Sony Walkman WM-EX170, Walkman WM-EX172 Service Manual

WM-EX170/EX172

Canadian Model

WM-EX170

AEP Model

E Model

WM-EX170/172

SERVICE MANUAL

CASSETTE PLAYER

MICROFILM

SPECIFICATIONS

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism Type MT-WMEX170-1 14

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

• Power requirements

3V DC batteries R6 (AA) × 2 / External DC 3V power sources

• Dimensions

88.5 × 111.5 × 37.6 mm

(3

1

/2 × 4 1/2 × 1 1/2 inches) (w / h/ d) incl. projecting parts and controls

• Mass

EX170 : Approx. 125 g (4.5 oz) / Approx. 185 g (6.6 oz) incl.

batteries and a cassette

EX172 : Approx. 130 g (4.6 oz) / Approx. 190g (6.8 oz) incl.

batteries and a cassette

• Supplied accessories

Stereo headphones or Stereo earphones (1) / Belt clip (1)

Design and specifications are subject to change without notice.

Photo : WM-EX172

— 2 —

TABLE OF CONTENTS

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron aroud 270˚ C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SECTION 1

GENERAL

1. GENERAL ······································································2

2. DISASSEMBLY

2-1. Cabinet (Front) Assy ··························································3

2-2. Main Board ········································································· 4

2-3. Cassette Lid ········································································4

2-4. Mechanism Deck ································································ 5

2-5. Belt, Motor (Reel/Capstan) ················································5

3. MECHANICAL ADJUSTMENT ······························ 6

4. ELECTRICAL ADJUSTMENT ································6

5. DIAGRAMS

5-1. Block Diagram ···································································7

5-2. Printed Wiring Board (EX170 Model) ······························· 9

5-3. Schematic Diagram (EX170 Model) ································ 11

5-4. Printed Wiring Board (EX172 Model) ····························· 13

5-5. Schematic Diagram (EX172 Model) ································ 15

5-6. IC Block Diagrams ··························································· 17

6. EXPLODED VIEWS

6-1. Cabinet Section································································· 18

6-2. Main Board Section ·························································· 19

6-3. Mechanism Section-1 (MT-WMEX170-114) ··················20

6-4. Mechanism Section-2 (MT-WMEX170-114) ··················21

7. ELECTRICAL PARTS LIST ···································22

This section is extracted

from instruction manual.

