Sony TRINITRON CDP-4402 Service Manual

SPECIFICATIONS

F99

Picture tube

Video image area

Resolution

Standard image

area

Input signal

Video

Sync

0.24 mm (center) -0.25mm (edge)

aperture grill pitch

19 inches measured diagonally

90-degree deflection

(18" maximum viewing image)

Approx. 364.8 X 273.6 mm (w/h)

(14

3/8

x 10

7/8

inches)

Horizontal: Max. 1600 dots

Vertical: Max. 1200 lines

Approx. 352 x 264 mm (w/h)

(13

7/8

x 10

1/2

inches)

Analog RGB (75 ohms typical)

0.7 Vp-p, Positive

Separate Horizontal and Vertical

TTL level, Positive or Negative

Video Composite (Sync on Green)

0.3 Vp-p

Power Consumption

Maximum

Nominal

Deflection frequency

AC input voltage/current

Dimensions

Mass

CHASSIS

140 W, 478 BTU/h

100 W, 341BTU/h

Horizontal: 30 to 107 KHz (automatic)

Vertical: 48 to120 Hz (automatic)

220 to 240V, 50/60Hz,

1.0A (RMS) at 240 VAC

449 x 463 x 463 mm (w/h/d)

(17

2/3

x 18

7/10

x 18

1/5

inches)

Approx. 26.0 kg (57 lb 5 oz)

SERVICE MANUAL

Design and specifications are subject to change without notice.

CPD-4402

TRINITRON® COLOR MONITOR

CPD-4402

AEP Model

Chassis No. SCC-L30N-A

CPD-4402

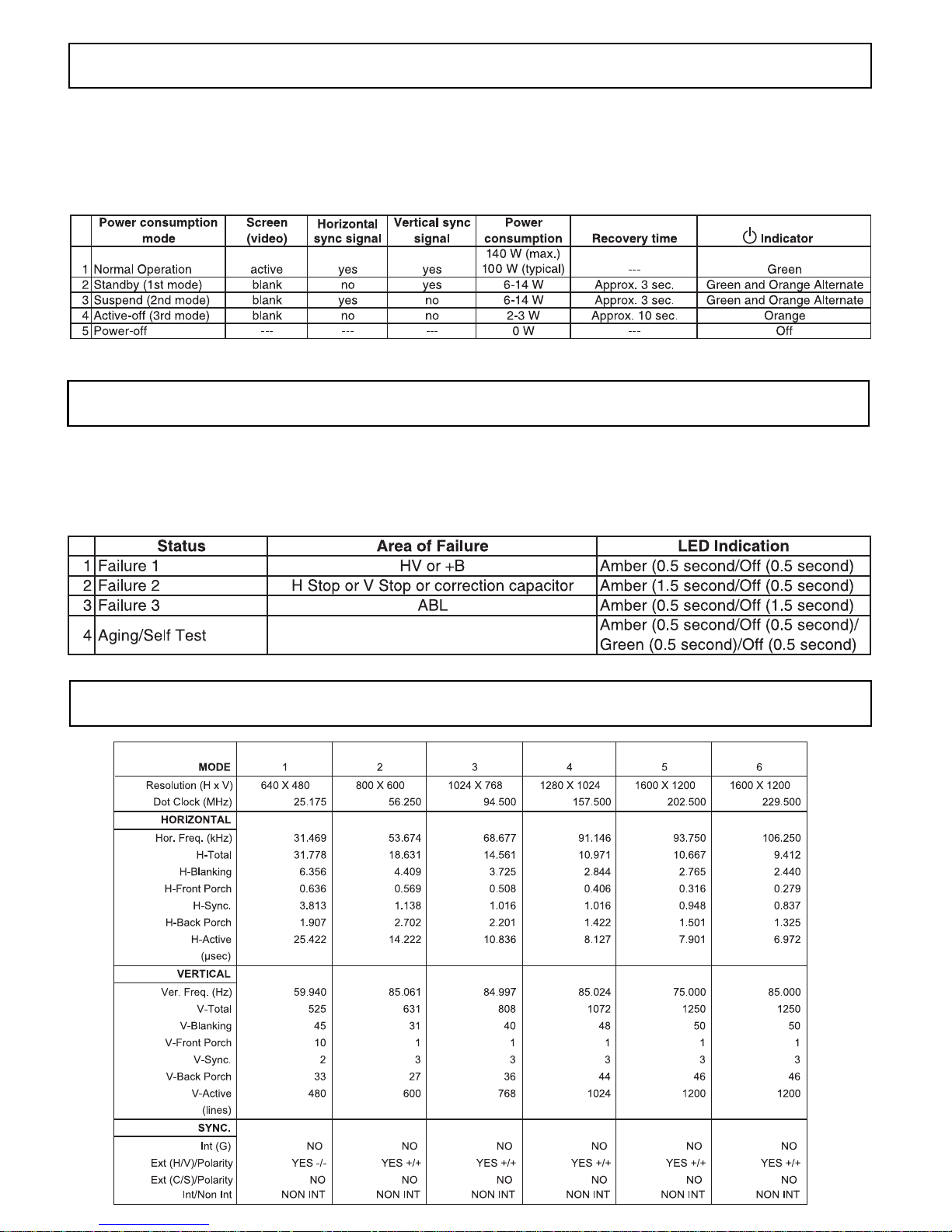

If you have VESA's DPMS compliance display card or software installed in your PC, the monitor can automatically reduce

its power consumption when not in use. If input from keyboard, mouse, or other input devices is detected, the monitor

will automatically "wake up." The following table shows the power consumption and signaling of this automatic power

saving feature.

When a failure occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

SELF DIAGNOSTIC FUNCTION

POWER MANAGEMENT MODES

TIMING SPECIFICA TIONS

TABLE OF CONTENTS

Section Title Page

SAFETY CHECK-OUT .......................................................................................................................... 4

1. DISASSEMBL Y

1-1. Cabinet/Shield Removal ............................................................................................ 5

1-2. Service Position .......................................................................................................... 5

1-3. D, A, H and N Board Removal .................................................................................... 5

1-4. Picture Tube Removal................................................................................................ 6

2. SAFETY RELA TED ADJUSTMENTS

2-1. HV Regulator Check................................................................................................... 7

2-2. HV Protector Check .................................................................................................... 7

2-3. Beam Current Protector Check (Software Logic)...................................................... 7

2-4. B± Maximum Check.................................................................................................... 7

3. ADJUSTMENTS

3-1. Landing Rough Adjustment ....................................................................................... 8

3-2. Landing Fine Adjustment ........................................................................................... 8

3-3. Convergence Rough Adjustment ............................................................................... 8

3-4. Convergence Fine Adjustment ................................................................................... 8

3-5. Zero Positions of Ring Magnets ................................................................................ 9

3-6. White Balance Adjustment Specification ................................................................... 9

3-7. Vertical and Horizontal Position and Size Specification............................................ 9

3-8. Convergence Specification......................................................................................... 9

3-9. Focus Adjustment ....................................................................................................... 9

