Sony SLM1, SDM-N80 Service Manual

SDM-N80

p

SERVICE MANUAL

SPECIFICATIONS

LCD panel Panel type: a-Si TFT Active Matrix

Picture size: 18.1 inch (46 cm)

Input signal format RGB operating frequency*

Horizontal: 28 – 107 kHz (analog

RGB signal)

28-92 kHz (digital RGB signal)

Vertical: 48 – 85 Hz**

Resolution** Horizontal: Max.1280 dots

Vertical: Max.1024 lines

Video input connector Analog RGB: HD15

Digital/analog RGB: DVI-I 29 pins

Input signal levels Analog RGB video signal

0.700 Vp-p, 75

SYNC signal

TTL level, 2 k

positive or negative

(Separate horizontal andvertical,

or composite sync)

0.3 Vp-p, 75

(Sync on green)

Digital RGB (DVI) video signal

TMDS (Single link)

Audio output 1 W × 2

Headphones jack Stereo minijack

Accepts impedance of 16 – 48

AUDIO IN jacks Stereo minijack × 2

Accepts impedance of 47 k

ts level 0.5 Vrms

Acce

Ω, positive

Ω,

Ω

,negative

Ω

Ω

Power requirements 100 – 240 V, 50 – 60 Hz, 0.7 – 0.4 A

Power consumption Max. 67 W

Operating temperature 5 – 35

Dimensions (w/h/d) Display (upright):

Mass Display:

Plug & Play DDC2B

* Recommended horizontal and vertical timing condition

Horizontalsyncwidth duty should be more than 4.8% oftotal

horizontal time or 0.8 µs, whichever is larger.

Horizontal blanking width should be more than 2.5 µsec.

Vertical blanking width should be more than 450 µsec.

**A 1600 × 1200 resolution signal is acceptable only when it is a

digital RGB signal and its vertical frequency is 60 Hz.

Design and specifications are subject to change without notice.

US Model

Canadian Model

AEP Model

Chassis No. SCC-L37A-A

SLM1

°

C

Approx. 432 400 195 mm

1

/

8

(17

Media engine:

Approx. 94 × 212 × 204 mm

3

/

4

× 8

(3

Approx. 6.5 kg (14 lb 5 oz)

Media engine:

Approx. 1.5 kg (3 lb 5 oz)

CHASSIS

3

3

/

4

× 8

/4inches)

× 7

1

/8inches)

× 15

3

/

8

TFT LCD COLOR COMPUTER DISPLAY

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values. Make sure your

instruments are accurate; be suspicious of your HV meter if sets always

have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC Leakage. Check leakage as

described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson 250

and Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

SDM-N80 (E) 2

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICH THE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ¡ ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION ARE

IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA BOBINE DE

DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET UNE

MARQUE ¡ SONT CRITIQUES POUR LA SÉCURITÉ. NE LES

REMPLACER QUE PAR UNE PIÈCE PORTANT LE NUMÉRO

SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

SDM-N80 (E) 3

POWER SAVING FUNCTION

This monitor meets the power-saving guidelines set by VESA,ENERGYSTAR, and NUTEK. If the monitor is connected to a computer

or video graphics board that is DPMS (Display Power Management Signaling) compliant, the monitor will automatically enter the power

saving mode. It automatically enters the low power consumption mode when the user sensor detects the absence of a user.

Power consumption state Power consumption AC power indicator (power) indicator

normal operation W green green

1 low power consumption mode W* green green and orange alternate

2 power saving mode W* orange orange

(power): off W red off

AC power: off 0 W off off

*Figures reflectpower consumption when the computer connected to the USB upstream connector on the monitor is turned off.

< 67

< 8.5

< 1.3

< 1

SDM-N80 (E) 4

1 Low power consumption mode (user sensor)

2 Power saving mode

When the user sensor in the monitor detects the absence of a user,

the monitor enters low power consumption mode after about 20

seconds.The icon of user sensor appears and flashes on the screen

before the monitor enters this mode. In low power consumption

mode, the monitor is in a power saving state and shuts off power

to all circuitry (except for that of the sensors) regardless of the

setting of the computer.

The monitor returns to normal operation mode when the presence

of a user is detected by the user sensor.

When the monitor enters the power saving mode (as set according

to the computer’s settings), the power saving mode takes

precedence over the low power consumption mode. In this case,

the monitor stays in the power saving mode regardless of the

presence or absence of a user.

To return the monitor to normal operation mode, reset the

computer’s power saving mode.

If the user sensor does not seem to function properly, refer to the

instructions on the next page.

DPMS defines the active off state according to the state of the

sync signals supplied from the computer. This monitor’s power

consumption is input at approximately 1.3 W or less in this state

if the power saving function is set to ON.

When your computer enters the power saving mode, the input

signal is cut and NO INPUT SIGNAL appears on the screen.

After a few seconds, the monitor enters power saving mode.

Power saving

Sync signal state

state

active off (deep sleep)* horizontal: off / vertical: off

* “Deep sleep” is a power saving mode defined by the Environmental

Protection Agency.

Notes

• The p ower saving function may not work normally depending on the

pattern of supplied sync signals. In such a case, set the power saving

function to OFF.

• When you connect a computer whose power is connected to the USB

upstream connector on the monitor, the monitor will not enter the

power saving mode.

SDM-N80 (E) 5

DIAGNOSIS

Failre

+B failure

Horizontal / Vertical Deflection

failure, Thermal protector

ABL protector

HV failure

Aging / Self Test

Out of scan range

Aging mode: In the NO INPUT SIGNAL state with the POWER SAVE MODE in OFF state, press the MENU continuously for 10

seconds.

Amber → Off

(0.5 sec) (0.5 sec)

Amber → Off

(1.5 sec) (0.5 sec)

Amber → Off

(0.5 sec) (1.5 sec)

Amber → Off → Amber → Off

(0.25 sec) (0.25 sec) (0.25 sec) (1.25 sec)

Amber → Off → Green → Off

(0.5 sec) (0.5 sec) (0.5 sec) (0.5 sec)

Green (OSD indication)

Power LED

SDM-N80 (E) 6

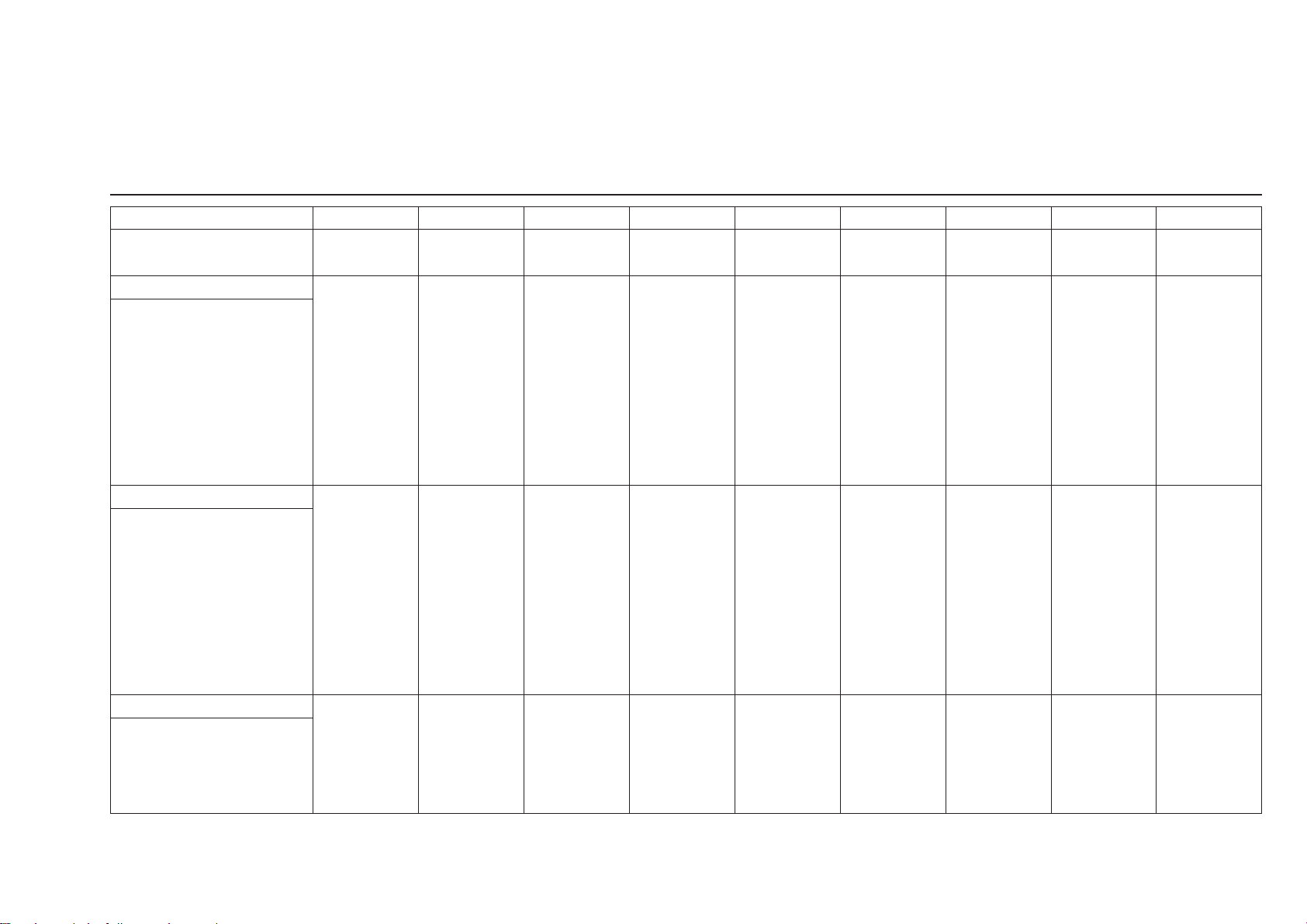

TIMING SPECIFICATION

MODE AT PRODUCTION

RESOLUTION

CLOCK

– HORIZONTAL –

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

– VERTICAL –

V. FREQ (Hz)

V. T OTA L

V. BLK

V. F P

V. SYNC

V. B P

V. ACTIV

– SYNC –

INT (G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

NIT/NON INT

MODE 0 MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7 MODE 8

640 X 480 640 X 480 640 X 480 640 X 480 720 X 400 720 X 400 720 X 480 800 X 600

25.175 MHz 30.240 MHz 31.500 MHz 36.000 MHz 28.350 MHz 35.500 MHz 31.505 MHz 36.000 MHz

31.469 kHz 35.000 kHz 37.500 kHz 43.269 kHz 31.500 kHz 37.927 kHz #DIV/01 35.162 kHz 35.156 kHz

usec usec usec usec usec usec usec usec usec

31.778 28.571 26.667 23.111 31.746 26.366 #DIV/01 28.44 28.444

6.356 7.407 6.349 5.333 6.349 6.085 #DIV/01 5.586 6.222

0.636 2.116 0.508 1.556 0.635 1.014 #DIV/01 1.079 0.667

3.813 2.116 2.032 1.556 3.81 2.028 #DIV/01 1.27 2

1.907 3.175 3.81 2.222 1.905 3.042 #DIV/01 3.282 3.556

25.422 21.164 20.317 17.778 25.397 20.282 #DIV/01 22.854 22.222

59.940 Hz 66.667 Hz 75.000 Hz 85.008 Hz 70.156 Hz 85.039 Hz #DIV/01 59.901 Hz 56.250 Hz

lines lines lines lines lines lines lines lines lines

525 525 500 509 449 446 #DIV/01 587 625

45 45 20 29 49 46 #DIV/01 107 25

10 3 1 1 12 1 #DIV/01 12 1

233333#DIV/01 2 2

33 39 16 25 34 42 #DIV/01 93 22

480 480 480 480 400 400 #DIV/01 480 600

NO NO NO NO NO NO NO NO NO

YES N/N YES N/N YES N/N YES N/N YES N/P YES N/P YES YES N/N YES N/N

NO NO NO NO NO NO NO NO NO

NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

SDM-N80 (E) 7

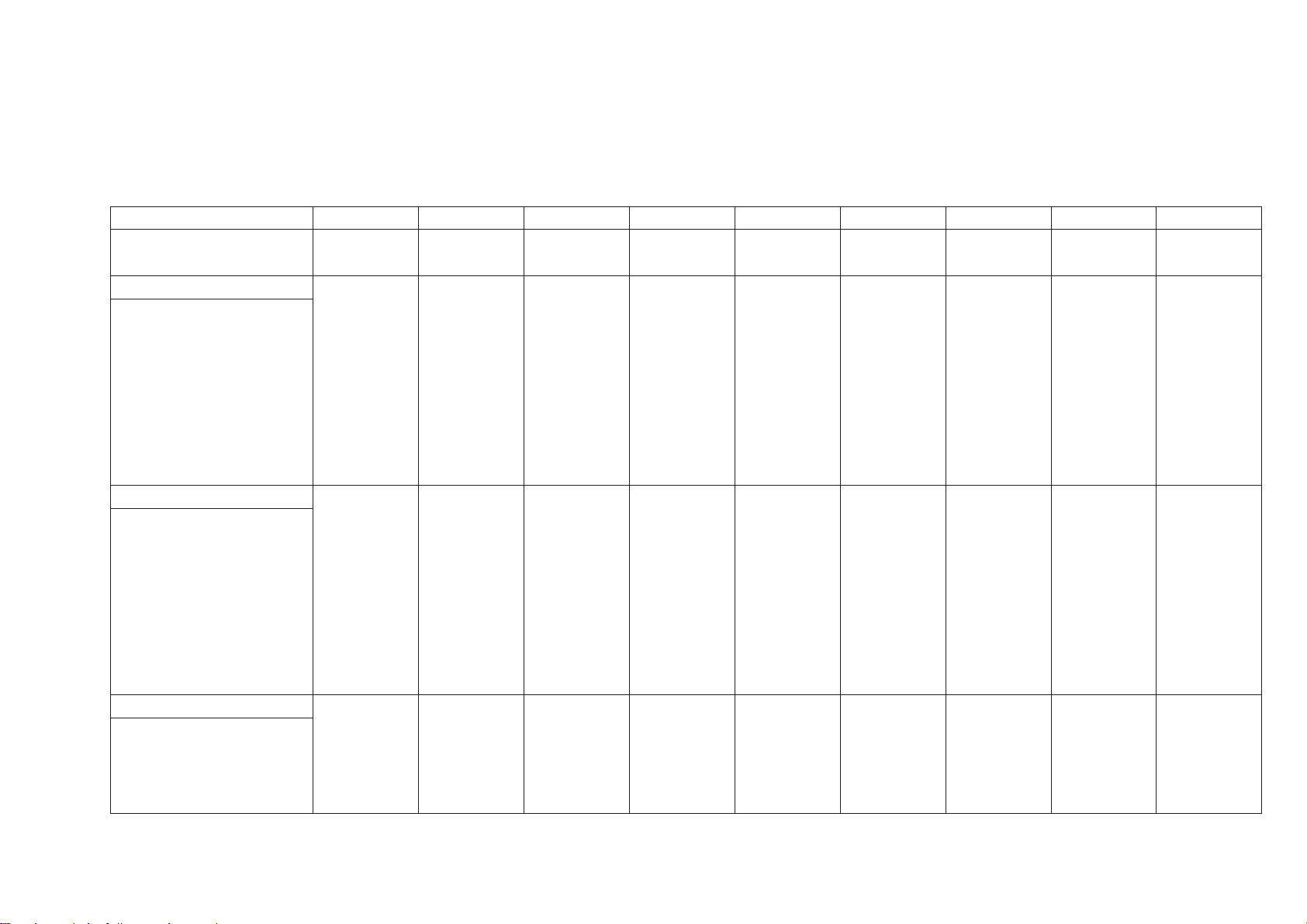

MODE AT PRODUCTION

RESOLUTION

CLOCK

– HORIZONTAL –

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

– VERTICAL –

V. FREQ (Hz)

V. T OTA L

V. BLK

V. F P

V. SYNC

V. B P

V. ACTIV

– SYNC –

INT (G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

NIT/NON INT

MODE 9 MODE 10 MODE 11 MODE 12 MODE 13 MODE 14 MODE 15 MODE 16 MODE 17

800 X 600 800 X 600 800 X 600 800 X 600 848 X 480 832 X 624 1024 X 768 1024 X 768 1024 X 768

40.000 MHz 49.500 MHz 56.250 MHz 57.299 MHz 49.847 MHz 57.285 MHz 65.000 MHz 75.000 MHz 78.750 MHz

37.879 kHz 46.875 kHz 53.674 kHz 54.675 kHz 45.900 kHz 49.727 kHz 48.363 kHz 56.476 kHz 60.023 kHz

