Sony WMFX-655 Service manual

WM-FX651/FX653/FX655

SERVICE MANUAL

Ver 1.1 2002. 01

Photo : WM-FX651

AEP Model

WM-FX651/FX653/FX655

E Model

WM-FX653/FX655

Australian Model

Tourist Model

WM-FX655

Canadian Model

WN-FX653

9-923-157-12

2002A1600-1

© 2002.1

RADIO CASSETTE PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

TABLE OF CONTENTS

Specification ················································································· 1

1. GENERAL ·········································································· 3

2. SERVICE NOTE ······························································· 3

3. DISASSEMBLY

3-1. Case Assy Removal ······················································· 4

3-2. Tuner Board Removal ··················································· 4

3-3. Audio Board Removal··················································· 5

3-4. Cassette Lid Assy Removal ··········································· 5

3-5. Mechanism Deck Removal ··········································· 6

4. MECHANICAL ADJUSTMENT ·································· 7

5. ELECTRICAL ADJUSTMENT ···································· 7

6. EXPLANATION OF IC TERMINALS························· 9

7. DIAGRAMS

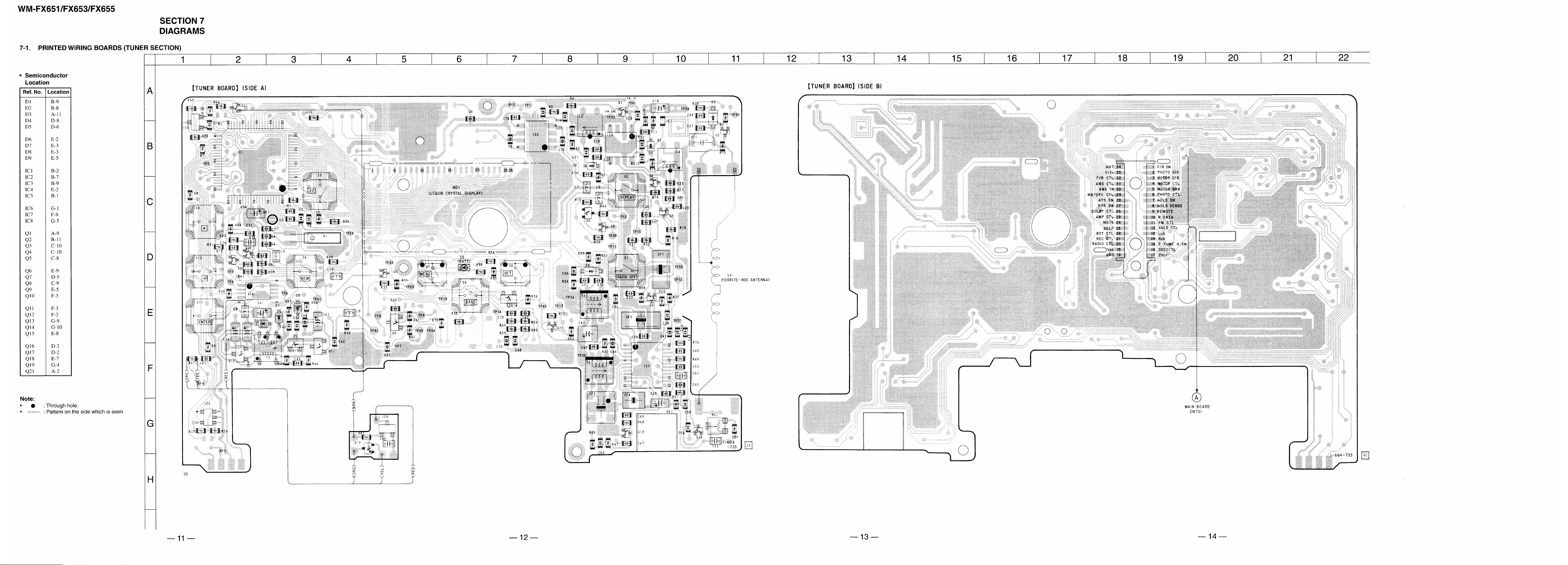

7-1. Printed Wiring Boards (Tuner Section) ······················· 11

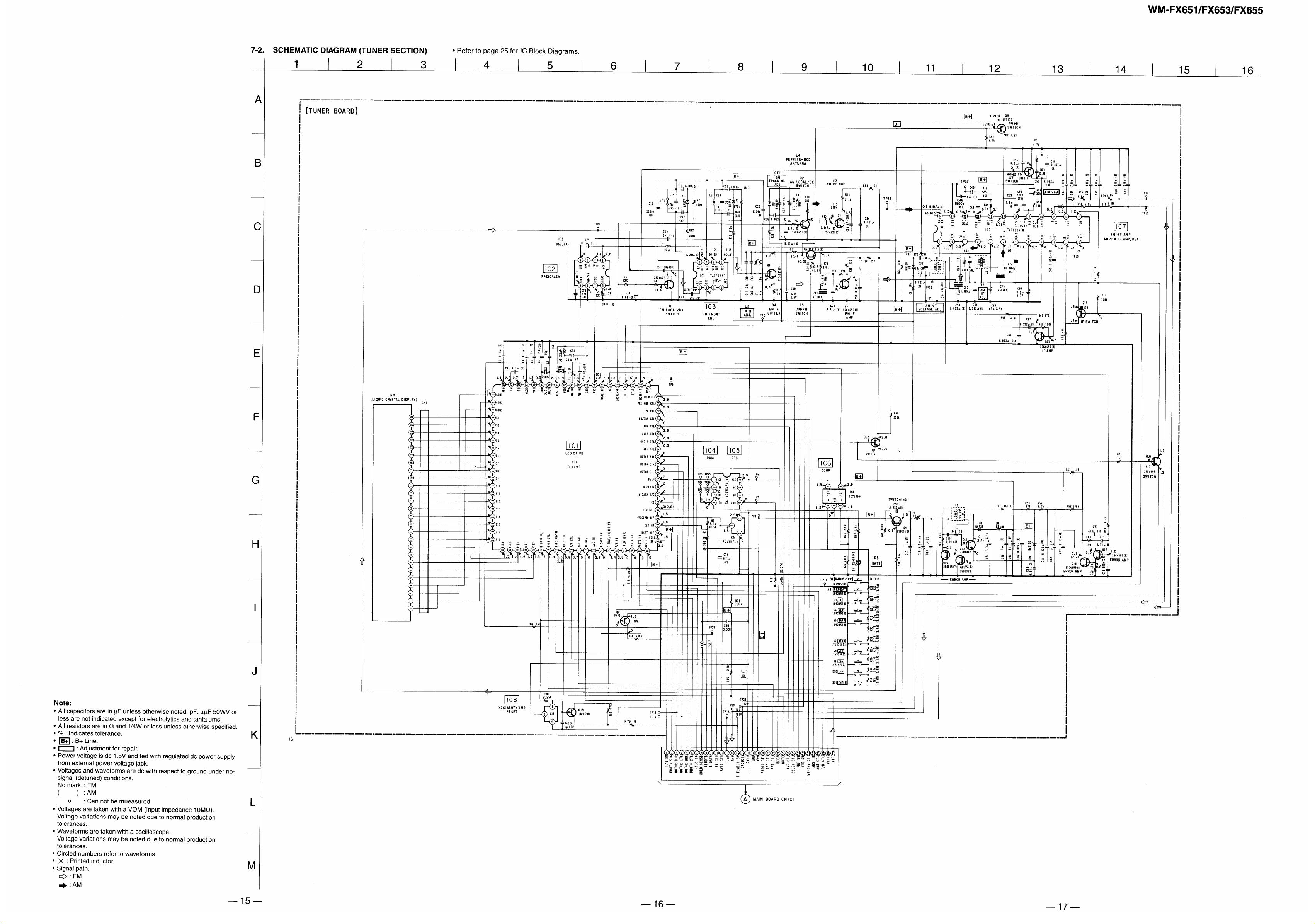

7-2. Schematic Diagram (Tuner Section) ··························· 15

7-3. Schematic Diagram (Audio Section)···························18

7-4. Printed Wiring Board (Audio Section) ························ 21

8. EXPLODED VIEWS

8-1. Cabinet Section ··························································· 27

8-2. Audio, Tuner Board Section ········································ 28

8-3. Mechanism Section (MT-WMEX550-125) ················· 29

9. ELECTRICAL PARTS LIST ······································· 30

— 2 —

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron aroud 270˚ C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

