Page 1

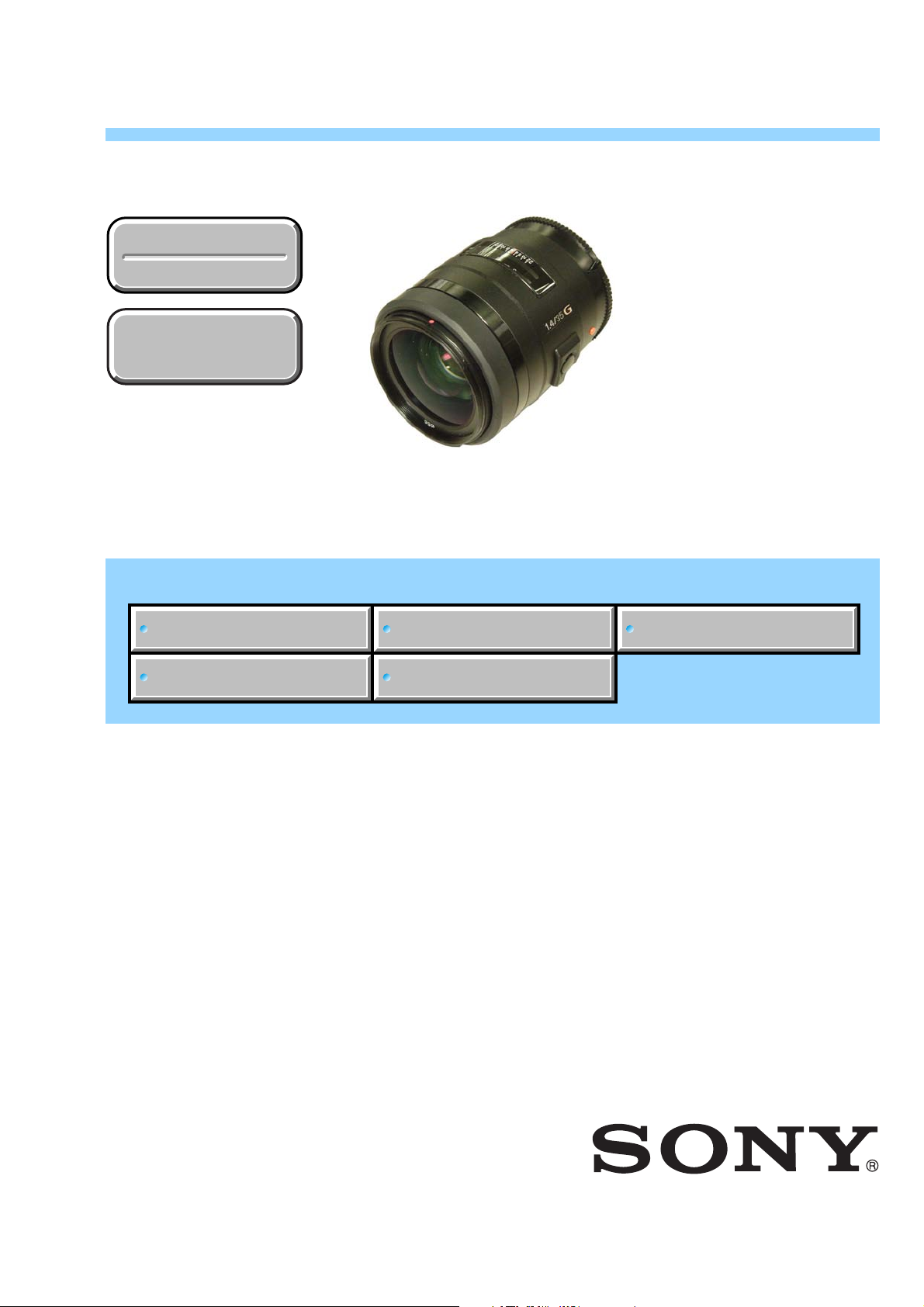

SERVICE MANUAL

SAL35F14G

(1.4/35G) (35mm F1.4G)

Ver 1.1 2007.02

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

SPECIFICATIONS

US Model

Canadian Model

AEP Model

Chinese Model

DISASSEMBLY ADJUSTMENTS

SERVICE NOTE

REPAIR PARTS LIST

LENS FOR DSLR CAMERA

SAL35F14G (1.4/35G) (35mm F1.4G)

Sony EMCS Co.

2007B0800-1

© 2007.02

Published by Kohda TEC9-852-108-11

Page 2

SPECIFICATIONS

• This lens is equipped with a distance encoder. The distance encoder allows more accurate measurement (ADI) by using a flash for ADI.

• Depending on the lens mechanism, the focal length may change with any change of the shooting distance. The focal length assumes the lens is focused

at infinity.

Equivalent 35mm-format focal length *1 (mm)

52.5

*1The value for equivalent 35mm-format focal length is based on Digital Single Lens Reflex Cameras equipped with an APS-C sized image sensor.

Lens groups elements

8-10

Angle of view 1 *

63°

Angle of view 2 *

44°

*2The value of angle of view 1 is based on 35mm-format cameras, and that of angle of view 2 is based on Digital Single Lens Reflex Cameras

equipped with an APS-C sized image sensor.

Minimum focus (m (feet)) *

0.3 (1.0)

*3Minimum focus is the shortest distance from the image sensor to the subject.

Maximum magnification (

0.2

Minimum f-stop

f/22

Filter diameter (mm)

55

Dimensions (maximum diameter

Approx. 69 × 76 (2 3/4 × 3)

Mass (g (oz.))

Approx. 510 (18)

Included items

Lens (1), Front lens cap (1), Rear lens cap (1), Lens hood (1), Carrying case (1), Set of printed documentation

2

2

3

××

×)

××

××

× height) (mm (in.))

××

Designs and specifications are subject to change without notice.

SAL35F14G (1.4/35G) (35mm F1.4G)

— 2 —

Page 3

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Chemicals ·······································································1-1

1-2. Exterior Parts ·································································· 1-1

1-3. Unleaded Solder ·····························································1-1

1-4. Safety Check-out ····························································1-2

1-5. Troubleshooting ····························································· 1-3

2. DISASSEMBLY

2-1. Disassembly ··································································· 2-2

3. REPAIR PARTS LIST

3-1. Exploded Views ······························································3-1

3-2. Supplied Accessories ······················································3-8

4. ADJUSTMENTS

4-1. Preparations ···································································· 4-1

4-2. Aperture Diameter Check/Adjustment ························· 4-13

4-3. Projective Resolving Power Check ······························4-18

4-4. Flange Back (f’F) Check/Adjustment ·························· 4-21

4-5. Focus-shift Check/Adjustment (Aperture (Amount of

Spherical Aberration)) ·················································· 4-24

4-6. Lens ROM Check ·························································4-25

4-7. Focus Brush Position Check/Adjustment·····················4-27

4-8. Focus Hold Button Check (Focus Hold Button) ··········4-34

4-9. Write dSB ····································································· 4-36

SAL35F14G (1.4/35G) (35mm F1.4G)

— 3 —

Page 4

1. SERVICE NOTE

1-1. Chemicals

Some chemicals used for servicing are highly volatile.

Their evaporation caused by improper management affects your health and environment, and wastes resources.

Manage the chemicals carefully as follows.

• Store chemicals sealed in a specific place to prevent from exposure to high temperature or direct sunlight.

• Avoid dividing chemicals into excessive numbers of small containers to reduce natural evaporation.

• Keep containers sealed to avoid natural evaporation when chemicals are not in use.

• Avoid using chemicals as much as possible. When using chemicals, divide only required amount to a small plate from the container and

use up it.

1-2. Exterior Parts

Be careful to the following points for exterior parts used in this unit.

• Use a piece of cleaning paper or cleaning cloth for cleaning exterior parts. Avoid using chemicals.

Even if you have to use chemicals to clean heavy dirt, don’t use paint thinner, ketone, nor alcohol.

• Insert the specific screws vertically to the part when installing a exterior part.

Be careful not to tighten screws too much.

1-3. Unleaded Solder

This unit uses unleaded solder.

Boards requiring use of unleaded solder are printed with the lead free mark (LF) indicating the solder contains no lead.

(

Caution: Some printed circuit boards may not come printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

Be careful to the following points to solder or unsolder.

• Set the soldering iron tip temperature to 350 °C approximately.

If cannot control temperature, solder/unsolder at high temperature for a short time.

Caution: The printed pattern (copper foil) may peel away if the heated tip is applied for too long, so be careful!

Unleaded solder is more viscous (sticky, less prone to flow) than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Be sure to control soldering iron tips used for unleaded solder and those for leaded solder so they are managed separately. Mixing

unleaded solder and leaded solder will cause detachment phenomenon.

SAL35F14G (1.4/35G) (35mm F1.4G)

1-1

Page 5

1-4. SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs of deterioration. Point them out to the customer and recommend their

replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C during repairing.

• Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or unsoldering.

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAL35F14G (1.4/35G) (35mm F1.4G)

1-2

Page 6

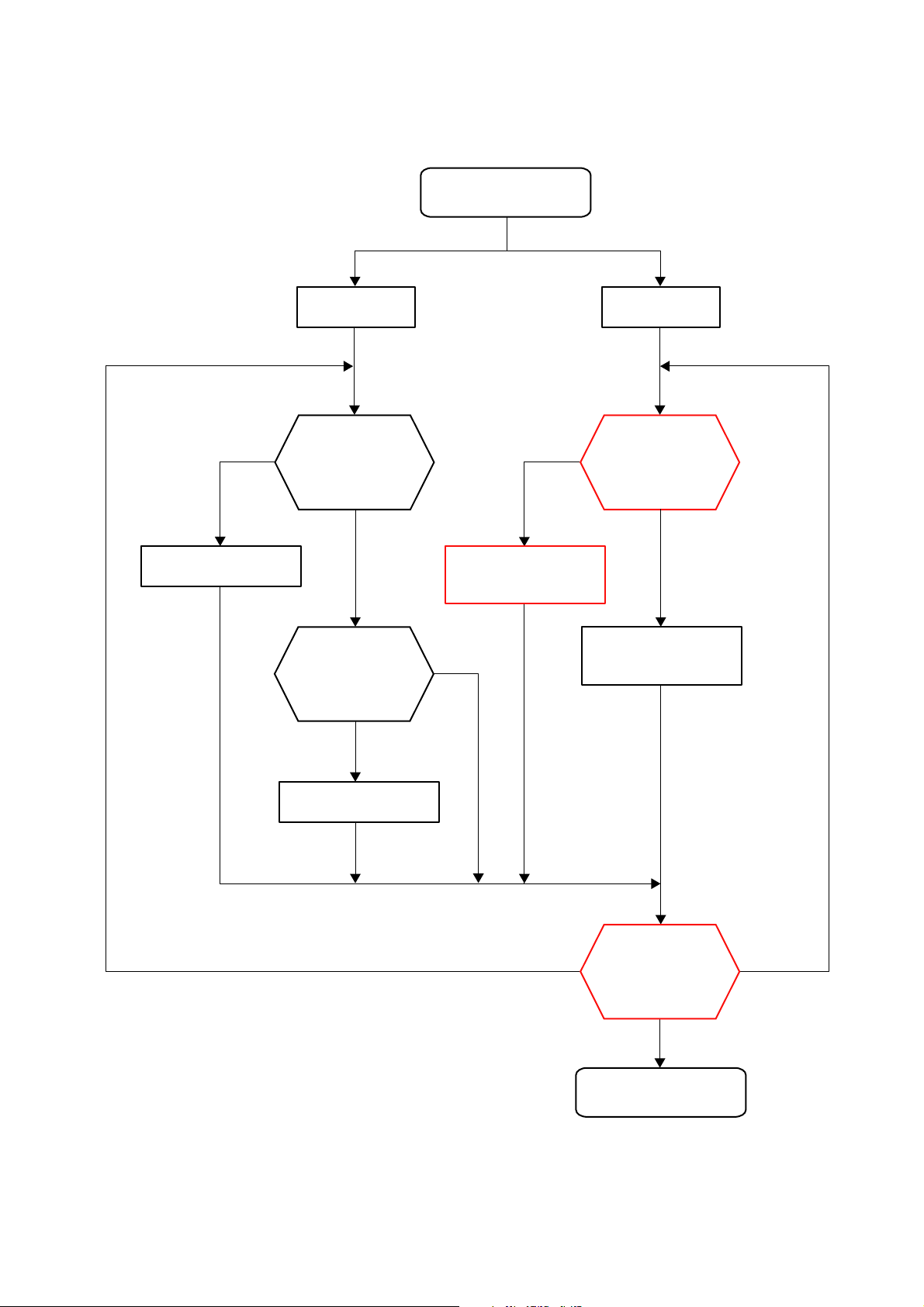

1-5. TROUBLESHOOTING

1-5-1. Aperture Trouble

Function NG F No. NG

Aperture trouble

NG

Replace the defective part.