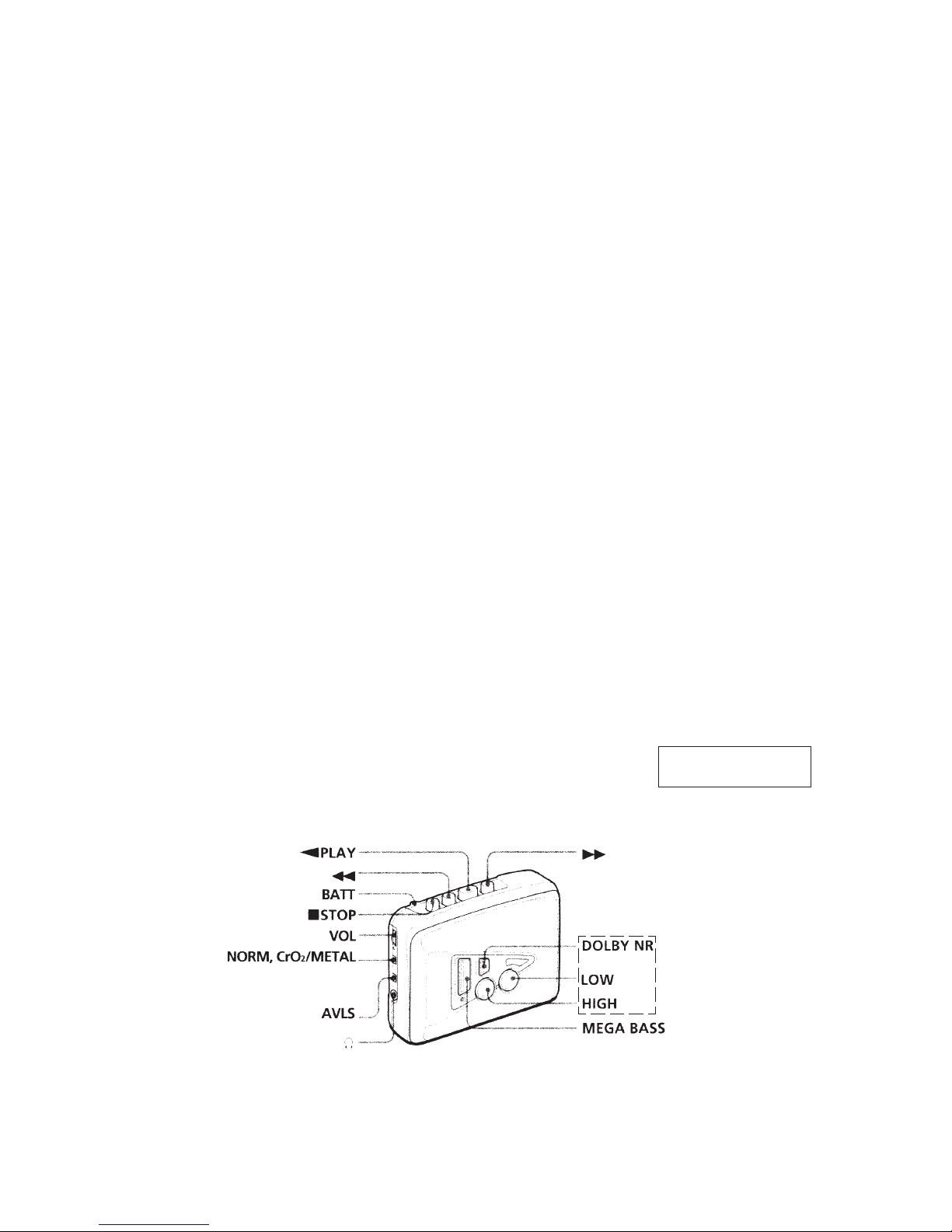

EX172 MODEL

— 3 —

Cassette, lid

Cabinet (front) assy

A

1

T wo screws

[Screw (B1.7

×

9), tapping]

