Sony WMEX-2000 Service manual

WM-EX2000

SERVICE MANUAL

Ver 1.2 2003. 11

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks

of Dolby Laboratories Licensing Corporation.

SPECIFICATIONS

US Model

AEP Model

Chinese Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

Tape T ransport Mechanism T ype MT -WMEX2000-162

Frequency response

(Dolby NR off) Playback: 30 – 18,000 Hz

Output Headphones (i jack)

Load impedance 8 – 300 Ω

Power requirements 1.2 V

One rechargeable battery

Dimensions (w/h/d) Approx. 76.3 × 108.4 × 17.5 mm

(31/8 × 43/8 × 23/32 inches)

Mass Approx. 145 g (5.2 oz.)

Supplied accessories Stereo headphones or earphones with

remote control (1)

Battery charging stand (1)

AC power adaptor (1)

Rechargeable battery (NH-14WM (A),

1.2V, 1 350 mAh (MIN), Ni-MH) (1)

Rechargeable battery carrying case (1)

Carrying pouch (1)

Design and specifications are subject to change without notice

9-873-022-13

2003K16-1

© 2003.11

CASSETTE PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

TABLE OF CONTENTS

1. GENERAL ·········································································· 2

2. SERVICE NOTE ······························································· 3

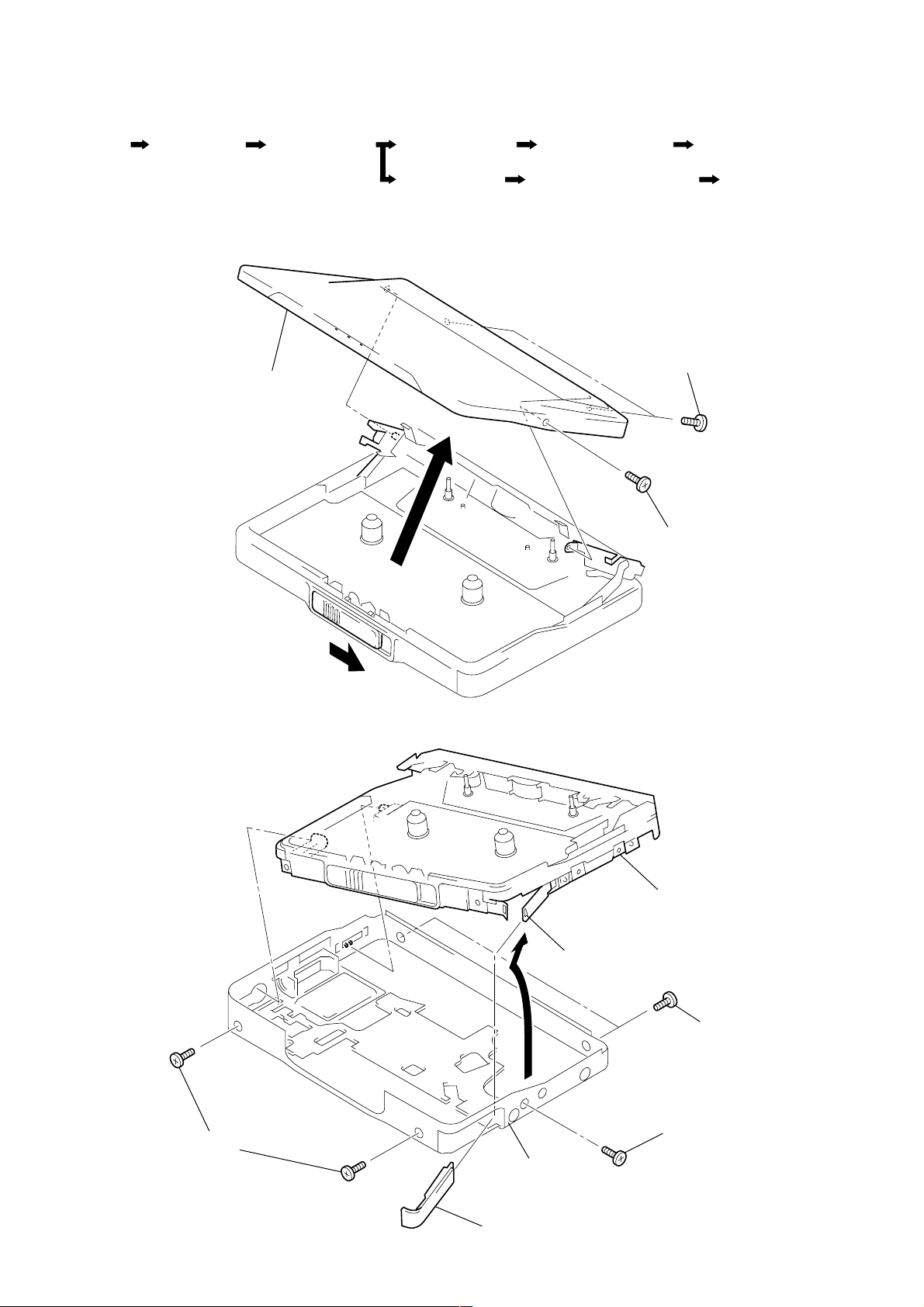

3. DISASSEMBLY

3-1. Lid Block Assy, Cassette ················································ 5

3-2. Case Block Assy ····························································· 5

3-3. Ornament (Open) Block Assy·········································6

3-4. “Switch, Leaf (S704)”, Main Board ······························· 6

3-5. Belt (F0), Motor (M601)·················································7

3-6. Holder (FA) Assy ···························································· 7

