Sony WM-GX100 Service Manual

WM-GX100

SERVICE MANUAL

Ver 1.0 2000.10

SPECIFICATIONS

• Frequency range

FM: 65.0 - 107.9 MHz (Eastern Europe)

87.5 - 108 MHz (Italy and Saudi Arabia)

87.6 - 108 MHz (North, Central and South America)

87.6 - 107.9 MHz (Other countries)

AM:526.5 - 1,606.5 kHz (Italy and Saudi Arabia)

530 - 1,710 kHz (North, Central and South America)

531 - 1,602 kHz (Other countries)

• Power requirement

– 3V DC batteries R6 (AA) x 2

– External DC 3 V power sources

• Dimensions

88.8 x 118.6 x 38.0 mm (3 1⁄2 x 4 3⁄4 x 1 1⁄2 inches) (w/h/d)

• Mass

Approx. 160 g (5.7 oz)

• Supplied accessories

Stereo headphones or Stereo earphones (1), Belt clip (1),

Stereo microphone (1)

E Model

Chinese Model

Model Name Using Mechanism Type WM-SR1

Similar Mechanism Tape Transport MF-WMSR1-114

Battery life (approximate hours) (EIAJ*)

Sony alkaline LR6 (SG)** Sony R6P (SR)

playback 24 7

radio 50 16

mic recording 11 3.5

radio recording 10 2.5

* Measured value by the standard of EIAJ (Electronic Industries

Association of Japan). (Using a Sony HF series cassette tape)

** When using LR6 (SG) Sony “STAMINA” alkaline dry batteries

(produced in Japan).

Note

• The battery life may be shorter depending on the operating condition,

the surrounding temperature and battery type.

Design and specifications are subject to change without notice.

RADIO CASSETTE-CORDER

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Location and Function of Controls .................................... 2

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

2. DISASSEMBLY

2-1. Cabinet (Rear)............................................................. 3

2-2. Main Board ................................................................. 4

2-3. Mechanism Deck ........................................................ 4

2-4. Motor (M901), “Head, Magnetic” (HRP901) ............ 5

2-5. Holder Sub ASSY, Cassette ........................................ 5

2-6. Setting the Pointer ...................................................... 6

