Sony WMFX-495 Service manual

WM-FX495

SERVICE MANUAL

Ver. 1.2 2005.12

Model Name Using Similar Mechanism NEW

MD Mechanism Type MF-WMFX495-147

SPECIFICATIONS

US Model

AEP Model

• Frequency range

FM : 87.5 - 108 MHz

AM: 530 - 1 710 kHz (North, America)

531 - 1 602 kHz (Other countries)

• Output

Headphones (i) jack Load impedance 8 - 300 Ω

• Power requirements

1.5V DC, battery R6 (size AA) x 1

• Dimensions (w/h/d)

Approx. 81.1 x 111.2 x 29.3 mm (31⁄4 x 41⁄2 x13⁄16 in.), excl.

projecting parts and controls

• Mass

Approx. 137 g (4.9 oz) (main unit only)

• Supplied accessories

Stereo headphones or earphones with remote control (1)

Carrying case or Carrying pouch or Hand strap (1)

Design and specifications are subject to change without notice.

Battery life* (approximate hours)

Sony alkaline Sony R6P

LR6 (SG)** (SR)

Tape playback 35 9

Radio reception 40 14

* Measured value by the standard of JEITA (Japan Electronics and

Information Technology Industries Association).

(Using a Sony HF series cassette tape)

**When using a Sony LR6(SG) “STAMINA” alkaline dry

battery (produced in Japan).

Note

• The battery life may be shorter depending on the operating condition, the

surrounding temperature and battery type.

9-877-098-03

2005L02-1

© 2005.12

RADIO CASSETTE PLAYER

Sony Corporation

Personal Audio Division

Published by Sony Engineering Corporation

WM-FX495

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE ...................................................... 3

2. GENERAL ...................................................................... 4

3. DISASSEMBLY

3-1. Cabinet (Front)Sub Assy ............................................ 5

3-2. Main Board ................................................................. 6

3-3. Mechanism Deck ........................................................ 6

3-4. Cassette Holder Sub Assy........................................... 7

4. ADJUSTMENTS

4-1. Mechanical Adjustments ............................................ 8

4-2. Electrical Adjustments ................................................ 8

5. DIAGRAMS

5-1. Block Diagram ........................................................... 11

5-2. Printed Wiring Boards .............................................. 12

5-3. Schematic Diagram –Main Section (1/2)– ............... 13

5-4. Schematic Diagram –Main Section (2/2)– ............... 14

5-5. IC Block Diagrams ................................................... 15

6. EXPLODED VIEWS

6-1. Cabinet Section ......................................................... 17

6-2. Mechanism Deck Section

(MF-WMFX495-147) ....................... 18

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

7. ELECTRICAL PARTS LIST ................................... 19

2

SECTION 1

p

SERVICING NOTES

WM-FX495

This set detects the rotation of the idler gear (A) (side S) using the

photo reflector (PH751). The PH751 is mounted on the MAIN

board, therefore the idler gear (A) (side S) cannot be detected with

the MAIN board removed. As a result, the motor (M601) cannot

be controlled, causing malfunction.

Further, the MD CONT switch (S601) is also mounted on the

MAIN board, and with the board removed, the mechanism position cannot be detected and the operation is not changed over.

Therefore, when the voltage check is executed with the MAIN

board removed, follow the procedure provided below.

1. Setting

1) Refer to “3. DISASSEMBLY”, and remove the MAIN board.

2) Connect the MAIN board to the motor (M601) using jumper

wires. These can be connected easily with the use of the

extension tool (Part No. 1-769-143-11) (ten in one set).

3) Connect the AF oscillator to the TP752 and the BT401 (BATT–

).

4) Supply 1.5 V to the battery terminals using the regulated power

supply.

2. Preset state

To set the PLAY, FF, REW modes, the preset state must be set.

1) Check that the slider (NRA) and the MD CONT switch (S601)

are set to the center position. If not, set the preset state as follow.

2) Move the MD CONT switch (S601) to the side, which the

slider (NRA) is facing.

3) The slider (NRA) will move when the regulated power supply

switch is set to OFF once and then set to ON. Move the MD

CONT switch (S601) according to this timing and set to the

center position.

