Sony WM-FX171, WM-FX173, WM-FX177 Service Manual

WM-FX171/FX173/FX177

SERVICE MANUAL

Ver 1.2 2000. 01

With SUPPLEMENT (9-923-333-81)

Photo : WM-FX173

Canadian Model

WM-FX173/FX177

AEP Model

E Model

WM-FX171/FX173

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MF-WMFX171-114

SPECIFICATIONS

• Frequency range

FM : 87.6 - 107.9 MHz

AM : 531 - 1,602 kHz

• Power requirements

3V DC batteries R6 (AA) × 2 / External DC 3V power sources

• Dimensions

FX173 : 88.5 × 118.6 × 38.2 mm

(3 1/2 × 4 3/4 × 1 9/16 inches) (w / h / d) incl. projecting parts and controls

FX171/FX177 : 88.5 × 118.6 × 37.6 mm

(3 1/2 × 4 3/4 × 1 1/2 inches) (w / h / d) incl. projecting parts and controls

• Mass

FX173 : Approx. 165 g (5.9 oz) / Approx. 245g (8.7 oz) incl. batteries

and a cassette

FX171/FX177 : Approx. 160 g (5.7 oz) / Approx. 240 g (8.5 oz) incl.

batteries and a cassette

• Supplied accessories

Stereo headphone or Stereo earphones (1) / Belt clip (1)

Design and specifications are subject to change without notice.

MICROFILM

RADIO CASSETTE PLAYER

TABLE OF CONTENTS

1. GENERAL ······································································2

2. DISASSEMBLY

2-1. Cabinet (Front) Assy ··························································3

2-2. Main Board ········································································· 4

2-3. Cassette Lid ········································································4

2-4. Mechanism Deck ································································5

2-5. Belt, Motor (Reel/Capstan) ················································5

3. MECHANICAL ADJUSTMENT ······························ 6

4. ELECTRICAL ADJUSTMENT ································6

5. DIAGRAMS

5-1. Block Diagram ···································································8

5-2. Schematic Diagram (FX171/FX177 Models) ··················10

5-3. Printed Wiring Board (FX171/FX177 Models)················13

5-4. Printed Wiring Board (FX173 Model) ····························· 17

5-5. Schematic Diagram (FX173 Model) ································ 21

5-6. IC Block Diagrams ··························································· 24

6. EXPLODED VIEWS

6-1. Cabinet Section·································································25

6-2. Main Board Section ·························································· 27

6-3. Mechanism Section-1 ······················································· 28

6-4. Mechanism Section-2 ······················································· 29

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron aroud 270˚ C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