4. DIAGRAMS

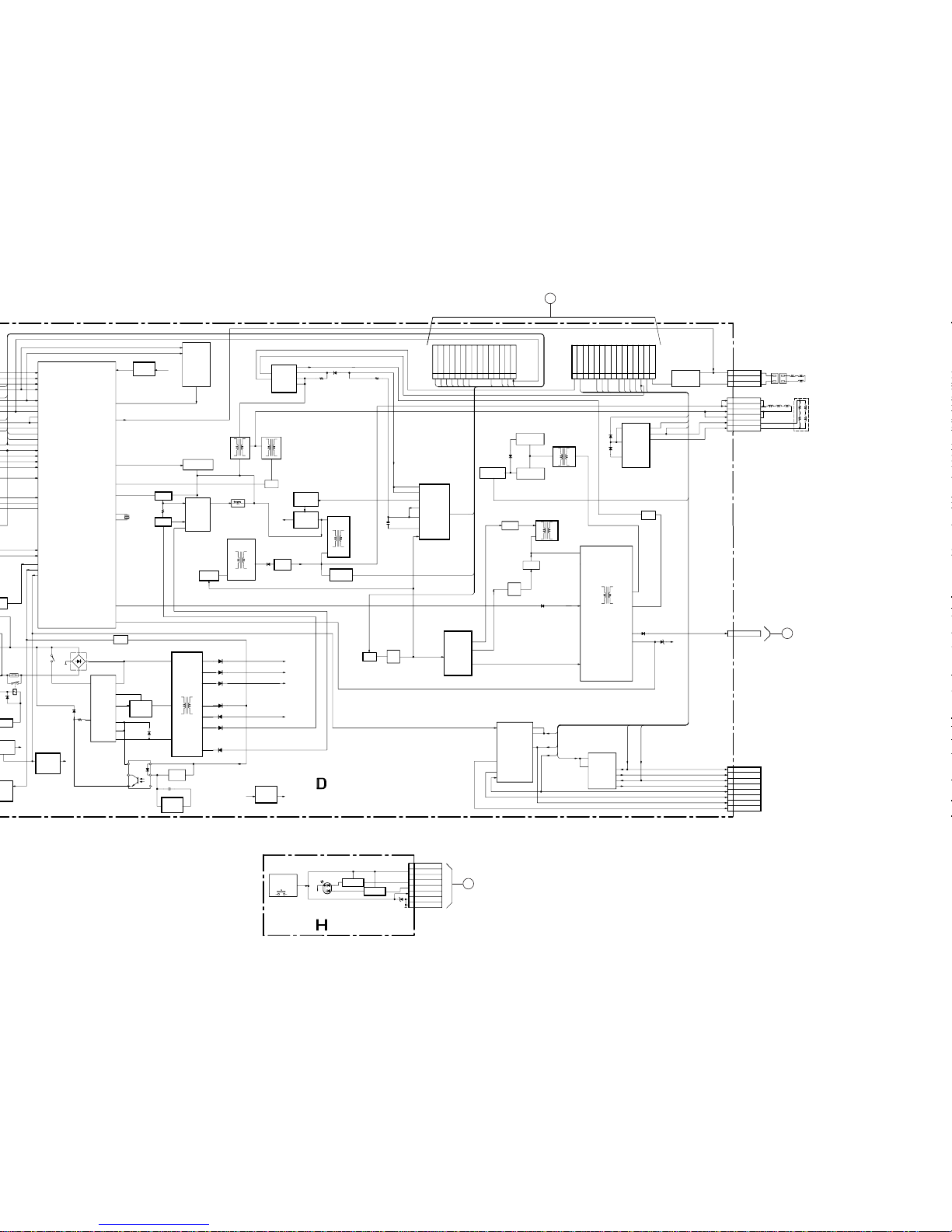

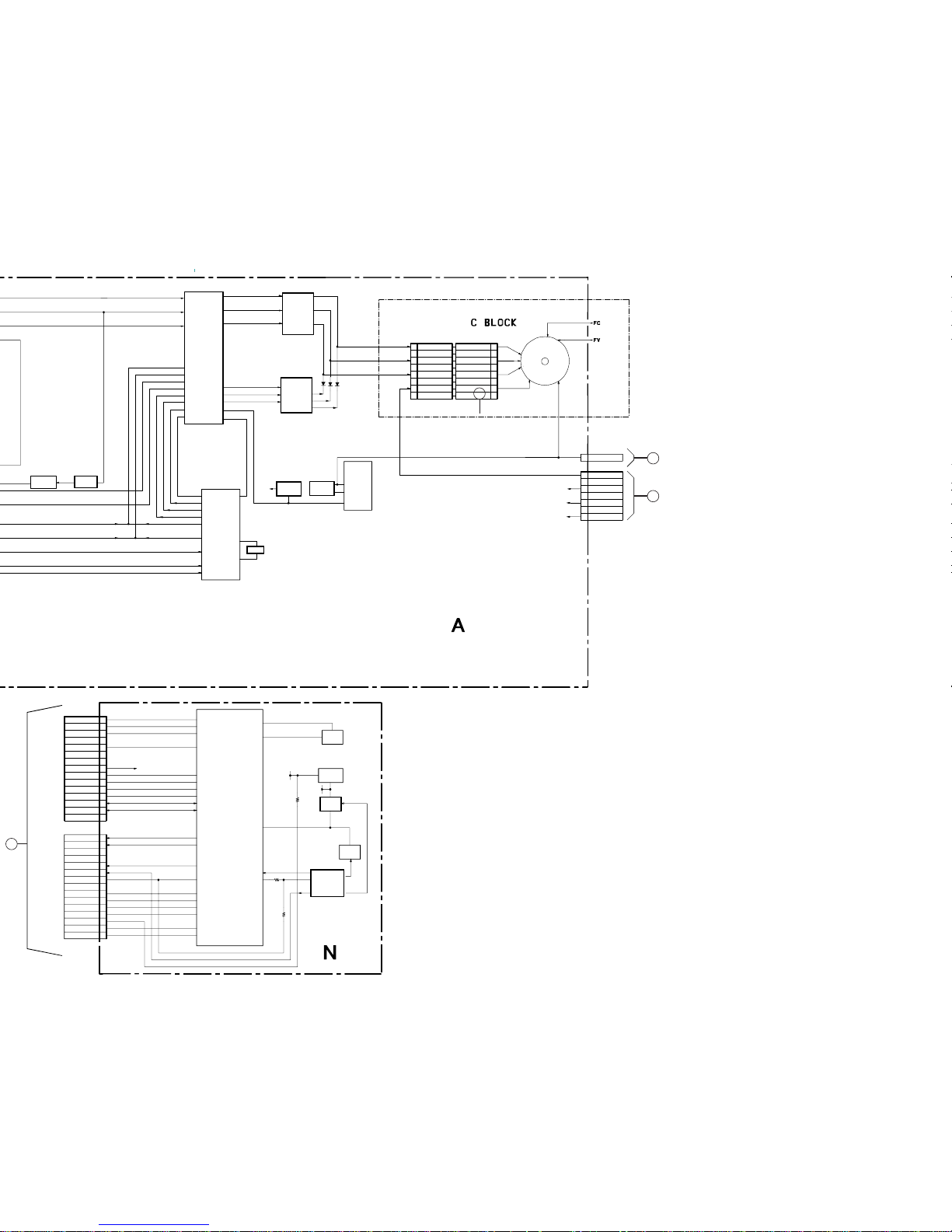

4-1. Block Diagram .......................................................................................................... 10

4-2. Circuit Boards Location ............................................................................................ 12

4-3. Schematic Diagrams and Printed Wiring Boards ................................................... 1 2

• D Board - Schematic Diagram ............................................................................. 1 3

• A Board - Schematic Diagram .............................................................................. 19

• H Board - Schematic Diagram ............................................................................. 2 1

• N Board - Schematic Diagram ............................................................................. 2 2

4-4. Semiconductors ....................................................................................................... 24

5. EXPLODED VIEWS

5-1. Chassis .................................................................................................................... 26

5-2. Packaging Materials ................................................................................................. 27

6. ELECTRICAL PARTS LIST ......................................................................................................... 28

SAFETY CHECK-OUT

After correcting the original service problem, perform

the following safety checks before releasing the set to

the customer:

1. Check the area of your repair for unsoldered or poorlysoldered connections. Check the entire board surface

for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires

are “pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps, and mounting hardware have been replaced.

Be absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous

repair. Point them out to the customer and

recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out to the

customer and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord

to the customer.

7. Check the B+ and HV to see if they are specified

values. Make sure your instruments are accurate; be

suspicious of your HV meter if sets always have low

HV.

8. Check the antenna terminals, metal trim, “metallized"

knobs, screws, and all other exposed metal parts for

AC Leakage. Check leakage as follows.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part

having a return to chassis, must not exceed 0.5 mA (500

microampere). Leakage current can be measured by any one

of three methods.

1. A commercial leakage tester, such as the Simpson 229

or RCA WT-540A. Follow the manufacturers' instructions

to use these instructions.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of

a VOM or battery-operated AC voltmeter. The "limit"

indication is 0.75 V, so analog meters must have an

accurate low voltage scale. The Simpson's 250 and Sanwa

SH-63TRD are examples of passive VOMs that are

suitable. Nearly all battery operated digital multimeters

that have a 2V AC range are suitable. (See Figure A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICH THE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELA TED COMPONENT W ARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ON THE

SCHEMA TIC DIAGRAMS, EXPLODED VIEWS AND IN THE P ARTS

LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE

CRITICAL FOR SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL

COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

Figure A

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA BOBINE DE

DEMAGNETISATION EST ENLEVEE.

ATTENTION AUX COMPOSANTS RELA TIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES P AR UNE TRAME ET P AR UNE

MARQUE SUR LES SCHEMAS DE PRINCIPE, LES VUES

EXPLOSEES ET LES LISTES DE PIECES SONT D'UNE

IMPORTANCE CRITIQUE POUR LA SECURITE DU

FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST

INDIQUE DANS LE PRESENT MANUEL OU DANS DES

SUPPLEMENTS PUBLIES PAR SONY. LES REGLAGES DE

CIRCUIT DONT L'IMPORTANCE EST CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS

LE PRESENT MANUEL. SUIVRE CES PROCEDURES LORS DE

CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU

LORSQU'UN MAUVAIS FONTIONNEMENT SUSPECTE.

CPD-4402

1

2

A board

D board

rotate 180º

1-3. D, A, H and N BOARD REMOVAL

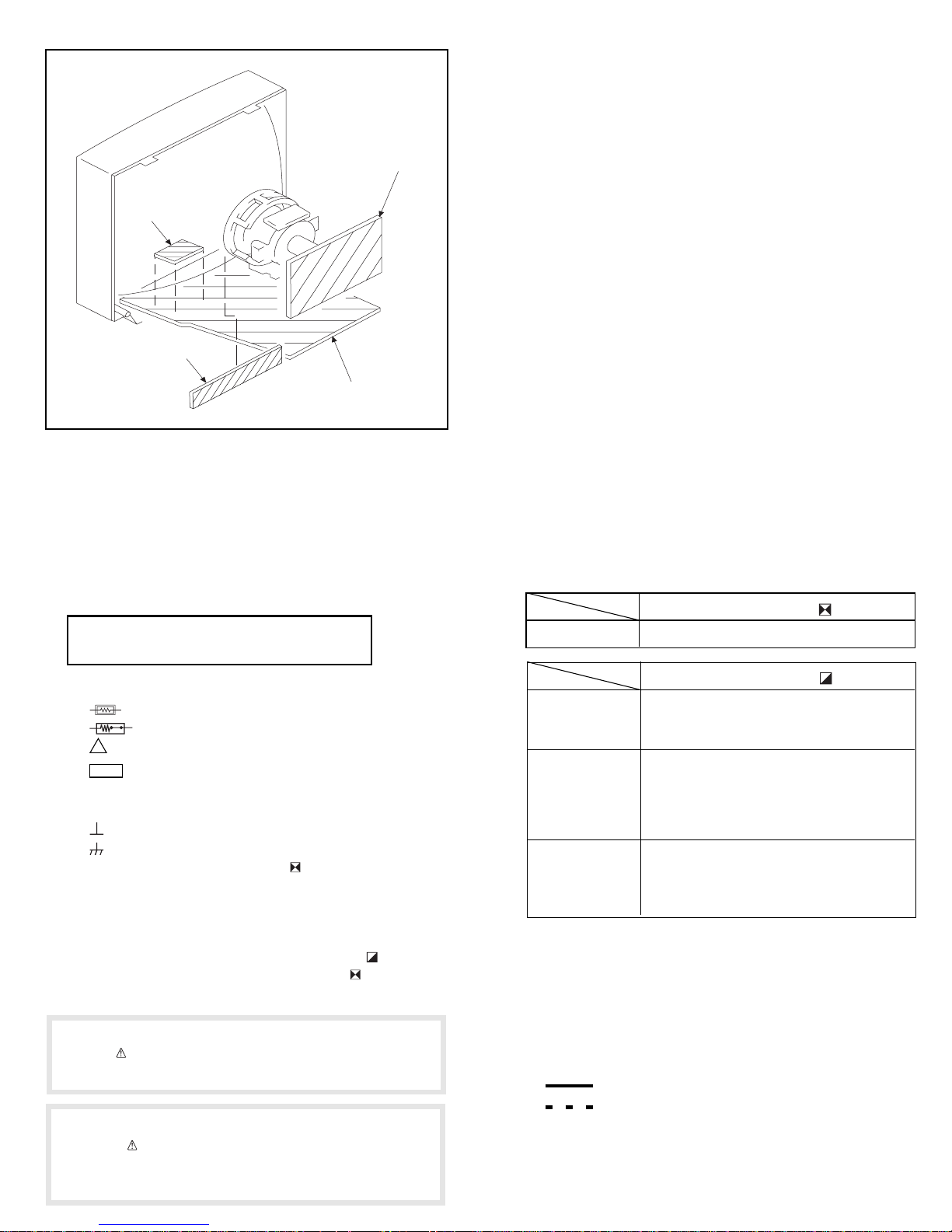

1-1. CABINET/SHIELD REMOV AL 1-2. SERVICE POSITION

SECTION 1

DISASSEMBLY

1 When the D board is placed in service position, the Safety Earth Wire

(black wire) is disconnected.

