Sony WMGX-221 Service manual

WM-GX221

SERVICE MANUAL

Ver 1.1 2002. 06

Model Name Using Similar Mechanism New

Tape Transport Mechanism Type MT-WMGX221-175

SPECIFICATIONS

US Model

E Model

Chinese Model

Frequency range

FM: 87.5-108 MHz (Italy and Saudi Arabia)

87.6-108 MHz (North, Central and South America)

87.6-107.9 MHz (Other countries)

AM: 526.5-1 606.5 kHz (Italy and Saudi Arabia)

530-1 710 kHz (North, Central and South America)

531-1 602 kHz (Other countries)

Frequency response Playback: 40 - 15 000 Hz

Input Microphone (MIC) jack

Output Headphones (i) jack

Power requirements 3 V DC batteries R6 (size AA)

Dimensions (w/h/d) Approx. 112.0

Mass Approx. 190 g (6.8oz) (main unit

Supplied accessories Stereo headphones or earphones (1)

Design and specifications are subject to change without notice.

Recording: 100 - 8 000 Hz (when

setting 2x REC TIME to NORM)

Load impedance 8 - 300 Ω

External DC 3V power sources

1

(4

/

projecting parts and controls

only)

Stereo microphone (1)

Carrying case (1)

×

3 1/

2

×

82.5 × 38.0 mm

×

1 1/2 inches), excl.

4

×

2

Battery life (Approx. hours) (JEITA*)

Sony alkaline LR6(SG)

(using headphones/earphones)

playback 24 7

radio 48 15

mic recording 20 4.5

radio recording 12 3

(using the speakers)

playback 15 4.5

radio 26 6

radio recording 11.5 3

*Measured value by the standard of JEITA (Japan

Electronics and Information Technology Industries

Association) (using a Sony HF series cassette tape).

**When using Sony LR6(SG) “STAMINA” alkaline dry

batteries (produced in Japan).

Note

•The battery life may be shorter depending on the

operating condition, the surrounding temperature

and battery type.

