Sony WMFX-481 Service manual

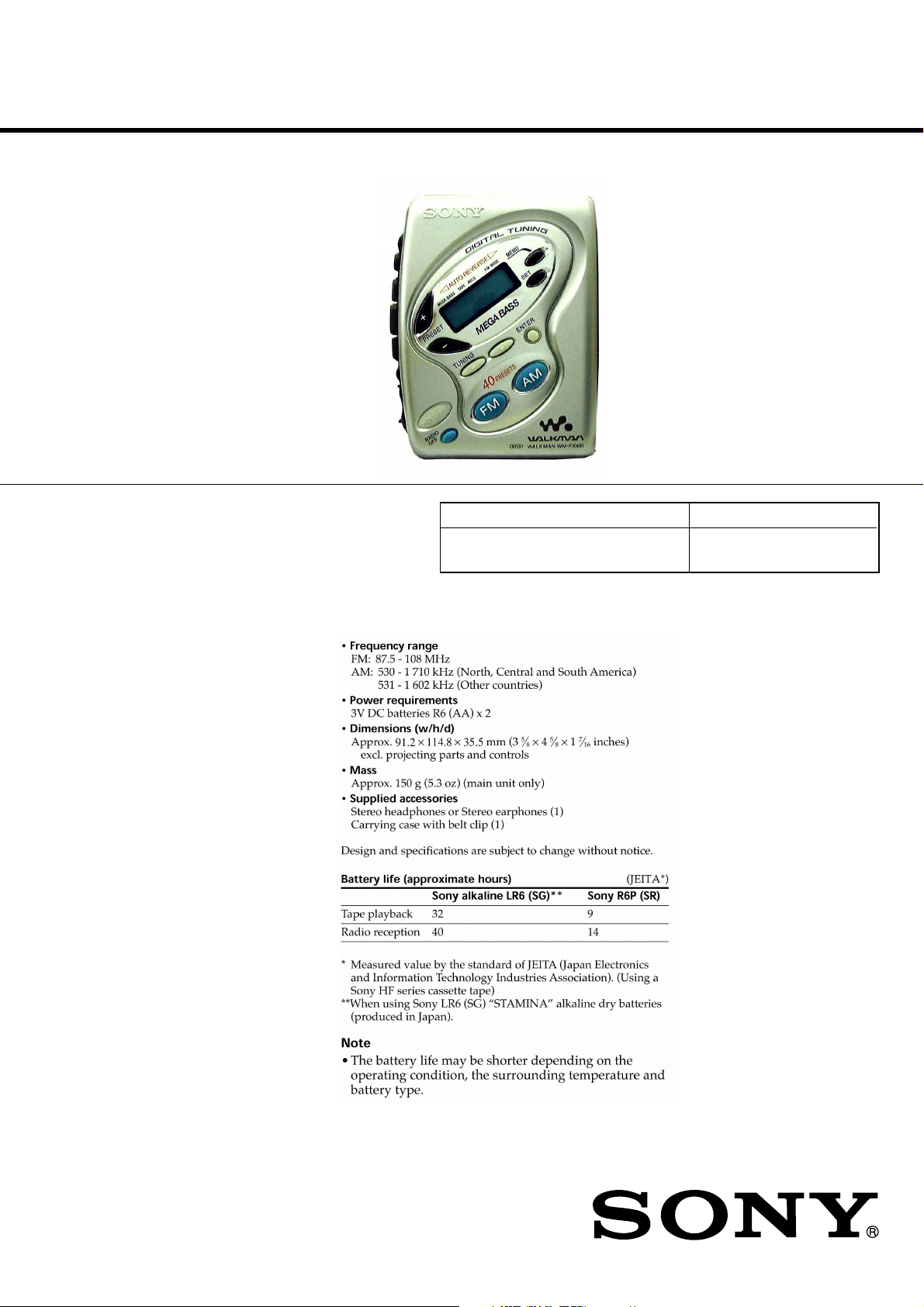

WM-FX481

SERVICE MANUAL

Ver 1.0 2001.04

Model Name Using Similar Mechanism NEW

MD Mechanism Type

SPECIFICATIONS

E Model

Chinese Model

MF-WMFX481-114 (5E, 6E, 9E)

MF-WMFX467-114 (CH)

• Abbreviation

CH : Chinese

9E : No Indication of country of origin

5E, 6E : Indication of country of origin

9-873-125-11

2001D0200-1

© 2001.4

RADIO CASSETTE PLAYER

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Production Group

WM-FX481

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL ...................................................................... 2

