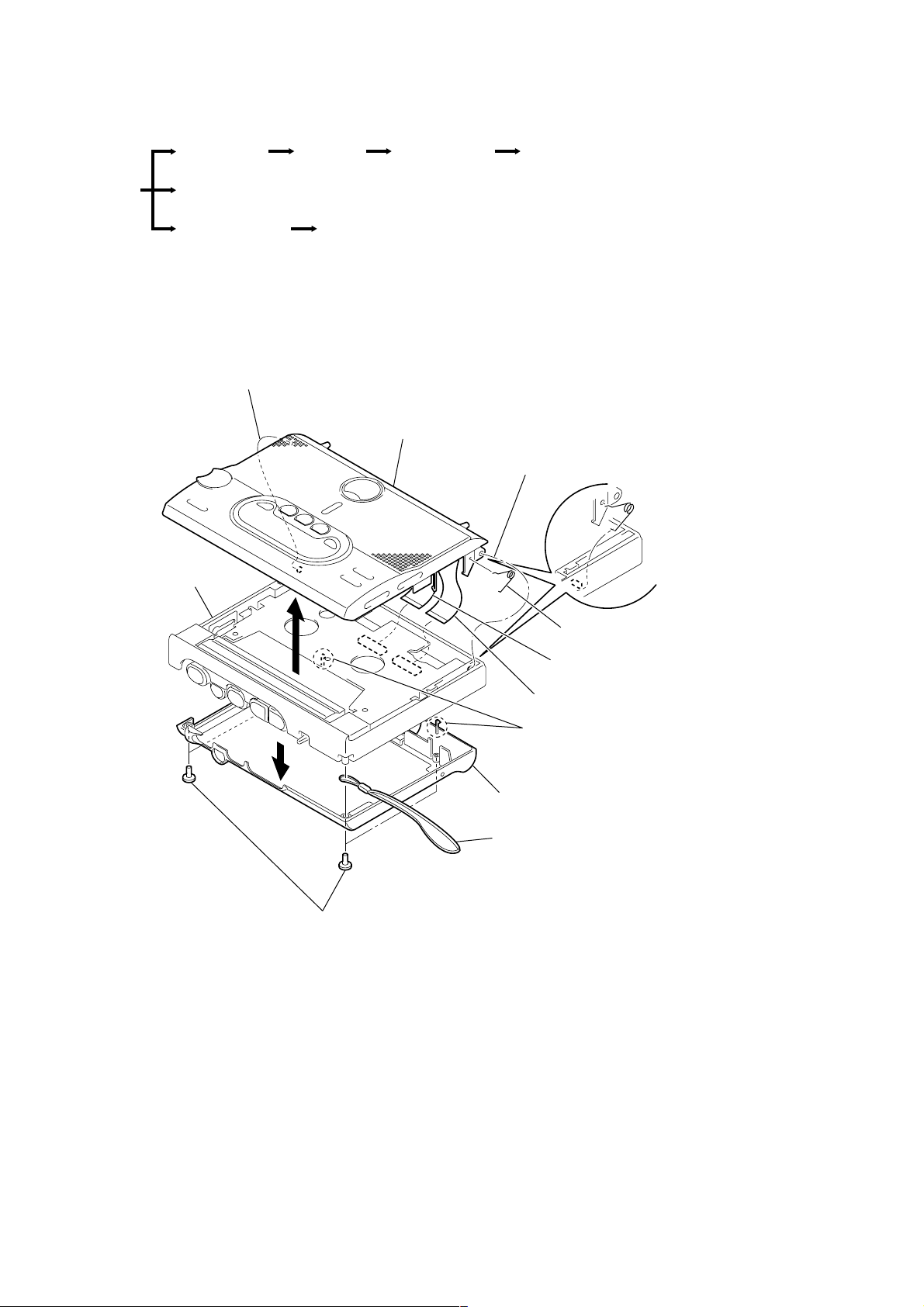

• The equipment can be removed using the following procedure.

WM-GX400

HRPE301 (REC/PB/ERASE head),

M601 (CAPSTAN/REEL motor), Belt (AR)

Set

Cabinet (Front) Main board

Cabinet (Rear)

Mechanism deck

Lid, cassette ASSY Display board

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (FRONT), CABINET (REAR), "LID, CASSETTE ASSY"

6 Remove from projection

Lid, cassette ASSY

6 Remove from projection

Cabinet (front)

Note on installing the

cassette lid assy

When installing the cassette lid ASSY,

insert the one side of the spring (toggle)

and set the other side into the gap on the

cabinet (front) as shown in the figure.