3-7. Pinch Lever (NF)/(RF) Assy ··········································· 8

3-8. Head, Magnetic (HP701) ················································8

4. MECHANICAL ADJUSTMENT ·································· 9

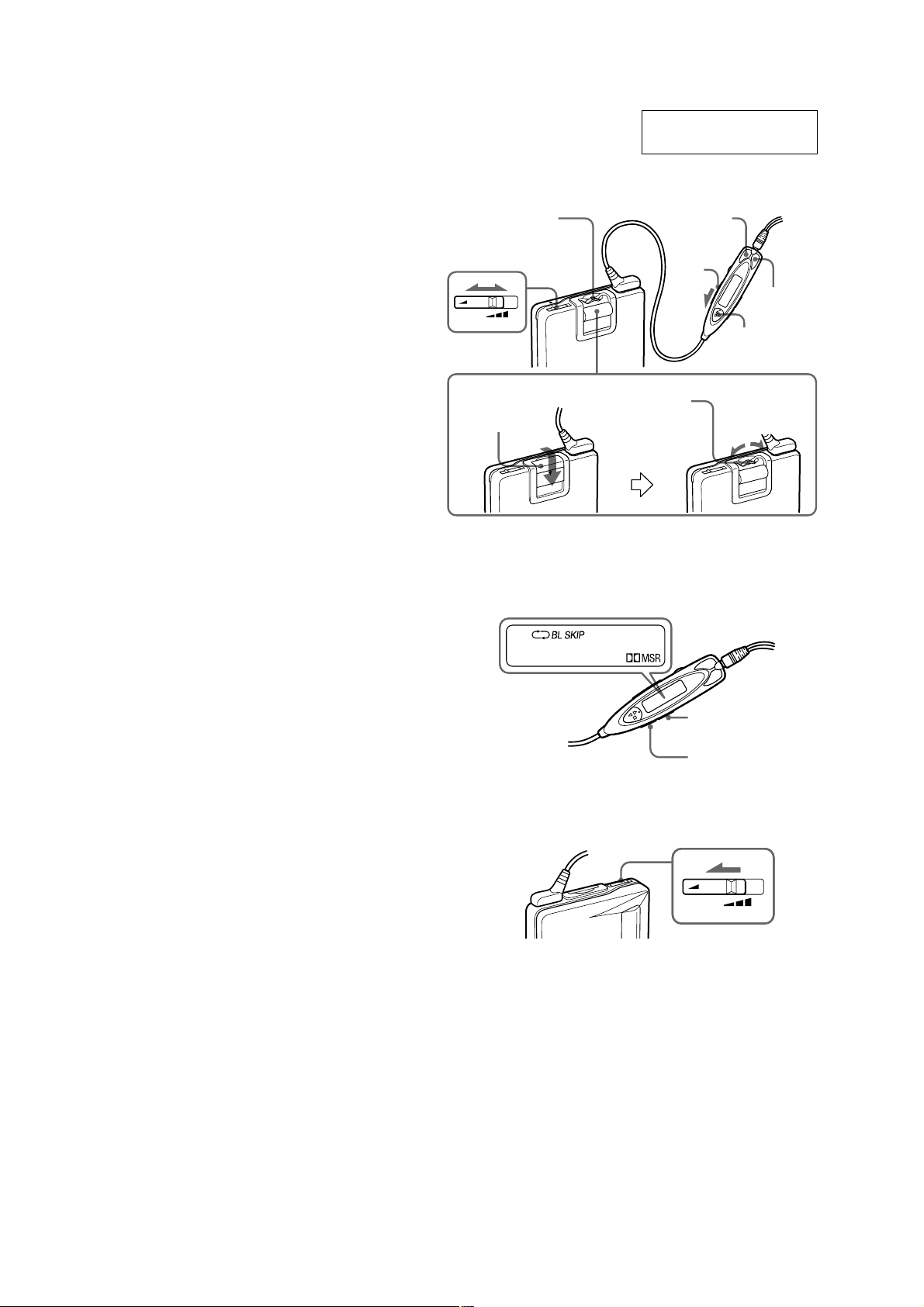

VOL

AVLS

Jog lever

Levier Jog

Jog-Hebel

SECTION 1

GENERAL

This section is extracted

from instruction manual.

Plug in firmly.

Branchez fermement.

Fest einstecken.

FF (+)

HOLD

REW (–)

Y•x

5. ELECTRICAL ADJUSTMENT ···································· 9

6. DIAGRAMS

6-1. Block Diagram ······························································ 10

6-2. Printed Wiring Board···················································· 12

6-3. Schematic Diagram (1/2) ·············································· 15

6-4. Schematic Diagram (2/2) ·············································· 18

6-5. IC Block Diagrams ······················································· 21

6-6. IC Pin Function Description ·········································23

7. EXPLODED VIEWS

7-1. Cabinet Block ······························································· 24

7-2. Mechanism Deck Block ················································ 25

8. ELECTRICAL PARTS LIST ·······································26

Hold shutter

Cache de

verrouillage

Schutzschieber

Jog lever

Levier Jog

Jog-Hebel

N

E

