Page 1

SPP-68

SERVICE MANUAL

SPECIFICATIONS

E Model

MICROFILM

CORDLESS TELEPHONE

Page 2

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL

Setting up the phone ....................................................... 4

Making and receiving calls ............................................. 4

Speed dialing ................................................................... 5

Resetting the digital security code.................................. 5

Paging .............................................................................. 5

3. DISASSEMBLY ......................................................... 6

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

4. TEST MODE

4-1. Base Unit Section............................................................ 8

4-2. Handset Section............................................................... 10

5. ELECTRICAL ADJUSTMENTS

5-1. Base Unit Section............................................................ 13

5-2. Handset Section............................................................... 14

6. DIAGRAMS

6-1. Block Diagram – BASE UNIT Section –...................... 19

6-2. Block Diagram – HANDSET Section –........................ 21

6-3. Notes for Printed Wiring Board and

Schematic Diagram ......................................................... 23

6-4. Printed Wiring Boards – BASE UNIT Section – .......... 25

6-5. Schematic Diagram – BASE UNIT Section –................ 27

6-6. Printed Wiring Board – HANDSET Section –.............. 29

6-7. Schematic Diagram – HANDSET Section –................. 31

6-8. IC Pin Function Description ........................................... 33

7. EXPLODED VIEWS ................................................ 35

8. ELECTRICAL PARTS LIST ............................... 37

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 3

SECTION 1

SERVICING NOTES

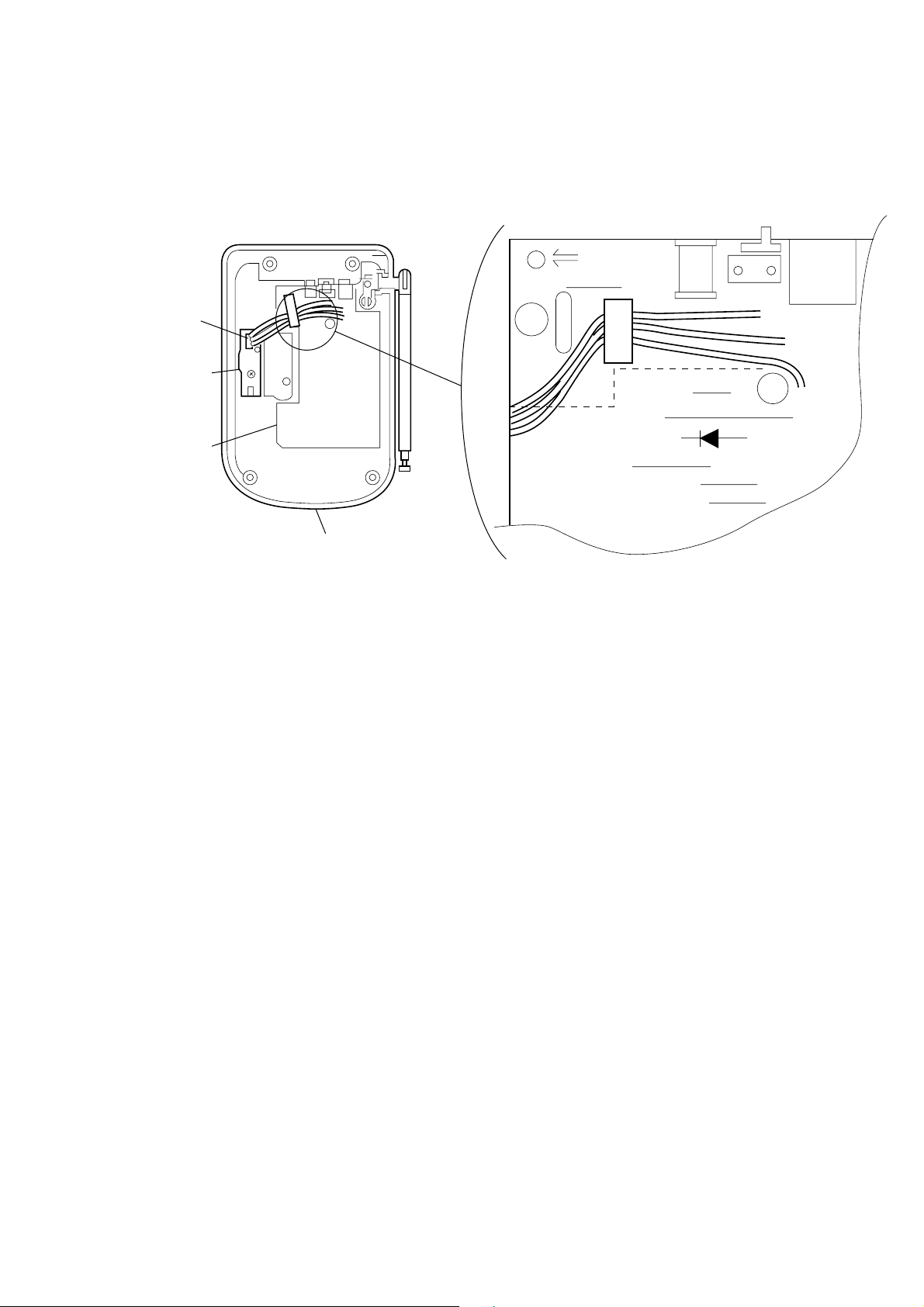

PREVENT ELECTROSTATIC DESTRUCTION

• To prevent electrostatic destruction in replacing the main board, etc., fasten the CN602 cable as shown below.

JW5

CN602

SUB board

BASE MAIN board

cabinet lower

C502

X501

JW12

JW6

JW10

D101

JW7

C303

JW3

– 3 –

Page 4

SECTION 2

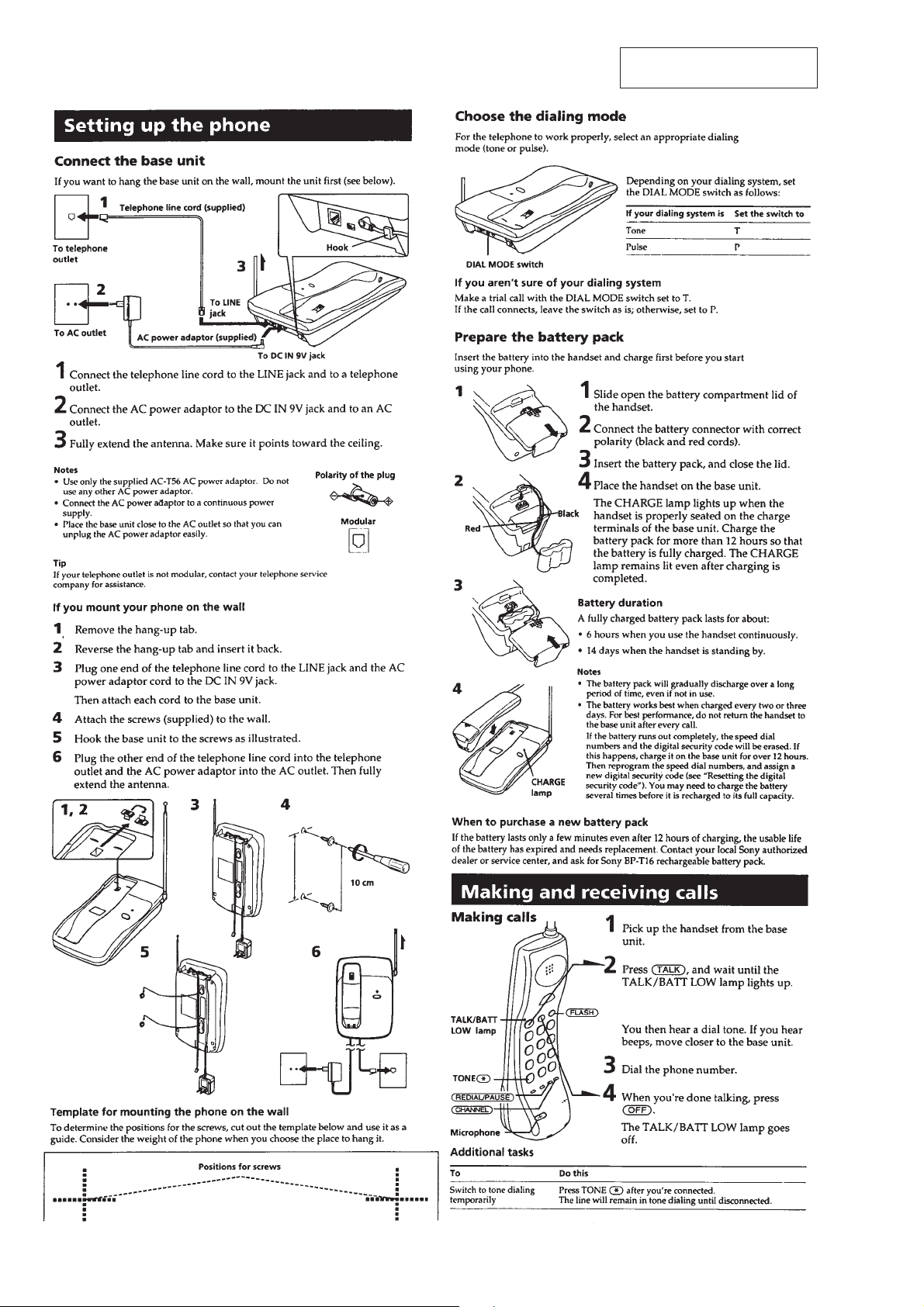

GENERAL

This section is extracted from

instruction manual.

