Page 1

AIT Autoloader

4-673-839-12 (1)

Operating Instructions

Before operating the unit, please read this manual

thoroughly and retain it for future reference.

LIB-D81

© 2003 Sony Corporation

Page 2

WARNING

To prevent fire or shock hazard, do not expose the unit to rain or moisture.

To avoid electrical shock, do not open the cabinet.

Refer servicing to qua lified personnel only.

Caution

The mains plug on this equipment must be used to disconnect mains power.

Please ensure that the socket outlet is installed near the equipment and shall be easily accessible.

NOTICE

Use the power cord set approved by the appr opri ate te sting o r gani zati on for t he specific coun tri es where thi s un it i s t o be

used.

Achtung

Zur Trennung vom Netz ist der Netzsecker aus der Steckdose zu ziehen, welche sich in der Nähe des Gerätes befinden

muß und leicht zugänglich sein soll.

Hinweis

Der höchste Schalldruckpegel beträgt 70 dB(A) order weniger gemäß ISO7779.

Ratings

Voltage

AC 100 V - 240 V

Current

0.7 A - 0.35 A

Frequency

50 / 60 Hz

Max. Ambient Temperature

40°C

A certified power supply cord has to be used with this equipment.

The relevant national installation and/or equipment regulations shall be considered.

A certified power supply cord not lighter than ordinary polyvinyl chloride flexible cord according to IEC 60227

(designation H05VV-F 3G 0.75 mm

synthetic rubber according to IEC 60245 (designation H05RR-F 3G 0.75 mm

Zum Netzanschluss dieses Gerätes ist eine geprüfte Leitung zu verwenden.

Es sind die zutreffenden nationalen Errichtungs- und/oder Gerätebestimmungen zu beachten.

Es ist eine geprüft e flexible PVC- ummantelte Leitu ng entsprechend I EC 60227 (H05VV-F 3G 0.75 mm

F 3G 0.75 mm

(Bauartkurzzeichen H05RR-F 3G 0.75 mm

2

) zu verwenden. Andernfalls ist eine fl exible Lei tung aus synth etische m Gummi entspreche nd IEC 6024 5

2

or H05VVH2-F2 3G 0.75 mm2) shall be used. Alternative a flexible cord be of

2

) zu verwenden.

2

) shall be used.

2

oder H05VVH2-

2

Page 3

INFORMATION

You are cautioned that any changes or modifications not expressly approved in this manual could void your authority to

operate this equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limit s are desi gned to provi de reas onable pr otection against harmful inter ference in a r esidenti al

installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause ha rmful interferenc e to radio communications. However, there is no guaran tee that interference

will not occur in a particular installation. If thi s equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equ ipment off and on, t he u ser is encou ra ged to t ry t o co rrect the in terference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experience radio/TV technician for help.

The shielded interface cab le recommended in this manua l m ust be used with this equipment in order to comply with the

limits for a digital device pursuant to Subpart B of Part 15 of FCC Rules.

If you have any questions about this product, please access Sony Support Center written in the warranty card.

Declaration of Conformity

Trade Name: SONY

Model No.: LIB-D81

Responsible Party: Sony Electronics Inc.

Address: 680 Kinderkamack Road Oradell, NJ 07649-1601

Telephone No.: 201-930-6972

This device complies wi th Part 15 of the FCC Rules. Operation is subject to the following two conditio ns:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired operation.

Ratings are indicated on the rear, while regulatory agency marks are separately affixed on the bottom.

3

Page 4

Table of Contents

Chapter 1 Introduction

Chapter 2 Installation

Overview.......................................................................7

Product Features and Functions ...............................8

Front................................................................................8

Rear.................................................................................9

Interior (Front) ..............................................................10

AIT Drive (Front)..........................................................11

System Structure.......................................................12

Compatible Cartridges..............................................12

AIT Cartridges ..............................................................12

Cleaning Cartridge........................................................13

Software .....................................................................13

Precautions................................................................13

Overview.....................................................................14

Unpacking..................................................................14

Package Contents .....................................................15

Preparing the Host Computer ..................................15

Installing the AIT Autoloader....................................16

Connecting the Power Cable....................................17

Connecting to the Host Computer...........................17

Setting the DIP Switches ..........................................19

Setting the SCSI ID....................................................21

Connecting SCSI Peripheral Devices......................22

Turning the Power On/Off.........................................22

Setting Cartridges .....................................................24

Preparing Cartridges .....................................................24

Inserting Cartridges.......................................................25

Setting Application Software....................................27

4

Page 5

Chapter 3 Basic Usage

Overview.....................................................................28

Control Panel.............................................................28

Using the Control Panel................................................28

Message Display ...........................................................29

Warnings....................................................................29

Errors..........................................................................30

Disaster Recovery Function.....................................31

Assigned Element Addresses..................................32

Handling the Cartridges............................................32

Handling........................................................................32

Storing...........................................................................33

Maintenance...............................................................33

Chapter 4 Operating the AIT Autoloader

Overview.....................................................................34

Using Cartridges........................................................34

Ejecting/Changing Cartridges.......................................34

Chapter 5 Cleaning the AIT Drive

Overview.....................................................................37

Cleaning the AIT Drive..............................................37

Appendix

Cleaning the Air Filter...............................................41

Troubleshooting........................................................42

Transporting the AIT Autoloader.............................44

Hardware Specifications...........................................45

Hardware.......................................................................45

Memory.........................................................................45

SCSI Cable and Terminator Specifications .............46

SCSI Cable....................................................................46

SCSI Cable Length........................................................46

SCSI Specifications...................................................46

About the SCSI Components........................................46

About the SCSI Bus......................................................46

Error Code List ..........................................................47

Other Messages.........................................................52

Index...........................................................................55

5

Page 6

© 2003 Sony Corporation. All rights reserved.

Trademarks

• Sony, StorStation and Advanced Intelligent Tape are trademarks or registered trademarks of Sony Corporation in this

country, other countries, or both.

• Other product names are trademarks or registered trademarks of their respective owners in this coun try, other count ries,

or both.

6

Page 7

Overview

Introduction

The LIB-D81 is a desktop AIT (Advanced Intelligent Tape) automatic loader

(hereafter, “AIT autoloader”) with a built-in AIT drive. Up to 8 cartridges can

be inserted in the AIT autoloader. The unit can also be connected to and used

with a workstation or server.

Up to 8 cartridges can be used

Up to 8 AIT cartridges can be used. Cartridges can be replaced from the front

panel. The following types of cartridges can be used in this AIT autoloader:

• AIT-3 cartridge: rec ords up to 1.6 terabytes of data

• AIT-2 cartridge: rec ords up to 0.8 terabytes of data

• AIT-1 cartridge: records up to 0.56 terabytes of data

Notes

• Cartridges that can be used vary according to the type of built-in drive.

• The memory capacity mentioned above assumes a data compression ratio of

2:1.

Chapter

1

Compact

Because of its compact size ( 17 0 × 350 × 2 24 mm) and li ght wei ght (approx. 7

kg), the LIB-D81 is the perfect desktop AIT Autoloader.

Wide LVD SCSI compliant

The AIT autoloader is Wide LVD SCSI compliant.

Chapter 1 Introduction

7

Page 8

Product Features and Functions

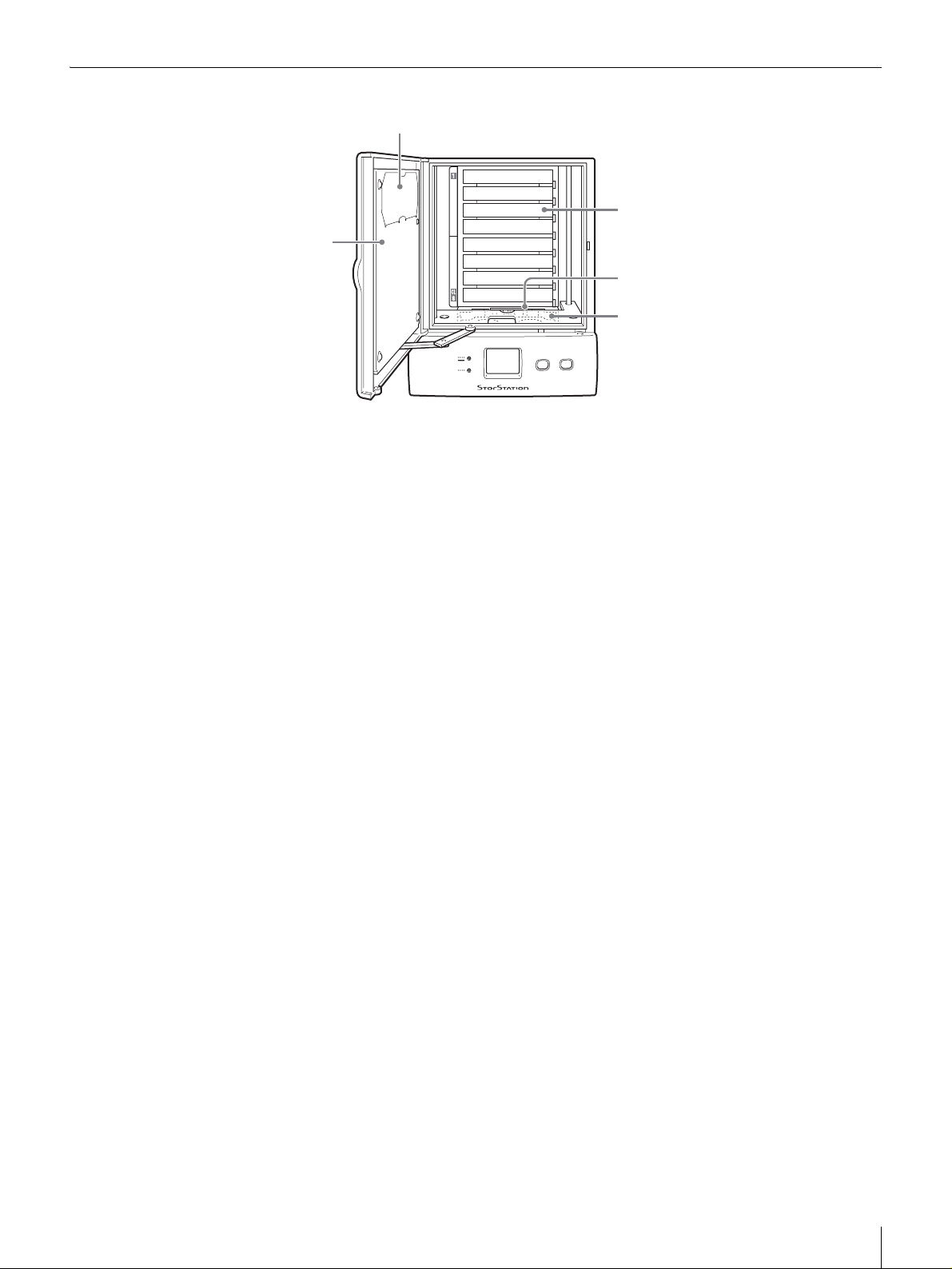

Front

AIT LIBRARY LIB-D81

5

CLEAN DOOR

4

ERROR

WARNING

CLEANING

6

7

A Ventilation Holes

Be careful not to block the ventilation holes. If the ventilation holes are blocked,

the AIT autoloader may overheat, resulting in damage.

