Sony WMEX-372 Service manual

WM-EX372

SERVICE MANUAL

Ver 1.2 1999. 03

With SUPPLEMENT 1

(9-923-319-81)

With SUPPLEMENT 2

(9-923-319-82)

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

AEP Model

E Model

TC-K6/K7

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MT-WMEX372-114

MICROFILM

CASSETTE PLAYER

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY ......................................................... 4

3. MECHANICAL ADJUSTMENTS....................... 8

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

4. ELECTRICAL ADJUSTMENTS......................... 8

5. DIAGRAMS

5-1. Block Diagram ................................................................ 9

5-2. Printed Wiring Board ...................................................... 11

5-3. Schematic Diagram ......................................................... 13

6. EXPLODED VIEWS ................................................ 16

7. ELECTRICAL PARTS LIST ............................... 19

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

– 2 –

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

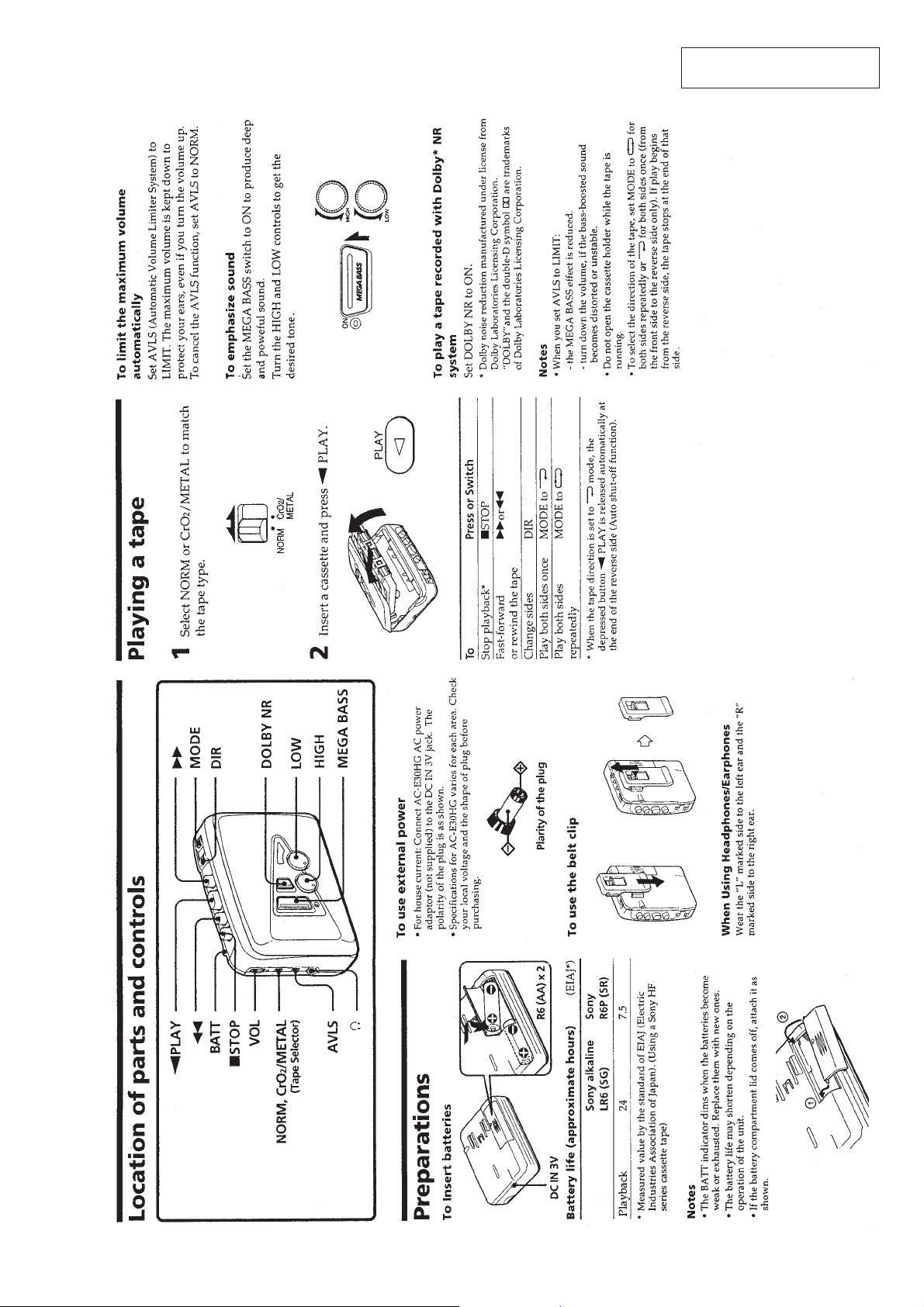

• This set can be disassembled in the order shown below.

