Page 1

SPP-SS950

SERVICE MANUAL

Ver 1.2 2000. 06

With SUPPLEMENT-1

(9-925-727-81)

SPECIFICATIONS

General

Spread method Direct-Sequence Spread-Spectrum

Access method FDMA-TDD

Frequency band 902 – 928 MHz

Operation channel 20 channels

Supplied Accessories AC power adaptor AC-T37 (1) (US model)

AC power adaptor AC-T47 (1) (E model)

Telephone line cords (2) (US model)

Telephone line cord (1) (E model)

Rechargeable battery pack BP-T18 (1)

Directories (2 sheets)

Wall bracket/stand (1)

Screws (2) (E model)

US Model

E Model

Base unit

Power source DC 9V from AC power adaptor

Battery charging time Approx. 12 hours

Dimensions Approx. 128 × 58 × 208 mm (w/h/d), antenna

excluded

Antenna: 165 mm

Mass Approx. 320 g, wall bracket excluded

Design and specifications are subject to change without notice.

Handset

Power source Rechargeable battery pakc BP-T18

Battery life Standby: Approx. 7 days (RING ON mode)

Approx. 3 weeks (BATT SAVE mode)

Talk: Approx. 4 hours

Dimensions Approx. 58 × 177 × 46 mm (w/h/d), antenna

excluded

Antenna: 72 mm

Mass Approx. 250 g, battery included

CORDLESS TELEPHONE

MICROFILM

Page 2

TABLE OF CONTENTS

SERVICING NOTES

1. GENERAL

Setting up the phone ........................................................3

Making and receiving calls.............................................. 3

Speed dialing ................................................................... 4

Paging .............................................................................. 4

Mounting the base unit on a wall .................................... 4

2. DISASSEMBLY..........................................................5

3. 900MHz SYSTEM OPERATION

3-1. Access method ................................................................. 7

3-2. Protocol............................................................................7

4. TEST MODE

4-1. Base Unit Test Mode A.................................................... 10

4-2. Base Unit Test Mode B....................................................10

4-3. Handset Test Mode .......................................................... 1 1

5. ELECTRICAL ADJUSTMENTS

5-1. Base Unit Section ............................................................ 12

5-2. Handset Section ...............................................................13

6. DIAGRAMS

6-1. Schematic Diagram – Base Unit Section –...................... 16

6-2. Printed Wiring board – Base Unit Section – ................... 19

6-3. Printed Wiring Board – Handset Section –...................... 21

6-4. Schematic Diagram – Handset Section – ........................ 23

6-5. IC Pin Function Description ............................................26

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY.