7. ELECTRICAL PARTS LIST ···································30

SECTION 1

GENERAL

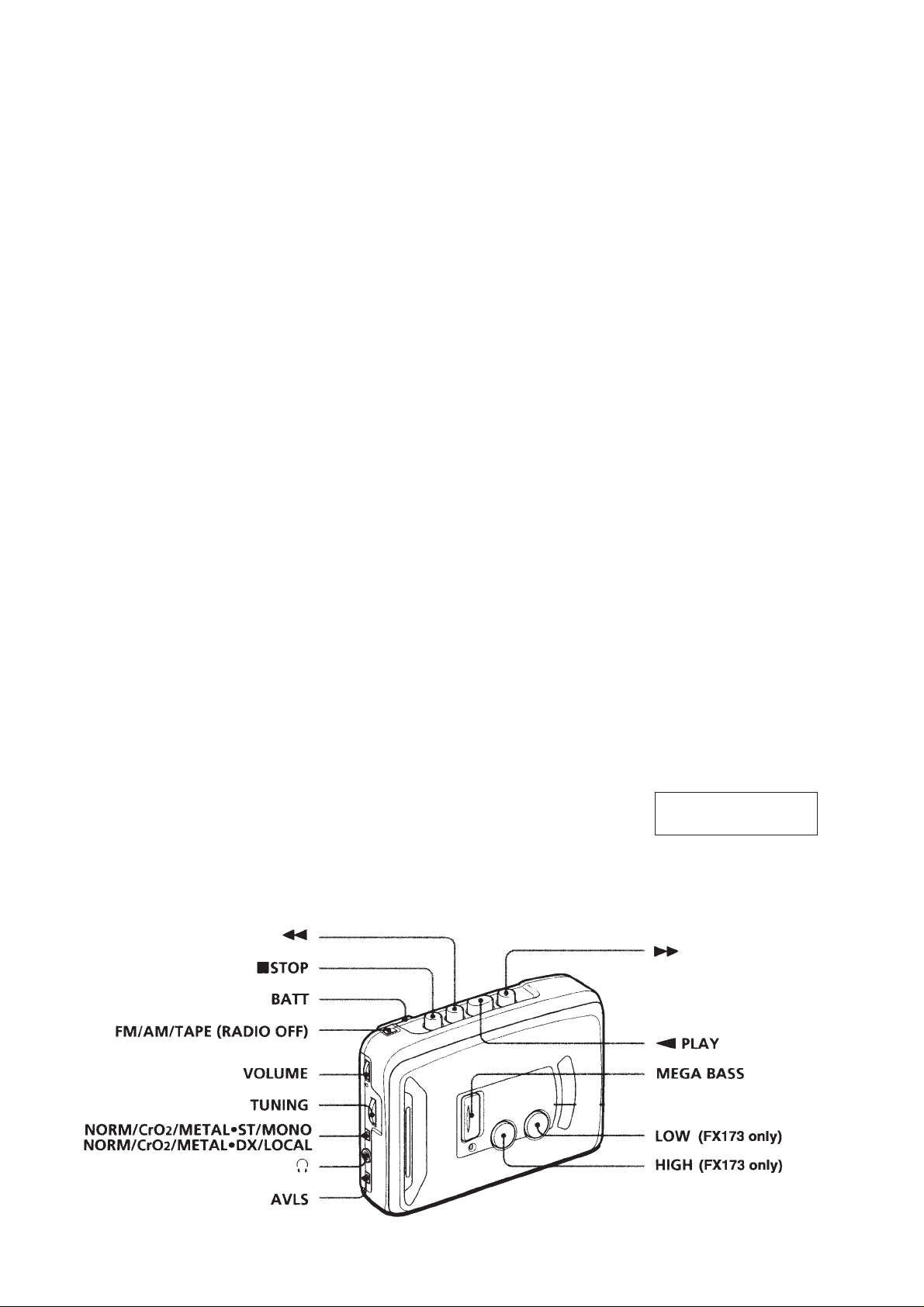

• LOCATION OF CONTROL

This section is extracted

from instruction manual.

— 2 —

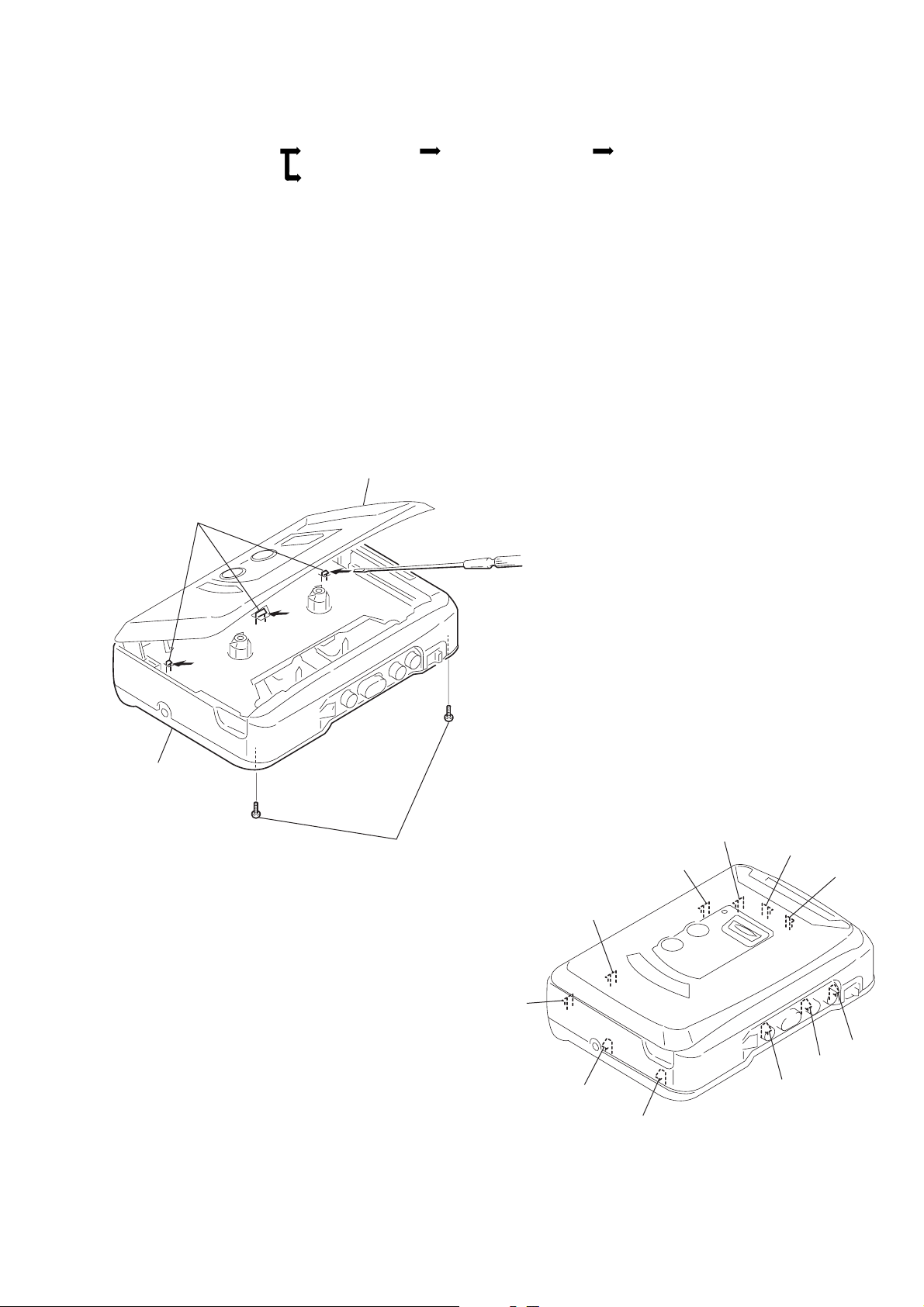

• This set can be disassembled in the order shown below.

N)

SECTION 2

DISASSEMBLY

2-1. CABINET (FRONT) ASSY 2-2. MAIN BOARD

2-3. CASSETTE LID

2-4. MECHANISM DECK 2-5. BELT, MOTOR (REEL/CAPSTA

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (FRONT) ASSY

2

Insert the precision screwdriver

(1.4 mm flat-blade) into the slit

at claw

3

(Release all claws

alphabetical order.)

