Sony WMFX-271, WMFX-275 Service manual

WM-FX271/FX275

SERVICE MANUAL

Ver 1.0 1999. 02

Photo: WM-FX271

SPECIFICATIONS

Frequency range

FM: 65 – 74/87.5 – 108 MHz (East European)

87.5 – 108 MHz (Except East European)

AM:530 – 1,710 kHz (US, Canadian)

531 – 1,602 kHz (Except US, Canadian)

Power requirements

3 V DC batteries R6 (AA) × 2/External DC 3 V power sources

Dimensions

91.4 × 115.5 × 35.9 mm (3 5/8 × 4 5/8 × 1 7/16 inches) (w/h/d) incl.

projecting parts and controls

Mass

Approx. 150 g (5.3 oz.)

Approx. 230 g (8.2 oz.) incl.batteries and a tape

Supplied accessories

Stereo headphones or Stereo earphones (1)/Carrying case (1)

Design and specifications are subject to change without

notice.

US Model

WM-FX271/FX275

Canadian Model

AEP Model

E Model

Chinese Model

WM-FX271

Model Name Using Similar Mechanism WM-FX171

Tape Transport Mechanism Type MF-WMFX171-114

MICROFILM

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

RADIO CASSETTE PLAYER

– 1 –

TABLE OF CONTENTS

1. GENERAL ........................................................................... 3

2. DISASSEMBLY

2-1. Cabinet (Front) Sub Assy....................................................4

2-2. Main Board ......................................................................... 5

2-3. Holder (Sub) Assy, Cassette ................................................ 5

2-4. Mechanism Deck................................................................. 6

2-5. Belt and Motor .................................................................... 6

3. MECHANICAL ADJUSTMENTS.................................7

4. ELECTRICAL ADJUSTMENTS

Tape Section ............................................................................ 7

Tuner Section........................................................................... 8

5. DIAGRAMS

5-1. IC Pin Description.............................................................10

5-2. Block Diagram .................................................................. 11

5-3. Printed Wiring Board ........................................................ 13

5-4. Schematic Diagram ........................................................... 15

6. EXPLODED VIEWS

6-1. Cabinet Section .................................................................18

6-2. Tape Mechanism Section-1 ............................................... 19

6-3. Tape Mechanism Section-2 ............................................... 20

7. ELECTRICAL PARTS LIST ........................................ 21

– 2 –

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

SECTION 2

6

DISASSEMBLY

• The equipment can be removed using the following procedure.