3. ADJUSTMENTS

3-1. Mechanical Adjustments............................................. 7

3-2. Electrical Adjustments................................................ 7

4. DIAGRAMS

4-1. Block Diagram (1/2) ................................................... 9

4-2. Block Diagram (2/2) ..................................................11

4-3. Printed Wiring Boards .............................................. 13

4-4. Schematic Diagram (1/2).......................................... 15

4-5. Schematic Diagram (2/2).......................................... 17

5. EXPLODED VIEWS

5-1. Cabinet Section......................................................... 21

5-2. Mechanism Deck Section ......................................... 22

6. ELECTRICAL PARTS LIST................................... 23

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

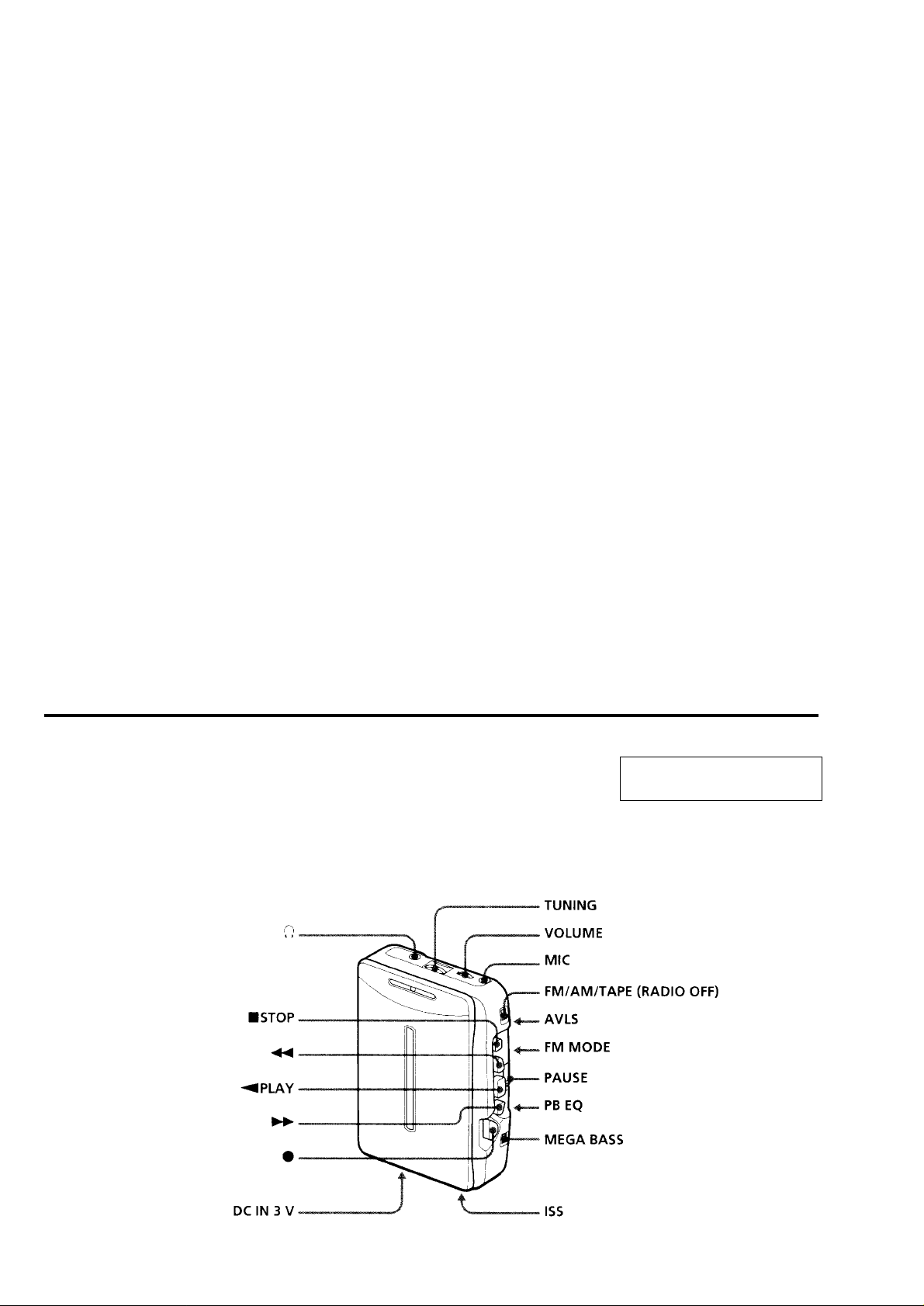

LOCATION AND FUNCTION OF CONTROLS

SECTION 1

GENERAL

This section is extracted from

instruction manual.