** Sony R6P(SR)

9-873-412-02

2002F1600-1

© 2002.06

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

WM-GX221

TABLE OF CONTENTS

1. SERVICE NOTE ··············································································· 3

2. GENERAL ·························································································· 4

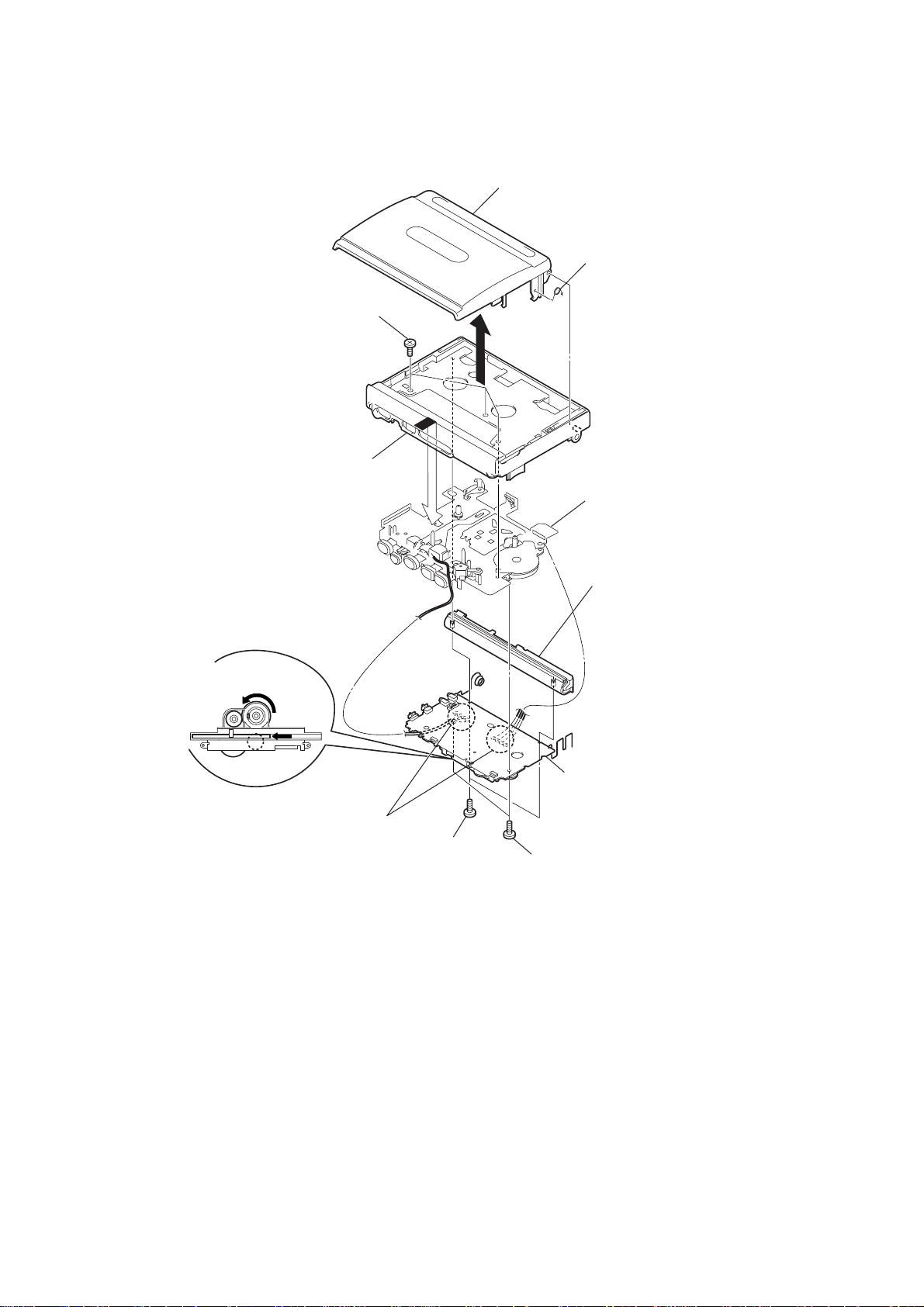

3. DISASSEMBLY ················································································ 5

3-1. Panel (Cabinet Front), Cabinet (Front) Assy ·································· 5

3-2. MAIN Board, Mechanism Deck (MT-WMGX221-175) ················ 6

3-3. HE901, HRP901, M601, Belts························································ 7

3-4. SUB Board ······················································································ 7

4. MECHANICAL ADJUSTMENT ·················································· 8

5. ELECTRICAL ADJUSTMENT······················································ 8

6. DIAGRAMS ······················································································ 10

6-1. Block Diagram – Tuner Section –················································· 11

6-2. Block Diagram – Main Section – ················································· 12

6-3. Printed Wiring Boards ·································································· 13

6-4. Schematic Diagram – MAIN Board (1/2) –·································· 14

6-5. Schematic Diagram – MAIN Board (2/2) –·································· 15

6-6. IC Block Diagrams ······································································· 16

7. EXPLODED VIEWS ······································································ 17

7-1. Overall Section ············································································· 17

7-2. Cabinet (Front) Section································································· 18

7-3. Mechanism Deck Block-1 (MT-WMGX221-175) ······················· 19

7-4. Mechanism Deck Block-2 (MT-WMGX221-175) ······················· 20

8. ELECTRICAL PARTS LIST ······················································· 21

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2

SECTION 1

SERVICE NOTE

In this set, record/play mode is detected using the switch S704 (TAPE POWER).

S704 is mounted on the MAIN board. If MAIN board is removed, it becomes impossible to detect

record/play mode.

Where MAIN board is removed, when you measure operation and voltage of each part of the mechanism

deck, please turn on S704.