– 4 –

Page 5

– 5 –

Page 6

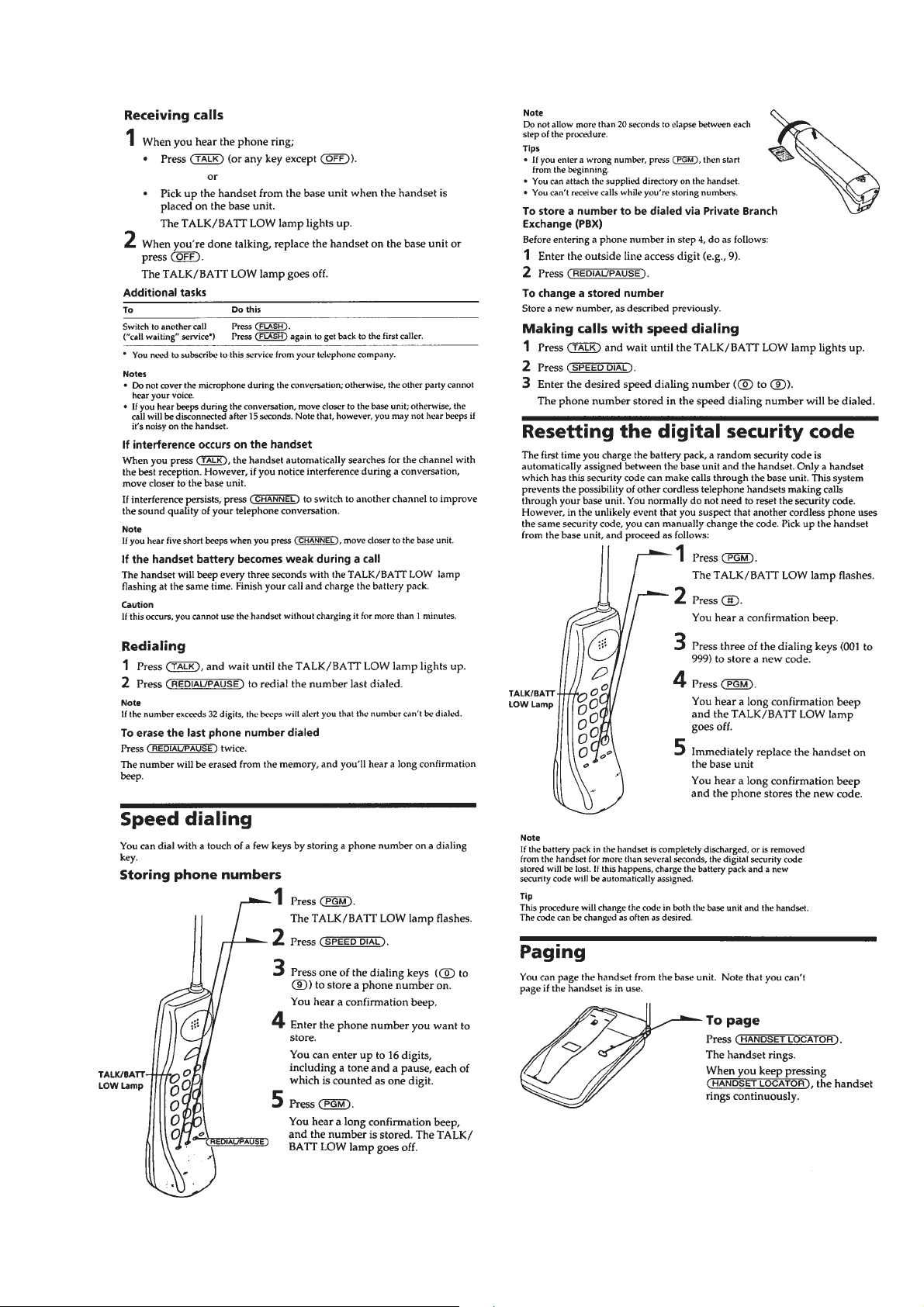

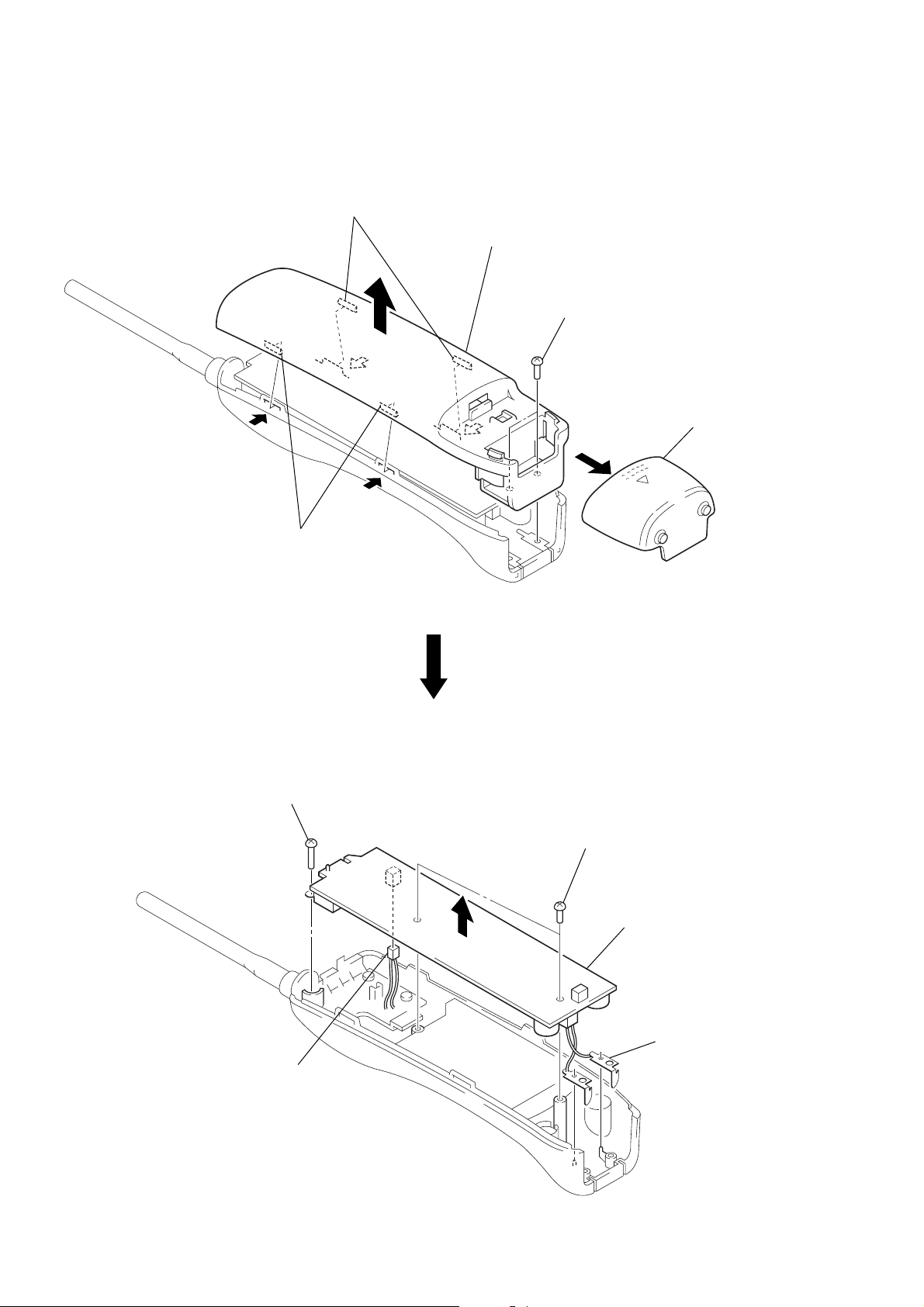

SECTION 3

d

y

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

• HANDSET

REAR CABINET

3

two claws

A

4

Removal the rear cabinet to

direction of the arrow

2

two screws

(BTP2.6

A

.

×

8)

1

battery case li

HAND MAIN BOARD

1

screw

(BTP2.6

3

two claws

×

12)

2

two screws

(BTP2.6

×

8)

3

HAND MAIN board

5

connector

(CN101)

– 6 –

4

terminal ass’

(charge)

Page 7

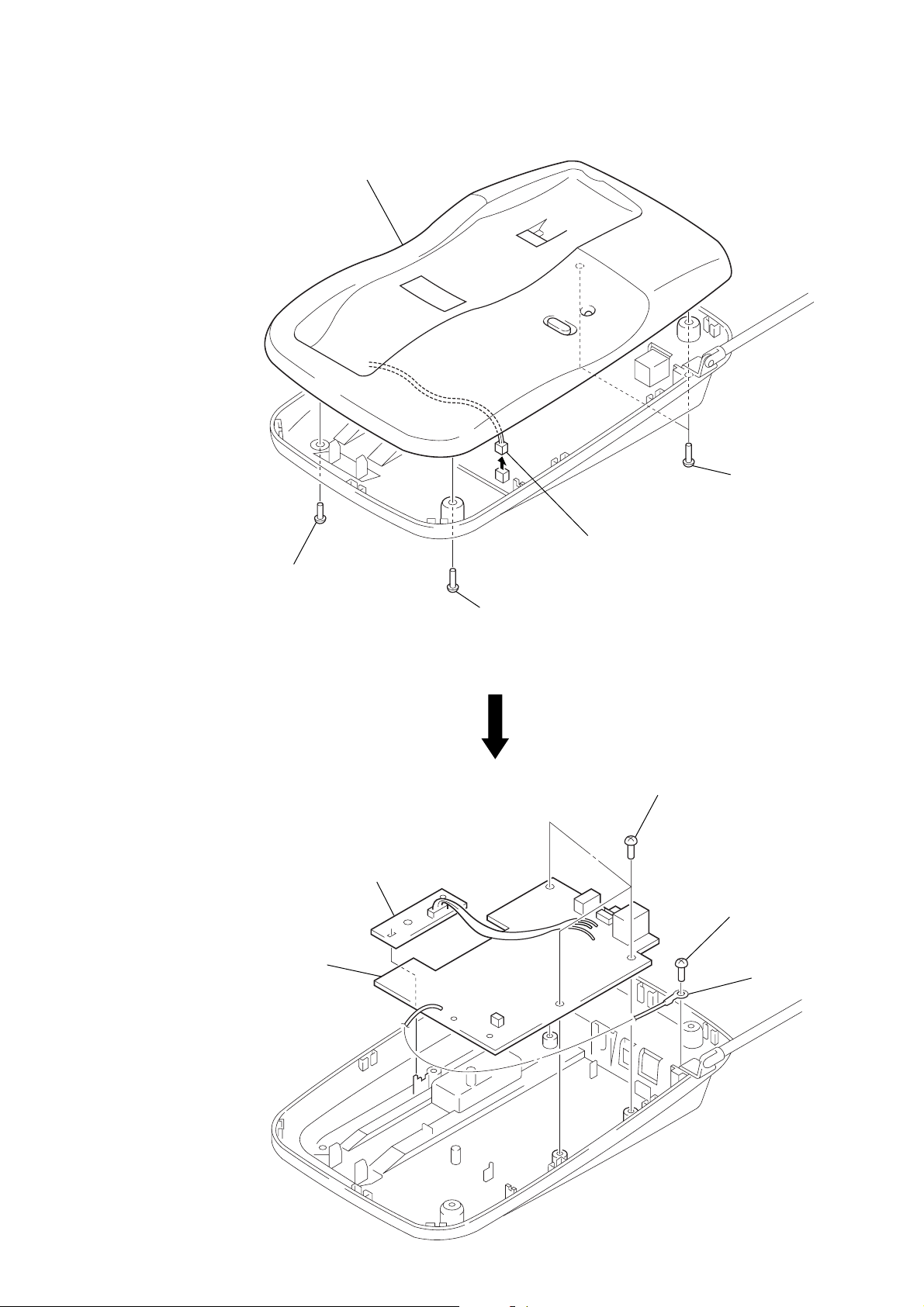

• BASESET

l

BASESET (UPPER) ASS’Y

1

2

baseset (upper) ass’y

screw

(P3

×

10)

1

screw

(P3

×

10)

3

connector

(CN301)

1

two screws

(P3

×

10)

BASE MAIN BOARD

4

BASE MAIN board

4

SUB board

1

three screws

(BTP2.6

×

8)

2

screw

(BTP2.6

3

ring termina

×

8)

– 7 –

Page 8

SECTION 4

)

TEST MODE

4-1. BASE UNIT SECTION

<Enter the Test Mode>

Manual T est Mode

1. Set the [DIALMODE] switch to “P” (pulse).

2. While pressing the [PAGE] key, switch on the power supply

(Reset start).

3. With the [PAGE] key, still held down, switch the [DIALMODE]

switch “P” (pulse) n “T” (tone) n “P” (pulse).

4. When you release the [PAGE] key, test mode starts.

5. Frist dial “0” at 10 pps. Then ouput “1”, “4”, “8” and “#”

with DTMF.

