Sony PMW-EX1R, VCL-EX0877 Service Manual

SOLID-STATE MEMORY CAMCORDER

PMW-EX1R

WIDE CONVERSION LENS

VCL-EX0877

SERVICE MANUAL

1st Edition

!警告

このマニュアルは,サービス専用です。

お客様が,このマニュアルに記載された設置や保守,点検,修理などを行うと感電や火災,

人身事故につながることがあります。

危険をさけるため,サービストレーニングを受けた技術者のみご使用ください。

! WARNING

This manual is intended for qualifi ed service personnel only.

To reduce the risk of electric shock, fi re or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualifi ed to do so. Refer all servicing to

qualifi ed service personnel.

! WARNUNG

Die Anleitung ist nur für qualifi ziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifi ziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afi n

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifi é pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

PMW-EX1R

注意

FÖRSIKTIGHET!

指定以外の電池に交換すると,破裂する危険があります。

必ず指定の電池に交換してください。

使用済みの電池は,国または地域の法令に従って

処理してください。

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

When you dispose of the battery, you must obey the

law in the relative area or country.

ATTENTION

Il y a danger d’explosion s’il y a remplacement incor-

rect de la batterie. Remplacer uniquement avec

une batterie du même type ou d’un type équivalent

recommandé par le constructeur.

Lorsque vous mettez la batterie au rebut, vous devez

respecter la législation en vigueur dans le pays ou la

région où vous vous trouvez.

Fara för explosion vid felaktigt placerat batteri.

Byt endast mot samma eller likvärdig typ av batteri,

enligt tillverkarens rekommendationer.

När du kasserar batteriet ska du följa rådande lagar

för regionen eller landet.

PAS PÅ

Fare for eksplosion, hvis batteriet ikke udskiftes

korrekt.

Udskift kun med et batteri af samme eller tilsvarende

type, som er anbefalet af fabrikanten.

Når du bortskaffer batteriet, skal du følge

lovgivningen i det pågældende område eller land.

HUOMIO

Räjähdysvaara, jos akku vaihdetaan virheellisesti.

Vaihda vain samanlaiseen tai vastaavantyyppiseen,

valmistajan suosittelemaan akkuun.

Noudata akun hävittämisessä oman maasi tai

alueesi lakeja.

VORSICHT

Explosionsgefahr bei Verwendung falscher Batterien.

Batterien nur durch den vom Hersteller empfohlenen

oder einen gleichwertigen Typ ersetzen.

Wenn Sie die Batterie entsorgen, müssen Sie die

Gesetze der jeweiligen Region und des jeweiligen

Landes befolgen.

FORSIKTIG

Eksplosjonsfare hvis feil type batteri settes i.

Bytt ut kun med samme type eller tilsvarende

anbefalt av produsenten.

Kasser batteriet i henhold til gjeldende avfallsregler.

PMW-EX1R

1 (P)

Table of Contents

Manual Structure

Purpose of this manual ............................................................ 3 (E)

Related manuals ...................................................................... 3 (E)

1. Service Overview

1-1. External Connectors .................................................. 1-1 (E)

1-1-1. Signal Inputs and Outputs ................................ 1-1 (E)

1-2. Location of the Printed Wiring Boards .....................1-3 (E)

1-3. Circuit Description .................................................... 1-4 (E)

1-4. Service Tools/Measuring Equipment List ............... 1-12 (E)

1-4-1. Service Tools ..................................................1-12 (E)

1-4-2. Measuring Equipment ....................................1-12 (E)

1-5. Firmware Upgrade...................................................1-13 (E)

1-6. Recommended Replacement Parts .......................... 1-14 (E)

1-7. Circuit Protection Part List ...................................... 1-15 (E)

1-7-1. Circuit Protection Element.............................1-15 (E)

1-7-2. Replacing Fuse ............................................... 1-15 (E)

1-8. Note on Service ....................................................... 1-16 (E)

1-8-1. Requirements on Replacement of Boards

or Parts ........................................................... 1-16 (E)

1-8-2. Requirements on Replacement of Lens .........1-16 (E)

1-8-3. Note on Replacement of Parts on

the Board ........................................................ 1-16 (E)

1-8-4. Description of Number Seal on the Prism ..... 1-16 (E)

1-8-5. Memory Backup Battery ................................ 1-17 (E)

1-8-6. Unleaded Solder ............................................. 1-17 (E)

1-9. Connector Location Diagram on Board ..................1-18 (E)

1-10. Connecting/Disconnecting the Flexible

Card Wire ................................................................1-19 (E)

1-11. Replacing the Coaxial Cable with Connector

(Fine Pitch Coaxial Cable) ..........................................1-20 (E)

2. Replacement of Main Parts

2-1. Outline of Replacement Procedures .........................2-1 (E)

2-2. Replacement Procedures ...........................................2-2 (E)

2-2-1. Lithium Battery ............................................... 2-2 (E)

2-2-2. Case (Bottom) L/R and Front Panel

Assembly .........................................................2-2 (E)

2-2-3. Microphone Holder Assembly ........................ 2-4 (E)

2-2-4. EVF Assembly ................................................. 2-4 (E)

2-2-5. Handle Assembly ............................................. 2-5 (E)

2-2-6. DAP-41 Board and AU-326 Board .................. 2-7 (E)

2-2-7. SW-1478 Board................................................2-8 (E)

2-2-8. Inside Panel Assembly/Outside Panel

Assembly .........................................................2-8 (E)

2-2-9. Rear Panel Assembly .....................................2-10 (E)

2-2-10. Express Card Assembly ................................. 2-11 (E)

2-2-11. RE-272 Board and RE-273 Board ................. 2-12 (E)

2-2-12. Battery Case, TX-131 Board .........................2-13 (E)

2-2-13. DPR-311 Board ..............................................2-15 (E)

2-2-14. Case L Assembly............................................ 2-16 (E)

2-2-15. Case R ............................................................2-17 (E)

2-2-16. Prism Assembly .............................................2-18 (E)

2-2-17. ND Filter ........................................................2-18 (E)

2-2-18. Lens Unit........................................................2-19 (E)

2-2-19. DR-644 Board ................................................ 2-19 (E)

2-2-20. LED-491 Board..............................................2-20 (E)

2-2-21. Speaker...........................................................2-20 (E)

2-2-22. KSW-55 Board, HN-361 Board .....................2-21 (E)

2-2-23. Microphone Unit Assembly ........................... 2-22 (E)

2-2-24. Microphone Unit ............................................ 2-23 (E)

2-2-25. DET-52 Board ................................................ 2-24 (E)

2-2-26. 3.5-inch LCD Assembly ................................ 2-25 (E)

2-2-27. Replacing the Parts in the Lens Grip ............. 2-26 (E)

3. SERVICE Menu

3-1. Outline of SERVICE Menu .......................................3-1 (E)

3-1-1. Basic Menu Operations .................................... 3-1 (E)

3-1-2. SERVICE Menu Structure ............................... 3-1 (E)

3-1-3. Displaying the SERVICE Menu ......................3-1 (E)

3-2. SERVICE Menu List .................................................3-2 (E)

3-2-1. MAINTENANCE Menu .................................. 3-2 (E)

3-2-2. RPN CORRECT Menu ....................................3-2 (E)

3-2-3. INFORMATION Menu ................................... 3-3 (E)

3-3. Self-Diagnostic Function...........................................3-4 (E)

3-4. Executing Log Dump ................................................ 3-9 (E)

3-5. List of Error Numbers on the LCD Display ............3-10 (E)

PMW-EX1R

1 (E)

4. Alignment

6. Block Diagrams

4-1. Servicing software “ServiceNavi-EX” ......................4-1 (E)

4-2. Preparation ................................................................ 4-1 (E)

4-2-1. Service Tools and Equipment ..........................4-1 (E)

4-2-2. Connection ....................................................... 4-1 (E)

4-3. MAINTENANCE Menu ........................................... 4-1 (E)

4-3-1. Test Saw Setting ............................................... 4-1 (E)

4-3-2. Executing Auto Black Balance ........................ 4-2 (E)

4-3-3. Black Shading Adjustment...............................4-2 (E)

4-3-4. White Shading Adjustment ..............................4-3 (E)

4-3-5. Flare Adjustment .............................................. 4-5 (E)

4-3-6. Executing Auto FB Adjust ...............................4-6 (E)

4-4. RPN CORRECT Menu .............................................4-8 (E)

4-4-1. Executing Auto Detection ................................ 4-8 (E)

4-4-2. Correction Mode Settings ................................ 4-8 (E)

4-4-3. Channel Setting ................................................ 4-8 (E)

4-4-4. Cursor Setting .................................................. 4-8 (E)

4-4-5. Cursor H Position Setting ................................ 4-9 (E)

4-4-6. Cursor V Position Setting ................................ 4-9 (E)

4-4-7. Operating Cursor Next ..................................... 4-9 (E)

4-4-8. Operating Cursor Prev ..................................... 4-9 (E)

4-4-9. Compensation Level Display ........................... 4-9 (E)

4-4-10. Executing Record ............................................. 4-9 (E)

4-4-11. Executing Delete ............................................ 4-10 (E)

4-4-12. Readout Mode Setting ...................................4-10 (E)

4-4-13. Executing Reset .............................................4-10 (E)

5. Spare Parts

5-1. Notes on Repair Parts ......................................................5-1

5-2. Exploded Views ............................................................... 5-2

5-3. Supplied Accessories ..................................................... 5-18

Overall ............................................................................. 6-2

AU-326 ............................................................................6-3

AXM-42 ...................................................................... 6-3, 8

DAP-41................................................................6-3, 4, 6, 7

HN-356 ................................................................ 6-3, 4, 6, 7

HN-360 ............................................................................6-3

HN-361 ............................................................................6-3

KSW-55 .......................................................................6-3, 8

MA-183 ........................................................................... 6-3

SW-1478 ...................................................................... 6-3, 4

SWC-50 ........................................................................... 6-3

BI-202.............................................................................. 6-4

BI-203.............................................................................. 6-4

BI-204.............................................................................. 6-4

DPR-311 .............................................................. 6-4, 5, 6, 7

CN-3273 .................................................................... 6-5, 11

EC-68 .............................................................................. 6-5

DET-52 ............................................................................ 6-8

DR-644 ............................................................................ 6-8

HN-363 ............................................................................ 6-8

RM-224 ........................................................................... 6-8

CN-3258 .......................................................................... 6-9

DC-152 ............................................................................ 6-9

RE-272 ............................................................................ 6-9

CN-3259 ........................................................................ 6-10

RE-273 .......................................................................... 6-10

ASW-68 ......................................................................... 6-11

LED-491 ........................................................................ 6-11

LED-494 ........................................................................ 6-11

SW-1484 ........................................................................ 6-11

TX-131 .......................................................................... 6-12

VIF-46 ........................................................................... 6-12

2 (E)

7. Schematic Diagrams

Frame Wiring...................................................................7-1

PMW-EX1R

Purpose of this manual

Related manuals

Manual Structure

The service manual is intended for use by trained system and service engineers, and

provides the information of maintenance and detailed service.