– MAIN BOARD (SIDE A) —

WM-GX221

S704

3

WM-GX221

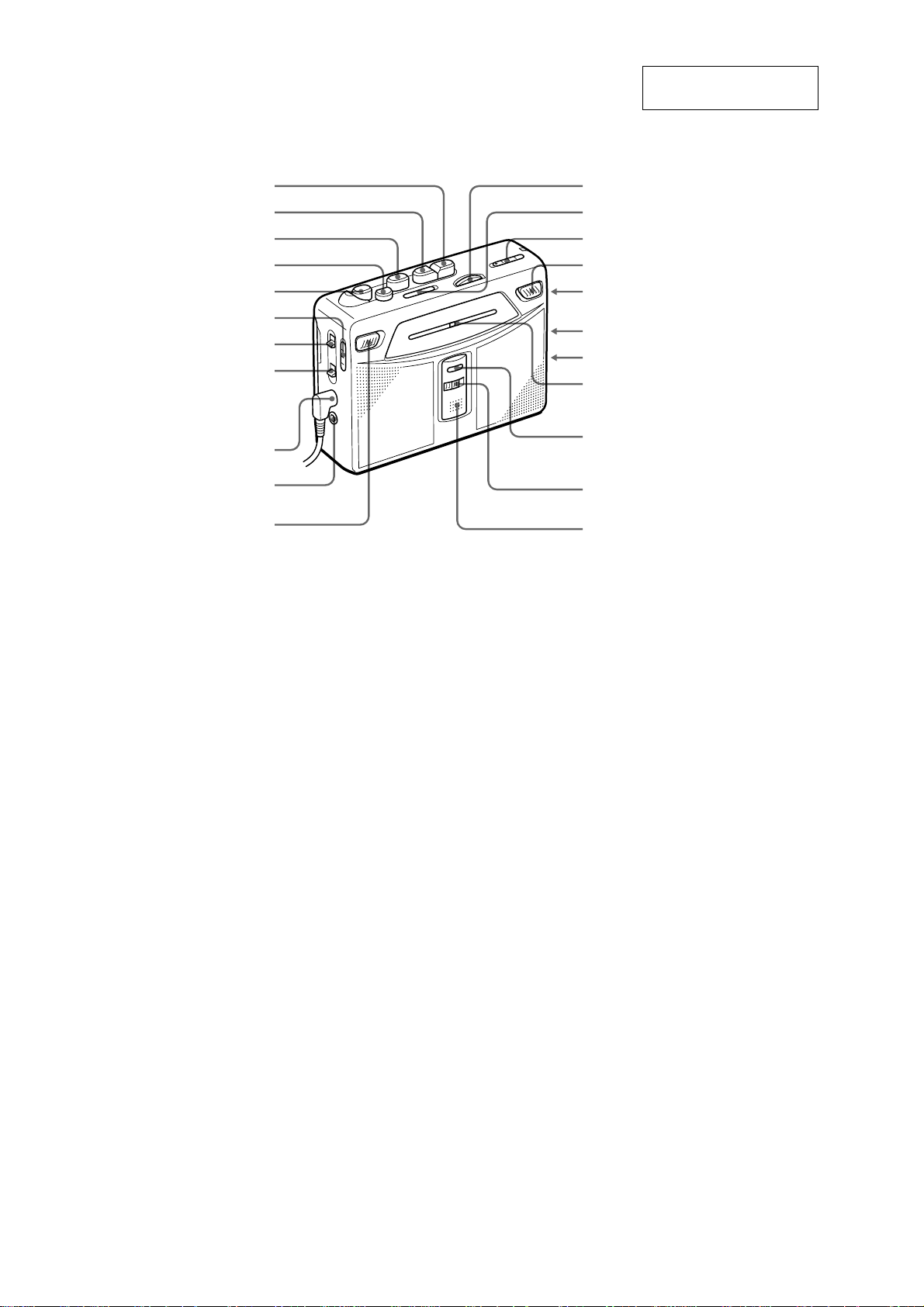

• LOCATION OF CONTROLS

SECTION 2

GENERAL

This section is extracted

from instruction manual.

M FF/CUE

m REW/REVIEW

N PLAY**

x STOP

z REC

AVLS (NORM/LIMIT)

ISS

NORM/CrO2/METAL•

MIC (PLUG IN POWER)**

FLUNCTION (TAPE/RADIO)

FM ST/MONO

DX/LOCAL

* There is a tactile dot beside VOL on the main unit to show the direction to turn up the

volume.