6. Set to TX ON. Goes to external line state in 1 CH.

• Release the Test Mode

1. Pull out the AC adapter and turn off the power.

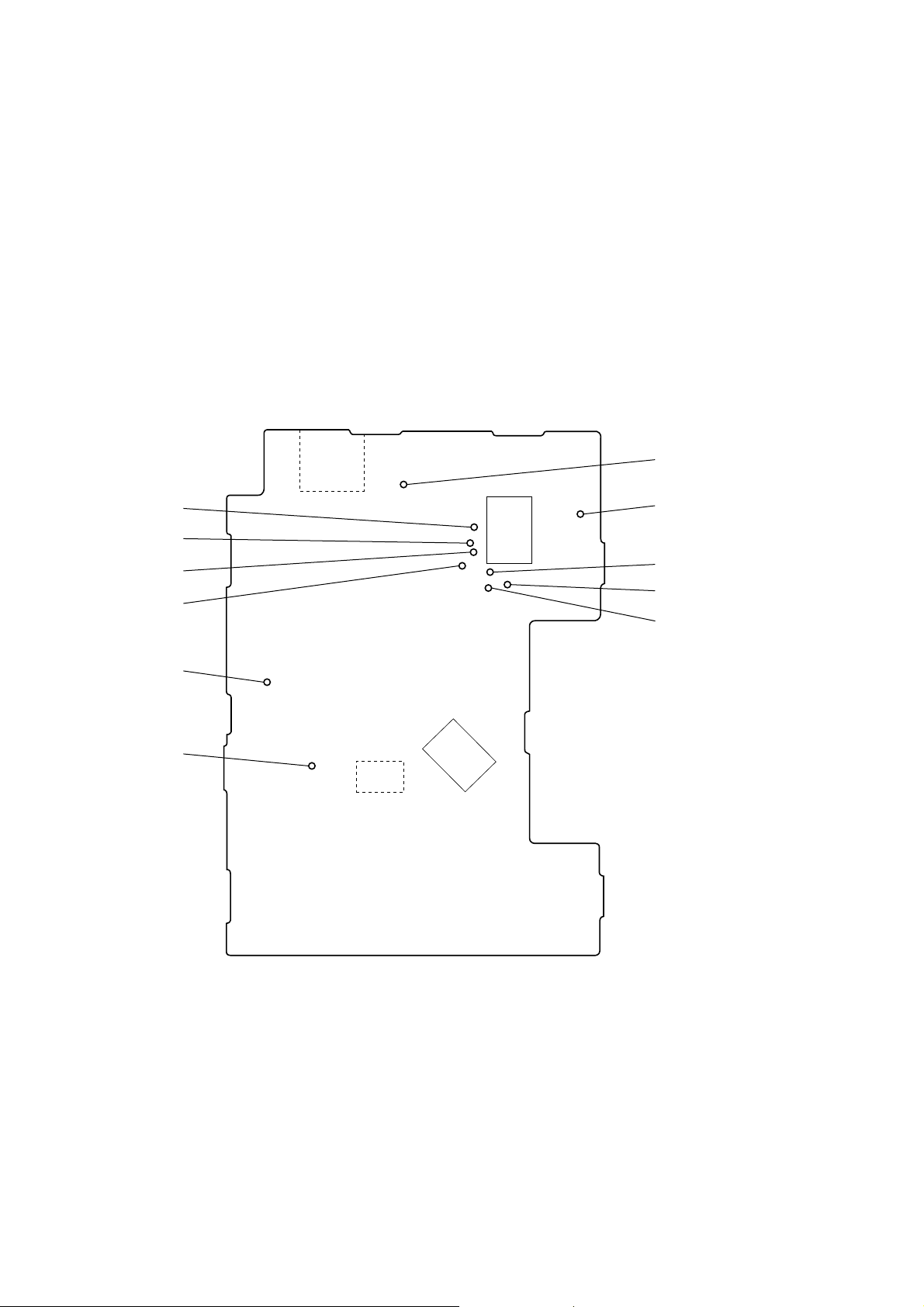

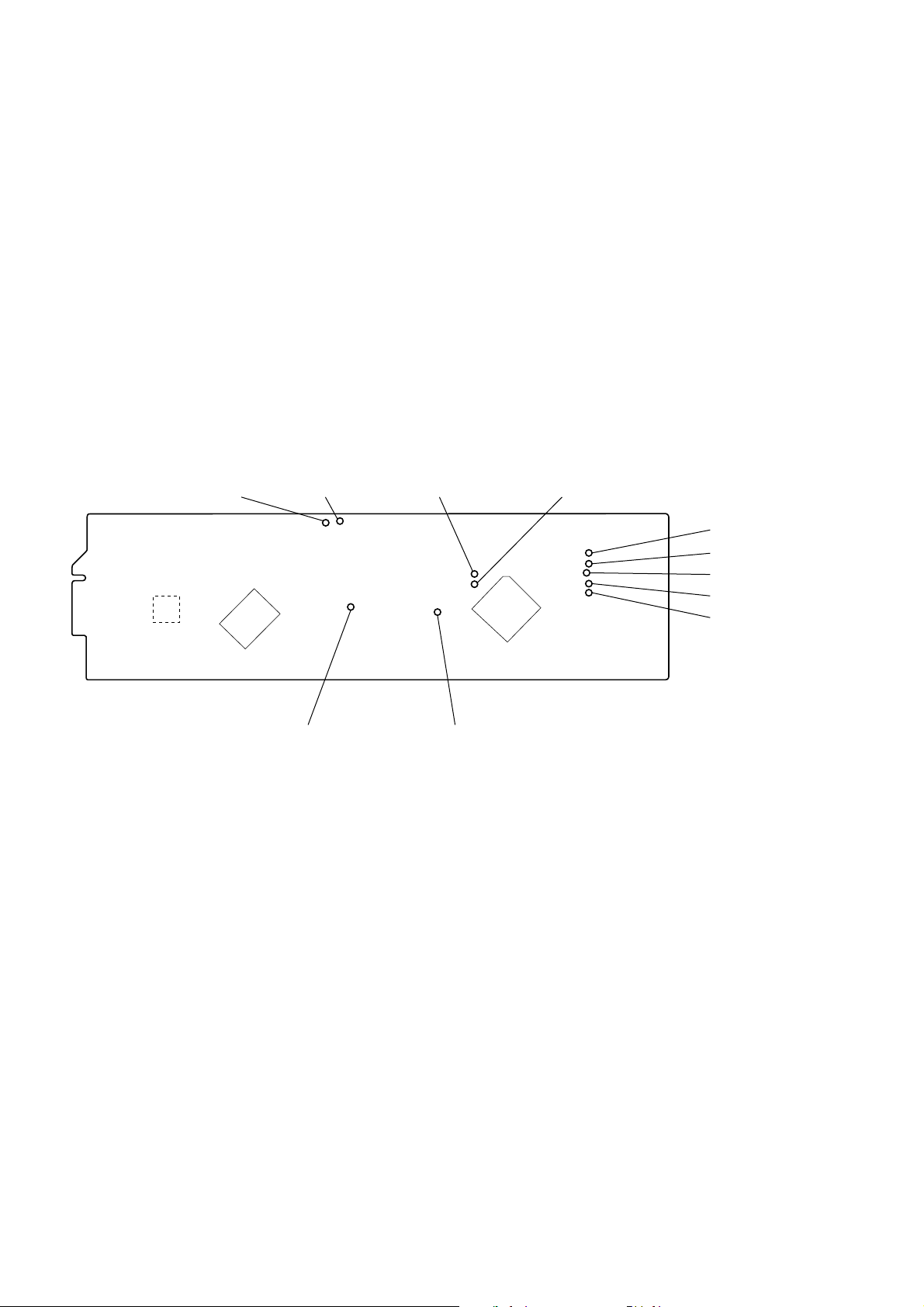

[BASE MAIN Board] (Conductor side)

Machine Test Mode

1. With one of the CH setting terminals in “H” input state, cause

Reset of Power ON. Equipment enters machine test mode.

2. Setting of CH according to logic input with CH setting terminal.

3. ON/OFF of TX is according to the input logic of the Dial Mode

terminal.

• Release the Test Mode

1. Pull out the AC adapter and turn off the power.

2. Remove the short plug and turn on the power again.

TP61 (M1)

TP62 (M2)

TP63 (M3)

TP66 (TEST2)

TP21 (CHG DET)

TP46 (PAGE)

MJ201

TP47 (DIAL MODE

TP106 (5V)

IC501

TP67 (TEST1)

TP64 (M4)

TP65 (TEST3)

IC101

CF101

– 8 –

Page 9

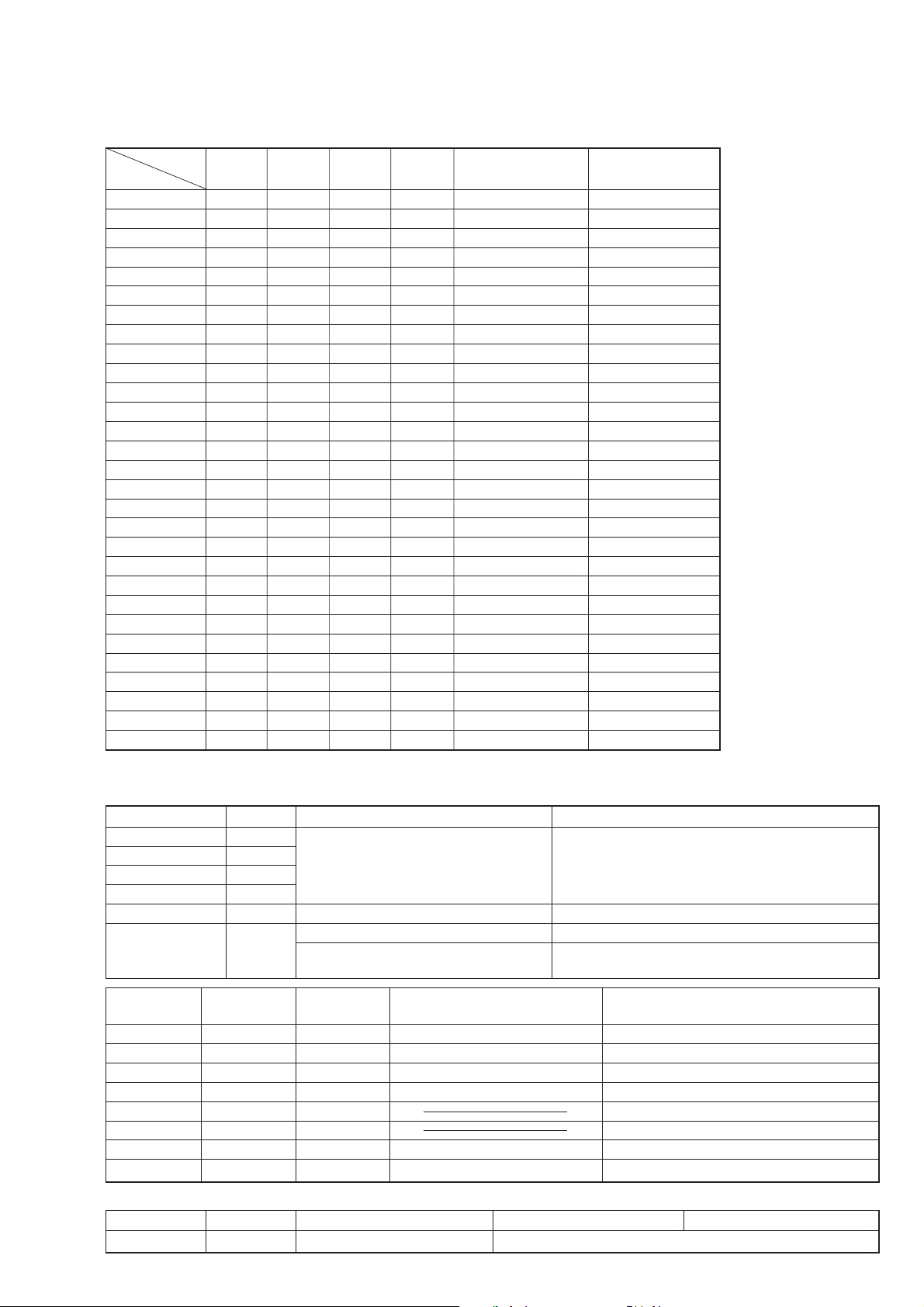

Channel Setting

During startup in machine test mode, make the following channel settings by loading the terminal input data.