The following manuals are available in this model.

If this manual is required, please contact your local Sony Sales Offi ce/Service Center.

. Operating Instructions (Supplied with unit)

This manual is necessary for application and operation of this unit.

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

Part number: 9-968-546-06

PMW-EX1R

3 (E)

Section 1

Service Overview

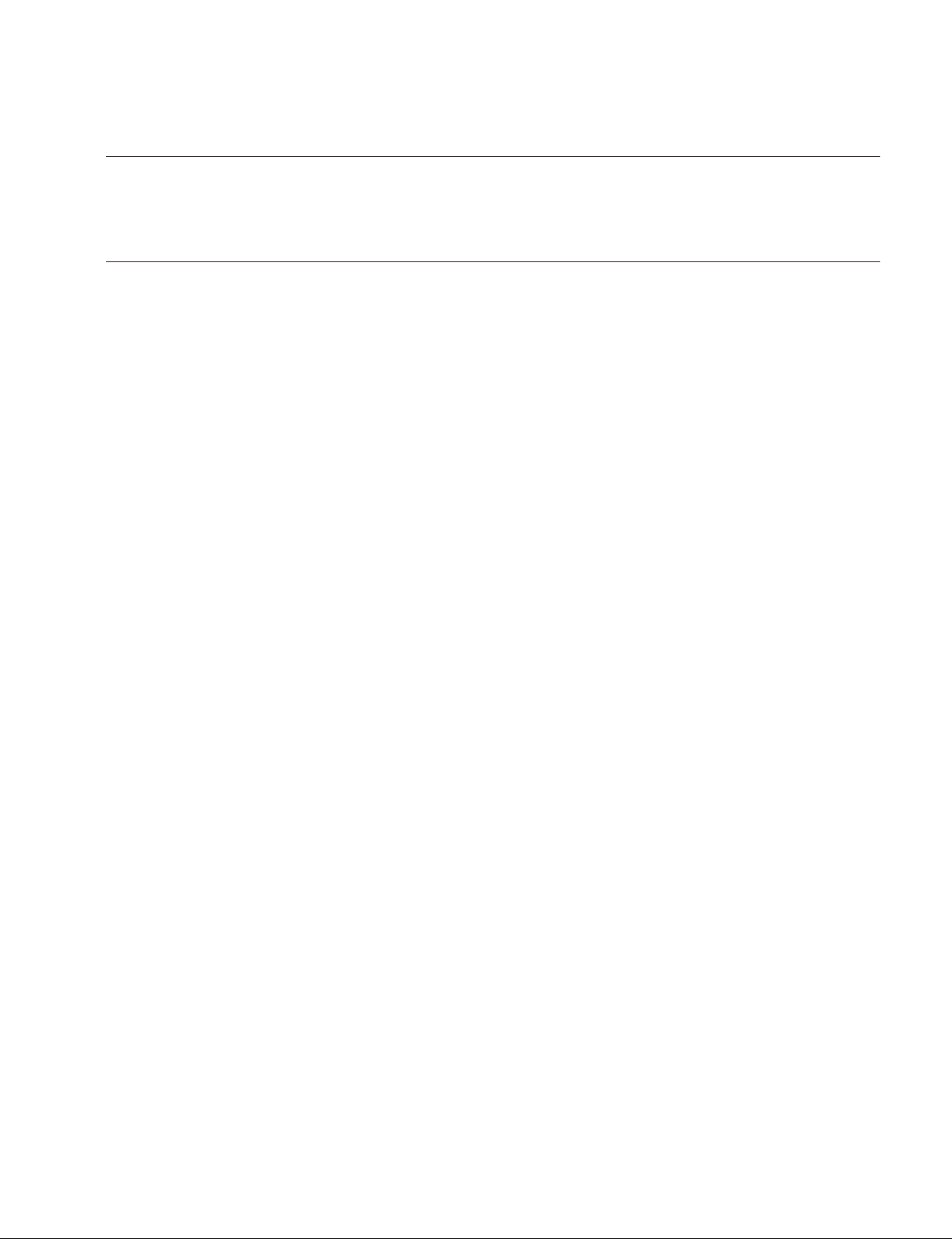

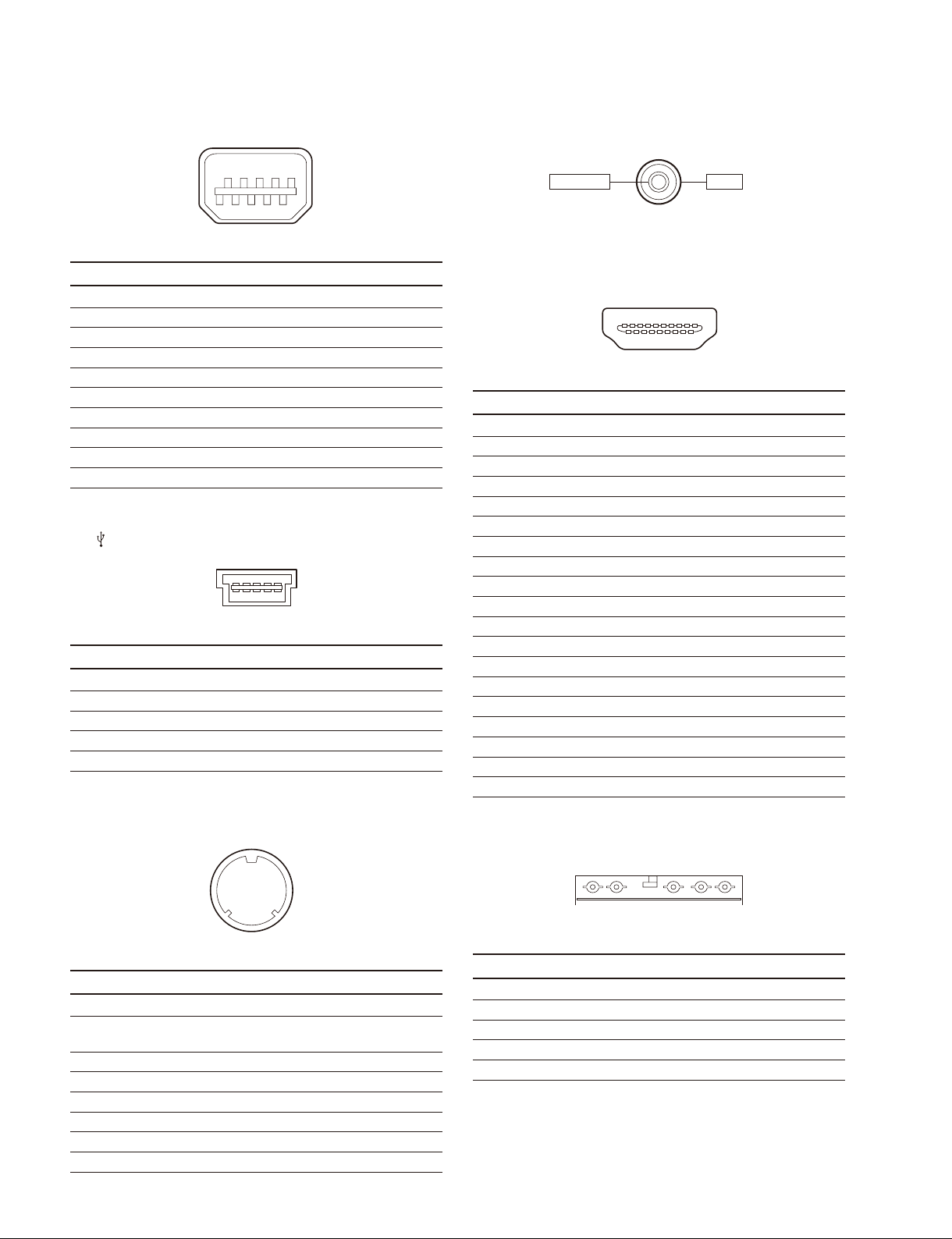

1-1. External Connectors

1-1-1. Signal Inputs and Outputs

SIDE VIEW

FRONT VIEW

3 AUDIO IN CH-1, CH-2: XLR (3P, Female)

2

_ EXT VIEW _

1

3

(0 dBu = 0.775 V rms)

No. Signal I/O Specifi cations

1 MIC/LINE (G) _ _65 dBu to _8 dBu

2 MIC/LINE (H) IN +4 dBu, selectable

3 MIC/LINE (C) IN High impedance, Balanced

4 A/V OUT: Multiconnector (10P)

10

9

_ EXT VIEW _

2

1

REAR VIEW

CANCEL

SEL/SET

PICTURE

PROFILE

AUTO

INTMIC

CH-1

EXT

MANUAL

AUTO

INTMIC

CH-2

MANUAL

EXT

PMW-EX1R

EXPANDED

REC

REVIEW

FOCUS

DC IN

START/

STOP

RELEASE

OFF

CAMERA

MEDIA

MENU

1 SDI OUT: BNC type

SDI output signal

2 (HEADPHONES): Stereo mini jack

Sound monitor, monaural/stereo selectable

_20.5 dBu (Reference level 16 Z loaded)

No. Signal I/O Specifi cations

1 LINE_MONI1_L (A/V) O LINE OUT (L)

2 LANC_SIG _ NC

3 S_GND _ GND

4 LANC_DC _ NC

5 S-C O NC

6 LINE_MONI2_R (A/V) O LINE OUT (R)

7 AV_SW I

8 VIDEO/AUDIO_GND _ GND

9 VIDEO O Composite OUT

10 S-Y O NC

5 HDV/DV: i.LINK connector (IEEE1394, S400) (4P)

14

_ EXT VIEW _

No. Signal I/O Specifi cations

1 TPB_ I/O Strobe on receive, data on

transmit B (_)

2 TPB+ I/O Strobe on receive, data on

transmit B (+)

3 TPA_ I/O Data on receive, strobe on

transmit A (_)

4 TPA+ I/O Data on receive, strobe on

transmit A (+)

PMW-EX1R

1-1 (E)