3. FF, REW modes

1) Check that the preset state is set.

2) Input the square wave or sine wave to the TP752 and the BT401

(BATT–).

3) Press the [FF] button or [REW] button .

4. PLAY mode

1) Check that the preset state is set.

2) Input the square wave to the TP752 and the BT401 (BATT–).

3) Press the Y button will move the slider (NRA) once towards

the side REV and then to the side FWD. Move the MD CONT

switch (S601) according to this timing will set the PLAY mode

(side FWD). Press the Y button another time for a second

and move the MD CONT switch (S601) according to the movement of the slider (NRA) will set the PLAY mode (side REV).

Note 1: If the above fails, perform from preset again.

Note 2: When using headphones, the timing for move the MD

CONT switch (S601) can be determined from the beep

sound.

– MAIN Board (Component Side) – – MAIN Board (Conductor Side) –

PH751

TP752

(PHOTO)

RVS

tt

REW

t

FF

FWD

S601

(MD CONT)

BT401

battery terminal

AF oscillator

1k

Ω

+

–

square wave

2 Hz, 2 VdB

battery

terminal

3

#

2Vp-

connect to themotor (M601)

3

WM-FX495

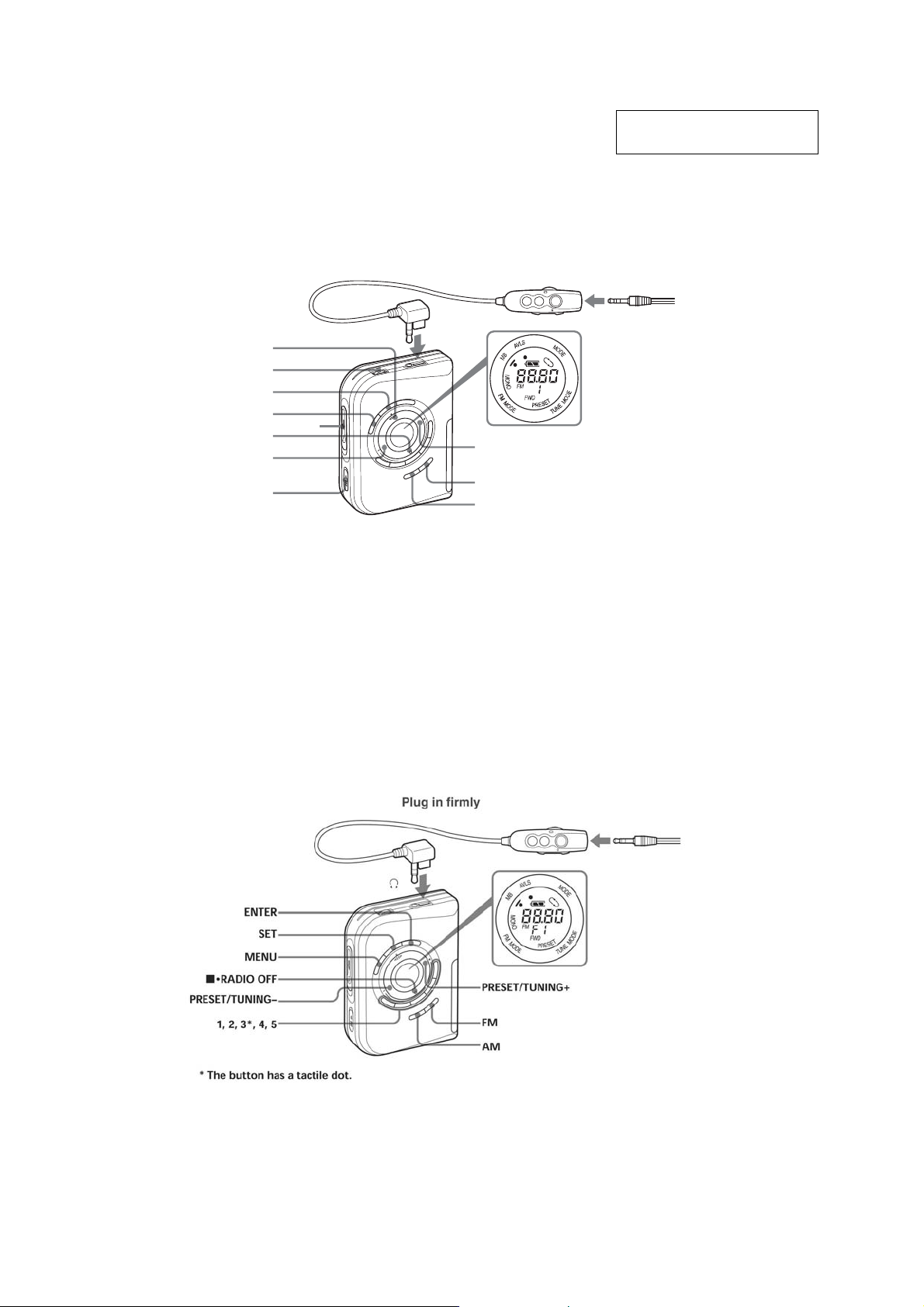

LOCATING THE CONTROLS

–Tape mode–

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Plug in firmly.

–Radio mode–

Y •DIRECTION**

VOL*

SET

MENU

x•RADIO OFF

REW•PRESET/

TUNING –

* There is a tactile dot beside VOL on the main unit to show the direction to turn up the volume.

