Page 1

GDM-F500/F500T9

SERVICE MANUAL

GDM-F500

US Model

REVISED

SPECIFICATIONS

Canadian Model

AEP Model

Chassis No. SCC-L03C-A

GDM-F500T9

AEP Model

Chassis No. SCC-L03CA

N3P

CHASSIS

MICROFILM

TRINITRON

®

COLOR GRAPHIC DISPLAY

Page 2

GDM-F500/F500T9

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values.

Make sure your instruments are accurate; be suspicious of

your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

Leakage. Check leakage as described below.

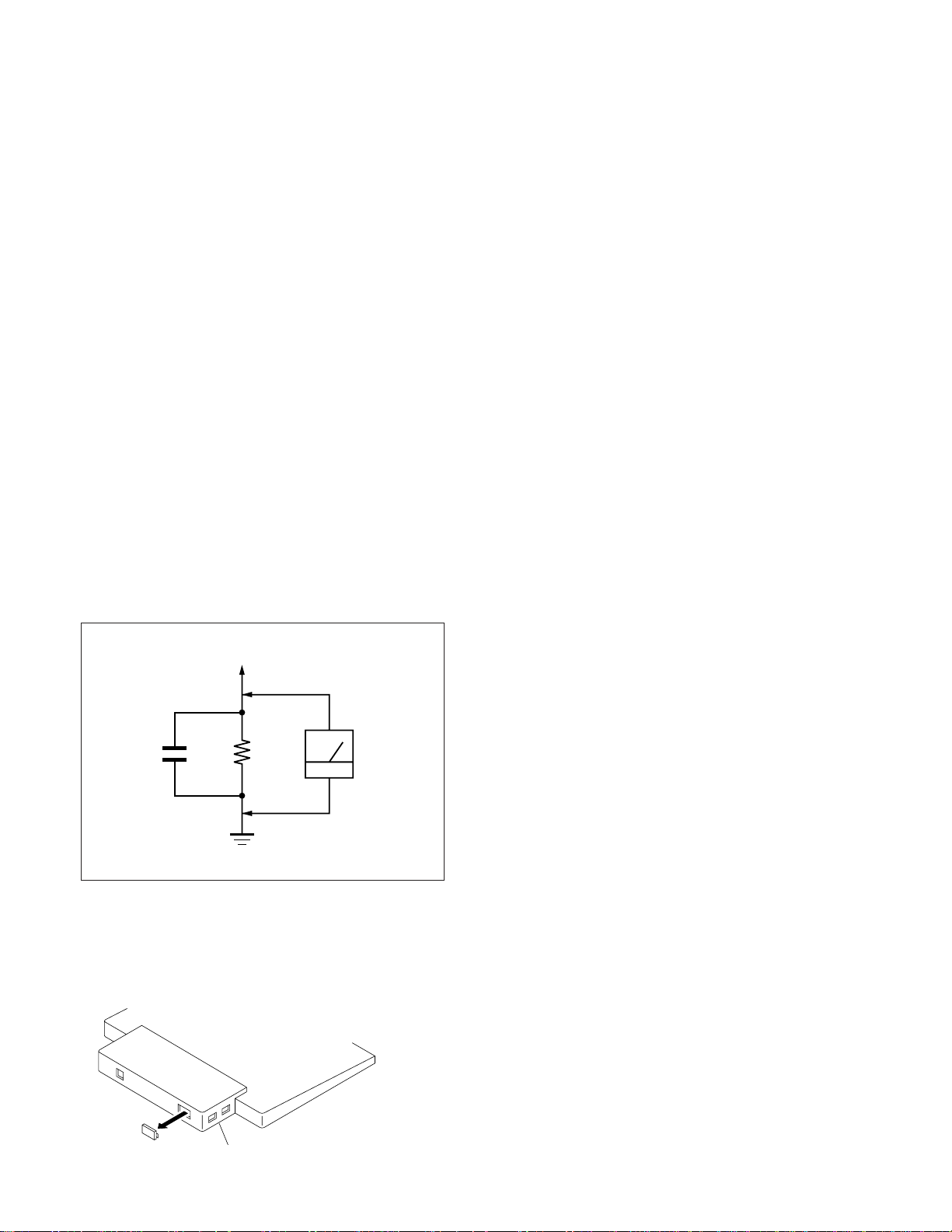

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Voltmeter

(0.75 V)

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500

microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 V AC

range are suitable. (See Fig. A)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL FOR

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS

ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION ON DAS (ECS) CONNECTOR

• The connector for DAS (ECS) adjustment is provided inside

the cover shown below. Be careful with an electrical shock

when connecting the connector with the power supplied. Also,

return the removed cover to the home position.

STAND

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA

BOBINE DE DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET

UNE MARQUE

¡ SONT CRITIQUES POUR LA SÉCURITÉ.

NE LES REMPLACER QUE PAR UNE PIÈCE PORTANT LE

NUMÉRO SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT

L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU

FONCTIONNEMENT SONT IDENTIFIÉS DANS LE

PRÉSENT MANUEL. SUIVRE CES PROCÉDURES LORS

DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNE-MENT

EST SUSPECTÉ.

– 2 –

Page 3

POWER SAVING FUNCTION

This monitor meets the power-saving guidelines set by VESA,

E

NERGY STAR, and NUTEK. If the monitor is connected to a

computer or video graphics board that is DPMS (Display Power

Management Signaling) compliant, the monitor will

automatically reduce power consumption in three stages as shown

below.

* Figures reflect power consumption when no USB compatible

peripherals are connected to the monitor.

**When your computer enters the “active off” mode, the input signal is

cut and NO INPUT SIGNAL appears on the screen. After the time set

in “Changing the power saving delay time.” (page 1-6) has elapsed, the

monitor enters the power saving mode.

To change the power saving delay time

See page 1-6.

Power mode Power

consumption*

1 (power)

indicator

normal

operation

≤ 160 W green

1 standby ≤ 100 W green and orange

alternate

2 suspend ≤ 15 W green and orange

alternate

3 active off** ≤ 1 W orange

power off 0 W off

GDM-F500/F500T9

DIAGNOSIS

This monitor is equipped with a self-diagnosis function. If there is

a problem with your monitor or computer(s), the screen will go

blank and the

1 (power) indicator will either light up green or

flash orange. If the 1 (power) indicator is lit in orange, the

computer is in power saving mode. Try pressing any key on the

keyboard.

RESET ASC INPUT MENU

HD15 BNC

1 (power) indicator

If the 1 (power) indicator is green

1

Remove any plugs from the video input 1 and 2

connectors, or turn off the connected computer(s).

2

Press the 1 (power) button to turn the monitor off

and on.

3

Move the joystick to the right for 2 seconds before

the monitor enters power saving mode.

If all four color bars appear (white, red, green, blue), the monitor

is working properly. Reconnect the video input cables and check

the condition of your computer(s).

If the color bars do not appear, there is a potential monitor failure.

Inform your authorized Sony dealer of the monitor’s condition.

If the 1 (power) indicator is flashing orange

Press the 1 (power) button to turn the monitor off and

on.

If the 1 (power) indicator lights up green, the monitor is working

properly.

If the 1 (power) indicator is still flashing, there is a potential

monitor failure. Count the number of seconds between orange

flashes of the 1 (power) indicator and inform your authorized

Sony dealer of the monitor’s condition. Be sure to note the model

name and serial number of your monitor. Also note the make and

model of your computer and video board.

– 3 –

Page 4

GDM-F500/F500T9

TIMING SPECIFICATION

MODE AT PRODUCTION MODE 1 MODE 2 MODE 3 MODE 4 MODE 5

RESOLUTION 738 X 414 1600 X 1200 1800 X 1440 1800 X 1350 1364 X 1201

CLOCK 28.322 MHZ 229.500 MHZ 299.436 MHZ 299.000 MHZ 195.500 MHZ

— HORIZONTAL —

H-FREQ 31.469 kHz 106.250 kHz 120.740 kHz 120.565 kHz 106.250 kHz

usec usec usec usec usec

H. TOTAL 31.777 9.412 8.282 8.294 9.412

H. BLK 5.720 2.440 2.271 2.274 2.435

H. FP 0.318 0.279 0.668 0.669 0.276

H. SYNC 3.813 0.837 0.481 0.482 0.839

H. BP 1.589 1.325 1.122 1.124 1.320

H. ACTIV 26.057 6.972 6.011 6.020 6.977

— VERTICAL —

V. FREQ(HZ) 70.087 Hz 85.000 Hz 80.120 Hz 85.084 Hz 85.000 Hz

lines lines lines lines lines

V. TOTAL 449 1250 1507 1417 1250

V. BLK 35 50 67 67 49

V. FP 5 1 1 1 1

V. SYNC 2 3 3 3 3

V. BP 28 46 63 63 45

V. ACTIV 414 1200 1440 1350 1201

— SYNC —

INT(G) NO NO NO NO NO

EXT(H/V)/POLARITY YES N/P YES P/P YES P / P YES P / P YES P/P

EXT(CS) /POLARITY NO NO NO NO NO

INT/NON INT NON INT NON INT NON INT NON INT NON INT

SIZE (21") 388 X 291mm 388 X 291mm 364 X 291mm 388 X 291mm 388 X 291 mm

98. 4.27 VER.

– 4 –

Page 5

TABLE OF CONTENTS

Section Title Page

1. GENERAL ................................................................. 1-1

2. DISASSEMBLY

2-1. Cabinet Removal ............................................... 2-1

2-2. D Board Removal .............................................. 2-1

2-3. G Board Removal .............................................. 2-2

2-4. A Board Removal .............................................. 2-2

2-5. L Board Removal .............................................. 2-3

2-6. Service Position .................................................. 2-3

2-7. H1, H2 and J Boards Removal .......................... 2-4

2-8. US Board Removal............................................. 2-4

2-9. Picture Tube Removal ....................................... 2-5

2-10. Harness Location ................................................ 2-6

3. SAFETY RELATED ADJUSTMENT............. 3-1

GDM-F500/F500T9

4. ADJUSTMENTS ..................................................... 4-1

5. DIAGRAMS

5-1. Block Diagrams .................................................. 5-1

5-2. Frame Shcematic Diagram ................................. 5-7

5-3. Circuit Boards Location ..................................... 5-9

5-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 5-9

(1) Schematic Diagrams of D (1/2, 2/2) Board ...... 5-13

(2) Schematic Diagrams of G, H1, H2, J and

L Boards ............................................................ 5-17

(3) Schematic Diagram of A Board ........................ 5-24

(4) Schematic Diagram of US Board (-11)

(OLD) ................................................................ 5-29

(5) Schematic Diagram of US Board (-12, -13)

(NEW) .............................................................. 5-33

5-5. Semiconductors ................................................. 5-35

6. EXPLODED VIEWS

6-1. Chassis ............................................................... 6-1

6-2. Picture Tube ...................................................... 6-2

6-3. Packing Materials .............................................. 6-3

7. ELECTRICAL PARTS LIST ............................ 7-1

Note: Hand degauss must be used on stand-by or power-off condition.

This model has an automatic earth magnetism correction function by using an earth

magnetism sensor and a LCC coil. When using a hand degauss while monitor (LCC

coil) is being operated, it sometimes gets magnetized, and the system may not work

properly as a result.

– 5 –

Page 6

The operating instructions mentioned here are partial abstracts

4

Precautions

Warning on power connections

• Use the supplied power cord. If you use a different power cord,

be sure that it is compatible with your local power supply.

For the customers in the U.S.A.

If you do not use the appropriate cord, this monitor will not

conform to mandatory FCC standards.

• Before disconnecting the power cord, wait at least 30 seconds

after turning off the power to allow the static electricity on the

screen’s surface to discharge.

• After the power is turned on, the screen is demagnetized

(degaussed) for about 3 seconds. This generates a strong

magnetic field around the screen which may affect data stored

on magnetic tapes and disks placed near the monitor. Be sure to

keep magnetic recording equipment, tapes, and disks away

from the monitor.

Installation

Do not install the monitor in the following places:

• on surfaces (rugs, blankets, etc.) or near materials (curtains,

draperies, etc.) that may block the ventilation holes

• near heat sources such as radiators or air ducts, or in a place

subject to direct sunlight

• in a place subject to severe temperature changes

• in a place subject to mechanical vibration or shock

• on an unstable surface

• near equipment which generates magnetism, such as a

transformer or high voltage power lines

• near or on an electrically charged metal surface

Maintenance

• Clean the screen with a soft cloth. If you use a glass cleaning

liquid, do not use any type of cleaner containing an anti-static

solution or similar additive as this may scratch the screen’s

coating.

• Do not rub, touch, or tap the surface of the screen with sharp or

abrasive items such as a ballpoint pen or screwdriver. This type

of contact may result in a scratched picture tube.

• Clean the cabinet, panel and controls with a soft cloth lightly

moistened with a mild detergent solution. Do not use any type

of abrasive pad, scouring powder or solvent, such as alcohol or

benzene.

Transportation

When you transport this monitor for repair or shipment, use the

original carton and packing materials.