3

7

Spring (toggle)

4 Flexible board (22 core) (CN301)

5 Flexible board (22 core) (CN302)

2 Claws

Cabinet (rear)

Hand strap

1 Screws (+B1.7X9)

3

WM-GX400

)

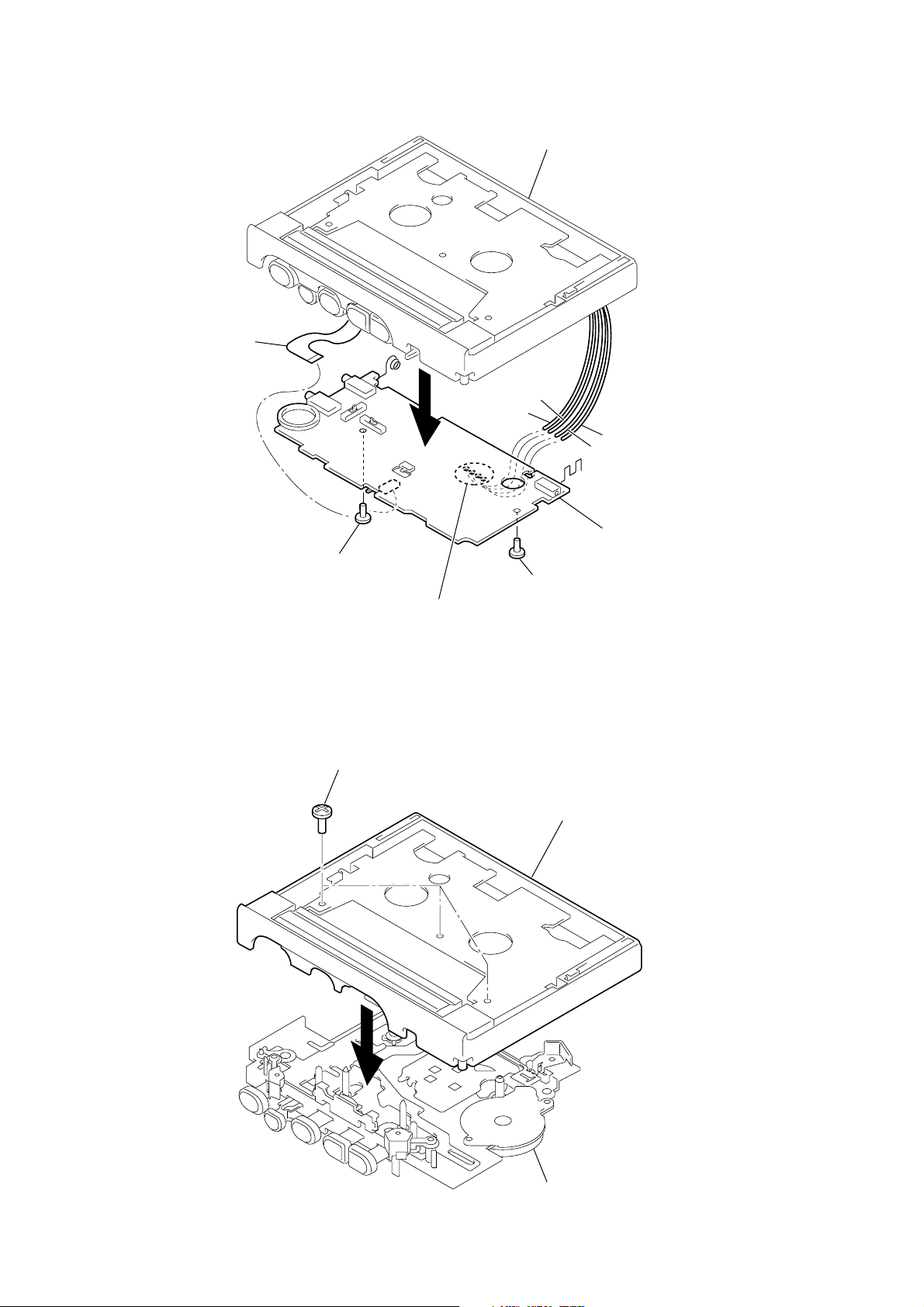

2-2. MAIN BOARD

2 Flexible board (9 core)

(CN303)

Cabinet (front)

2-3. MECHANISM DECK

3 Screw (M1.4)

1 Screws (IB LOCK)

4

1 Remove soldering

(four places)

White

Red

3 Screw (M1.4)

Black

Orange

Main board

Cabinet (front)

2

Mechanism deck (MT-WMGX400-175

4

)