usec usec usec usec usec usec usec usec usec

26.4 21.333 18.631 18.29 21.787 20.11 20.677 17.707 16.66

6.4 5.172 4.409 4.328 4.815 5.586 4.923 4.053 3.657

1 0.323 0.569 0.558 1.083 0.559 0.369 0.32 0.203

3.2 1.616 1.138 1.117 1.204 1.117 2.092 1.813 1.219

2.2 3.232 2.702 2.653 2.488 3.91 2.462 1.92 2.235

20 16.162 14.222 13.962 17.012 14.524 15.754 13.653 13.003

60.317 Hz 75.000 Hz 85.061 Hz 86.648 Hz 88.269 Hz 74.553 Hz 60.004 Hz 70.069 Hz 75.029 Hz

lines lines lines lines lines lines lines lines lines

628 625 631 631 520 667 806 806 800

28 25 31 31 40 43 38 38 32

111193331

433363663

23 21 27 27 25 37 29 29 28

600 600 600 600 480 624 768 768 768

NO NO NO NO NO NO NO NO NO

YES P/P NO P/P YES P/P YES P/P YES P/P YES N/N YES N/N YES N/N YES P/P

NO NO NO NO NO NO NO NO NO

NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

SDM-N80 (E) 8

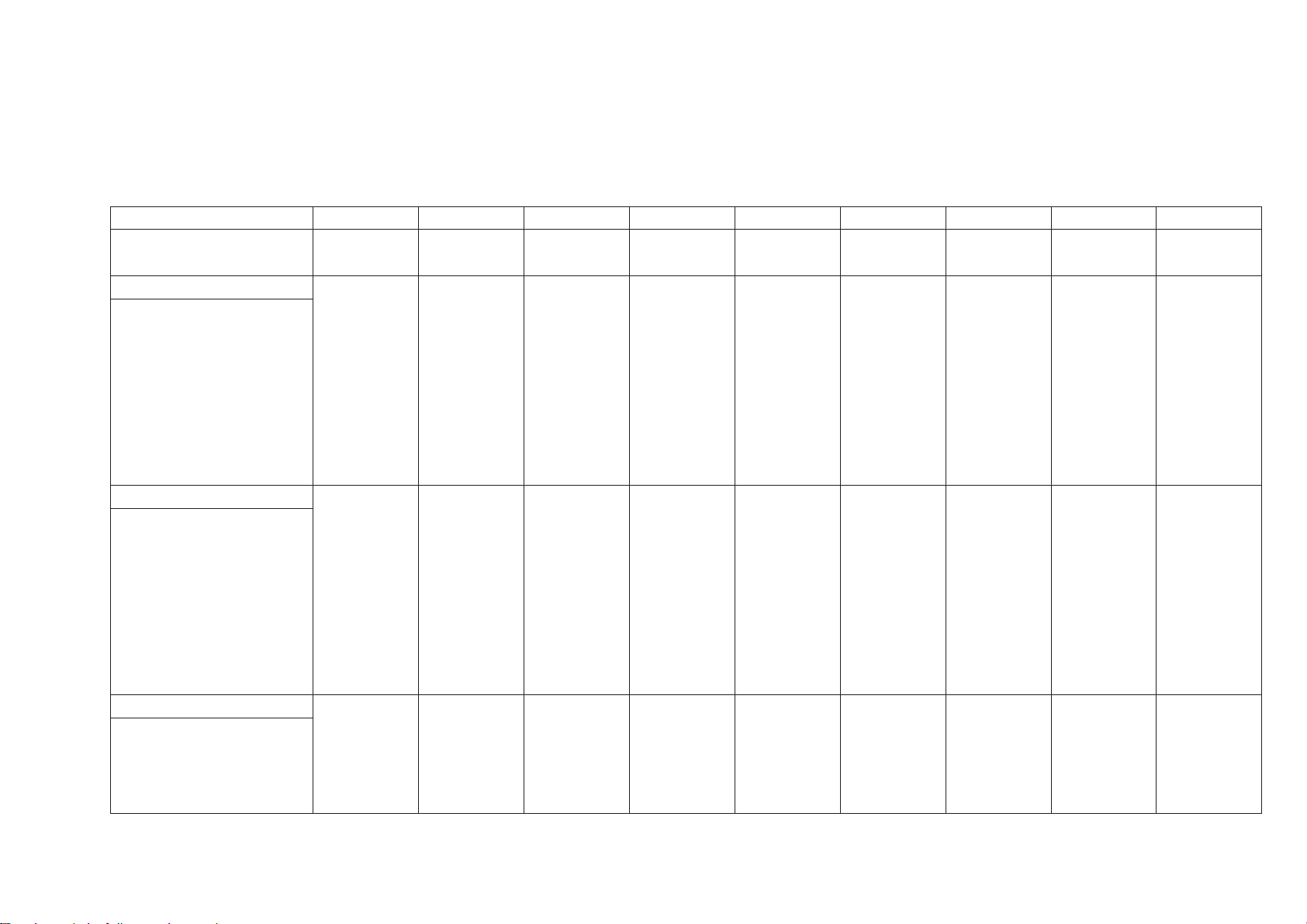

MODE AT PRODUCTION

RESOLUTION

CLOCK

– HORIZONTAL –

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

– VERTICAL –

V. FREQ (Hz)

V. T OTA L

V. BLK

V. F P

V. SYNC

V. B P

V. ACTIV

– SYNC –

INT (G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

NIT/NON INT

MODE 18 MODE 19 MODE 20 MODE 21 MODE 22 MODE 23 MODE 24 MODE 25 MODE 26

1024 X 768 1152 X 864 1152 X 864 1152 X 870 1120 X 750 1152 X 900 1152 X 900 1170 X 584 1024 X 800

94.500 MHz 108.000 MHz 121.500 MHz 100.000 MHz 78.430 MHz 92.940 MHz 105.590 MHz 46.200 MHz 92.940 MHz

68.677 kHz 67.500 kHz 77.487 kHz 68.681 kHz 50.019 kHz 61.795 kHz 71.732 kHz 31.216 kHz 70.838 kHz

usec usec usec usec usec usec usec usec usec

14.561 14.815 12.905 14.56 19.992 16.182 13.941 32.035 14.117

3.725 4.148 3.424 3.04 5.712 3.787 3.031 6.71 3.099

0.508 0.593 0.527 0.32 2.193 0.323 0.152 0.801 0.258

1.016 1.185 1.053 1.28 1.428 1.377 0.909 2.792 1.033

2.201 2.37 1.844 1.44 2.091 2.087 1.97 3.117 1.808

10.836 10.667 9.481 11.52 14.28 12.395 10.91 25.325 11.018

84.997 Hz 75.000 Hz 86.057 Hz 75.062 Hz 60.047 Hz 65.950 Hz 76.068 Hz 50.026 Hz 84.031 Hz

lines lines lines lines lines lines lines lines lines

808 900 911 915 833 937 943 624 843

40 36 47 45 83 37 43 40 43

1113272232

3333104838

36 32 43 39 46 31 33 34 33

768 864 864 870 750 900 900 584 800

NO NO NO NO NO NO NO NO NO

YES P/P YES P/P NO P/P YES N/N YES N/N YES N/N YES N/N YES N/N YES N/N

NO NO NO NO NO NO NO NO NO

NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

SDM-N80 (E) 9

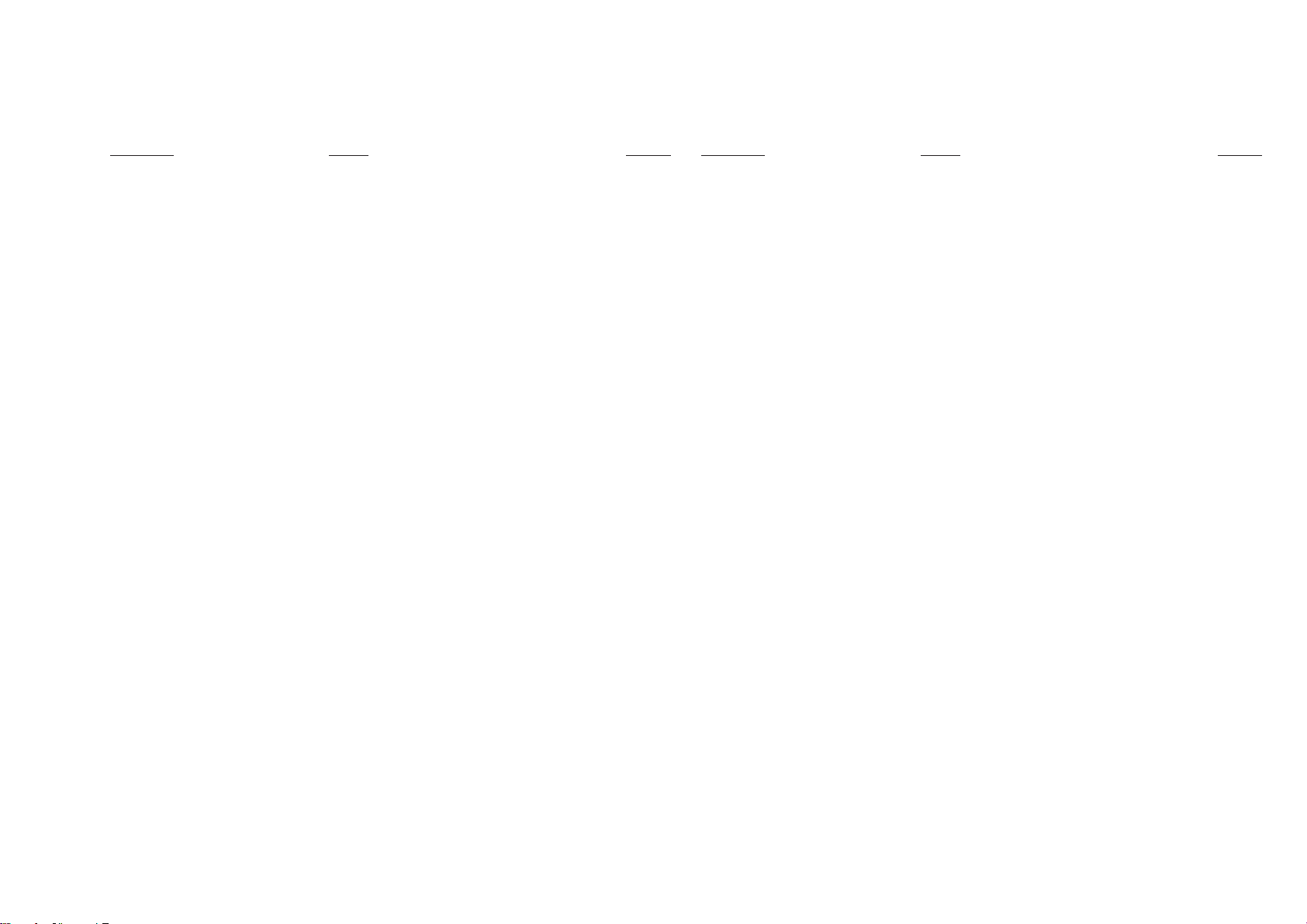

MODE AT PRODUCTION

RESOLUTION

CLOCK

– HORIZONTAL –

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

– VERTICAL –

V. FREQ (Hz)

V. T OTA L

V. BLK

V. F P

V. SYNC

V. B P

V. ACTIV

– SYNC –

INT (G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

NIT/NON INT

MODE 27 MODE 28 MODE 29 MODE 30 MODE 31 MODE 32 MODE 33 MODE 34 MODE 35

1280 X 960 1280 X 960 1280 X 1024 1280 X 1024 1280 X 1024 1280 X 1024 1024 X 768

108.000 MHz 148.500 MHz 108.000 MHz 135.000 MHz 157.500 MHz 148.000 MHz 80.000 MHz

60.000 kHz 85.938 kHz 63.981 kHz 79.976 kHz 91.146 kHz 81.319 kHz 60.241 kHz - -

usec usec usec usec usec usec usec usec usec

16.667 11.636 15.63 12.504 10.971 12.297 16.6 - -

4.815 3.017 3.778 3.022 2.844 3.649 3.8 - -

0.889 0.431 0.444 0.119 0.406 0.27 0.4 - -

1.037 1.077 1.037 1.067 1.016 1.378 1.2 - -

2.889 1.508 2.296 1.837 1.422 2 2.2 - -

11.852 8.62 11.852 9.481 8.127 8.649 12.8 - -

60.000 Hz 85.002 Hz 60.020 Hz 75.025 Hz 85.024 Hz 77.006 Hz 74.927 Hz - -

lines lines lines lines lines lines lines lines lines

1000 1011 1066 1066 1072 1056 804 - -

40 51 42 42 48 32 36 - -

1111133- -

3333333- -

36 47 38 38 44 26 30 - -

960 960 1024 1024 1024 1024 768 - -

NO NO NO NO NO YES NO - -

YES P/P YES P/P YES P/P YES P/P YES P/P NO YES N/N - -

NO NO NO NO NO NO NO - -

NON INT NON INT NON INT NON INT NON INT NON INT NON INT - -

SDM-N80 (E) 10

MODE AT PRODUCTION

RESOLUTION

CLOCK

– HORIZONTAL –

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

– VERTICAL –

V. FREQ (Hz)

V. T OTA L

V. BLK

V. F P

V. SYNC

V. B P

V. ACTIV

– SYNC –

INT (G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

NIT/NON INT

MODE 36 MODE 37 MODE 38 MODE 39 MODE 40 MODE 41 MODE 42 MODE 43 MODE 44

1280 X 1024 800 X 600 1024 X 768 1280 X 1024 1600 X 1200 1600 X 1200 1600 X 1200 1600 X 1200 1600 X 1200

135.000 MHz 50.000 MHz 71.640 MHz 100.000 MHz 162.000 MHz 175.500 MHz 189.000 MHz 202.500 MHz 229.500 MHz

81.130 kHz 48.077 kHz 53.946 kHz 60.680 kHz 75.000 kHz 81.250 kHz 87.500 kHz 93.750 kHz 106.250 kHz