R

y

SECTION 2

DISASSEMBLY

SET

Note: Follow the disassembly procedure in the numerical order given.

CABINET (REAR) ASS’Y MECHANISM DECK

MAIN BOARD

(MT-WMEX372-114)

CASSETTE HOLDER ASS’Y

MEGA BASS UNIT (DOLBY)

CABINET (REAR) ASS’Y

2

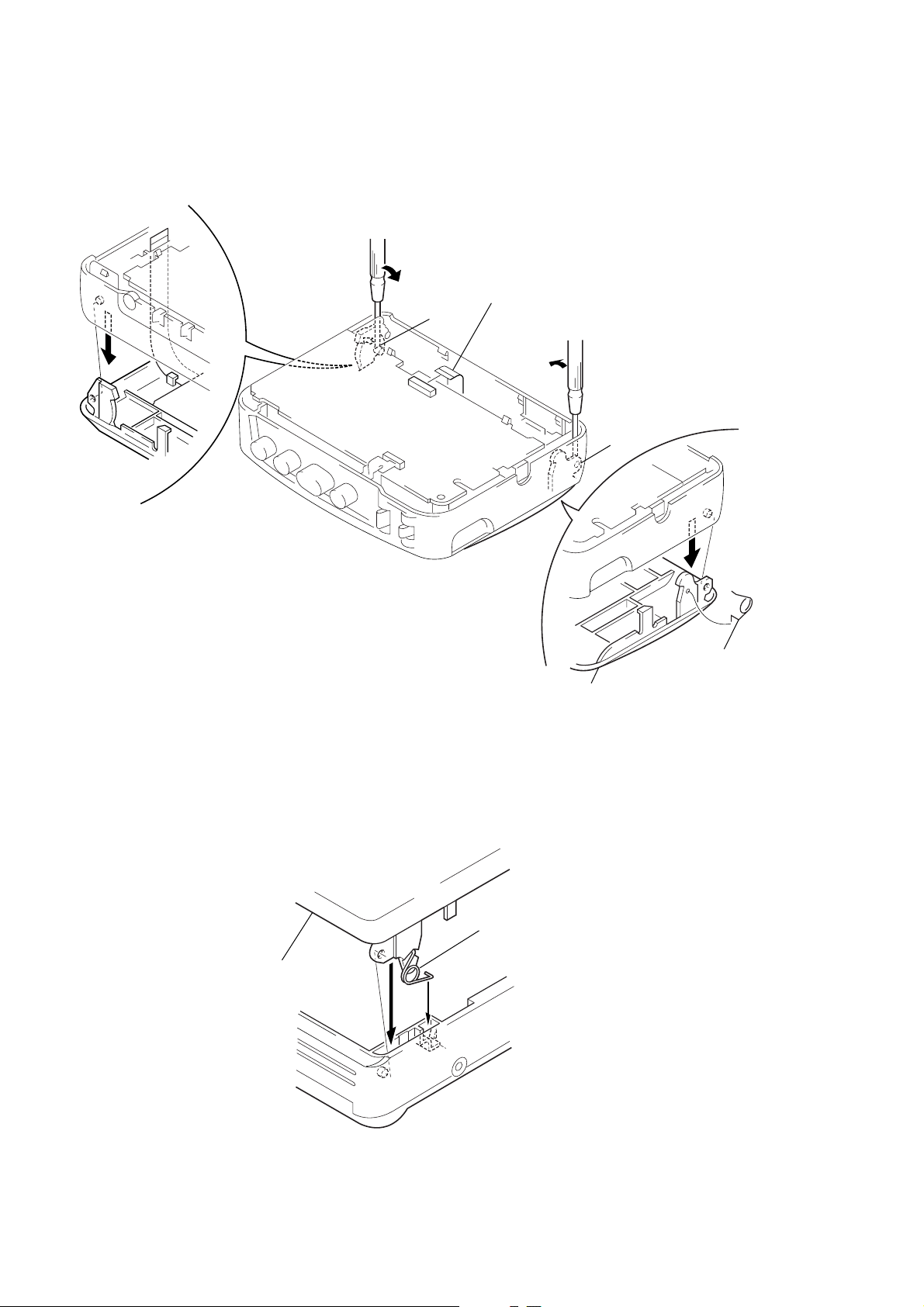

Insert the precision screw driver (1.4 mm flat-blade) in to the slit at claw A and release the claw.

3

Remove the cabinet (rear) ass’y. (Release all claw B to N in alphabetical order.)

