Sony VAIO PCG-F610, VAIO PCG-F630 Service Manual

PCG-F610/F630

SERVICE MANUAL

Ver 5-2002A

Revision History

Illust : PCG-F630

US Model

Canadian Model

S400

Confidential

9-872-145-15

NOTEBOOK COMPUTER

Information in this document is subject to change without notice.

Sony and VAIO are trademarks of Sony . Intel logo and Intel Inside

logo are registered trademarks of Intel Corporation. Pentium MMX

is a trademark of Intel Corporation. Microsoft, MS-DOS, W indows,

the W indows 95 and W indows 98 log o are trademarks of Microsoft

Corporation.

All other trademarks are trademarks or registered trademarks of

their respective owners. Other tr ademarks and trade names may be

used in this document to refer to the entitles claiming the marks and

names or their produces. Sony Corporation disclaims any proprietary

interest in trademarks and trade names other than its own.

Caution Markings for Lithium/Ion Battery - The following or similar

texts shall be provided on battery pack of equipment or in both the

operating and the service instructions.

CAUTION: Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer. Discard used batteries according to the

manufacturer’s instructions.

CAUTION: The battery pack used in this de vice may present a f ire

or chemical burn hazard if mistreated. Do not disassemble, heat

above 100°C (212°F) or incinerate.

Dispose of used battery promptly.

Keep away from children.

CAUTION: Changing the back up battery.

• Overcharging, short circuiting, reverse charging, multilation or

incineration of the cells must be avoided to prev ent one or more of

the following occurrences; release of toxic materials, release of

hydrogen and/or oxygen gas, rise in surface temperature.

• If a cell has leaked or vented, it should be replaced immediately

while avoiding to touch it without any protection.

Service and Inspection Precautions

1. Obey precautionary markings and instructions

Labels and stamps on the cabinet, chassis, and components identify areas

requiring special precautions. Be sure to observe these precautions, as well

as all precautions listed in the operating manual and other associated

documents.

2. Use designated parts only

The set’s components possess important safety characteristics, such as

noncombustibility and the ability to tolerate large voltages. Be sure that

replacement parts possess the same safety characteristics as the originals.

Also remember that the 0 mark, which appears in circuit diagrams and

parts lists, denotes components that have particularly important safety

functions; be extra sure to use only the designated components.

3. Always follow the original design when mounting

parts and routing wires

The original layout includes various safety features, such as inclusion of

insulating materials (tubes and tape) and the mounting of parts above the

printer board. In addition, internal wiring has been routed and clamped so

as to keep it away from hot or high-voltage parts. When mounting parts or

routing wires, therefore, be sure to duplicate the original layout.

4. Inspect after completing service

After servicing, inspect to make sure that all screws, components, and wiring

have been returned to their original condition. Also check the area around

the repair location to ensure that repair work has caused no damage, and

confirm safety.

5. When replacing chip components...

Never reuse components. Also remember that the negati ve side of tantalum

capacitors is easily damaged by heat.

6. When handling flexible print boards...

•The temperature of the soldering-iron tip should be about 270C.

•Do not apply the tip more than three times to the same pattern.

•Handle patterns with care; never apply force.

Caution: Remember that hard disk drives are easily damaged by

vibration. Always handle with care.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Confidential

PCG-F610/F630 (UC)

— 2 —

TABLE OF CONTENTS

Section Title Page

CHAPTER 1. REMOVAL

1-1. Flowchart ......................................................................... 1-1

1-2. Main Electrical Parts Location Diagram ......................... 1-1

1-3. Removal ........................................................................... 1-2

1. Hinge Cover ..................................................................... 1-2

2. Keyboard Unit, Palm Rest Assy, Hood Keyboard Assy

Touch Pad, CNX-100 Board ............................................ 1-2

3. Display Assy, CD-ROM Drive, DVD-ROM Drive.......... 1-3

4. HDD Assy, Cooling Unit ................................................. 1-3

5. SWX-57 Board, Latch Detector Unit, PWS-9 Board ...... 1-4

6. Modem Unit, MBX-39 Board.......................................... 1-4

7. Speaker Unit, SWX-56 Board ......................................... 1-5

8. SO-DIMM........................................................................ 1-5

9. LCD Section (F630 Model) – Made by SA – .................. 1-6

1. Bezel Housing Assy..................................................... 1-6

2. LCD Harness, Bracket LCD Left, Bracket LCD Right,

LCD unit (13inch) ....................................................... 1-7

3. FPC, Inverter Assy, Display Housing Assy.................. 1-7

10.LCD Section (F610 Model) – Made by SA –.................. 1-8

1. Bezel Housing Assy..................................................... 1-8

2. LCD Harness, Bracket LCD Left, Bracket LCD Right,

Hinge Left, Hinge Right, LCD unit (12inch)............... 1-9

3. FPC, Inverter Assy, Display Housing Assy.................. 1-9

1-4. Replacing the CPU ........................................................ 1-10

1. Removing the CPU ........................................................ 1-10

2. Installing the CPU.......................................................... 1-10

1-5. Replacing Various Connectors on the MBX-39 Board.. 1-11

1. Removing the I/O Bracket ............................................. 1-11

2. Removing the Various Connectors ................................. 1-11

1-6. Using Common Flexible Boards and

Dedicated Flexible Boards Differently As Specified *.. 1-12

(to 1-15)

Section Title Page

CHAPTER 2. SELF DIAGNOSTICS

2-1. Required Tools and Peripheral Devices........................... 2-1

2-2. Tools and Peripheral Device Connection.........................2-3

2-3. Starting up the Service Diagnostics ................................. 2-4

2-4. Outline of Service Diagnostics Functions ....................... 2-4

2-5. Inspecting W indows.........................................................2-7

(to 2-7)

CHAPTER 3. BLOCK DIAGRAM............................... 3-1

(to 3-2)

CHAPTER 4. FRAME HARNESS DIAGRAM........ 4-1

(to 4-2)

CHAPTER 5. EXPLODED VIEWS AND

PARTS LIST............................................5-1

5-1. Main Section .................................................................... 5-2

5-2. LCD Section (F630 Model) – Made by SA –................. 5-5

5-3. LCD Section (F610 Model) – Made by SA –.................. 5-7

5-4. Connector Section............................................................ 5-9

(to 5-10)

∗ Be sure to read section “1-6. Using Common Flexible Boards

and Dedicated Flexible Boards Differently AS Specified”

• Abbreviations

UC : US model / Canadian model

History of the changes is shown as the

“Revision History” at the end of this data.