** The button has a tactile dot.

OPEN

HOLD

i

FF•PRESET/

TUNING+

FM

AM

4

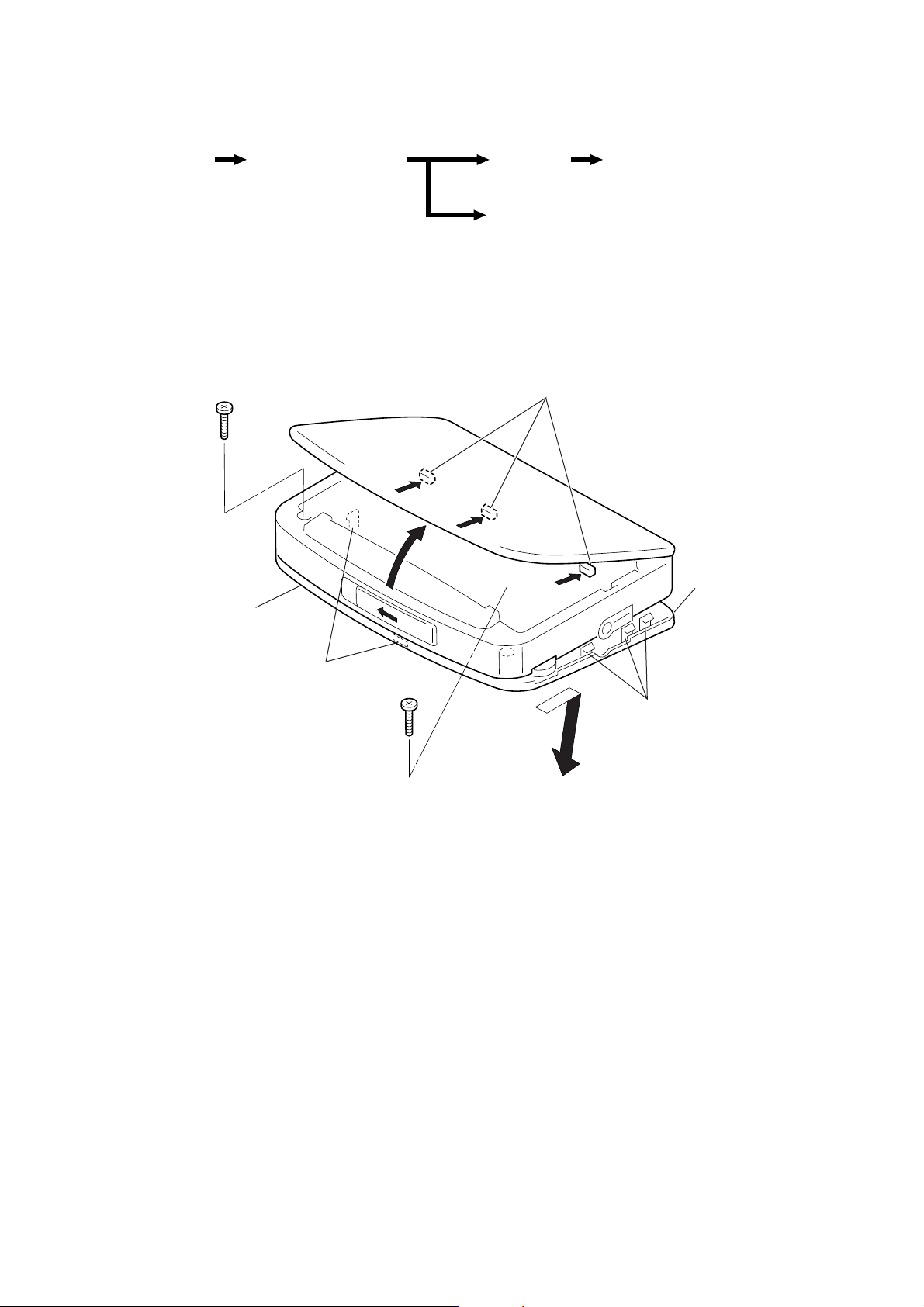

DISASSEMBLY

Y

z

The equipment can be removed using the following procedure.

WM-FX495

SECTION 3

Set

Cabinet (front) sub ASSY

MAIN board

Cassette holder sub ASSY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CABINET (FRONT) SUB ASSY