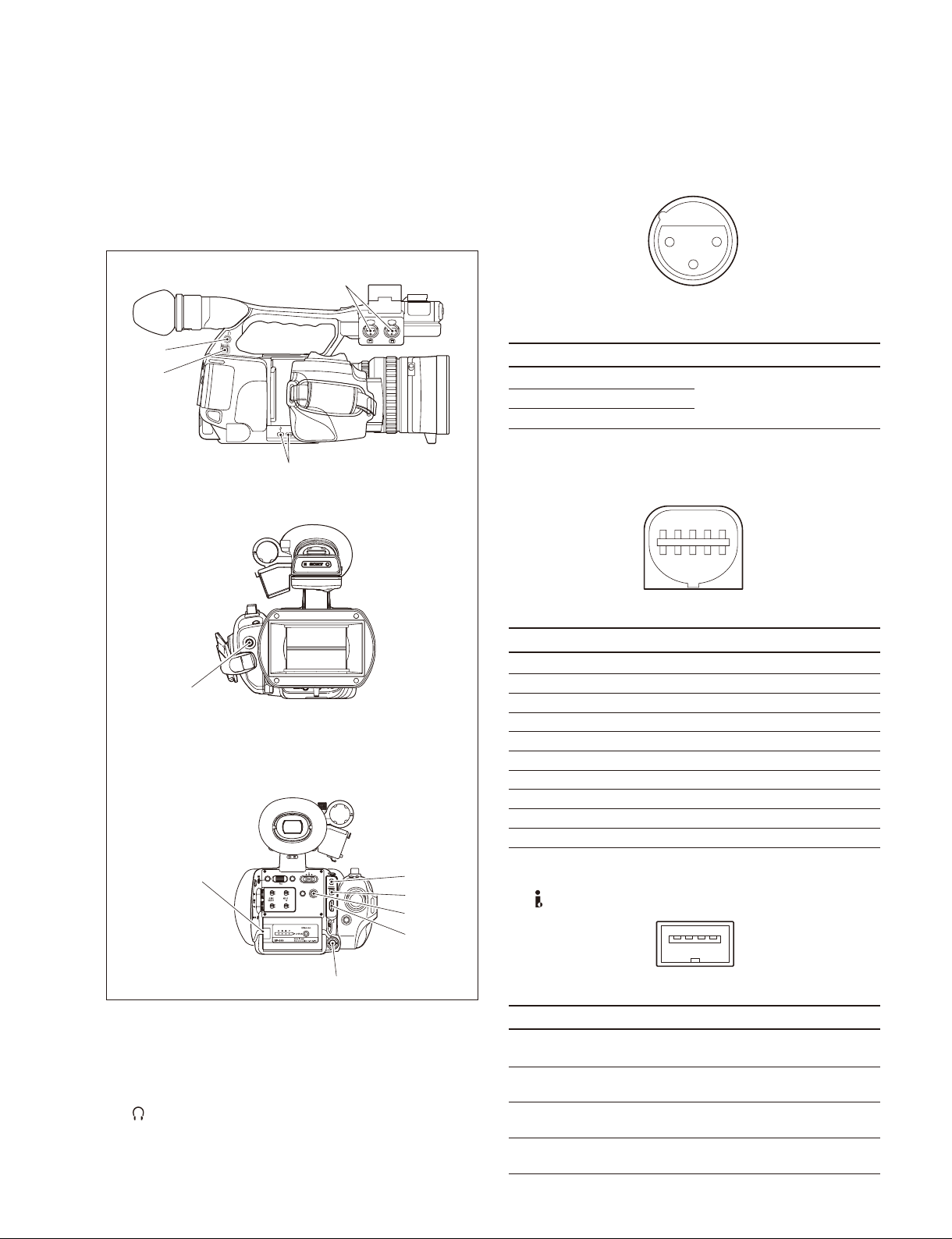

6 COMPONENT OUT: Mini D terminal (10P)

9 DC IN: 2P (DC JACK TYPE 4)

19

210

_ EXT VIEW _

No. Signal I/O Specifi cations

1 Y O COMPONENT (Y)

2 YGND _ Y GND

3 PB O COMPONENT (Pb)

4 PBPR_GND _ PBPR GND

5 PR O COMPONENT (Pr)

6 NC _

7 NC _

8 NC _

9 SW_GND _

10 SW I

7 (USB): Mini-B connector (5P)

15

_ EXT VIEW _

No. Signal I/O Specifi cations

1 VCC _ USB Vcc

2 D_ I/O USB_

3 D+ I/O USB+

4 ID _ NC

5 GND _ Ground

GNDEXT DC

_ EXT VIEW _

0 HDMI OUT: (19P)

19 1

18 2

_ EXT VIEW _

No. Signal I/O

1 TMDS_DATA2+ O

2 TMDS_DATA2_SHIELD _

3 TMDS_DATA2_ O

4 TMDS_DATA1+ O

5 TMDS_DATA1_SHIELD _

6 TMDS_DATA1_ O

7 TMDS_DATA0+ O

8 TMDS_DATA0_SHIELD _

9 TMDS_DATA0_ O

10 TMDS_CLOCK+ O

11 TMDS_CLOCK_SHIELD _

12 TMDS_CLOCK_ O

13 CEC (N.C.) _

14 RESERVED (N.C.) _

15 SCL O

16 SDA I/O

17 DDC/CEC_GND _

18 +5V_POWER O

19 HPD I

8 LENS REMOTE: (8P FEMALE)

18

2

3

4

7

6

5

_ EXT VIEW _

No. Signal I/O Specifi cations

1 COMMON_V O GND

2 ZOOM I GND: WIDE 1.66V: STOP

3.33V: TELE

3 COMMON+V O 3.33V

4 COMMON I 1.66V

5 REC I GND: ON OPEN: OFF

6 RET I GND: ON OPEN: OFF

7 SW COMMON O GND

8 FRAME GND _

1-2 (E)

!- Battery: (5P)

12

_ EXT VIEW _

No. Signal I/O Specifi cations

1 BATT (+) _ +11 to +17 V dc

2 BAT_SCL O

3 BAT_SDA I/O

4 BATT_ID_DATA I

5 BATT (_) _

345

PMW-EX1R

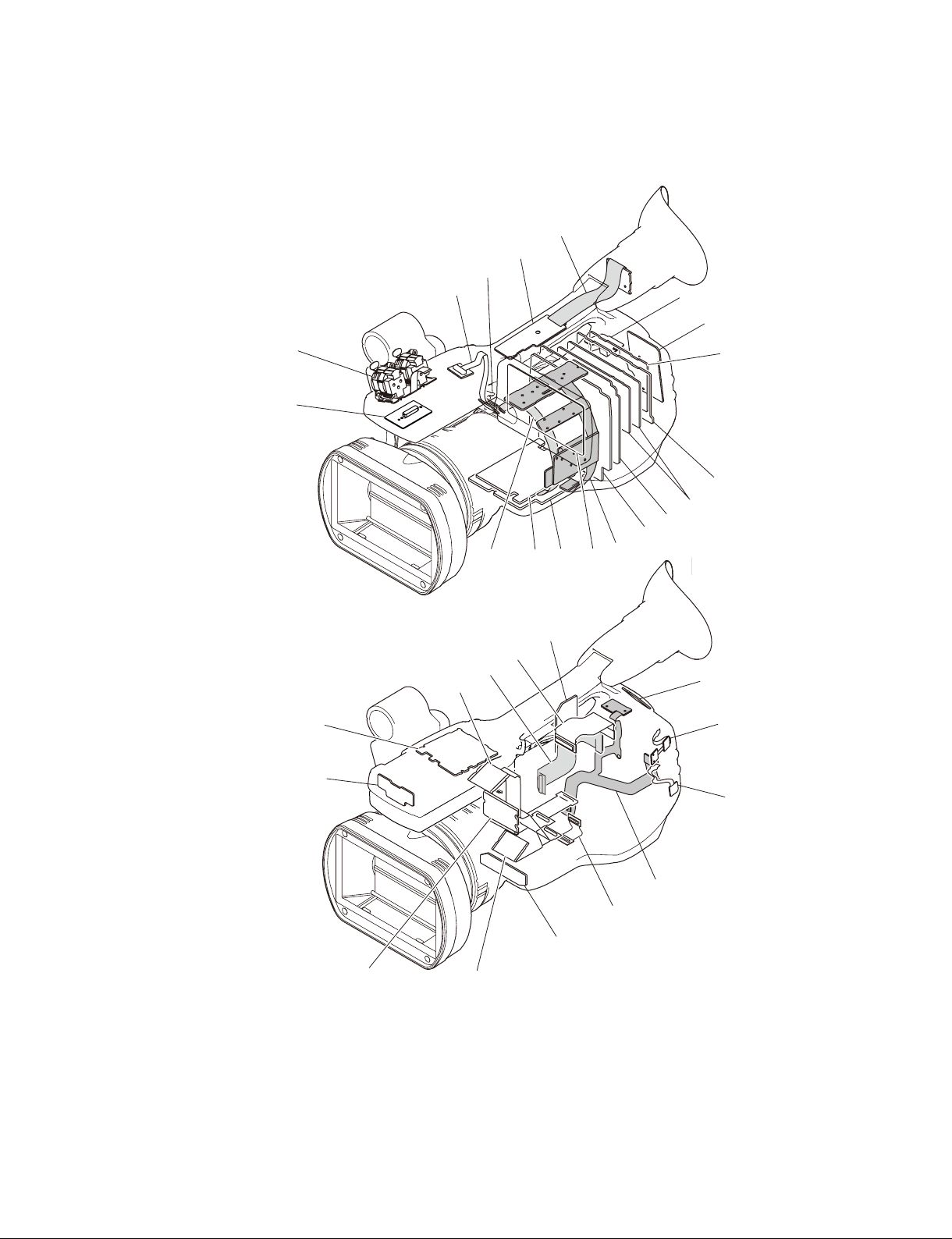

1-2. Location of the Printed Wiring Boards

1 ASW-68 board

2 AU-326 board

3 AXM-42 board

4 BI-202 board

5 BI-203 board

6 BI-204 board

7 CN-3258 board

8 CN-3259 board

9 CN-3273 board

0 DAP-41 board

!- DC-152 board

!= DET-52 board

![ DPR-311 board

!] DR-644 board

!\ EC-68 board

!; HN-356 board

!' HN-360 board

!, HN-361 board

!. HN-363 board

@/ IF-1127 board

@- KSW-55 board

@= LED-491 board

@[ LED-494 board

@] MA-183 board

@\ RE-272 board

@; RE-273 board

@' RM-224 board

@, SW-1478 board

@. SW-1484 board

#/ SWC-50 board

#- TX-131 board

#= VIF-46 board

PMW-EX1R

1-3 (E)

1-3. Circuit Description

1. CMOS Block System

BI-202/203/204 Board

The BI-202, BI-203 and BI-204 boards are the rigid fl exible boards connecting the CMOS image sensors (IC1) to the

DPR-311 board.

The CMOS image sensor receives the three primary colors of R, G and B that are separated from the incoming light by the

prism. The CMOS image sensor converts the incoming primary color to electric signal. The built-in 12-bit column A/D

converters then convert the R, G and B analog video signals to the digital video signals respectively.

The electronic shutter, analog gain amplifi er and black level clamp functions are also provided in the above boards.