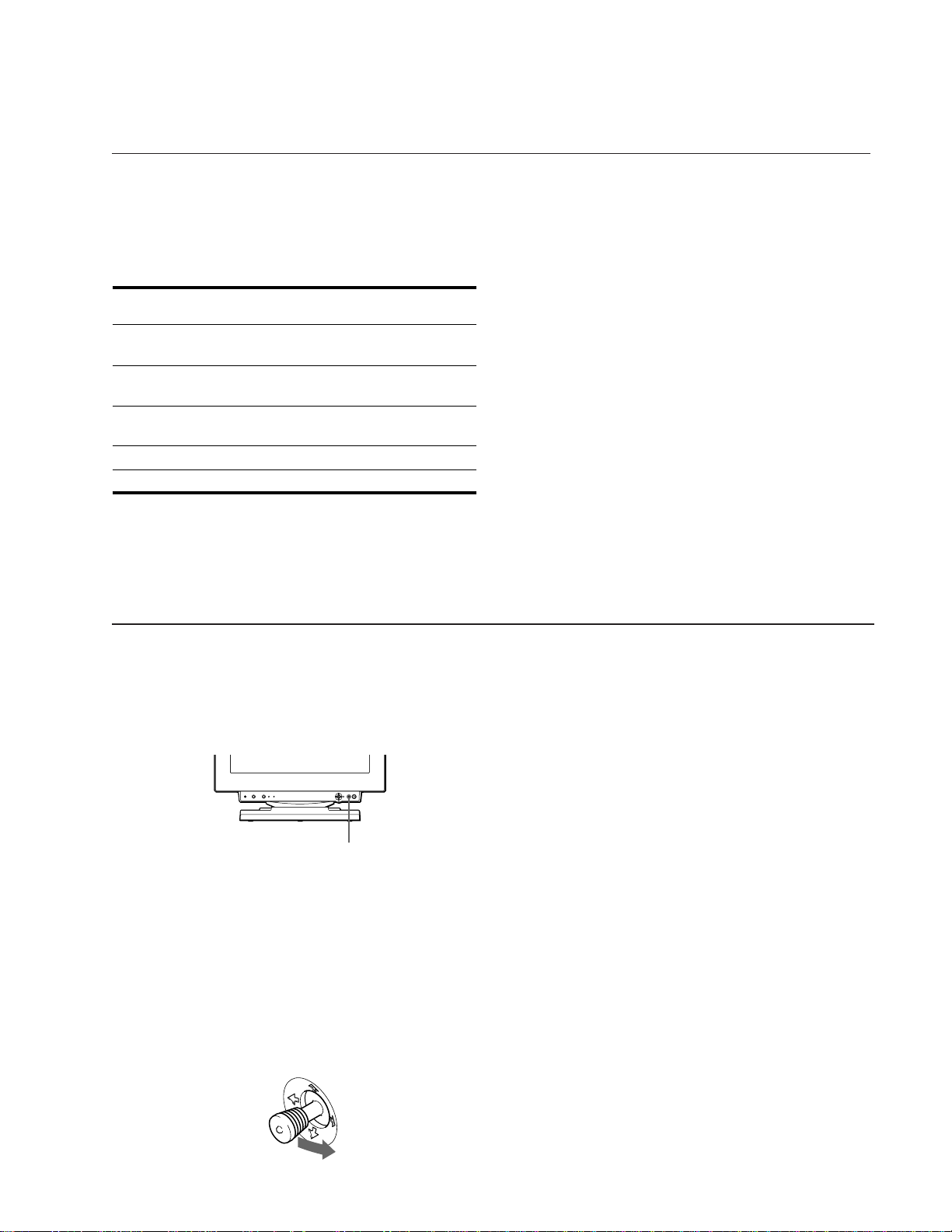

Use of the tilt-swivel

This monitor can be adjusted within the angles shown below. To

turn the monitor vertically or horizontally, hold it at the bottom

with both hands.

The equipment should be installed near an easily accessible

outlet.

Example of plug types

for 100 to 120 V AC for 200 to 240 V AC

90˚

5˚

90˚

12˚

GDM-F400

90˚

5˚

90˚

15˚

GDM-F500

5

EN

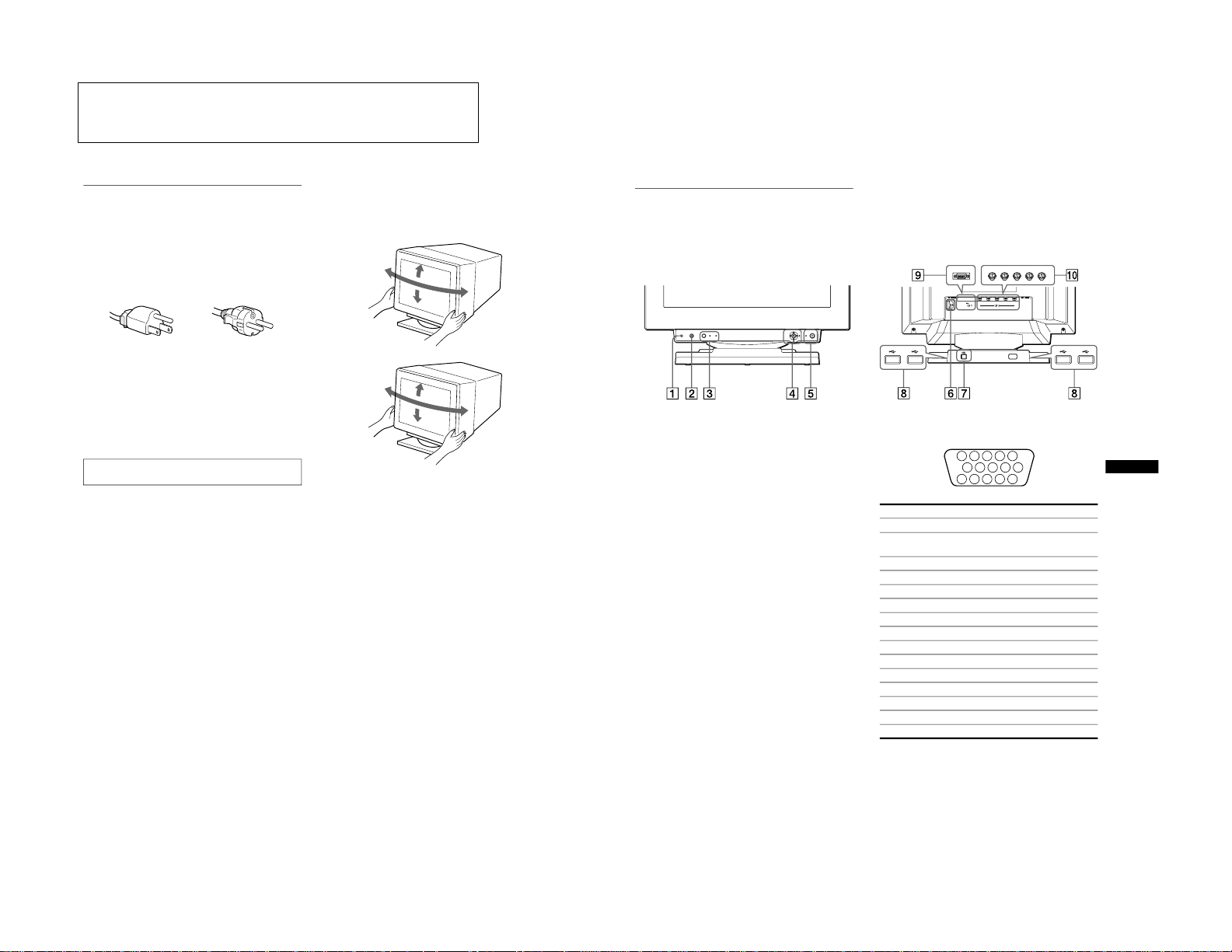

Identifying parts and controls

See the pages in parentheses for further details. GDM-F500 is

used for illustration purposes throughout this manual.

1

RESET button (page 14)

This button resets the adjustments to the factory settings.

2

ASC (auto sizing and centering) button (page 9)

This button automatically adjusts the size and centering of the

picture.

3

INPUT button and HD 15/BNC indicators (page 9)

This button selects the HD15 or BNC video input signal. The

input signal and corresponding input indicator change each

time you press this button.

4

Joystick (page 11)

The joystick is used to display the menu and make

adjustments to the monitor, including brightness and contrast

adjustments.

5 1

(power) switch and indicator (pages 7, 15, 18)

This button turns the monitor on and off. The power indicator

lights up in green when the monitor is turned on, and either

flashes in green and orange, or lights up in orange when the

monitor is in power saving mode.

6

AC IN connector (page 7)

This connector provides AC power to the monitor.

7

USB (universal serial bus) upstream connector

(page 8)

Use this connector to link the monitor to a USB compliant

computer.

8

USB (universal serial bus) downstream connectors

(page 8)

Use these connectors to link USB peripheral devices to the

monitor.

9

Video input 1 connector (HD15) (page 6)

This connector inputs RGB video signals (0.700 Vp-p,

positive) and sync signals.

* DDC (Display Data Channel) is a standard of VESA.

q;

Video input 2 connector (BNC) (page 6)

This connector inputs RGB video signals (0.700 Vp-p,

positive) and sync signals.

(HD15) (BNC)

RGBHDVD

RESET ASC INPUT MENUHD15

BNC

RearFront

Pin No. Signal

1 Red

2 Green

(Composite Sync on Green)

3 Blue

4 ID (Ground)

5 DDC Ground*

6 Red Ground

7 Green Ground

8 Blue Ground

9 DDC + 5V*

10 Ground

11 ID (Ground)

12 Bi-Directional Data (SDA)*

13 H. Sync

14 V. Sync

15 Data Clock (SCL)*

5 4 3 2

1

6

78910

1112131415

SECTION 1

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remain as in the manual.

GENERAL

1-1

Page 7

6

Setup

Before using your monitor, check that the following accessories

are included in your carton:

• Power cord (1)

• HD15 video signal cable (1)

• USB cable (1)

• Macintosh adapter (1)

• Windows Monitor Information Disk (1)

• Warranty card (1)

• Notes on cleaning the screen’s surface (1)

• This instruction manual (1)

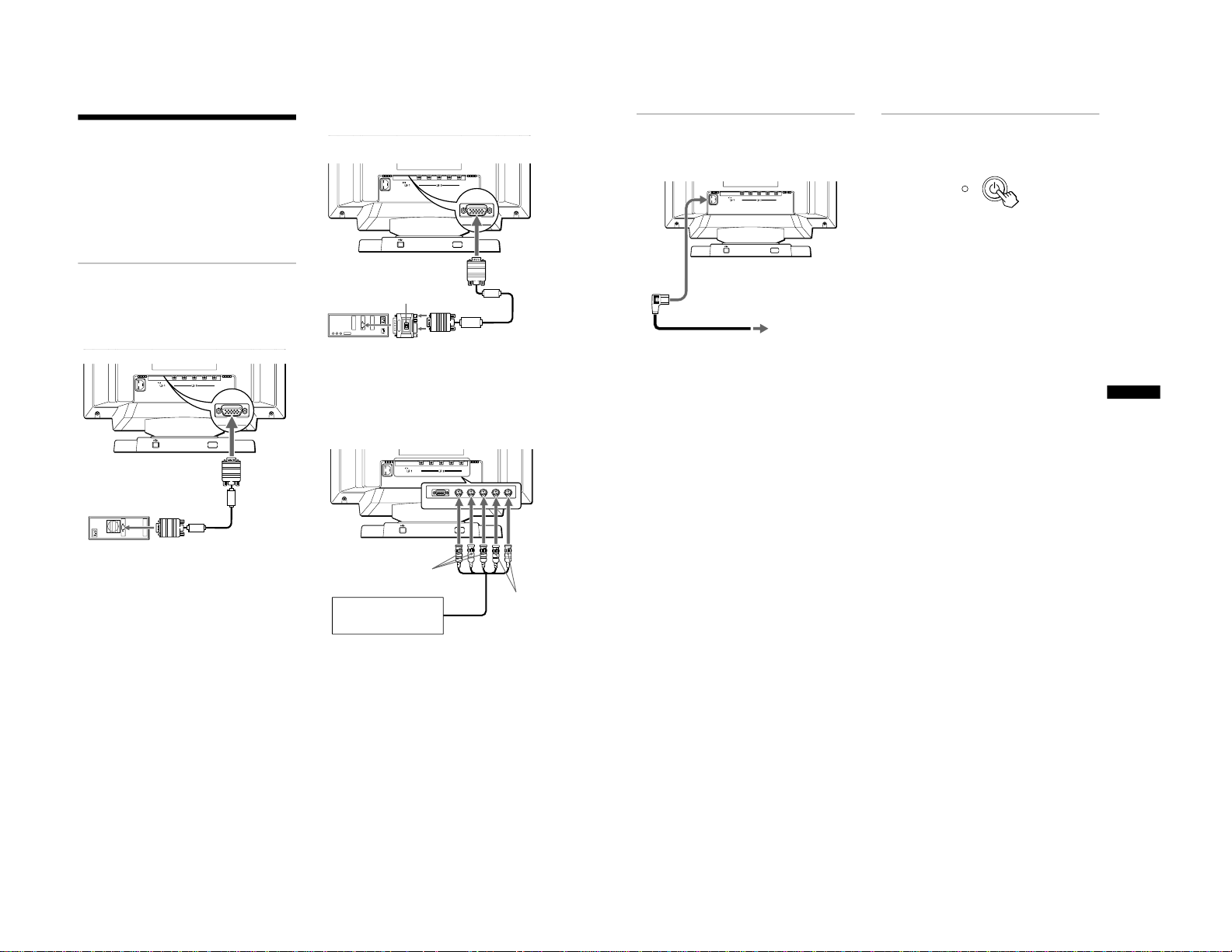

Step 1:Connect your monitor to

your computer

Turn off the monitor and computer before connecting.

x

Connecting to an IBM PC/AT or compatible

computer

If your PC system is not compatible with Plug & Play (DDC2AB

or DDC2B+)

This monitor uses the No.9 pin in the video signal connector for Plug &

Play (DDC2AB or DDC2B+) compatibility. See page 5 for the location of

the No.9 pin.