usec usec usec usec usec usec usec usec usec

12.326 20.8 18.537 16.48 13.333 12.308 11.429 10.667 9.412

2.844 4.8 4.243 3.68 3.457 3.191 2.963 2.765 2.44

0.237 1.12 0.223 0.24 0.395 0.365 0.339 0.316 0.279

0.474 2.4 2.457 1.12 1.185 1.094 1.016 0.948 0.837

2.133 1.28 1.563 2.32 1.877 1.732 1.608 1.501 1.325

9.481 16 14.294 12.8 9.877 9.117 8.466 7.901 6.972

76.107 Hz 72.188 Hz 66.110 Hz 57.030 Hz 60.000 Hz 65.000 Hz 70.000 Hz 75.000 Hz 85.000 Hz

lines lines lines lines lines lines lines lines lines

1066 666 816 1064 1250 1250 1250 1250 1250

42 66 48 40 50 50 50 50 50

2378311111

864333333

32 23 36 34 46 46 46 46 46

1024 600 768 1024 1200 1200 1200 1200 1200

NO NO NO NO NO NO NO NO NO

YES N/N YES N/N YES N/N YES N/N YES P/P YES P/P YES P/P YES P/P YES P/P

NO NO NO NO NO NO NO NO NO

NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

SDM-N80 (E) 11

TABLE OF CONTENTS

Section Title Page Section Title Page

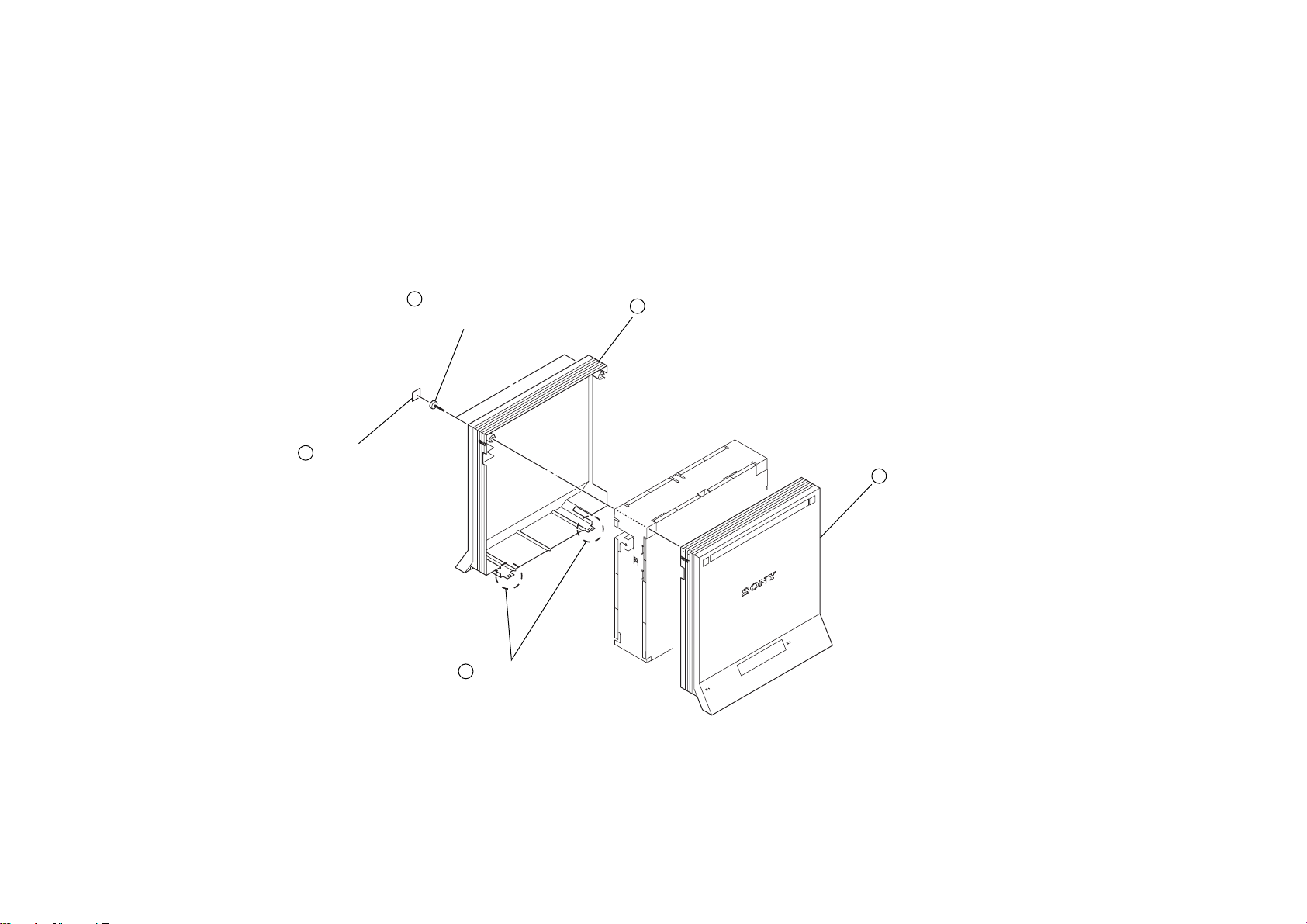

1. DISASSEMBLY

1-1. Rear Section Removal .......................................... 1-1

1-2. B Board Removal ................................................. 1-2

1-3. LCD Module Removal ......................................... 1-3

1-4. U Board, H Board Removal ................................. 1-4

1-5. US Board Removal .............................................. 1-5

1-6. Case (L)/(R) Assembly Removal.......................... 1-6

1-7. A Board Removal ................................................. 1-7

1-8. H2 Board Removal .............................................. 1-8

1-9. Q Board, Switching Regulator Removal .............. 1-9

2. ADJUSTMENTS ...................................................... 2-1

3. DIAGRAMS

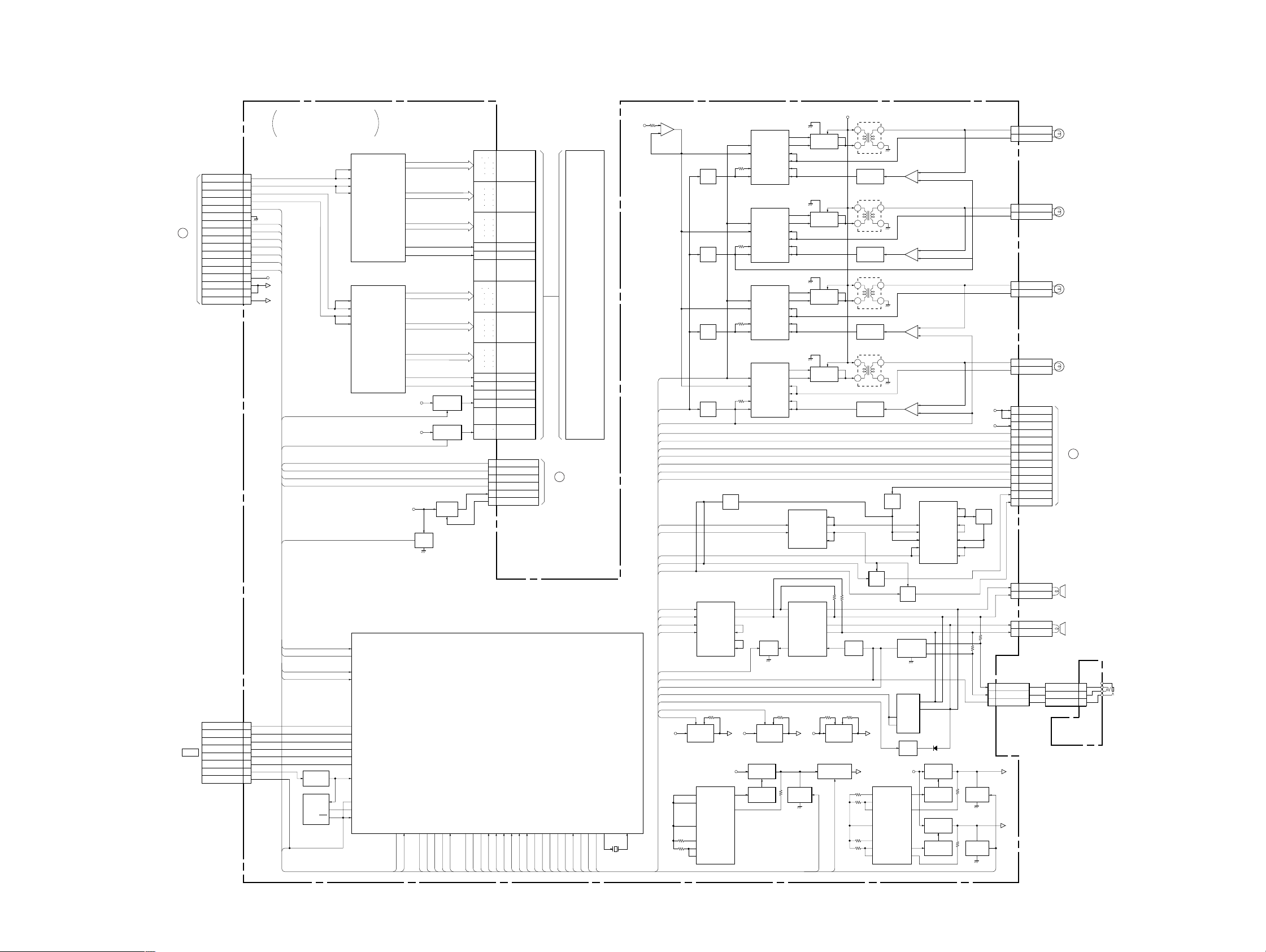

3-1. Block Diagrams .................................................... 3-1

