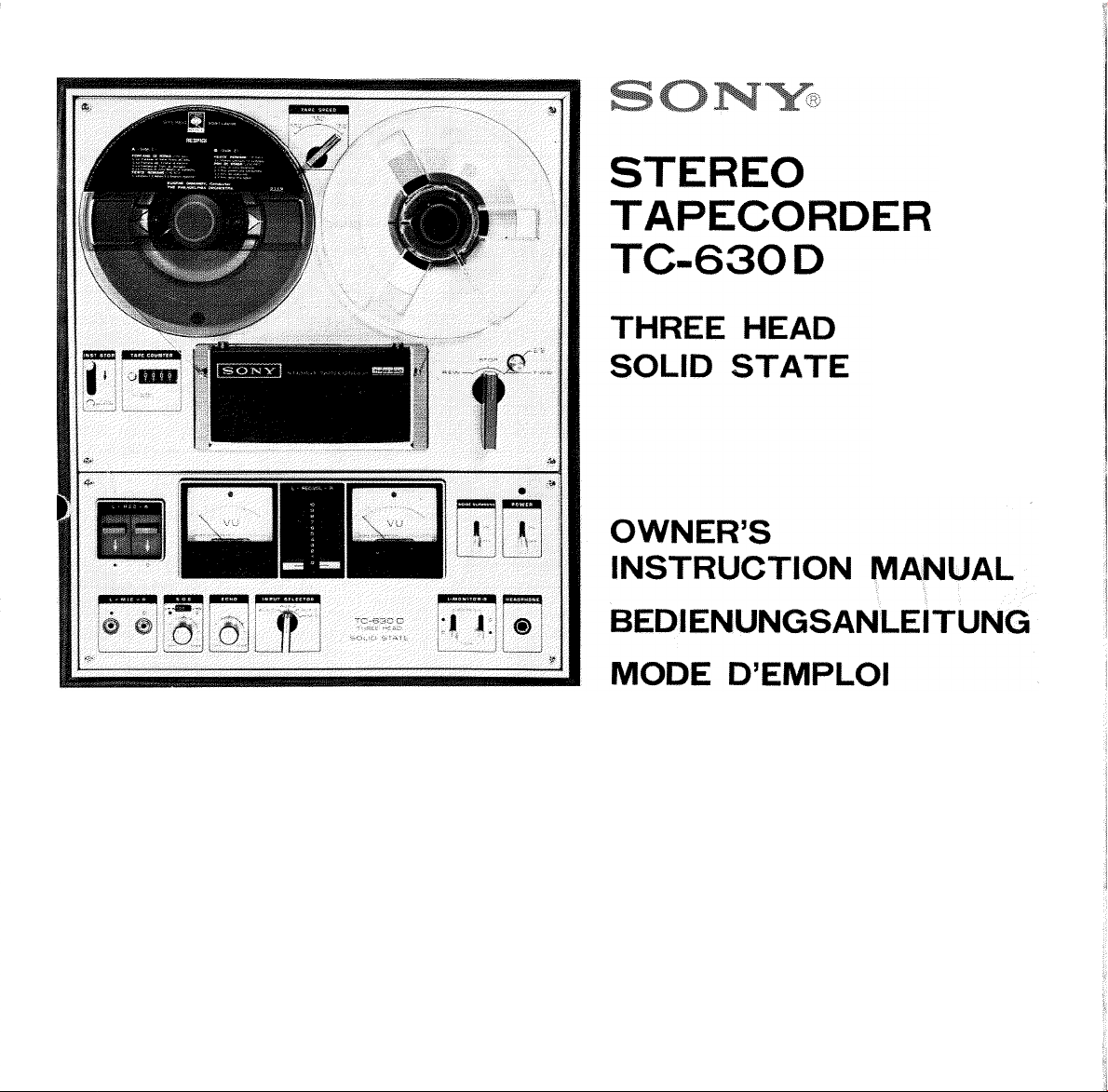

Page 1

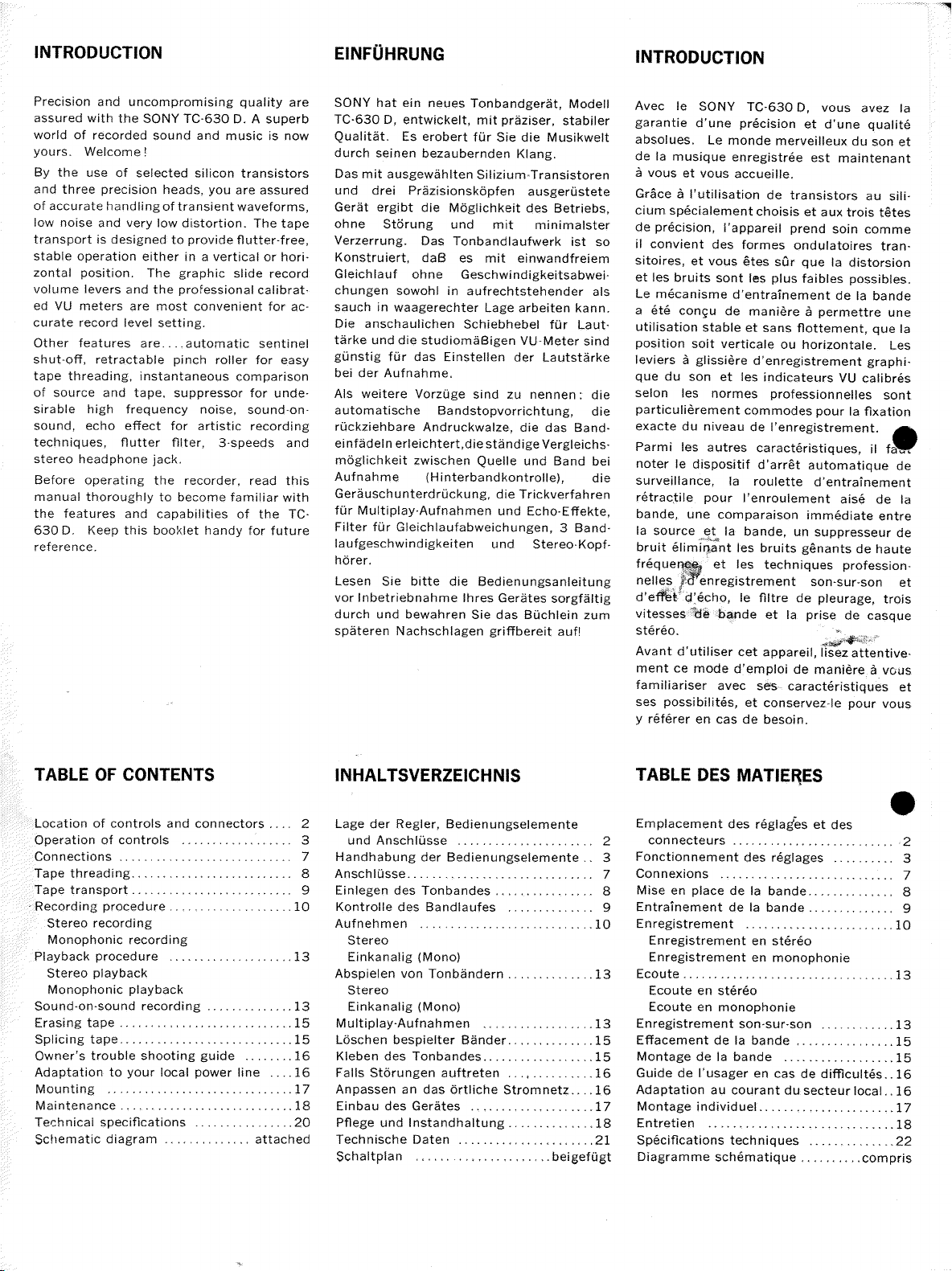

Page 2

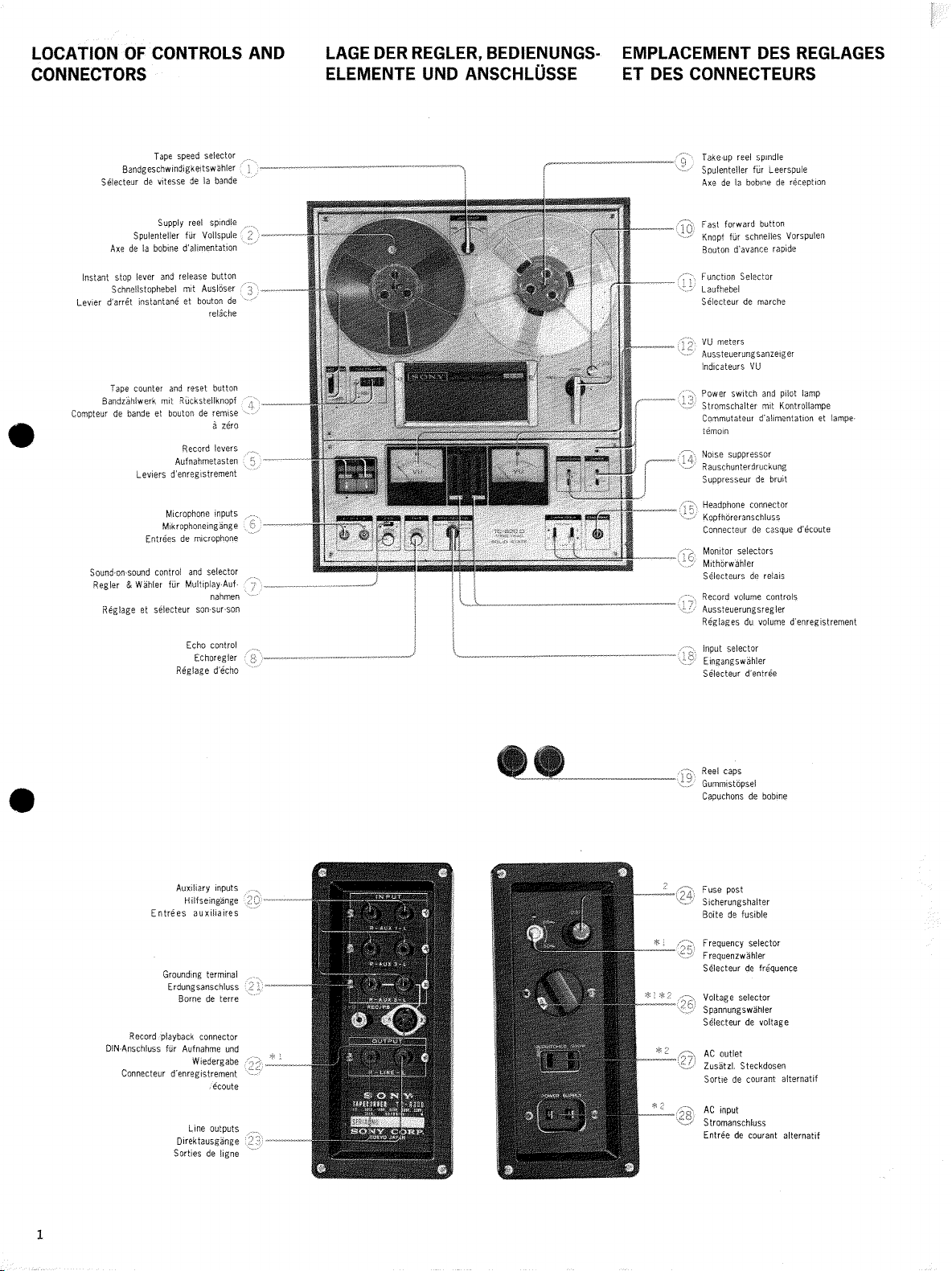