** The button/jack has a tactile dot.

TUNING

PAUSE

BAND (FM/AM)

SOUND BOOST

(OFF/ON)

VOL *

SPEAKER/ i

DC IN 3V

Tuning indicator

REC/BATT indicator

i

2x REC TIME

(NORM/DOUBLE)

Built-in microphone

4

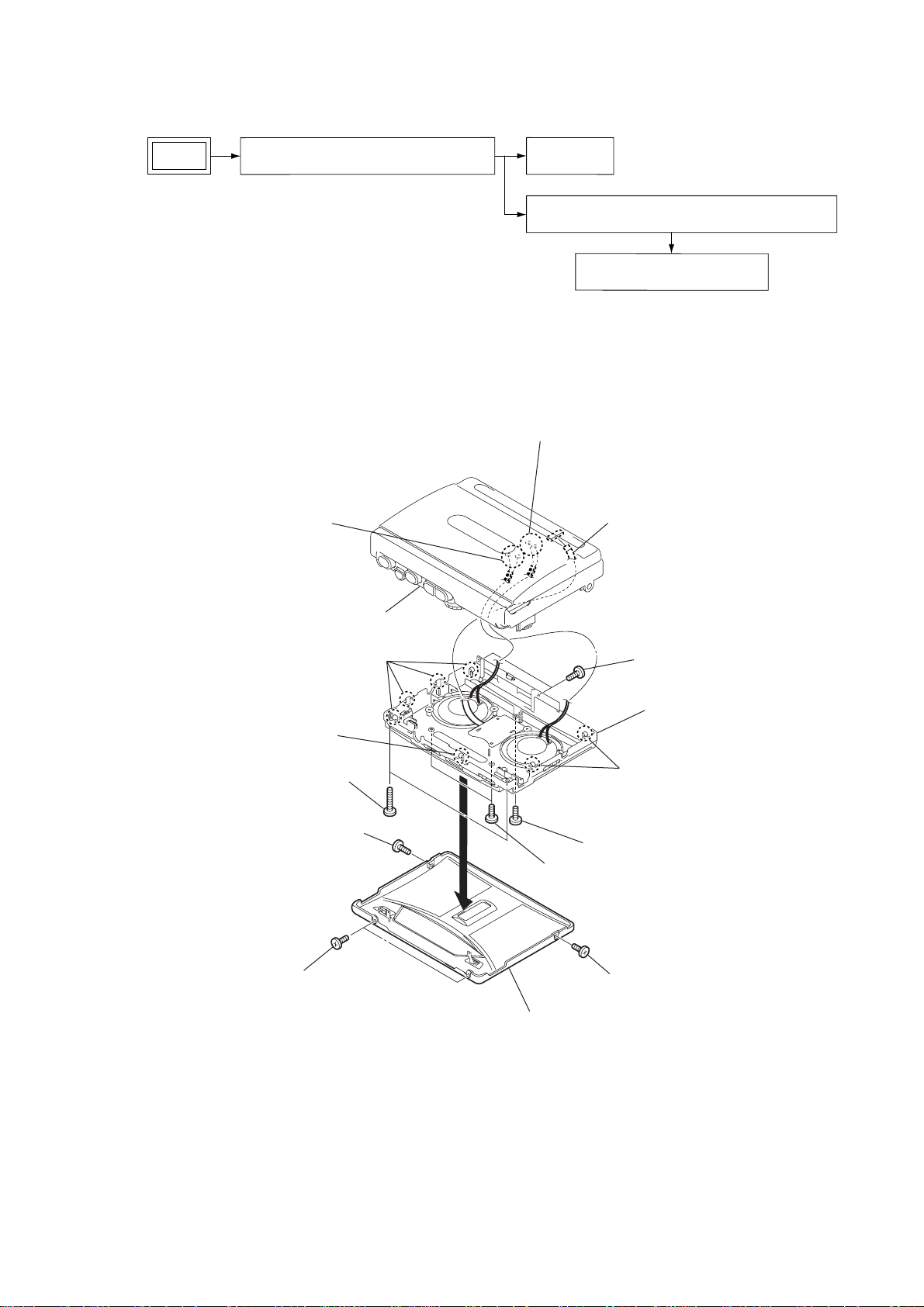

Note : Disassemble the unit in the order as shown below.