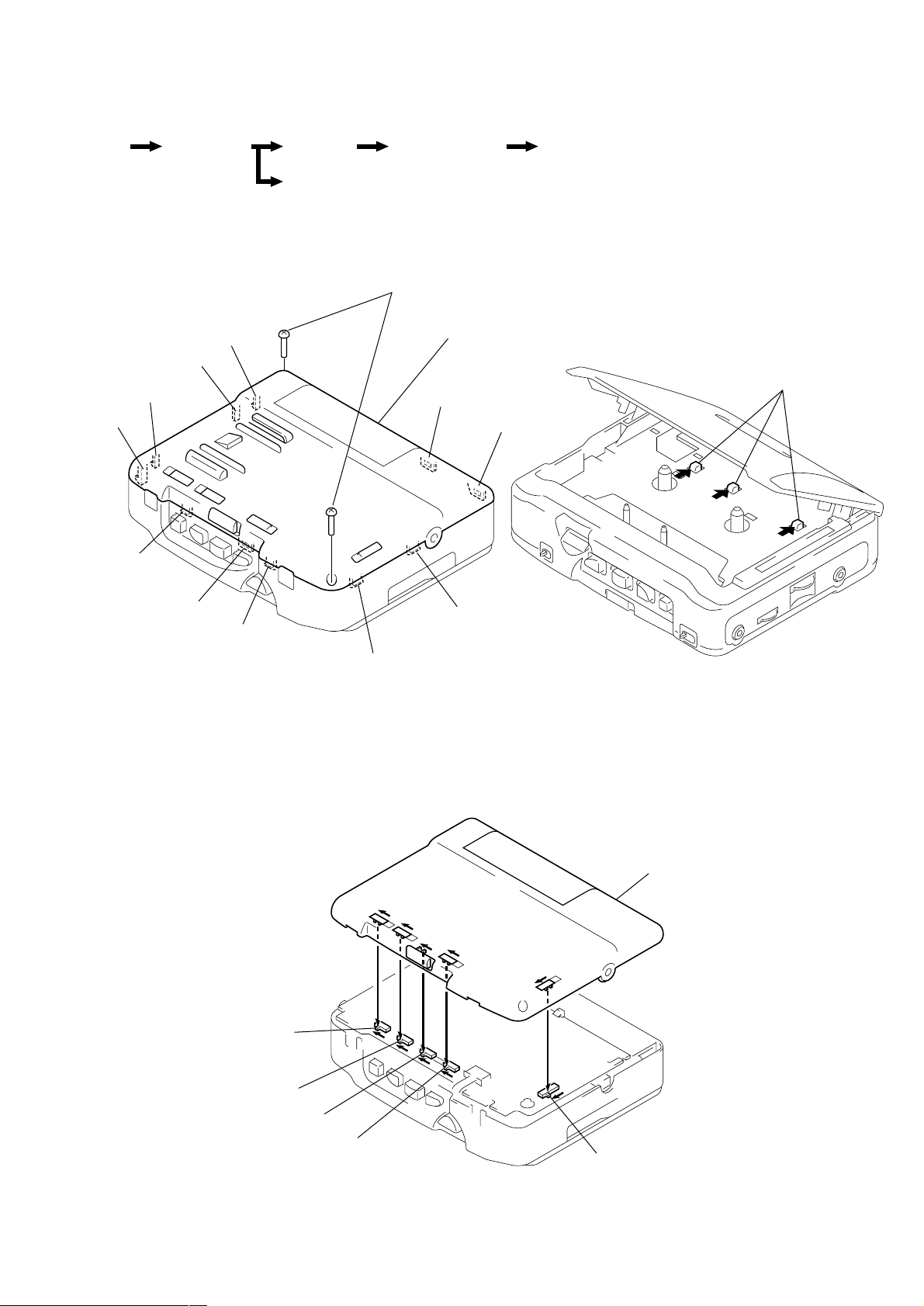

SECTION 2

)

DISASSEMBLY

z

The equipment can be removed using the following procedure.

Set

Main boardCabinet (rear)

“Holder sub ASSY, Cassette”

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR)

L

K

J

I

Mechanism deck

(MF-WMSR1-114)

1

Screws (B 1.7)

2

Cabinet (rear)

A– L

(

B

Motor (M901), “Head, Magnetic” (HRP901)

: Claws

A

C

H

G

F

E

z

CAUTIONS DURING CABINET (REAR) ASSEMBLY

Align switches and knobs with arrow direction

D

Cabinet (Front)