(1) Schematic Diagrams of

A (a, b, c, d, e, f) Board ....................... 3-9

(2) Schematic Diagrams of

B (a, b, c, d, e, f) Board ....................... 3-16

(3) Schematic Diagrams of H (a, b, c) Board .... 3-23

(4) Schematic Diagram of H2 Board ......................... 3-27

(5) Schematic Diagram of Q Board ........................... 3-29

(6) Schematic Diagram of U Board ............................ 3-31

(7) Schematic Diagram of US Board.......................... 3-33

3-5. Semiconductors .................................................... 3-35

4. EXPLODED VIEWS .............................................. 4-1

4-1. LCD Display ........................................................ 4-2

4-2. Media Engine ....................................................... 4-3

4-3. Packing Materials ................................................. 4-4

3-2. Frame Schematic Diagram.................................... 3-5

3-3. Circuit Boards Location........................................ 3-6

3-4. Schematic Diagrams and Printed Wiring

Boards ................................................................... 3-7

5. ELECTRICAL PARTS LIST ............................... 5-1

SDM-N80 (E) 12

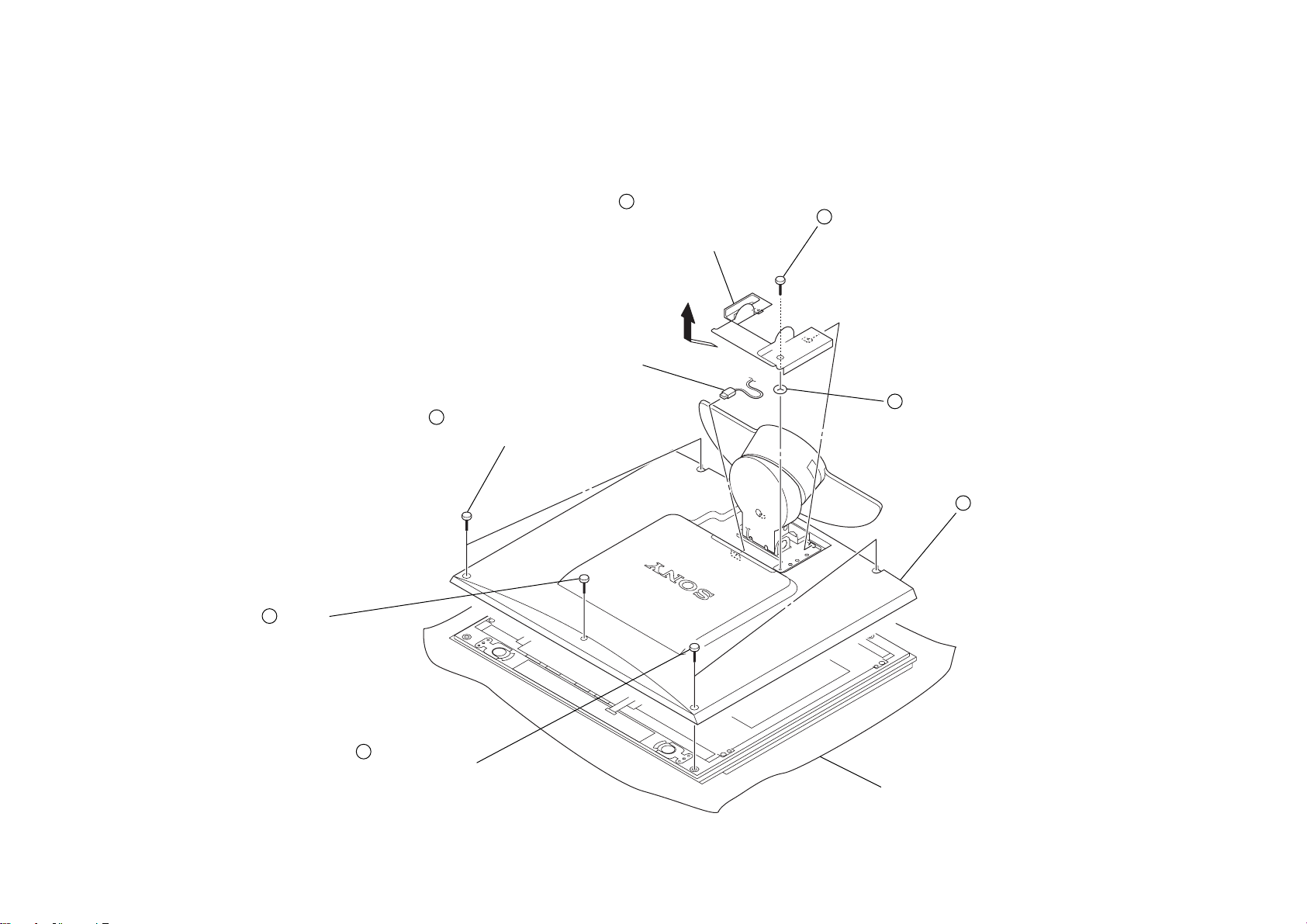

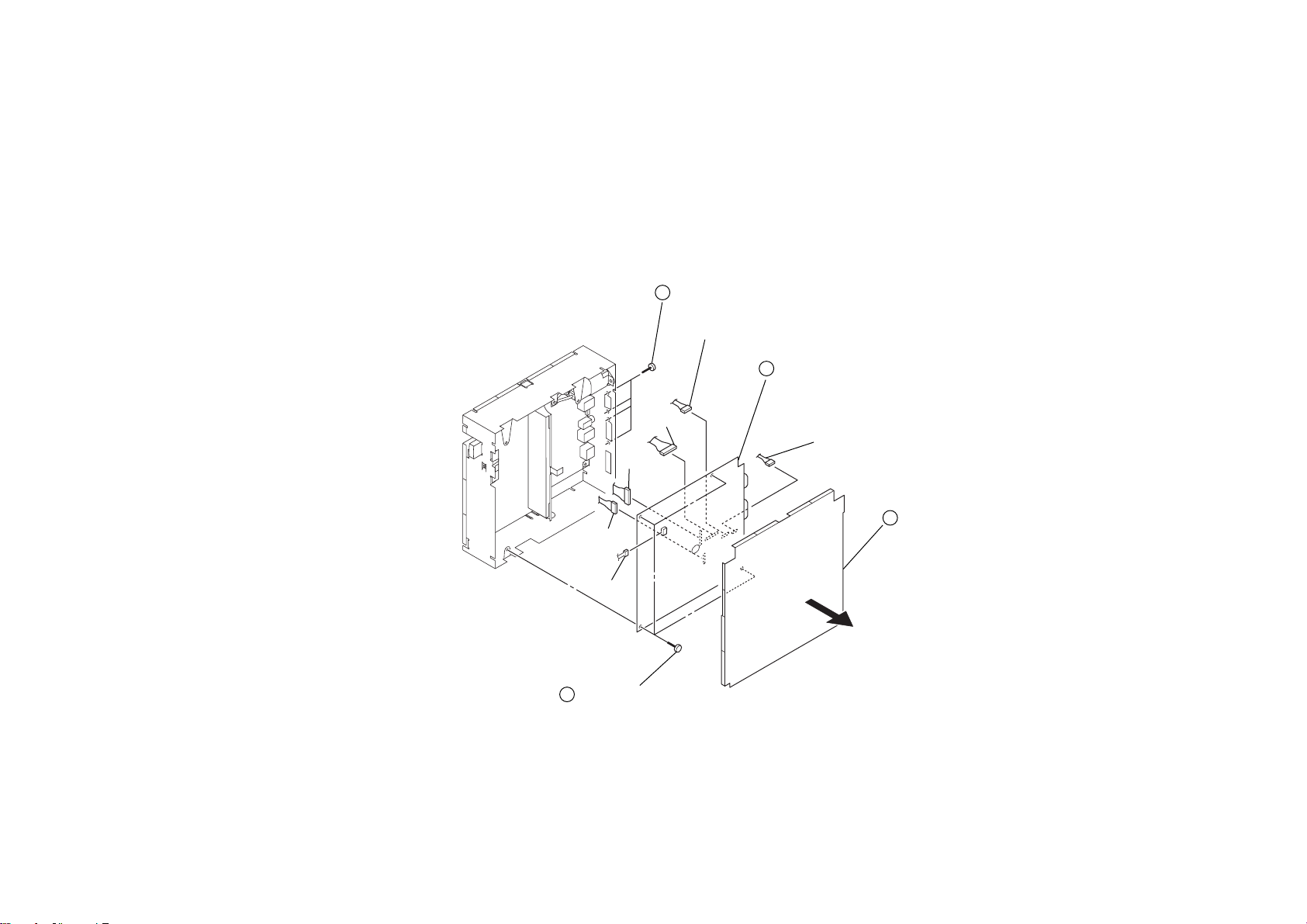

1-1. REAR SECTION REMOVAL

5

Two screws

(+BVTP 4X10)

SECTION 1

DISASSEMBLY

2

Remove the P hinge

cover (upper) in the

direction of arrow.

CN1203

1

Screw (M3)

3

Washer (M3)

6

Rear section

4

Screw

(+BVTP 3X14)

5

Two screw

(+BVTP 4X10)

Cushion

SDM-N80 (E) 1-1

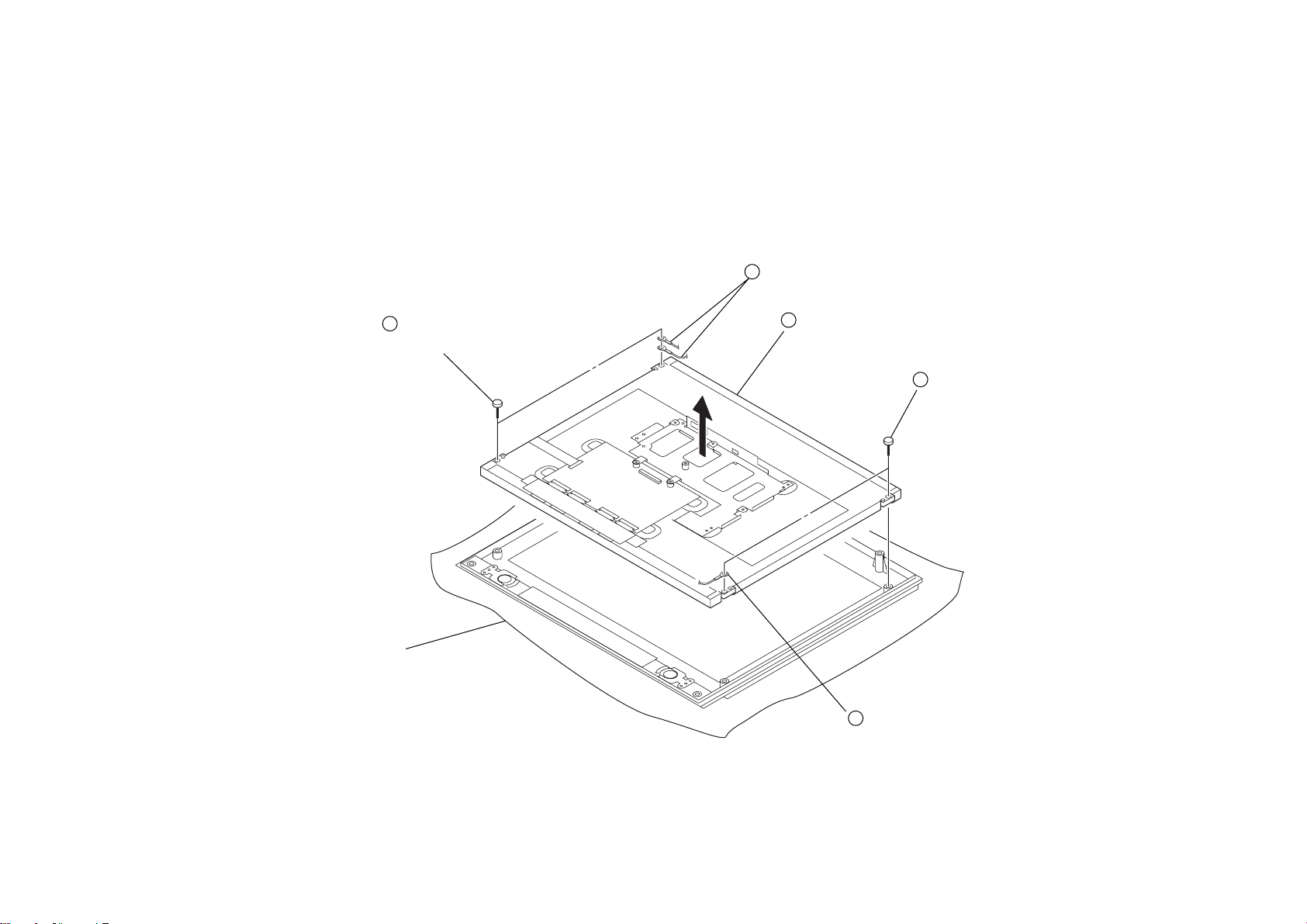

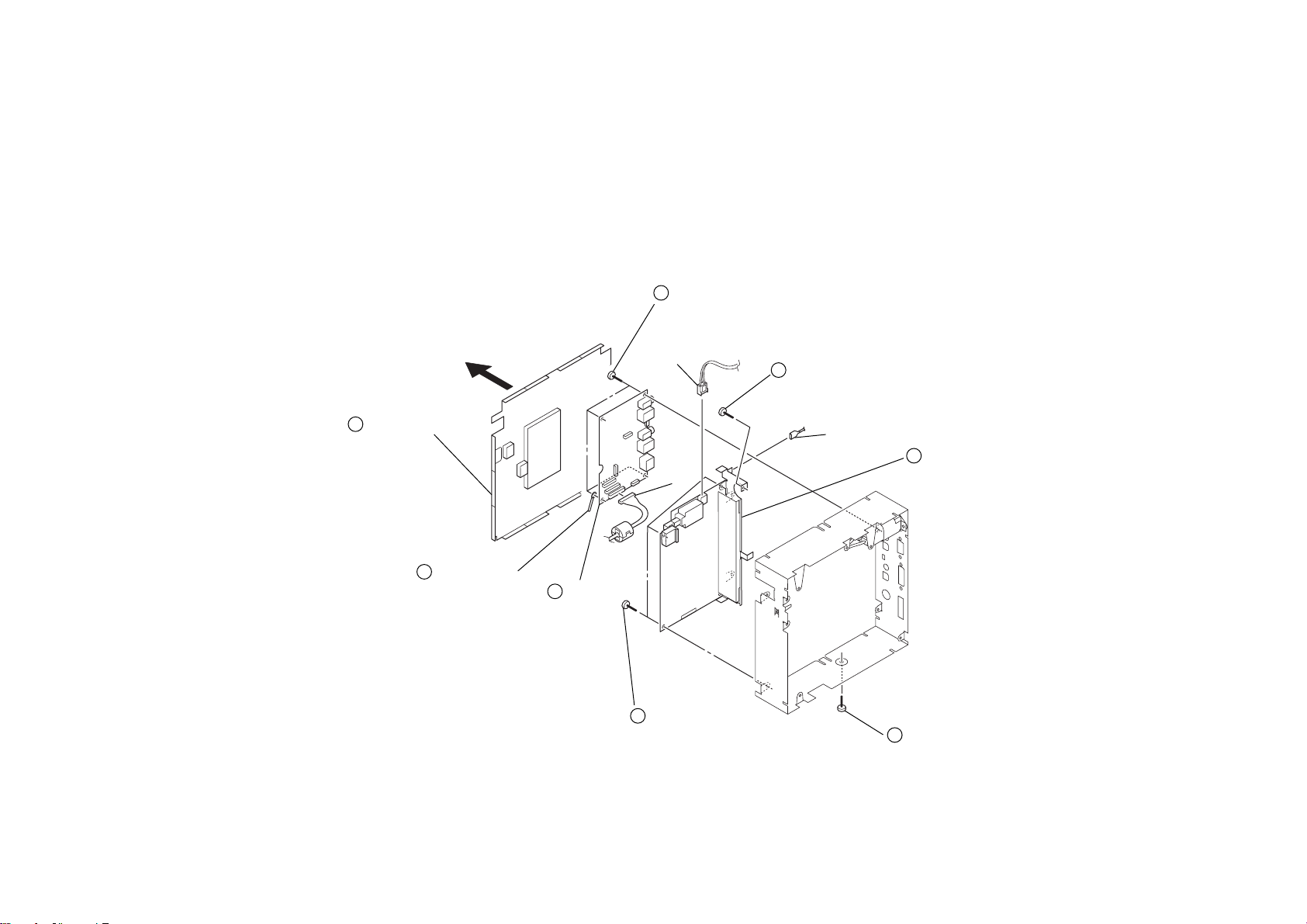

1-2. B BOARD REMOVAL

2

3

Two screws

(+PSW 3X10)

CN1503

Heat sink

1

Two screws

(M3X4)

4

Three screws

(M3X4)

