Sony Walkman WM-DD 3 Service Manual

SERVICE

MANUAL

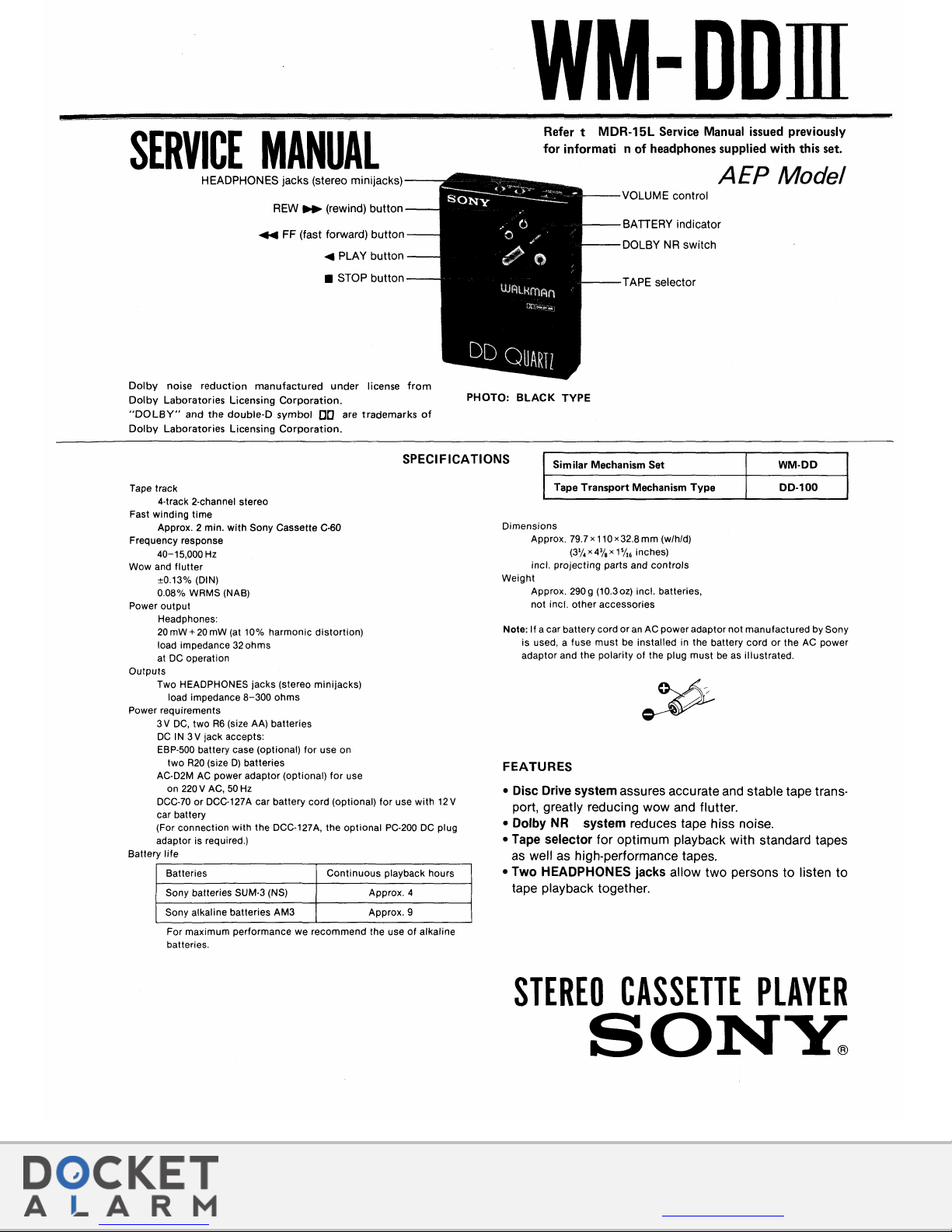

HEADPHONES jacks (stereo minijacks)

REW

11+

(rewind) button

~

FF (fast forward) button

~

PLAY button

• STOP button

Dolby

noise

reduction

manufactured

under

license

from

Dolby

Laboratories

Licensing

Corporation.