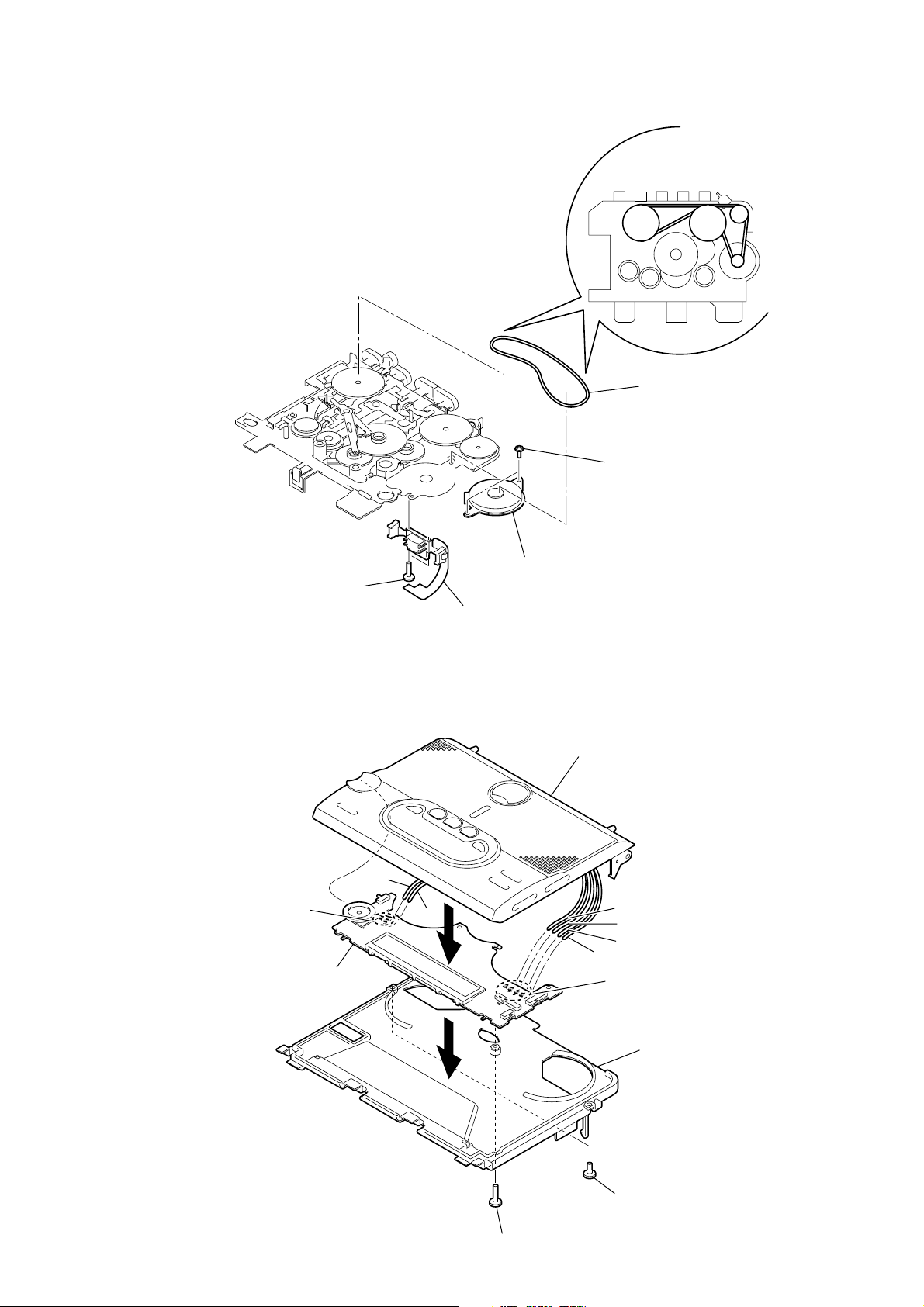

2-4. HRPE301 (REC/PB/ERASE HEAD),

M601 (CAPSTAN/REEL MOTOR), BELT (AR)

WM-GX400

Attaching belt (AR)

3 Belt (AR)

4 Screws (M1.4)

1 Screws (M1.4)

2-5. DISPLAY BOARD

4 Remove soldering (from MIC301)

(two places)

Display board

Red

Black

5

5 M601 (CAPSTAN/REEL motor)

2 HRPE301 (REC/PB/ERASE head)

Lid, cassette ASSY

Gray

White

Brown

Orange

4 Remove soldering (from SP101, SP201

(four places)

3

1 Screw (+BTP1.7X5)

Holder, cassette

2 Screws (+BTP1.7)

5

WM-GX400

r

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured alcohol-moistened

swab :