7. EXPLODED VIEWS ................................................ 30

8. ELECTRICAL PARTS LIST................................ 32

– 2 –

Page 3

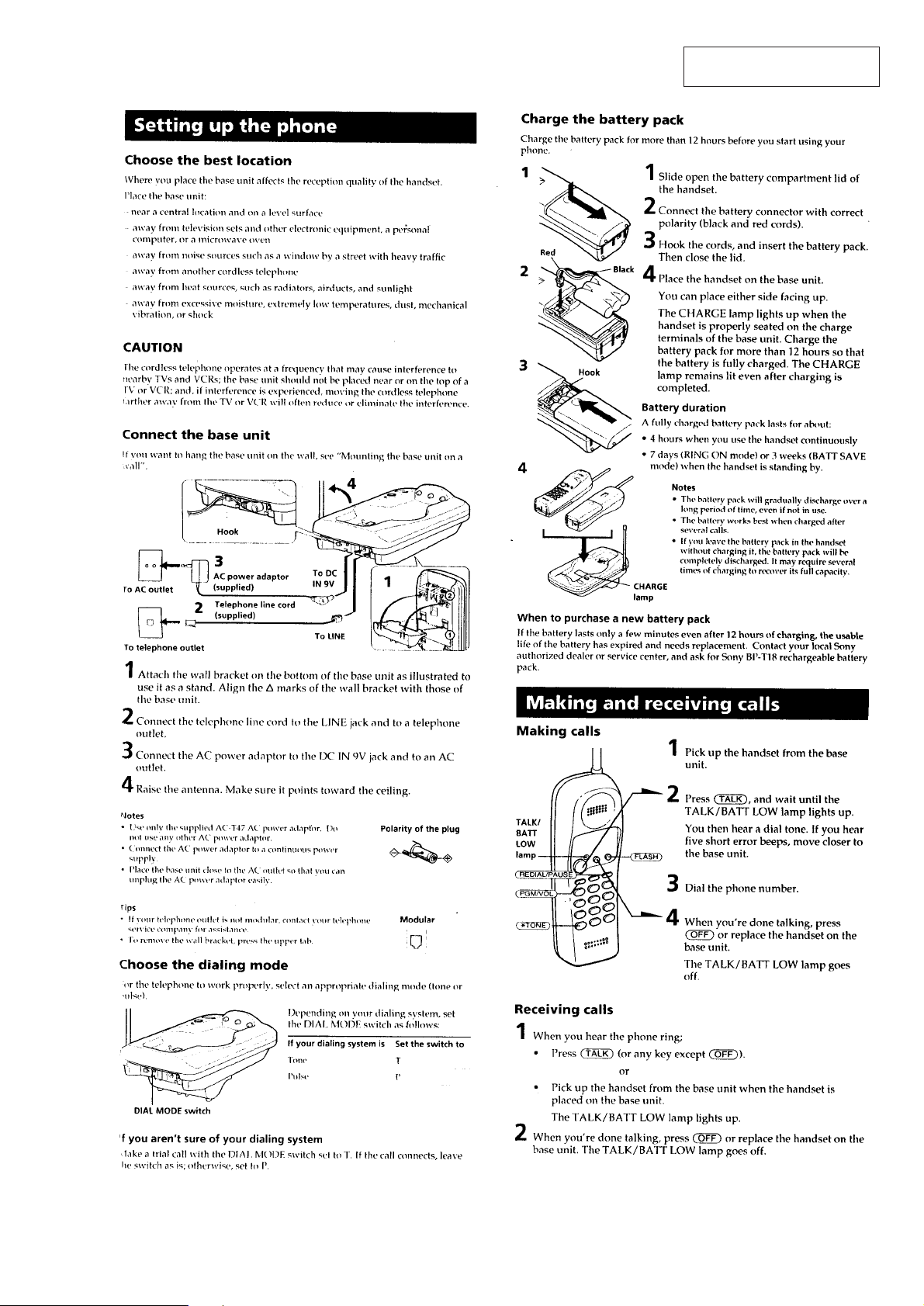

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 3 –

Page 4

– 4 –

Page 5

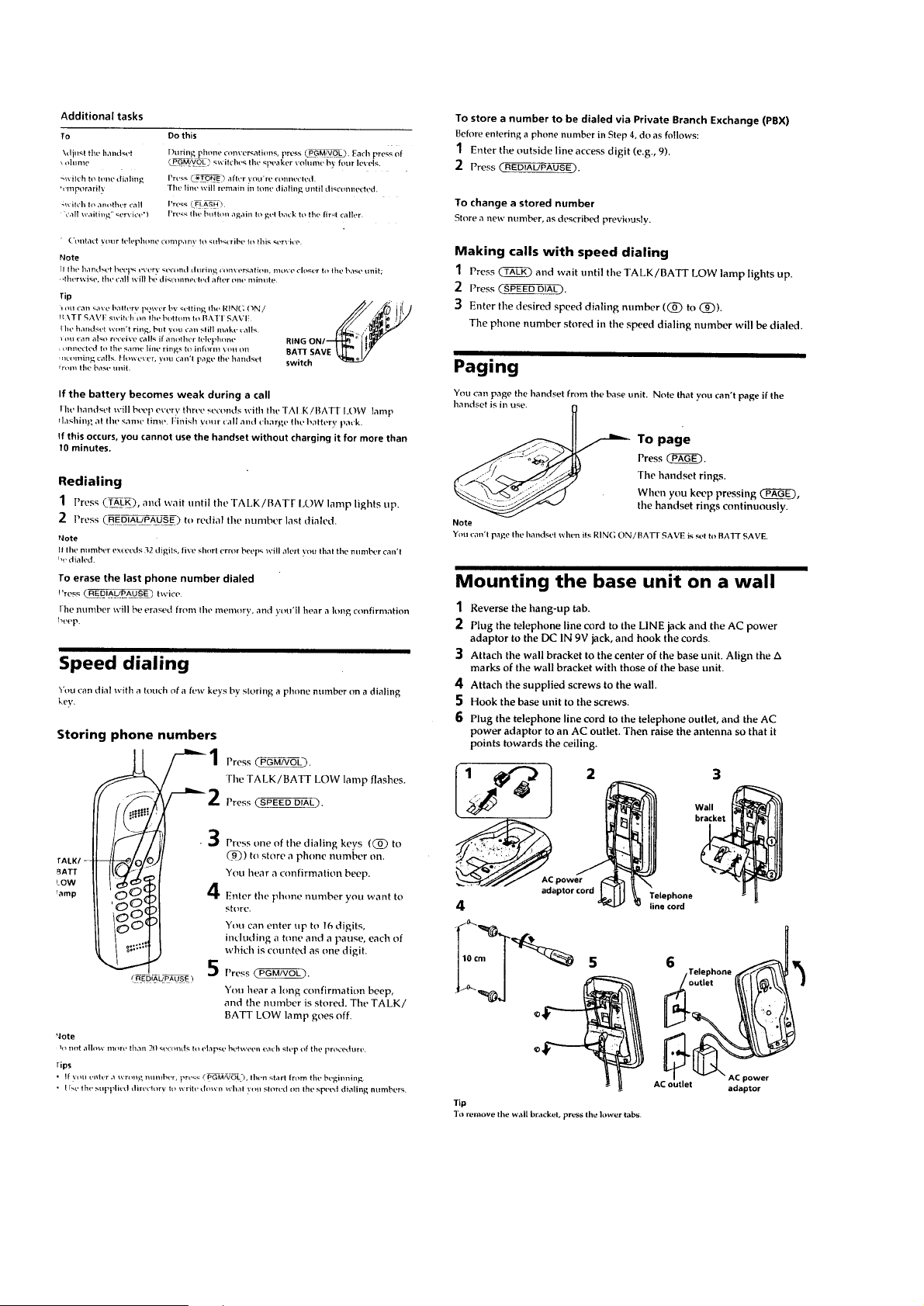

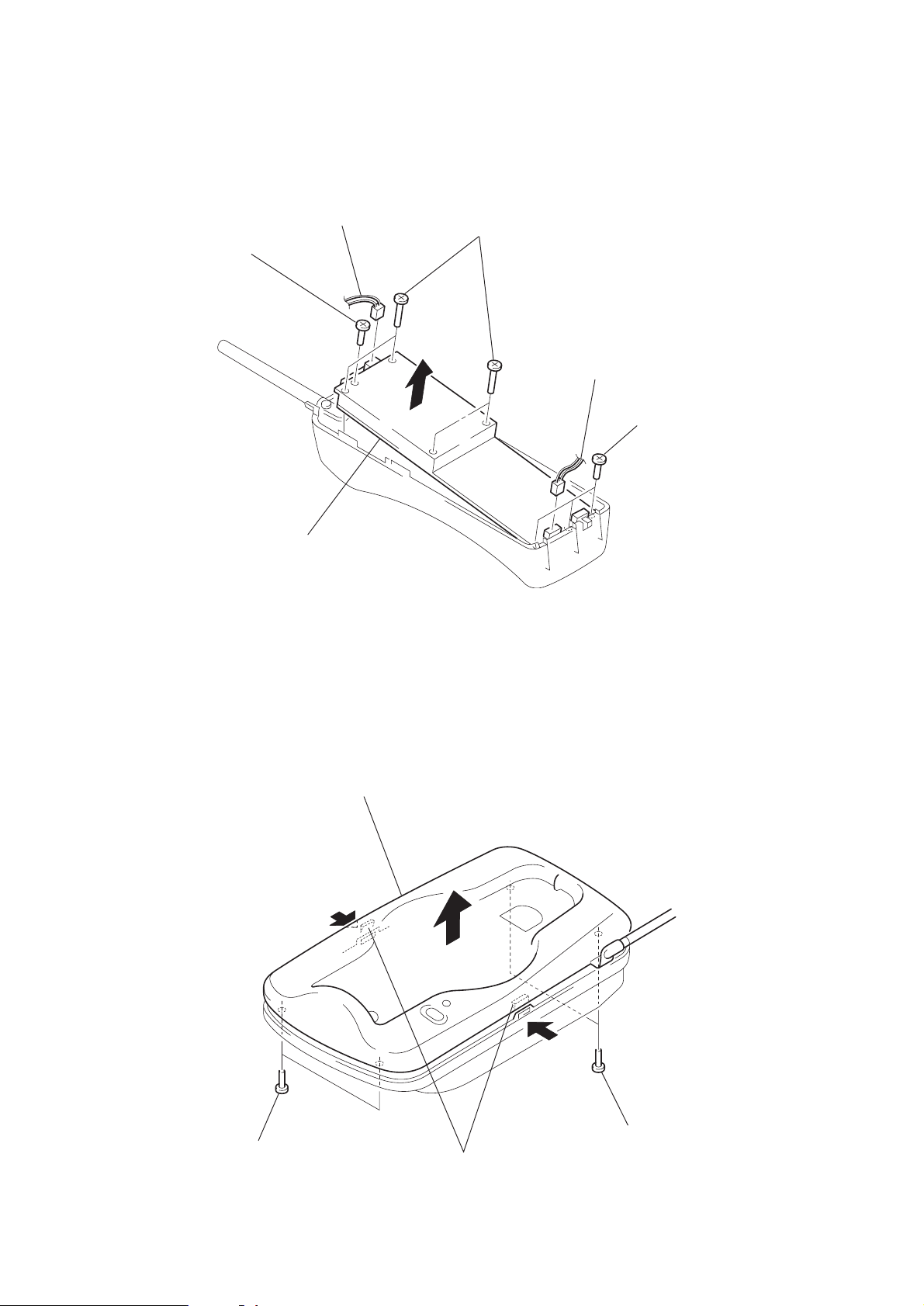

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

REAR CABINET

2

two screws

(BTP 2.6 × 10)

1

Remove the battery case lid

to direction of the arrow A.

A

5

Remove the rear cabinet to

direction of the arrow B.

3

4

claw

two claws

B

3

two claws

– 5 –

Page 6

HAND MAIN BOARD

3

screw

(BTP 2.6 × 8)

1

connector

4

HAND MAIN board

2

four screws

(P 3 × 16)

1

connector

3

three screws

(BTP 2.6 × 8)

LOWER CABINET

1

two screws

(BTP 2.6 × 8)

3

lower cabinet

2

two claws

1

two screws

(BTP 2.6 × 8)

– 6 –

Page 7

SECTION 3

900MHz SYSTEM OPERATION

3-1. ACCESS METHOD

1. Transfer format & rate

The transfer format & rate of our system is as follows;

Table 3-1. Transfer method

Access method FDMA-TDD

Channel number 20 channel

Channel spacing 1.2MHz

Modulation method DBPSK

Baseband transfer rate 960Kbps

Spread method Direct Sequence Spread Spectrum

Chip rate 12 chips/bit

Data transfer rate 80 Kbps

2. Channel Number & Frequencies

RF channels occupy the frequency band 902 – 928 MHz are numbered 1 to 20.

RF channel numbers & center frequencies are specified as follows.

Table 3-2. Channel number & Channel frequency

Channle Channel Center Channel Channel Center

Number Frequency (MHz) Number Frequency (MHz)

1 903.6 11 915.6

2 904.8 12 916.8

3 906.0 13 918.0

4 907.2 14 919.2

5 908.4 15 920.4

6 909.6 16 921.6

7 910.8 17 922.8

8 912.0 18 824.0

9 913.2 19 925.2

10 914.4 20 926.4

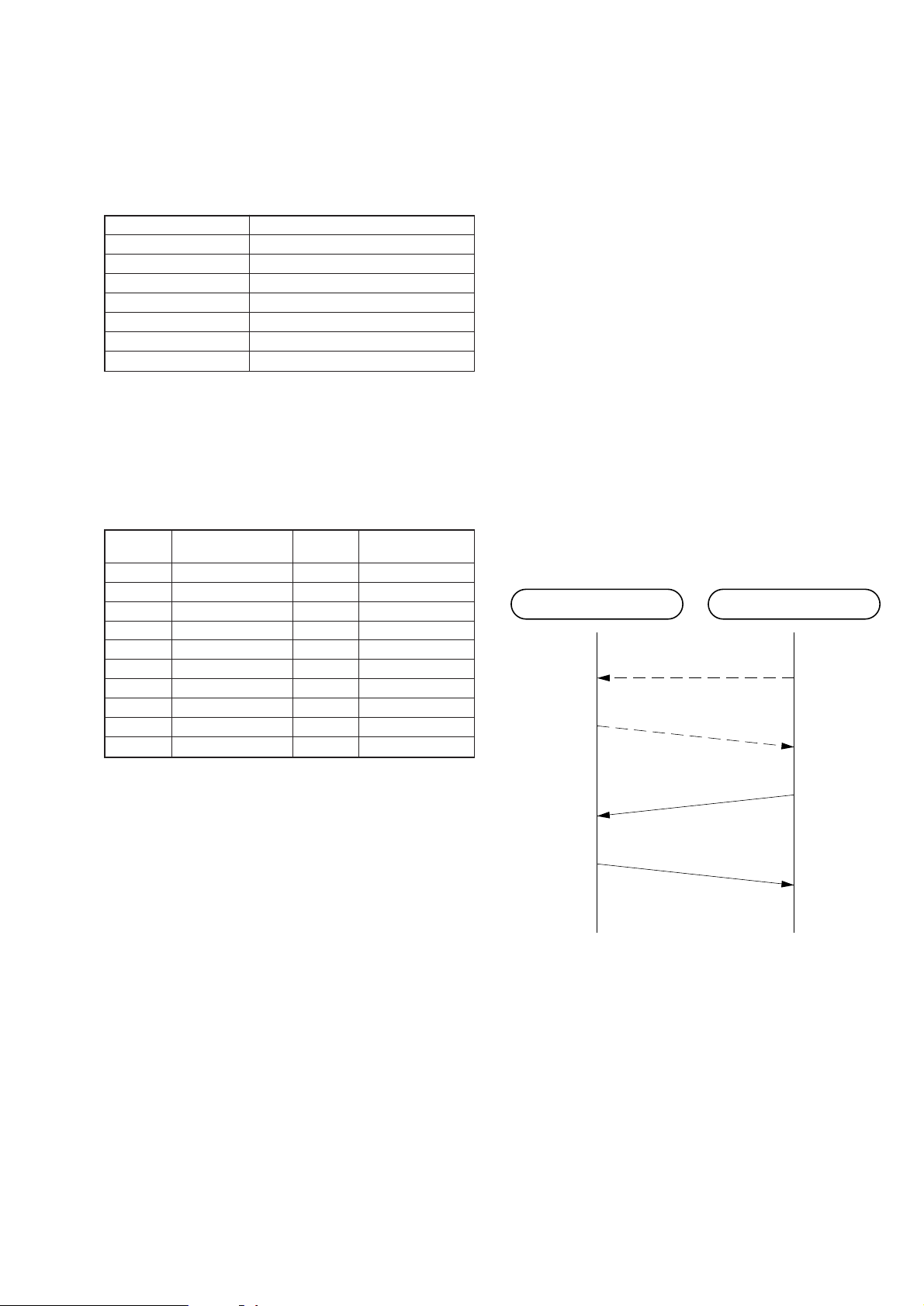

3-2. PROTOCAL

1. General

This system realizes the TX/RX superframe by TDD system. The

relation of master/slave dose not decide identification regarding

the protocol between BS and HS, but the initiated side is the master and the requested side is the slave when the RF link has been

established.

