Sony Trinitron HMD-A230 Service Manual

CHASSIS

SERVICE MANUAL

SPECIFICATIONS

HMD-A230

17VC

AEP Model

Chassis No. SCC-L38F-A

TORINITORON

®

COLOR COMPUTER DISPLAY

´´

´

´

´

CRT 0.24 mm aperture grille pitch (center)

17 inches measured diagonally

90-degree deflection

FD Trinitron

Viewable image size

Approx. 327 243 mm (w/h)

(12

7

/895/8inches)

Viewing image Approx. 406 mm (16.0 inches)

Resolution

Maximum Horizontal: 1280 dots

Vertical: 1024 lines

Recommended Horizontal: 1024 dots

Vertical: 768 lines

Standard image area

Approx. 312

234 mm (w/h)

(12

3

/891/4inches)

Deflection frequency

Horizontal: 30 to 80 kHz

Vertical: 48 to 170 Hz

AC input voltage/current

220 to 240 V, 50-60 Hz, Max. 0.7 A

Power consumption Approx.100 W

Operating temperature

10 ¼C to 40 ¼C

Dimensions

Approx. 418 416 426 mm (w/h/d)

´´

(161/2161/

2

16

7

/8inches)

Mass Approx. 19 kg (41.9 lb)

Plug and Play DDC2B/DDC2Bi

GTF

Supplied accessories

Power cord (1)

Warranty card (1)

Notes on cleaning the screenÕs surface (1)

This instruction manual

´

1

£

£

Preset and user modes

When the monitor receives an input signal, it automatically matches the

signal toone of the factorypreset modes storedin the monitorÕs memory to

provide a high quality picture

.

For input signals that do not ma tch one of the factory preset modes, the

digital Multiscan technology of this monitor ensures that a clear picture

appears on the screen for any timing in the monitorÕs frequency range

(horizontal: 30 Ð 80 kHz, vertical: 48 Ð 170 Hz). If the picture is adjusted,

the adjustment data is stored as a user mode and automatically recalled

whenever the same input signal is received.

Power saving function

This monitor meets the power-saving guidelines set by VESA,ENERGY

S

TAR,andNUTEK.Ifnosignalisreceivedbythemonitorfromyour

computer, the monitor will automatically reduce power consumption as

shown below.

* When your computer is in active off mode, MONITOR IS IN POWER

SAVE MODE appears on the screen if you press any button on the

monitor. After a few seconds, the monitor enters the power saving

mode again.

Design and specifications are subject to change without notice.

Power mode Power consumption (power)

indicator

normal operation 100 W green

active off* 3 W orange

power off 0 W (Approx.) off

HMD-A230(E) 2

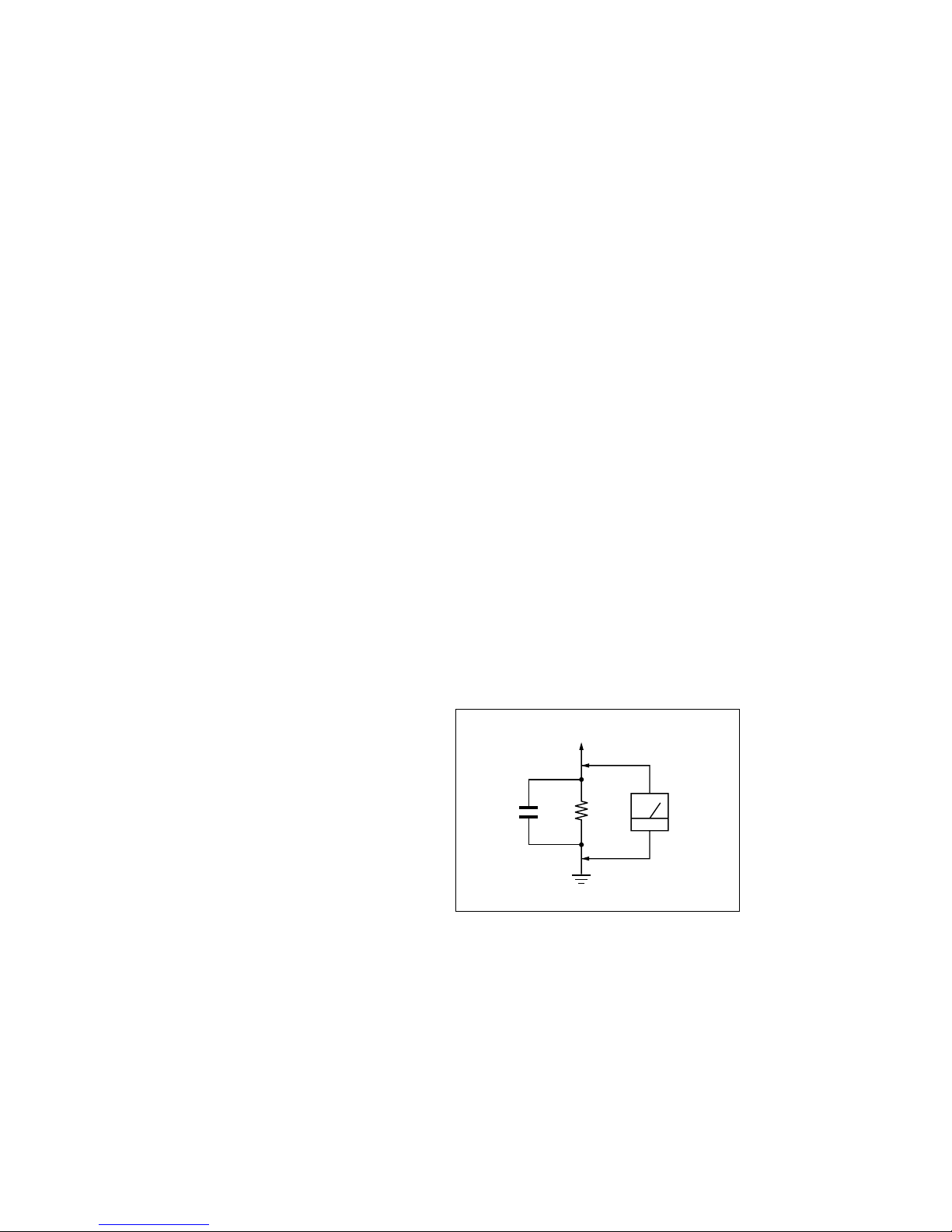

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog

meters must have an accurate low-voltage scale. The Simpson 250 and

Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

tions. Check the entire board surface for solder splashes and bridges.

tact high-wattage resistors.

ing hardware have been replaced. Be absolutely certain that you have

replaced all the insulators.

