Sony WM-FX244 Service Manual

WM-FX244

SERVICE MANUAL

Ver. 1.0 2004.11

Model Name Using Similar Mechanism WM-FX288

MD Mechanism Type MF-WMFX241-114

SPECIFICATIONS

E Model

• Frequency range

FM: 87.5 - 108 MHz

AM: 530 - 1 710 kHz (North, Central and South America)

531 - 1 602 kHz (Other countries)

• Power requirements

3V DC, batteries R6 (size AA) x 2

• Dimensions (w/h/d)

Approx. 91.4 x 115.5 x 37.8 mm (3 5 ⁄8 x 4 5 ⁄8 x 1 1 ⁄2 inches)

excl. projecting parts and controls

• Mass

Approx. 149 g (5.3 oz) (main unit only)

• Supplied accessories

Stereo headphones or Stereo earphones (1)

Carrying case with belt clip or Carrying pouch (1)

Design and specifications are subject to change without notice.

Battery life* (approximate hours)

Sony alkaline LR6 (SG)** Sony R6P (SR)

Tape playback 25 7.5

Radio reception 40 14

* Measured value by the standard of JEITA (Japan Electronics and

Information Technology Industries Association).

(Using a Sony HF series cassette tape)

** When using Sony LR6(SG) “STAMINA” alkaline dry batteries

(produced in Japan).

Note

• The battery life may be shorter depending on the operating condition,

the surrounding temperature and battery type.

9-879-312-01

2004K02-1

© 2004.11

RADIO CASSETTE PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

WM-FX244

TABLE OF CONTENTS

Specifications ............................................................................ 1

1. GENERAL ................................................................... 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 4

2-2. Cassette Holder Assy, Cabinet (Front) ............................ 4

2-3. Main Board ...................................................................... 4

2-4. Mechanism Deck ............................................................. 5

2-5. Belt, Capstan/Reel Motor (M601), Magnetic Head

(HP601) ........................................................................... 5

2-6. Casette Holder ................................................................. 6

3. ADJUSTMENTS

3-1. Mechanical Adjustments ................................................. 7

3-2. Electrical Adjustments ..................................................... 7

4. DIAGRAMS

4-1. IC Pin Function Description ............................................ 10

4-2. Block Diagrams ............................................................... 11

4-3. Printed Wiring Boards – MAIN Section – ...................... 12

4-4. Schematic Diagram ......................................................... 13

5. EXPLODED VIEWS

5-1. Cabinet Section ................................................................ 15