S305

S2

S308

S310

S307

– 3 –

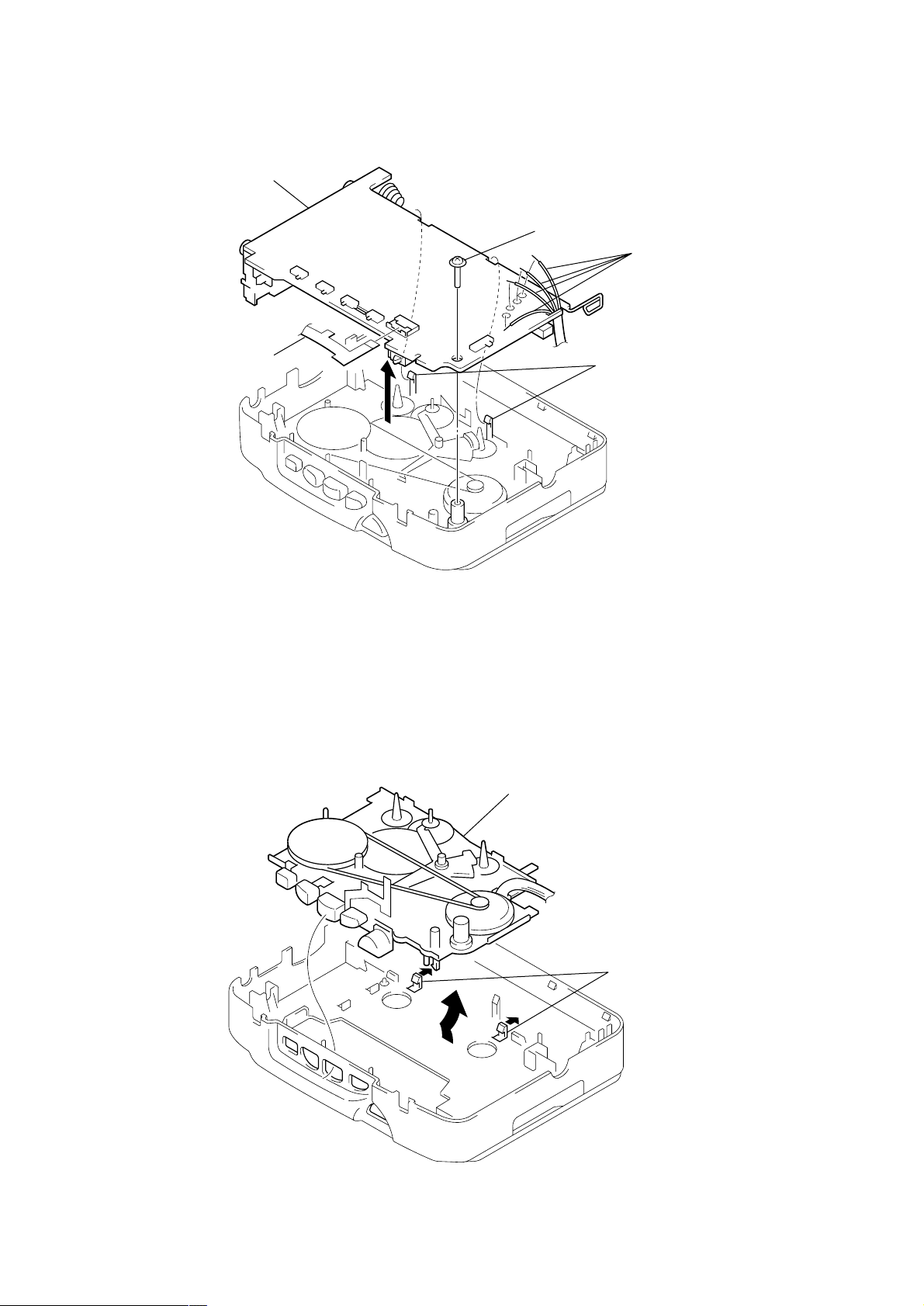

2-2. MAIN BOARD

s

2

Head flexible board

(CN301)

Main board

5

3

Screw (M1.4)

4

1

Remove solder (4 places)

(M901)

