Sony Trinitron KV-27FS120, Trinitron KV-29FA310, Trinitron KV-29FS120, KV-27FS120 Service Manual

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

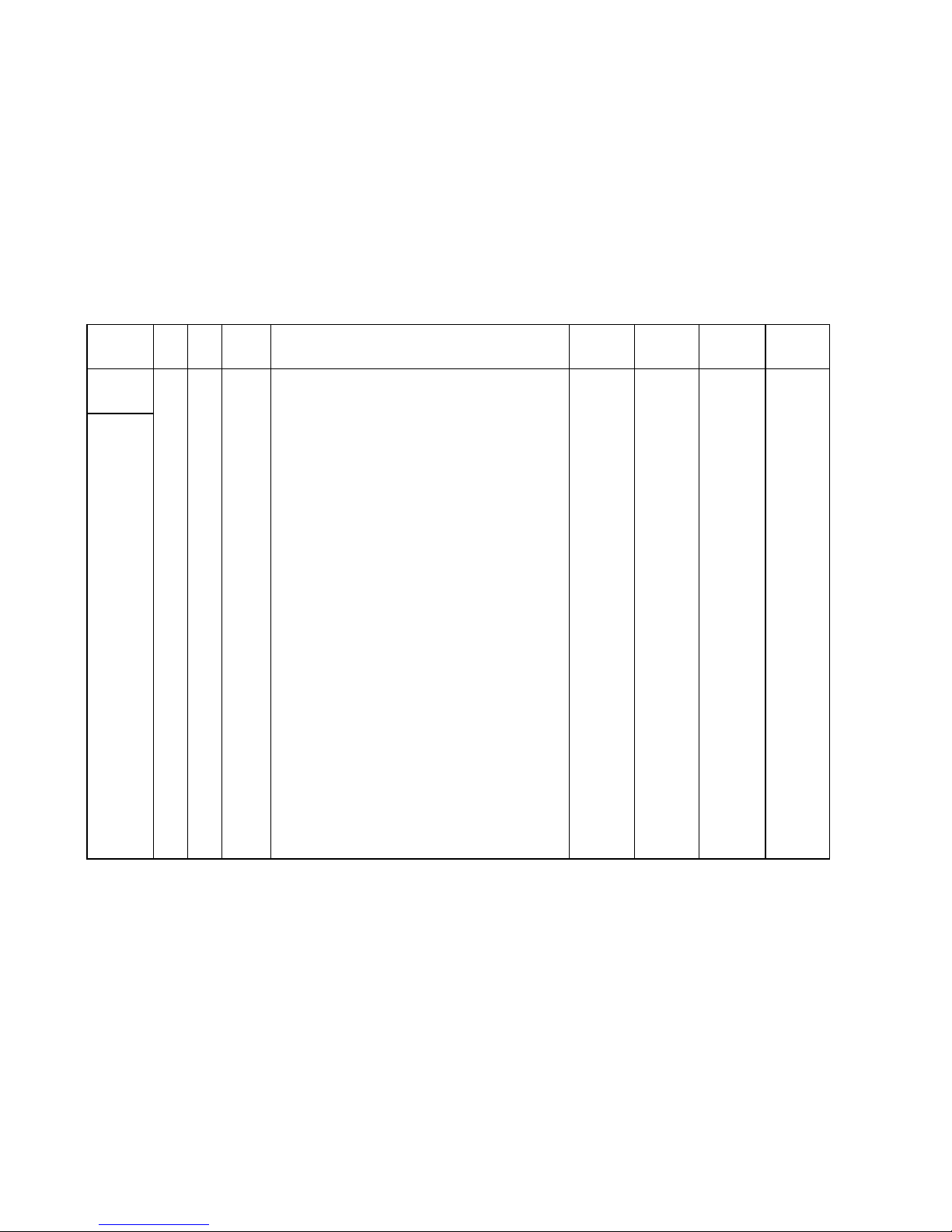

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-27FS120

KV-27FS120

KV-29FA310

KV-29FA310

KV-29FS120

KV-29FS120

RM-Y195 US SCC-S61N-A

RM-Y195 CANADA SCC-S59J-A

RM-Y180 LATIN NORTH SCC-S60V-A

RM-Y180 LATIN SOUTH SCC-S60W-A

RM-Y195 LATIN NORTH SCC-S73D-A

RM-Y195 LATIN SOUTH SCC-S73E-A

BA-6

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 3/2004

REVISION DATE SUBJECT

3/2004 No revisions or updates are applicable at this time.

9-965-960-01

TRINITRON® COLOR TELEVISION

Self Diagnosis

Supported model

SERVICE MANUAL

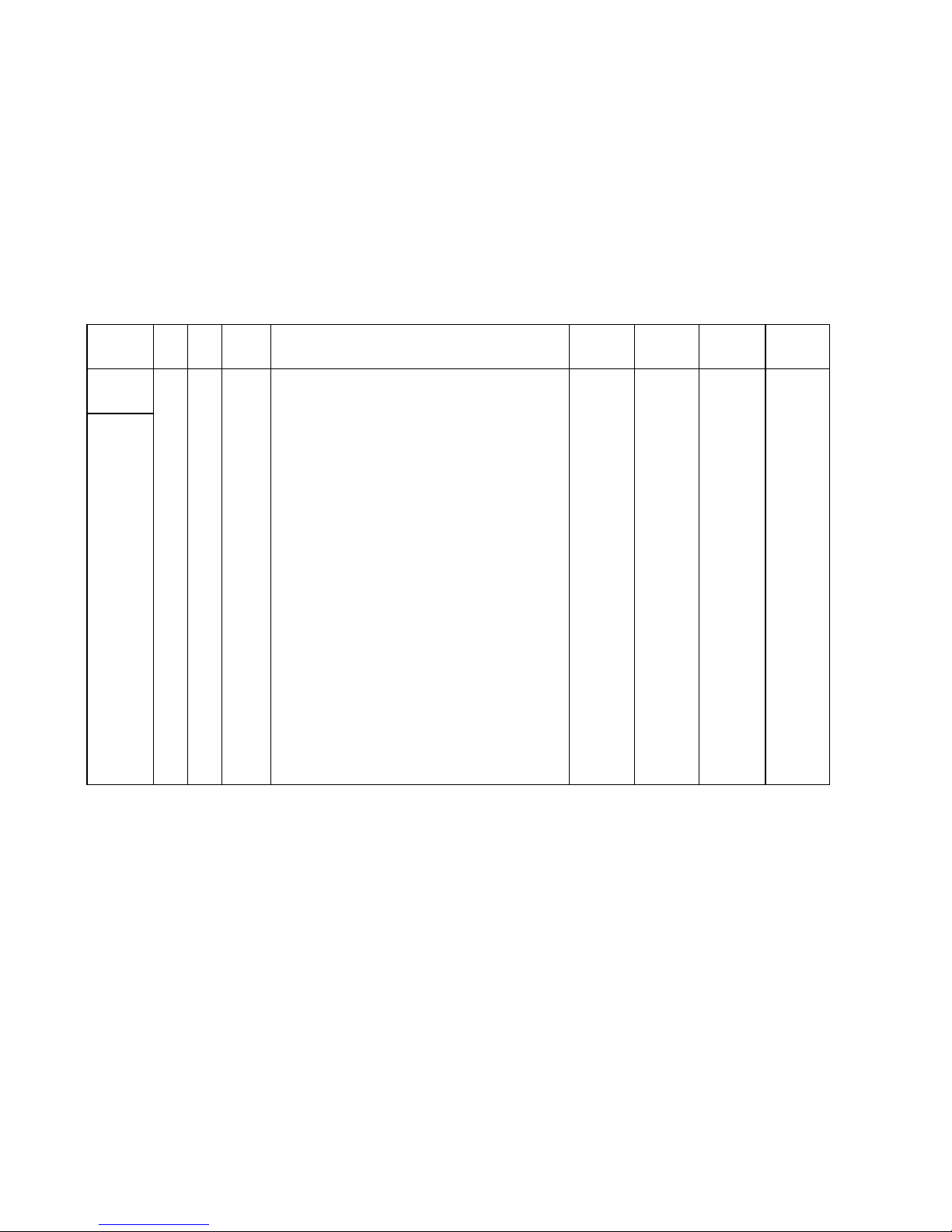

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-27FS120

KV-27FS120

KV-29FA310

KV-29FA310

KV-29FS120

KV-29FS120

RM-Y195 US SCC-S61N-A

RM-Y195 CANADA SCC-S59J-A

RM-Y180 LATIN NORTH SCC-S60V-A

RM-Y180 LATIN SOUTH SCC-S60W-A

RM-Y195 LATIN NORTH SCC-S73D-A

RM-Y195 LATIN SOUTH SCC-S73E-A

BA-6

CHASSIS

KV-27FS120 KV-29FA310

9-965-960-01

TRINITRON® COLOR TELEVISION

KV-27FS120/29FA310/29FS120

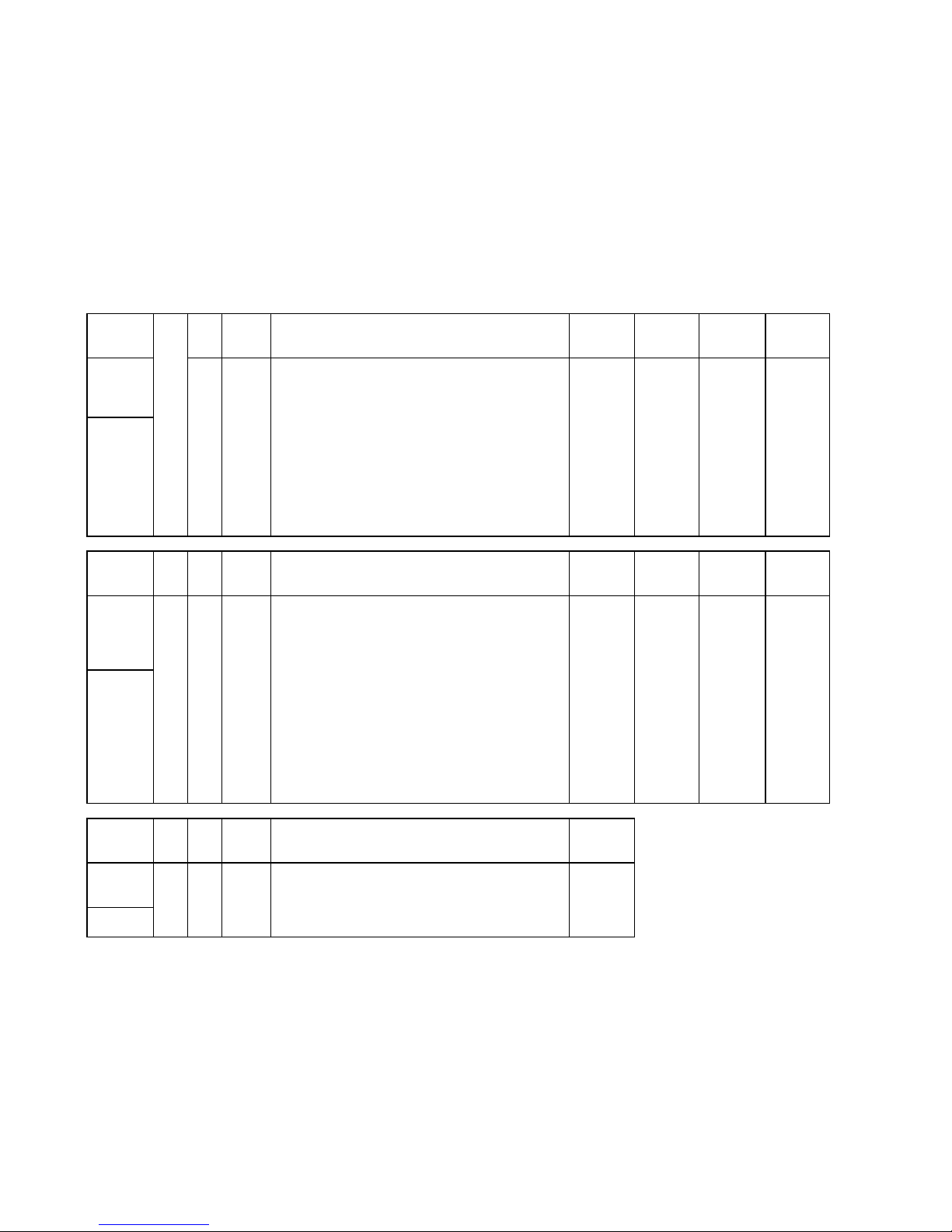

TABLE OF CONTENTS

SECTION TITLE PAG E

Specifi cations ............................................................................................................................................................................. 4

Warnings and Cautions .............................................................................................................................................................. 5

Safety Check-Out ....................................................................................................................................................................... 6

Self-Diagnostic Function............................................................................................................................................................. 7

SECTION 1: DISASSEMBLY............................................................................................................................................................. 9

1-1. Rear Cover Removal (All Except KV-29FA310)................................................................................................................. 9

1-2. Rear Cover Removal (KV-29FA310 Only).......................................................................................................................... 9

1-3. Chassis Assembly Removal (All Except KV-29FA310) .................................................................................................... 10

1-4. Chassis Assembly Removal (KV-29FA310 Only)............................................................................................................. 10

1-5. Service Position (All Except KV-29FA310)........................................................................................................................11

1-6. Service Position (KV-29FA310 Only) ................................................................................................................................11

1-7. Picture Tube Removal...................................................................................................................................................... 12

Anode Cap Removal Procedure....................................................................................................................................... 12

SECTION 2: SET-UP ADJUSTMENTS............................................................................................................................................ 13

2-1. Beam Landing .................................................................................................................................................................. 13

2-2. Convergence.................................................................................................................................................................... 14

2-3. Focus ............................................................................................................................................................................... 15

2-4. Screen (G2)...................................................................................................................................................................... 16

2-5. Method of Setting the Service Adjustment Mode ............................................................................................................. 16

2-6. White Balance Adjustments ............................................................................................................................................. 16

SECTION 3: SAFETY RELATED ADJUSTMENTS......................................................................................................................... 17

3-1.

X

R564 Confi rmation Method (HV Hold-Down Confi rmation) and Readjustments ........................................................ 17

3-2. B+ Voltage Confi rmation and Adjustment ........................................................................................................................ 17

SECTION 4: CIRCUIT ADJUSTMENTS.......................................................................................................................................... 19

4-1. Setting the Service Adjustment Mode .............................................................................................................................. 19

4-2. Memory Write Confi rmation Method ................................................................................................................................ 19

4-3. Remote Adjustment Buttons and Indicators ..................................................................................................................... 19

4-4. Service Data Lists ............................................................................................................................................................ 20

4-4. ID Map Table .................................................................................................................................................................... 32

4-5. A Board Adjustments........................................................................................................................................................ 32

SECTION 5: DIAGRAMS................................................................................................................................................................. 35

5-1. Circuit Boards Location .................................................................................................................................................... 35

5-2. Printed Wiring Board and Schematic Diagram Information.............................................................................................. 35

5.3. Block Diagram and Schematics ....................................................................................................................................... 36

A Board Schematic Diagram ........................................................................................................................................... 37

CW Board Schematic Diagram ....................................................................................................................................... 39

D Board Schematic Diagram (All Except KV-29FA310) .................................................................................................. 40

HS Board Schematic Diagram (All Except KV-29FA310)................................................................................................. 41

V Board Schematic Diagram ........................................................................................................................................... 41

GD Board Schematic Diagram (KV-29FA310 Only) ......................................................................................................... 44

HR Board Schematic Diagram (KV-29FA310 Only) ......................................................................................................... 47

HU Board Schematic Diagram (KV-29FA310 Only) ......................................................................................................... 49

K Board Schematic Diagram (KV-29FA310 Only) ........................................................................................................... 52

5-4. Semiconductors ............................................................................................................................................................... 53

SECTION 6: EXPLODED VIEWS.................................................................................................................................................... 54

6-1. Picture Tube (KV-27FS120/29FS120 Only) ..................................................................................................................... 54

6-2. Chassis (KV-27FS120/29FS120 Only)............................................................................................................................. 55

6-3. Picture Tube (KV-29FA310 Only)..................................................................................................................................... 56

6-4. Chassis (KV-29FA310 Only) ............................................................................................................................................ 57

SECTION 7: ELECTRICAL PARTS LIST....................................................................................................................................... 58