A

and release the claw.

Remove the cabinet (front) assy.

A

B

to L in

Cassette lid

Cabinet (front) assy

1

Two screws

[screw (B 1.7

×

9), tapping]

B

L

C

K

D

E

F

G

H

I

J

— 3 —

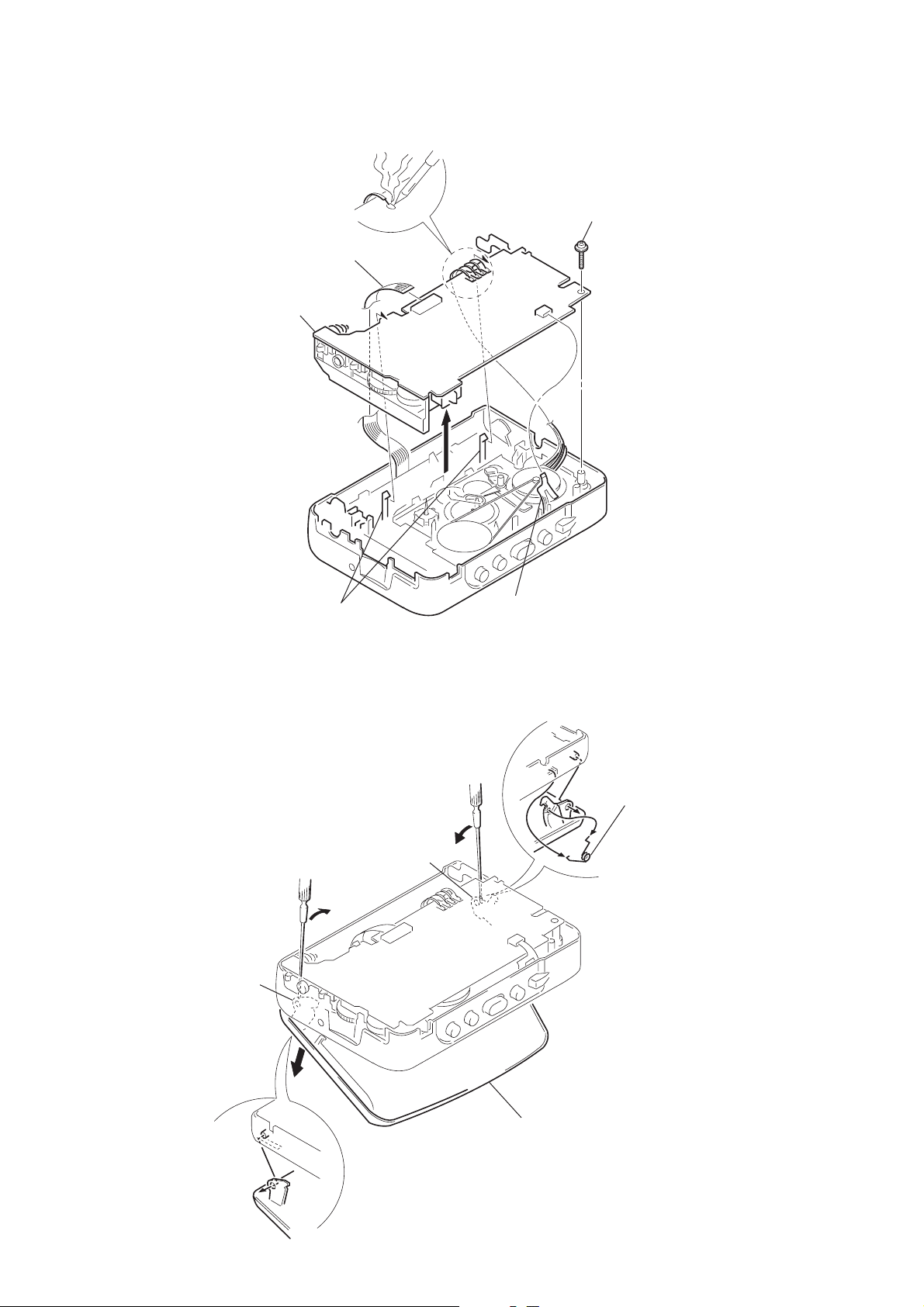

2-2. MAIN BOARD

)

3

Remove the four solders.

2

Flexible board (CN302)

6

MAIN board

4

Screw (M 1.4), toothed lock (WH

2-3. CASSETTE LID

2

Insert a precision screwdriver

(1.4 mm flat-blade) vertically

into portion

hinge plate.

3

Portion B to release the

hinge plate.

A

to release the

A

5

Two claws

B

1

Head flexible board (CN301)

5

Spring (torsion)

— 4 —

Open the cassette lid.