— 3 —

Confidential

PCG-F610/F630 (UC)

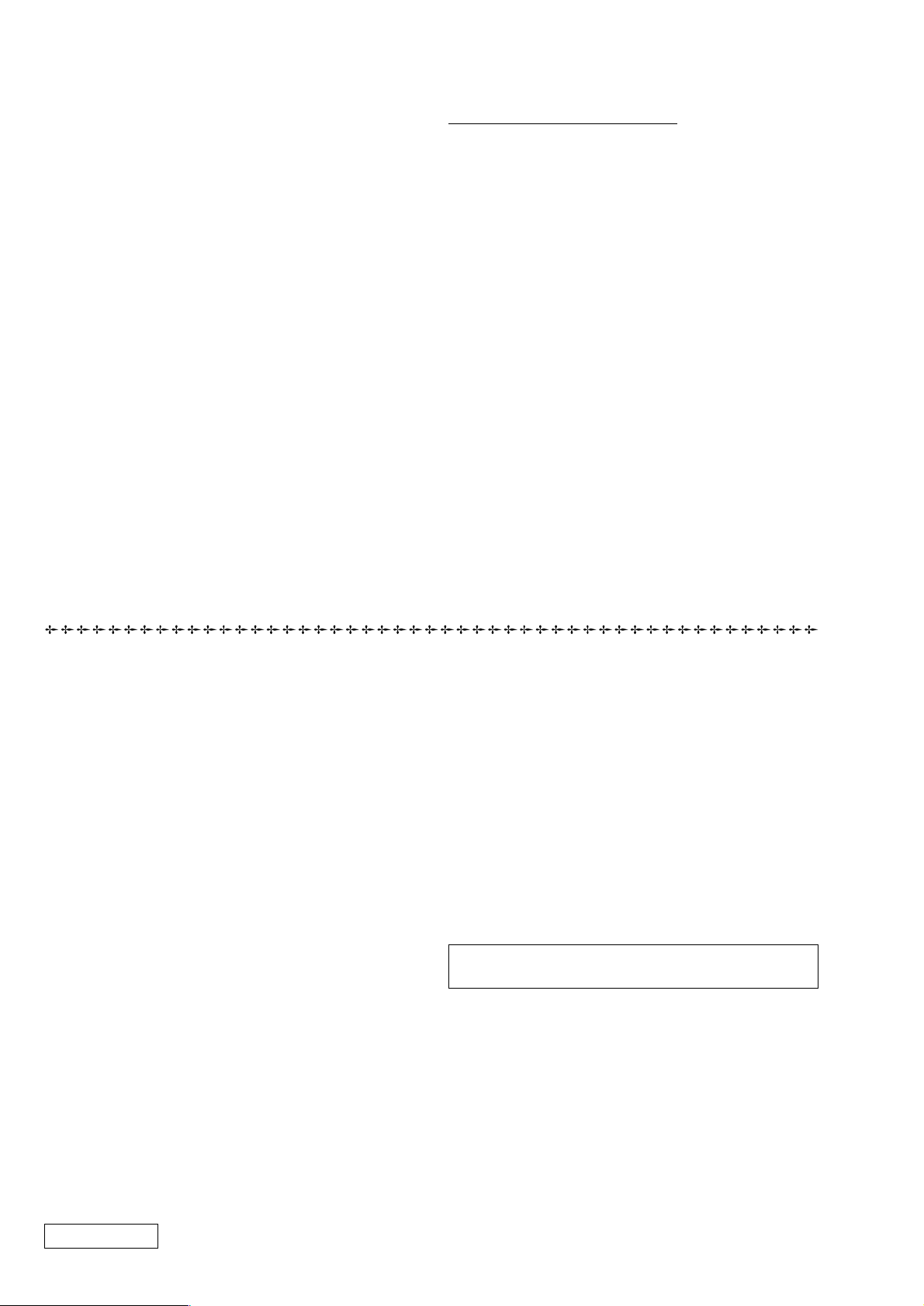

1-1. Flowchart

CHAPTER 1.

REMOVAL

POWER

OFF

HOOD

KEYBOARD

ASSY

SO-DIMM

BATTERY

PACK

FDD

HINGE

COVER

P 1-2

KEYBOARD

UNIT

P 1-2P 1-2

SPEAKER

UNIT

P 1-5P 1-5

SWX-56

BOARD

P 1-5

P ALM REST

ASSY

P 1-2 P 1-3

HDD

P 1-3

P ALM REST

PLA TE

CD-ROM/

DVD-ROM

DRIVE

PWS-9

BOARD

P 1-4

BRACKET

PAT

P 1-2 P 1-2P 1-2

DISPLAY

ASSY

P 1-3

DETECTOR

CNX-100

LA TCH

P 1-4

TOUCH

PAD

BOARD

P 1-2

BEZEL

HOUSING

ASSY

∗

P 1-6

(P1-8)

COOLING

UNIT

P 1-3

SWX-57

BOARD

P 1-4

LCD

UNIT

∗ P 1-7

(P1-9)

MODEM

UNIT

P 1-4

5, 9through 0

• P XX means pages that appears in this manual.

• Remember that hard disk drives are easily damaged by vibration. Always handle with care.

INVERTER

ASSY

∗ P 1-7

(P1-9)

MBX-39

BOARD

P 1-4

∗ : F630 Model (Made by SA)

( ) : F610 Model (Made by SA)

LCD

HARNESS

∗

P 1-7

(P1-9)

FPC

∗ P 1-7

(P1-9)

BRACKET

LCD LEFT

∗ P 1-7

(P1-9)

BRACKET

LCD RIGHT

∗ P 1-7

(P1-9)

DISPLAY

HOUSING

ASSY

∗ P 1-7

(P1-9)