2. Initial acquistition

In order to establish the RF link between BS and HS, both of BS

and HS need to have the same system ID. When “power” is applied to this system, the system have to do Initial Acquisition in

order to have the same system ID. It si to exchange a parameter

when the HS is parked on the BS, as soon as the system do System

Parameters Re-initilization.

3. System parameter re-initilization

This System Parameters Re-initilization can realize that the HS is

parked on the BS. So after the BS recoginized to be parked the

HS, the BS calculates a system parameter, and then it outputs this

data from the ARTO port, and then the system establishs the RF

link. In order to establish this link, the HS send the A-Frame to the

BS after the HS received the system parameter, and then the BS

send the A-Frame to the HS. The process of System Parameters

Re-initilization is as follows.

Base Station Handset

(PARK)

(Park Detect)(Park Detect)

System Parameters

A-Frame

System ID

confirmed

A-Frame

Fig. 3-1. System Parameters Re-initialization

System ID

confirmed

– 7 –

Page 8

4. Stand-by Mode Operation

(1) HS

When the HS is the stand-by mode (sleep mode), the HS do the

intermittent operation for power save, because the HS is the battery operation.

This process of stand-by mode operation is as follows.

10 sec

Heart-Beat

10 sec

Heart-Beat Heart-Beat

RX RX RX RX RX

1 sec 1 sec

RX

10 sec

1 sec

2 msec

2 msec 10 msec

10 msec

RXTXRX

Heart Beat

(Exchange A-Frame for Link confirmation purpose)

Fig. 3-2. Stand-by mode operation (HS)

(2) BS

The BS is supplied the power by AC line. While the BS is the

stand-by, the BS is always a wake state. While the BS monitors

the current channel, the BS monitors also the other channel at the

same time

Because if the current channel can not use by some interference,

the system needs the clear channel information as a part of system

parameter for a channel hop.

If the BS can not receive the A-Frame of Heart-beat from the HS,

it become “link error”, and the system become error recovery mode.

RX

– 8 –

Page 9

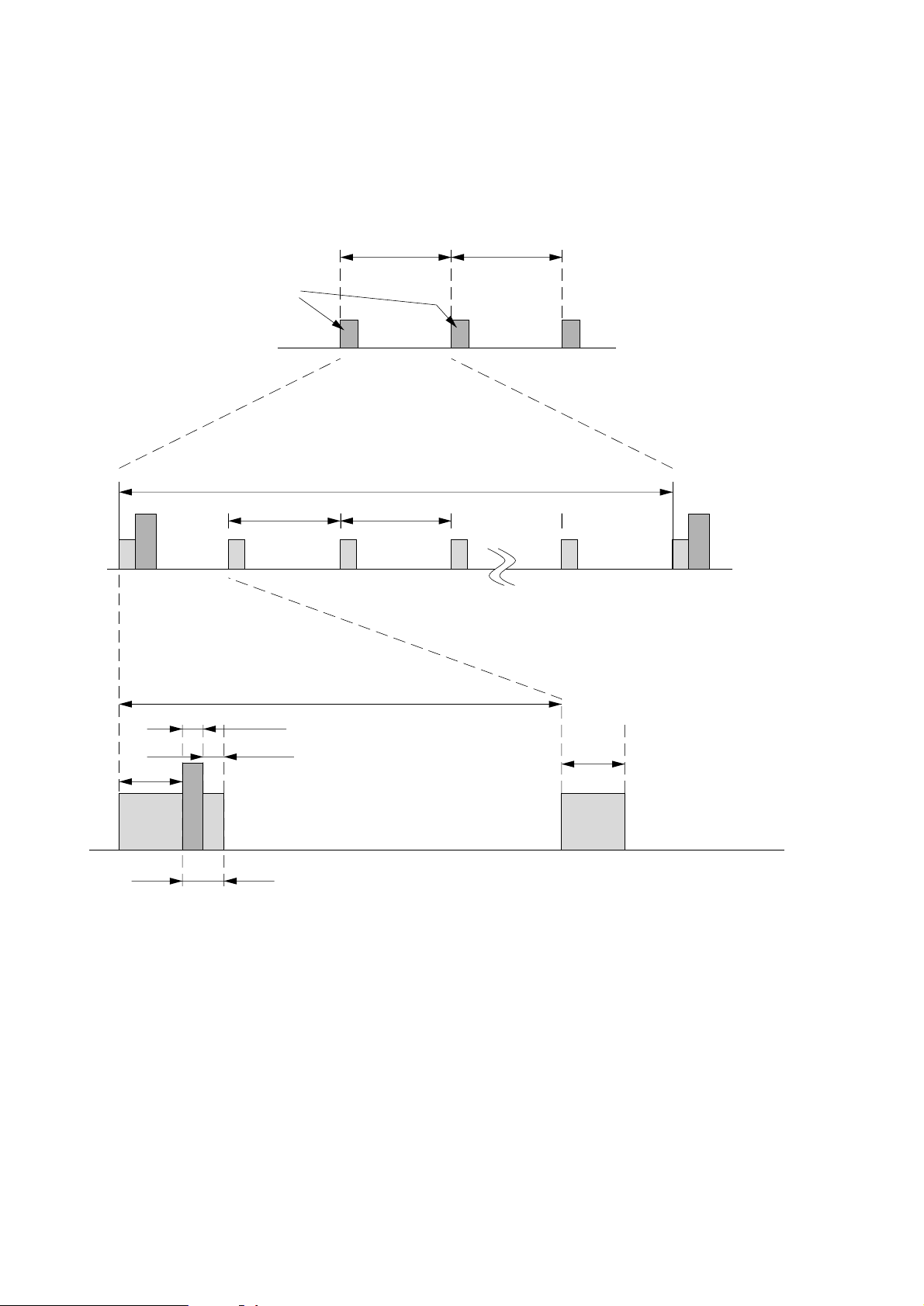

5. Link Establishment

Accoding to the following Fig. 3-1, the requested side for link

establishment is the master.

The system have to exchange the A-Frame for link establishment,

and each system ID should be the same ID, and then the system

link is established.

The protocol and timing chart of link establishment are as follows.

Master Slave

A-Frame

System ID

confirmed

Fig. 3-3. Link Establishment protocol

A-Frame

V-Frame

V-Frame

V-Frame

V-Frame

System ID

confirmed

Master

Time Slot

Master TX

Master RX

Slave RX

Slave TX

Trip Delay

TX RX TX RX TX

AV

A' V

Fig. 3-4. Link Establishment Timing Chart

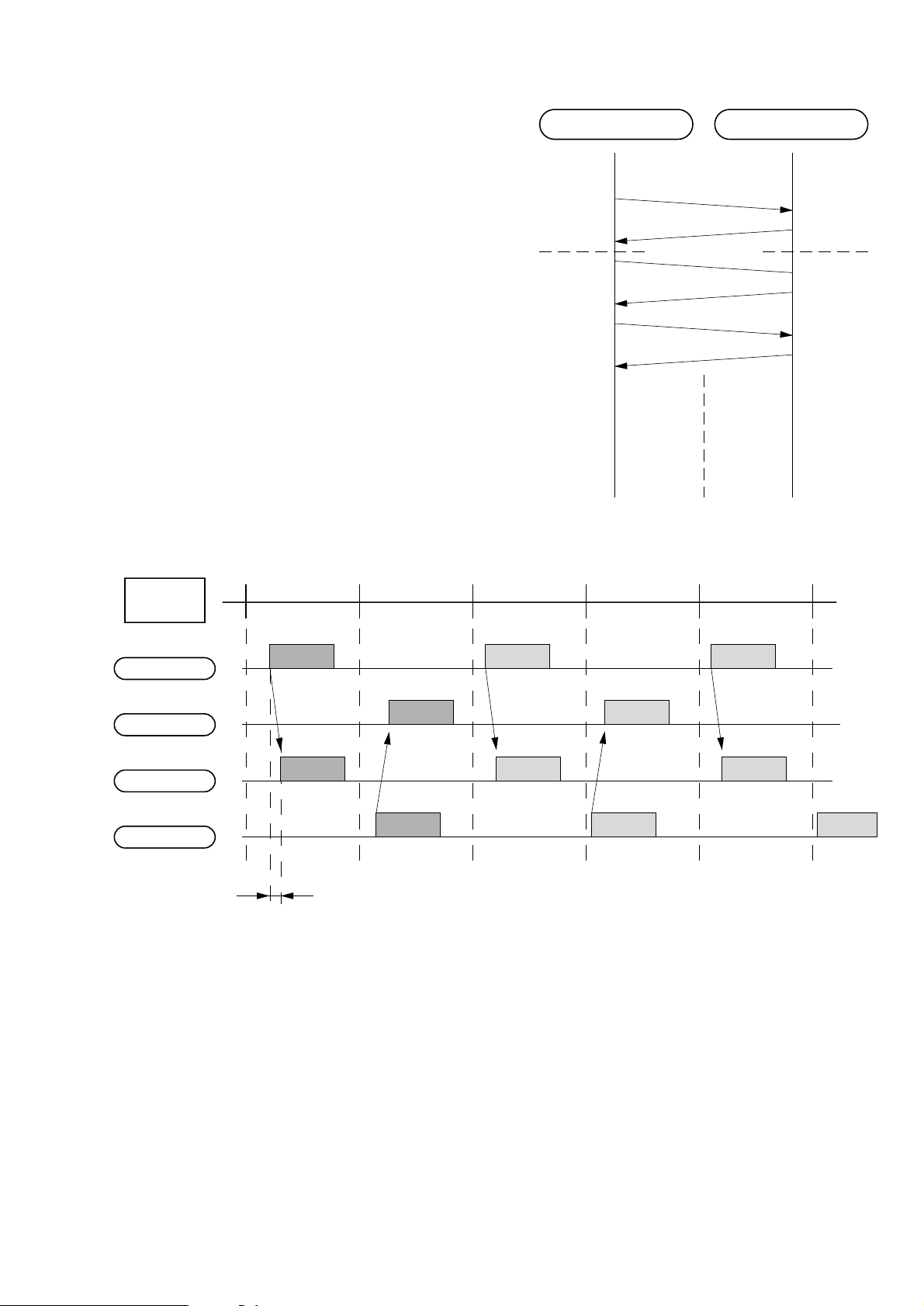

6. State Change/Tarmination

After the RF link between HS and BS was established, a movement of each state (State: ON-Hook, OFF-Hook, P A GE, InterCom,

etc) is sent through supervisory bits.