• If your computer accepts the No.9 pin, use the supplied HD15 video

signal cable.

• If your computer does not accept the No.9 pin, please consult your

dealer for advice on obtaining an HD15 adapter.

x

Connecting to a Macintosh or compatible

computer

* Connect the supplied Macintosh adapter to the computer before

connecting the cable. This adapter is compatible with Macintosh LC,

Performa, Quadra, Power Macintosh and Power Macintosh G3 series

computers. Macintosh II series and some older versions of PowerBook

models may need an adapter with micro switches (not supplied).

x

Connecting to the five BNC connectors

* Connect the cables from left to right in the following order: Red-Green-

Blue-HD-VD.

Notes

• Do not touch the pins of the video cable connector as this might bend

the pins.

• Plug & Play (DDC) does not apply to the five BNC connectors. If you

want to use Plug & Play, connect your computer to the HD15 connector

using the supplied video signal cable.

(HD15) (BNC)

R G B HD VD

HD15 video signal

cable (supplied)

to video output

IBM PC/AT or compatible

computer

to HD15

(HD15) (BNC)

R G B HD VD

Use the supplied Macintosh adapter.

to HD15

Macintosh adapter (supplied)

*

Macintosh or

compatible computer

to video

output

HD15 video signal

cable (supplied)

(HD15) (BNC)

R G B HD VD

to VIDEO IN R/G/B

to SYNC IN

HD/VD

Refer to the preceding

examples to connect to your

computer.

video signal cable

(SMF-400, not supplied)

*

7

EN

Step 2:Connect the power cord

With the monitor and computer switched off, first connect the

power cord to the monitor, then connect it to a power outlet.

Step 3:Turn on the monitor and

computer

First turn on the monitor, then turn on the computer.

The installation of your monitor is complete.

If necessary, use the monitor’s controls to adjust the picture.

If no picture appears on your screen

• Check that the monitor is correctly connected to the computer.

• If NO INPUT SIGNAL appears on the screen, try changing the

input signal (page 9), and confirm that your computer’s graphic

board is completely seated in the correct bus slot.

• If you are replacing an old monitor with this model and OUT

OF SCAN RANGE appears on the screen, reconnect the old

monitor. Then adjust the computer’s graphic board so that the

horizontal frequency is between 30 – 107 kHz (GDM-F400) or

30 – 121 kHz (GDM-F500), and the vertical frequency is

between 48 – 160 Hz.

For more information about the on-screen messages, see “Trouble

symptoms and remedies” on page 16.

For customers using Windows 95/98

To maximize the potential of your monitor, install the new model

information file from the supplied Windows Monitor Information Disk

onto your PC.

This monitor complies with the “VESA DDC” Plug & Play standard. If

your PC/graphics board complies with DDC, select “Plug & Play Monitor

(VESA DDC)” or this monitor’s model name as the monitor type in the

“Control Panel” of Windows 95/98. If your PC/graphics board has

difficulty communicating with this monitor, load the Windows Monitor

Information Disk and select this monitor’s model name as the monitor

type.

For customers using Windows NT4.0

Monitor setup in Windows NT4.0 is different from Windows 95/98 and

does not involve the selection of monitor type. Refer to the Windows

NT4.0 instruction manual for further details on adjusting the resolution,

refresh rate, and number of colors.

Adjusting the monitor’s resolution and color number

Adjust the monitor’s resolution and color number by referring to your

computer’s instruction manual. The color number may vary according to

your computer or video board. The color palette setting and the actual

number of colors are as follows:

• High Color (16 bit) t 65,536 colors

• True Color (24 bit) t about 16.77 million colors

In true color mode (24 bit), speed may be slower.

(HD15) (BNC)

R G B HD VD

to AC IN

to a power outlet

power cord (supplied)

1-2

Page 8

8

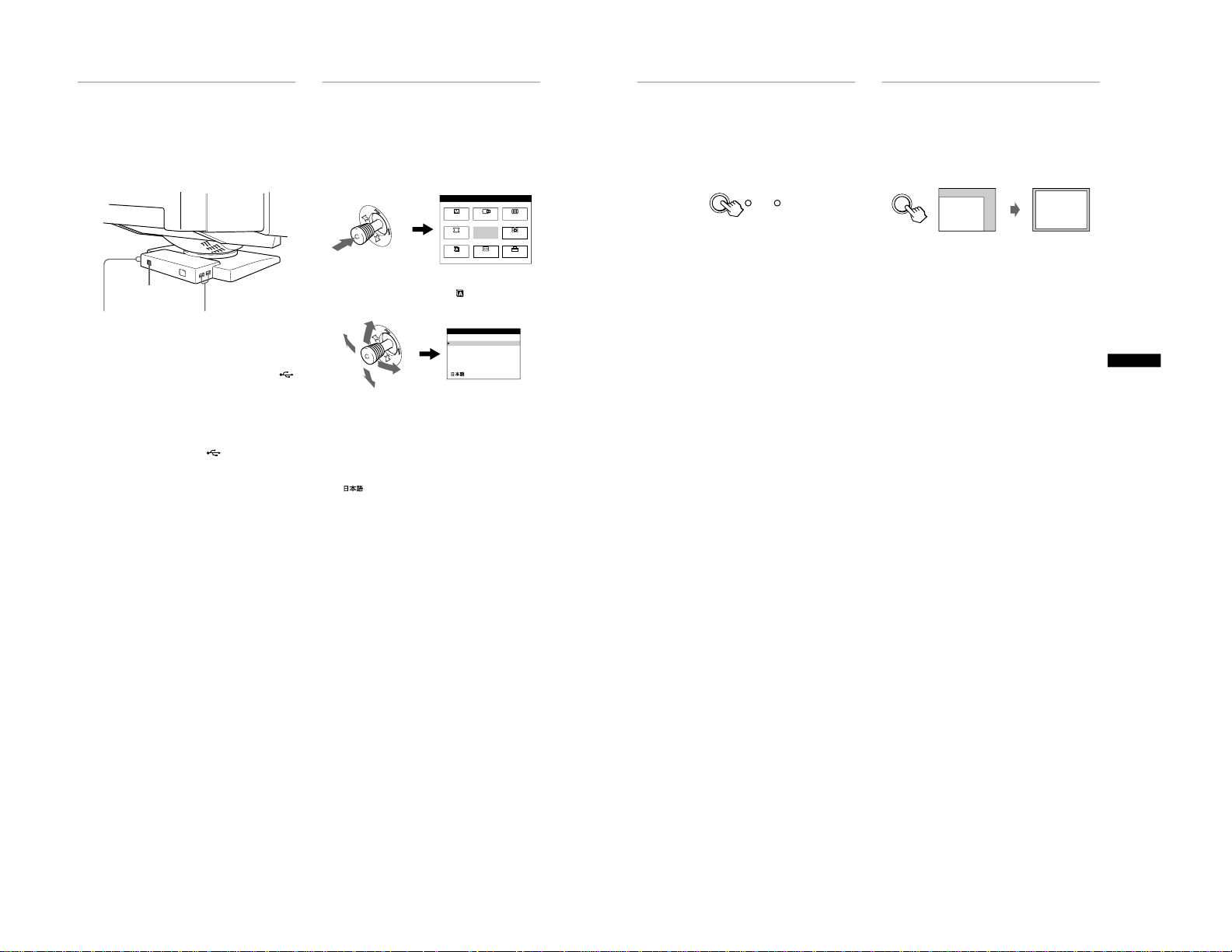

Connecting Universal Serial Bus

(USB) compliant peripherals

Your monitor has one upstream and four downstream USB

connectors. They provide a fast and easy way to connect USB

compliant peripheral devices (such as keyboards, mice, printers

and scanners) to your computer using a standardized USB cable.

To use your monitor as a hub for your peripheral devices, connect

the USBs as illustrated below.

1

Turn on the monitor and computer.

2

Connect your computer to the square upstream

connector using the supplied USB cable.

For customers using Windows

If a message appears on your screen, follow the on-screen instructions

and select Generic USB Hub as the default setting.

3

Connect your USB compliant peripheral devices to

the rectangular downstream USB connectors.

Notes

• Not all computers and /or operating systems support USB

configurations. Check your computer’s instruction manual to see if you

can connect USB devices.

• In most cases, USB driver software needs to be installed on the host

computer. Refer to the peripheral device’s instruction manual for

further details.

• The monitor functions as a USB hub as long as the monitor is either

“on” or in power saving mode.

• If you connect a keyboard or mouse to the USB connectors and then

boot your computer for the first time, the peripheral devices may not

function. First connect the keyboard and mouse directly to the

computer and set up the USB compliant devices. Then connect them to

this monitor.

• Do not lean on the monitor when plugging in the USB cables. The

monitor may suddenly shift and cause injury.

Selecting the on-screen menu

language (LANG)

English, French, German, Spanish, Italian, and Japanese versions

of the on-screen menus are available. The default setting is

English.

1

Press the joystick

See page 11 for more information on using the joystick.

2

Move the joystick to highlight LANG and press

the joystick again.

3

Move the joystick up or down to select a language

and press the joystick again.

• ENGLISH

• FRANÇAIS: French

• DEUTSCH: German

• ESPAÑOL: Spanish

• ITALIANO: Italian

• : Japanese

To close the menu

Press the joystick once to return to the main menu, and twice to return to

normal viewing. If no buttons are pressed, the menu closes automatically

after about 30 seconds.

To reset to English

Press the RESET button while the LANGUAGE menu is displayed on the

screen.

to USB compliant

peripheral devices

to a USB compliant

computer

to USB compliant

peripheral devices

MENU

EXIT

CENTER

SIZE

GEOM

COLOR

LANG

ZOOM

SCREEN

OPTION

MENU

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

ITA LIANO

LANGUAGE

9

EN

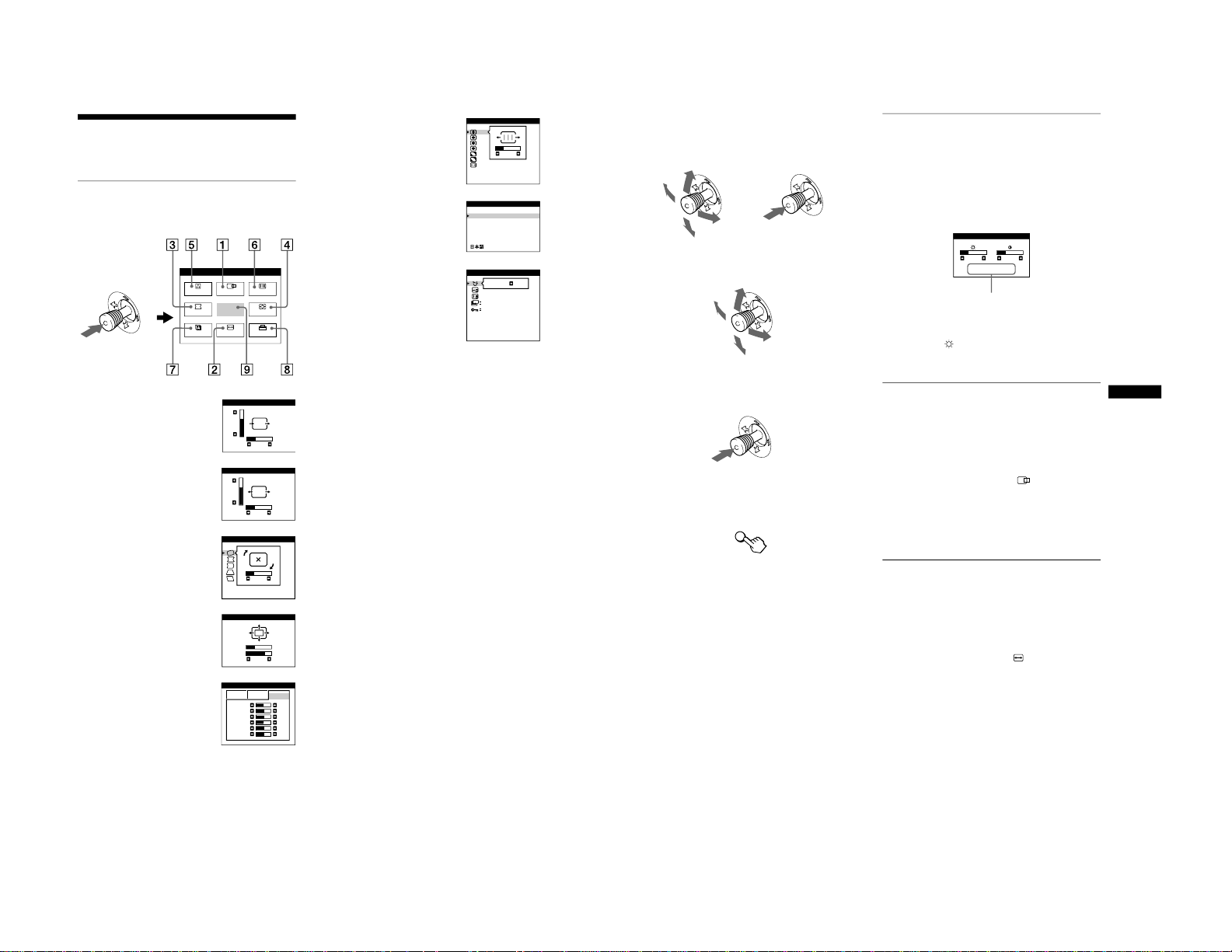

Selecting the input signal

You can connect two computers to this monitor using the HD15

and BNC connectors. To switch between the two computers, use

the INPUT button.