Replace the defective part.

Check operation of

the preset ring.

OK

Check operation

of the diaphragm

control block.

NG

Perform the aperture

diameter adjustment.

(See page 4-16.)

OK

Perform the aperture

NG

diameter check.

(See page 4-13.)

Check operation of the

preset ring, and replace

the defective part.

OK

SAL35F14G (1.4/35G) (35mm F1.4G)

1-3

Perform the aperture

diameter check.

(See page 4-13.)

OK

END

NGNG

Page 7

1-5-2. Focus Trouble

Focus trouble

Function NG Position NG

NGNG

Check the coupler.

Check the installation of

the main flexible block.

Replace the defective part

or apply the grease.

NG

OK

Check the fixed holding

tube and distance

control tube.

NG

Replace the defective part

or apply the grease.

Check the operation

again.

OK

Reinstall the main

flexible block.

NG

Clean the pattern of the

main flexible block.

OK

Check pattern

of the main flexible block.

OK

Replace the

main flexible block.

SAL35F14G (1.4/35G) (35mm F1.4G)

OK

1-4

Check the foecusing

operation again.

OK

END

NG

Page 8

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, dont’ pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, dont’ press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded flexible board.

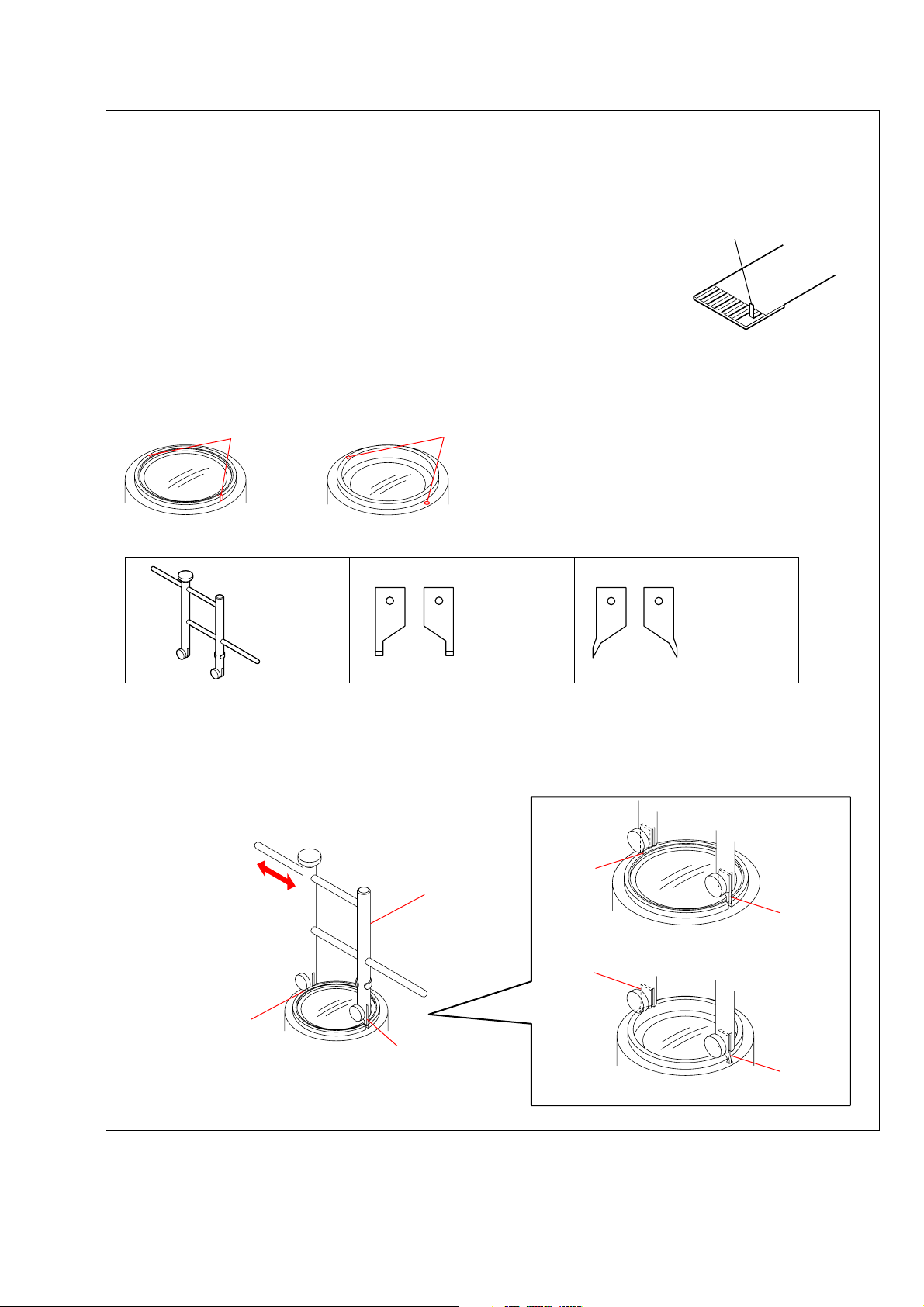

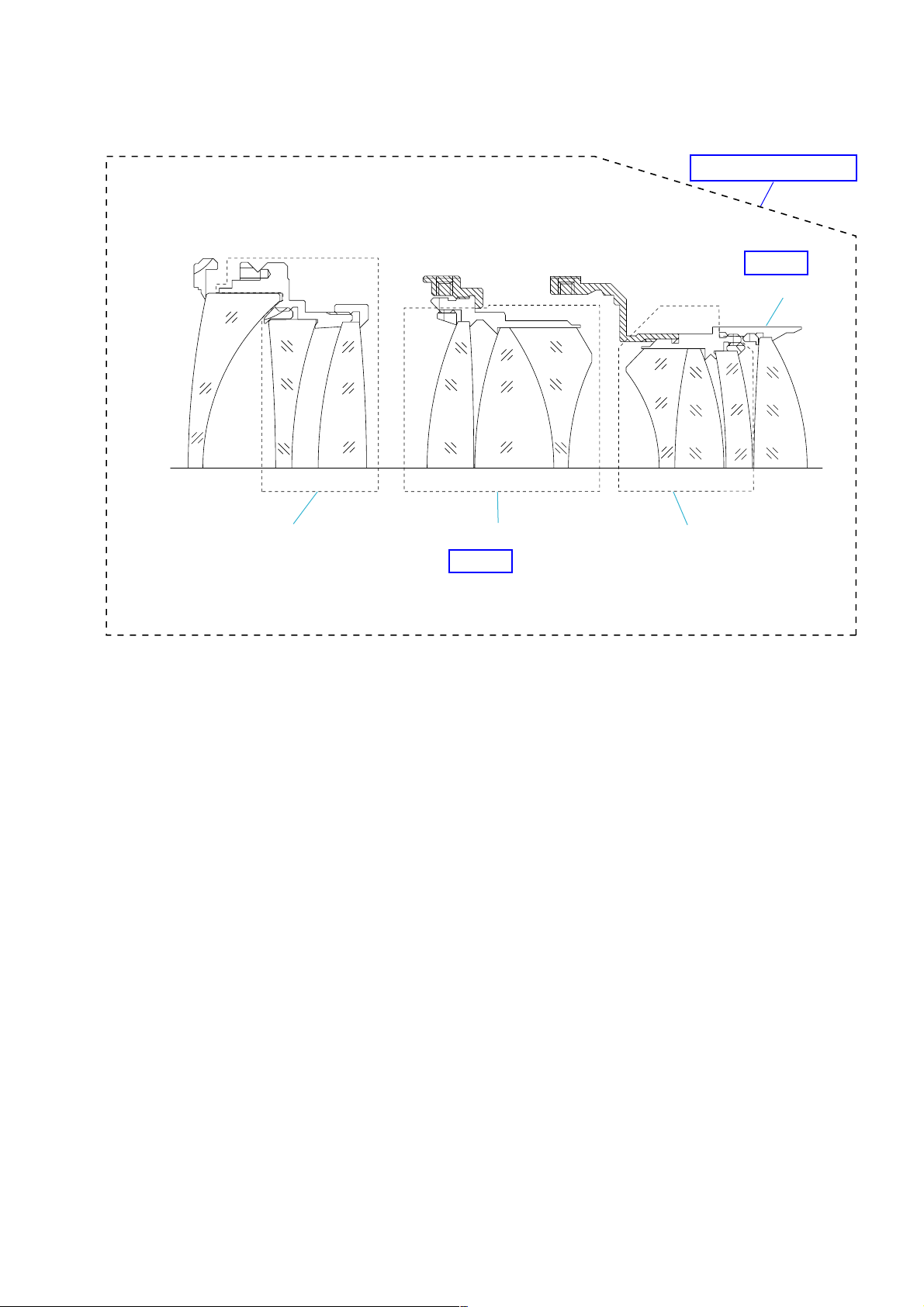

UNIVERSAL WRENCH

In case of the following notches or holes are located in the lens block, etc during disassembling/

assembling the lens, Use the universal wrench.

Notches Holes

How to Use

Universal wrench

J-6082-609-A

Chip-A for

universal wrench:

J-6082-609-1

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

Chip-B for

universal wrench:

J-6082-609-2

Attach the chip-A or chip-B to the universal wrench.

For the notches: chip-A

For the holes: chip-B

Match the universal wrench to the holes or notches of the lens block, etc.

Match the universal wrench

to the width of holes or notches.

Chip

Universal wrench

Chip

Chip-A

Chip-A

Notches

Chip-B

Chip-B

Holes

SAL35F14G (1.4/35G) (35mm F1.4G)