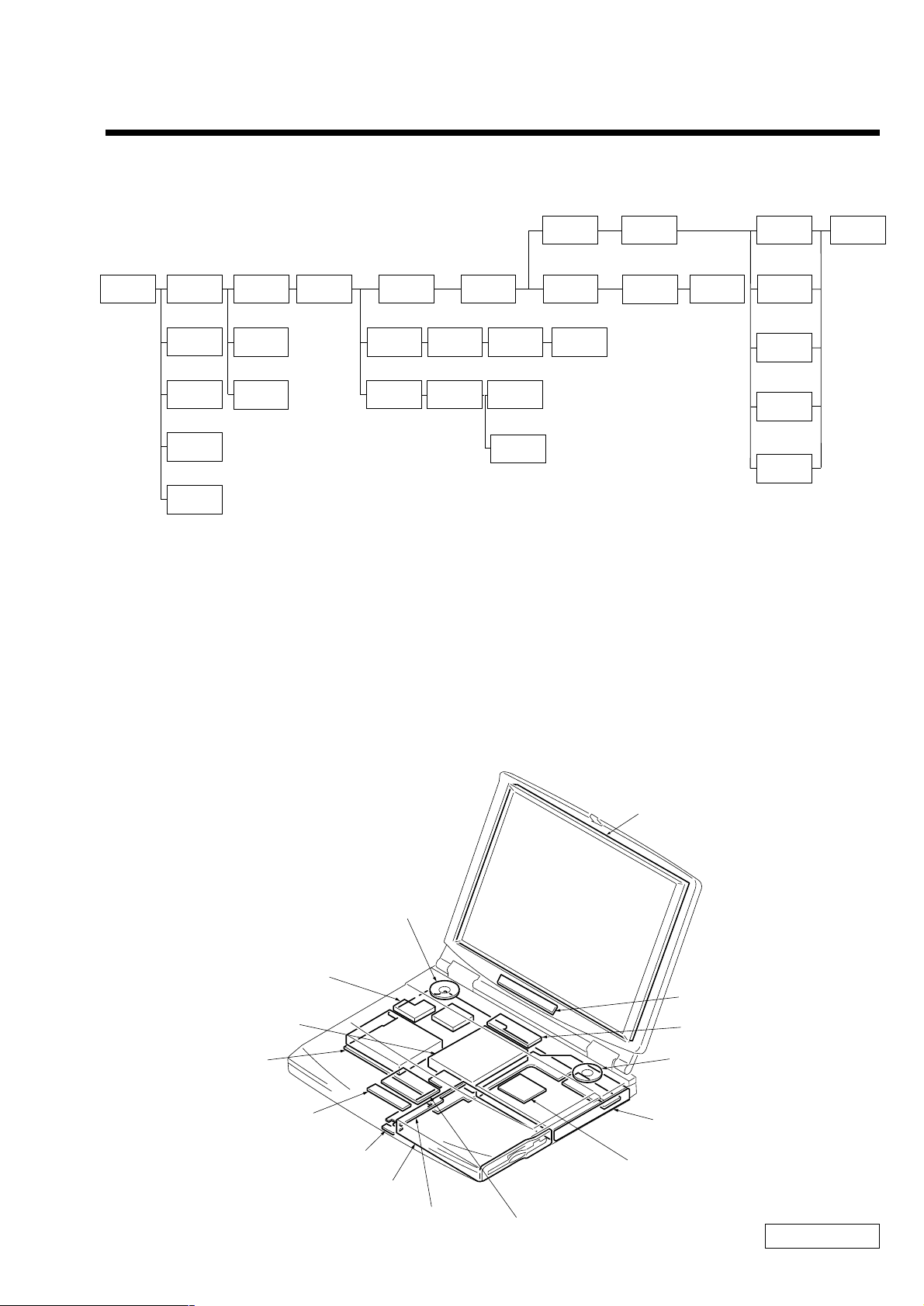

1-2. Main Electrical Parts Location Diagram

LCD Unit

Speaker Unit

Cooling Unit

HDD

MBX-39 Board

CNX-100 Board

SWX-57 Board

FD Drive

CD-ROM Drive

DVD ROM Drive

Modem Unit

Inverter Unit

SWX-56 Board

Speaker Unit

or

PWS-9 Board

Touch Pad

1-1

Confidential

PCG-F610/F630 (UC)

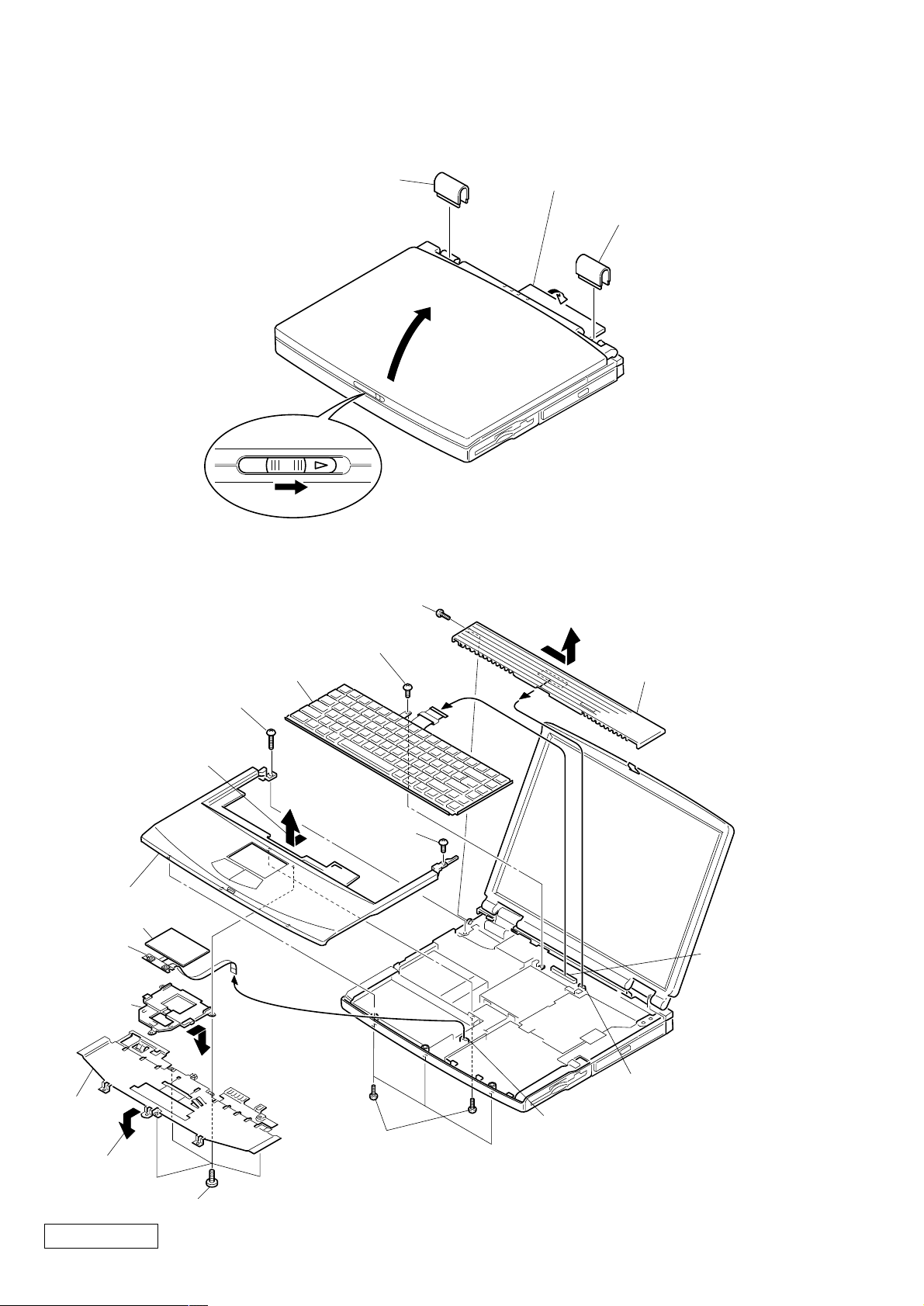

1-3.Removal

1. Hinge Cover

2Hinge Cover

4

3

1Door I/O

2Hinge Cover

2. Keyboard Unit, Palm Rest Assy, Hood Keyboard Assy, Touch Pad, CNX-100 Board

1M2X4 Special Head

3M2X4 Special Head

Keyboard Unit

4

6+B 2X18

2Pull it up sliding it

to the right.

