Sony SSTSL-10 Service manual

SA-WSLF10/

SS-CTL10/TSL10/TSL11

SERVICE MANUAL

Ver. 1.0 2005.03

SA-WSLF10 SS-CTL10 SS-TSL10 SS-TSL11 STAND ASSY

• SA-WSLF10 is the subwoofer in DAV-LF10.

• SS-CTL10 is the center speaker in DAV-LF10.

• SS-TSL10 is the front speaker in DAV-LF10.

• SS-TSL11 is the surround speaker in DAV-LF10.

US Model

E Model

Australian Model

This system incorporates with Dolby* Digital and Dolby Pro Logic (II)

adaptive matrix surround decoder and the DTS** Digital Surround

System.

* Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic”, and the double-D symbol are trademarks of

Dolby Laboratories.

**Manufactured under license from Digital Theater Systems, Inc.

“DTS”, “DTS-ES”, and “DTS Digital Surround” are trademarks of

Digital Theater Systems, Inc.

For the US model

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND

TOTAL HARMONIC

DISTORTION: With 4 ohm loads, both

Amplifier section SA-WSLF10

Stereo mode (rated) 86 W + 86 W (4 ohms at

Surround mode (reference) music power output

*Depending on the sound field settings and the source,

there may be no sound output.

Inputs VIDEO/SAT:

channels driven, fro m

200 – 20,000 Hz; rated

65 watts per channel

minimum RMS power,

with no more than 0.7 %

total harmonic distortion

from 250 milli watts to

rated output.

1 kHz, THD 10 %)

86

W (each)

Front:

(with SS-TSL10)

86

Center*:

(with SS-CTL10)

Surround*:

(with SS-TSL11)

Subwoofer*:

(with SA-WSLF10)

Sensitivity: 300 mV

Impedance: 50 kilohms

W

86

85

W

W × 2

SPECIFICATIONS

Phones Accepts low-and high-

impedance headphones.

Tuner section SA-WSLF10

System PLL quartz-locked digital

synthesizer system

FM tuner section

Tuning range

North American models: 87.5 – 108.0 MHz

(100 kHz step)

Other models: 87.5 – 108.0 MHz

(50 kHz step)

Antenna (aerial) FM wire antenna (aerial)

Antenna (aerial) terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

North American models: 530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,710 kHz (with the

interval set at 9 kHz)

Other models: 530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,602 kHz (with the

interval set at 9 kHz)

Antenna (aerial) AM loop antenna (aerial)

Intermediate frequency 450 kHz

Video section SA-WSLF10

Outputs Video: 1 Vp-p 75 ohms

Inputs

Speakers

Fro

nt SS-TSL10

Speaker system Two-way bass reflex,

Speaker unit 50 mm (2 inches) dia. cone

Rated impedance 4 ohms

Dimensions (approx.) 68 × 380 × 53 mm (2

S video:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

P

B/CB

, PR/CR: 0.7 Vp-p

75 ohms

Video: 1 Vp-p 75 ohms

magnetically shielded

type × 2, 25 mm (1 inch)

dia. balance-dome-type

tweeter

3

1

/8 inches) (w/h/d)

15 × 2

220 × (398 – 530) × 220

3

mm (8

/4 × (15 3/4 – 20 7/8)

3

/4 inches) (w/h/d ) with

× 8

stand

– Continued on next page –

/4 ×

SPEAKER SYSTEM

9-879-563-01

2005C05-1

© 2005.03

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

SA-WSLF10/SS-CTL10/TSL10/TSL11

r

Mass (approx.) 1.3 kg (2 lb 14 oz)

Center SS-CTL10

Speaker system Two-way bass reflex,

Speaker unit 50 mm (2 inches) dia. cone

Rated impedance 4 ohms

Dimensions (approx.) 68 × 380 × 53 mm (2

Mass (approx.) 1.3 kg (2 lb 14 oz)

Surround SS-TSL11

Speaker system Two-way bass reflex,

Speaker unit 50 mm (2 inches) dia. cone

Rated impedance 4 ohms

Dimensions (approx.) 68 × 240 × 53 mm (2

Mass (approx.) 1.0 kg (2 lb 4 oz)

Subwoofer SA-WSLF10

Speaker system Bass reflex

Speaker unit 180 mm (7

Rated impedance 4 ohms × 2

Dimensions (approx.) 241 × 606 × 241 mm

Mass (approx.) 14 kg (30 lb 14 oz)

Power requirements

North American models: 120 V AC, 60 Hz

Taiwan model: 120 V AC, 50/60 Hz

Other models: 220-240 V AC, 50/60 Hz

Power consumption 120 W

2.7 kg (6 lb) with stand

magnetically sh ie lded

type ×2, 25 mm (1 inch )

dia. balance-dome-type

tweeter

3

1

/8 inches) (w/h/d)

15 × 2

magnetically sh ie lded

type ×2, 25 mm (1 inch )

dia. balance-dome-type

tweeter

1

/2 × 2 1/8 inches) (w/h/d)

9

1

cone type

1

/2 × 23 7/8 × 9 1/2

(9

inches) (w/h/d)

0.3 W (at the Power Saving

mode)

/4 ×

3

/4 ×

/8 inches) dia.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

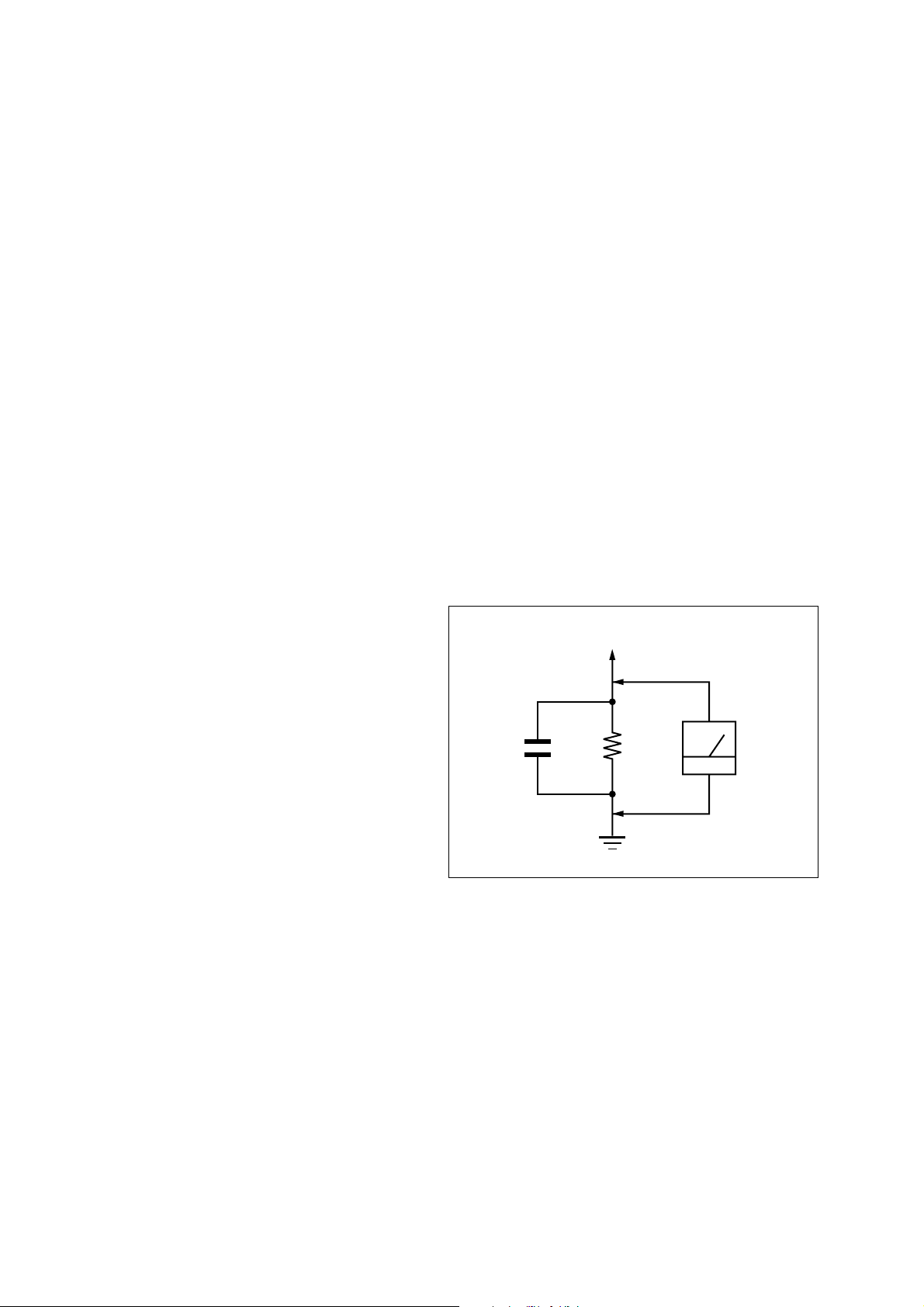

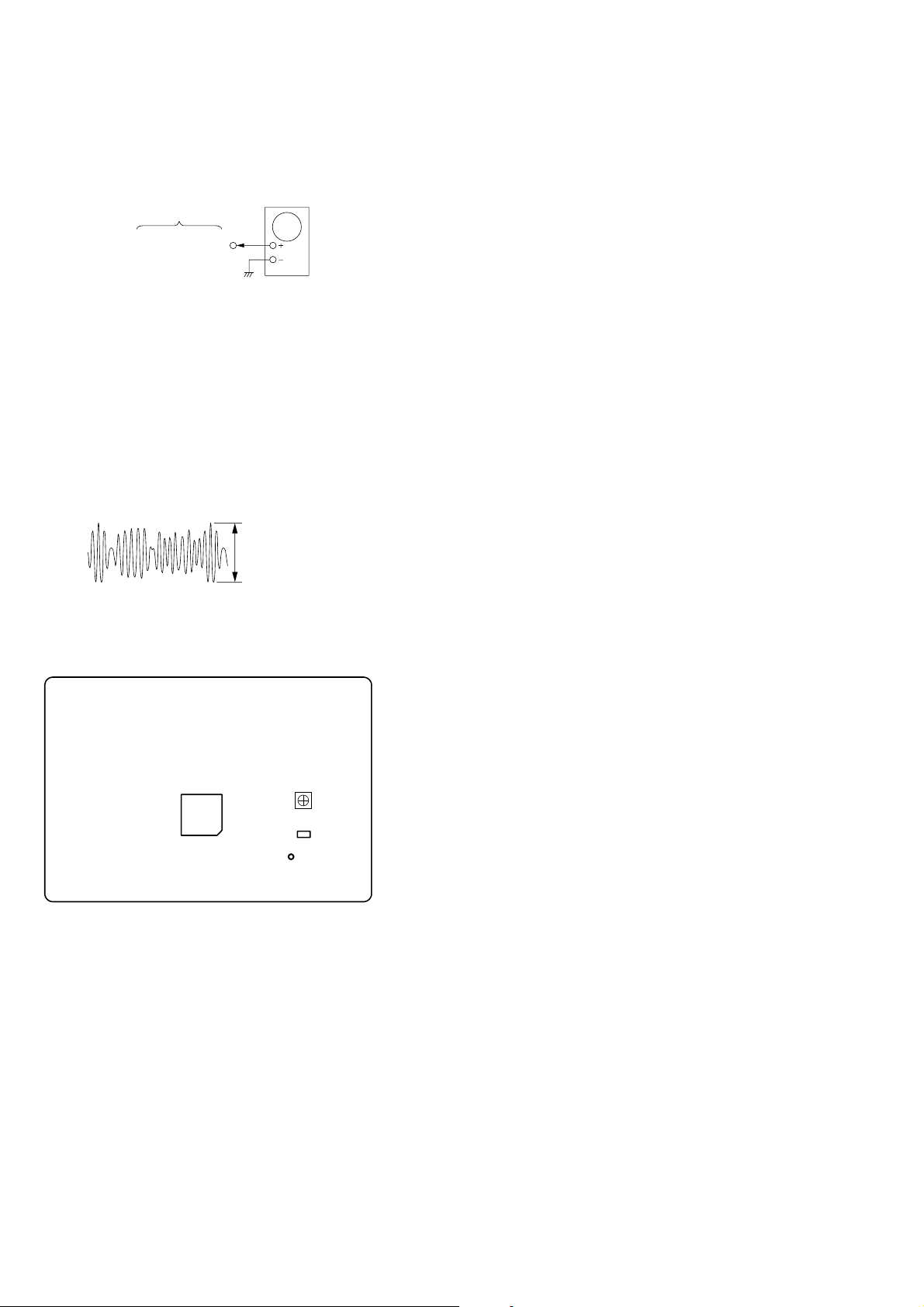

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

Design and specifications are subject to change

without notice.

AC

0.15 µF

1.5 k

Ω

voltmete

(0.75 V)