2-1

Page 9

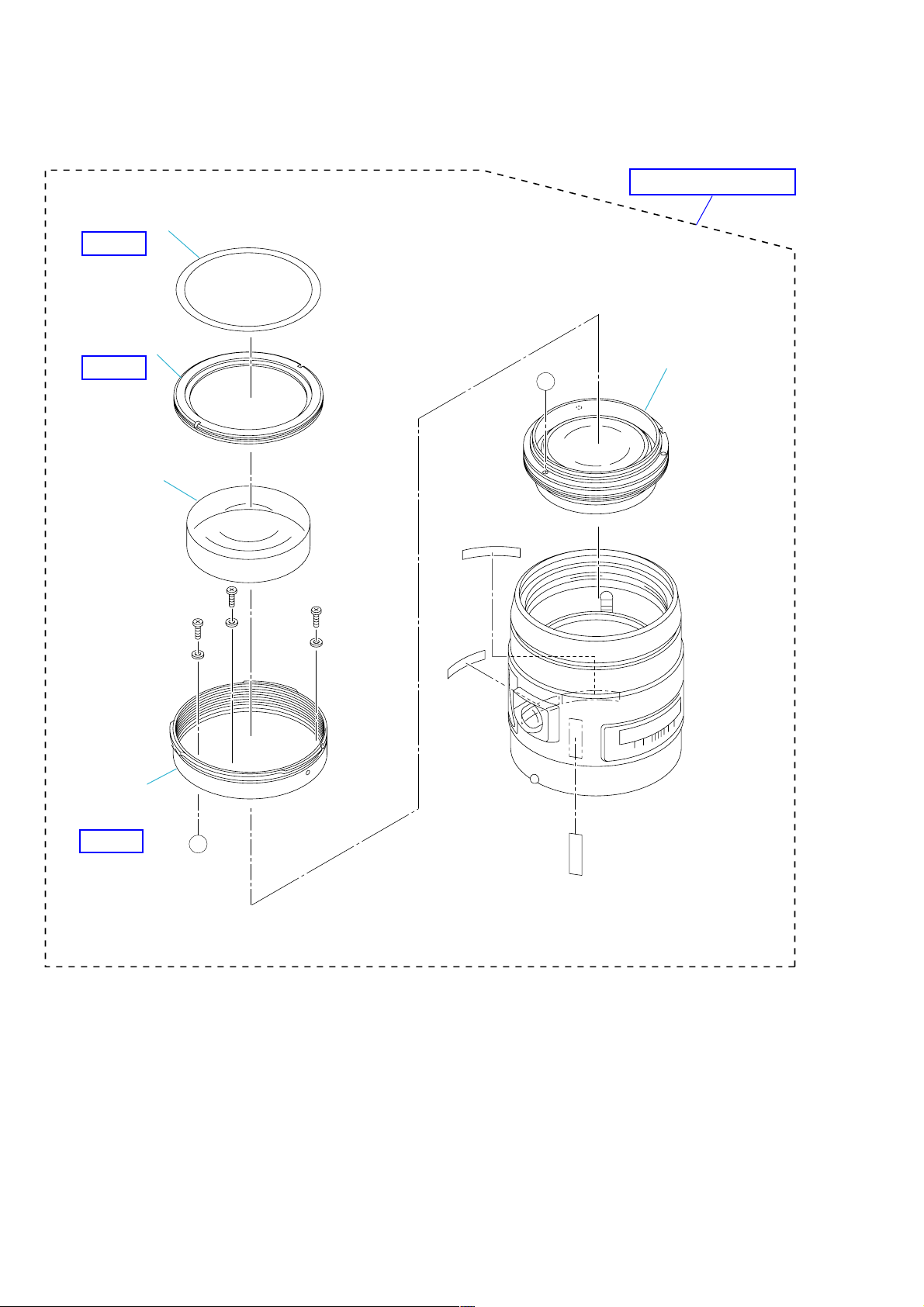

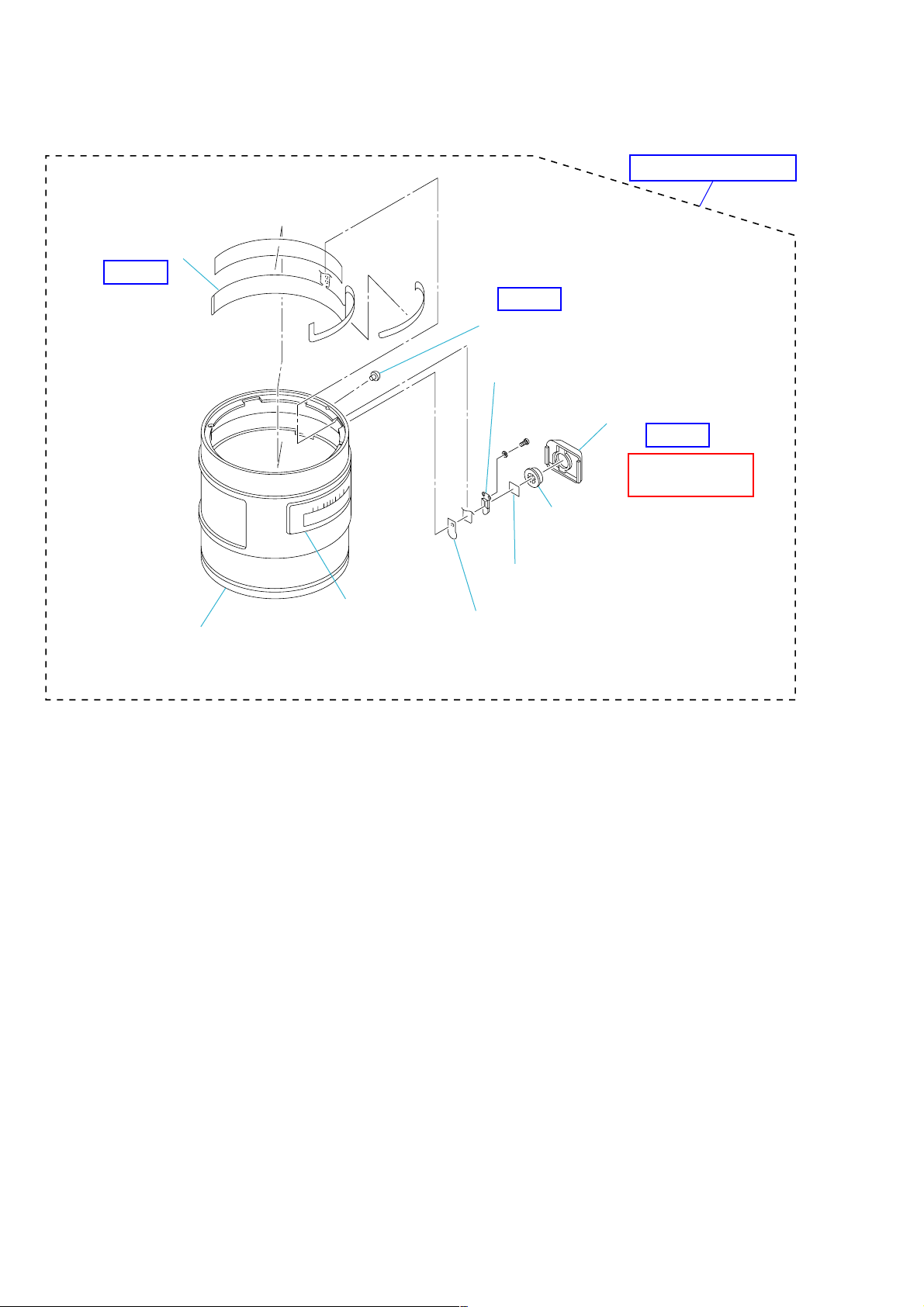

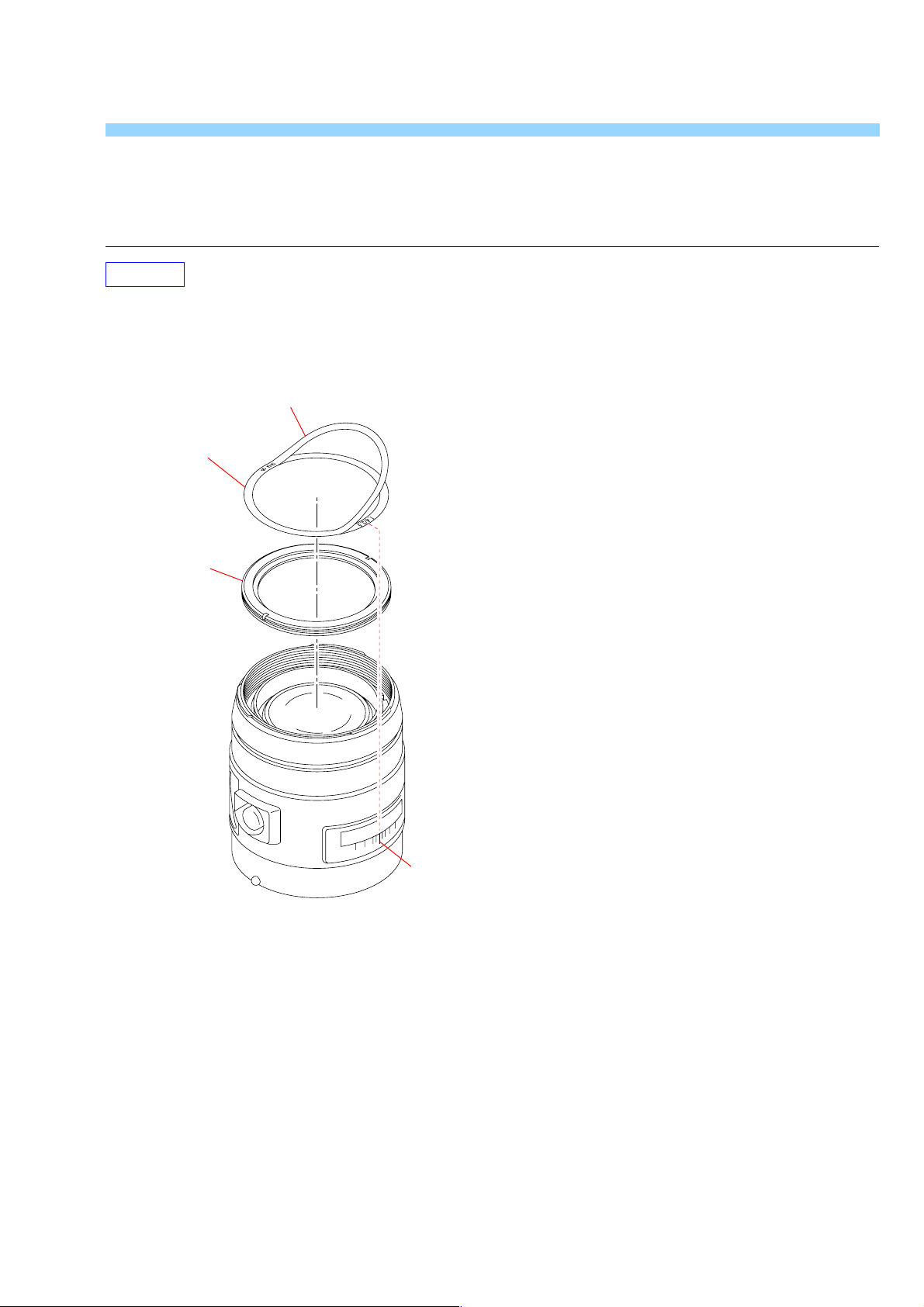

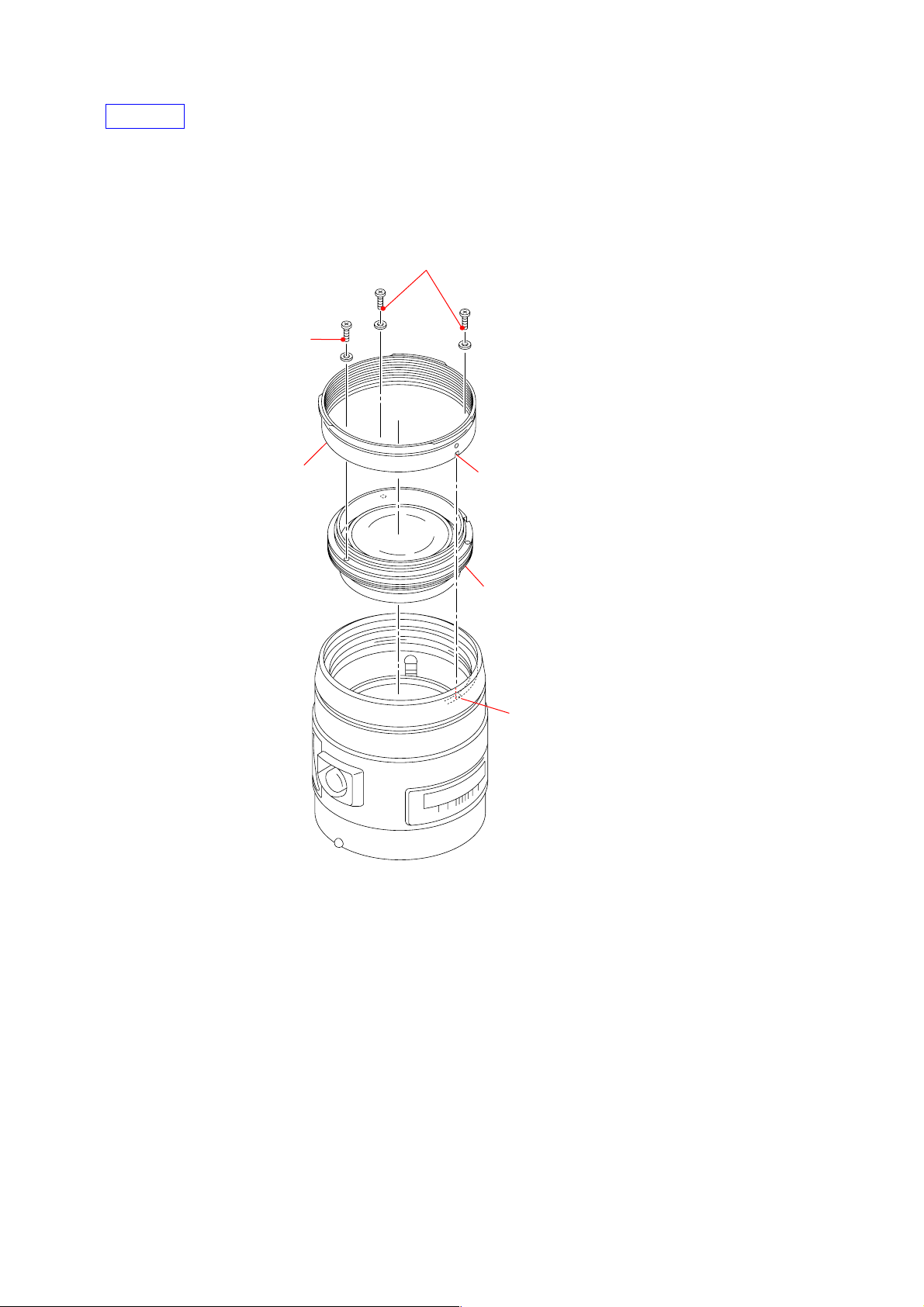

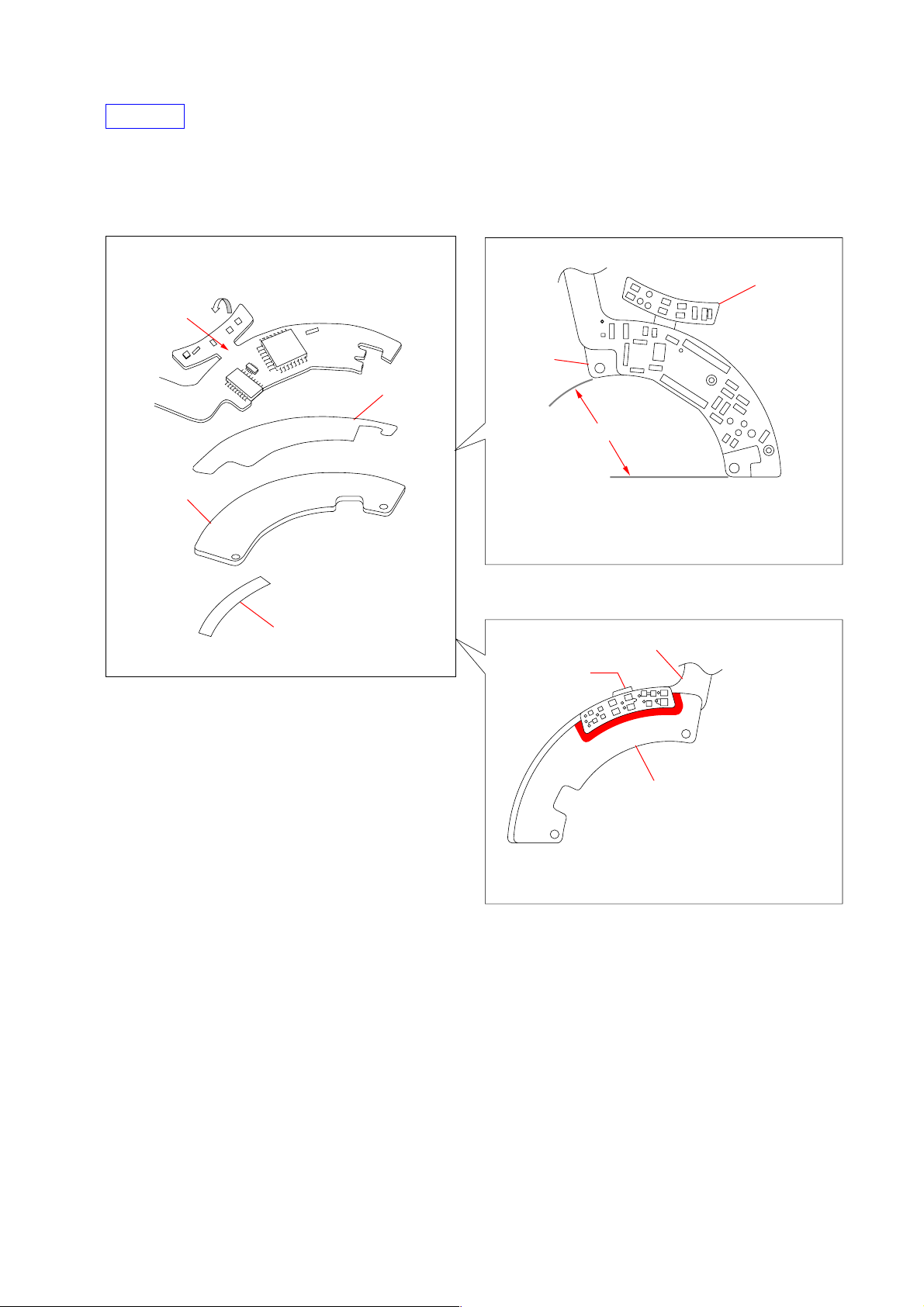

2-1. DISASSEMBLY

2-1-1. ORNAMENTAL RING LABEL AND MIRROR BARREL TUBE BLOCK

1 Ornamental Ring Label

HELP01

EXPLODED VIEW

2 Ornamental Ring

HELP02

3 G1

5 1 Group Lens Block

A

4 Mirror Barrel

Tube Block

HELP03

A

1.4/35G

SAL35F14G (1.4/35G) (35mm F1.4G)

2-2

Page 10

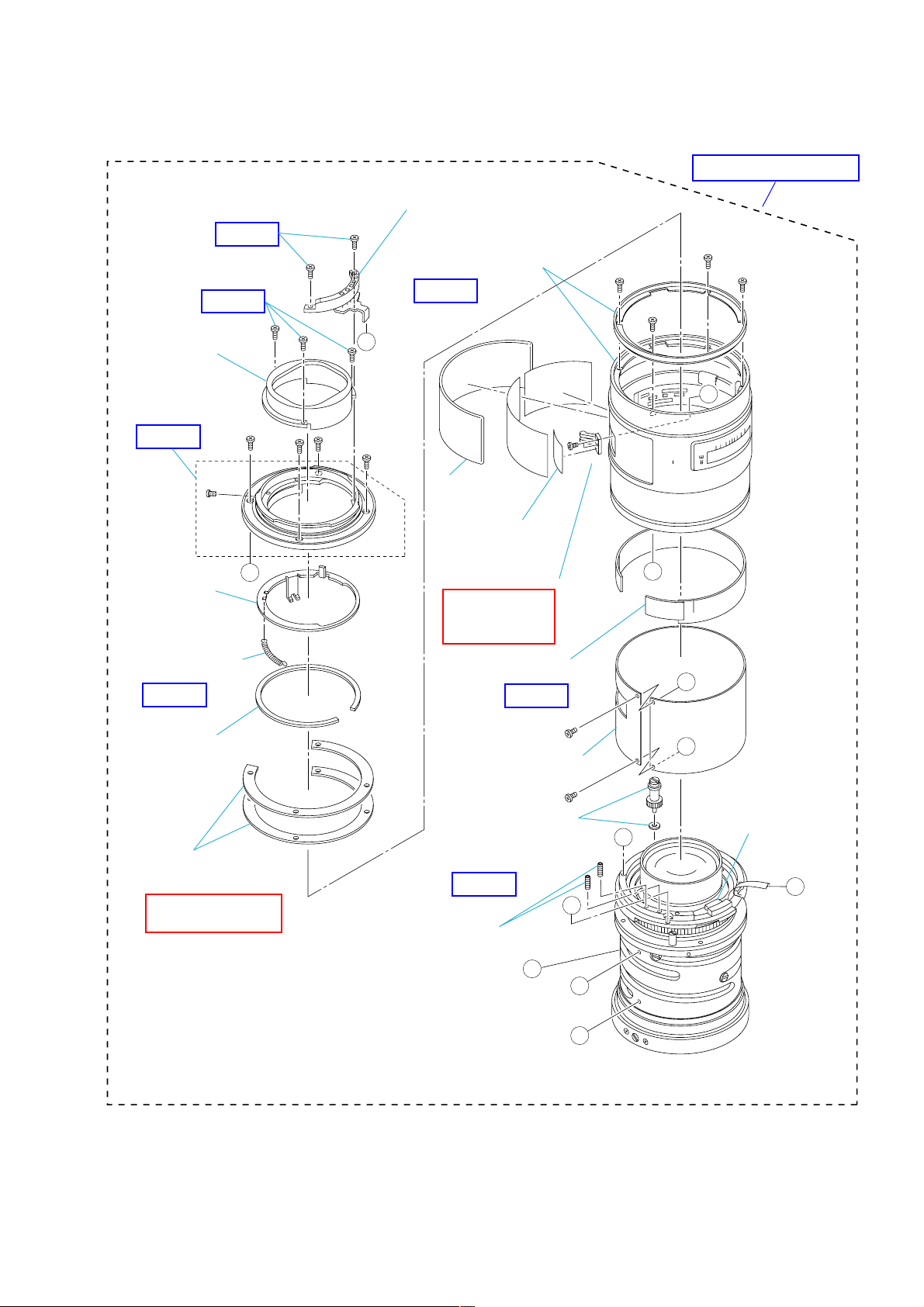