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

ration. Point them out to the customer and recommend their replacement.

ment of any such line cord to the customer.

instruments are accurate; be suspicious of your HV meter if sets always

have low HV.

all other exposed metal parts for AC Leakage. Check leakage as described right.

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

HMD-A230(E) 3

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICH THE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA BOBINE DE

DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET UNE

MARQUE ! SONT CRITIQUES POUR LA SÉCURITÉ. NE LES

REMPLACER QUE PAR UNE PIÈCE PORTANT LE NUMÉRO

SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

HMD-A230(E) 4

HMD-A230(E) 5

Failre

Power LED

Amber → Off

(1.5 sec) (0.5 sec)

Amber → Off

(0.5 sec) (1.5 sec)

Amber → Off

(0.5 sec) (0.5 sec)

Amber → Off → Green → Off

(0.5 sec) (0.5 sec) (0.5 sec) (0.5 sec)

Green (OSD indication)

HMD-A230(E) 6

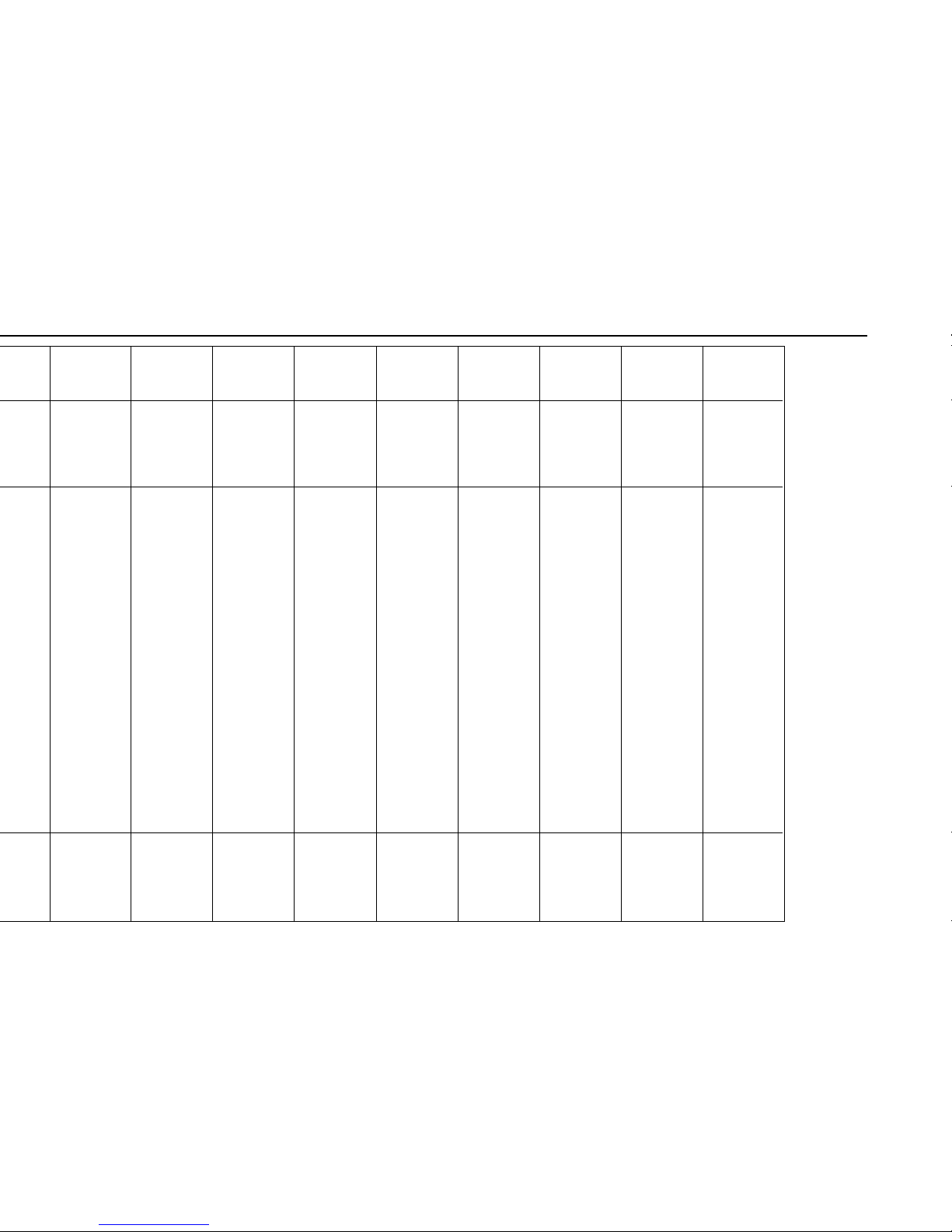

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7 MODE 8 MODE 9

640 X 480 640 X 480 720 X 400 800 X 600 800 X 600 1024 X 768 1024 X 768 1280 X 1024 1280 X 1024

25.175 MHz 36.000 MHz 28.322 MHz 40.000 MHz 56.250 MHz 65.000 MHz 94.500 MHz 108.000 MHz 135.000 MHz

31.469 kHz 43.269 kHz 31.469 kHz 37.879 kHz 53.674 kHz 48.400 kHz 68.677 kHz 63.981 kHz 79.976 kHz