The BI-202 board is for the R-channel signal, the BI-203 board is for the G-channel signal and the BI-204 board is for the

B-channel signal.

The CMOS image sensor receives the sync signal and the serial communication signal from the DPR-311 board. The 12-bit

digital video signals that are supplied from the CMOS image sensors pass through the EMI fi lters (FL1 to FL4) and are

input to the DPR-311 board.

Various decoupling capacitors and the damping resistors are also mounted in the above boards.

IC3 of the BI-203 board is a temperature sensor that sends the temperature data to the CAMERA MICON (camera

μ-processor: IC500) on the DPR-311 board via I2C bus.

2. Camera Block System

DPR-311 Board

The DPR-311 board consists of the Camera Signal Processor IC (IC200) and the CAMERA MICON (camera μ-processor:

IC500) whereas the Camera Signal Processor IC (IC200) performs various processing on the digital video signal supplied

from the CMOS image sensor, and the CAMERA MICON (IC500) performs control of IC200 and other various controls

such as control of the CMOS image sensor and of lens. And the output digital video (Y/C) signal is sent to the next circuit

the video (baseband video) signal processing circuit.

The 12-bit digital video (RGB) signals supplied from the CMOS block (BI-202, BI-203 and BI-204 boards) fi rst enter the

camera signal processor IC (IC200). In the camera signal processor IC (IC200), average value, peak value of the RGB

digital video signals that are required for the following AUTO operations of the camera are detected.

The detected signals are sent to the CAMERA MICON (camera μ-processor: IC500).

. Auto white balance

. Auto black balance

. Auto focus

. Auto iris

. Auto knee

The digital video signal from the CMOS image sensor enters fi rst the selector circuit selecting either the digital video signal

from the CMOS image sensor or the internal TEST signal. The output video signal from the selector enters the compensation circuits consisting of the CMOS imager-related compensation circuit and the lens-related compensation circuit. The

video signal then receives the white balance processing, and the matrix signal and the detail signal are added to the video

signal. The video signal then receives the pedestal control, knee compensation, gamma correction and white/black clip

processing. The video signal fi nally enters the baseband processing IC (IC600).

The pixel number conversion processing from 1920/1080 to 1440/1080 or 1280/720 is also performed inside IC200.

1-4 (E)

PMW-EX1R

The CAMERA MICON (camera μ-processor: IC500) performs the overall control over the entire camera system and is controlled by the camera system controller (IC2900).

Peripheral ICs of the CAMERA MICON (camera μ-processor: IC500) are FLAH ROM (IC413) and SDRAM (IC414).

3. Video Signal System

DPR-311 Board

The digital video (Y/C) signal output from the camera signal processor IC (IC200) enters the baseband processing IC

(IC600).

The baseband processing IC (IC600) performs the overall baseband processing of video and audio signals with a single chip

IC containing the various scaler functions (supporting the multiple format outputs), various OSD functions, PLL function

(54 MHz → 74 MHz) and CPU.

The baseband processing IC (IC600) provides the following outputs:

. HD/SD Component (digital): To TX-131 board

. HD/SD Component (analog): To TX-131 board

. Composite (analog): To TX-131 board

. LCD signal (digital): To LCD module

. EVF signal (analog): To DR-644 board

The input/output signals of the baseband processing IC (IC600) are the following signals:

. MPEG encoder/decoder I/F signal (digital): To IC1500

. Audio I/F signal (digital): To IC1300

Peripheral circuits of the baseband processing IC (IC600) are the master clock 54 MHz VCXO (X800) control circuit

(IC803, IC804, IC806, IC807, IC808) and the Mobile DDR SDRAM memory (IC1100, IC1101).

Peripheral circuits of the built-in CPU are FLASH ROM (IC1003) and SDRAM (IC1000).

The baseband processing IC (IC600) is controlled by the system controller (IC2900). The LCD driver IC, the EVF driver

IC, SDI Co-pro, the audio system and the power save control of the output systems are controlled by the built-in CPU

inside IC600.

4. Media Recording and Playback

DPR-311 Board

Output from the baseband processing IC (IC600) is input into the MPEG encoder/decoder (IC1500).

The MPEG encoder/decoder (IC1500) is the single-chip MPEG Codec IC that encodes and decodes both the high-quality

HD video signal and audio signal in real-time. It has various interfaces with signals such as MPEG video, video input/

output, MPEG audio, audio input/output, bit stream input/output, and interface with the host.

IC1500 output is then input into LSI (IC1600) for AVIT signal processing.

LSI (IC1600) for AVIT signal processing contains the built-in CPU and has interfaces for DDR2 SDRAM memory (IC1800,

IC1801), PCI bus, PCI-Express bus, I/O for IC1500, and serial communication with system controller (IC2900).

IC1600 is also connected to the NOR-type Flash ROM (IC1901) to read the CPU program in the IC1600 during initial startup.

LSI (IC1600) for AVIT signal processing is controlled by the system controller (IC2900), in the same way as other main

devices, and provides the following types of functions: video/audio stream control, access to the SxS memory card, mass

storage operations when connected to USB and HDV device controls when connected to i-LINK.

Explanation of peripheral devices

<SxS memory card slot>

Two memory card slot boards (EC-68) are connected to the dual channel PCI-Express signals coming from IC1600 through

a 0.4 mm pitch, 30-pin fi ne coaxial cables connected to CN2400 and CN2401.

Furthermore, dual channel USB host signals output from USB host controller (IC2300) are connect to the EC-68 board

through fi ne coaxial cables just as with the PCI-Express signals.

IC2300 is controlled by PCI bus from IC1600.

PMW-EX1R

1-5 (E)

<USB device controller>

USB device signal output from USB device controller (IC2000) is connected to output board (DAP-41) through the bothsided fl exible board (HN-356) from CN3302 connector, and then it is connected to USB Mini-B connector (CN106) on the

DAP-41 board.

IC2000 is controlled by the dedicated bus from IC1600.

If there is no USB connection, the power supply for IC2000 drops off.

<i-Link controller>

The i-Link signal output from the i-Link controller (IC2200) is connected to the 4-pin i-Link connector (CN3) on the

CN-3273 board passing through the both-sided fl exible board (CN-3273) from the CN3400 connector.

IC2200 is controlled by the PCI bus from IC1600.

5. Audio system

This overview explains the audio system according to the audio block diagram shown in Fig. 1.

MA-183 Board

The MA-183 board contains a built-in microphone unit. The MA-183 board amplifi es the audio signal with the microphone bias

power supply and head amplifi er (Q5, Q7, and Q9, and Q6, Q8, and Q10). It provides the balanced output for the audio signal.

AXM-42 Board

The AXM-42 board is a connector board on which XLR (3-pin) connector for external LINE/MIC input and the [LINE/

MIC/MIC +48V] input selection switch for two channels are mounted on this connector board.

KSW-55 Board

This board performs the read and tally controls for the switch on the handle. The audio signal block relays the audio signal

between the MA-183 board and AXM-42 board.

HN-360/HN-361 Flexible board

This board relays the audio signal between the KSW-55 board and the AU-326 board.

AU-326 Board (Audio block)

This board controls the analog audio input signal processing, as well as microphone +48 V power supply and serial signal.

. Audio signal from the built-in microphone on the MA-183 board is input to the balanced input amplifi er IC200 and IC201

of this board. Output of the balanced amplifi er is connected to the analog switch (IC208, IC209) for switching between

[INT/EXT].

. The DC-DC converter (IC100, Q100) for microphone power +48 V is built-in, and when EXT MIC +48 V is going to be

supplied, the EXT MIC +48 V is supplied by the switch (Q200, Q201, Q202 and Q203).

. The audio input signals from MIC and LINE are input to a common circuit that receives both of the MIC input level (_20

dBu to _65 dBu) and the LINE input level (+4 dBu). The input attenuator is inserted in the circuit switch (Q212, Q213,

Q214, Q215 and Q216 to Q219) as required. This audio input signal is received by the balanced input amplifi er (IC202,

IC203) that performs amplifi cation of 0/+12 dB and switching (Q224, Q225, Q226, Q227) in accordance with the level

that is set by INPUT TRIM. After that, the audio signal is connected to the [INT/EXT] switch (IC208, IC209).

. The [INT/EXT] switch (IC208, IC209) performs not only the INT/EXT switching but also performs the input channel

mode selection [CH1/ (CH1/CH2)].

. SEL (IC204, IC205)/AMP (IC206, IC207) are a signal selector and buffer amplifi er to perform AGC link.

DAP-41 Board (Audio block)

The DAP-41 board is comprised of two pieces of the Audio Codec IC and the IC202, IC203.

(RTC is also built on this board, but the explanation has been omitted here.)

1-6 (E)

PMW-EX1R

. Audio Codec (IC202, IC203)

The analog audio signal from the AU-326 board is connected to IC202 and IC203 that are the Audio Codec (PGA, ADC,

2

DSP, Digital IF, headphones amplifi er, speaker amplifi er are built on one chip and the parameters are set with I

C).

The analog signal after level adjustment by the Input TRIM (PGA) is converted to the digital signal with the ADC.

The digital signal receives the [Wind Filter] (on/off) processing of the Audio Level control, AGC Limiter and Internal

mic from the DSP. After the audio signal receives these processing, the digital signal is output for audio recording.

Playback output (including EE) is the digital signal that is connected to Audio Codec where it is converted to the analog

signal with DAC and output to the ASW-68 board.

Furthermore, the audio signal that is processed for audio monitoring in the ASW-68 board is connected to the headphones

amplifi er and speaker amplifi er through the monitor level control from the IN2LP input and IN2RP input of IC202.

From the DPR-311 board, BEEP (IC600) is level-controlled internally by IN2LN (IC202), and output to the speaker HP.

. FPGA (IC1300) on the DPR-311 Board

The digital signal output signal is supplied to the Display Block (Base band) from the Audio Codec. FPGA (IC1300) also

receives the playback output signal from the Display Block.

The playback system selects CH1/CH2 or CH3/CH4, connects EE, and connects TEST TONE from the Display Block

depending on the data.

Furthermore, FPGA divides the clock signal that is supplied from the Display Block to Audio Codec on the DAP-41 board.