2 After service is completed and the D board reinstalled, the Safety Earth

Wire must be reattached to the chassis. This must be confirmed before

any subsequent procedures are attempted.

To remove the rear cover of the unit, press in and unsnap the claw on

the right side of the unit, then press in and unsnap the right claw at the

top of the unit. Repeat this with the claw on the left side and top left

of the unit and remove.

Video shield

Two claws

Three screws

(+BVTT 4 x 8)

Two screws

(+ BVTP 4 x 16)

1

2

6

7

5

4

3

2

Two claws

Four screws

(+ BVTP 4 x 8)

Top cover

Bezel assembly

Bezel assembly

Cabinet

Cabinet

Push in the tip of a screwdriver

about 5mm to unlock the claw.

Cabinet

Three screws

(+BVTT 4 x 8)

8

Three screws

(+BVTT 4 x 8)

8

9

Side cover

9

Side cover

Cable bracket

D board

Five screws

(BVTP 3 x 8)

2

6

4

8

Holder

5

A board

N board

10

H board

11

One screw

(BVTT 4 x 8)

3

Three screws

(BVTT 4 x 8)

1

Two screws

(BVTT 4 x 8)

9

One screw

(BVTT 4 x 8)

7

One screw

(BVTT 4 x 8)

7

CPD-4402

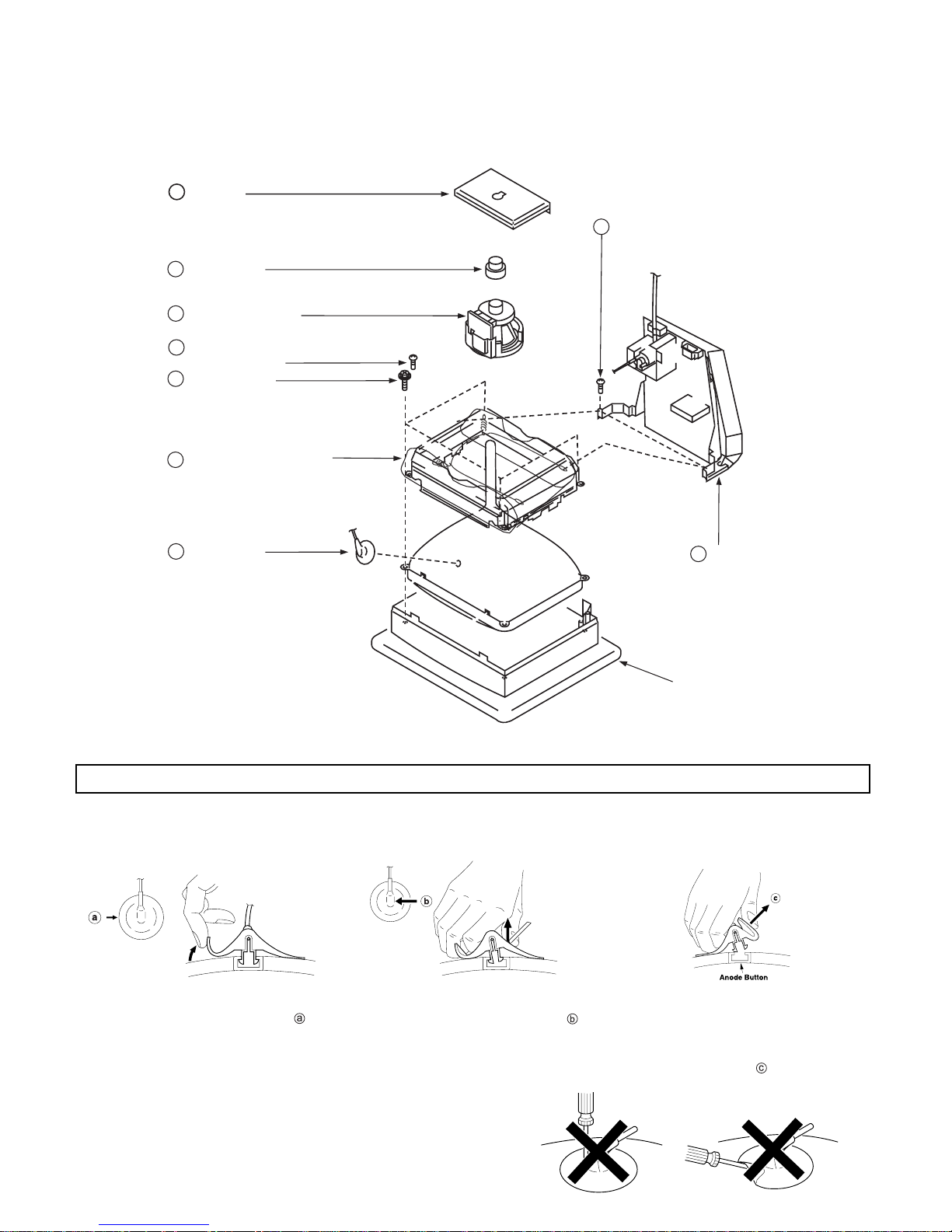

1-4. PICTURE TUBE REMOVAL

HOW TO HANDLE AN ANODE-CAP

1. Do not use sharp objects which may cause damage to the surface

of the anode-cap.

2. Do not squeeze the rubber covering too hard to avoid damaging the

anode-cap. A material fitting called a shatter-hook terminal is built into

the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the

shatter-hook terminal to protrude and damage the rubber.

REMOVAL OF THE ANODE-CAP

WARNING: Short circuit the anode of the picture tube and the anode-cap to the metal chassis, CRT shield or carbon painted on the

CRT, after removing the anode.

REMOVAL PROCEDURES

A board

2

Neck ass'y

3

Deflection yoke

4

Four screws

(Tapping screw 5)

6

Anode-cap

1

Stand

ass'y

(D board)

8

Two screws

(BVTP 4 x 16)

7

Cushion

Tension spring

Demagnetization coil

Picture tube shield

9

Two screws

(BVTP 4 x 16)

5

2. Use your thumb to pull the rubber cap firmly

in the direction indicated by arrow .

1. Turn up one side of the rubber cap in

the direction indicated by arrow .

3. When one side of the rubber cap

separates from the anode button, the

anode-cap can be removed by turning

the rubber cap and pulling it in the

direction of arrow .

SECTION 2

SAFETY RELA TED ADJUSTMENT

When replacing parts shown in the table below, the following

operational checks must be performed as a safety precaution

against X-ray emissions from the unit.

Part Replaced ( )

HV ADJ

HV Protector T901 (FBT), R917, R918, R923, R920,

Circuit R919, R1004, C920, D91 1, D912

Beam Current R933, R932, R921, R1006, D915,

Protector Circuit D917, IC901, T901 (FBT)

HV Regulator T901 (FBT), IC901, R924, R925,

Circuit RV901

Allow the unit to warm-up for one minute prior to checking

the following conditions:

RV901

Part Replaced ( )

2-1. HV Regulator Check

1) Input white cross hatch signal. (fH = 106.3 kHz)

2) CONT and BRT Control normal condition.

3) Input voltage: 120 ± 2 VAC

4) Confirm that the voltage is within the voltage range shown

below .

Standard voltage: 27.0KV ± 0.2KV

5) When replacing components identified by

sure to recheck the High Voltage.

6) Verify the High V oltage as shown above (27.0KV

+0.2KV) is within specification. If not, RV904 on D board.

7) After adjusting the High Voltage within specification, put

the RV cover on RV901 as shown below and apply

sufficient amount of RTV around RV901.

, make

2-2. HV Protector Check

1) Confirm the voltage more than 15.0 VDC between D912

cathode and GND on D Board.

2) Using an external DC power supply, apply the voltage

shown below between cathode of D915 on D Board and

GND.

Confirm that the HV protector circuit (Hold down) works

and CRT screen disappears when applying the voltage

protector as shown below.

Standard DC Voltage: 21.1 +0.00 / - 0.05 VDC

Check Condition

• Input voltage : 120 ± 2 VAC

• Input signal : (fH = 31.4 kHz), Cross Hatch

• CONT and BRT Control: Normal Condition

2-3. Beam Current Protector Check

(Software Logic)

1) Using an external current source, apply 1.68mA from pin

of T901 (FBT) to GND on D Board. Confirm that the

software logic beam current protector works and that the

CRT screen disappears.

Check Condition

• Input voltage : 120 ± 2 VAC

• Input signal : (fH = 31.4 kHz), Cross Hatch

• CONT and BRT Control: Normal Condition

2-4. B± Maximum Check

1) Input white cross hatch (fH = 106.3 kHz) signal.

2) Beam control: Normal condition

3) Input voltage: 100 - 120 VAC

Note: Use NF power supply or make sure that

distortion factor is 3% or less.

4) Confirm that the voltage is within the voltage range

shown below.