5-2. Mechanism Section (MF-WMFX241-114) ..................... 16

6. ELECTRICAL PARTS LIST .................................. 17

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Unleaded solder

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

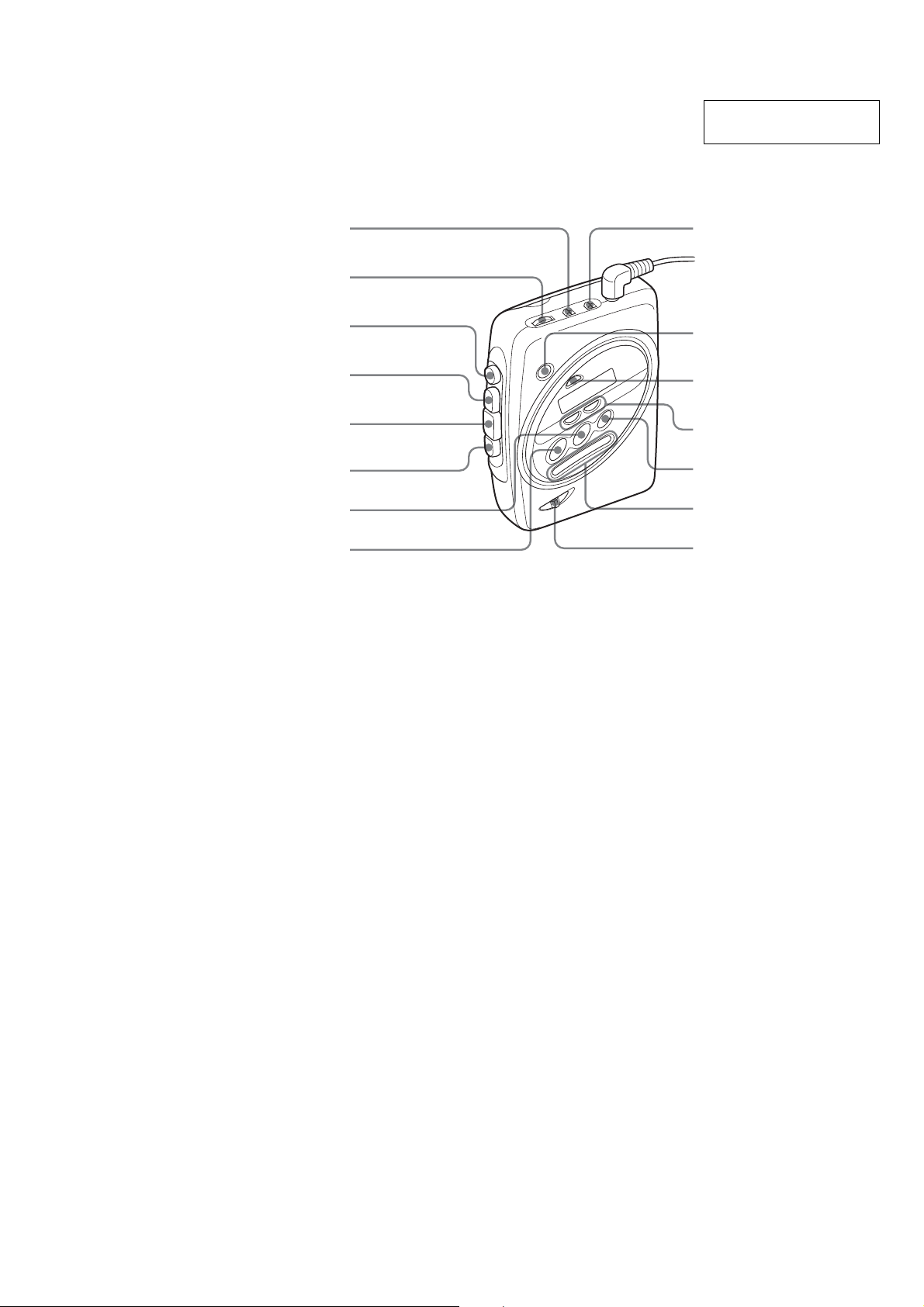

LOCATING THE CONTROLS

WM-FX244

SECTION 1

GENERAL

This section is extracted

from instruction manual.