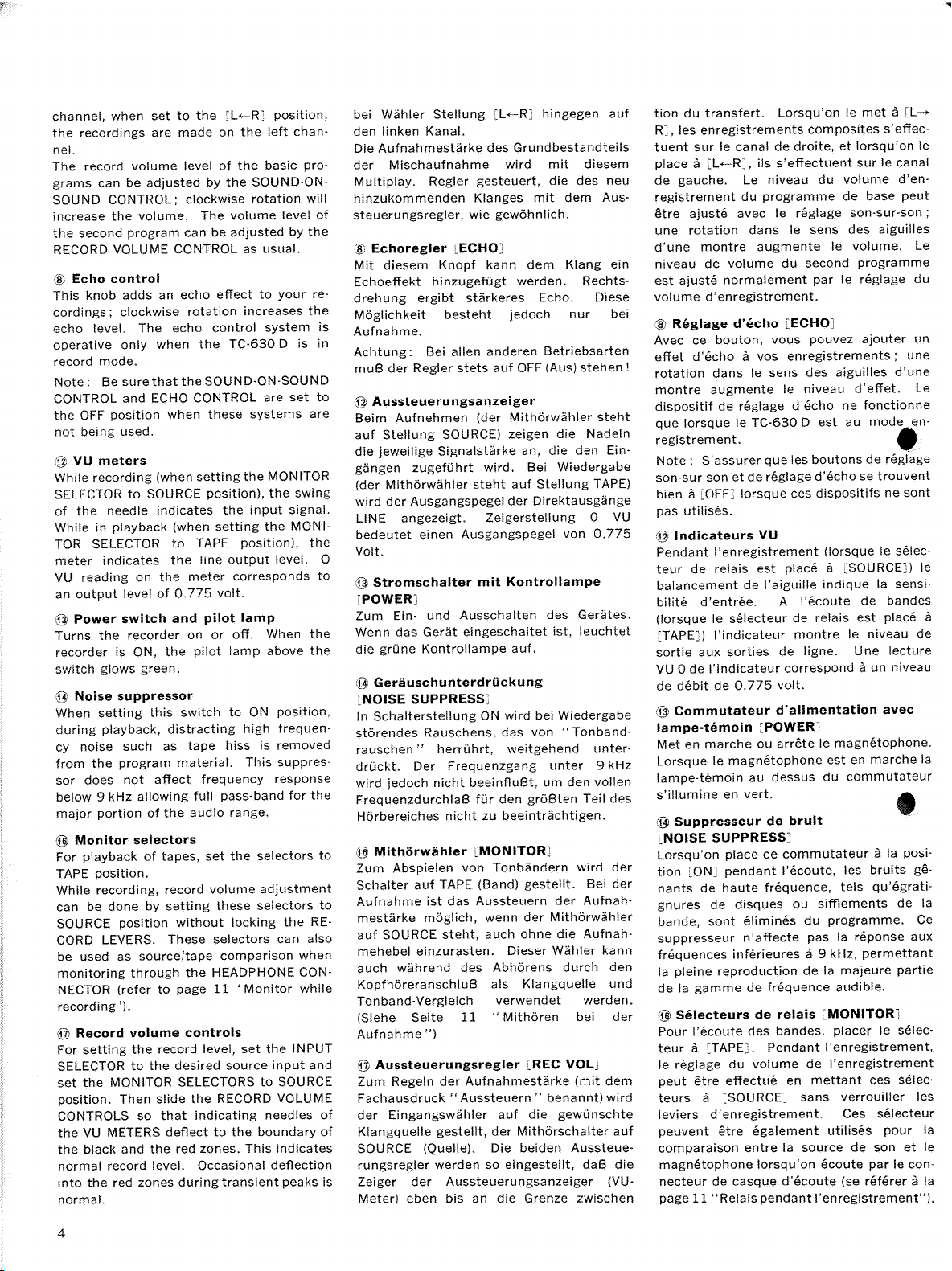

Page 3

Page 4

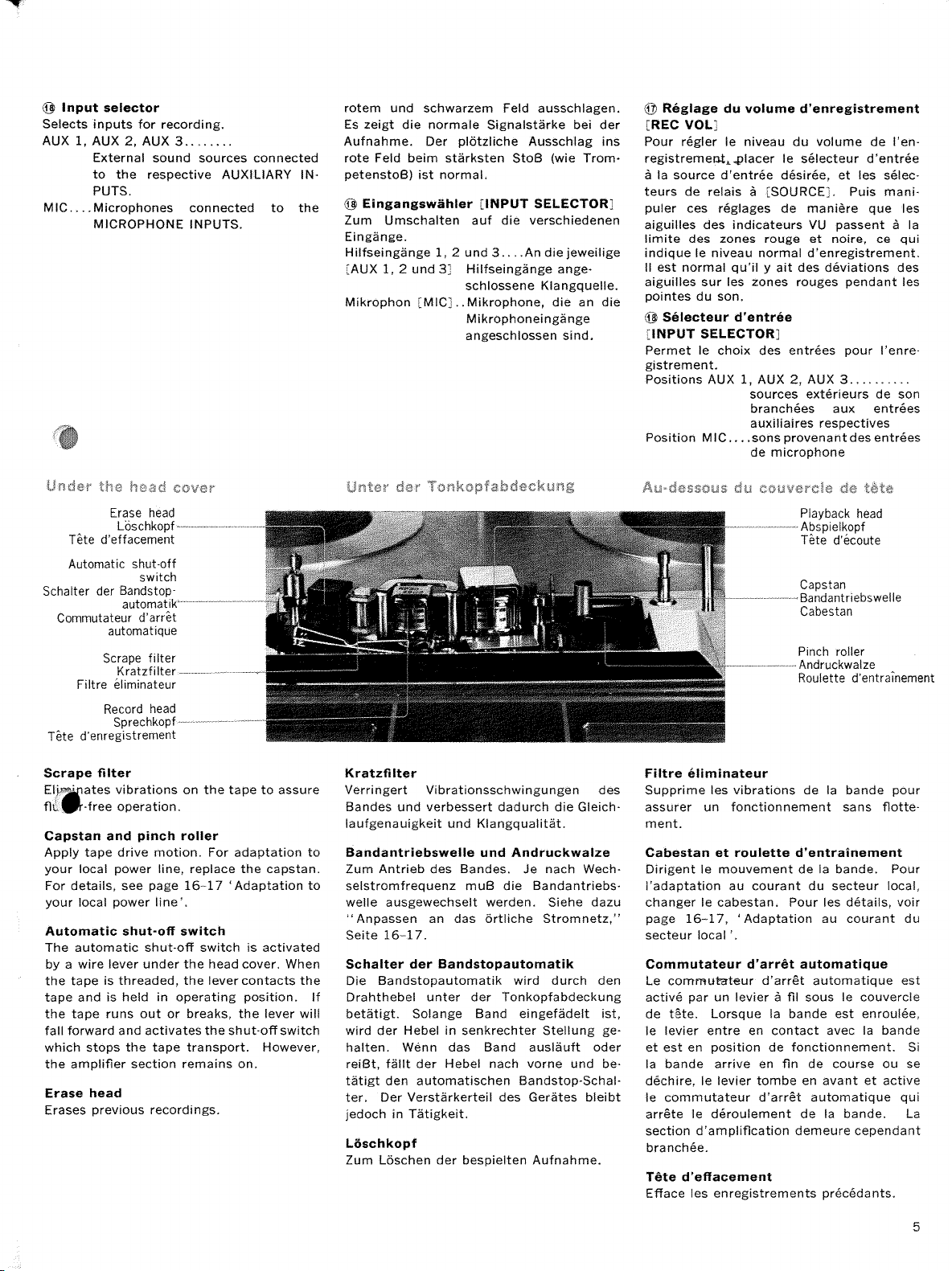

Page 5

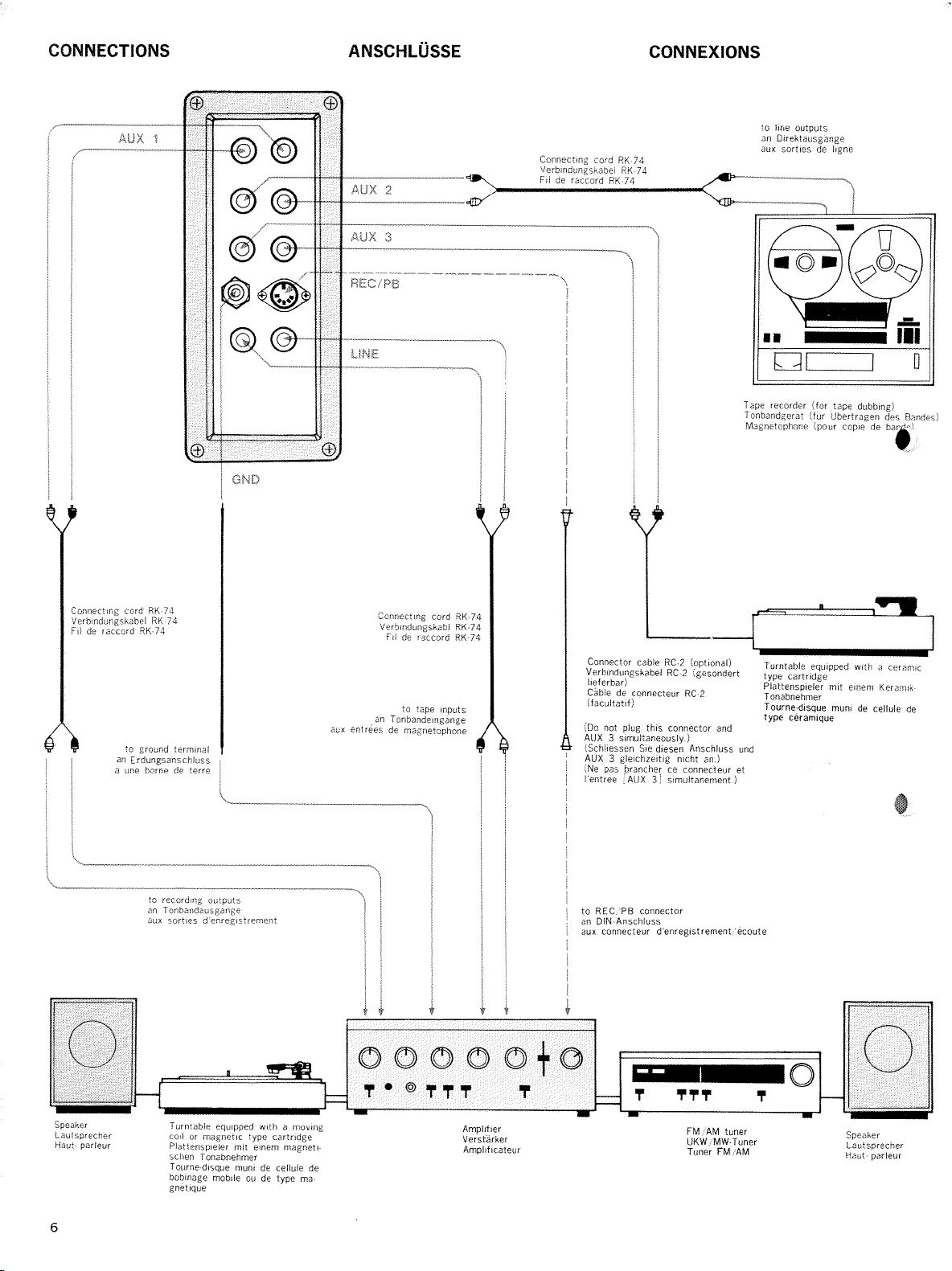