1

screw (B1.7 × 9)

N

M

L

K

BELT

MAGNETIC HEAD

(HP901)

B

MOTO

(M901)

1

screw (B1.7 × 9)

C

D

cassette holder

E

J

I

F

H

G

A

– 4 –

cabinet (rear) ass’

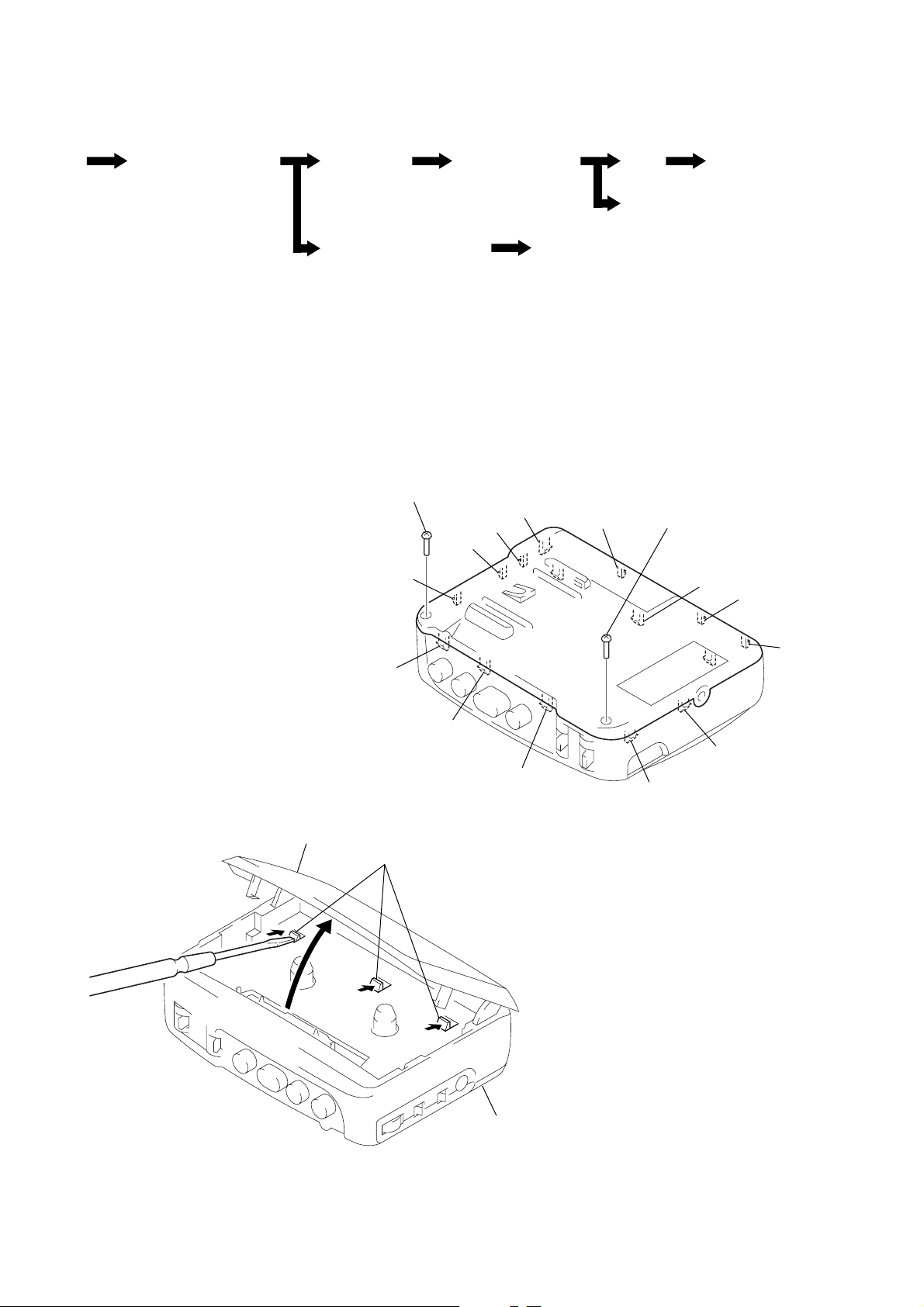

MAIN BOARD, MECHANISM DECK (MT-WMEX372-114)

w

s

6

main board

3

head flexible board

(CN301)

8

Remove the mechanism

deck (MT-WMEX372-114)

to direction of the arrow.

7

claw

2

flexible board (CN302)

4

toothed lock (WH) scre

(M1.4)

1

Remove four solders of

motor lead (M901).