V

VA

VA'

V

V

7. Error Recovery

In case of the following situation, The system becomes “Error

Recovery Mode”.

(1) The system failed to move to “Heart-Beat” during “Stand-by

mode, or failed “link establishment”.

(2) The system failed to keep the link.

– 9 –

Page 10

SECTION 4

TEST MODE

4-1. BASE UNIT TEST MODE A

[Start-up]

1. Set [DIALMODE] switch to the P (PULSE) side.

2. With [PAGE] button kept pressed, reset the POWER ON (connect the A C adapter plug) and return [DIALMODE] switch from

P (PULSE) side to T (TONE) side, then again to the P (PULSE)

side.

3. Release the [PAGE] button, and the Test Mode A will start.

4. When the Test Mode A started, the Dial Test is carried out.

5. If [DIALMODE] switch is changed over from P (PULSE) to T

(TONE) side, the base set goes in Test Mode Idle A status.

[Dial Test]

1. When the Test Mode started, a line is connected.

2. “0” is output with 10pps (PLUSE) signal.

3. After 2 seconds, “1” “4” “8” “#” are output with DTMF

(TONE) signals.

4. Then, the line is placed in the busy status.

[TDD Test Mode on Each Channel]

1. In the Test Mode Idle A status, the statused of respectiv e blocks

are as follows:

Radio block – TDD mode (Master timing, 1CH)

Audio block – Line busy status

2. Each time [PAGE] button is pressed, channels are changed ov er

as follows:

4-2. BASE UNIT TEST MODE B

[Start-up]

1. Set [DIALMODE] switch to the T (TONE) side.

2. With [PAGE] button kept pressed, reset the POWER ON (connect the A C adapter plug) and return [DIALMODE] switc h from

T (TONE) side to P (PULSE) side, then again to the T (TONE)

side.

3. Release the [PAGE] button, and the Test Mode B will start.

4. In the Test Mode B, two kinds of idle statuses can be selected

depending on the[DIALMODE] switch setting.

DIAL MODE switch Idle statuses

T (TONE) side Test Mode Idle B-1 *1

P (PULSE) ise Test Mode Idle B-2 *2

*1: Radio block – TDD mode (Master timing)

Audio block – Line busy status

*2: Radio block – Standby status

Audio block – Line open

[Charging Detection Test, ARTO Pin Output Test, and

EEPROM Clear]

1. In the Test Mode Idle B-1 status, if charging is detected, a rectangular wave of 2.4 kHz is output from the IC751 Pin #¢

(ART0 pin).

2. At this time, the contents of the EEPROM memory are all

clearered.

Test Mode

Idle A → 2CH → 3CH → 4CH → . . . → 20CH

(1CH)

↑

3. On the channels 2 to 20, the statuses of respective blocks are as

follows:

Radio block – TDD mode (Slave timing)

Audio block – Line busy status

[Charging Detection Test, ARTO Pin Output Test, and

EEPROM Clear]

1. In the Test Mode Idle A status, if charging is detected, a rectangular wave of 2.4 kHz is output from the IC751 Pin #¢ (ARTO

pin).

2. At this time, the contents of the EEPROM memory are all

cleared.

[Terminating Signal Detection Test]

1. In the Test Mode Idle B-2 status, if a terminating signal is

detected, H → L → . . . are output from the IC751 Pin *ª in

synchronization with H → L → . . . of terminating signal detected.

[Continuous Receive Mode, Continuous Transmit Mode

and TDD Test Mode with High, Mid, and Low Power]

In the T est Mode Idle B-2 status, each time [PAGE] button is pressed,

the mode changes as follows:

[PAGE] button

pressing times

1 CONT. RECEIVE (1CH, LNA ON, AGC ON)

2 CONT. RECEIVE (10CH, LNA ON, AGC ON)

3 CONT. RECEIVE (20CH, LNA ON, AGC ON)

4 CONT. TRANSMIT (1CH, High power)

5 CONT. TRANSMIT (1CH, Mid power)

6 CONT. TRANSMIT (1CH, Low pwer)

7 CONT. TRANSMIT (10CH, High pwer)

8 CONT. TRANSMIT (10CH, Mid pwer)

9 CONT. TRANSMIT (10CH, Low pwer)

10 CONT. TRANSMIT (20CH, High pwer)

11 CONT. TRANSMIT (20CH, Mid pwer)

12 CONT. TRANSMIT (20CH, Low pwer)

13 TDD Mode (Master timing, 1CH, High power)

14 TDD Mode (Master timing, 1CH, Mid power)

15 TDD Mode (Master timing, 1CH, Low power)

16 Return to Test Mode Idle B-2

* In the statuses of 1 – 15, the audio block is placed in the line busy status.

Radio Block

– 10 –

Page 11

4-3. HAND SET

[Key Matrix Test Mode and LED Test Mode]

[Start-up]

1. With the po wer supplied, press [TALK] [0] [1] keys simultaneously ,

and the Test Mode will start.

2. Immediately after the Test Mode started, the ringer sounds for

500 msec, and the handset goes in Test Mode Idle status.

3. In the Test Mode Idle status, the statuses of respective blocks

are as follows:

Radio block – TDD Mode (Master timing, 1CH)

Audio block – Line busy status

4. In the Test Mode Idle status, respective test modes can be executed by key input properly.

5. In respective test modes, the Test Mode Idle status is resumed

by entering “0 1 #” keys.

6. In any mode, if “0 0 #” keys are entered, the Test Mode is cancelled and normal operating condition is resumed.

[Continuous Receive Mode]

1. Enter “1 1 #” keys, and the Continuous Receive (1CH, LHA

ON, AGC ON) mode is activated.

2. Each time [*] key is pressed, channels are changed over as follows:

1CH → 2CH → 3CH → 4CH → . . . → 20CH

↑

[Continuous T ransmit mode]

1. Enter “2 1 #” keys, and the Continuous Transmit (1CH, High

power) mode is activated.

2. Enter “2 2 #” key to activate Continuous Transmit (1CH, Mid

power) mode.

3. Enter “2 3 #” key to activate Continuous Transmit (1CH, Low

power) mode.

4. In respective modes, each time [*] key is pressed, channels are

changed over as follows:

1CH → 2CH → 3CH → 4CH → . . . → 20CH

↑

• Key Matrix Test mode

1. Enter “5 1 #” keys, and the Key Matrix Test mode is activated.

2. If pressing the keys in the order shown below, an acknowledge

tone is output. Or, if pressing other keys, and error tone will be

output.

[TALK] → [OFF] → [FLASH] → [PGM/VOL] → [SPEEDDIAL] →

[REDIAL/PAUSE] → [1] → [2] → [3] → [4] → [5] → [6] → [7] →

[8] → [9] → [*] → [0] → [#]

3. When an acknowledge tone or error tone is output, the initial

status of key matrix test and LED test mode is activated. From

this status, the key matrix test and LED test can be executed

with the key input.

• LED Test mode

1. Enter “5 4 #” keys, and the LED Test mode is activated.

2. When LED Test mode started, all LEDs turn on immediately.

[TDD Test Mode on Each Channel]

1. Enter “6 1 #” keys, and the TDD mode (Master timing, 1CH,

Line busy status) is activated.

2. Each time [*] key is pressed, channels are changed over as follows:

1CH → 2CH → 3CH → 4 CH → . . . → 20CH

↑

[EEPROM Clear]

Enter “7 1 #” keys, and the contents of EEPROM memory are all

cleared.

[Loopback T est Mode]

Key input Test mode

31# Code Forward Loopback (L1)

32# ADPCM Forward Loopback (L2)

33# ADPCM → RADIO Loopback

34# ADPCM Reverse Loopback

[TDD Test Mode with High, Mid, and Low Power]

Key input

41#

42#

43#

44#

Radio block

TDD mode (Master timing,

1CH, High power)

TDD mode (Master timing,

1CH, Mid power)

TDD mode (Master timing,

1CH, Low power)

TDD mode (Slave timing)

Audio block

Line busy status

Line busy status

Line busy status

Standby status

– 11 –

Page 12

SECTION 5

L

L

L

ELECTRICAL ADJUSTMENTS

5-1. BASE UNIT SECTION

• Make the set in Test mode (see page 10)

1. Checking RX I&Q Output Level

Setting:

oscilloscope

+

–

SG

Procedure:

1. Place the base unit in the Continous Receive mode (1CH, LNA

ON, AGC ON).

2. Set the SSG frequency to the frequency on 1CH + 300 kHz,

and the RF output level to –95 dBm.

3. Measure the output level of RXIN, RXIP, RXQN and RXQP

with a level meter. At this time, confirm with an oscilloscope

that a sine wave of 300 kHz is output.

4. confirm that the measured output level is –25.2 to –20.5 dBV.

If IC951 was replaced (there is no ID data), the output level

is –30.2 to –25.5 dBV.

5. Also, execute steps 1 through 4 for the channels 10 and 20.

level meter

+

–

TP903: RXIP

TP904: RXIN

TP905: RXQP

TP906: RXQN

TP919: GND

ANTENNA TERMINA

3. Checking TX Output

Setting:

peak power meter

+

–

ANTENNA TERMINA

Procedure:

1. Place the base unit in the Continuous Transmit mode (1CH,

High power).

2. Measure the ANT OUT output of the RF module in the base

unit using a peak power meter.