P

O

SOUND

MODE

REW

FF

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

VOL

AVLS

— 2 —

SECTION 2

SERVICE NOTE

[Service Mode]

The service mode enables to operate the mechanism of WM-EX2000

while the MAIN board is opened.

Rotation of the idler gear (A) (S side) is detected using the photoreflector (PH702) in the WM-EX2000. PH702 is located on the

MAIN board, therefore the rotation of the idler gear (A) (S side)

cannot be detected by PH702 when the MAIN board is removed.

As a result, the motor cannot be controlled and cannot run correctly .

To repair the machine after the MAIN board is removed while the

main power is turned on, follow the procedures as described below.

1. Setting

1) Remove the cabinets referring to section “3. DISASSEMBL Y”.

Open the MAIN board.

2) Connect the motor (M601) and the plunger solenoid (PM701)

to the MAIN board using the jumper wires. When the extension

jig (1-769-143-11) (10 wires as a set) is used, they can be

connected easily.

3) Short the T APE IN switch land (BP1) with solder . Input a square

(or sine) wave of 10 Hz (at 1.3 Vp-p) to both PH IN T land

(TP31) and PH IN S land (TP32) with jumper wire.

4) Connect DC 1.3 V from e xternal regulated power supply to 3

and # terminals of the battery.

2. PRE-SET status

The set must be in this state before the PLAY, FF and REW modes

can be entered.