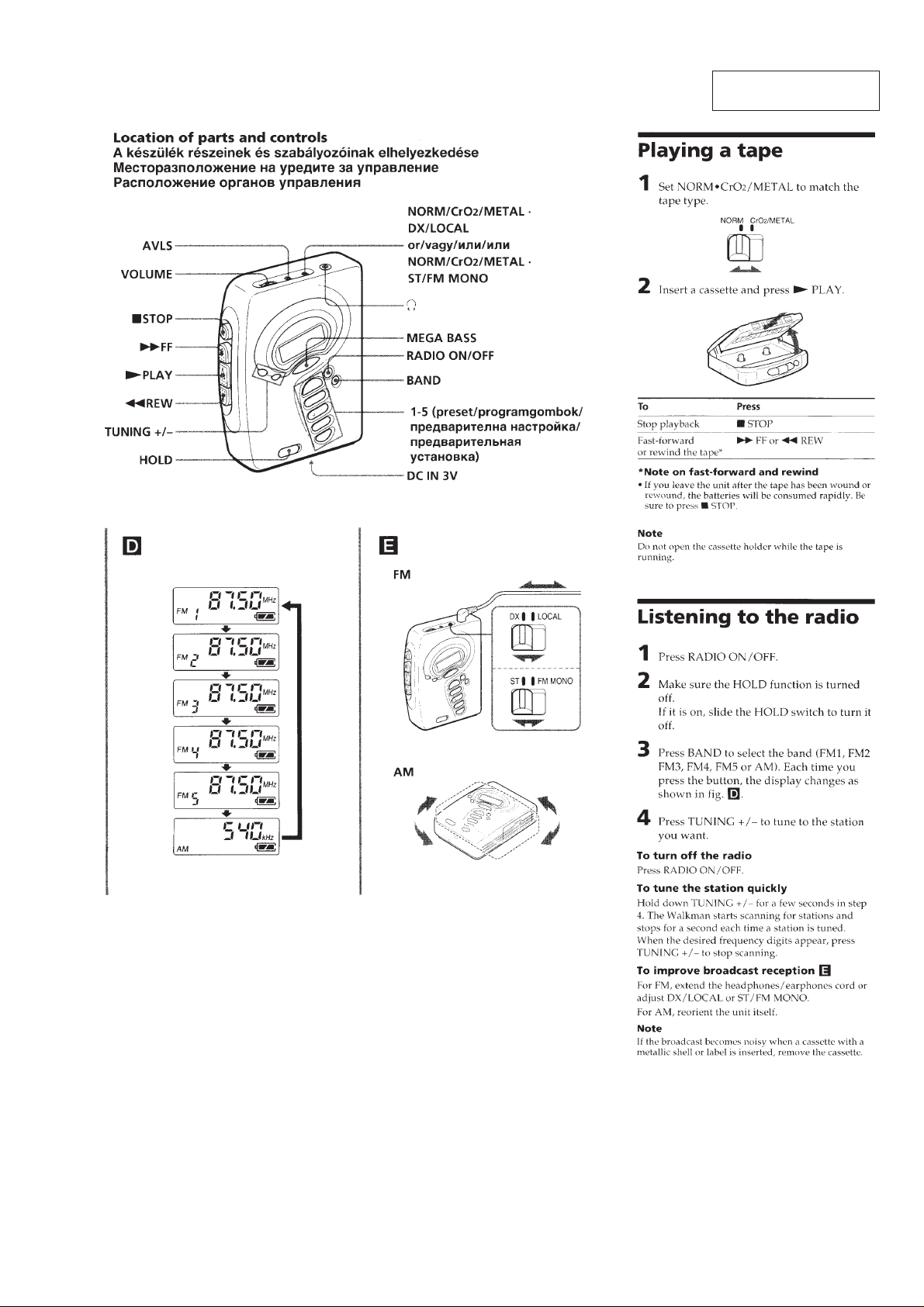

Cabinet (front) sub assy Main boardSet Holder (sub) assy, cassette Belt and Motor

Mechanism deck

Note : Follow the disassemb ly procedure in the numerical order given.

2-1. CABINET (FRONT) SUB ASSY

Note : When installing, fit the knobs and s witches .

1

Insert the precision screwdriver

(1.4 mm flat-blade) into the slit

at claw A and release the claw.

2

Remove the cabinet (front) sub assy.

(Release all claws B to N in

alphabetical order.)

A

holder (sub) assy, cassette

cabinet (front) sub assy

cabinet (front) sub assy

E

D

C

B

F

G

Note :When removing the cabinet, put cloth

on the end of a screwdriver or use a

polyacetal driver to avoid damage to

the cabinet.