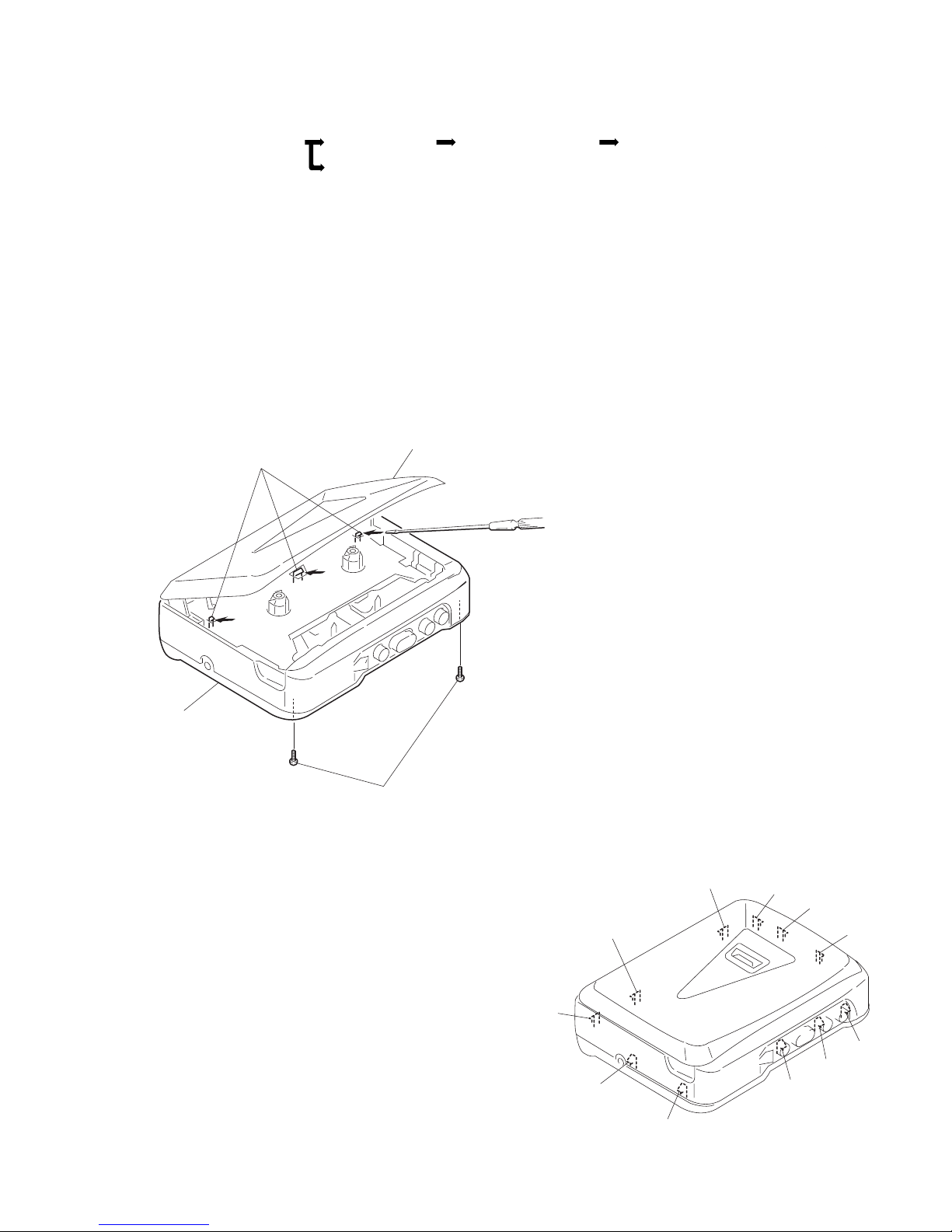

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (FRONT) ASSY

2

Insert the precision screwdriver

(1.4 mm flat-blade) into the slit

at claw

A

and release the claw.

3

Remove the cabinet (front) assy.

(Release all claws

B

to L in

alphabetical order.)

• This set can be disassembled in the order shown below.

2-1. CABINET (FRONT) ASSY 2-2. MAIN BOARD

2-3. CASSETTE LID

2-4. MECHANISM DECK 2-5. BELT, MOTOR (REEL/CAPSTA

N)