1

2

3

B Front Door

Used in inserting and ejecting AIT cartridges. Press the DOOR button to unlock

and open the door. The AIT autoloader cannot operate when the door is open,

therefore when inserting or replacing a cartridge, be that the door is securely

closed. When the door is closed it locks automatically.

C DOOR Button

Press to open the front door . Do not press th is button while the AIT autoload er

is operating.

D CLEAN Button

Insert the cleaning cartridge in slot CL/8 and press for at least three seconds to

clean the AIT drive.

E Message Display

The message display displays how many cartridges are in the AIT autoloader.

When in normal standby state, it displays the status of the AIT autoloader.

F ERROR/WARNING LED

Lights or flashes orange when a specific operation is necessary or an error

occurs. When it lights it indicates a warning, whereas when it flashes it indicat es

an error. When this happens, a 2-character code appears o n the message display.

For details about these codes, see “Error Code List” (page 47), “Other

Messages” (page 52), or the code reference table.

G CLEANING LED

Flashes green when the AIT drive is in need of cleaning. For details about

cleaning the AIT drive, see “Cleaning the AIT Drive” (page 37).

Chapter 1 Introduction

8

Page 9

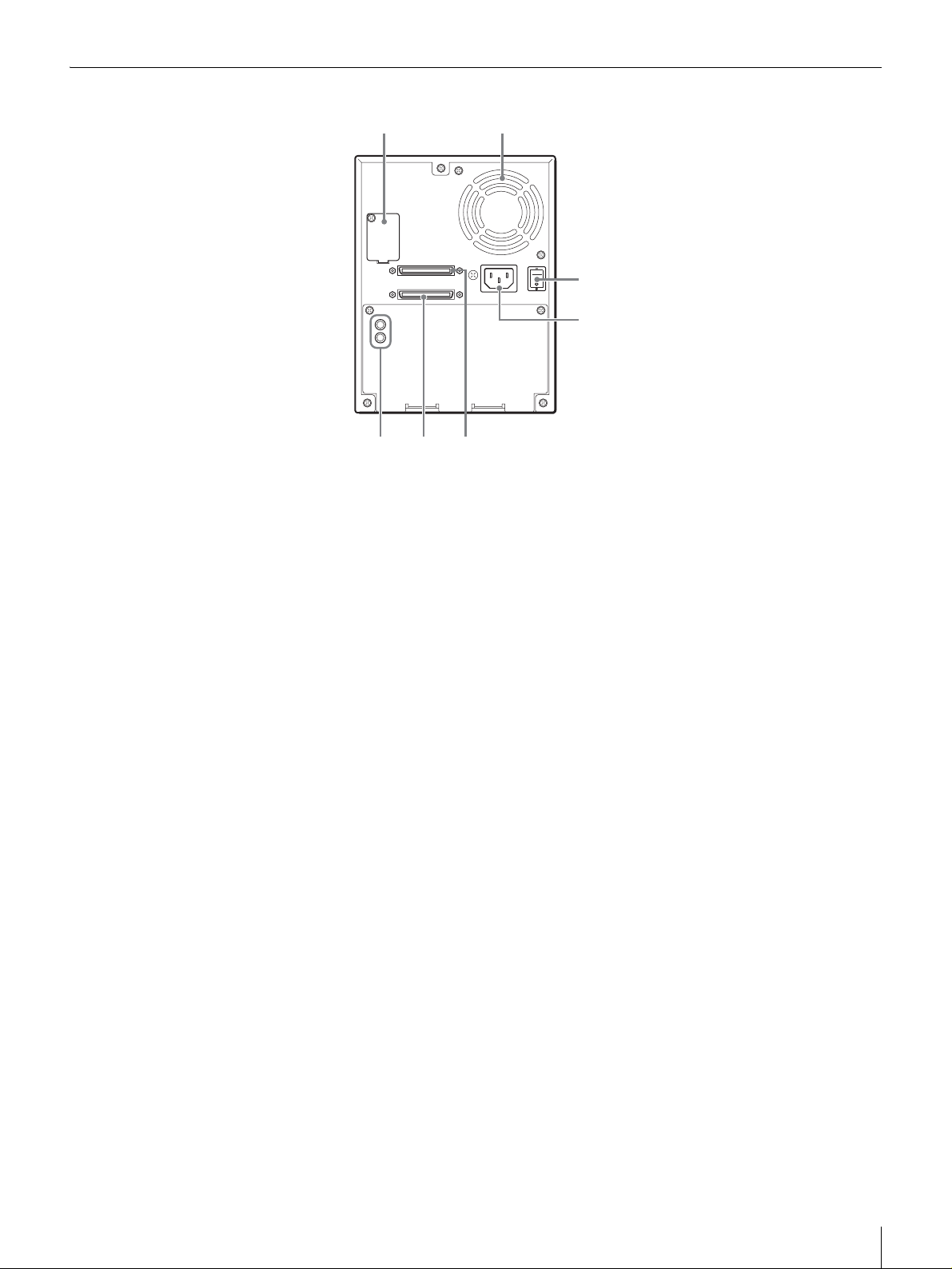

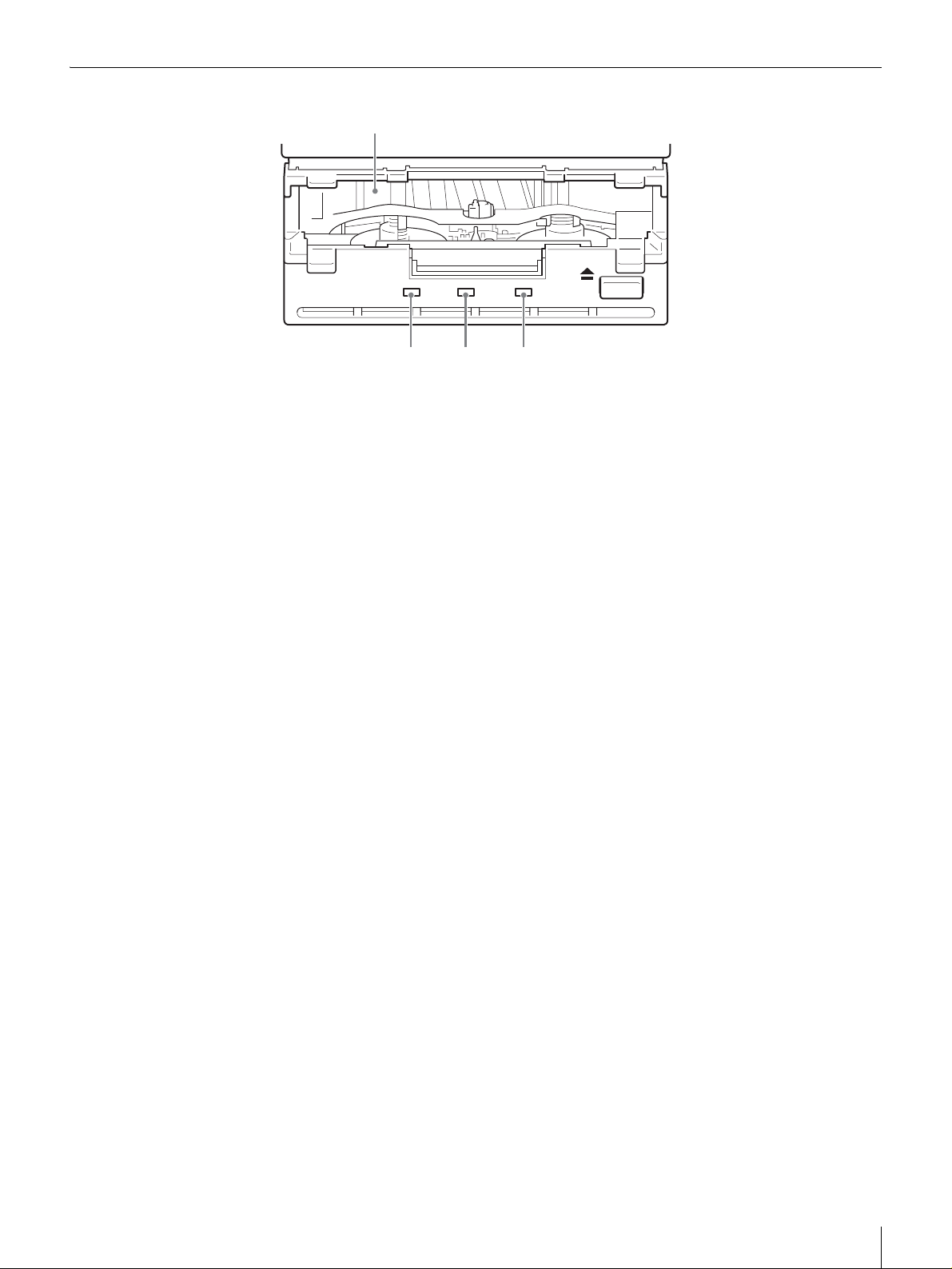

Rear

1 2

3

4

567

A Setup DIP Switches and DIP Switch Cover

Used to set up the AIT autoloader. Remove the screws and cover to access the

DIP switches. For details, see “Setting the DIP Switches” (page 19).

B Ventilation Holes

Please be careful not to block the ventilation holes. If the ventilation holes are

blocked, the AIT autoloader may overheat, resulting in damage.

C Power Switch

To turn the AIT autoloader on or off , press this power swit ch. When you restar t

the AIT autoloader, be sure to wait at least 10 seconds befor e turning it on again.

D Power Supply Connector

Plug the provided power cord into this connector.

E SCSI connector 1 6 SCSI connector 2

For information about connecting t he S CSI conn ect ors, see “Connecting to the

Host Computer” (page 17) and “Connecting SCSI Peripheral Devices” (page

22) in Chapter 2, “Installation”.