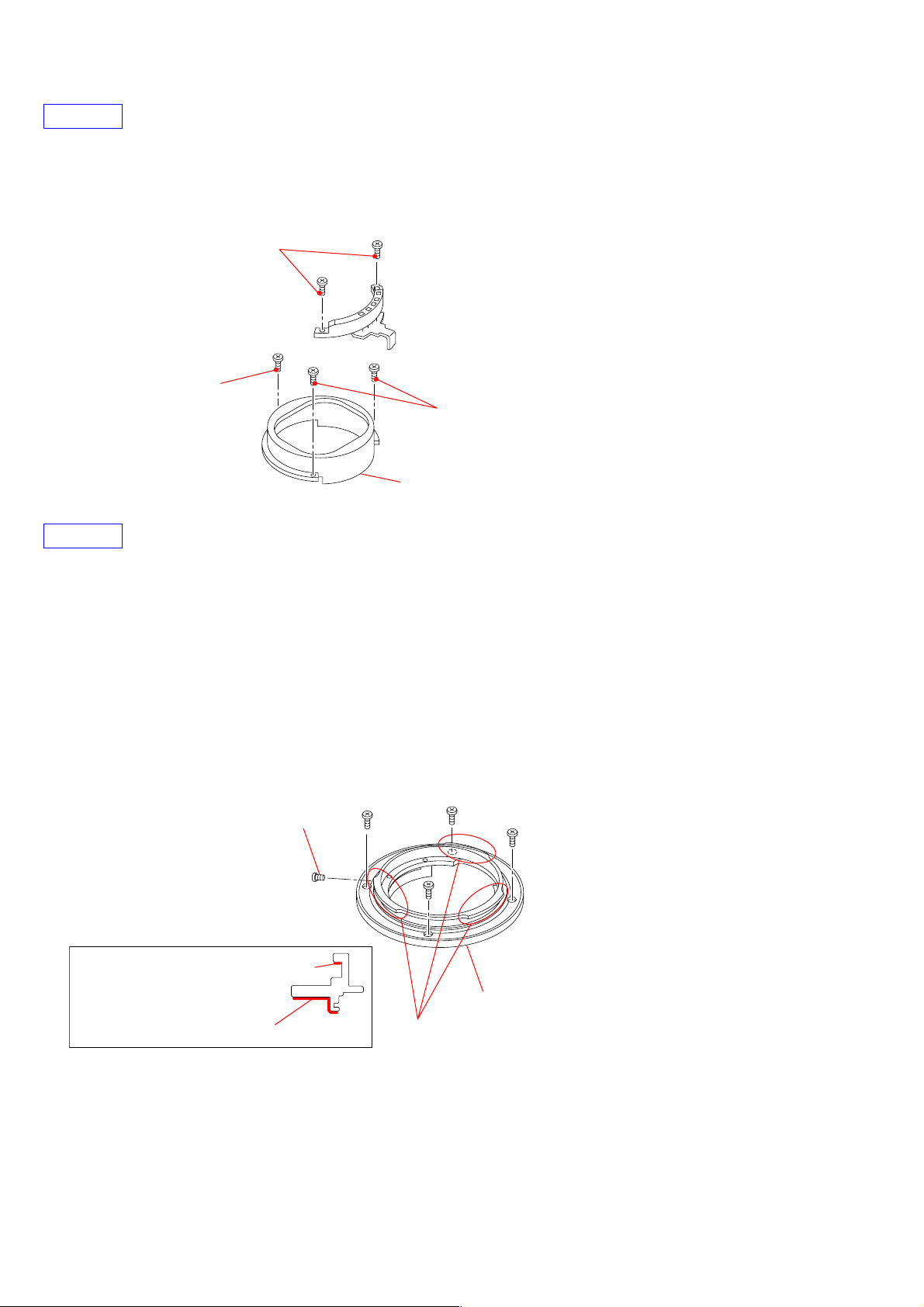

2-1-2. LENS MOUNT RIVETING BLOCK AND LIGHT INTER CEPTION TUBE

2 Connection Box

EXPLODED VIEW

HELP04

HELP04

1 Light Interception

Tube

3 Lens Mount

Riveting Block

HELP05

A

Preset Ring

Main Spring

HELP06

!- Orange Ring and

G Ornamental

Ring Block

HELP07

F

C

SONY

7 Beam

Leather

8 Brush Hole

Cover

9 Focus Brush

FOCUS BRUSH

POSITION

ADJUSTMENT

B

!= Distance Scale

Plate

HELP08

D

Preset Ring

Retainer

4 Back Adjustment

Washer

FLANGE BACK (f F)