Hood Keyboard Assy

7Pull it to the front slightly

and raise to remove it.

Palm Rest Assy

Touch Pad

CNX-100

Board

Bracket Pat

Palm Rest

Plate

9Remove by

pulling slightly

to the front

8M2X4 Special Head (x4)

0Remove by

pressing to

the rear

5Screw (M2),

0 Number P3 Kind (X4)

6M2X4

Special Head

MBX-39 Board

CON16

MBX-39 Board

CON22

PWS-9 Board

BCN2

Confidential

PCG-F610/F630 (UC)

1-2

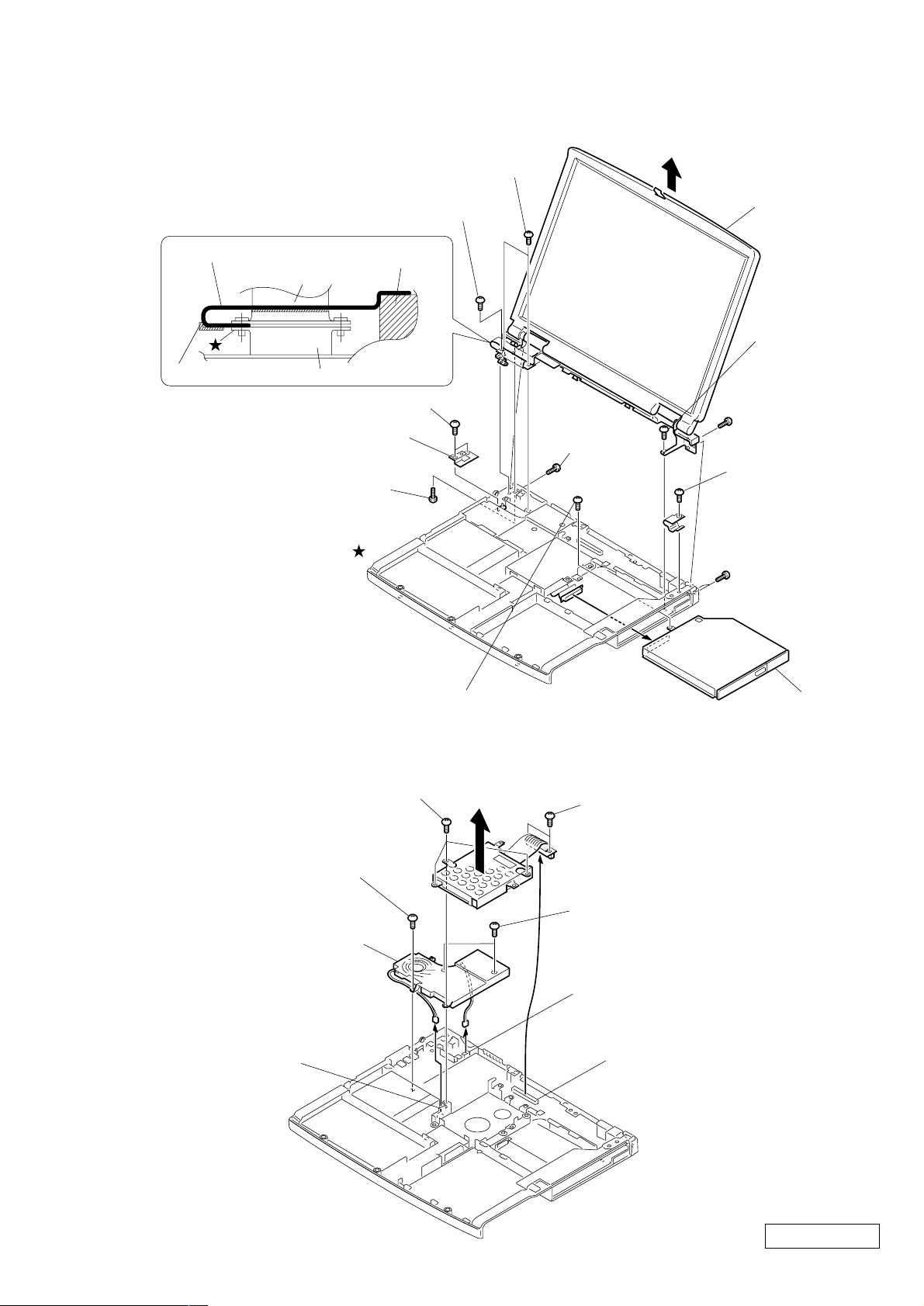

3. Display Assy, CD-ROM Drive, DVD-ROM Drive

∗1

9M2X6 Special Head

Shield Tape (FPC)

Cooling unit

FPC

Hinge Left

MBX-39 Board CON4

5M2X4 Special Head (X2)

6GND Plate Hinge

1Screw (M2),

0 Number P3 Kind

∗1

The FPC is fixed to the shield tape (FPC)

on the connector (CON4) (star marked )

on the MBX-39 board by a screw.

The shield tape (FPC) fixed by the scre w is

bent on the Hinge Left and it is attached to

the Hinge Left, FPC and cooling unit.

8M2X6 Special Head

(X2)

7M2.6 Cross

(Hole) Bind

4

q;

Display Assy

9M2X6 Special

Head

7 M2.6 Cross (Hole)

Bind (X2)

2Bolt (M2X2)

Spring

7M2.6 Cross (Hole)

Bind (X2)

4. HDD Assy, Cooling Unit

3M2X4 Special Head (X3)

6M2X6 Special Head

7Cooling Unit

MBX-39 Board

CON15

3M2X4 Special Head

4HDD Assy

2FPC 50 Pin (for HDD)

5

CD-ROM Drive or

DVD-ROM Drive

1M2X4 Special Head

(X2)

6M2X8 Special Head (X2)

MBX-39 Board

CON17

MBX-39 Board

CON10

1-3

Confidential

PCG-F610/F630 (UC)