Standard voltage: 195.0 -205.0 VDC

RV901

SECTION 3

a

b

ADJUSTMENTS

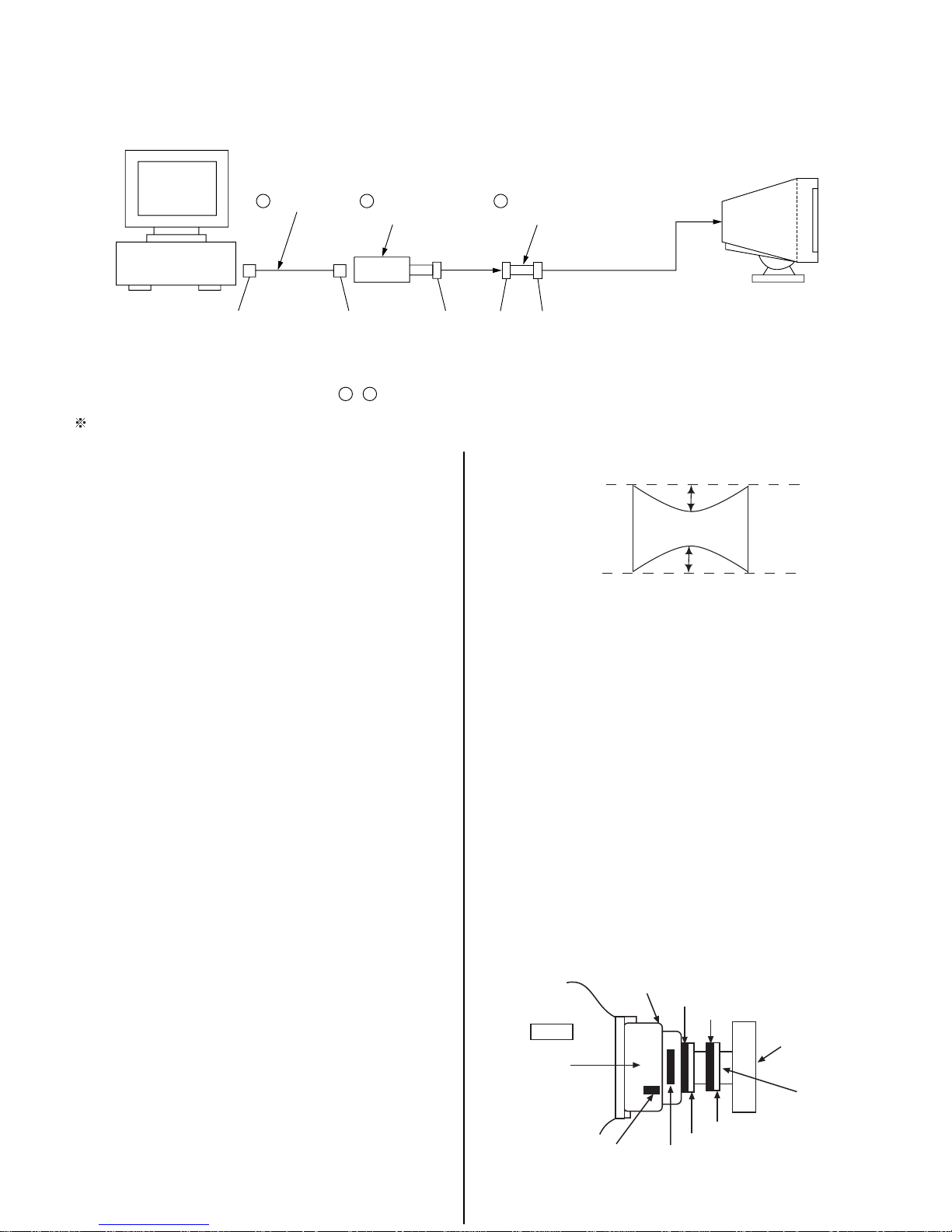

Connect the communication cable of the connector located on the D board on the monitor. Run the service software and then follow

these instructions.

IBM AT Computer

as a Jig

1-690-391-21

1

D-sub

(9 Pin [female])

*The parts above ( ~ ) are necessary for DAS adjustment.

mini Din

(8Pin)

1

A-1500-819-A

2

Interface Unit

3

4 Pin

3

4 Pin 4 Pin

Allow a 30 minute warm-up period prior to making the following adjustments:

3-1. Landing Rough Adjustment

1. Enter the full white signal.

2. Adjust the contrast to the maximum.

3. Input full green signal.

(Note: Turn off the outputs from R ch and B ch of SG)

4. Move the DY backward and adjust the purity magnet

coarsely so that a green raster positions in the center of

screen.

5. Moving the DY forward, adjust so that an entire screen

becomes pure green.

6. Adjust DY Tilt, use TLV of DY for this adjustment. Fix

the Register "TILT" to 0.

7. Lightly tighten the DY screw.

14. If landing does not meet specifications, correct with a

15. Perform auto-degauss.

16. Remove sensor and wobbling coil.

17. Confirm that there is no DY tilt. Affix purity magnet on

3-702-691-01

Connector Attachment

To BUS CONNECTOR

disc magnet.

DY using white paint.

3-2. Landing Fine Adjustment

1. Place the set in the Helmholtz coil.

2. Set TLH plate to the zero position.

3. Adjust Purity Magnet on the Neck Assembly to zero

position and secure it with white pin.

4. Set "VPIN SAW TOP" and "VPIN SAW BTM" to zero

position.

5. Display a plain green pattern.

6. Degauss CRT and shield with hand-degausser.

7. Perform auto-degauss.

8. Attach a wobbling coil to the specified position of CRT.

9. Attach a landing adjuster sensor on the CRT.

10. Using a landing checker, adjust the DY position, purity,

tilt of DY.

11. Tighten the DY screw.

Clamping torque: 22 ± 2 kg.cm (2.2 ± 0.2 N.m)

12. Perform auto-degauss.

13. Adjust top and bottom pin pitching DY by up and down

with two wedges so that (a) is equal to (b)(see the figure

at right). Also, leave the yaw of DY to the physical

center position with another two wedges.

Fasten wedges so that DY does not move.

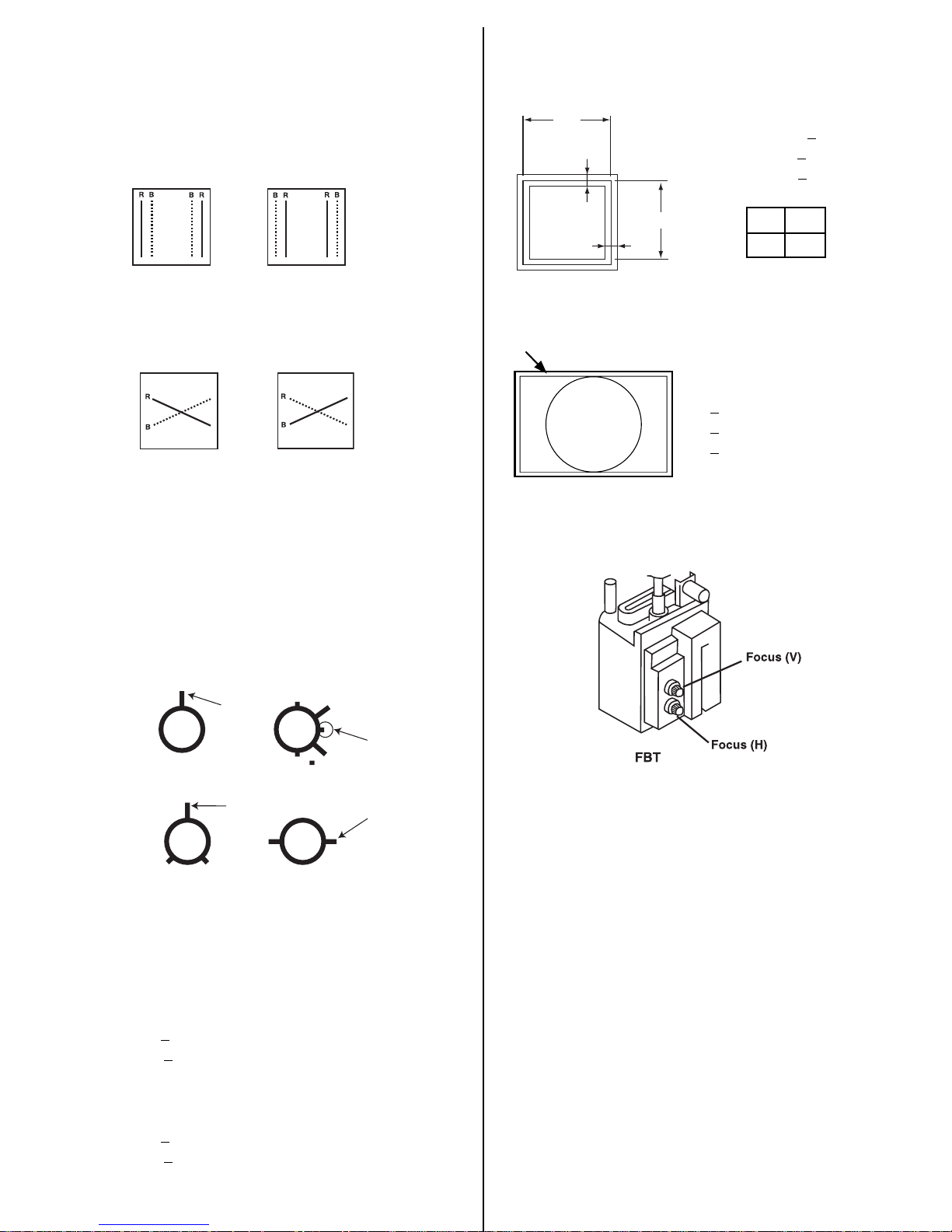

3-3. Convergence Rough Adjustment

1. Enter the white crosshatch signal.

2. Roughly adjust the H. STAT and V. STAT with a

four-pole magnet.

3. Roughly adjust HMC and VMC with a six-pole magnet.

3-4. Convergence Fine Adjustment

1. Display crosshatch pattern with R and B.

2. Adjust H. STAT and V. STAT with 4-pole magnet.

(Do not adjust H.STAT and V.STAT with resistor.)

TLV VR (Unused)

CRT

DY

XCV Core

2 Pole

6 Pole Mg

A Board

Neck Assy

2 Pole (Unused)

4 Pole Mg

TLH Plate

CPD-4402

A

B

b

b

a

a

3. Display white crosshatch pattern.

4. Adjust HMC and VMC with 6-pole magnet.

5. Display crosshatch pattern with R and B.

6. Adjust H.STAT and V.STAT with 4-pole magnet.

7. Fine adjust H. STAT and V. STAT with use register

'HSTAT" and "VSTAT" in the range of 0 ± 10.