3. Confirm that the measured output is 17.7 mW (MIN 5.9 mW).

4. Also, execute steps 1 through 4 for the channels 10 and 20.

* For the frequency on each channel, see page 7.

2. Checking TX Center Frequency

Setting :

• short: TP918 ↔ TP919

frequency counter

+

–

ANTENNA TERMINA

Procedure:

1. Short TP918 and TP919 (GND) on the MAIN board in the base

unit.

2. Place the base unit in the Continuous Transmit mode (1CH,

High power).

3. Measure the ANT OUT frequency of the RF module in the base

unit using a frequency counter.

4. Confirm that the measured freuquency is 903.600 MHz ±

27 kHz.

5. Also, execute steps 1 through 4 for the channels 10 and 20.

– 12 –

Page 13

5-2. HANDSET SECTION

L

L

L

• Make the set in Test mode (see page 11)

1. Checking RX I&Q Output Level

Setting:

oscilloscope

+

–

SG

Procedure:

1. Place the handset in the Continuous Receive mode (1CH, LNA,

AGC ON).

2. Set the SSG frequency to the frequency on 1CH + 300 kHz,

and the RF output level to –95 dBm.

3. Measure the output lvel of RXIN, RXIP, RXQN, and RXQP

with a level meter. At this time, confirm with an oscilloscope

that a sine wave of 300 kHz is output.

4. confirm that the measured output level is –23.3 to –20.9 dBV.

If IC502 was replaced (there is no ID data), the output level

is –28.3 to –25.9 dBV.

5. Also, execute steps 1 through 4 for the channels 2 – 20.

level meter

+

–

TP520: RXIP

TP521: RXIN

TP522: RXQP

TP523: RXQP

TP553: GND

ANTENNA TERMINA

3. Checking TX output

Setting:

peak power meter

+

–

ANTENNA TERMINA

Procedure:

1. Place the handset in the Continuous Transmit mode (1CH, High

power).

2. Measure the ANT OUT output of the RF module in the handset

using a peak power meter.

3. Confirm that the measured output is 29 mW (MIN 17.4 mW).

4. Also, execute steps 1 through 4 for the channels 2 – 20.

* for the frequency on each channel, see page 7.

2. Checking TX Center Frequency

Setting:

• short: TP555 ↔ TP553

frequency counter

+

–

ANTENNA TERMINA

Procedure:

1. Short TP555 and TP553 (GND) on the MAIN board in the base

unit.

2. Place the handset in the Continuous Transmit mode (1CH, High

power).

3. Measure the ANT OUT frequency of the RF module in the handset using a frequency counter.

4. Confirm that the measured freuquency is 903.600 MHz ±

27 kHz.

5. Also, execute steps 1 through 4 for the channels 2 – 20.

– 13 –

Page 14

ADJUSTMENT LOCATION:

[BASE MAIN BOARD] (Conductor Side)

ANTENNA TERMINAL

SG : Checking RX I&Q Output level

frequency counter : Checking TX Center Frequency

peak power meter : Checking TX Output

TP918 and TP919 short:

Checking TX Center Frequency

TP903: RXIP

TP904: RXIN

TP905: RXQP

TP906: RXQN

level meter: Checking RX I & Q Output Level

– 14 –

Page 15

[HAND MAIN BOARD] (Conductor Side)

ANTENNA TERMINAL

SG : Checking RX I&Q Output level

frequency counter : Checking TX Center Frequency

peak power meter : Checking TX Output

TP555 and TP553 short:

Checking TX Center Frequency

TP520: RXIP

TP521: RXIN

TP522: RXQP

TP523: RXQN

level meter:

Checking RX I & Q Output Level

– 15 –

Page 16

SPP-SS950

p

• Wavef orm

1 IC751 oj (XTALI)

SECTION 6

DIAGRAMS

4 Vp-

9.6 MHz

– 16 –

– 17 –

– 18 –

Page 17

SPP-SS950

– 19 – – 20 –

Page 18

SPP-SS950

– 21 –

– 22 –

Page 19

• IC Block Diagram

IC401, 701 10497-14

REFCNTL

XCLKONCICLK

RESETB

MCLK

DVSS

DVDD

DATAI

DATAO

25

26

27

28

29

30

31

NC

32

NC

16 BIT

REGISTOR

CONTROL

REGISTOR

16 BIT

REGISTOR

2 345 6 7 8

1

NCNCNCNCNC

• Wavef orm

1 IC501 oj (XTALI)

FRAM

SPKPO

SPKMO

MODULATOR

& FILTER

MODULATOR

& FILTER

AGND

1719 182021222324

VREF

LINEO

MICBIAS

SPP-SS950

16

VOXRNT

VOXSND

15

14

AVDD

LINE-IN

13

AVSS

12

11

MICIN

10

RBIAS

9

NC

9.6 MHz

2.9 Vp-p

– 23 –

– 24 –

– 25 –

Page 20

6-5. IC PIN FUNCTION DESCRIPTION

• BASE MAIN BAORD IC751 C7302-11 (RDSSS9M-ASIC)

Pin No. Pin Name I/O Function

1 KEYPADB5 — Not used

2-4 D0-2 — Not used

5 D3 I DIAL MAKE rate selection input H: 40%, L: 33%

6 D4 I Model selection input H: SPP-SS950

7-9 D5-7 — Not used

10-14 KEY PADI0-4 — Not used

15 KEYPADI5 I PAGE key input

16 VSSC — Ground

17 VDDC — Power supply (+5 V)

18 VDDP — Power supplu (+5 V)

19 VSSC — Ground

20, 21 OSC1, 2 — Not used

22, 23 KEYPADB3, 4 — Not used

24 CDCDATAI I CODEC DATA input

25 CDCDATAO I/O CODEC DATA output

26 CDCMCLK O CODEC master CLK output

27 RESETO O Reset signal output

28 CDCICLK O CODEC interface CLK output

29 VDDP — Power supply (+5 V)

30 VSSP — Ground

31 KEYPADB2 O PAGE key output

32 CDCFRAME O CODEC FRAM output

33 ARTI I ART input

34 ARTO O ART output

35, 36 KEYPADB1, 0 — Not used

37 GPIOB7 O RELAY ON/OFF output H: active

38 VDDP — Power supply (+5 V)

39 LCDCS — Not used

40 VDDC — Power supply (+5 V)

41 VSSC — Ground

42 TEST I Test mode select input L: active

43 LNAATN O LNA gain select output H: low gain

44 RXEN O RX enable output H: active

45 VDDA — Power supply (+5 V)

46 VSSA — Ground

47 VDDA — Power supply (+5V)

48 VSSA — Ground

49 TXDATA O TX DATA output

50 VRP O Analog standard voltage output

51 RXIP I RX input (I positive)

52 RXIN I RX input (I negative)

53 RXQP I RX input (Q positive)

54 RXQN I RX input (Q negative)

55 NC — Not used

56 IBIAS I Analog bias input

57 AGND O Analog ground

– 26 –

Page 21

Pin No. Pin Name I/O Function

58 BATTERY I Battery voltage input (Pull up)

59 AFC — Not used

60 AGC O AGC control output

61 CALLER-ID — Not used

62 PARKP I Charging detection input L: active

63 VDDC — Power supply (+5 V)

64 VSSP — Ground

65 SYNDATA O Synthesizer DATA output

66

SYNTH5MCLK

67, 68 LED3, 4 — Not used

69 LCDRW — Not used

70 LCDRS — Not used

71 SYNCLK O Synthesizer CLK output

72 SYNSTB O Synthesizer strobe output

73 VDDP — Power supply (+5 V)

74 VSSP — Ground

75 SYNEN O Synthesizer power control output H: active

76 NVDI I/O EEPROM SDA input/output

77 NVDO O EEPROM SCL output

78 LED2 — Not used

79 TXEN O TX enable output H: active

80 TXPWRI O PA power select output

81 GPIOB6 I Terminating signal detection input L: active

82 TXRXSEL O TX/RX select output

83 RING OFF — Not used

84 BASEP I HAND/BASE select input H: HAND, L: BASE

85 TXPWRO O PA power select output

86 GPIOB5 — Not used

87 NVCS — Not used

88 AUDPWRP I DTMF/PULSE select switch input H: DTMF, L: PULSE

89 LED1 — Not used

90 VDDC — Power supply (+5 V)

91 VSSC — Ground

92 LCDPWRP — Not used

93 SLEEP — Not used

94 GPIOB4 — Not used

95 NVCLK O Reception muting during dial transmission. L: during dial transmission.

96 RESETI I Power-on reset input. L: active

97 XTALI I 9.6 MHz OSC input

98 XTALO O 9.6 MHz OSC output

99 VDDP — Power supply (+5 V)

100 VSSP — Ground

O Synthesizer REF OSC output

– 27 –

Page 22

• HAND MAIN BOARD IC501 C7302-11 (RDSSS9M-ASIC)