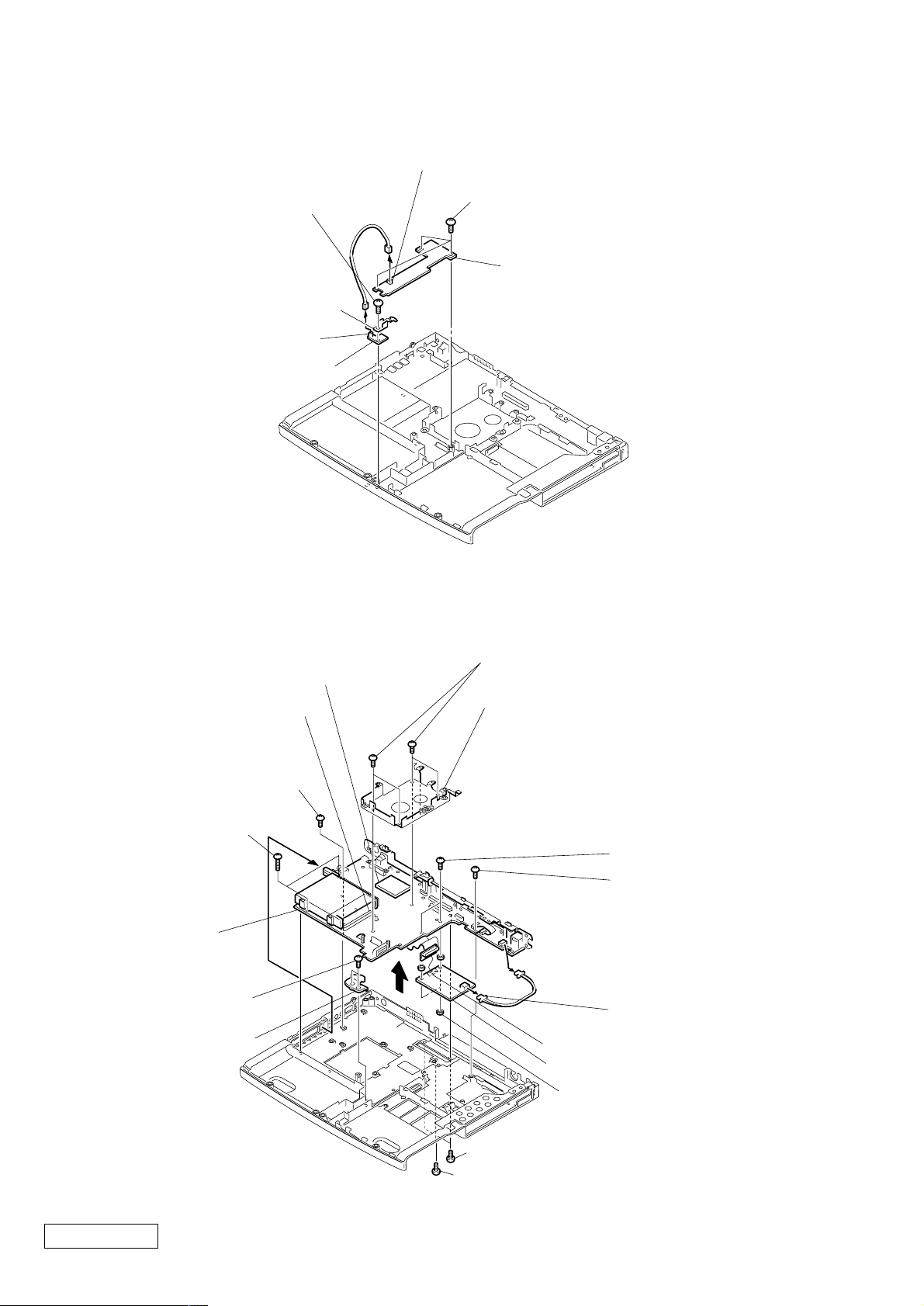

5. SWX-57 Board, Latch Detector Unit, PWS-9 Board

PWS-9 Board BCN3

3M2X4 Special Head

4Latch Detector Unit

SWX-57 Board CN5101

4SWX-57 Board

6. Modem Unit, MBX-39 Board

1M2X4 Special Head (X3)

2PWS-9 Board

MBX-39 Board CON7

4M2X4 Special Head

3+B 2X18 (X2)

MBX-39 Board

5M2X4 Special Head

(X2)

Bracket Bay Connector

∗1

When removing the CPU, refer to

“1-4. Replacing the CPU”.

CPU

1

∗

2HDD Bracket

5M2X6 Special Head (X2)

5M2X4 Special Head

9

1M2X6 Special Head(X4)

8

9

Modem Unit J2

Modem Unit J1

Modem Unit

q;

Nut M2 Type2 (X2)

7M2X4 Special Head(X2)

6M2X4 Special Head

Confidential

PCG-F610/F630 (UC)