1) Make sure that the slider (F/R) is in the center position and that

the F/R switch (S702) is in the center position. Make sure that

the reel gear does not rotate by rotating the flywheel on the F

side clockwise. If improper, place the set in the preset state

according to the following instructions:

2) Repeat the step below some times to ensure the above

conditions.

* Pull away the trigger level from the plunger with tweezers or

other means. Then rotate the flywheel on the F side clockwise.

3) Turn the stabilized power supply OFF once and then ON.

3. FF, REW modes

1) Check for “2. Preset state” and push the FF switch and the

REW switch.

2) Move the F/R switch (S702) to the movement of the slider to

enter the FF/REW mode.

4. PLAY mode

1) Check for “2. Preset state”.

2) Push the nN switch on the remote commander to move the

lever (SW) toward the R side . With timing to this, move the F/

R switch (S702) to enter the PLAY (R side) mode.

Note 1: If failed, retry from the preset state.

Note 2: The nN, x, FF, and REW switches on the remote

commander should be used whenever possible.

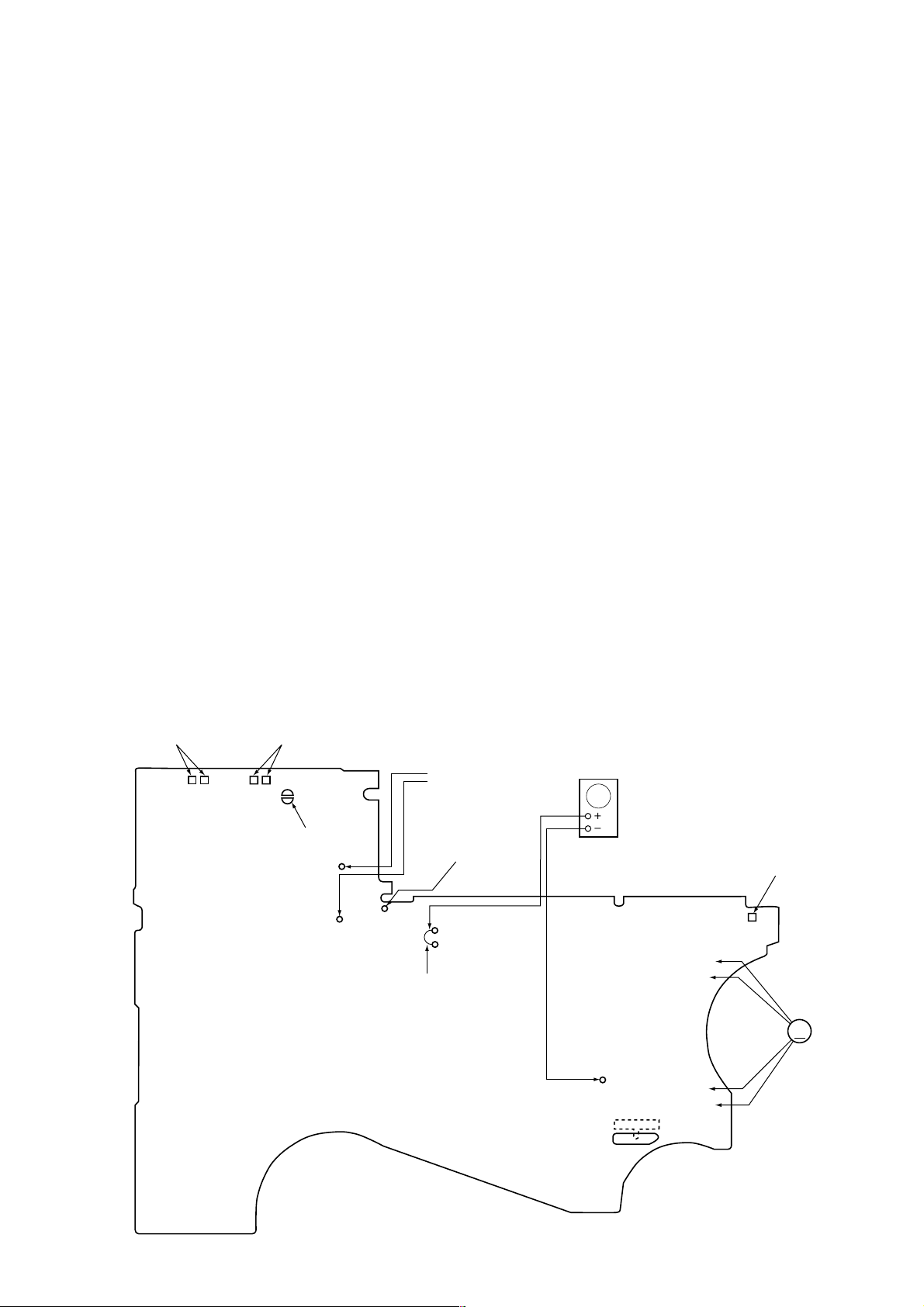

– MAIN BOARD (SIDE B) —

TAPE IN

SWITCH

(S704-1)

SWITCH

(S704-2)

ATS

BP1

Plunger (PM701)

Battery terminal #

S PH IN(S)(TP32)

T PH IN(S)(TP31)

jumper

AF OSC

Square wave

(sine wave)

10 Hz, -3.5 dBs

GND (TP10)

(S702)

FWD←CNT→REV

Battery terminal 3

M

M601

— 3 —

[ Slider (NR) ]