ADJUSTMENT

2-1-3. OUTER TUBE AND JOINT TUBE

HELP10 HELP10

EXPLODED VIEW

1 Outer Tube

Main Flexible Block

HELP11

2 Flexible Base Plate

Stopper Pin

3 Joint Tube

HELP12

HELP13

Guide Pin

Guide Roller

HELP13

Guide Pin

HELP13

Guide Pin

Guide Roller

Guide Roller

HELP13

Guide Pin

Guide Roller

5 3 Group

Lens Block

HELP14

6 Iris Control

Plate Block

Iris Feather

Unit

Iris Retainer

Tube

Guide Roller

Guide Roller

Guide Pin

HELP13

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP13

Guide Pin

2-4

Iris Retainer

Tube SP

4 2 Group Lens Block

Page 12

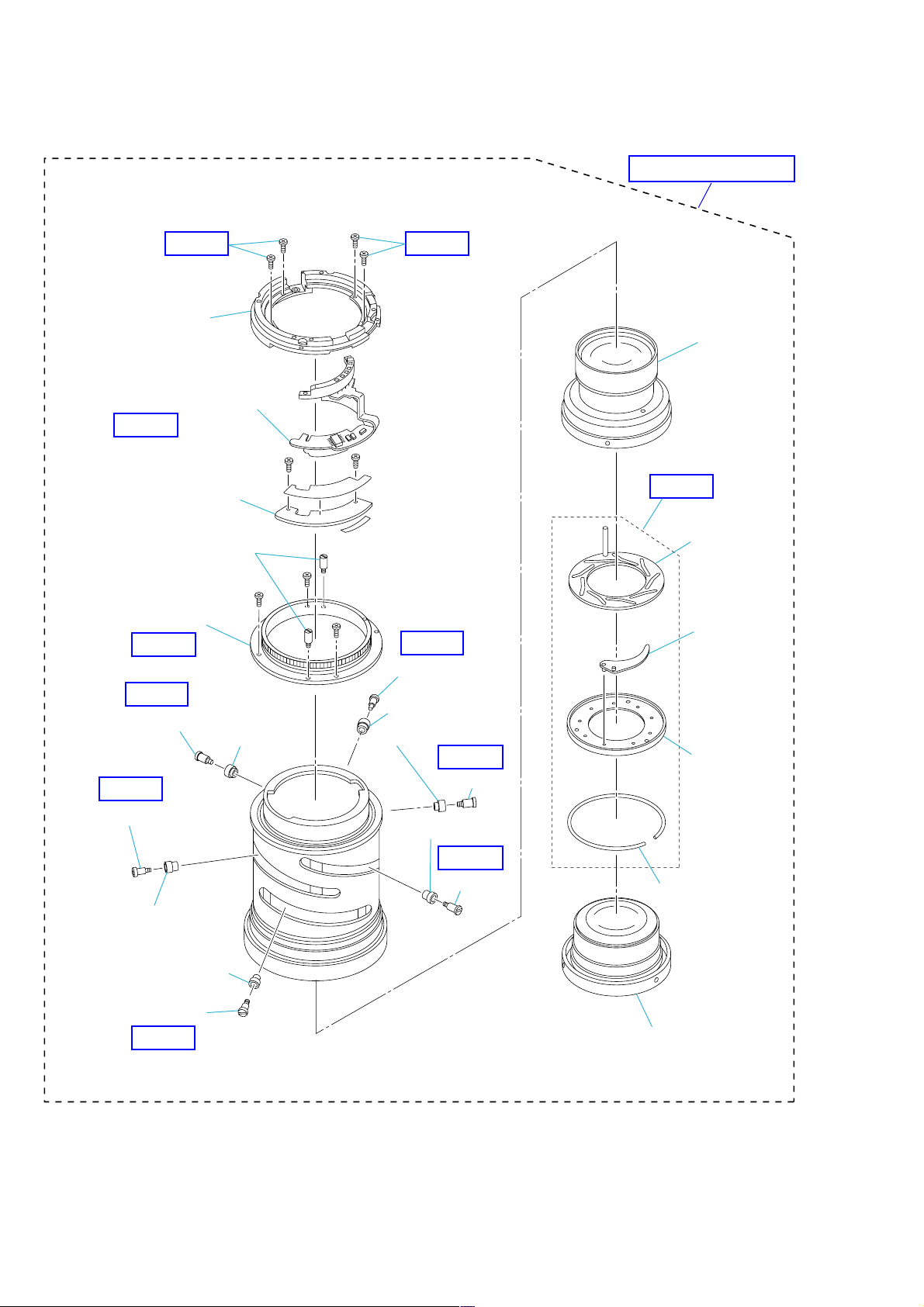

2-1-4. FIXED TUBE BLOCK AND DISTANCE CONTROL TUBE

EXPLODED VIEW

HELP15

HELP15

HELP16

HELP18

HELP17

2 Cam Tube Retainer

3 Fixed Tube

Block

6 Friction (SP)

7 Torque Ring

Punching

Stopper

7 Torque Ring

Punching

Stopper

7 Torque Ring

Punching

Stopper

Fixed Tube

Cam Tube

Torque

Ring A

5 Torque Ring A,

Float Ring,

Scissors Lever Block,

Torque Ring B

Torque

Ring B

Friction

Cloth A

Float Ring

Scissors

Lever Block

4 Distance Control

Tube and Control

Tube Guide Pin

1 Distance Tube

Rubber Ring

Friction Cloth B

C

A

B

C

A

B

SAL35F14G (1.4/35G) (35mm F1.4G)

2-5

Page 13

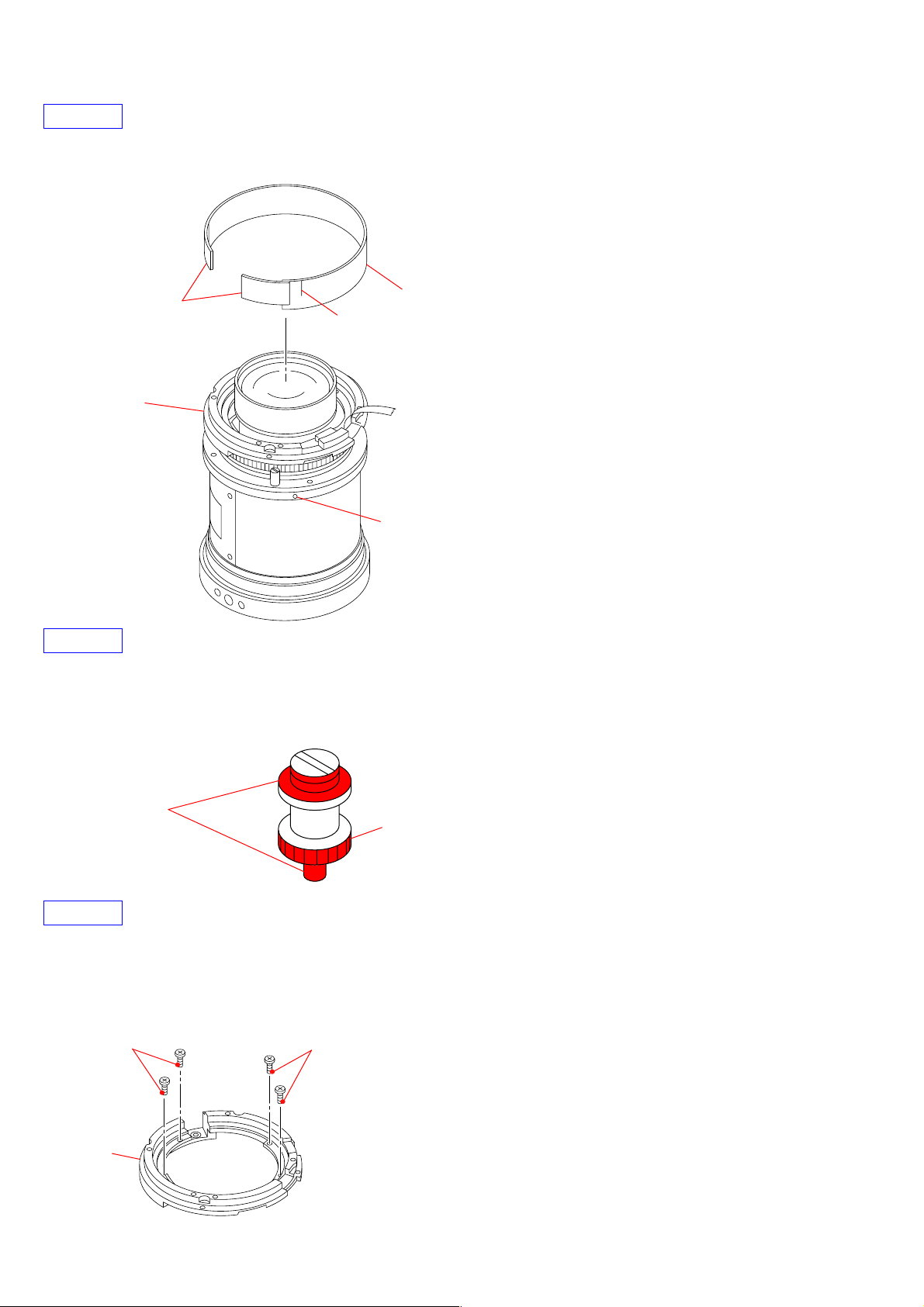

2-1-5. G ORNAMENTAL RING BLOCK AND FOCUS HOLD BUTTON BASE

DV-FH Flexible

HELP19

HELP20

Mount Guide Mark

Click Plate

Focus Hold Button Base

SONY

m

ft

Focus Hold Button

EXPLODED VIEW

HELP21

FOCUS HOLD

BUTTON CHECK

G Ornamental Ring Block

Distance Scale Window

Dust Protection Tape

FHB ADHESION TAPE

SAL35F14G (1.4/35G) (35mm F1.4G)

2-6

Page 14

2-1-6. 1 GROUP, 2 GROUP AND 3 GROUP LENS BLOCK

G1 G2 G3

G4 G5

G7 G8 G9 G10

G6

EXPLODED VIEW

1 Group Lens Block 2 Group Lens Block

HELP22

3 Group Lens Block

G10 Retainer

HELP23

SAL35F14G (1.4/35G) (35mm F1.4G)

2-7

Page 15

HELP

Note for assembling and grease applying positions are shown.

HELP01

1. Align of ”/” of “1.4/35” of the ornamental ring label with range index, and stick the ornamental ring label onto the ornamental ring.

2. Remove the masking tape of the ornamental ring label.

Note: Tolerance: ±2.5 = ±1 mm

Masking Tape

Ornamental Ring Label

Ornamental Ring

SAL35F14G (1.4/35G) (35mm F1.4G)

Range Index

HELP

Page 16

HELP02

Adhesive bond (B-10): J-6082-612-A

After applying the adhesive bond (B-10) to the indicated portion, tighten the ornamental ring with the special lens fixture.

Ornamental Ring

Apply the adhesive bond (B-10) in width 10mm.