KV-27FS120/29FA310/29FS120

3

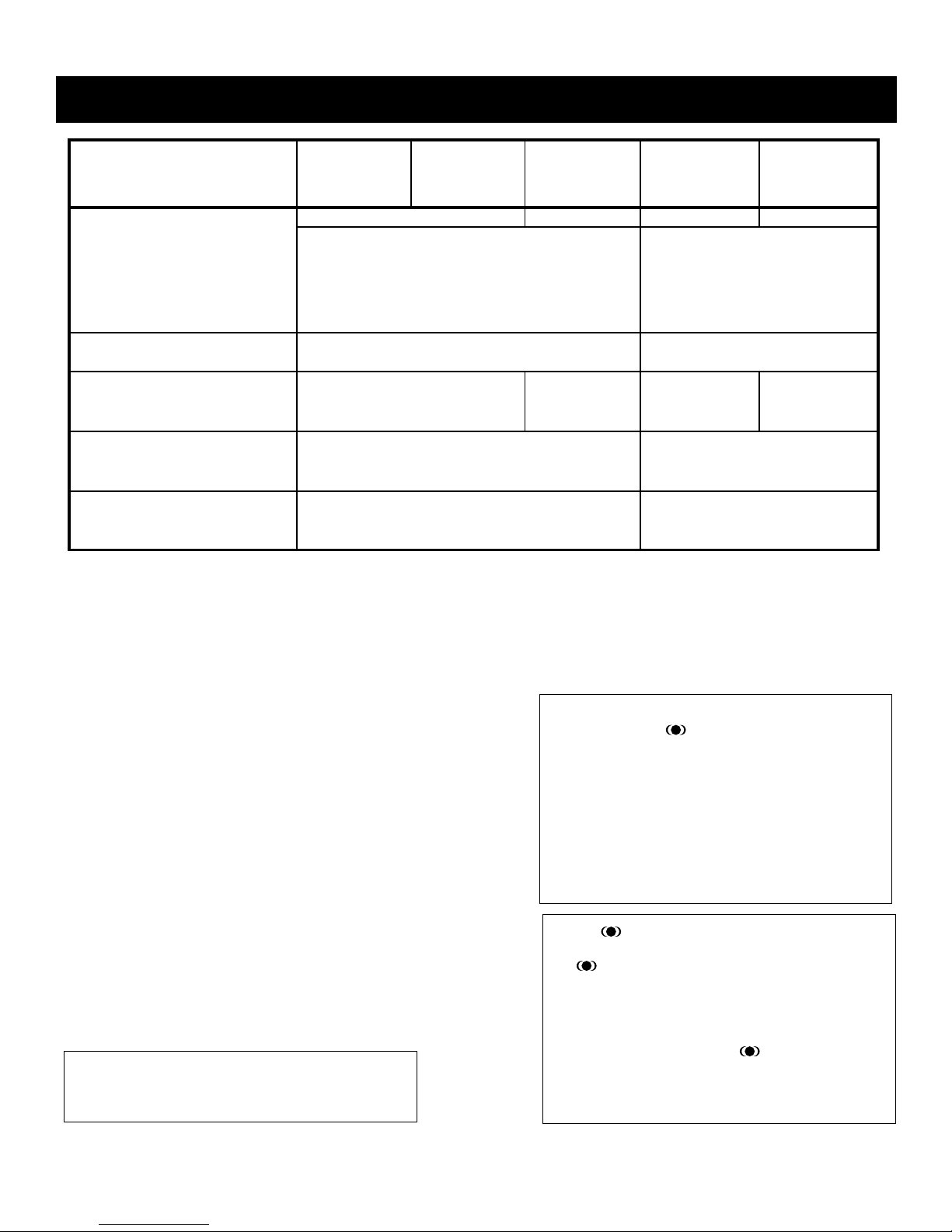

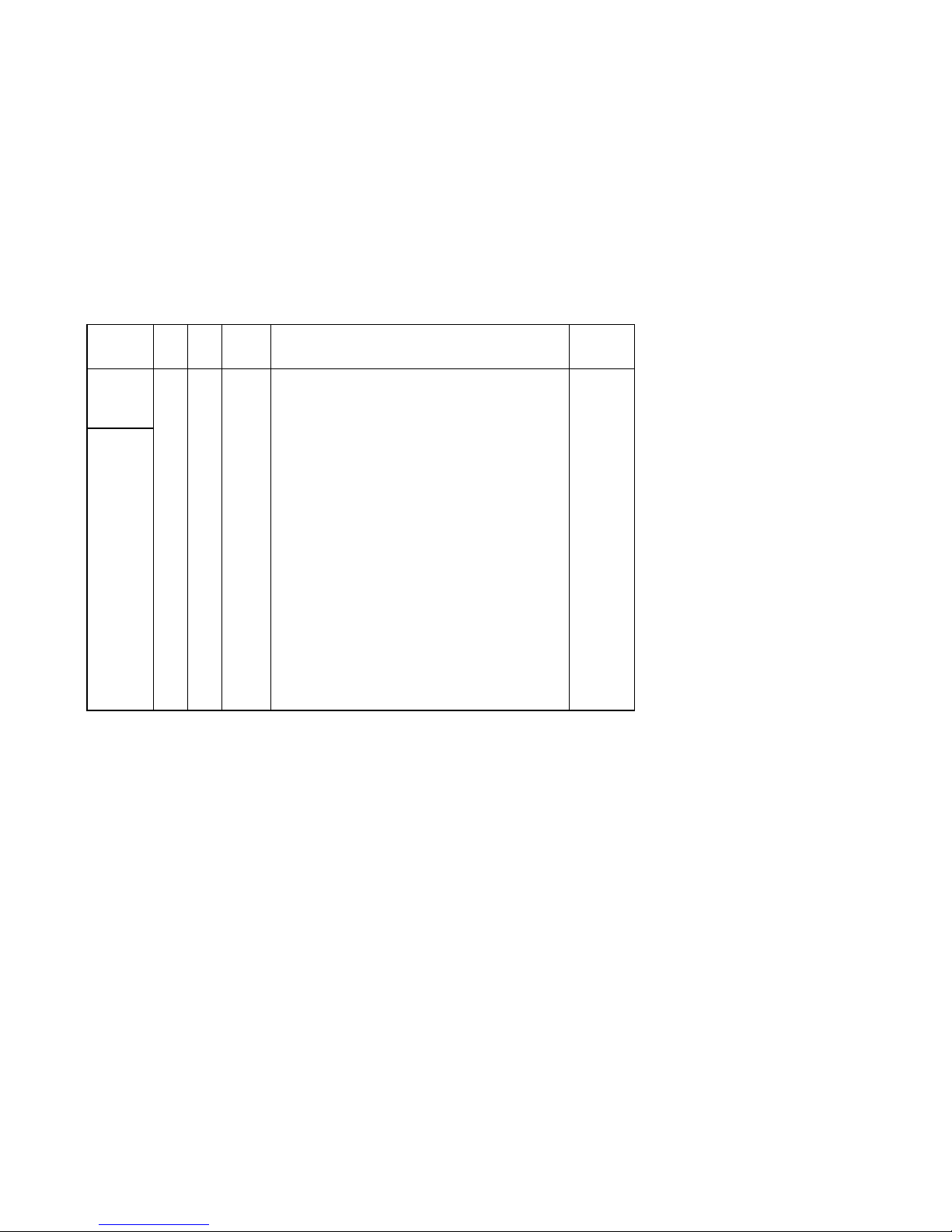

SPECIFICATIONS

)

r

KV-27FS120/29FA310/29FS120

KV-27FS120

Power Requirements 220V, 50/60Hz 120V, 60Hz 220V, 50/60Hz

120V, 60Hz

KV-29FS120

(L. NORTH)

KV-29FS120

(L. SOUTH)

KV-29FA320

(L. NORTH)

KV-29FA320

(L. SOUTH)

Number of Inputs/Outputs

1)

Video

S Video

Y,PB, P

R

Audio

Speaker Output(W

Subwoofe

2)

3)

4)

3

1

1

2

10W x 2

N/A

3

1

1

2

7W x 3

20W

Power Consumption (W)

In Use (Max) 175W 220W 215W

In Standby (Max)

5)

180W

1W

1W 1W 1W

Dimensions (W x H x D)

mm

in

768 x 589 x 497 mm

30

1/4

x 23

1/4

x 19

5/8

in

784 x 678 x 520.5 mm

7/8

x 26 3/4 x 20

30

1/2

in

Mass

50 kg

110 lbs 4 oz

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

kg

lbs

45.2 kg

99 lbs 10 oz

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR Vp-p, 75 ohms.

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

This specifi cation is the maximum wattage.

Picture tube

FD Trinitron® tube

Visible screen size

27-inch picture measured diagonally

Actual screen size

29-inch measured diagonally

Supplied Accessories

Remote Commander RM-Y195

(All Except KV-29FA310 Only)

Remote Commander RM-Y180

(KV-29FA310 Only)

Two Size AA (R6) Batteries

© 2004 Dolby Laboratories, Inc.

Dolby, Pro Logic, and the double-D symbol are registered

trademarks of Dolby Laboratories.

TruSurround

TruSurround is a trademark of SRS Labs, Inc. SRS and the SRS

symbol are registered trademarks of SRS Labs, Inc. in the United

States and in select foreign countries. SRS and TruSurround are

incorporated under license from SRS Labs, Inc. and are protected

under United States Patent Nos. 4,748,669 and 4,841,572 with

numerous additional issued and pending foreign patents. Purchase of this product does not convey the right to sell recordings

made with the TruSurround technology.

by SRS

™

®

SRS (SOUND RETRIEVAL SYSTEM)

The SRS (SOUND RETRIEVAL SYSTEM) is manufactured

by Sony Corporation under license from SRS Labs, Inc. It is

covered by U.S. Patent No. 4,748,669. Other U.S. and foreign

patents pending.

The word ‘SRS’ and the SRS symbol are registered trademarks of SRS Labs, Inc. BBE and BBE symbol are trademarks of

BBE Sound, Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

KV-27FS120/29FA310/29FS120

Design and specifi cations are subject to change without notice.

4

KV-27FS120/29FA310/29FS120

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance

est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque

remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KV-27FS120/29FA310/29FS120