AVLS

NORM • LIMIT

VOLUME*

x STOP

M FF

N PLAY**

m REW

AM

FM

ST • FM MONO

i

MEGA BASS

ENTER

TUNING +/–

OFF

PRESET +/–

HOLD

3

WM-FX244

s

Y

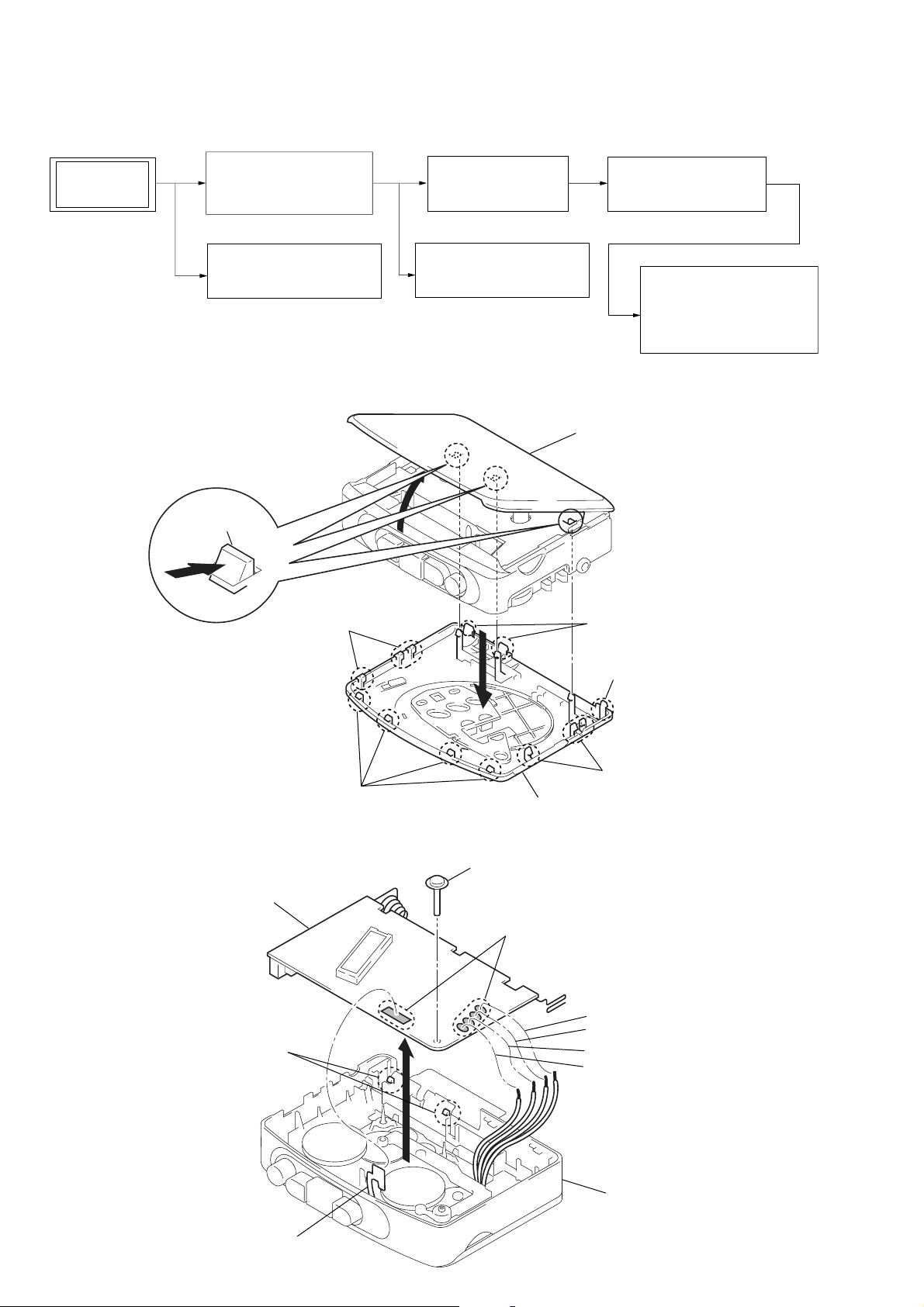

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SECTION 2

DISASSEMBLY

SET

Note: Follow the disassembly procedure in the numerical order given.

2-2. CASSETTE HOLDER

ASSY

(Page 4)

2-2. CABINET (FRONT)

(Page 4)

2-2. CASSETTE HOLDER ASSY, CABINET (FRONT)

3

Three claws

1

Two claws

2-3. MAIN BOARD

(Page 4)

2-6. CASSETTE HOLDER

(Page 6)

Cassette holder ASSY

2

2-4. MECHANISM DECK

(Page 5)

2-5. BELT, CAPSTAN/REEL

MOTOR (M601),

MAGNETIC HEAD

(PLAYBACK)(HP601)

(Page 5)

4

Two claws

2-3. MAIN BAORD

Main board

3

Two claws

1

Four claws

4

5

1

Cabinet (Front)

Screw

2

Remove solder (five places)