Press the INPUT button.

The input signal and corresponding input indicator change each

time you press this button.

Notes

• If no signal is input to the selected connector, the monitor automatically

switches to the other connector.

• If you restart the computer you want to view, or that computer is in

power saving mode, the monitor may automatically switch to the other

connector’s signal. If this happens, manually select the desired signal

using the INPUT button.

Automatically sizing and centering

the picture

You can easily adjust the picture to fill the screen by pressing the

ASC (auto sizing and centering) button.

Press the ASC button.

The picture automatically fills the screen.

Notes

• This function is intended for use with a computer running Windows or

similar graphic user interface software that provides a full-screen

picture. It may not work properly if the background color is dark or if

the input picture does not fill the screen to the edges (such as an MSDOS prompt).

• Pictures with an aspect ratio of 5:4 (resolution: 1280 × 1024, 1800 ×

1440*) are displayed at their actual resolution and do not fill the screen

to the edges.

• The screen may go blank for a few seconds when the ASC button is

pressed. This is not a malfunction.

* GDM-F500 only

INPUT HD15 BNC

ASC

1-3

Page 9

10

Customizing Your Monitor

You can make numerous adjustments to your monitor using the

on-screen menu.

Navigating the menu

Press the joystick to display the main MENU on your screen. See

page 11 for more information on using the joystick.

Use the joystick to select one of the following menus.

1

CENTER (page 11)

Select the CENTER menu to adjust

the picture’s centering.

2

SIZE (page 11)

Select the SIZE menu to adjust the

picture’s horizontal and vertical

size.

3

GEOM (page 12)

Select the GEOM menu to adjust the

picture’s rotation and shape.

4

ZOOM (page 12)

Select the ZOOM menu to enlarge

or reduce the picture.

5

COLOR (page 12)

Select the COLOR menu to adjust

the picture’s color temperature. You

can use this to match the monitor’s

colors to a printed picture’s colors.

MENU

EXIT

CENTER

SIZE

GEOM

COLOR

LANG

ZOOM

SCREEN

OPTION

MENU

CENTER

26

73

SIZE

26

73

ROTATION

GEOMETRY

26

ZOOM

73V

26H

COLOR

R BI AS

5000K 6500K

50

G BI AS

50

B BI AS

50

R GAIN

50

G GAIN

50

B GAIN

50

9300K

6

SCREEN (page 13)

Select the SCREEN menu to adjust

the picture’s quality. You can adjust

the vertical and horizontal

convergence, landing, and moire

cancellation effect.

7

LANG (page 8)

Select LANG to choose the onscreen menu’s language.

8

OPTION (page 14)

Select OPTION to adjust the

monitor’s options. The options

include:

• degaussing the screen

• changing the on-screen menu

position

• changing the power saving delay

time

• locking the controls

9

EXIT

Select EXIT to close the menu.

SCREEN

TOP

BOT

H CONVERGENCE

26

ADJ

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

ITA LIANO

LANGUAGE

ON

MANUAL DEGAUSS

UNLOCK

5 SEC

OPTION

ZZ...

11

EN

x

Using the joystick

1

Select the menu you want to adjust.

Move the joystick up, down, left, or right to highlight the

desired menu. Press the joystick to select the menu item.

2

Adjust the menu.

Move the joystick up, down, left, or right to make the

adjustment.

3

Close the menu.

Press the joystick once to return to the main menu, and twice

to return to normal viewing. If no buttons are pressed, the

menu closes automatically after about 30 seconds.

x

Resetting the adjustments

Press the RESET button. See page 14 for more information on

resetting the adjustments.

Adjusting the brightness and

contrast

Brightness and contrast adjustments are made using a separate

BRIGHTNESS/CONTRAST menu.

These settings are stored in memory for all input signals.

1

Move the joystick in any direction.

The BRIGHTNESS/CONTRAST menu appears on the

screen.

2

Move the joystick up or down to adjust the

brightness ( ), and left or right to adjust the

contrast ( 6 ).

The menu automatically disappears after about 3 seconds.

Adjusting the centering of the

picture (CENTER)

This setting is stored in memory for the current input signal.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight CENTER and

press the joystick again.

The CENTER menu appears on the screen.

3

Move the joystick up or down to adjust the vertical

centering, and left or right to adjust the horizontal

centering.

Adjusting the size of the picture

(SIZE)

This setting is stored in memory for the current input signal.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight SIZE and press the

joystick again.

The SIZE menu appears on the screen.

3

Move the joystick up or down to adjust the vertical

size, and left or right to adjust the horizontal size.

b

RESET

BRIGHTNESS/CONTRAST

26 26

80.0kHz/ 75Hz

the horizontal and vertical frequencies of the

current input signal

1-4

Page 10

12

Adjusting the shape of the picture

(GEOM)

The GEOM settings allow you to adjust the rotation and shape of

the picture.

The rotation setting is stored in memory for all input signals. All

other settings are stored in memory for the current input signal.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight GEOM and press

the joystick again.

The GEOMETRY menu appears on the screen.

3

First move the joystick up or down to select the

desired adjustment item. Then move the joystick left

or right to make the adjustment.

Enlarging or reducing the picture

(ZOOM)

This setting is stored in memory for the current input signal.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight ZOOM and press

the joystick again.

The ZOOM menu appears on the screen.

3

Move the joystick left or right to enlarge or reduce

the picture.

Note

Adjustment stops when either the horizontal or vertical size reaches its

maximum or minimum value.

Adjusting the color of the picture

(COLOR)

The COLOR settings allow you to adjust the picture’s color

temperature by changing the color level of the white color field.

Colors appear reddish if the temperature is low, and bluish if the

temperature is high. This adjustment is useful for matching the

monitor’s colors to a printed picture’s colors.

This setting is stored in memory for all input signals.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight COLOR and press

the joystick again.

The COLOR menu appears on the screen.

3

Move the joystick left or right to select a color

temperature.

The preset color temperatures are 5000K, 6500K, and 9300K.

Since the default setting is 9300K, the whites will change

from a bluish hue to a reddish hue as the temperature is

lowered to 6500K and 5000K.

4

If necessary, fine tune the color temperature.

First move the joystick up or down to select the desired

adjustment item. Then move the joystick left or right to make

the adjustment.

1

Adjusting the BIAS (black level)

This changes the brightness of both the dark and light

areas of an image.

2

Adjusting the GAIN (white level)

This changes the contrast of just the light areas of an

image.

You can adjust the R(Red), G(Green), and B(Blue)

component of the input signal when making changes to items

1

and 2 .

If you fine tune the color temperature, the new color settings

are stored in memory for each of the three color temperatures

and item 3 of the on-screen menu changes as follows:

• [5000K] t [1]

• [6500K] t [2]

• [9300K] t [3]

Select To

ROTATION

rotate the picture

PINCUSHION

expand or contract the picture sides

PIN BALANCE

shift the picture sides to the left or right

KEYSTONE

adjust the picture width at the top of

the screen

KEY BALANCE

shift the picture to the left or right at

the top of the screen

COLOR

6500K 9300K

G BI AS

50

B BI AS

50

R GAIN

50

G GAIN

50

B GAIN

50

R BI AS 76

1

13

EN

Adjusting the quality of the picture

(SCREEN)

The SCREEN settings allow you to adjust the quality of the

picture by controlling the convergence, moire, and landing.

• If you see red or blue shadows around letters or lines, adjust the

convergence.

• If elliptical or wavy patterns appear on the screen, cancel the

moire.

• If the color is irregular at the corners of the screen, adjust the

landing.

The CANCEL MOIRE and MOIRE ADJUST settings are stored

in memory for the current input signal. All other settings are

stored in memory for all input signals.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight SCREEN and

press the joystick again.

The SCREEN menu appears on the screen.

3

First move the joystick up or down to select the

desired adjustment item. Then move the joystick left

or right to make the adjustment.

* Moire is a type of natural interference which produces soft, wavy lines

on your screen. It may appear due to interference between the pattern

of the picture on the screen and the phosphor pitch pattern of the

monitor.

Note

The picture may become fuzzy when CANCEL MOIRE is set to ON.

Select To

H CONVERGENCE

horizontally shift red or blue shadows

V CONVERGENCE

vertically shift red or blue shadows

TOP

V CONVER TOP

vertically shift red or blue shadows at

the top of the screen

BOT

V CONVER BOT

vertically shift red or blue shadows at

the bottom of the screen

LANDING

select one of the four corners of the

screen

ADJ

LANDING ADJUST

reduce any irregularities in the color

of the corner selected in LANDING

to a minimum

:top left

:bottom left

:top right

:bottom right

CANCEL MOIRE *

turn the moire cancellation function

ON or OFF

ADJ (MOIRE ADJUST) appears

in the menu when you select ON

ADJ

MOIRE ADJUST

adjust the degree of moire

cancellation until the moire is at a

minimum

Select To

Example of moire

1-5

Page 11

14

Additional settings (OPTION)

You can manually degauss (demagnetize) the monitor, change the

menu position, set the power saving delay time, and lock the

controls.

1

Press the joystick.

The main MENU appears on the screen.

2

Move the joystick to highlight OPTION and press

the joystick again.

The OPTION menu appears on the screen.

3

Move the joystick to highlight the desired

adjustment item.

Adjust the selected item according to the following

instructions.

Degaussing the screen

The monitor is automatically demagnetized when the power is

turned on.

To manually degauss the monitor, first move the

joystick up or down to select (MANUAL DEGAUSS).

Then move the joystick to the right.

The screen is degaussed for about 3 seconds. If a second degauss

cycle is needed, allow a minimum interval of 20 minutes for the

best result.

Changing the menu’s position.

Change the menu’s position if it is blocking an image on the

screen.

To change the menu’s on-screen position, first move

the joystick up or down to select (OSD H POSITION)

for horizontal adjustment, or (OSD V POSITION) for

vertical adjustment. Then move the joystick to the left

or right to shift the on-screen menu.

Changing the power saving delay time.

To adjust the time it takes to enter the power saving

mode, first move the joystick up or down to select

(PWR SAVE DELAY). Then move the joystick to the left

or right to select the desired time.

If you select OFF, the monitor does not enter power saving mode.

See page 15 for more information about the monitor’s power

saving capabilities.

Locking the controls.

To protect adjustment data by locking the controls, first

move the joystick up or down to select (CONTROL

LOCK). Then move the joystick to the right to select

LOCK.

Only the 1 (power) switch, EXIT, and (CONTROL LOCK)

of the OPTION menu will operate. If any other items are

selected, the mark appears on the screen.

To cancel the control lock

Repeat the procedure above and set (CONTROL LOCK) to

UNLOCK.

Resetting the adjustments

This monitor has the following three reset methods. Use the

RESET button to reset the adjustments.

Resetting a single adjustment item

Use the joystick to select the adjustment item you want to reset,

and press the RESET button.

Resetting all of the adjustment data for the

current input signal

Press the RESET button when no menu is displayed on the screen.

Note that the following items are not reset by this method:

• on-screen menu language (page 8)

• on-screen menu position (page 14)

• power saving delay time (page 14)

• control lock (page 14)

Resetting all of the adjustment data for all input

signals

Press and hold the reset button for more than two seconds.

Note

The RESET button does not function when

(CONTROL LOCK)

is set to LOCK.

ZZ...

RESET

15

EN

Technical Features

Preset and user modes

When the monitor receives an input signal, it automatically

matches the signal to one of the factory preset modes stored in the

monitor’s memory to provide a high quality picture at the center

of the screen. (See page i for a list of the factory preset modes.)

For input signals that do not match one of the factory preset

modes, the digital Multiscan technology of this monitor ensures

that a clear picture appears on the screen for any timing in the

monitor’s frequency range (horizontal: 30 – 107 kHz (GDMF400) or 30 – 121 kHz (GDM-F500), vertical: 48 – 160 Hz) . If

the picture is adjusted, the adjustment data is stored as a user

mode and automatically recalled whenever the same input signal

is received.

Note for Windows users

For Windows users, check your video board manual or the utility

program which comes with your graphic board and select the

highest available refresh rate to maximize monitor performance.

Power saving function

This monitor meets the power-saving guidelines set by VESA,

E

NERGY

S

TAR, and NUTEK. If the monitor is connected to a

computer or video graphics board that is DPMS (Display Power

Management Signaling) compliant, the monitor will

automatically reduce power consumption in three stages as shown

below.

* Figures reflect power consumption when no USB compatible

peripherals are connected to the monitor.

**When your computer enters the “active off” mode, the input signal is

cut and NO INPUT SIGNAL appears on the screen. After the time set

in “Changing the power saving delay time.” (page 14) has elapsed, the

monitor enters the power saving mode.

To change the power saving delay time

See page 14.

Troubleshooting

Before contacting technical support, refer to this section.