1

4

Cassette lid.

k

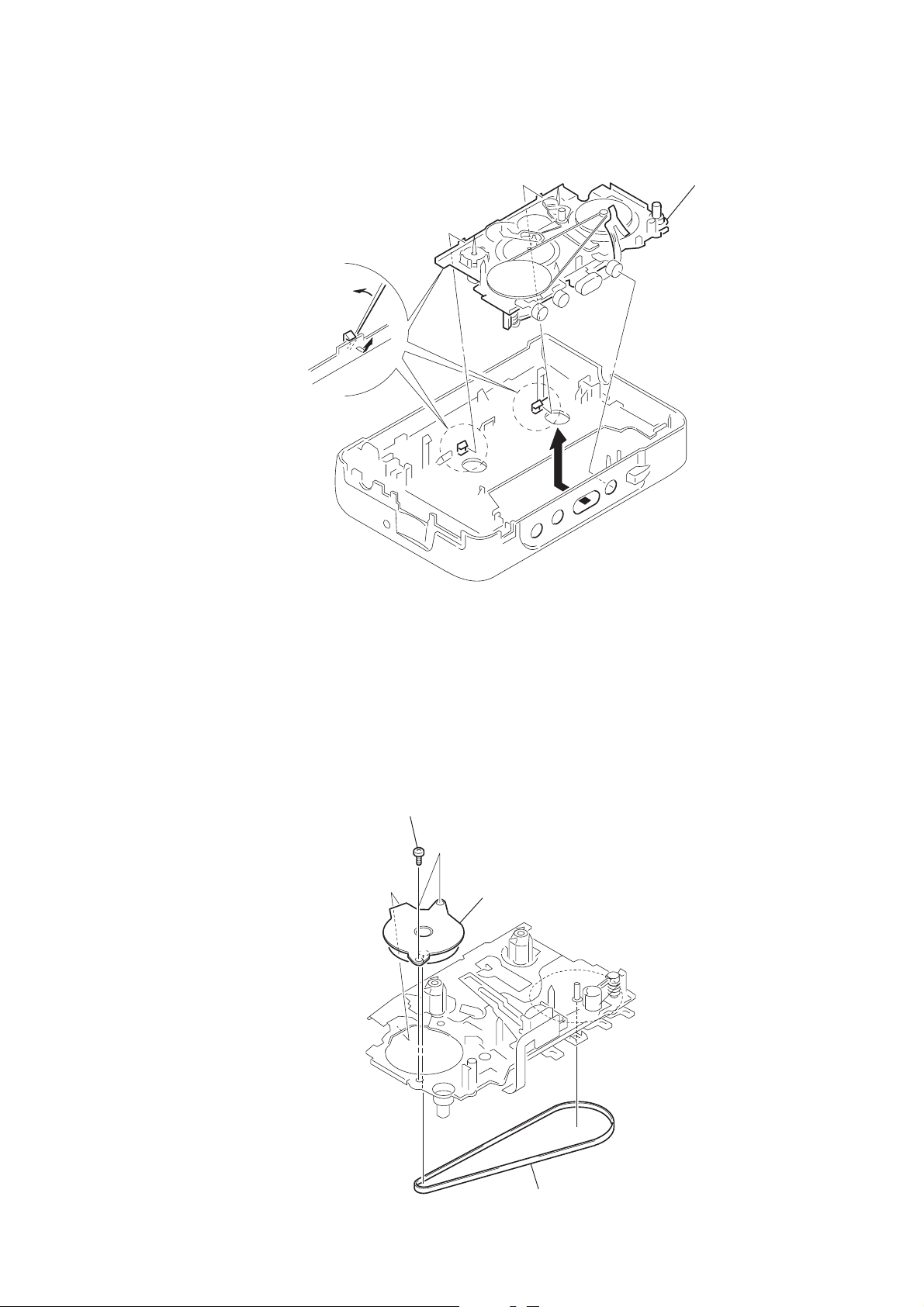

2-4. MECHANISM DECK

1

Insert the precision screwdriver

(1.4 mm flat-blabe) in to the slit

and release two claws.

2

Remove the mechanism dec

in the direction of the arrow,

2-5. BELT, MOTOR (REEL/CAPSTAN)

2

Two screws [screw (M 1.4), special head]

3

Motor (reel/capstan)

— 5 —

1

Belt

SECTION 3

r

MECHANICAL ADJUSTMENT

SECTION 4

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcahol-moistened

sweb :

Playback head Pinch roller

Rubber belt Capstan

2. Demagnetize the playback head using a demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (3.0V) to

perform the adjustments.

Torqu Measurement

Mode

FWD

FWD

Back Tension

REV

REV

Back Tension

FF

REW

Torque meter

CQ-102C

CQ-102RC

CQ-201B

Meter reading

20 - 30 g · cm

0.4 - 2.0 g · cm

20 - 30 g · cm

0.4 - 2.0 g · cm

More than 40 g · cm

PRECAUTION

1. Specified voltage : 3.0V

2. Switch position

AVLS switch : NORM

CASSETTE SECTION

T est Tape

Type

WS-48A

Tape Speed Adjustmnet

Procedure :

Test tape

WS-48A

(3kHz, 0dB)

1. Playback WS-48A (Tape center part) and adjust RV601 so that

the frequency counter reading becomes 3,000Hz ± 15Hz.

2. Playback WS-48A (Tape top and end).

Check that frequency counter reading is within 1.5% of the

reading of step1.

Signal

3kHz, 0dB

Set

Purpose

Tape Speed Adjustment

Frequency counte

*

1

+

–

PHONES jack

Adjustment Point :

[MAIN BOARD] — SIDE B —

*1

16Ω: E, EA, C & SA, PA Models.

32Ω: AEP, IT, E, CND, FR Models.