Orange

Black

White

Red

4

Claw

1

Two claw

Cassette holder ASS

Head flexible board

4

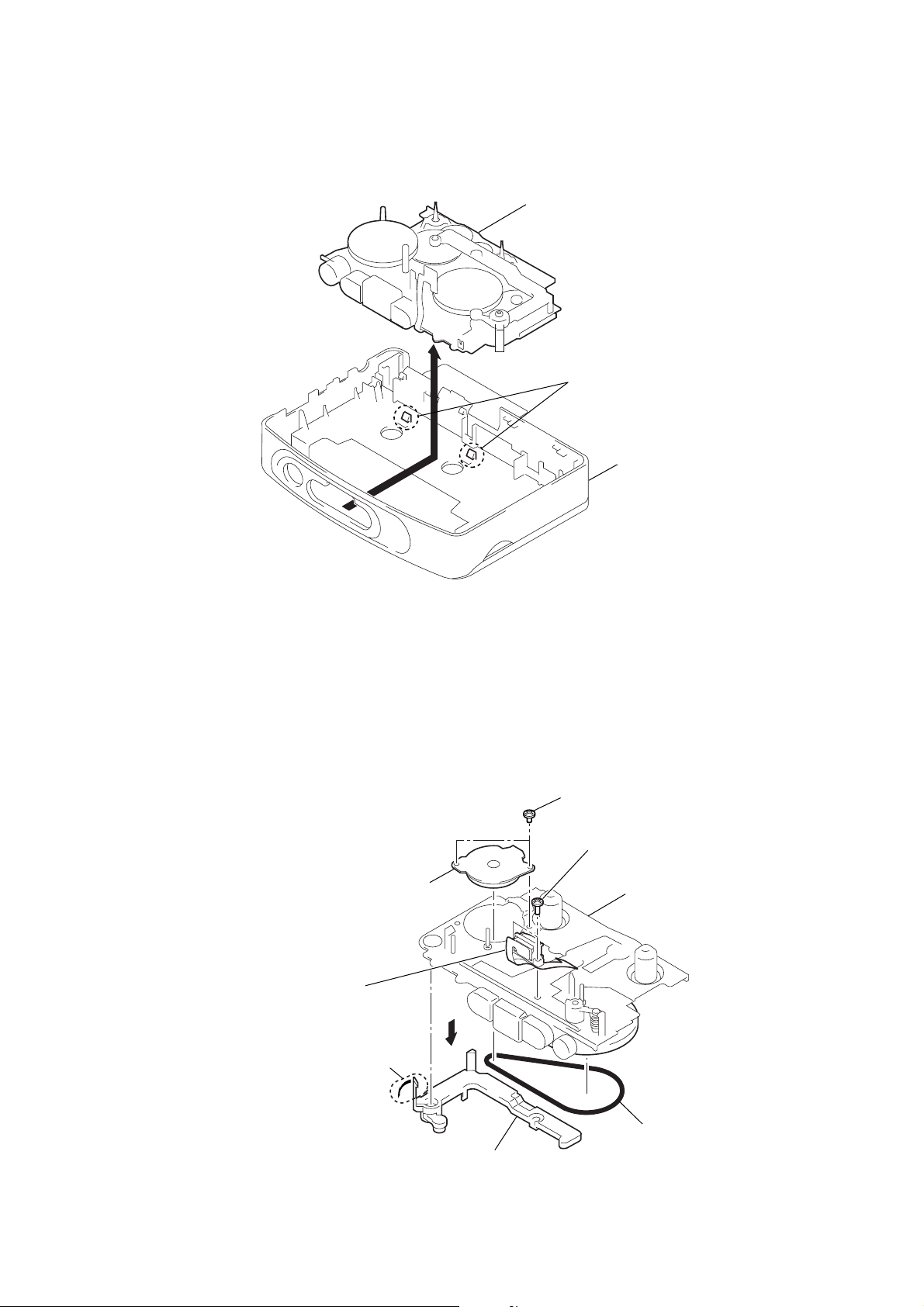

2-4. MECHANISM DECK

Y

k

Mechanism deck

1

Two claws

WM-FX244

2

Cassette holder ASS

2-5. BELT, CAPSTAN/REEL MOTOR (M601), MAGNETIC HEAD (PLAYBACK)(HP601)

4

Two screws (M1.4)

6

Screws (M1.4)

5

Capstan/reel motor

(M601)

Mechanism dec

7

magnetic head

(PLAYBACK)

(HP601)