8. Adjust H.TILT with TLH plate.

or

Move of THL Plate

9. Adjust XCV with XCV core.

or

Move of XCV Volume

3-7. Vertical and Horizontal Position and

Size Specification

fH < 60 KHz

2.4 mm

2.4 mm

fH > 60 KHz

a

< 2.0 mm

b

< 2.4 mm

A B

264 352

3-8. Convergence Specification

C

A

Horizontal and Vertical

B

Prime Mode

A

< 0.25 mm

B

< 0.30 mm

C

< 0.35 mm

Other Mode

0.30 mm

0.35 mm

0.40 mm

10. Repeat steps 2-8 to optimize condition of whole screen.

11. Affix 4-pole magnet, 6-pole magnet and TLH plate and

XCV core with white paint.

3-5. Zero Positions of Ring Magnets

are Indicated by Arrows

[2pole magnet on DY] [4pole magnet]

[2pole magnet on Neck Assy][6pole magnet]

3-6. White Balance Adjustment

Specification

3-9. Focus Adjustment

Adjust focus (V) and focus (H) for optimum focus.

1. 9300K

x=0.283

y=0.298

2. 5000K

x=0.346

y=0.359

(All White)

(All White)

+0.015

+0.015

+0.015

+0.015

CPD-4402

— 10 —

1

2

3

4

5

6

1

2

43

5

6

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

2

3

4

5

6

7

8

1

2

3

11

G

R

D2001

X1001

IC607

CN2001

CN701

CN510

CN501

CN702

CN1005CN1006

PHOTOCOUPLER

CONTROL

3P

WHT

:S-MICRO

CY4-

CY3-

CY3+

CY2-

CY2+

CY1-

CY1+

CY4+

ROTATION-

ROTATION+

NC

1

237

6

5

G

N

D

H

F

B

P

H

S

H

A

P

E

H

D

O

U

T

N

C

C

B

L

A

N

K

+

5

V

-

2

G

N

D

H

S

Y

N

C

O

V

S

Y

N

C

O

P

O

C

P

L

L

L

O

C

K

I

I

C

D

A

T

A

I

I

C

C

L

K

D

S

P

R

E

S

E

T

O

OSCOUT

GND

GND

GND

KEY SCAN

LED1

LED2

GND

+5V

INPUT SEL

(FUNCTION CTRL)

IC1001

CPU

IC1003

RESET

IC1005

EPROM

H SIZE

ERROR

AMP

IC503

H CENTER

IC502

AMP

IC603

CONTROL

SW REG

IC605

REG

HEATER

12V

REG

IC608

ERROR

AMP

5V REG

IC609

STBY

IC702

D CONV OUT

IC701

S CONV OUT

IC901

DEFLECTION

CONTROL

IC501

ROTATION

IC703

V OUT

IC401

H DY+

H DY+

H DY-

H DY-

V DY-

V DY+

G

N

D

G

N

D

N

C

V

S

A

W

N

D

C

C

2

V

F

B

P

V

.

D

F

H

.

D

F

Y

D

C

R

E

F

D

C

X

D

C

D

.

T

I

L

T

X

S

C

Y

S

C

D

A

C

R

E

F

2

4

1

V FBP

V SAWN

DCC2

4

5

2

H.DF

6

3

7

T701

Q701

H DEF OUT

Q703,Q705

H DEF OUT

Q702,Q704

BUFFER

Q706

HV REG

Q901

HV OUT

Q902

H FBP

HD OUT

H

S

H

A

P

E

V DEF

T901

T902

HV

OUT

Q903,

Q904

1 KV

9

7

1

3

X

S

C

Y

S

C

IOUTA

INA-

INA+

INB+

INB-

IOUTB

4

6

DAC REF

REF DC

11

5

6

1

3

4

2

OUT B(Y)

OUT A(X)

-IN A(X)

STBY

-IN B(Y)

+IN A(X)

YDC

XDC

-IN B(Y)

FUNCTION

SWITCH

14

SW

Q501

11

3

5

PWMOUT

HVD

HDIN

Q502,

Q503

H

DRIVE

PWM OUT

6

7

9

18

11

10

14

3

REFIN

ERRIN

ERROUT

MIXOUT

MIX-

HDIN

VREG9

PWMOUT

S-CAPCHANGE

Q511-516

DRIVE

Q510

T503

T504

Q505

Q506

Q507

H OUT

T502

H SIZE

REG OUT

Q508,Q509

BUFFER

H RTRC

4

Q504

H DRIVE

T501

L503

Q519

Q517

2

1

4

2

3

45

44

SW

BUFFER

46 TO 50, 53

54

9

OUT

3

IN

5

6

SDA

SCL

7

WC

P6.7/SCLD

P6.6/SDAD

P3.7/HSYNCI2

P6.0/SDAI

P6.1/SCLI

VSYNCI2/INTO/P5.7

P5.0/HFBACK

WDOUT/INT2/P5.3

VSYNCO/P5.2

HSYNCO

AIN6/P6.3

WDIN/INT1/P5.5

INT3/P5.4

PWM6/P4.6

CLAMPOUT/MOIRE/P5.6

CSYNCI/P5.1

VSYNCI1

HSYNCI1

AIN3/P8.5

P8.6

P8.7

OSCIN

PWM3/P4.3

PWM5/P4.5

PWM4/P4.4

P9.1

RESET

36

37

34

35

33

27

25

32

21

1

22

20

30

28

15

51

52

26

18

23

24

7

8

5

16

17

39

38

SW

Q606

P3.6/SIN

P3.5/SOUT

PWM2/P4.2

INTCLK/P9.0

PWMN0/P4.0

AIN5/P6.4

AIN4/P6.5

T602

-15V

15V

80V

200V

12V

STBY

5V

PROT

Q609

1

3

Q605

SW REG

OUT

13

6

7

4

5

114

9

DEM

VAUX

DS

DRIVER

ISENSE

VCTRL

OOB

VIN

AC-RECT

D601

4

1

1

SW

Q607

BUFFER

BUFFER

Q2001

Q2002

(DEFLECTION)

(CONVERGENCE)

(POWER)

FBT

12V

200V

+STBY5V

5V-2

12V

SECTION 4

DIAGRAMS

G

A

F

CPD-4402

— 11 —

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

CN315

CN316

CN305

CN801

CN802

CN301

KB

GND

KG

GND

KR

GND

HEATER

GND

KB

GND

KG

GND

KR

GND

HEATER

GND

+12V

H1

GND

+80V

NC

GND

6

7

5

+200V

OUT

+

-

HSHAPE

HFBP

HD OUT

NC

CBLANK

D.GND

D.GND

+5V-2

PLL LOCK

POC

VSYNCO

HSYNCO

IICDATA

IICCLK

DSP RESET

V.DF

H.DF

A.GND

A.GND

VFBP

VSAWN

DCC2

NC

XDC

REFDC

YDC

YSC

DAC REF

XSC

D.TILT

TO D.BOARD

TO D.BOARD

CN1005

CN1006

(DSP)

48

47

46

44

40

42

64

58

H-OUT

FBP-IN

POC-OUT

BLK

H-IN

LOCK-DET

SDA

SCL

27

25

32

E/W

BUFFER

Q805

TILT

VDF1

HDF1

V-FBP

57

OUT

1

BUFFER

13

3

7

5

2

86

7

8

61

60

59

63

1

10

TEST19

VSAWN

39

DCC2

XDC

DCC

YDC

XSC

YSC

VDF2

Q804

BUFFER

Q801

PC1-FIL

V-IN

20

PC2-FIL

3.3V

5V

IN

OUT

OUT

+

OUT

+

IC801

DSP

IC803

V SAW

IC802

REG

BUFFER

Q002

BUFFER

Q003

1

3

4

5

6

7

8

17

16

15

14

Q006

Q001

X001

11

12

FBLK

ROUT

GOUT

BOUT

SDA

SCL

HFLY

VSYNC

HSYNC

XTALOUT

XTALIN

AV

BUFFER

G2 AMP

OSD

IC003

CONTROL

CUTOFF

IC005

27

23

20

11

9

8

5

3

1

B IN

G IN

B OUT

G OUT

R OUT

R.IN

G.IN

B.IN

G.OUT

B.OUT

R.OUT

R IN

10

11

12

32

31

30

15

16

14

13

6

5

4

3

29

1

SDA

SCL

CLAMP

BLK

B OSD

G OSD

R OSD

OSD BLK

G2

B BKG

G BKG

R BKG

V DET

15

14

13

3

5

7

R_OUT

G_OUT

B_OUT

R_IN

G_IN

B_IN

IC004

AMP

CUTOFF

RGBDRIVE

IC001

RGB OUT

IC002

KR

KG

KB

G2

7

8

9

J001

H

FC

FV

1 KV

1

(VIDEO)