"DOLBY"

and

the

double-D

symbol

DO

are

trademarks

of

Dolby

Laboratories

Licensing

Corporation.

WM-DDill

Refer t MDR-15L Service Manual issued previously

for informati n

of

headphones supplied

with

this set.

PHOTO:

BLACK

TYPE

AEP

Model

VOLUME control

BATTERY indicator

DOLBY

NR

switch

TAPE selector

SPECIFICATIONS

Similar Mechanism

Set

WM-00

Tape track

4-track 2-channel stereo

Fast winding

time

Approx. 2 min.

with

Sony Cassette C-60

Frequency response

40-15,000

Hz

Wow and

flutter

±0.13% (DIN)

0.08% WRMS

(NAB)

Power

output

Headphones:

20

mW + 20

mW (at 10% harmonic distortion)

load impedance

32

ohms

at

DC

operation

Outputs

Two HEADPHONES jacks (stereo minijacks)

load impedance

8-300

ohms

Power requirements

3 V

DC,

two

R6

(size AA) batteries

DC

IN

3 V jack accepts:

EBP-500 battery case (optional) for use on

two

R20

(size

D)

batteries

AC-D2M

AC

power adaptor (optional) for use

on

220 V AC,

50

Hz

DCC-70 or DCC-127A car battery cord (optional) for use with

12

V

car battery

(For connection

with

the DCC-127A, the optional

PC-200

DC

plug

adaptor is required.)

Battery

life

Batteries

Continuous

playback hours

Sony batteries SUM-3 (NS) Approx. 4

Sony alkaline batteries AM3 Approx. 9

For maximum performance we recommend the use

of

alkaline

batteries.

Tape Transport Mechanism

Type

Dimensions

Approx.

79.7x110x32.8mm

(w/h/d)

(3

1

/

4

x43fax

1

5

/

16

inches)

incl.

projecting

parts and

controls

Weight

Approx.

290

g (10.3

oz)

incl. batteries,

not

incl.

other

accessories

00-100

Note: If a car battery cord or

an

AC power adaptor not manufactured by Sony

is used, a fuse

must

be installed in the battery

cord

or

the

AC

power

adaptor and the polarity

of

the plug must

be

as illustrated.

FEATURES

• Disc Drive system assures accurate and stable tape transport, greatly reducing wow and flutter.

• Dolby

NR

system reduces tape hiss noise.

• Tape selector for optimum playback with standard tapes

as well as high-performance tapes.

• Two HEADPHONES jacks allow two persons to listen

to

tape playback together.

STEREO

CASSETTE

PLAYER

SONY.

Apple Inc., et al.

Exhibit 1010

Apple Inc., et al. v. Global Touch Solutions, Inc.

IPR2015-01174

f

Find authenticated court documents without watermarks at docketalarm.com.