5

SAFETY CHECK-OUT

KV-27FS120/29FA310/29FS120

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

0.15 F

1.5 K Ω

Earth Ground

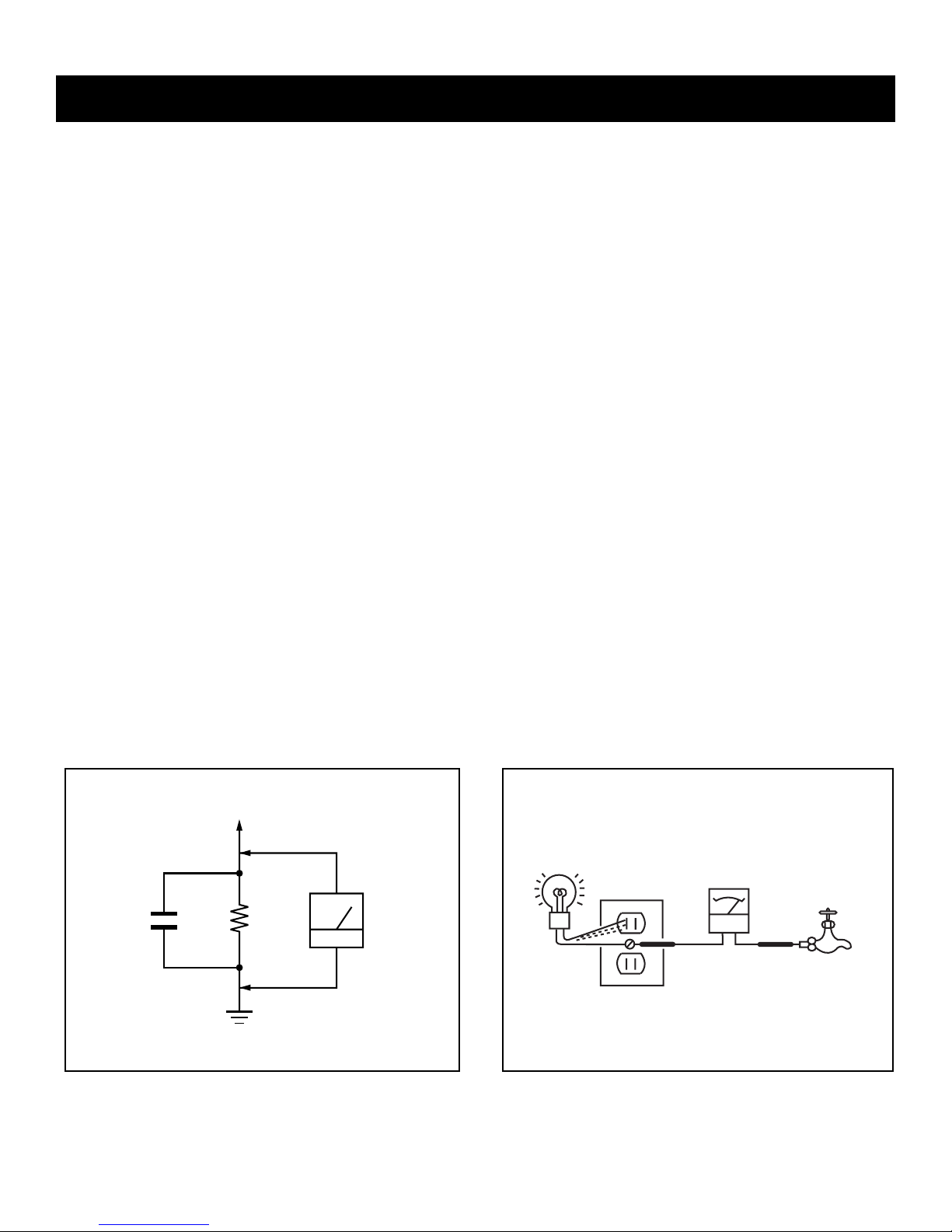

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KV-27FS120/29FA310/29FS120

AC

Voltmeter

(0.75 V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

6

KV-27FS120/29FA310/29FS120

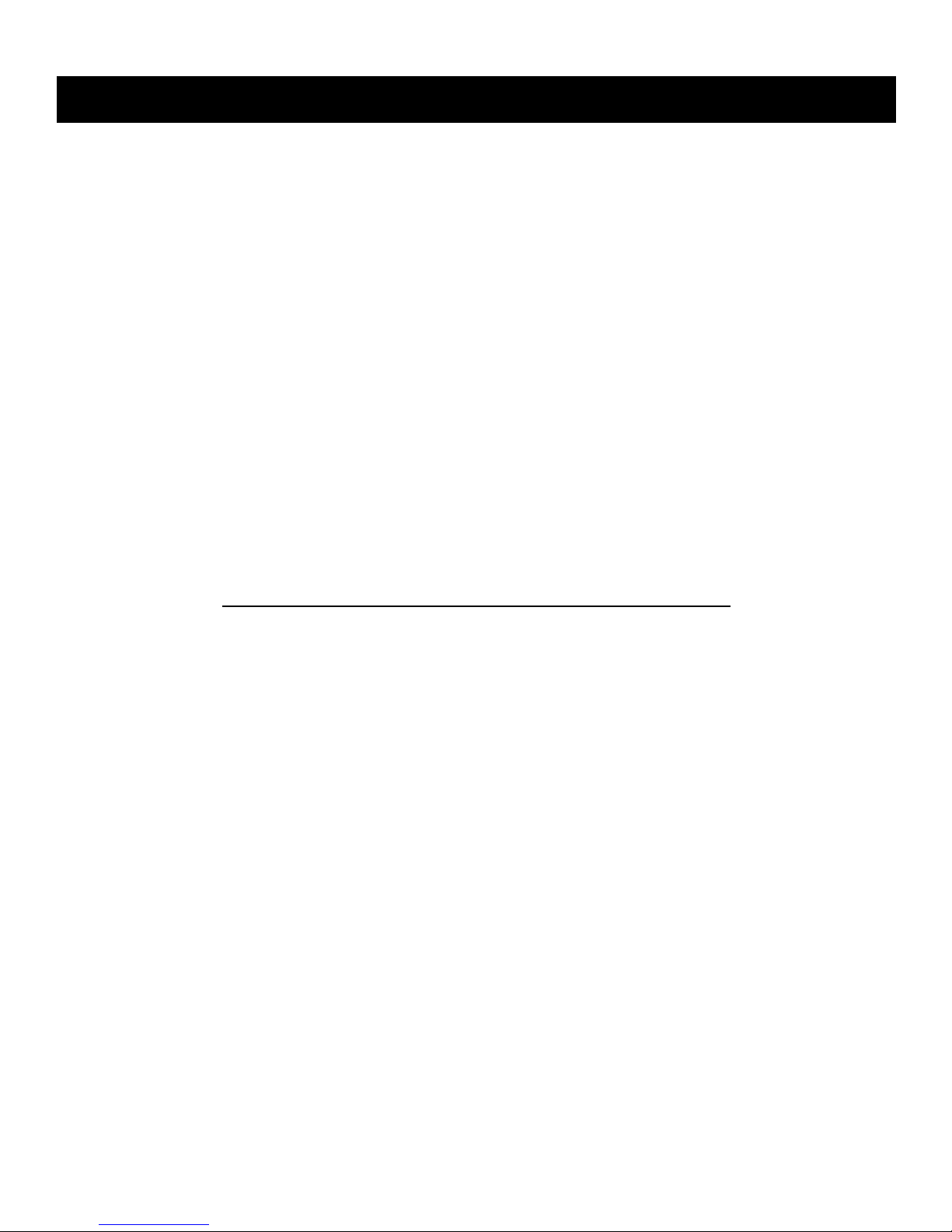

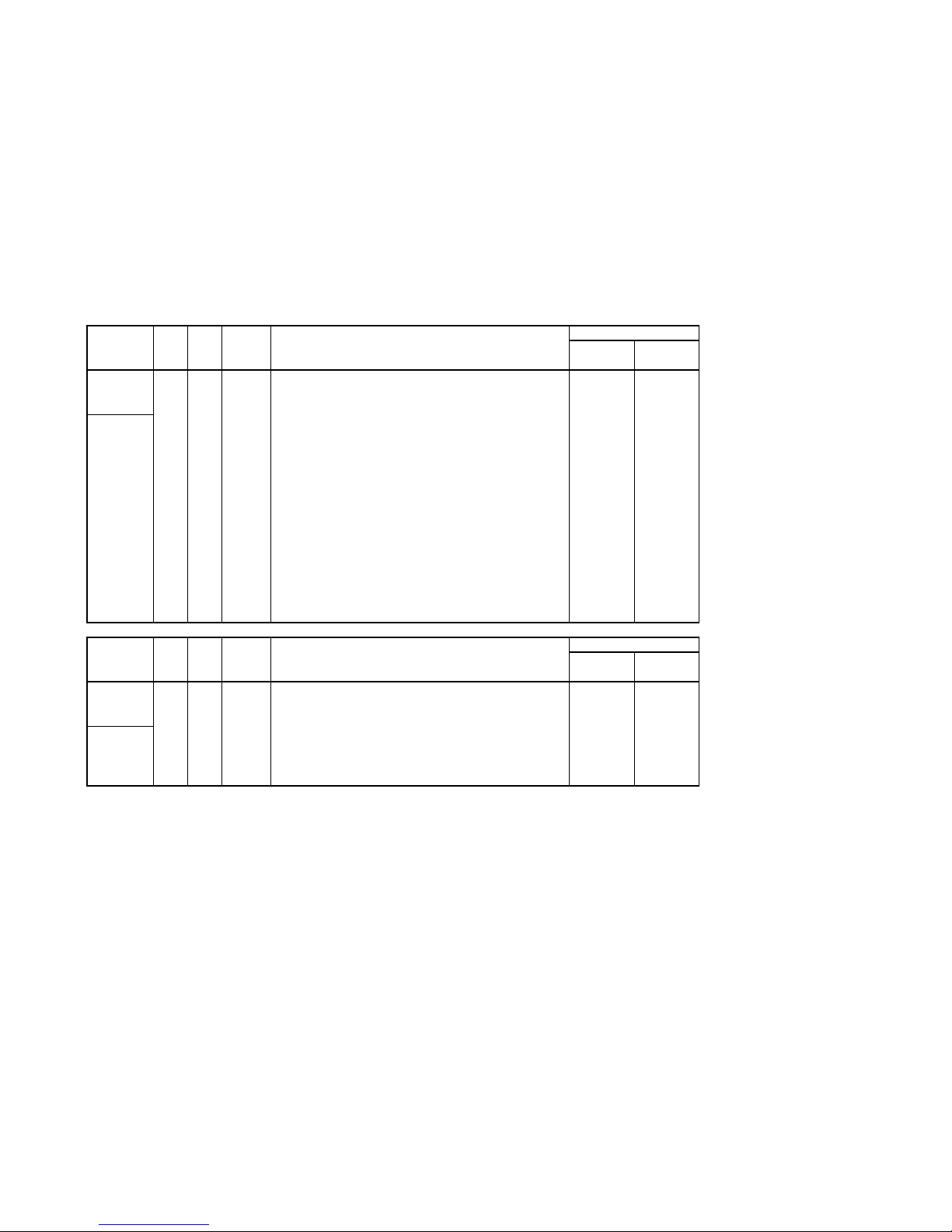

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

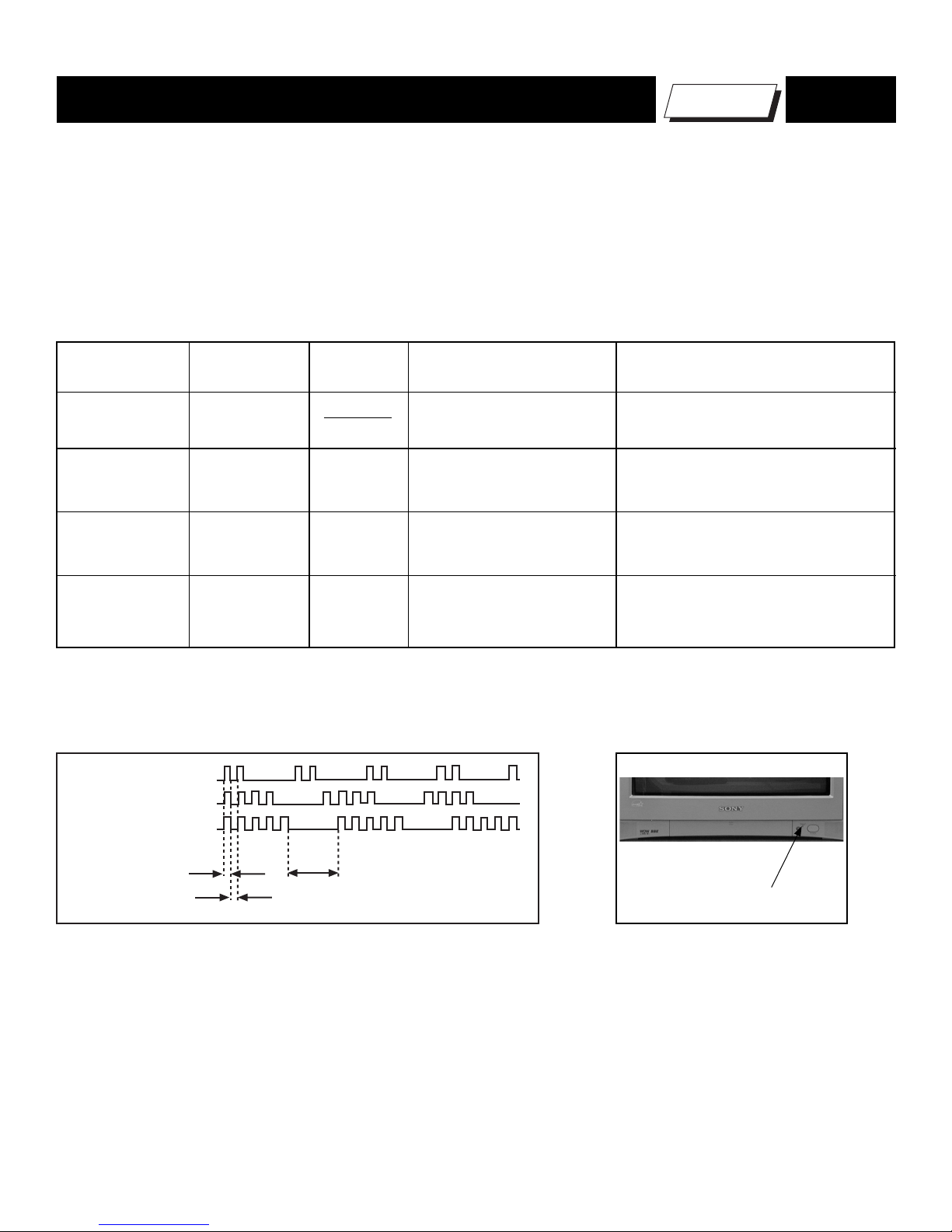

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

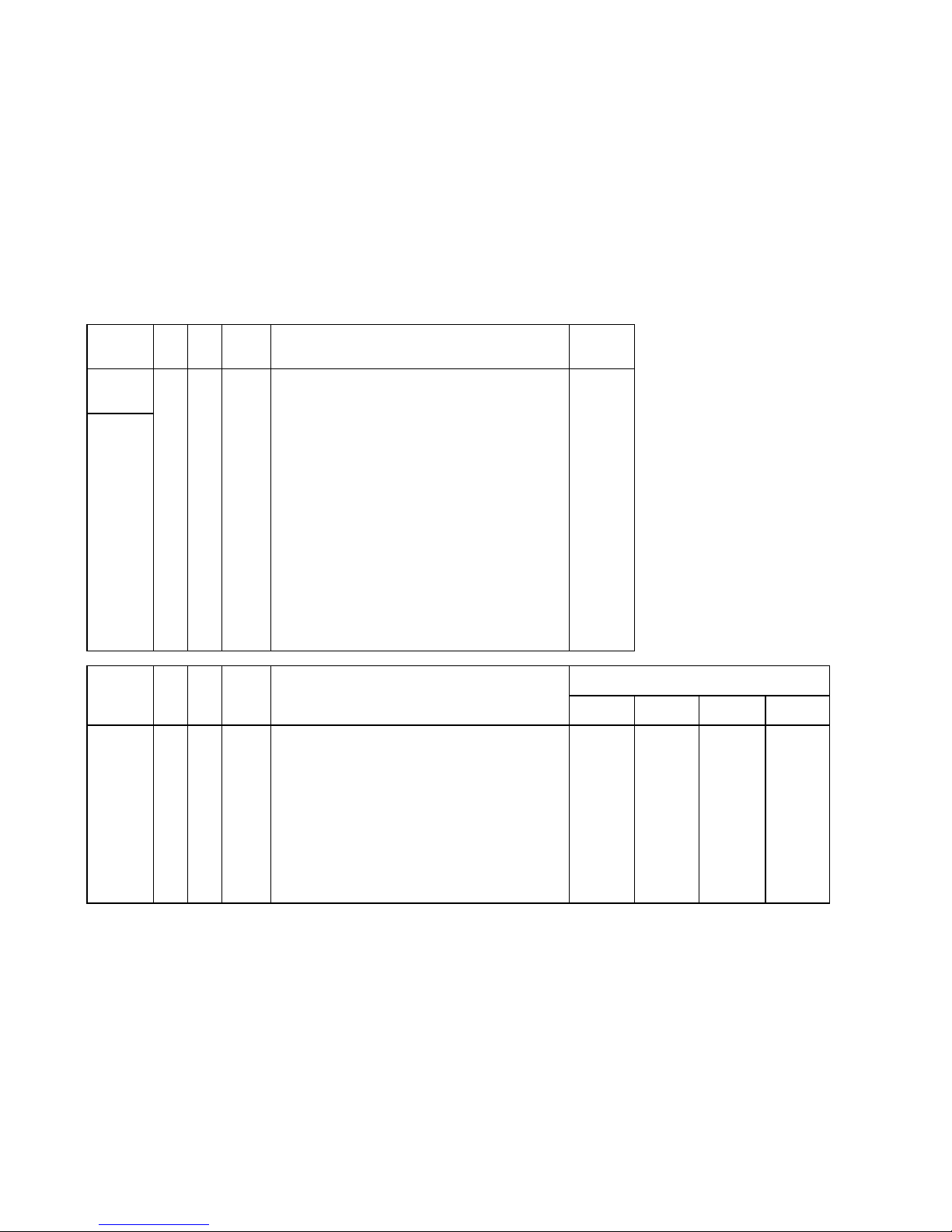

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on

+B overcurrent (OCP)*

I-Prot

IK (AKB)

STANDBY/ TIMER

No. of times

lamp fl ashes

Does not light

2 times

4 times

5 times

Self-Diagnositc

Display/

Diagnostic Result

2:0 or 2:1

4:0 or 4:1

5:0 or 5:1

Probable Cause Location

• Power cord is not plugged in.

• Fuse is burned out (F601). (A Board)

• H.OUT (Q505) is shorted. (A Board)

• IC2751 is shorted. (CW Board)

• +13V is not supplied. (A Board)

• IC545 is faulty. (A Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly adjusted.**

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Has entered standby state after horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT Cathode current detection reference pulse

output is small.

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the

mircrocontroller is displayed on the screen.