Pin No. @£ @¢ @∞ @§ TX Frequency RX Frequency

Channel M1 (TP61) M2 (TP62) M3 (TP63) M4 (TP64) (MHz) (MHz)

CH1 H L L L 43.720 48.760

CH2 L H L L 43.740 48.840

CH3 H H L L 43.820 48.860

CH4 L L H L 43.840 48.920

CH5 43.920 49.020

CH6 43.960 49.080

CH7 44.120 49.100

CH8 44.160 49.160

CH9 44.180 49.200

CH10 44.200 49.240

CH11 44.320 49.280

CH12 44.360 49.360

CH13 44.400 49.400

CH14 H L H L 44.460 49.460

CH15 L H H L 44.480 49.500

CH16 H H H L 46.610 49.670

CH17 L L L H 46.630 49.845

CH18 46.670 49.860

CH19 46.710 49.770

CH20 46.730 49.875

CH21 46.770 49.830

CH22 46.830 49.890

CH23 H L L H 46.870 49.930

CH24 L H L H 46.930 49.990

CH25 H H L H 46.970 49.970

TEST1 L L H H 43.780 48.800

TEST2 H L H H 43.890 48.970

TEST3 L H H H 46.800 49.910

TEST4 H H H H 46.900 49.950

Machine Test Mode Input/Output

1. Input (Input ports for other than main tasks)

Pin Name Pin No. Function Logic

M1 (TP61) @£

M2 (TP62) @¢

M3 (TP63) @∞

M4 (TP64) @§

DIAL MODE (TP47) !¶ Setting the TX ON/OFF H (T); OFF, L (P): ON

PAGE (TP46) !§ Machine: Dial data “5” is output to Key input with “L” input. The first time there is

TEST 1 (TP67) TEST 2 (TP66) TEST 3 (TP65)

@ª @• @¶

L L L If RSSI (H) is, detected: Light ON If RSSI (H) is, detected: Light ON

L L H If RSSI (L) is, detected: Light ON If RSSI (L) is, detected: Light ON

L H L If TX LOCK is detected: Light OFF If TX LOCK is detected: Light OFF

L H H If RX LOCK is detected: Light OFF If RX LOCK is detected: Light OFF

H L L BEEP output

H L H ID CODE output

H H L If RING is detected: Light ON If RING is detected: Light ON

H H H If PAGE KEY is input: Light ON If PAGE KEY is input: Light ON

Setting the CH (channel) Refer to channel setting

Manual: Channel increment Incrementing of channels in order from 16 to 25.

DTMF/DP exchange output of “5” with DTMF.

Operation with CHARGE LED Operation with TX ON

2. Output (Output ports for other than main tasks)

Pin Name Pin No. Function H Logic L Logic

CHARGE DET !• State in section 1. Input Refer to Section 1. Input

– 9 –

Page 10

4-2. HANDSET SECTION

)

)

)

)

)

<Enter the Test Mode>

Manual T est Mode

1. Enter the test mode by pressing [0] key while pressing the [1]

key and [TALK] when in idle condition.

(Key operation: [0] n [1] n [TALK] )

2. The RINGER will ring for 500msec when the test mode is

started.

3. Measurement mode of consumption current. (42# state. Refer

to 2-3)

4. Use key input to carry out the various settings.

5. Use port inputs to set output from LED terminals.

• Release the Test Mode

1. Press the [0], [0] and [#] key.

2. Turn OFF the power. (Remove the battery and replace them)

[HAND MAIN Board] (Conductor side)

L102

IC101

Machine Test Mode

1. When power on reset is applied while a H (high) is input to the

TEST SW (TP43) terminal (IC501 pin $º), the RING (Level

H, 500 msec) sounds.

2. Following that, at a timing in which the TEST SW terminal

has “H” (High) input, there is output of “L” by the CH (Channel) setting control terminal. Then there is PLL setting to the

CH which was read to with the CH setting terminal according

to that “L” output.

3. Set the TX setting to TX OFF.

4. The TX channel is used by voice, not by data.

5. Use port inputs to set output from LED terminals

• Release the Test Mode

1. Turn off the power.

2. Remove the short plug and turn on the power.

TP44 (TEST ACT)TP43 (TEST SW)TP36 (H)TP35 (TALK LED)

TP13 (ROW 5

TP14 (ROW 4

TP15 (ROW 3

IC501

TP16 (ROW 2

TP17 (ROW 1

TP55 (KEY LED)

TP33 (TEST CH)

– 10 –

Page 11

Channel Setting

During startup in machine test mode, make the following channel settings by loading the terminal input data.

Pin No. #¢ #£ #™ #¡ @ª RX Frequency TX Frequency

Channel ROW 5 (TP13) RO W 4 (TP14) ROW 3 (TP15) ROW 2 (TP16) RO W 1 (TP17) (MHz) (MHz)

CH1HLLLL 43.720 48.760

CH2 H L L L H 43.740 48.840

CH3 H L L H L 43.820 48.860

CH4 H L L H H 43.840 48.920

CH5 H L H L L 43.920 49.020

CH6 H L H L H 43.960 49.080

CH7 H L H H L 44.120 49.100

CH8 H L H H H 44.160 49.160

CH9 H H L L L 44.180 49.200

CH10 H H L L H 44.200 49.240

CH11 H H L H L 44.320 49.280

CH12 H H L H H 44.360 49.360

CH13 H H H L L 44.400 49.400

CH14 H H H L H 44.460 49.460

CH15 H H H H L 44.480 49.500

CH16 L L H H L 46.610 49.670

CH17 L L H H H 46.630 49.845

CH18 L H L L L 46.670 49.860

CH19 L H L L H 46.710 49.770

CH20 L H L H L 46.730 49.875

CH21 L H L H H 46.770 49.830

CH22 L H H L L 46.830 49.890

CH23 L H H L H 46.870 49.930

CH24 L H H H L 46.930 49.990

CH25 L H H H H 46.970 49.970

TEST1 L L L H L 43.780 48.800

TEST2 L L L H H 43.890 48.970

TEST3 L L H L L 46.800 49.910

TEST4 L L H L H 46.900 49.950

Machine Test Mode Input/Output

1. Input (Input ports for other than main tasks)

Pin Name Pin No. Function Logic

ROW 1 (TP17) @ª

ROW 2 (TP16) #¡

ROW 3 (TP15) #™ Setting the CH (channel) Refer to channel setting

ROW 4 (TP14) #£

ROW 5 (TP13) #¢

TEST CH (TP33) 1 Control terminal for setting the CH (channel) H: OFF, L: ON

TEST SW (TP43) $º Start up of test mode H: Start, L: No start

TEST ACT (TP44) $¢

During test mode, causes start of intermittent operation

with external input.

H: Intermittent start

2. Output (Output ports for other than main tasks)

Pin Name Pin No. Function H Logic L Logic

TALK LED (TP35) $•

KEY LED (TP55) 2

Various input/output monitor output (default: RSSI(H)

detection).

During test mode: All lights lit, However, does not include

measurement of consumption current.

No detection Detection

No light Light

– 11 –

Page 12

Key processing (Setting the manual test mode)

1. (Upper position) (Lower Position) Set with #.

2. 3X# can be substituted with X

.

Upper

position

Lower

position RF AF

0 QUIT 10ch 20ch Batt Alarm H A L T G KEY TEST

1 1ch 11ch 21ch CHARG DET Gg G G G

2 2ch 12ch 22ch GggGG

3 3ch 13ch 23ch gg G G G

4 4ch 14ch 24ch RX LOCK gggGG

5 5ch 15ch 25ch TX LOCK gg g g G

6 6ch 16ch T1ch RSSI (H) ggggg

7 7ch 17ch T2ch RSSI (L) – – – – –

8 8ch 18ch T3ch DATA TX – – – – –

9 9ch 19ch T4ch – – – – –

Purpose CH setting only

Application

0123 7

SIGOUT General

control operation

The standard is external line communication

state.

State for standard electrical adjustment process.

Condition

suveillance Measurement mode of consumption

with TALK current.

LED.

TX

RX RX

4

MIC Lk

• By pressing the CH key there is increment of the channel. However, this does not include the test channel.

• Control of the power source during 38# DATA TX is (TX&RX

RF&RX AF=ON) in 44# state.

• Control of the power source during the 70# key check mode is

41# state (TX OFF).

• For CH setting, SIGOUT control and power source control (with

the exception of above-mentioned 38# state) the state can be set

independently.

Example: In 15 c h, the order for carrying out TX modulation

level and RSSI (H) sensitivity setting is as follows:

The following are possible:15# n 44# n 36#

36# n 15# n 44#

44# n 36# n 15#

g: ON, G: OFF

Lk: KEY LED

– 12 –

Page 13

SECTION 5

d

d

d

level meter

600

Ω

+

–

PBX tester or

TP105

TP104

BASE MAIN

board

F.B.

DC 48 V

ELECTRICAL ADJUSTMENTS

5-1. BASE UNIT SECTION

• Apply 9 V dc from regulated DC power supply.

• Set to base unit machine test mode. (See page 8)

• Switch position:

SW302 (DIAL MODE): P (pulse)

TX Section Adjustment

• Perform the adjustment at T3CH (28CH: 46.8 MHz) as a rule.

Note: The electrolytic capacitor (10 µF/10 V) connected TP23 (DET) to

GND. (Only TX section adjustment)

BASE MAIN board

TP23 (DET)

10 µF

set

1. TX VT Adjustment

Setting:

digital voltmeter

+

–

+

BASE MAIN boar

TP6 (TX VT)

TP19 (GND)

RX Section Adjustment

1. RX Level Adjustment

• Perform the adjustment at T3CH (28CH: 49.910 MHz) as a rule.

Setting :

FM RF SSG

BASE MAIN boar

TP2

TP3 (RF GND)

Procedure :

1. FM RF SSG condition :

Carrier frequency : 49.910 MHz

Modulation frequency: 1 kHz

Deviation : 3 kHz

Output level : 60 dBµV (1 mV) (EMF)

2. Adjust the FL101 for the maximum reading on the level meter .

Also check that the output level is within the specified values.

Procedure :

1. The digital voltmeter connected TP6 (TX VT) to TP19 (GND).

2. Adjust the L52 for 2.2 ± 0.05 V reading on the digital voltmeter.

Adjustment Location: BASE MAIN board (See page 16)

Specified value: – 2.6 to – 10.6 dBV

Adjustment Location: BASE MAIN board (See page 16)

2. RX VT Adjustment

Setting:

digital voltmeter

BASE MAIN boar

+

–

TP5 (RX VT)

TP19 (GND)

Procedure :

1. The digital voltmeter connected TP5 (RX VT) to TP19 (GND).

2. Adjust the L101 for 2.4 ± 0.05 V reading on the digital voltmeter.

Adjustment Location: BASE MAIN board (See page 16)

– 13 –

Page 14

3. RSSI (H) Sensitivity Adjustment

d

T

d

)

• Perform the adjustment at T3CH (28CH: 49.910 MHz) as a rule.

Setting :

5-2. HANDSET SECTION

• Apply 4 V dc from regulated DC power supply.

• Set to handset machine test mode. (See page 10)

AF ocillator

output: 20 Hz

FM RF SSG

BASE MAIN boar

TP2

TP3 (RF GND)

Procedure :

1. FM RF SSG condition :

Carrier frequency : 49.910 MHz

Modulation frequency: 20 Hz (EXT)

Deviation : AM 50%

Output level : 60 dBµV (1mV) (EMF)

2. Use the oscilloscope to confirm the FM RF SSG input (AF)

signal waveform and RSSI signal, and use the RV101 so that

they are synchronized matched (duty is synchronized).

oscilloscope

(DC range)

BASE MAIN boar

+

–

RSSI WAVEFORM

TP9 (SIG OUT)

TP19

TX Section Adjustment

• Perform the adjustments at T1CH (26CH: 43.780 MHz) as a

rule.