10

F99-861-BD

5V-2

12V

4

13

12V

80V

200V

F

G

E

G

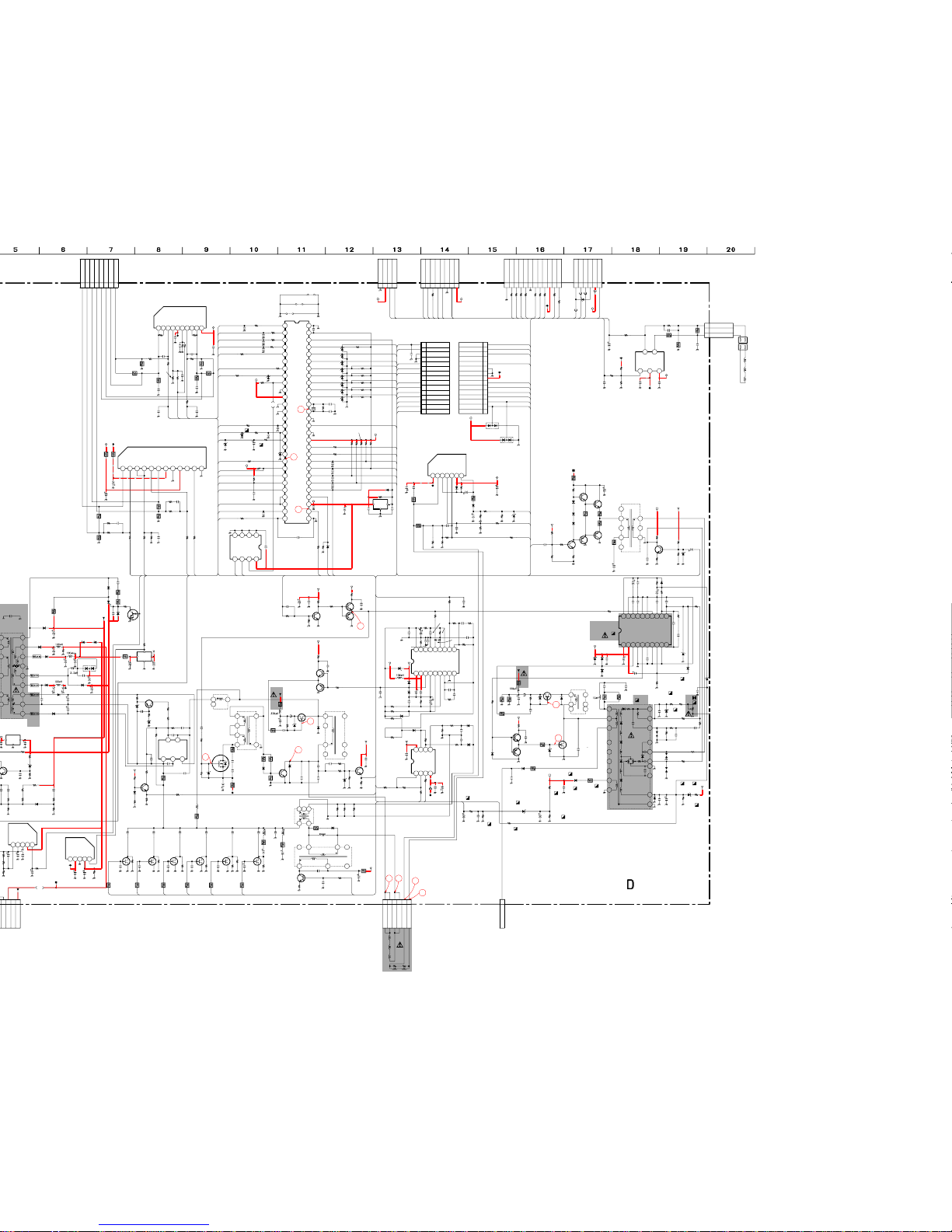

4-2. CIRCUIT BOARDS LOCATION

N

H

D

A

4-3. SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytic.

• Indication of resistance, which does not have one for rating

electrical power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP: 1/10 W)

• All resistors are in ohms.

• : nonflammable resistor.

•

•

: fusible resistor.

: internal component.

• : panel designation and adjustment for repair.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

: earth-ground

•

: earth-chassis.

•

• The components identified by in this basic schematic

diagram have been carefully factory-selected for each set in

order to satisfy regulations regarding X-ray radiation.

Should replacement be required, replace only with the value

originally used.

• When replacing components identified by

, make the

necessary adjustments by using RV901 ( ) as indicated.

(See page 7)

Note: The components identified by shading and

mark are critical for safety. Replace only with

part number specified.

Note: Les composants identifies per un trame et une

marque sont critiques pour la securite. Ne les

remplacer que par une piece portant le numero

specifie.

• When replacing parts shown in the table below, be sure to

perform the safety related adjustment.

HV ADJ

HV Regulator

Circuit

HV Protector

Circuit

Beam Current

Protector

Circuit

• All voltages are in volts.

• Readings are taken with a 10 M W digital multimeter

• Readings are taken with a color-bar signal input.

• V oltage variations may be noted due to normal production

tolerances.

• * : Cannot be measured.

• Circled numbers are waveform references.

•

•

: B +bus.

: B - bus.

Part Replaced ( )

RV901

Part Replaced ( )