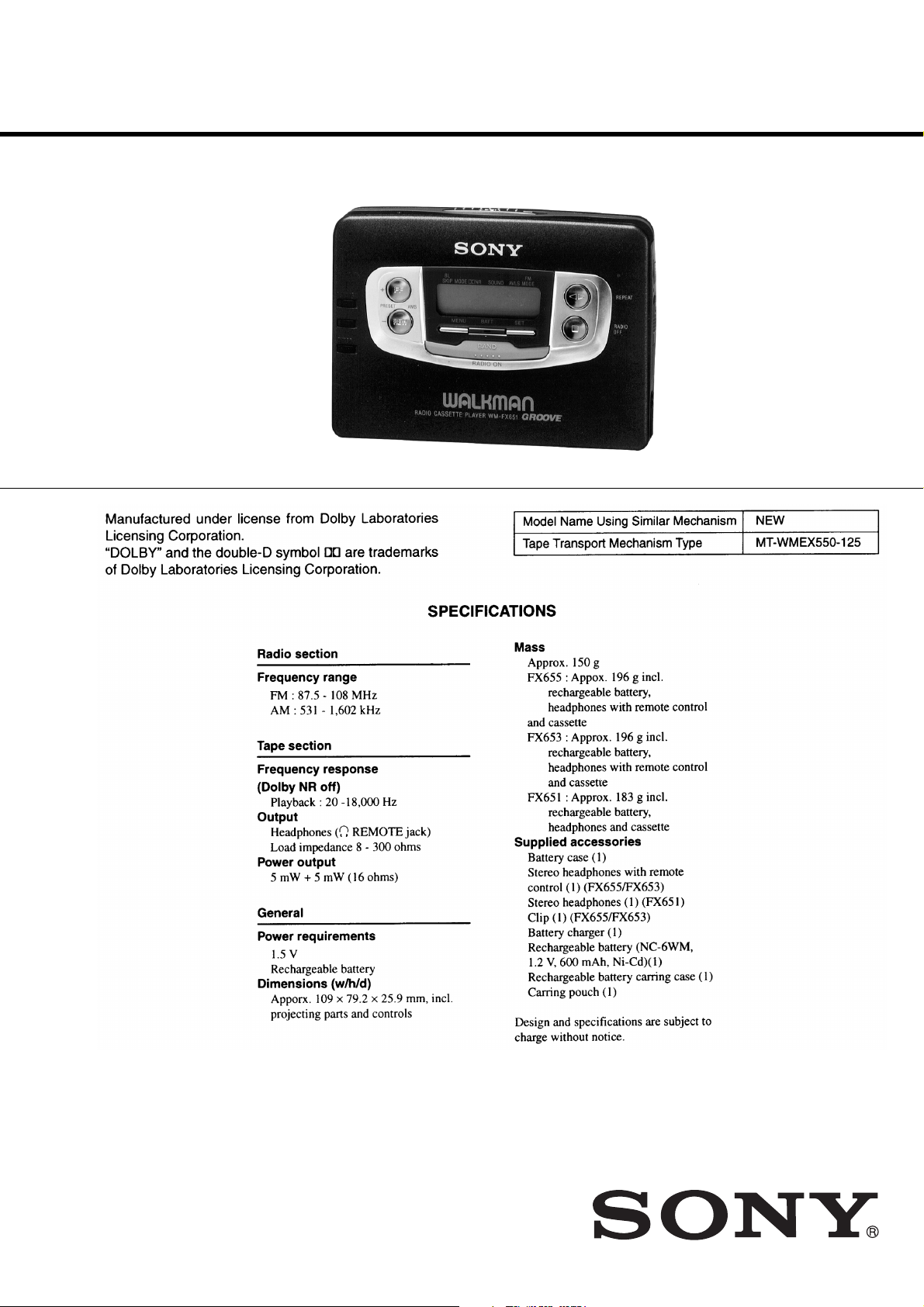

• LOCATION OF CONTROL

SECTION 1

GENERAL

1 OPEN knob

2 PRESET + /AMS FF button

4

5

6

3

0

2

9

!