Exhibit 1010, Page 001

WM-DDm

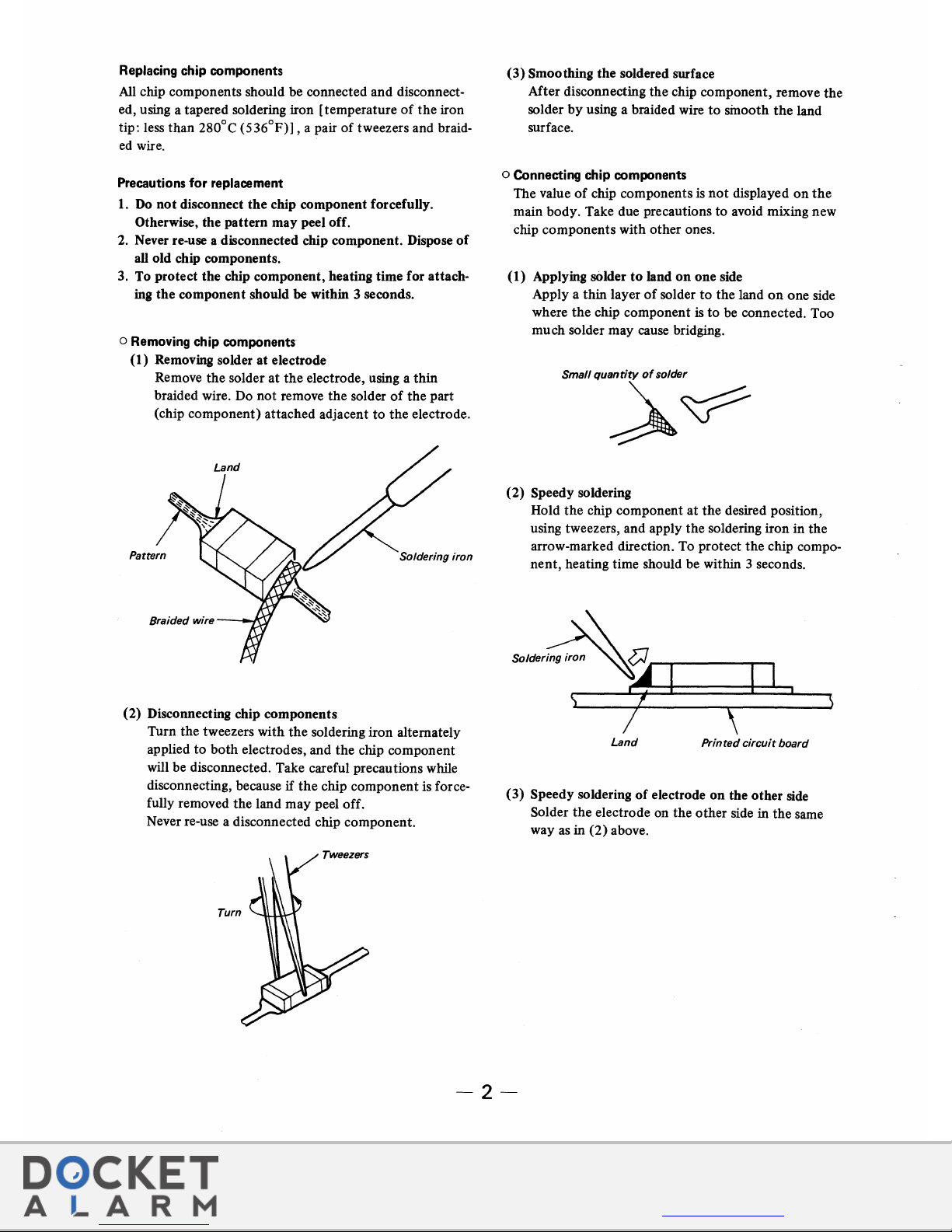

Replacing chip components

All

chip components should be connected and disconnect-

ed, using a tapered soldering iron [temperature

of

the

iron

tip: less than

280°C

(536°F)],

a pair

of

tweezers and braid-

ed

wire.

Precautions for replacement

1.

Do

not

disconnect

the

chip component forcefully.

Otherwise, the pattern may peel off.

2. Never re-use a disconnected chip component. Dispose

of

all old chip components.

3.

To protect the chip component, heating time for attaching the component should

be within 3 seconds.

o Removing chip components

(l)

Removing solder at electrode

Remove the solder

at

the

electrode, using a thin

braided wire. Do not remove the solder

of

the part

(chip component) attached adjacent

to

the electrode.

Braided wire

(2) Disconnecting chip components

Turn the tweezers with

the

soldering iron alternately

applied

to

both

electrodes, and the chip component

will be disconnected. Take careful precautions while

disconnecting, because

if

the

chip component is forcefully removed the land may peel off.

Never re-use a disconnected chip component.

(3)

Smoothing the soldered surface

After disconnecting the chip component, remove the

solder

by

using a braided wire

to

sinooth

the

land

surface.

o Connecting chip components

The value

of

chip components

is

not

displayed

on

the

main body. Take due precautions to avoid mixing new

chip components with other ones.