CN1302

CN1501

CN1451

CN1502

CN1301

CN1204

CN1300

CN1303

5

B board

Cushion

SDM-N80 (E) 1-2

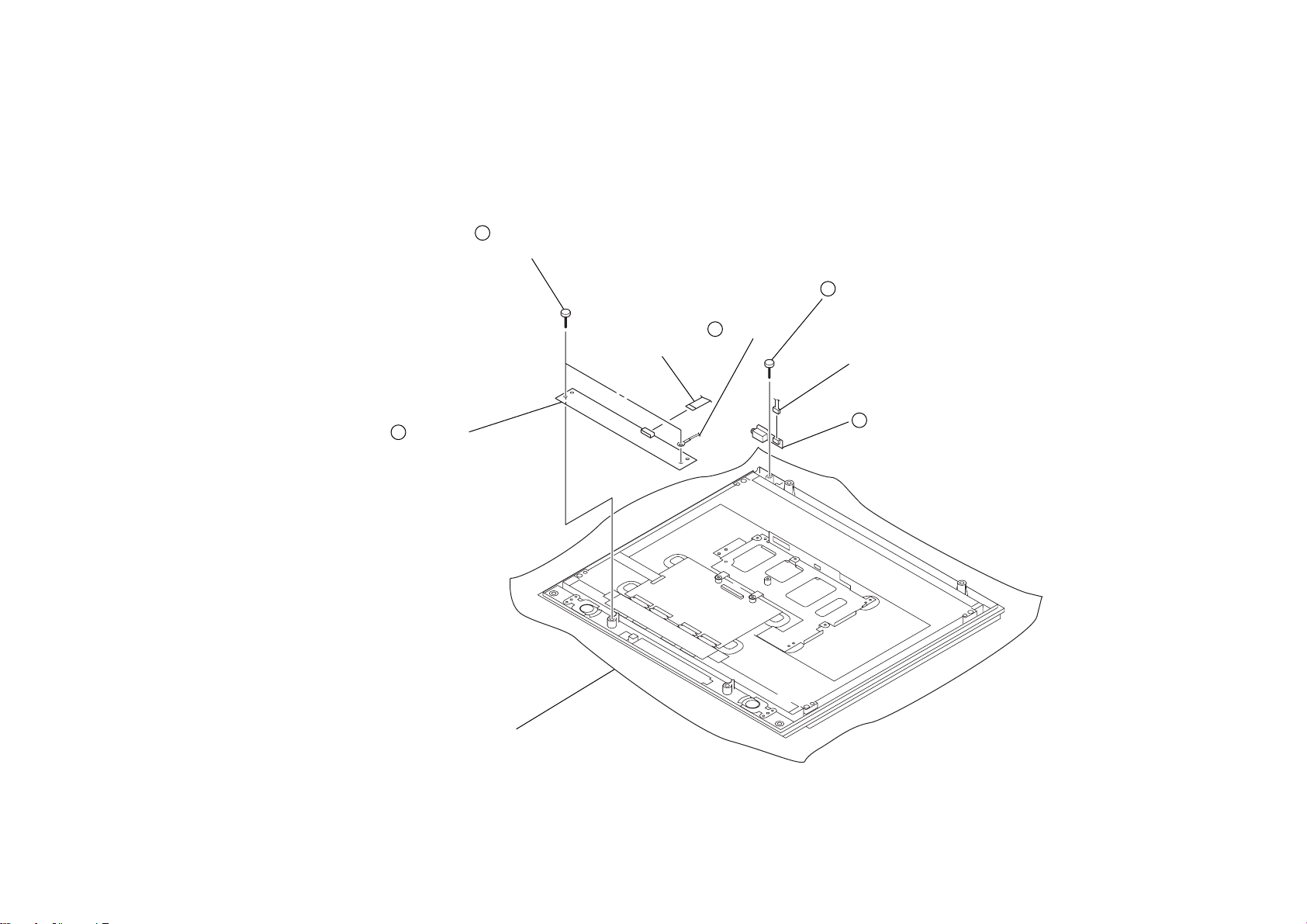

1-3. LCD MODULE REMOVAL

1

Two screws

(+BVTP 4X14)

2

Two harnesses

5

LCD MODULE (TFT)

3

Two screws

(+BVTP 4X14)

Cushion

4

Harness

SDM-N80 (E) 1-3

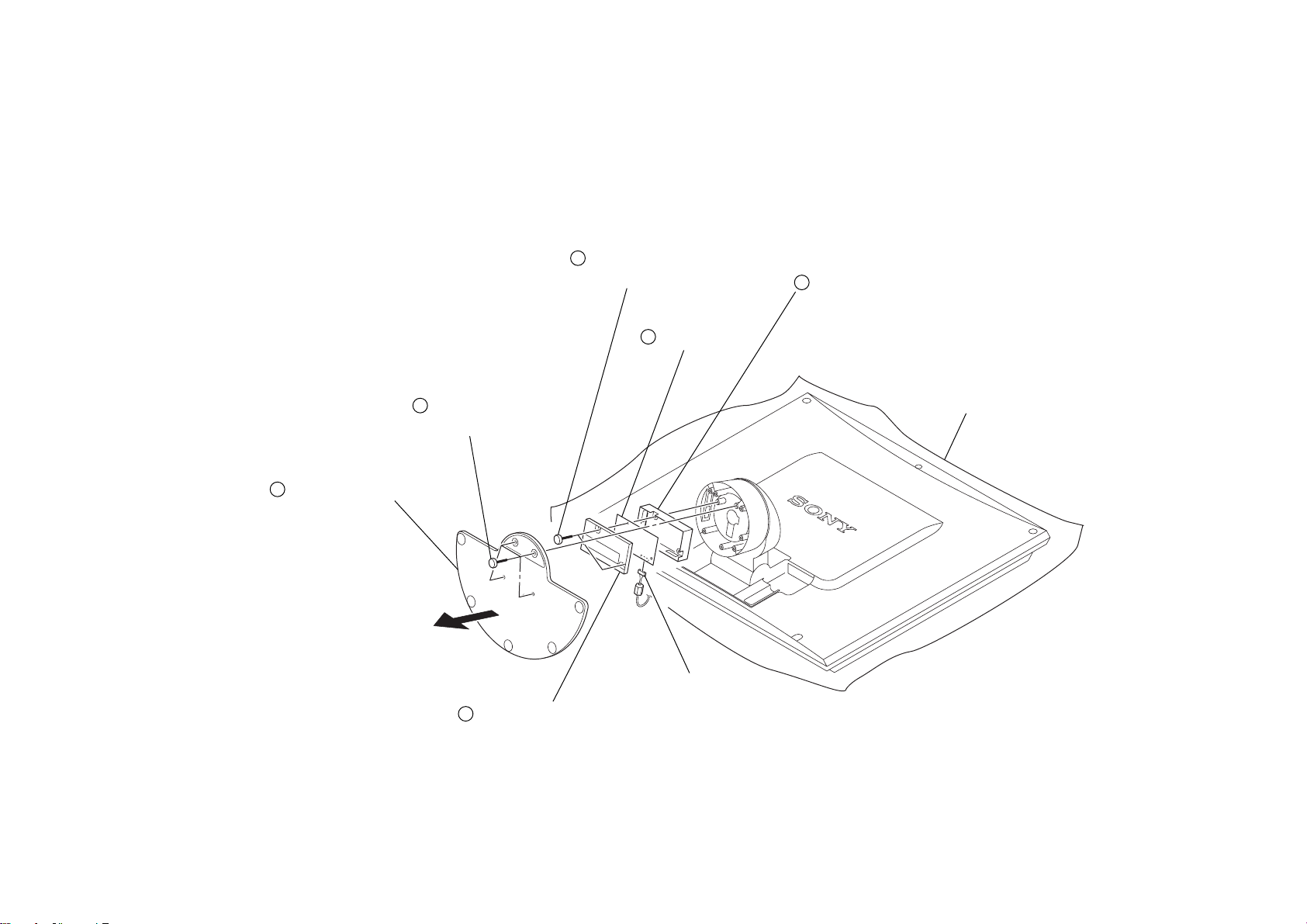

1-4. U BOARD, H BOARD REMOVAL

3

Two screws

(+BVTP 3X10)

5

H board

CN001

4

Harness

1

Screw (washer head)

(+P 3X12)

CN1701

2

U board

Cushion

SDM-N80 (E) 1-4

1-5. US BOARD REMOVAL

3

Two screws

(+BVTP 3X10)

6

US board

5

Shield case (USB)

2

Stand (bottom) cover

assembly

1

Four screws

(+BVTP 4X10)

4

Shield lid (USB)

Cushion

CN1101

SDM-N80 (E) 1-5

1-6. CASE (L)/(R) ASSEMBLY REMOVAL

2

Two screws

(+BVTP 3X14)

1

Sheet

4

Case (L) assembly

5

Case (R) assembly

3

Two claws

SDM-N80 (E) 1-6

1-7. A BOARD REMOVAL

CN501

CN302

CN502

3

Four hexagon screws

CN601

CN604

4

A board

CN602

1

Shield (R)

2

Four screws

(+BTP 3X6)

SDM-N80 (E) 1-7

1-8. H2 BOARD REMOVAL

3

Dowel

CN95

2

Screw (+BTP 3X6)

2

Shield (R)

4

H2 board

SDM-N80 (E) 1-8

1-9. Q BOARD, SWITCHING REGULATOR REMOVAL

2

Four screws

(+BTP 3X6)

1

Shield (L)

3

Wire holder

4

Q board

CN1

CN960

7

Three screws

(+BTP 3X6)

6

Screw (+BTP 3X6)

GND

8

Switching regulator

5

Screw (+BTP 3X6)

SDM-N80 (E) 1-9

SECTION 2

Computer for jig

Audio input

to USB upstream

to INPUT 1

to INPUT 2

USB checker

Analog signal

generator

(VG-819, etc)

Digital signal

generator

(VG-828, etc)

USB mouse

[Measuring instrument position]

H/ L side:

C/ O side:

H Center

V Center

V Center

H Center

ADJUSTMENTS

Connect the personal computer, monitor, and signal generator as shown below, and control the monitor.

• Adjustment conditions

(1) impressed voltage:10%UP than rating voltage

(2) time: 30 minutes or more

(3) temperature: 25 ± 3˚C

(4) Brightness: Aging mode

• Adjustment of preset mode

Check the screen in the following five modes of the preset frequencies.

< Signal mode >

1. MODE 0 (640x480 60Hz)

2. MODE 11 (800x600 85Hz)

3. MODE 18 (1024x768 85Hz)

4. MODE 29 (1280x1024 60Hz)

5. MODE 40 (1600x1200 60Hz)

1.Generate the crosshatch signal.

2.Observing the ends, check that both ends can be seen or a white line at the end is not far away

from the edge of display area.

Note: Deviation up to 2 dots is allowable.

OK if either left or right side satisfies the above specification.

• Adjustment of white balance (Analog input 1)

SDM-N80 (E) 2-1

1.Adjustment of 9300K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with the input 1. Set SOURCEID1=00h.

(2) Set R_USER_DRV=235.

Set R_USER_BKG=132.

(3) Make adjustment with G/B_USER_DRV to set the chromaticity within the specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 9300K (x, y) = (0.285, 0.298)

Within 3JND at 80IRE

9300K (x, y) = (0.277, 0.287)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the B/G_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

2. Adjustment of 6500K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with the input 1. Set SOURCEID1=01h.

(2) Set R_USER_DRV=235.

Set R_USER_BKG=132.

(3) Make adjustment with G/B_USER_DRV to set the chromaticity within the specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 6500K (x, y) = (0.314, 0.328)

Within 3JND at 80IRE

6500K (x, y) = (0.298, 0.317)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the G/B_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

3. Adjustment of 5000K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with the input 1. Set SOURCEID1=02h.

(2) Set R_USER_DRV=235.

Set R_USER_BKG=135.

(3) Make adjustment with G/B_USER_DRV to set the chromaticity within the specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 5000K (x, y) = (0.345, 0.358)

Within 3JND at 80IRE

5000K (x, y) = (0.316, 0.335)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the G/B_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

4. Data copy to USER

Set SOURCEID1=03h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=01h (Adjustment of 6500K).

5. Data copy to analog 2 input

(1) 9300K data copy

Set SOURCEID1=20h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=00h (Adjustment of 9300K).

(2) 6500K data copy

Set SOURCEID1=21h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=01h (Adjustment of 6500K).

(3) 5000K data copy

Set SOURCEID1=22h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=02h (Adjustment of 5000K).

(4) USER data copy

Set SOURCEID1=23h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=01h (Adjustment of 6500K).

SDM-N80 (E) 2-2

• Adjustment of white balance (Digital input)

1.Adjustment of 9300K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with digital input. Set SOURCEID1=10h.

(2) Set R_USER_DRV=230.

Set R_USER_BKG=132.

(3) Make adjustment with G/B_USER_DRV to set the chromaticity within specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 9300K (x, y) = (0.285, 0.298)

Within 3JND at 80IRE

9300K (x, y) = (0.277, 0.287)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the R/B_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

2.Adjustment of 6500K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with digital input. Set SOURCEID1=11h.

(2) Set R_USER_DRV=220.

Set R_USER_BKG=128.

(3) Make adjustment with G/B_USER_DRV to set the chromaticity within the specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 6500K (x, y) = (0.314, 0.328)

Within 3JND at 80IRE

6500K (x, y) = (0.298, 0.317)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the G/B_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

3. Adjustment of 5000K

(1) Receive MODE 29 (1280x1024 60Hz) 80IRE with the digital input. Set SOURCEID1=12h.

(2) Set R_USER_DRV=215.

Set R_USER_BKG=130.

(3) Make adjustment with R/B_USER_DRV to set the chromaticity within the specification.

x adjustment ..... Make adjustment with B_USER_DRV.

(The value y also changes.)

B_USER_DRV UP Values x and y decrease.

B_USER_DRV DOWN Values x and y increase.

y adjustment ..... Make adjustment with G_USER_DRV.

G_USER_DRV UP Value y increases.

G_USER_DRV DOWN Value y decreases.

Spec: 5000K (x, y) = (0.345, 0.358)

Within 3JND at 80IRE

5000K (x, y) = (0.316, 0.335)

Within 4JND at 20IRE

Note: Make adjustment up to ± 0.002.

(4) Make the signal 20IRE all white to check that it is within the specification.

(5) Input a gray scale to check the picture quality.

(5) (4) If out of specification, adjust the G/B_USER_BKG so as to satisfy the specification.

(6) Input a gray scale to check the picture quality.

4. Data copy to USER

Set SOURCEID1=13h and copy the data of R/G/B USER DRV and R/G/B USER BKG of

SOURCEID1=11h (Adjustment of 6500K).

SDM-N80 (E) 2-3

• User Sensor Adjustment

(4)After several seconds, check that IR_STATUS is 140 or less.

If IR_STATUS is not less than 140, write smaller value to

(1)After clearing up to the position of 2m in front of the set, place an object

for sensor detection in front of the set.

< Condition >

The panel must be vertical.

Object: A4 size paper for instance

Position: Flush with right end of the screen at the height of set stand

Distance: 1m from the screen

(TOP VIEW)

SET

1m

Object for detection

(SIDE VIEW)

SET

Object for detection

1m

IRLED_PW1.

(5) Raise IRLED_PW1 by 3 steps, and after about 2 seconds, check if

IR_STATUS is 160 or more.

If IR_STATUS is not more than 160, raise further the IRLED by 3

steps.

Repeat this until the IR_STATUS exceeds 160.

(6)When IR_STATUS exceeded 160, write value attained by adding 30 to

the IRLED_PW1 value to the following:

IRLED_PW1

IRLED_PW2

IRLED_PW3

(7)Write 0 to AUTO_PW for service saving.

(2)Set the AUTO_PW_SW to “1”.

(3)Write 40 to IRLED_PW1.