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

SA-WSLF10/SS-CTL10/TSL10/TSL11

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 6

3. DISASSEMBLY ......................................................... 7

4. ELECTRICAL ADJUSTMENT ............................ 8

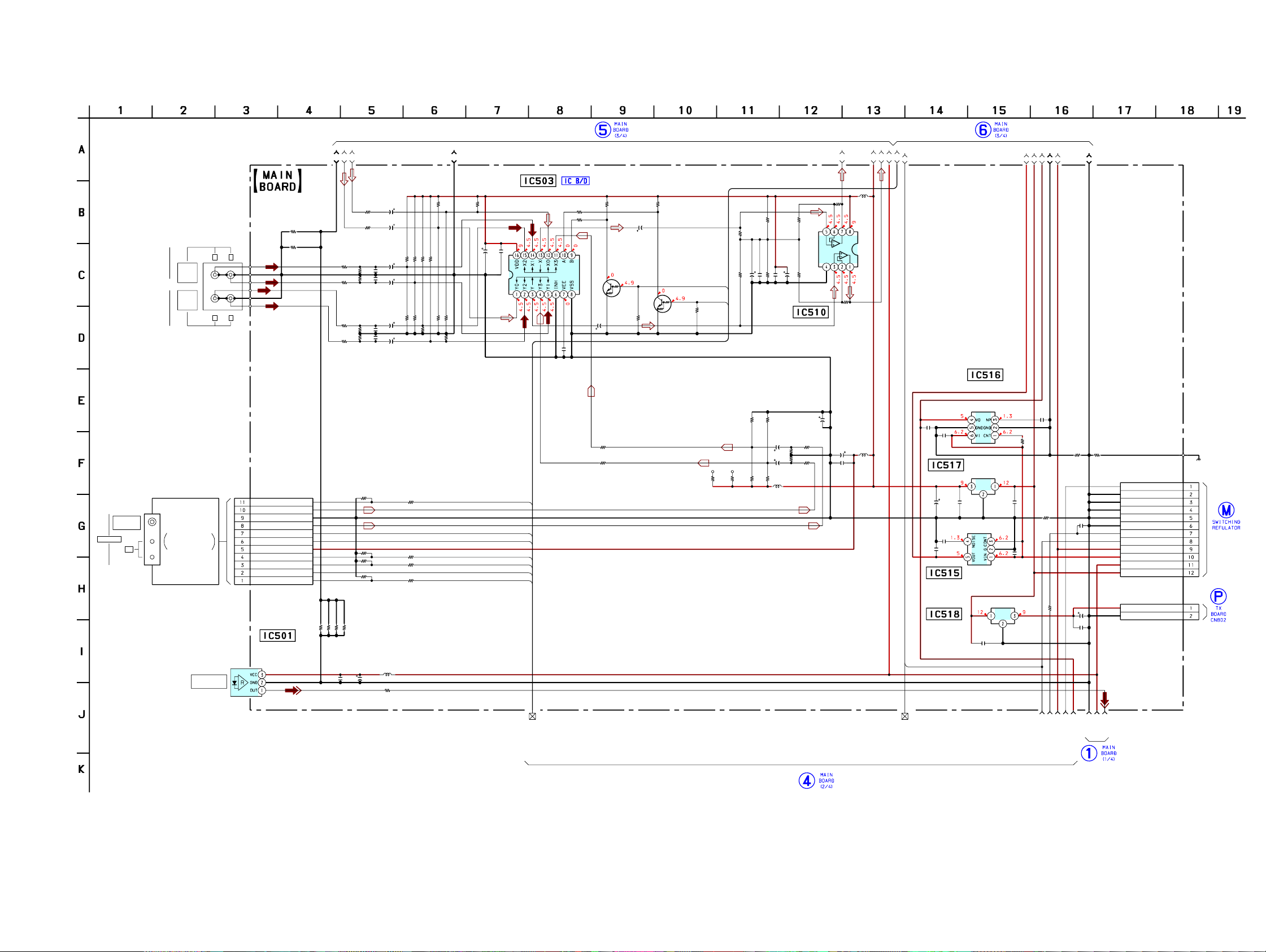

5. DIAGRAMS

5-1. Block Diagram – AUDIO DSP Section –........................ 9

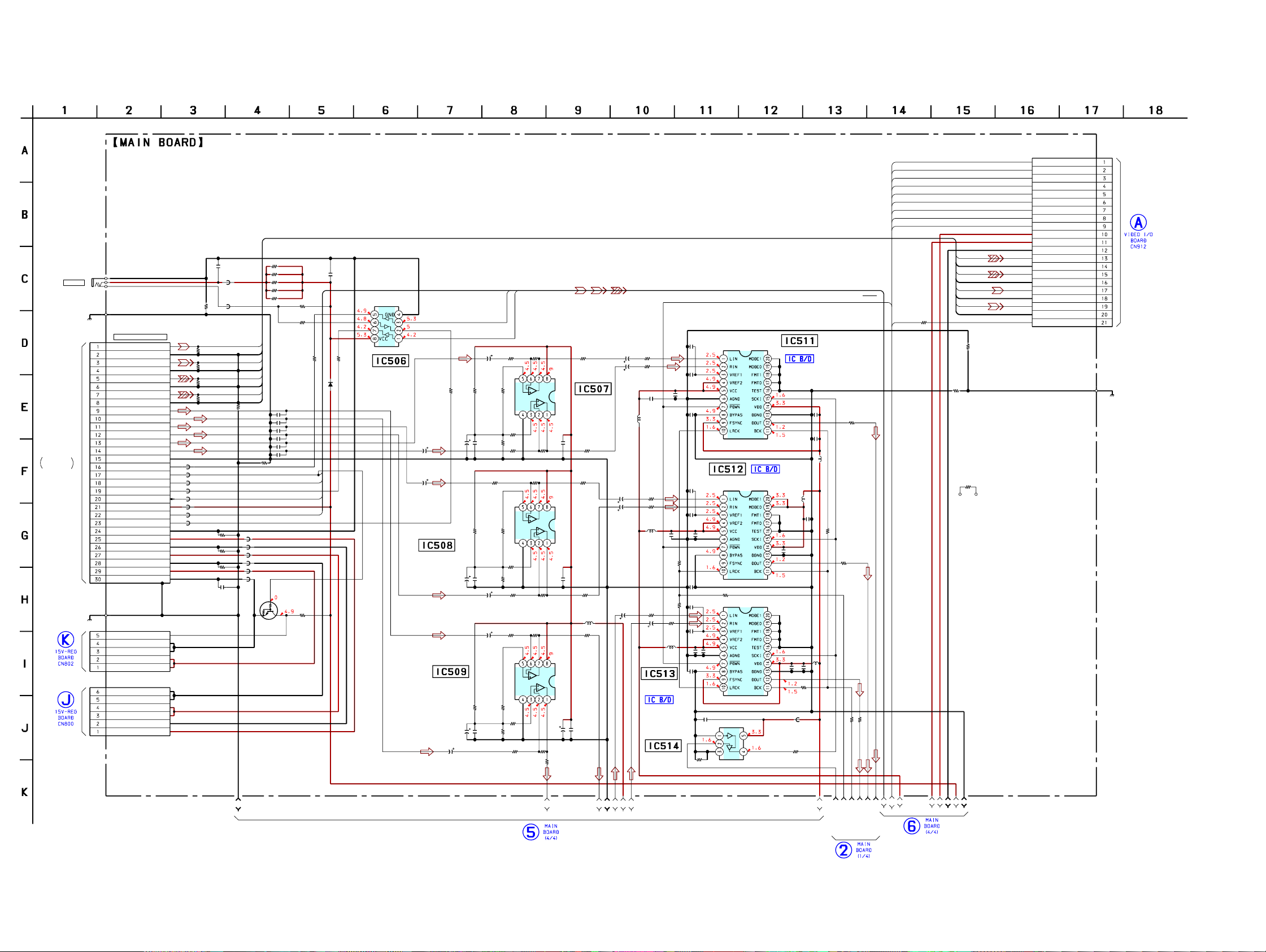

5-2. Block Diagram – AUDIO Section –................................ 10

5-3. Block Diagram

– VIDEO/POWER SUPPLY Section – ........................... 11

5-4. Printed Wiring Board

– MAIN Board (Component Side) – ............................... 14

5-5. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................. 15

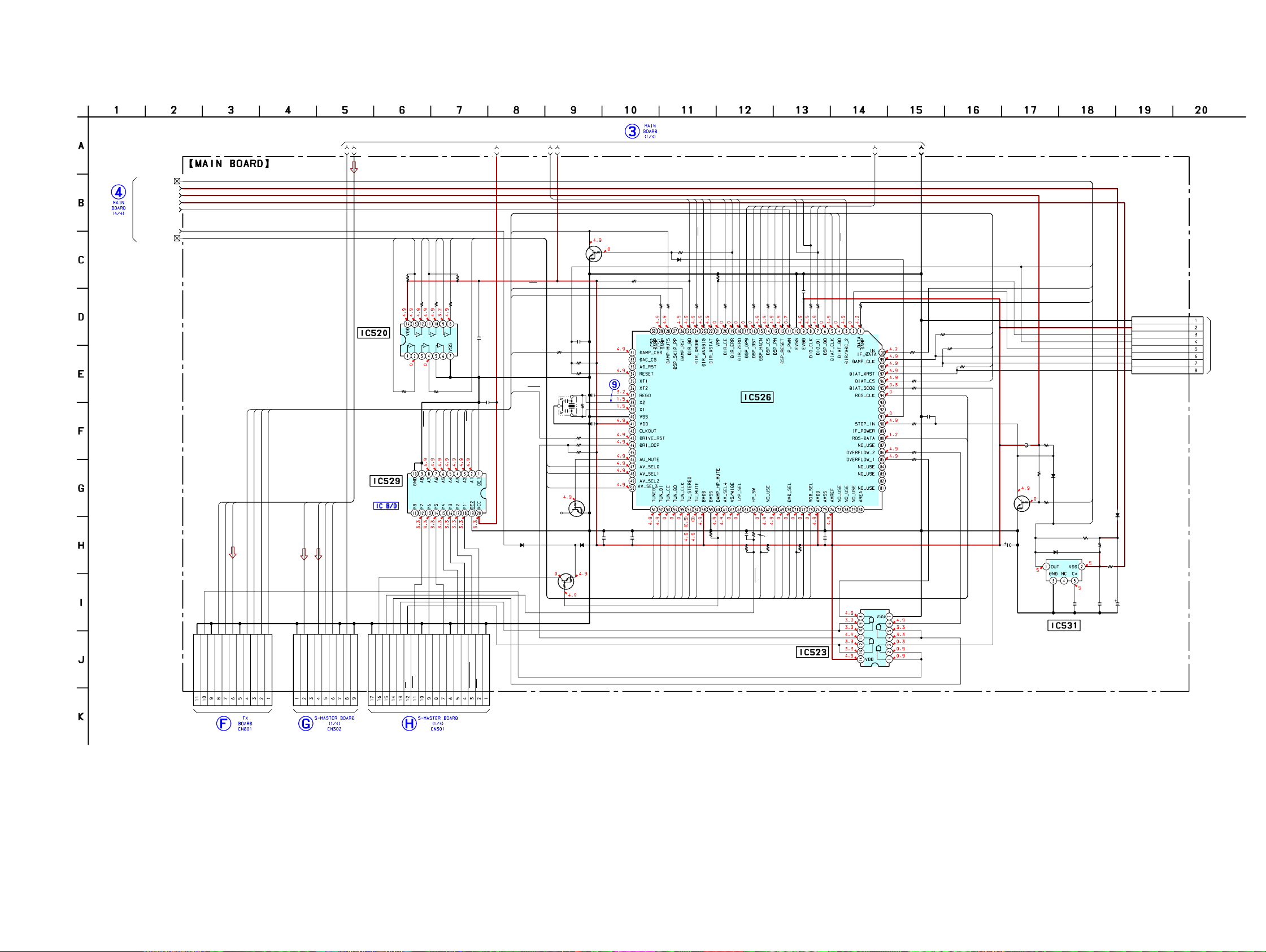

5-6. Schematic Diagram – MAIN Board (1/4) – .................... 16

5-7. Schematic Diagram – MAIN Board (2/4) – .................... 17

5-8. Schematic Diagram – MAIN Board (3/4) – .................... 18

5-9. Schematic Diagram – MAIN Board (4/4) – .................... 19

5-10. Printed Wiring Board

– S-MASTER Board (Component Side) – ...................... 20

5-11. Printed Wiring Board

– S-MASTER Board (Conductor Side) –........................ 21

5-12. Schematic Diagram – S-MASTER Board (1/4) – ........... 22

5-13. Schematic Diagram – S-MASTER Board (2/4) – ........... 23

5-14. Schematic Diagram – S-MASTER Board (3/4) – ........... 24

5-15. Schematic Diagram – S-MASTER Board (4/4) – ........... 25

5-16. Printed Wiring Board – TX Board –................................ 26

5-17. Schematic Diagram – TX Board – .................................. 27

5-18. Printed Wiring Board – VIDEO I/O Board – .................. 28

5-19. Schematic Diagram – VIDEO I/O Board – ..................... 29

5-20. Printed Wiring Boards

– COMPONENT/SPK-OUT Boards –............................ 30

5-21. Schematic Diagram

– COMPONENT/SPK-OUT Boards –............................ 31

5-22. Printed Wiring Boards – POWER SUPPLY Section –.... 32

5-23. Schematic Diagram – POWER SUPPLY Section – ........ 33

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

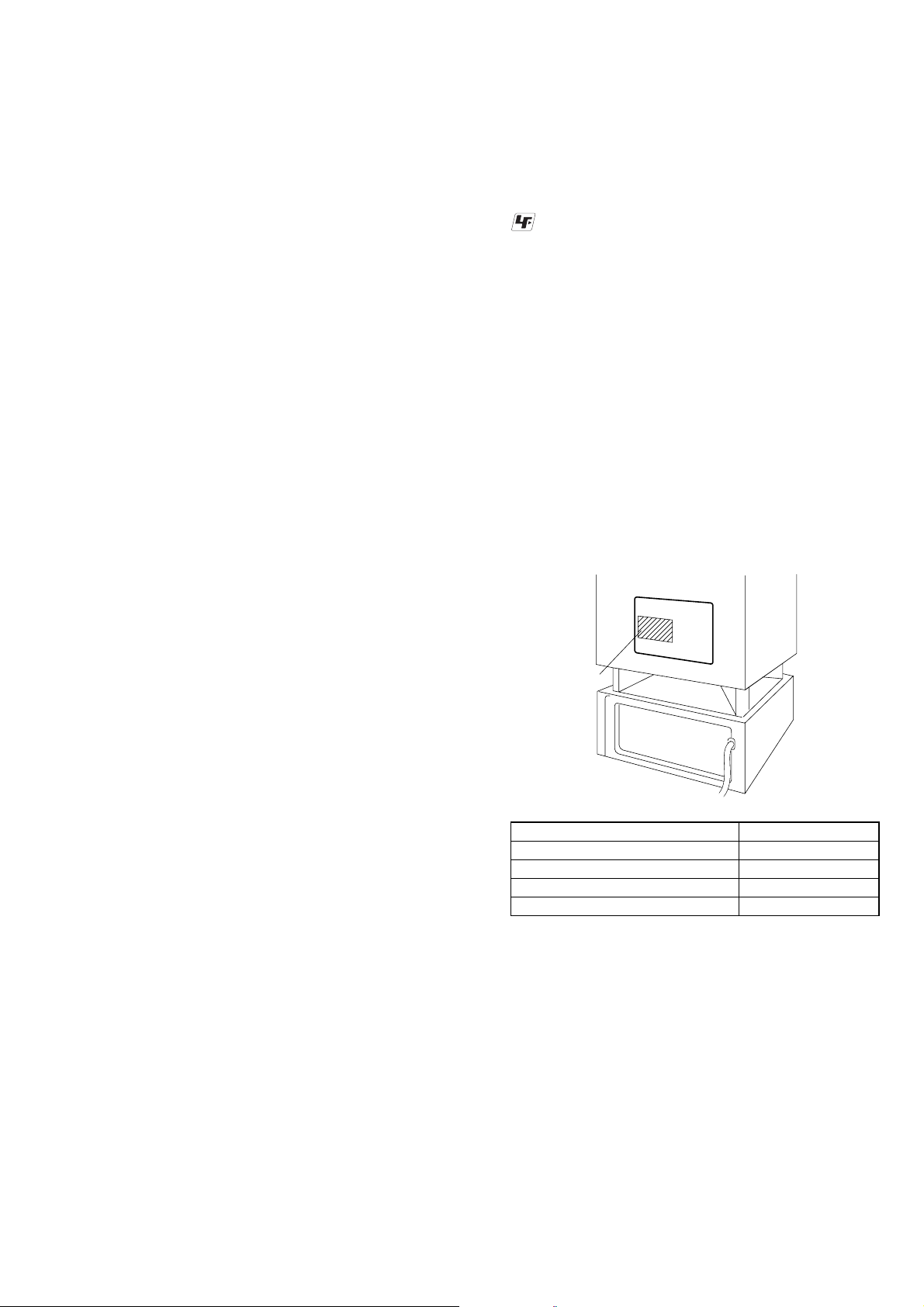

MODEL IDENTIFICATION

– Rear View –

Part No.