!¢

1

3 PRESET – /AMS REW button

4 TUNING + button

5 TUNING – button

6 ENTER button

7 ˇ /REPEAT button

7

!`

!“

8 p /RADIO OFF button

9 MENU button

0 SET button

!` VOLUME knob

!£

8

!“ HOLD knob

2 REMOTE jack

!£

!¢ Display window

! BAND button

SECTION 2

SERVICE NOTE

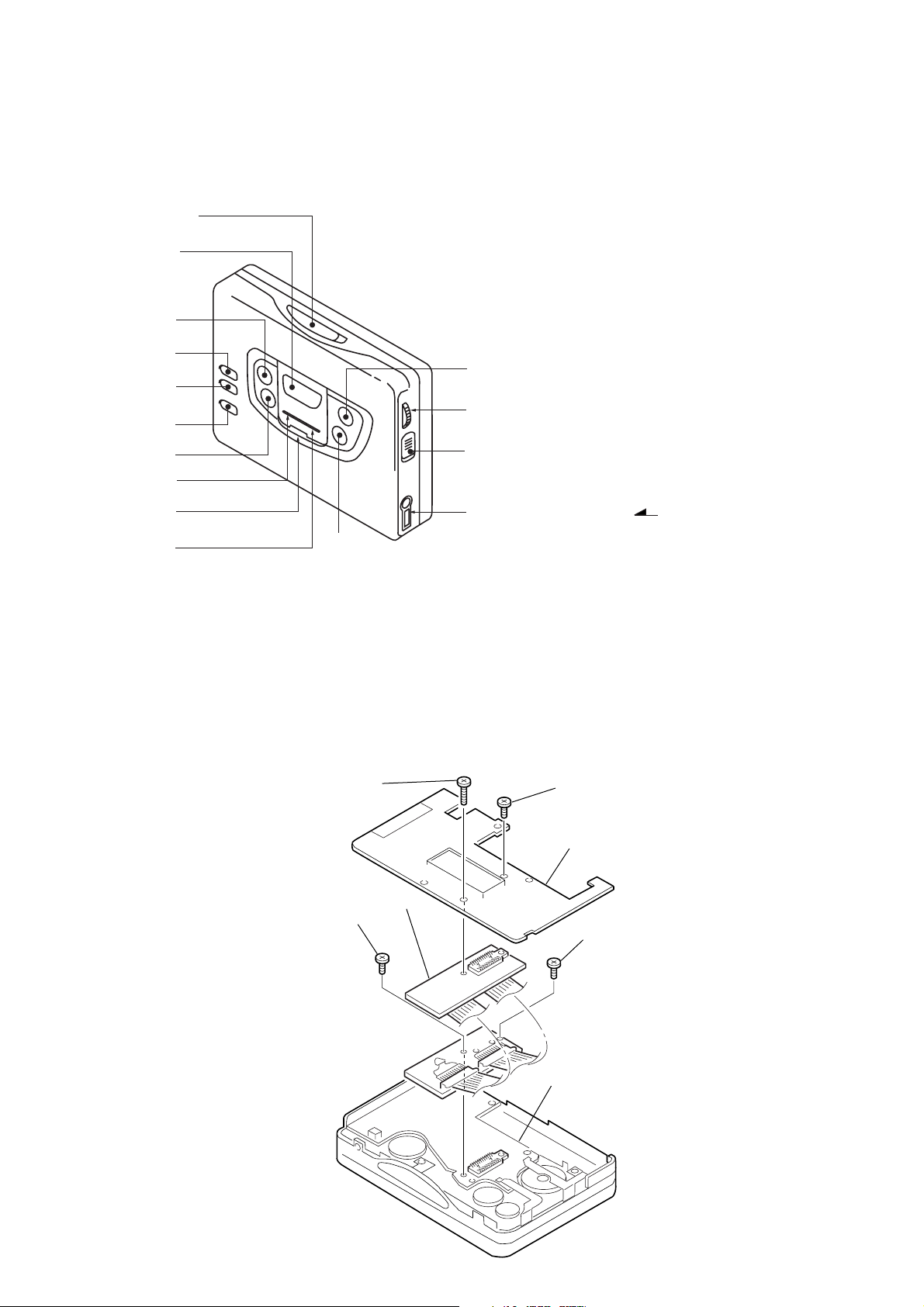

• Regarding the method of adjustment and voltage check, perform sections 3-1 and 3-2 of the DISASSEMBLY, and attach the JIG to the

