Page 1

TMR-RF940R

SERVICE MANUAL

TMR-RF940R is transmitter

unit in MDR-RF940RK.

SPECIFICATIONS

AEP Model

MICROFILM

TRANSMITTER

Page 2

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering

This section is extracted from

instruction manual.

SECTION 1

GENERAL

– 2 –

Page 3

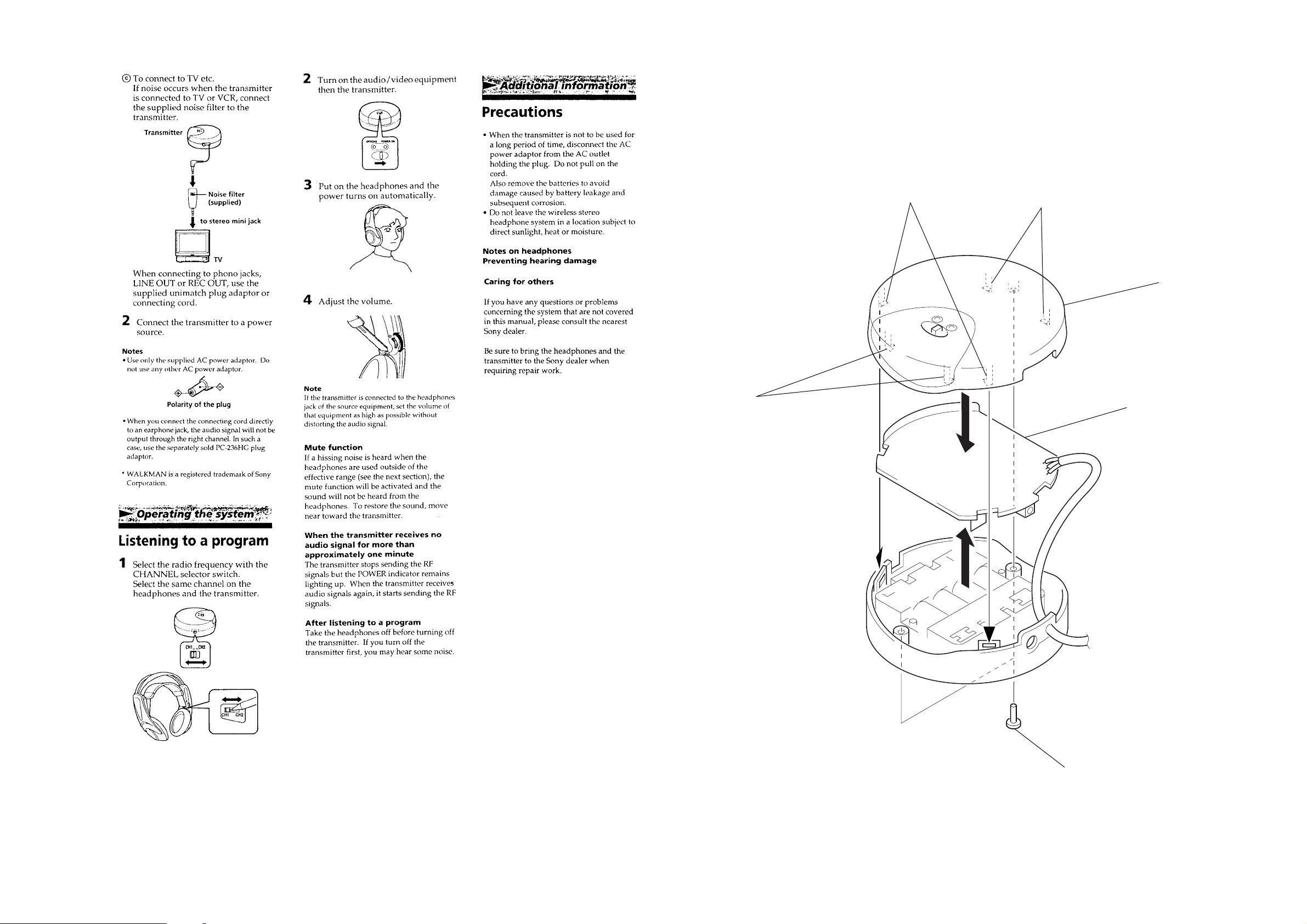

SECTION 2

y

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CABINET (UPPER) ASS’Y

2

two claws

4

two claws

3

cabinet (upper) ass’

4

two claws

5

TX board

– 3 –

– 4 –

1

two screws

(P2.6

×

10)

Page 4

Page 5

Page 6

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

4

SECTION 4

EXPLEDED VIEW

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference number in the exploded views are not supplied.