record/playback/erase head pinch roller

capstan rubber belts

2. Demagnetize the record/playback/erase head with a head demag-

netizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

6. Power supply voltage : 3V DC.

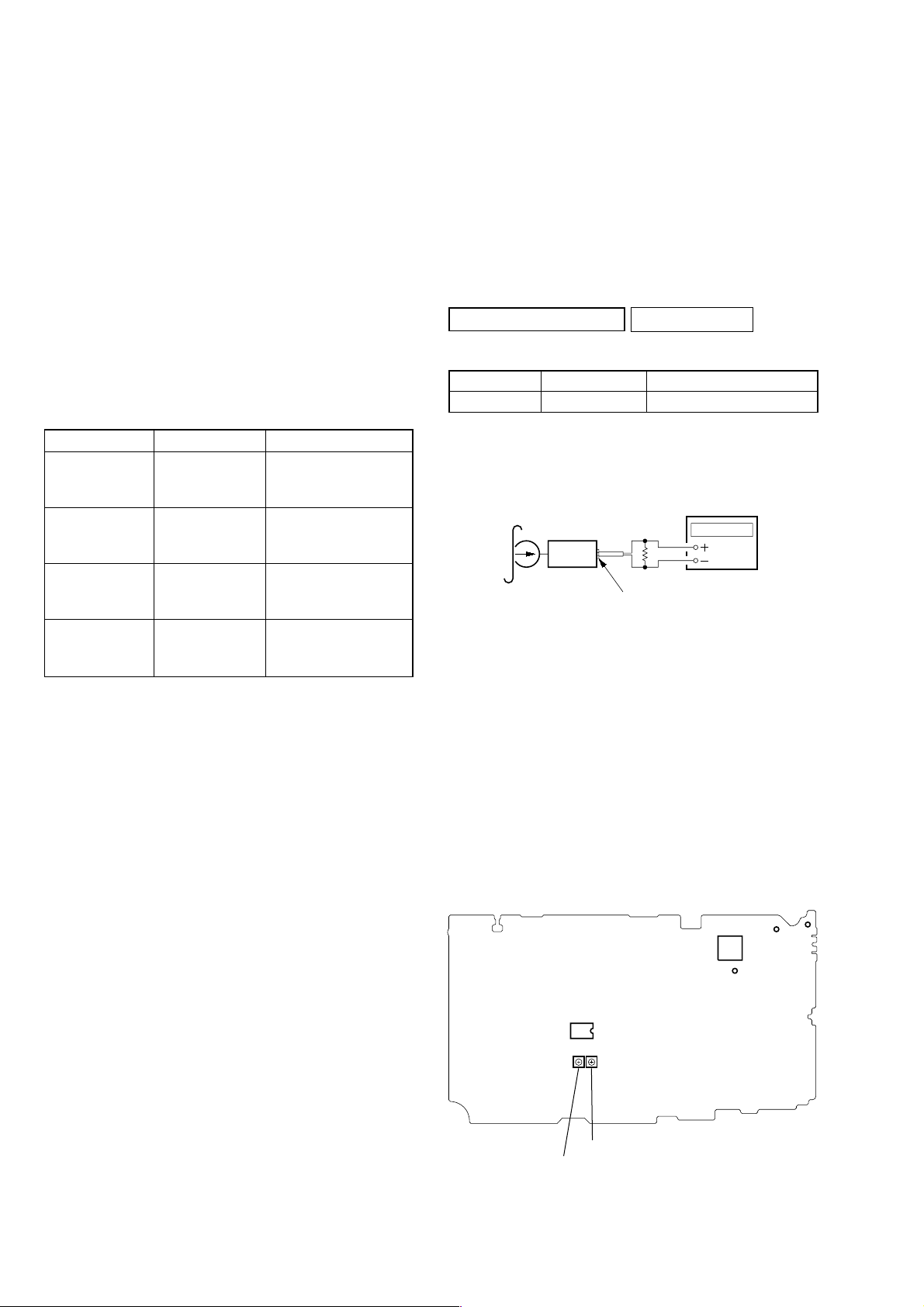

Torque Measurement

Mode Torque Meter Meter Reading

1.97 to 3.92 mN • m

Forward/Reverse CQ-102C (20 to 40 g • cm)

(0.28 to 0.55 oz• inch)

Forward

Back Tension

Reverse

Back Tension

Fast Forward

and Rewind

CQ-102C (0.5 to 5.0 g • cm)

CQ-102RC (0.5 to 5.0 g • cm)

CQ-201B (50 g • cm)

0.05 to 0.49 mN • m

(0.007 to 0.07 oz• inch)

0.05 to 0.49 mN • m

(0.007 to 0.07 oz• inch)

more than 4.90 mN • m

(0.7 oz• inch)

3-2. ELECTRICAL ADJUSTMENTS

Note:

1. Supplied voltage: 3 V (DC)

2. Switch and control position

VOLUME control : maximum

SPEAKER/HEADPHONE switch : i (headphone)

AVLS switch : OFF

FUNCTION switch : OFF

ISS switch : 1

TAPE DECK SECTION 0 dB = 0.775 V

Test Tape

Type Signal Used for

WS-48A 3 kHz, 0 dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure:

test tape

WS-48A

(3kHz, 0dB)

set

i headphone jack (J301)

1. Set REC TIME switch (S706) to NORMAL (4.8cm/s).

2. Play back the center portion of tape in REVmode, adjust RV602

so that the reading on the frequency counter becomes 3,000 Hz.

3. Set REC TIME switch (S706) to DOUBLE (2.4cm/s).

4. Play back the center portion of tape in REVmode, adjust RV601

so that the reading on the frequency counter becomes 1,500 Hz.

Specifications:

NORMAL (4.8cm/s) : 2,985Hz - 3,015Hz

DOUBLE (2.4cm/s) : 1,485Hz - 1,515Hz

5. Confirm the frequency difference between the beginning and

the end of tape should be 1.5%.

NORMAL (4.8cm/s) : 45Hz

DOUBLE (2.4cm/s) : 22.5Hz

frequency counte

16Ω

Adjustment Location:

[MAIN BOARD] (SIDE B)

IC1

TP1

IC301

RV602

RV602: Tape Speed Adjustment (4.8cm/s)

RV601

RV601: Tape Speed Adjustment (2.4cm/s)

GND

TP2

6

SECTION 4

)

)