usec usec usec usec usec usec usec

31.778 23.111 31.777 26.400 18.631 20.677 14.561 15.630 12.504

6.356 5.333 6.355 6.400 4.409 4.923 3.725 3.778 3.022

3.813 1.556 3.813 3.200 1.138 2.092 1.016 1.037 1.067

1.907 2.222 1.907 2.200 2.702 2.462 2.201 2.296 1.837

25.422 17.778 25.422 20.000 14.222 15.754 10.836 11.852 9.481

59.940 Hz 85.008 Hz 70.087 Hz 60.000 Hz 85.061 Hz 60.000 Hz 84.997 Hz 60.020 Hz 75.025 Hz

lines lines lines lines lines lines lines lines lines

HMD-A230(E) 7

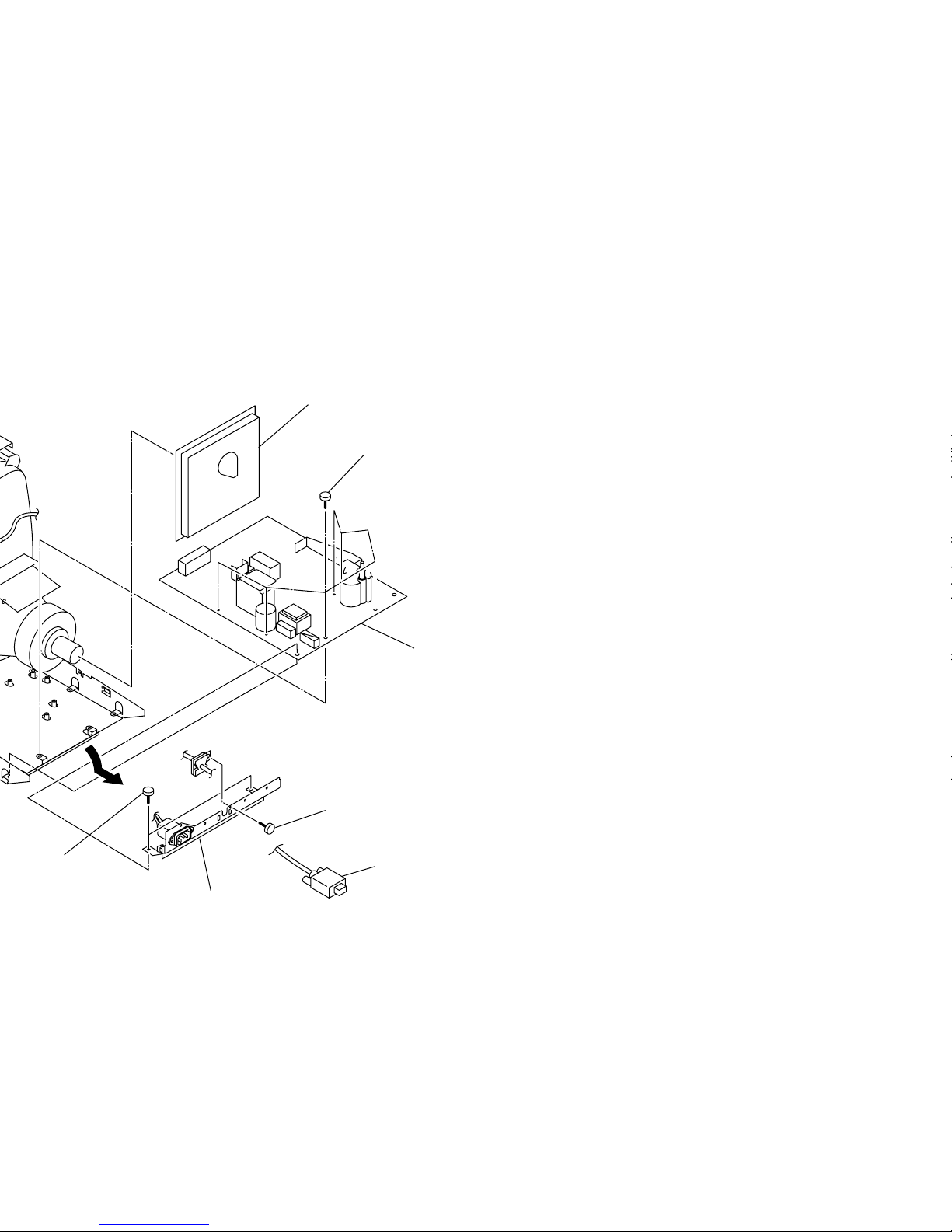

1-1. Cabinet Assembly Removal ................................. 1-1

1-2. A AND D Boards Removal ................................. 1-2

1-3. Service Position ................................................... 1-3

1-4. H1 AND J Boards Removal ................................. 1-4

1-5. Picture Tube Removal ......................................... 1-5

4-1. Block Diagrams .................................................... 4-1

4-2. Frame Schematic Diagram.................................... 4-3

4-3. Circuit Boards Location........................................ 4-4

4-4. Schematic Diagrams and Printed Wiring

Boards ................................................................... 4-5

(1) Schematic Diagram of A Board ........................... 4-7

TABLE OF CONTENTS

(2) Schematic Diagrams of D (a, b, c, d ) Board

.............................................................................. 4-9