D board T901, IC901, R924, R925,

RV901

D board T901, R917, R918, R923,

R920, R919, R1004, C920,

D911, D912

D board R933, R932, R921, R1006,

D915, D917, IC901, T901

— 13 —

CPD-4402

13

HV

17

14

15

16

11

12

FV1

FV2

4

1

2

6

8

10

9

7

5

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

282

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

3

7

3

8

3

9

4

0

4

1

4

2

4

3

4

4

4

5

4

6

4

7

4

8

4

9

5

0

5

1

5

2

5

3

5

4

5

5

5

6

S

1

3

4 5

6

8

2

4

5

6

10

1

9

1

1

2

3

4

1 2 3 4 5 6 7 8 9

10

1 2 3 4 5 6 7 8 9

10 11 12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1 2 3 4 5 6 7 8 9

10

11121314151617181920

1 2 3 4 5 6 7 8 9

101112131415161718

1234

5 6 7 8

IO

G

12345

2

3

5

7

8

9

10

11

12

13

14

15

16

17

18

1 2 3 4

5678

1

2

3

4

5

IO

G

-2 -2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

-2

S

1

2

3

456

7

8

1 8

4 5

3

2

-2

1

2

3

4

5

6

-2

-2

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

-2

12345

-2

S

S

152

3

4

SS

12345

SSSS

1

2

3

4

5

6

7

8

1

2

3

4

5

6

12345

1

2

5

6

9

7

1

2

1 2 3 4 5 6 7

OUTVCC

GND

1

2

3

4

5

6

7

8

123

1

2

3

SG902

T502

R401

R403

R405

SG903

C930

R917

L901

C929

C409

L501

R407

R402

C402

L902

X1001

C1024

C1025

R1065

R1094

C1042

R1104

R1047

R1048

R1049

R1050

R1051

C1038

R1095

R1098

R1097

R1083

R901

SG901

RV901

C515

R503

R1096

R1073

R1074

R1085

L604

L603

L606

C1037

R735

R737

C1061

R418

R417

R416

R410

R409

L505

C503

C508

C510

R507

R509

R513

R516

R520

R524

R526

C518

C522

C523

R530

R532

R533

R535

R536

R537

R538

R540

C529

R544

R547

R550

R552

R553

R555

C539

C540

C541C543

C545

R557

R559

R561

R563

R564R565

R566

R567

R568

R902

C901

C902

C904

C905

C906

C909

C915 C916

R909 R910

R912

R915

C918

C919

C920

R916

R919

R920

R921

R923

C922

C923

C924

R924

R925

R926

R928

R929

R930

R931

C926

R701

R703

R705

R706

R707

R708

R709

R713

R714

R715

C704

C706

R717

C707

C708

R718

R719

R722

R725

C714

R731

R732

R733

R734

C716

R741

R744

R745

R746

C721

C724

R738

R753

R700

C609

R651

R657

C622

C623

C624

C629

C630

C631

C632

C633

R677

R679

R684

R685

R686

R687

R692

C650

R1086

C1026

C1006

C1036

R914

C712

R720

R721

R730

R729

R728

R727

R726

R724

R723 C711

C727

C726

C530

C531

C547

C701

C501

C703

C717

C718

C719

C723

C917

C921

C1013

C509

C512

R904

R905

C1031

R1070

R1072

C1050

C513

R579

R1011

R1015

R691

R573

R572

R569

R582

R1001

C553

C1030

C549

R747

R404

C516

R649

R650

R658

R748

R749

R751

C725

R523

R525

R528

R531

L504

C521

L506

L507

C653

C511

R504

R505

R740

C654

C551

C507

R515

C525

T701

R541

T504

R510

R508

C504

C514

C534

C535

R545

C559

R501 R502

R653

R664

C644

R652

C500

D1018

R406

R521

R697

R698

R576

C556

R570

C562

R752

C1062

L502

T503

L503

T602

C621

C1063

C1064

R1010

T901

R918

C908

R1005

R506

R1039

R584

C532

C903

R933

C564

C528

R549

C538

R932C563

C524

C557

C533

C608

C931

R1020

R1019

R1021

R

1

0

1

4

R1022

C1046

C1047

R527

R710

R711

R712

R659

C656

R681

R682

R680

R676

R755

R754

C555

R906

C925

R934

T902

R529

R539

R585

T501

R1013

R742

R743

R739

R518

R517

R577

R581

R583

R587

C658

C505

R736

R546

C537

R1017

R1018

C520

R927

C648

C628

C560

R574

R601

R908

C914

R911

C536

R548

L607

C646

C647

C401

C404

C403

R586

R519

R522

C558

C659

R408

C565

R542

R543

R512

R514

R511

R1007

C506

C900

R907

C1001

C1056

C1057

C406

C407

C527

C625

C626C627

C642

C657

C720

C728

C729

C730

C731

C907

C913

C927

FB501

R716

IC703

IC701

IC702

IC401

IC1003

IC1001

IC1005

IC901

IC501

IC604

IC609

IC502

IC503

IC605

Q706

Q705

Q703

Q701

Q704

Q702

FB901

Q901

Q903

Q904

Q902

Q509

Q508

Q501

Q503

Q502

Q606

Q609

Q519

Q517

D502

Q504

Q505

Q506

Q507

Q510

Q511Q512Q513

Q514

Q515

Q516

D1025

D1007

D1008

D1009

D1010

D1011

D1012

D1013

D1014

D1027

D1003

D1021

D1022

D1024

D620

D402

D401

D405

D622

D517

D519

D507

D508

D514

D509

D512

D518

D503 D510

D505

D511

D504

D501

D506

D515

D516

D615

D616

D614

D634 D635

D618

D617

D619D636

D623D613

D624

D630

D629

D701

D702

D703

D705

D901

D921

D920

D922

D916

D903

D904

D906

D907

D913

D909

D908

D910

D911

D914

D915

D912

C705

C732

R1008

R1092

R1004

R1006

R1084

R1046

R1012

R1016

JR603

JR604

JW1001

R645

R647

R648

FB1000

FB1001

FB1002

FB1004

C912

C911

D917

C910

FB502

R580

C554

C517

C713

C550

C548

C546

C544 C542

CN1003

CN1002

CN1001

CN701

CN1004

CN702

CN901

CN510

CN501

CN1005 CN1006

R575

0.01

:PT

1.5

:FPRD

1.5

1/2W

:RN

1.5

1/2W

:RN

2.2

:FPRD

22

100

22

:FPRD

330

1W

:RS

10p

CH:CHIP

10p

CH:CHIP

47p

CH:CHIP

0.01

B:CHIP

100k

0.01

B:CHIP

0.01

:PT

0.0022

100V

:PT

22k

1

:FPRD

27

1W

:RS

4.7k

3.3k

:RN-CP

0.1

25V

B:CHIP

22

0.01

B:CHIP

3.3k

:RN-CP

22k

:RN-CP

22k

:RN:CP

22k

:RN-CP

47k

:RN-CP

47k

:RN-CP

0.01

:PT

10

:FPRD

39

:RN

1M

47k

47k

47k

47k

47k

47k

100

25V

0.01

B:CHIP

0.1

B:CHIP

470p

CH:CHIP

100

25V

0.0033

:PT

220

3W

:RS

220

3W

:RS

22

:FPRD

2000p

1.2kV

:PP

2.2

:FPRD

4.7

10

100

25V

10k

:RN-CP

270k

:RN-CP

330k

1/2W

:RC

4.7k

1/2W

:RC

4.7k

1/2W

:RC

0.1

100V

:PT

2.2

2.2

100

1W

:RS

27

1W

:RS

2.2

1W

:RS

15

1W

:RS

100

1W

:RS

2.2

1W

:RS

0.1

:PT

0.1

:PT

0.47

:FPRD

1000

25V

1000

25V

82

1W

:RS

1

2W

:RS

82

1W

:RS

1

2W

:RS

1.0

1.5

:FPRD

150

1W

:RS

1.0

:MPS

470

:FPRD

4.7

:FPRD

4.7

:FPRD

47

100V

10

:FPRD

100k

220

25V

470

470

220

10V

82k

:RN

10k

:RN-CP

100p

CH:CHIP

0.01

2kV

F

0.01

2kV

F

0.1

25V

B:CHIP

22

1W

:RS

100k

:RN

0.1

25V

F:CHIP

0.1

25V

F:CHIP

0.1

25V

F:CHIP

330p

B:CHIP

330p

B:CHIP

68p

CH:CHIP

68p

CH:CHIP

0.1

25V

B:CHIP

0.1

25V

F:CHIP

0.1

25V

F:CHIP

33

100V

0.1

25V

F:CHIP

0.1

25V

F:CHIP

0.1

25V

F:CHIP

0.1

25V

F:CHIP

0.1

25V

F:CHIP

1000

10V

0.1

25V

F:CHIP

0.1

25V

F:CHIP

2.2k

:RN-CHIP

4.7k

:RN-CHIP

4.3k

:RN-CHIP

2.2k

:RN-CHIP

4.7k

:RN-CHIP

100p

2kV

SL

470p

B

0.1 25V B:CHIP

0.1 25V B:CHIP

0.1

25V

F:CHIP

4.7mH

15k

:RN-CP

3.3k

:RN-CP

47k

:RN-CP

100

:FPRD

100

:FPRD

100

:FPRD

100

:FPRD

100

:FPRD

100

:FPRD

15k

:RN-CP

15k

:RN-CP

4.7k

:RN-CP

2.2k

:RN-CHIP

47k

:RN-CP

0.22

100V

:PT

0.1

25V

F:CHIP

2.7k

:RN-CP

0.47

3W

:RS

0.22 F:CHIP

10k

10k :RN-CP

100k

1/2W

:RC

4.7k

:RN

100

16V

22k

:RN-CHIP

1.8k

:RN-CP

22k

:RN-CP

2.7k

:RN-CP

4.7mH

0.022

B:CHIP

4.7k

33k

:RN-CP

0.1

25V

F:CHIP

0.1

F:CHIP

220p

CH:CHIP

0.0047

:PT

0.0047

:PT

0.1

25V

F:CHIP

0.1

25V

F:CHIP

0.1 25V B:CHIP

100p

CH:CHIP

0.0047

B:CHIP

0.01 B:CHIP

220p

B:CHIP

0.0022

B:CHIP

100p

500V

:B

1000

25V

220

25V

470p

2kV

B

22

MA111-TX

4.7mH

15k

:RN

3.3k

:RN-CP

47

1W

:RS

1.8

10W

:RN

100

4.7k

:RN-CP

9.1k

:RN-CP

2.7k

:RN-CP

10k

3W

:RS

47k

2W

:RS

0.56

1W

:RS

47k

2W

:RS

47k

3W

:RS

47k 3W :RS

4.7

1W

:RS

0.1

25V

B:CHIP

0.1

B:CHIP

0.1

25V

B:CHIP

47

25V

100

100V

220

16V

:FBT

2.2

F:CHIP

1M

:RN

220

0.033

:PT

4.7

250V

0.1

B:CHIP

68

1/2W

:FPRD

56

3W

:RS

8.2k

:RN-CP

4.3k

:RN-CP

100

16V

470

16V

47

25V

100

4700p

1.8kV

:PP

0.022

B:CHIP

0.68

250V

:PP

0.33

250V

:PP

0.15

250V

:PP

0.033

400V

:PP

3.3

0.33

200V

:PP

22k

:RN-CP

0.1

B:CHIP

0.47

25V

F:CHIP

47p CH:CHIP

47p CH:CHIP

47k

:RN-CP

10k

:RN-CP

15k

:RN-CP

0.12 1/2W :RF

0.12

1/2W

:RF

4.7k

82k

:RN

2.7k

:RN-CP

75k

:RN

56k

:RN

5MH

:HOC

10k

:RN-CP

12k

:RN-CP

0.47

:MPS

0.01

:PT

100k

:RN-CP

0.47

:FPRD

27k

10k

:RN-CP

47p

500V

8.2k

:RN-CP

390

:RN-CP

0.018

B:CHIP

0.16

400V

:PP

47

3W

:RS

6.8k

1/2W

:RC

0.082

250V

:PP

330

25V

220

250V

47

25V

:HCC

470k

:CHIP

220k

:CHIP

100

:CHIP

220

:CHIP

22k

:CHIP

47k

:CHIP

220

:CHIP

220

:CHIP

120k

:CHIP

2.2k

:CHIP

2.2k

:CHIP

2.2k

:CHIP

100

:CHIP

22

:CHIP

39k

:CHIP

22k

:CHIP

22k

:CHIP

2.2k

:CHIP

8.2k

:CHIP

47k

:CHIP

5.6k

:CHIP

330

:CHIP

33k

:CHIP

100k

:CHIP

47k

:CHIP

2.2k

:CHIP

470

:CHIP

47k

:CHIP

220

:CHIP

47

:CHIP

1

0

0

:

C

H

I

P

220

:CHIP

2.2k

:CHIP

2.2k

:CHIP

47

:CHIP

47

:CHIP

100

:CHIP

100

:CHIP

100

:CHIP

100

:CHIP

470k

:CHIP

15k

:CHIP

15k

:CHIP

:HDT

:LCT

:SRT

:HRC

1

10V

B:CHIP

82

4.7k

470

25V

220

470

25V

100

16V

:HT

100

16V

:HT

150

1/2W

:FPRD

100k :CHIP

100

:CHIP

0.22

3W

:RS

4.7k

22

:FPRD

100

:CHIP

2.2k

:CHIP

680p

B:CHIP

:HST

1.0

B:CHIP

22k

:CHIP

220p

CH:CHIP

:DFT

0.047

250V

:MPS

0.47

400V

1.5

250V

:PP

0.0047

250V

E

0.047

250V

:MPS

0.047

250V

:MPS

120

:RN

120

:RN

120

:RN

150k

1/2W

0.47

:FPRD

:HLC

22

:FPRD

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k

:CHIP

1k :CHIP

1k

:CHIP

1k :CHIP

1k :CHIP

2200

25V

:HT

22

250V

100

25V

10

10

10

100p

CH:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

0

:CHIP

0

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k

:CHIP

10k :CHIP

4.7k

:CHIP

4.7k :CHIP

4.7k :CHIP

4.7k :CHIP

4.7k :CHIP

4.7k :CHIP

4.7k :CHIP

4.7k

:CHIP

4.7k :CHIP

4.7k :CHIP

4.7k

:CHIP

220p

220p

0.0022

:PT

0.0033

B:CHIP

0.0068

B:CHIP

0.001

25V

:HR

0.0018

25V

:HR

0.001

25V

:HR

0.0047

B:CHIP

0.001

500V

0.01

B:CHIP

0.0047

B:CHIP

0.0047

B:CHIP

0.0047

B:CHIP

0.0047

B:CHIP

0.001

CH:CHIP

33

250V

0.0022

200V

:PT

0UH

2.2

:FPRD

LA6500-FA

ROTATION

LA6510

S CONV OUT

STK391-110

D CONV OUT

LA78040

V OUT

PST574CMT-T1

RESET

CXD9523S/JCN

CPU

CAT2WC16J-TE13

EPROM

BA9758AFS-E2

PWR CONT

BA9759F-E2

DEFLECT CTRL

PQ12RD8S

12V REG

BA05T

STBY 5V REG

LA6500-FA

H CENTER AMP

NJM4558M-TE2

V DEF OUT

BA05ST-V5

HEATER REG

2SC3491A

V DEF

2SA1358

H DEF

2SA1049

H DEF

2SC2362KG

H DEF

2SC3421

BUFFER

2SC2459

BUFFER

0UH

IRFI9634G-LF35

HV REG

2SC2412K

HV OUT

2SA1036K

HV OUT

FS5KM-18A-AY

HV OUT

2SA1036K

BUFFER

2SC2411K

BUFFER

2SC1623

SW

2SA1037K

H DRIVE

2SC2411K

H DRIVE

DTC114EKA-T146

HEATER SW

2SC3311A

PROT

2SA1037AK

STBY SW

2SC3209LK

H CNT CTRL

D3S4M

IRFU110

H DRIVE OUT

2SC5445(LBSONY1)