6. EXPLODED VIEWS

6-1. Overall Section (SA-WSLF10) ....................................... 44

6-2. AMP Assy Section (SA-WSLF10).................................. 45

6-3. MAIN Board Section (SA-WSLF10).............................. 46

6-4. SS-CTL10/TSL10/TSL11 Section .................................. 47

6-5. Stand Section ................................................................... 48

7. ELECTRICAL PARTS LIST................................ 49

MODEL PART No.

US model 2-590-864-0[]

Taiwan model 2-590-866-0[]

Singapore model 2-590-867-0[]

Australian model 2-591-603-0[]

3

SA-WSLF10/SS-CTL10/TSL10/TSL11

• The units that are required for the system operation check during repair service

Units required for

Unit.

need to

checking

Super audio CD/

DVD player : HCD-LF10

Sub woofer :

SA-WSLF10

Front speaker :

SS-TSL10

Center speaker :

SS-CTL10

Surround speaker :

SS-TSL11

Remote commander :

RM-SP320

*1 Only the defective unit. *2 Either one of them.

Units with a mark: The units that are required for the system operation check during repair service

However, there can be a case that some units of the system need to not be brought into repair shop depending on the unit. that became defective.

operation

Super audio CD/

DVD player :

check

HCD-LF10

a

a

a

a

Sub woofer :

SA-WSLF10

a

a

a

a

Front speaker :

SS-TSL10

a*1

a*2

Center

speaker :

SS-CTL10

a

Surround

speaker :

SS-TSL11

a*1

Remote

commander :

RM-SP320

a

a

a

a

a

Remote

sensor :

DIR-R4

Surround

amplifier :

TA-SB500WR

a

a

a

aaaa

IR transmitter :

DIR-T1

IR receiver :

DIR-R1

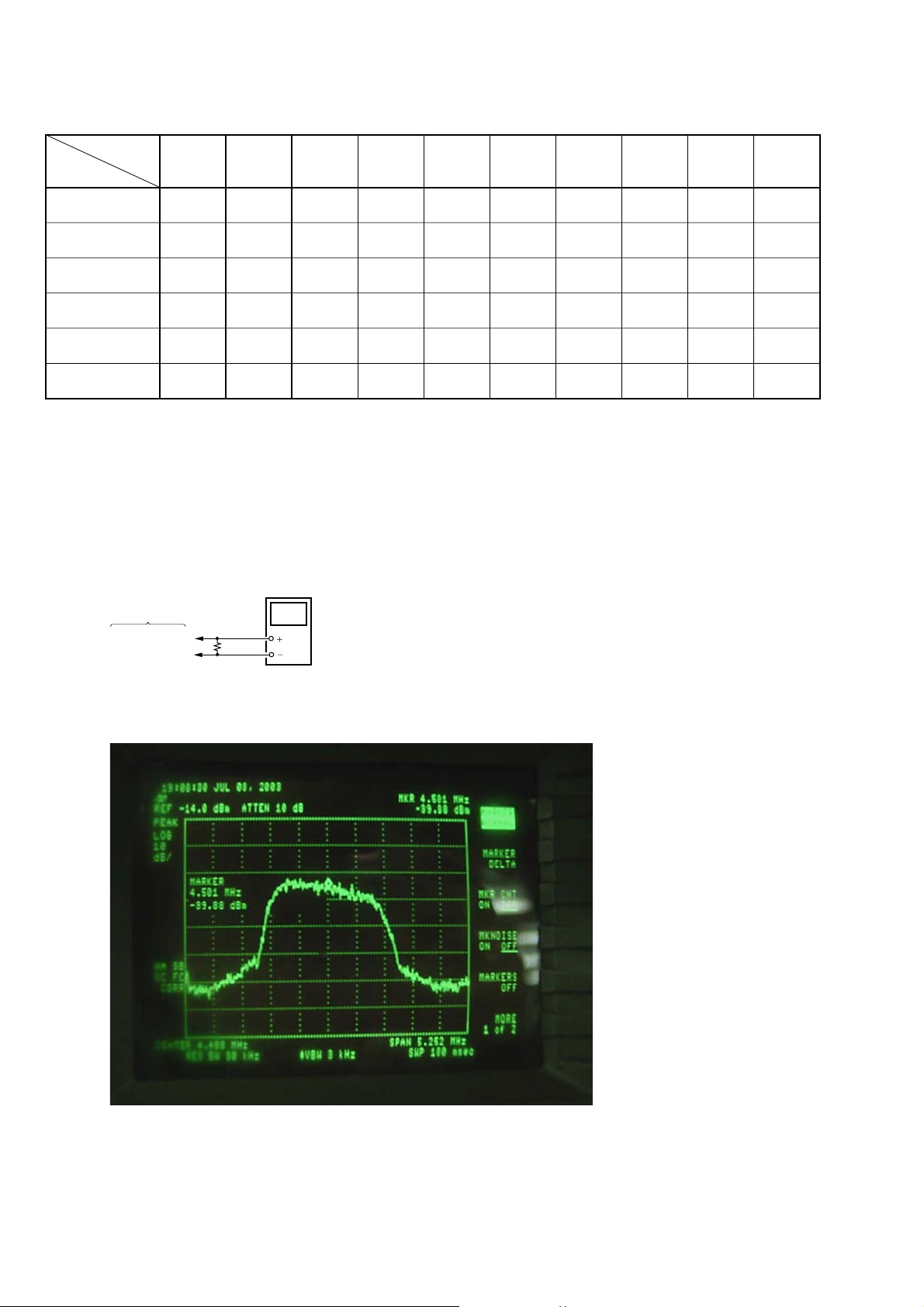

THE CHECK METHOD OF THE OUTPUT SIGNAL FROM TX BOARD

Procedure:

1. A spectrum analyzer is connected to pin 1 and pin 2 of the output connector (CN803) of TX board.

digital

voltmeter

TX board

pin

10 Ω (0.5%)

1

2

CN803 pin

2. Conf irm that it is spectrum as shown in a f igure with the spectrum analyzer . It is normal if the signal of a 3MHz to 6MHz zone (a center

is 4.5MHz) can be checked.

3. When the output signal from TX board is normal, pin 8 (SDATA), pin 4 (LRCKO) and pin 5 (BCKO) of the input signal connector

(CN801) are investigated.

4

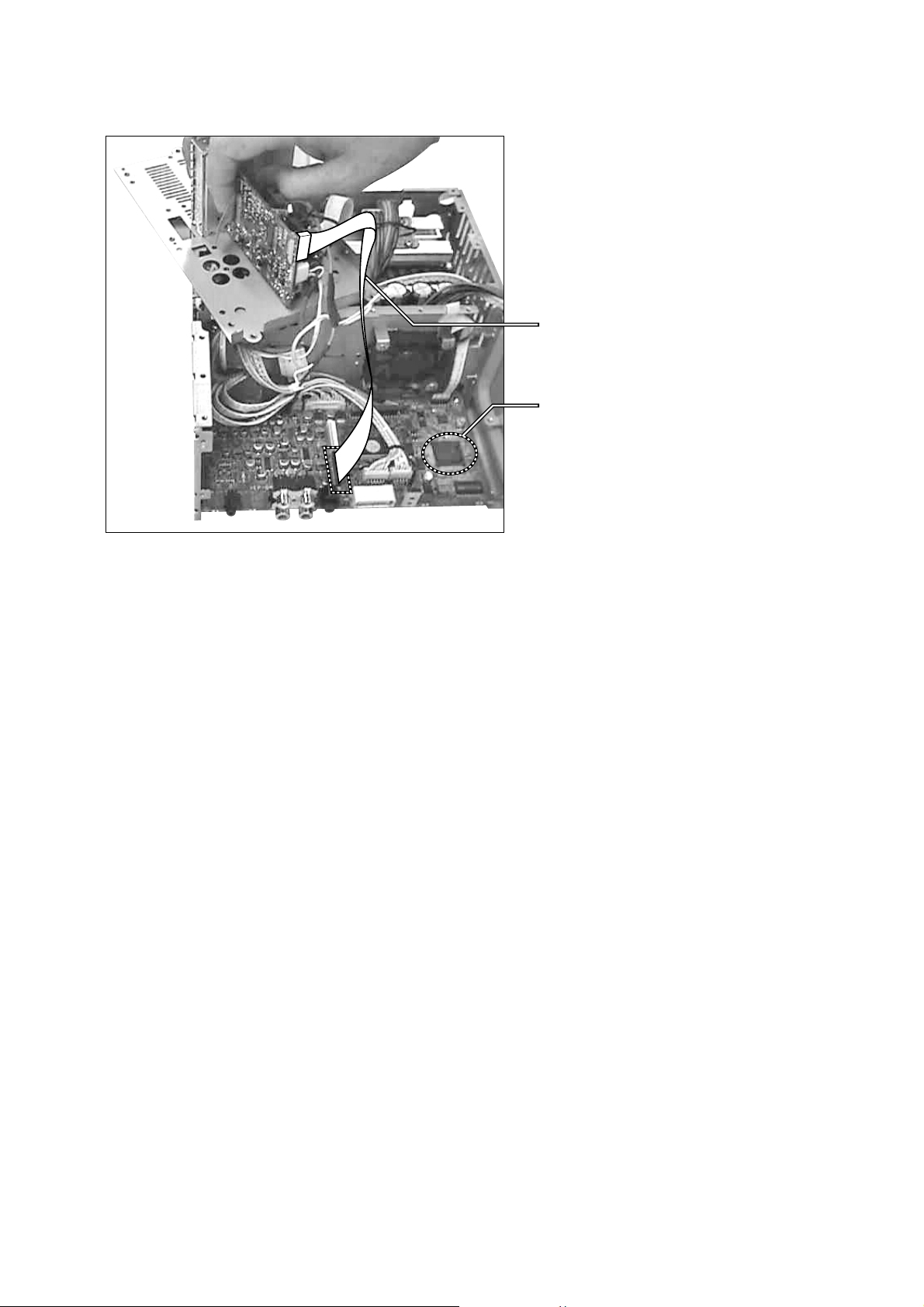

SERVICING POSITION (MAIN Board)

SA-WSLF10/SS-CTL10/TSL10/TSL11

Connect the MAIN board and the VIDEO I/O board

using the extension cable and check the MAIN board.

J-2501-245-A

(1mm/23P/L300)

IC525 on the MAIN board

CAUTION:

Keep your eyes 10 cm or more away from the infrared laser unit (DIR-T1).

Do not view directly the laser beam.

5

SA-WSLF10/SS-CTL10/TSL10/TSL11

SECTION 2

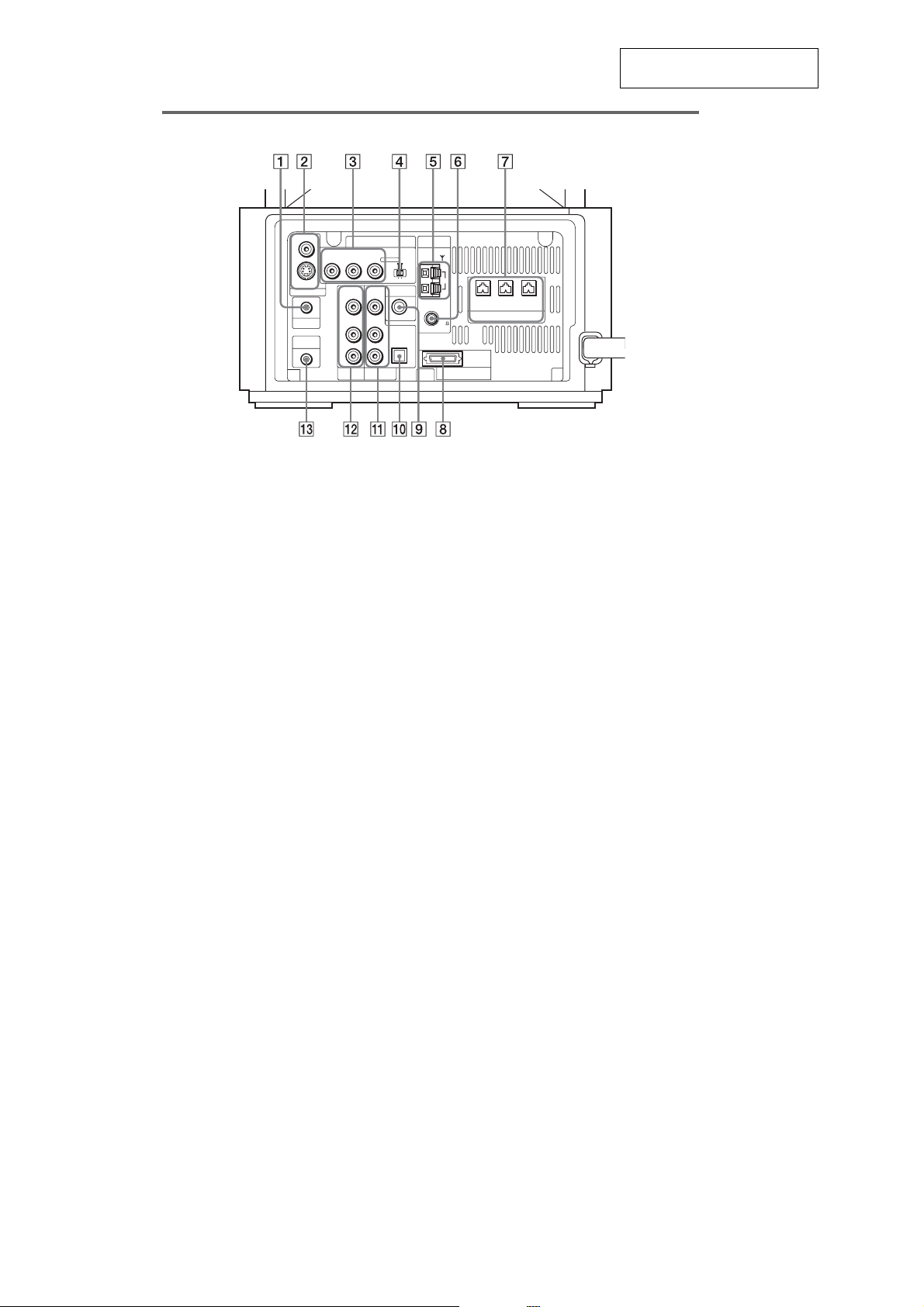

Subwoofer (Rear Panel)

GENERAL

This section is extracted from

instruction manual.