Pin No. Pin Name I/O Function

1 KEYPADB5 — Not used

2-5 D0-3 — Not used

6 D4 I Model selection input H: SPP-SS950

7-9 D5-7 — Not used

10-15 KEY PADI0-5 I Key matrix scan input L: KEY ON

16 VSSC — Ground

17 VDDC — Power supply (+3.6 V)

18 VDDP — Power supplu (+3.6 V)

19 VSSP — Ground

20 OSCI — Not used

21 OSCO — Not used

22 KEYPADB3 O Key matrix scan output

23 KEYPADB4 — Not used

24 CDCDATAI I CODEC DATA input

25 CDCDATAO I/O CODEC DATA output

26 CDCMCLK O CODEC master CLK output

27 RESETO O P ower-on reset output

28 CDCICLK O CODEC interface CLK output

29 VDDP — Power supply (+3.6 V)

30 VSSP — Ground

31 KEYPADB2 O Key matrix scan output

32 CDCFRAME O CODEC FRAM output

33 ARTI I ART input

34 ARTO — Not used

35, 36 KEYPADB1, 0 O Key matrix scan output

37 GPIOB — Not used

38 VDDP — Power supply (+3.6 V)

39 LCDCS — Not used

40 VDDC — Power supply (+3.6 V)

41 VSSC — Ground

42 TEST I Test mode select input L: active

43 LNAATN O LNA gain select output H: low gain

44 RXEN O RX enable output H: active

45 VDDA — Power supply (+3.6 V)

46 VSSA — Ground

47 VDDA — Power supply (+3.6 V)

48 VSSA — Ground

49 TXDATA O TX DATA output

50 VRP O Analog standard voltage output

51 RXIP I RX input (I positive)

52 RXIN I RX input (I negative)

53 RXQP I RX input (Q positive)

54 RXQN I RX input (Q negative)

55 NC — Not used

56 IBIAS I Analog bias input

57 AGND O Analog ground

– 28 –

Page 23

Pin No. Pin Name I/O Function

58 BATTERY I Battery voltage input (Pull up)

59 AFC — Not used

60 AGC O AGC control output

61 CALLER-ID — Not used

62 PARKP I Charging detection input L: active

63 VDDC — Power supply (+3.6 V)

64 VSSP — Ground

65 SYNDATA O Synthesizer DATA output

66

SYNTH5MCLK

67 LCDRS — Not used

68 LED4 — Not used

69, 70 JOG (A), (B) — Not used

71 SYNCLK O Synthesizer CLK output

72 SYNSTB O Synthesizer strobe output

73 VDDP — Power supply (+3.6 V)

74 VSSP — Ground

75 SYNEN O Synthesizer power control output H: active

76 NVDI I/O EEPROM SDA input/output

77 NVDO O EEPROM SCL output

78 LCDRW — Not used

79 TXEN O TX enable output H: active

80 TXPWRI O PA power select output

81 JOG (SW) — Not used

82 TXRXSEL O TX/RX select output

83 RING OFF I RING ON/BATT. SAVE input H: RING ON, L: BATT SAVE

84 BASEP I HAND/BASE select input H: HAND, L: BASE

85 TXPWRO O PA power select output

86 GPIOB5 — Not used

87 NVCS — Not used

88 GPIOA7 — Not used

89 LED1 O TAKE LED output L: LED ON

90 VDDC — Power supply (+3.6 V)

91 VSSC — Ground

92 LCDPWRP — Not used

93 SLEEP — Not used

94 GPIOB4 — Not used

95 NVCLK — Not used

96 RESETI I Power-on reset input L: active

97 XTALI I 96 MHz OSC input

98 XTALO O 96 MHz OSC output

99 VDDP — Power supply (+3.6 V)

100 VSSP — Ground

O Synthesizer REF OSC output

– 29 –

Page 24

SECTION 7

EXPLODED VIEWS

Ver 1.2 2000. 06

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) HANDSET SECTION

SP401

2

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

ANT501

#1

3

#3

4

6

#2

#3

#2

1

8

9

10

Ref. No. Part No. Description Remark

1 3-014-528-01 CABINET (FRONT)

2 3-372-738-01 GASKET (RECEIVER) (TWN)

3 3-012-365-01 HOLDER (SP)

4 3-012-363-01 CABINET (REAR)

6 3-954-192-01 LABEL (A), NI-CD RECYCLE

7

#3

12

Ref. No. Part No. Description Remark

9 3-012-366-01 TERMINAL (HAND), CHARGE

* 10 3-935-519-11 CUSHION (BUZZER)

11 3-012-364-01 LID, BATTERY CASE

12 3-935-520-01 CUSHION (BATTERY)

ANT501 1-501-933-11 ANTENNA

11

* 7 A-3622-106-A HAND MAIN BOARD, COMPLETE

8 1-771-137-11 SWITCH, RUBBER KEY

SP401 1-504-829-11 SPEAKER (28MM)

– 30 –

Page 25

(2) BASESET SECTION

56

53

52

60

55

54

#3

#3

59

#1

57

58

#3

ANT901

#3

51

#3

Ref. No. Part No. Description Remark

51 X-3374-536-1 CABINET (LOWER) ASSY

* 52 A-3622-107-A BASE MAIN BOARD, COMPLETE (US)

* 52 A-3622-108-A BASE MAIN BOARD, COMPLETE (E)

53 3-012-378-01 TERMINAL (BASE), CHARGE

54 3-012-376-01 LENS (CHARGE)

55 3-012-373-01 BUTTON (PAGE)

#3

Ref. No. Part No. Description Remark

56 3-012-371-11 CABINET (UPPER)

57 3-012-374-01 HOLDER (HANDSET)

58 3-012-375-01 HOLDER (ANTENNA)

59 3-007-173-01 LABEL (TERMINAL CAUTION) (/S)

ANT901 1-501-932-11 ANTENNA

– 31 –

Page 26

BASE MAIN

SECTION 8

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when order-

Ref. No. Part No. Description Remark

* A-3622-107-A BASE MAIN BOARD, COMPLETE (US)

* A-3622-108-A BASE MAIN BOARD, COMPLETE (E)

**************************

7-685-134-19 SCREW +BTP 2.6X8 TYPE2 N-S

7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S (E)

< CAPACITOR >

C101 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

! C102 1-162-117-00 CERAMIC 100PF 10% 500V

! C104 1-162-117-00 CERAMIC 100PF 10% 500V

! C105 1-136-193-11 FILM 0.47uF 10% 250V

C109 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C111 1-115-868-11 ELECT 0.22uF 20% 50V

C112 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C113 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C115 1-126-960-11 ELECT 1uF 20% 50V

C131 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C137 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C138 1-126-963-11 ELECT 4.7uF 20% 50V

C191 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C192 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C193 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C194 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C195 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C196 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C197 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C198 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C199 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C601 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C602 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C605 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C606 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C607 1-126-916-11 ELECT 1000uF 20% 6.3V

C608 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C609 1-126-963-11 ELECT 4.7uF 20% 50V

C650 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C651 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C701 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C702 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C703 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C704 1-126-925-11 ELECT 470uF 20% 10V

C705 1-164-222-11 CERAMIC CHIP 0.22uF 25V

ing these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

Ref. No. Part No. Description Remark

C706 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C707 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C751 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C754 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C755 1-126-964-11 ELECT 10uF 20% 50V

C756 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C757 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C758 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C759 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C760 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C766 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C767 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C768 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C790 1-102-514-11 CERAMIC CHIP 22PF 5% 50V

C791 1-102-514-11 CERAMIC CHIP 22PF 5% 50V

C901 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C902 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C903 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C904 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C951 1-163-031-11 CERAMIC CHIP 0.01uF 50V

< CONNECTOR >

* CN651 1-506-985-11 PIN, CONNECTOR (PC BOARD) 3P

* CN901 1-779-773-11 PIN, CONNECTOR (PC BOARD)

* CN902 1-779-774-11 PIN, CONNECTOR (PC BOARD)

< DIODE >

D100 8-719-991-33 DIODE 1SS133T-77

D101 8-719-991-33 DIODE 1SS133T-77

! D102 8-719-109-89 DIODE RD5.6ESB2

! D103 8-719-109-89 DIODE RD5.6ESB2

! D104 8-719-991-33 DIODE 1SS133T-77

D105 8-719-157-36 DIODE RD6.8M-B

D108 8-719-914-42 DIODE DA204K

D109 8-719-914-42 DIODE DA204K

D110 8-719-914-42 DIODE DA204K

D652 8-719-991-33 DIODE 1SS133T-77

D653 8-719-991-33 DIODE 1SS133T-77

D654 8-719-050-05 DIODE SLR-325VRT31 (CHARGE)

< IC >

IC101 8-759-909-71 IC BA4558F

– 32 –

Page 27

BASE MAIN

Ref. No. Part No. Description Remark

IC601 8-759-482-72 IC uPC29M05HF

IC602 8-759-519-46 IC S-80730AN-DT-S

IC701 8-759-475-69 IC 10497-14

IC751 8-759-475-70 IC C7302-11

IC951 8-759-487-03 IC S-24C01AFJA-TB-01

< JACK >

J601 1-778-380-11 JACK,DC(POLARITY UNIFIED TYPE)(DC IN 9V)

< JUMPER RESISTOR >

JR11 1-216-296-00 CONDUCTOR, CHIP (3216)

JR12 1-216-296-00 CONDUCTOR, CHIP (3216)

JR13 1-216-296-00 CONDUCTOR, CHIP (3216)

JR14 1-216-296-00 CONDUCTOR, CHIP (3216)

JR15 1-216-296-00 CONDUCTOR, CHIP (3216)

JR16 1-216-296-00 CONDUCTOR, CHIP (3216)

JR17 1-216-296-00 CONDUCTOR, CHIP (3216)

JR18 1-216-296-00 CONDUCTOR, CHIP (3216)

JR19 1-216-296-00 CONDUCTOR, CHIP (3216)

JR20 1-216-296-00 CONDUCTOR, CHIP (3216)

JR21 1-216-296-00 CONDUCTOR, CHIP (3216)

JR24 1-216-296-00 CONDUCTOR, CHIP (3216)

JR25 1-216-296-00 CONDUCTOR, CHIP (3216)

JR26 1-216-296-00 CONDUCTOR, CHIP (3216)

JR27 1-216-296-00 CONDUCTOR, CHIP (3216)

JR28 1-216-296-00 CONDUCTOR, CHIP (3216)

JR29 1-216-295-00 CONDUCTOR, CHIP (2012)

< COIL >

L101 1-410-470-11 INDUCTOR 10uH

L102 1-410-470-11 INDUCTOR 10uH

L601 1-410-468-11 INDUCTOR 6.8uH

L602 1-410-468-11 INDUCTOR 6.8uH

L750 1-412-945-11 INDUCTOR 3.3uH

< MODULAR JACK >

! MJ101 1-766-250-11 JACK, MODULAR (2C) 6P (LINE)

< PHOTO COUPLER >

! PH101 8-719-156-73 PHOTO COUPLER PS2501-1LA

< TRANSISTOR >

Q101 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q102 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q103 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q171 8-729-016-90 TRANSISTOR 2SA1179R-M5M6-TB