**Refer to Screen (G2) Adjustments in Section 2-4. of this manual.

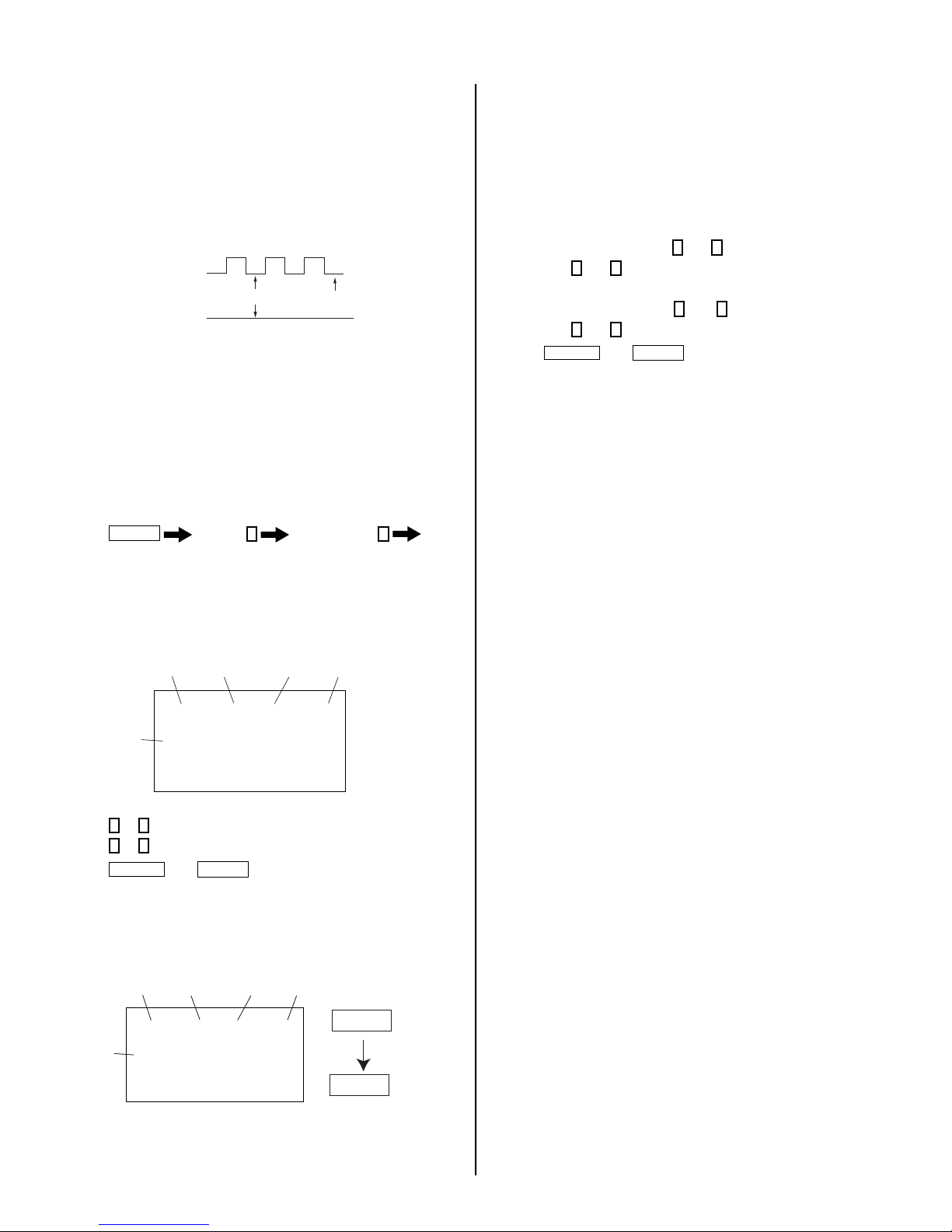

Display of Standby/Timer LED Flash Count

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

Standby/Timer LED

Diagnostic Item Flash Count*

+B Overcurrent 2 times

I-Prot 4 times

IK (AKB) 5 times

*One fl ash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

KV-27FS120/29FA310/29FS120

7

KV-27FS120/29FA310/29FS120

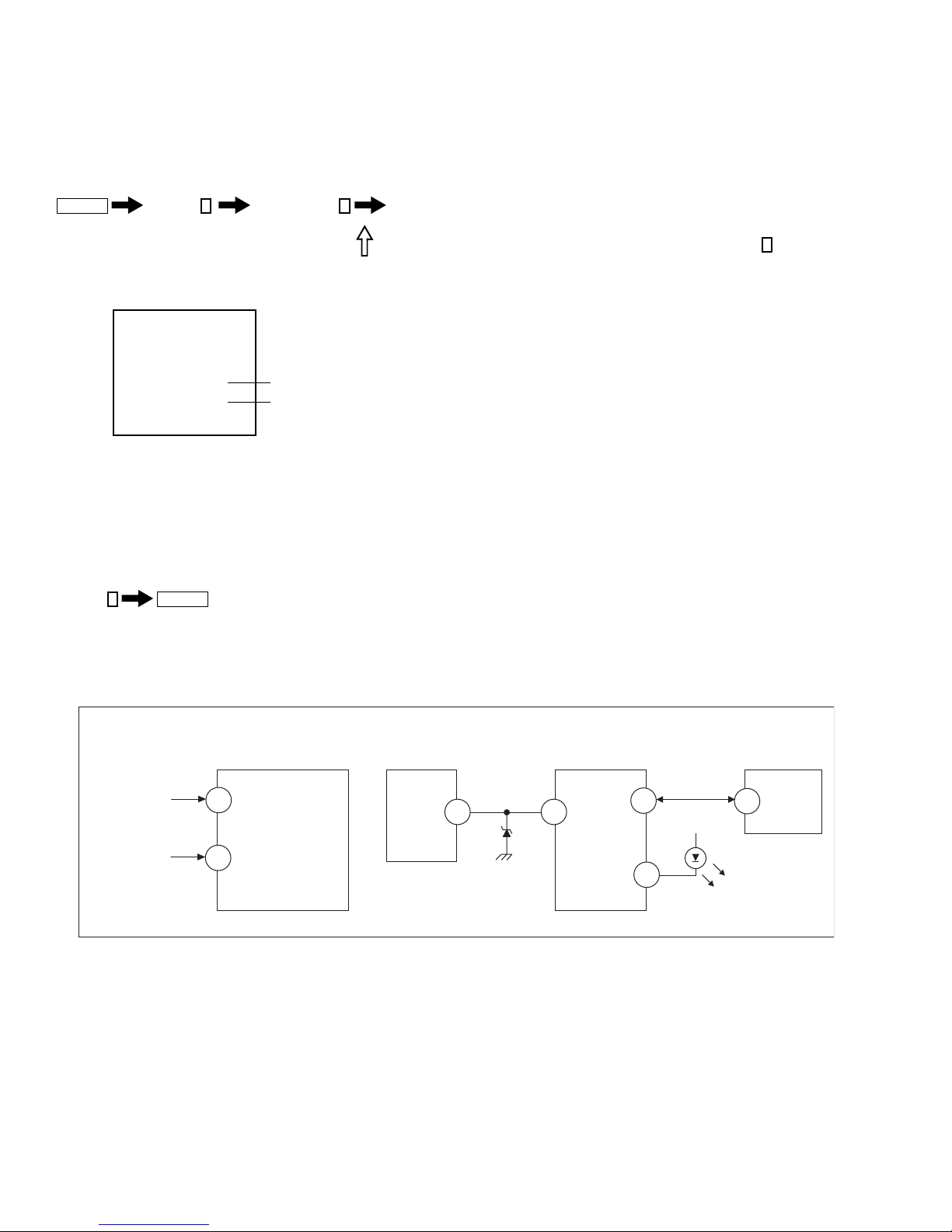

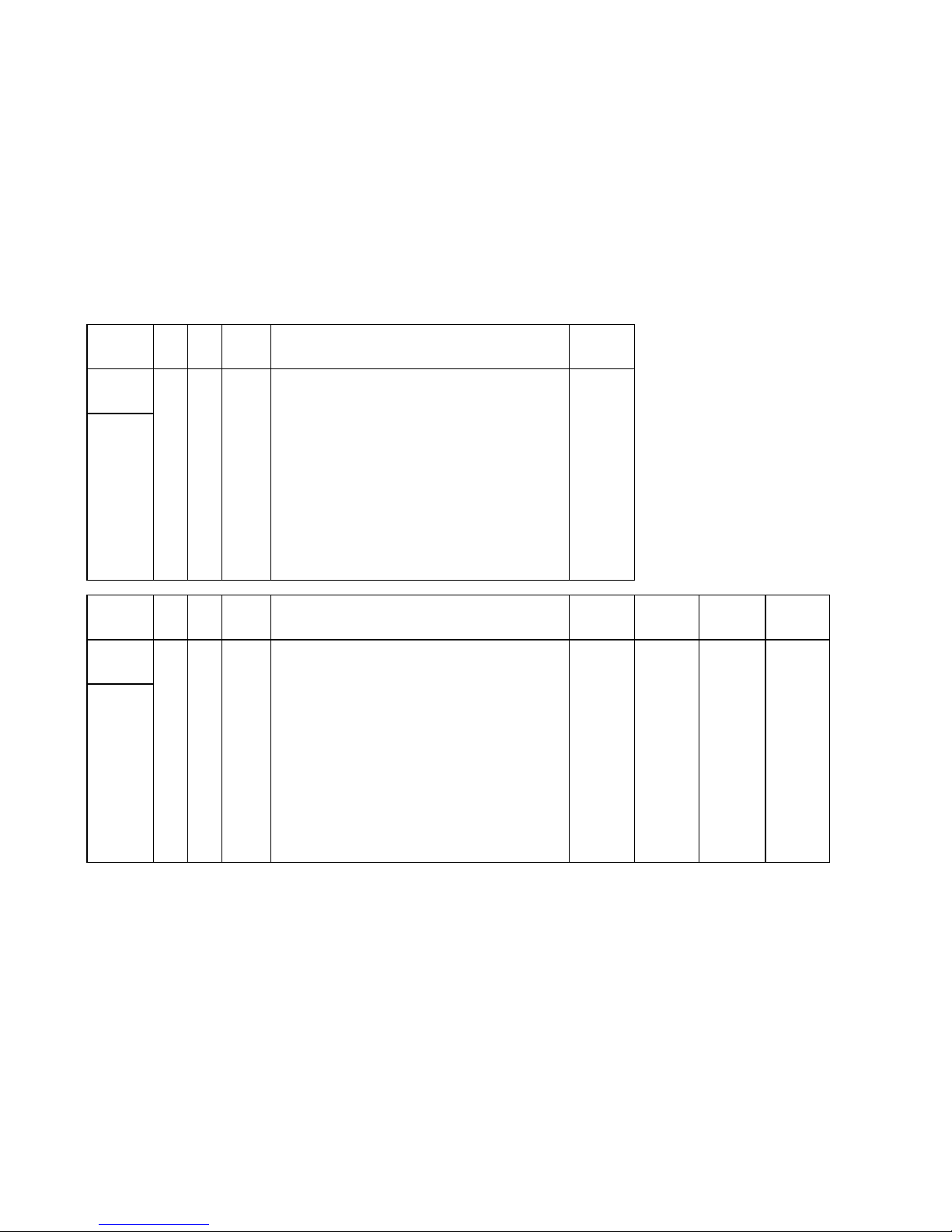

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

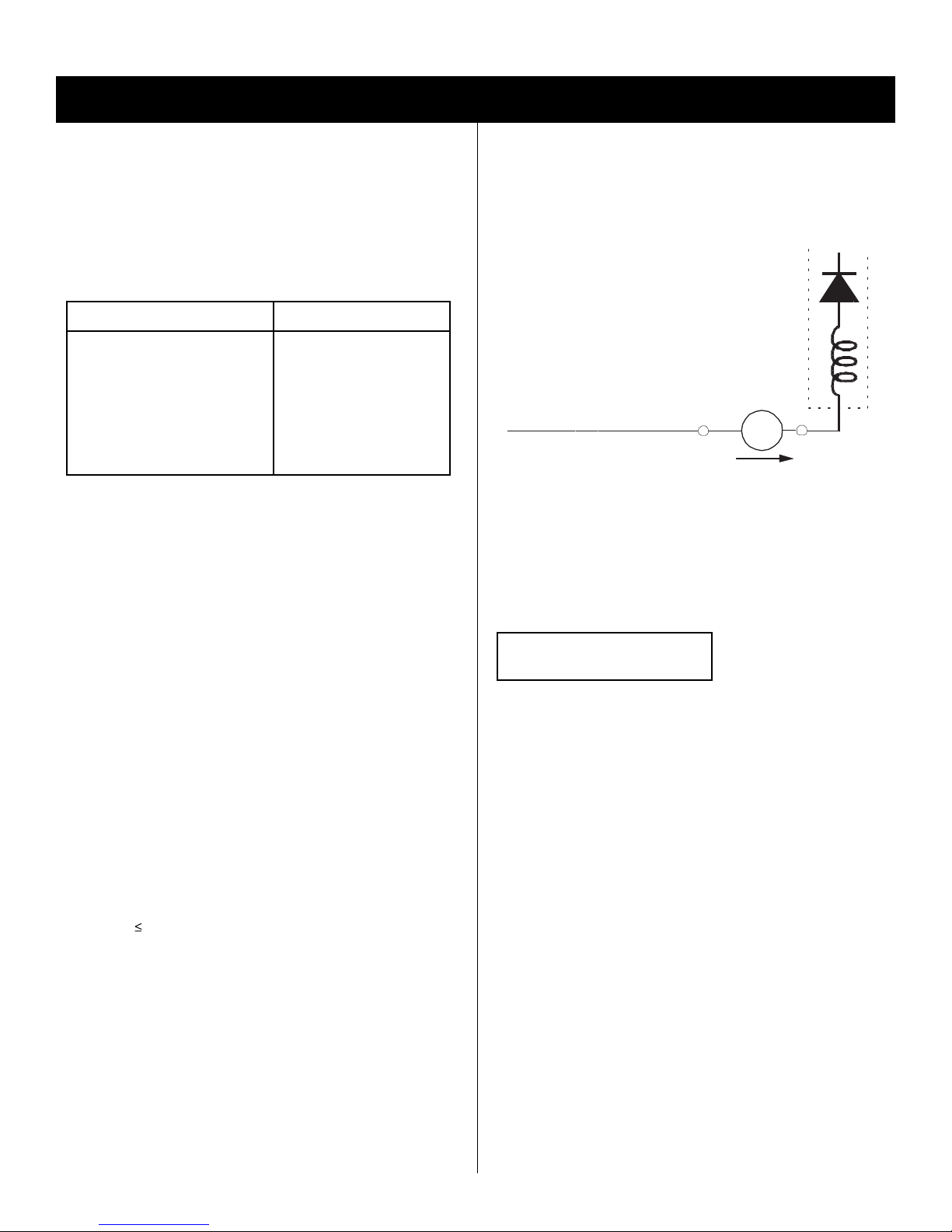

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display

Self-Diagnostic Screen Display

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Channel

SELF DIAGNOSTIC

2: +B OCP 0

3: +B OVP N/A

4: VSTOP 0

5: AKB 1

101: WDT N/A

8

ENTER

5

Sound Volume

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

-

Power ON

Note that this differs from entering the Service Mode (Sound Volume

+

).

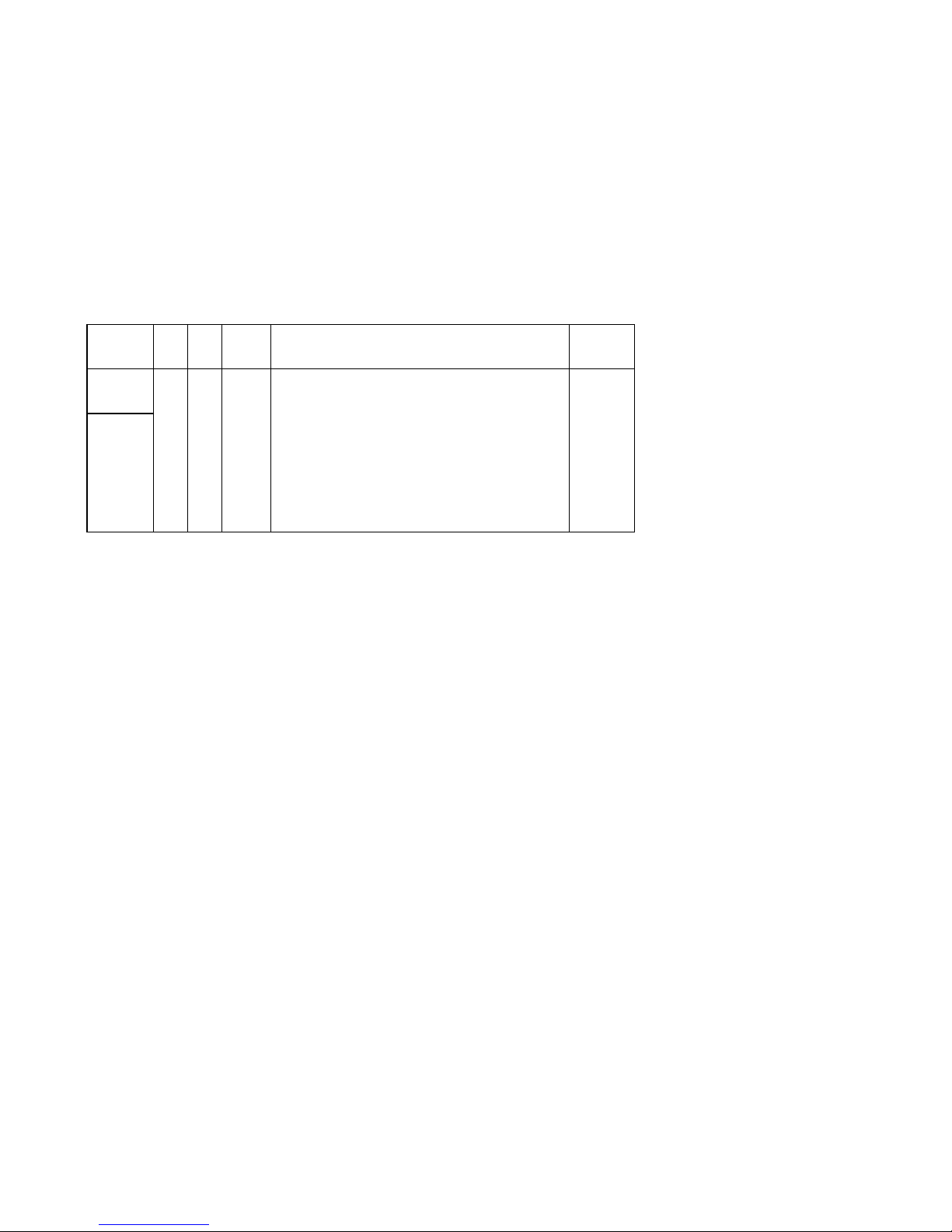

Self-Diagnostic Circuit

FROM

CW BOARD

IC2751 PIN 5

A BOARD

IC001

Y/CHROMA JUNGLE

51

IK-AKBIN

A BOARD

IC545

V. OUT

REF

3

A BOARD

IC001

SYSTEM

IO-BDAT

78

I-Prot

53

A BOARD

IC002

MEMORY

5

BDA

FROM

72

A BOARD

IC561

PIN 7

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (135V) line is detected by pin 72 of IC001 (A Board). If the voltage of pin 72 of IC001 (A Board) is less than 1V

when V.SYNC is more than seven verticals in a period, the unit will automatically turn off.

I-Prot

Occurs when an absence of the vertical defl ection pulse is detected by pin 78 of IC001 (A Board). Power supply will shut down when waveform interval

exceeds 2 seconds.

IK (AKB)

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC001 (A Board). TV will stay on, but

there will be no picture.