If thin lines appear on your screen

(damper wires)

The lines you are experiencing on your screen are normal for the

Trinitron monitor and are not a malfunction. These are shadows

from the damper wires used to stabilize the aperture grille and are

most noticeable when the screen’s background is light (usually

white). The aperture grille is the essential element that makes a

Trinitron picture tube unique by allowing more light to reach the

screen, resulting in a brighter, more detailed picture.

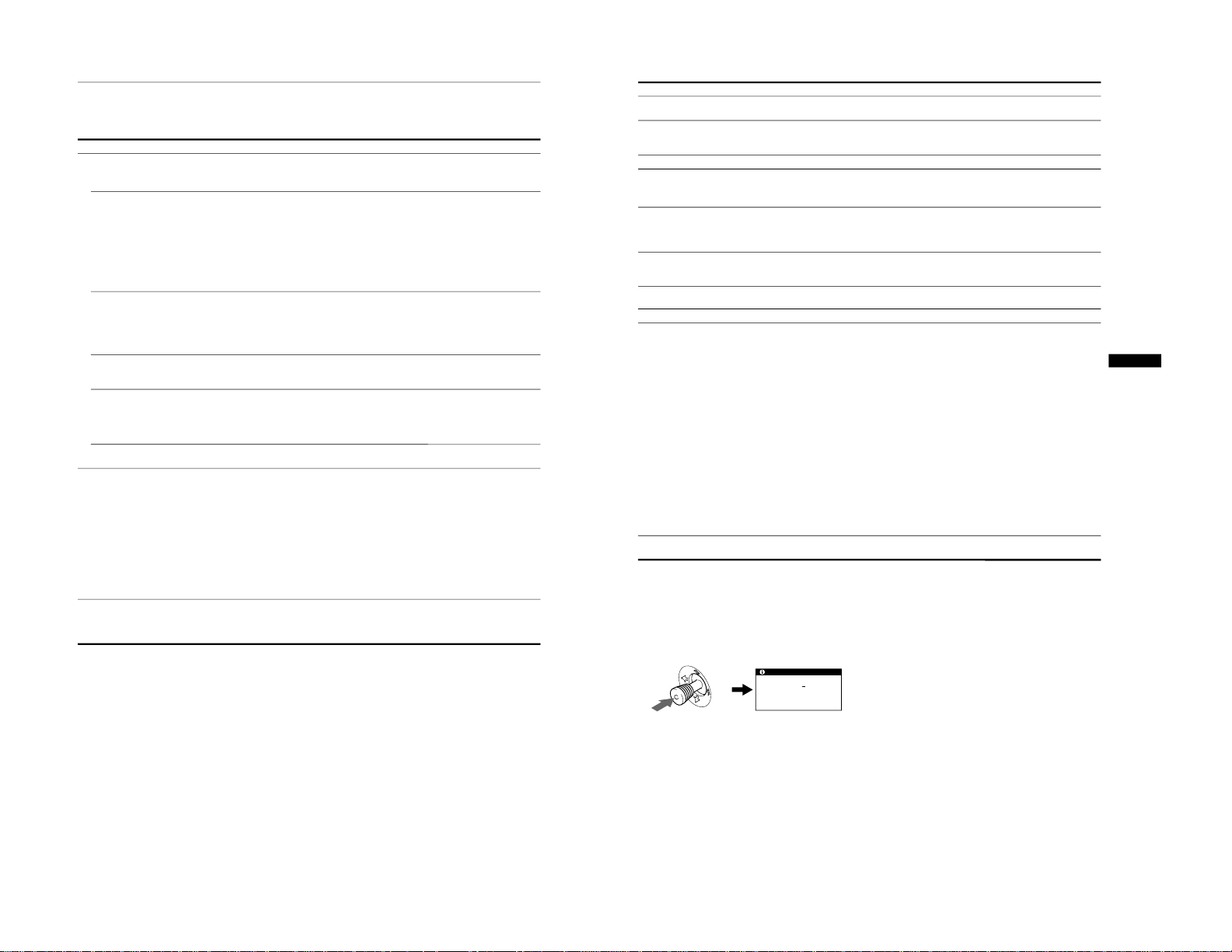

On-screen messages

If there is something wrong with the input signal, one of the

following messages appears on the screen. To solve the problem,

see “Trouble symptoms and remedies” on page 16.

1

The input signal condition

OUT OF SCAN RANGE

indicates that the input signal is not supported by the

monitor’s specifications.

NO INPUT SIGNAL

indicates that no signal is input, or that no signal is input from

the selected connector (HD15 or BNC).

2

The connector indicator

This message indicates which connector is receiving the

wrong signal. If there is something wrong with the signal

from both connectors, HD15 and BNC are displayed

alternately.

Power mode Power

consumption *

1

(power)

indicator

normal

operation

≤

160 W (GDM-F500)

≤

140 W (GDM-F400)

green

1 standby ≤ 100 W (GDM-F500)

≤

80 W (GDM-F400)

green and orange

alternate

2 suspend ≤ 15 W (GDM-F500)

≤

10 W (GDM-F400)

green and orange

alternate

3 active off** ≤ 1 W (GDM-F500)

≤

3 W (GDM-F400)

orange

power off 0 W off

Damper wires

INFORMATION

OUT OF SCAN RANGE

INPUT : HD15

1-6

Page 12

16

Trouble symptoms and remedies

If the problem is caused by the connected computer or other equipment, please refer to the connected equipment’s instruction manual.

Use the self-diagnosis function (page 18) if the following recommendations do not resolve the problem.

Symptom Check these items

No picture

If the 1 (power) indicator is not lit • Check that the power cord is properly connected.

• Check that the 1 (power) switch is in the “on” position.

If the NO INPUT SIGNAL message

appears on the screen, or if the 1

(power) indicator is either orange or

alternating between green and

orange

• Check that the video signal cable is properly connected and all plugs are firmly seated in

their sockets. If you are using the five BNC connectors, connect them in the correct order

(from left to right: Red-Green-Blue-HD-VD) (page 6).

• Check that the input select setting is correct (page 9).

• Check that the HD15 video input connector’s pins are not bent or pushed in.

x

Problems caused by the connected computer or other equipment

• The computer is in power saving mode. Try pressing any key on the computer keyboard.

• Check that the computer’s power is “on.”

• Check that the graphic board is completely seated in the proper bus slot.

If the OUT OF SCAN RANGE

message appears on the screen

x

Problems caused by the connected computer or other equipment

• Check that the video frequency range is within that specified for the monitor. If you

replaced an old monitor with this monitor, reconnect the old monitor and adjust the

frequency range to the following.

Horizontal: 30 – 107 kHz (GDM-F400), 30 – 121 kHz (GDM-F500)

Vertical: 48 – 160 Hz

If no message is displayed and the 1

(power) indicator is green or flashing

orange

• Use the Self-diagnosis function (page 18).

If using Windows 95/98 • If you replaced an old monitor with this monitor, reconnect the old monitor and do the

following. Install the Windows Monitor Information Disk (page 7) and select this monitor

(“GDM-F400” or “GDM-F500”) from among the Sony monitors in the Windows 95/98

monitor selection screen. If you choose to select “Plug and Play,” connect the monitor to

the computer with the HD15 video signal cable. You cannot use the five BNC connectors.

If using a Macintosh system • Check that the Macintosh adapter and the video signal cable are properly connected

(page 6).

Picture flickers, bounces,

oscillates, or is scrambled

• Isolate and eliminate any potential sources of electric or magnetic fields such as other

monitors, laser printers, electric fans, fluorescent lighting, or televisions.

• Move the monitor away from power lines or place a magnetic shield near the monitor.

• Try plugging the monitor into a different AC outlet, preferably on a different circuit.

• Try turning the monitor 90 ° to the left or right.

x

Problems caused by the connected computer or other equipment

• Check your graphics board manual for the proper monitor setting.

• Confirm that the graphics mode (VESA, Macintosh 21" Color, etc.) and the frequency of

the input signal are supported by this monitor (page i). Even if the frequency is within the

proper range, some video boards may have a sync pulse that is too narrow for the monitor

to sync correctly.

• Adjust the computer’s refresh rate (vertical frequency) to obtain the best possible picture.

Picture is fuzzy

• Adjust the brightness and contrast (page 11).

• Degauss the monitor* (page 14).

• If CANCEL MOIRE is ON, the picture may become fuzzy. Decrease the moire

cancellation effect or set CANCEL MOIRE to OFF (page 13).

17

EN

* If a second degauss cycle is needed, allow a minimum interval of 20 minutes for the best result. A humming noise may be heard, but this is not a

malfunction.

Displaying this monitor’s name, serial number,

and date of manufacture.

While the monitor is receiving a video signal, press and hold the

joystick for more than three seconds to display this monitor’s

information box.

If the problem persists, call your authorized Sony dealer and give

the following information.

• Model name: GDM-F400, GDM-F500

• Serial number

• Name and specifications of your computer and graphics board.

Picture is ghosting

• Eliminate the use of video cable extensions and/or video switch boxes.

• Check that all plugs are firmly seated in their sockets.

Picture is not centered or sized

properly

• Press the ASC button (page 9).

• Adjust the size (page 11) or centering (page 11). Note that some video modes do not fill

the screen to the edges.

Edges of the image are curved • Adjust the geometry (page 12).

Wavy or elliptical pattern (moire)

is visible

• Cancel the moire (page 13).

x

Problems caused by the connected computer or other equipment

• Change your desktop pattern.

Color is not uniform

• Degauss the monitor* (page 14). If you place equipment that generates a magnetic field,

such as a speaker, near the monitor, or if you change the direction the monitor faces, color

may lose uniformity.

• Adjust the landing (page 13).

White does not look white

• Adjust the color temperature (page 12).

• Check that the five BNC connectors are connected in the correct order (from left to right:

Red-Green-Blue-HD-VD) (page 6).

Letters and lines show red or blue

shadows at the edges

• Adjust the convergence (page 13).

Monitor buttons do not operate • If the control lock is set to LOCK, set it to UNLOCK (page 14).

USB peripherals do not function • Check that the appropriate USB connectors are securely connected (page 8).

• Check that the 1 (power) switch is in the “on” position.

x

Problems caused by the connected computer or other equipment

• Check that the power of any self-powered USB compliant peripheral devices is “on.”

• Install the latest version of the device driver on your computer. Contact your device’s

manufacturer for information about the appropriate device driver.

• If your USB compliant keyboard or mouse does not function, connect them directly to

your computer, reboot your computer, and make any necessary adjustments to the USB

settings. Then reconnect the keyboard or mouse to the monitor.

• For customers using Windows 95

1. Right-click on My Computer and select Properties.

2. Click on the Device Manager tab. Scroll down and select Universal Serial Bus

Controller.

,

If Universal Serial Bus Controller does not appear, you need to load a USB

supplement disk. Contact your computer’s manufacturer for more information about

obtaining a USB supplement disk.

3. Select Generic USB Device from the USB controller list and click on Properties.

4. If there is a check in the box next to “Disable in this hardware profile,” remove the

check.

5. Click on Refresh.

A hum is heard right after the

power is turned on

• This is the sound of the auto-degauss cycle. When the power is turned on, the monitor is

automatically degaussed for three seconds.

Symptom Check these items

SER NO : 1234567

MODEL : GDM F500

MANUFACTURED

: 1998-52

INFORMATION

Example

1-7

Page 13

18

Self-diagnosis function

This monitor is equipped with a self-diagnosis function. If there is

a problem with your monitor or computer(s), the screen will go

blank and the 1 (power) indicator will either light up green or

flash orange. If the 1 (power) indicator is lit in orange, the

computer is in power saving mode. Try pressing any key on the

keyboard.

If the

1 (power) indicator is green

1

Remove any plugs from the video input 1 and 2

connectors, or turn off the connected computer(s).

2

Press the 1 (power) button to turn the monitor off

and on.

3

Move the joystick to the right for 2 seconds before

the monitor enters power saving mode.

If all four color bars appear (white, red, green, blue), the monitor

is working properly. Reconnect the video input cables and check

the condition of your computer(s).

If the color bars do not appear, there is a potential monitor failure.

Inform your authorized Sony dealer of the monitor’s condition.

If the 1 (power) indicator is flashing orange

Press the 1 (power) button to turn the monitor off and

on.

If the 1 (power) indicator lights up green, the monitor is working

properly.

If the 1 (power) indicator is still flashing, there is a potential

monitor failure. Count the number of seconds between orange

flashes of the 1 (power) indicator and inform your authorized

Sony dealer of the monitor’s condition. Be sure to note the model

name and serial number of your monitor. Also note the make and

model of your computer and video board.