(3) Schematic Diagram of H1 Board ......................... 4-14

(4) Schematic Diagram of J Board ............................ 4-16

4-5. Semiconductors .................................................... 4-17

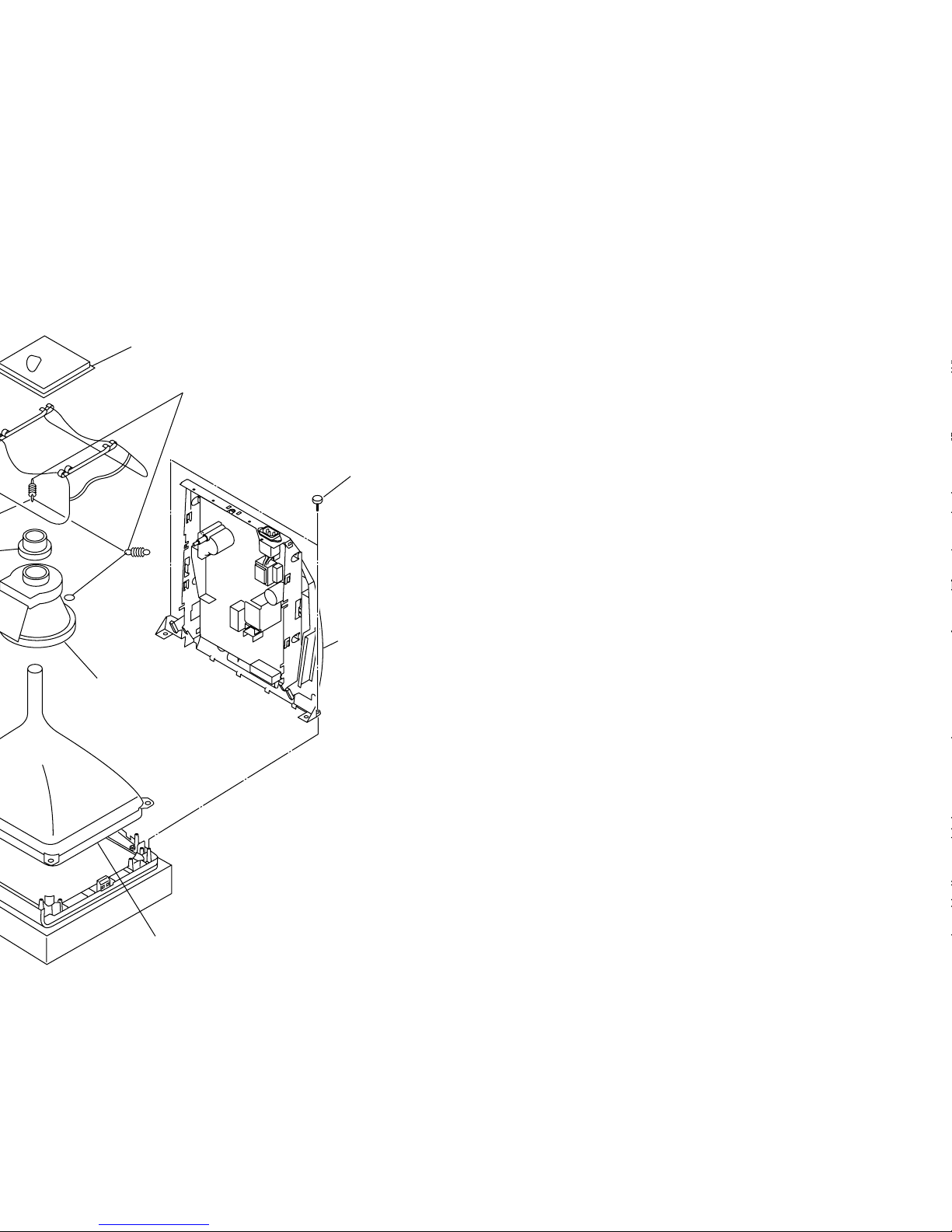

5. EXPLODED VIEWS .............................................. 5-1

5-1. Cabinet ................................................................. 5-2

5-2. Chassis ................................................................. 5-3

5-3. Picture Tube ......................................................... 5-4

5-4. Packing Materials ................................................. 5-5

6. ELECTRICAL PARTS LIST ............................... 6-1

HMD-A230(E) 1-1

SECTION 1

DISASSEMBLY

5 Two screws

(+BVTP 3x8)

4 Four screws

(+BVTP 3x8)

1 Two screws

(+BVTP 4x16)

2 Two screws

(+BVTP 4x16)

3 Cabinet

Cover cable

Push driver into opening

and remove claws.

Bezel

EMI

shield

Cabinet

HMD-A230(E) 1-2

4 A board

6 D board

3 Cable holder

5 Eight screws

(+BVTP 3x8)

1 One screw

(+BVTP 3x8)

Cable assy

HMD-A230(E) 1-3

HMD-A230(E) 1-4

1 Two screws

(+BVTP 3x8)

2 Bracket

3 H1 Board

4 Joystick

HMD-A230(E) 1-5

4 Stand assy

3 Two screws

(+BVTP 4x16)