TX

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

SECTION 5

ELECTRICAL PARTS LIST

F: nonflammable

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

When indicating parts by reference

number, please include the board.

15

3

2

14

not supplied

1

12

11

Ref. No. Part No. Description Remark

1 3-895-784-01 SPRING

2 4-957-332-01 CABINET (LOWER)

* 3 A-4542-442-A TX BOARD, COMPLETE

4 X-4948-054-1 CABINET (UPPER) ASSY

5 1-559-892-11 CORD (WITH PLUG)

6 4-958-633-01 CUSHION (BATTERY CASE LID)

7 4-957-333-01 LID, BATTERY CASE

8 7-685-135-19 SCREW +P 2.6X10 TYPE2 NON-SLIT

15

not supplied

5

6

13

8

not supplied

10

Ref. No. Part No. Description Remark

9 4-987-337-01 LABEL (CHG), WARNING

10 4-989-335-01 TERMINAL, CHARGE

11 4-986-508-01 COVER (BATTERY CASE)

12 4-989-336-01 TERMINAL (COMMONNESS), CHARGE

13 3-846-312-01 SPACER

14 3-561-902-01 CLOTH, RETAINING, CASSETTE

15 3-880-474-01 CUSHION, 15X5X0.3

Ref. No. Part No. Description Remark

* A-4542-442-A TX BOARD, COMPLETE

C01 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C02 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C03 1-128-007-11 ELECT CHIP 2.2uF 20% 35V

C11 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C12 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C13 1-128-007-11 ELECT CHIP 2.2uF 20% 35V

C21 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C22 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C23 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C24 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C31 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

C32 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C41 1-128-393-11 ELECT CHIP 100uF 20% 10V

C42 1-164-222-11 CERAMIC CHIP 0.22uF 25V

9

7

C43 1-126-246-11 ELECT CHIP 220uF 20% 4V

C44 1-126-205-11 ELECT CHIP 47uF 20% 6.3V

C45 1-126-205-11 ELECT CHIP 47uF 20% 6.3V

C51 1-164-489-11 CERAMIC CHIP 0.22uF 10% 16V

C52 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C53 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C54 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C55 1-163-116-00 CERAMIC CHIP 91PF 5% 50V

C56 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C57 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C58 1-163-116-00 CERAMIC CHIP 91PF 5% 50V

C59 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C60 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C61 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C62 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C63 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C64 1-163-112-00 CERAMIC CHIP 62PF 5% 50V

C65 1-163-108-00 CERAMIC CHIP 43PF 5% 50V

C66 1-163-059-91 CERAMIC CHIP 0.01uF 10% 50V

C67 1-163-089-00 CERAMIC CHIP 6PF 50V

C68 1-163-088-00 CERAMIC CHIP 5PF 50V

C69 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C70 1-163-094-00 CERAMIC CHIP 11PF 5% 50V

C71 1-163-096-00 CERAMIC CHIP 13PF 5% 50V

C72 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C73 1-163-092-00 CERAMIC CHIP 9PF 0.25PF 50V

*******************

< CAPACITOR >

Ref. No. Part No. Description Remark

C74 1-163-091-00 CERAMIC CHIP 8PF 50V

C75 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C76 1-163-091-00 CERAMIC CHIP 8PF 50V

C77 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C78 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C79 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C80 1-163-094-00 CERAMIC CHIP 11PF 5% 50V

C81 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C82 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C83 1-163-091-00 CERAMIC CHIP 8PF 50V

C84 1-163-090-00 CERAMIC CHIP 7PF 50V

C85 1-163-229-11 CERAMIC CHIP 12PF 5% 50V

C86 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C87 1-163-229-11 CERAMIC CHIP 12PF 5% 50V

C88 1-163-083-00 CERAMIC CHIP 1PF 50V

C89 1-163-087-00 CERAMIC CHIP 4PF 50V

C90 1-104-908-11 TANTALUM CHIP 47uF 20% 4V

C91 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C92 1-163-113-00 CERAMIC CHIP 68PF 5% 50V