F SCSI ID Setup Switch

Used to set the SCSI ID of the AIT autoloader. For details, see“Setting the SCSI

ID” (page 21).

Chapter 1 Introduction

9

Page 10

Interior (Front)

2

3

1

4

5

1

8

D

-

B

I

L

Y

R

A

R

B

I

L

T

I

A

R

O

DO

WARNING

CLEANING

ERROR

CLEAN

A Front Door

B Air Filter

Periodically clean the air filter with a vacu um cleaner (we recommend month ly

cleaning). For details about how to replace the air filter, see “Cleaning the Air

Filter” (page 41).

C Cartridge Case

You can insert up to eight AIT cartri dges in the case. Slots are numbered 1 to 8,

from the highest slot down. When using it, make sure that you insert the

cleaning cartridge in slot CL/8 (the lowest slot).

D AIT Drive

The AIT autoloader is equipped with one AIT drive.

E Elevator

Lowers cartridges to the AIT drive and returns them to their slots. When you

turn on the AIT autoloader, the elevator moves up and down counting the

cartridges, whose number appears on the message display.

Chapter 1 Introduction

10

Page 11

AIT Drive (Front)

1

234

BUSY TAPE STATUS

A Cartridge Sl ot

Used to insert and eject AIT cartridges from the AIT drive.

B STATUS LED

Lights when the cartridge in the drive is write-protected. It flashes in the

following situations.

Drive needs cleaning

Repetitive long on, short off.

During cleaning; tape is spent

Regular fl a s hing.

Drive is malfunctioning

Repetitive two short on, one long off.

C TAP E LED

Lights when a cartridge is being loaded. It flashes in the following situations.

When inserting or ejecting a cartridge

Regular fl a s hing.

Cartridge is spent

Repetitive long on, short off.

D BUSY LED

Lights when data is transferred through the SCSI interface. Flashes regularly

when data is read from or written to a cartridge.

Do not restart the AIT autoloader when this LED is lit as this may cause read

and write errors, or irreparable damage to the data cartridge.

Chapter 1 Introduction

11

Page 12

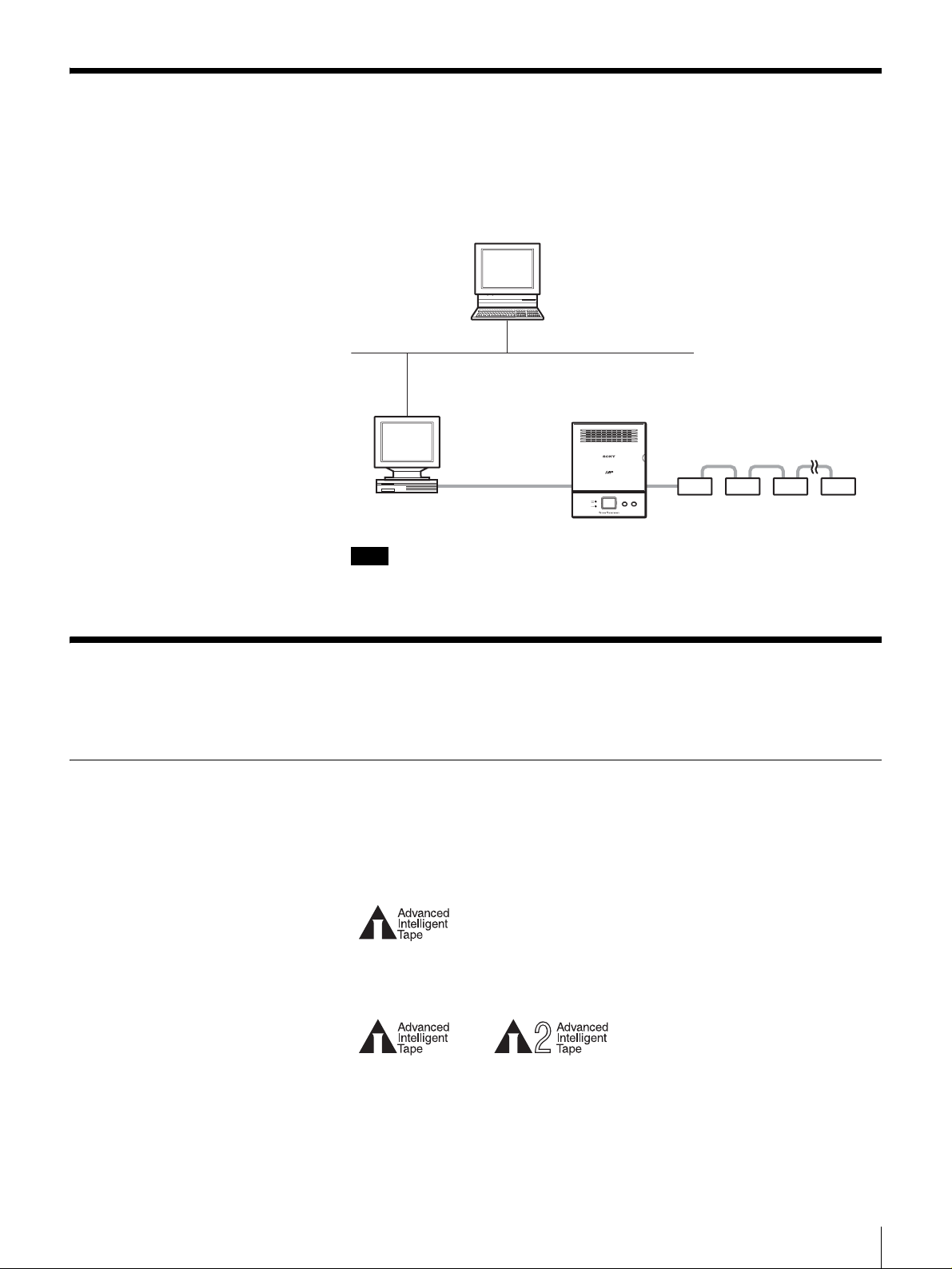

System Structure

To obtain the best performance out o f you r AIT drive, we recommend that you

connect the AIT autoloader to a host computer equipped with an Ultr a 160 Wide

SCSI LVD/SE interface. The autoloader is controlled through the host

computer.

Computer

Ethernet (example)

LIB-D81

68-pin cable

AIT LIBRARY LIB-D81

CLEAN DOOR

ERROR

Host computer

Wide SCSI

WARNING

CLEANING

Wide SCSI peripheral devices

Note

A SCSI host adapter card must be installed in the host computer.

Compatible Cartridges

This section describes what AIT cartridges are used in the AIT autoloader.

AIT Cartridges

To achieve the maximum transfer rate and recording capacity, use the

appropriate type of AIT cartridge for your drive. For information on recording

capacities, see “Hardware Specifications” (page 45) in the “Appendix”.

AIT-1 Drive

AIT-1 mark

AIT-2 Drive

AIT-2 markAIT-1 mark

Chapter 1 Introduction

12

Page 13

AIT-3 Drive

Cleaning Cartridge

Software

AIT-2 markAIT-1 mark

Caution

Do not use 8 mm video tapes sold at stores. An 8 mm video tape looks a lot like

an AIT cartridge, but has different specifications. Do not use any other

cartridges other than AIT cartridges.

To clean the AIT drive, use an AIT Cleaning cartridge (sold separately). For

information on cleaning, see “Cleaning the AIT Drive” (page 37) in Chapter 5,

“Cleaning the AIT Drive”.

For guidance on application software that can be used with the AIT autoloa der

and supported operating systems, contact your dealer.

AIT-3 mark

Precautions

• Use cartridges suited to the type of AIT drive installed. Using cartridges other

than AIT cartridges may cause improper operations. For information about

cartridges that can be used with the AIT autoloader, see “Compatible

Cartridges” (page 12).

• Do not insert anything except AIT cartrid ges i n the slot of t he c artridge case,

as doing so may result in damage.

Chapter 1 Introduction

13

Page 14

Overview

Unpacking

Installation

This chapter explains general procedures for positioning the AIT autoloader,

connecting it to the host computer and turning on the AIT autoloader. This

chapter also explains initial setup. Installation and setup procedures may vary

depending on your system.

Note

You will need the box and packing materials if you wish to move or transport

the AIT autoloader in the future. Retain them for future use.

Chapter

2

1

Remove the AIT autoloader from the box as indicated on the box.

Remove the packing materials, such as plastic covers and tapes.

Chapter 2 Installation

14

Page 15

Package Contents

After opening the box, make sure that all the following items a re present.

Contact your dealer if anything is missing.

• LIB-D81 (1)

• Power cable (1)

• SCSI terminator (1)

• Cleaning cartridge (1)

• Quick Start Guide (1)

• CD-ROM (containing this document) (1)

Note

In addition to the above, other documentation and/or documents may be

included in the package.

Preparing the Host Computer

Prepare the host computer before installing the AIT autoloader as follows.

1

Make sure that a SCSI host adapter card is installed in the host computer.

2

Install the application software supporting the autoloader on the host

computer.

For guidance on application software that can be used with the AIT

autoloader and supported operating systems, contact your dealer.