8 Two extention spring

2 A board

0 Deflection yoke

6 Picture tube

HMD-A230(E) 1-6

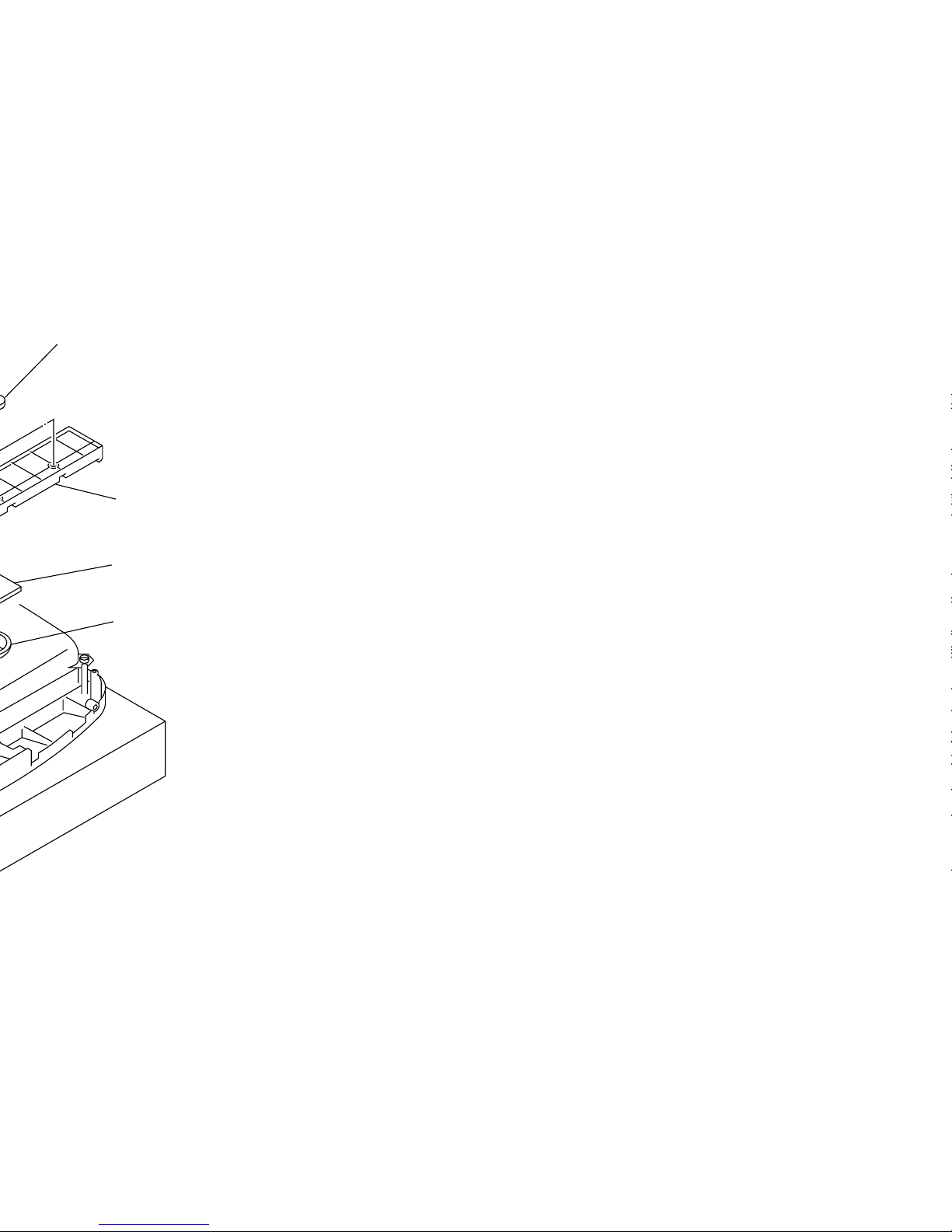

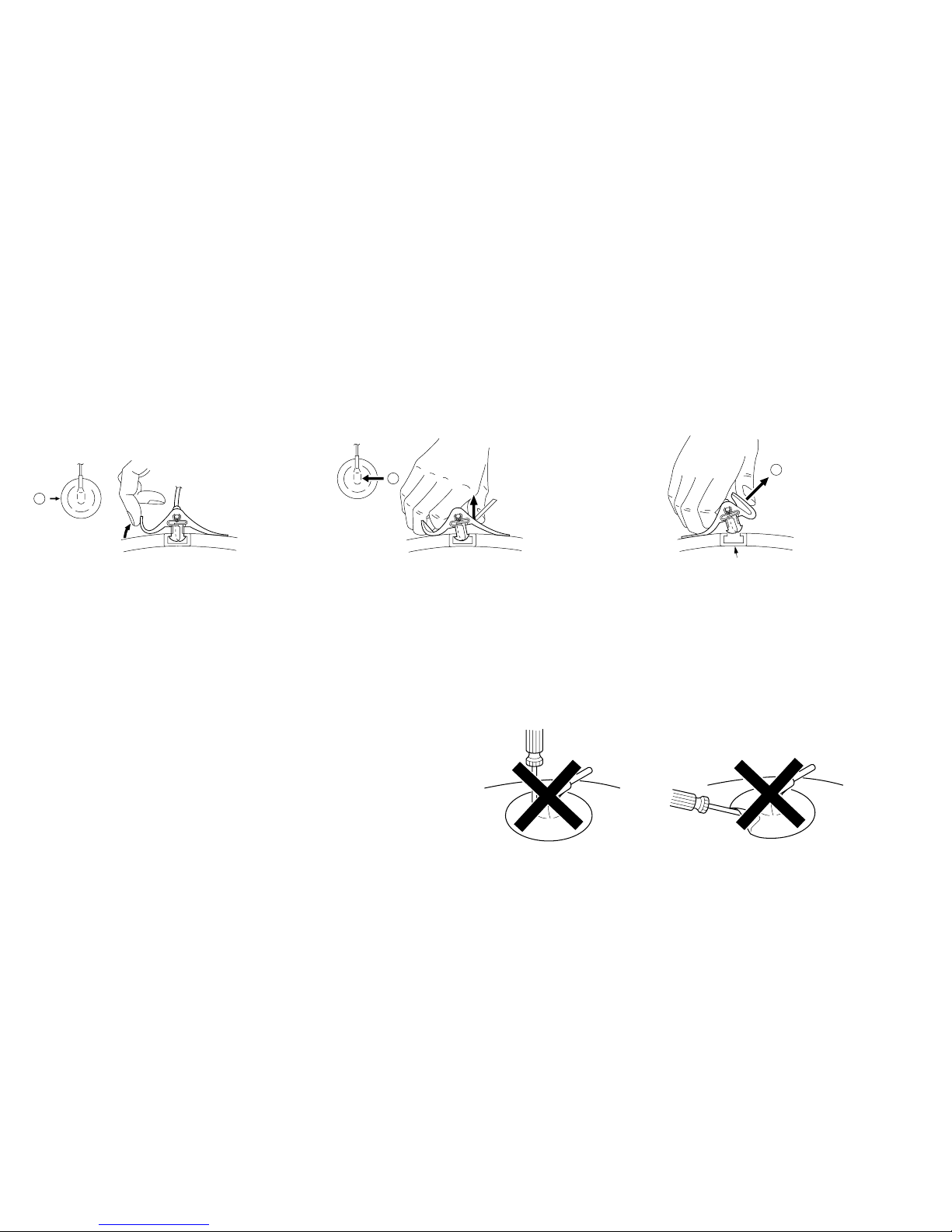

3When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning up

the rubber cap and pulling up it in the

direction of the arrow c.

removing the anode.

2Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

a

b

c

Anode Button

HMD-A230(E) 2-1

Part Replaced ([)

RV501

SECTION 2

SAFETY RELATED ADJUSTMENT

• HV Protector Circuit Check

Using an external DC Power Supply, apply the voltage shown below

between cathode of D517 on D board and GND, and confirm that the

HV HOLD DOWN circuite works. (TV Raster disappears)

Standard voltage : 35.90

V DC

Check Condition

• Input voltage : 120 ± 2 V AC

• Input signal : Cross hatch (white lines on black) at

69kHz (Primary Mode)

• Beam control : CONT, BRT ; minimum "0 "

• Beam Current Protector Check

An ammeter in series between FBT 11 pin on D board and GND, then,

decrease gradually the resistance of the variable resistor from

maximum to minimum, and confirm that the Beam Current

Protector Circuite works (TV Raster disappears). The current must

be within the range shown below.

• Standard current : 1.55

mA

Check Condition

• Input voltage : 120 ± 2 V AC

• Input signal : Cross hatch (white lines on black) at 69kHz

• Beam control : CONT, BRT ; minimum "0"

+0.00

- 0.01

+0.00

- 0.01

Part Replaced (])

D board IC501, C532, C534,

C539, C553, C554,

C555, C556, C558,

C561, R540, R541,

R542, R544, R564,

R567, R568, RV501,

T501 (FBT)

D board IC607, IC901, D515,

D517, C540, C542,

C544, C951, R510,

R543, R547, R549,

R552, R595,

T501 (FBT)

D board IC605,IC607,IC901,

C535, C541,R545,

R546, R548,R550,

R596, R934,

T501 (FBT)

HMD-A230(E) 2-2

HMD-A230(E) 3-1

SECTION 3

ADJUSTMENTS

5. Attach the wobbling coil to the designated part of the CRT neck.

6. Attach the sensor of the landing adjustment unit on the CRT surface.

7. Adjust the DY position and purity, and the DY tilt.

8. Fasten DY with screw.

Note:Torque 22 ±2kgcm (2.2 ± 0.2 Nm)

Perform auto degaussing.

Purity Magnet <<Zero Position>>

L/D control specification

± 5 ± 5 ± 5

± 5 ± 5 ± 5

± 5 ± 5 ± 4

Purity magnet position

± 4

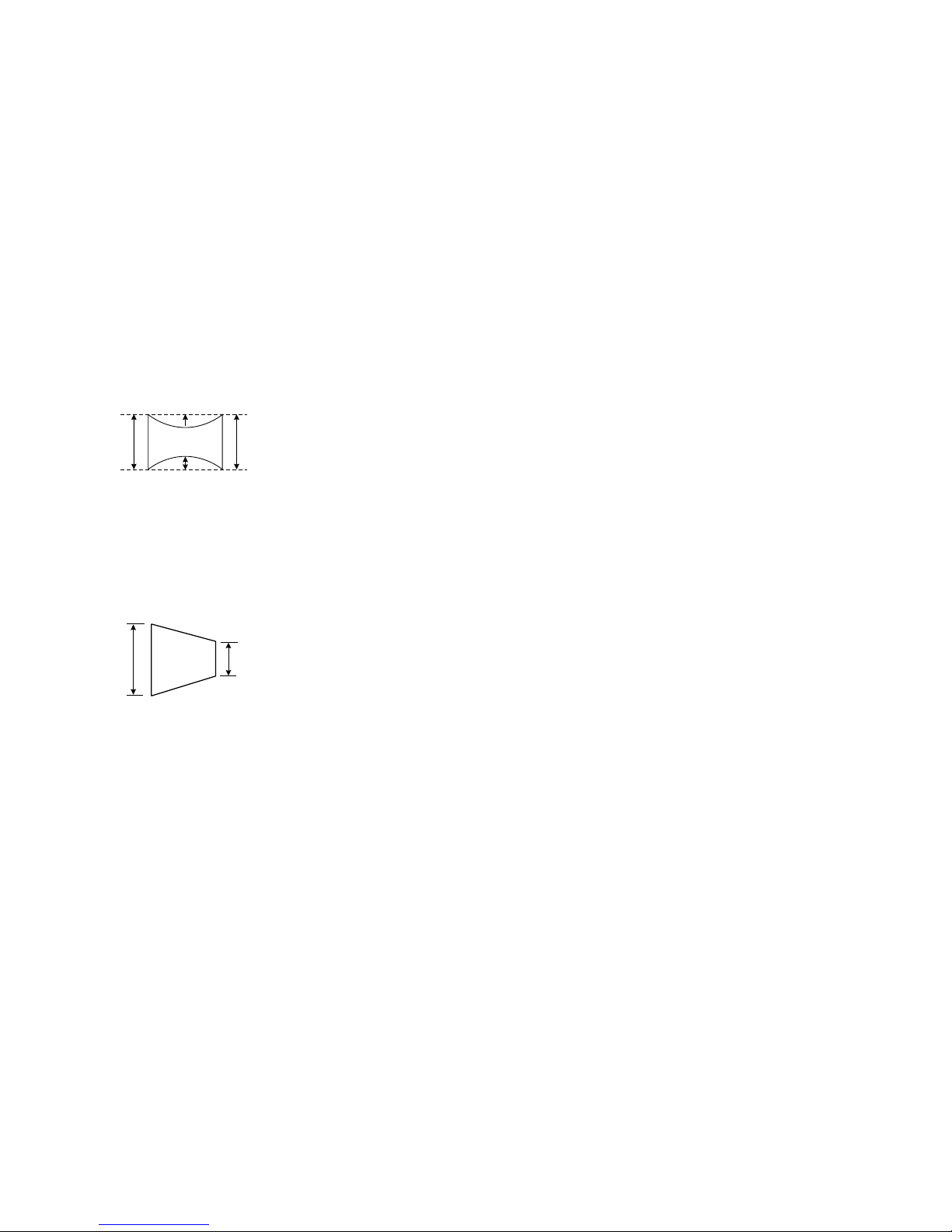

HMD-A230(E) 3-2

neck right and left. (When fixing DY with wedges, insert wedges

completely so that the DY does not shake.)

ajust the V.Size simulation.

equol to the [b]

D adjustment standards.

convergence and the distortion would be alterable.

magnet.

a

b

cd

"a" and "b" must be equal.

c

d

13. If using the magnet, be sure to demagnetize with the degausser and

check.