Claws

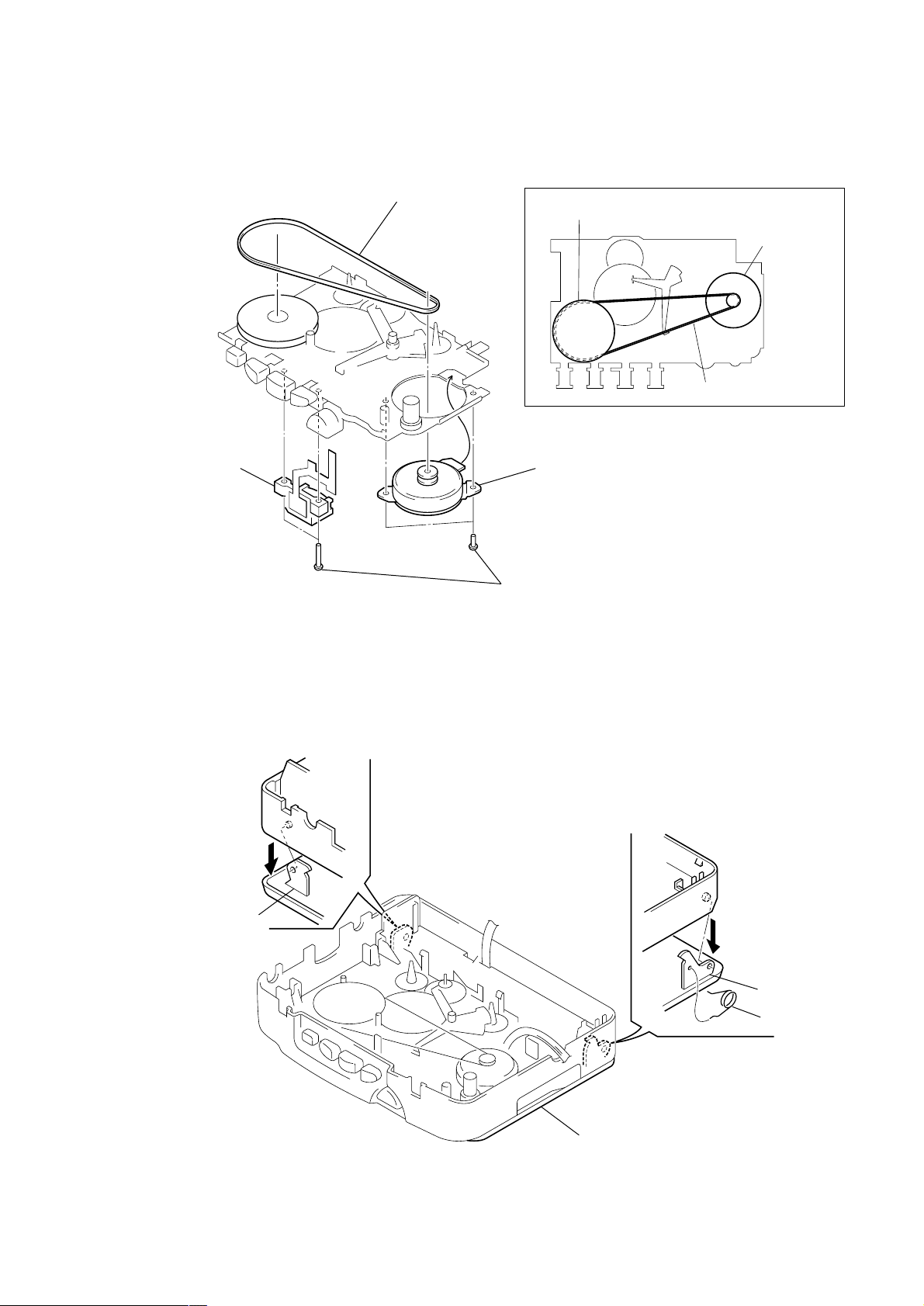

2-3. MECHANISM DECK (MF-WMSR1-114)

2

Mechanism deck

(MF-WMSR1-114)

1

Claw

– 4 –

2-4. MOTOR (M901), “HEAD, MAGNETIC” (HRP901)

4

“Head, Magnetic”

(HRP901)

1

Belt

How to apply the belt

Wheel ASSY (NP), capstan

3

Motor (M901)

2

Screws (M1.4)

M901

Belt

2-5. HOLDER SUB ASSY, CASSETTE

1

Move hinge awsy

from projection

Hinge

4

Holder sub ASSY, cassette

2

1

Move hinge awsy

from projection

Hinge

3

Spring (tortion)