Chapter 2 Installation

15

Page 16

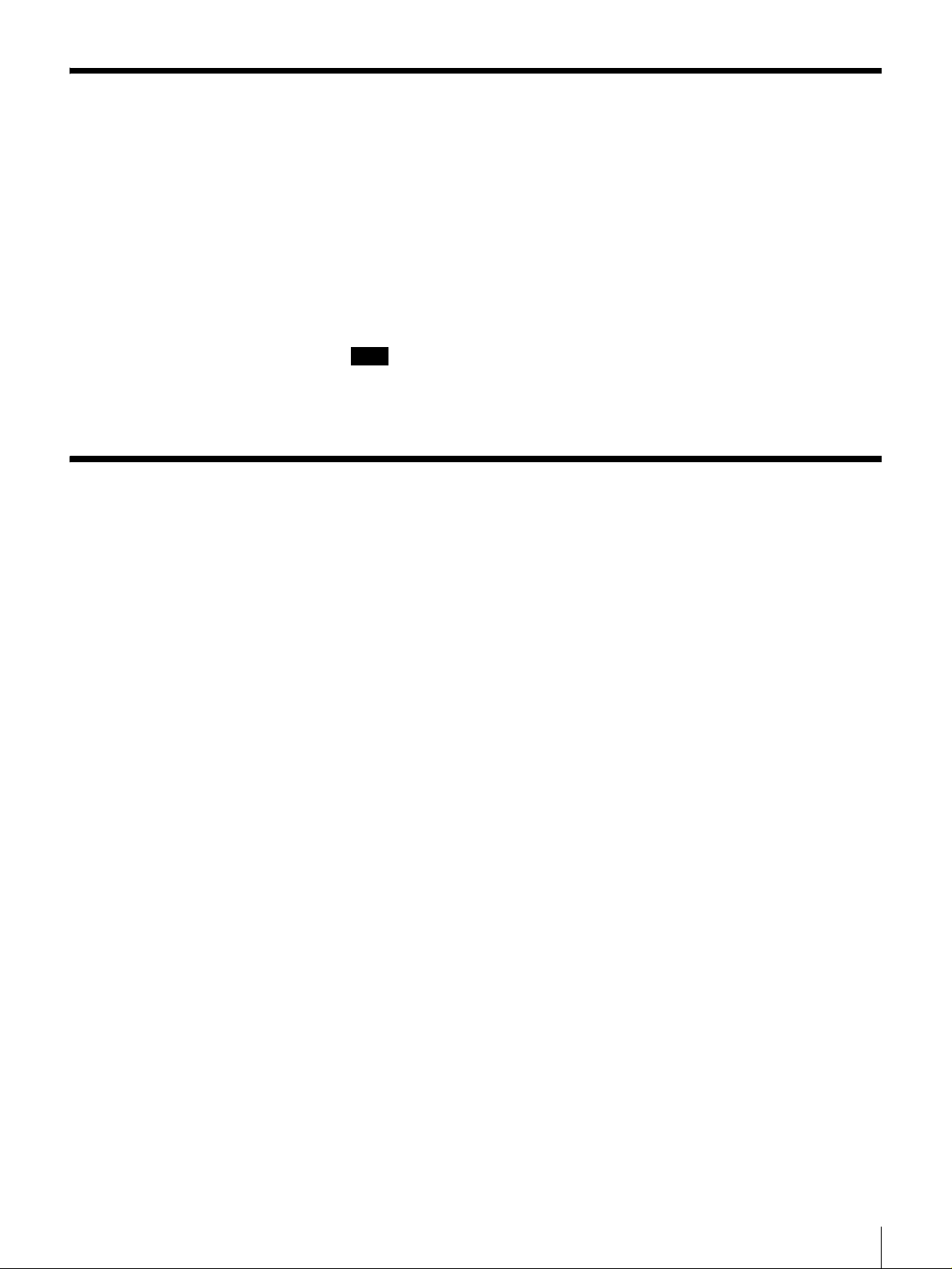

Installing the AIT Autoloader

The autoloader weighs about 7 kg (1 5.4 l b.) an d has t he fol l owing di mensi on s.

Before installing the autoloader, make sure that the surface is appropriate.

N

Note

Install the AIT autoloader on a horizontal surface near an AC power outlet. Also

leave a gap of about 150 mm (5.9 in.) behind the rear of the uni t to allo w air to

circulate.

220 mm (8.7 in.)

224 mm (8.8 in.)

(including rubber

feet)

170 mm

(6.7 in.)

Caution

350 mm (13.8 in.)

Make sure that you position the AIT autoloade r as indicated in the illustration.

Correct operation is not guaranteed if you place the AIT autoloader on its side.

50 mm (2.0 in.)

Rear

Front

170 mm (6.7 in.)

150 mm

(5.9 in.)

350 mm (13.8 in.)

50 mm (2.0 in.)

Chapter 2 Installation

16

Page 17

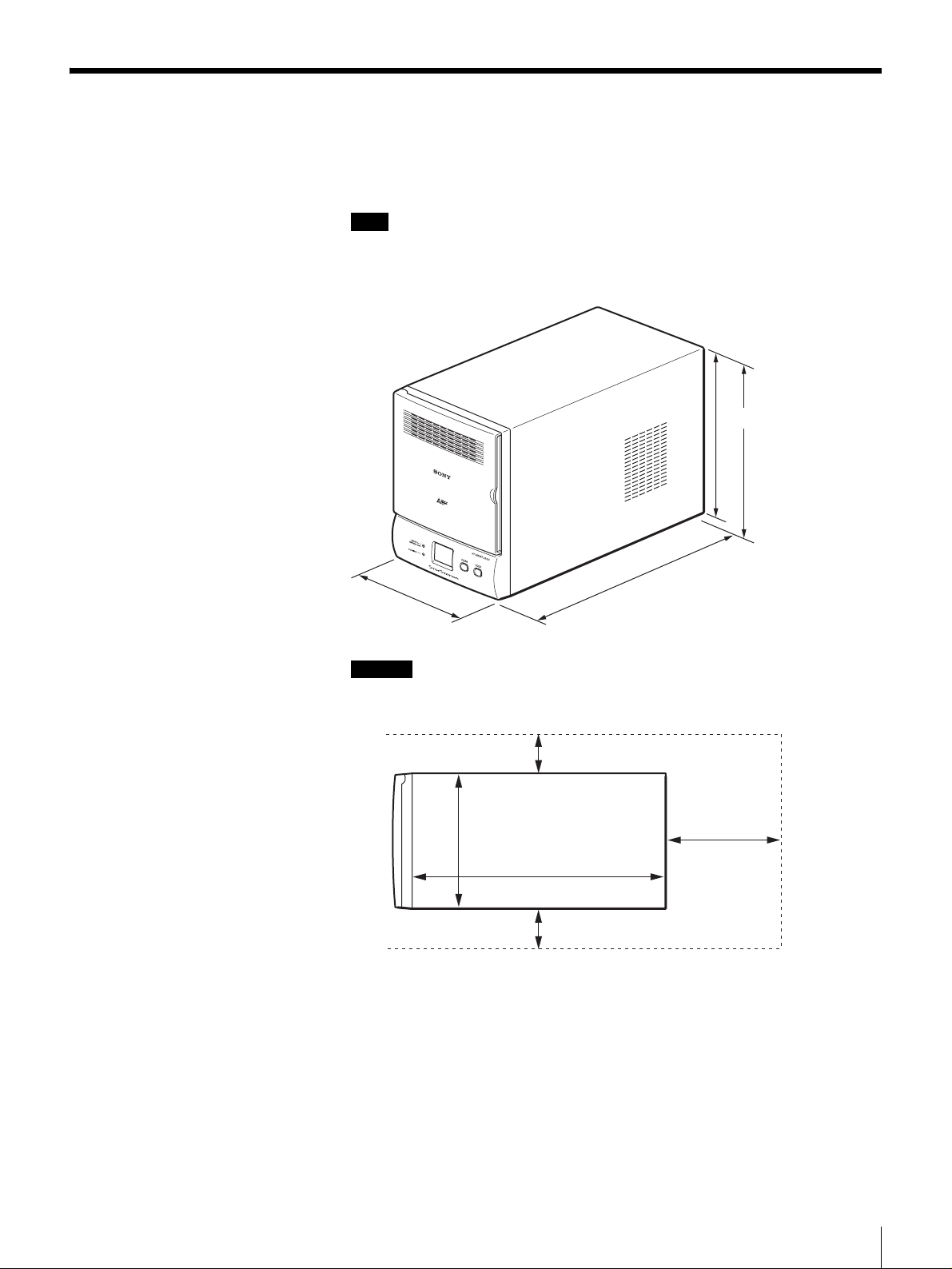

Connecting the Power Cable

1

Make sure that the power switch on the rear of the AIT autoloader is in the

off position (a is depressed).

2

Connect one end of the power c able to th e power supply conn ector and the

other end to the power outlet.

Connecting to the Host Computer

Connect the AIT autoloader and the host computer with a SCSI cable. This

section explains general connection steps. To connect, use an Ultra2 Wide SCSI

LVD cable commonly sold in stores. However, when using a model equipped

with an AIT-3 drive, use an Ultra 160/m SCSI LVD cable. The autoloader side

uses the 68-pin half pitch connector.

When connecting other SCSI devices along with the AIT autoloader, see

“Connecting SCSI Peripheral Devices” (page 22).

Caution

• Do not connect the AIT autoloader to the HVD (High Voltage Differential)

SCSI bus. If connected, the autoloader or other devices on the SCSI bus may

be damaged.

Chapter 2 Installation

17

Page 18

• When connecting the Wide S CSI cable, turn of f all of the conn ecting device s,

including the AIT autoloader and the ho st computer.

• When connecting the AIT autoloader as the last device on the SCSI bus, be

sure to attach the provided terminator.

• In LVD (Low Voltage Differential) SCSI, make the total length of the SCSI

cable (internal and external), which co nnects the host computer and t he device

at the end of the SCSI b us, shorter than 12 m (39.4 ft.). ( The length of the AIT

autoloader internal cable is 0.5 m (19.7 in.).)

• Using SCSI cables longer than 30 cm (11.8 in.) to connect between devices is

recommended.

• SCSI cables cannot be branched.

Notes

• For information about the SCSI bus, see “SCSI Specifications” (page 46) in

the “Appendix”.

• Prepare the necessary SCSI cables. For information about SCSI cable

specifications, see “SCSI Cable and Terminator Specifications” (page 46) in

the “Appendix”.

1

Confirm that the power to the host computer and AIT autoloader are off.

2

Connect the SCSI cable and terminator as shown in the figure below.

1 Use a commercial SCSI cable to connect the AIT autoloader to the host

computer.

2 Connect the provided terminator to connector.

Host computer

Terminator

2

1

Chapter 2 Installation

18

Page 19

Setting the DIP Switches

By setting the DIP switches at the back of the AIT autoloader, you can:

• Supply power to the SCSI terminator (on by default)

When you are using several SCSI devices, you can set the AIT autoloader to

supply power to the SCSI terminator.

• Display warning messages when specific parts reach the end of their life or

when in need of cleaning (on by default)

You can set the AIT autoloader to display warning messages when specific

parts reach the end of their service life or when need of cleaning (weekly).

• Use the autoloader option function (off by default)

You can set the AIT autoloader to monitor the AIT drive status on a regular

basis, as well as automatically eject and insert cartridges.

DIP switches for setupRear

1

0

on

off

1

2

3

4

5

6

7

8

The default settings of the DIP switches are as follows.

DIP SW (DEFAULT)

10

off on

1

2

3

4

5

6

7

8

TERM PWR

MAINTENANCE

LOADER SEL

CONTINUOUS

AUTOLOAD

RMIC

RESERVED

RESERVED

Switches are off when in the “0” position and on in the “1” position. The default

setting of the DIP switches is indicated in brackets.

1 TERM PWA (on)

0: Power is n ot supplied to the SCSI terminator.

1: Power is supplied to the SCSI terminator.

Chapter 2 Installation

19

Page 20

2 MAINTENANCE (on)

0: Warning messages are not displayed when specific parts reach the end of

their service life or when in need of cleaning (weekly).