2. DISASSEMBLY

2-1. Cabinet (Front), Cabinet (Center) Sub ASSY ............ 3

2-2. Main Board ................................................................. 3

2-3. Mechanism Deck ........................................................ 4

2-4. Belt, Capstan/reel Motor (M601),

Magnetic Head (Playback) (HP601) ........................... 4

2-5. Cassette Holder ........................................................... 5

3. ADJUSTMENTS

3-1. Mechanical Adjustments............................................. 6

3-2. Electrical Adjustments ................................................ 6

4. DIAGRAMS

4-1. Explanation of IC Terminals ....................................... 9

4-2. Block Diagram .......................................................... 10

4-3. Schematic Diagram ....................................................11

4-4. Printed Wiring Boards – Main Section (Side A) – ... 12

4-5. Printed Wiring Boards – Main Section (Side B) – ... 13

5. EXPLODED VIEWS

5-1. Cabinet Section ......................................................... 15

5-2. Mechanism Deck Section

(MF-WMFX467-114:CH)

(MF-WMFX281-114:5E, 6E, 9E)..... 16

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

6. ELECTRICAL PARTS LIST ................................... 17

SECTION 1

GENERAL

2

SECTION 2

Y

Y

DISASSEMBLY

z

The equipment can be removed using the following procedure.

Set

Cabinet (front)

Main boardCabinet (center) sub ASSY

Cassette holder

Note : Follow the disassembly procedure in the numerical order given.