B

L

K

C

D

E

F

G

H

I

J

— 4 —

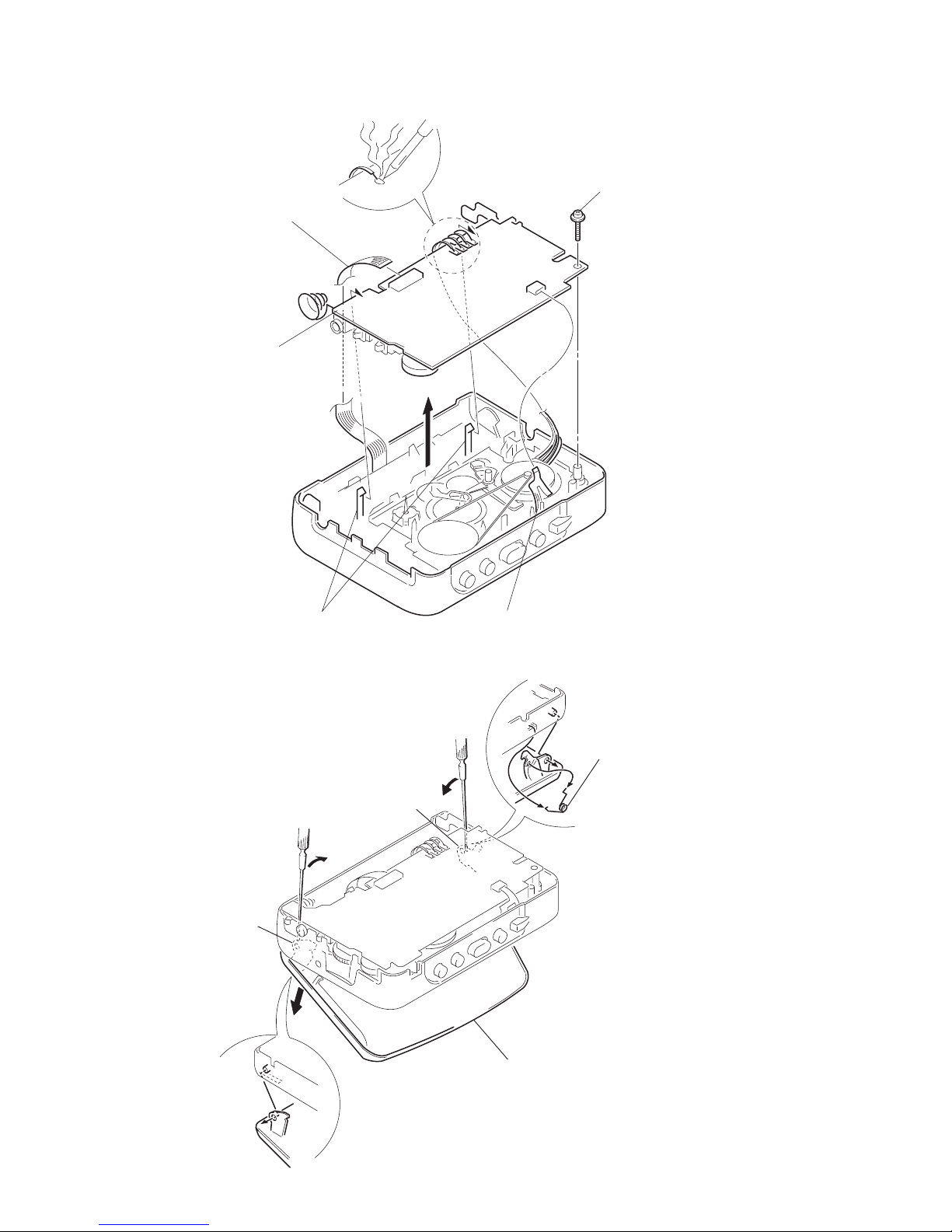

5

Spring (torsion)

B

A

1

Open the cassette lid.

4

Cassette lid.

2-2. MAIN BOARD

2-3. CASSETTE LID

2

Insert a precision screwdriver

(1.4 mm flat-blade) vertically

into portion

A

to release the

hinge plate.

3

Portion B to release the

hinge plate.

1

Head flexible board (CN301)

5

Two claws

6

MAIN board

3

Remove the four solders.

4

Screw (M1.4), toothed lock (WH

)

2

Flexible board (CN302)