1: Warning messages are displayed when specific parts reach the e nd of their

service life or when in need of cleaning (weekly).

3 LOADER SEL (off)

0: The autoloader option function is not active.

1: The au toloader option function is active.

When this setting is active, the AIT autoloader monitors the AIT drive

status on a regular basis, as well as perform the following.

- When a cartridge is unloaded, it is automaticall y ejected and ret urned to

its original slot, and the c artridge from the next slot is inserted into the

AIT drive.

- When the cleaning cartridge is in the AIT drive and cleaning ends, the

cleaning cartridge is automatically ejected and returned to its original

slot, and the cartridge fr om the next slot is inserted into the AIT drive.

4 CONTINUOUS (off)

0: The autoloader option function is not in continuous mode.

1: The autoloader option function is in continuous mode.

You can use this setting only if LOADER SEL in set to “1”. When you

activate this setting and the autoloader option function returns a cartridge

to slot CL/8 (the last slot), it automatically inserts the cartridge from the

newest slot into the AIT drive.

5 AUTOLOAD (off)

0: The autoloader option function is not in automatic loading mode.

1: The autoloader op tion function is in autom atic loading mode.

You can use this setting only if LOADER SEL in set to “1”. When you

activate this setting and turn on the AIT autoloader, the AIT autoloader

automatically inserts the cartridge from the newest slot in the AIT drive.

6RMIC (off)

This function is not supported.

7 RESERVED (off)

Extension. Do not use.

8 RESERVED (off)

Extension. Do not use.

1

Make sure that the power switch on the rear of the AIT autoloader is in the

off position (a is depressed).

2

Use a pointed object such as a machinist’s screwdriver to change the

settings of the DIP switche s.

3

Press the power switch to turn on the pow er .

If you change the SCSI ID settings or connect SCSI peripheral devices, do

not turn on the power from here. Instead, see “Setting the SCSI ID” (page

21) and “Connecting SCSI Peripheral Devices” (page 22).

Chapter 2 Installation

20

Page 21

Setting the SCSI ID

Use the SCSI ID switches at the back of the AIT autoloader to set the AIT drive

and/or AIT autoloader SCSI ID.

The default settings of the switches are as follows.

Use the upper switch to set the AIT drive SCSI ID and the lower switc h to set

the AIT autoloader SCSI ID.

AIT drive SCSI ID

4

5

3

6

2

7

1

8

0

9

F

A

E

B

D

C

4

5

3

6

2

7

1

8

0

9

F

A

E

B

D

C

AIT autoloader SCSI ID

Caution

• Do not set the same SCSI ID for the AIT drive and AIT autoloader.

• Make sure that you perform these settings before turning on the AIT

autoloader.

1

Make sure that the power switch on the rear of the AIT autoloader is in the

off position (a is depressed).

2

Use a pointed object such as a machinist’s screwdriver to turn the switches

until their arrows match the setting that you want.

3

Press the power switch to turn on the pow er .

If you want to connect SC SI peripheral devices, see “Connecting SCSI

Peripheral Devices” (page 22).

Chapter 2 Installation

21

Page 22

Connecting SCSI Peripheral Devices

SCSI peripheral devices can be connected to the SCSI connectors of the AIT

autoloader. The SCSI configuration of the autoloader is as shown below.

Connect the devices according to the system environment.

AIT drive

SCSI ID : 0

Loader controller

SCSI ID : 1

Notes

• The default factory settings of the SCSI IDs are as follows.

-AIT drive: 0

-Loader: 1

• Do not use repetitive SCSI IDs.

• Connect peripheral devices before turning on the AIT autoloader and host

computer.

SCSI connectors

Turning the Power On/Off

Turn On the Power

Turn on the AIT autoloader, then turn on the host computer.

1

Press the power switch on the rear of the autoloader, as illustrated.

Chapter 2 Installation

22

Page 23

The message display changes as follows and the startup process begins.

(Startup takes several minutes.)

During startup, the following appears on the message display.

Moves gradually up and down during the elevator check.

Indicates the startup phase, from 0 to 3.

When startup is complete, the message display indicates the number of

cartridges in the AIT autoloader.

Starting up Startup complete

2

After pressing the standby switch on the autoloader’s front panel, wait at

least 10 seconds before turning on the host computer.

Notes

• If you start the host computer before the autoloader, the SCSI ID is not

detected correctly. Therefore, you must always start the autoloader

before starting the host computer.

• If the autoloader does not work as above, see “Troubleshooting” (page

42).

Chapter 2 Installation

23

Page 24

Turn Off the Power

AIT-1AIT

AIT-3

Press the power switch on the rear of the AIT autoloader to turn it off.

Caution

Do not turn off the AIT autoloader when it is in use or there is a cartridge in the

AIT drive, as this could damage data.

Note

After turning the AIT auto loader off, wait at least 10 seco nds before turning it

on again.

Setting Cartridges

Prepare cartridges and insert them into the AIT autoloader.

Preparing Cartridges

Make sure that cartridges are not write-protected and prepare them for use.

Verify whether the write-protected tab is in the write-enable position. If the tab

is orange, data can be written to a cartridge.

Lid

If the tab is moved to the left, data

can be written to and erased from

the cartridge.K

If the tab is moved to the right, data

cannot be written or accidentally

erased from the cartridge.k

-2,

Lid

If the tab is lowered, data can be

written to and erased from the

cartridge.j

If the tab is raised, data cannot be

written to or accidentally erased

from the cartridge.J

Chapter 2 Installation

24

Page 25

Inserting Cartridges

Insert cartridges into the AIT autoloader as outlined below.

1

On the front of the AIT autoloader, press the DOOR button.

[o P] flashes on the message display.

The AIT autoloader is p reparing to open the front door. Wait until the

display stops flashing, which may take up to a minu te.

Flashing display Steady display

When the display stops flashing, the front door unlocks.

Note

To prevent the front door from opening during operation, it automatically

locks when it is closed. Attempting to open the door without unlocking it

may damage the AIT autoloader.

Chapter 2 Installation

25

Page 26

2

When you are certain that [o P] on the message display has stopped

flashing, open the front door as illustrated here.

When you open the front door, [o P] remains displayed on the message

display.

Caution

• It is possible for the host computer to prevent the front door from being

opened or closed. When this is the case and you press the DOOR button,

the ERROR/WARNING LED lights and [0 5] appears on the message

display indicating that the door cannot be opened.

• If the front door is not opened within 3 minutes of [o P] appearing

steadily on the message d isplay, the doo r is automatical ly locked and the

message display reverts to normal.

3

Insert cartridges into the AIT a utoloader.

Make sure that you i nsert cartridges in the rig ht direction, and push them i n

the AIT autoloader until you hear a click.

Slot in the AIT autoloader are number ed 1 to 8, from the highest slot down.

(Slot numbers match SCSI element numbers.)

1

8

D

-

B

I

L

Y

R

A

R

B

I

L

T

I

A

R

O

DO

N

EA

WARNING

CLEANING

ERROR

CL

Caution

The AIT autoloader contains a large number of wires and parts. Do not

touch any part other than the slots inside the AIT autoloader as this may

lead to damage and/or injury.

Chapter 2 Installation

26

Page 27

4

Close the front door.

When you hear the door click, it is closed. Make sure that the door clicks

when you close it.

When the door is completely closed, the cartridges that you inserted into

the AIT autoloader are counted and their number is displayed on the

message display.

Caution

If cartridges protrude from slots or are otherwise improperly inserted into

slots inside the AIT autoloader, the ERROR/WARNING LED lights

orange and [0 1] appears on the message display, indicating an error, and

the front door is automatically unlocked. Open the front door and correct

any problems as necessary.

Setting Application Software

Make the necessary setting s to be able to use the AIT autoload er. Refer to the

documentation of the application software used with the AIT autoloader for

details about the necessary settings.

Chapter 2 Installation

27

Page 28

Overview

Control Panel

Basic Usage

This chapter explains the control panel, basic settings, handling cartridges,

element address assignments, and Maintenance.

You can use the control panel to display informati on about the AIT autoloader

and clean the AIT drive.

This section explains the operation of the control panel and the information

displayed by the message display.

Chapter

3

Using the Control Panel

Use the control panel to perform the following.

• Display information related to the AIT autoloader.

• Clean the AIT drive.

• Perform disaster recovery.

Note

Disaster recovery is a function through which all the data on the host comput er

is backed up on cartridg es, which can then b e used to re store your sy stem in the

unlikely event of a catastrophic failure, for example.

Chapter 3 Basic Usage

28

Page 29

Message Display

The message display displays the current number of c artridges in the AIT

autoloader, the AIT autoloader’s operational status, as well as warning an d error

messages.

Left of the display

ERROR

WARNING

CLEANING

Right of the display

Normal display

• The left of the display indicates the operational status of the autoloader.

• The right of the d isplay indicates the curren t number of cartridges i n t he AI T

autoloader.

Display during user operations, requests to user s, error messages

A two-character code appears on the display. For details about the meaning of

the various codes, see “Error Code List” (page 47) and “Other Messages” (page

52).

Warnings

When the AIT drive needs to be clea ned or speci fic pa rts need to be replaced a t

the end of their service life, LED light o n t he front panel o f th e AIT aut oloader

and messages appear on the message display, as illustrated here.

Cleaning request

The CLEANING LED flashes green and t he [ C L] c ode f lashes on th e message

display. By default, you are notified that the AIT drive needs cleaning when th e

AIT autoloader has been online for approximately a week.

ERROR

WARNING

CLEANING

Chapter 3 Basic Usage

29

Page 30

High internal temperature

The ERROR/WARNING LED lights orange and the [0 6] code appears on the

message display. Suspend operation or lower ambient temperature. When the

AIT autoloader internal temperature returns to normal levels, the ERROR/

WARNING LED goes out. It is possible for the air filter to become clogged with

dust or other particles. To prevent this from happening, be sure to clean the air

filter regularly. For details, see “Maintenance” (page 33).

ERROR

WARNING

CLEANING

Specific parts have reached t he end of their service life

The ERROR/WARNING LED lights orange and the [0 7] code appears on the

message display. Contact customer service.

ERROR

WARNING

CLEANING

Errors

When an error occurs in the AIT autoloader, the ERROR/WARNING LED

flashes orange and an error code appears on the message display. For

information about error codes, see “Error Code List” (page 47) in the

“Appendix”.

Example: Problem with a cartridge

[C ] and [XX], where “XX” is the error code, appear alternatively on the

message display.