1. TX VT Adjustment

Setting:

digital voltmeter

+

–

Procedure:

1. The digital voltmeter connected TP6 (TX VT) to TP3 (RX

GND).

2. Adjust the L52 for 0.9 V ± 0.05 V reading on the digital

voltmeter.

Adjustment Location: HAND MAIN board (See page 17)

TP6 (TX VT)

TP3 (RX GND

RSSI output waveform

0V

Adjust so that they

synchronize at 0V.

RF signal EX

signal 20Hz

Adjustment Location: BASE MAIN board (See page 16)

– 14 –

Page 15

RX Section Adjustment

d

RSSI WAVEFORM

RSSI output waveform

RF signal EXT

signal 20Hz

0V

Adjust so that they

synchronize at 0V.

)

1. RX Level Adjustment

• Perform the adjustment at T1CH (26CH: 43.780 MHz) as a rule.

Setting :

FM RF SSG

HAND MAIN board

TP2

TP3 (RX GND)

3. RSSI (H) Sensitivity Adjustment

• Perform the adjustment at T1CH (26CH: 43.780 MHz) as a

rule.

Setting :

AF ocillator

output: 20 Hz

FM RF SSG

HAND MAIN board

TP2

TP3 (RX GND)

Procedure :

1. FM RF SSG condition :

Carrier frequency : 43.780 MHz

Modulation : 1 kHz

Deviation : 3 kHz

Output level : 60 dBµV (1 mV) (EMF)

2. Adjust the FL101 for the maximum reading on the level meter .

Also check that the output level is within the specified values.

level meter

HAND MAIN boar

+

–

TP27 (SP)

TP26 (SP)

Specified value: –16.6 to –8.6 dBV

Adjustment Location: HAND MAIN board (See page 17)

2. RX VT Adjustment

Setting:

digital voltmeter

+

–

TP5 (RX VT)

TP3 (RX GND

Procedure:

1. The digital voltmeter connected TP5 (RX VT) to TP3 (RX

GND).

2. Adjust the L102 for 0.8 V ± 0.05 V reading on the digital

voltmeter.

Procedure :

1. FM RF SSG condition :

Carrier frequency : 43.780 MHz

Modulation frequency : 20 Hz (EXT)

Deviation : AM 50%

Output level : 2 dBµV (1.259 µV) (EMF)

2. Use the oscilloscope to confirm the FM RF SSG input (AF)

signal waveform and RSSI signal, and use the RV101 so that

they are synchronized matched (duty is synchronized).

oscilloscope

(DC range)

HAND MAIN board

+

–

TP9 (SIG IN)

TP3 (RX GND)

Adjustment Location: HAND MAIN board (See page 17)

Adjustment Location: HAND MAIN board (See page 17)

– 15 –

Page 16

Adjustment Location :

t

[BASE MAIN Board] (Component Side)

FL101 RX Level Adjustment

L101 RX VT Adjustment

L52 TX VT Adjustment

[BASE MAIN Board] (Conductor Side)

TP2

TP3 (RF GND)

RV101 RSSI (H) Sensitivity Adjustmen

TP5

(RX VT)

TP6 (TX VT)

IC101

TP9 (SIG OUT)

IC501

CF101

TP19 (GND)

TP105

TP104

MJ201

– 16 –

Page 17

Adjustment Location :

[HAND MAIN Board] (Component Side)

L102 RX VT Adjustment

FL101 RX Level Adjustment

[HAND MAIN Board] (Conductor Side)

TP26 (SP)

TP27 (SP)

TP3 (RX GND)

TP2

RV101 RSSI (H) Sensitivity Adjustment

L52 TX VT Adjustment

L102

TP5

(RX VT)

IC101

TP6 (TX VT)

IC501

TP9

(SIGIN)

– 17 –

Page 18

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM – BASE UNIT Section –

MIX, IF AMP, LIMITER AMP,

ANT1

TELESCOPIC

ANTENNA

RX FREQUENCY:

49.67 – 49.99MHz

B.P.F.

TX FREQUENCY:

46.61 – 46.97MHz

B.P.F.

BPF51

BPF1

(RX VCO)

RX SYSTEM B+

RF AMP

Q1

L101

RX VT

TX AMP

Q51

B.P.F.

BPF2

43

44

42

46

41

L52

(TX VCO)

TX VT

PLL, EXPANDER/COMPRESSOR

LO OUT

LO IN

CONTR

PD OUT

VCC2

TX VCO

Q52

IC101 (1/2)

MIX1

IN1

40

IC101

1ST

MIX

RX

VCO

RX

PLL

MODULATOR

MIX1

D51

OUT

38

10.68MHz

9

47

CF102

FIL OUT

PD

OUT

SPP-68

D205

RECT

HOOK ON/OFF

SWITCH

PH202

HOOK ON/OFF

Q201

• SIGNAL PATH

: RX

: TX

: BELL

RINGER

DETECT

PH201

MJ201

LINE

FL101

(DET)

RX LEVEL

28

MIX2

MIX2

IN

36

2ND

MIX

LOCAL

OSCILLATOR

TX

SPLATTER

TX

PLL

OUT

CF101

460kHz

34

LO1

LO2

FIL IN

3

4

IF

IN

32

X101

10.22MHz

AMP

IF

11

QUADRATURE

DETECTOR

RSSI

COMP

OUT

QUAD

TX

MUTE

CARRIER

DETECTOR

AF

OUT

L.P.F.

SIG

OUT

RSSI

H/L

COMPRESSOR/

LIMITER

27

22

RV101

RSSI (H)

SENSITIVITY

MIC

IN

MIC AMP

1410

IC101 (2/2)

PRE

IN

15

COMP

IN

24

PREAMP

DATA

COMP

EXPANDER

DA OUT

23

CPU

INTERFACE

DATA

CLK

CLK

DATA

LATCH

8567

LATCH

RX

MUTE

EXP

OUT

AMP

SIDE TONE

CANCEL

AMP

OUT

AMP

OUT

19

20

T201

LINE TRANSFORMER

+

LINE TX

DRIVE

Q203

SWITCH CONTROL

AMP

IN

17

+

D101

RECEIVER

18

TEL AMP

Q202

TVCOIN

1

X501

4.048MHz

10

9

OSC1

OSC2

PAGE

16

05

S301

PAGE

DIALMODE

17 12

SW302

DIAL MODE

T

P

7

TX-DATA

SYSTEM CONTROLLER

IC501

19

RSSI H/L

5

SIG-IN

6

H-MUTE

CLK

DATA

LATCH

2

3

CHG-DET

TX +B CTRL

DATA

CLK

RESET

1

STB

RESET

SWITCH

Q302

TX SYSTEM B+

B+

21

POW-DET

DTMF

VOLTAGE

DETECT

IC301

B+ SWITCH

Q54

REGULATOR

Q301

REGULATOR

Q601

4 20

RX-DATA

18 22 14

DP

–

30

RING

J301

DC IN 9V

+

D401

POWER

CHARGE/IN USE

– 19 – – 20 –

REGULATOR

CHARGE DETECT

Q401

CHARGE

Q402

CURRENT

LIMITER

Q403

+

CHARGE

TERMINAL

–

Page 19

SPP-68

6-2. BLOCK DIAGRAM – HANDSET Section –

MIX, IF AMP, LIMITER AMP,

ANT2

RX FREQUENCY:

46.61 – 46.97MHz

B.P.F.

TX FREQUENCY:

49.67 – 49.99MHz

RX SYSTEM B+

B.P.F.

BPF51

BPF1

L102

(RX VCO)

RX VT

RF AMP

Q1

D101

TX AMP

Q51

B.P.F.

BPF2

43

44

42

46

41

L52

(TX VCO)

TX VT

PLL, EXPANDER/COMPRESSOR

LO OUT

LO IN

CONTR

PD OUT

VCC2

TX VCO

Q52

IC101 (1/2)

MIX1

IN1

40

IC101

1ST

MIX

RX

VCO

RX

PLL

MODULATOR

D51

MIX1

OUT

38

CF102

10.66MHz

FIL OUT

9

PD

OUT

47

TVCOIN

1

FL101

(DET)

RX LEVEL

• SIGNAL PATH

: RX

: TX

: BELL

28

MIX2

MIX2

IN

36

2ND

MIX

LOCAL

OSCILLATOR

TX

SPLATTER

TX

PLL

OUT

CF101

460kHz

34

LO1

LO2

FIL IN

3

4

IF

IN

32

X101

10.22MHz

AMP

IF

11

QUADRATURE

DETECTOR

RSSI

COMP

OUT

QUAD

TX

MUTE

CARRIER

DETECTOR

AF

OUT

L.P.F.

SIG

OUT

RSSI

H/L

COMPRESSOR/

LIMITER

27

22

MIC AMP

RV101

RSSI (H)

SENSITIVITY

MIC

IN

1410

MIC1

IC101 (2/2)

PRE

IN

15

COMP

IN

24

PREAMP

DATA

COMP

EXPANDER

DA OUT

23

CPU

INTERFACE

DATA

CLK

CLK

DATA

LATCH

8567

LATCH

RX

MUTE

EXP

OUT

AMP

BATTERY

DETECT

BATTERY LOW

SWITCHING

Q502

AMP

OUT

AMP

OUT

BATT

19

20

IN

33

SP1

B+

BUZZER

DRIVE

Q301

BZ301

(BUZZER)

AMP

IN

17

RECEIVER

18

DET

OUT

21

B+

X501

4.048MHz

MIC

45

3 37

46

SIG-IN

H-MUTE

RSSI H/L

TX +B CTRL

13

HOLD/RESET

SWITCH

Q501

HOLD

12

B+

17

20

OSC1

OSC2

48

D501

TALK/

BATT LOW

05

LED

9

10

TX-DATA

TX-DATA

SYSTEM CONTROLLER

ROW1 – ROW5

29, 31 – 34

KEY MATRIX

(SEET KEY)

IC501

COL0 – COL3

24 – 27

COL3

28

8

RX-DATA

DATA

5

PLL-DATA

D502

CLK

7

PLL-CLK

D504

LATCH

4

PLL-STB

22

ACT3

RESET

21

MAIN

GROUND

TX SYSTEM B+

23

ACT4

BATT-LOW

RESET

SWITCH

Q201

GROUND ISOLATION

SWITCHING

B+

Q202

B+ SWITCH

Q54

VOLTAGE

DETECT

IC201

POWER

GROUND

11

BEEP

47

BATT-DET

D202

CHG-DET

38

+

CHARGE

TERMINAL

–

BT901

RECHARGEABLE

BATTERY PACK

(BP-T16)

– 21 – – 22 –

Page 20

6-3. NOTES FOR PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 9 V and fed with regulated dc power

• Power voltage is dc 12 V and fed with regulated dc power

• Power voltage is dc 3.6 V and fed with regulated dc power

• Voltages and wav eforms are dc with respect to ground in

• Voltages are taken with a VOM (Input impedance 10 M Ω).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

supply from external power voltage jack (J301 on the

BASE MAIN board).

supply from modular jack (MJ201 on the BASE MAIN

board) with 100 Ω in series.

supply from battery jack (CN201 on the HAND MAIN

board).

test mode.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

N : RX

O : TX

P : bell

: Impossible to measure

∗

4

W or less unless otherwise

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

¢

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

: internal component.