1-4

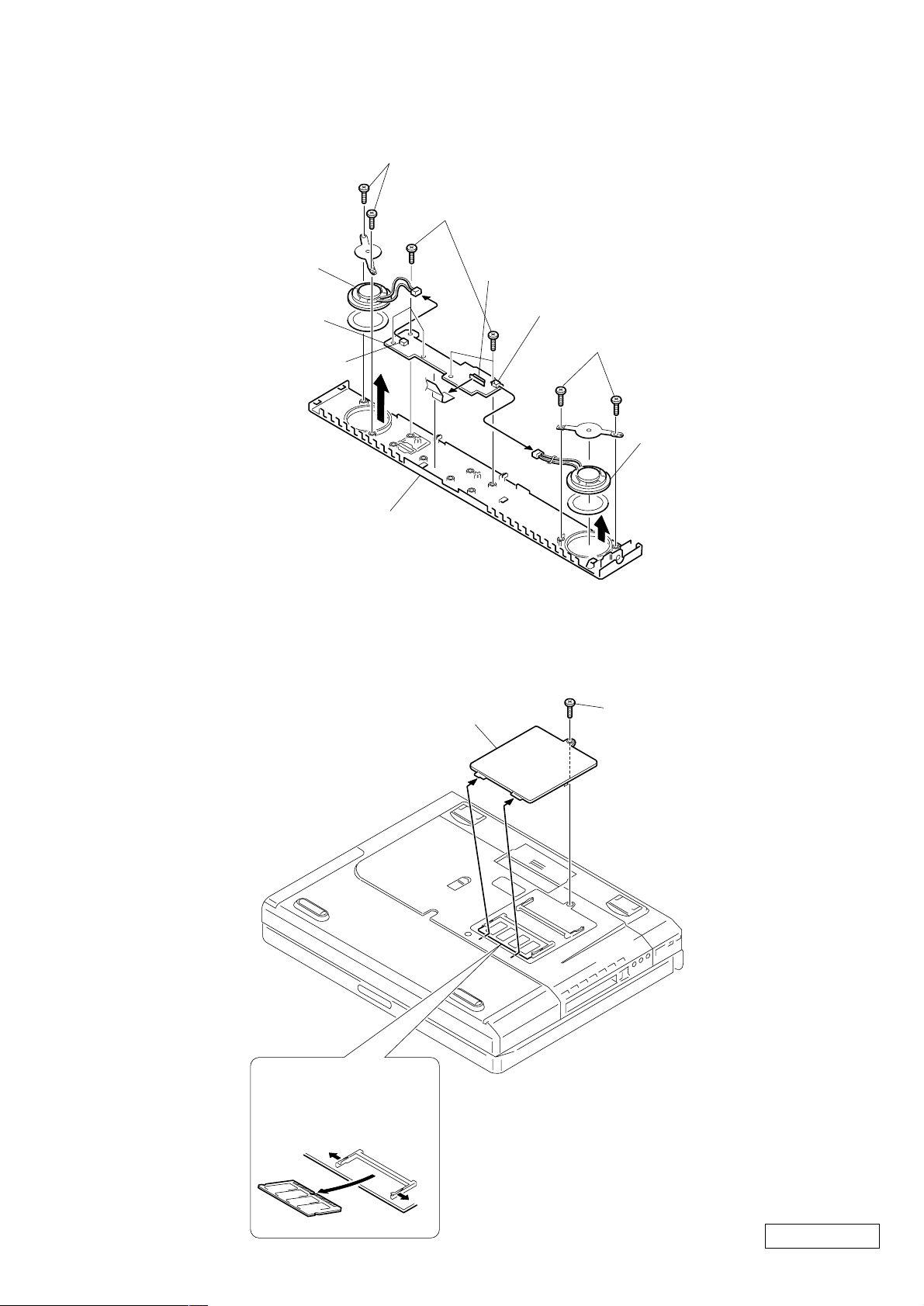

7. Speaker Unit, SWX-56 Board

3M2X4 (X2)

2M2X4 (X5)

8. SO-DIMM

Speaker Unit

SWX-56 Board

SWX-56 Board

JP1

1

Hood Keyboard

SWX-56 Board

JP2

SWX-56 Board

JP3

3M2X4 (X2)

1

1

Speaker Unit

2DIMM Door

Removal of SO-DIMM

a → b

a

1M2X4 Special Head

b

a

1-5

Confidential

PCG-F610/F630 (UC)

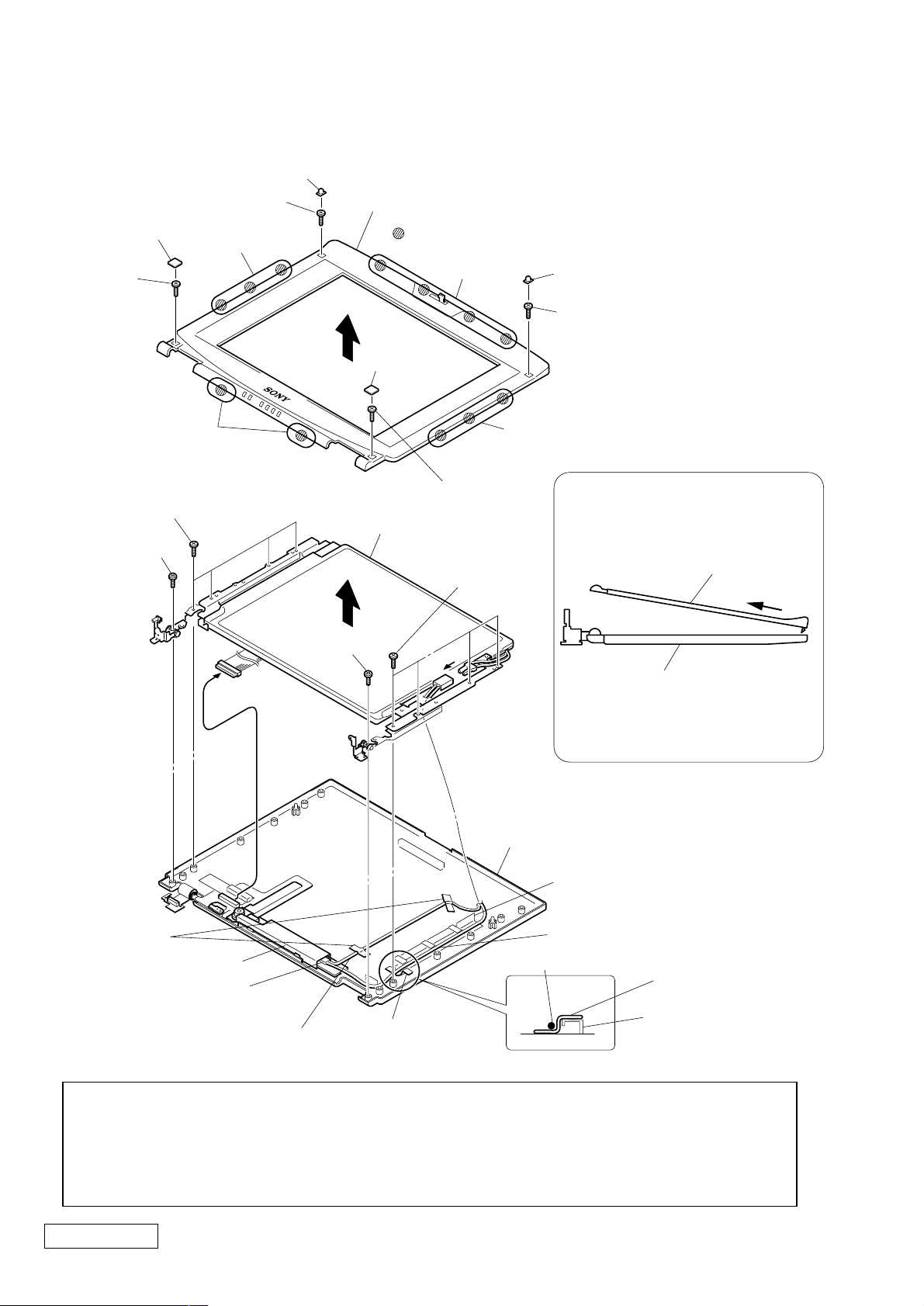

9. LCD Section (F630 Model) – Made by SA –

1. Bezel Housing Assy

1Lower Screw Cover (x2)

4M2X4

Special

Head (X4)

2M2X4

Special

Head (X2)

B

C

3

Bezel Housing Assy

: claw part

A

LCD Unit

7

1Upper Screw Cover (x2)

2M2X4

Special

Head (X2)

B

How to release the claw A.

Bezel Housing Assy

A

5

Inverter Assy

Inverter Assy

CN2

6

Display Housing Assy

4M2X4

Special

Head (X4)

Pull the Bezel Housing Assy

as shown to release the claw A.