MA-183

INT MIC1

with

HEAD AMP

+10dB

INT MIC2

with

HEAD AMP

+10dB

MIC/LINE

1

(XLR)

MIC/LINE

2

(XLR)

AXM-42

AV Monitor

Out 1

(Line Out1)

AV Monitor

Out 2

(Line Out2)

VIF-46

HP Out

(PHONE

MINI)

SPEAKER

KSW-55

LED-491

HN-361

DPR-311

WIND FILTER1

NH-360

FIL

ATT

+48V /MIC / LINE -1

WIND FILTER2

FIL

ATT

+48V /MIC / LINE -2

AU-326

MUTE

MUTE

MUTE

MUTE

PWR or

DET

ASW-68

+48V

+48V

IC204 (1/2)

IC204 (2/2)

COPY1to2, LINK2to1, LINK1to2

BAL

AMP

INT/EXT 1

BAL

AMP

IC200

IC203

BAL

AMP

0/12dB-1

Control

with PGA

IC202

BAL

AMP

INT/EXT 2

0/12dB-2

Control

with PGA

AMP

AMP

MUTE

MONI1-1,2-1,

MONI2-2,2-1

INT/EXT1,INT/EXT2

MIC/LINE/+48V-1,

MIC/LINE/+48V-2,

WIND FILTER1,

WIND FILTER2

COPY1to 2

SEL/

MIX1

IC200,

IC202 (1/2)

MONI 1-1

MONI 2-1

SEL/

IC201,

MIX2

IC202 (2/2)

MONI2-2

MONI1-2

IC203, 205

GPIO

SEL/

MIX1

LINK 2 1

SEL/

MIX2

LINK 1 2

CN-3273

PGA

GAIN

PGA

GAIN

PGA

GAIN

PGA

GAIN

DAP-41

A/D

A/D

AMP

AMP

AMP

MONITOR LEVEL

IC205,206,207,208

IC202(1/2)

AGC/

FIL LVL

LIM

IC203

AGC/

FIL

IC202 IC203

LIM

IC202(2/2)

+

IC201

I2C MPX

(DEVICE CONTROL)

LVL

D/A

MIX

AMP

GPIO

IN2LP(L)

IN2RP(R)

IN2LN

DIGITAL

AUDIO IF

DIGITAL

AUDIO IF

I2C

CONTROL

(T-one)

IC600

FPGA

Digital Audio 1

CLOCK DIV

(1fs,64fs,256fs)

Digital Audio 2

Digital Audio

1/2 , 3/4

CLOCK DIV

(1fs,64fs,256fs)

IC1300

LINE 3/4

DPR-311

IC600

BEEP

(T-one)

IC600

CONTROL

I2C

(T-one)

PMW-EX1R

Fig. 1. Audio block diagram

1-7 (E)

. Serial control

2

The I

C control signal from Display Block (Base band) is converted into GPI, and performs switching

such as [INT/EXT], [LINE/MIC/MIC+48], [CH1/ (CH/CH)], and AGC [Linked/Separated] for CH1

and CH2.

2

The I

C control from Display Block (Base band) selects either IC202 or IC203 for the target with I2C

MPX (IC201) and sets the register of IC202 or IC203.

CN-3273 Flexible board

It relays the audio signal from the DPR-311 board to the ASW-68 board.

ASW-68 Board (Audio block)

. Analog output from the DAP-41 board Audio Codec is buffered by IC204 and is output to the A/V

connector after passing through the audio MUTE control.

. Analog output from Audio Codec on the DAP-41 board re-enters into the IN2LP input and IN2RP input

of the DAP-41 board Audio Codec after passing through the monitor selector/mixer (IC200, IC201,

IC202), and becomes the monitor signal.

. Serial control

2

I

C control signal from Display Block (Base band) is output at GPI, and performs the switching be-

tween MONITOR [CH1/CH2] / [CH1+CH2] / [CH1] / [CH2] for CH1 and CH2 respectively.

VIF-46 Board (Audio block)

The audio output from the ASW-68 board is connected to A/V multi-connector and connector board.

LED-491 Board (Audio block)

The headphones output signal is connected to the headphones jack (CN3) of the LED-491 board, and the

speaker output signal is connected to the speaker connector (CN2).

The headphones output is muted by the MUTE (Q2, Q3).

Switch/Volume control (Audio controller block)

Operation panel functions relating to audio signal are built into the following blocks.

ASW-68 Board (Audio block)

For CH1 and CH2, the switches [INT/EXT] and [AUTO/MANUAL] are connected to PIO of CPU

(IC301), and the volume control [AUDIO LEVEL] is connected to ADC of CPU (IC301).

KSW-55 Board (Audio block)

The switch [LINE/MIC/MIC+48] on the AXM-42 board is connected to PIO of CPU (IC100) for CH1

and CH2 respectively. The switch [MONITOR (AUDIO) +/_] that is common to CH1 and CH2 is connected to PIO of CPU (IC100).

6. System Control

DPR-311 Board

The 32-bit RISC CPU (ARM) with ARM core is built-in as the system controller (IC2900).

It has the peripheral interface functions of SDRAM, USB, SCI, and I2C. It operates on a 27 MHz clock

(X2900). FLASH ROM (IC2908), SDRAM (IC2909), and EEPROM (IC3205) are mounted as the peripheral ICs.

It performs the system control through serial communication with IC500 of the camera block system,

IC600 of the video signal system, and IC1600 of the media recording/playback system.

1-8 (E)

PMW-EX1R

Main functions of the system controller and peripherals

(1) Reading operation switch information

2

Reading the switch information and the LED control are performed by I

C bus communication with each

sub-microprocessor.

. Handle switch: IC100 on the KSW-55 board

. Inside panel switch: IC200 on the SWC-50 board

. Rear panel switch: IC301 on the ASW-68 board

. Power supply switch: IC1001 on the RE-273 board

(2) Watch IC (RTC) control

The watch IC (IC100) is built onto the DAP-41 board.

The watch IC (IC100) is backed up by a lithium coin battery, and the current time is read or set via IC200

on the SWC-50 board.

(3) Infrared remote control demodulation

The RM-224 board has an IC (IC1) for infrared remote control signal demodulation, and it receives the

command codes via IC100 on the KSW-55 board.

(4) Info-Battery communication

The Info-Battery of SM bus specifi cations is supported.

The serial terminal of the battery connector is connected to IC1001 on the RE-273 board. This IC1001

read the battery authentication, battery type, remaining power, and other information and send them to the

system controller via I

2

C bus communication.

(5) Power supply voltage detection

The power supply voltage at the DC IN connector is measured by the A/D port on IC1001 on the RE-273

board, and it is posted to the system controller as the input voltage value.

(6) Power system control

IC1001 on the RE-273 board checks that the power switch on the PMW-EX1R is turned ON, and turns on

the system controller of IC2900. After that, it controls the power for each circuit block according to the

system controller.

The system controller controls the respective power supply systems in the RE-272 and RE-273 boards

according to the operation mode of the device, via the power supply μ-processor (IC1001) on the RE-273

board.

By turning off the power systems to unnecessary circuits blocks, power can be saved.

7. EVF/SDI System

SDI block

TX-131 Board

This board receives the parallel video signal with FPGA (IC200) and outputs the SDI signal.

Furthermore, it performs audio or timecode embedding.

The video and audio signals are supplied from CN700 on the DPR-311 board to CN100 on the TX-131

board with B to B connector.

Output SDI signals are supplied to CN500 through the cable driver (IC500).

Output SDI signals are then supplied from CN500 to the coaxial connector via the mini coaxial connector

and mini coaxial cable.

The PLL circuit is used to reduce jitter of the HD-SDI clock signal.

The FPGA (IC200) is controlled by IC600 on the DPR-311 board through 4-line serial communication.

PMW-EX1R

1-9 (E)

8. Power supply system

RE-272/273 Board

This board is comprised of the power supply circuit and the POWER SUPPLY MICON (power supply

μ-processor: IC1001 on the RE-273 board).

However, part of the low-voltage power supply is mounted on the DPR-311 board.

(1) Input power supply (UNREG) system operations

When the UNREG power is input, the EVER power state is established.

In this state, the ON/OFF state of the Power switch can be recognized.

If the POWER SUPPLY MICON (power supply μ-processor: IC1001) recognizes that Power switch is

ON, the power is turned on for the system control system and the POWER SUPPLY MICON (power

supply μ-processor: IC1001) controls the power supply for each block according to the system controller

(DPR-311 board: IC2900).

The normal value for the input power supply (UNREG) is in the range of about +10.5 V to +18 V.

. Battery/EXT-DC select

Input power comes in two systems: Battery and EXT-DC. This switch monitors the input voltage for

each input and automatically switches the circuit settings with priority given to EXT-DC.

. Input overvoltage protection

If the voltage is too high in the UNREG power supply, the overvoltage protection circuit starts operat-

ing around the set value of +17.9 V, and the camera shuts down. When the input power supply voltage

to this circuit becomes less than +17.9 V, the power supply immediately switches on with automatic

recovery.

. Input low-voltage protection

If the voltage is too low in the UNREG power supply, the low-voltage protection circuit starts operating

around the set value of +10.5 V according to the control by the POWER SUPPLY MICON (power

supply μ-processor: IC1001), and the camera shuts down. When the input power supply voltage becomes higher than +10.5 V, the power supply immediately switches on with automatic recovery according to the control by the POWER SUPPLY MICON (power supply μ-processor: IC1001)

. Overcurrent detection

The overcurrent detection circuit is comprised of IC308 on the RE-272 board. The setting value is

approximately 4.3 (A). Even after clearing IC308 after overcurrent detection, automatic recovery is not

performed and the power must be turned on again.

. Power supply reverse connection protection

If the input power has reverse voltage, Q301 on the RE-272 board is immediately turned off and UN-

REG power is stopped on the GND side, and the protection function works.

. Power saving function during standby

When the power switch of the camera is turned off, the POWER SUPPLY MICON (power supply

μ-processor: IC1001) enters the Sleep mode in order to save the power by minimizing the detection

circuit of the camera power switch.

1-10 (E)

PMW-EX1R

(2) DC/DC converter function

The power supply output is divided into 25 systems, which are separated into four blocks as seen below.

. CMOS/camera block system, 7 systems

(+4.6 V, +3.1 V, UNREG, etc.)

. Audio/video signal system, 7 systems

(+13.5 V, _4.6 V, +4.6 V, etc.)

. System controller system, 5 systems

(+4.6 V, +3.1 V, +2.5 V, etc.)

. Media recording/playback system, 6 systems

(+3.1 V, +2.5 V, +1.8 V, etc.)

The sequence control (powering up and powering down) for the power supply system is controlled by the

POWER SUPPLY MICON (power supply μ-processor: IC1001) for the respective power supply blocks of

each block.

By turning off the power for each block according to the operation mode (camera mode or media mode),

the optimal power consumption for each operation is achieved.

. Short-circuit protection for each power supply system

The circuit settings monitor each output voltage or current for each power supply system and operate

the protection circuits per block.

Even after the protection circuit is cleared, automatic recovery is not performed and the power must be

turned on again.

Even after short-circuit is cleared, the protection circuit does not recover automatically and the power

must be turned on again.

(3) Battery information functions

. Battery authentication function

The authentication function checks whether the battery is of the specifi ed type. This helps prevent one

cause of major accidents when using batteries as a power supply. If the attached batter is not the specifi ed type of batter, the camera immediately turns off.