Specifications

GDM-F400

CRT 0.22 mm aperture grille pitch

19 inches measured diagonally

90-degree deflection

FD Trinitron

Viewable image size Approx. 364.8 × 273.6 mm (w/h)

(14

3

/

8

×

10

7

/

8

inches)

18.0" viewing image

Resolution Horizontal: Max. 1600 dots

Vertical: Max. 1200 lines

Standard image area Approx. 352 × 264 mm (w/h)

(13

7

/

8

×

10

1

/

2

inches)

or

Approx. 330 × 264 mm (w/h)

(13 × 10

1

/

2

inches)

Deflection frequency* Horizontal: 30 to 107 kHz

Vertical: 48 to 160 Hz

AC input voltage/current 100 to 240 V, 50 – 60 Hz, 1.8 – 1.0 A

Power consumption Max. 140 W (with no USB devices

connected)

Dimensions

Approx. 444

×

476 × 455 mm (w/h/d)

(17

1

/

2

×

18

3

/

4

×

18 inches)

Mass Approx. 28 kg (61 lb 12 oz)

Plug and Play DDC1/DDC2B/DDC2Bi/DDC2B+

Supplied accessories See page 6

GDM-F500

CRT 0.22 mm aperture grille pitch

21 inches measured diagonally

90-degree deflection

FD Trinitron

Viewable image size Approx. 403.8 × 302.2 mm (w/h)

(16 × 12 inches)

19.8" viewing image

Resolution Horizontal: Max. 1800 dots

Vertical: Max. 1440 lines

Standard image area Approx. 388 × 291 mm (w/h)

(15

3

/

8

×

11

1

/

2

inches)

or

Approx. 364 × 291 mm (w/h)

(14

3

/

8

×

11

1

/

2

inches)

Deflection frequency* Horizontal: 30 to 121 kHz

Vertical: 48 to 160 Hz

AC input voltage/current 100 to 240 V, 50 – 60 Hz, 2.0 – 1.0 A

Power consumption Max. 160 W (with no USB devices

connected)

Dimensions

Approx. 502

×

511 × 486.3 mm (w/h/d)

(19

7

/

8

×

20

1

/

8

×

19

1

/

4

inches)

Mass Approx. 34 kg (74 lb 15 oz)

Plug and Play DDC1/DDC2B/DDC2AB/DDC2B+

Supplied accessories See page 6

* Recommended horizontal and vertical timing condition

• Horizontal sync width duty should be more than 4.8% of total

horizontal time or 0.8 µs, whichever is larger.

• Horizontal blanking width should be more than 2.5 µsec.

• Vertical blanking width should be more than 450 µsec.

Design and specifications are subject to change without notice.

RESET ASC INPUT MENUHD15 BNC

1 (power) indicator

1-8

Page 14

GDM-F500/F500T9

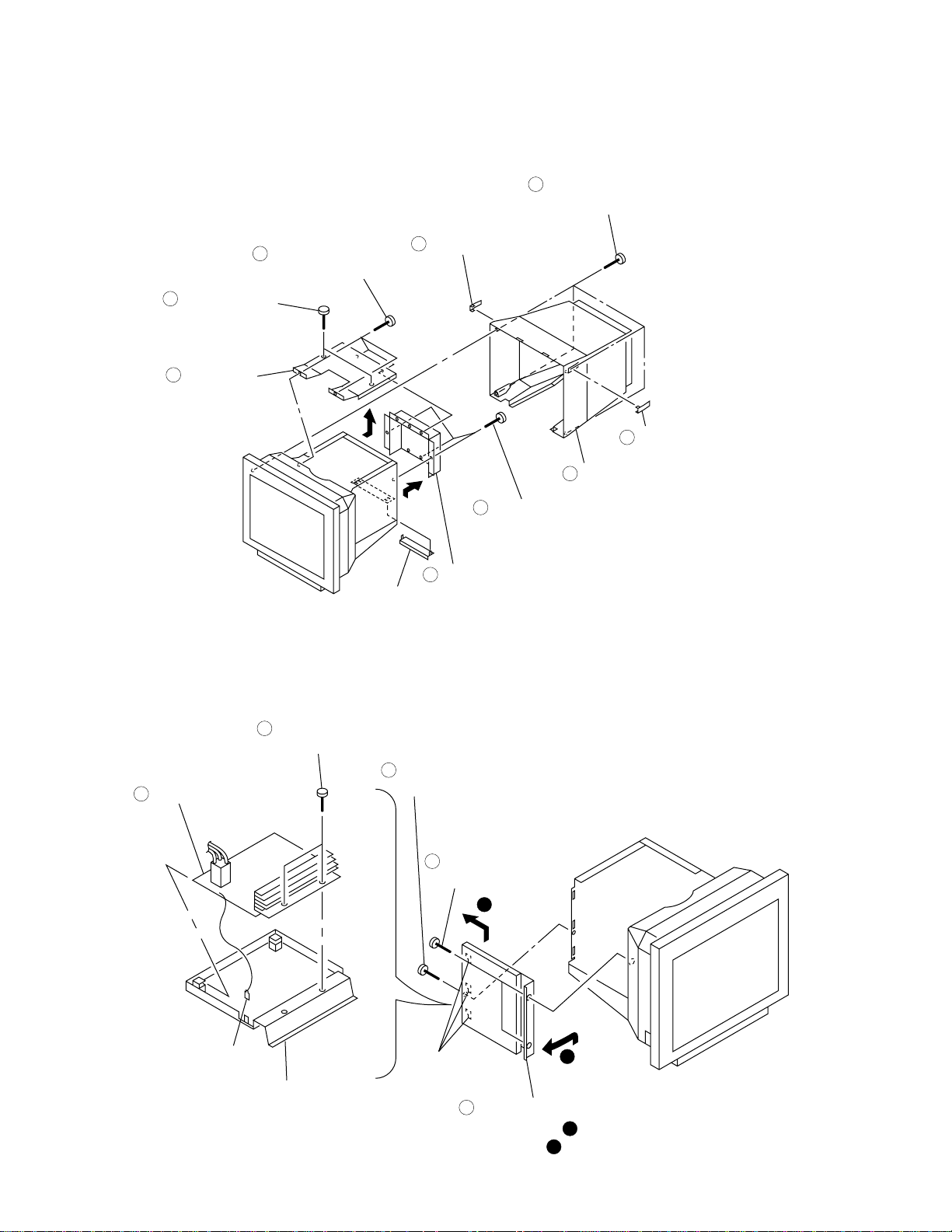

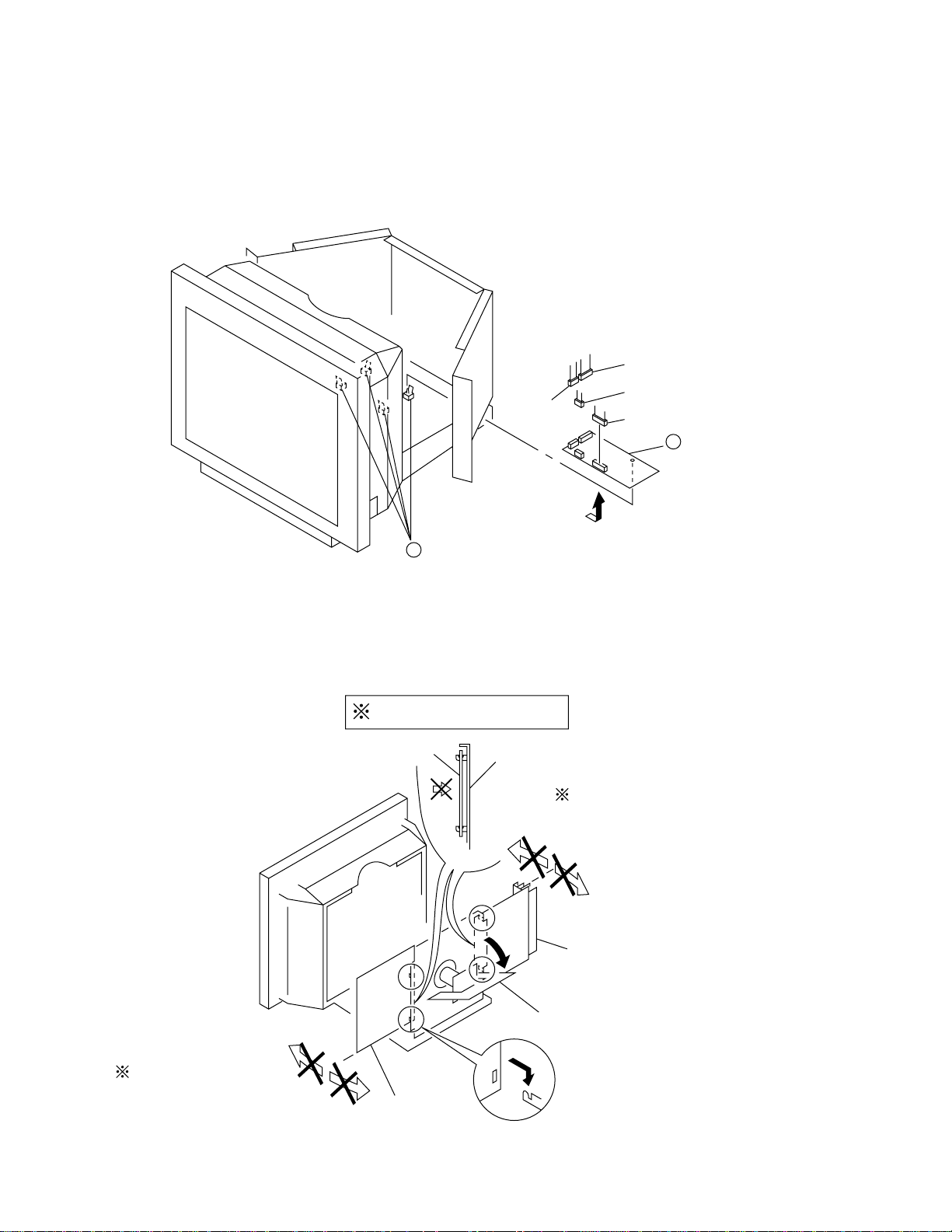

2-1. CABINET REMOVAL

6

Two screws

(+ BVTT 4 x 8)

7

Top cover

5

Four screws

(+ BVTT 4 x 8)

SECTION 2

DISASSEMBLY

1

Screw cover

3

Four screws

(+ BVTP 4 x 16)

4

Cabinet

2

Screw cover

2-2. D BOARD REMOVAL

4

Two screws

(+ BVTP 3 x 10)

5

D board

Attachment

1

Screw

(+ BVTT 4 x 8)

Three screws

8

(+ BVTT 4 x 8)

9

Video shield

2

Two screws

(+ BVTT 4 x 8)

B

GND

Side cover (D) assembly

Three hooks

3

Open the D block in the direction

of the arrow and remove of

the arrow .