Order of releasing the claws C → B → A

Order of locking the claws A → B → C

Display Housing Assy

Confidential

PCG-F610/F630 (UC)

1-6

2. LCD Harness, Bracket LCD Left, Bracket LCD Right, LCD Unit (13inch)

2+P M2X3 Lock (X2)

LCD Unit

2+P M2X3 Lock (X3)

Bracket LCD Left

1

LCD

Harness

3. FPC, Inverter Assy, Display Housing Assy

2M2X4

Special Head

3M2X4

Special

Head (X2)

Inverter Bracket

Inverter Assy

CN1

Inverter Assy

Bracket LCD Right

FPC

Display Housing Assy

: claw part

1-7

Confidential

PCG-F610/F630 (UC)

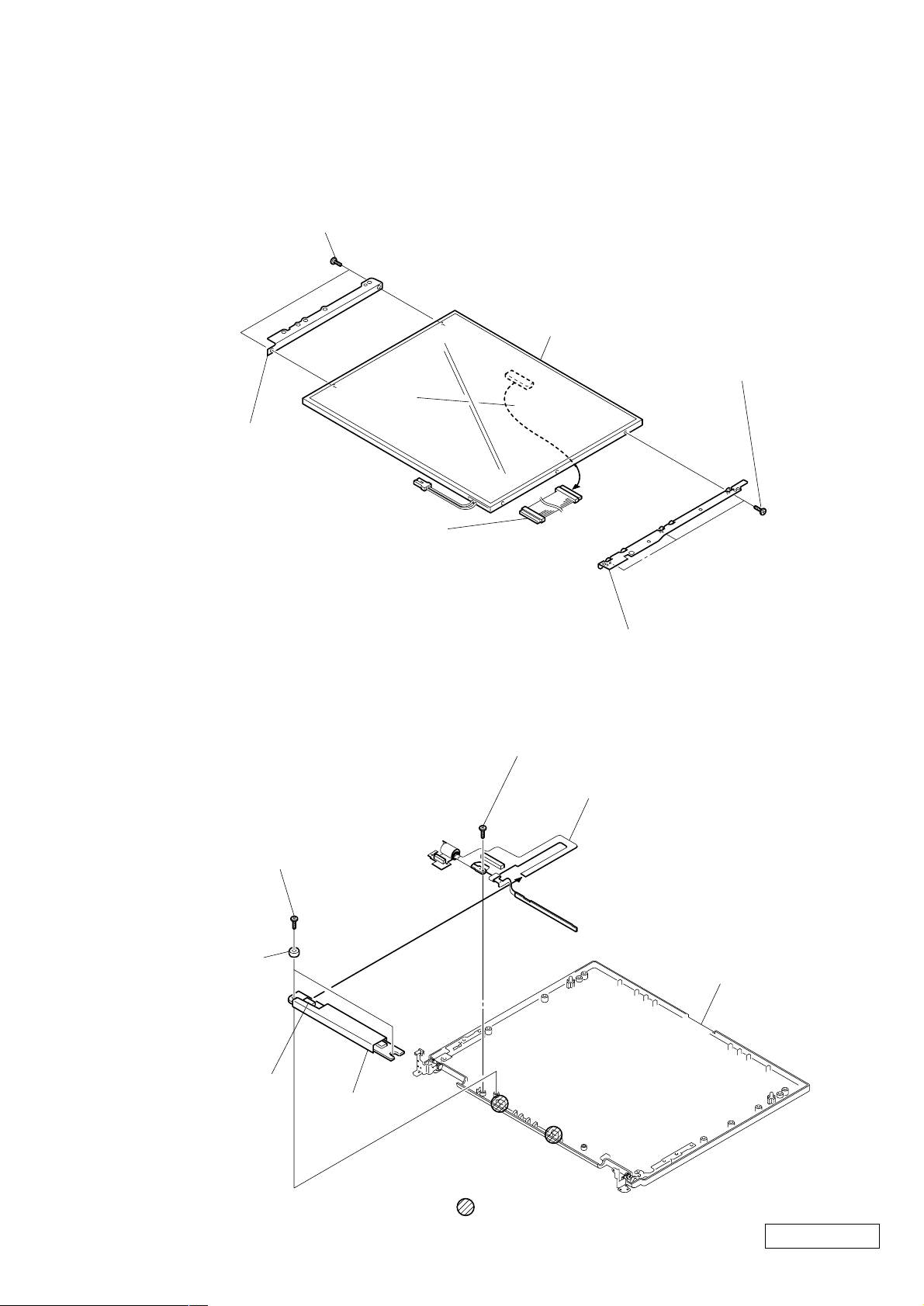

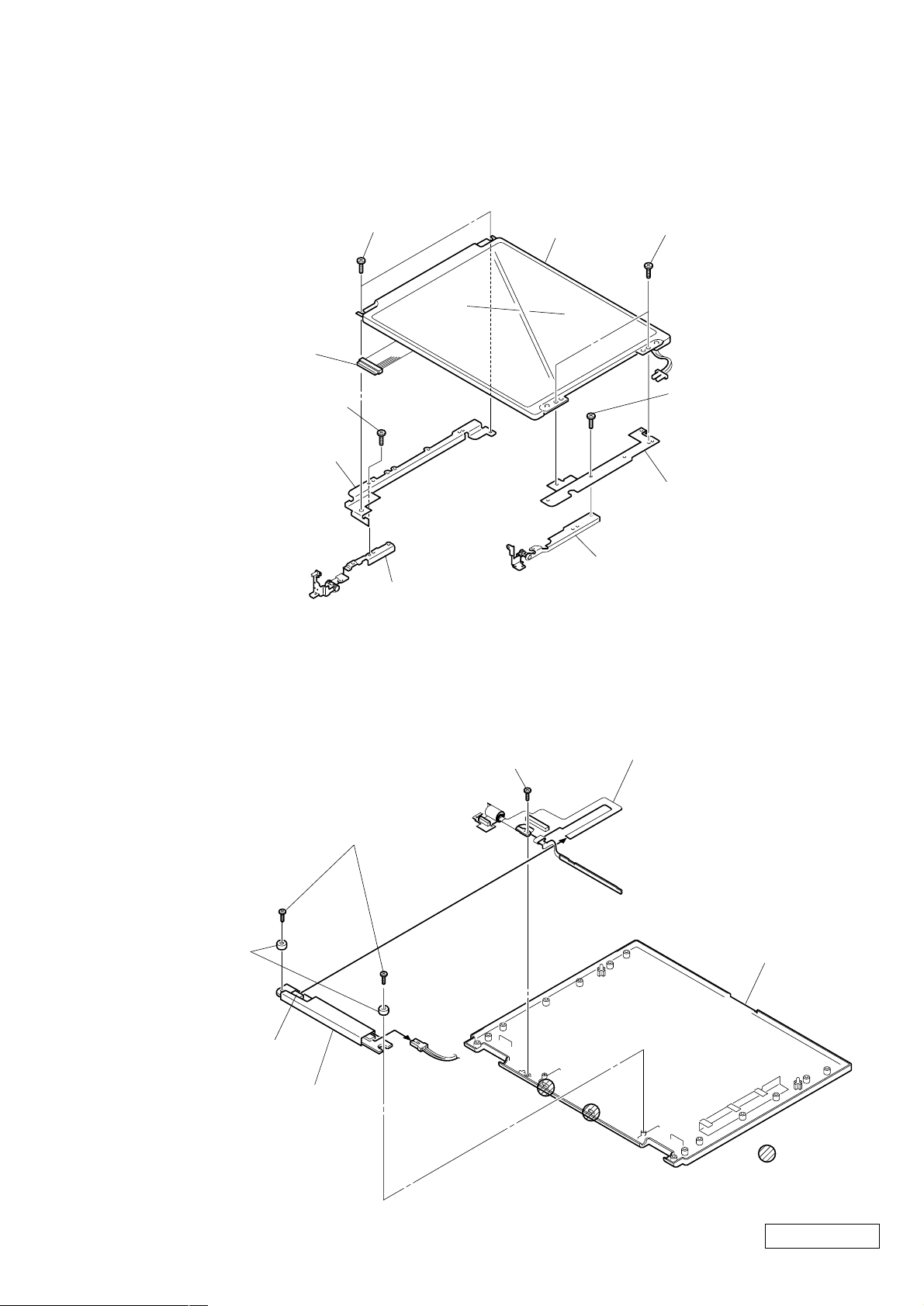

10. LCD Section (F610 Model) – Made by SA –

1. Bezel Housing Assy

1Upper Screw Cover

2M2X4 Special Head

1Lower Screw Cover

2M2X4

Special

Head

C

4M2X4

Special

Head (X4)