2

Screw (B 1.7 × 9), tapping

1

Cabinet center

4

Claws

Mechanism deck

8

Cabinet (front) sub ASS

6

Claws

3

Screw (B 1.7 × 9), tapping

7

5

Claws

5

WM-FX495

Y

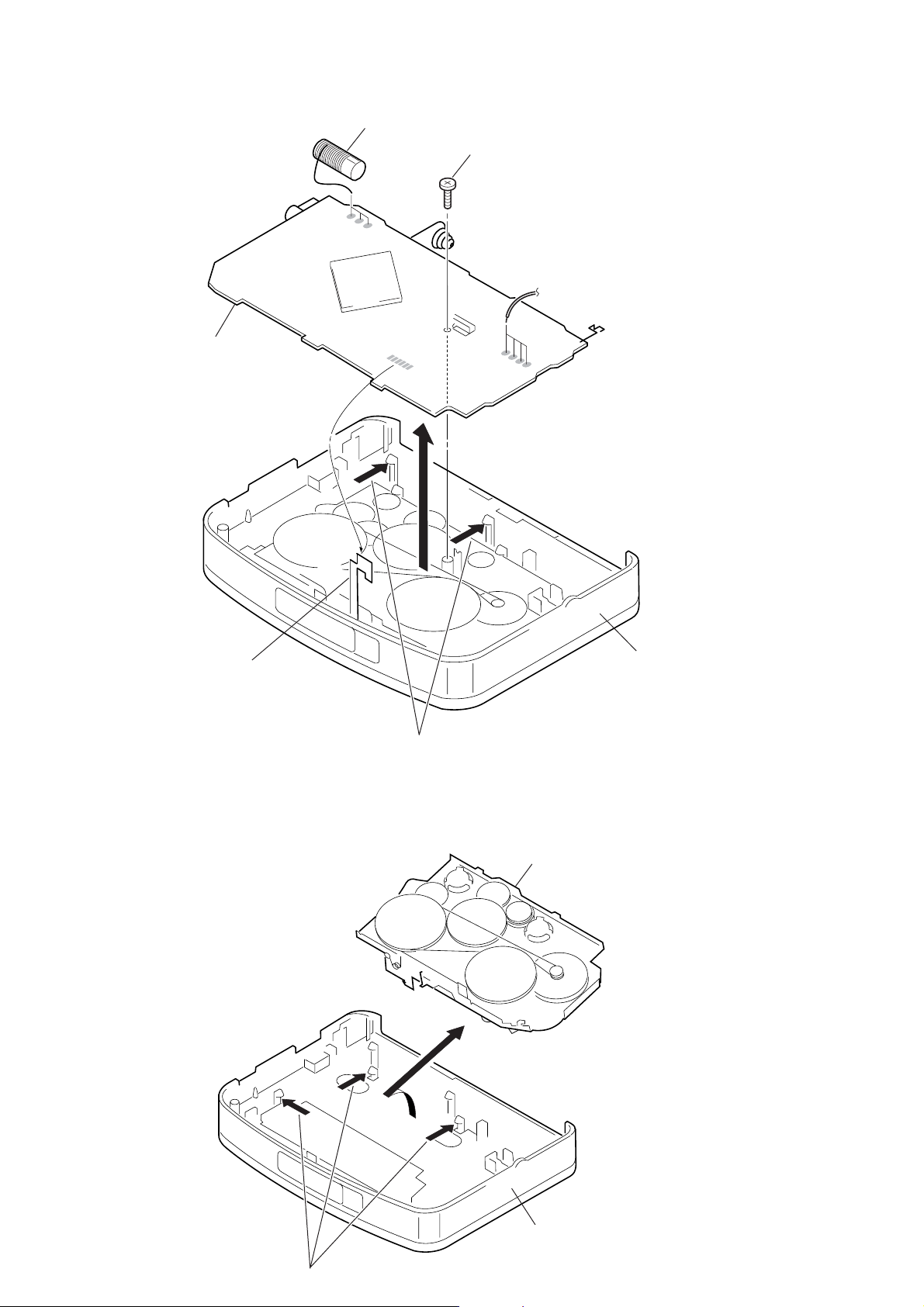

3-2. MAIN BOARD

7

MAIN board

3

Unsolder L4 leads (three places)

4

Screw (1.7 × 2.5), tapping

6

2

Unsolder leads from motor (four places)