I-HLDWN

O-LED

79

DISPLAY

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

KV-27FS120/29FA310/29FS120

8

SECTION 1: DISASSEMBLY

1-1. REAR COVER REMOVAL (ALL EXCEPT KV-29FA310)

4

Screws +BVTP 4X16 TYPE2 TT(B)

Rear Cover

2

Screws +BVTP 4X16 TYPE2 TT(B)

KV-27FS120/29FA310/29FS120

2

Screws +BVTP 4X16 TYPE2 TT(B)

5

Screws +BVTP 3X12 TYPE2 TT(B)

1-2. REAR COVER REMOVAL (KV-29FA310 ONLY)

3

Screws +BVTP 4X16 TYPE2 IT3

Rear Cover

3

Screws +BVTP 4X16 TYPE2 IT3

2

Screws +BVTP 4X16 TYPE2 TT(B)

3

Screws +BVTP 4X16 TYPE2 IT3

KV-27FS120/29FA310/29FS120

5

Screws +BVTP 3X10 TYPE2 IT3

6

Screws +BVTP 4X16 TYPE2 IT3

9

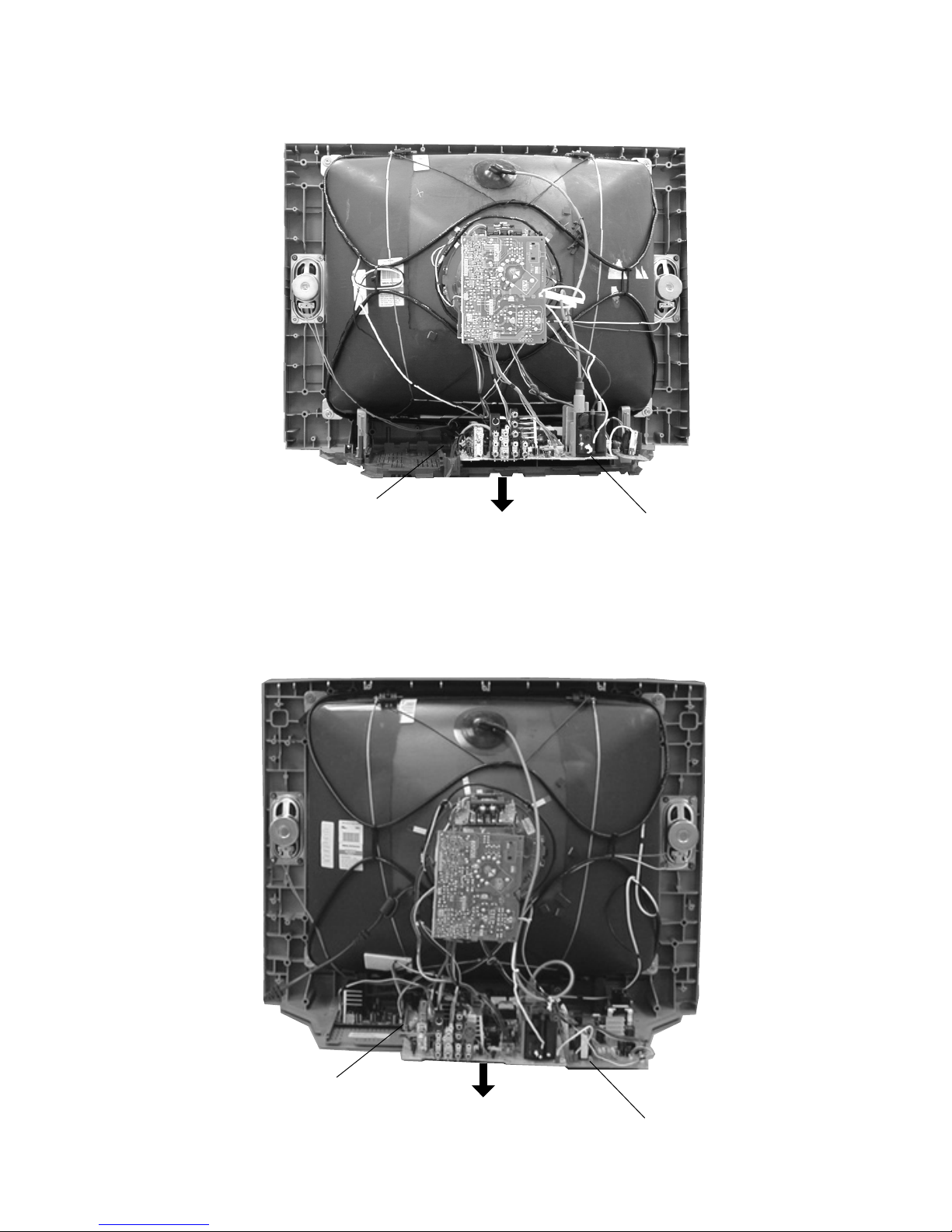

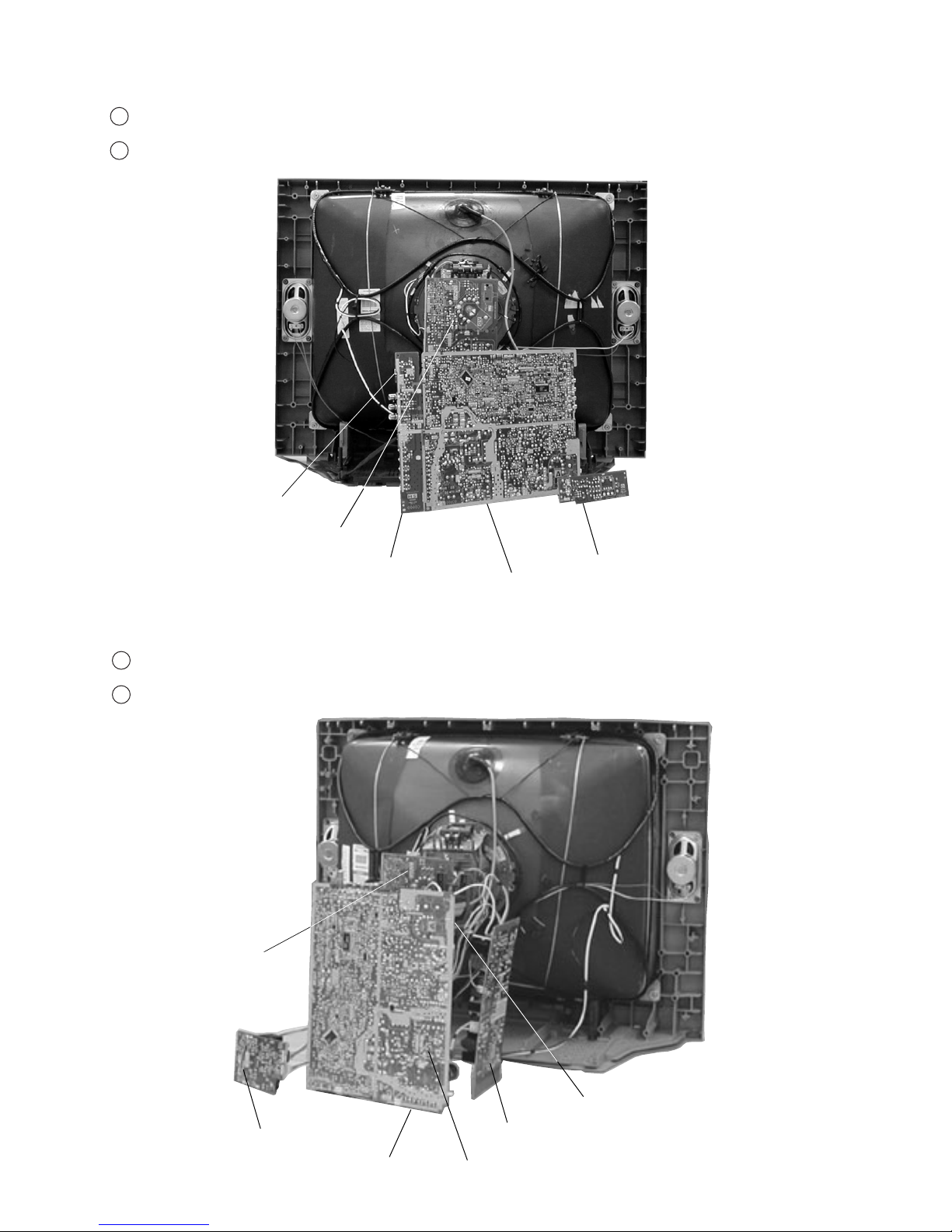

1-3. CHASSIS ASSEMBLY REMOVAL (ALL EXCEPT KV-29FA310)

KV-27FS120/29FA310/29FS120

Claw

1-4. CHASSIS ASSEMBLY REMOVAL (KV-29FA310 ONLY)

Chassis Assembly

Claw

KV-27FS120/29FA310/29FS120

Chassis Assembly

10

1-5. SERVICE POSITION (ALL EXCEPT KV-29FA310)

1

Press on catch tab to release A Board.

2

Disconnect cables as needed to allow A Board to be removed.

KV-27FS120/29FA310/29FS120

V Board

CW Board

HS Board

1-6. SERVICE POSITION (KV-29FA310 ONLY)

1

Press on catch tab to release A Board.

2

Disconnect cables as needed to allow A Board to be removed.

D Board

A Board

CW Board

K Board

KV-27FS120/29FA310/29FS120

HU Board

V Board

GD Board

A Board

11

1-7. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

1

10

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the defl ection yoke, neck

8

7

3

6

2

5

9

4

assembly, degaussing coils and CRT grounding strap.

3. Remove the CW Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion and remove

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fi xing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the CRT

by the neck].

KV-27FS120/29FA310/29FS120

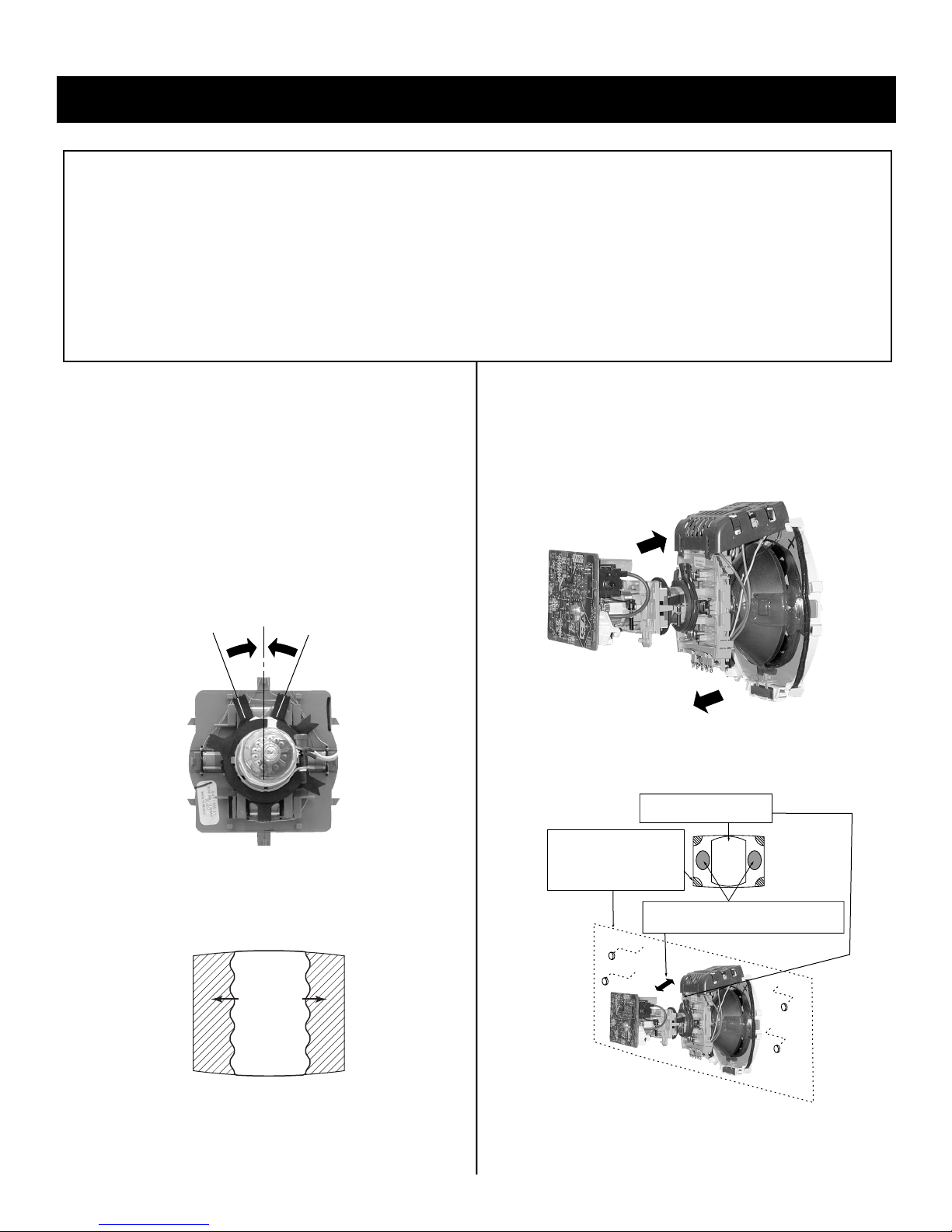

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or carbon

painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

Turn up one side of the rubber cap in

the direction indicated by arrow

a

.

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow

.

b

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow

.

c

KV-27FS120/29FA310/29FS120

12

SECTION 2: SET-UP ADJUSTMENTS

KV-27FS120/29FA310/29FS120

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: Pro

PICTURE CONTROL: Normal

BRIGHTNESS CONTROL: Normal

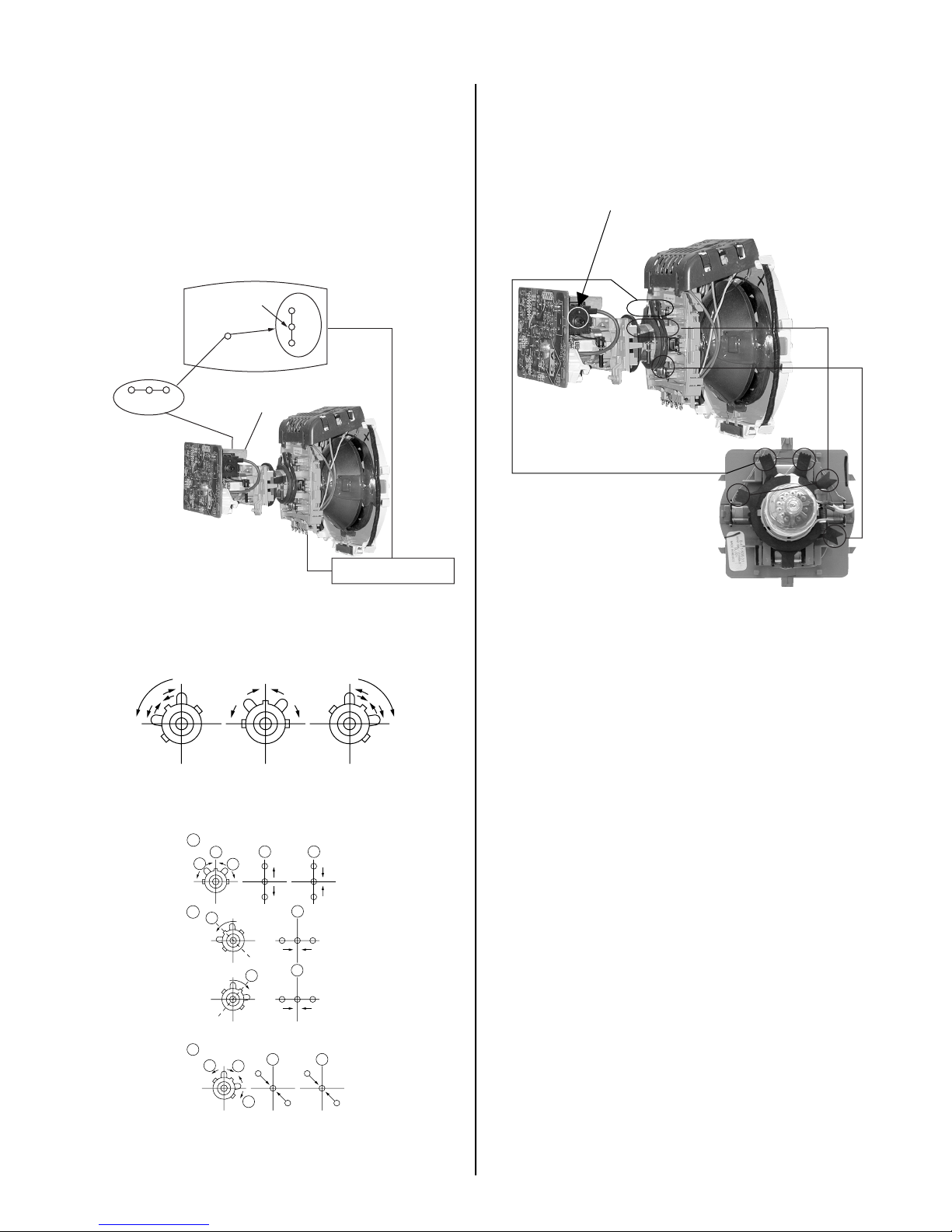

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Degauss the entire screen.

2. Feed in the white pattern signal.

Adjustment Procedure

1. Input a raster signal with the pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity

control to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk magnets.

3. Turn the raster signal of the pattern generator to green.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire

screen becomes green.

KV-27FS120/29FA310/29FS120

Purity control

corrects this area.

Disk magnets

or rotatable disk

magnets correct

these areas (a-d).

Deflection yoke positioning

b

d

a

b

cd

corrects these areas.

a

c

13

KV-27FS120/29FA310/29FS120

2-2. CONVERGENCE

Before starting convergence adjustments:

1 Perform FOCUS, VLIN and VSIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

Vertical Static Convergence

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen.

Center dot

RV2750

R

B

G

H.STAT

R

G

B

Horizontal Static Convergence

If the blue dot does not converge with the red and green dots, perform

the following:

1. Move H STAT VR magnet (a) to correct insuffi cient H.Static

convergence.

H STAT VR

V. STAT

BMC MAGNET

PURITY

V.STAT magnet

2. Tilt the V. STAT magnet and adjust static convergence to open or

close the V. STAT magnet.