H

I

J

K

L

M

N

S71

– 4 –

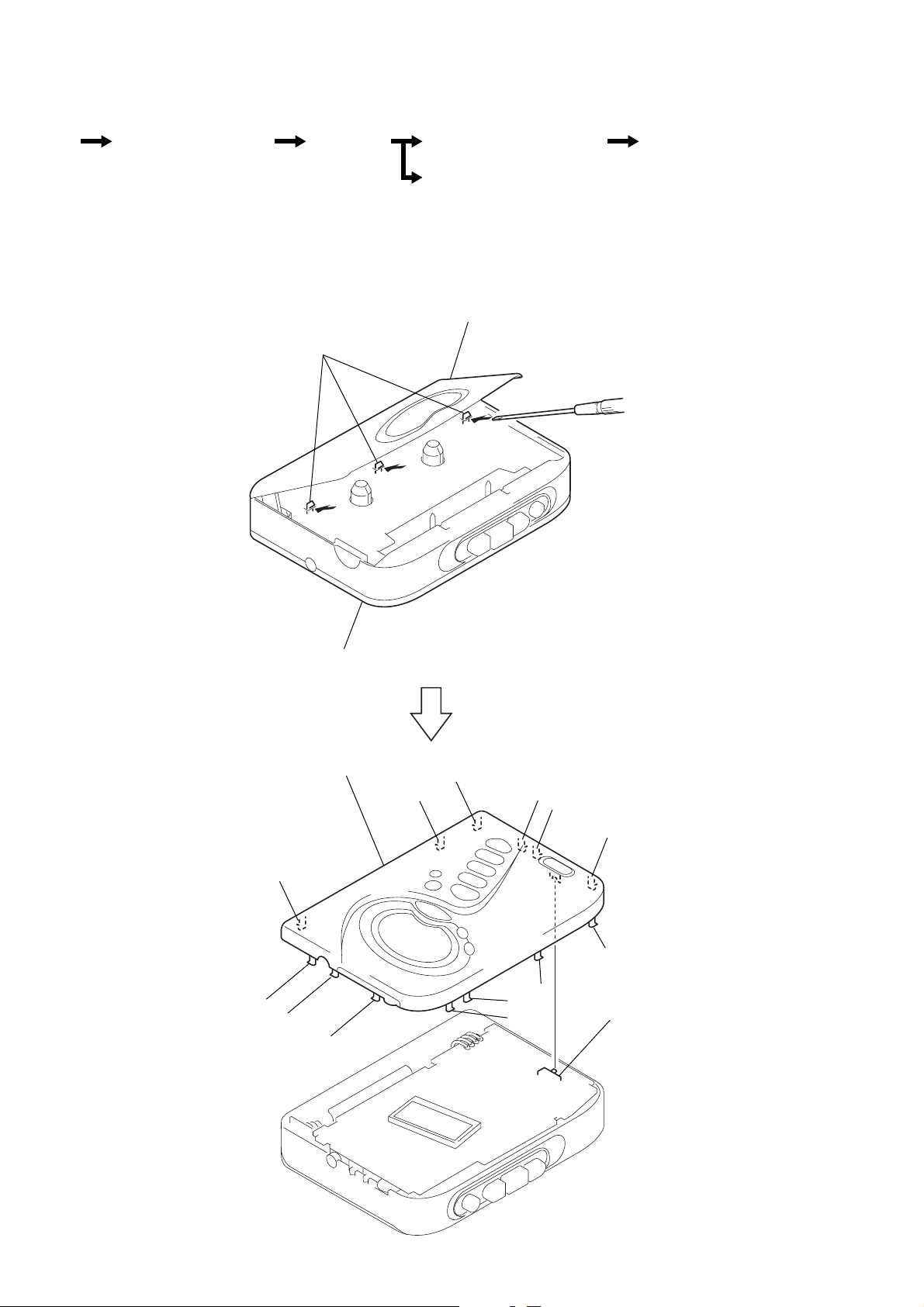

2-2. MAIN BOARD

)

2

Unsolder the 4 places.

5

MAIN board

3

screw (M1.4), toothed lock (WH)

4

two claws

2-3. HOLDER (SUB) ASSY, CASSETTE

2

Insert a precision screwdriver

(1.4 mm flat-blade) vertically

into portion A to release the

hinge plate.

3

Portion B to release the

hinge plate.

A

B

1

HEAD FLEXIBLE board (CN301)

spring (torsion

5

– 5 –

1

Open the holder (sub) assy, cassette.

4

holder (sub) assy, cassette.