5

two claws

BELT, MOTOR (M901), MAGNETIC HEAD (HP901)

1

belt

7

claw

5

magnetic head

(HP901)

4

two screws

– 5 –

3

motor (M901)

2

two special head screw

(M1.4)

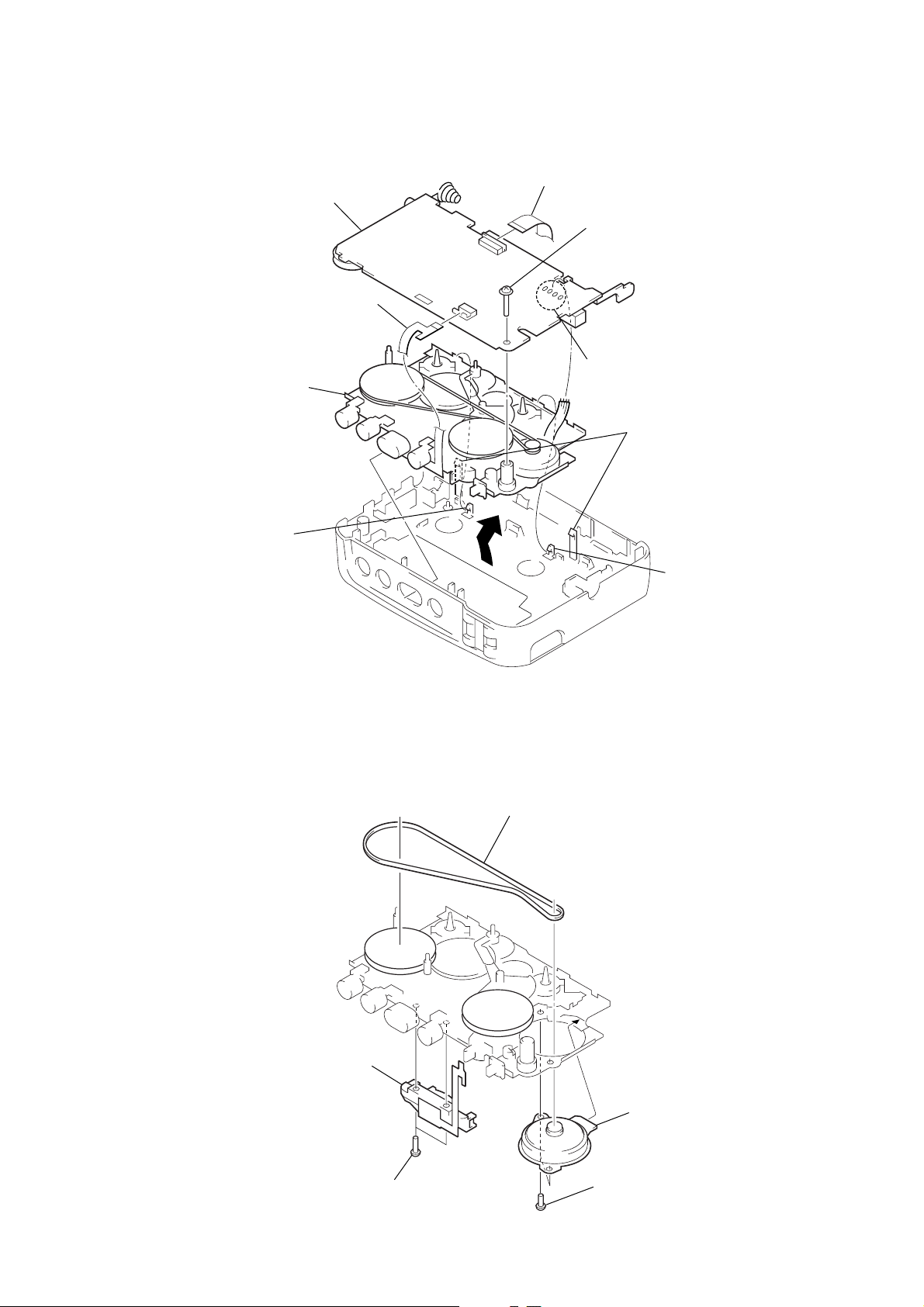

CASSETTE HOLDER ASS’Y

2

Insert a precision screwdriver (1.4 mm flat-blade)

vertically in to portion A to release the hinge plate.

1

flexible board

(CN302)

A

3

portion B to release

the hinge plate.

B

NOTE FOR INSTALLATION

Note: Follow the assembly procedure in the numerical order given.

• SPRING (TORSION)

3

cassette holder ass’y

A

4

cassette holder ass’y

1

Attach the spring (torsion) as

shown in the figure.

2

Insert the spring (torsion) in the

ditch to direction of the arrow

5

spring (torsion)

A

.

– 6 –

Loading...

Loading...