( 1) Applying

s<>lder

to

land

on

one side

Apply a thin layer

of

solder

to

the land

on

one side

where

the

chip component

is

to

be connected. Too

much solder may cause bridging.

(2)

Speedy soldering

Hold the chip component at the desired position,

using tweezers, and apply the soldering iron in the

arrow-marked direction. To protect

the

chip compo-

nent,

heating time should be within 3 seconds.

~~~,~-------------

\

~

I

\

Land

Printed

circuit

board

(3) Speedy soldering

of

electrode

on

the other side

Solder

the

electrode on the other side in the same

way as in

(2)

above.

-2-

f

Find authenticated court documents without watermarks at docketalarm.com.

Exhibit 1010, Page 002

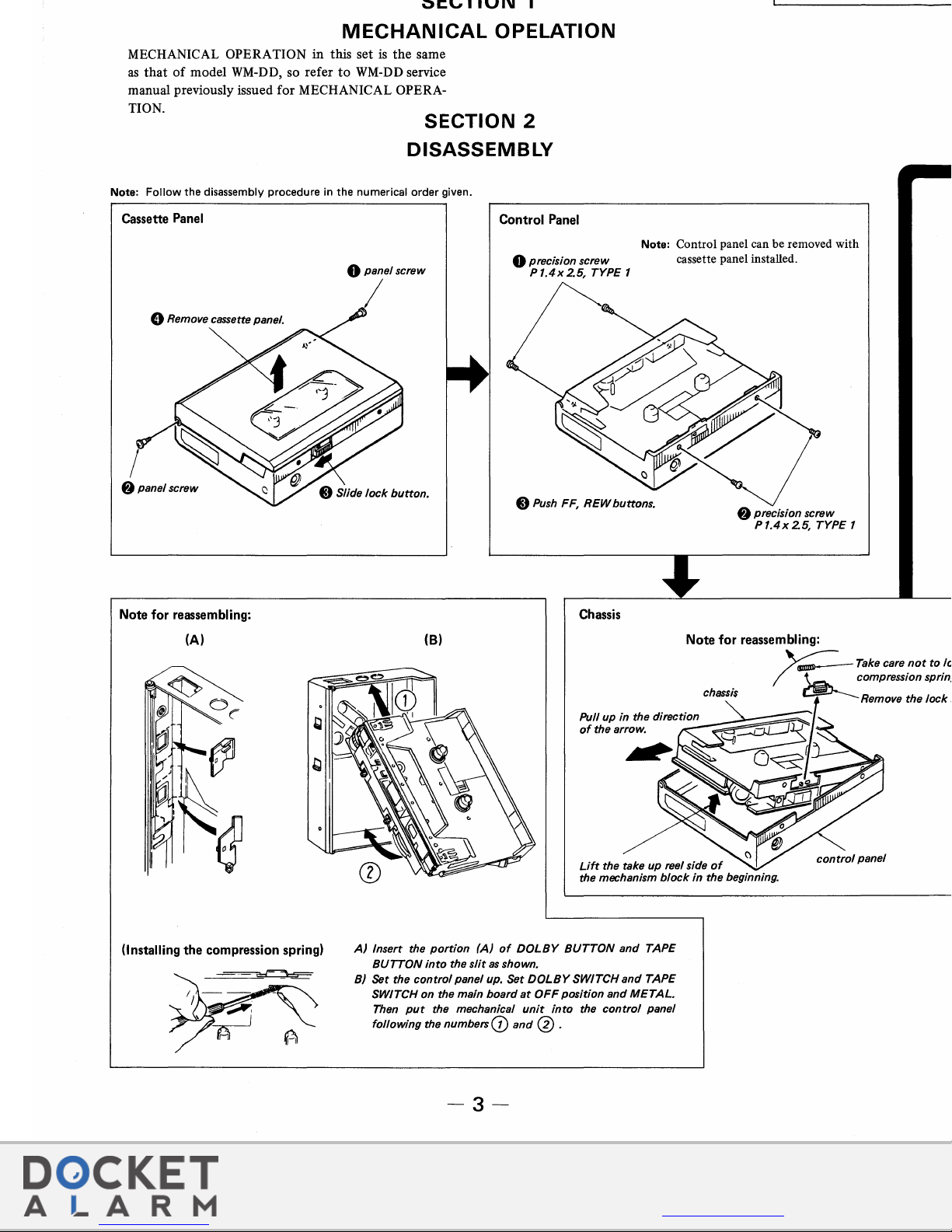

SECTION

1

MECHANICAL

OPELATION

MECHANICAL OPERATION

in

this

set

is

the

same

as

that

of

model WM-DD, so refer

to

WM-DD service

manual previously issued

for

MECHANICAL OPERA-

TION.

SECTION 2

DISASSEMBLY

Note:

Follow

the

disassembly

procedure

in

the

numerical

order

given.

Cassette Panel

Control Panel

WM-DDm

0 panel screw

0 precision screw

Note:

Control panel can be removed with

cassette panel installed.

8 Remove cassette panel.

8 panel screw

Note

for

reassembling:

(A)

(Installing