1

Unsolder HEAD flexible board

3-3. MECHANISM DECK

5

Claws

2

3

Mechanism deck

Cabinet (center) ASSY

Cabinet (center) ASS

1

6

Claws

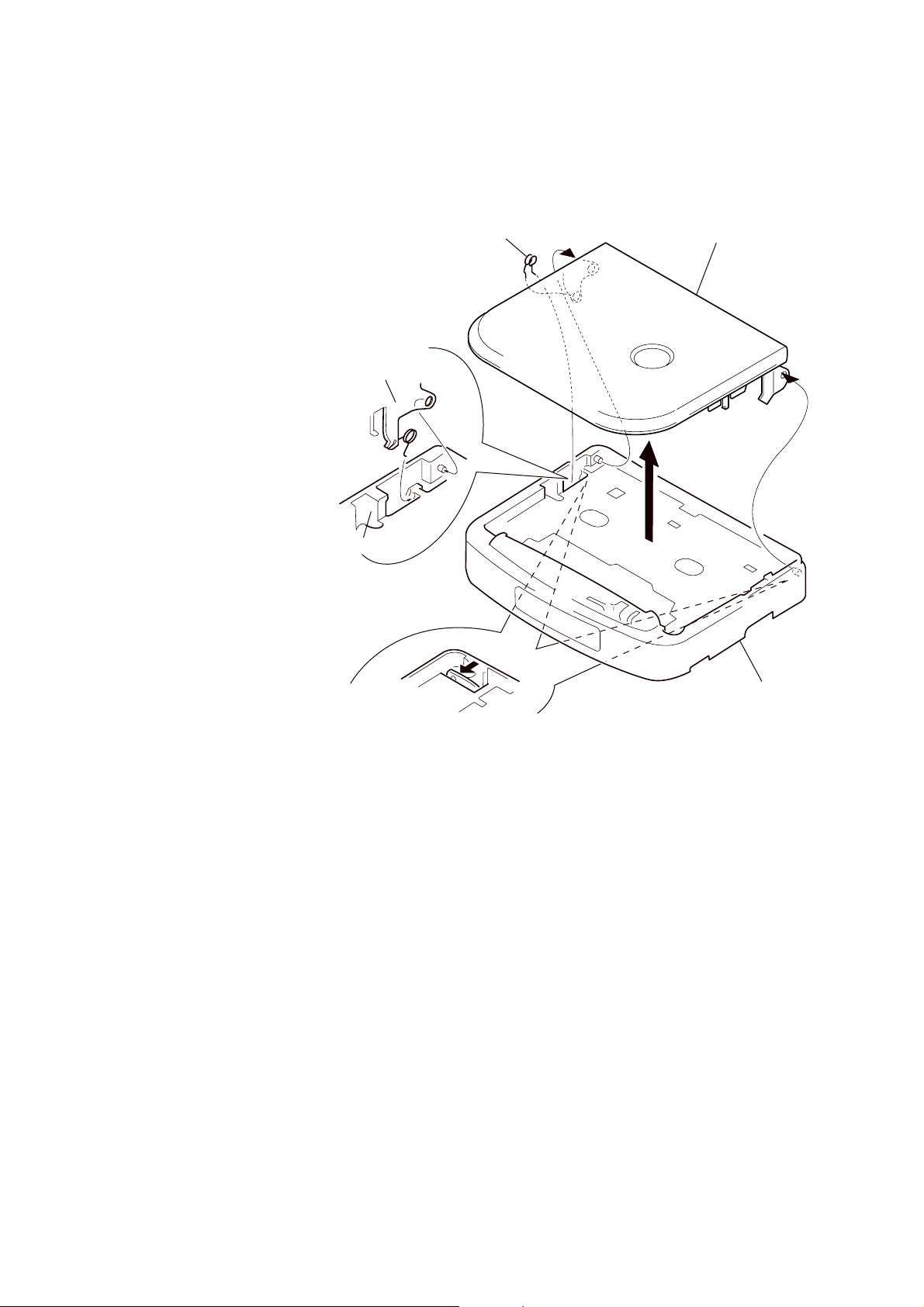

3-4. CASSETTE HOLDER SUB ASSY

Y

• Use caution when installing the cassette holder assy

Install the cassette holder sub ASSY with the spring (lid up)

as shown below in the drawing so that it fits into the holes

on the cabinet center. Once installed, fit the left and right

pieces on.

Cassette holder sub ASSY

3

Spring (lid up)

WM-FX495

4

Cassette holder sub ASS

2

Cabinet center

1

• Press on the left & right clips from the rear of the

cabinet center and remove the boss.

Cabinet center

7

WM-FX495

t

r

SECTION 4

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch roller

capstan rubber belt

2. Demagnetize the playback head with a head demagnetizer.

Do not use a magnetized screwdriver for the adjustments.

3. These measurement and adjustment should be performed with

the rated power supply voltage (1.5 V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

FWD

CQ-102C

FWD

back tension

REV 20 – 42 g • cm

CQ-102RC

REV

back tension

FF, REW CQ-201B

1.97 – 4.11 mN • m

20 – 42 g • cm

(0.28 – 0.58 oz• inch)

less than 0.19 mN • m

less than 2 g • cm

(less than 0.027 oz• inch)

1.97 – 4.11 mN • m

(0.28 – 0.58 oz• inch)

less than 0.19 mN • m

less than 2 g • cm

(less than 0.027 oz• inch)

more than 5.89 mN • m

more than 60 g • cm

(more than 0.84 oz• inch)