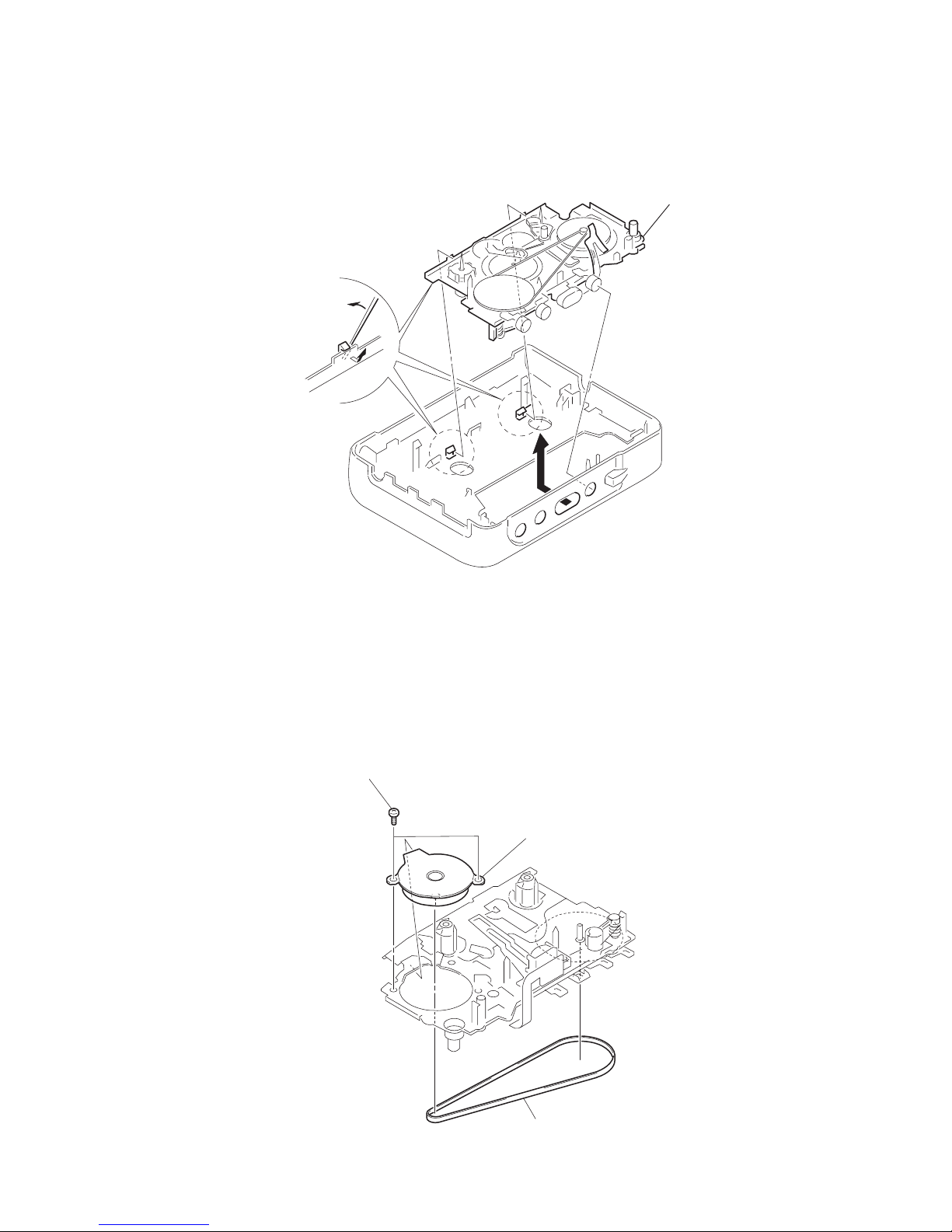

— 5 —

2

Two screw [screw (M1.4), special head]

3

Motor (reel/capstan

)

1

Belt

2-4. MECHANISM DECK

2-5. BELT, MOTOR (REEL/CAPSTAN)

1

Insert the precision screwdriver

(1.4 mm flat-blabe) in to the slit

and release two claws.

2

Remove the mechanism deck

in the direction of the arrow.

— 6 —

SECTION 3

MECHANICAL ADJUSTMENT

SECTION 4

ELECTRICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alcahol-moistened

sweb :

Playback head Pinch roller

Rubber belt Capstan

2. Demagnetize the playback head using a demagnetizer.

3. Do not use a magnetized screwdriver for adjustments.

4. After adjusting, apply screw-locking compound onto the

adjusted parts.

5. Unless specified otherwise, use a specified voltage (3.0V) to

perform the adjustments.

Torqu Measurement

Mode

FWD

FWD

Back Tension

REV

REV

Back Tension

FF

REW

Torqu meter

CQ-102C

CQ-102RC

CQ-201B

Meter reading

20 - 30 g · cm

0.4 - 2.0 g · cm

20 - 30 g · cm

0.4 - 2.0 g · cm

More than 40 g · cm

PRECAUTION

1. Specified voltage : 3.0V

2. Switch position

DOLBY NR switch : OFF (EX172 MODEL)