C93 1-163-038-91 CERAMIC CHIP 0.1uF 25V

C94 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C95 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C96 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C97 1-135-158-21 TANTALUM CHIP 15uF 20% 4V

C98 1-163-141-00 CERAMIC CHIP 0.001uF 5% 50V

C100 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

< DIODE >

D41 8-719-404-49 DIODE MA111

D42 8-719-975-06 LED CL-70G-CD (OFF/CHG)

D43 8-719-018-51 LED CL-170R-CD (POWER ON)

D44 8-719-045-99 DIODE RD2.2M-T1B

D51 8-719-939-02 DIODE SVC203CP

D52 8-719-421-40 DIODE MA77

D53 8-719-421-40 DIODE MA77

< FERRITE BEAD >

FB01 1-500-419-21 INDUCTOR, FERRITE BEAD

< IC >

IC01 8-759-998-71 IC BA3308F

IC21 8-759-701-39 IC NJM3404AM

IC22 8-759-177-69 IC TLV2362ID-ELL2500

– 9 –

– 10 –

Page 7

TX

Ref. No. Part No. Description Remark

< JACK >

J41 1-568-907-31 JACK,DC (POLARITY UNIFEID TYPE)

(DC IN 4.5V)

< CHIP CONDUCTOR >

JC01 1-216-296-00 CONDUCTOR, CHIP (3216)

JC02 1-216-296-00 CONDUCTOR, CHIP (3216)

JC03 1-216-296-00 CONDUCTOR, CHIP (3216)

JC04 1-216-296-00 CONDUCTOR, CHIP (3216)

JC05 1-216-296-00 CONDUCTOR, CHIP (3216)

JC06 1-216-296-00 CONDUCTOR, CHIP (3216)

JC07 1-216-295-00 CONDUCTOR, CHIP (2012)

JC08 1-216-295-00 CONDUCTOR, CHIP (2012)

< COIL >

L51 1-412-946-11 INDUCTOR ,CHIP 3.9uH

L52 1-412-948-11 INDUCTOR ,CHIP 5.6uH

L53 1-412-946-11 INDUCTOR ,CHIP 3.9uH

L66 1-416-385-11 COIL, AIR-CORE (TMR)

L67 1-416-385-11 COIL, AIR-CORE (TMR)

L68 1-416-385-21 COIL, AIR-CORE (TMR)

L69 1-416-385-21 COIL, AIR-CORE (TMR)

L70 1-412-925-11 INDUCTOR ,CHIP 68NH

L71 1-412-946-11 INDUCTOR ,CHIP 3.9uH

L72 1-412-946-11 INDUCTOR ,CHIP 3.9uH

< LINE FILTER >

LF01 1-403-601-21 FILTER, COMMON MODE

LF41 1-411-236-11 FILTER, EMI

LF42 1-411-236-11 FILTER, EMI

< TRANSISTOR/CHIP CONDUCTOR >

Q21 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q22 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q23 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q24 8-729-216-22 TRANSISTOR 2SA1162-G

Q25 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q31 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q43 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q44 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q45 8-729-200-63 TRANSISTOR 2SC2712L-TE85R

Q46 8-729-200-87 TRANSISTOR 2SC2714-Y

Q47 8-729-200-87 TRANSISTOR 2SC2714-Y

Q48 8-729-209-45 TRANSISTOR 2SC3120-TE85R

Q49 8-729-230-81 TRANSISTOR 2SC3606

Q50 8-729-230-81 TRANSISTOR 2SC3606

Q51 8-729-230-81 TRANSISTOR 2SC3606

Q52 8-729-216-22 TRANSISTOR 2SA1162-G

< RESISTOR/CHIP CONDUCTOR >

R01 1-216-085-00 METAL CHIP 33K 5% 1/10W

R02 1-216-049-00 METAL CHIP 1K 5% 1/10W

Ref. No. Part No. Description Remark

R03 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R04 1-216-097-00 METAL CHIP 100K 5% 1/10W

R05 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R06 1-216-033-00 METAL CHIP 220 5% 1/10W

R07 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R08 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R11 1-216-085-00 METAL CHIP 33K 5% 1/10W

R12 1-216-049-00 METAL CHIP 1K 5% 1/10W

R13 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R14 1-216-097-00 METAL CHIP 100K 5% 1/10W