C

R11

DIAGRAMS

WM-GX400

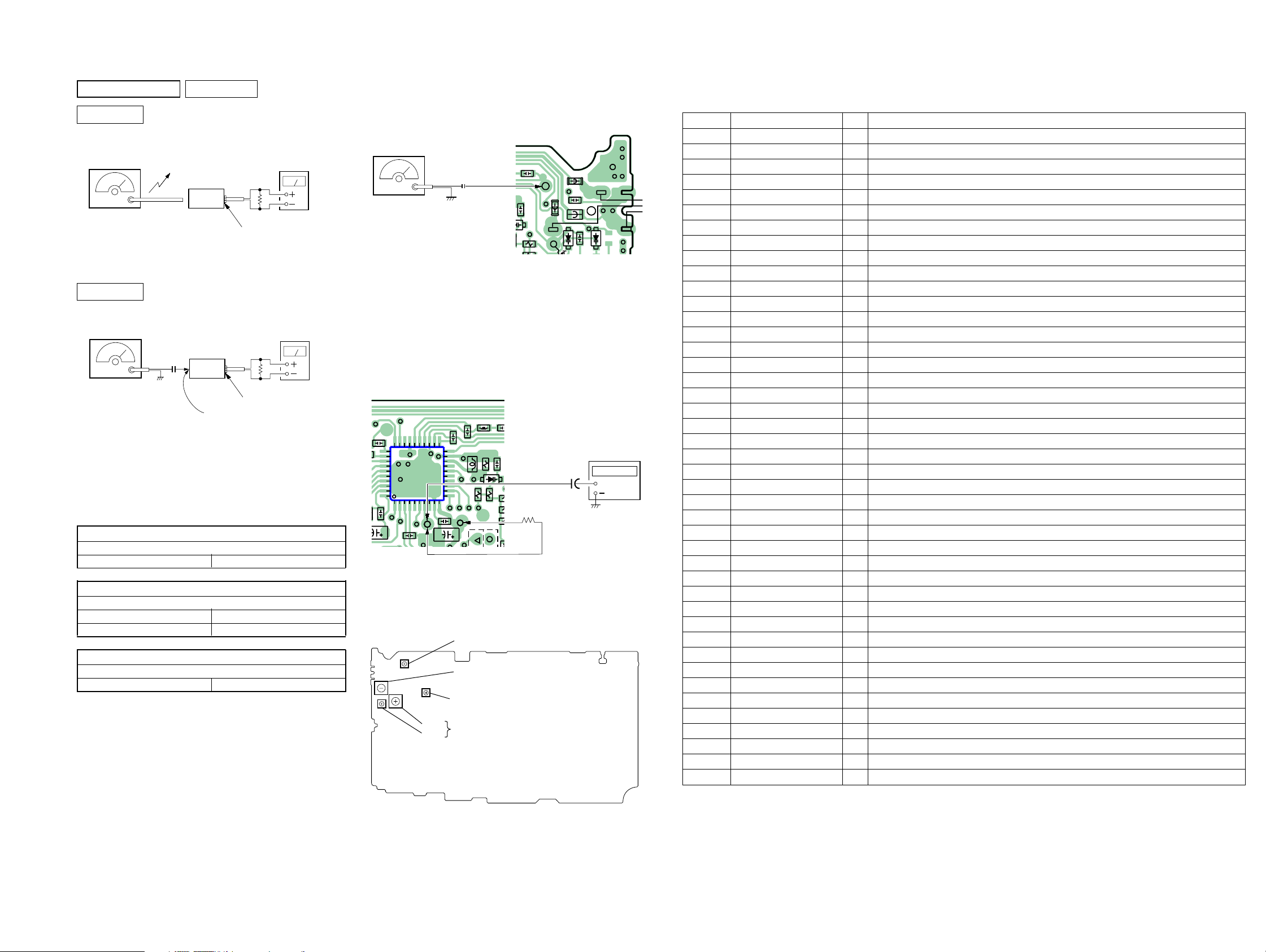

TUNER SECTION 0 dB = 1 µV

AM Section

FUNCTION switch: AM

AM RF SSG

30% amplitude modulation by

400Hz signal.

Output level : as low as possible

FM Section

FUNCTION switch: FM

FM RF SSG

30% amplitude

modulation by

1kHz signal.

Deviation : ±75kHz

Output level : as low

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

Adjust for a maximum reading on level meter.

RV2 999 kHz <1,000kHz>

Adjust for a maximum reading on level meter.

CT1 1,404 kHz <1,400kHz>

Adjust for a maximum reading on level meter.

Put the lead-wire

antenna close to

the set.

16

Ω

level meter

set

i

headphone jack (J301

level meter

Ω

0.01

µ

F

16

set

i

headphone jack (J301

main board

(side B)

TP2

as possible

no mark : 9kHz step

< > : 10kHz step

AM IF ADJUSTMENT

AM TRACKING ADJUSTMENT

L7 621 kHz <620kHz>

FM TRACKING ADJUSTMENT

L4 96.0 MHz

FM VCO Adjustment

Procedure:

[MAIN BOARD] (SIDE B)

FM RF SSG

C15

C28

D4

TP369

R15

TP2

FB201

TP368

FB101

FB301

C3

TP370

D2

3

47

0.01µF

Carrier frequency : 96MHz

Deviation : none

Output level : 562

µ

TP2

(ANT)

V (55dB)

1. Connect the resistor 10kΩ between TP1 and TP332.

2. Connect the frequency counter to TP1 (IC1 7 pin).

3. Set FUNCTION switch to FM.

4. Tune the set in 96MHz.

5. Adjust RV1 so that the reading on the frequency counter becomes 76 kHz.

Specifications: 75 kHz - 77 kHz

[MAIN BOARD] (SIDE B)

C9

TP331

31

40

12

30

1

C8

C18

IC1

TP1

C21

C10

C1

L2

C20

21

20

L6

11

10

TP332

TP333

-4

R18

C28

R20

R17

C34

TP1

D

(IC1 7 pin)

10k

Ω

1

+

µ

F

frequency

counter

+

Adjustment Location:

[MAIN BOARD] (SIDE B)

RV2: AM IF Adjustment

L4: FM Tracking Adjustment

RV1: FM VCO Adjustment

L7:

AM Tracking Adjustment

CT1:

4-1. EXPLANATION OF IC TERMINALS

IC701 (SYSTEM CONTROL/LCD DRIVE) LC72349W-9A27

Pin No. Pin name I/O Description

1 XOUT O Connected to 75kHz Crystal oscillator

2 TEST2 I For Test

3 – 6 PA3 – 0 I Control key inputs

7 RADIO ON O Radio on/off control signal output

8, 9 PB2, 1 O Key source signal outputs

10 MOTOR BRK O Motor brake control signal output

11 PUSH I Tuning dial (S701) common switch signal input

12 PAUSE I Pause switch (S303) signal input

13 VERSION I Destination select signal input

14 BAND O Band select signal output

15 SD I SD input

16 COMP I COMP input

17 TU MODE I Tuning mode select switch (S707) signal input

18 TUNING-A I Tuning dial (S701) A switch signal input

19 AMP ON O Power amplifier on/off control signal output

20 BEEP O Beep signal output

21 BACK UP I Back-up voltage detection signal input

22 BATT I Battery voltage detection signal input

23 FACTORY — Not used Pull-up

24 VSS — Power supply ground terminal

25 MUTE O Mute signal output

26 MOTOR CTL O Motor control signal output

27 N/R SW O N/R switch signal output

28 REC I REC detection signal input

29 TAPE I Tape on/off detection signal input

30 X2 I Tape speed select switch (S706) signal input

31 TUNING-B I Tuning dial (S701) B switch signal input

32 PRE CTL — Not used

33 – 44 S12 – S1 O LCD driver segment output terminal

45 – 48 COM4 – 1 O LCD driver common output terminal

49 – 52 DBR4 – 1 I For LCD power supply booster

53 XRESET I System reset signal input

54 TU O Output for tuning voltage generator

55 VDD — Power supply terminal

56 FM IN I FM VCO input

57 AM IN I AM VCO input

58 VSS — Power supply ground terminal

59 E0 O Main charge pump output

60 AIN I LPF amplifier input

61 AOUT O LPF amplifier output

62 AGND — LPF amplifier ground

63 TEST1 I For test

64 XIN I Connected to 75kHz Crystal oscillator