• Waveforms

– BASE MAIN Board –

1 IC101 3 (Test Mode)

1.4 Vp-p

97.8 ns

2 IC501 9 (OSC2) (Tset Mode)

3.1 Vp-p

247 ns

– HAND MAIN Board –

1 IC101 3 (Test Mode)

97.8 ns

2 IC501 @º (OSC2) (Tset Mode)

247 ns

680 mVp-p

3.6 Vp-p

– 23 –

– 24 –

Page 21

SPP-68

6-4. PRINTED WIRING BOARDS – BASE UNIT Section –

• Semiconductor

Location

Ref. No. Location

D1 H-3

D51 I-7

D101 C-4

D201 B-2

D203 C-2

D204 C-2

D205 C-1

D301 C-3

D401 E-2

D501 D-7

D602 C-3

IC101 F-5

IC301 A-7

IC501 B-6

PH201 C-3

PH202 D-2

Q1 H-3

Q51 I-5

Q52 I-6

Q54 I-5

Q201 E-2

Q202 D-4

Q203 D-1

Q301 C-4

Q302 A-6

Q401 I-1

Q402 F-2

Q403 F-2

– 25 – – 26 –

Page 22

6-5. SCHEMATIC DIAGRAM – BASE UNIT Section – • See page 24 for Waveforms.

SPP-68

– 27 – – 28 –

Page 23

SPP-68

6-6. PRINTED WIRING BOARD – HANDSET Section –

• Semiconductor Location

(Conductor Side)

Ref. No. Location

D51 A-3

D101 C-3

D202 B-13

D301 A-13

D501 D-6

D502 A-10

D504 A-11

IC101 B-4

IC201 D-13

IC501 B-10

Ref. No. Location

Q1 C-2

Q51 A-1

Q52 A-2

Q54 B-1

Q201 D-9

Q202 C-13

Q301 A-13

Q501 C-8

Q502 C-8

– 29 – – 30 –

Page 24

6-7. SCHEMATIC DIAGRAM – HANDSET Section – • See page 24 for Waveforms.

SPP-68

– 31 – – 32 –

Page 25

6-8. IC PIN FUNCTION DESCRIPTION

• BASE MAIN BOARD IC501 SB662106A-4J90-TLM (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

1 STB O PLL serial data latch pulse signal output to the TB31223F (IC101)

2 DATA O PLL serial data output to the TB31223F (IC101)

3 CLK O

4 RX-DATA I

5 SIG-IN I

6 H-MUTE O

7 TX-DATA O Transmit data output terminal

8 VSS —

9 OSC2 O

10 OSC1 I

11 VDD —

12 RESET I

13 TEST I

14 POW-DET I

15 MBR I

16 PAGE I

17 DIALMODE I

18 CHG-DET I

19 RSSI H/L O

20 DP O

21 DTMF O

22 TX +B CTRL O Power on/off control signal output of the transmit system “L”: power on

23 to 26 M1 to M4 I

27 TEST3 I

28 TEST2 I

29 TEST1 I

30 RING I

PLL serial data transfer clock signal output to the TB31223F (IC101)

Receive data input from the TB31223F (IC101)

Squelch signal (carrier detection signal) input from the TB31223F (IC101)

“L”: carrier present, “H”: no carrier

Halt muting on/off control signal output for the receiving data “L”: muting on

Ground terminal

Main system clock output terminal (4.048 MHz)

Main system clock input terminal (4.048 MHz)

Power supply terminal (+5V)

System reset signal input from the reset signal generator (Q302 and IC301) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Test terminal (fixed at “L”)

Power down detection signal input from the voltage detector (IC301) “L”: power down

Setting terminal for the make 30% or 40% select “L”: 40%, “H”: 30%

Fixed at “H” in this set

PAGE switch (S301) input terminal When key pressing: “L”

Detect signal input of the should dial in pulse mode or tone mode “L”: pulse, “H”: tone

Charge on/off detection signal input terminal “L”: charge on

RSSI sensitivity H/L selection signal output to the TB31223F (IC101) “L”: low sensitivity

Hook on/off control signal output terminal “H”: hook on

DTMF tone signal output terminal

Channel setting terminal for the test mode Normally: fixed at “L”

Setting terminal for the test mode-3

Setting terminal for the test mode-2

Setting terminal for the test mode-1

Detect signal input of the ringer coming “L”: ringer coming

• HAND MAIN BOARD IC501 SH66358C-4J91 (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

1 TEST CH O

2 KEY LED O

3 SIG-IN I

4 PLL-STB O PLL serial data latch pulse signal output to the TB31223F (IC101)

5 PLL-DATA O PLL serial data output to the TB31223F (IC101)

6NCO

7 PLL-CLK O

8 RX-DATA I

9, 10 TX-DATA O Transmit data output terminal

11 BEEP O

12 HOLD I

13 TX +B CTRL O

14 RX +B CTRL O

15 TEST I

16 VSS —

17 OSC1 I

18, 19 NC O

20 OSC2 O

21 RESET I

22 ACT3 O

23 ACT4 O

24 to 27 COL0 to COL3 I

28 MIC O

29 ROW1 O

30 NC O

31 to 34 ROW2 to ROW5 O

35, 36 NC O

37 BATT-LOW I

38 CHG-DET I

39 VDD —

40 TEST SW I

41 — I

42, 43 NC O

44 TEST ACT I

45 RSSI H/L O

46 H-MUTE O

47 BATT-DET I

48 LED O

Test mode channel control output terminal “H” active

LED drive signal output of the key illumination LED “L”: LED on Not used (open)

Squelch signal (carrier detection signal) input from the TB31223F (IC101)

“L”: carrier present, “H”: no carrier

Not used (open)

PLL serial data transfer clock signal output to the TB31223F (IC101)

Receive data input from the TB31223F (IC101)

Buzzer drive signal output terminal

Hold control signal input terminal “L”: hold Used for the released standby

Power on/off control signal output of the transmit system “L”: power on

Power on/off control signal output of the receiver system “L”: power on Not used (open)

Test terminal (fixed at “L”)

Ground terminal

Main system clock input terminal (4.048 MHz)

Not used (open)

Main system clock output terminal (4.048 MHz)

System reset signal input from the reset signal generator (Q201 and IC201) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Intermittent reception activation control output terminal “L” active

Intermittent reception activation control output terminal “L” active

Key return signal input from the key matrix When key pressing: “L”

Microphone bias control signal output terminal

Key send signal output to the key matrix

Not used (open)

Key send signal output to the key matrix

Not used (open)

Battery voltage detection signal input from the TB31223F (IC101) “L”: power down

Charge on/off detection signal input terminal “H”: charge on

Power supply terminal (+3.6V)

Start-up of the test mode “L”: no start, “H”: start Normally: fixed at “L”

Not used (fixed at “L”)

Not used (open)

During test mode, causes start of intermittent operation with external input

“H”: intermittent start Normally: fixed at “L”

RSSI sensitivity H/L selection signal output to the TB31223F (IC101) “L”: low sensitivity

Halt muting on/off control signal output for the receiving data “L”: muting on

Power down detection input terminal “L”: power down

LED drive signal output of the TALK/BATT LOW LED (D501) “L”: LED on

– 33 –

– 34 –

Page 26

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) HANDSET SECTION

ANT2

SP1

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

6

5

4

#1

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

7

#2

#1

3

11

2

13

14

1

Ref. No. Part No. Description Remark

1 3-935-513-01 CABINET (FRONT)

2 3-939-071-01 SPONGE (MICROPHONE)

* 3 3-935-522-01 CUSHION (SP) (2)

* 4 3-935-516-03 HOLDER (SPEAKER)

5 3-939-070-01 TERMINAL, ANTENNA

#1

8

12

10

Ref. No. Part No. Description Remark

9 3-370-982-01 FOOT (H) (TWN), RUBBER

10 3-935-520-01 CUSHION (BATTERY)

11 3-935-518-01 CUSHION (MICROPHONE)

12 3-935-517-01 TERMINAL ASSY, CHARGE

13 1-762-664-11 SWITCH, RUBBER KEY

9

* 6 A-3672-609-A HAND MAIN BOARD, COMPLETE

7 3-935-514-01 CABINET (REAR)

8 3-935-515-01 LID, BATTERY CASE

* 14 3-935-519-11 CUSHION (BUZZER)

ANT2 1-501-839-11 ANTENNA (HANDSET)

SP1 1-505-333-11 SPEAKER (2.1cm)

– 35 –

Page 27

(2) BASESET SECTION

59

52

58

#1

#1

54

53

55

Sub board

(included in

56

(including sub board)

56

)

ANT1

#1

#1

not

supplied

51

Ref. No. Part No. Description Remark

51 3-936-691-01 CABINET (LOWER)

52 3-936-695-01 TERMINAL (CHARGE)

53 3-027-558-21 CABINET (UPPER)

54 3-936-692-01 BUTTON (PAGE)

55 3-936-693-01 LENS

#3

#3

57

Ref. No. Part No. Description Remark

* 56 A-3672-611-A BASE MAIN BOARD, COMPLETE

57 3-936-696-21 FOOT, RUBBER

58 3-007-173-01 LABEL (TERMINAL CAUTION) (/S)

59 3-936-694-01 CLAW (WALL HOOK)

ANT1 1-501-511-11 ANTENNA, TELESCOPIC (BASESET)

– 36 –

Page 28

SECTION 8

ELECTRICAL PARTS LIST

BASE MAIN

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* A-3672-611-A BASE MAIN BOARD, COMPLETE

**************************

< BAND PASS FILTER >

BPF1 1-239-916-11 FILTER, BAND PASS

BPF2 1-233-692-11 FILTER, BAND PASS

BPF51 1-239-918-11 FILTER, BAND PASS

< CAPACITOR >

C2 1-163-031-11 CERAMIC CHIP 0.01MF 50V

C3 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C7 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C51 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C52 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C53 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C54 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C55 1-163-113-00 CERAMIC CHIP 68PF 5% 50V

C56 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C57 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C58 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C59 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C60 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C61 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C62 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C63 1-162-587-11 CERAMIC CHIP 0.039uF 10% 25V

C64 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C65 1-164-337-11 CERAMIC CHIP 2.2uF 16V

C66 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C67 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C68 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C69 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C70 1-163-099-00 CERAMIC CHIP 18PF 5% 50V

C71 1-163-224-11 CERAMIC CHIP 7PF 0.25PF 50V

C101 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C102 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

C103 1-163-106-00 CERAMIC CHIP 36PF 5% 50V

C105 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C106 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C107 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C108 1-126-964-11 ELECT 10uF 20% 50V

C109 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C110 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C111 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

C112 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

(Including SUB BOARD)

C113 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C114 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C115 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C116 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C117 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C118 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C122 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C123 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C125 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C127 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C128 1-126-964-11 ELECT 10uF 20% 50V

C129 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C130 1-126-791-11 ELECT 10uF 20% 16V

C131 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C133 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C134 1-126-791-11 ELECT 10uF 20% 16V

C135 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C136 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C137 1-126-791-11 ELECT 10uF 20% 16V

C138 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C201 1-136-193-11 FILM 0.47uF 10% 250V

C202 1-104-664-11 ELECT 47uF 20% 16V

C204 1-164-346-11 CERAMIC CHIP 1uF 16V

C205 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C206 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C209 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C210 1-126-960-11 ELECT 1uF 20% 50V

C211 1-163-034-00 CERAMIC CHIP 0.033uF 50V

C212 1-126-961-11 ELECT 2.2uF 20% 50V

C213 1-126-961-11 ELECT 2.2uF 20% 50V

C301 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C303 1-126-964-11 ELECT 10uF 20% 50V

C304 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C305 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C306 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C401 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C502 1-126-934-11 ELECT 220uF 20% 10V

C503 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C504 1-163-104-00 CERAMIC CHIP 30PF 5% 50V