14. Remove the sensor and wobbling coil.

15. Fix the purity magnet paisted on the DY with the white pen.Fix it with

the RTV.

•Convergence Rough Adjustment

1. Enter the white crosshatch signal (white lines on black).

2. Adjust roughly the horizontal and vertical convergence at four-pole

magnet.

3. Adjust roughly HMC and VMC at six-pole magnet.

•Convergence Adjustment

< Static convergence >

1. Change the "CONV SW" to 0.

2. Receive the crosshatch of R and B. (on black)

3. Adjust H. STAT and V. STAT with 4 pole magnet.

4. Recieve the white crosshatch signal.(White line on black)

5. Adjust HMC and VMC with the 6 pole magnet.

6. Recieve the crosshatch of R and B. (on black)

Note:Adjust H. STAT and V. STAT in the beggining by 4 pole magnet not

adjust them by register immediately.

HMD-A230(E) 3-3

Purity Mg

4-pole Mg

6-pole Mg

XCV

YCH

H-Trap

TLH

TLV

TB, Pin VI

4 Pole 6 Pole

[ Neck Assy's Zero Position ]

Purity

B

R

RB

R

B

B

R

R

B B

R

XCV YCH

TLV

TLH

B

A

A

0.20 mm

B

MODE All mode

0.24 mm

•White Balance Adjustmen Specification

(1) 9300K

Part of shadow line

for the right figure.

(2) 5000K

Part of shadow line

for the right figure.

•Convergence Specification

VR

x = 0.283

y = 0.298

0.005

0.005

x = 0.346

y = 0.359

0.005

0.005

HMD-A230(E) 3-4

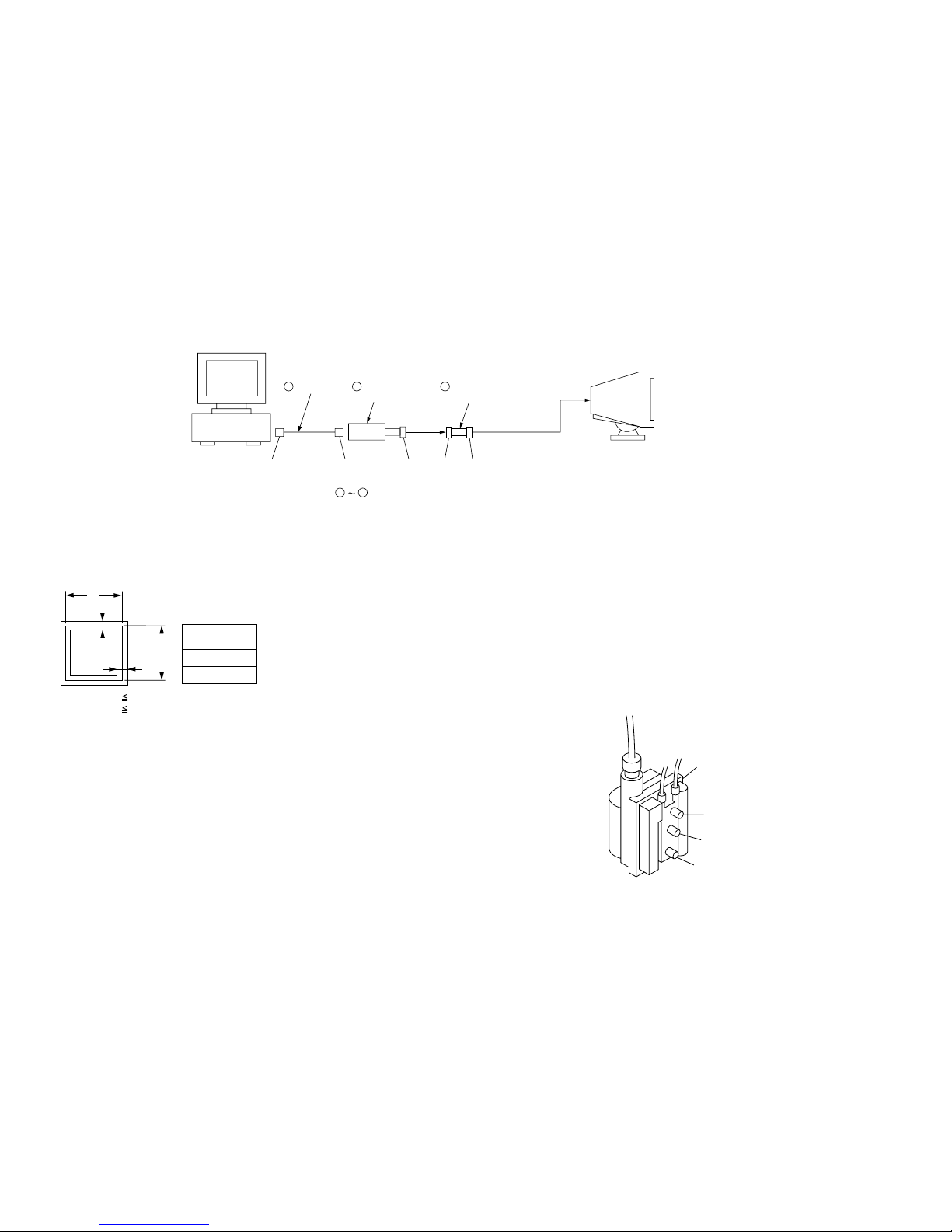

IBM AT Computer

as a Jig

1-690-391-211A-1500-819-A

Interface Unit

2

*The parts above ( ) are necessary for DAS adjustment.