R15 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R16 1-216-033-00 METAL CHIP 220 5% 1/10W

R17 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R18 1-216-073-00 METAL CHIP 10K 5% 1/10W

R21 1-216-073-00 METAL CHIP 10K 5% 1/10W

R22 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R23 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R24 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R25 1-216-093-00 METAL CHIP 68K 5% 1/10W

R26 1-216-085-00 METAL CHIP 33K 5% 1/10W

R27 1-216-081-00 METAL CHIP 22K 5% 1/10W

R28 1-216-081-00 METAL CHIP 22K 5% 1/10W

R29 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R30 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R31 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R32 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R33 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R42 1-216-023-00 METAL CHIP 82 5% 1/10W

R43 1-216-009-00 METAL CHIP 22 5% 1/10W

R44 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R45 1-216-033-00 METAL CHIP 220 5% 1/10W

R49 1-216-133-00 METAL CHIP 3.3M 5% 1/10W

R51 1-216-097-00 METAL CHIP 100K 5% 1/10W

R52 1-216-109-00 METAL CHIP 330K 5% 1/10W

R53 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R54 1-216-033-00 METAL CHIP 220 5% 1/10W

R55 1-216-097-00 METAL CHIP 100K 5% 1/10W

R56 1-216-033-00 METAL CHIP 220 5% 1/10W

R57 1-216-091-00 METAL CHIP 56K 5% 1/10W

R58 1-216-295-00 CONDUCTOR, CHIP (2012)

R59 1-216-001-00 METAL CHIP 10 5% 1/10W

R60 1-216-001-00 METAL CHIP 10 5% 1/10W

R61 1-216-001-00 METAL CHIP 10 5% 1/10W

R62 1-216-079-00 METAL CHIP 18K 5% 1/10W

R63 1-216-150-00 METAL CHIP 10 5% 1/8W

R64 1-216-001-00 METAL CHIP 10 5% 1/10W

R65 1-216-295-00 CONDUCTOR, CHIP (2012)

R66 1-216-001-00 METAL CHIP 10 5% 1/10W

R67 1-216-077-00 METAL CHIP 15K 5% 1/10W

R68 1-216-295-00 CONDUCTOR, CHIP (2012)

R69 1-216-001-00 METAL CHIP 10 5% 1/10W

R70 1-216-295-00 CONDUCTOR, CHIP (2012)

R71 1-216-001-00 METAL CHIP 10 5% 1/10W

– 11 –

Page 8

TMR-RF940R

TX

Ref. No. Part No. Description Remark

R72 1-216-073-00 METAL CHIP 10K 5% 1/10W

R73 1-216-073-00 METAL CHIP 10K 5% 1/10W

R74 1-216-295-00 CONDUCTOR, CHIP (2012)

R75 1-216-017-00 METAL CHIP 47 5% 1/10W

R76 1-216-001-00 METAL CHIP 10 5% 1/10W

R77 1-216-001-00 METAL CHIP 10 5% 1/10W

R78 1-216-077-00 METAL CHIP 15K 5% 1/10W

R79 1-216-003-11 METAL CHIP 12 5% 1/10W

R80 1-216-073-00 METAL CHIP 10K 5% 1/10W

R81 1-216-073-00 METAL CHIP 10K 5% 1/10W

R82 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R83 1-216-097-00 METAL CHIP 100K 5% 1/10W

R84 1-216-089-00 METAL CHIP 47K 5% 1/10W

R85 1-216-115-00 METAL CHIP 560K 5% 1/10W

R86 1-216-121-00 METAL CHIP 1M 5% 1/10W

R87 1-216-121-00 METAL CHIP 1M 5% 1/10W

R88 1-216-049-00 METAL CHIP 1K 5% 1/10W

R89 1-216-097-00 METAL CHIP 100K 5% 1/10W

R90 1-216-073-00 METAL CHIP 10K 5% 1/10W

R91 1-216-200-11 METAL CHIP 1.2K 5% 1/8W

R92 1-216-073-00 METAL CHIP 10K 5% 1/10W

R93 1-216-073-00 METAL CHIP 10K 5% 1/10W

< VARIABLE RESISTOR >

RV21 1-238-856-11 RES, ADJ, CERMET 10K

RV51 1-238-857-11 RES, ADJ, CERMET 22K

RV52 1-238-857-11 RES, ADJ, CERMET 22K

< SWITCH >

S41 1-571-674-11 SWITCH, SLIDE (POWER)