When the V. STAT magnet is moved in the direction of arrow a and b,

red, green, and blue dots move as shown below:

1

a

b

2

a

a

b

B

G

R

b

b

B

G

R

a

RGB

b

BGR

3

b

a

a

R

b

B

G

G

B

KV-27FS120/29FA310/29FS120

b

R

14

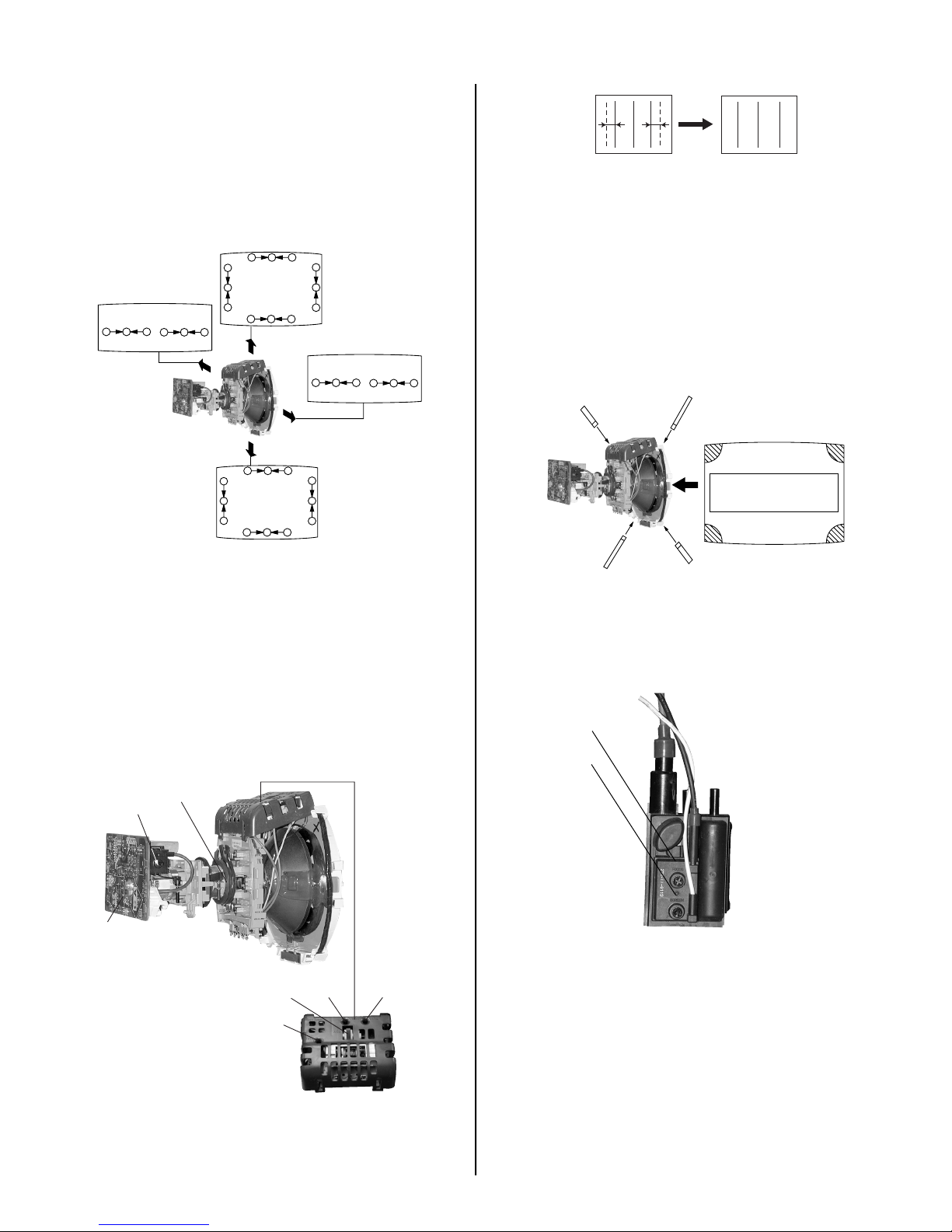

Dynamic Convergence Adjustment

Before performing this adjustment, perform Horizontal and Vertical Static

Convergence Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as

shown below:

G

B

R

R

G

B

BGR

B

G

R

R

B

G

R

B

G

KV-27FS120/29FA310/29FS120

B R R B

(R)(B) (B)(R)

4. Adjust XCV core to balance X axis.

5. Adjust YCH VR to balance Y axis.

6. Adjust vertical red and blue convergence with V.TILT (TLV VR.)

Note: Perform adjustment 3-6 while tracking items 1 and 2.

TLH+

TLH-

Screen-Corner Convergence

BGR

B

G

R

B

G

R

B

R

G

B

R

G

R

GB

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

TLH Plate Adjustment

1. Input crosshatch pattern.

2. Adjust PICTURE QUALITY to standard, PICTURE and BRIGHTNESS

to 50%, and OTHER to standard.

3 Adjust the Horizontal Convergence of red and blue dots by tilting the

TLH plate on the defl ection yoke.

RV2750

V.STAT

TLH Plate

1. Affi x a permalloy assembly corresponding to the misconverged areas:

b

a

ba

a-d: screen-corner

misconvergence

c

d

c

d

2-3. FOCUS

1. Adjust FOCUS control for best pictures.

Focus (FV)

Screen (G2)

CW

Board

YCH

XCV

(TLV)

KV-27FS120/29FA310/29FS120

TLV

15

2-4. SCREEN (G2)

1. Input a dot pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum and

COLOR control at normal.

3. Adjust SBRT, GCUT, BCUT in service mode with an oscilloscope as

shown below so that voltages on the red, green, and blue cathodes

are 160 ± 2VDC.

±

160 – 2VDC

Pedestal

Ground

4. Observe the screen and adjust SCREEN (G2) VR in FBT to obtain

the faintly visible background of dot signal.

2-5. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE

Service Mode Procedure

KV-27FS120/29FA310/29FS120

2-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal with burst.

2. Set to Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Adjust with SBRT if necessary.

ENTER

1

and 4 .

1

4

and

.

to save into the memory.

5. Select GCUT and BCUT with

3

6. Adjust with

6

and

for the best white balance.

7. Set the PICTURE and BRIGHTNESS to maximum.

8. Select GDRV and BDRV with

9. Adjust with

10. Press

3

and 6 for the best white balance.

MUTING

then

1. Standby mode (power off).

2. Press

Display

Channel

Sound Volume

5

Power

+

on the Remote Commander (press each button within a second).

Service Adjustment Mode On

1. The CRT displays the time being adjusted.

2. Press

3. Press

4. Press

Display

hsiz 16

to save into the memory.

service

ntsc

vchp

then

Category

defl

00000000

ENTER

Mode

Signal

Type

1

or 4 on the Remote Commander to select the time.

3

or 6 on the Remote Commander to change the data.

MUTING

Item

00000000

Display

Item

Service Adjustment Mode Memory

Turn the set off then on to exit Service Adjustment Mode.

Mode

Category

Display

Item

Item

Data

service defl hsiz 16

Signal

Type

ntsc

vchp 00000000 00000000

write

KV-27FS120/29FA310/29FS120

MUTING

ENTER

Green

Red

16

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-27FS120/29FA310/29FS120

3-1. X R564 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when replacing

the following components which are marked with

diagram:

Part Replaced (Y ) Adjustment (X)

DY, T585, CRT, IC001, IC561,

IC600, IC604, C506, C507,

C508, C510, C511, C513,

C514, L588, D566, D567,

D568, PH602, R526, R564,

R565, R566, R851, T510,

T511……....A Board

HV HOLD-DOWN

R564

Y

on the schematic

Preparation Before Confi rmation

1. Using a Variac, apply AC input voltage: 120 ± 2 VAC.

2. Turn the POWER switch ON.

3. Input a white signal and set the PICTURE and BRIGHTNESS

controls to maximum.

4. Confi rm that the voltage between C566 (+) or TP30 and ground is

more than 99VDC.

Hold-Down Readjustment

If the setting indicated in Step 2 of Hold-Down Operation Confi rmation

cannot be met, readjustment should be performed by altering the

resistance value of R564 component marked with

X

.

T585

FBT

ammeter

3.0 mA DC

range

ABL

+

-

A

IABL

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Note: The following adjustments should always be performed when

replacing the following components, which are marked with

schematic diagram on the A Board:

A BOARD: Y IC604, PH602

Y

on the

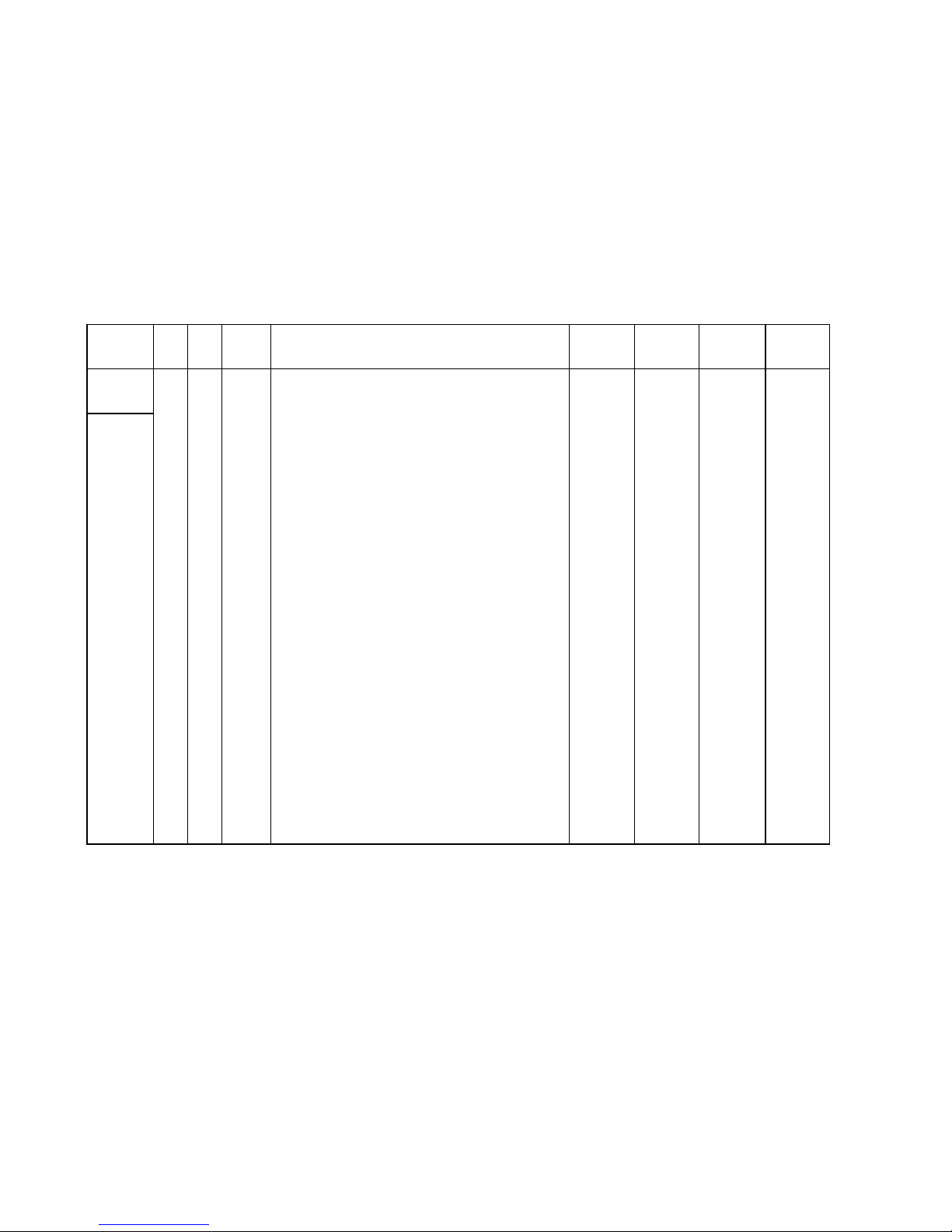

Hold-Down Operation Confi rmation

1. Connect the current meter between Pin 11 of the FBT (T585) and the

PWB land where Pin 11 would normally attach (See Figure 1 on the

next page).

2. Input a dot signal and adjust the ABL current to follow with the

PICTURE and BRIGHTNESS control: IABL = 140 ± 100µA.

3. Confi rm the voltage of A Board TP-23 is 135.6 ± 1.0VDC.

4. Connect the digital voltmeter and the DC power supply via Diode

1SS119 to C566 (+) and ground (See Figure 1 on next page).

5. Increase the DC power voltage gradually until the picture blanks out.

6. Turn DC power source off immediately.

7. Read the digital voltmeter indication

(Standard

8. Input 100 IRE White Signal and adjust the ABL current to follow with

the PICTURE and BRIGHTNESS control: IABL = 1820µA ± 200µA.

9. Repeat steps 4 through 7.

114.6 +OVDC/-0.3DC).

1. Using a Variac, apply AC input voltage: 130 + 2.0 / - 0.0 VAC.

2. Input a DOT pattern at Q.C.

3. Set the PICTURE and the BRIGHTNESS controls to minimum.

4. Confi rm the voltage of A Board between TP-23 & Ground is =135.6

± 1VDC.

5. If step 4 is not satisfi ed, replace the components listed above, then

repeat steps 1 throught 3.

KV-27FS120/29FA310/29FS120

17

(

)

FIGURE 1

KV-27FS120/29FA310/29FS120

DIGITAL

MULTIMETER

+

-

X

R564

R

5

3

1

0

4

S

P

R

5

1

1

J

R

1

R

4

3

7

0

6

R

C

4

5

1

C

5

D

5

6

5

2

R

5

8

9

T

2

P

4

2

9

L

3

7

0

1

5

6

C

1

5

T

2

8

6

2

R

5

3

2

L

3

7

1

1

1

5

C

R

2

1

5

C

1

1

5

L

1

C

5

3

1

5

L

0

2

B

2

P

5

T

R

5

0

4

R

5

3

3

C

5

4

0

5

S

5

6

5

C

I

C

5

3

0

6

2

5

D

5

2

5

L

5

1

0

6

2

5

C

1

5

C

4

1

5

C

2

H

5

Q

B

5

2

5

C

3

L

5

1

5

R

5

3

7

R

5

6

2

2

R

5

5

2

2

E

C

5

2

7

R

5

4

9

R

5

1

5

6

7

C

5

6

1

R

5

4

6

5

4

5

D

6

R

5

4

8

C

5

4

5

R

9

0

R

5

4

0

0

D

2

7

C

R

5

4

7

6

0

1

5

L

R

5

6

C

5

4

8

1

J

R

5

0

POWER

SUPPLY

+

1SS119

C566

Q

4

0

2

R

4

0

8

R

4

1

1

O

R

.

T

H

P

R

P

T

3

0

6

6

5

D

R

5

2

9

C

5

6

2

C

5

2

9

1

6

5

C

I

C

5

4

4

2

C

5

9

7

1

T

P

V

.

O

U

T

5

4

7

5

4

5

C

I

4

1

C

5

9

5

P

7

T

1

R

9

0

1

5

1

2

C

2

5

2

8

D

5

2

8

D

5

6

1

R

5

8

3

2

8

5

C

P

T

3

3

Q

5

2

1

5

7

5

R

C

5

7

1

R

5

6

8

D

5

6

8

6

7

R

5

7

0

D

5

6

R

R

2

8

5

L

9

5

2

6

R

5

6

5

9

7

4

D

6

3

0

6

0

1

2

0

6

C

6

1

0

0

2

4

TP23

8

9

5

E

R

5

0

R

5

9

3

3

0

5

R

C

5

9

0

1

9

5

R

B

0

9

5

Q

R

5

9

4

T

P

1

3

4

2

6

E

C

C

P

3

T

2

1

6

8

C

6

4

0

4

2

6

D

4

5

0

5

C

H

-

O

Q

5

C

5

0

4

1

6

5

0

5

R

U

T

E

0

5

6

0

5

C

6

0

5

D

3

4

R

5

0

6

C

5

1

T

2

P

2

0

C

4

1

5

R

2

1

5

R

H

D

T

5

0

5

T

H

B

5

8

8

R

8

5

L

T

U

O

6

0

5

Q

6

G

2

0

0

V

8

N

/

C

V

D

Y

+

P

T

2

1

V

D

Y

-

T

2

P

7

H

D

Y

-

P

T

2

8

H

D

Y

-

H

D

Y

+

T

P

H

D

Y

+

3

1

H

-

O

2

9

1

5

5

N

C

D

R

5

9

8

T

1

P

9

H

E

A

T

E

R

N

D

5

V

U

T

-

1

3

V

G

N

D

G

N

D

G

N

D

5

5

T

+

1

3

V

N

/

C

A

B

L

T

2

P

0

R

5

8

8

F

B

T

1

AMMETER

3mA dc range

A

+

-

KV-27FS120/29FA310/29FS120

18

SECTION 4: CIRCUIT ADJUSTMENTS

Electrical AdjustmenTs by Remote Commander

Use the Remote Commander (RM-Y180, RM-Y195) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

KV-27FS120/29FA310/29FS120

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

Display

Channel

5

Sound Volumne

Power

+

Service Adjustment Mode On

1. The CRT displays the item being adjusted.

Item

Data

41

2. Press

3. Press

4. Press

Signal

Category

Display

Item

1

or 4 on the Remote Commander to select the item.