VIDEO

S VIDEO (DVD ONLY)

MONITOR OUTPUT

PHONES

DIR-R4

COMPONENT VIDEO OUT ANTENNA

PB/CBPR/CRSCAN SELECT

Y

VIDEO

VIDEO DIR-T1

IN

IN

AUDIO

AUDIO

IN

IN

OPTICAL

LL

R

VIDEO

DIGITAL IN

R

SAT

A PHONES jack

B MONITOR OUTPUT (VIDEO/S VIDEO)

jacks

C COMPONENT VIDEO OUT jacks

D COMPONENT VIDEO OUT/SCAN

SELECT switch

E AM terminals

F FM 75Ω COAXIAL jack

G SPEAKER jacks

INTERLACESELECTABLE

AM

CENTER FRONT L

FRONT R

(FOR SS-TSL10 , SS-CTL10)

FM

75

COAXIAL

SYSTEM CONNECTOR

SPEAKER

FOR HCD-LF10

H SYSTEM CONNECTOR jack

I DIR-T1 jack

J SAT OPTICAL DIGITAL IN jack

K SAT (VIDEO IN/AUDIO IN (L/R)) jacks

L VIDEO (VIDEO IN/AUDIO IN (L/R)) jacks

M DIR-R4 jack

6

SA-WSLF10/SS-CTL10/TSL10/TSL11

SECTION 3

DISASSEMBLY

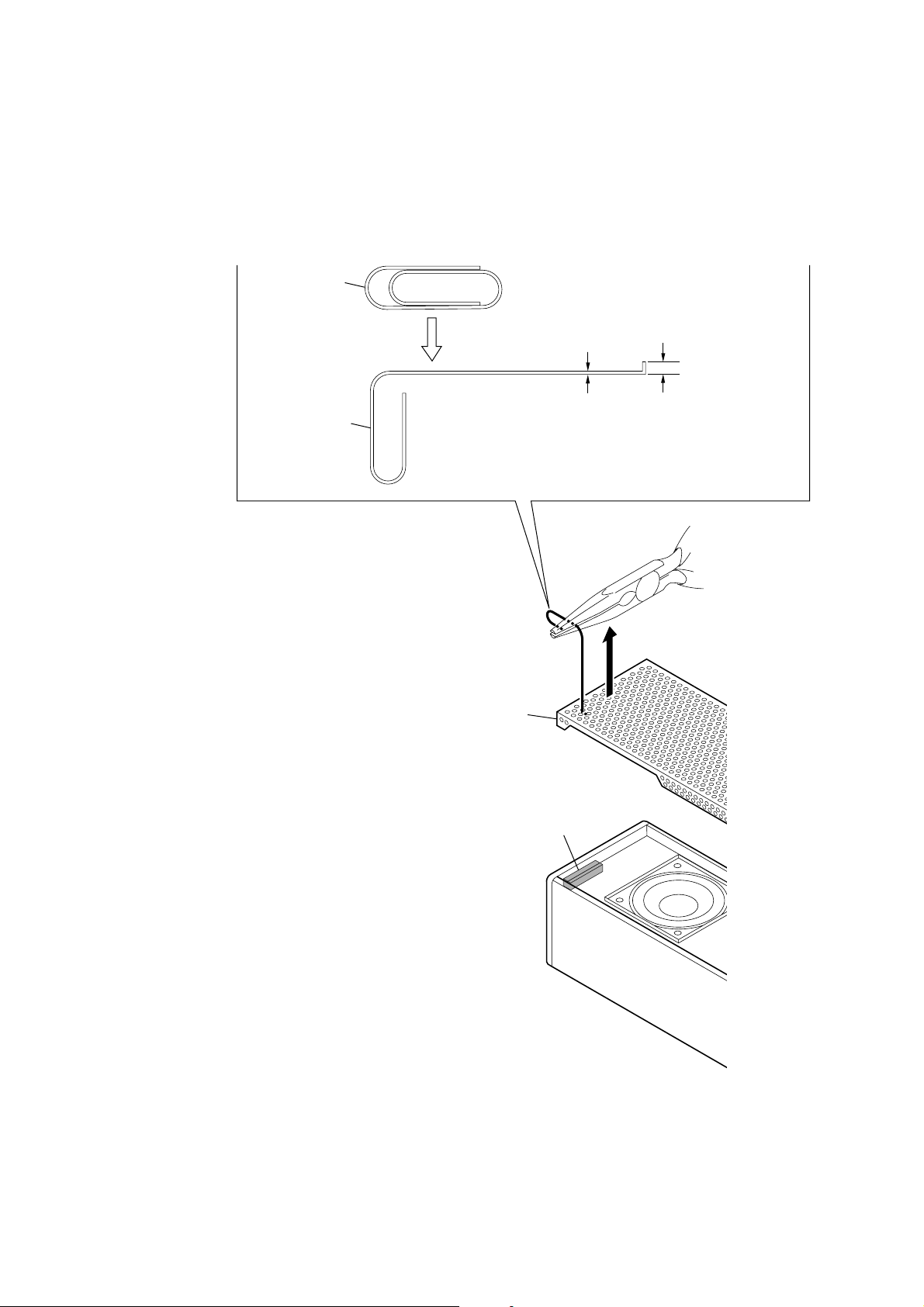

HOW TO REMOVE THE FRONT GRILLE (SS-CTL10/TSL10/TSL11)

Raise the front grille gently through the following procedure.

1

Prepare one clip (thickness φ0.8 mm).

2

Bend the leading end by about 3 mm.

3

Insert the clip into a hole in the front grille and raise the front grille.

clip

φ

0.8mm

clip

3mm

Note: The front grille has been stuck with the rubber.

(The sticking location is different depending on the speaker.)

front grille

rubber

7

SA-WSLF10/SS-CTL10/TSL10/TSL11

p

e

SECTION 4

ELECTRICAL ADJUSTMENT

DIAT SIGNAL RF LEVEL ADJUSTMENT

This adjustment is performed in order to adjust the transmission

distance of RF signal for DIAT communication.

Connection:

TX board

TP815

(RF AMP OUT)

Procedure:

1. Connect the oscilloscope to TP815 (RF AMP OUT) and GND

on the TX board.

2. Connect DIR-T1 to DIR-T1 jack (J908).

3. Adjust RV801 on the TX board so that the center of waveform

becomes trigger level 1.05 Vp-p.

(*Trigger position: –4 DIV)

4. Confirm trigger is locked.

5. Adjust RV801 on the TX board so that the center of waveform

becomes 2.2 to 2.4 Vp-p.

oscilloscop

VOLT/DIV : 500 mV

TIME/DIV : 500 ns

level : 2.2 to 2.4 Vp-

RF Signal Reference Waveform

Adjustment Location:

– TX BOARD (Component Side) –

IC804

RV801

DIAT Signal

RF Level Adjustment

IC805

TP815

(RF AMP OUT)

8

SECTION 5

DIAGRAMS

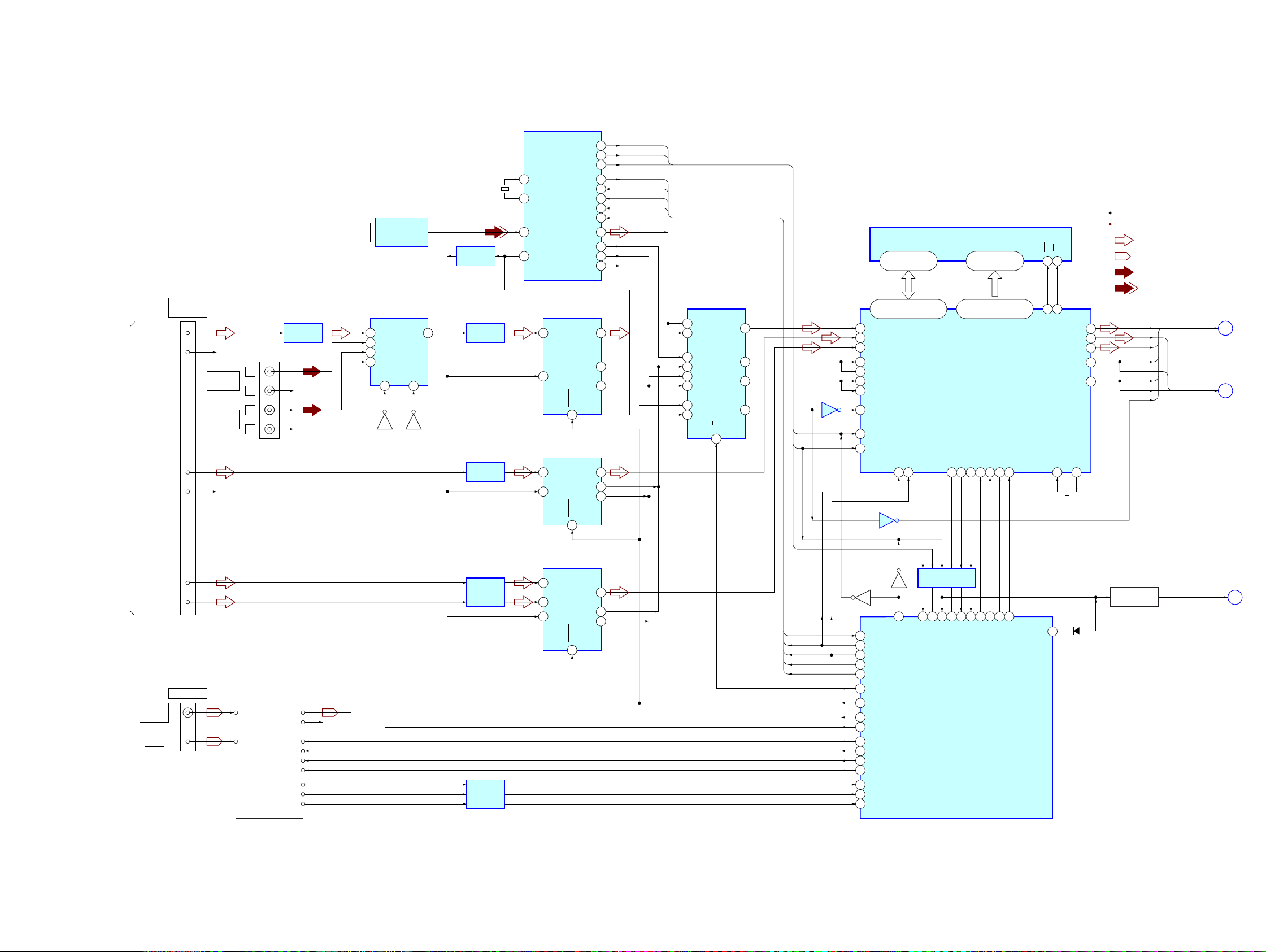

5-1. BLOCK DIAGRAM – AUDIO DSP Section –

CN502 (1/3)

SYSTEM

CONNECTOR

(FROM HCD-LF10)

FRONT-L

FRONT-R

SURROUND-L

SURROUND-R

9

10

11

12

R-CH

VIDEO

AUDIO IN

SAT

AUDIO IN

R-CH

L

R

L

R

J501

LINE AMP

IC509

R-CH

R-CH

OPTICAL

DIGITAL IN

DIGITAL OPTICAL

12 X0 13X

14 X1

15 X2

13 X3

Q504 Q503

RECEIVER

IC501

SELECTOR

IC503

A

10

SA-WSLF10/SS-CTL10/TSL10/TSL11

DIGITAL AUDIO

INTERFACE RECEIVER

IC519

24AUDIO (O)

34ERROR (O)

17XSTATE (O)

X500

24.576MHz

LEVEL SHIFT

IC514

LINE AMP

IC510

B

9

LINE AMP

IC508

22 XIN (I)

21 XOUT (O)

4DIN1 (I)

20 XMCK (O)

A/D CONVERTER

1 12LIN

15 SCKI

A/D CONVERTER

1 12LIN

15 SCKI

IC513

7

IC512

7

DOUT

LRCK

PDWN

DOUT

LRCK

PDWN

35DO (O)

36DI (I)

38CL (I)

37CE (I)

48XMODE (I)

16DATA (0)

14BCK (0)

15LRCK (0)

13CKOUT (0)

11BCK

10

11BCK

10

AUDIO

ERROR

XSTATE

DIR_DO

DIR_HDIN

DIR_HCLK

DIR_CE

DIR_XMODE

21A

31B

52A

62B

11 3A

10 3B

14 4A

13 4B

SELECTOR

IC522

/BA

1

S-RAM

IC527

D0 – D15 A0 – A15

7 – 10, 13 – 16,

29 – 32, 35 – 38

5 – 1, 44 – 42,

27 – 24, 21 – 18

WEWE0

CSCE0

17

6

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: AUDIO

: TUNER

: AUX IN (AUDIO)

: DIGITAL IN

108, 107, 105 – 102,

99, 98, 80 – 77, 75 – 72

D0 – D15

HDIN33HCLK

34

IC521

IC530

18 SDI1

114 S D I 3

30 SDI2

17 BCKI1

29 BCKI2

15 LRCKI1

28 LRCKI2

22 KFSIO

69 GP8

59 EXLOCK

41Y

72Y

93Y

124Y

AUDIO

ERROR

112, 110, 109, 97 – 92,

82 – 85, 66 – 64

A0 – A15

AUDIO DIGITAL

SIGNAL PROCESSOR

IC525

HCSDSP_CS

HDOUTDSP_DO

HACNDSP_HACN

BSTDSP_BST

GP9DSP_GP9

36

35

32

56

68

113

PMDSP_PM

XRSTDSP_RESET

2

45

44

MCLK1

9

X501

13.9MHz

12

23SDO1

25SDO3

24SDO2

20BCKO

19LRCKO

MCLK2

SDO1

SDO2

SDO3

BCKO

BCKO

LRCKO

LRCKO

SCK

SDO1, SDO3,

BCKO, LRCKO, SCK

SDO2,

BCKO, LRCKO

A

(Page 10)

B

(Page 11)

CENTER

SW (LFE)

FM 75Ω

COAXIAL

AM

13

11

ANTENNA

TUNER UNIT

FM ANT

AM ANT

L-CH

R-CH

MUTE

TUNED

STEREO

A/D CONVERTER

IC511

1

LINE AMP

IC507

R-CH

DI

CK

CE

DO

LEVEL SHIFT

IC520

LIN

2RIN

15 SCKI

PDWN

7

DOUT

LRCK

12

11BCK

10

XSTATE

DIR_DO

DIR_HDIN

DIR_HCLK

DIR_CE

DIR_XMODE

Q514

Q515

25 DIR_DO

7DIG_DI

8DIG_CLK

20 DIR_CE

24 DIR_XMODE

3DIR/ADC_2

66 ADC_PDOWN

48 AV_SEL1

47 AV_SEL0

54 TUN_DO

55 TUN_CLK

53 TUN_CE

57 TU_MUTE

52 TUN_DI

51 TUNED

56 TU_STEREO

23

DIR_ANADIG

18

LEVEL SHIFT

IC524

14

6

15

19

DIR_ERR

DIR_XSTAT

IC526 (1/3)

17

22

DIR_ZERO

SYSTEM CONTROLLER

MUTIG SWITCH

Q516

16

13

12

91UNMUTE

D503

AMP_SOFT MUTE

C

(Page 10)