Example: Problem with the autoloader

[L ] and [XX], where “XX” is the error code, appear alternately on the message

display.

Chapter 3 Basic Usage

30

Page 31

Example: Problem with the drive

[d ] and [XX], where “XX” is the error code, appear alternately on the message

display.

Note

For illustration purposes, we have used the autoloader in error code examples

throughout the document.

Disaster Recovery Function

Disaster recovery is a function through which all the data on the host comput er

is backed up on cartridg es, which can then b e used to re store your sy stem in the

unlikely event of a catastrophic failure, for example. Perform disaster recovery

with the application software on the host computer.

For details about operations and settings on the host computer, refer to the

documentation accompanying the computer and software applications.

1

Prepare to perform disaster recovery.

1 Create a disaster recovery tape with the host computer.

2 Place the AIT drive in Disaster recovery mode.

Send the AIT drive mode selection command from the host computer.

The AIT drive enters Disaster recovery mode.

You can also place the AIT dri ve in Disaster recovery mode b y following

the instructions of step 2 below.

2

Begin disaster recovery.

1 Insert the disaster recovery tape into slot 1.

2 Simultaneously press the CLEAN and DOOR butt ons at th e fro nt of th e

AIT autoloader for at least 5 seconds. The AIT drive enters Disaster

recovery mode. When the AIT drive enters Disaster recovery mode, [d r]

appears flashing on the message display.

3 Turn off the AIT autoloader, wait approximately 10 sec onds, then restart

it.

The disaster recovery tap e is automatically inserted into the AIT drive.

Refer to the documentation accompanying the computer and software

applications to perform the disaster recovery procedure.

Chapter 3 Basic Usage

31

Page 32

Assigned Element Addresses

An element is a physical location where a cartridge is kept. Applications use

element addresses to differentiate between the element s of t he AIT aut oloader.

In AIT autoloader, the element add resses are assigned t o the cart ridge slots a nd

the AIT drive as illustrat ed below.

Note

Because element addresses of the AIT autoloader are fixed numbers, they

cannot be reassigned.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

Handling the Cartridges

When handling or storing the cartridges, note the following.

Handling

• Do not subject the cartridges to strong vibrations. Do not drop the cartridges.

• When loading a cartridge into the AIT autoloader, the lid of the cartridge

opens up automatically. Do not manually open the lid and touch the interior

tape.

• The cartridge is preadjusted at the factory, so do not disassemble it.

• The tab of a cartridge is used to prevent writing to the cartridge by accident.

If the cartridge does not need to be written to, move the tab to write-protect it.

t “Preparing Cartridges” (page 24) in Chapter 2, “Installation”.

AIT drive (element address 82)

Elevator (element address 0)

Chapter 3 Basic Usage

32

Page 33

Storing

• If the AIT autoloader is used in a h igh-humidity environment or a locat ion that

is subject to wide variations in temperature, condensation may prevent the

cartridge read/write operation.

• If the cartridge does not need to be written to or read from, do not insert or

eject it too often.

• Store cartridges in an appropriate environment.

Store cartridges according to the temperature and other surrounding

conditions written on the package. Also, try to keep the temperature and

humidity of the environment constant. Store cartridges out of the direct sun

rays. Do not store them near heating systems. Never place cartridges on a

dashboard or in the glove compartment of a car.

• Store cartridges in a dustless environment.

Eliminate sources of dust. Avoid e ating, drinking, or smokin g near the storage

location. Also, do not store cartridges near copying machine s or printers t hat

emit toner and paper dust.

• When storing cartridge, set the er ase-pr otecti on ta b so that the d ata cann ot be

over written.

• After removing a cartridge from the autoloader, store it in an appropriate

location as soon as possible.

Avoid, as much as possible, changes of temperature and density,

contamination by dust and scratches made by touching the interior tape.

Maintenance

Perform the following periodically.

• Clean the air filter.

If the front panel air filter becomes clogged with dust, the AIT autoload er may

overheat, resulting in damage. Periodically cl ean the ai r filte r with a vacu um

cleaner. (We recommend monthly cle aning.) For details about how to remove

the air filter, see “Cleaning the Air Filter” (page 41) in the “Appendix”.

• Clean the AIT drive.

Clean the AIT drive on a weekly basis. You are notified that the AIT drive

needs cleaning by a flashing gre en CLEANING LED and a message when the

AIT autoloader has been online for approximately a week. If the 2

MAINTENANCE DIP switch at the back of the AIT autoloader is in the off

position, you are not notified when cleaning becomes necessary. By default,

this DIP switch is in the on position. For details, see “Set ting the DIP

Switches” (page 19).

Chapter 3 Basic Usage

33

Page 34

Operating the

AIT Autoloader

Overview

This chapter explains how to eject and change cartridges.

Using Cartridges

This section explains how to eject and change cartridges.

For information about how to prepare and insert cartridges, see “Inserting

Cartridges” (page 25) in Chapter 2, “Installation”.

Ejecting/Changin g Cartridges

Chapter

4

To eject and change cartridges set in slots of the AIT autoloader, perform the

following.

1

On the front of the AIT autoloader, press the DOOR button.

[o P] flashes on the message display.

Chapter 4 Operating the AIT Autoloader

34

Page 35

The AIT autoloader is p reparing to open the front door. Wait until the

display stops flashing, which may take up to a minu te.

Flashing display Steady display

When the display stops flashing, the front door unlocks.

Note

To prevent the front door from opening during operation, it automatically

locks when it is closed. Attempting to open the door without unlocking it

may damage the AIT autoloader.

2

When you are certain that [o P] on the message display has stopped

flashing, open the front door as illustrated here.

When you open the front door, [o P] remains displayed on the message

display.

Caution

• It is possible for the host computer to prevent the front door from being

opened or closed. When this is the case and you press the DOOR button,

the ERROR/WARNING LED lights and [0 5] appears on the message

display indicating that the door cannot be opened.

• If the front door is not opened within 3 minutes of [o P] appearing

steadily on the message d isplay, the doo r is automatical ly locked and the

message display reverts to normal.

Chapter 4 Operating the AIT Autoloader

35

Page 36

3

Eject the cartridge from the slot as illustrated below.

1

8

D

-

B

I

L

Y

R

A

R

B

I

L

T

I

A

R

O

DO

N

EA

WARNING

CLEANING

ERROR

CL

Caution

The AIT autoloader contains a large number of wires and parts. Do not

touch any part other than the slots inside the AIT autoloader as this may

lead to damage and/or injury.

Note

If the cartridge that you want to eject in the AIT drive, see “Transporting

the AIT Autoloader” (page 44) in the “Appendix”.

4

When you want to change cartridges, insert a new cartridge in the empty

slot.

Make sure that you i nsert cartridges in the rig ht direction, and push them i n

the AIT autoloader until you hear a click.

5

Close the front door.

When you hear the door click, it is closed. Make sure that the door clicks

when you close it.

When the door is completely closed, the cartridges that you inserted into

the AIT autoloader are counted and their number is displayed on the

message display.

Caution

If cartridges protrude from slots or are otherwise improperly inserted into

slots inside the AIT autoloader, the ERROR/WARNING LED lights

orange and [0 1] appears on the message display, indicating an error, and

the front door is automatically unlocked. Open the front door and correct

any problems as necessary.

Chapter 4 Operating the AIT Autoloader

36

Page 37

Cleaning the AIT Drive

Overview

This chapter explains how to clean the AIT drive.

Cleaning the AIT Drive

When the AIT drive is in need of cleaning, the CLEANING LED flashes green

and the following appears on the message display.

ERROR

WARNING

Chapter

5

CLEANING

To clean the AIT drive, insert a cleaning cartridge (sold separately) into the

drive. Make sure that you insert the cleanin g cartridge into the slot CL/8 before

you proceed.

Caution

• If there is a cartridge in t he AIT drive when you b egin cleani ng the drive , it is

returned to its original slot before the cleaning procedure starts.

• If the 2 MAINTENANCE DIP switch at the back of the AIT autoloader is in

the off position, you are not notified when cleaning becomes necessary. By

default, this DIP swit ch is in th e on po siti on. In t his po siti on, you are n otified

to clean the AIT drive when the AIT autoloader has been online for

approximately a week. For details, see “Setting the DIP Switches” (page 19).

1

Prepare your cleaning cartridge.

2

On the front of the AIT autoloader, press the DOOR button, open the front

door, and insert the cartr idge into slot CL/8 (the lowe st slot).

Chapter 5 Cleaning the AIT Drive

37

Page 38

For details about how to insert a ca rtridge into a slot, see “Settin g

Cartridges” (page 24) in Chapter 2, “Installation”.

Cleaning cartridge

1

8

D

-

B

I

L

Y

R

A

R

B

I

L

IT

A

R

DOO

EAN

WARNING

CLEANING

ERROR

CL

Caution

The AIT autoloader contains a large number of wires and parts. Do not

touch any part other than the slots inside the AIT autoloader as this may

lead to damage and/or injury.

3

Close the front door.

When you hear the door click, it is closed. Make sure that the door clicks

when you close it.

When the door is completely closed, the cartridges that you inserted into

the AIT autoloader are counted and their number is displayed on the

message display.

Caution

If cartridges protrude from slots or are otherwise improperly inserted into

slots inside the AIT autoloader, the ERROR/WARNING LED lights

orange and [0 1] appears on the message display, indicating an error, and

the front door is automatically unlocked. Open the front door and correct

any problems as necessary.

4

On the front of the AIT autoloader, press the CLEAN button for at least

three seconds.

Chapter 5 Cleaning the AIT Drive

38

Page 39

[C L] flashes on the message display and cleaning starts.

Flashing display

When cleaning ends, the cleaning cartridge is returned to slot CL/8 and the

CLEANING LED goes out.

5

When the CLEANING LED goes out, press the DOOR button, open the

front door, and eject the cleaning cartridge.

Caution

• If the CLEANING LED does not go out, it is possible that the cleaning

cartridge is spent. Replace the cleaning cartridge with a new one and

perform the cleaning procedure again.

• If there is a cartridge in the AIT d rive when you begin cleaning the drive,

it is returned to its original slot before the cleaning procedure starts.

• If you are writing to a damaged cartridge, unloadi ng may take some time.

For this reason, cleaning can take up to 20 minutes.

Note

If the AIT autoloader cannot clean the AIT drive, the following error

messages may appear.

If there is no cartridge in slot CL/8

The ERROR/WARNING LED lights and [0 3] appears on the message

display.

ERROR

WARNING

CLEANING

If there is an AIT cartridge in slot CL/8

The ERROR/WARNING LED lights and [0 4] appears on the message

display.