1

Claw

2

Stopper

3

Belt

5

WM-FX244

r

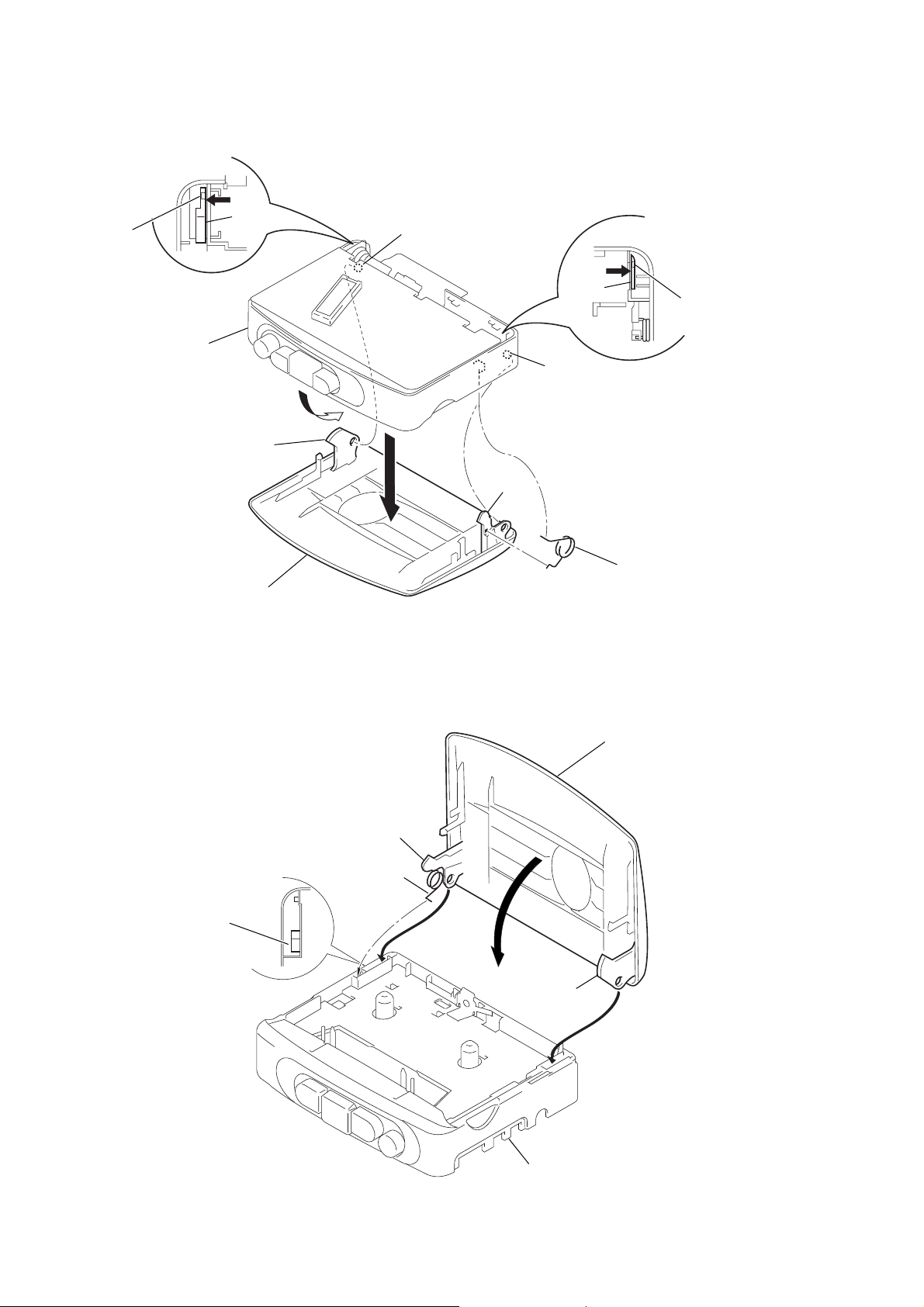

2-6. CASSETTE HOLDER

2

Move the hinge away

from projection

Projection

Cabinet (center)

Hinge

Hinge

Cassette holder

1

Projection

5

Hinge

Hinge

Projection

3

Move the hinge away

from projection

Projection

4

Spring (torsion)

z

CAUTIONS DURING ASSEMBLY

1 Insert the spring (torsion) to the L shape slot as shown in the figure.

2,3 Insert the hinge of the “Cassette holder ”.

4 Close the “Cassette holder” then press it.

Hinge

Spring (torsion)

L shape slot

1

2

Cassette holde

4

Hinge

3

Cabinet (center)

6

Loading...

Loading...