RV601 : Tape Speed

• Abbreviation

CND : Canadian

IT : Italian

EE : East European

EA : Saudi Arabia

FR : French

PA : Panama

C & SA : Central and South America

— 6 —

SECTION 5

Set

jack

*

1

+

–

Level meter

(AC : 0.5 – 5V range)

2

t

t

8

AM IF IN

FM IF

IN

7

IC301

31

L

R

30

32

1

23

18

15

17

12

6

T1

CF1

CF2

AM IFT

4

35

RV301

VOLUME

HP901

PLAYBACK

HEAD

M901

REEL/CAPSTAN

MOTOR

34

24 18

15

17

2023

19

36

1

8

4

LIMIT

NORMAL

14

L

OUT

13

R

OUT

AM MIX

AM OSC

FM OSC

FM RF OUT

AM RF IN

FM RF IN

PRE + POWER AMP

IC601

MOTOR DRIVE

IC1

FM/AM,RF/AF AMP

MAIN BOARD

J302

J301

DC IN 3V

Q301

PHONES

POWER

MUTE

Q302

ST/MONO

SW

Q2

TU +B

SW

S305

AVLS

D120

BATT

S302

(POWER)

S303(2/2)

DX– LOCAL

15

14

4U

W

IN+

13

S/S

V

VREF

5

6

21 22

9

3

7

25

RV601

TAPE SPEED

S303(1/2)

NORM

Q101

Q201

TAPE SELECT SW

S304

FM – AM – TAPE

LP1

VCC2

16

LP2

VREF

PRE

OUT2

L

MIX IN

2L

MIX

OUT L

MIX

OUT R

PWR

IN2 L

PWR

IN1 R

HP IN

2L

MIX IN

1R

HP IN

1R

PRE

OUT1

R

VREF

L2

FM

TRACKING

CT1(2/4)

CV2(2/4)

X2

QUAD

DET

OUT

MPX

IN

L3

FM

FREQ.

COVER

CT1(3/4)

CV3(3/4)

20

L4

AM

FREQ.

COVER

CT1(4/4)

CV4(4/4)

24

L1

AM

TRACKING

CT1(1/4)

CV1(1/4)

CP1

22

VCC1

6

21

RV351

HIGH

RV352

LOW

S351

MEGA BASS

OFF – ON

14

VREF

S351

MEGA BASS

OFF – ON

VREF

M.B

ON/OFF

LOW

BOOST

GAIN

COM

VCC

PWR

MUTE

10

PRE

MUTE

AVLS

PWR

OUT

1(R)

PWR

OUT

2(L)

MEGA BASS UNIT MEGA BASS UNIT

FX-171 MODELFX173 MODEL

BPF

C&SA,CND

MODEL

EXCEPT

C&SA,CND

MODEL

EXCEPT

C&SA,CND

MODEL

S303(2/2)

ST-MONO

C&SA,CND

MODEL

26

(TAPE SELECTOR)

CrO2/

METAL

1/2

2/2

FX171 MODEL

FX171

MODEL

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

2pcs, 3V

DIAGRAMS

WM-FX171/FX173/FX177

TUNER SECTION

[AM]

BAND switch : AM

AM RF signal

generator

30% amplitude modulation

by 400Hz signal.

Output level : as low as possible

[FM]

BAND switch : FM

FM RF signal

generator

75kHz(100%) frequency

deviation by 1Hz signal.

Output level : as low as possible.

Set

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4

( ) : EA, IT Models [ ] : AEP, E, FR, EE Models

CT1 (4/4)

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 620 kHz (800 kHz)

CT1 (1/4) 1,400 kHz (1,300 kHz)

( ) : EA, IT, EE Models

Put the lead-wire antenna

close to the set.

0.01µF

Level meter

*

1

+

–

PHONES

505 kHz ± 5 kHz

(516.5 kHz ± 5 kHz)

1,770 kHz ± 20 kHz

(1,631.5 kHz ± 10 kHz)

[1,690 kHz ± 10 kHz]

to IC1 pin

AM IF ADJUSTMENT

5-1. BLOCK DIAGRAM

Adjust for a maximum reading on level meter.

T1

1,000 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

86.0 MHz ± 0.2 MHz

L3

(87.35 MHz ± 0.1 MHz)

[64.0 MHz ± 0.2 MHz]

109.5 MHz ± 0.3 MHz

(108.25 MHz ± 0.2 MHz)

CT1 (3/4)

( ) : EA, IT Models [ ] : EE Model

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

1

L2 86 MHz (87.35 MHz)

CT1 (2/4) 109.5 MHz (108.25 MHz)