2-1

A

A

B

Page 15

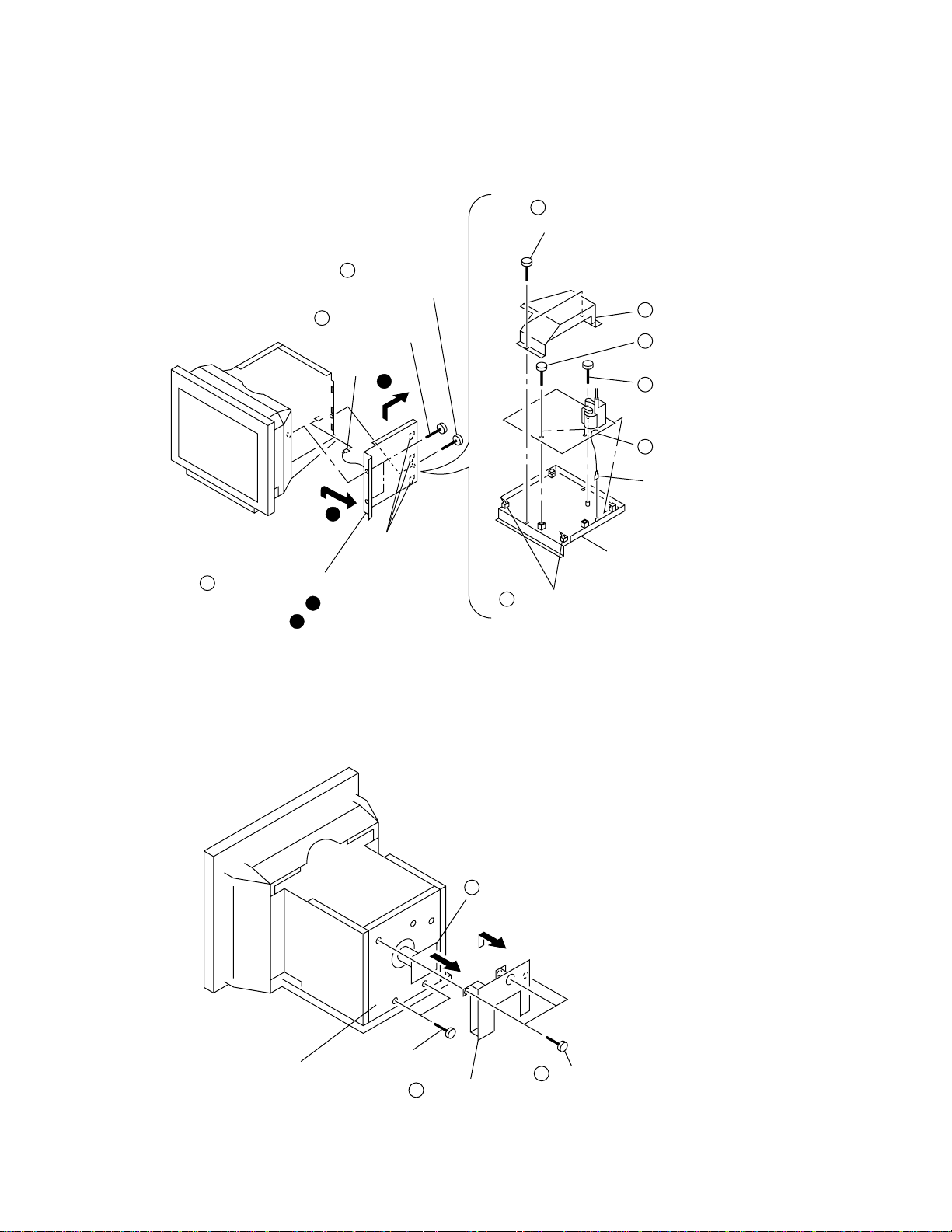

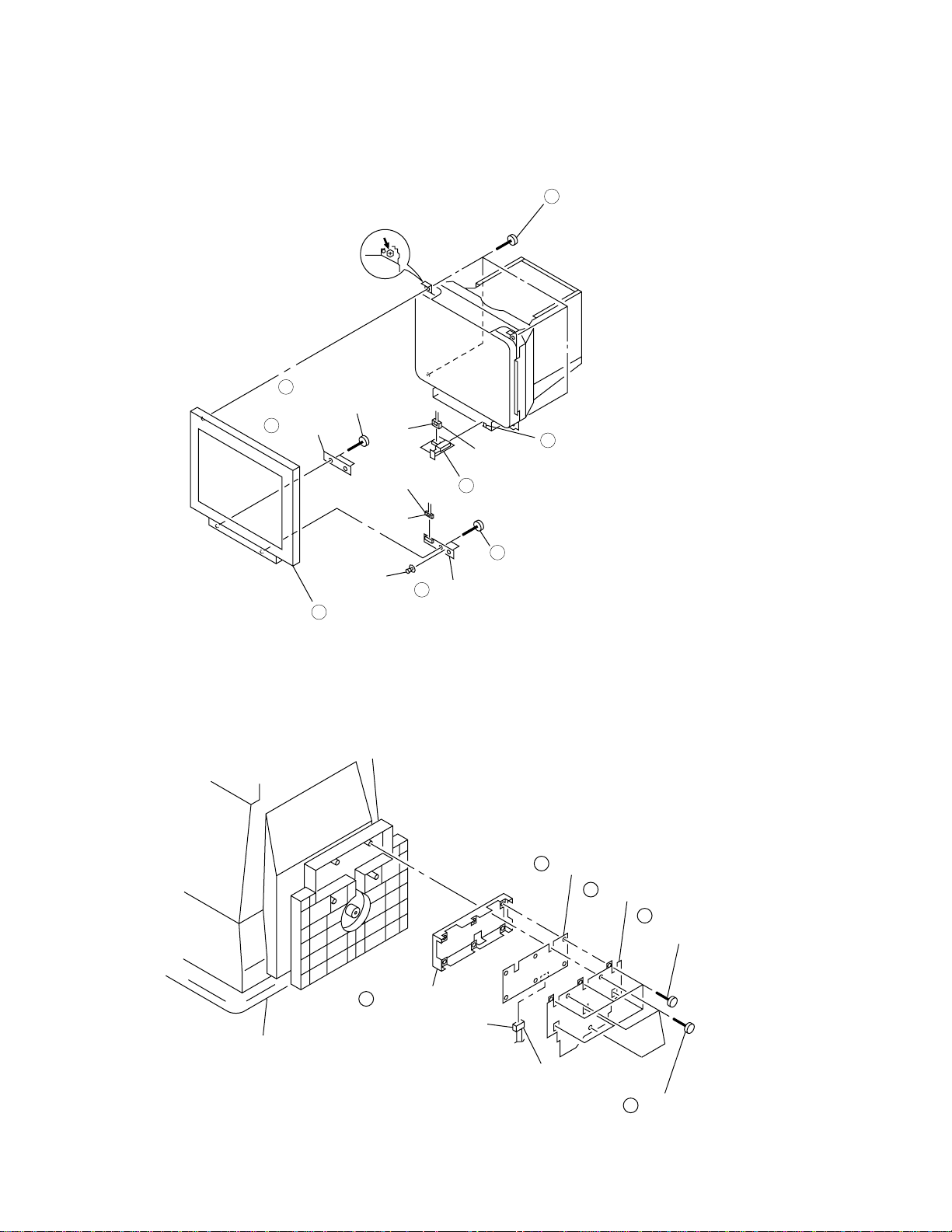

2-3. G BOARD REMOVAL

2

1

Screw

(+ BVTT 4 x 8)

Two screws

(+ BVTT 4 x 8)

GND

B

4

Two screws

(+ BVTP 3 x 10)

5

G shield

6

Two screws

(+ BVTP 3 x 10)

7

Screw

(+ P 3.5 x 20)

9

G board

GND

GDM-F500/F500T9

3

Open the G block in the direction

of the arrow and remove of

the arrow .

A

B

2-4. A BOARD REMOVAL

A

Three hooks

8

Two printed circuit board holders

3

A board (2/2)

Side cover (G) assembly

Rear shield assembly

Two screws

(+BVTT 4 x 8)

2

A board (1/2)

2-2

1

Three screws

(+BVTT 4 x 8)

Page 16

GDM-F500/F500T9

2-5. L BOARD REMOVAL

CN5002

CN5001

CN5004

CN5003

2

L board

2-6. SERVICE POSITION

1

Four printed circuit board holders

CAUTION : SHORT

D,G boards

Rear shield

If the claw is hooked,

opening and closing the

board is impossible.

Do not try to do it by force.

D board (Refer to 2-2. )

If the claw is hooked,

opening and closing the

board is impossible.

Do not try to do it by force.

A board (Refer to 2-4. )

G board

(Refer to 2-3.)

2-3

Page 17

2-7. H1, H2 AND J BOARDS REMOVAL

5

Two screws

(+ BVTP 3 x 10)

6

H2 board

Claw

CN801

CN891

8

J board

1

Four screws

(Tapping screw 5)

7

Claw

GDM-F500/F500T9

2

Bezel assembly

2-8. US BOARD REMOVAL

Knob

Claw

4

H1 board

3

Two screws

(+ BVTP 3 x 10)

5

US board

2

Stand cover

3

Six screws

(+ BVTP 3 x 10)

Cushion

4

Shield case

Claw

2-4

CN2601

1

Three screws

(+ BVTP 3 x 10)

Page 18

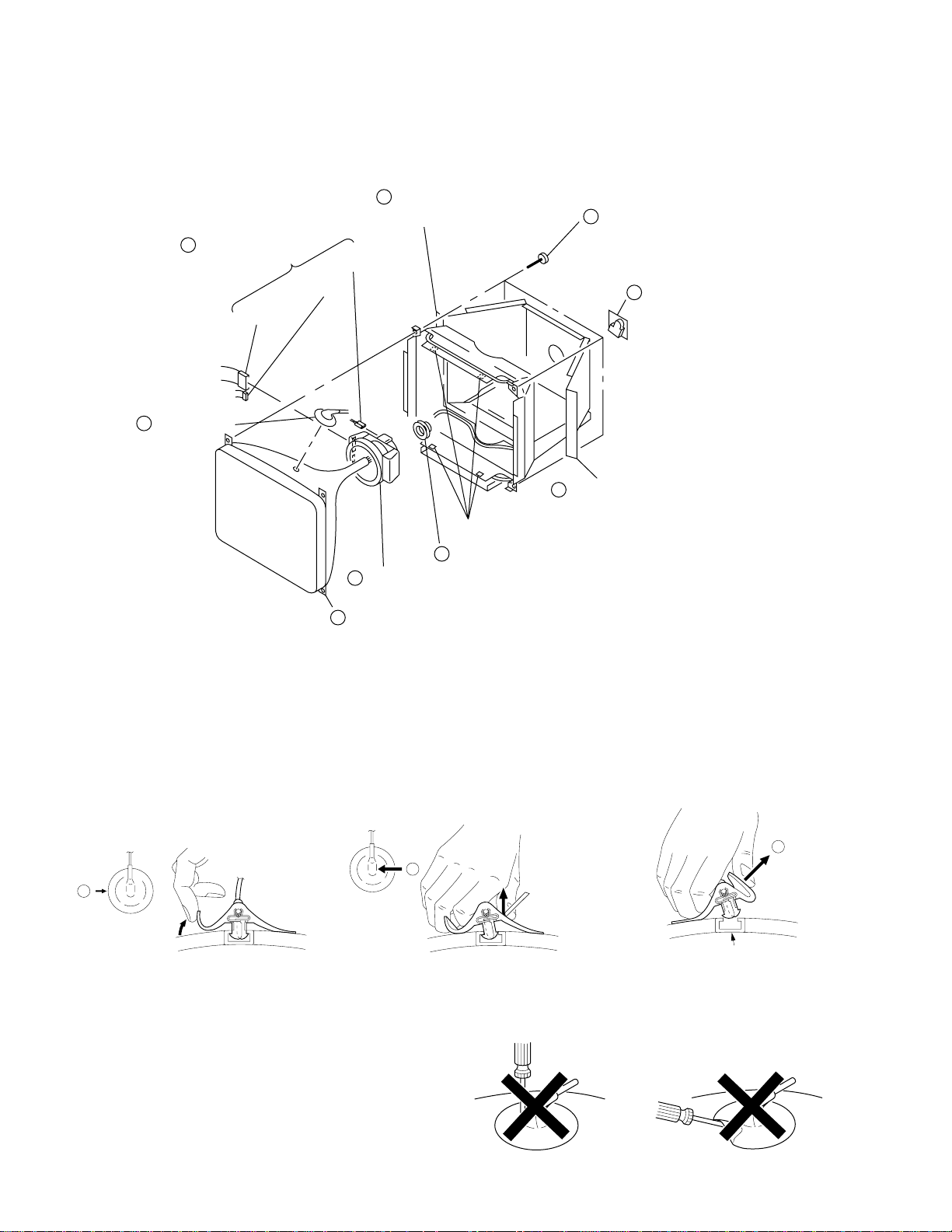

GDM-F500/F500T9

2-9. PICTURE TUBE REMOVAL

4

Three connectors

10P (DY)

5

Anode cap

GND (DY)

6P (DY)

1

Open the D block

(Refer to 2-2.)

9

Deflection yoke

EMI spring (4)

8

Neck assembly

6

Four screws

(+ BVTT 4 x 8)

3

A board

2

Open the G block

(Refer to 2-3.)

7

Picture tube

• REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

removing the anode.

• REMOVING PROCEDURES

c

b

a

Anode Button

1 Turn up one side of the rubber cap in

the direction indicated by the arrow a.

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

• HOW TO HANDLE AN ANODE-CAP

1 Don’t hurt the surface of anode-caps with shartp shaped

material!

2 Don’t press the rubber hardly not to hurt inside of anode-caps!

A material fitting called as shatter-hook terminal is built in the

rubber.

3 Don’t turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or hurt the rubber.

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in the

direction of the arrow c.

2-5

Page 19

2-10. HARNESS LOCATION

Stand assembly

CN2601

US board

Picture tube

J board

H1 board H2 board

CN802

CN801

CN891

CN803

GDM-F500/F500T9

CN671 CN672

CN673

CN901

FBT

CN690

G board

CN605

CN604

L board

AC inlet

CN603

CN407CN403

CN5003

CN5004

CN5002

CN409

CN5001

Rear shield

I/O terminal board

assembly

CN406CN405

CN520CN504CN503CN510

CN506

CN511

CN501

D board

CN513

CN509

CN502

CN508

CN512

CN402

CN401

2-6

CN408

A board

Page 20

GDM-F500/F500T9

SECTION 3

SAFETY RELATED ADJUSTMENT

When replacing or repairing the shown below table, the

following operational checks must be performed as a

safety precaution against X-rays emissions from the unit.

Part Replaced (])

HV Regulator

Circuit Check

HV Protector

Circuit Check

Beam Current

Protector Circuit

Check

* Confirm one minute later turning on the power.

a) B+ Voltage Check

Check Condition

• Input voltage : 100 ~ 240 VAC

• Input signal : White Cross Hatch at 120.7 kHz

• Beam control : BRT and CONT → MAX

• Standard : 200 ± 3.0 V DC

G Board IC901, T901

• Mounted G board

G Board Q907, Q908, D913,

D916, C923, R920,

R927, R952, T901

• Mounted G board

D Board R011, R1068

• Mounted D board

G Board IC901, IC902, Q907,

Q908, D902, D918,

D919, R923, R928,

R933, R934, R942,

R944, R945, R947,

R948, R951, R952,

T901

• Mounted G board

d) Beam Current Protector Circuit Check-1

(Hardware)

Connect a variable resistor (20 kΩ or more) and an ammeter in series between pin !¡ of T901 (FBT) and –15

V line. Decrease gradually the resistance of the variable resistor from maximum to minimum, and confirm

that the Beam Current Protector Circuit works and TV

Raster disappears. The current must be within the

range shown below.

Check Condition

• Input signal : White Cross Hatch at 120.7 kHz

• Beam control : BRT = 0, CONT = 0

• Standard : 1.49 mA

e) Beam Current Protector Circuit Check-2

(Software)

1) Short between + of C937 and GND.

2) Connect a variable resistor (20 kΩ or more) and an

ammeter in series between pin !¡ of T901 (FBT) and

–15 V line. Decrease gradually the resistance of the

variable resistor from maximum to minimum, and

confirm that the Beam Current Protector Circuit

works and TV Raster disappears. The current must

be within the range shown below.

Check Condition

• Input signal : White Cross Hatch at 120.7 kHz

• Beam control : BRT = 0, CONT = 0

• Standard : 1.59 mA

b) HV Regulator Circuit Check

1) Confirm that the voltage of the + side of C910 on G

board is within the voltage range shown below.