ERROR

WARNING

CLEANING

Chapter 5 Cleaning the AIT Drive

39

Page 40

If cleaning fails for any other reason

The ERROR/WARNING LED flashes, [L ] and [XX] or [d ] and [XX]

(where “XX” is an error code) appear alternately on the message display.

ERROR

WARNING

CLEANING

Or

ERROR

WARNING

CLEANING

Chapter 5 Cleaning the AIT Drive

40

Page 41

Appendix

Cleaning the Air Filter

Note

Clean the air filter once a month using a vacuum cleaner.

1

Press the DOOR button and open the front door.

2

Turn off the AIT autoloader.

3

Extract the air filter from the AIT autoloader.

Caution

Take care not to cut yourself o n the metal corners of the air filter.

4

Clean the air filter with a vacuum cleaner.

5

Reinsert the air filter.

6

Close the front door.

7

Turn on the AIT autoloader.

Appendix

41

Page 42

Troubleshooting

Before contacting a Sony Service center, please check the following. If the

problem persists, contact a Sony Service center.

The AIT autoloader does not work

• Verify that the power is on.

• Verify that the power cable is connected correctly.

• Verify that the front door is closed.

• Verify that the terminator is attached correctly.

• Verify that the SCSI cabl e is co r rec tly connected from the AIT autoloader to

the host computer.

• Verify that the ho s t computer is on.

• Verify that no erro r code is displayed on the message display. For information

about error codes, see “Error Code List” (page 47).

• Only restart the AIT autoloader 10 seconds after it is turned off.

The AIT autoloader and the host computer cannot

communicate with each other

• Verify that the SCSI IDs of the a utoloader, AIT drive, and host computer are

unique. Duplicate SC SI IDs canno t be used on on e SCSI bus. t “Setting t he

SCSI ID” (page 21) in Chapter 2, “Installation”.

• Verify that the SCSI cable is co nnected correctly. t“Connecting to the Ho st

Computer” (page 17) in Chapter 2, “Installation”.

• Verify that the SCSI adapter card is correctly installed in the computer.

• Verify that all the connected SCSI devices are LVD devices. The AIT

autoloader is an LVD device. Do n ot co nnec t HDV dev ic es t o t he aut oloade r.

• Verify that all the devices on the SCSI bus are Wide SCSI devices. The AIT

autoloader is a Wide SCSI device. All the devices on the SCSI bus must be

Wide SCSI devices. (Wide-Narrow adapters can also be used.)

• Verify that the length of the SCSI cable that connects the host computer and

the AIT autoloader at the end of the SCSI bus is shorter than 12 m (39.4 ft.).

• Verify that the SCSI bus is terminated correctly. t “SCSI Specifications”

(page 46).

• Verify that the AIT autoloader supports the application software. For

guidance on application software that can be used on the AIT aut oloader and

on compatible operating systems, contact your dealer.

• Verify that the application software is correctly installed and correctly set up

on the host computer.

• Verify that the host computer was turned on more than 10 seconds after

turning on the autoloader. If the host computer is turned on too soon after

turning on the autoloader, the host computer may not detect the SCSI devices.

Data cannot be written or read even though the

application and the autoloader are working properly

• Verify that the write-protect tab of the cartridge is in the write-enable position.

t “Preparing Cartridges” (page 24) in Chapter 2, “Installation”.

• Only use Sony AIT cartridges. Verify that the AIT drive supports the

cartridges.

• If a cartridge has been used for a long time or very frequently, replace it with

a new cartridge.

• Verify that the car tridge is not damaged.

Appendix

42

Page 43

• Try cleaning the AIT drive. t “Cleaning the AIT Drive” (page 37) in

Chapter 5, “Cleaning the AIT Drive”.

The cartridges cannot be ejected

• Follow the instructions in “Ejecting/Changing Cartridges” (page 34) in

Chapter 4, “Operating the AIT Autoloader”.

If you are still unable to eject cartridges, please contact your dealer for

assistance.

• If you are unable to eject the cartridge in the AIT drive, perform the following

procedure.

1 On the front of the AIT autoloader, press the DOOR button for

at least five seconds.

[E J] flashes on the message display. The cartridge in th e AIT drive is

automatically ejected and returned to its original slot.

The front door is then unlocked and [o P] appears on the message display.

Notes

• When the original position of the cartridge is unknown, such as after

restarting the AIT autoloader, the cartridge is insert ed in the highest

available slot.

• When you press the DOOR button for at least five seconds when there is

not cartridge in the AIT drive, [E J] flashes on the message display and

the front door is unlocked.

2 When you are certain that [o P] on the message display has

stopped flashing, open the front door and eject the cartridge.

The front door does not open

If pressing the DOOR button fails to unlock the front door, perform the

following.

• On the front of the AIT autoloader, press the DOOR for at least five seconds.

[E J] flashes on the message display and the front door is unlocked.

• If the above fails, remove the pr otective cap at the base of th e AIT autoloader

as illustrated below, and then use a pointed object such as a ballpoint pen to

press the release button. The front door unlocks allowing you to open it.

Remove the protective cap with a

screwdriver, and then use a pointed

object such as a ballpoint pen to

press the release button.

AIT autoloader base

Appendix

43

Page 44

Miscellaneous

Verify that the front door is secure ly closed. The AIT autoloader cannot operate

normally if the front door is not closed.

Transporting the AIT Autoloader

If you are transporting the AIT autoloader for any reason, such as when mov ing

or repairing the autoloader, make the following preparations.

• When packing, perform the unpacking procedure outlined in “Unpacking”

(page 14) in reverse.

• Eject all the cartridges in the aut oloader. If the cartridg es cannot be ejected by

normally, see “The cartridges cannot be ejected” (page 43) in

“Troubleshooting”.

• Remove all the cables such as the power cable, the SCSI cab le, the terminator,

and the network cable.

Appendix

44

Page 45

Hardware Specifications

Hardware

AIT Drive

Number of drives that can be installed

Number of cartridges that can be inserted

Data transfer rate

Message display 7-segment LED display, displays 2 characters

LED Two

External connectors

SCSI 68-pin (2)

Operating environment

Power AC100 V to 240 V ±10% (50/60 Hz)

Power consumption

External Dimensions

Mass 7 kg (15.4 lb.)

LIB-D81/A1: SDX-400C/L (1)

LIB-D81/A2: SDX-500C/L (1)

LIB-D81/A3: SDX-700C/L (1)

One drive

Maximum of 8

Native

AIT-3 12 MB/s

AIT-2 6 MB/s

AIT-1 4 MB/s

Loader

Wide SCSI LVD/SE

Drive

AIT-1 and AIT-2 drives: Ultra Wide SCSI LVD/SE

AIT-3 drive: Ultra 160 SCSI LVD/SE

Temperature: 5ºC to 40ºC

Humidity: 20% to 80%

(Avoid condensation)

AIT-1 Model 40 W (Max)

AIT-2 Model 40 W (Max)

AIT-3 Model 45 W (Max)

170 (W) × 224 (H) × 350 (D) mm

(6.7 (W) × 8.8 (H) × 13.8 (D) in.)

Memory

AIT-3 cartridge: 1.6 terabytes

AIT-2 cartridge: 0.8 terabytes

AIT-1 cartridge: 0.56 terabytes

(When data compression is 2:1)

Please note: Due to constant improvements, the specifications and outward

appearance of the AIT autoloader may change without prior announcements.

Appendix

45

Page 46

SCSI Cable and Terminator Specifications

SCSI Cable

For impedance and primary conductor, use a Ultra Wide LVD SCSI cable that

conforms to SCSI-3 specifications. However, when using a model equipped

with an AIT-3 drive, use an Ultra 160/m SCSI LVD cable.

SCSI Cable Length

The total allowable length of SCSI cables used in one LVD SCSI bus is as

follows. (This length includes the length of all internal and external cables.)

• The length of the AIT autoloader internal cable is 0.5 m (19.7 in.).

• If there are more than three devices on an LVD SCSI bus, the total allowable

length is 12 m (39.4 ft.).

SCSI Specifications

This section describes common specifications of SCSI components and SCSI

buses.

About the SCSI Components

The SCSI system is composed of the following components.

• Initiator

•Bus

•Targets

About the SCSI Bus

When you are setting up the AIT autoloader using a SCSI bus, please note the

following precautions

This is a host computer system that functions as an initiator program of

commands. The system consists of the application software, the operating

system, the device driver and the SCSI adapter card.

By connecting the SCSI cables to the SCSI adapter card, the autoloader and

other devices, a path (or a bus) is created for transferring commands.

The AIT autoloader and the AIT drive are peripheral devices (or targets) that

receive commands from the host computer. Up to 16 devices (including the

host computer) can be connected to the Wide SCSI bus. Al so, up to 8 devic es

can be connected to the Narrow SCSI bus.

LVD SCSI

The AIT autoloader is an LVD SCSI device. All SCSI devices connected to th e

AIT autoloader on the SCSI bus must be LVD SCSI devices.

Appendix

46

Page 47

Wide SCSI

SCSI ID

SCSI Bus Termination

The interface of the AIT autoloader is Wide SCSI. In order to connect the AIT

autoloader to a Narrow SCSI bus, use a 50-pin to 68-pin LVD SCSI adapter.

Also, make sure every unused data lines are terminated by an adapter.

Set a unique SCSI ID for each device on a SCSI bus. The host computer uses

these SCSI IDs to differentiate between the devices. Al so, the SCSI IDs are used

to prioritize the order of communication when several devices are

communicating with the host computer. The lower the ID number, the l ower the

priority it has.

Caution

The SCSI ID of a device has nothing to do with its physical location. For

example, in a SCSI bus that has multiple devices connected to it, the SCSI ID

of the last device can be 2.

If the AIT autoloader is the device connected to the end edge of the SCSI bus,

you must attach a terminator to the unused SCSI connector to terminate the

SCSI bus. Now, the AIT autoloader can su pply electric power to t he terminator.

For information about details, see “Setting the DIP Switches” (page 19) in

Chapter 2, “Installation ”.

Error Code List

When the AIT autoloader generates an error, an error code appears on the

message display. The following is the list of error code s that can appear on the

message display. If a message from the list appears on the message display,

contact customer service.

If an error code appears on the message displa y th at do es not figure i n thi s li st ,

before contacting customer service verify the LED on the front of the AIT

autoloader, as well as perform the operations outlined in “Other Messages”

(page 52)

If the problem persists, contact customer service.

Error code Description Display Logged

00

01

02

03

20

21

No valid error code

information.