SDM-N80 (E) 2-4

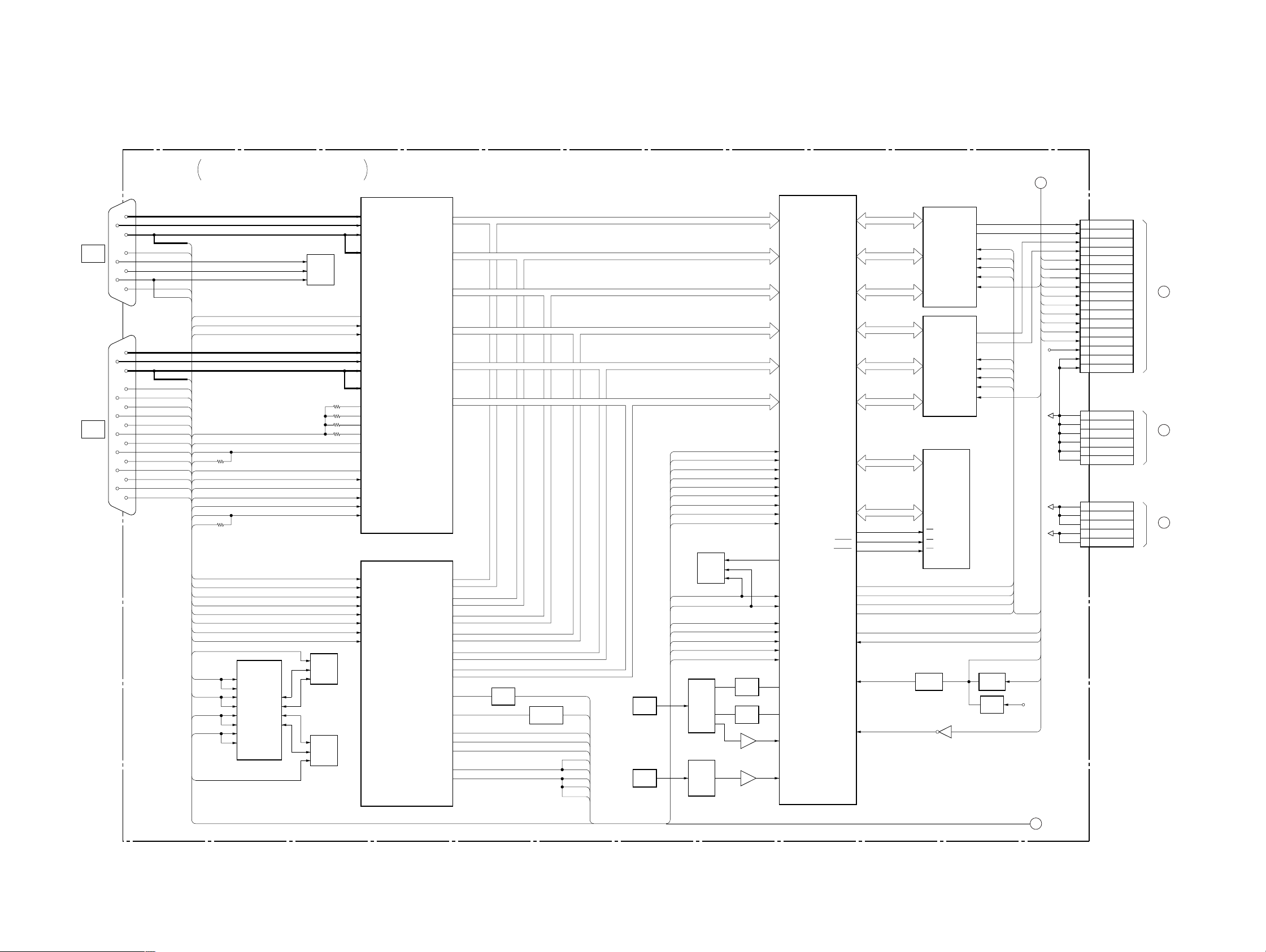

3-1. BLOCK DIAGRAMS

SECTION 3

DIAGRAMS

CN101

INPUT1

(HD15)

CN201

INPUT2

(DVI-I)

A (1/2)

GREEN1

DDCGND1

H1

V1

GREEN2

DDCGND2

SDA2

SCL2

H2

V2

RXC–

RXC+

RX0–

RX0+

RX1–

RX1+

RX2–

RX2+

A/D CONVERTER, TMDS RECEIVER, DDC,

SCAN CONVERETER, GVIF TRANSMITTER

139

133

124

IC203

ROM

IC202

ROM

132

141

136

126

135

100

101

103

105

106

108

143

111

112

113

6

9

10

98

99

90

89

87

86

84

83

81

80

ADPDN

SDA_SC

SCL_SC

GCLK

GFBK

GSOG

GHS_A

GCOAST

GHSFOUT

G_SEPIN

H1_ADIN

H2_ADIN

CLAMP

GBLKSPL

RXC–

RXC+

RX0–

RX0+

RX1–

RX1+

RX2–

RX2+

DDC_WP

SDA2

SCL2

ANALOG

DIGITAL

V2

10

12

13

2

3

9

5

6

OI1

OI2

OI3

OI4

C2

C3

C4

C1

SELECTOR

IC201

5

SDA

6

SCL

7

VCLK

IC101

ROM

7

VCLK

6

SCL

5

SDA

1

IO1

11

IO4

4

IO2

8

IO3

5

SDA

6

SCL

7

VCLK

A/D CONVERTER

R/CrN1

B/CbIN1

G/YIN1

SOGIN1

XPOWER SAVE

SDA

SCL

R/CrIN2

B/CbIN2

G/YIN2

SOGIN2

XCLK

CLK

1/2XCLK

1/2CLK

DSYNC/DIVOUT

SOGOUT

HOLD

EVEN/ODD

G/YOUT

SYNCIN1

SYNCIN2

CLPIN

TMDS RECEIVER

RXC–

RXC+

RX0–

RX0+

RX1–

RX1+

RX2–

RX2+

IC102

IC204

21, 22, 24 – 28, 31 208, 213 – 216, 221 – 223

GRE0 – 7 GRE0 – 7

RA0 – 7

34 – 41 190 – 192, 197 – 200, 207

GRO0 – 7 GRO0 – 7

RB0 – 7

45, 44, 51 – 53 26, 51, 52, 77, 78, 102, 109, 110

GBE0 – 7 GBE0 – 7

BA0 – 7

56 – 58, 60 – 64 23, 24, 48, 49, 74, 75, 99, 100

GBO0 – 7 GBO0 – 7

BB0 – 7

68 – 75 128, 133, 135, 181 – 184, 189

GGE0 – 7 GGE0 – 7

GA0 – 7

78, 81 – 85,

87, 88

GGO – 7 GGO0 – 7

GB0 – 7

30 – 37

QE16 – 23

GRE0 – 7

69 – 75, 77

QQ16 – 23

GRO0 – 7

10 – 17

QE0 – 7

GBE0 – 7

49 – 56

QQ0 – 7

GBO0 – 7

20 – 27

QE8 – 15

GGE0 – 7

59 – 66

QE8 – 15

GG0 – 7

PDO

SCDT

PD

ODCK

DE

VSYNC

HSYNC

9

8

2

44

46

SW

Q201

INVERTER

Q310

PDO

SCDT

PD

GCLK

GPEN

GVS_D

H348

GHS_D

GFBK

X401

21.6MHz

V347

X402

21.6MHz

GHS

GVS

GHSFOUT

GBLKSPL

GFBK

GCLK

GSOG

GPEN

GCOART

SDA_SC

SCL_SC

PRE_PXOFF

PRE_ADCPD

BL_MUTE

AU_MUTE

PX_WD

IC406

PLL CLOCK

MULTIPLIER

1

X1

IC407

PLL CLOCK

MULTIPLIER

1

X1 CLK

103, 104, 111, 112, 117 – 120

IC408

ROM

WP

SCL

SDA

S1

S0

CLK

IC401

SCAN CONVERTER

GRE0 –7

GRO0 – 7

GBE0 –7

GBO0 –7

GGE0 –7

GGO0 –7

144

GHS

159

GVS

166

GHSFOUT

141

GBLKSPL

136

GFBK

158

GCLK

151

GSOG

152

GPEN

142

GCOART

7

6

5

5

5

SW

Q406

SW

Q405

IC409

83

PORTA4

53

PORTA0

54

PORTA1

4

PORTB3

58

PORTB4

31

PORTB5

5

PORTB6

32

PORTB7

34

26

341

65

DCKEXT

315

32

MCKEXT

DRE0 – 7

DBE0 – 7

DGE0 – 7

DRO0 – 7

DBO0 – 7

DGO0 – 7

A1 – 18

D0 – 15

PORTA2

ROMOE

ROMWE

DENG

DCLK

DHS

DVS

RXD

TXD

RESET

PORTA5

231, 237 – 240,

248, 273, 274

DRE0 – 7

292, 295,

317 – 319, 322,

323, 349

DBE0 – 7

245, 270, 272,

297, 300, 324,

350, 351

DGE0 – 7

260, 286,

310 – 312,

337 – 339

DRO0 – 7

254, 279, 303,

305 – 307,

330, 332

DBO0 – 7

256, 257, 282,

283, 309, 333,

334, 336

DGO0 – 7

209 – 212, 217,

219, 220, 233,

235, 242 – 244,

249, 251, 275,

276, 301, 327

130, 131, 139,

140, 145, 146,

153 – 156, 163,

164, 169,

170 – 172

264

287

263

289

79

80

105

29

16 – 23

2 – 5,

44 – 47

6 – 11,

14, 15

16, 23

2 – 5,

44 – 47

6 – 11,

14, 15

3 – 11,

34 – 42

15 – 22,

24 – 31

GVIF TRANSMITTER

R0 – 7

B0 – 7

G0 – 7

R0 – 7

B0 – 7

G0 – 7

GVIF TRANSMITTER

IC410

FLASH ROM

A0 – 17A1 – 18

DQ0 – 15D0 – 15

227

WP

14186

QE

43185

WE

IC405

INVERTER

IC309 (1/3)

IC601

IC602

SDATAN

SDATAP

DE

SFTCLK

HSYNC

VSYNC

CE

SDATAN

SDATAP

DE

SFTCLK

HSYNC

VSYNC

CE

31

30

40

DCLK

41

42

43

26

GVIF_ON

31

30

40

DCLK

41

42

43

26

DENG

DCLK

INVERTER

Q404

IC404

RESET

DEN

DHS

DVS

DEN

DHS

DVS

DHS

DVS

GVIF_ON

DVS

RXD

TXD

RX_RSTN

RESET_SC

+3.3V

PANEL_MODE

1

CPU_ST

PANEL_MODE

SUB_SCL

SUB_SDA

AUDIO_R

AUDIO_L

USB POWER

D–

D+

HOTPLUG

+5V

+18V

+4V

+6V

CN603

SDATAN-B

4

SDATAP-B

6

SDATAN-A

9

SDATAP-A

11

B-CPU-ST

15

PANEL MODE

16

SCL

17

SDA

18

AUDIO-R

24

AUDIO-L

26

USB POWER

31

USB SIG–

33

USB SIG+

35

HOTPLUG

36

STBY6V

13

PANEL/DVIF 18V

2

BL18V

38

CN604

+18V

1

+18V

2

+18V

3

+18V

4

+18V

5

+18V

6

CN502

CONV_4V

1

CONV_4V

2

CONV_4C

3

CONV_6V

7

CONV_6V

8

A

TO B BOARD

CN1201

B

TO Q BOARD

CN961

C

TO Q BOARD

CN963

2

B-SS3558<U/C>-BD1-EPS05

SDM-N80 (E) 3-1

A (2/2)

IC302

CPU

1

µ-COM, SYNC_IRQ GENERATOR,

SYNC SEPARATOR, INPUT SELECT

H1 75

H2 76

V1

V2

GREEN1 97

GREEN2 98

GHS 65

GVS 23

CLAMP 82

G_SEPIN 83

GHS_A 84

GHS_D

GVS_D

H1

H2

H3

V1

V2

V3

H1_ADIN

H2_ADIN

DDC_GND1 113

DDC_GND2 114

ADPDN 101

SCDT 77

PDO 100

PD 99

DDC_WP 102

PRE_PXOFF 40

PRE_ADCPD 41

BL_MUTE 50

AU_MUTE 51

PX_WD 52

ANALOG 61

SYNC_IRQ

GENERATOR

IC103,

Q101 – Q128

SYNC

SEPARATOR

IC301, IC308

IC314, Q304

H_SEPIN

V_SEPIN

INPUT

SELECT

IC310 – IC313

INVERTER

Q305

SYNC_IRQ1

SYNC_IRQ2

COMP1

COMP2

HIN

VIN

POLH

EXIH

POLV

EXIV

65

IC309

(2/3)

IC304

EEP ROM

X302

32.768kHz

X301

4MHz

7

WC

6

SCL

5

SDA

85

58

74

73

92

93

103

55

56

57

SYNC1_IRQ

SYNC2_IRQ

COMP1

COMP2

HIN

VSIN

SYNC_SEP1

SYNC_SEP2

SYNC_SEP3

SYNC_SEP4

ANA_DIG

X0A

X1A

X0

X1

INPUT_SEL

EEP_WP

EEP_SCL

EEP_SDA

DDC_GND1

DDC_GND2

ADP_DN

SCDT

PDD

PD

DDC_WP

P73/DA0

P74/DA1

P84/AN4

P85/AN5

P86/AN6

DIGITAL

VSOUT

PANEL_DET2

PANEL_MODE

RESET_SC

GVIF_ON

SUB_SDA

SUB_SCL

SUB_IRQ

P_MEM

SC_SEL

SC_RX

SC_TX

ECS_RX

ECS_TX

WDT

HST

RESET

WDT_STOP

TCK

TAUX

MD2

MD0

USB_SEL

HUBON

USB1_EXIST

USB2_EXIST

AUDIO_SEL

LED_GREEN

LED_RED

POWER_ON

PON_4

PON_6

PON_13

PON_S33

24

HOTPLUG

53

PANEL_MODE

60

RESET_SC

116

GVIF_ON

81

SVB_SDA

70

SVB_SCL

71

72

112

14

12

13

9

10

118

86

90

117

11

95

87

89

69

66

64

67

68

110

109

111

106

107

108

105

DVS

CPU_ST

+6V

IC305 D-FF

3

1CK

11

2CK

5

1Q

SW

Q307

3

+5V

2

IO IO IO IO

IC501

+5V REG

1PR

2PR

IC303 RESET/WDT

3

8

IC509

+

1

–

+5V

1D

CLK

RSTN

2

4

10

RCT

SW

Q306

IC502

+3.3V REG

INVERTER

Q302

6

SW

Q501, 502

INVERTER

Q303

FLASH SW

Q301

+4V

+3.3V +4V +3.3V +4V

+5V

+2.5V

IC504

+3.3 REG

IC503, IC505

+3.3V REG

4

Y

IC306

TXD

45

IC307

6

2

A

1

OE

+3.3V +6V +5V +4V

RXD

IC309

(3/3)