3

or 6 on the Remote Commander to change the data.

MUTING

DEF NTSC 1 NVM OK

M65582AMF-101FPZ0

then

Type

H SIZE

ENTER

Display

Item #

to write into memory.

Service Adjustment Mode Memory

1. Press

Signal

Type

Category

Mode

service defl hsiz 16

Signal

Type

8

then

Mode

service defl hsiz 16

ntsc

vchp 00000000 00000000

ntsc

vchp 00000000 00000000

ENTER

Category

on the Remote Commander to initialize.

Display

Item

write

Display

Item

Data

Item

Item

Data

write

Carry out Step 1 when adjusting

IDs 0-7 and when replacing and

adjusting IC002

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace

the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

MUTING

(Enter into

memory)

1

Disp. (Item up)

2

(Device Item Up)

4

Disp. (Item down)

8

(Initialize)

VOLUME (+)

(Service Mode)

RM-Y180

POWER

(Service Mode)

DISPLAY

(Service Mode)

3

Item

(Data up)

6

Item

(Data down)

5

(Device item

down)

ENTER

(Enter into

memory)

0

(Remove from

memory)

2. Press

MUTING

then

ENTER

to write into memory.

3. Turn set off then on to exit Service Adjustment Mode.

KV-27FS120/29FA310/29FS120

19

20

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

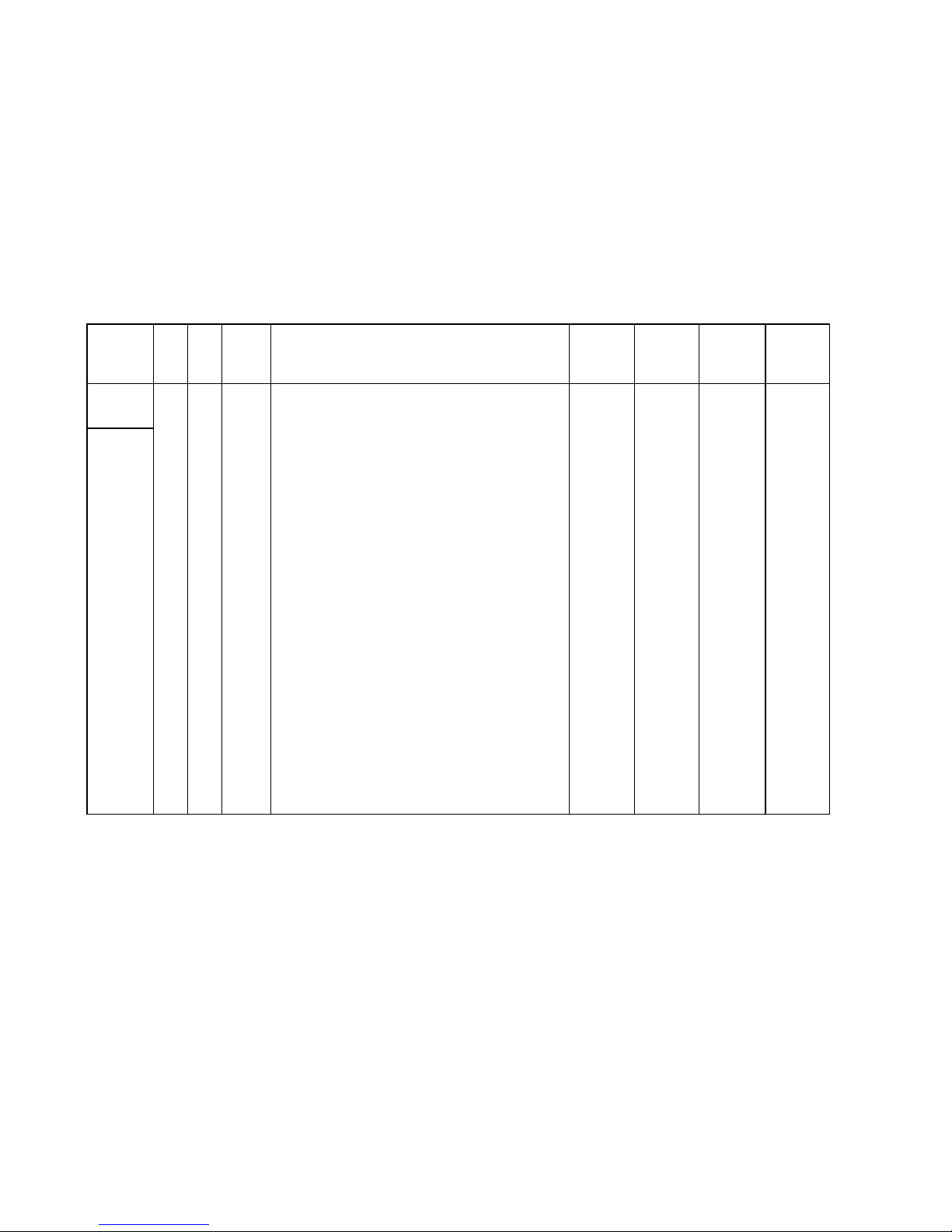

4-4. SERVICE DATA LISTS

NTSC

Init

Data

VERSION Fix 0 VER

Micro

p

rocessor version information

=

VAR

1HSIZ

H-SIZE ( EW DC : YUV OFFSET )

47

VAR

2HPOS

H POSITION: YUV OFFSET

36

VAR

3 VSIZ

V RAMP SIZE: YUV OFFSET

28

VAR 4 VPOS

V POSITION (RAMP DC) NOT USEFUL: YUV OFFSET

37

VAR

5VLIN

V LINEARITY

32

VAR

6SCOR

S CORRECTION

49

VAR

7 VBOW

BOW

31

VAR

8 VANG

ANGLE

37

VAR

9TRAP

EW TRAPESIUM

24

VAR

10 PAMP

PARABOLA ( EW PIN )

49

VAR

11 UPIN

UPPER CORNER ( UPPER PIN )

31

VAR

12 LPIN

LOWER CORNER ( LOWER PIN )

30

VAR

13 TROT

TROT

109

VAR

14 HBL

K

FBPBLK ( H BLK MODE SELECT )

0

VAR

15 RBL

K

HBLK R POS ( HBLK REAR TIMING: YUV OFFSET )

15

VAR

16 LBL

K

HBLK F POS ( HBLK FRONT TIMING: YUV OFFSET )

41

FIX

17 VBL

K

VBLK POS ( V BLK WIDTH )

0

FIX 18 HMSK

Macro OFF ( TOP VEND [ WHEN MACROVISION ] PREVENT

OFF )

0

FIX

19 HDW

IIC_HOUT_DUTY ( H PULSE WIDTH [ 25u/19u ]

1

FIX

20 AFC

H AFC Gain ( AFC GAIN )

0

FIX

21 AFC1

H Charge pump ( AFC1 TIME CONSTANT )

3

FIX

22 AFCW

AFC1 PULLIN ( AFC1 PULL IN WIDE )

0

FIX

23 CDMD

V CD MODE ( V DET WINDOW SW TIMING )

1

FIX

24 HSS

SYNC SLICE LVL(H) ( SYNC SLICE LEVEL [ H sepa ] )

0

FIX

25 VSS

SYNC SLICE LVL(L) ( SYNC SLICE LEVEL [ V sepa ] )

3

FIX

26 SLDN

AUTO SLICE DOWN ( AUTO SLICE LEVEL DOWN )

0

FIX

27 SLUP

AUTO SLICE UP ( AUTO SLICE LEVEL UP )

0

FIX

28 JPSW

VJPSW ( JUMP SW )

0

FIX 29 HOSC

H VCO FOR OFFSET ADJUST OFFSET

7

FIX

30 EHT

EHT

4

FIX

31 EHTG

EHT GAIN ( EHT MODE )

1

Name Description

Fix/

Var

No.

Service

Group

DEF

21

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init

Data

VAR

1 VSIZ

V RAMP SIZE

48

VAR

2 VPOS

V POSITION ( RAMP DC )

40

VAR

3VLIN

V LINEARITY

26

VAR

4SCOR

S CORRECTION

24

VAR

5TRAP

EW TRAPESIUM

22

VAR

6 PAMP

PARABOLA ( EW PIN )

24

VAR

7UPIN

UPPER CORNER ( UPPER PIN )

31

VAR

8LPIN

LOWER CORNER ( LOWER PIN )

31

VAR

9 ABLG

ABL GAIN

15

VAR

10 SCON

SUB CONTRAST LEVEL

13

VAR

11 VPW

JUMP PULSE WIDTH

1

Fix/

Var

No.

Service

Group

Item name & ( Description )Name

16 : 9

22

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init Video YUV 16:09

Data

VAR

1 RDRV

R DRIVE

64

64 64 N/A

VAR 2 GDRV

G DRIVE: GDOF OFFSET ( only Color Temp. "Warm")

45 45 48 N/A

VAR 3 BDRV

B DRIVE: BDOF OFFSET ( only Color Temp. "Warm")

45 45 44 N/A

VAR

4 RCUT

HARDWARE AKB (R) CMP DATA

120

120 120 N/A

VAR 5 GCUT

HARDWARE AKB (G) CMP DATA

91 91 90 N/A

VAR 6 BCUT

HARDWARE AKB (B) CMP DATA

87 87 105 N/A

VAR

7SCON

SUB CONTRAST LEVEL

19

19 19 N/A

VAR

8 SHUE

SUB TINT (HUE)

777

N/A

VAR

9SCOL

SUB COLOR LEVEL

14 14 24

N/A

VAR

10 SBRT

SUB BRIGHTNESS

13 13 15

N/A

FIX 11 RON

R OUTPUT ON ( 0:R OUTPUT OFF 1:R OUTPUT ON )

1

FIX 12 GON

G OUTPUT ON ( 0:R OUTPUT OFF 1:R OUTPUT ON )

1

FIX 13 BON

B OUTPUT ON ( 0:R OUTPUT OFF 1:R OUTPUT ON )

1

FIX 14 BLLV

BLUE STRETCH ( 00:NO<->11:DEEP ) only Color Temp "Cool"

1

FIX

15 MTRX

MATRIX RATIO SELECT

0

FIX

16 AXIS

R-Y PHASE SELECT

52

VAR 17 SSHO

SUB SHARPNESS GAIN (OVER) RF/VIDEO

10 25 25 N/A

VAR 18 SSHP

SUB SHARPNESS GAIN (PRE) RF/VIDEO

15 30 30 N/A

VAR 19 SHPF

SHARPNESS FOR ( 00:2 CLK <-> 11:5 CLK )

100N/A

FIX 20 SHCL

SHARPNESS CORING LEVEL

0

FIX

21 SHMX

SHARPNESS LIMITER LEVEL

15

FIX

22 ACLV

ACL GAIN

0

FIX

23 AKBD

AKB SELF DIAGNOSTIC COUNTER (@1 SEC)

2

FIX

24 AKBS

AKB SWITCH ( 0:AKB OFF 1:H/W AKB ON )

1

FIX

25 REFP

AKB REFPLS TIMING

0

FIX

26 YNRC

YNR LIMITER LEVEL

15

FIX

27 BKON

BLACK STRETCH ON

1

FIX 28 BKAT

BLACK STRETCH DETECTOR TIME CONSTANT1

15

FIX 29 BKRC

BLACK STRETCH DETECTOR TIME CONSTANT2

4

FIX 30 BKDP

BLACK STRETCH DEPTH

soft cont'l

FIX

31 BKSP

BLKSTPNT BLACK STRETCH POINT

2

Name Item name & ( Description )No.

VP1

Service

Group

Fix/

Var

23

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init Video YUV 16:09

Data

FIX

1VMOF

VM GAIN(Off) ( VM LEVEL AT "OFF" SETTING ) 2

FIX

2VMLO

VM GAIN(Low) ( VM LEVEL AT "LOW" SETTING )

4

FIX

3VMHI

VM GAIN(High) ( VM LEVEL AT "HIGH"SETTING )

7

FIX

4VMDL

VM DELAY ( VM DELAY )

6

FIX

5VMPL

VM POL ( VM POLARITY )

0

FIX

6VMWD

VM WIDTH ( VM WIDTH )

0

FIX

7VMCL

VM CORING LEVEL ( VM CORING LEVEL )

0

FIX

8 VMMX

VM MAX ( VM LIMITER LEVEL )

15

FIX

9CKLV

KILLER LEVEL ( VM COLOR KILLER VTH )

1

10N/A

FIX

10 CKON

FORCE KILLER ( FORCE KILLER )

0

FIX

11 ALFA

ALFA ( ADAPTIVE DET SENSITIVITY )

2

FIX 12 YCMD

MANEXP ( YC SEPA FORCE SELECT [ 00:ADAPTIVE 01:H 10:V

11:HV ] )

0

FIX 13 VACL

V APERTURE CORING LV ( V APERTURE CORING LEVEL )

0

FIX

14 VAGA

V APERTURE GAIN ( V APERTURE GAIN LEVEL )

soft cont'l

FIX 15 VAMX

V APERTURE MAX GAIN (V APERTURE LIMITER LEVEL)

5

FIX

16 GAMM

GAMMA ( GAMMA [ 00:NO <-> 11:DEEP ] )

soft cont'l

FIX

17 YDLY

Y DELAY ( Y DELAY TIME )

1

13N/A

FIX

18 CDLY

C DELAY ( C DELAY TIME )

0

FIX

19 YOFF

Y Mute ( Y OUTPUT MUTE )

0

FIX

20 CBPF

SAW FILTER(7.2MHzBPF) ( C BPF FOR HI )

0

FIX

21 BGPP

BGP POS ( BGP [ FOR C DECODER ] TIMING )

9

928N/A

VAR

22 GDOF

G DRIVE OFFSET only Color Temp. "Warm"

9

VAR

23 BDOF

B DRIVE OFFSET only Color Temp. "Warm"

14

VAR

24 GCOF

G CUT CMP DATA OFFSET only Color Temp. "Warm"

11

VAR

25 BCOF

B CUT CMP DATA OFFSET only Color Temp. "Warm"

28

VAR

26 DCTV

DCTRAN VTH<6:0> ( DCTRANSFER VTH )

30

FIX

27 DCTG

DCTRAN GAIN<4:0> ( DCTRANFER GAIN )

soft cont'l

No. Name Item name & ( Description )

Service

Group

Fix/

Var

VP2

24

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init

Data

VAR

1SCOL

SUB COLOR LEVEL 14

VAR

2 SHCL

SHARPNESS CORING LEVEL

15

VAR

3SHMX

SHARPNESS LIMITER LEVEL

7

FIX

4 YNRC

YNR LIMITER LEVEL

7

FIX

5VMHI

VM LEVEL AT " HIGH " SETTING

10

FIX

6VMCL

VM CORING LEVEL

0

FIX

7 VMMX

VM LIMITER LEVEL

7

FIX

8 VAMX

V APERTURE LIMITER LEVEL

0

FIX

9GAMM

GAMMA ( 00: NO < - > 11:DEEP)

0

FIX

10 YNRS

YNR ON

1

FIX

11 WSTH

WEAK SIGNAL VTH

7

FIX

12 WSVA

WEAK SIGNAL VIDEO ATT

0

FIX

13 WSCA

WEAK SIGNAL CHROMA ATT

5

FIX

14 NRCH

THRNZV1( NOISE DET TIME CONSTANT )

0

FIX

15 NRCL

THRNZV2 ( NOISE DET TIME CONSTANT )

16

FIX

16 NRVL

THRNZH1 ( NOISE DET VTH )

2

FIX

17 NRVH

THRNZH2 ( NOISE DET VTH )

0

FIX

18 IPNC

DETNZ STATUS COUNTER

2

FIX

19 IPNV

DETECTION PERIOD

10

PALLET

= VIVID

PALLET

= STD

PALLET

= MOVIE

PALLET

= PRO

FIX

1 VPIC

PICTURE

63 50 37 31

FIX

2 VBRI

BRIGHTNESS

27 30 31 31

FIX

3VCOL

COLOR

37 32 31 31

FIX

4 VHUE

HUE

31 31 31 31

FIX

5 VSHA

SHARPNESS

31 32 31 21

FIX

6 VVM

VM

2100

FIX

7VTRI

COLOR TEMP

0121

FIX

8 VAPA

APERTURE G

5530

FIX

9VGMA

GAMMA

3100

FIX

10 VDCT

DCT LV

23 15 2 2

FIX 11 VBKP

BLACK STRETCH DEPTH ( VIDEO )

3347

FIX 12 TBKD

BLACK STRETCH DEPTH ( TUNER )

3347

Service

Group

Fix/

Var

No. Name

Name

Item name & ( Description )

Item name & ( Description )

NTSC

BA6 DATA (DEC)

Fix/

Var

No.