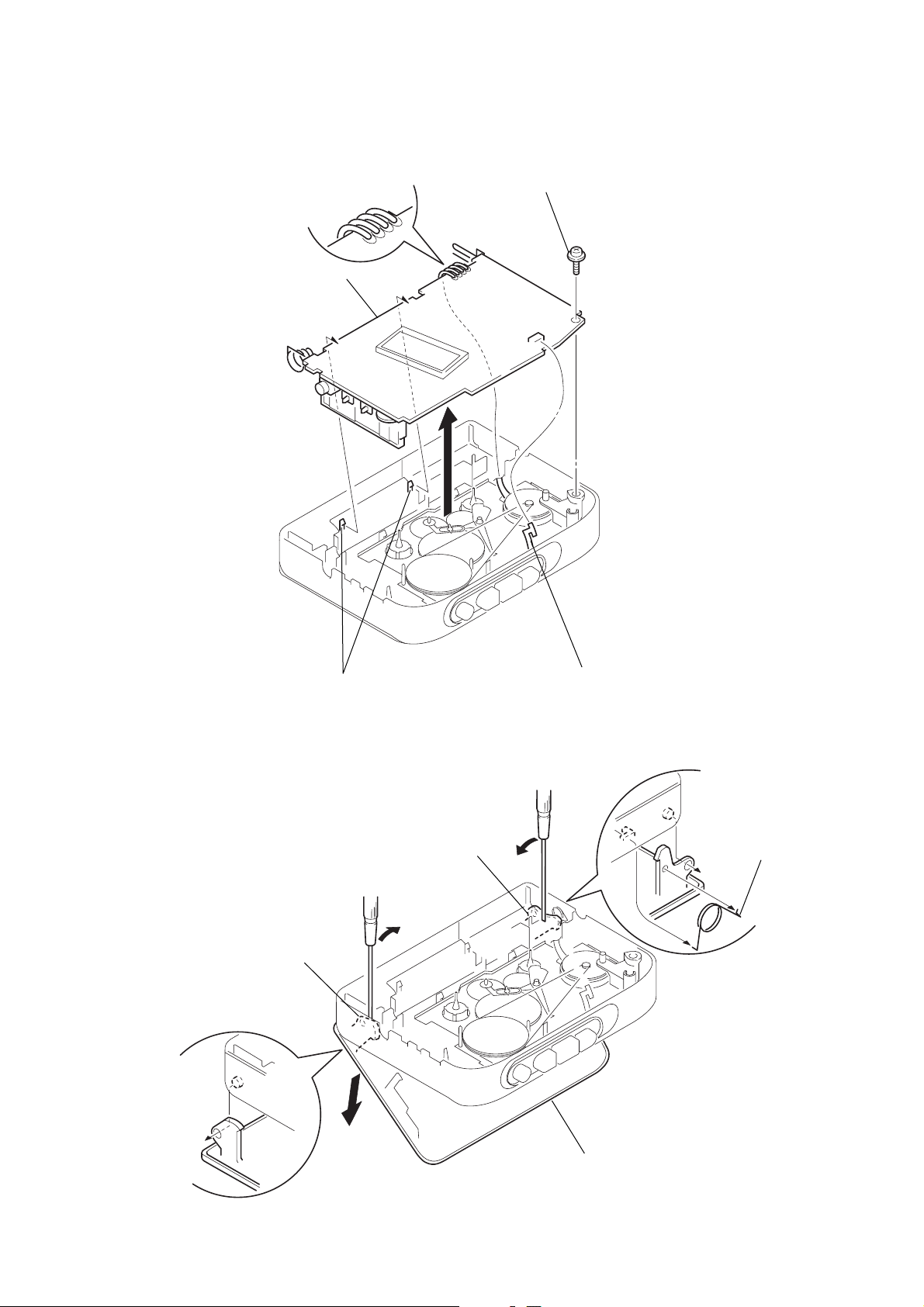

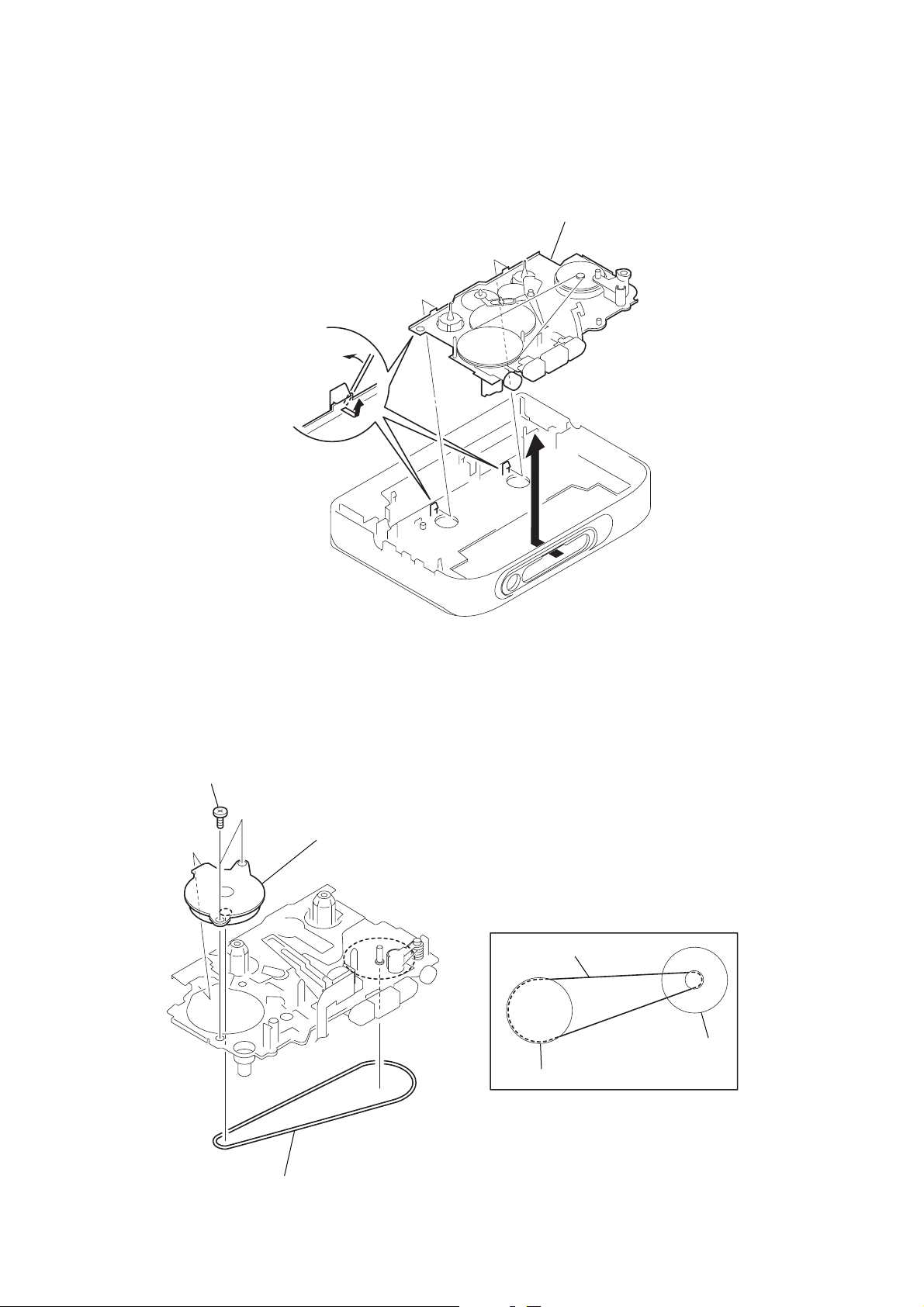

2-4. MECHANISM DECK

1

Insert the precision screwdriver

(1.4 mm flat-blade) into the slit

and release three claws.

2

Remove the mechanism deck

in the direction of the arrow.

2-5. BELT AND MOTOR

2

two screws (screw (M1.4), special head)

3

motor

• How to apply the belt

belt

M901

wheel assy (NP), capstan

1

belt

– 6 –

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

playback head pinch lever assy

capstan wheel assy rubber belt

2. Demagnetize the playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage (2.5 V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

FWD CQ-102C

FWD

Back Tension (less than 0.03 oz • inch)

FF, REW CQ-201B

CQ-102C

20 – 42 g • cm

(0.28 – 0.58 oz • inch)

less than 2 g • cm

more than 60 g • cm

(more than 0.83 oz • inch)