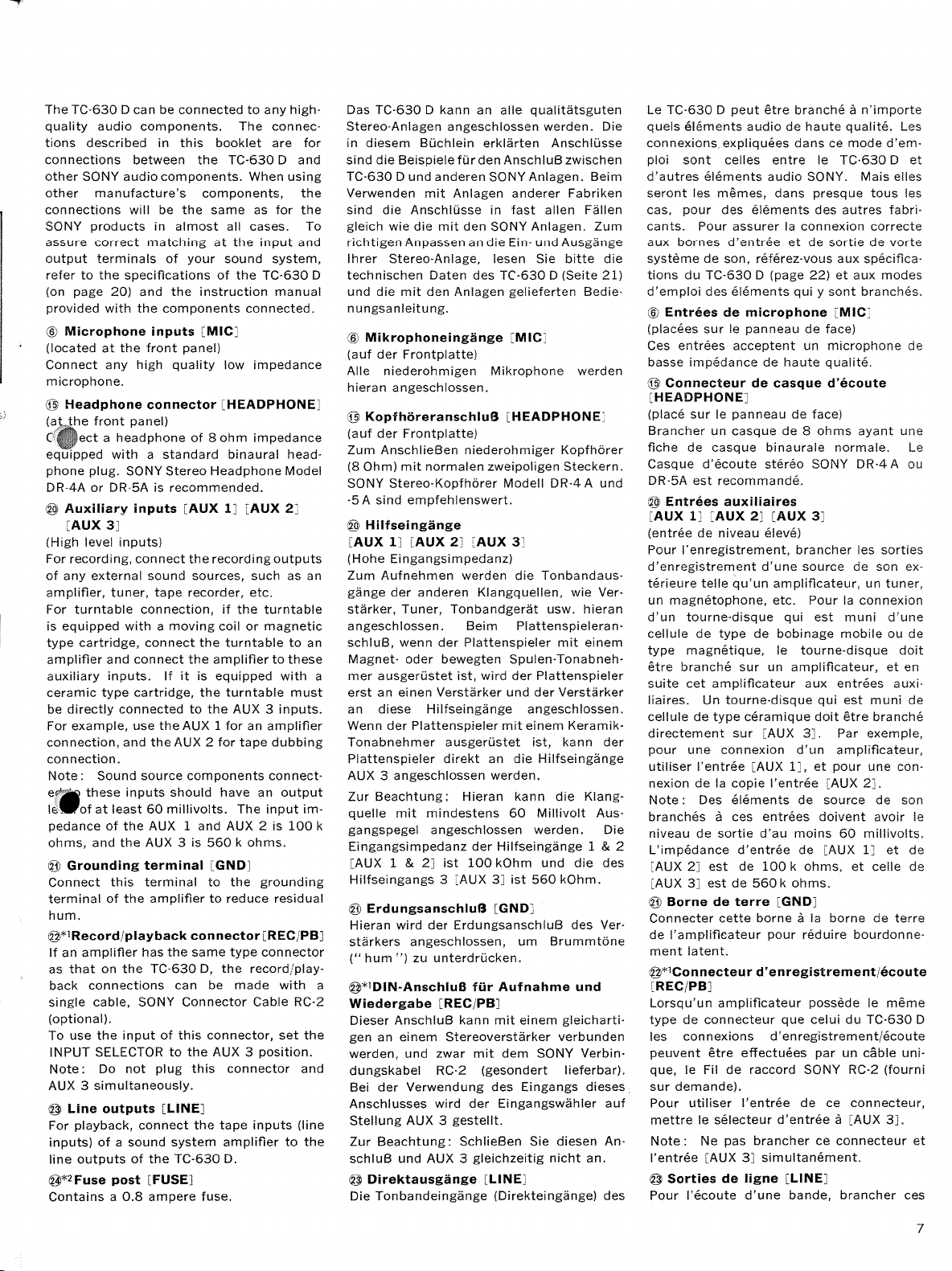

Page 6

Page 7

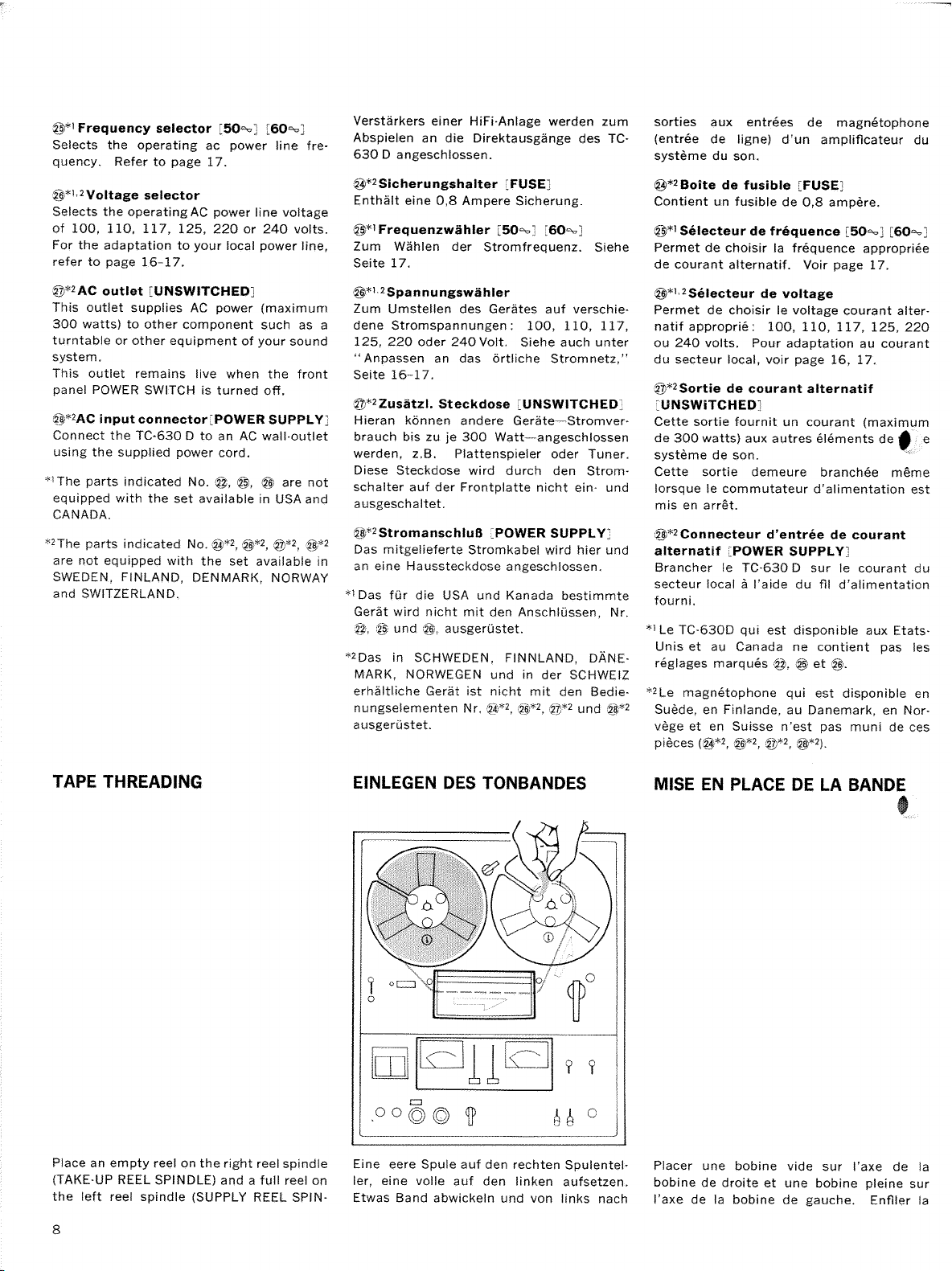

Page 8

Page 9

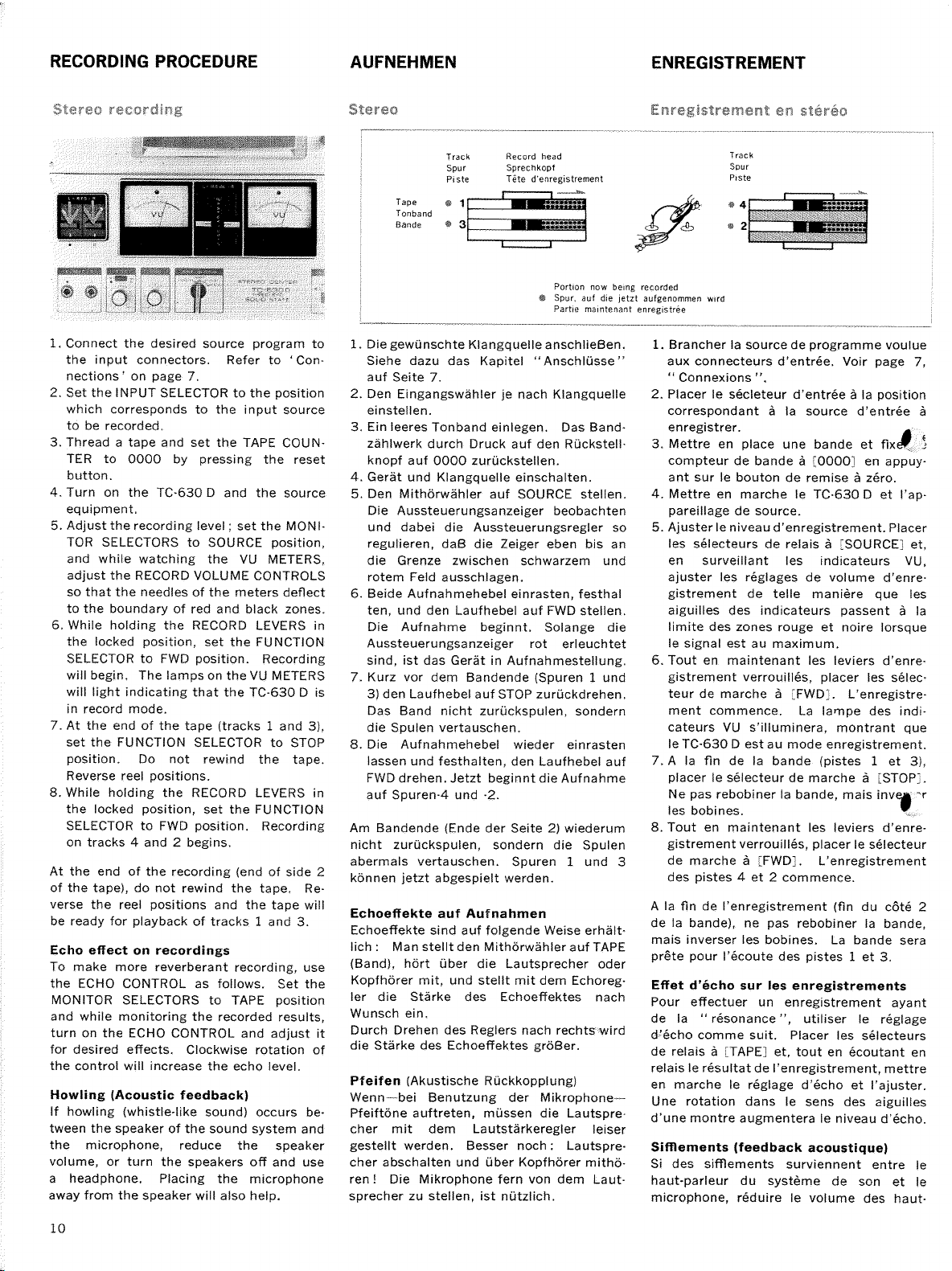