Detected a microcode

anomaly upon startup.

Detected a base RAM

anomaly upon startup.

Detected a buffer RAM

anomaly upon startup.

The Identify message

detected a SCSI parity error

after selection.

Detected SCSI parity error.

Message Out phase retried

but gave up.

—No

[0 1] appears on the

message displa y.

[0 2] appears on the

message displa y.

[L ] and [0 3] appear

alternately on the messa ge

display.

—Yes

—Yes

No

No

No

Appendix

47

Page 48

Error code Description Display Logged

Detected SCSI parity error.

22

23

24

25

26

27

28

29

2A

2B

2C

2F

30 Reports a unit attention event. — Yes

31

32 Loader not yet ready. — Yes

33 Loader front door open. — Yes

34

35 Currently in menu mode . — Yes

36

41

42

43

70

Command phase retried but

gave up.

Detected SCSI parity error.

Data Out phase retried but

gave up.

Detected a parity error

message. Message In phase

retried but gave up.

Received Initiator detected

error message. Message

phase retried but gave up.

Received Initiator detected

error messag e. C ommand

phase retried but gave up.

Received Initiator detected

error message. Status phase

retried but gave up.

Received Initiator detected

error message. Data In phase

retried but gave up.

Received Initiator detected

error message. Data Out

phase retried but gave up.

Received an illegal message

from the SCSI interface.

Received an illegal Identify

message at the SCSI interfac e

Faile d reselection. Reselec tion

retried but gave up.

REQ/ACK handshake timeout

or controller chip interruption

timeout at the SCSI interfac e .

An as yet unsupported LUN

specified at the SCSI

interface.

Currently in reprogr am mi ng

mode.

Reported an information

exception condition.

Reception of drive data

timeout at the drive interface.

Received data of abnormal

length from drive at the drive

interface.

Drive detected as offlin e at the

drive inter face.

Detected calibration error

(lower sensor readings

abnormal).

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

—Yes

[L ] and [4 1] appear

alternately on the messa ge

display.

[L ] and [4 2] appear

alternately on the messa ge

display.

[L ] and [4 3] appear

alternately on the messa ge

display.

[L ] and [7 0] appear

alternately on the messa ge

display.

Yes

Yes

Yes

Yes

Appendix

48

Page 49

Error code Description Display Logged

71

72

78

7A

7B

7C

80

81

82

83

88

89

8A

90

91

92

Detected calibration error

(notch readings abnormal).

Detected calibration error.

(Upon calibration of the lower

edge of the drive rim, it was

detected that it needed to be

calibrated above the upper

limit.)

Because cartridge pickup

failed, when performing

recovery it is impossible to do

so because there are no

available slots.

The door lock sensor doe s not

close when attempting to lock

the front door.

The door lock sensor doe s not

lock when attempting to lock

the front door.

The door lock sensor doe s not

unlock when attempting to

open the front door.

Detected a GAP when the

elevator is in movement.

Cannot detect the normal

number of notches when the

elevator is in movement.

The pulse of the last notch is

determined to be ±xx mm out

of position when the elevator

is in movement.

The pass sensor fails to

change ev en if space betw een

notches is 1.5 times wider

when the elevator is in

movement.

Cannot detect the lower edge

of the elevator during the

initialization MOVE.

Cannot detect the lower edge

of the elevator during the

calibration MOVE (in Type

Drive).

Cannot detect the notch edge

during the initialization MOVE.

Detected a GAP at the end of

the picker move ment .

Cannot detect the R VS se nsor

during pi cker m ovement.

Cannot detect the FWD

sensor during picke r

movement.

[L ] and [7 1] appear

alternately on the messa ge

display.

[L ] and [7 2] appear

alternately on the messa ge

display.

[L ] and [7 8] appear

alternately on the messa ge

display. Yes

[L ] and [7 A] appear

alternately on the messa ge

display.

[L ] and [7 B] appear

alternately on the messa ge

display.

[L ] and [7 C] appear

alternately on the messa ge

display.

[L ] and [8 0] appear

alternately on the messa ge

display.

[L ] and [8 1] appear

alternately on the messa ge

display.

[L ] and [8 2] appear

alternately on the messa ge

display.

[L ] and [8 3] appear

alternately on the messa ge

display. Yes

[L ] and [8 8] appear

alternately on the messa ge

display.

[L ] and [8 9] appear

alternately on the messa ge

display.

[L ] and [8 A] appear

alternately on the messa ge

display.

[L ] and [9 0] appear

alternately on the messa ge

display.

[L ] and [9 1] appear

alternately on the messa ge

display.

[L ] and [9 2] appear

alternately on the messa ge

display.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Appendix

49

Page 50

Error code Description Display Logged

93

98

99

9A

9B

9C

9D

9E

9F

A0

A1

A2

A3

A4

A7

A8

A9

AA

Cannot detect the RVS/FWD

sensors during the

initialization MOVE.

Failed cartridge pickup during

GET operation. (Cann ot detect

the CTRG. sensor at the end

of the GET operation.)

Cannot clear the GAP during

the GAP clear operation when

retrying GET.

Failed to detect RVS sensor

during elevator movement of

the GET operation.

Failed to detect FWD sensor

during elevator movement of

the GET operation.

Detected a GAP at the end of

the PUT operation.

The pass sensor cannot

detect the cartridge at the end

of the PUT operation.

Failed to detect RVS sensor

during elevator movement of

the PUT operation.

Failed to detect FWD sensor

during elevator movement of

the PUT operation.

Detected an empty slot. [L ] and [A 0] appear

Cannot perform the GET

operation because the picker

contains a cartridge.

Detected that all slots are

occupied.

Cannot perform the PUT

operation because the picker

does not contain a cartridge.

The picker made a GET

operation request while in the

RVS position.

Detected a sensor anomaly.

(GAP, cartridge, or pass.)

Detected a drive hardware

error.

Detected a drive medium

error.

Drive did not enter MOUNT

state after a lapse of three

seconds during the PUT

operation.

[L ] and [9 3] appear

alternately on the messa ge

display.

[L ] and [9 4] appear

alternately on the messa ge

display.

[L ] and [9 9] appear

alternately on the messa ge

display.

[L ] and [9 A] appear

alternately on the messa ge

display.

[L ] and [9 B] appear

alternately on the messa ge

display.

[L ] and [9 C] appear

alternately on the messa ge

display.

[L ] and [9 D] appear

alternately on the messa ge

display.

[L ] and [9 E] appear

alternately on the messa ge

display.

[L ] and [9 F] appear

alternately on the messa ge

display.

alternately on the messa ge

display.

[L ] and [A 1] appear

alternately on the messa ge

display.

[L ] and [A 2] appear

alternately on the messa ge

display.

[L ] and [A 3] appear

alternately on the messa ge

display.

[L ] and [A 4] appear

alternately on the messa ge

display.

[L ] and [A 7] appear

alternately on the messa ge

display.

[L ] and [A 8] appear

alternately on the messa ge

display.

[L ] and [A 9] appear

alternately on the messa ge

display.

[L ] and [A A] appear

alternately on the messa ge

display.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Appendix

50

Page 51

Error code Description Display Logged

Detected a check sum

C0

C1

C8

E0

E1

E8

F0

F1

F2

F3

F4

F5

F6

F7

anomaly during microcode

update.

Detected a F/W ID anomaly

during microcode update.

Detected a timeout when

ejecting the media from the

drive.

Cannot write data to flash

memory within 1 ms.

Cannot clear flash memory

sectors within 10 s.

Detected a check sum

anomaly in the flash memory

device setting area.

Detected a GAP sensor

anomaly.

Detected a pass sensor

anomaly.

Detected a cartridge sensor

anomaly.

Detected a picker forward

sensor anomaly.

Detected a picker reverse

sensor anomaly.

Detected an elevator lower

sensor anomaly.

Detected a door lock sensor

anomaly.

Detected a door close sensor

anomaly.

—Yes

—Yes

[L ] and [E 8] appear

alternately on the messa ge

display.

[L ] and [E 0] appear

alternately on the messa ge

display.

[L ] and [E 1] appear

alternately on the messa ge

display.

[L ] and [E 0] appear

alternately on the messa ge

display.

[L ] and [F 0] appear

alternately on the messa ge

display.

[L ] and [F 1] appear

alternately on the messa ge

display.

[L ] and [F 2] appear

alternately on the messa ge

display.

[L ] and [F 3] appear

alternately on the messa ge

display.

[L ] and [F 4] appear

alternately on the messa ge

display.

[L ] and [F 5] appear

alternately on the messa ge

display.

[L ] and [F 6] appear

alternately on the messa ge

display.

[L ] and [F 7] appear

alternately on the messa ge

display.

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Appendix

51

Page 52

Other Messages

Messages displayed during operation

ERROR

WARNING

CLEANING

Left of the display Right of the display Description

Flashing

consecutively up

and down

Flashing

consecutively up

and down

Rotating clock wi se

o (flashing) P (flashing) Unlocking the front door.

C (flashing) L (flashing)

E (flashing) J (flashing)

d (flashing) r (flashing)

Message display

8 (lit) 8 (lit)

Changes from 0 to 3

Number of the

moving cartridge,

flashing

Number of cartridges

Cartridge currently in

drive, flashing

o (lit) P (lit) Front door unlocked and open.

Immediately after turning on the AIT

autoloader.

During startup. (The ERROR/

WARNING and CLEANING LED

also flash.)

During cartridge movement or

inventory.

Standby.

Displays the number of cartridges in

the loader.

AIT drive in operation.

When the CLEAN button is pressed

or during cleaning. (See note 7 on

page 54.)

When forcibly ejecting cartridges.

(See note 4 on page 54.)

Disaster recovery mode. (See the

note below.)

Note

For details about the disaster recovery function, see “Disaster Recovery

Function” (page 31).

Appendix

52

Page 53

When problems occur

When problems occur, the ERROR/WARNING or CLEANING LED lights or

flashes, and one of the following codes appears on the message display.

ERROR

WARNING

CLEANING

LED Lit/Flashing Code Description Remedy

[L ] and [X X]

ERROR/

WARNING Flashing (orange)

ERROR/

WARNING Lit (orange)

CLEANING

Flashing (green)

appear alternately

on the message

display.

[d ] and [X X]

appear alternately

on the message

display.

[C ] and [X X]

appear alternately

on the message

display.

0 1

0 3

0 4

0 5

0 6

0 7 Parts replacement needed.

0 8

0 9

C L AIT drive cleaning request.

Loader error.

AIT drive error.

Data cartridge error.

Cartridge not completely

inserted.

Cleaning cartridge not