77

WM-GX400

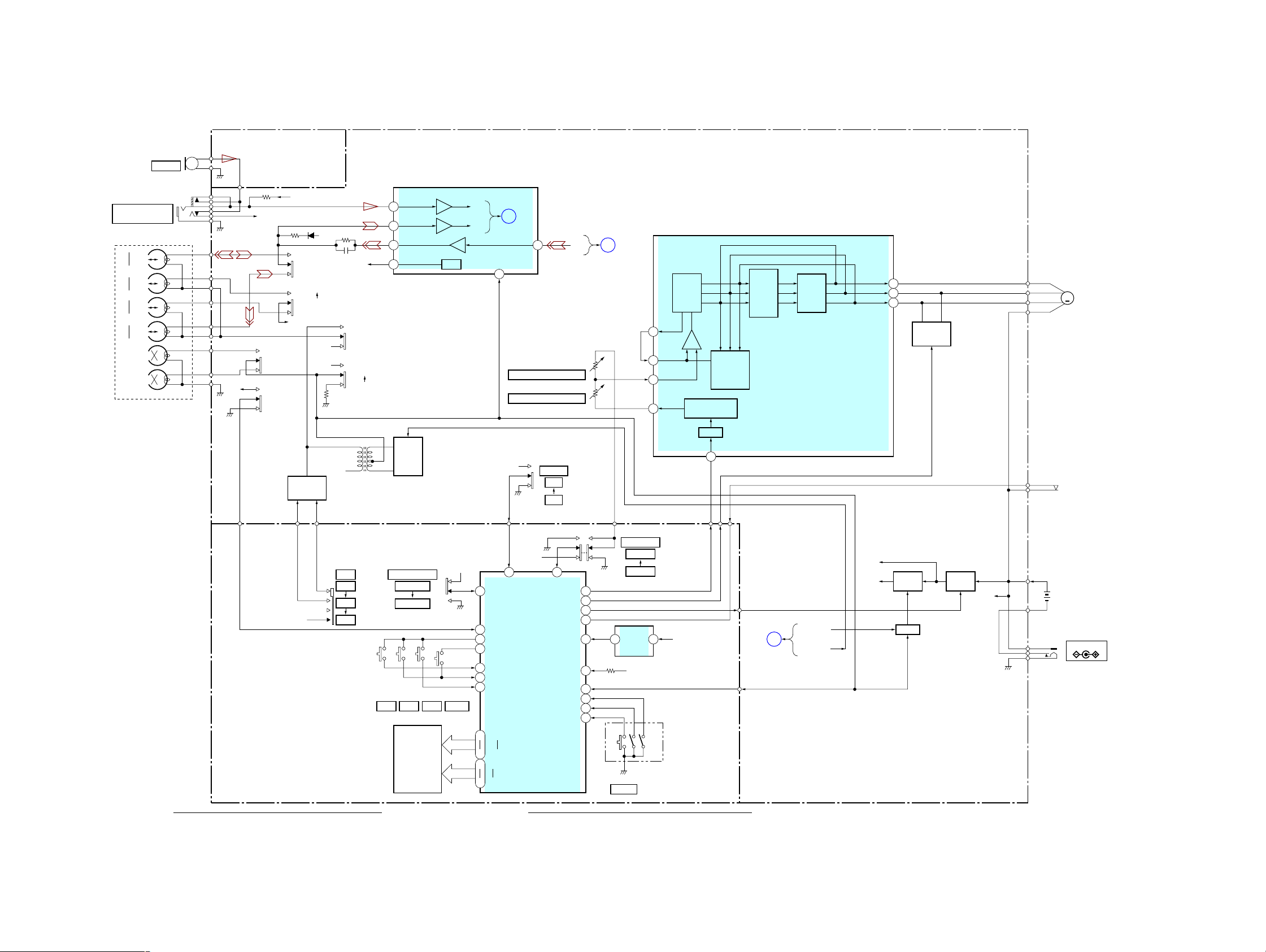

4-2. BLOCK DIAGRAMS – TAPE SECTION –

MIC301

Flat Mic

[DISPLAY BOARD] (1/3)

R-CH

S301-2

S301-1

MIC

VCC

S301-3

S301-4

R-CH

D406

ISS

SWITCH

Q335

S301

FWD

REV

VREF

VCC

REC

S302-2

S302-1

VREF

J302

MIC

(PLUG IN POWER)

HRPE301

REC/PB/ERASE HEAD

L

FWD

R

R

REV

L

FWD

REV

VCC

[MAIN BOARD] (1/2)

MIC

INPUT (L)

2

PB PRE

INPUT (L)

3

REC DRIVE

OUTPUT (L)

10

VREF

T331

S302

REC

PB

REFERENCE

1

BIAS

OSC

Q334,336

REC AMP

IC302

REC/PB AMP

MIC AMP

PRE AMP

REF

(1/2)

MIC

PR

REC DRIVE

INPUT (L)

PB/REC

SELECTOR

13

BATT

IC302

B

(2/2)

9

RV601

TAPE SPEED 2.4cm/S

RV602

TAPE SPEED 4.8cm/S

S303

PAUSE

ON

OFF

REC

SG

MAIN

BOARD

A

(2/2)

WAVE-

CURRENT

DETECT

17

OUT

-+

VSP

16

IN+

15

SPEED

DETECT

FORM

DETECT

MOTIVE

LOGIC

SOFT

SWITCH

PRE

DRIVE

MOTOR DRIVE/

SPEED CONTROL

U OUT

V OUT

W OUT

4

5

6

MOTOR

BRAKE

Q601-603

COM

U

V

W

M

CAPSTAN/REEL

M601

MOTOR

IC301

SPEED CONTROL

VREF

14

REF

BIAS

13

S/S

S601

(TAPE POWER)

[DISPLAY BOARD] (2/3)

VCC

S703

ISS

S706

TAPE SPEED

S707

TUNING MODE

3

2

1

MANUAL

PRESET

S708AMS709

FM

CRYSTAL

DISPLAY

ND701

LIQUID

S712

S710

OFF ENTER

BATT

17 26

TUN MODE MOTOR CTL

N/R SW

27

PB1

9

PB2

8

6

PA0

PA1

5

PA2

4

48

COM1

COM4

45

44

S1

S2

33

BATT

12 30

PAUSE X2

MOTOR BLK

SYSTEM

CONTROL

IC701

(1/2)

VERSION

TUNING-A

TUNING-B

AMP ON

TAPE

BATT

REC

PUSH

10

19

29

13

28

18

31

11

NORMAL

DOUBLE

BATT

DETECT

2 322

IC702

VDD

CBA

S701 (ROTALY)

TUNING

COM

BATT

MAIN

BOARD

(2/2)

VCC

SWITCH

MIC

VCC

RADIO ON

C

MUTE

Q356

GATE

Q354-355

REG

Q501, 502

BATT

DRY BATTERY

+

SIZE “AA”

(IEE DESIGNATION LR6)

2PCS, 3V

J501

DC IN 3V

R–CH IS OMITTED: SAME AS L–CH

• Signal path.