. Battery Info function

In an intelligent (specifi ed) battery, the battery can monitor information, such as how many times the

battery has been recycled or the internal temperature for the battery. This helps provide detailed information about the battery, including whether the battery is damaged or how long the life is, in order to

provide optimal operations.

PMW-EX1R

1-11 (E)

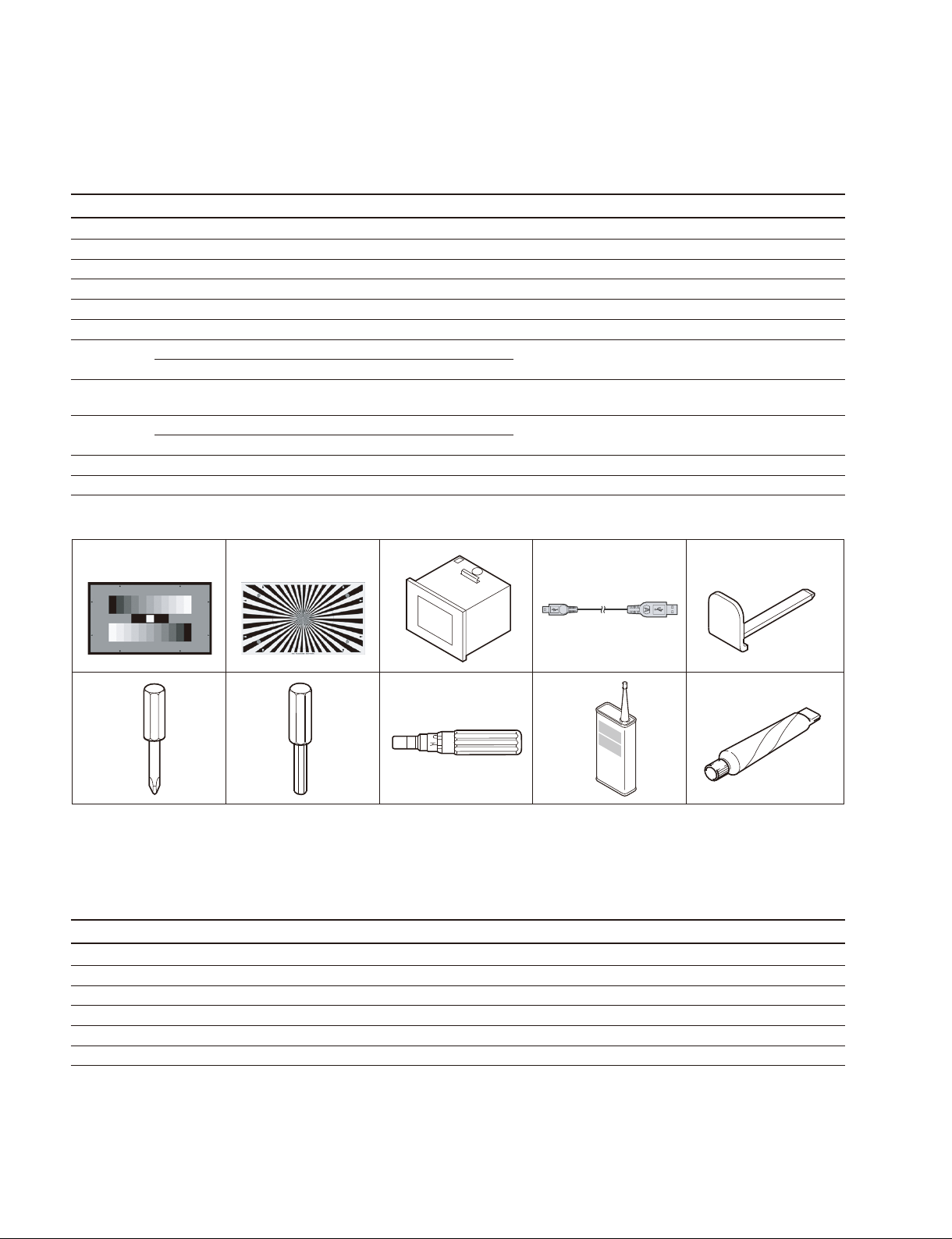

1-4. Service Tools/Measuring Equipment List

1-4-1. Service Tools

Figure No. Part No. Name Usage/Note

1 Commercially available Grayscale chart Refl ective type (16 : 9), Camera adjustment on market

2 Commercially available Star chart Refl ective type, camera adjustment on market

3 J-6394-080-A Grayscale chart Transparent type (16 : 9), Camera adjustment on market

4 J-6029-140-B Pattern box PTB-500 Camera adjustment

5 * Mini USB cable For fi rmware version-upgrade

6 3-292-755-01 XLR tool For removing the mounted circuit board

7 J-6325-110-A Bit for torque driver (M1.4/M1.7) For tightening screw

J-6325-380-A Bit for torque driver (M2)

8 J-6326-120-A Hexagon bit (For torque screwdriver) For tightening screw

(size 1.5)

9 J-6325-400-A Torque driver (3 kg.cm) (0.3 N.m) For tightening screw

J-6252-510-A Torque driver (6 kg.cm) (0.6 N.m)

!/ 7-432-114-11 Locking compound 200 g For preventing screw from being loosened

!- 7-651-000-10 Sony (SGL-601) 50 g grease Lubricant

* : This cable is supplied with PMW-EX1R.

,

1-4-2. Measuring Equipment

Use the calibrated equipment or equivalent as listed below for the adjustments.

Equipment Model name

Oscilloscope Tektronix TDS3054 or equivalent (150 MHz or more)

HD waveform monitor LEADER ELECTRONICS CORP.LV5152DA or equivalent

Frequency counter Advantest TR5821AK or equivalent

Digital voltmeter Advantest TR6845 or equivalent

Color monitor Sony HDM-20E1U/14E1U/14E5U or equivalent

Luminance meter Konica Minolta LS-110 or equivalent

1-12 (E)

PMW-EX1R

1-5. Firmware Upgrade

Upgrade the fi rmware for the PMW-EX1R through a USB connection to a computer.

For detailed information about the upgrade procedure, check the readme fi le that comes with the upgrade

software.

For inquiry or comments about the fi rmware upgrade, please contact the Sony sales offi ce.

Firmware Upgrade Procedure

Download the software for the new fi rmware upgrade onto the computer before starting these operations.

1. Check that the power switch on the PMW-EX1R is turned OFF.

2. Remove the cover on the USB maintenance connector.

Cover

USB maintenance connector

3. Use the USB connector that comes with the PMW-EX1R to connect the computer and the USB

maintenance connector.

4. Switch the power switch to CAMERA and turn the power ON.

5. Run the software for the fi rmware upgrade on the computer.

6. When the upgrade is complete, turn OFF the power and remove the USB cable.

7. Attach the cover on the USB maintenance connector.

When the PMW-EX1R is connected to the computer for the fi rst time, the driver software will need to be

installed into the computer. For more details, check the readme fi le that comes with the upgrade software.

PMW-EX1R

1-13 (E)

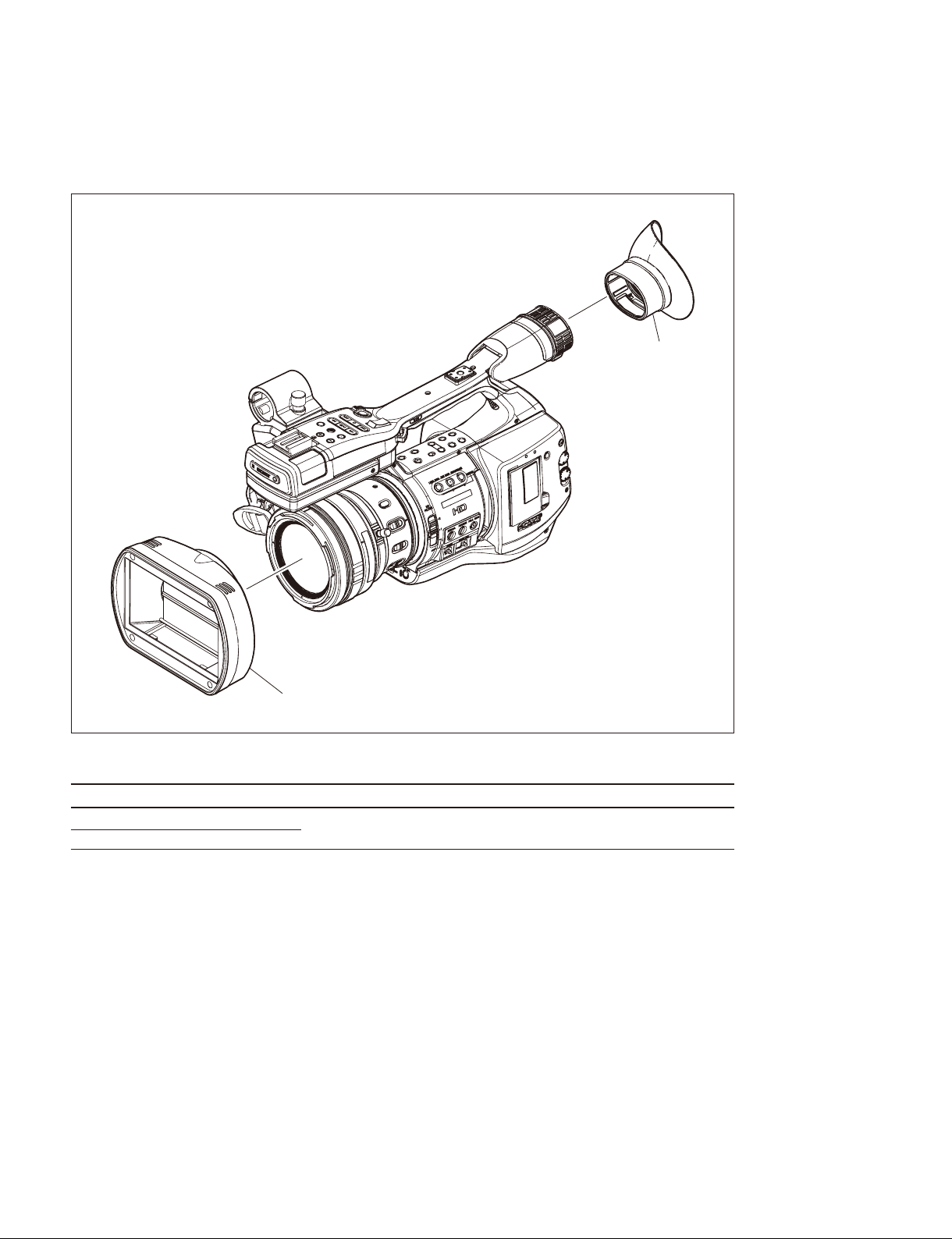

1-6. Recommended Replacement Parts

This section describes the recommended replacement parts and recommended replacement time.