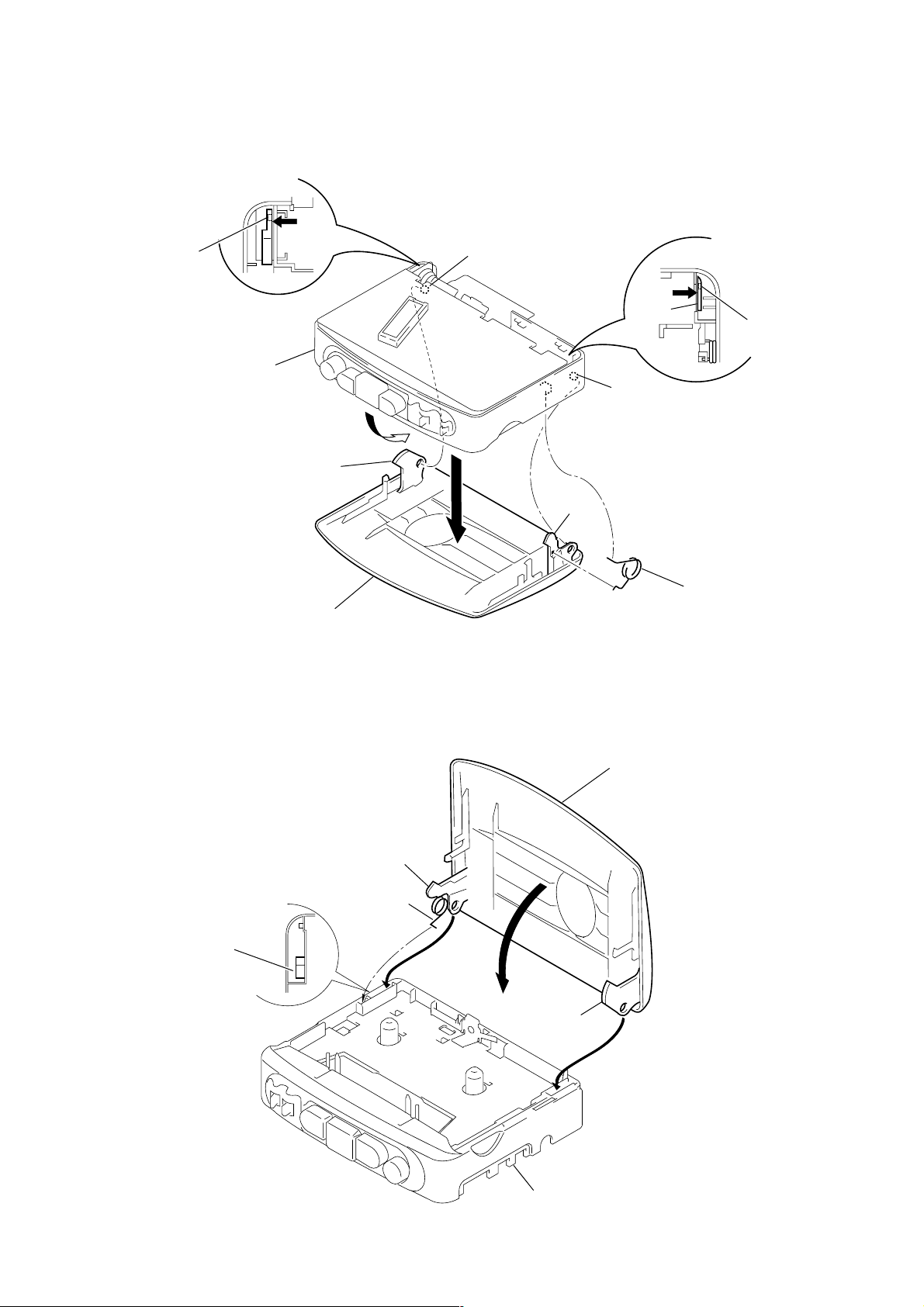

2-1. CABINET (FRONT), CABINET (CENTER) SUB ASSY

Note : Use the precision driver with coverd a point

by cloth to release the claw.

Be careful not to damage claws.

Cassette holder

Mechanism deck Belt, Capstan/reel motor (M601)

WM-FX481

Magnetic head (playback) (HP601)

3 Claws

2-2. MAIN BOARD

Main board

1 Claws

1 Claws

2

5

Cabinet (center) sub ASS

4 Claw

4 Claw

1 Claws

Cabinet (Front)

1 Screw

3 Claws

Head flexible board

4

2 Remove solder

Orange

Black

White

Red

Cabinet (center) sub ASS

3

WM-FX481

Y

2-3. MECHANISM DECK

Mechanism deck

1 Claws

2

Cabinet (center) sub ASS

2-4. BELT, CAPSTAN/REEL MOTOR (M601), MAGNETIC HEAD (PLAYBACK) (HP601)

3

Screws (M1.4)

5

Screws (M1.4)

4

Capstan/reel motor

(M601)

6

magnetic head

(PLAYBACK)

(HP601)

Mechanism deck

• How to apply the belt

Belt

Capstan/reel motor

(M601)

1

Claw

wheel ASSY (P), capstan

wheel ASSY (P), capstan

Stopper

2

Belt

4

2-5. CASSETTE HOLDER

r

2 Move the hinge away

from projection

WM-FX481

Projection

Cabinet (center)

sub ASSY

Hinge

Hinge

Cassette holder

1

Projection

5

Hinge

Hinge

Projection

3 Move the hinge away

from projection

Projection

4 Spring (torsion)

z

CAUTIONS DURING ASSEMBLY

1 Insert the spring (torsion) to the L shape slot as shown in the figure.

2,3 Insert the hinge of the “Cassette holder ”.

4 Close the “Cassette holder” then press it.

Hinge

Spring (torsion)

L shape slot

1

2

4

Cassette holde

Hinge

3

Cabinet (center) sub ASSY

5

WM-FX481

r

t

SECTION 3

ADJUSTMENTS

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch roller

capstan rubber belt

2. Demagnetize the playback head with a head demagnetizer.

Do not use a magnetized screwdriver for the adjustments.

3. These measurement and adjustment should be performed with

the rated power supply voltage (2.5 V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

FWD

CQ-102C

FWD

back tension

REV 20 – 42 g • cm

CQ-102RC

REV

back tension

FF, REW CQ-201B

1.97 – 4.11 mN • m

20 – 42 g • cm

(0.28 – 0.58 oz• inch)

less than 0.19 mN • m

less than 2 g • cm

(less than 0.027 oz• inch)

1.97 – 4.11 mN • m

(0.28 – 0.58 oz• inch)

less than 0.19 mN • m

less than 2 g • cm

(less than 0.027 oz• inch)

more than 5.89 mN • m

more than 60 g • cm

(more than 0.84 oz• inch)