E : PB

a : REC

N : MIC

88

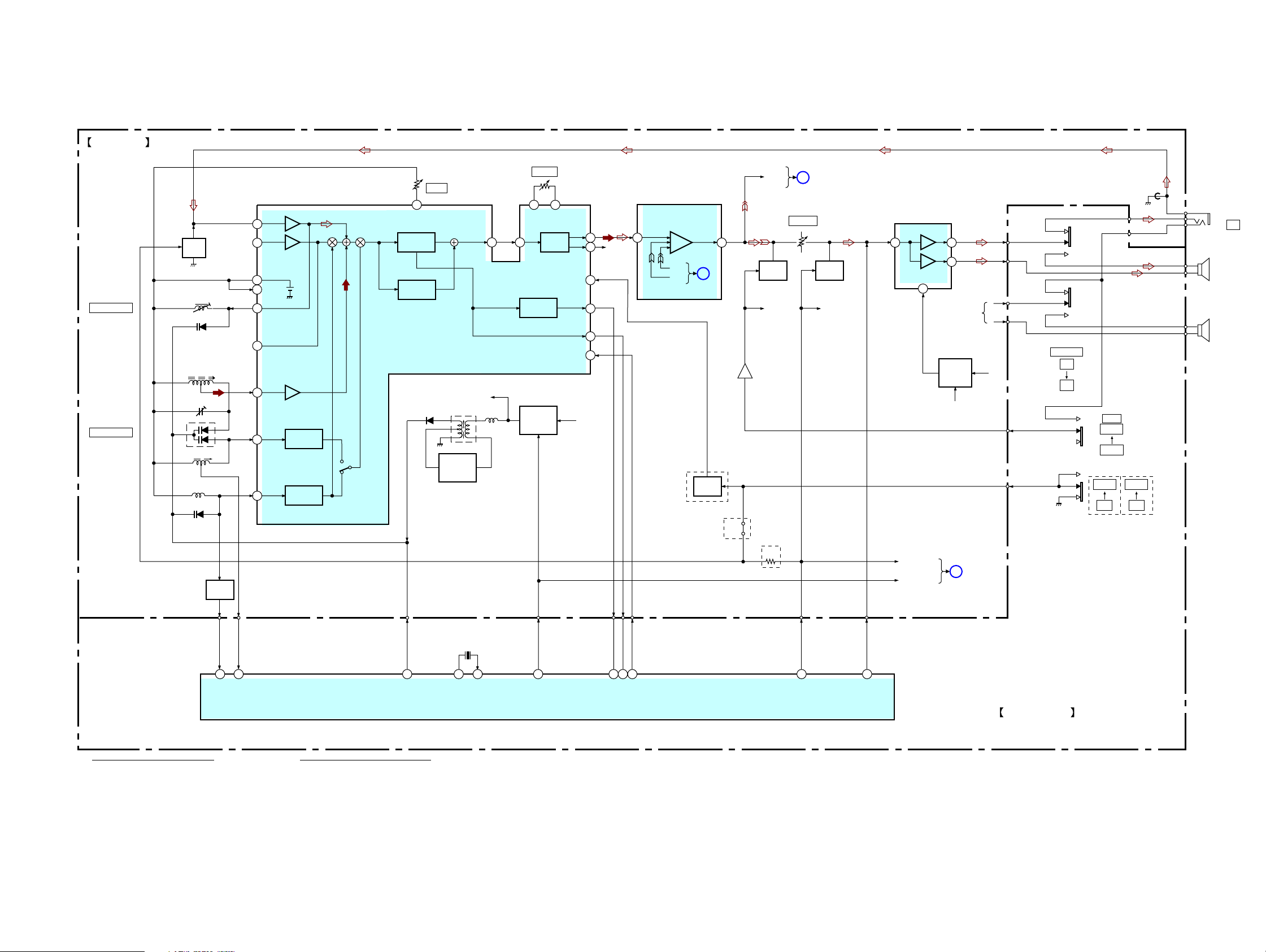

4-3. BLOCK DIAGRAMS – TUNER SECTION –

MAIN BOARD (2/2)

FRONT-END,

IF, DET, FM MPX

FM IN

25

TV IN

24

REGV

19

MREF

27

FMRO

22

TVRO

20

ARFI

26

AMLO

16

FTLO

18

AM

OSC

FM/TV

OSC

L4

FM TRACKING

L7, CT1

AM TRACKING

ATT

Q1

L4

D2

L3

AM FERRITE BAR

ANTENNA

CT1

D1

L7

L6

D4

BUFFER

Q3

IC1

FM/AM/TV

RV2

AM IF

29 2 1

IFCT

TUNER VCC

T401

DC-DC

CONVERTER

Q401

DFTO

35 36

L401

FM/TV LPF

FM DET.

AM BPF

AGC

LPF OUT

D402

MPRG

MPXI

TUNER B+

Q307, 308

RV1

FM VCO

LEVEL

DETECT

SWITCH

RADIO ON

VCO

MPX

LOUT

ROUT

PLT2

COMP

TUNE

BAND

VCC

3 7

4

R-CH

37

13

11

12

IC302

TUNER

INPUT (L)

PRE AMP

MIC

PB

REC

(2/2)

LINE

OUT (L)

8 6 3

B

IC302

(1/2)

SWITCH

Q2

EXCEPT CND, 5E

JC2

CND, 5E

SG

AVLS

Q405

R-CH

Q301, 302

R22

EXCEPT CND, 5E

A

RV301

VOLUME

MUTE

MAIN BOARD

(2/2)

MUTE

Q101

R-CH

IC101

IC201

BTL

POWER AMP

+

VCC

2

MUTE

RADIO ON

-

(L-CH)

(R-CH)

1

AMP B+

SWITCH

Q371-374

MIC VCC

C

R-CH

VCC

MAIN BOARD

(1/2)

WM-GX400

J301

i

SP101

SPEAKER

(L-CH)

SP201

SPEAKER

(R-CH)

S702

SPEAKER

OFF

ON

S702-1

S702-2

MONO

ST

EXCEPT

CND, 5E

S704

AVLS

NORM

LIMIT

S705

LOCAL

DX

CND, 5E

+

-

+

-

+

-

+

-

X701

75kHz

56 57 61 16 15 14 25 2071 64

FM IN

AM IN

R–CH IS OMITTED: SAME AS L–CH

SYSTEM CONTROL

IC701

(2/2)

AOUT

XOUT

XIN

RADIO ON

COMP

SD

BAND

MUTE

BEEP

DISPLAY BOARD (3/3)

• Signal path.

F : FM

f : AM

a : REC

E : PB

• Abbreviation

CND : Canadian

5E : Indication of country of origin (DX, LOCAL)

99

Loading...

Loading...