Page 10

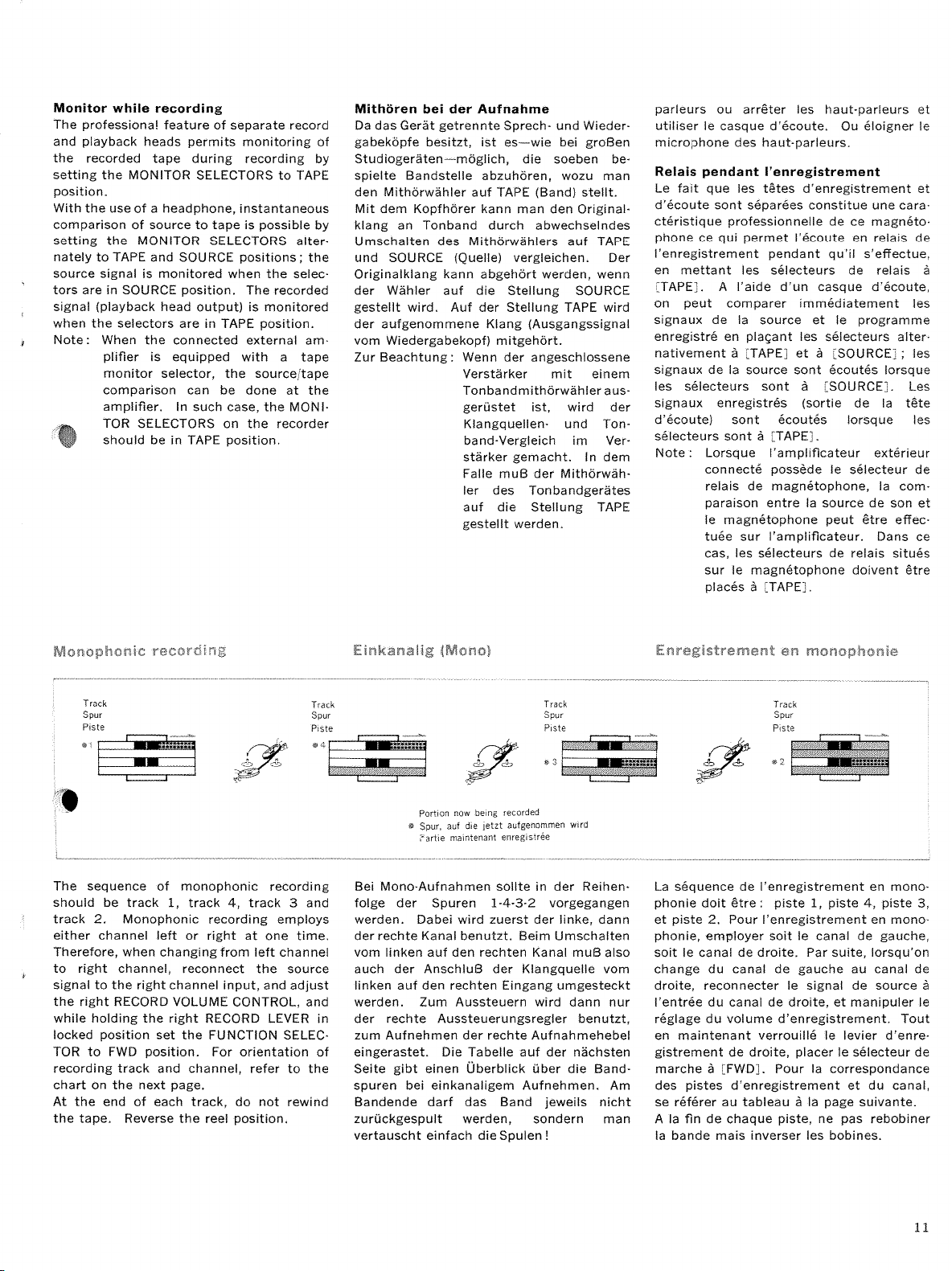

Page 11

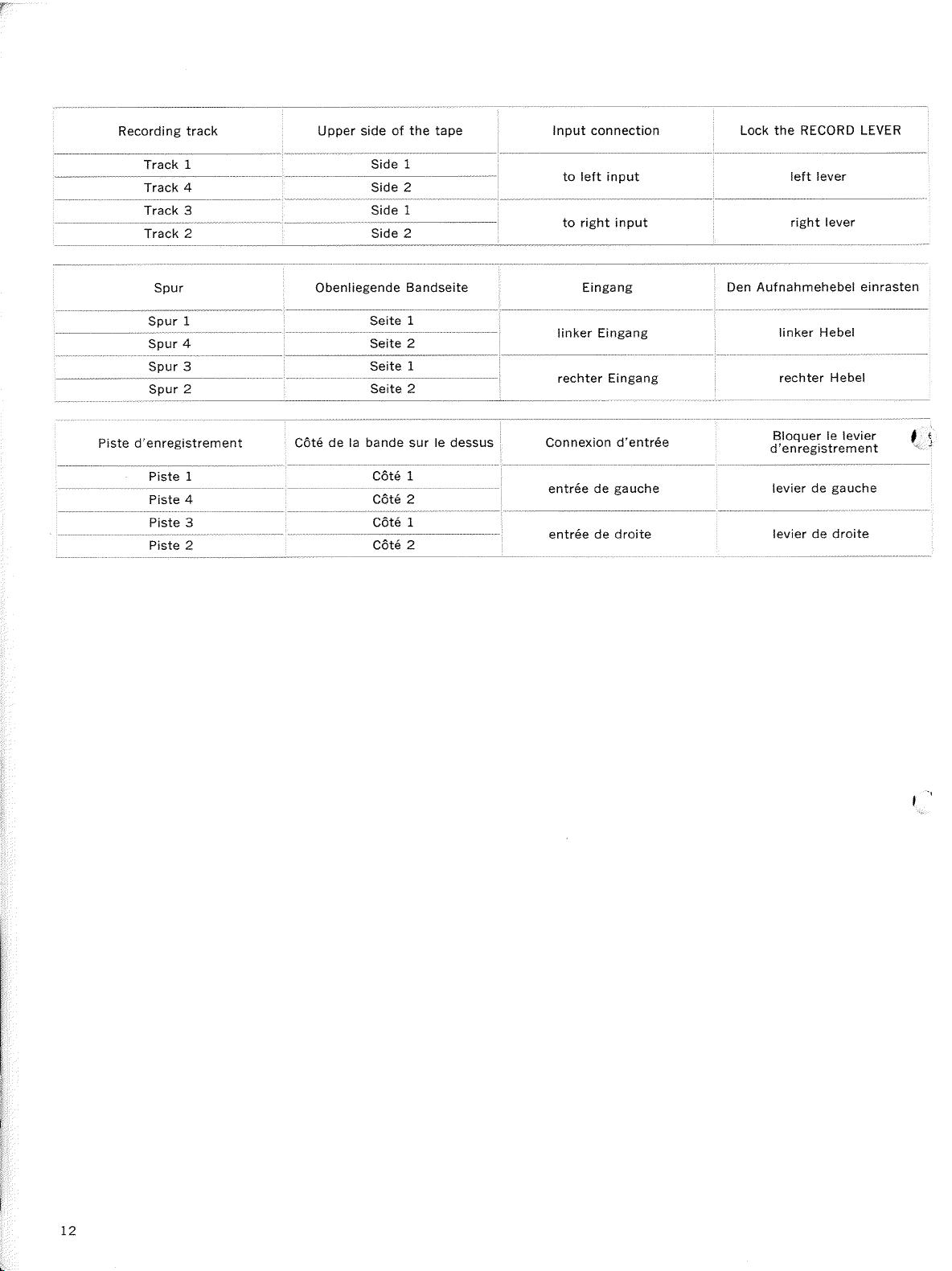

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

.."r.--,

.:t,_.,

,

.

..

:_:

a.

-r

Power Requirement:

Frequency

Signal-to-Noise

Recording

Harmonic

.