3

1

2

IOIO

IC507, IC508

+5V REG

+2.5V REG

9

8

10 9

IC506

8

11

13

12

POWER_ON

M_RSTN

M_RSTN

PON_4

PON_6

PON_13

+2.5V

+6V

POWER_ON

PON_4

PON_6

PON_13

ANALOG

DIGITAL

D+

D–

USB POWER

AUDIO_R

AUDIO_L

+5V

+6V

STBY_6V

1

STBY_6V

2

POWERON

5

PON_4

6

PON_6

7

PON_13

8

ANALOG

12

DIGITAL

13

RXD

10

TXD

11

PX_RSTN

10

RXD

7

TXD

8

TVPP1

3

TRES

4

TCK

6

TAUS

5

TAUX3

2

TMODE

1

D+

7

D–

6

US_P_CONT

5

HUBON

4

USB_SEL

3

UP2_EXIST

2

UP1_EXIST

1

AUDIO_R

1

AUDIO_L

3

AUDIO_SEL

5

LED_GREEN

2

LED_RED

3

STBY 5V

1

CONV_4V

1

CONV_4V

2

CONV_4V

3

CONV_6V

7

CONV_6V

8

CN501

CN301

CN602

CN601

CN302

CN502

D

TO Q BOARD

CN962

FLASH

E

TO Q BOARD

CN903

F

TO Q BOARD

CN932

G

TO Q BOARD

CN963

CN95

LED_GREEN

LED_RED

STBY 5V

+5V

G

R

LED DRIVE

Q96

3

2

+5V

4

LED DRIVE

Q95

H2 (AC POWER LED)

D95

AC

POWER

2

B-SS3558<U/C>-BD2-EPS05

SDM-N80 (E) 3-2

A

TO A BOARD

CN603

FLASH

CN1201

SDATAN-A

SDATAP-A

SDATAN-B

SDATAP-B

B-CPU-ST

PANEL MODE

SCL

SDA

AUDIO_R

AUDIO_L

USB_POWER

USB SIG–

USB SIG+

HOT PLUG

PANEL /DVIF 18V

BL18V

STBY6V

CN1402

TMODE

TAUX3

TAUX

TCX

RXD

TXD

TVPP1

TRES

B

9

11

4

6

15

16

17

18

24

26

USB POWER

31

33

35

36

2

38

13

1

2

5

6

7

8

3

4

SUB µ-COM, GVIF RECEIVER,

D/D CONVERTER, INVERTER,

AUDIO, SENSOR AMP

B_CPU_ST

SCL

SDA

AUDIO_R

AUDIO_L

USB D–

USB D+

+5V

+18V

+6V

BL_ON_P

PON_P12

PROTECT

USB POWER

USB D–

USB D+

USB DET

B_CPU_ST

BL_ON_P

SDA

SCL

FLASH SW

Q1401

6

RCT

3

CK

8

RST

IC1401

RESET/ WDT

RESET

IC1201 GVIF RECEIVER

42

REFRQN

41

SDATAN

40

SDATAP

39

REFRQP

IC1202 GVIF RECEIVER

42

REFRQN

41

SDATAN

40

SDATAP

39

REFRQP

48

P71/IRQ1

92

P07/IRQ1

28

P50/SDA0/SOT0

29

P51/SCL0/SIN0

49

MD0

51

MD2

85

P00/AD00

18

P40/SCK

20

P42/SIN

19

P41/SOT

76

FLASH SW

52

HSTX

78

PA2

77

RSTX

SFTCLK

SFTCLK

99PON_P12

DE

DE

P16/AD14

18, 19, 22 – 25, 30, 31

R OLD0 – 7R0 –7

6, 7, 10 – 15

G OLD0 – 7G0 –7

2 – 5, 58, 59, 62, 63

B OLD0 – 7B0 –7

51

50

18, 19, 22 – 25, 30, 31

R NEW0 – 7R0 –7

6, 7, 10 – 15

G NEW0 – 7G0 –7

2 – 5, 58, 59, 62, 63

B NEW0 – 7B0 –7

51

50

+5V

+12V

+18V

SW

Q1204

P21/A17

P20/A16

P80/TIN0

2H_PWLEDR

1H_PWLEDG

59USB DET

BL ON SW

Q1205

+12V SW

Q1202, 1203

+18V SW

Q1201

P23/A19

P22/A18

4H_IRLED2

3H_IRLED1

P24/A20

5HP_STAT

P27/A23

9H_LEDCLK

8MUTE

A7 A8

A10 A11

A13 A14

A17 A18

A20 A21

A23 A24

A27 A28

A30 A31

A37 A38

A40 A41

A43 A44

A46 A47

B7 B8

B10 B11

B13 B14

B17 B18

B20 B21

B23 B24

B27 B28

B30 B31

B37 B38

B40 B41

B43 B44

B46 B47

A1 – A3

B1 – B3

P30/ALE

10H_LEDDATA

CN1204

RA0

RA7

GA0

GA7

BA0

BA7

A33 CLKA

A35 DEA

RB0

RB7

GB0

GB7

BB0

BB7

B33 CLKB

B35 DEB

A5

BLON_P

VCC

CN1203

PROTECT

2

USB POWER CONT

3

USB D–

4

USB D+

5

USB 18V

1

USB DET

8

IC1402 SUB-CPU

P63/AN3

P61/AN1

P60/AN0

P31/RDX

44H_BRTDET

41IROUT

39BL_STAT

38BL ON

ı

ı

ı

ı

ı

ı

P67/AN7

P65/AN5

46H_KEY

P86/IN2

P70/IRQ0

65H_REM

47H_PWKEY

H

TO US BOARD

CN1101

P96/PPG4

P94/PPG2

P92/PPG0

73H_PPG4

71H_PPG2

69PWM

DISPLAY

P11/AD09

P10/AD08

94AUSDA

93PROTECT

LCD

P12/AD10

95AUSCL

P13/AD11

P17/AD15

96PON_5AU

100PON_G33R

X0

82X183

X1401

4MHz

IC1300

+5V

3

+

1

2

–

SW

Q1308

SW

Q1306

SW

Q1304

BL ON

PWM

BL_STAT

H_PWKEY

H_KEY

H_PWLEDG

H_PWLEDR

H_LEDCLK

H_LEDDATA

H_BRTDET

H_PPG2

H_PPG4

IROUT

H_IRLED1

H_IRLED2

AUDIO_R

AUDIO_L

SDA

SCL

RESET

HP_STAT

MUTE

AUDIO_ON

PON_5AU

PON_G33R

AUDIO ON

SW

Q1301

AMP

Q1452

IC1502

AUDIO CONTROL

6

R_OUT

IN_R

11

L_IN

L_OUT

19

BOUT_R

SDA

20

SCL

BIN_R

BOUT_L

BIN_L

IO

16

11

13

12

+9V+18V

IC1503

+9V REG

310

NON1 OUT2

6

DT1

NON2

VREF

DT2

INV2

FB2

IC1310

INVERTER CONTROLLER

12

ENA

14

CT

5

ADJ

1

REF

INVERTER CONTROLLER

12

ENA

14

CT

5

ADJ

1

REF

INVERTER CONTROLLER

12

ENA

14

CT

5

ADJ

1

REF

INVERTER CONTROLLER

12

ENA

14

CT

5

ADJ

1

REF

16

17

15

14

13

12

IC1204, IC1205

+18V +5V

SWITCHING

Q1615

Q1610, 1611

14

1110G1

NDA

PDA

7

CMP

6

FB

3

LCLMP

2

HCLMP

IC1307

1110G1

NDA

PDA

7

CMP

6

FB

3

LCLMP

2

HCLMP

IC1305

1110G1

NDA

PDA

7

CMP

6

FB

3

LCLMP

2

HCLMP

IC1302

1110G1

NDA

PDA

7

CMP

6

FB

3

LCLMP

2

HCLMP

3

IN1+

5

IN2+

POWER AMP

6

IN_A–

15

IN_B–

1

RESET

SDOWN

Q1505

+3.3V REG

+3.3V+5V

PROTECT

Q1612

IO

AMP

G2

G2

G2

G2

IC1452 AMP

IC1501

S1 S2

SWITCHING

Q1312

S1 S2

SWITCHING

Q1311

S1 S2

SWITCHING

Q1310

S1 S2

SWITCHING

Q1309

IN1–

OUT1

OUT2

IN2–

3

OUT_A+

5

OUT_A–

18

OUT_B+

16

OUT_B–

20

HP_IN

IO

AUDIO +5V SW

Q1613, 1614

PROTECT

D1

D2

D1

D2

D1

D2

D1

D2

IC1203

+5V REG

AUDIO ON

+18V

HP SW

Q1506

T1303

4 8

2

CLAMP SW

Q1307

T1302

4 8

2

CLAMP SW

Q1305

T1301

4 8

2

CLAMP SW

Q1303

T1300

4 8

2

CLAMP SW

Q1300

Q1455

+5V+6V

IC1651 SW CONTROLLERIC1601 SW CONTROLLER

6

4

5

16

11

13

12

AMP

DT1

INV1

FB1

VREF

DT2

INV2

FB2

6

6

6

6

BUFF

Q1451

7

1

IC1309

(2/2)

7

IC1309

(1/2)

1

IC1304

(2/2)

7

IC1304

(1/2)

1

AMP

Q1456

MUTE SW

Q1503, 1504,

1508

IC1505 AMP

INB–

INA–

OUTB

OUTA

LATCH

Q1512

+18V

10

OUT2

14

NON2

OUT1

NON1

–

+

–

+

–

+

–

+

3

5

10

13

14

7

3

6

5

2

3

6

5

2

3

IC1451 AMP

IN1+

IN2+

IN3+

IN4+

OUT4

6

2

SWITCHING

Q1660, 1661

SWITCHING

Q1680, 1681

Q1665

AMP

Q1685

AMP

6

IN2–

7

OUT2

12

IN4+

8

OUT3

9

IN3–

1

OUT1

2

IN1–

PROTECT

Q1662

PROTECT

Q1682

PROTECT

B-SS3558<U/C>-BD3-EPS05

BUFF

Q1454

+5V

+12V

3

2

5

CN1503

R OUT

L OUT

HP_STAT

+12V

+5V

1

2

1

2

1

2

1

2

2

3

4

7

8

9

10

11

12

16

15

13

14

1

2

1

2

CN1303

HOT-4

COOL-4

CN1302

HOT-3

COOL-3

CN1301

HOT-2

COOL-2

CN1300

HOT-1

COOL-1

CN1451

5V (STBY)

5V (SENS)

12V

PWKEY

KEY

PWLED_G

PWLED_R

LEDCLK

LEDDATA

BRT DET

IRDET

IRLED1

IRLED2

CN1501

ROUT+

ROUT–

CN1502

LOUT+

LOUT–

LCD

BACK LIGHT

LCD

BACK LIGHT

LCD

BACK LIGHT

LCD

BACK LIGHT

I

TO H1 BOARD

CN001

(SPEAKER R)

(SPEAKER L)

CN1701

R OUT

L OUT

HP_STAT

U

(PHONE)

3

2

5

CN1700

(HEADPHONE)

SDM-N80 (E) 3-3

Q

D/D CONVERTER,

AUDIO IN,

USB CONTROL

CN902

3

2

1

CN901

3

2

1

CN930

INPUT1

AUDIO IN

CN931

INPUT2

AUDIO IN

AC IN

IC906

USB SELCTOR

1

10E

3

20E

5

2A

2

1A

9

3A

12

4A

AUDIO_L INPUT SELECT

1

V1

3

V2

AUDIO_R INPUT SELECT

1

V1

3

V2

SWITCHING

REGULATOR

11

DT2

13

INV2

12

FB2

REF

6

DT1

4

INV1

5

FB1

IC960 SW CONTROLLER

30E

40E

1B

4B

2B

3B

IC931

IC932

10

13

3

11

6

8

SW1

V_OUT

SW1

V_OUT

OUT2

NON2

OUT1

NON1

INVERTER

Q902

+3.3V

2

7

2

7

J961

ECS

POWER_ON

10

AMP

Q962, 963

14

7

AMP

Q966, 967

3

X901

12MHz

IO

IC902

RESET

8 7 6

5 4 3

2 1

CN960

+18V

8

+18V

7

+18V

6

STBY 6V

1

2

5

3

1

25

24

41

40

37

6

2

+18V

+6V

+18V

XOUT

XIN

DM0

DP0

RST

–IN2

–IN1

SWITCHING

Q964

SWITCHING

Q965

IC901

USB HUB

IC930

ISOLATOR

13

R1IN

14

T1OUT

2

V+

10

POW_1

43

DM1

42

DP1

7

OUT2

1

OUT1

IC965

RS232 DRIVER

R1OUT

T1IN

S960

ANALOG

DIGITAL

+5V

OI

IC963

+5V REG

POWER SW

Q901

+3.3V +5V

OI

IC903

+3.3V REG

+18V

IC961

+12V REG

+12V

OI

12

11

+6V

CONV_4V

1

CONV_4V

2

CONV_4V

3

CONV_6V

7

CONV_6V

8

USB_SEL

3

US_P_CONT

5

D–

6

D+

7

UP1_EXIST

1

UP2_EXIST

2

HUB ON

4

AUDIO_SEL

5

AUDIO_L

3

AUDIO_R

1

18V

1

18V

2

18V

3

18V

4

18V

5

18V

6

PON_12

8

STBY 6V

1

STBY 6V

2

RXD

10

TXD

11

ANALOG

12

DIGITAL

13

POWER_ON

5

CN963

CN903

CN932

CN961

CN962

G

TO A BOARD

CN502

E

TO A BOARD

CN602

F

TO A BOARD

CN601

B

TO A BOARD

CN604

D

TO A BOARD

CN501

I

TO B BOARD

CN1451

H

TO B BOARD

CN1203

CN001

LEDCLK

LEDDATA

PWKEY

PWLED_G

PWLED_R

KEY

BRTDET

IRDET

5V (STBY)

5V (SENS)

12V

IRLED2

IRLED1

CN1101

PROTECT

USB D–

USB D+

USB POWER CONT

USB 18V

10

14

12

11

13

19

18

17

9

5

6

7

8

+5V

2

4

5

3

1

+5V

+12V

IN1

AMP

Q016

IR SENSOR

Q015

LED DRIVE

Q013

LED DRIVE

Q011, 012

(USB CONTROL)

US

+5.5V

IC1103 SW CONTROLLER

14

12

16

6

4

5

3

CLOCK

2

+5V

+5V

KEY

+12V

D011 – D013

IR LED

7

3

DATA

+3.3V

SWITCHING

Q1106

BUFF

Q1101, 1102

PWKEY

LED_G

LED_R

IC011

AMP

3

7

OUT1

OUT2

IN2

35

OUT

VCC

IC011

LIGHT SENSOR

D013

D011, 012

PROTECT

Q1105

IC1105 +3.3V REG

IO IO

NON2

DT2

VREF

DT1

INV1

FBI

OUT1

NON1

+12V

Q0

4

D22

D21

TP001

MENU

D021, 022

MENU

IC1104

RESET

D35

D25

D025+D026

–

D035UPD036

DOWN

+5.5V

X1101

12MHz

Q2

Q6

Q3

6

TP002

TP003

–/

DOWN

IC031, 032, 041, 051, 052, 061, 071,

D027

VOLUME

41

DM0

40

DP0

37

RST

25

XOUT

24

XIN

Q1

5

7

10

D36 D23 D24 D28

D26 D37

TP004

+/

UP

BRIGHT

DET OUT

072, 081, Q001 – 006

D023

BRIGHT

IC1101

UBS HUB

DP1

DM1

DVR-1

POW_1

POW_2

DVR-2

DM2

DP2

Q4

8

D024

CONTRAST

42

43

31

10

11

32

3

2

TP005

CONTRAST

POWER SW

Q1104

POWER SW

Q1103

Q8

12

D028

INPUT

D37

OK

9

Q5

TP006

INPUT/

1

15

16

11

12

5

D38

CONTROL

Q10

14

+5V

A

V OUT1

V OUT2

Q9

13

D39D27

OK

D38

IN-1

D39

IN-2

IC1106 REGULATOR

FLG1

VC1

VC1

VC2

VC2

FLG2

IC36

LED

+5V

D001

G

S001

LED_R

LED_G

PWKEY

D001, S001

POWER

H

(USER CONTROL)