G1

Mirror Barrel Tube

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 17

HELP03

Adhesive bond (B-40): J-6082-614-A

1. Align the ring positioning pin of the mirror barrel tube block to U groove of the fixed tube, attach them.

2. Apply the adhesive bond (B-40) to 3 screws shown in figure and tighten the screws.

Apply the adhesive bond (B-40)

Apply the adhesive bond (B-40)

Mirror Barrel Tube Block

Ring Positioning Pin

1 Group Lens Block

U Groove

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 18

HELP04

Adhesive bond (B-40): J-6082-614-A

Apply the adhesive bond (B-40) to 5 screws shown in figure and tighten the screws.

Apply the adhesive bond (B-40)

Apply the adhesive bond (B-40)

Apply the adhesive bond (B-40)

Light Interception Tube

HELP05

Adhesive bond (LOCTITE 460) (Note)

Note: Use adhesive bond (LOCTITE 460) or an equivalent article.

Do not use what becomes white after drying like quick-drying glue.

Anti-diffusion agent (A-20): J-6082-611-A

Grease (G-85): J-6082-626-A

1. Apply the anti-diffusion agent (A-20) to the indicated portions of lens mount.

2. Apply the grease (G-85) to 3 locations of indicated portion3 (3 locations) of lens mount.

3. Apply the adhesive bond (LOCTITE 460) to the stopper screw and attach it to the lens mount.

Apply the adhesive bond (LOCTITE 460)

Apply the grease (G-85) to 3 locations of

indicated portion.

Lens Mount

Apply the anti-diffusion agent (A-20)

to all circumferences of indicated Portion.

Apply the grease (G-85) (rear side)

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 19

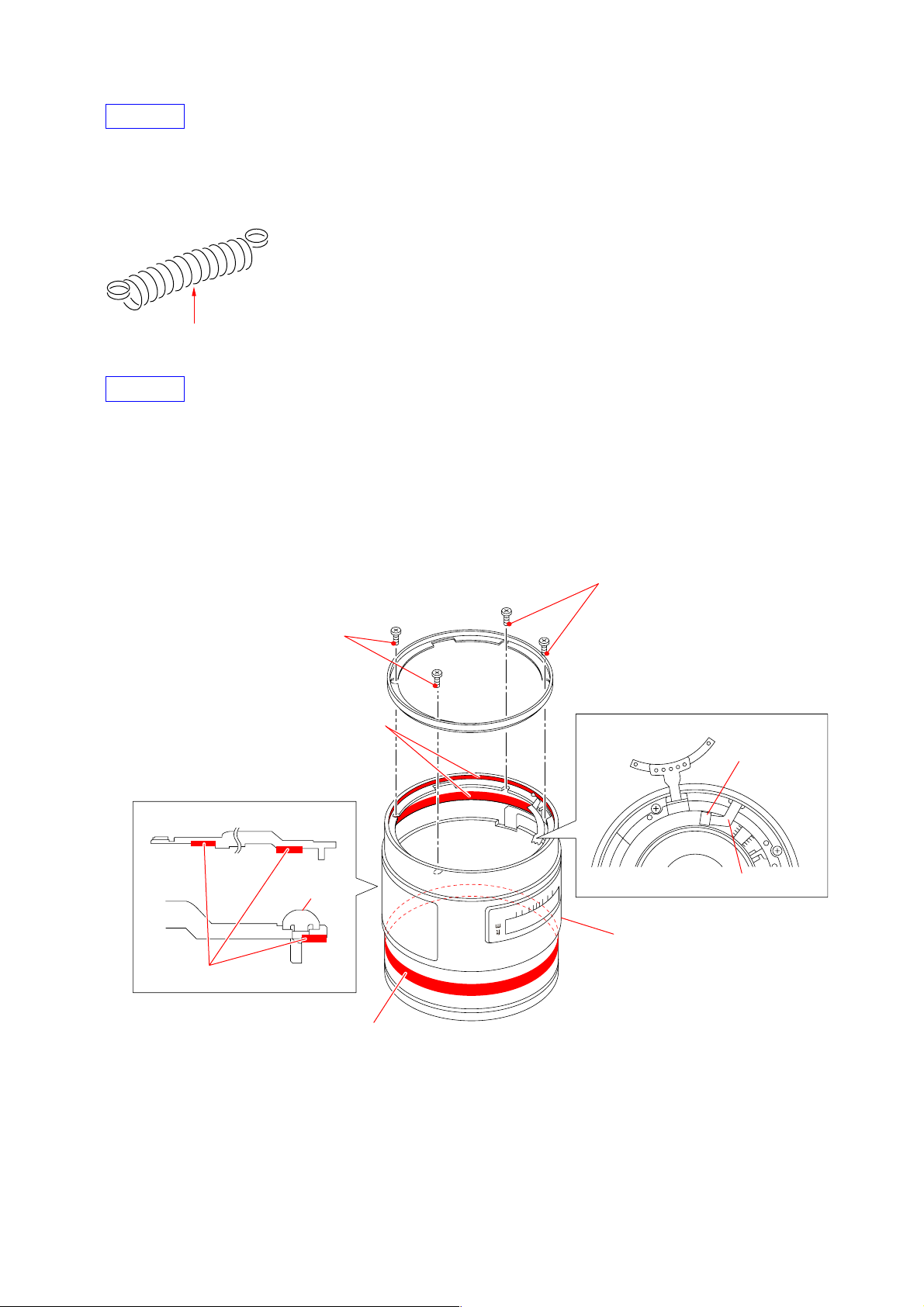

HELP06

Oil (O-20): J-6082-610-A

Apply small amount of oil (O-20) to the instruction portion of the main spring.

Aplly small amount(O-20)(On contact area)

HELP07

Adhesive bond (B-40): J-6082-614-A

Anti-diffusion agent (A-20): J-6082-611-A

1. Apply the anti-diffusion agent (A-20) to the indicated portion of G ornamental ring.

2. Apply the adhesive bond (B-40) to 4 screws shown in figure and tighten the screws.

3. Lay out the DV-FH flexible properly.

Apply the adhesive bond (B-40)

Apply the anti-diffusion agent (A-20) to

all circumferences of indicated portions.

G Ornamental Ring Block

Mount Guide

Mark

Apply the anti-diffusion agent (A-20)

Apply the adhesive bond (B-40)

Layout DV-FH Flexible

Connector

DV-FH Flexible

G Ornamental Ring Block

SAL35F14G (1.4/35G) (35mm F1.4G)

Apply the anti-diffusion agent (A-20) (inside) to

all circumferences of indicated portions.

HELP

Page 20

HELP08

Affix the distance scale plate with distance scale plate set tape, aligning with the punch mark on the cam tube set.

Distance Scale Plate

Distance Scale Plate

Set Tape

Fixed Tube Block

Align with the punch mark on the

fixed Tube block.

Punch Mark

HELP09

Grease (G-85): J-6082-626-A

Apply grease (G-85) to the gear of coupler and the slide portion.

Apply grease (G-85).

(slide portion)

Apply grease (G-85).

(gear)

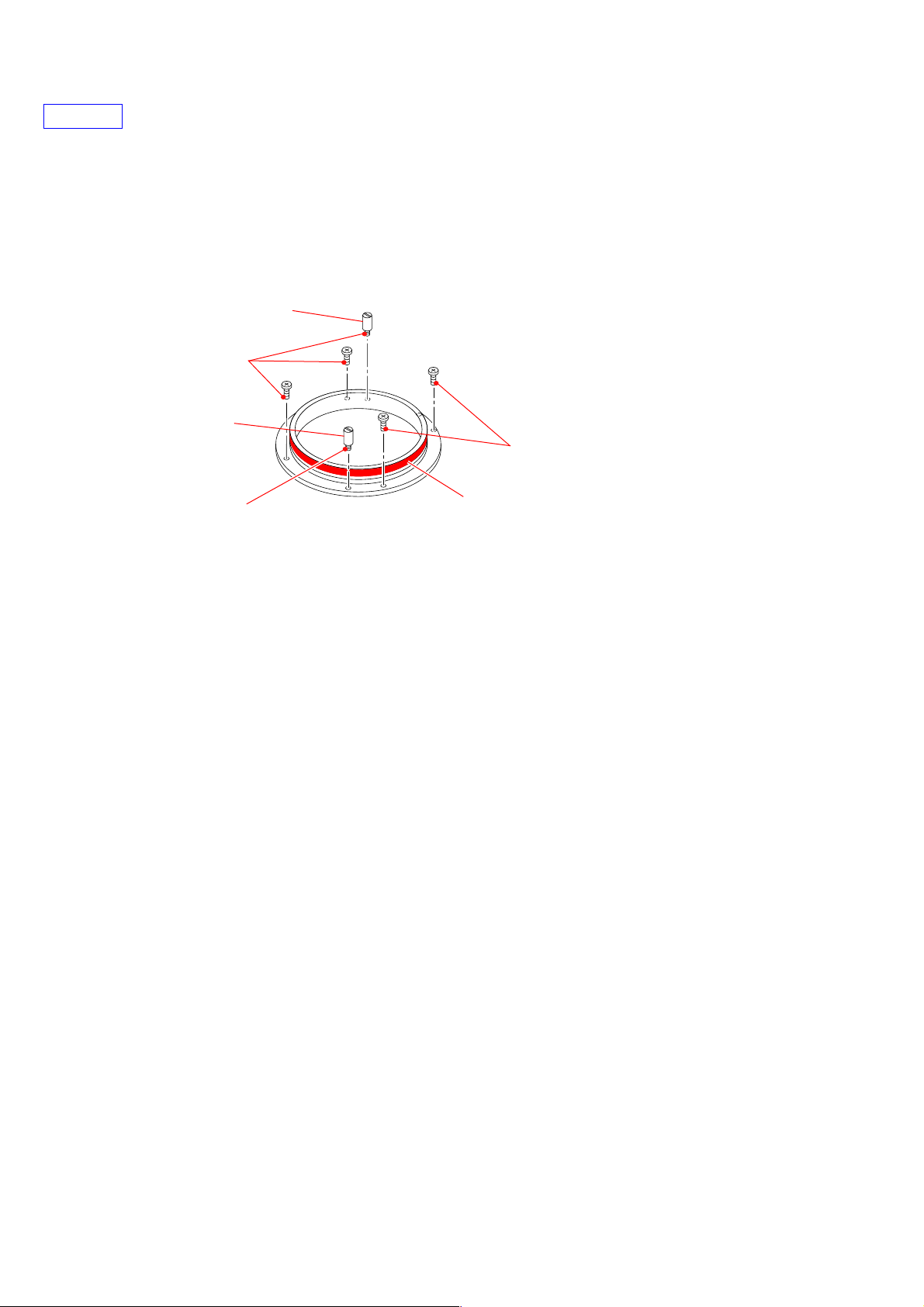

HELP10

Adhesive bond (B-40): J-6082-614-A

Apply bond (B-40) to 4 screws shown in figure and tighten the screws.

Apply the adhesive bond (B-40)

Apply the adhesive bond (B-40)

Outer Tube

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 21

HELP11

Main Flexible Block

Flexible

Base Plate

Flexible

Base Plate

Flexible Block

Flexible Tape B

Flexible Set Tape D

Flexible base plate

Part A is bent in the direction of the arrow, and it puts it.

A

Main Flexible Block is turned in part A, put,

and the adhesive bond (B-60) is spread on

the instruction part in figure.

A

Flexible tape B is put on the flexible base plate and

after putting, Main flexible block is put along the

putting standard.

Sticking standard

Adhesive bond (B-60): J-6082-616-A

Please follow the following points at the time of obtaining a main flexible block.