PALLET NR

Service

Group

25

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init

Data

FIX 1 YNRS

YNR SW

(

YNR ON

)

0

FIX 2 YTHR

Y THR 2D

(

Y SIGNAL THROUGH 2DYCS

)

0

FIX 3 Y2D

Y2D Fix

(

Y SIGNAL GENERATE from 2DYCS

)

0

FIX 4 2DFX

C BPF Fix

(

C SIGNAL GENERATE from H/V BPF onl

y

1

FIX 5 CLPS

CLAMP CONTROL SW ( 0: CLAMP OFF. 1:

CLAMP AUTO. 2: CLAMP ON

]

1

FIX 6 VLPF

VIDEO LPF

(

Y_LPF [ ANALOG ] for adjust

)

3

FIX 7 CLPF

CHROMA LPF

(

C_LPF [ ANALOG ] for adjust

)

3

FIX 8 BPFB

YCS HBPF BACK

(

YCS HBPF SELECT [ BACK ]

)

1

FIX 9 BPFF

YCS HBPF FRONT

(

YCS HBPF SELECT [ FRONT ]

)

1

FIX 10 BKTS

BS T2 IFON

(

BLACK STRETCH RECOVER TIME OUT

0

FIX 11

VMG

2

VMGAIN2 ( MODULATOR FEEDBACK GAIN CONTROL

3

FIX 12 CLPT

CLAMP KEEP TIMER ( CLAMP AUTO ON KEEP TIMER COUNT [

@ 100 MS

])

15

A8

Init Video YUV 16:09

Data

FIX 1

A1FL

AMP OFF1 L ( ANALOG ACC hysteresis )

90

FIX 2

A1ON

AMP ON ( ANALOG ACC AMP ON LEVEL)

4

FIX 3

ACCS

ACC SW ( ACC ON/OFF )

0

01N/A

FIX 4 AASL

AVE SEL

(

C DECODER TIME CONSTANT [32, 16, 8, 1H ]

)

2

FIX 5

BASL

B2AVE SEL ( ACC TIME CONSTANT )

0

FIX 6

XFFR

FREE RUN ( VCXO FORCE FREERUN )

0

01N/A

FIX 7

A2ON

AMP2 ON Thresh ( ABL VTH )

4

FIX 8

A3ON

AMP3 ON Thresh ( ACL VTH )

4

FIX 9

A2FL

AMP2 OFF Thresh L ( AMP2 OFF LEVEL LOWER )

64

FIX 10

A3FL

AMP3 OFF Thresh L ( AMP3 OFF LEVEL LOWER )

64

FIX 11

AXTH

AXIS HYS ( AXS HYS )

30

FIX 12

ACTH

ROM HYS ( ROM HYS )

10

FIX 13

AVAV

AVE SEL AV (AVE SEL AV )

3

FIX 14

B2TH

B2COMP ( B2COMP )

0

FIX 15

ACCP

ACC COMP ( ACC COMP )

0

No.

Name

Name Item name & ( Description )

Item name & ( Description )

Service

Group

C

Fix/

Var

No.

Y

Fix/

Var

Service

Group

26

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init Video YUV 16:09

Data

FIX

1AMUT

RGB POWER ON MUTE ( RGB POWER ON MUTE )

0

FIX

2PMUT

RGB Mute before OSD ( RGB MUTE [ EXCEPT OSD ]

1

FIX

3CORL

CUTOFF R L ( R CUTOFF LOWER )

212

FIX

4CORH

CUTOFF R H ( R CUTOFF UPPER )

0

FIX 5 COGL

CUTOFF G L ( G CUTOFF LOWER WHEN TEMP IS "COOL" AND

"NEUTRAL"

197

FIX 6 COGH

CUTOFF G H ( G CUTOFF LOWER WHEN TEMP IS "COOL" AND

"NEUTRAL"

0

FIX 7 COBL

CUTOFF B L ( B CUT OFF LOWER WHEN TEMP IS "COOL" AND

"NEUTRAL"

176

FIX 8 COBH

CUTOFF B H ( B CUT OFF LOWER WHEN TEMP IS "COOL" AND

"NEUTRAL"

0

FIX

9 ABLS

ABL SEL ( ABL SELECT )

0

FIX

10 ALSP

ACL SPEED ( ACL SPEED )

0

FIX

11 ALRS

ACL SPE ( ACL RECOVER SPEED )

2

FIX

12 ALAS

ACL ASPE ( ACL ATACK SPEED )

9

FIX

13 ABLG

ABL GAIN ( ABL GAIN )

5

FIX

14 ALS2

ACLASPE2 ( ACL ATACK SPEED [ 2 ] )

2

FIX

15 AKBM

AKB MODE ( AKB MODE )

0

FIX

16 AKBP

AKB P[5:0] ( AKB PULSE HEIGHT )

16

FIX

17 OSDL

OSD LIMIT ( OSD LIMMIT SELECT )

0

FIX

18 UVIN

Y/U/V UVINV ( U/V INVERT )

0

FIX

19 UVG

U/V GAIN ( U/V OFFSET CANCELER ON )

0

FIX 20 UOFS

U IN OFFSET

(

U IN OFF SET

)

15

FIX

21 VOFS

V IN OFFSET ( V IN OFFSET )

12

FIX

22 AALG

ANA ACL GAIN ( ANALOG ACL GAIN CONTROL )

0

FIX

23 AALS

ANA ACL ON ( ANALOG ACL ON/OFF CONTROL)

1

FIX

24 UVDE

UV_DITHER_EN ( UVIN DITHER ENABLE )

0

01N/A

FIX

25 UVDT

UV_DITHER_TEST ( UVIN DITHER TEST )

0

06N/A

RGB

Item name & ( Description )

Service

Group

Fix/

Var

No. Name

27

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init Video YUV 16:09

Data

FIX

1 HFFR

AFC FREE RUN ( AFC1 FORCE FREE RUN )

0

FIX

2HFUP

HFREE UP ( H FREE RUN FREQUENCY UP [ 700 Hz ]

0

FIX

3JSWW

VJP WIDTH ( JUMP PULSE WIDTH )

0

FIX 4 EWCL V/EW DAC CLK CONTROL ( EW/VRAMP DA CLOCK SELECT ) 0 0 0 N/A

FIX

5XF0A

FREE RUN OFFSET ( VCXO FREE RUN ADJUST)

0

FIX

6BGST

BG START ( BGP [ FOR PLL ] TIMING )

16

16 1 N/A

FIX

7 XPHA

VCXO CTL ( VXCO PHASE ADJUST )

10

FIX

8 HRMP

Ramp Slew Rate ( AFC2 TIME CONSTANT )

3

FIX

9RPLU

Ref Charge pump ( REF PLL TIME CONSTANT )

3

FIX

10 RPLB

Ref VCO ( REF PLL TIME CONSTANT )

1

FIX

11 XF0B

VCXO FREE RUN ( VXCO Fo ADJUST )

0

FIX

12 RPLS

REF FB SW ( REF VCO FB LOOP SELECT )

0

FIX

13 SSM

Sync Sepa Mask ( SyncSepaMasking CONTROL )

0

FIX

14 VSAG

V-sag ( V-SAG prevent ON )

0

FIX

15 AFC2

AFC2 Gain ( AFC2 GAIN CONTROL )

3

FIX

16 VRFL

V RAMP FIL OFF ( V RAMP FILTER SWITCHING OFF )

1

FIX

17 SSLP

LPY SYNC ( LFP pre SYNC SEPA ON/OFF

1

FIX

18 XPLU

B PLL Change pump ( ACP TIME CONSTANT )

1

FIX

19 8FSC

8FSC SEL ( 8fsCLK Skew OFF )

1

10N/A

FIX

20 4FS2

4FSC SEL2 ( 4fsCLK Skew OFF )

1

10N/A

FIX

21 CDM2

V_CD_MODE2 ( V_LOGIC SW )

1

FIX

22 BGPC

Add. FTN BGP C ( BGP C )

0

FIX

23 MHDL

Add. FTN BGP SEL ( BBP SEL )

1

FIX

24 BFRE

V FREE ( FORCE V FREE RUN )

0

FIX 25 HRPP AFC2 RAMP POS ( FRAMP RRAMP H OUT CONTROL RANGE 8

FIX

26 DSC

K

CLOCK SEL ( DS DAC CLK SW 2 )

1

110

FIX

27 VBH

K

VBLK HALFKIL ( V BLK HALF KILL )

0

FIX

28 VPW

V PLS WIDTH ( V Pulse Wide )

1

FIX 29 DTH

D THRESHOLD LEVEL ( DITHER THRESHOLD LEVEL

CONTROL AT IIC AUTOD= ON

0

FIX

30 SLON

LPF SYNC ON ( LPF SYNC ON )

1

Item name & ( Description )Name

Fix/

Var

No.

Service

Group

DEFD

28

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init Video YUV 16:09

Data

FIX 31 VSSW

SYNC SLICE LVL(V)_W ( SYNC SLICE LEVEL [ V ] Wide Window

0

FIX

32 AF2S

AFC2_SEL ( ADC2 TIMING SW )

0

FIX

33 VSL2

V_SYNC_LPF_2 ( DIGITAL V_SINC_LPF [ Fall ] )

0

FIX

34 VSL1

V_SYNC_LPF_1 ( DIGITAL V_SINC_LPF [ Rise ] )

1

FIX

35 VYUV

YUV VSIZE OFFSET ( YUV V-SIZE OFFSET )

8

FIX

36 VYVP

YUV VPOS OFFSET ( YUV V-POSITION OFFSET )

8

FIX

37 VYHS

YUV HSIZE OFFSET ( YUV H-SIZE OFFSET )

8

FIX

38 VYHP

YUV HPOS OFFSET ( YUV H-POSITION OFFSET)

7

FIX

39 VSHE

V-SHRINK MODE ( V-SHRINK MODE for AV )

0

FIX

40 VYRB

YUV RBLK ( YUV RBLK OFFSET )

7

FIX

41 VYLB

YUV LBLK ( YUV LBLK OFFSET )

7

NTSC

Init Video YUV 16:09

Data

FIX 1 PCLP

pedestal CLAMP ON/OFF ( SYNC TIP/PEDESTAL CLAMP

SELECT )

0

FIX 2 VRT

VRT Voltage ( ADC REFERENCE [ 00:1.15Vpp 01:1.25 Vpp

10:1.35 Vpp 11:1.45 Vpp ] )

1

FIX

3 14HI

INV 14H CLK ( 4fsc [ Skew ] CLK POLARITY )

0

00N/A

FIX

4 14HD

14H CLK DLY ( 4fscCLK [ Skew ] CLK DELAY ADJUST )

0

00N/A

FIX

5DSI

INV DS CLK ( 8fscCLK POLARITY )

0

00N/A

FIX

6DSD

DS CLK DLY ( 8fscCLK DELAY ADJUST )

0

00N/A

FIX

7 ADCD

AD CLK DLY ( ADC CLK DELAY ADJUSTO )

0

01N/A

FIX

84FSC

4FSC SW ( AD/LOGIC CLK SWAP )

0

FIX

9WSTH

WEAK_SIG_VTH ( WEAK_SIGNAL VTH )

0

FIX

10 WSVA

WEAK SIG VIDEO ATT ( WEAK SIGNAL VIDEO ATT )

0

00N/A

FIX

11 WSCA

WEAK SIG CHROMA ATT (WEAK SIGNAL CHROMA ATT)

0

00N/A

FIX

12 VREF

VREF_SEL ( AD REFERENCE SELECT [ VZ ] )

0

NTSC

Init

Data

FIX 1

HT

HT ( HALF TONE LEVEL )

0

FIX 2

OSLR

OSD LVL R ( R OSD LEVEL )

25

FIX

3OSLG

OSD LVL G ( G OSD LEVEL )

25

FIX

4OSDC

OSD COMP ( OSD COMP )

0

FIX

5OSLB

OSD LVL B ( B OSD LEVEL )

25

Item name & ( Description )

Item name & ( Description )

Name

Name Item name & ( Description )

Service

Group

Fix/

Var

No.

NameNo.

Service

Group

Fix/

Var

No.

Service

Group

Fix/

Var

OSD OTHER DEFD

29

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

NTSC

Init

Data

FIX

1 HRIL

H/W AKB R INI DATA L ( H/W AKB RED OUTPUT LOWER )

soft cont'l

FIX

2 HRIH

H/W AKB R INI DATA H ( H/W AKB RED OUTPUT UPPER )

soft cont'l

FIX 3 HGIL

H/W AKB G INI DATA L ( H/W AKB GREEN OUTPUT LOWER )

soft cont'l

FIX 4 HGIH

H/W AKB G INI DATA H ( H/W AKB GREEN OUTPUT UPPER )

soft cont'l

FIX

5HBIL

H/W AKB B INI DATA L (H/W AKB BLUE OUTPUT LOWER)

soft cont'l

FIX

6HBIH

H/W AKB B INI DATA H (H/W AKB BLUE OUTPUT UPPER)

soft cont'l

FIX

7HLM1

AKB_LIM1<7:0> ( H/W AKB LIM1 )

6

FIX

8HLM2

AKB_LIM2<7:0> ( H/W AKB LIM2 )

12

FIX

9HLM3

AKA_LIM3<7:0> ( H/W AKB LIM3 )

21

FIX

10 HAD1

AKB_ADD1<7:0> ( H/W AKB SPEED1 )

2

FIX

11 HAD2

AKB_ADD2<7:0> ( H/W AKB SPEED2 )

6

FIX

12 HAKE

AKB_EN ( H/W AKB MANUAL [ MCU ] / HARD

1

FIX 13 HASP

AKB_SPEED

(

H/W AKB SPEED

)

3

FIX 14 HERL

AKB_SWERR<7:0>

(

H/W AKB ERROR DET THRESH

)

40

FIX

15 HLMC

AKB_ERRC<7:0> ( H/W AKB ERROR DET TIME )

20

FIX

16 HPWL

AKBSWPON<7:0> ( H/W AKB POWER ON TRESH )

4

FIX

17 HPWC

AKB_PWERRC ( H/W AKB POWER ON TIME )

90

FIX 18 HFMT

H/W AKB2 HOLD TIMER ( H/W AKB2 HOLD TIMER (@

100 MSEC ) [ 0: No hold ]

20

FIX 19 SPMT

AKB POW ON MUTE EXIT ( AKB POWER ON MUTE EXIT

TIMMER )

120

Service

Group

Fix/

Var

Item name & ( Description )No. Name

H/W AKB

30

KV-27FS120/29FA310/29FS120

KV-27FS120/29FA310/29FS120

29FA310 27FS120

VAR

1 SBAL

SBAL ( SUB BALANCE )

44

VAR

2 SBAS

SBAS ( SUB BASS )

00

VAR

3STRE

STRE ( SUB TREBLE )

60

VAR

4SRL

SRL ( SURROUND LEVEL )

00

VAR

5 BBOL

BBOL ( SURROUND OFF-BBE LOW )

86

VAR

6 BBOH

BBOH ( SURROUND OFF-BBE HIGH)

45

VAR

7 BBSL

BBSL ( SIMULATE BBE LOW )

24

VAR

8 BBSH

BBSH ( SIMULATE BBE HIGH )

44

VAR

9 BBGL

BBGL ( WOW GAME BBE LOW )

60

VAR

10 BBGH

BBGH ( WOW GAME BBE HIGH )

40

VAR

11 BBTL

BBTL ( SRS BBE LOW )

06

VAR

12 BBTH

BBTH ( SRS BBE HIGH )

04

VAR

13 BBDL

BBDL ( Audio Processor Prologic BBE Low for DOLBY )

60

VAR

14 BBDH

BBDH ( Audio Processor Prologic BBE High for DOLBY )

40

VAR

15 VFIX

VFIX ( AUDIO OUTPUT FIX DATA )

0 243

VAR

16 AGCL

AGCL ( AGC LEVEL )

22

VAR

17 VCOF

RF OFFSET DATA

99

29FA310 27FS120

VAR

1 BBEL

SUB AUDIO PROCESSOR PROLOGIC BBE LOW

90

VAR

2 BBEH

SUB AUDIO PROCESSOR PROLOGIC BBE HIGH

90

VAR

3 BBOL

SURROUND OFF-BBE LOW

90

VAR

4 BBSL

SIMULATE BBE LOW

50

VAR

5 BBGL

WOW GAME BBE LOW

10 0

VAR

6AGCL

SUB AUDIO PROCESSOR AGC LEVEL

20

VAR

7 DDOF

DOLBY OFFSET DATA

15 0

No. Name Item name & ( Description )

Item name & ( Description )

Service

Group

Fix/

Var

AP2

Service

Group

Fix/

Var

NTSC

NTSC

AUDIO

PROCE

SSOR

No. Name

Loading...

Loading...