– 5 –

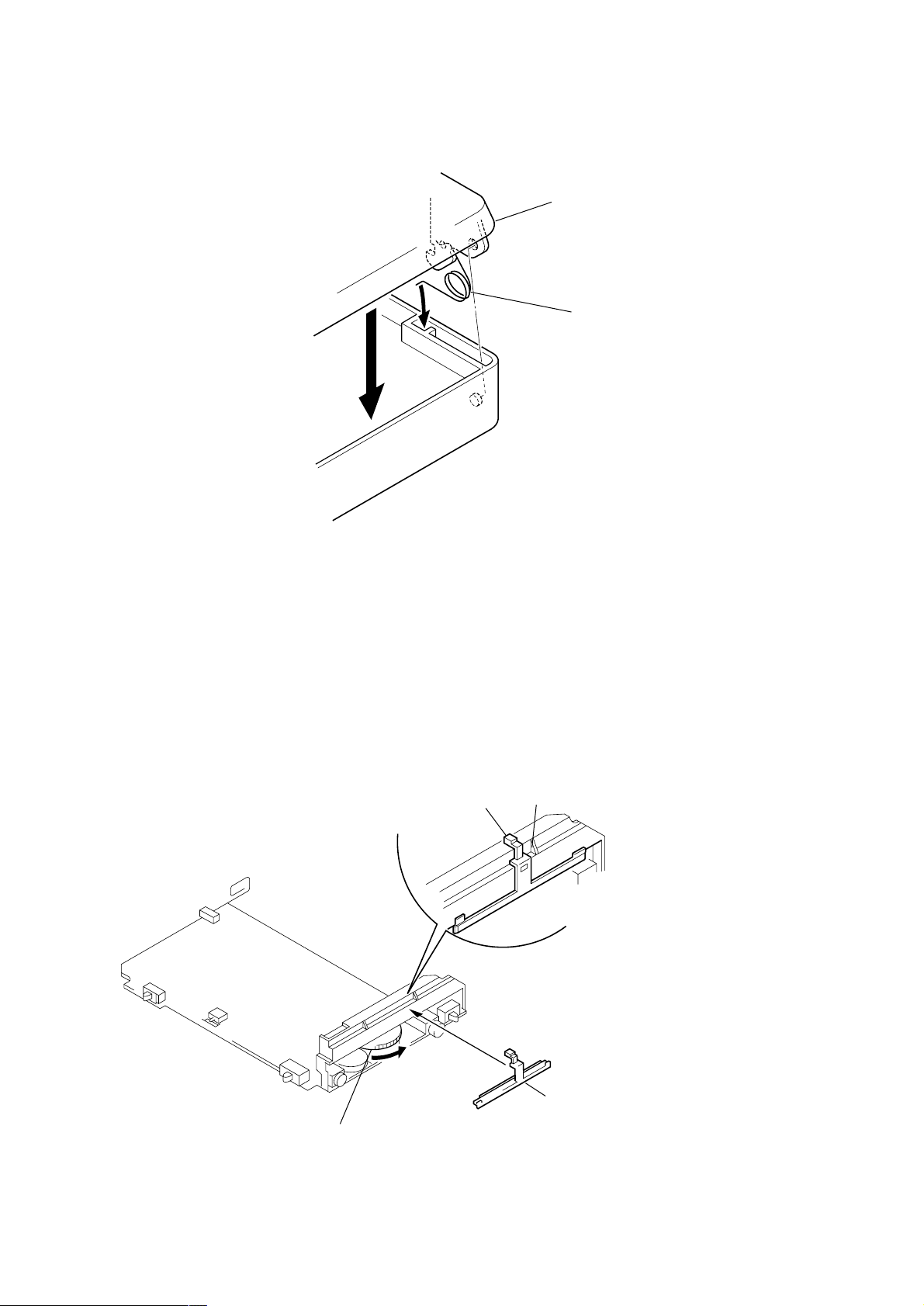

z

e

CAUTIONS DURING “HOLDER SUB ASSY, CASSETTE” ASSEMBLY

4

Holder sub ASSY, cassett

3

Close the “Holder sub ASSY,

cassette” then press it

2-6. SETTING THE POINTER

2

1

Spring (tortion)