PRECAUTION

• Supplied voltage : 2.5V

• Switch and control position

VOLUME control : maximum

AVLS switch : NORM

• Test Tape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

TAPE SECTION 0 dB = 0.775 V

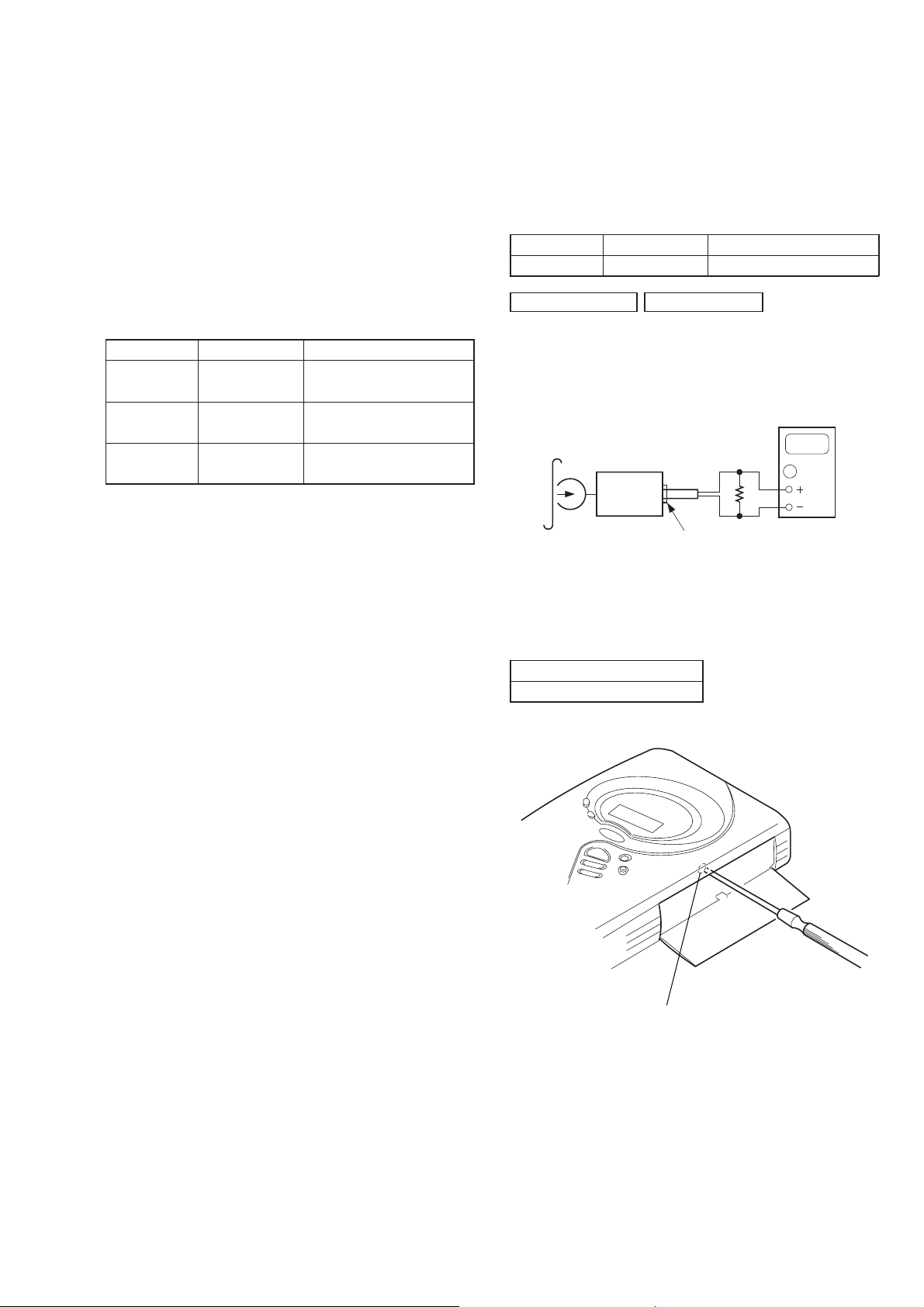

T ape Speed Adjustment

Procedure:

test tape

WS-48A

(3 kHz, 0 dB)

set

2

jack (J301)

digital frequency

counter

Ω

16

0000

1. Playback WS-48A (tape center part) in the FWD state and

adjust RV601 so that the frequency counter reading

becomes 3,000 Hz.

Specification V alue:

Digital frequency counter

2,985 to 3,015 Hz

Adjustment Location:

RV601

– 7 –

)

digital

voltmeter

TP (VT)

Main board

TUNER SECTION 0 dB = 1 µV

d

)