AVLS switch : NORM

CASSETTE SECTION

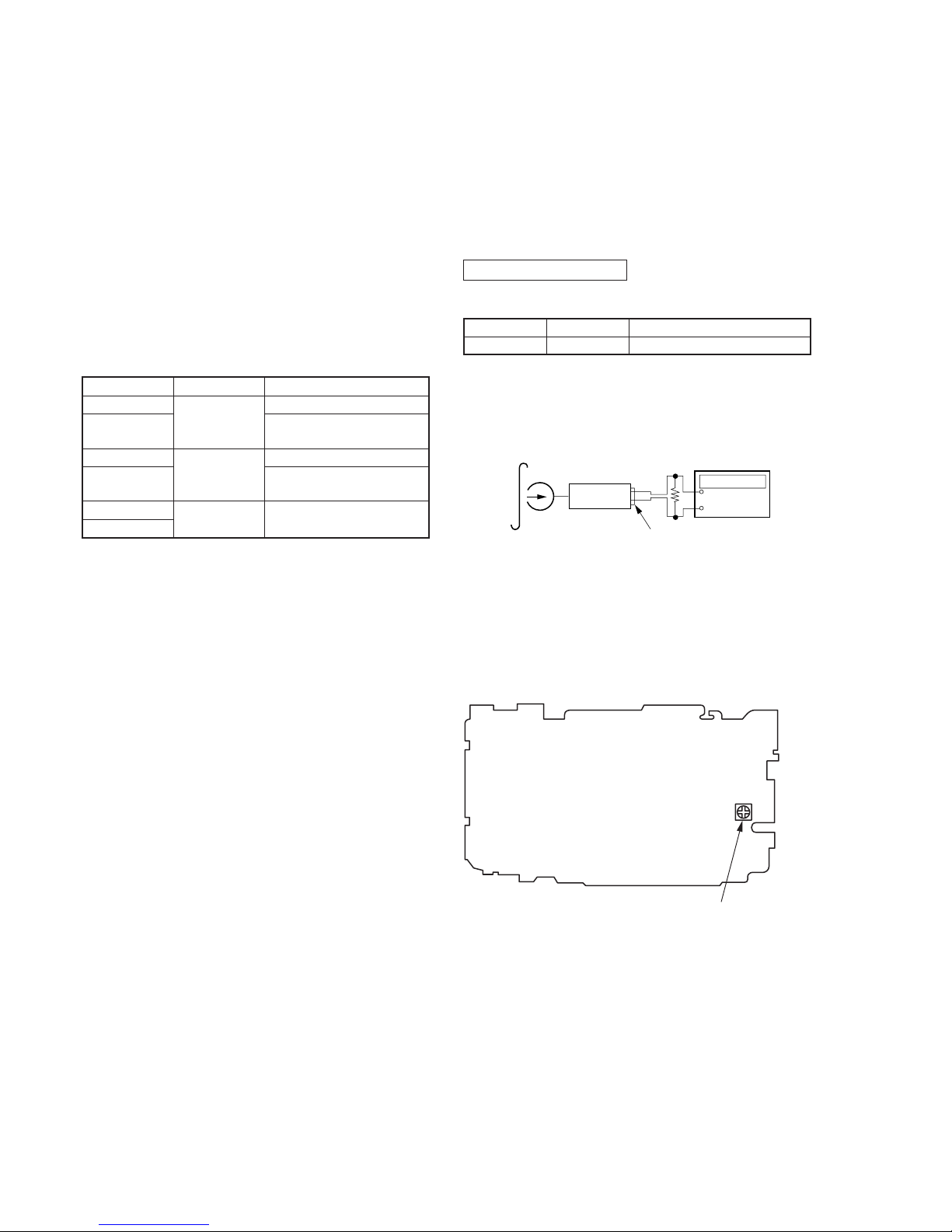

T est Tape

T ape Speed Adjustmnet

Procedure :

1. Playback WS-48A (Tape center part) and adjust RV601 so that

the frequency counter reading becomes 3,000Hz ± 15Hz.

2. Playback WS-48A (Tape top and end).

Check that frequency counter reading is within 1.5% of the

reading of step1.

Adjustment Point :

[MAIN BOARD] —CONDUCTOR SIDE —

Type

WS-48A

Signal

3kHz, 0dB

Purpose

Tape Speed Adjustment

Test tape

WS-48A

(3kHz, 0dB)

Set

16

Ω

PHONES jack

+

–

Frequency counte

r

RV601: Tape speed

Loading...

Loading...