Q651 8-729-922-26 TRANSISTOR 2SD1758F5-Q

Q652 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q653 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q750 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q751 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q952 8-729-120-28 TRANSISTOR 2SC1623-L5L6

< RESISTOR >

R9 1-216-041-00 METAL CHIP 470 5% 1/10W

! R101 1-215-864-00 METAL OXIDE 150 5% 1W F

! R103 1-215-877-11 METAL OXIDE 22K 5% 1W F

Ref. No. Part No. Description Remark

R104 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R105 1-216-085-00 METAL CHIP 33K 5% 1/10W

R107 1-216-021-00 METAL CHIP 68 5% 1/10W

R108 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R109 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R110 1-216-073-00 METAL CHIP 10K 5% 1/10W

R111 1-216-073-00 METAL CHIP 10K 5% 1/10W

R112 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R115 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R121 1-216-025-00 METAL GLAZE 100 5% 1/10W

! R125 1-215-869-11 METAL OXIDE 1K 5% 1W F

R126 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R127 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R128 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R129 1-216-081-00 METAL CHIP 22K 5% 1/10W

R130 1-216-025-00 METAL CHIP 100 5% 1/10W

R132 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R134 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R135 1-216-101-00 METAL CHIP 150K 5% 1/10W

R137 1-216-101-00 METAL CHIP 150K 5% 1/10W

R139 1-216-073-00 METAL CHIP 10K 5% 1/10W

R141 1-216-025-00 METAL CHIP 100 5% 1/10W

R156 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R173 1-216-073-00 METAL CHIP 10K 5% 1/10W

R175 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R190 1-216-025-00 METAL GLAZE 100 5% 1/10W

R191 1-216-025-00 METAL GLAZE 100 5% 1/10W

R601 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R651 1-249-411-11 CARBON 330 5% 1/4W

R653 1-249-393-11 CARBON 10 5% 1/4W F

R654 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R655 1-216-101-00 METAL CHIP 150K 5% 1/10W

R656 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R657 1-216-041-00 METAL CHIP 470 5% 1/10W

R658 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R659 1-216-101-00 METAL CHIP 150K 5% 1/10W

R701 1-414-981-11 INDUCTOR CHIP 680nH

R702 1-218-754-11 METAL CHIP 120K 0.50% 1/10W

R703 1-216-009-00 METAL CHIP 22 5% 1/10W

R750 1-216-813-11 METAL CHIP 220 5% 1/16W

R751 1-216-073-00 METAL CHIP 10K 5% 1/10W

R752 1-216-073-00 METAL CHIP 10K 5% 1/10W (E)

R754 1-216-045-00 METAL CHIP 680 5% 1/10W

R755 1-216-073-00 METAL CHIP 10K 5% 1/10W

R759 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R760 1-216-073-00 METAL CHIP 10K 5% 1/10W

R761 1-216-041-00 METAL CHIP 470 5% 1/10W

R762 1-216-073-00 METAL CHIP 10K 5% 1/10W

R764 1-216-041-00 METAL CHIP 470 5% 1/10W

R765 1-216-001-00 METAL CHIP 10 5% 1/10W

R766 1-218-754-11 METAL CHIP 120K 0.50% 1/10W

R767 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R768 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R769 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R771 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R772 1-216-025-00 METAL GLAZE 100 5% 1/10W

R781 1-216-041-00 METAL CHIP 470 5% 1/10W

– 33 –

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number

specified.

Page 28

BASE MAIN HAND MAIN

Ref. No. Part No. Description Remark

R782 1-216-041-00 METAL CHIP 470 5% 1/10W

R787 1-216-041-00 METAL CHIP 470 5% 1/10W

R790 1-216-041-00 METAL CHIP 470 5% 1/10W

R792 1-216-041-00 METAL CHIP 470 5% 1/10W

R793 1-216-041-00 METAL CHIP 470 5% 1/10W

R794 1-216-041-00 METAL CHIP 470 5% 1/10W

R798 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R800 1-216-041-00 METAL CHIP 470 5% 1/10W

R801 1-216-041-00 METAL CHIP 470 5% 1/10W

R802 1-216-041-00 METAL CHIP 470 5% 1/10W

R803 1-216-041-00 METAL CHIP 470 5% 1/10W

R804 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R902 1-216-041-00 METAL CHIP 470 5% 1/10W

R913 1-216-041-00 METAL CHIP 470 5% 1/10W

R914 1-216-041-00 METAL CHIP 470 5% 1/10W

R954 1-216-073-00 METAL CHIP 10K 5% 1/10W

R955 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R956 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R957 1-216-073-00 METAL CHIP 10K 5% 1/10W

< RF UNIT >

RFU901 1-475-242-11 RF UNIT

< RELAY >

! RY101 1-755-150-11 RELAY

< SPARK GAP >

Ref. No. Part No. Description Remark

C403 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C404 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C405 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C406 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 50V

C407 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C409 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C410 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C411 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C412 1-165-320-11 CERAMIC CHIP 0.47uF 10% 16V

C413 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C414 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C415 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C416 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C417 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C420 1-102-514-11 CERAMIC CHIP 22PF 5% 50V

C421 1-102-514-11 CERAMIC CHIP 22PF 5% 50V

C422 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C423 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C424 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C425 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C501 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C502 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C505 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C506 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C507 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C508 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C509 1-124-779-00 ELECT CHIP 10uF 20% 16V

SG101 1-517-224-11 GAP, DISCHARGE (E)

< SWITCH >

SW951 1-692-991-11 SWITCH, SLIDE (DIAL MODE)

SW952 1-572-381-21 SWITCH, KEY BOARD (PAGE)

< TRANSFORMER >

! T101 1-429-648-11 TRANSFORMER, LINE

< VIBRATOR >

X752 1-767-566-21 VIBRATOR, CRYSTAL (9.6MHz)

************************************************************

* A-3622-106-A HAND MAIN BOARD, COMPLETE

**************************

7-685-134-19 SCREW +BTP 2.6X8 TYPE2 N-S

< BUZZER >

BZ401 1-544-603-11 BUZZER

< CAPACITOR >

C301 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C302 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C303 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C305 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C307 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C308 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C401 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C402 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C510 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C511 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C512 1-164-222-11 CERAMIC CHIP 0.22uF 25V

C513 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C514 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C516 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C523 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C585 1-163-031-11 CERAMIC CHIP 0.01uF 50V

< CONNECTOR >

CN301 1-766-180-11 PIN, CONNECTOR (PC BOARD) 2P

* CN302 1-506-985-11 PIN, CONNECTOR (PC BOARD) 3P

* CN401 1-506-984-11 PIN, CONNECTOR (PC BOARD) 2P

* CN501 1-779-773-11 PIN, CONNECTOR (PC BOARD)

* CN502 1-779-774-11 PIN, CONNECTOR (PC BOARD)

< DIODE >

D301 8-719-938-75 DIODE SB05-05CP

D302 8-719-938-75 DIODE SB05-05CP

D303 8-719-938-75 DIODE SB05-05CP

D304 8-719-938-75 DIODE SB05-05CP

D305 8-719-914-43 DIODE DAN202K

D306 8-719-066-61 DIODE RD5.6P-T1

D308 8-719-105-91 DIODE RD5.6M-B2

D401 8-719-914-43 DIODE DAN202K

D402 8-719-914-43 DIODE DAN202K

D404 8-719-105-91 DIODE RD5.6M-B2

D501 8-719-051-89 DIODE SML-010VT-T87 (TALK/BATT LOW)

D505 8-719-914-42 DIODE DA204K (TALK)

– 34 –

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number

specified.

Page 29

HAND MAIN

Ref. No. Part No. Description Remark

< IC >

IC301 8-759-519-46 IC S-80730AN-DT-S

IC401 8-759-475-69 IC 10497-14

IC501 8-759-475-70 IC C7302-11

IC502 8-759-487-02 IC S-24C02AFJA-TB-01

< JUMPER RESISTOR >

JR1 1-216-296-00 CONDUCTOR, CHIP (3216)

JR2 1-216-296-00 CONDUCTOR, CHIP (3216)

JR3 1-216-296-00 CONDUCTOR, CHIP (3216)

JR4 1-216-296-00 CONDUCTOR, CHIP (3216)

JR7 1-216-295-00 CONDUCTOR, CHIP (2012)

JR8 1-216-295-00 CONDUCTOR, CHIP (2012)

JR11 1-216-295-00 CONDUCTOR, CHIP (2012)

JR12 1-216-295-00 CONDUCTOR, CHIP (2012)

JR13 1-216-296-00 CONDUCTOR, CHIP (3216)

JR14 1-216-296-00 CONDUCTOR, CHIP (3216)

JR15 1-216-296-00 CONDUCTOR, CHIP (3216)

JR18 1-216-296-00 CONDUCTOR, CHIP (3216)

JR20 1-216-296-00 CONDUCTOR, CHIP (3216)

JR21 1-216-029-00 METAL CHIP 150 5% 1/10W

JR22 1-216-295-00 CONDUCTOR, CHIP (2012)

JR23 1-216-295-00 CONDUCTOR, CHIP (2012)

Ref. No. Part No. Description Remark

R413 1-216-025-00 METAL GLAZE 100 5% 1/10W

R414 1-216-025-00 METAL GLAZE 100 5% 1/10W

R415 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R501 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R502 1-216-025-00 METAL GLAZE 100 5% 1/10W

R506 1-216-001-00 METAL CHIP 10 5% 1/10W

R507 1-218-754-11 METAL CHIP 120K 0.50% 1/10W

R508 1-218-754-11 METAL CHIP 120K 0.50% 1/10W

R509 1-218-756-11 METAL CHIP 150K 0.50% 1/10W

R510 1-216-073-00 METAL CHIP 10K 5% 1/10W

R511 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R512 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R513 1-216-821-11 METAL CHIP 1K 5% 1/16W