AUDIO board as shown below.

Screw

(M1.4 × 5.0)

Screw

(M1.4 × 5.0)

JIG

Screw (M1.4 × 5.0)

TUNER board

Screw (M1.7 × 4.0)

AUDIO board

— 3 —

SECTION 3

)

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE ASSY REMOVAL

5 Case assy

1 Screw

(M1.4 × 2.2)

3 Screw

(M1.4 × 2.2)

2 Screw

(M1.4 × 2.2

4

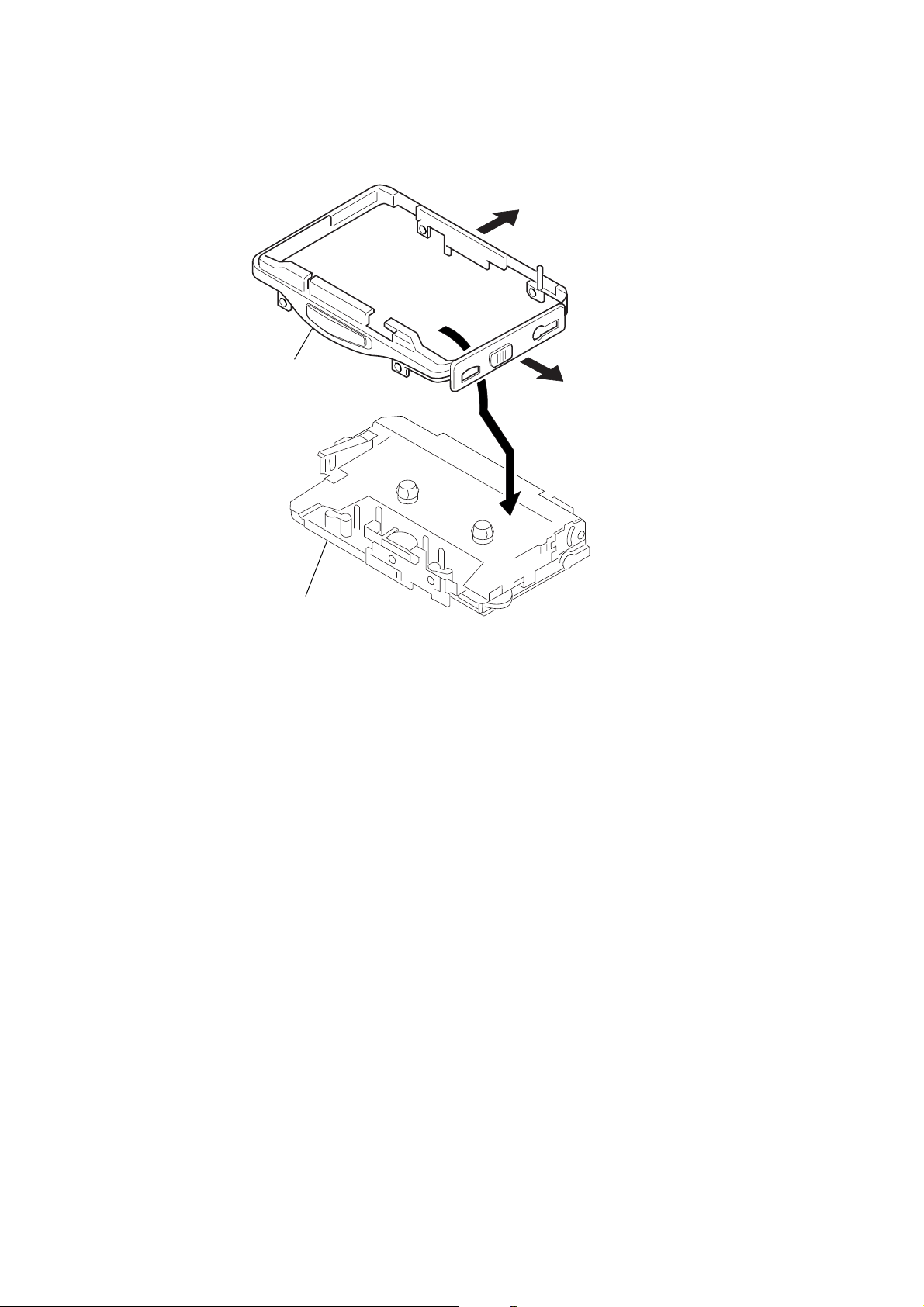

3-2. TUNER BOARD REMOVAL

4 TUNER board

1 Scew (M1.7 × 6)

2 Scew (M1.7 × 3)

3 Scew

(M1.4 × 4.5)