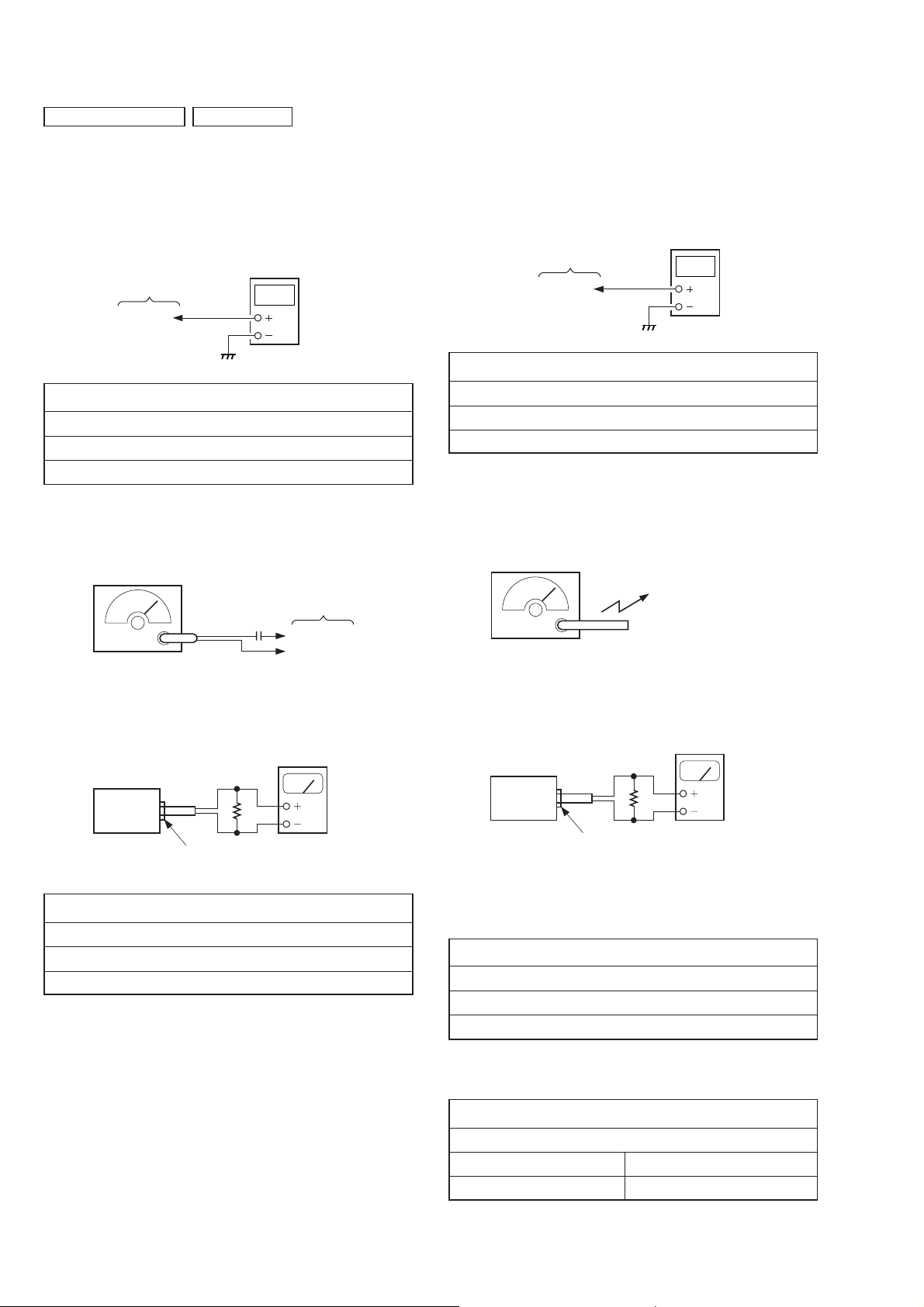

• FM Section

Setting:

RADIO ON/OFF switch: ON

BAND switch : FM

FM T uning V oltage Adjustment

digital

voltmeter

Main board

TP (VT)

FM TUNING VOLTA GE ADJUSTMENT

Adjust for a 8.5 ± 0.3 (14.5 ± 0.5) Vdc reading on digital voltmeter.

L3

108 MHz

FM T racking Adjustment

FM RF signal

generator

0.01 µF

Modulation: 1 kHz, 75 kHz dev. (100%)

Output level: as low as possible

Main boar

(FM RF IN)

(GND)

• AM Section

Setting:

RADIO ON/OFF switch: ON

BAND switch : AM

AM T uning Voltage Adjustment

AM TUNING VOL T AGE ADJUSTMENT

Adjust for a 1.1 ± 0.1 Vdc reading on digital voltmeter.

L4

530 (531) kHz

( ): Except US, Canadian model

AM IF Adjustment, AM Tracking Adjustment

AM RF signal

generator

Put the lead-wire

antenna close to

the set.

Modulation: 400Hz, 30%

Output level: as low as possible

Adjust for a maximum reading on level meter.