C505 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

C506 1-163-104-00 CERAMIC CHIP 30PF 5% 50V

C604 1-163-033-00 CERAMIC CHIP 0.022uF 50V

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

– 37 –

Page 29

BASE MAIN

Ref. No. Part No. Description Remark

< FILTER >

CF101 1-760-418-11 FILTER, CERAMIC (460kHz)

CF102 1-767-129-81 FILTER, CERAMIC (10.68MHz)

< CONNECTOR >

* CN301 1-506-984-11 PIN, CONNECTOR (PC BOARD) 2P

* CN602 1-506-985-11 PIN, CONNECTOR (PC BOARD) 3P

< DIODE >

D1 8-719-991-33 DIODE 1SS133T-77

D51 8-719-055-14 DIODE KV1832CTR3

D101 8-719-991-33 DIODE 1SS133T-77

D201 8-719-991-33 DIODE 1SS133T-77

D203 8-719-109-89 DIODE RD5.6ESB2

D204 8-719-109-89 DIODE RD5.6ESB2

D205 8-719-820-97 DIODE U05G4B48

D301 8-719-109-97 DIODE RD6.8ES-B2

D401 8-719-059-87 LED SLR-342VRTB7

(POWER CHARGE/IN USE)

D501 8-719-991-33 DIODE 1SS133T-77

D602 8-719-109-89 DIODE RD5.6ESB2

< FILTER >

FL101 1-409-671-11 COIL, IFT

< IC >

Ref. No. Part No. Description Remark

< COIL >

L1 1-414-108-11 INDUCTOR 0.68uH

L51 1-408-958-21 INDUCTOR 1uH

L52 1-411-884-11 COIL, OSC

L101 1-409-798-11 COIL, OSC

L501 1-408-958-21 INDUCTOR 1uH

< MODULAR JACK >

MJ201 1-766-250-11 JACK, MODULAR (2C) 6P (LINE)

< PHOTO COUPTER >

PH201 8-719-156-73 PHOTO COUPLER PS2501-1LA

PH202 8-719-024-09 PHOTO COUPLER PS2532-1

< TRANSISTOR >

Q1 8-729-031-85 TRANSISTOR 2SC4365-34-TB

Q51 8-729-031-85 TRANSISTOR 2SC4365-34-TB

Q52 8-729-031-86 TRANSISTOR 2SC3142-J3J4-TB

Q54 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q201 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q202 8-729-106-68 TRANSISTOR 2SD1615A-GP

Q203 8-729-032-66 TRANSISTOR 2SC5069-TD

Q301 8-729-106-68 TRANSISTOR 2SD1615A-GP

Q302 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q401 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q402 8-729-106-68 TRANSISTOR 2SD1615A-GP

Q403 8-729-120-28 TRANSISTOR 2SC1623-L5L6

IC101 8-759-361-65 IC TB31223F

IC301 8-759-273-93 IC S-80740AL-A4-T1

IC501 8-759-487-52 IC SB662106A-4J90-TLM

< JACK >

J301 1-778-380-11 JACK, DC (POLARITY UNIFIED TYPE)

< SHORT >

JR1 1-216-295-00 SHORT 0

JR2 1-216-295-00 SHORT 0

JR3 1-216-296-00 SHORT 0

JR4 1-216-295-00 SHORT 0

JR5 1-216-296-00 SHORT 0

JR7 1-216-296-00 SHORT 0

JR8 1-216-296-00 SHORT 0

JR9 1-216-296-00 SHORT 0

JR10 1-216-295-00 SHORT 0

JR11 1-216-295-00 SHORT 0

JR12 1-216-296-00 SHORT 0

JR15 1-216-295-00 SHORT 0

JR16 1-216-295-00 SHORT 0

JR17 1-216-296-00 SHORT 0

JR18 1-216-296-00 SHORT 0

JR19 1-216-296-00 SHORT 0

JR20 1-216-295-00 SHORT 0

JR21 1-216-295-00 SHORT 0

JR22 1-216-295-00 SHORT 0

< RESISTOR >

R1 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R2 1-216-019-00 METAL CHIP 56 5% 1/10W

R3 1-216-025-00 RES, CHIP 100 5% 1/10W

R4 1-216-037-00 METAL CHIP 330 5% 1/10W

R51 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

(DC IN 9V)

R52 1-216-073-00 METAL CHIP 10K 5% 1/10W

R53 1-216-037-00 METAL CHIP 330 5% 1/10W

R54 1-216-025-00 RES, CHIP 100 5% 1/10W

R55 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R57 1-216-085-00 METAL CHIP 33K 5% 1/10W

R58 1-216-049-11 RES, CHIP 1K 5% 1/10W

R63 1-216-085-00 METAL CHIP 33K 5% 1/10W

R64 1-216-073-00 METAL CHIP 10K 5% 1/10W

R65 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R66 1-216-115-00 METAL CHIP 560K 5% 1/10W

R68 1-216-097-00 RES, CHIP 100K 5% 1/10W

R69 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R101 1-216-095-00 METAL CHIP 82K 5% 1/10W

R102 1-216-105-00 RES, CHIP 220K 5% 1/10W

R103 1-216-105-00 RES, CHIP 220K 5% 1/10W

R104 1-216-105-00 RES, CHIP 220K 5% 1/10W

R105 1-216-118-00 RES, CHIP 750K 5% 1/10W

R106 1-216-095-00 METAL CHIP 82K 5% 1/10W

R107 1-216-081-00 METAL CHIP 22K 5% 1/10W

R111 1-216-109-00 METAL CHIP 330K 5% 1/10W

R112 1-216-097-00 RES, CHIP 100K 5% 1/10W

R113 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R114 1-216-081-00 METAL CHIP 22K 5% 1/10W

– 38 –

Page 30

BASE MAIN HAND MAIN

Ref. No. Part No. Description Remark

R115 1-216-089-00 RES, CHIP 47K 5% 1/10W

R116 1-216-091-00 METAL CHIP 56K 5% 1/10W

R118 1-216-073-00 METAL CHIP 10K 5% 1/10W

R119 1-216-246-00 RES, CHIP 100K 5% 1/8W

R123 1-216-109-00 METAL CHIP 330K 5% 1/10W

R126 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R136 1-216-073-00 METAL CHIP 10K 5% 1/10W

R142 1-216-081-00 METAL CHIP 22K 5% 1/10W

R151 1-216-073-00 METAL CHIP 10K 5% 1/10W

R201 1-215-861-00 METAL OXIDE 47 5% 1W

R202 1-215-877-11 METAL OXIDE 22K 5% 1W

R204 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R206 1-216-174-00 RES, CHIP 100 5% 1/8W

R207 1-216-049-11 RES, CHIP 1K 5% 1/10W

R208 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R209 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R210 1-216-041-00 METAL CHIP 470 5% 1/10W

R211 1-216-178-00 RES, CHIP 150 5% 1/8W

R212 1-216-176-11 RES, CHIP 120 5% 1/8W

R213 1-216-178-00 RES, CHIP 150 5% 1/8W

R215 1-216-085-00 METAL CHIP 33K 5% 1/10W

R216 1-215-859-00 METAL OXIDE 22 5% 1W

R217 1-216-037-00 METAL CHIP 330 5% 1/10W

R301 1-216-033-00 METAL CHIP 220 5% 1/10W

R305 1-216-097-00 RES, CHIP 100K 5% 1/10W

R306 1-216-097-00 RES, CHIP 100K 5% 1/10W

R307 1-216-113-00 METAL CHIP 470K 5% 1/10W

R308 1-216-097-00 RES, CHIP 100K 5% 1/10W

R309 1-216-097-00 RES, CHIP 100K 5% 1/10W

R310 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R401 1-216-190-00 RES, CHIP 470 5% 1/8W

R402 1-216-025-00 RES, CHIP 100 5% 1/10W

R403 1-216-005-00 METAL CHIP 15 5% 1/10W

R404 1-216-005-00 METAL CHIP 15 5% 1/10W

R405 1-216-025-00 RES, CHIP 100 5% 1/10W

R406 1-216-073-00 METAL CHIP 10K 5% 1/10W

R408 1-216-041-00 METAL CHIP 470 5% 1/10W

R409 1-216-017-00 RES, CHIP 47 5% 1/10W

R411 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R503 1-216-073-00 METAL CHIP 10K 5% 1/10W

R505 1-216-049-11 RES, CHIP 1K 5% 1/10W

R506 1-216-049-11 RES, CHIP 1K 5% 1/10W

R507 1-216-049-11 RES, CHIP 1K 5% 1/10W

R508 1-216-097-00 RES, CHIP 100K 5% 1/10W

R509 1-216-117-00 METAL CHIP 680K 5% 1/10W

R510 1-216-246-00 RES, CHIP 100K 5% 1/8W

R513 1-216-075-00 METAL CHIP 12K 5% 1/10W

R514 1-216-073-00 METAL CHIP 10K 5% 1/10W

R515 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R522 1-216-097-00 RES, CHIP 100K 5% 1/10W

R523 1-216-097-00 RES, CHIP 100K 5% 1/10W

R524 1-216-097-00 RES, CHIP 100K 5% 1/10W

R525 1-216-097-00 RES, CHIP 100K 5% 1/10W

R526 1-216-097-00 RES, CHIP 100K 5% 1/10W

R527 1-216-097-00 RES, CHIP 100K 5% 1/10W

R528 1-216-097-00 RES, CHIP 100K 5% 1/10W

R604 1-216-029-00 METAL CHIP 150 5% 1/10W

Ref. No. Part No. Description Remark

< VARIABLE RESISTOR >

RV101 1-223-387-21 RES, ADJ, CARBON 330K

< SWITCH >

S301 1-571-977-11 SWITCH, TACTIL (PAGE)

SW302 1-692-991-11 SWITCH, SLIDE (DIAL MODE)

< TRANSFORMER >

T201 1-431-832-11 TRANSFORMER, LINE

< VIBRATOR >

X101 1-760-325-11 VIBRATOR, CRYSTAL (10.22MHz)

X501 1-760-324-11 VIBRATOR, CRYSTAL (4.048MHz)

************************************************************

* A-3672-609-A HAND MAIN BOARD, COMPLETE

***************************

3-935-517-01 TERMINAL ASSY, CHARGE

3-935-518-01 CUSHION (MICROPHONE)

3-939-070-01 TERMINAL, ANTENNA

< BAND PASS FILTER >

BPF1 1-239-918-11 FILTER, BAND PASS

BPF2 1-233-667-11 FILTER, BAND PASS

BPF51 1-239-916-11 FILTER, BAND PASS

< BUZZER >

BZ301 1-544-603-11 BUZZER

< CAPACITOR >

C2 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C3 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C4 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C51 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C52 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C53 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C54 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C55 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C56 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C57 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C58 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C59 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C60 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C61 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C62 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C63 1-162-587-11 CERAMIC CHIP 0.039uF 10% 25V

C64 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C65 1-164-337-11 CERAMIC CHIP 2.2uF 16V

C66 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C67 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C69 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C101 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C102 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C103 1-163-239-11 CERAMIC CHIP 33PF 5% 50V

C105 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C106 1-163-137-00 CERAMIC CHIP 680PF 5% 50V

– 39 –

Page 31

HAND MAIN

Ref. No. Part No. Description Remark

C107 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C108 1-126-964-11 ELECT 10uF 20% 50V

C109 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C110 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C111 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C112 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C113 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C115 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C116 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C117 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C118 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C119 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C120 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C121 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C122 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C123 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C125 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C127 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C128 1-126-791-11 ELECT 10uF 20% 16V

C129 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C130 1-126-791-11 ELECT 10uF 20% 16V

C131 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C132 1-126-791-11 ELECT 10uF 20% 16V