SA-WSLF10/SS-CTL10/TSL10/TSL11

99

SA-WSLF10/SS-CTL10/TSL10/TSL11

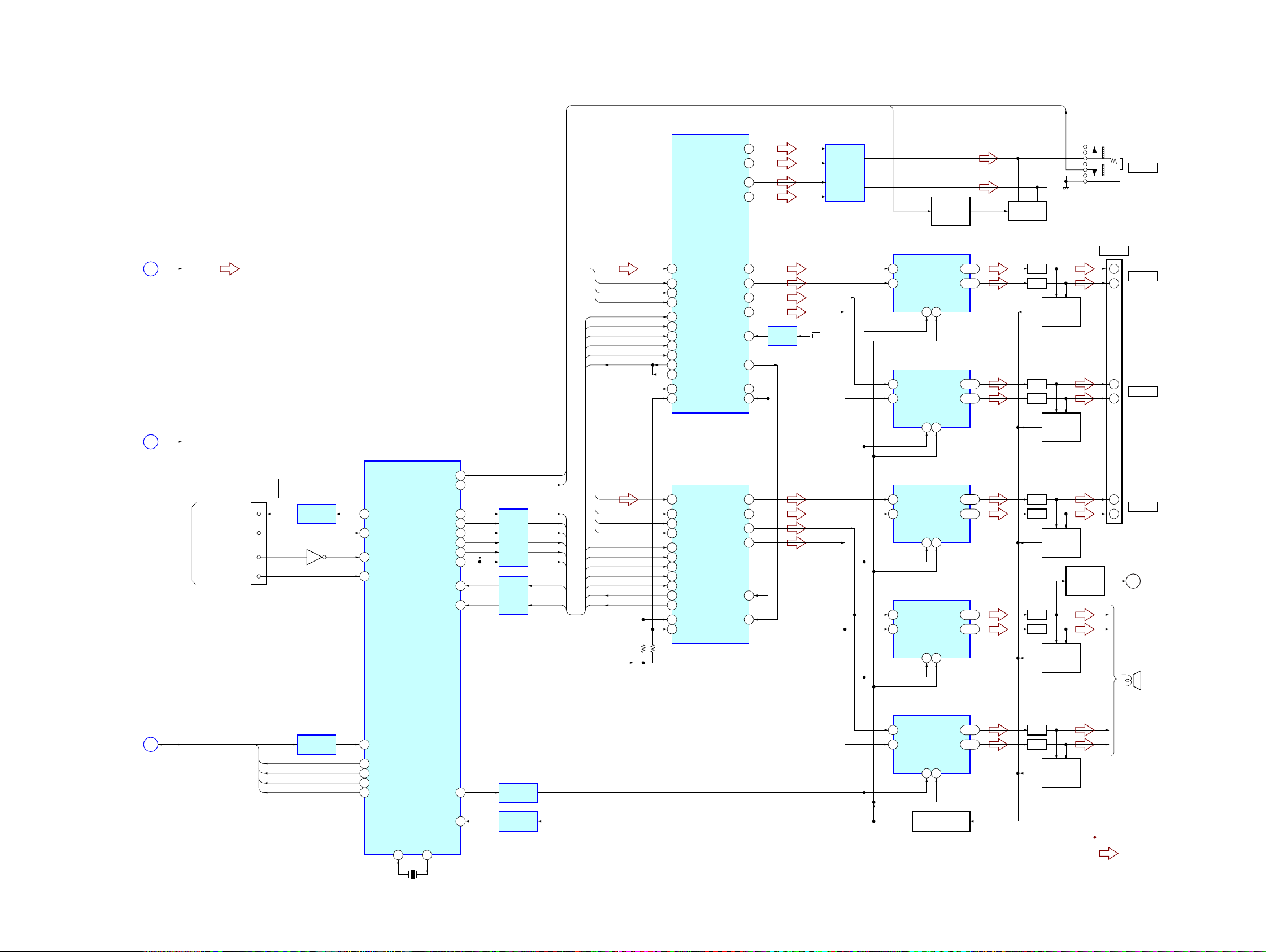

5-2. BLOCK DIAGRAM – AUDIO Section –

STREAM PROCESSOR

IC108

HPOUTL1

HPOUTL2

HPOUTR1

HPOUTR2

HPMUTE

45

43

41

39

HEADPHONE

AMP

IC301

MUTING

CONTROL

Q517

MUTING

Q903 – 906

HPSW

J903

PHONES

(Page 9)

(Page 9)

(Page 11)

SDO1, SDO3,

BCKO, LRCKO, SCKO

A

AMP_SOFTMUTE

C

(FROM HCD-LF10)

CSOD, SDATA,

SCLK, XLAT, XRST

D

UCOM-DO

UCOM-DI

CABLE_DETECT2

AMPMICOM_RESET

CN502 (2/3)

SYSTEM

CONNECTOR

19

18

20

22

CSOD

SDATA

SCLK

XLAT

XRST

LEVEL SHIFT

IC506 (1/2)

Q508

LEVEL SHIFT

IC523 (1/3)

1

DAMP_DATA

100

IF_DATA_IN

98

STOP_IN

34

RESET

SYSTEM CONTROLLER

DIAT_CSOD

95

DIAT_DO

4

DIAT_CLK

5

DIAT_CS

96

DIAT_XRST

97

DAMP_HP_MUTE

DAMP_DATA

DAMP_CLK

DAMP_CS1

DAMP_CS3

DAMP_RST

DAMP_MUTS

OVERFLOW_1

OVERFLOW_2

IC526 (2/3)

DRICE_RST

HP_SW

POWER DRIVER

IC101

SDO1

SCK

BCKO

LRCKO

SCDT

SHIFT

LATCH1

INIT

SOFTMUTE

OVF

65

60

98

99

29

31

26

28

85

86

43

LEVEL

SHIFT

IC529

(1/2)

LEVEL

SHIFT

IC523

(2/3)

LEVEL SHIFT

IC529 (2/2)

HPSW

HPMUTE

SCDT

SHIFT

LATCH1

LATCH3

INIT

SOFTMUTE

OVF

OVF2

SDO3

SCK

BCKO

LRCKO

SCDT

SHIFT

LATCH3

INIT

SOFTMUTE

OVF

OVF2

AMP +3.3V

31 DATA

36 XFSIN

30 BCK

29 LRCK

21 SCDT

22 SCSHIFT

23 SCLATCH

27 INIT

19 SOFTMUTE

25 OVF FLAGR

24 OVF FLAGL

18 NSPMUTE

20 PGMUTE

STREAM PROCESSOR

IC110

31 DATA

36 XFSIN

30 BCK

29 LRCK

21 SCDT

22 SCSHIFT

23 SCLATCH

27 INIT

19 SOFTMUTE

25 OVF FLAGR

24 OVF FLAGL

18 NSPMUTE

20 PGMUTE

OUTR1 6

OUTR2 4

OUTL1 11

OUTL2 9

XFSOIN

XFSOOUT 14

FSOCKO

FSOI

OUTR1 6

OUTR2 4

OUTL1 11

OUTL2 9

FSOI

XFSOIN 48

PWM_BP

2

PWM_AP

17

OSC

48

IC305

X450

49.152MHz

2

37

38

38

17

2

17

2

17

2

17

PWM_BP

PWM_AP

PWM_BP

PWM_AP

PWM_BP

PWM_AP

PWM_BP

PWM_AP

OUT_B

OUT_A

/SD

/RST

13

4

POWER DRIVER

IC102

OUT_B

OUT_A

/SD

/RST

13

4

POWER DRIVER

IC105

OUT_B

OUT_A

/SD

/RST

13

4

POWER DRIVER

IC106

OUT_B

OUT_A

/SD

/RST

13

4

POWER DRIVER

IC107

OUT_B

OUT_A

/SD

/RST

13

4

29, 30

25, 26

29, 30

25, 26

29, 30

25, 26

29, 30

25, 26

29, 30

25, 26

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

L.P.F.

OVER LOAD

DETECT

Q101, 102

OVER LOAD

DETECT

Q103, 104

OVER LOAD

DETECT

Q109, 110

OVER LOAD

DETECT

Q111, 112

OVER LOAD

DETECT

Q113, 114

FAN MOTOR

Q303, 304

DRIVER

J906

SPEAKER

+

–

+

–

+

–

FRONT L

FRONT R

CENTER

M301

M

(FAN)

(SUB WOOFER)

SP901

SA-WSLF10/SS-CTL10/TSL10/TSL11

DRI_OCP

X139X2

38

X502

20MHz

44

LEVEL SHIFT

IC523 (3/3)

PROTECT DETECT

Q301

SIGNAL PATH

: AUDIO

1010

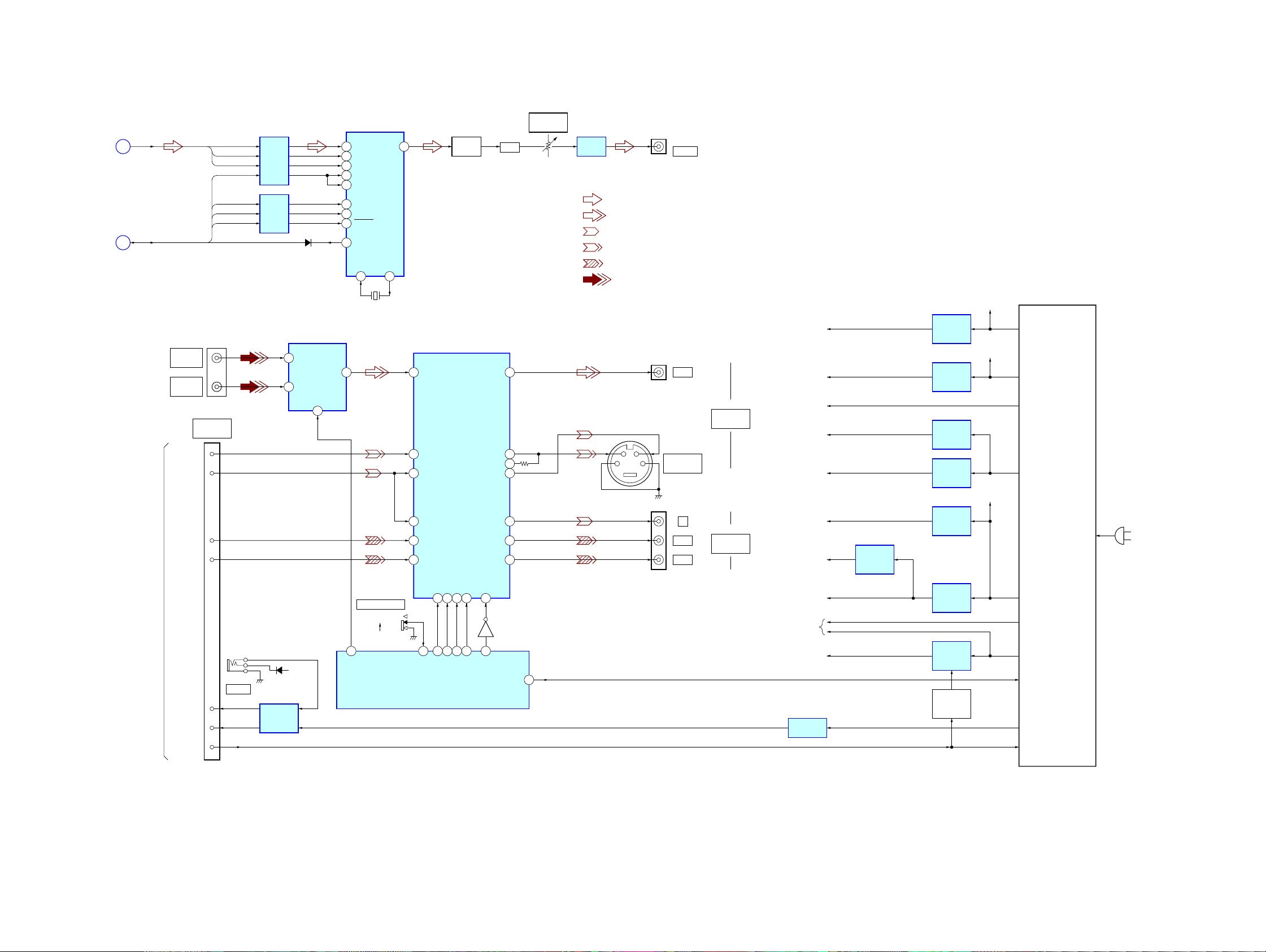

5-3. BLOCK DIAGRAM – VIDEO/POWER SUPPLY Section –

SA-WSLF10/SS-CTL10/TSL10/TSL11

(Page 9)

(Page 10)

SDO2, BCKO, LRCKO

B

CSOD, SDATA,

SCLK, XLAT, XRST

D

VIDEO

VIDEO IN

SAT

VIDEO IN

C/CVBS

CB/R

CR/R

J904

CN502 (3/3)

SYSTEM

CONNECTOR

3

1

Y/G

7

5

SDO2

BCKO

LRCKO

XRST

SDATA

SCLK

XLAT

CSOD

LEVEL

SHIFT

IC802

LEVEL

SHIFT

IC803

1

3

D800

SELECTOR

IC903

IN1

IN2

2

YOUT

SW1

RF MODULATOR,

D/A CONVERTER

IC804

48

DTIN

DAAOUT

50

BCK

49

LRCK

64

XRST

41

APS

15

SWDT

13

SCLK

14

XCSEN

16

CSOD

OSCI57OSCO

X801

24.756MHz

7

RV801

DIAT SIGNAL

RF LEVEL

21

BUFFER

Q801

L.P.F.