1

2

ID Part name Sony part No. Recommended replacement timing

1 Eye cup 4-164-856-01 Check for deformation and deterioration from time to time.

2 Lens hood 4-179-065-01

Replace it as necessary.

1-14 (E)

PMW-EX1R

1-7. Circuit Protection Part List

1-7-1. Circuit Protection Element

This unit is equipped with the positive characteristics thermister (s) (power thermister) as the circuit

protection element. The positive characteristics thermister limits the electric current fl owing through the

circuit as the internal resistance increases when an excessive current fl ows or when the ambient tempera-

ture increases.

If the positive characteristics thermister works, turn off the main power of the unit and inspect the internal

circuit of this unit. After the cause of the fault is eliminated and the positive characteristics thermister is

cooled down, turn on the main power again. The unit works normally.

It takes about one minute to cool down the positive characteristics thermister after the main power is

turned off.

Board Ref. No. (Address) Part No. Hold Current

CN-3273 THP1 (A-1/Side A) ! 1-805-726-11 0.20 A/25dC

THP2 (A-1/Side A)

THP3 (A-1/Side A)

THP4 (A-1/Side A)

1-7-2. Replacing Fuse

w

The fuse is an essential part for safe operation.

Replace the components with Sony parts whose part numbers appear in the manual published by Sony. If

the components are replaced with any parts other than the specifi ed ones, this may cause a fi re or electric

shock.

c

If the fuse is replaced while the main power is kept on, this may cause electric shock.

Before replacing the fuse, not only turn off the POWER switch but also disconnect the cable that is connected to the DC IN connector.

This unit is equipped with fuses.

The fuses blow if an excessive current fl ows due to abnormality inside the equipment. If fuses blow, turn

off the main power of the equipment once, and inspect inside of the equipment and remove the cause of

excessive current. After that, replace the fuses.

Board Ref. No. (Address) Part No./Name

RE-272 F1 (B-1/Side B) ! 1-533-627-21 Fuse 5 A, 125 V

F2 (A-2/Side B)

PMW-EX1R

1-15 (E)

1-8. Note on Service

1-8-1. Requirements on Replacement of Boards or Parts

This section explains the necessary setups required when replacing boards or parts.

1. When any of the following boards is replaced, upgrade the fi rmware version.

All data are written at once when upgrading the fi rmware version. (Refer to Section 1-5.)

Board name : . DPR-311

. KSW-55

. SWC-50

. ASW-68

. RE-273

. TX-131

2. Adjusted values are stored in the following boards and parts. The values need to be readjusted when

they are replaced.

For readjustment, the dedicated service software “ServiceNavi-EX” is required.

(Refer to Section 4-1.)

Board name : . DPR-311

. IF-1127

Part name : . CMOS block

. EVF block

. LCD module

*1: The adjusted values for the CMOS block, the EVF block, and the LCD module are stored in the DPR-311 board.

*2: The adjusted values for the LCD module are stored in the LCD module (IF-1127 board), but the adjusted values need to be

copied to the DPR-311 board.

*1

*2

*2

3. The user setting values are stored in IC3250 on the DPR-311 board. The user data must be stored (Restore) in SxS before replacing the board and it must be read (Recall) after replacing the board.

1-8-2. Requirements on Replacement of Lens

When the lens is replaced, perform the fl ange-back adjustment.

1-8-3. Note on Replacement of Parts on the Board

1. The BI-202, BI-203 and BI-204 boards cannot be replaced on the board-level service or part-level

service. If parts become defective, replace the entire CMOS block.

2. Parts labels also cannot be replaced in the respective boards. If parts become defective, replace the

entire mounted board.

1-8-4. Description of Number Seal on the Prism

The number seal is put in the prism unit, the serial number of prism unit.

Every prism unit has its own number called prism serial number.

1-16 (E)

PMW-EX1R

1-8-5. Memory Backup Battery

For replacing the battery, refer to “Backup Battery” of the “Appendixes” in the Operating Instructions.

When the backup battery is replaced, the date and time in the internal clock need to be set. Refer to “Setting the Clock” of the “Preparations” in the Operating Instructions.

1-8-6. Unleaded Solder

Boards requiring use of unleaded solder are printed with a lead free mark (LF) indicating the solder

contains no lead.

(Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular

size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC higher than the ordinary solder, therefore, it is

recommended to use the soldering iron having a temperature regulator.

. The ordinary soldering iron can be used but the iron tip has to be applied to the solder joint for a slightly

longer time. The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so

be careful.

PMW-EX1R

1-17 (E)

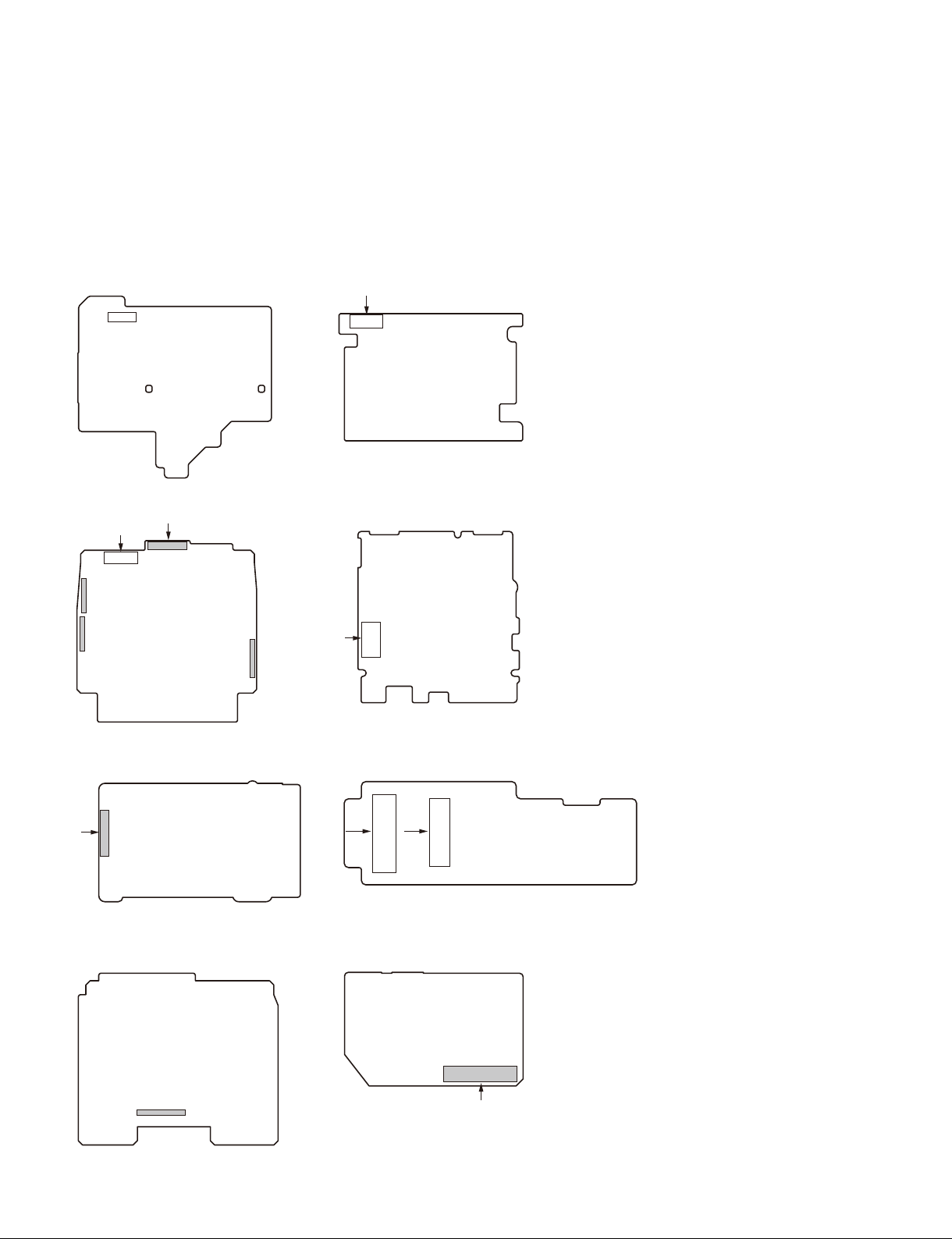

1-9. Connector Location Diagram on Board

The PWM-EX1R uses fl exible card wires and coaxial cables with connector. The following diagrams

indicate the location of each connector. The location of fl exible card cables are indicated by the circle

number A and B, and the location of coaxial cables with connector are indicated by the circle number

C and D

ASW-68 board (B side) AU-326 board (B side)

CN302

CN100

DPR-311 board (A side) KSW-55 board (A side)

CN3401

CN2401

CN2400

CN900

CN5

CN3402

EC-68 board (B side) DR-644 board (A side)

CN1

CN1

CN3

TX-131 board (B side) VIF-46 board (B side)

CN1

CN901

1-18 (E)