6 GUIDE (TU )

5

— 4 —

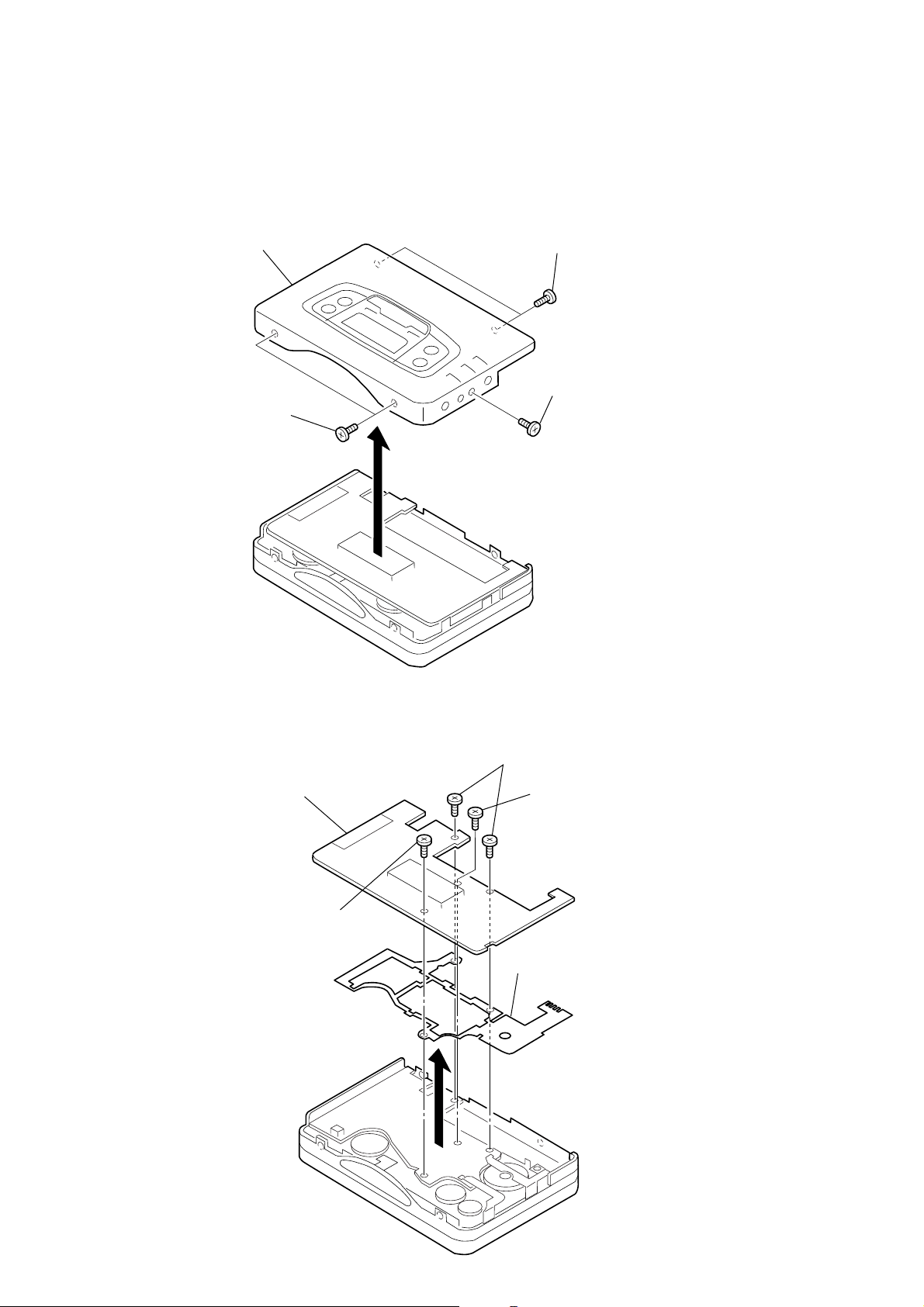

3-3. AUDIO BOARD REMOVAL

7 AUDIO board

4 Flexible board

2 Remove solder

1 Screw (M1.7 × 3)

6

3 Remove solder

5

3-4. CASSETTE LID ASSY REMOVAL

2 Screw (M1.4 × 2)

5 Cassette lid assy

3 Screw (M1.4 × 2)

4

1 OPEN button

— 5 —

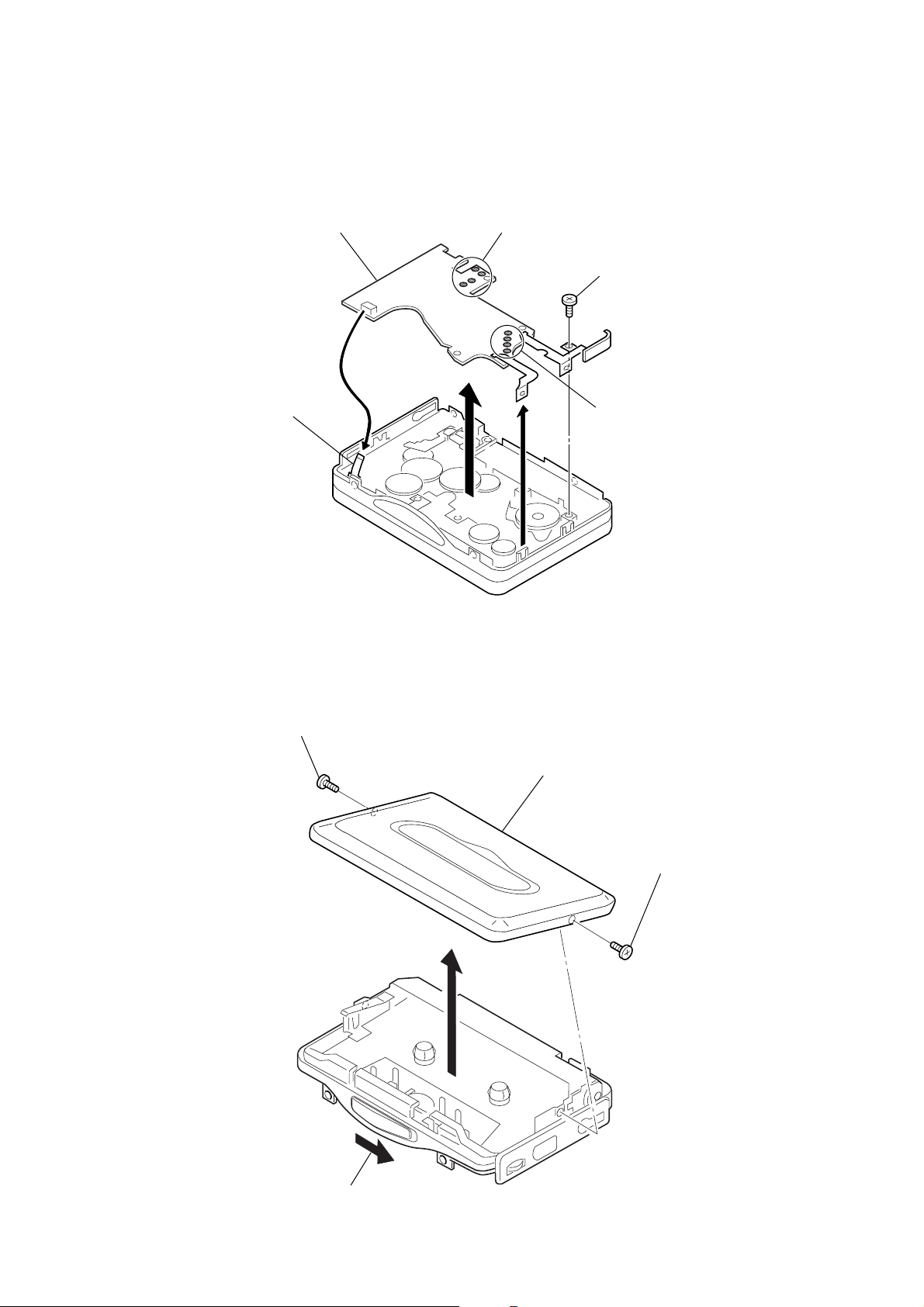

3-5. MECHANISM DECK REMOVAL

2

4 Reel ornament

5 Mechanism deck

1

3

— 6 —

SECTION 4

r

)

)

r

MECHANICAL ADJUSTMENT

SECTION 5

ELECTRICAL ADJUSTMENT

SECTION 6

EXPLANATION OF IC TERMINALS

PRECAUTION

1. Clean the following parts with a denatured-alcahol-moistened

sweb :

Playback head Pinch roller

Rubber belt Capstan

2. Demagnetize the playback head using a demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (1.3V) to

perform the adjustments.

Torqu Measurement

Mode

FWD

FWD

Back Tension

REV

REV

Back Tension

FF

REW

Torqu meter

CQ-102C

CQ-102RC

CQ-201B

Meter reading

20 - 30 g · cm

0.4 - 2.0 g · cm

20 - 30 g · cm

0.4 - 2.0 g · cm

More than 40 g · cm

PRECAUTION

1. Specified voltage : 1.3V

2. Switch position

DOLBY NR switch : OFF

AVLS switch : OFF

CASSETTE SECTION

Test Tape

Type

WS-48A

Tape Speed Adjustmnet

Procedure :

Test tape

WS-48A

(3kHz, 0dB)

1. Playback WS-48A (Tape center part) in the FWD state and

adjust RV601 so that the frequency counter reading becomes

3,000Hz ± 30Hz.

2. Playback WS-48A (Tape center) in the REV state.

Check that frequency counter reading is within 2.0% of the

reading of step1.

Adjustment Point :

[MAIN BOARD] — SIDE A —

Signal

3kHz, 0dB

Set

Purpose

Tape Speed Adjustment

Frequency counte

16Ω

+

–

PHONES jack

RV601 : Tape speed

TUNER SECTION

[AM]

BAND switch : AM

AM RF signal

generator

30% amplitude modulation

by 400Hz signal.

Output level : as low as possible

[FM]

BAND switch : FM

FM RF signal

generator

22.5kHz frequency

deviation by 400Hz signal.

Output level : as low as possible.