RF AMP

IC805

J908

DIR-T1

• SIGNAL PATH

: AUDIO

: VIDEO

: Y

: CHROMA

: COMPONENT VIDEO

59

VIDEO AMP, 75Ω DRIVER

IC902

4

2

6

10

12

14

CVBSIN

CIN

YIN

CYIN

CBIN

CRIN

CVBS OUT

C OUT

S-DCOUT

YOUT

CYOUT

CBOUT

CROUT

23

26

27

21

20

18

16

: AUX IN (VIDEO)

VIDEO

CY

S VIDEO

(DVD ONLY)

Y

PB/CB

PR/CR

J907

MONITOR

OUTPUT

J909

COMPONENT

VIDEO OUT

+1.8V

+2.6V

+5V

+5V

+9V

+2.5V

+2.5V

REGULATOR

IC801

+1.8V

REGULATOR

IC303

+2.6V

REGULATOR

IC528

+5V

REGULATOR

IC515

+5V

REGULATOR

IC516

+9V

REGULATOR

IC517

AMP +3.3V

+3.3V

+12V

3.3V

3.3V

E5.6V+5.6V

6.2V

SWITCHING

REGULATOR

(AC IN)

(FROM HCD-LF10)

SIRCS

AC-DETECT

P. CONT1

MUTE1

70

50

IP_SW

3

13

61

AV_SEL3

MUTE25YC-MIX25S1

69

AV_SEL4

S901

SCAN SELECT

INTERLACE

SELECTABLE

72

J502

DIR-T4

23

16

17

D502

LEVEL SHIFT

IC506 (2/2)

+5.6V

AV_SEL5

IC526 (3/3)

SYSTEM CONTROLLER

62

YC-MIX

VS/WIDE

I/P

9

63

I/P_SEL

Q913

P-PWM

+9V

POWER DRIVER

B+

+15V

11

DETECTOR

IC531

+9V

REGULATOR

IC518

+15V

REGULATOR

IC800

REGULATOR

CONTROL

Q506, 801

12V

12V

18V – 30V

V-CONT

AC-DET

ON/OFF

(STANDBY/POWER)

SA-WSLF10/SS-CTL10/TSL10/TSL11

1111

SA-WSLF10/SS-CTL10/TSL10/TSL11

d

• Note for Printed Wiring Boards and Schematic Diagrams

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor

: internal component.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : DVD PLAY

(): TUNER (FM/AM)

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage var iations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage var iations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

L : VIDEO

E : Y

a : CHROMA

r : COMPONENT VIDEO

f : AUX IN (AUDIO)

h : DIGITAL IN

i : AUX IN (VIDEO)

• Abbreviation

AUS: Australian model

SP : Singapore model

TW : Taiwan model

4

W or less unless otherwise

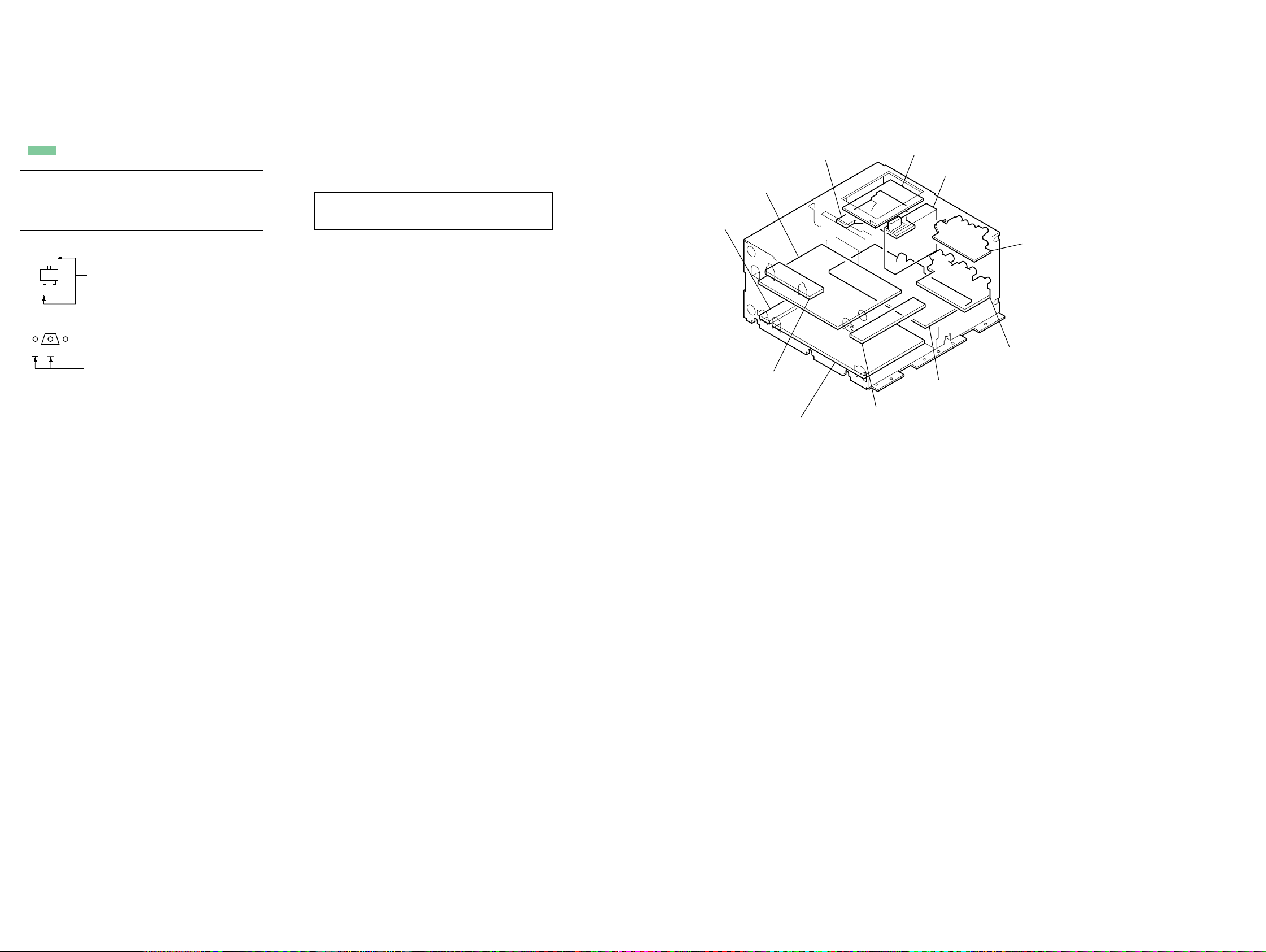

• Circuit Boards Location

S-MASTER board

PLF board

15V-RELAY board

SPK-OUT board

SWITCHING REGULATOR

TX board

TUNER UNIT

COMPONENT boar

VIDEO I/O board

MAIN board

15V-REG board

SA-WSLF10/SS-CTL10/TSL10/TSL11

1212

SA-WSLF10/SS-CTL10/TSL10/TSL11

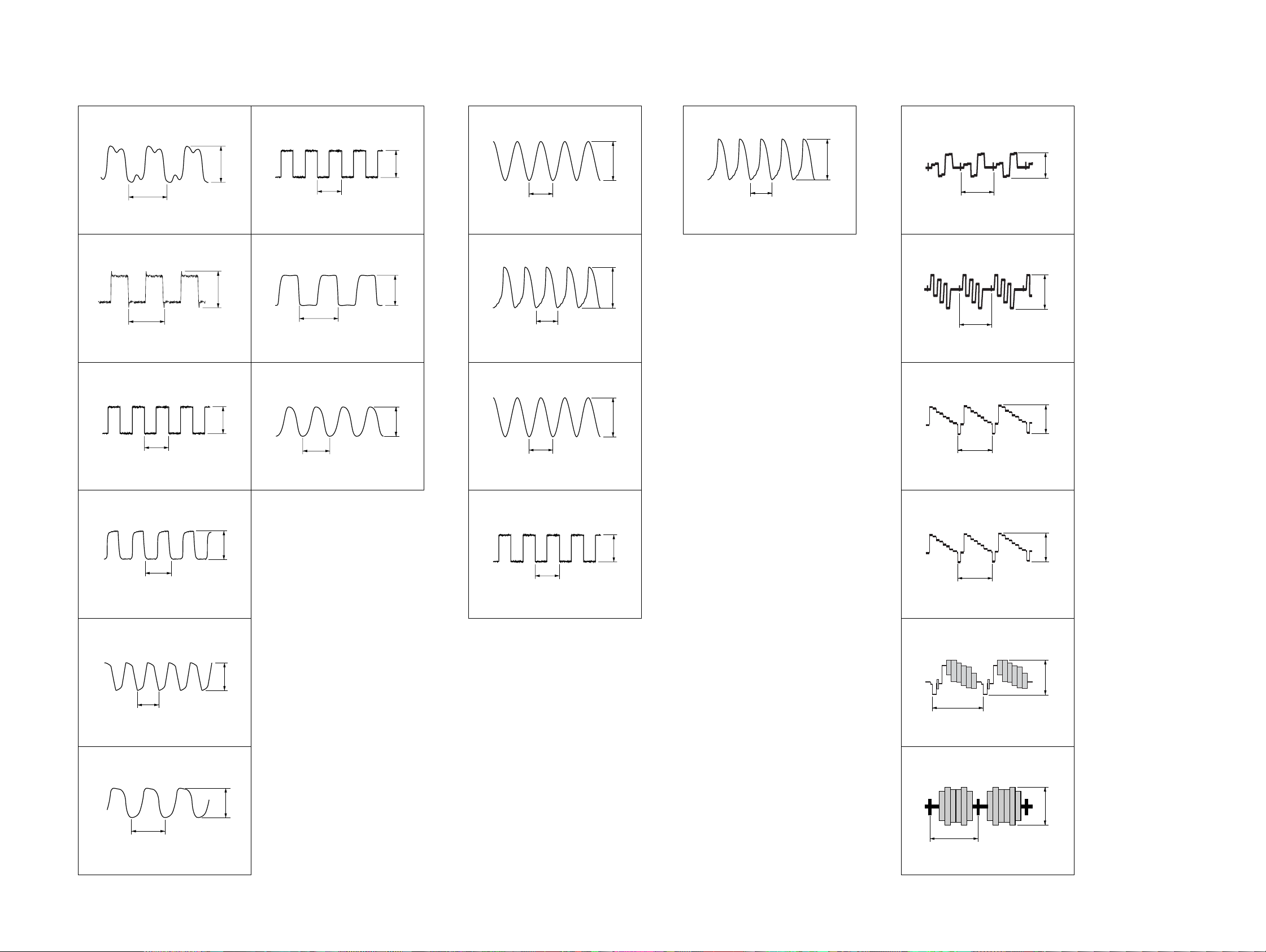

• Waveform

– MAIN Board – – S-MASTER Board – – VIDEO I/O Board –

IC519 qd (CKOUT (O))

1

IC525 ql (LRCKO)

7

qa

IC305 2

– TX Board –

IC804 tl (OSCO)

wa

IC902 qh (CROUT)

ea

(DVD play mode)

40.6 ns

2 V/DIV, 10 ns/DIV

IC519 qf (BCK (O))

2

163 ns

2 V/DIV, 50 ns/DIV

IC519 qg (LRCK (O))

3

10.4 µs

2 V/DIV, 5 µs/DIV

IC519 w; (XMCK (O))

4

3.8 Vp-p

3.8 Vp-p

3.7 Vp-p

IC525 w; (BCKO)

8

IC526 ek (X2)

9

20.8 µs

2 V/DIV, 10 µs/DIV

326 ns

2 V/DIV, 100 ns/DIV

50 ns

1 V/DIV, 20 ns/DIV

3.6 Vp-p

3.5 Vp-p

1.9 Vp-p

20.4 ns

500 mV/DIV, 10 ns/DIV

IC305 4

qs

20.4 ns

1 V/DIV, 10 ns/DIV

IC108 qf (XFSOOUT)

qd

20.4 ns

1 V/DIV, 10 ns/DIV

IC108 ej (FSOCKO)

qf

1.6 Vp-p

3.8 Vp-p

3.2 Vp-p

40.6 ns

1 V/DIV, 20 ns/DIV

2.8 Vp-p

500 mV/DIV, 20 µs/DIV

IC902 qk (CBOUT)

es

(DVD play mode)

500 mV/DIV, 20 µs/DIV

IC902 w; (CYOUT)

ed

(DVD play mode)

500 mV/DIV, 20 µs/DIV

IC902 wa (YOUT)

ef

(DVD play mode)

H

1.4 Vp-p

1.4 Vp-p

H

2.1 Vp-p

H

2 V/DIV, 50 ns/DIV

IC519 wa (XOUT (O))

5

40.8 ns

2 V/DIV, 20 ns/DIV

IC525 qs (MCLK2)

6

72.2 ns

2 V/DIV, 20 ns/DIV

81 ns

3.4 Vp-p

3.8 Vp-p

3.4Vp-p

20.8 µs

2 V/DIV, 10 µs/DIV

3.8 Vp-p

500 mV/DIV, 20 µs/DIV

IC902 wd (CVBS)

eg

(DVD play mode)

500 mV/DIV, 10 µs/DIV

IC902 wh (COUT)

eh

(DVD play mode)

H

500 mV/DIV, 10 µs/DIV

2.1 Vp-p

H

2.4 Vp-p

H

1.6 Vp-p

SA-WSLF10/SS-CTL10/TSL10/TSL11

1313

SA-WSLF10/SS-CTL10/TSL10/TSL11

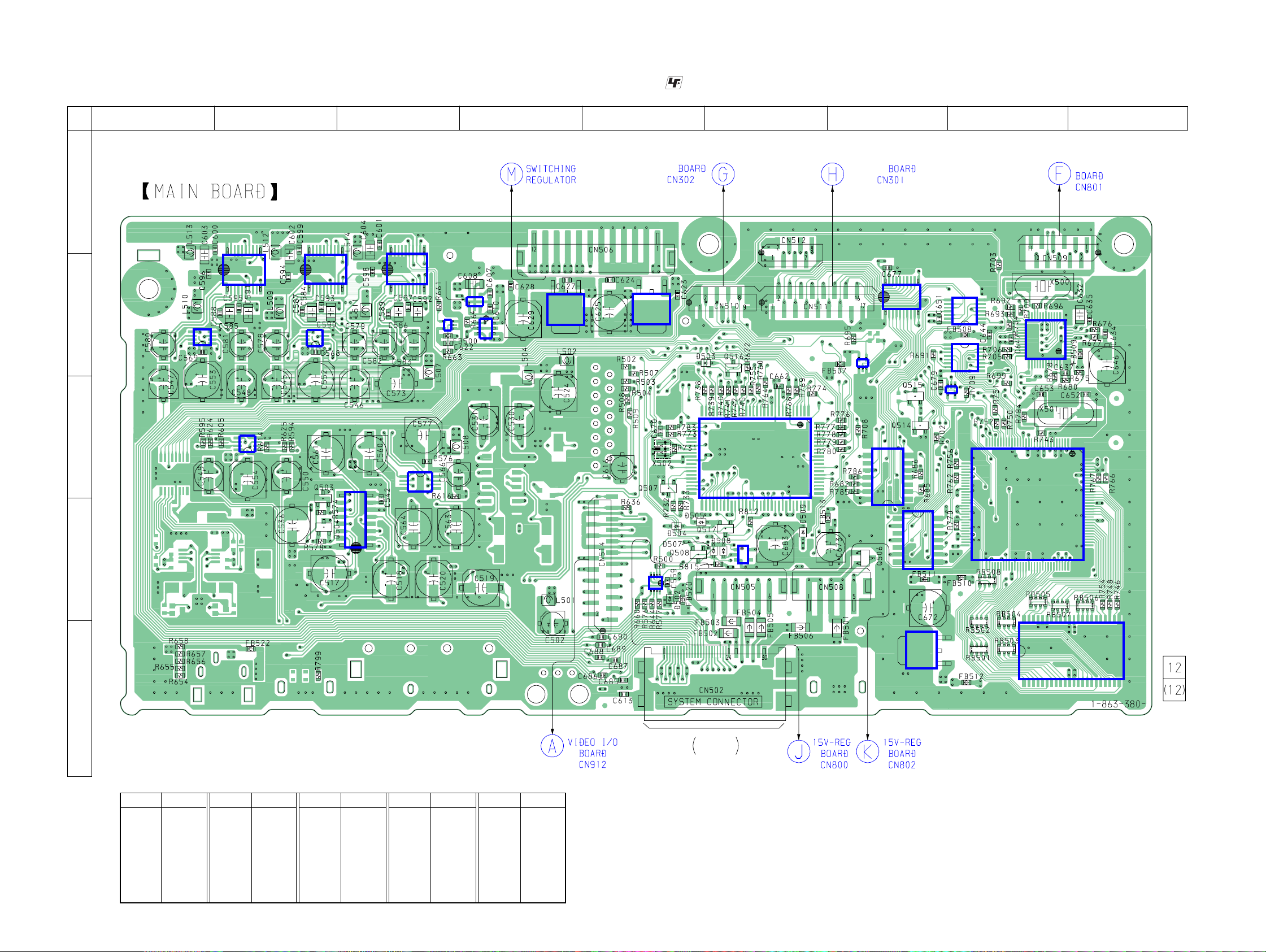

5-4. PRINTED WIRING BOARD – MAIN Board (Component Side) –

A

12

(COMPONENT SIDE)

IC512

20

1

11

10

IC511

20

1

11

10

34567

IC513

20

11

1

10

B

C

IC508

5

8

4

1

IC509

4

5

8

1

4

5

8

1

IC507

E

E

IC503

9

16

1

8

1

45

IC510

D

• See page 12 for Circuit Boards Location. : Uses unleaded solder.