5+PS 2.6X5

B

Bezel Housing Assy

3

LCD Unit

8

5+PS 2.6X5

: claw part

A

1Lower Screw

Cover

B

2M2X4 Special Head

4M2X4

Special

Head (X4)

6

1Upper Screw Cover

2M2X4 Special Head

How to release the claw A.

Bezel Housing Assy

A

7

Display Housing Assy

Pull the Bezel Housing Assy

as shown to release the claw A.

Order of releasing the claws C → B → A

Order of locking the claws A → B → C

Display Housing Assy

Insurator (Harness INV)

Adhesive tape

(Filament tape)

Inverter Assy

Inverter Assy

Lamp Harness (Pink)

Lamp Harness (Pink)

Filament tape

CN2

Lamp Harness (White)

Adhesive tape

Bracket LCD Right

(Filament tape)

• When Lamp Harness is installed, fix the Lamp Harness (white) using the adhesive tape (Filament tape) on the

Display Housing Assy as sho wn. Route the Lamp Harness (pink) through the Insula tor (Harness INV) as shown.

• Attach the adhesive tape (Filament tape) as shown to prevent the Lamp Harness (pink) from going under the

Bracket LCD Right.

• Be careful not to cover the screw hole with adhesive tape (Filament tape).

Confidential

PCG-F610/F630 (UC)

1-8

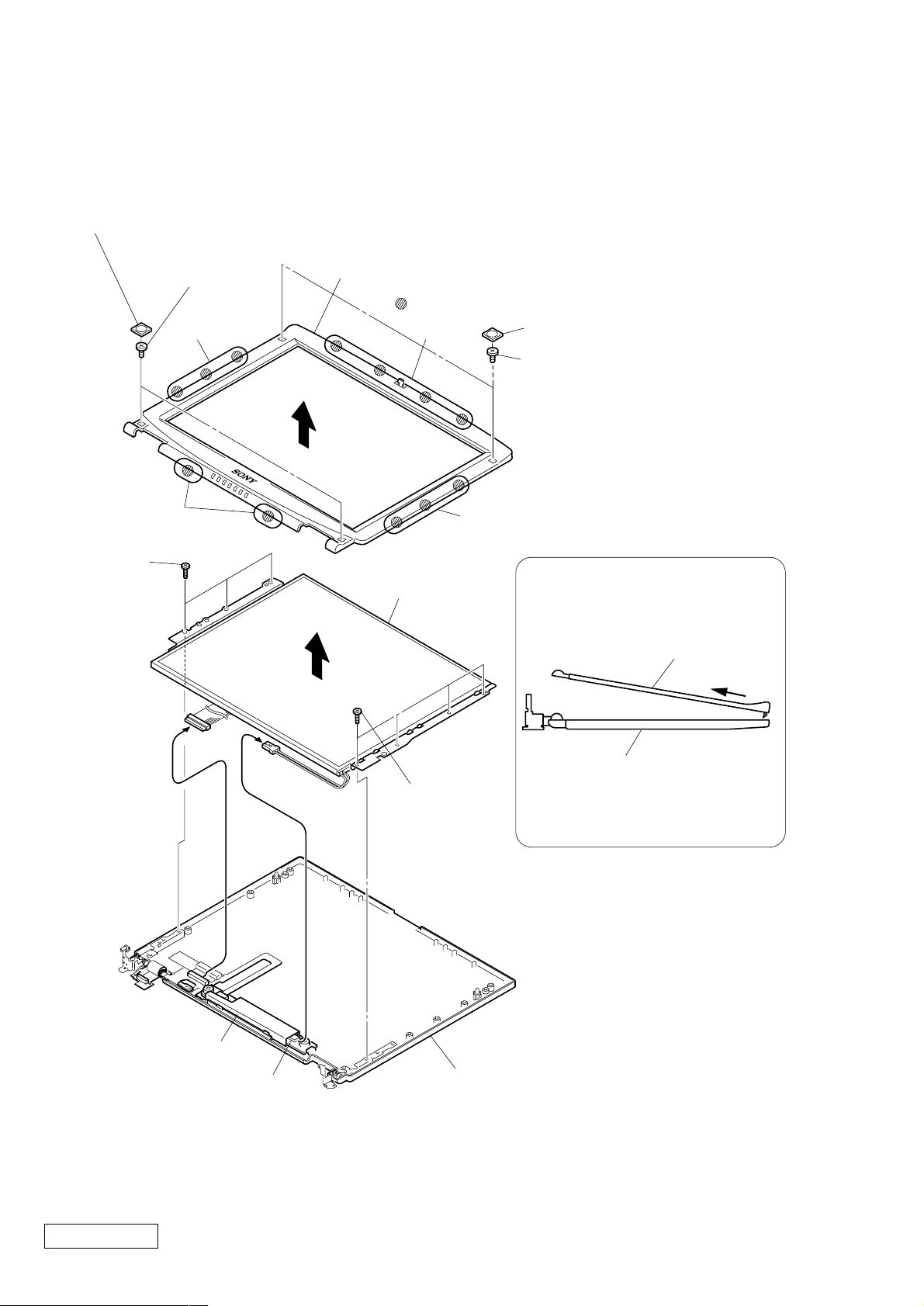

2. LCD Harness, Bracket LCD Left, Bracket LCD Right, Hinge Left, Hinge Right, LCD Unit (12inch)

LCD Harness

M2X4 Special Head

Bracket LCD Left

M3X4 (X2)

Hinge Left

LCD Unit

M3X4 (X2)

M2X4 Special Head

Bracket LCD Right

Hinge Right

3. FPC, Inverter Assy, Display Housing Assy

2M2X4

Special Head

3M2X4

Special

Head (X2)

Inverter Bracket

Inverter Assy

CN1

Inverter Assy

FPC

1

Display Housing Assy

1-9

: claw part

Confidential

PCG-F610/F630 (UC)

Loading...

Loading...