y

y

F side

flywheel

F side center R side

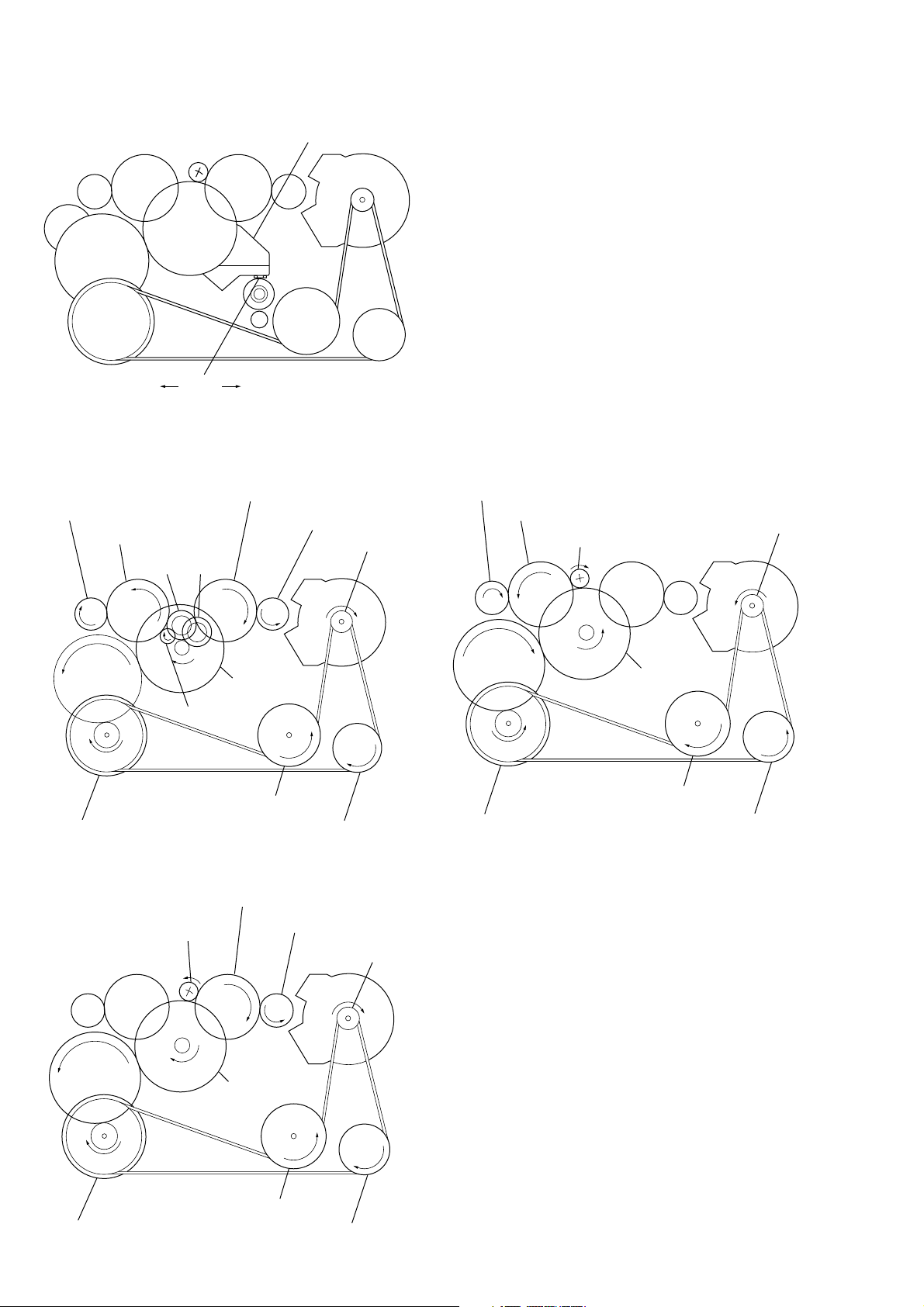

[ Rotational system ]

1. Rotational System of PLAY Mode

idler gear (A) (S side)

gear (reel) (T side)

idler gear (A) (T side)

gear (NR)

FWD

REV

gear (reel) (S side)

slider (NR)

motor pulle

2. Rotational System of FF Mode

gear (reel) (T side)

idler gear (A) (T side)

motor pulley

gear (FR)

gear (Y)

idler gear (B)

flywheel (N) assy

clutch

assy (F)

flywheel (R) assy

3. Rotational System of REW Mode

idler gear (A) (S side)

gear (FR)

gear (Y)

gear (reel) (S side)

clutch

assy (F)

reverse pulley

motor pulle

gear (Y)

flywheel (N) assy

clutch

assy (F)

flywheel (R) assy

reverse pulley

flywheel (N) assy

flywheel (R) assy

reverse pulley

— 4 —

SECTION 3

DISASSEMBLY

• The equipment can be removed using the following procedure.

Lid Block Assy,

Cassette

Note : Follow the disassembly procedure in the numerical order given.

Case Block Assy

3-1. LID BLOCK ASSY, CASSETTE

Lid block assy, cassette

Ornament (OPEN)

Block Assy

Holder (FA) Assy Pinch Lever (NF)/(RF) Assy Head, Magnetic (HP701)

"Switch, Leaf (S704)"