Standard: 8.940 ~ 9.065 V DC

c) HV Protector Circuit Check

1) Confirm that the voltage between cathode of D913

on G board and GND is more than 26.5 V DC.

2) Confirm that the HV protector circuit works and TV

Raster disappears when apply the voltage as shown

below between cathode of D913 and GND using an

external DC power supply.

Check Condition

• Input voltage : 100 ~ 240 VAC

• Input signal : White Cross Hatch at 120.7 kHz

• Beam control : BRT and CONT → MIN

• Standard : Less than 34.20 V DC

3-1

Page 21

SECTION 4

ADJUSTMENTS

GDM-F500/F500T9

Note: Hand degauss

This model has an automatic earth magnetism correction function by using an earth magnetism sensor

and a LCC coil. When using a hand degauss while monitor (LCC coil) is being operated, it sometimes

gets magnetized, and the system may not work properly as a result.

• Landing Rough Adjustment

1. Enter the full white signal. (or the full black dots signal).

2. Adjust the contrast to the maximum.

3. Make the screen monogreen.

Note: Off the outputs from R ch and B ch of SG.

4. Reverse the DY, and adjust coarsely the purity magnet so

that a green raster positions in the center of screen.

5. Adjust the tilt of DY, and fix lightly with a clamp.

Note: “TILT” shall be set at 128.

• Landing Fine Adjustment

1. Put the set inside the Helmholtz coil. (“LCC SW” = “12”)

2. Input the single green signal and set the CONT control to

MAX.

Note: After the W/B adjustment with 9300K, measure an aver-

age of ΣIk when a full white signal is entered in the CONT

MAX/BRT CENT status. Then make adjustment so that

the specified screen can be attained after aging for 2 hours

with Ik equivalent to 30% of the average value.

3. Demagnetize the metal part of the chassis with the hand degausser and coil degausser, and the CRT surface with the

hand degausser.

Input AC 230V to AC IN, turn on and off the power to perform auto degaussing. (Perform auto degaussing by setting

“MON CON REG2”=152. Return to the original value after

use.)

Demagnetize the CRT surface with the hand degausser

again.

Note:

(1) Hand degauss

tion.

This model has an automatic earth magnetism correction

function by using an earth magnetism sensor and a LCC coil.

When using a hand degauss while monitor (LCC coil) is being operated, it sometimes gets magnetized, and the system

may not work properly as a result.

(2) Adjust in a non-magnetic field. BV=45uT.

(3) If adjusting in a magnetic fields, add the shift from the non-

magnetic field in your estimation.

4. Attach the wobbling coil to the designated part of the CRT

neck.

5. Attach the sensor of the landing adjustment unit on the CRT

surface.

6. Adjust the DY position and purity, and the DY tilt, and landing of the center and 4 corners with the landing checker.

• Write terrestrial magnetism sensor reading VX and VY to

“LCC VX” and LCC VY” respectively. Adjust the landing by moving “LCC NS”, “LCC LT”, “LCC LB”, “LCC

RT” and “LCC RB”. However, the register adjustment

must be limited within the following range.

“LCC NS” 128 ± 15

“LCC LT”, “LCC LB”, “LCC RT”, “LCC RB”

After adjustment, set “LCC SW” to “13” and save the service data.

must be used on stand-by or power-off condi-

must be used on stand-by or power-off condition.

128 ± 40

<Specifications>

Adjust so that the green is within

the specification given right.

Adjust target : within ± 1

The red and blue must be within

the specification given right with

respect to the green.

A difference between red and blue

must be within the specification

given right.

* Adjustment and measurement should be made at the points

one inch inside the fluorescent screen.

7. Insert wedges to make the DY neck stand upright without

moving it.

At this time, without shaking the DY, firmly insert the

wedges.

8. Check the landing of each corner, and if it does not satisfy

the specification, adjust the landing of four corners using

“LCC LT“, “LCC LB”, “LCC RT” and “LCC RB”.

However, the register adjustment must be limited within the

following range.

“LCC NS” 128 ± 15

“LCC LT”, “LCC LB”, “LCC RT”, “LCC RB”

After adjustment, save the service data.

If it does not yet satisfy the specification, paste a Disk-Mg

onto the funnel and adjust.

Note:

(1) Do not paste more than two magnets on one corner.

(2) Magnets will be placed in a range 80 ~ 100 mm from the DY

along diagonal lines.

(3) After placing magnets, absolutely hand degauss and check

the results. (Hand degauss must be used on stand-by or

power-off condition.)

9. Remove the sensor and wobbling coil.

10. Switch the signal to R.G.B., and check that each color is

pure.

11. Check that the DY is not tilting, and fix the purity Mg with a

white pen.

4-1

0 ± 3 0 ± 7.5 0 ± 3

0 ± 5 0 ± 5 0 ± 5

0 ± 3 0 ± 7.5 0 ± 3

± 6 ± 6 ± 6

± 6 ± 4 ± 6

± 6 ± 6 ± 6

10 10 10

10 7 10

10 10 10

(µm)

(µm)

(µm)

128 ± 40

Page 22

GDM-F500/F500T9

Connect the communication cable of the computer to the connector located on the D board or US board on the monitor. Run the service

software and then follow the instruction.

IBM AT Computer

as a Jig

1-690-391-211A-1500-819-A

D-sub

(9 Pin [female])

*The parts above ( ) are necessary for DAS adjustment.

mini Din

(8Pin)

1

2

Interface Unit

3

• Convergence Rough Adjustment

(1) Receive an image of the white crosshatch signals (white

lines on black).

(2) Place the protrusions of the 6-fold poles magnet attached to

the CRT neck upon each other. (Fig. 1)

(3) Make rough adjustment of the H and V direction conver-

gence by using 4-fold poles magnet.

TLH correction plate (Put in one side only)

Protrusions

Fig. 1

*

Fig. 3 Fig. 2

YBH

YCH

TLV

60°

XBVXCV

B

* Set so that the protruding parts of

the 2 magnet rings agree with

each other.

TLH

R

XBV

XCV

APH

3-702-691-01

3

Connector Attachment

To BUS CONNECTOR or

4 Pin

4 Pin 4 Pin

• Convergence Specification

Bezel opening

B

A

C

Picture

• White Balance Adjustment Specification

1. 9300K

x=0.283 ± 0.005

y=0.298 ± 0.005

(All White)

2. 6500K

x=0.313 ± 0.005

y=0.329 ± 0.005

(All White)

3. 5000K

x=0.346 ± 0.005

y=0.359 ± 0.005

(All White)

• Vertical and Horizontal Position and Size

Specification

A

b

fH 60kHz 60kHz

A Zone 0.24 mm 0.24 mm

B Zone 0.28 mm 0.32 mm

C Zone 0.32 mm 0.36 mm

TLV

R

R

B

B

R

R B

B

YBHYCH

R

R B

BBR

b

a

a

a 3.2 mm

b 3.2 mm

• Focus adjustment

MODE

B

1, 2, 4, 5

AB388 mm

291 mm

3

364 mm

291 mm

Adjust the focus volume 1 and 2 for the optimum focus.

HDK

Focus 2

Focus 1

4-2

Page 23

5-1. BLOCK DIAGRAMS

SECTION 5

DIAGRAMS

5-1 5-2

Page 24

5-3 5-4

Page 25

OLD MODEL

F500(U/C) : S/N 2,700,001 to 2,701,030

F500(AEP) : S/N 2,800,001 to 2,801,280

()

CN2601

1

USB 7V

2

USB 7V

D

N

FOR

BUS

5

UPSTREAM +5V

6

USB TX

7

USB RX

8

STBY +5V

CN2906

2

STBY +5V

3

RX D

4

TX D

CN2901

1

V BUS1

2

D-

3

D+

CN2902

1

V BUS1

2

D-1

3

D+1

CN2903

1

V BUS2

2

D-2

3

D+2

CN2904

1

V BUS3

2

D-3

3

D+3

CN2905

1

V BUS4

2

D-4

3

D+4

NEW MODEL

F500(U/C) : S/N 2,701,031 and later

F500(AEP) : S/N 2,801,281 and later

(

F500T9 : All units

(USB CONTROL)

US

DD+

1

2

5

6

7

8

2

3

4

CN2901

1

2

3

1

T2601

2

1

IC2601

5V REG

X2901

+5V

3

IC2902

RESET

+5V

VC

I

O

3

2

IC2606

STBY

OVER C SW

Q2606

3

OVR1

1

OVR2

26

OVR3

19

OVR4

5

DM0

4

DP0

23

XTAL1

22

XTAL2

18

RST

D

N

FOR

BUS

CN2601

USB 7V

USB 7V

UPSTREAM +5V

USB TX

USB RX

STBY +5V

CN2906

STBY +5V

RX D

TX D

BUS1

VCC

+5V

IC2901

USB CONTROL

)

VOLT SW

Q2605

POWER SW

Q2607

POWER1

POWER2

POWER3

POWER4

DM1

DP1

DM2

DP2

DM3

DP3

DM4

DP4

CN2902

CN2903

CN2904

CN2905

1

2

3

1

2

3

1

2

3

1

2

3

V BUS1

D-1

D+1

V BUS2

D-2

D+2

V BUS3

D-3

D+3

V BUS4

D-4

D+4

I

O

OVER C DET

Q2601

OVER C DET

Q2602

OVER C DET

Q2603

OVER C DET

Q2604

2

28

25

20

8

7

12

11

15

14

17

16

IC2602

REG

I

IC2603

REG

I

IC2604

REG

I

IC2605

REG

D2605

O

O

O

D2606

D2607

D2608

B-SS3447<U/C>-BD3-05

5-2. FRAME SCHEMATIC DIAGRAM

123456789

FV

MV

FC

L

C.SYNC_1

:S-MICRO

GND

H CONV

12345

12345

GND

H CONV

:S-MICRO

ROTATION

H.STA

V.STA

LCC-LT

LCC-LB

LCC-RT

LCC-RB

LCC-NS

FASTEN

V.DY

V.DY

ROTATION+

ROTATION-

H STATH STAT+

V STATV STAT+

H.DY

6

5

4

3

2

1

1

GND

2

V.DY C

3

V.DY H

4

NC

5

H.DY C

6

H.DY C

7

NC

8

NC

9

H.DY H

10

H.DY H

1

ROTATION-

2

ROTATION+

1

LCC-LT(+)

2

LCC-LT(-)

3

LCC-LB(+)

4

LCC-LB(-)

5

LCC-RT(+)

6

LCC-RT(-)

7

LCC-RB(+)

8

LCC-RB(-)

9

LCC-NS(+)

10

LCC-NS(-)

FOCUS

CN508

10P

:VH

CN509 CN520 CN512 CN501

2P

WHT

:S-MICRO

CN5003

10P

WHT

:S-MICRO

CONNECTOR PANEL

5BNC

5

10

12

3

4

9

6

8

7

1112131415

HD15

123

D GND

LCC_RB

LCC_RT

LCC_LB

LCC_RB

LCC_RT

LCC_LB

RXD

STBY+5V

CN505

4P

WHT

LCC_LT

LCC_NS

LCC_LT

LCC_NS

4

TXD

:S-MICRO

10

11

GND

V.SYNC_1

C.SYNC_2

V.SYNC_2

DDC_SDA_1

HOST+5V_1

DDC_SCL_1

DDC_SDA_2

HOST+5V_2

CN511 CN901

11P

WHT

:S-MICRO

6P

WHT

VY

VX

GND

V CONV

6

6

VY

VX

GND

V CONV

CN5002

6P

WHT

DDC_SCL_2

9P

WHT

:S-MICRO

GND

GND

+15V

-15V

123456789

123456789

GND

GND

+15V

-15V

D

CN5001

9P

WHT

123456789

CLP

C.BLK

SYNC_DET

SYNC_ON_G

CN506

10P

WHT

:S-MICRO

µ

-COM,

GND

GND

VIDEO

10

KT_DRI

HSTAT_H/V_GAIN

HSTAT_V_GAIN

DEFLECTION

10P

YEL

:S-MICRO

LED0

LED1

LED2

LED3

1W_SW

1W_+5V

123456789

123456789

LED0

LED1

LED2

LED3

1W_SW

1W_+5V

CN801

12P

:XA

KEY_DET

KEY_DET

V.STAT,H.STAT,LCC,

GEO MAGNETIC SENSOR

CN5004

4P

WHT

:S-MICRO

H1

123456789

ASC_SW

STBY+5V

INPUT_SW

HEATER_SW

KT_DRI_RESET

CN503

12P

BLK

:S-MICRO

D GND

STBY+5V

ENV_DRI

10

TO SHIELD

101112

GND

GND

D GND

STBY+5V

ENV_DRI

1

LED2

2

LED3

3

KEY_DET_SUB

4

5

STBY+5V

6

D GND

CN802 CN803

6P

WHT-L

:S-MICRO

CLK

MOSI

OSD_SEL

101112

HFBP

VRET

DAC_SEL

CN514

#

:S-MICRO

LUMI

123

1

2

3

4

5

6

NC

GND

STBY+5V

KEY_DETKEY_DET

KEY_DET_SUB

STBY+5V

:S-MICRO

(USER CONTROL)

V STAT+

V STAT-

H STAT+

H STAT-

123

4

1

R IN 1

CN401

G IN 1

B IN 1

R IN 2

G IN 2