R527 1-216-073-00 METAL CHIP 10K 5% 1/10W

R528 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R529 1-216-073-00 METAL CHIP 10K 5% 1/10W

R534 1-216-295-00 CONDUCTOR, CHIP (2012)

R539 1-216-295-00 CONDUCTOR, CHIP (2012)

R541 1-216-295-00 CONDUCTOR, CHIP (2012)

R542 1-216-296-00 CONDUCTOR, CHIP (3216)

R544 1-216-817-11 METAL CHIP 470 5% 1/16W

R545 1-216-817-11 METAL CHIP 470 5% 1/16W

R546 1-216-821-11 METAL CHIP 1K 5% 1/16W

R547 1-216-864-11 METAL CHIP 0 5% 1/16W

< COIL >

L501 1-410-198-51 INDUCTOR CHIP 3.3uH

< MICROPHONE >

MIC401 1-542-118-11 MICROPHONE, ELECTRET CONDENSER

< TRANSISTOR >

Q301 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q302 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q303 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q502 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q503 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q504 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q505 8-729-120-28 TRANSISTOR 2SC1623-L5L6

< RESISTOR >

R301 1-216-093-00 METAL CHIP 68K 5% 1/10W

R302 1-216-085-00 METAL CHIP 33K 5% 1/10W

R303 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R304 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R305 1-216-073-00 METAL CHIP 10K 5% 1/10W

R308 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R309 1-216-073-00 METAL CHIP 10K 5% 1/10W

R310 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R311 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R312 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R548 1-216-295-00 CONDUCTOR, CHIP (2012)

R549 1-216-295-00 CONDUCTOR, CHIP (2012)

R550 1-216-295-00 CONDUCTOR, CHIP (2012)

R551 1-216-041-00 METAL CHIP 470 5% 1/10W

R552 1-216-041-00 METAL CHIP 470 5% 1/10W

R554 1-216-817-11 METAL CHIP 470 5% 1/16W

R555 1-216-817-11 METAL CHIP 470 5% 1/16W

R556 1-216-817-11 METAL CHIP 470 5% 1/16W

R557 1-216-041-00 METAL CHIP 470 5% 1/10W

R558 1-216-041-00 METAL CHIP 470 5% 1/10W

R560 1-216-041-00 METAL CHIP 470 5% 1/10W

R561 1-216-295-00 CONDUCTOR, CHIP (2012)

R570 1-216-073-00 METAL CHIP 10K 5% 1/10W

R573 1-216-073-00 METAL CHIP 10K 5% 1/10W

R583 1-216-045-00 METAL CHIP 680 5% 1/10W

R584 1-216-833-11 METAL CHIP 10K 5% 1/16W

R585 1-216-813-11 METAL CHIP 220 5% 1/16W

R586 1-216-073-00 METAL CHIP 10K 5% 1/10W

R590 1-216-041-00 METAL CHIP 470 5% 1/10W

R591 1-216-041-00 METAL CHIP 470 5% 1/10W

< RF UNIT >

RFU501 1-475-242-21 RF UNIT

< SWITCH >

S501 1-692-991-11 SWITCH, SLIDE (RING ON/BATT SAVE)

S502 1-570-909-11 SWITCH, TACTIL (REFLOW TYPE) (TALK)

R401 1-216-017-00 METAL GLAZE 47 5% 1/10W

R402 1-218-754-11 METAL CHIP 120K 0.50% 1/10W

R403 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R405 1-414-481-11 INDUCTOR CHIP 68nH

R409 1-216-029-00 METAL CHIP 150 5% 1/10W

R410 1-216-097-00 METAL GLAZE 100K 5% 1/10W

< VIBRATOR >

X501 1-767-566-21 VIBRATOR, CRYSTAL (9.6MHz)

************************************************************

– 35 –

Page 30

SPP-SS950

Ref. No. Part No. Description Remark

MISCELLANEOUS

***************

8 1-771-137-11 SWITCH, RUBBER KEY

ANT501 1-501-933-11 ANTENNA

ANT901 1-501-932-11 ANTENNA

SP401 1-504-829-11 SPEAKER (28MM)

************************************************************

**************

HARDWARE LIST

**************

#1 7-685-650-79 SCREW +P 3X16 TYPE2 NON-SLIT

#2 7-685-135-19 SCREW +B 2.6X10

#3 7-685-134-19 SCREW +BTP 2.6X8 TYPE2 N-S

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

! 1-467-081-21 ADAPTOR, AC (AC-T37) (US)

! 1-467-498-21 ADAPTOR, AC (AC-T47) (E)

1-528-489-11 BATTERY PACK (BP-T18)

1-696-453-21 CORD (WITH MODULAR PLUG) (LINE) (22cm)

1-696-454-11 CORD (WITH MODULAR PLUG) (LINE) (2m15cm)

3-012-379-01 CASE, WALL HOOK

3-860-219-11 MANUAL, INSTRUCTION

3-860-219-21 MANUAL, INSTRUCTION

3-860-219-31 MANUAL, INSTRUCTION

3-936-680-01 LABEL (ADRESS)

X-3368-367-1 SCREW ASSY (E)

(ENGLISH, SPANISH) (US)

(ENGLISH, SPANISH) (E)

(RUSSIAN, CHINESE) (E)

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number

specified.

9-925-727-11

Sony Corporation

Personal & Mobile Communication Company

– 36 –

Printed in Singapore © 1997. 8

97H057027-1

Published by Quality Assurance Dept.

Page 31

SERVICE MANUAL

1998. 09

SUPPLEMENT-1

File this supplement with the service manual.

Subject:

Argentine model Addition

SPP-SS950

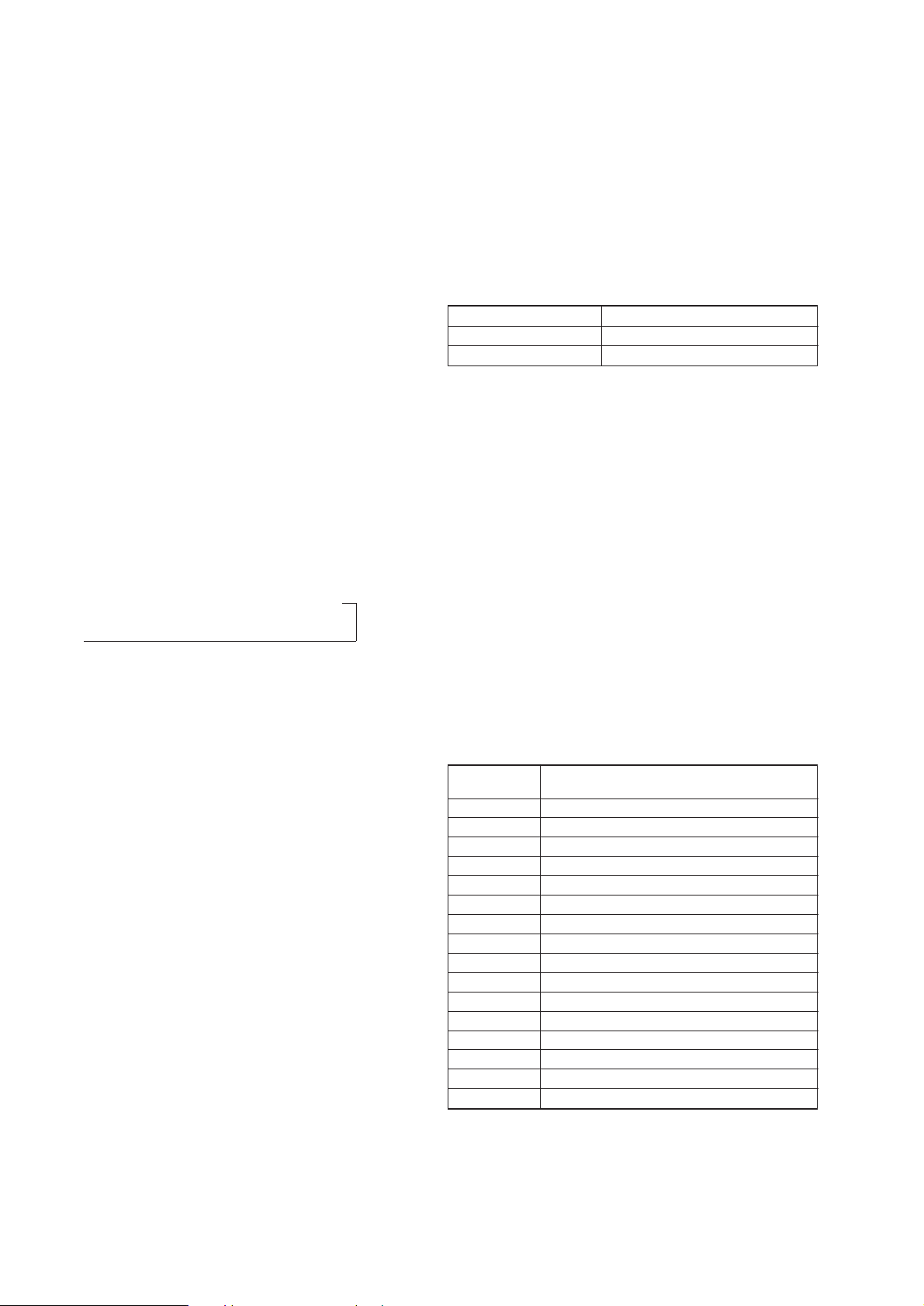

US Model

E Model

(ENG-98016)

Argentine model is almost the same as E model.

The difference parts from E model are described in this service manual.

Please refer to SPP-SS950 service manual previously issued for the other infomation.

• DIFFERENCE PARTS LIST

Page E model Argentine model

Ref. No. Part No. Description Remark

36

1-467-498-21 AC ADAPTOR (AC-T47)

Ref. No. Part No. Description Remark

1-418-223-11 AC ADAPTOR (AC-T126)

9-925-727-81

Sony Corporation

Personal & Mobile Communication Company

Printed in Japan © 1998. 9

98IXX002-1

Published by Quality Assurance Dept.

Loading...

Loading...