C133 1-165-319-11 CERAMIC CHIP 0.1uF 50V

Ref. No. Part No. Description Remark

< DIODE >

D51 8-719-055-14 DIODE KV1832CTR3

D101 8-719-055-14 DIODE KV1832CTR3

D202 8-719-938-75 DIODE SB05-05CP

D301 8-719-914-43 DIODE DAN202K

D501 8-719-059-87 LED SLR-342VRTB7 (TALK/BATT LOW)

D502 8-719-914-43 DIODE DAN202K

D504 8-719-941-04 DIODE SB007-03CP

< FILTER >

FL101 1-409-671-11 COIL, IFT (460kHz)

< IC >

IC101 8-759-361-65 IC TB31223F

IC201 8-759-082-66 IC S-80727AL-AQ-T1

IC501 8-759-487-53 IC SH66358C-4J91

< SHORT/RESISTOR >

JR101 1-216-296-00 SHORT 0

JR102 1-216-296-00 SHORT 0

JR103 1-216-296-00 SHORT 0

JR104 1-216-296-00 SHORT 0

JR105 1-216-296-00 SHORT 0

C134 1-126-924-11 ELECT 330uF 20% 6.3V

C136 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C137 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C138 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C140 1-126-791-11 ELECT 10uF 20% 16V

C141 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C142 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C143 1-162-638-11 CERAMIC CHIP 1uF 16V

C148 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C202 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C204 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C205 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C207 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C208 1-163-809-11 CERAMIC CHIP 0.047uF 10% 25V

C210 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C501 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C505 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C511 1-163-104-00 CERAMIC CHIP 30PF 5% 50V

C513 1-163-104-00 CERAMIC CHIP 30PF 5% 50V

C514 1-163-031-11 CERAMIC CHIP 0.01uF 50V

C515 1-107-682-11 CERAMIC CHIP 1uF 10% 16V

C516 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

< FILTER >

CF101 1-760-418-11 FILTER, CERAMIC (460kHz)

CF102 1-767-129-81 FILTER, CERAMIC (10.66MHz)

< CONNECTOR >

* CN101 1-506-984-11 PIN, CONNECTOR (PC BOARD) 2P

CN201 1-766-180-11 PIN, CONNECTOR (PC BOARD) 2P

* CN202 1-506-984-11 PIN, CONNECTOR (PC BOARD) 2P

JR106 1-216-296-00 SHORT 0

JR108 1-216-296-00 SHORT 0

JR110 1-216-296-00 SHORT 0

JR111 1-216-296-00 SHORT 0

JR112 1-216-296-00 SHORT 0

JR113 1-216-296-00 SHORT 0

JR114 1-216-296-00 SHORT 0

JR115 1-216-296-00 SHORT 0

JR116 1-216-296-00 SHORT 0

JR117 1-216-296-00 SHORT 0

JR119 1-216-296-00 SHORT 0

JR124 1-216-296-00 SHORT 0

JR127 1-216-296-00 SHORT 0

JR128 1-216-296-00 SHORT 0

JR129 1-216-296-00 SHORT 0

JR130 1-216-296-00 SHORT 0

JR133 1-216-222-00 RES, CHIP 10K 5% 1/8W

JR134 1-216-296-00 SHORT 0

JR135 1-216-296-00 SHORT 0

JR136 1-216-296-00 SHORT 0

JR137 1-216-296-00 SHORT 0

JR138 1-216-296-00 SHORT 0

JR140 1-216-296-00 SHORT 0

< COIL >

L1 1-408-958-21 INDUCTOR 1uH

L2 1-408-958-21 INDUCTOR 1uH

L52 1-411-883-11 COIL, OSC

L102 1-409-670-11 COIL, OSC

< MICROPHONE >

MIC1 1-542-118-11 MICROPHONE, ELECTRET CONDENSER

– 40 –

Page 32

HAND MAIN SUB

Ref. No. Part No. Description Remark

< TRANSISTOR >

Q1 8-729-031-86 TRANSISTOR 2SC3142-J3J4-TB

Q51 8-729-031-85 TRANSISTOR 2SC4365-34-TB

Q52 8-729-031-86 TRANSISTOR 2SC3142-J3J4-TB

Q54 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q201 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q202 8-729-028-27 FET 2SK2009 (TE85L)

Q301 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q501 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

Q502 8-729-026-49 TRANSISTOR 2SA1037AK-T146-R

< RESISTOR >

R1 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R2 1-216-033-00 METAL CHIP 220 5% 1/10W

R3 1-216-025-00 RES, CHIP 100 5% 1/10W

R4 1-216-049-11 RES, CHIP 1K 5% 1/10W

R5 1-216-041-00 METAL CHIP 470 5% 1/10W

R51 1-216-017-00 RES, CHIP 47 5% 1/10W

R52 1-216-073-00 METAL CHIP 10K 5% 1/10W

R53 1-216-037-00 METAL CHIP 330 5% 1/10W

R54 1-216-025-00 RES, CHIP 100 5% 1/10W

R55 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R57 1-216-085-00 METAL CHIP 33K 5% 1/10W

R58 1-216-049-11 RES, CHIP 1K 5% 1/10W

R63 1-216-085-00 METAL CHIP 33K 5% 1/10W

R64 1-216-073-00 METAL CHIP 10K 5% 1/10W

R65 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R66 1-216-112-00 RES, CHIP 430K 5% 1/10W

R68 1-216-097-00 RES, CHIP 100K 5% 1/10W

R69 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R101 1-216-093-00 METAL CHIP 68K 5% 1/10W

R102 1-216-105-00 RES, CHIP 220K 5% 1/10W

Ref. No. Part No. Description Remark

R203 1-216-097-00 RES, CHIP 100K 5% 1/10W

R204 1-216-097-00 RES, CHIP 100K 5% 1/10W

R205 1-216-073-00 METAL CHIP 10K 5% 1/10W

R301 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R501 1-216-073-00 METAL CHIP 10K 5% 1/10W

R502 1-216-073-00 METAL CHIP 10K 5% 1/10W

R503 1-216-073-00 METAL CHIP 10K 5% 1/10W

R504 1-216-073-00 METAL CHIP 10K 5% 1/10W

R505 1-216-073-00 METAL CHIP 10K 5% 1/10W

R506 1-216-097-00 RES, CHIP 100K 5% 1/10W

R507 1-216-041-00 METAL CHIP 470 5% 1/10W

R508 1-216-097-00 RES, CHIP 100K 5% 1/10W

R509 1-216-097-00 RES, CHIP 100K 5% 1/10W

R510 1-216-097-00 RES, CHIP 100K 5% 1/10W

R511 1-216-097-00 RES, CHIP 100K 5% 1/10W

R512 1-216-049-11 RES, CHIP 1K 5% 1/10W

R513 1-216-049-11 RES, CHIP 1K 5% 1/10W

R514 1-216-049-11 RES, CHIP 1K 5% 1/10W

R515 1-216-073-00 METAL CHIP 10K 5% 1/10W

R518 1-216-073-00 METAL CHIP 10K 5% 1/10W

R519 1-216-073-00 METAL CHIP 10K 5% 1/10W

R520 1-216-121-00 RES, CHIP 1M 5% 1/10W

R521 1-216-097-00 RES, CHIP 100K 5% 1/10W

R522 1-216-129-00 METAL CHIP 2.2M 5% 1/10W

R532 1-216-073-00 METAL CHIP 10K 5% 1/10W

R533 1-216-097-00 RES, CHIP 100K 5% 1/10W

R534 1-216-097-00 RES, CHIP 100K 5% 1/10W

R541 1-216-112-00 RES, CHIP 430K 5% 1/10W

R555 1-216-097-00 RES, CHIP 100K 5% 1/10W

< VARIABLE RESISTOR >

RV101 1-223-387-21 RES, ADJ, CARBON 330K

R103 1-216-105-00 RES, CHIP 220K 5% 1/10W

R104 1-216-101-00 METAL CHIP 150K 5% 1/10W

R105 1-216-117-00 METAL CHIP 680K 5% 1/10W

R106 1-216-049-11 RES, CHIP 1K 5% 1/10W

R107 1-216-077-00 METAL CHIP 15K 5% 1/10W

R108 1-216-246-00 RES, CHIP 100K 5% 1/8W

R109 1-216-097-00 RES, CHIP 100K 5% 1/10W

R110 1-216-097-00 RES, CHIP 100K 5% 1/10W

R111 1-216-109-00 METAL CHIP 330K 5% 1/10W

R112 1-216-093-00 METAL CHIP 68K 5% 1/10W

R113 1-216-083-00 METAL CHIP 27K 5% 1/10W

R114 1-216-093-00 METAL CHIP 68K 5% 1/10W

R115 1-216-081-00 METAL CHIP 22K 5% 1/10W

R116 1-216-097-00 RES, CHIP 100K 5% 1/10W

R118 1-216-073-00 METAL CHIP 10K 5% 1/10W

R119 1-216-121-00 RES, CHIP 1M 5% 1/10W

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R126 1-216-037-00 METAL CHIP 330 5% 1/10W

R127 1-216-085-00 METAL CHIP 33K 5% 1/10W

R128 1-216-085-00 METAL CHIP 33K 5% 1/10W

R130 1-216-081-00 METAL CHIP 22K 5% 1/10W

R141 1-216-206-00 RES, CHIP 2.2K 5% 1/8W

R142 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R201 1-216-295-00 SHORT 0

R202 1-216-113-00 METAL CHIP 470K 5% 1/10W

< VIBRATOR >

X101 1-760-326-11 VIBRATOR, CRYSTAL (10.2MHz)

X501 1-760-324-11 VIBRATOR, CRYSTAL (4.048MHz)

************************************************************

SUB BOARD

**********

(Included in BASE MAIN BOARD, COMPLETE)

< CAPACITOR >

C601 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C603 1-164-336-11 CERAMIC CHIP 0.33uF 25V

< DIODE >

D601 8-719-110-17 DIODE RD10ESB2

< TRANSISTOR >

Q601 8-729-106-68 TRANSISTOR 2SD1615A-GP

< RESISTOR >

R601 1-216-045-00 METAL CHIP 680 5% 1/10W

R602 1-249-415-11 CARBON 680 5% 1/4W

R603 1-249-415-11 CARBON 680 5% 1/4W

************************************************************

– 41 –

Page 33

SPP-68

Ref. No. Part No. Description Remark

MISCELLANEOUS

**************

13 1-762-664-11 SWITCH, RUBBER KEY

ANT1 1-501-511-11 ANTENNA, TELESCOPIC (BASESET)

ANT2 1-501-839-11 ANTENNA (HANDSET)

SP1 1-505-333-11 SPEAKER (2.1cm)

************************************************************

**************

HARDWARE LIST

**************

#1 7-685-134-19 SCREW +BTP 2.6X8 TYPE2 N-S

#2 7-685-136-19 SCREW +BTP 2.6X12 TYPE2 N-S

#3 7-685-647-79 SCREW +P 3X10 TYPE2 NON-SLIT

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

! 1-475-210-11 ADAPTOR, AC (AC-T56)

1-528-710-12 BATTERY, NICKEL CADMIUM(BP-T16)

1-696-454-11 CORD (WITH MODULAR PLUG) (LINE)

(2m15cm)

3-864-806-11 MANUAL, INSTRUCTION (ENGLISH, CHINESE)

3-936-680-01 LABEL (ADRESS)

Ref. No. Part No. Description Remark

X-3368-367-1 SCREW ASSY

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Sony Corporation

Personal & Mobile Communication Company9-926-018-11

– 42 –

Published by Quality Assurance Dept.

Printed in Japan © 1998. 9

98I0521-1

Loading...

Loading...