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 22

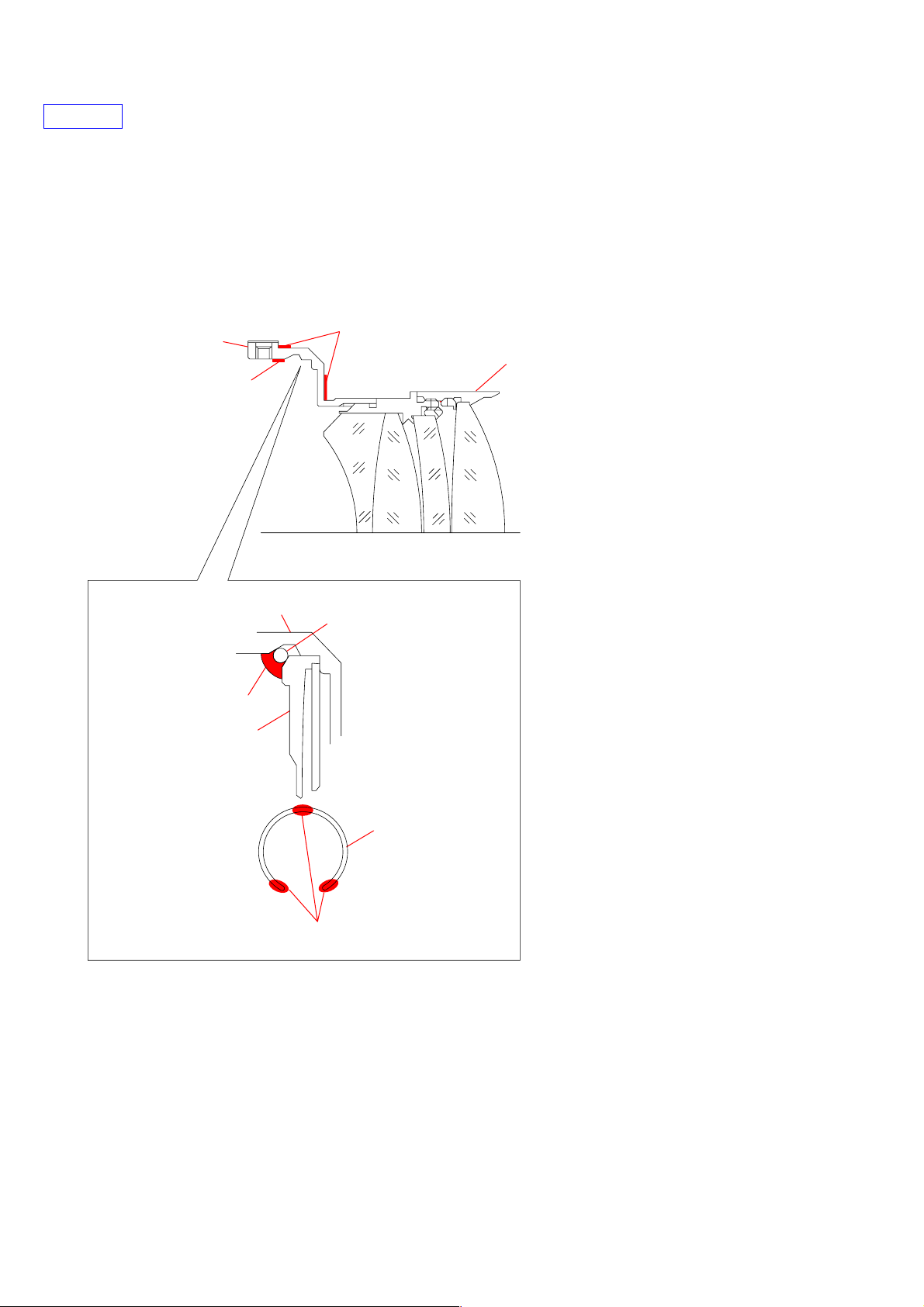

HELP12

Adhesive bond (B-40): J-6082-614-A

Grease (G-85): J-6082-626-A

1. Apply the adhesive bond (B-40) to the tips of screwed portions of 2 stopper pins and tighten 2 stopper pins.

2. Apply the adhesive bond (B-40) to the tips of 4 screws shown in figure and tighten 4 screws.

3. Apply the grease (G-85) to all circumferences of gear of joint tube.

Stopper pin

Apply the adhesive bond (B-40)

Stopper pin

Apply the adhesive bond (B-40)

Apply the grease (G-85)

Apply the adhesive bond (B-40)

to the circumference of gear.

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 23

HELP13

Adhesive bond (B-40): J-6082-614-A

1. Rotarting the cam tube, affix indicated hole of the cam tube and U groove of the fixed tube.

2. Align the notch of the fixed tube and pin of the iris control plate block, attach the inner tube.

3. Select the guide rollers fitting to the grooves of cam tube set, apply the adhesive bond (B-40) to the tips of screwed portions of guide

pins, and tighten the guide pins.

Note: Confirm that the cam tube rotates smoothly.

Apply the adhesive

bond (B-40)

Guide Pin

Apply the adhesive

bond (B-40)

Notch

Notch

Fixed Tube

Guide Roller

Hole

Apply the adhesive

bond (B-40)

Cam Tube

U Groove

Guide Pin

Guide Roller

Apply the adhesive

bond (B-40)

Guide Pin

Guide Roller

Guide Roller

Guide Pin

Guide Roller

Apply the adhesive

bond (B-40)

Guide Pin

Pin of iris control plate block

Inner Tube

2 Group Lens Block

SAL35F14G (1.4/35G) (35mm F1.4G)

Apply the adhesive

bond (B-40)

Guide Pin

Guide Roller

HELP

Page 24

HELP14

Anti-diffusion agent (A-20): J-6082-611-A

Adhesive bond (B-10): J-6082-612-A

1. Apply anti-diffusion agent (A-20) to the indicated portion of Inner Tube.

2. After “4-2-2. Aperture Diameter Adjustment”, apply the adhesive bond (B-10) in with of 10mm to all circumferences of portions

indicated in figure at Inner Tube, Iries Retainer Tube and Iris Retainer (SP).

Apply the anti-diffusion agent (A-20) to

all circumference of indicated portion.

Inner tube

G10 Retainer

Apply the anti-diffusion agent (A-20) to

all circumference of indicated portion.

G7 G8 G9 G10

3 group lens block

Inner Tube

Apply the adhesive bond (B-10)

Iris Retainer Tube

Apply the adhesive bond (B-10)

(width of 10mm to 3 locations)

Iris Retainer Tube (SP)

Iris Retainer Tube (SP)

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 25

HELP15

Adhesive bond (B-10): J-6082-612-A

Grease (G-35): J-6082-621-A

Anti-diffusion agent (A-20): J-6082-611-A

1. Apply the anti-diffusion agent (A-20) to the indicated portions of cam tube.

2. Apply the grease (G-35) to the cam tube, cam groove and them contact zone.

3. Attach the float ring so that the groove of cam tube places the bosses of float ring.

4. Apply the grease (G-35) to the indicated portions of cam tube retainer.

5. After tightening the cam tube retainer, loosen it about 10 to 15mm from dead end, apply the adhesive bond (B-10) to indicated

portion.

6. Comform the movement of the cam tube.

After confirming the movement,

apply the adhesive bond (B-10) in

width of 5 to 10mm to 2 locations.

Cam Tube Retainer

Apply the grease (G-35) to holding

surface sides of cam tube retainer.

Cam Tube

Apply the anti-diffusion agent (A-20)

Apply the grease (G-35)

(6 locations of cam groove)

Apply the anti-diffusion agent (A-20)

Groove

Fixed Tube

Apply the grease (G-35)

Boss of float ring

Distance Control Tube

Apply the anti-diffusion agent (A-20)

Cam Tube

Apply the grease

(G-35)

Fixed Tube

Apply the grease (G-35)

(6 locations of cam groove)

Apply the grease (G-35)

Apply the adhesive bond (B-10)

(circumference of 2 locations,

width of 5 to 10mm)

Cam Tube

Cam Tube Retainer

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 26

HELP16

Adhesive bond (B-40): J-6082-614-A

Grease (G-35): J-6082-621-A

Grease (G-80): J-6082-625-A

Anti-diffusion agent (A-20): J-6082-611-A

1. Apply the anti-diffusion agent (A-20) and the grease (G-35) to the indicated portion of the fixed tube.

2. Apply the grease (G-80) to contact zone of the torque ring B, the fixed tube and the friction (SP).

3. Apply the grease (G-80) to contact zone of the torque ring punching stopper and the float ring and the fixed tube.

4. Attach the torque ring punching stopper to the fixed tube with indicated.

5. Attach the friction (SP) and torque ring A shown in the figure, apply the adhesive bond (B-40) to the screws and tighten them.

6. Apply the grease (G-80) to contact zone of the distance control tube and the control tube guide pin.

7. Loosen the stopper screw of the scissors lever block, align the distance control tube to the scissors lever and attach them. Apply the

adhesive bond (B-40) to the control tube guide pin and tighten them.

8. Tighten the stopper screw of the scissors lever block.

Apply the adhesive bond (B-40)

Apply the adhesive

bond (B-40)

Torque Ring A

Friction (SP)

Fixed Tube

Apply the grease

(G-35)

Scissors lever block

Apply the adhesive bond (B-40)

Torque Ring

Punching Stopper

long

short

Apply the grease

(G-35)

Apply the anti-diffusion agent (A-20)

Fixed Tube

Torque Ring B Torque Ring A

Friction (SP)

Fixed Tube

Apply the grease (G-80)

short

long

Torque Ring

Punching Stopper

Control Tube Guide Pin

Apply the adhesive

bond (B-40)

Distance Control Tube

SAL35F14G (1.4/35G) (35mm F1.4G)

long

short

Torque Ring

Punching Stopper

Groove

Control Tube Guide Pin

Control Tube

Guide Pin

Apply the adhesive

bond (B-40)

Apply the adhesive

bond (B-40)

Fixed Tube

Distance Control Tube

Control Tube

Guide Pin

Torque Ring

Punching Stopper

Apply the grease

(G-80)

Apply the grease (G-80)

HELP

Page 27

HELP17

Adhesive bond (B-40): J-6082-614-A

Grease (G-115): J-6082-627-A

Anti-diffusion agent (A-20): J-6082-611-A

1. Apply the anti-diffusion agent (A-20) to the indicated portions of the torque ring A.

2. Apply the grease (G-115) to contact zone of the torque ring A, the float ring and the scissors lever block.

3. Attach the float ring and the scissors lever block to the torque ring A, tighten the screw temporarily.

Note: When turning the float ring, to become shake is minimized and to become turn the float ring smoothly, do the adjustment of

the changing wick pin of scissors lever block.

4. Attach the float ring B to float ring A shown in the figure, apply the adhesive bond (B-40) to the screws and tighten them.

Apply the adhesive bond (B-40)

Torque Ring A

Apply the anti-diffusion

agent (A-20)

Apply the adhesive

bond (B-40)

Float RIng

Scissors lever block

Torque Ring B

Apply the anti-diffusion agent (A-20)

Apply the adhesive bond (B-40)

Torque Ring A

Scissors

lever block

Scissors

lever block

Apply the grease (G-115)

Apply the anti-diffusion agent (A-20)

Charging Wick Pin

Torque Ring A

Float RIng

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 28

HELP18

Anti-diffusion agent (A-20): J-6082-611-A

1. Apply the anti-diffusion agent (A-20) to the indicated portion of the distance control tube.

2. Affix the friction cloth B shown in figure.

Note: Do not flow the anti-diffusion agent into affix side of friction cloth B.

Friction Cloth B

• Affix to shaded portion.

Standard position

of taping

Apply the anti-diffusion agent

(A-20)

Do not float, Do not peel off

Do not protrude from the

upper part.

Distance Control Tube

Apply the anti-diffusion agent (A-20)

Distance Control Tube

Apply the anti-diffusion agent (A-20)

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 29

HELP19

1. Affix the flexible set tape A, the flexible set tape D and the FHB adhesion tape to the DV-FH flexible shown in figure.

DV-FH Flexible

FHB Adhesive Tape

Flexble Set Tape D

Standard

position

Standard

position

Flexble Set Tape A

2. Affix the DV-FH flexible to G ornamental block shown in figure.

DV-FH Flexible

Standard

position

G Ornamental Block

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 30

HELP20

Adhesive bond (LOCTITE 460) (Note)

Note: Use adhesive bond (LOCTITE 460) or an equivalent article.

Do not use what becomes white after drying like quick-drying glue.

Apply the adhesive bond (LOCTITE 460) to the tip of mount guide mark and install it to the G ornamental block.

Apply the adhesive bond (LOCTITE 460)

to the tip mount guide mark

Mount guide mark

G Ornamental Block

m

ft

HELP21

Adhesive bond (LOCTITE 460) (Note)

Note: Use adhesive bond (LOCTITE 460) or an equivalent article.

Do not use what becomes white after drying like quick-drying glue.