S51 1-571-478-11 SWITCH, SLIDE (CH1-CH2)

< VIBRATOR >

X51 1-767-455-11 VIBRATOR, CRYSTAL (16.090MHz)

X52 1-767-456-11 VIBRATOR, CRYSTAL (16.110MHz)

************************************************************

MISCELLANEOUS

***************

5 1-559-892-11 CORD (WITH PLUG)

9-923-239-11

Sony Corporation

Personal A&V Products Company

– 12 –

Printed in Hungary © 1997. 8

97H057546-1

Published by Quality Engineering Dept.

(Shibaura)

Page 9

TMR-RF940R

SERVICE MANUAL

Ver. 1.0 1998. 05

SUPPLEMENT-1

File this supplement with the service manual.

Subject:

1. Modification

2. Electrical Adjustments

AEP Model

Page 10

1. MODIFICATION

You can use any of the following capacitors.

• Countermeasure for distortion and white noise.

Improvement of TMR-RF940R (TX board) Increase the capacity

of C21.

Add a 22 µF or 47 µF electrolytic capacitor in parallel with C21.

SCHEMATIC DIAGRAM

• Original Service Manual page 7.

(Location E – G, 6 – 8)

!: Added portion

[TX Board]

Part No.

22 µF/4 V 1-124-430-∏ 1-126-263-∏

22 µF/6.3 V 1-115-863-∏ 1-123-618-∏ 1-124-222-∏ 1-126-153-∏

1-126-419-∏ 1-126-555-∏ 1-126-269-∏

22 µF/10 V 1-124-638-∏ 1-123-644-∏ 1-124-228-∏ 1-126-273-∏

1-126-427-∏ 1-126-783-∏ 1-128-054-∏

47 µF/4 V 1-107-294-∏ 1-126-265-∏ 1-126-553-∏ 1-126-779-∏

47 µF/6.3 V 1-123-293-∏ 1-123-647-∏ 1-124-224-∏ 1-126-154-∏

1-126-271-∏ 1-126-421-∏ 1-126-513-∏ 1-126-557-∏

47 µF/10 V 1-104-657-∏ 1-111-239-∏ 1-123-294-∏ 1-124-892-∏

1-126-640-∏ 1-126-744-∏ 1-126-785-∏

(Any capacitor can be used if its capacity is more than 22 µF and also

small enough for the case of this set.)

$

PRINTED WIRING BOARD

• Original Service Manual page 5 and 6.

(Location A – B, 4 – 6)

!: Added portion

[TX Board] – Conductor Side –

@

– 2 –

Page 11

2. ELECTRICAL ADJUSTMENTS

Note:

• Perform countermeasure for distortion before adjustments.

Adjust and confirm the unit by following procedure shown below after this countermeasure.

• Please adjust the transmitter and the headphone together.

Procedure for Measurements and Adjustments

Lastly, we would like to explain the procedure for adjusting this model. As this model adopts a Stereo Modulation method called “FMFM”, it is difficult to perform the adjustments with common measurement equipments.

The following adjustment should be performed with a spectrum analyzer.

Measurement of White noise level

1) Set the models and necessary equipments as shown in the figure1.

2) Observe the waveform of the oscilloscope. In case that a beat can be seen in the waveform, select a channel (CH1 or CH2) with less

beat.

3) Use the CCIR/ARM Filter for the noise meter and measure the white noise level. If the value is belo w –63 dBV (0.7 mVrms), the lev el

is acceptable.

1 m

AC adaptor

AC-E455D (supplied)

AC 230 V 50 Hz

noise filter

(supplied)

Connect nothing to the plug

of noise filter.

Adjustment of Transmitter

Set the transmitter and a spectrum analyzer as shown below.

Observe the waveform on the spectrum analyzer

without Audio input signal into transmitter.

Use supplied

Ni-cd battery.

Figure 1.

spectrum analyzer

VOL MAX.

SP1 Lch

or

SP2 Rch

noise meter

oscilloscope

Use CCIR/ARM filter.

AC 230 V 50 Hz

AC-E455D (supplied)

Connect nothing.

ANT

Figure 2.

– 3 –

Page 12

Confirm the main carrier frequency (CH1, CH2) (See “a” in the figure 3)

The correct value is as follows.