3

7

B-SS3558<U/C>-BD4-EPS05

CN1102

3

2

1

CN1103

1

2

3

SDM-N80 (E) 3-4

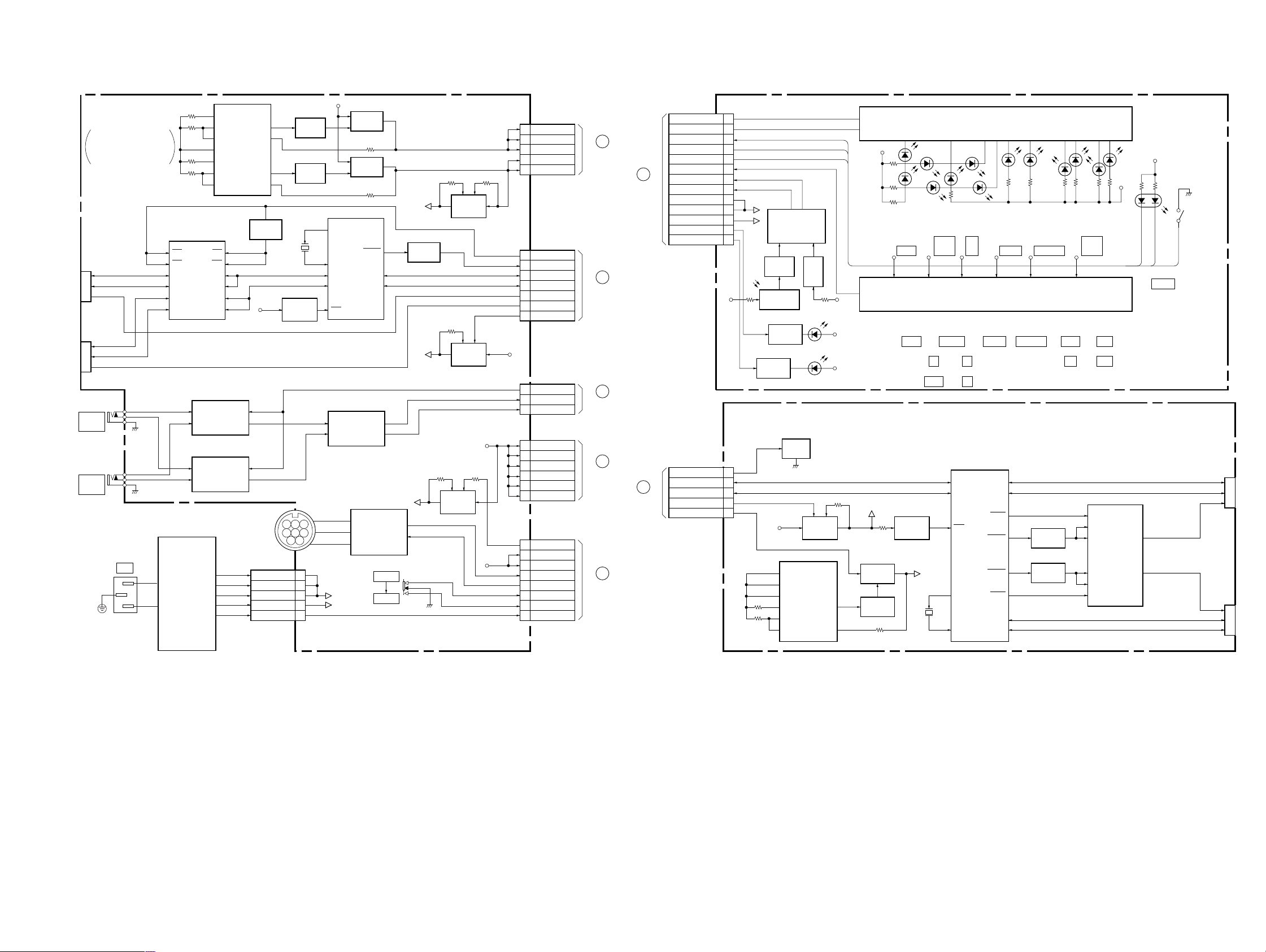

3-2. FRAME SCHEMATIC DIAGRAM

CN101

HD15P

INPUT1

CN201

DVI-I

INPUT1

FLASH

CN603

38P

PANEL/GVIF GND

1

PANEL/GVIF 18V

2

GVIF-GND

3

4

SDATAN-B

5

SDATAGND-A

6

SDATAP-B

7

GVIF-GND

8

GVIF-GND

9

SDATAN-A

10

SDATAGND-B

11

SDATAP-A

12

GVIF-GND

13

STBY5V

14

A/D CONVERTER, SYNC_IRQ GENERATOR,

A

TMDS RECEIVER, DDC, µ-COM, INPUT SELECT,

SYNC SEPARATOR, SCAN CONVERTER,

()

GVIF TRANSMITTER

CN301

10P

1

TMODE

2

TAUX3

3

TVPP1

4

TRES

5

TAUS

6

TCK

7

RXD

8

TXD

9

GND

10

PX_RSTN

A1

B1

A2

B2

A3

B3

A4

B4

A5

B5

A6

B6

A7

B7

A8

B8

A9

B9

A10

B10

A11

B11

A12

B12

A13

B13

A14

B14

A15

B15

A16

B16

A17

B17

A18

B18

A19

B19

A20

B20

A21

B21

A22

B22

A23

B23

A24

B24

A25

B25

A26

B26

A27

B27

A28

B28

A29

B29

A30

B30

A31

B31

A32

B32

A33

B33

A34

B34

A35

B35

CN401

70P

GND

A19

GND

A18

GND

A17

GND

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

GND

BHENN

GND

ROMOEN

GND

ROMOEN

3.3V

ROMWEN

3.3V

ROMWEN

3.3V

CS2

3.3V

CS3

GND

RESETN

GND

NMI

GND

FCEN

GND

BOOTWE

GND

VPPEN

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

NC

NC

6V

6V

6V

6V

CN501

13P

STBY_6V

STBY_6V

GND

GND

POWERON

PON_4

PON_6

PON_13

GND

RXD

TXD

ANALOG

DIGITAL

CN502

10P

CONV_4V

CONV_4V

CONV_4V

GND

GND

GND

CONV_6V

CONV_6V

GND

GND

CN604

12P

+18V

+18V

+18V

+18V

+18V

+18V

GND

GND

GND

GND

GND

GND

CN601

AUDIO_R

AUDIO_GND

AUDIO_L

AUDIO_GND

AUDIO_SEL

CN602

UP1_EXIST

UP2_EXIST

USB_SEL

HUBON

US_P_CONT

CN302

4P

STBY5V

LED_GREEN

LED_RED

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

11

12

5P

1

2

3

4

5

8P

1

2

3

4

5

6

D-

7

D+

8

GND

1

2

3

4

STBY 6V

2

STBY 6V

3

GND

4

GND

5

POWER_ON

6

PON_4

7

PON_6

8

PON_12

9

GND

10

RXD

11

TXD

12

ANALOG

13

DIGITAL

1

CONV_4V

2

CONV_4V

3

CONV_4V

4

GND

5

GND

6

GND

7

CONV_6V

8

CONV_6V

9

GND

10

GND

CN961

1

18V

2

18V

3

18V

4

18V

5

18V

6

18V

7

GND

8

GND

9

GND

10

GND

11

GND

12

GND

CN932

1

AUDIO_R

2

AUDIO_GND

3

AUDIO_L

4

AUDIO_GND

5

AUDIO_SEL

CN903

1

UP1_EXIST

2

UP2_EXIST

3

USB_SEL

4

HUB ON

5

US_P_CONT

6

D-

7

D+

8

GND

STBY 5V

4

LED_GREEN

3

LED_RED

2

1

GND

CN963

10P

12P

5P

8P

CN95

4P

CN962

13P

1

CN-SENS

15

B-CPU-ST

16

PANEL MODE

17

SCL

18

SDA

19

GND

20

AUDIO-GND1

21

AUDIO-GND1

22

AUDIO-GND1

23

AUDIO-GND1

24

AUDIO-R

25

AUDIO-GND2

26

AUDIO-L

IEEE1394 TPB*

27

IEEE1394 TPB*

28

IEEE1394 TPA*

29

IEEE1394 TPA*

30

31

USB POWER

USB POWER GND

32

33

USB SIG-

USB SHIELD GND

34

35

USB SIG+

36

HOT PLUG

37

BL GND

BL18V

38

Q

D/D CONVERTER,

AUDIO IN,

()

USB CONTROL

8 7 6

J961

5 4 3

ECS

2 1

CN930

3P

INPUT1

AUDIO IN

CN931

3P

INPUT2

AUDIO IN

CN960

8P

8

+18V

+18V

+18V

GND

GND

GND

POWER_ON

STBY 6V

7

6

5

4

3

2

1

SWITCHING

REGULATOR

AC IN

H2

(AC POWER LED)

FLASH

CN603

38P

PANEL/GVIF GND

1

PANEL/GVIF 18V

2

GVIF-GND

3

4

SDATAN-B

5

SDATAGND-A

6

SDATAP-B

7

GVIF-GND

8

GVIF-GND

9

SDATAN-A

10

SDATAGND-B

11

SDATAP-A

12

GVIF-GND

13

STBY5V

14

CN-SENS

15

B-CPU-ST

16

PANEL MODE

17

SCL

18

SDA

19

GND

20

AUDIO-GND1

21

AUDIO-GND1

22

AUDIO-GND1

23

AUDIO-GND1

24

AUDIO-R

25

AUDIO-GND2

26

AUDIO-L

IEEE1394 TPB*

27

IEEE1394 TPB*

28

IEEE1394 TPA*

29

IEEE1394 TPA*

30

31

USB POWER

USB POWER GND

32

33

USB SIG-

USB SHIELD GND

34

35

USB SIG+

36

HOT PLUG

37

BL GND

BL18V

38

CN1402

10P

TMODE

1

1

TAUX3

2

2

TVPP1

3

3

TRES

4

4

TAUX

5

5

TCK

6

6

RXD

7

7

TXD

8

8

GND

9

9

SUB5V

10

10

20P

CN1451

12V

5V(STBY)

5V(SENS)

PON_5KY

123456789

19

20

12V

CN001

(20P)

PON_5KY

5V(STBY)

5V(SENS)

GND

GND

PWLED_G

PWLED_R

LEDDATA

IRLED1

IRLED2

IRDET

LEDCLK

PWKEY

KEY

101112131415161718

101112131415161718

GND

GND

KEY

PWKEY

H

(USER CONTROL)

PWLED_G

PWLED_R

LEDCLK

LEDDATA

IRLED1

IRLED2

IRDET

H_AGND

BRTDET

H_AGND

BRTDET

H_AGND

H_AGND

CN1700

(HEAD PHONE)

SUB µ-COM, GVIF RECEIVER,

B

D/D CONVERTER,

(

INVERTER, AUDIO, SENSOR AMP

8P

H_REV1

H_REV2

20

19

123456789

H_REV1

H_REV2

CN1203

USB 18V

1234567

1234567

8P

USB 18V

CN1101

US

(USB CONTROL)

U

(PHONE)

USB POWER CONT

USB D-

USB D+

PROTECT

USB D-

USB D+

PROTECT

USB POWER CONT

CN1701

7P

S-GND

S-GND

L OUT

R OUT

HP_STAT

(SPEAKER R)

(SPEAKER L)

USB SHIELD GND

USB GND

USB GND

USB SHIELD GND

GND

GND

USB DET

8

8

USB DET

7

6

5

4

3

2

1

)

1

2

3

4

5

1

2

1

2

CN1503

5P

GND

L OUT

R OUT

GND

HP-STAT

CN1501

ROUT+

ROUT-

CN1502

2P WHITE

LOUT+

LOUT-

2P RED

CN1204

FX10A-100S

A1

VCC

B1

VCC

A2

VCC

B2

VCC

A3

VCC

B3

VCC

A4

GND

B4

GND

A5

BLON-P

B5

WHT

A6

GND

B6

GND

A7

RA7

B7

RB7

A8

RA6

B8

RB6

A9

GND

B9

GND

A10

RA5

B10

RB5

A11

RA4

B11

RB4

A12

GND

B12

GND

A13

RA3

B13

RB3

A14

RA2

B14

RB2

A15

GND

B15

GND

A16

GND

B16

GND

A17

RA1

B17

RB1

A18

RA0

B18

RB0

A19

GND

B19

GND

A20

GA7

B20

GB7

A21

GA6

B21

GB6

A22

GND

B22

GND

A23

GA5

B23

GB5

A24

GA4

B24

GB4

A25

GND

B25

GND

A26

GND

B26

GND

A27

GA3

B27

GB3

A28

GA2

B28

GB2

A29

GND

B29

GND

A30

GA1

B30

GB1

A31

GA0

B31

GB0

A32

GND

B32

GND

A33

CLKA

B33

CLKB

A34

GND

B34

GND

A35

DEA

B35

DEB

A36

GND

B36

GND

A37

BA7

B37

BB7

A38

BA6

B38

BB6

A39

GND

B39

GND

A40

BA5

B40

BB5

A41

BA4

B41

BB4

A42

GND

B42

GND

A43

BA3

B43

BB3

A44

BA2

B44

BB2

A45

GND

B45

GND

A46

BA1

B46

BB1

A47

BA0

B47

BB0

A48

GND

B48

GND

A49

GND

B49

GND

A50

GND

B50

GND

CN1300

2P

BHS

1

HOT-1

2

COOL-1

CN1301

2P

BHS

1

HOT-2

2

COOL-2

CN1302

2P

BHS

1

HOT-3

2

COOL-3

CN1303

2P

BHS

1

HOT-4

2

COOL-4

B-SSS3558<U/C>-KESSENZU-EPS05

LCD

BACK LIGHT

LCD

BACK LIGHT

LCD

BACK LIGHT

LCD

BACK LIGHT

LCD

DISPLAY

SDM-N80 (E) 3-5

Loading...

Loading...