Pointer

1

Turn the tuning knob in the arrow direction

A

Pointer

2

Install the pointer and

align it with

A

section

– 6 –

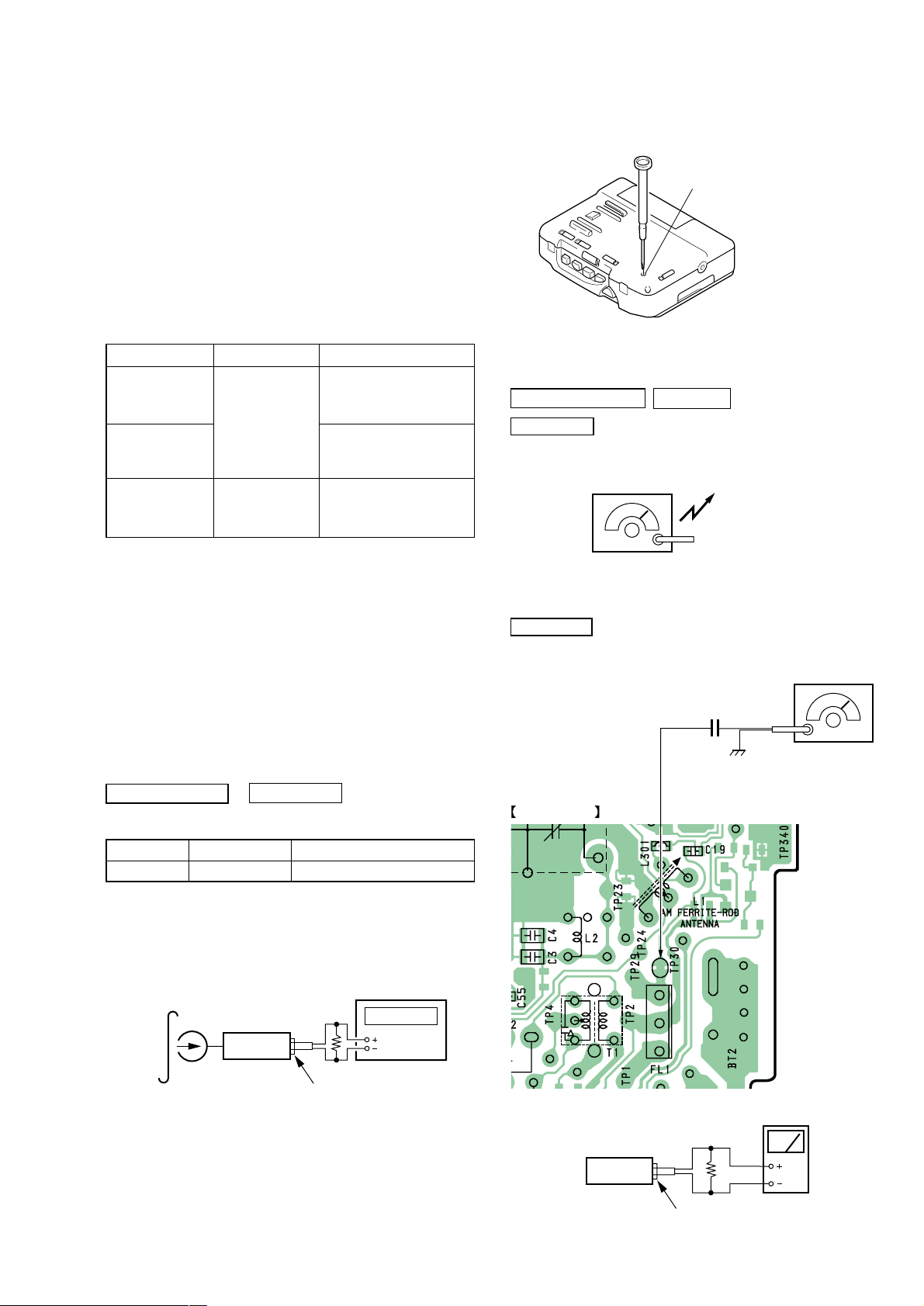

SECTION 3

r

RV601 : Tape speed Adjustment

FM RF signal

generator

22.5kHz frequency

deviation by 400Hz signal.

Output level :

as low as possible

ANT (TP30)

0.01

µ

F

MAIN BOARD (SIDE A)

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch roller

capstan rubber belt

2. Demagnetize the playback head with a head demagnetizer.

Do not use a magnetized screwdriver for the adjustments.

3. These measurement and adjustment should be performed with

the rated power supply voltage (2.5 V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

1.97 – 2.94 mN•m

FWD (20 – 30 g • cm)

CQ-102D

FWD

back tension

FF, REW CQ-201B (more than 40 g • cm)

(0.28 – 0.41 oz• inch)

less than 0.19 mN•m

(less than 2 g • cm)

(less than 0.027 oz• inch)

more than 3.93 mN•m

(more than 0.56 oz• inch)

3-2. ELECTRICAL ADJUSTMENTS

PRECAUTION

• Supplied voltage : 2.5V.

• Switch and control position

MEGA BASS : OFF

VOLUME control : maximum

AVLS : NORM

PB EQ : NORM

ISS : 1

FM MODE : ST

Adjustment Location :

TUNER SECTION

AM Section

BAND : AM

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM Section

BAND : FM

0 dB = 1µV

Put the lead-wire

antenna close to

the set.

TAPE SECTION

Test T ape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure :

1. Playback WS-48A (tape center part) and adjust RV601 so that

the frequency counter reading becomes 3,000Hz.

Standard value : 2,985–3,015Hz

2. Playback WS-48A (tape top and end) .

Check that frequency counter reading is within ±1.5% of the

reading of step 1.

0 dB = 0.775V

test tape

WS-48A

(3kHz, 0dB)

set

phones jack (J301)

frequency counte

16

Ω

CT1-2

set

level meter

16

Ω

phones jack (J301)

– 7 –

Loading...

Loading...