CH1: 433.6 MHz ± 200 kHz

CH2: 434.2 MHz ± 200 kHz

Confirm the sub carrier frequency (See “b” in the figure 3)

The correct value is 42 kHz ± 2 kHz

Adjust the modulation of sub carrier to be 15 dB ± 0.5 dB as follows (See “c” in the figure 3)

CH1 Deviation adjustment: Turning RV51.

CH2 Deviation adjustment: Turning RV52.

Confirm Sub carrier frequency.

b

10 dB/DIV

Confirm Main carrier

frequency.

a

C

RBW 1 kHz

VBW 1 kHz

SWP

2.0 sec.

L-R Deviation adjustment

10 dB/DIV

RBW 1 kHz

VBW 1 kHz

SPAN 200 kHz

*

Adjust CENTER Frequency to the main carrier frequency.

Figure 3.

Sub spectrum “A”

Confirm Sub carrier

modulation degrees.

SWP

2.0 sec.

SPAN 200 kHz

*

Adjust CENTER Frequency to the main carrier frequency.

1) Set the equipments as the same as the figure 2.

2) Input a signal of 1 kHz 316 mVrms to Lch of the transmitter.

Figure 4.

– 4 –

Page 13

3) Observe the waveform on the spectrum analyzer and turn RV21 to adjust the modulation degree of a sub spectrum “A” in the figure 4

r

to be narrowest as shown below.

4) At this time, measure AC voltage of IC21 Pin 1 on the TX board with AC voltmeter and define the value as “V0” for the next

adjustment.

5) Turn the RV21 again so that the AC voltage of IC21 Pin 1 becomes the same value as the two thirds of “V0”. (V1=V0 × 2/3)

Adjustment Location: TX board (See page 6.)

Adjustment and confirmation without a spectrum analyzer

Please confirm the units by following procedure shown below.

Here a series of procedure which can be performed without a spectrum analyzer is introduced.

Deviation adjustment/confirmation

1) Input a 400 Hz 316 mV signal into the left channel of transmitter.

2) Measure the AC voltage at the Pin 1 of IC21 (MJM2100M) with AC voltmeter.

Spec.: 100 ± 10 mVrms

If not, turn RV21 for obtaining the value.

Adjustment Location: TX board (See page 6.)

Sub-carrier frequency and output level confirmation

1) No signal is input into transmitter.

2) Connect a oscilloscope and a frequency counter to the test point TP1.

3) Confirm the voltage is within the following spec.

Spec.: 0.55 Vp-p

0.55 Vp-p

4) Confirm the frequency is within the following spec.

fsub=42 ± 2 kHz

SCHEMATIC DIAGRAM

• Original Service Manual page 7.

(Location C – E, 6 – 8)

!: Connection point

[TX Board]

^

PRINTED WIRING BOARD

• Original Service Manual page 5.

(Location A – C, 4 – 6)

oscilloscope

+

OUT

–

coaxial cable

[TX Board] – Conductor Side –

frequency counte

IN

– 5 –

Page 14

r

TMR-RF940R

Carrier frequency modulation adjustment/confirmation

This has to be done for a pair of set.

Before starting, match the channel of both units.

1) Input a 400 Hz 316 mV signal into the left channel of transmitter.

2) Measure the AC voltage at the test point TP2 of MDR-RF940R RX board with AC voltmeter.

Spec.: 13 ± 1.5 mVrms

If not, turn RV51 of TMR-RF940R (channel 1) or RV52 (channel 2) for obtaining the value.

SCHEMATIC DIAGRAM

• MDR-RF940R Service Manual page 8.

(Location B – D, 9 – 11)

!: Connection point

[RX Board]

^

PRINTED WIRING BOARD

• MDR-RF940R Service Manual page 5.

(Location F – H, 4 – 6)

[RX Board] – Side A –

AC voltmete

+

–

Adjustment Location:

[TX Board] – Conductor Side –

Carrier

Frequency

Modulation

Adjustment

RV51 (CH1)

RV52 (CH2)

RV21

Deviation Adjustment

1

IC21

IC01

9-923-239-81

Sony Corporation

Personal A&V Products Company

– 6 –

Printed in Japan © 1998. 5

98E0539-1

Published by Quarity Engineering Dept.

(Shibaura)

Loading...

Loading...