Main Board

Belt (F0), Motor (M601)Set

1 Two screws (1.4)

3-2. CASE BLOCK ASSY

3

4

5

2 Screw (1.4)

Mechanism deck block

Claw

2 Two screws (1.4)

3 Two screws (1.4)

4 Screw (1.4)

Case block assy

1 Lid, battery case

— 5 —

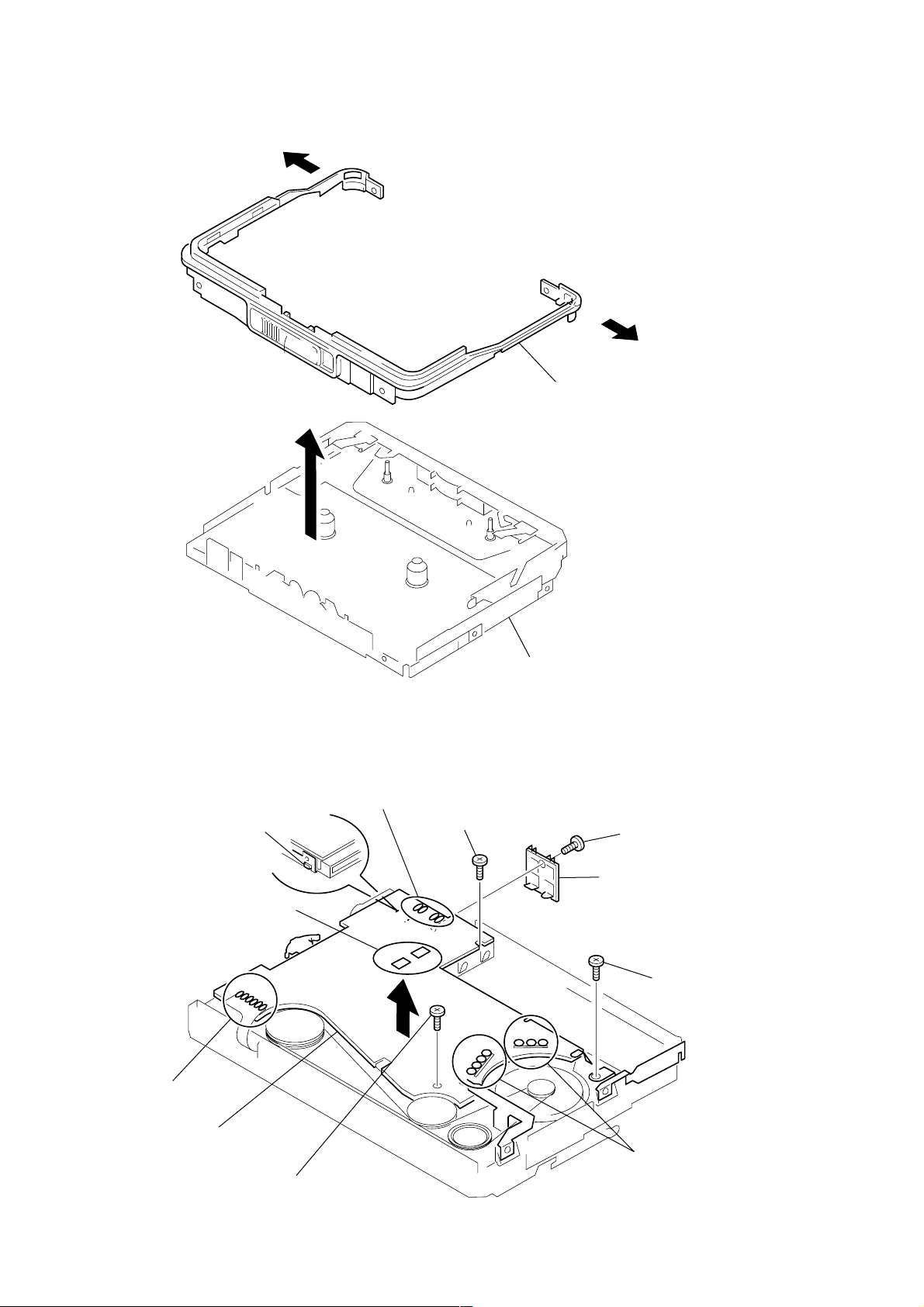

3-3. ORNAMENT (OPEN) BLOCK ASSY

y

1

2

1

Ornament (open) block ass

3-4. “SWITCH, LEAF (S704)”, MAIN BOARD

4 Unsolder the 4 places.

0 Claw

7 Unsolder the

plunger.

8 Unsolder the

flexible board.