S-MASTER S-MASTER

(Page 32)

(Page 21)

IC515

5

1

4

3

5

1

IC514

4

3

1

6

3

4

IC516

3

2

IC518

1

13

2

IC517

E

30

31

EXCEPT

AEP,UK,RU

IC526

8

E

50

21

20

1

4

51

E

IC531

5

E

1

3

4

IC506

58

(FOR CHECK)

1

100

8 9

TX

(Page 21)

1120

IC523

87

1

10

IC529

IC522

4

5

3

1

IC521

7

8

81

80

14

IC520

1

1

E

IC530

E

14

14

1

89

1

3

45

31

1

16

30

24

25

37

36

IC519

IC525

E

7

IC524

8

60

61

13

48

(Page 26)

12

1

1

90

120

91

E

• Semiconductor Location

Ref. No. LocationRef. No. Location

D502 D-5

D503 B-6

D504 D-5

D505 D-5

D507 D-6

D508 D-6

D509 D-6

IC503 D-3

SA-WSLF10/SS-CTL10/TSL10/TSL11

IC506 D-5

IC507 B-2

IC508 B-1

IC509 C-2

IC510 C-3

IC511 B-2

IC512 B-2

IC513 B-3

IC514 B-3

Ref. No. Location Ref. No. Location Ref. No. Location

IC515 B-4

IC516 B-4

IC517 B-5

IC518 B-4

IC519 B-8

IC520 C-7

IC521 B-7

IC522 B-8

IC523 B-8

IC524 D-7

IC525 D-8

IC526 C-6

IC527 E-9

IC528 E-7

IC529 B-7

IC530 C-8

IC531 D-6

Q503 C-2

Q504 D-3

Q506 D-7

Q507 C-5

Q508 D-5

Q514 C-7

Q515 C-7

Q516 B-6

Q517 D-6

(Page 28)

3

2

1

44 23

IC527

122

IC528

TO

HCD-LF10

(Page 32) (Page 32)

1414

SA-WSLF10/SS-CTL10/TSL10/TSL11

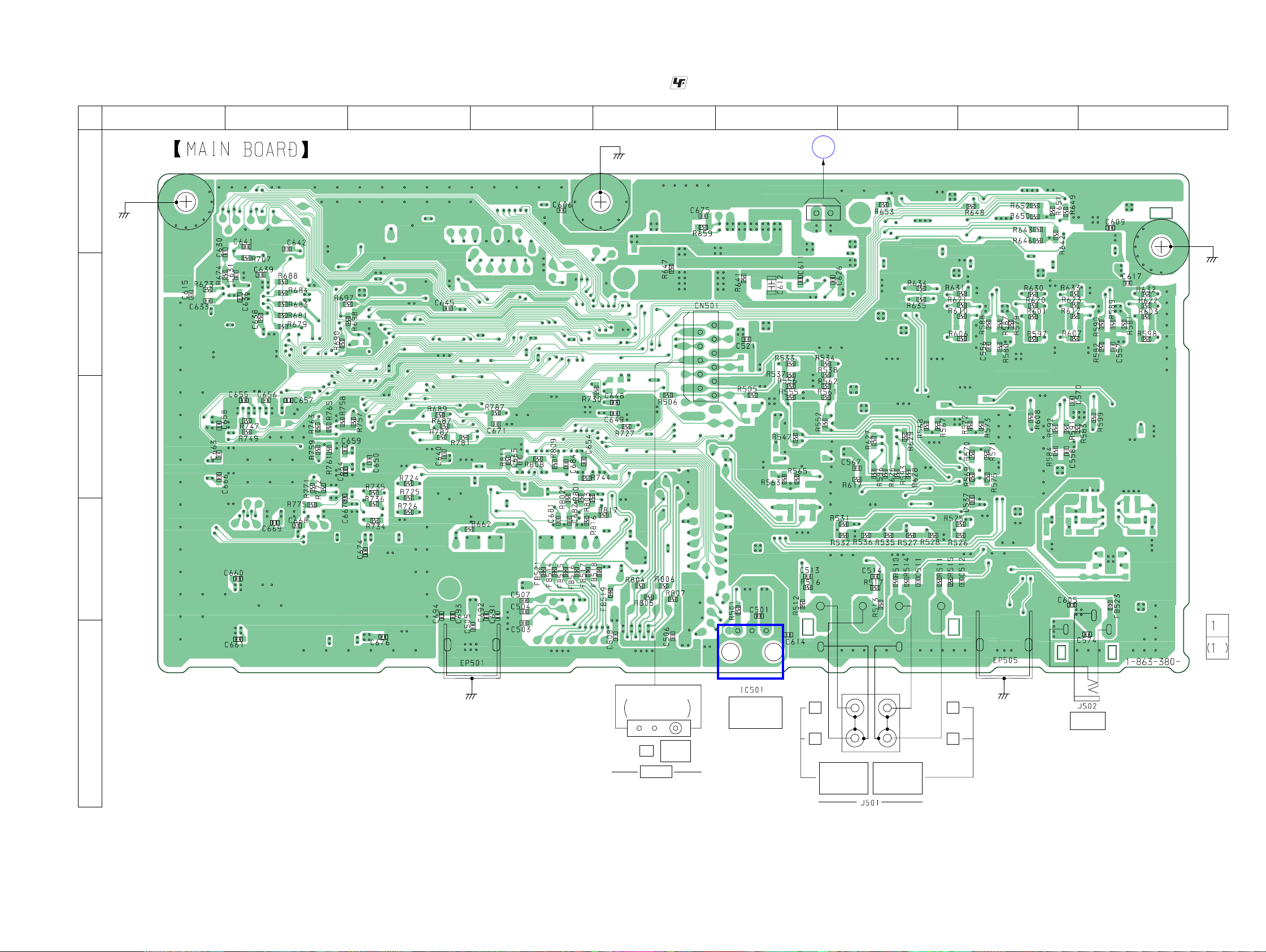

5-5. PRINTED WIRING BOARD – MAIN Board (Conductor Side) –

12

34567

(CONDUCTOR SIDE)

A

(CHASSIS)

B

• See page 12 for Circuit Boards Location. : Uses unleaded solder.

(CHASSIS)

CN507

1

2

10

11

TX

BOARD

P

CN802

12

8 9

(Page 26)

(CHASSIS)

C

D

E

13

IC501

TUNER UNIT

(CHASSIS) (CHASSIS)

SUPPLIED WITH THE

ASSEMBLED BLOCK

FM 75Ω

AM

COAXIAL

ANTENNA

OPTICAL

DIGITAL IN

L

R

AUDIO IN

SAT

L

R

VIDEO

AUDIO IN

2

2

DIR-T4

SA-WSLF10/SS-CTL10/TSL10/TSL11

1515

SA-WSLF10/SS-CTL10/TSL10/TSL11

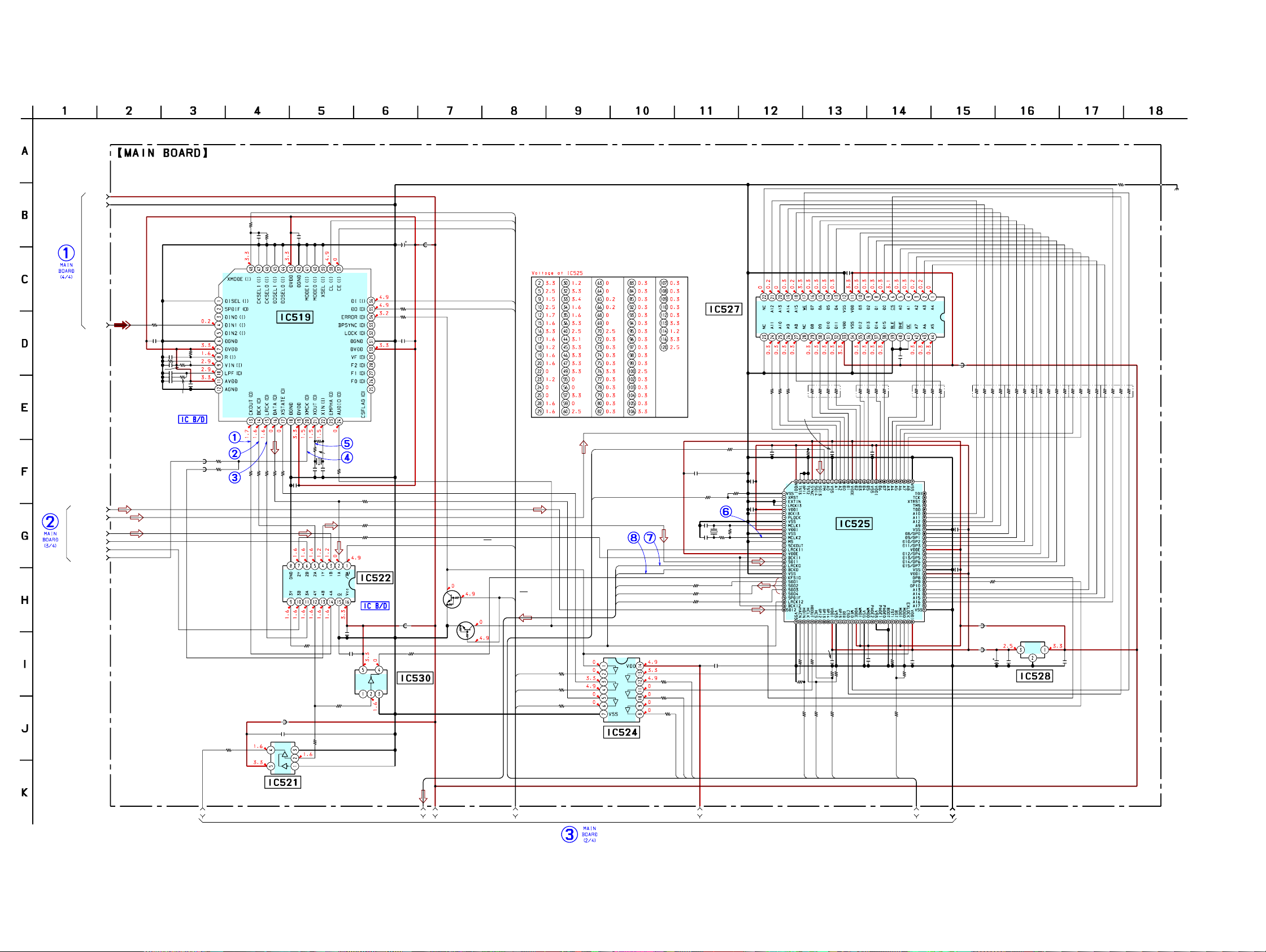

5-6. SCHEMATIC DIAGRAM – MAIN Board (1/4) –

(1/4)

D3.3V

DGND

R678

C637

4.7k

0.01

(Page 19)

R675

100

R677

R674 C632

100 10

5.6k

R692

R703

47

R704 R693

47

R695

68

1

C636

0.01

0.01

C633

33k

R673

0.1

C634

4.7k

R676

0.01

C635

0.1

C630

0.1

C631

1k

100

R679

R681

DIGITAL AUDIO

INTERFACE RECEIVER

100

100

100

R683

R684

R688

R690

FB507

V

LEVEL SHIFT

IC521

SN74LVC1G125DCKR

(Page

18)

OPT IN

C/SW_DATA

SL/SR_DATA

FL/FR_DATA

ADBCK

ADLRCK

AD_MCK

• See page 13 for Waveforms. • See page 34 for IC Block Diagrams. • See page 38 for IC Pin Function Description.

DIR_XMODE

DIR_HCLK

Q514,515

INVERTER

Q514

DTC124EKA-

T146

Q515

DTC124EKA-

T146

DIR_HDIN

DIR/ADC_2

DIR_CE

DIR_DO

DIR/ADC

DIR_ERR

DIR_XSTATE

DIR_ZERO

4

S-RAM

IC527

IS61LV6416-10TLT

RB506

100

100

100

100

C663

R746

R748

R754

0.1

DSP_PM

C657

DSP_XRST

C653

12p

LRCKO

BCKO

SDO1(FL/FR)

SDO2(SL/SR)

SDO3(FC/SW)

R724

100

R725

100

R726

100

LEVEL SHIFT

IC524

TC74HCT7007AF

(EL)

R735

100

R736

100

R734

100

DSP_HACN

DSP_HDOUT

DSP_GP9

R766

4.7k

0.1

C656

R747

R749

4.7k

C652

12p

R784

X501

680

13.9MHz

R750

100

R751

100

R752

100

C650

5

0.1

10k

C655

0.1

R743

1M

0.1

R767

C658

10k

0.1

R758

10k

DSP_HDIN

IC519

LC89056W-E

100

C645

0.1

G

C638R680

0.110k

R696

1M

R707

270

24.576MHz

0.1

R700

C642

3.3k

5p

R702

R699

R691

SELECTOR

IC522

SN74LV157APWR

C644

0.1

C679

0.1

V

GNC

IC530

MC74VHC1GU04DFT1

R698

100

R697

100

C641

7p

X500

C639

FB509

C646

220

4V

R705

100

R706

3.3k

C647

0.1

1k

100

100

FB508

R709

22

INVERTER

3

2

C659

0.1

R762R756

100100

R765

10k

R759R757 R763

4.7k4.7k 4.7k

DSP_HCLK

C661

0.01

AUDIO DIGITAL

SIGNAL PROCESSOR

CXD9720BQ

(OPEN_OK)

R761

10k

DSP_CS

C615

0

(CHASSIS)

FB512

C660

0.01

RB504

RB505

RB507

100

C666

0.1

IC525

(OPEN_OK)

(OPEN_OK)

(OPEN_OK)

C664

0.1

C667

0.1

R772

R770

10k

10k

R771

4.7k

DSP_BST

6

100

100

C668

C669

0.1

FB511

FB510

7

100

100

RB503

RB502

0.1

R775

100

IC528

NJM2391DL1-26

(TE1)

OI

G

C674

C672 C676

0.1

220

4V

+2.6V REGULATOR

100

100

RB501

RB508

0.1

SA-WSLF10/SS-CTL10/TSL10/TSL11

(Page 17)

1616

SA-WSLF10/SS-CTL10/TSL10/TSL11

5-7. SCHEMATIC DIAGRAM – MAIN Board (2/4) –

(2/4)

PANEL_IF

E5.6V

D5V

AC_DET

V_CONT

(Page 19)

ANALOG_CONT

PCONT1

T

T

A

T

A

LK

S

L

A

C

R

X

_

X

_

T

_D

_

T

T

T

IA

IA

IA

D

IA

D

D

D

)

O

O

R

K

K

C

C

/S

L

B

R

L

2(S

0

D

S

)

)

O

O

W

K

K

/FR

C

C

/S

L

B

R

L

(F

(FC

1

3

0

0

D

D

S

S

• See page 13 for Waveforms. • See page 34 for IC Block Diagrams. • See page 38 for IC Pin Function Description.