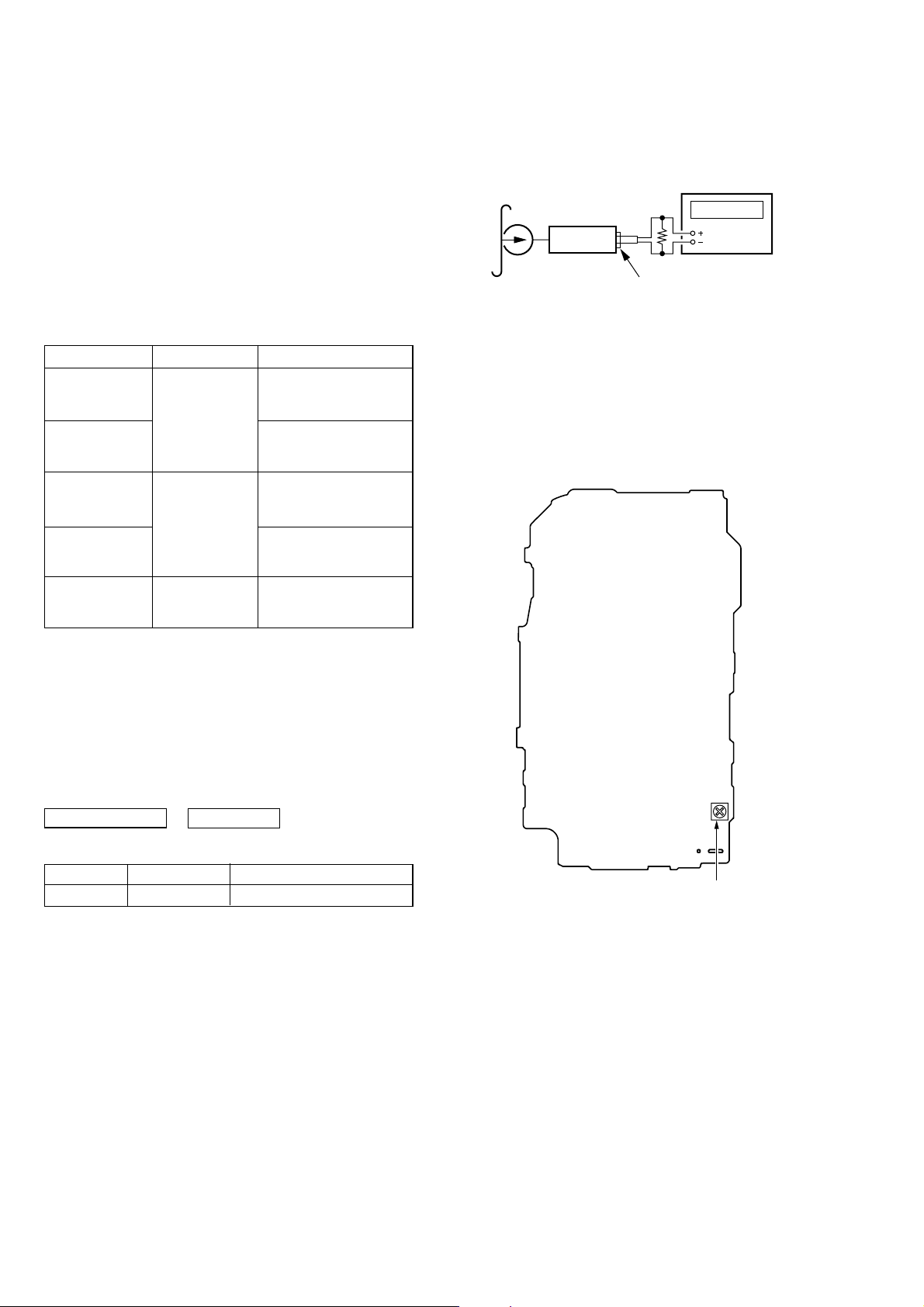

Tape Speed Adjustment

Procedure :

test tape

WS-48A

(3kHz, 0dB)

set

frequency counte

16 Ω

phones jack (J301)

1. Playback WS-48A (tape center part) in the FWD state and adjust RV601 so that the frequency counter reading becomes

3,000Hz.

Standard value : 2,910–3,090Hz

2. Playback WS-48A (tape center part) in the REV state.

Check that frequency counter reading is within ±1.5%

(apporox.45Hz) of the reading of step 1.

Adjustment Location :

MAIN BOARD (SIDE B)

4-2. ELECTRICAL ADJUSTMENTS

PRECAUTION

• Supplied voltage : 1.5V.

• Switch and control position

VOLUME control (RV301) : maximum

HOLD : OFF

TAPE SECTION

Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

0 dB = 0.775V

RV601 : Tape speed adjustmen

8

Loading...

Loading...