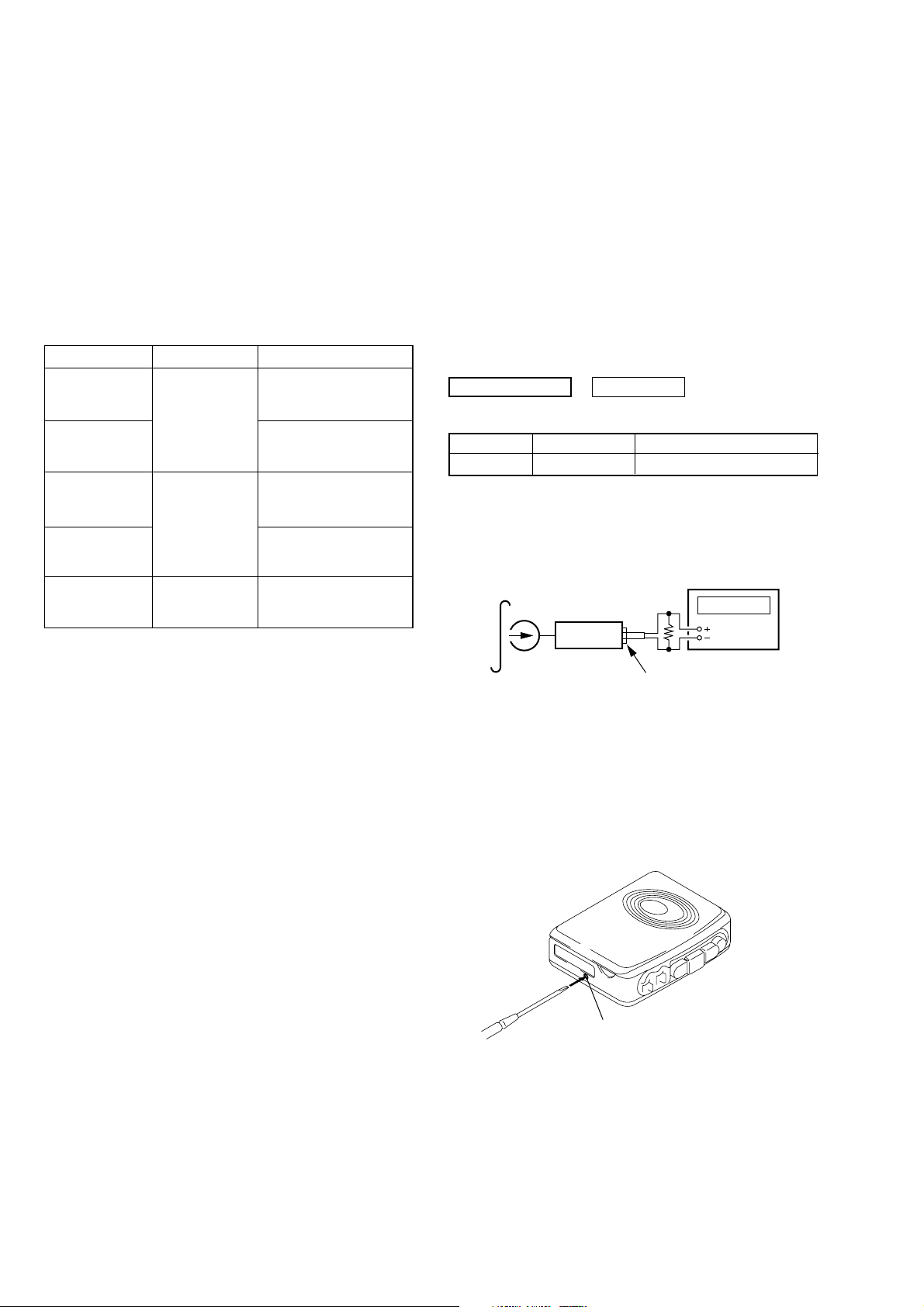

3-2. ELECTRICAL ADJUSTMENTS

PRECAUTION

• Supplied voltage : 2.5V.

• Switch and control position (MENU display)

MEGA BASS : OFF

VOLUME control (RV301) : maximum

AVLS : OFF (No indicated)

FM MODE : 5E, 6E : DX (No indicated)

9E, CH : STEREO (No indicated)

• Abbreviation

CH : Chinese

9E : No Indication of country of origin

5E, 6E: Indication of country of origin

TAPE SECTION

Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure :

test tape

WS-48A

(3kHz, 0dB)

0 dB = 0.775V

frequency counte

16 Ω

set

phones jack (J301)

1. Playback WS-48A (tape center part) in the FWD state and adjust RV601 so that the frequency counter reading becomes

3,000Hz.

Standard value : 2,985–3,015Hz

2. Playback WS-48A (tape center part) in the REV state.

Check that frequency counter reading is within ±1.0% of the

reading of step 1.

Adjustment Location :

RV601 : Tape speed Adjustmen

6

Loading...

Loading...