(Page 16)

1

2

LEVEL SHIFT

TC74HCT7007AF

IC520

(EL)

LEVEL SHIFT

IC529

SN74LV541APWR

5

K

L

C

_

S

D

R

R785

10k

R685 R686

100 100

5

5

3

3

EO

R

E

T

S

_

U

T

I5

I3

O

D

D

D

ED

E

E

_

_

N

R

N

U

U

TU

TU

TE

T

T

S

_

_

_

R786

U

U

T

TU

T

0

0

1

2

8

6

R

10k

00

1

7

8

6

R

R689

100

3

1

E

K

A

ET

S

E

R

_

P

M

A

D

T

T

L

S

S

A

U

C

C

C

_

_

_

D

_

M

P

P

P

P

M

M

M

FT

M

A

A

A

O

A

D

D

D

S

D

_

P

M

A

3

AMP_SOFT MUTE

5

A

T

A

D

_

S

D

R

DAMP_INIT

DAMP_CS1

C640

0.1

DAMP_CS3

DAMP_RESET

C677

0.1

IT

IN

_

P

M

A

D

D504

1SS388

4

5

DTC124EKA-

MUTING

SWITCH

R730

100

R783

10k

R773

100

X502 R731

20MHz 15k

R732

R733

AVSEL0

AVSEL1

AVSEL3

Q507

DTC144EKA-T146

NOT USED

Q517

DTA114EKA-

T146

MUTING

CONTROL

6

E

E

C

O

T

D

D

D

A

_

O

T

/A

M

S

IR

IR

X

X

D

D

_

_

IR

IR

D

D

Q516

T146

C670

0.001

1

8

4

6

C

C649

R727

0.01

100

1k

10k

D505

1SS388

R740

NO_USE

C654C651

0.010.1

1SS355TE-17

R672

10k

D503

10k

R738

100

5

D

E

N

I5

U

T

D

_

_

U

U

T

T

0

0

1

1

4

7

R

R739

100

R744

4.7k

5

O

E

E

R

T

K

E

U

O

E

L

T

D

C

C

M

S

_

_

_

_

_

U

U

U

U

U

T

T

T

T

T

9

E

O

R

P

C

R

R

_

G

E

E

_

Z

_

IR

_

P

D

IR

S

IR

D

D

D

k

0

0

1

0

1

2

4

5

7

4

R

7

R

SYSTEM CONTROLLER

µPD70F3033BYGF-

C684

0.1

R808

10k

E

L

4

ID

E

L

E

S

/W

_

S

S

V

A

V

I/P

T

S

B

_

P

S

D

0

0

1

5

5

7

R

IC526

M68-3BA-A

E

S

U

_

O

N

T

S

N

M

S

C

C

P

_

R

A

_

P

X

H

P

_

S

_

S

P

D

P

D

S

S

D

D

0

0

0

0

1

1

0

4

6

6

7

7

R

R

N

W

E

O

N

D

E

_

IX

P

T

_

M

U

C

-

O

D

C

V

A

Y

R809

1k

R812

10k

N

E

W

L

N

E

D

E

IX

S

_

P

_

T

_

M

D

U

C

_

V

O

C

D

D

V

Y

A

T

K

K

IN

L

L

D

C

C

H

H

H

_

_

_

P

IR

IR

S

D

D

D

7

1

4

.0

8

0

6

7

2

R

6

6

C

5

W

L

S

E

_

S

V

IP

A

k

0

1

1

1

8

R

L

E

5

S

L

W

_

E

S

B

S

_

G

V

R

IP

A

2

K

A

IN

_

T

L

U

D

A

C

C

O

H

_

D

D

D

_

T

_

H

/A

T

P

IA

_

S

IR

IA

P

D

D

D

D

S

D

7

4

9

6

7

R

C665

0.01

IN

P

2

DAMP_DATA

NO_USE

NO_USE

UNMUTE

NO_USE

R774

47

7

AMPMICOM_RESET

IF_DATA_IN

AMPUCOM_DATA

R776

100

DAMP_CLK

R777

C671

0.1

R779

R780

100

R778

100

100

100

RDS_CLK5

RDS_DATA5

DAMP_DATA

DIAT_XRST

DIAT_XLAT

R815

FB513

10k

R816

10k

DTC144EKA-

INVERTER

C673

47

6.3V

D507

1SS355TE-17

R817

CABLE_DET2

1k

(AMP_MICOM)

Q508

T146

AC_DET/CABLE_DET

D508 R801 R802

1SS355TE-17 10k 10k

7

1

E

9

T

0

5

5

5

D

3

S

S

1

R803

10k

C683

C682C681

100

0.10.22

10V

R708

1k

R787

47k

R781

1k

R782

1k

CN512

8P

GND

VDD

VPP

RESET

2PIN

CLK

OUT

(FOR CHECK)

IN

D

D

D

N

N

O

G

G

-

-

S

D

D

C

SA-WSLF10/SS-CTL10/TSL10/TSL11

)

R

/S

O

L

O

K

S

K

C

(

2

C

R

B

L

D

(Page 27)

DETECTOR

IC531

PST3645NR

)

C

N

(

D

N

-G

D

CN510

A

T

A

D

S

9P

T

K

T

L

A

C

L

S

X

D

S

N

CN509

R

G

11P

X

D

O

D

O

K

N

K

C

1

2

3

G

C

R

D

D

D

B

L

D

(Page 22)

E

T

U

D

D

W

N

N

S

M

K

G

G

P

P

C

D

S

D

H

H

D

T

2

F

V

O

3

2

N

F

S

T

T

V

G

E

D

A

A

O

D

R

S

L

L

(Page 22)

E

T

U

M

T

D

1

N

T

G

A

D

L

D

T

T

N

F

IF

D

IT

CN511

G

O

C

H

S

17P

IN

S

S

D

LEVEL SHIFT

IC523

TC74VHCT08AFT

(EL)

1717

SA-WSLF10/SS-CTL10/TSL10/TSL11

5-8. SCHEMATIC DIAGRAM – MAIN Board (3/4) –

(3/4)

C574

J502

DIR-R4

TO

HCD-LF10

(Page 33)

(Page 33)

(CHASSIS)

(CHASSIS)

EP505

SYSTEM CONNECTOR

Y/G

Y/G_GND

C/CVBS

C_GND

CR/B

CR/B_GND

CB/R

CB/R_GND

FRONT-L

FRONT-R

SURROUND-L

SURROUND-R

CENTER

SW(LFE)

A-GND

AC-DETECT

P.CONT1

UCOM-DI

UCOM-DO

CABLE_DETECT2

EVER5.6V

AMPMICOM_RESET

SIRCS

D.GND

+15V(AUDIO)

A-GND

+15V(DIGITAL)

D-GND

+15V(MOTOR)

M-GND

EP501

CN508

5P

PCONT1

GND(M)

GND(M)

+15V(M)

+15V(M)

CN505

6P

GND(D)

GND(D)

+15V(D)

+15V(D)

GND(A)

+15V(A)

CN502

0.1

FB522

FB523

C605

0

30P

Y/CY/G

R807

75

V-GND

R806

75

V-GND

R805

R804

FB519

FB518

FB517

FB516

FB515

FB520

FB514

FB521

CR/R

75

V-GND

CB/B

75

V-GND

C506

C507

0

C504

0

C503

0

C505

0.1

C

0

CABLE_DET2

FB502

FB503

FB504

FB505

FB506

FB501

R654

R655

R656

R657

R658

C508

AMPMICOM_RESET

DTC124EKA-T146

REGULATOR

• See page 34 for IC Block Diagrams.

470

470

470

470

470

C685

C686

C687

C688

C689

C690

0

IF_DATA_IN

(AMP_MICOM)

Q506

CONTROL

R660

100k

R644

100

1000p

1000p

1000p

1000p

1000p

1000p

R662

10k

C559

0.1

1SS355TE-17

D502

IC506

SN74LVC3G34DCUR

R577R576

100100

LEVEL SHIFT

C546

47

6.3V

C547

47

6.3V

LINE AMP

AC_DET/CABLE_DET

C553

100

10V

LINE AMP

C554

100

10V

C550

47

6.3V

CN514

VOUT_ENE

YC_MIX

RGB_SEL

DVD_SEL

I/P_SEL

VS/WIDE

AVSEL4

AVSEL3

AVSEL5

CR/R

V-GND

CB/B

V-GND

Y/CY/G

V-GND

C

V-GND

C617

0

C609

0

R799

0

C602 R648

10 100

µH

L512 10

100

R650

R649

100

ADC_PDWN

100

R651

R636

0

IP_SW

100

R653

ATA

_D

AMPUCOM

R601R597

C545

47

6.3V

R587

R579R500

0

4.7k100

C552

100

10V

C556 R580

0.1 4.7k

R598

1k

R589

R581

0

4.7k

C557

R582

0.1

4.7k

C548

47

6.3V

C549

47

6.3V

R591

R583

0

4.7k

C558

R584

0.1

4.7k

2.2k1k

GND

R588

0

R606 R610

1k 2.2k

R603

2.2k

GND

R590

0

R607 R612

1k 2.2k

R605

2.2k

R599

1k

GND

R592

0

R608 R614

1k 2.2k

R620

470

VCC

C568

VCC

C569

VCC

C573

LINE AMP

IC507

NJM2140R

R621

0.1

470

R622

470

IC508

NJM2140R

0.1

R623

470

L507

10µH

R624

820

IC509

NJM2140R

100

10V

C570

0.1

R625

820

C578

10

R630

16V

3.3k

R631

C579

3.3k

10

16V

C590

L509

10µH

C580

R632

10

3.3k

16V

R633

C581

3.3k

10

16V

L510

10µH

C583

R634

10

1k

16V

C582

10

16V

A/D

CONVERTER

LEVEL SHIFT

IC514

SN74LVC1G125DCKR

C593

0.11010

C594

1000p

C591

10

R646

100

R643

100

R635

1k

L511

10µH

C587

0.1

C584

C588

0.1

C585

10

C595

C596

1000p

C589

0.1

10

C592

C586

10

C597

0.1 10

C598

1000p

R663

0

A/D CONVERTER

0.1

0.1

C622

G

PCM1802DBR

PCM1802DBR

R642

PCM1802DBR

V

IC511

IC512

100

IC513

A/D CONVERTER

C599

0.1

L513

10µH

C603

10

C600

0.1

C604

C601

0.1

R652

100

FB500

R661

100

µH

L514 10

VOUT-ENE

YC_MIX

RGB_SEL

DVD_SEL

I/P_SEL

VS/WIDE

AVSEL4

AVSEL3

AVSEL5

TV-L/IP_SW

V-GND

V-GND

Y/CY/G

V-GND

V-GND

21P

5V

12V

GND

CR/R

CB/B

(Page 29)

C

(CHASSIS)

SA-WSLF10/SS-CTL10/TSL10/TSL11

10

9

6

5

4

3

2

18

17

(Page 19)

16

15

14

13

12

11

ADBCK

ADLRCK

AD_MCK

C/SW_DATA

FL/FR_DATA

SL/SR_DATA

(Page 19)

1

(Page 16)

1818

SA-WSLF10/SS-CTL10/TSL10/TSL11

5-9. SCHEMATIC DIAGRAM – MAIN Board (4/4) –

18

(4/4)

C614

0

C613

0

OPTICAL

DIGITAL IN

RL

RL

CN501

11P

MUTE

R-CH

A.GND

L-CH

STEREO

TUNED

CE

DI

DO

CK

0

0

0

C694

C693

C692

DIGITAL OPTICAL

RECEIVER

IC501

TORX141L

C501

0.1

ANTENNA

FM 75Ω

COAXIAL

VIDEO

AUDIO

IN

J501

4P

SAT

AUDIO

IN

TUNER UNIT

SUPPLIED WITH

THE ASSEMBLED

AM

BLOCK

• See page 34 for IC Block Diagrams.

17

16

R595

1k

C561

R594

100 10V

1k

C560

100

10k

10k

10V

527

525

C517

R

R

100

R514R510

C511

10V

47k6.8k

220p

C512R515R511

C518

220p47k6.8k

100

10V

10k

10k

528

C519

R526

R

100

C513

R516R512

10V

220p

47k6.8k

C520

C514R517R513

100

220p47k6.8k

10V

R505

R504

R503

R502

0

C691

C502

22

6.3V

L501

10µH

R501

R506

10k

10k

R508

10k

R509

R507

10k

100

15

R572R567

10k10k

10k

10k

R531

R535

10k

10k

10k

R568

R573

R532

R536

10k

4.7k

4.7k

4.7k

4.7k

C536

100

10V

MC14052

C537

IC503

BDR2

0.1

TU_MUTE

TU_STEREO3

TU_TUNED3

TU_DI3

TU_CLK

TU_DO

TU_CE

SELECTOR

(Page 18)

14

13

12

11

10

9

L508

470

R626R616

2.2k

C577

100

10V

1538 R534

100K 6.8k

NJM4565V

R628

2.2k

LINE AMP

R533R537

6.8k100k

R627

IC510

(TE2)

C616

10

16V

10µH

VCC

GND

R629

470

+5V REGULATOR

TK11250CMCL-G

C612

PCONT1

10

C611

+9V REGULATOR

C625

39

16V 0.1

C607

0.01

C608

10

+5V REGULATOR

IC515

MM1575ANLEG

+9V REGULATOR

1

BA09FP-E2

C624

C524

100

L502

10V

10µH

C521

0.001

Q503

DTC124EKA-

T146

R574

10k

R575R571

10k10k

4.7k

C563

100

10V

Q503,504

INVERTER

AVSEL1

AVSEL0

R578

10k

Q504

DTC124EKA-

T146

R565 R563 R561 R555

10k 10k 33k 33k

R596

47k

16V

0.1

10

4.7k

0.1

C567

C566

R617

47k

R593

R562

C576

R556

33k

33k

C531

22

16V

C530

22

16V

L504

10µH

R569

100

100

R570

C564

100

10V

C542

0.1

R552

0

R547

0

(Page 18)

6

5

4

3

IC516

IC517

IO

G

C623

IC518

BA09FP-E2

IO

G

C627

1

C626

0.1

R664

0

1

R647

0

C610

1

4.7k

R659

2

R641 C606

00

C675

0.1

C629

39

16V

C628

0.1

1

(CHASSIS)

CN506

12VREG-GND

12VREG-GND

VCC(9V)

P-GND

CN507

12P

(Page 33)

2P

AC-DET

A-GND

M-GND

M-GND

D-GND

D-GND

V-CONT

ON/OFF(STANDBY/POWER)

E5.6V9V

6.2V

3.3V

12V

(Page 27)

SA-WSLF10/SS-CTL10/TSL10/TSL11

ANALOG_CONT

D5V

PANEL_IF

PCONT1

V_CONT

E5.6V

AC_DET

D3.3V

DGND

OPT IN

(Page 16)

(Page 17)

1919

Loading...

Loading...