the

compression spring)

P

1.4x

2.5, TYPE 1

I

8

Push

FF,

REW

buttons.

8 precision screw

P

1.4x

2.5, TYPE 1

Chassis

(B)

Lift

the take up reel side

of

control

panel

the mechanism

block

in

the beginning.

A)

Insert the

portion

(A)

of

DOLBY

BUTTON

and

TAPE

BUTTON

into

the

slit

as

shown.

B) Set the

control

panel up. Set

DOLBY

SWITCH

and

TAPE

SWITCH on the main board

at

OFF

position

and

METAL.

Then

put

the mechanical

unit

into

the

control

panel

following the

numbers(])

and

@ .

-3-

WM-DDm

Main B ard

f

Find authenticated court documents without watermarks at docketalarm.com.

WM-DDm

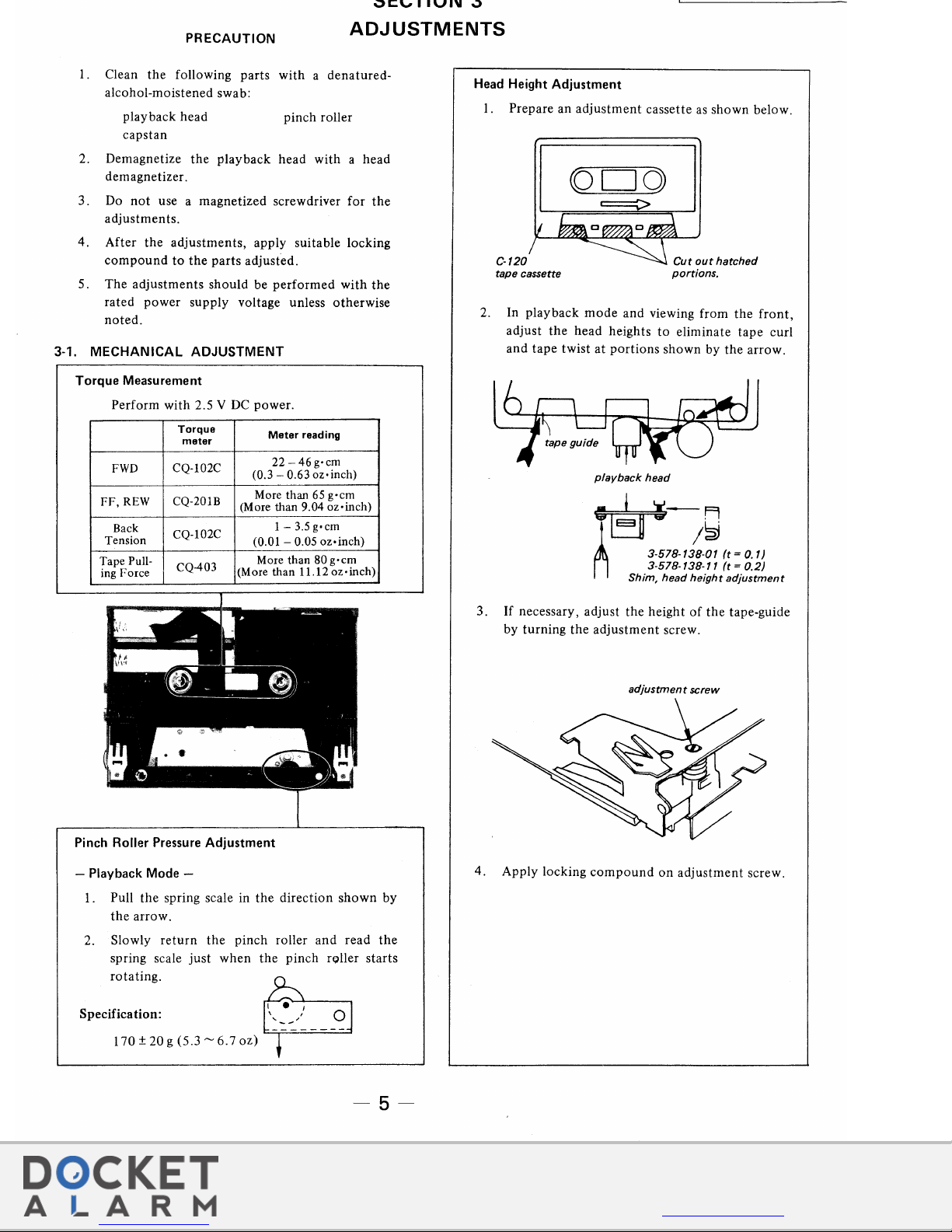

PRECAUTION

SECTION

3

ADJUSTMENTS

1. Clean

the

following

parts

with a denatured-

alcohol-moistened

swab:

playback

head

capstan

pinch

roller

2.

Demagnetize

the

playback

head

with a head

demagnetizer.

3.

Do

not

use a

magnetized

screwdriver

for

the

adjustments.

4.

After

the

adjustments,

apply

suitable

locking

compound

to

the

parts

adjusted.

5.

The

adjustments

should

be

performed

with

the

rated

power

supply

voltage unless

otherwise

noted.

3-1. MECHANICAL ADJUSTMENT

Torque

Measurement

Perform

with

2.5 V DC

power.

Torque

Meter

reading

meter