Set

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 621kHz

CT1 1,395kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 10.7MHz

FM VT VOLTAGE ADJUSTMENT

L2 76MHz

Put the lead-wire antenna

close to the set.

0.01µF

to ANT (TP1

Level meter

32Ω

+

–

PHONES

1.1V ± 0.05V

FM VCO Adjustment

Procedure :

FM RF signal

generator

0.01µF

to ANT (TP1

Carrier frequency : 98MHz

Modulation : No moduration

Output level : 0.1V (100dB)

1. Connect the frequency counter to the positions shown below.

2. Turn the set to 98MHz.

3. Adjust RV1 for 19kHz ± 100Hz reading on the frequency

counter.

Frequency counte

TP23

(IC7 pin !“)

IC7 pin 9

1µF

+

–

100Ω

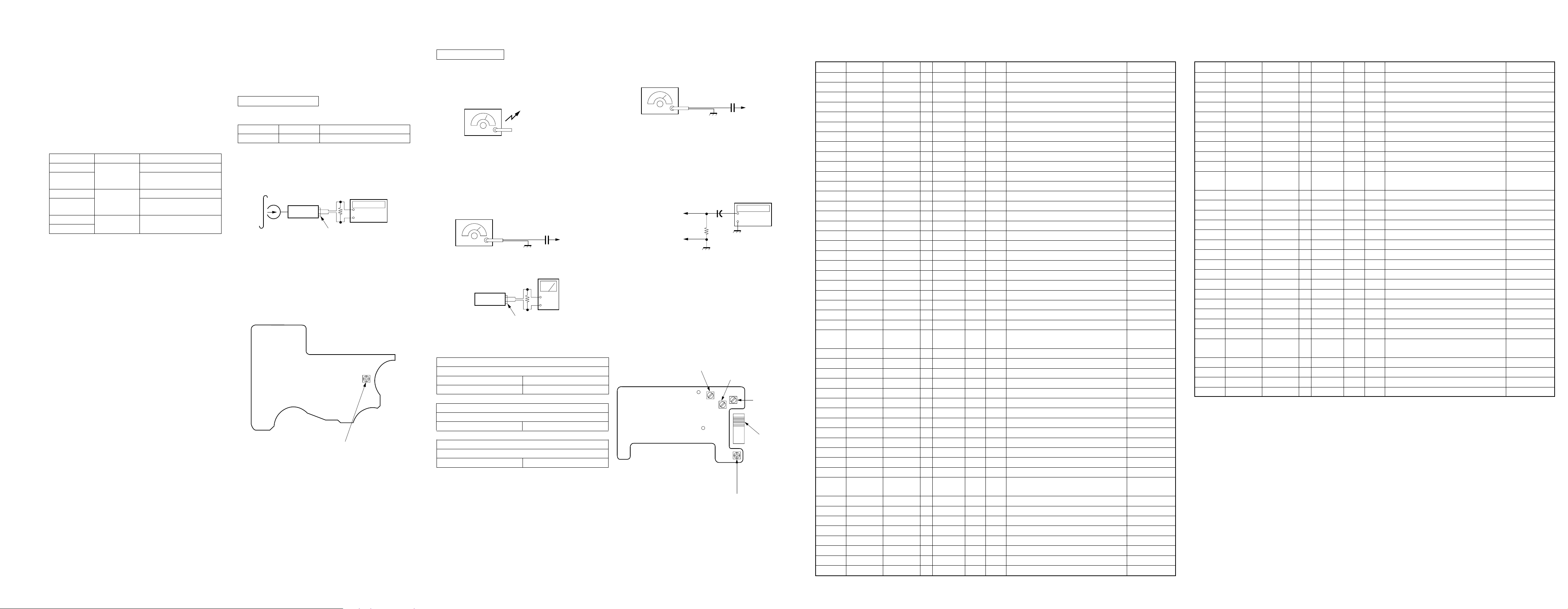

Adjustment Parts Location :

[TUNER BOARD] — SIDE A —

L2 : FM VT

Voltage Adjustment

L3 : FM IF Adjustment

TP1

TP13

RV1 : FM VCO Adjustment

CT1 : AM Tracking

Adjustment

L4 : AM Tracking

Adjustment

• IC1 TC9326F

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Function

COM 1

COM 2

COM 3

R DATA OUT

DDC1 CTL

BAND AM/FM

MUTE CTL

F/R CTL

BST CTL

IF REQ

HOLD SW

R DATA IN

HOLDER, TUME

F/R SW

HOLD SENS

PHOTO CTL

PHOTO IN

AMS CTL

AMS IN

BATT DET

KEY IN

AD Vref

LED CTL

M DATA I/O

M CLOCK

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

CS

BEEP

Pin Name

COM 1

COM 2

COM 3

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

P13-1

P13-2

P13-3

P14-0

P14-1

P14-2

P14-3

IN2

K0

K1

K2

K3

P1-1

P1-2

P1-3

P2-0/AD IN1

P2-1/AD IN2

P2-2

P2-3

P3-0

P3-1

P3-2

P3-3/BUZR

P4-0

I/O

O

O

Output (Nch)

O

Output (Nch)

O

Output (Nch)

O

Output (Nch)

O

Output (Nch)

O

Output (Nch)

I

I

I

I

I

O

Input/Output

I

Input/Output

O

Input/Output

I

Input/Output

I

Input/Output

I

Input/Output

I

Input/Output

O

Input/Output

O

Input/Output

I/O

Input/Output

O

Input/Output

O

Input/Output

Circuit

Output

Input

Input

Input

Input

Input

INT

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

H

Hi-imp

Hi-imp

Hi-imp

Hi-imp

L

Hi-imp

—

L

—

—

L

L

—

L

—

—

H

—

L

L

L

L

—

ACT

Common terminal.