( ): East European model

level meter

(range: 0.5-5 V ac

16

Ω

set

2

jack (J301)

FM TRACKING ADJUSTMENT

L2

87.5 (65.0) MHz

level meter

(range: 0.5-5 V ac

16

Ω

set

2

jack (J301)

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer capacitors.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1

1,000 (999) kHz

( ): Except US, Canadian model

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

620 (621) kHz 1,400 (1,395) kHz

( ): Except US, Canadian model

– 8 –

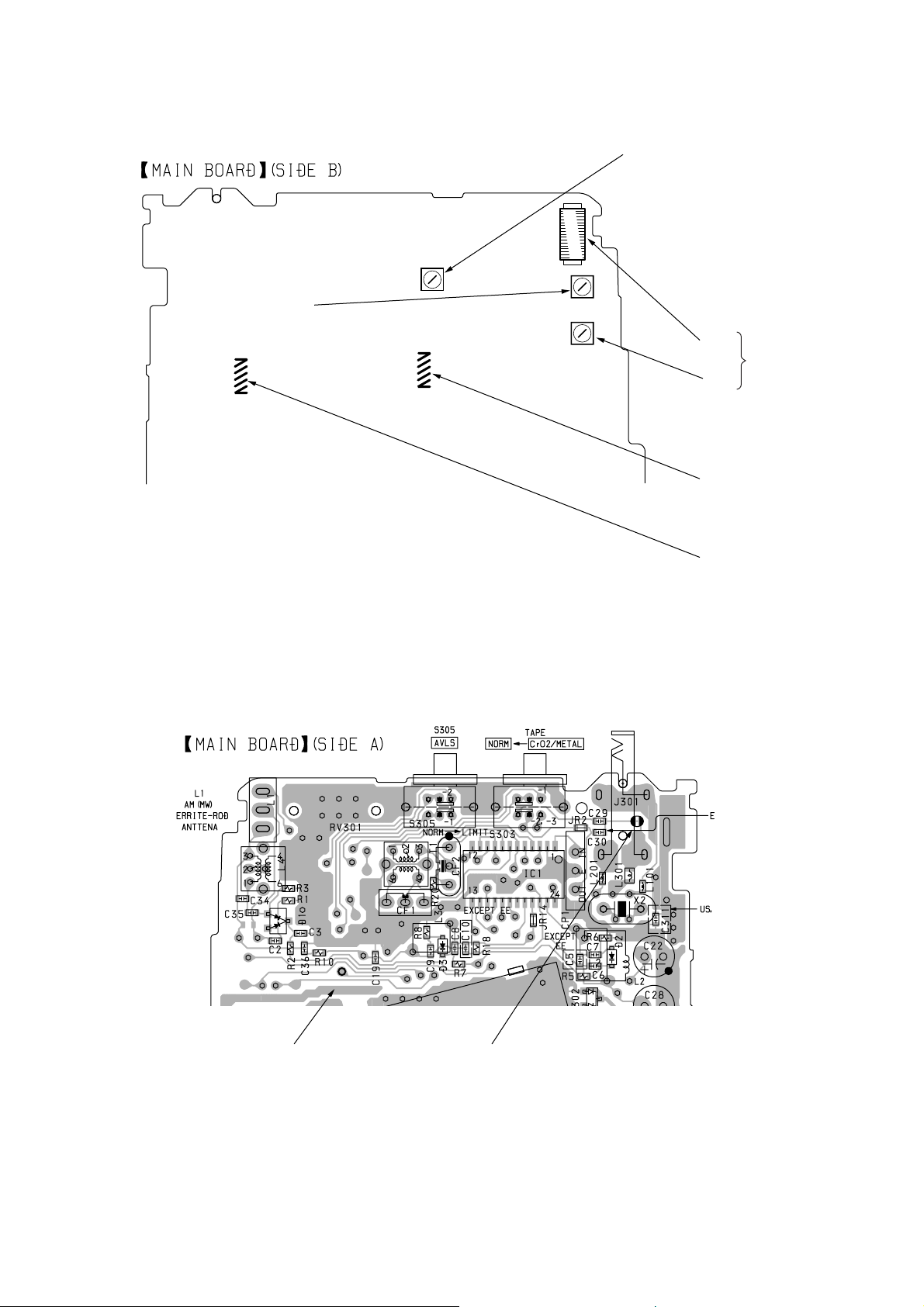

Adjustment Location: main board

L4

AM TUNING

VOLT AGE

ADJUSTMENT

T1

AM IF

ADJUSTMENT

L1

CT1

L3

FM TUNING

VOLT AGE

ADJUSTMENT

L2

FM TRACKING

ADJUSTMENT

AM TRACKING

ADJUSTMENT

Measurement Points: main board

(FM RF IN)

(VT)

FM RF INVT

– 9 –

Loading...

Loading...