Tape

Speeds:

Reel Size:

Recording

System:

Response:

Flutter and

Distortion

lndication

Level

Outputs:

Recording

(with

1,800ft

Semiconductors:

Dimensions:

Weight:

Wow:

Ratio

lnPuts:

Time:

tape)

Heads:

AC

l17 volts,60 Hz,

7'z ips,

7"

4-track

2O-22,OOOHz al 7'/

20-L7,OOOHz

20-10,000

Less

Less

Less than

:

Better

:

Less

Two Vu meters

:

Low lmpedance Microphone

High

Line

Headphone Outputs

Headphone Outputs

A-track

Transistor'. 22

Diode :

Record:

Playback : PP3O-29024

Erase: EFIA'29O24

16'1

t40.8x

24

3% ips and

(18cm)

than 0.0996 at

than O.L2?6 at

than

than L.2/6

lmpedance Auxiliary

smaller

or

Stereophonic

at 3jl

at lVs

Hz

O.I6t/6

52 dB

Outputs: O

Stereophonic

hrs.

6

lbs. 15 oz.

at

(W)x7

19.9

1/i ips

3

RP30-2902

%(Hlx1811il"

x48.0

(11.3

61

dBs

(for

(for

(4.8cm/s)

pcs.

pcs.

cm)

3OW

L76

or

7%

3;l

Ili ips

(19

ips

Monophonic

(19

ips

(9.5

ips

(4.8cm/s)

ips

(19

ips

(9.5

ips

(4.8

lnputs:

lnputs:

lO.775Vl,

monitoring) : Load impedance

listening) : Load impedance

s, 9.5 cmls

cmi

cmls)

cm,/s)

cm/s)

cm/s)

cm/s)

72

dBs

22

dBs

Load impedance

4-track Monophonic

(0.06

12 hrs. at

(D)

kgs.)

ffiffi-re-rury

and

(0.19

more

L%ips

V)

4.8

mV)

8Q

cm/s)

than

100ko

8Q

(4.8cm/s)

t\

SERVICE MANUAL

Page 27

ications

Specif

Diagram

Block

General

Technical

Cabinet

Cabinet

Chassis

Chassis

Method

........

Description..

Features

..

Views

Side

Top View.....

Top View.....

Bottom

View

of Disassembling

Preventive Maintenance

Transport

Tape

Mechanical

Electrical

Diagram

Level

Diagram

Wiring

Schematic

Mounting

Playback

Mechanism

Ad.iustment......

Ad.iustment

Diagram

Diagram

Amplifier

"

Record

Amplifier

,,

Bias oscillator

Power Supply

"

Exploded

Diagram

Cabinet

Head

Control

Chassis

Top View

Deck

Chassis

Top View

Top View

the Set

.....

(Conductor

(Component

(Conductor

lcomponent

Top

Coil

View

& Trap

(Conductor

(Component

TABLE

Side)...

Side)

Side)

Side)

(Conductor

(Component

Side)

Side)

OF CONTENTS

.

..

Side).

.

Side)

Page

3.t4

10-11

13- 16

17-19

.....

20

2r

-23

24-25

26

27

2A

29

30

5U

31

31

32

??

34

35--36

1

3

3

4

5

6

7

8

9

When ordering

attached

The

herewith.

reference

replacement

number or

parts you

symbol

shauld use

number should

PART NLJMBER

for ordering

used

not be

-2

tisted on

purposes.

the

Complete

Spare

Parts List

Page 28

Circuit Outline

on-Sound

Recording

and

of Sound-

Echo-Effect

(Fig.2)

(Fig.

3)

(Fic.4)

-4-

Page 29

(

Fig.

5)

1i

Page 30

-6-

(Fie.

6)

Page 31

-7-

Page 32

Removal

of

@-tou""

Knobs

n"oo

&

Head

Cover

:9€i Ornomenlol

Scres

Removal

oRF3x8

Reel & Control

of

scres

EPCS

Panels

Y

Y

ornom€nror

lgi'

' aPcs

wosher

xnou.

fi)

\

sOS control

-/

xnor.

/i"X

\:/ inpul

*!1

'(i\

s€lcctor

dX rnou,

!]Y

6!A x.oo.

slrde

\:7

xnor.

ecnoconlrot

nonilor

volume

sclcctor

coilrol

@

Knob.

noiSc

@

Removal

suPpresg

of

@ **0.

;;uer

sritGh

(

Fis. 8)

Chassis

switoh

_

z.riiL_/z

--6-\D<)l

\<.[n

g

(

Fig.

I

e

g

10)

E

1

E

g

jP Wosher,

e

l:

E

^E^

cdbrner

g

-8-

Page 33

The

year,

following

whichever

parts

occurs first.

1. Motor

Motor requires

2. Gapstan

Capstan

requires

3. Pinch Roller

Pinch Roller requires

ldler

4.

ldlers require lubrication

lf the oil

should spill on the

of the tape transport

Lubrication

drops

of SONY

of SONY

4

or 5

2 or 3 drops

2 or 3 drops

if they

only

rubber

mechanism

of importance

is

(light

Oil

Oil

of SONY

become

or the belt,

wheel

require

machine oil).

(light

machine

(light

Oil

noisy.

lubrication

to insure

oil)'

machine

no

Use

wipe

proper

oil).

more

it off

two

after

operation

one drop

than

immediately

thousand

of the

SONY

of

with alcohol.

of

hours

equipment.

(light

Oil

operation

machine

or

oil)'

once a

The

This

flutter

following

cleaning

wow, or

and

parts

Capstan

Pinch

Flywheel

ldler

Tape Guides

Heads

must

Roller

be

is of importance

poor

frequency

cleaned

forthe tape

response.

with a

liniless

threading

cloth

path to

moistened

with alcohol

prevent a loss

of

(methyl)

positive

optimum

for

drive at

performance'

capstan, drop-outs,

(Fie.

o_

11)

(

Fig.

12)

Page 34

Supply

Reel

Table

rn

SlriP r:-rode

REWIND

ldler

REWIND Belt

Motor Pulley

Take

up Reel Table

T ake-up

'

ldler

ON/OFF

B'ias

(OFF

Supply

Ree I

Table\,..

Lever

0N/oFF Switch

Bla\

(ON

Switch

Position)

Position)

FCRWARII

I

RFWiND

mocle

ldler

REWIND

Motor

f,

Belt

Pulley

Fu nc t

Selector

Cam

ior,

a

T

ke-up

Reel

Table

I aKe-up

ldler

Bras

ONr'OFF

(OFF

Switch

Position)

rn

Capstan

FEr!lND

REWIND

REWIND

){

-10-

mode

ldler

Motor

Belt

PulleY

ake'uP

T

Reel

T

Table

ake-uP

Page 35

at

7y2ips

(19cm/s)

R

-l

speed

EWIN D

*.

;

''

Motor

r\f

Take up ldler

Pul

ey

FAST

FORWARD

Crank

t'

Button

(

Fig.

16)

Se

Speed

lec

to r

Leve r

Motor

Pulley

I

Iake-up

I

Capstan

(

F ig, 17)

ldler

ldler

Speed Selector

Lever

Speed

aI Itiips

Se ector

$haft

(4

Bcm/s)

Motor

Pulley

+

0apstan

speed

6

ldler

Take

up

ldler

Speedj

Selector

Speed Se

ector

Lever

al 3)4ips

(9

5cm/s)

5pss6

#

Capstan

(

Take

ldler

Fig. 19)

-

up ldler

11

-

(Fig.

i8)

Page 36

(

ig. 20)

F

(r/64")

0.2-0.4 mm

in FAST

just

Ad

FORWARD

bending up or down

by

(Side

13

-

mode

View)

-

with

pliers,

(Fie.22)

in STOP

Adjust by bending

mode at

(Top

with

View)

the

pliers.

speed of

4.

Page 37

iir-i;,ir

Pinch Roller Shaft

143/64+O.OO8ol

L7.2+O.2mm

Pinch Roller

& Down Cam

Up

.--

i

(Front

When

i

.

Adjust

moving up or down as shown

adjusting

by bending

Pinch

with

Roller

View)

roughly

pliers

& Down Cam

Up

'a

Head

Do not make scratch.

When adjusting accurately

'

Adjust to oblain

below.

by

Shaft

After

Deck

t7.2+O.2mm

loosening Screw

trp

or down.

fastening

Screw, apply

and

143/64+O.OOBtl

moving

Lock Paint.

Down Cam

!l i

l$

speed

r

rf

S,

Capstan

..:.1

..:

4.8 cm/s

of

ldler Arm

(17l8

ips)

lL/64-5/64'l

O.5-2 mm

(

23)

Fig.

(Bottom

Rewind

View)

Lever

Z

-14-

(Top

'

supply

View)

lf

belt does

bending

by

Reel Table

(

21)

Fig.

not run

smoothly,

up or down with

Rewind

ldler

(Fie.24)

adjust

pliers.