( ) : EA, IT Models [ ] : EE Model

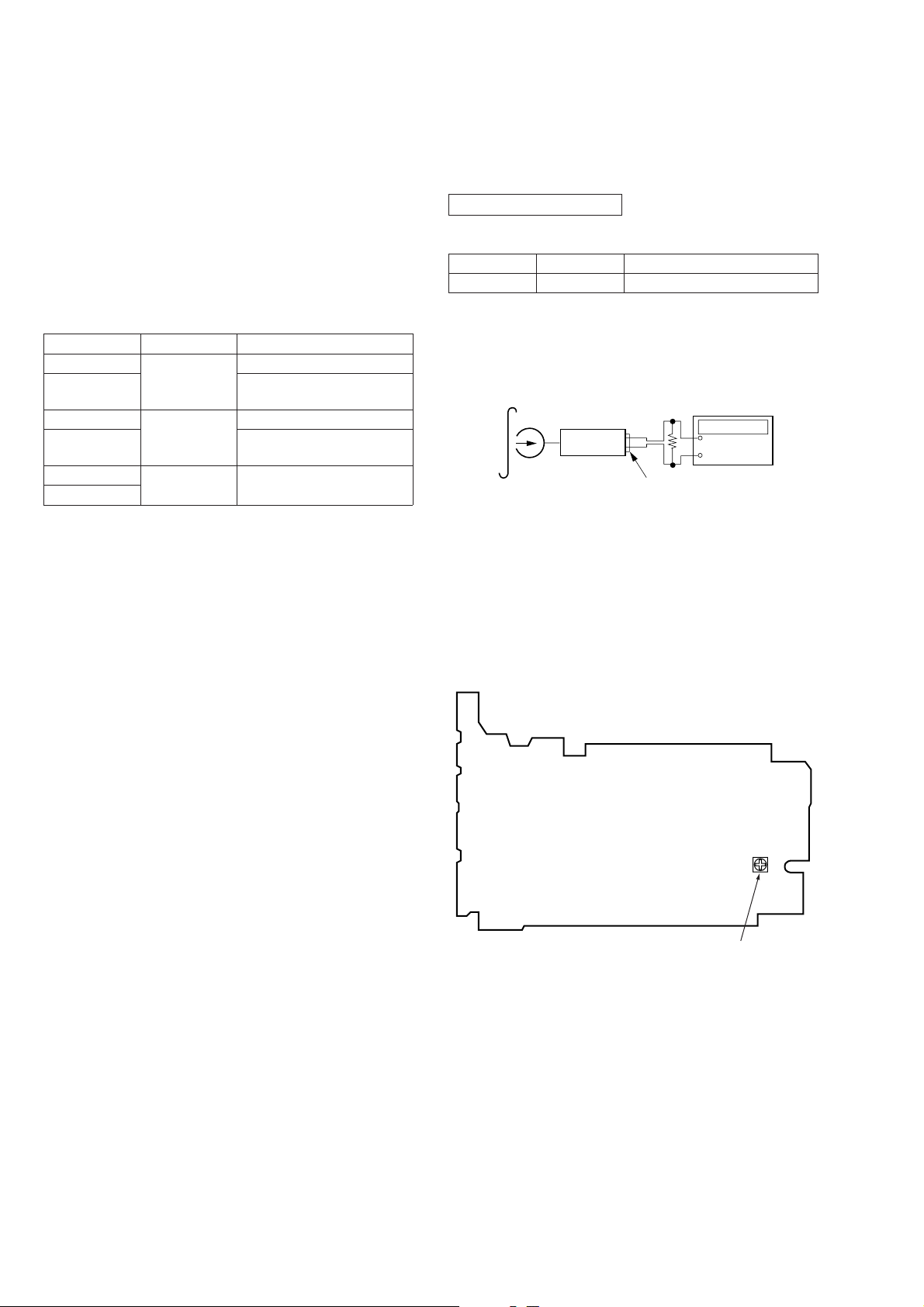

Adjustment Parts Location :

[MAIN BOARD] — SIDE A —

L4 : AM FREQUENCY COVERAGE Adjustment

L2 : FM TRACKING Adjustment

T1 : AM IF

L1 : AM TRACKING Adjustmen

L3 : FM FREQUENCY COVERAGE Adjustmen

[MAIN BOARD] — SIDE B —

CT1

(2/4)

CT1

(1/4)

CT1

(4/4)

CT1

(3/4)

[64.0 MHz]

— 7 — — 8 — — 9 —

• Signal path.