22-46

g•cm

FWD

CQ-102C

(0.3-

0.63 oz•inch)

FF,

REW

CQ-201B

More than

65

g·cm

(More than 9.04 oz•inch)

Back

CQ-102C

1-

3.5 g•cm

Tension

(0.01-

0.05 oz•inch)

Tape Pull-

CQ-403

More than

80 g•cm

ing Force

(More than

11.12oz•inch)

Pinch Roller Pressure Adjustment

- Playback Mode -

1 . Pull

the

spring scale in

the

direction

shown

by

the

arrow.

2. Slowly

return

the

pinch

roller

and

read

the

spring scale

just

when

the

pinch

roller

starts

rotating.

p

S

'f'

, I • 1

pect

tcahon:

'~:.

-:._"~

__

-~

170 ± 20 g (5.3

"'6.7

oz)

-5-

Head Height Adjustment

1.

Prepare

an

adjustment

cassette

as

shown

below.

C-120

tape cassette

Cut

out

hatched

portions.

2. In

playback

mode

and

viewing

from

the

front,

adjust

the

head

heights

to

eliminate

tape

curl

and

tape

twist

at

portions

shown

by

the

arrow.

playback

head

~-A

~

T~

~

~~

3-578-138-01

(t

= 0.1)

3-578-138-11

(t

= 0.2)

Shim, head height

adjustment

3.

If

necessary,

adjust

the

height

of

the

tape-guide

by

turning

the

adjustment

screw.

adjustment

screw

4.

Apply

locking

compound

on

adjustment

screw.

f

Find authenticated court documents without watermarks at docketalarm.com.

Exhibit 1010, Page 004

Loading...

Loading...