Page 38

r;;:cir

,

irl;iiioi:

in FORWARD

Acijus;;;:ent

mode

mm 11,/64n1

0.5

F

in

Adjusting Plate

!i'l::tant

FORWARD

lnstant

Stop

stop

mode withor

Lever

Lr

in FORWARD

pstan

Ca

just

Ad

by bending

ldler inclines when Flywheel

ldler

lf

slips, clean the surface

or down

up

alcohor

*S

STOP mode at the

tn

the

adjust

(Top

Viewl

i,i"1.,:!.ii-i

mode at

with

is

f inger-stopped.

iiliti

the speed of

pliers

in

of ldler

(Side

.- i'i-l: li.1l

idier F-r;!iii;ir

'

speed

position

:-,.,-,

case

with

of Head Deck.

l,.irp:i.i

4.8

Motor

View)

19cm/s

of

cm/s

Pulley

(7t

(

F ig.

(17le

(Fig.

zipsl

25t

28)

ips)

I/64-L/3241

Motor

H

I

i+e

O.5.*1.Ofiffi

iake-ui:

in FAST

Pulley

,1l.j:iJ;)-i

.;i;;.:

il

Pinch []

(ToP

iilier

nojt

this4,

(Side

Vievi

i!r,;t-lFF SW-

Switchu

r\

3

tr

N

t=

L.

k\

=l

to be flush

to be adjusted by finger-pushing

(Side

View)

-15--

up

or

down

(

Fig.31)

View

Side

Loosen Screws and adjust by slidin6

Page 39

Acjjl,.r.,t i''r

l\ier

airt

rt capstan sleeve attached

'

Loosen

position

the

Screw and

adjust

of Adjusting

Plate.

1r-

@l*1

lt=

#---=-

/iew)

Adjusi-.i,;r;

iD

mode

Table

>l

(Fig.26)

tn

Loosen Screw

i:

:-,

4+

in FORWARD

5:1,:.

FORWARD ffiod€

Screw

-,*i.t.i

shown and

(Top

-;;:;

i-,1r;,

mode

rake-uptdter

i'a;,t;,iil,.

corruct the

adjust by sliding

Aii;:.t .'.t"''tnr

t

position

Switch

of

Stider's end

Slider

Holder.

View) (Fic.27)

the

at

Take-up

speed of

Reel Table

4.Bcm/s

|-l

/nh

(17l8

-

in

ips)

ust by bending

;

crank up

v)

i(:

Off

T'I

Micro Switch

:

h

''l:

position

A ct uator

or

:..

:.'i

down with

j';

l-'

i

.l

i

Holder.

pliers

(Fie.29)

(Fig.32)

Loosen Sirews

/

take.up

so that

.*

dd

s ttr

shown,

Erase Head

mode,

there should

fast forward mode, tape should

ln

screw

and adjust

Pad

Hinge

lL,/64-L/32'l

ln forward

as

Make the adjustment

Loosen the

adjust

and

idler makes

(Side

'

...,':

-

in FORWARD

be the

with

sleeve

1Omm

Shifter

attached to

by

the

contact

View)

positioning

with the

mode

clearance of 0.5-1.0 mm

capstan and without sleeve.

0.5

-

11. /64-r /32',1

pulley

not contact with heads.

shifter.

of Motor

height

Pulley

shown'

as

lL/64-L/32'l

(

Fig.30)

-16-*

Page 40

ffi

l

Playback Head

Alignment

2. Playback

Level Adjustments

3. Playback

justment

Ad

7

lIl

).4

(2\

3i+

ips

4. Bias Trap

Head

Record

5.

Azimuth Alignment

&

Item

Level

Equalizer

(19

ips

(9.5

Coil

Height,Zenith

Azimuth

Meter

and

cm/s)

cm.s)

Adjustment

10kHz,

ment Tape,

1 kHz, 1st

ment Tape,

SONY

3rd

.

Monitor

Monitor

Alignment

Monitor

Alignment

SONY

Monitor

1 kHz,

6O

lnput

Signal

Source

section of

J-19-F2

Switch :

section of

J-I9-F2

Switch : TAPE

Tape,

Switch:

Tape, J-9.F1

Switch:

(0.78

dBs

Selector:

mV)

SONY

TAPE

SONY

J.I9.F2

TAPE

TAPE

MIC Jack

to

MIC

Align-

Align-

Output

VTVM and 100 kO

parallel

VTVM

parallel

VTVM and 10O

parallel

VTVM

VTVM and 100 k

parallel

to

and

to LINE OUT Jack

to

to Test Point

(See

to LINE

LINE

100 kO

LINE

Page 28,

Connection

OUT Jack

k

Q

OUT Jack

O

OUT Jack

Resistor in

Resistor in

Resistor in

and Ground

TP.l

Resistor

in

Mode

PLAYBACK

PLAYBACK

PLAYBACK

RECORD

RECORD

6. Record Head

Alignment

Azimuth

7. Record Bias Adjustment

Record

8.

9.

Dummy

1O.

.l.l're:;-

1) Before

2l The

3l The

4l

After

Level Adjustment

Record

Equali:er

justment

Ad

Coil

.

adjustments,

Sound-on.Sound

adjustments

adjustments,

Adjustment

should be made

and

clean

(SOS)

Switch

Lock Paint to the

apply

15

kHz,

J

ack

1 kHz,

lnput

-60

90 dBs

dBs

lnput

1 kHz,

Jack

60 dBs

-

lnput

k, 20 kHz,-90

I

Jack

lnput

demagnetize the Record Head, the

and the Noise

in numerical

adjusted

l24.5ttY)

Selector:

(0.78

mV) to MIC Jacl

Selector;

{0.78

Selector

dBs

{24.5.,rV)

Selector:

Suppressor

order.

points.

to MIC

MIC

MIC

mV) to MIC

: MIC

to MIC

MiC

Switch should

VTVM

parallel

VTVM

parallel

VTVM

parallel

VTVM

parallel

VTVM to Test Point

Playback

Head and the Erase Head.

be set

10O

and

to LINE

and

to LINE

and 10O

to

and 100 k

to LINE

{See

LINE

in

100

Page

OFF

OUT Jack

OUT

OUT

OUT

position.

k

O

k

O

Jack

k

O

Jack

Q

Jack

28, TP.)

Resistor

Resistor

Resistor in

Resistor

in

RECORD

in

RECORD

RECORD

in

RECORD

RECORD

-17

Page 41

Adjust

Procedures

and

Remarks

Playback Head Azimuth Alignment

Screw

L-CH: Rree

R'r, Rzss

See

R-CH:

See

Fig.

Fig.

35.

R266

37.

(2OkO

(5

kO

;

;

L"CH: Rroz R-CH: Rzo:

(B)

2 ko

Fig.

See

37.

L-CH: Rror R-CH : Rru,

(B)

3 ko

Fig. 37.

See

Fig.

See

Fig.

See

Fig.

See

R-CH :

Fig. 34

See

R.CH: R,,,,,

(Bl

See Fig.

R-CH

: Lrut

34,

35.

35.

Crnr

34

1,,,,

Zenith

-

Alignment

and

L-CH: Lror R-CH

l.8 mH

Record Head Height,

Azimuth Alignment Screws

Record

Screw

L.CH Crn,

L-CH:

L.CH : L,,,,

Head Azimuth

"'

3O

2O0pF

Rr:,,

ko

5

1.8/1 45 mH

Fig

CH

rtg

34

L,

34

See

L-CH: L,,,, R

1mH

I

see

Adjust the screw

B)

1.

B)

Adjust

2. Adjust Rrss

Deviation against the

Tape Section

After the adjustment,

Deviation

1.

Set source

2. Adiust to

1. Turn the

visually

2.

Set MONITOR

3. Turn'Height

tu

4.

Turn

alignment

5. Repeat Steps

L

Set

2. Turn Azimuth

screw,

1.

Set

2. Turn the

Recording

3.

VTVM

4.

Continue

reading.

Adjust

5.

Make sure

6.

7.

lf

1.

Set

2.

Feeding

o vu

Record

3.

4. Set

Ad.iust

5.

Set

Record

Record

the

Note: Two

1

Set

2.

Read the

Set

4.

Adjust

5.

Set

to obtain

(L-CH)

Rroo

(L-CH)

Frequency

L.CH

R-CH 3.512 dts LOi2

against

Tape Section

uency

Freq

L-CH

R.CH

rns.

Zenith

MONITOR

MONITOR

the

volume

obtain

screws

three

horizontal.

switch to

Alignment

Alignment

screws.

2 and 3 until

switch to

Alignment Screw

maximum reading

the

switch to

trimmer

signal, turn the

the

reads the

turn the capacitor

to

Read the VTVM

trimmer capacitor

the

that

reading of

not, repeat Steps

MONITOR switches

the

the

the

same as

source volume

the

the

stgnal, slide

the

1700%1.

signal on a blank

the

MONITOR switches

Rr:'

{R:zn)

MONITOR switches

1 kHz signal of

kHz

20

one of 1 kHz signal.

peaks

in

shown

VTVM

machine

L,"' so that

rirachine

maximum

and R,us

and Rzar

level

4th 3rd 5th

12.5

kHz

otZ dB

repeat

the

level

of 500

4th 5th

kHz

5

0+2 dB oa2

controls

minimum

(height,

TAPE.