)

WM-GX221

SECTION 3

DISASSEMBLY

Set

Panel (cabinet front), Cabinet (front) assy

Note : Follow the disassembly procedure in the numerical order given.

3-1. PANEL (CABINET FRONT), CABINET (FRONT) ASSY

Remove solder.

6

(two places)

Remove solder.

6

(two places)

SUB board

MAIN board, Mechanism deck (MT-WMGX221-175)

HE901, HRP901, M601, Belts

flexible board

5

4

two screws (B1.7 × 9)

3

screw (B1.7 × 1.4)

1

two screws (B1.7 × 1.4)

1

cabinet center

four claws

4

claw

2

4

screw

3

two screws

3

screw (B1.7 × 1.4)

1

panel (cabinet front)

two screws (B1.7 × 1.4

3

cabinet (front) assy

two claws

5

WM-GX221

3-2. MAIN BOARD, MECHANISM DECK (MT-WMGX221-175)

three screws (B1.7 × 9)

3

cassette holder sub assy

spring (torsion)

2

1

cabinet center

<Caution of the pointer attachment>

The pointer is slid, even a stopper is

brougth near, and CV1 is turned with

all its might clockwise, and is attached.

Remove solder

8

(four places)

4

5

two screws

9

two screws

6

MT-WMGX221-175

joint cover

7

MAIN board

6

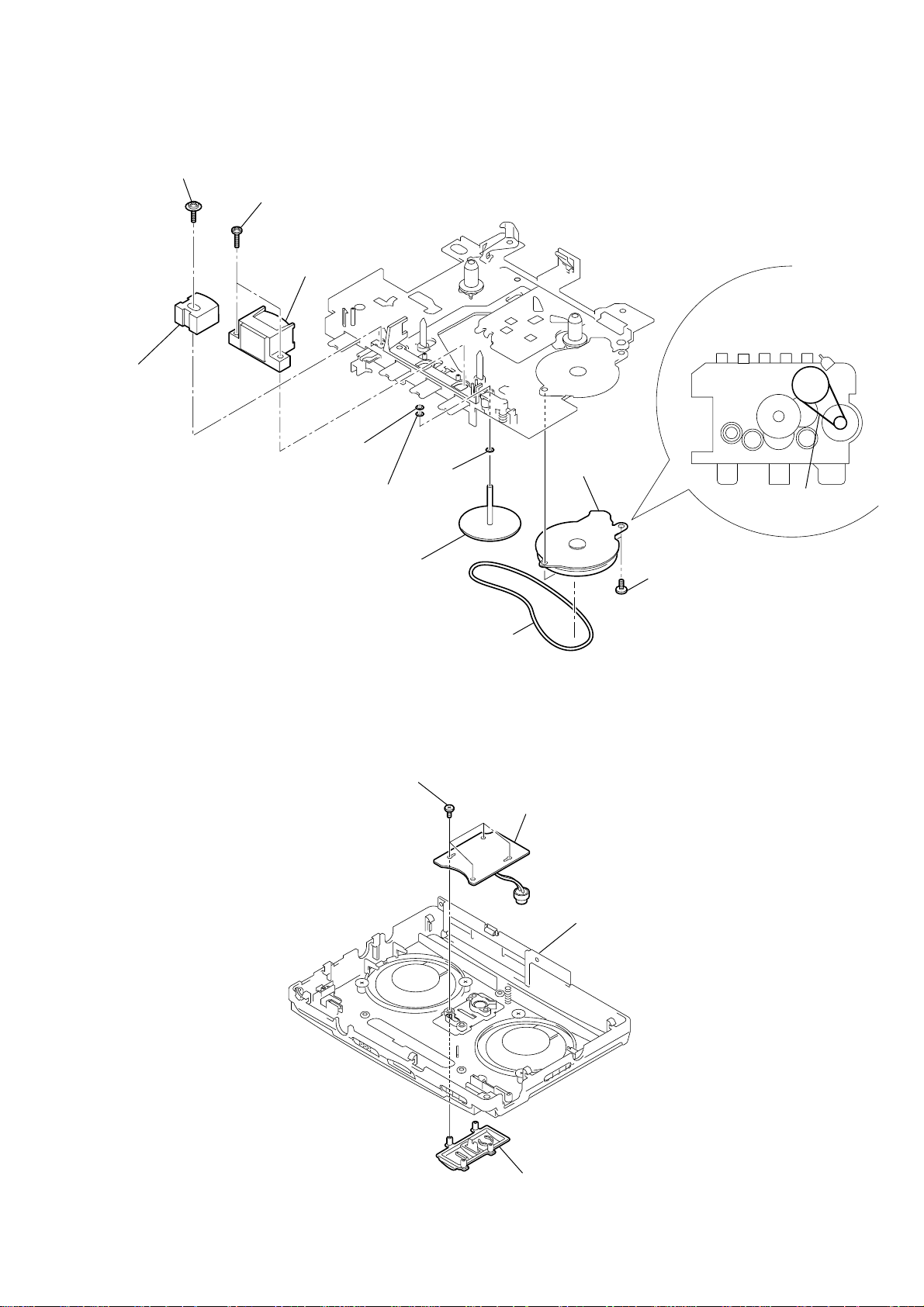

3-3. HE901, HRP901, M601, BELTS

y

screw

0

8

two screws

9

HRP901

(REC/PB head)

HE901

qa

(erase head)

6

washer

(stopper N)

5

washer

7

washer

M601

3

(capstan/reel

motor)

WM-GX221

z

Attaching belt (CAP)

and belt (pulley).

belt (CAP)

3-4. SUB BOARD

capstan fly assy (AR)

6

four screws (B1.7)

1

1

belt (CAP)

SUB board

2

two screws (M1.4)

2

cabinet (front) ass

panel (MIC)

7

WM-GX221

r

SECTION 4

MECHANICAL ADJUSTMENT

SECTION 5

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:

record/playback/erase head pinch roller

rubber belts capstan

2. Demagnetize the record/playback head with a head demagnet-

izer. (Do not bring a head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

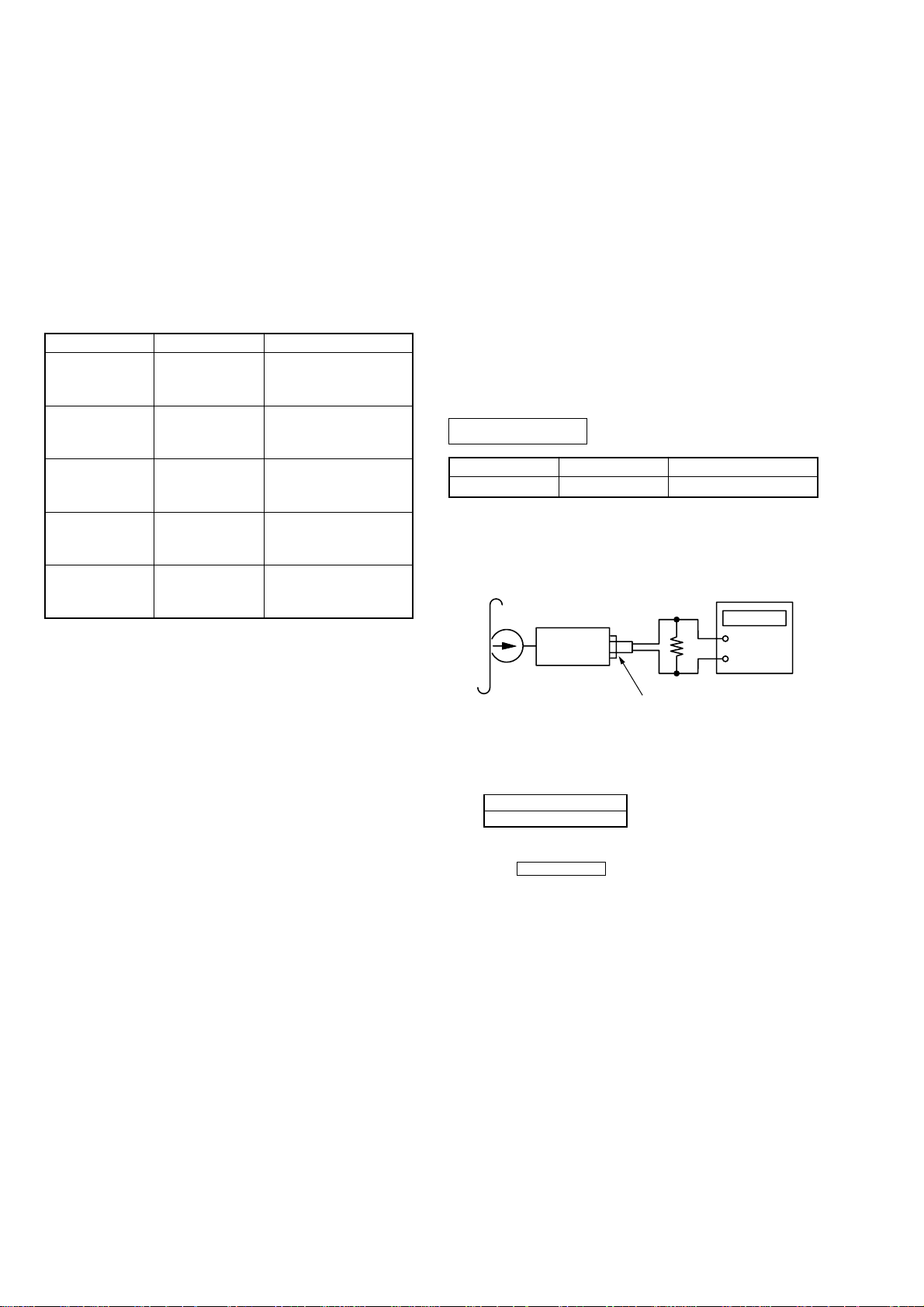

• Torque Measurement

Mode

FWD

FWD

Back Tension

REV

REV

Back Tension

FF, REW

Torque Meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

Meter Reading

19.6 to 29.4 mN•m

(20 to 30 g•cm)

(0.28 to 0.42 oz•inch)

Less than 1.96 mN•m

(Less than 2.0g•cm)

(Less than 0.028 oz•inch)

19.6 to 29.4 mN•m

(20 to 30 g•cm)

(0.28 to 0.42 oz•inch)

Less than 1.96 mN•m

(Less than 2.0g•cm)

(Less than 0.028 oz•inch)

More than 39.2 mN•m

(More than 40 g•cm)

(More than 0.56 oz•inch)

PRECAUTION

1. Specified voltage: 2.5 V (DC)

2. Switch and control position

VOL : MAX

SPEAKER : OFF

AVLS : NORM

SOUND BOOST : OFF

PB EQ : NORM

PAUSE : OFF

ISS : 1

FM SENSE : DX

(US, 5E)

FM MODE : FM ST

(EXCEPT US, 5E)

2X REC TIME : NORM

• Abbreviation

5E : E model with the indication of the country of origin.

TAPE SECTION

Tape

WS-48A

Tape Speed Adjustment

Procedure:

Test tape

WS-48A

(3kHz, 0dB)

Signal

3 kHz, 0 dB

Ω

(EXCEPT US MODEL)

16

32 Ω (US MODEL)

Used for

Tape Speed Adjustment

Set

2

jack (J301)

1. Enter the FWD playback mode.

2. Adjust RV601 so that the v alue of the frequency counter reading

becomes 3,000 Hz.

Specification value:

Frequency counter

2,985 Hz – 3,015 Hz

3. Check that the frequency deviation at the beginning and ending

of a tape is within 1.5 % (45 Hz).

4. Set the 2x REC TIME switch to DOUBLE (2.4 cm/s).

5. Adjust RV602 so that the v alue of the frequency counter reading

becomes 1,500 Hz.

Adjustment Location : MAIN board (see page 9)

+

–

Frequency counte

8

Loading...

Loading...