PMW-EX1R

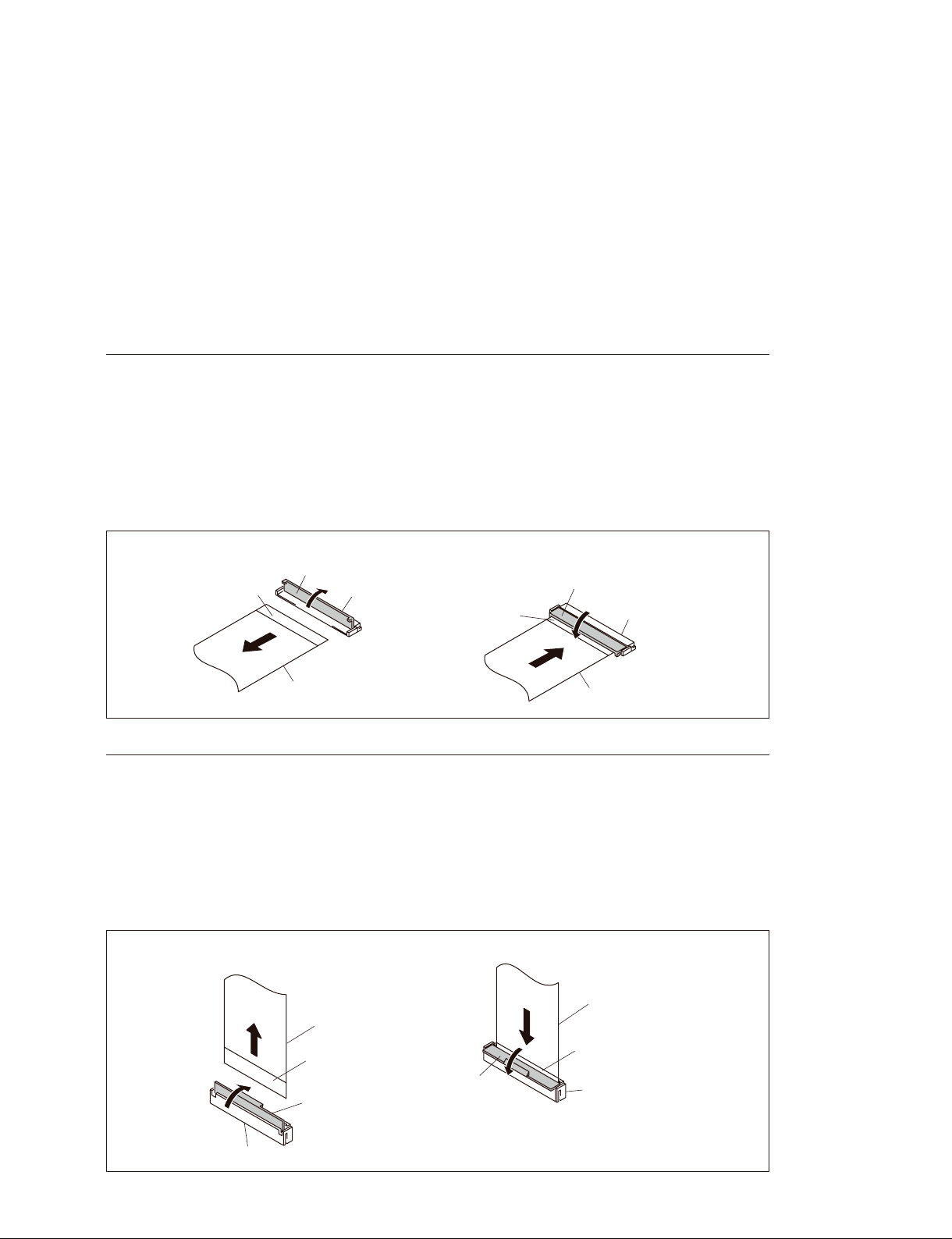

1-10. Connecting/Disconnecting the Flexible Card Wire

This unit uses the two types connectors for the fl exible card wires.

m

. Be very careful not to fold the fl exible card wire. Life of fl exible card wire will be signifi cantly short-

ened if it is folded.

. The fl exible card wire has the conductor side and the insulated area. If the conductor side and the insu-

lated area are connected in the wrong direction, the circuit will not function.

. Insert the fl exible card wire straight.

. Ensure that the conduction surface of the fl exible card wire is not contaminated.

Type A

Disconnecting

Open the latch of the connector in the direction of arrow A to unlock, and disconnect the fl exible card wire.

Connecting

1. Insert the fl exible card wire fi rmly as far as it will go, with the insulated side up.

2. Close the latch of the connector in the direction of arrow B to lock.

Disconnecting Connecting

Insulated side

Latch

A

Connector

Insulated side

Latch

B

Connector

Flexible card wire

Flexible card wire

Type B

Disconnecting

Open the latch of the connector in the direction of arrow C to unlock, and disconnect the fl exible card wire.

Connecting

1. Insert the fl exible card wire fi rmly as far as it will go, with its insulated side facing front.

2. Close the latch of the connector in the direction of arrow D to lock.

Disconnecting

Flexible card wire

Insulated side

C

Latch

Connecting

Latch

D

Flexible card wire

Insulated side

Connector

PMW-EX1R

Connector

1-19 (E)

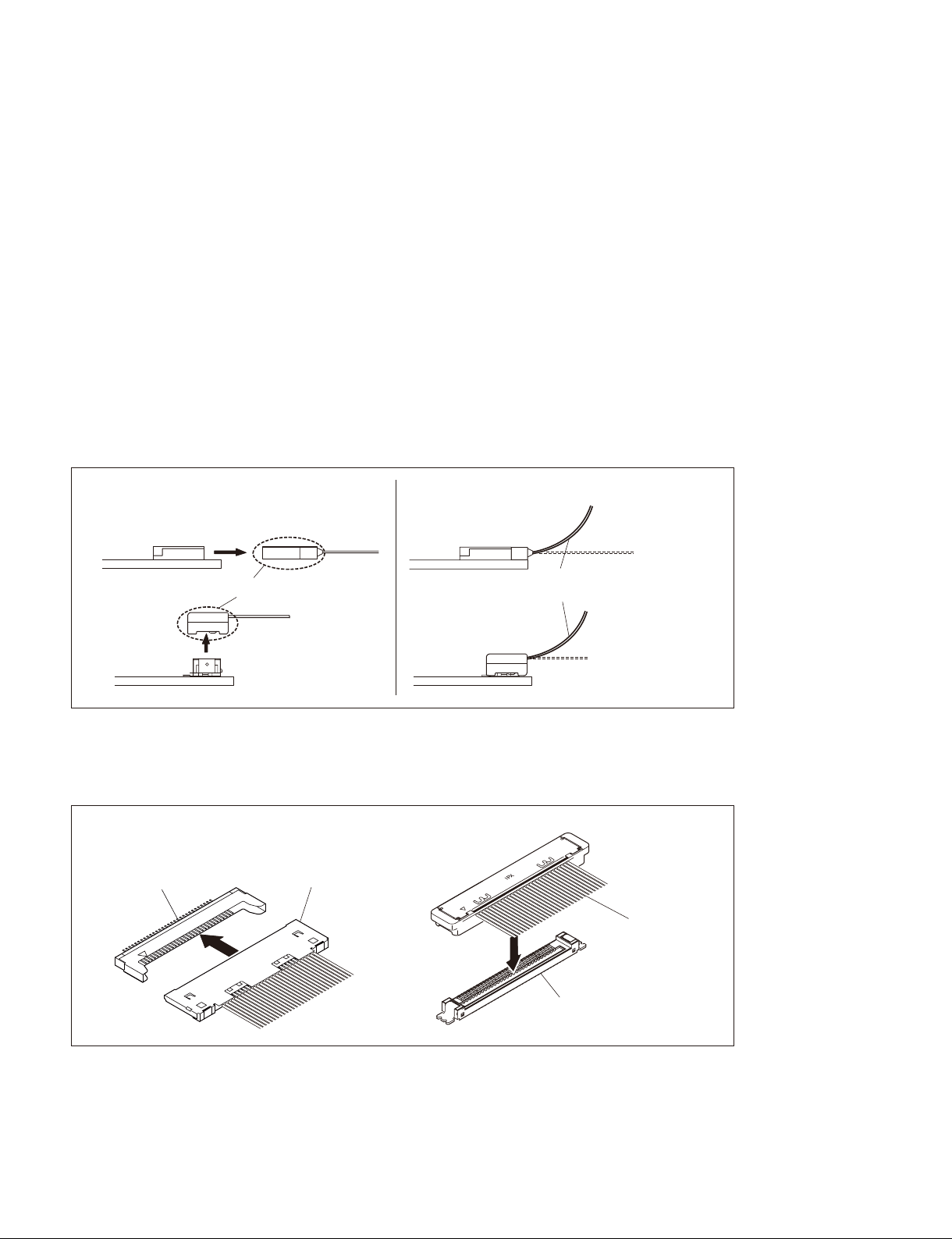

1-11. Replacing the Coaxial Cable with Connector (Fine Pitch Coaxial Cable)

This unit uses coaxial cables with connector.

The following precautions must be observed when removing or connecting the coaxial cable with connector.

m

. The coaxial cable with connector uses fi ne pitch coaxial cables. Be careful when arranging the cable.

. When disconnecting the coaxial cable with connector, do not attempt to remove by pulling the cable.

Be sure to hold the connector to remove.

. Do not insert the coaxial cable with connector at an angle.

. Check that the contact on the coaxial cable with connector is free from dirt or dust.

. When connecting the coaxial cable with connector, hold the connector, and align the polarity marks.

Then connect the coaxial cable with connector to the connector straight.

Disconnecting

Disconnect the coaxial cable with connector while holding the connector.

[OK]

Type C

Hold the connector to disconnect.

Type D

[NG]

Type C

Do not attempt to disconnect by

pulling the cables.

Type D

Connecting

Insert the connector of the coaxial cable with connector fi rmly as far as it will go.

Type C Type D

Coaxial cable

Connector

with connector

Coaxial cable

with connector

1-20 (E)

X

P

I

Connector

PMW-EX1R

Section 2

Replacement of Main Parts

2-1. Outline of Replacement Procedures

The following fi gures show the fl ow for removing the main parts. Refer to Section 2-2 for details of the replacement proce-

dures.

START

Battery

Lithium battery

Battery lid

Outside panel

assembly

Tripod

washer (D)

Rear panel assembly

Inside panel

assembly

Case (bottom) L

Front panel

assembly

Handle

assembly

Case (bottom) R

Handle cover

(upper) assembly

Microphone

holder

EVF assembly

Cover (center) assembly

PMW-EX1R

Express card

assembly

Battery case

RE-273 board

RE-272 board

Prism assembly

TX-131 board

ND filter

DPR-311 board

Case L

assembly

Case R

2-1 (E)

2-2. Replacement Procedures

m

. When tightening screw, be sure to tighten it with the specifi ed tightening torque.

. When reinstalling the removed tapping screw again, tighten it with slightly loose torque not to damage the threads of the

component side.

. If the tightening torque is not specifi ed in a specifi c item, use the tightening torque as specifi ed below.

M2 (+) screw: 18 x 10_2 ?0.02 N.m (1.8 ?0.2 kgf.cm)

M2.6 (+) screw: 53 x 10_2 ?0.07 N.m (5.3 ?0.7 kgf.cm)

M3 (+) screw: 80 x 10 ?0.01 N.m (8.0 ?0.1 kgf.cm)

. The life of the fl exible board and the fl exible card wire will be signifi cantly shortened if they are folded. Be very careful

not to fold them.

. The coaxial cable with connector uses fi ne pitch coaxial cables. Be careful when arranging the cable.

. When disconnecting the coaxial cable with connector, do not attempt to remove by pulling the cable. Be sure to hold the

connector to remove.

2-2-1. Lithium Battery

Removing lithium battery

1. Remove the screw, and remove the lithium

battery lid.

2. Remove the lithium battery.

Lithium battery

Battery holder

3. Reinstall the lithium battery by reversing the

steps of removal.

2-2-2. Case (Bottom) L/R and Front

Panel Assembly

1. Remove the lithium battery.

(Refer to Section 2-2-1.)

2. Remove the four screws of a, and remove

the tripod washer (D).

3. Remove the fi ve screws of b, and remove

the case (bottom) L in the direction of the

arrow.

4. Remove the case (bottom) R.

M2 x 4

(Black)

Lithium battery lid

Case (bottom) L

Tripod (D)

Three claws

Claw

Case

(bottom) R

n

Be careful not to drop or damage the USB cover.

2-2 (E)

: M2 x 6 (Black)

: M2 x 4 (Black)

USB cover

PMW-EX1R

Loading...

Loading...