F : FM

f : AM

E : PB

WM-FX171/FX173/FX177

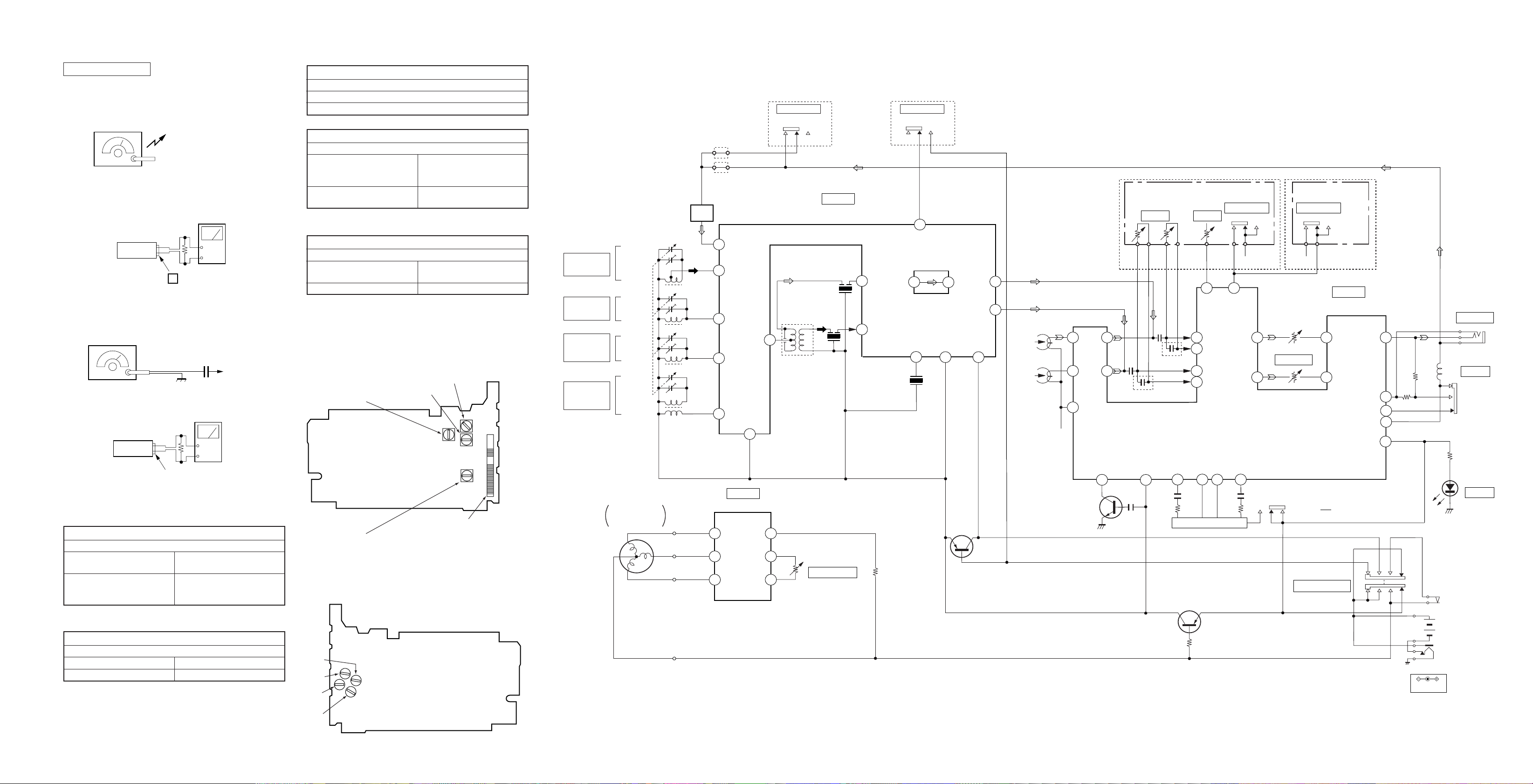

5-2. SCHEMATIC DIAGRAM

(FX171/FX177 MODELS)

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

¢

•

: internal component.

1

4

/

W or less unless otherwise

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Total current is measured with no cassette installed.

• Power voltage is dc 3V and fed with regulated dc power

supply from external power voltage jack.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : PB (TAPE)