1

3

D-sub

(9 Pin [female])

mini Din

(8Pin)

4 Pin

3-702-691-01

Connector Attachment

3

To BUS CONNECTOR

4 Pin 4 Pin

• Focus rough adjustment

1. Receive the mE pattern signal. (black characters on green)

2. Adjust the H FOCUS of the screen corner with Fcous VR in the bottom

of the FBT.

3. Receive the cross-hatch pattern signal .(green line on black)

4. Adjust the V FOCUS of the center and the y-axis with the FOCUS VR

in the top of FBT.

A

312 mm

B

MODE All mode

234 mm

a 1.8 mm

b 1.8 mm

a

B

A

b

FBT

Focus volume 1 (V)

Focus volume 2 (H)

G2 VR

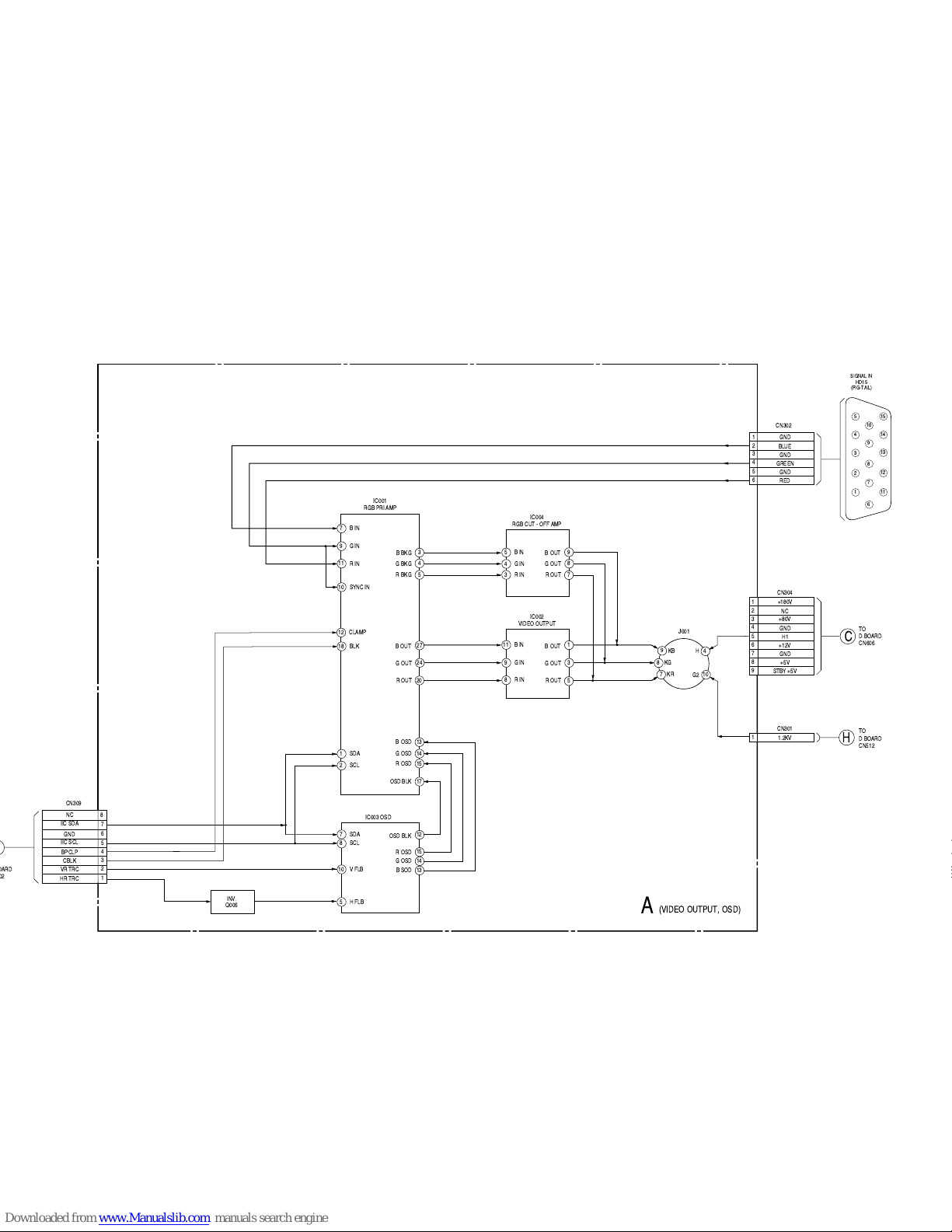

HMD-A230(E) 4-1

SECTION 4

DIAGRAMS

+180V1

2

3

CN304

NC

+80V

4

GND

5

H1

6

+12V

7

GND

8

+5V

9

STBY +5V

TO

D BOARD

CN606

C

TO

D BOARD

CN512

H

GND1

2

3

CN302

BLUE

GND

4

GREEN

5

GND

6

RED

1

1.2KV

CN301

11

9

8

1

3

5

IC002

VIDEO OUTPUT

J001

B OUT

G OUT

R OUT

BIN

GIN

RIN

KB

KG

KR

G2

H

7

9

11

10

27

24

20

IC001

RGB PRI AMP

B OUT

G OUT

R OUT

3

B BKG

4

G BKG

5R BKG

13

B OSD

14G OSD

15R OSD

17OSD BLK

BIN

GIN

RIN

SYNC IN

1

SDA

2

SCL

18

BLK

12

CLAMP

7

8

10

12

15

14

OSD BLK

R OSD

G OSD

13B SOD

SDA

SCL

V FLB

5

H FLB

5

4

3

9

8

7

IC004

RGB CUT - OFF AMP

IC003 OSD

B OUT

G OUT

R OUT

BIN

GIN

RIN

6

5

4

3

IIC SDA

IIC SCL

BPCLP

INV.

Q006

CBLK

2

VR TRC

1

HR TRC

9

8

7

4

10

(VIDEO OUTPUT, OSD)

A

7

8

GND

NC

CN309

SIGNAL IN

HD15

(PIG-TAIL)

13

14

11

12

15

9

10

7

6

8

3

4

1

2

5

Loading...

Loading...