Mechanism deck block

1 Screw

5 Screw (M1.4)

6 Switch leaf (S704)

3 Screw

qa MAIN board

9 Unsolder the motor.

2 Screw (M1.4)

— 6 —

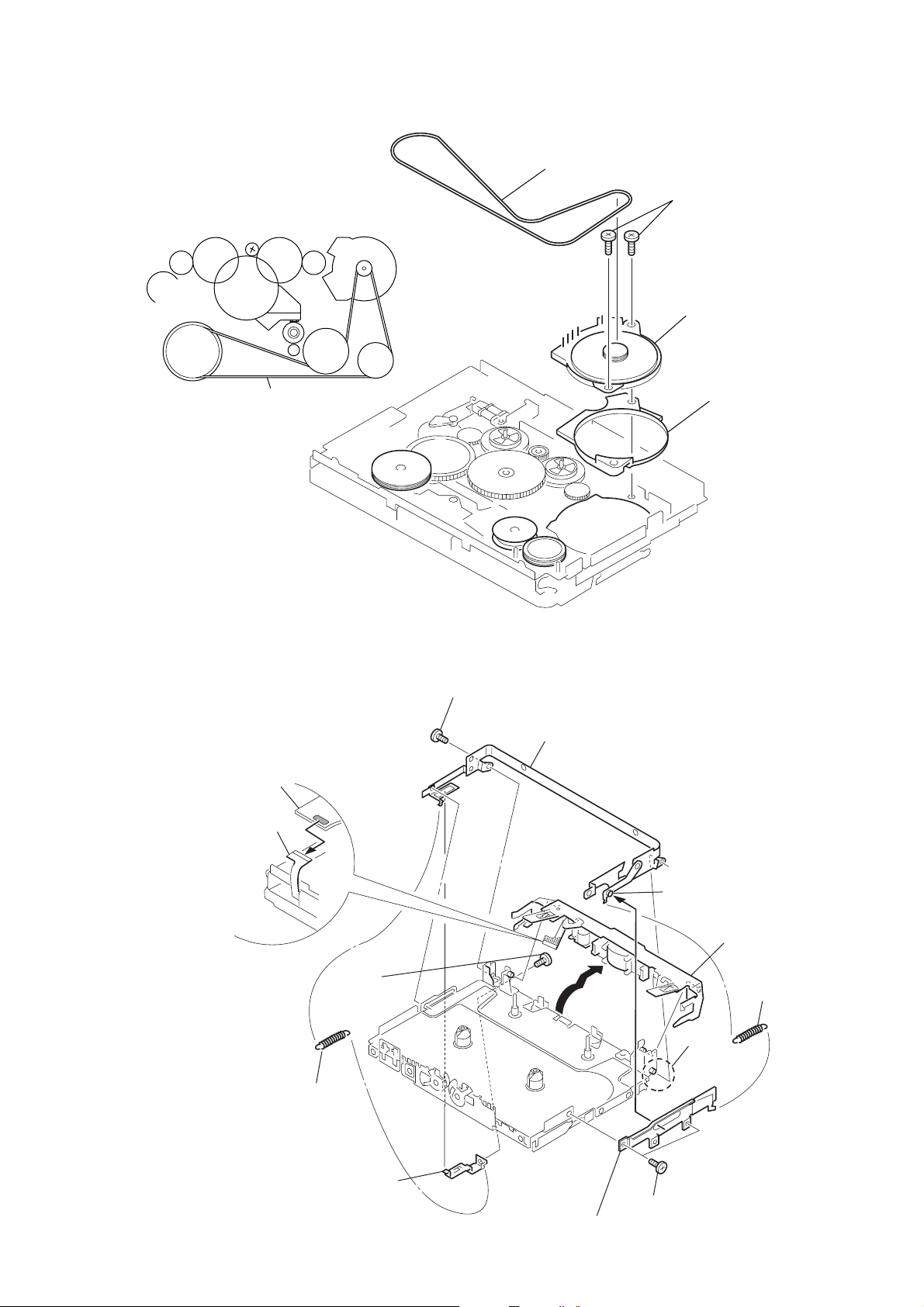

r

3-5. BELT (F0), MOTOR (M601)

)

Ver 1.2 2003. 11

1 Belt (F0)

2 Two screws (M1.4)

4 Motor (M601)

Belt (F0)

3-6. HOLDER (FA) ASSY

qa Remove soldering

from Head flexible board.

qs Head flexible

board

3 Retainer (F1), moto

8 Screw (M1.4)

0 Bracket (CASSETTE) assy

2 Screw

(M1.4)

1 Spring, tension

3 Hook, spring

6 Shaft

qd Remove the holder (FA

assy in the direction

of the arrow.

4 Spring, tension

9 Shaft

5 Two screws (M1.4)

7 Lever (B) assy, lock

— 7 —

Loading...

Loading...