( ) : AM

< > : FM

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

f : AM

E : PB

• Abbreviation

CND : Canadian model

IT : Italian model

EE : East European model

EA : Saudi Arabia model

FR : French model

PA : Panama model

C & SA: Central and South America models

101010

10

— 10 — — 11 — — 12 —

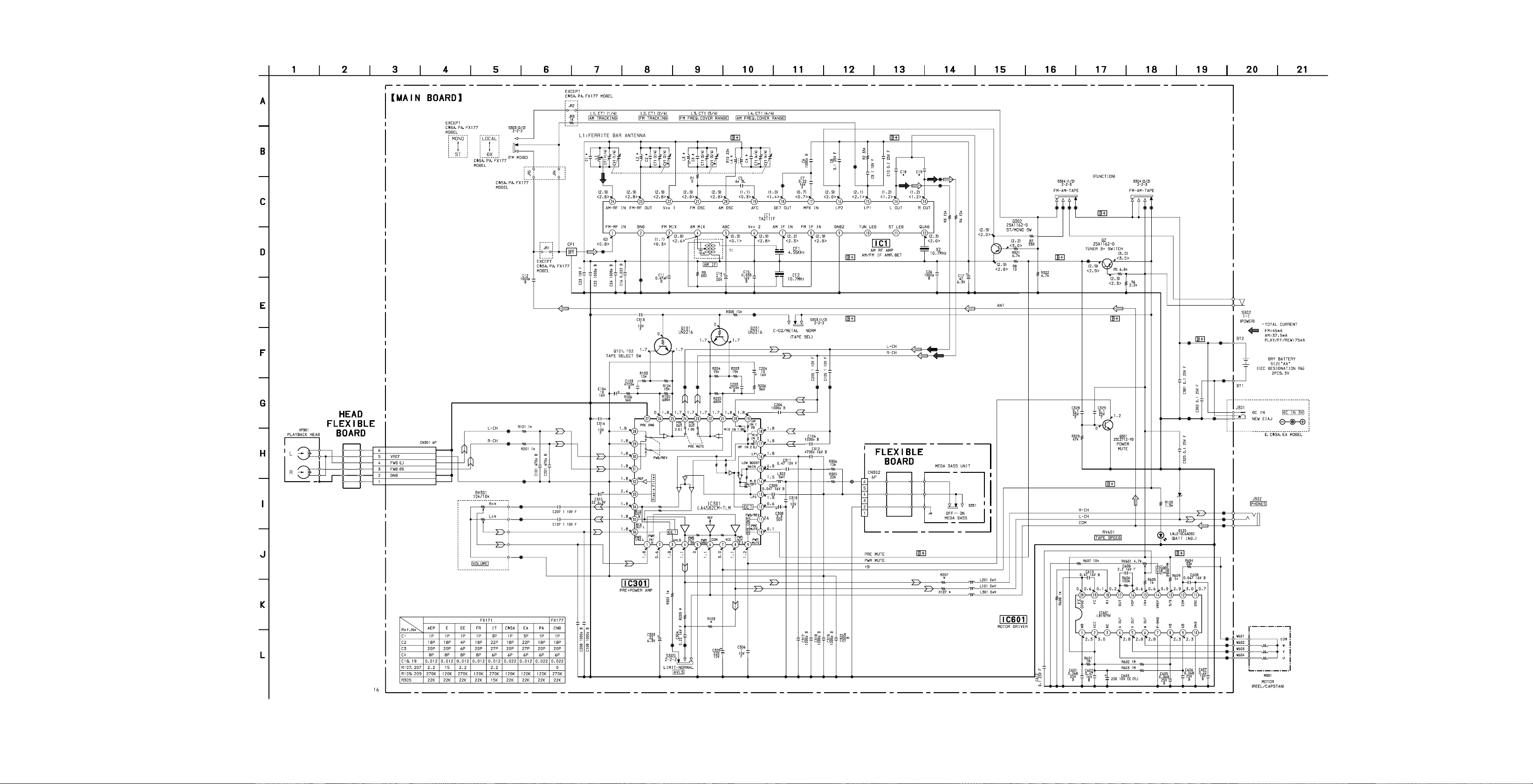

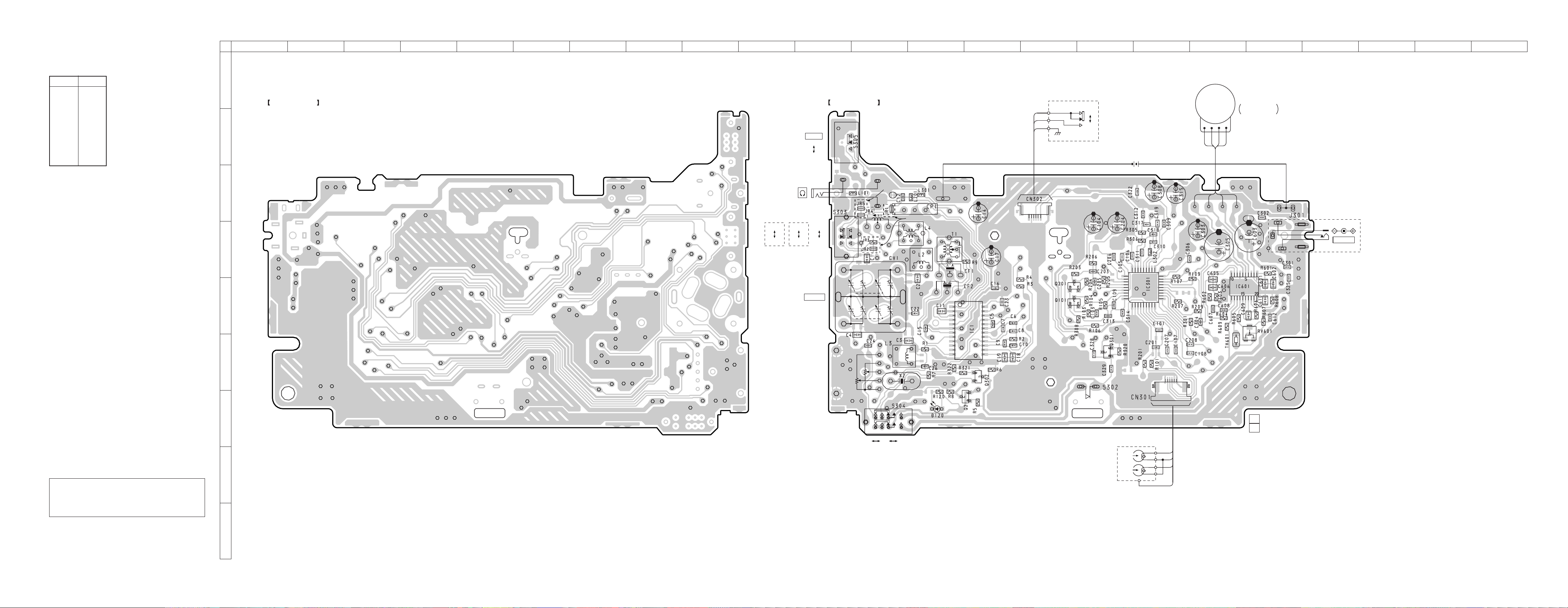

5-3. PRINTED WIRING BOARD

(FX171/FX177 MODELS)

• Semiconductor

Location

Ref. No. Location

D120 G-13

IC1 F-14

IC301 E-17

IC601 E-18

Q2 G-14

Q101 E-15

Q201 E-15

Q301 F-16

Q302 F-14

12

A

MAIN BOARD

B

(SIDE A)

WM-FX171/FX173/FX177

3 4 5 6 7 8 9 1011121314151617181920212223

S305

AVLS

NORM

LIMIT

MAIN BOARD

(SIDE B)

MEGA BASS UNIT

6

4

2

OFF

ON

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

2PCS, 3V

BLK

ORG

WHT

RED

M901

REEL/CAPSTAN

MOTOR

C

D

E

F

DX

LOCAL

C&SA,PA,

FX177

MODEL

J302

FM ST

MONO

EXCEPT

C&SA,PA,

FX177

MODEL

NORM

CrO

METAL

TUNING

2

/

1/4

4/4

RV301

(VOLUME)

C&SA,PA

FX177 MODEL

WHT

L1

L

R

EXCEPT C&SA,PA,FX177

2/4

3/4

MODEL

1

5

10

24

20

15

1312

16

(POWER)

10181915

25

27

30

28 36

9

5

1

16

ORG

BLK

RED

J301

DC IN 3V

E,C&SA,EA,PA

MODEL

Note:

• X : parts extracted from the component side.

®

•

: Through hole.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component A) the parts face are indicated.

• Abbreviation

CND : Canadian

IT : Italian

EE : East European

EA : Saudi Arabia

FR : French

PA : Panama

C & SA: Central and South America

G

16

FM AM

TAPE

(RADIO OFF)

(BATT)

H

I

— 13 — — 15 —

— 14 —

HP901

(PLAYBACK HEAD)

L

R

1-667-714-

4

5

3

2

11

(11)

— 16 —

Loading...

Loading...