—

Common terminal.

—

Common terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Segment output terminal.

—

Remote control data output.

—

DDC control terminal (when DDC ON = L).

L

BAND control output (when AM = Hi-imp, when FM = L).

—

MUTE control terminal (when MUTE ON = L).

L

HEAD select terminal (when FWD = Hi-imp, when REV = L).

—

Tone control terminal (when BOOST ON = Hi-imp, when OFF = L).

Hi-imp

IF REQ control terminal (when REQ = Hi-imp).

L

HOLDER detect input (when HOLDER CLOSE = H).

—

Communication request from the remote controller. (H = VCC).

VCC

HOLDER detect and TAPE error erase detect terminal.

—

TAPE rotating direction detect terminal.

—

Input when the key is pressed during HOLD (H = AD Vref).

AD Vrcl

Terminal for controlling the rotation detect circuit.

H

Rotation detect input.

—

AMS sensitivity select (when AMS = H, when BL.SKIP = L).

H

Tape sound existing or not-exiting detect (Music

—

exists: L, music does not exist: H.

Voltage detect input.

—

KEY input terminal.

—

Reference voltage of AD IN 1, 2.

—

LED output terminal.

H

E2PROM CS control terminal.

—

E2PROM DATA I/O.

—

E2PROM CLOCK terminal.

—

BEEP (when TC : 1.6 kHz, when CF : 3.0 kHz).

—

Description

Remarks

VLD at High level.

Pull-up at outside

(TUNER side).

Pull-up at outside (Vref).

Pull-up at outside (Vcc).

Pull-up at outside (Vcc).

Pull-up at outside (Vcc).

Pull-up at outside (Vref).

Pull-up at outside (V

A/D input.

A/D input.

A/D input.

A/D input.

Pull-down at outside.

Pull-up at outside.

LCD

).

Pin No.

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Function

MOTOR CTL

MOTOR DIR

MOTOR BRK

REC CTL

RADIO CTL

AVLS CTL

AMP CTL

GRV/MB CTL

PM CTL

PRE AMP CTL

DOLBY CTL

DDC2 CTL

MONO/ST

TEST

IF IN

LOCAL/DX

DO

HOLD

PSC

GND

FM IN

AM IN

VDD

RESET

XOUT

XIN

VXT

VLCD

C1

C2

VEE

Pin Name

P4-1

P4-1

P4-2

P4-3

P5-0

P5-1

P5-2

P5-3

P6-0

P6-1

P6-2

P6-3

MUTE

TEST

IF IN

DO1/OT

DO2

HOLD

PSC

GND

FM IN

AM IN

VDD

RESET

XOUT

XIN

VXT

VLCD

C1

C2

VEE

I/O

Circuit

O

Input/Output

O

Input/Output

O

Input/Output

O

Input/Output

O

Input/Output

O

Input/Output

O

Input/Output

O

Input/Output

O

Ternary output

O

Ternary output

O

Ternary output

O

Ternary output

O

Output

O

Output

I

External interrupt

INT

L

L

L

L

H

L

L

L

L

Hi-imp

Hi-imp

Hi-imp

L

—

—

L

—

H

—

—

—

—

—

L

—

—

—

—

—

—

—

ACT

H

MOTOR control terminal.

H

MOTOR control terminal.

H

REC circuit control output.

H

RADIO system control terminal (when RADIO ON = L).

L

Terminal for controlling AVLS (when ON = L).

L

AMP control output (when AMP ON = H).

H

Tone control terminal (when GRV = L, when MB = H).

H

PL control terminal.

H

TC/CF select output (when PRE OFF = H, when PRE ON = Hi-imp).

Hi-imp

Terminal for controlling DOLBY circuit

Hi-imp

(when OFF = H, when ON = Hi-imp).

DDC control terminal (ON at Hi-imp, OFF at L).

Hi-imp

TUNER MONO/STEREO select terminal (MONO at H).

—

TEST terminal (Normal operation at L or NC).

—

IF input.

—

TUNER sensitivity select terminal (LOCAL at H, DX at L).

—

Phase comparator output.

—

External interrupt terminal.

—

Pre-scaler output (FM at H).

H

Power supply GND terminal.

—

Pre-scaler input.

—

AM local oscillator output.

—

Power supply voltage.

—

RESET terminal (H during operation).

H

Terminal to which external oscillator is connected.

—

Terminal to which external oscillator is connected.

—

Terminal to which external capacitor is connected

—

to stabilize crystal oscillator power supply.

Terminal to step-up power supply voltage for LCD drive.

—

Terminal to step-up power supply voltage for LCD drive.

—

Terminal to step-up power supply voltage for LCD drive.

—

Terminal for 1.5 V constant voltage power supply of LCD drive.

—

Description

MOTOR control terminal.

Remarks

Open

— 7 — — 8 — — 9 — — 10 —

Loading...

Loading...