Screw

and

TAPE

TAPE

capacitors counter.clockwise

maximum value.

reading.

2-6 again.

the source

so that

signal of

Fig.

rcadings of

in

in R.CH RECORD

VTVM indicates

90 dBs

-

-90

appear during

36.

controls

L-CH RECORD

VTVM reading is

reading

(R-CH)

(R-CH)

1 kHz oI 2nd

of

10 kHz

ot2 dB

on VtVfrl.

to obtain

so that

0 dBs

pointers

section

7 kHz IOO Hz f,U HZ

ot2 dB

Meter Level Adjustment.

3rd

Hz of

3 kHz 2OOHz IOO Hz

dB

(Rr3r

& Rz33)

reading

zenith and

obtain

to

Azimuth

maximum

position.

to

should

position.

trimmer

until

{Cr,,,,,

is the same as

L'CH

&

{S,,,0

tape.

(Sr,'r

&

($1u,

&

124.51,Y)

Ort

turning Lr,i

(Rrj3

&

channels.

both

section

6th 7th

2i2 dB

25L2dB

minimum

to

VTVM.

on

aziml'th

maximum reading on VTVM. Memorize

Alignment

reading is

obtain

obtained. lf not, repeat the

be

Screws

maximum reading on VTVM.

and

capacitor

the VTVM reads a value 0.5 dB below

R

in

CH)

to

S,u'l

volume

to

S,u,')

to

S,',;)

,r4.51tY)

Rr.,,) to minimum.

mode.

the

same as one

mode

and adjust L,,

same

the

one read

SOURCE

controls

TAPE

O

dBs

{0

TAPE

blank tape and

on a

and adjust

1L:,

(0.775V)

Level Mcters

of

6th

3.Or2 dB 2.O!2dB

(J.542

dts

I.Oa2 dB

alignment) so

the same number

obtained

set them in minimum

(C:',,i,,

L-CH)

way.

in

position.

(Rrsr

& Rz::)

position

775V)

position.

Lror

Take

L).

the

read in

in the same way

,

on VTVM.

stay

at 0 VU

7th

dts

that Record Head will be

the number of

of

turns

Within one turn of the

adjustment as

capacitance

clockwise slowly until the

in

the

4

Step

level meters

so that

read

(Lzor)

peak

Step

VTVM reading

the

so that VTVM

where

the core is

2.

(1OO%).

of height

ltem

5.

position.

maximum

indicate

reading

"

is

"

b

Bias

Voltages

Erase Voltage applied

applied

to Rec, Head

Erase

to

Head

are

approximately (

is approximately

1A

16

(

14

\ rz

120

Votts

Volts

vort.

Volts.

al 7/

ips

at 3V|ips

at L/i

ips

(19

(9.5

(4.8

cm,

sl

cm,s)

cmi

\

.

f

/

s)

Page 42

(

Fig.

34)

(

Fig.

35)

Lror,

zor

Circuit Boord

(Fig.36)

I

Fis 37)

Page 43

CEt

tuP

CM

t00P

Cn

tuP

I.CH ft

HEAD

iL-cH

pd

ix-i-ec

nntUK

Otos Qto.

2SO6E'

2SC65t

AMp

eoaRD

@

0uk)

Stot'e

6m

30s

R-L

qilLt

7+

J]K

L.R

)

VR

PHat

PPno-2t02

fr.CH

P8

A

HEAD

R-CH

I

fraE IMK

Rtu

Otor

2SC6!r'

REC

/00K

Oror

250631

AMP

/6)

U/

Qco+

25C6:t3

-24-

lat-t

1m-e

Page 44

orr2SOS!{

LJOI

L-

1pr,'

E nnlily

Sare

o

ffi

Te

edlAN

Orc2!tC63{

erAs osC-eoARo

fiHt-t

Sprt

Schematic

1.

2

2.

fi

All

3.

pF

Resistor

4.

letter

The

5.

of

5. Voltage

VTVM

speed

noted

Voltage

Notes:

: Adjustable

: Grounding

resistors

respectively

whose

(N)

is

letter

potentiometer indicates

values

in PLAYBACK

7'/z ips

of

because

values

parentheses.

in

14

fl EnaE

tn 0. R4fl

EH20t

-290e4

ER|SE tuq

to Chassis

and capacitors

unless

rating

low-noise

(C)

(Bl

(A),

or

measured

are

and

(19

cm/s).

normal

of

RECORD

in

SUPruY

BOARD

rated

are

otherwise

value

resistor'

suff

specified.

is suffixed

to

ixed

characteristic'

its

ground

to

RECORD

production telerance'

mode at

Variations

are

mode

in

with the

rating

enclosed

Q

value

with

may

METER

PLW

METER

PLfi'

PLlil NWER

and

a

the

be

UMP

LAIIP

UMP

(L-CH)

(fr.CH)

Record/PlaYback

Selector

lnput

&

Speed

Monitor

Muting

Noise Suppress

Sound-On-Sound

Sound-On-Sound

Switch

Bias Switch

Power Switch

Auto-Shut-Off

fl

HI

I

il7v

A.C.

60llz

Equalizer

Switch

Switch

Switch

Switch

Switch

Switch

Switch

Selector

Switch

7%r

lI9

cm/sl

(\

o

c

E

I

(

(

{

I

o

-25-

Page 45

I

I

I

-\

o?

d

@

r

@

Cabinet

.49

Top

View

-

v

Plain

Spring Washer

SW:

Lock Washer

Nut

Retaining

E:

\

/*t

Washer

Ring

Number

1

Reference No.

listed in

List

Parts

i!"t

encircled

the Complete

shows

which

attached

€9

is

Spare

hereto.

..<

g

a

y

Y

aAr)

\

;

I

\

-'i4

-:a

Y

I

t ._

Page 46

/6\

5

F

,?'

lol \di

\;/v

/-::\

@

-:

It

3

(D

o-

o

a

U)

a

(E

-c

c)

-

A\

,/

\r\

,,

'''i...

. i\ /e,

is)

/a\

to_

,g€)

-1

-€,

*

a),O:'E

Y

dd

--

,ub,

' (|.)

35

--

tD\ \

J\0

980667 - I

Page 47

,'i',

j

%

,e..

-+,'

I t'r

'

-4,'

I

'

'

-/l

Cx.

'\t

r\

v

{\l

l

v

(.i

6-}

€bo

=

ah0

/Cl

\S/

,/iir

\cO

@o-o

q

@:

@-=

i_

rLi

P?-

f

rc

li'l-'_l

\,:/

\=/

-s

I

O

N

2.

\='

€.

--

--ie)

'\{-/

! .o @ 9.'5

O-!!.-^

ElES-9

oi

b;n(

c=oE-

o;

ooi

-

v

-</

"

:g?*E;

;eir€€

EE;;37

Eggt

&.

2

:I

rb0

-9-

9;9

3;3 v

3

*3

c.E:<

#,4!;p

v

f

or

i

.E

E

'6

=

o:

k

980667

=giz-

SONY

- 1

CORPORAT

,-

36

--

ION

Printed

in Jopon

Page 48

;

\'l

i,l't

:1!l,.--,.]

,A-

i.

-2-

G+t

Head

Deck

r_^\

qj

,,'ta\

'19

Top

t?F.,,. =,

,

isq

1>-

,l

.43

zii

I

,to

View

)

T

+(.)

.-/'''

.,/

t 12

PF).

,J

.

Y

v

v

l.li

:_,,---\

:.-

i

e,

g

il

e"

&--

,v

Plain Washer

Washer

Spring

Washer

Lock

Nut

Retaining

Ring

Number

Relerence

listed in the

Parts List attached

encircled

which

No-

ComPlete

shows

is

SPare

hereto.

Page 49

Control

Chassis

Top

View

--l

f)):,

,'-,

f

-s,r,

{

Q'-*-

-r:;\'

,6C

,oi)

(1*

,'@

8g

Frl

':

"'-/

6,/

1',8?-

e#-

B

@lr

@

\/

,/

t'i'

3v.'

L\}Y

l.

I

Piain

:

Spring

Lock

Nut

Retaining

oq

OP

,w

CIP'

CIe

Washer

Washer

Washer

Ring

34

e

0

g

a.O

%

Oo

-v

v

-_l

v

i

:

;

1

dl

U

I

I

t

Loading...

Loading...