H OUT

IRFI9634G-LF35

RE OUT

2SC2412K

H RTRC

2SC3311A

DRIVE

2SK2098

S CAP CHANGE

2SK2098

S CAP CHANGE

2SK2098

S CAP CHANGE

2SK2098

S CAP CHANGE

2SK2098

S CAP CHANGE

2SK2098

S CAP CHANGE

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

4.7K :CHIP

680K :RN-CP

1PS226-115

1PS226-115

MA111-TX

D10SC9M

UDZ-TE-17-5.6B

EGP10GPKG23

1SS133T-77

D4L20U

UDZ-TE-17-15B

UTZ-4.7B

MA111-TX

MA111-TX

RD4.7ES-T1B2

MA111-TX

MA111-TX

RD10ES-T1B2

HZS182-TE MA111-TX

D2L40-TA

MA111-TX

PG124S15

HZS182-TE

UDZ4.7B

MA111-TX

ERA91-02TP1

UF4007G23

BT149G-412-OT359

FMC-26UA

1SS133T-77 1SS133T-77

ERB38-06V1

1SS133T-77

FMN-G12SUDZ-TE-17-12B

EGP10DPKG23RGP10DG23

EGP10DPKG23

MTZJ-T-77-15B

MA111-TX

1SS133T-77

1SS133T-77

1SS133T-77

UDZ-TE-17-12B

MA111-TX

UDZ-TE-17-5.6B

UDZ-TE-17-5.6B

MA111-TX

UDZ-TE-17-12B

MA111-TX

MA111-TX

UDZ-TE-17-15B

D2L40-TA

RD16ES-T1B2

UDZ-TE-17-15B

MA111-TX

RGP02-17PKG23

RGP02-17PKG23

HSS82

RD5.1ESBT1B2

RD16ES-T1B2

0.1

25V

B:CH

0.01

B:CH

1k

:CHIP

220

:CHIP

220 :CHIP

220

:CHIP

470

:CHIP

4.7k :CHIP

47

:CHIP

220

:CHIP

0

:CHIP

0

:CHIP

17.5MM

JW(7.5MM)

JW(7.5MM)

JW(7.5MM)

0

:CHIP

100

:CHIP

100

:CHIP

0

:CHIP

0.01

B:CH

47p

CH:CH

RD9.1ES-T1B2

220p

CH:CHIP

0UH

2.2k

:RN-CHIP

220p

CH:CHIP

330p

CH:CH

0.01

B:CHIP

0.01

B:CHIP 0.01

B:CHIP

0.01

B:CHIP

0.01

B:CHIP

0.01

B:CHIP

12P

WHT

S:MICRO

8P

WHT

:S-MICRO

4P

WHT

8P

WHT

:S-MICRO

6P

WHT

:S-MICRO

3P

WHT

:S-MICRO

TO CHASSIS

6P

15P 15P

2.2k

RN-CP

W

P

80V

12V

300V

300V

12V

12V

12V

12V

15V

-15V

15V

-15V

12V

-15V

12V

15V

-15V

15V

-15V

12V

15V

-15V

5V

5V-2

5V-2

80V

5V

5V

5V

5V

15V

-15V

5V-2

200V

200V

200V

200V

5V-2

5V

80V

12V-2

12V-2

12V-2

12V-2

5V

5V

12V-2

12V-2

S

0

S

1

S

2

S

3

S

4

S

5

L

E

D

1

L

E

D

2

X

D

C

Y

D

C

R

E

M

O

T

E

O

N

/

O

F

F

R

E

F

D

C

DCC2

V FBP

V.DF

H.DF

YDC

REF DC

XDC

V SAWN

D

.

T

I

L

T

R

O

T

A

T

I

O

N

Y

S

C

D

A

C

R

E

F

X

S

C

H.DF

H SHAPE

A

B

L

D

E

T

H

S

Y

N

C

C

P

U

G

N

D

1

R

X

D

T

X

D

C

B

L

A

N

K

I

N

P

U

T

S

E

L

B

P

C

L

A

M

P

C

S

Y

N

C

V

S

Y

N

C

H

S

Y

N

C

C BLANK

H SYNC0

V SYNC0

POC

PLL LOCK

DCC2

H

D

O

U

T

D

D

C

C

L

K

D

D

C

D

A

T

A

C

P

U

G

N

D

1

H

S

Y

N

C

0

V

S

Y

N

C

0

K

E

Y

S

C

A

N

C

P

U

G

N

D

2

H

E

A

T

E

R

HEATER

REMOTE ON/OFF

DEGAUSS

H.CENT

H.LIN BAL

R

E

M

O

T

E

O

N

/

O

F

F

H SYNC0

C SYNC

V SYNC0

POC

PLL LOCK

BP CLAMP

CPU GND2

KEY SCAN

HV DET

ABL DET

V SYNC

S0

LED2

LED1

S1

S2

S3

S4

S5

V FBP

TXD

RXD

DDC DATA

DDC CLK

V FBP

V SAWN

H FBP

H

F

B

P

H

.

L

I

N

B

A

L

H

V

D

E

T

D

E

G

A

U

S

S

ROTATION

D

A

C

R

E

F

V

.

D

F

V.DF2

V

.

D

F

2

H

F

B

P

H.CENT

XSC

DAC REF

YSC

HD OUT

H SHAPE

H FBP

D.TILT

IIC CLK

IIC DATA

IIC CLK

IIC DATA

I

I

C

D

A

T

A

I

I

C

C

L

K

I

I

C

D

A

T

A

I

I

C

C

L

K

INPUT SEL

I

N

P

U

T

S

E

L

C

Y

4

-

C

Y

3

-

C

Y

3

+

C

Y

2

-

C

Y

2

+

C

Y

1

-

C

Y

1

+

C

Y

4

+

ROTATION-

ROTATION+

H

D

Y

+

H

D

Y

+

H

D

Y

-

H

D

Y

-

V

D

Y

-

V

D

Y

+

D

G

N

D

R

X

D

T

X

D

1

.

0

K

V

I

O

U

T

A

O

U

T

A

I

N

A

-

I

N

A

+

V

E

E

I

N

B

+

I

N

B

-

O

U

T

B

I

O

U

T

B

V

C

C

L

E

D

1

L

E

D

2

G

N

D

+

5

V

O

U

T

B

(

Y

)

-

I

N

B

(

Y

)

+

I

N

B

(

Y

)

-

I

N

A

(

X

)

O

U

T

A

(

X

)

V

E

E

V

C

C

S

T

B

Y

+

I

N

A

(

X

)

PWM6/P4.6

PWM5/P4.5

VPP

TEST0

PWM4/P4.4

PWM3/P4.3

PWM2/P4.2

RESET

P3.0/TXCLK/CLKOUT

P8.7

PWM1/P4.1

PWMN0/P4.0

INTCLK/P9.0

P9.1

AVSS

P8.6

P8.1

P8.0

P3.1/TOUTA/CTS

P3.2/TOUT/DCD

AVVD

AIN0/P8.2

AIN1/P8.3

AIN2/P8.4

AIN3/P8.5

AIN4/P6.5

AIN5/P6.4

P3.3/BLANKOUT

OSCIN

OSCOUT

XT

P3.4/RXCLK

VSS

VDD

AIN6/P6.3

VSYNCI1

VSYNCI2/INTO/P5.7

CLAMPOUT/MOIRE/P5.6

WDIN/INT1/P5.5

INT3/P5.4

WDOUT/INT2/P5.3

VSYNCO/P5.2

HSYNCO

CSYNCI/P5.1

VSS

HSYNCI1

VDD

P5.0/HFBACK

P3.7/HSYNCI2

P6.7/SCLD

P6.6/SDAD

P6.1/SCLI

P6.0/SDAI

P3.6/SIN

P3.5/SOUT

HVD

AGC

+

-

PWMOUT

PVcc

N

C

S

A

W

O

U

T

N

C

S

G

N

D

H

D

I

N

D

E

L

A

Y

V

R

E

G

9

S

V

c

c

P

G

N

D

H

V

D

C

A

P

N

C

S

L

O

W

S

W

N

C

E

R

R

O

U

T

P

V

C

C

P

W

M

O

U

T

P

G

N

D

S

L

O

W

S

W

V

R

E

G

9

S

A

W

R

S

A

W

O

U

T

S

G

N

D

H

D

I

N

N

C

M

I

X

+

M

I

X

-

M

I

X

O

U

T

V

C

C

R

E

F

I

N

E

R

R

I

N

N

C

E

R

R

O

U

T

S

D

A

V

S

S

S

C

L

A

2

A

1

W

C

V

C

C

A

0

G

N

D

+

8

0

V

N

C

V

A

D

J

O

U

T

G

N

D

V

C

C

C

T

L

I

N

P

U

T

S

E

L

B

P

C

L

A

M

P

C

S

Y

N

C

V

S

Y

N

C

G

N

D

C

B

L

A

N

K

D

D

C

C

L

K

C

P

U

G

N

D

1

D

D

C

D

A

T

A

I

I

C

D

A

T

A

H

F

B

P

+

5

V

-

2

V

S

Y

N

C

0

H

S

Y

N

C

0

G

N

D

I

I

C

C

L

K

H

S

Y

N

C

S

T

B

Y

+

5

V

+

+

-

-

V

C

C

V

E

E

0

0

+

2

0

0

V

K

E

Y

S

C

A

N

C

P

U

G

N

D

2

STBY

STBY

STBY

STBY

STBY

STBY

NC

+

S

T

B

Y

5

V

STBY

AIN0/P6.2

STBY

I

N

P

U

T

S

W

G

N

D

F99-875-D

GND

GND

GND

H FBP

NC

H SHAPE

HD OUT

V SAWN

DCC2

V FBP

V.DF

H.DF

NC

YDC

REF DC

XDC

C BLANK

+5V-2

GND

H SYNCO

V SYNCO

POC

PLL LOCK

IIC DATA

IIC CLK

D.TILT

XSC

YSC

DAC REF

DSP RESET

(CONVERGENCE)

(DEFLECTION)

(POWER)

TO CONVERGENCE YOKE FOR SERVICE

TO A BOARD

CN309

TO A BOARD

CN306&310

TO H BOARD

CN2001

TO A BOARD

CN301

1

2

3

4

5

6

7

8

9

13

12

1110

Loading...

Loading...