Adhesive bond (B-10): J-6082-612-A

1. Apply a little amount of the adhesive bond (LOCTITE 460) to the indicated portions of focus hold button base.

2. Apply the adhesive bond (B-10) to the tip of one screw shown in figure and tighten the screw.

3. Perform “4-8. FOCUS HOLD BUTTON CHECK (FOCUS HOLD BUTTON)”.

Apply the adhesive bond (B-10)

Washer

Click Plate

Apply the adhesive bond (LOCTITE 460)

Focus Hold Button Base

Focus Hold Button

Dust Protection Tape

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 31

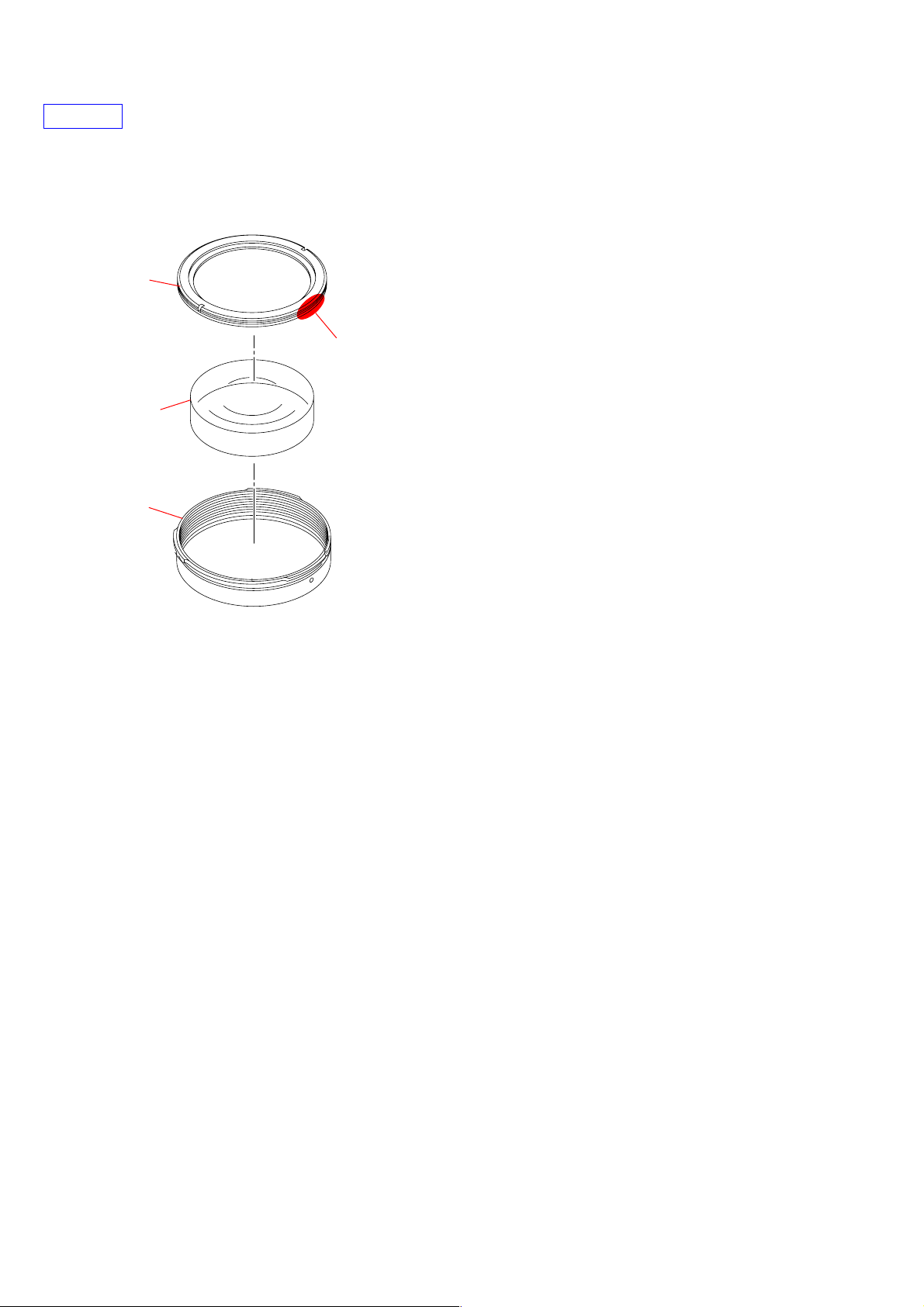

HELP22

Anti-diffusion agent (A-20): J-6082-611-A

Apply the anti-diffusion agent (A-20) to all circumferences of indicated portions.

Apply the anti-diffusion agent (A-20) to all

circumference of shaded portion.

Apply the anti-diffusion agent (A-20) to all

circumference of shaded portion.

Large 2 Group Move Frame

G4 G5 G6

2 Group Lens Block

HELP23

Adhesive bond (B-10): J-6082-612-A

After the optical axis adjustment (Refer to 4-22 page), apply the adhesive bond (B-10) to the indicated portion of G10 retainer.

Apply the adhesive bond (B-10)

G7 G8 G9 G10

3 Group Lens Block

G10 Retainer

SAL35F14G (1.4/35G) (35mm F1.4G)

HELP

Page 32

3. REPAIR PARTS LIST

NOTE:

• -XX and -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

3-1. EXPLODED VIEWS

3-1-1. ORNAMENTAL RING LABEL AND MIRROR BARREL TUBE BLOCK

2

• The mechanical parts with no reference number in

the exploded views are not supplied.

DISASSEMBLY

1

(See Page 3-6.)

3

4

5

A

(See Page 3-6.)

4

8

3

7

4

A

Ref. No. Part No. Description

1 2-684-732-01 RING, ORNAMENTAL

2 2-887-838-01 LABEL, ORNAMENTAL RING

3 2-684-731-01 SCREW, TAPPING M1.6X3.5

4 2-684-730-01 WASHER, FLAT

5 A-1191-451-A BLOCK, MIRROR BARREL TUBE

6 2-684-737-01 NAME PLATE 3514

7 2-684-073-01 LABEL, LENS (NO.)

8 2-695-837-01 LABEL, MODEL NAME

SAL35F14G (1.4/35G) (35mm F1.4G)

1.4/35G

6

3-1

Page 33

3-1-2. LENS MOUNT RIVETING BLOCK AND LIGHT INTER CEPTION TUBE

DISASSEMBLY

55

54

56

57

58

59

53

51

51

52

61

62

F

65

62

61

63

(See Page 3-5.)

51

C

54

64

65

66

67

SONY

68

69

A

B

70

71

D

60

(Note 1)

(Note 1) The number or type of these parts need to be selected

Ref. No. Part No. Description

51 2-684-064-01 SCREW, M1.4X2.2 P1

52 2-684-844-01 CONNECTION BOX

53 2-684-736-01 TUBE, LIGHT INTERCEPTION

54 2-687-685-01 SCREW, TAPPING M2.0X4.0

55 A-1191-450-A BLOCK, LENS MOUNT RIVETING

according to adjustment etc..

Select the part referring to page 3-7.

E

67

(Note 1)

74

73

72

A

B

C

D

E

Ref. No. Part No. Description

63 2-684-961-01 RING, ORANGE

64 2-684-740-01 LEATHER, BEAM

65 2-684-738-01 TAPE, BEAM LEATHER FIXED

66 2-684-739-01 COVER, BRUSH HOLE

67 2-684-774-01 SCREW, M1.4X2.0 P2

(See Page 3-3.)

F

56 2-684-244-01 SCREW, STOPPER

57 2-684-856-01 RING, PRESET

58 2-684-233-01 SPRING, MAIN

59 2-684-234-01 RETAINER, PRESET RING

60 Selection parts WASHER (A) to (E), BACK ADJUSTMENT (Note 1)

61 2-687-690-01 SCREW, M1.6X3.0

62 2-684-170-01 SCREW, M1.6X3.0

SAL35F14G (1.4/35G) (35mm F1.4G)

68 2-684-786-01 BRUSH, FOCUS

69 2-684-775-01 PLATE, DISTANCE SCALE

70 2-684-776-01 TAPE, DISTANCE SCALE PLATE SET

71 2-684-773-01 REINFORCEMENT, CAM TUBE

72 2-684-784-01 COUPLER

73 Selection Parts WASHER (A) to (E) (Note 1)

74 2-684-735-01 GROUND SP

3-2

Page 34

3-1-3. OUTER TUBE AND JOINT TUBE

DISASSEMBLY

101

102

101

108

101

104

105

101

(See Page 3-6.)

103

101

106

111

107

101107

112

113

109

109

110

(Note 1)

110

(Note 1)

109

110

(Note 1)

109

Ref. No. Part No. Description

101 2-687-690-01 SCREW, M1.4 P3 M1.6X3.0

102 2-684-781-01 TUBE, OUTER

103 A-1191-446-A BLOCK, MAIN FLEXIBLE

104 2-684-841-01 TAPE (B), FLEXIBLE

105 2-684-840-01 PLATE, FLEXIBLE BASE

110

(Note 1)

(See Page 3-4.)

114

110

(Note 1)

109

109

(See Page 3-6.)

110

(Note 1)

(Note 1) The number or type of these parts need to be selected

Ref. No. Part No. Description

108 2-684-777-01 TUBE, JOINT

109 2-684-749-01 PIN, GUIDE

110 Selection parts ROLLER (A) to (I), GUIDE (Note 1)

111 A-1191-444-A BLOCK, IRIS CONTROL PLATE

112 A-1191-443-A FEATHER UNIT, IRIS

according to adjustment etc..

Select the part referring to page 3-7.

106 2-684-842-01 TAPE (D), FLEXIBLE SET

107 2-684-779-01 PIN, STOPPER

SAL35F14G (1.4/35G) (35mm F1.4G)

113 2-684-814-01 TUBE, IRIS RETAINER

114 2-684-815-01 TUBE (SP), IRIS RETAINER

3-3

Page 35

3-1-4. FIXED TUBE BLOCK AND DISTANCE CONTROL TUBE

DISASSEMBLY

151

152

154

155

153

154

155

160

161

155

C

A

161

154

A

C

161

155

B

163

156

157

158

158

159

Ref. No. Part No. Description

151 2-684-748-01 RETAINER, CAM TUBE

152 A-1191-438-A BLOCK, FIXED TUBE

153 2-684-802-01 RING (A), TORQUE

154 2-684-119-01 SCREW, M1.6X2.5

155 2-684-762-01 SCREW, M1.6X2.5

158

B

163

163

164

164

Ref. No. Part No. Description

159 2-684-806-01 RING (B), TORQUE

160 2-684-745-01 FRICTION (SP)

161 2-684-746-01 STOPPER, TORQUE RING PUNCHING

162 2-684-811-01 TUBE, DISTANCE CONTROL

163 2-684-747-01 PIN, CONTROL TUBE GUIDE

162

164

165

156 2-684-803-01 CLOTH (A), FRICTION

157 2-684-804-01 RING, FLOAT

158 A-1191-440-A BLOCK, SCISSORS LEVER

SAL35F14G (1.4/35G) (35mm F1.4G)

164 2-684-812-01 CLOTH (B), FRICTION

165 2-684-741-01 RING, DISTANCE TUBE RUBBER

3-4

Page 36

3-1-5. G ORNAMENTAL RING BLOCK AND FOCUS HOLD BUTTON BASE

201

202

207

203

209

208

204

SONY

m

ft

205

206

210

212

211

(7.7 x 7 mm)

213

DISASSEMBLY

Ref. No. Part No. Description

201 2-684-847-01 TAPE (A), FLEXIBLE SET

202 2-684-848-01 TAPE (D), FLEXIBLE SET

203 2-683-692-01 GUIDE MARK, MOUNT

204 A-1191-448-A BLOCK, G ORNAMENTAL RING

205 A-1191-455-A WINDOW, DISTANCE SCALE

206 2-684-846-01 TAPE, FHB ADHESION

207 2-684-849-01 FLEXIBLE, DV-FH

Ref. No. Part No. Description

208 2-684-850-01 WASHER, STANDARD

209 2-684-209-01 SCREW, M1.4X1.5 P1

210 2-684-208-01 PLATE, CLICK

211 2-689-275-01 TAPE, DUST PROTECTION

212 2-684-853-01 BUTTON, FOCUS HOLD

213 2-684-852-01 BASE, FOCUS HOLD BUTTON

SAL35F14G (1.4/35G) (35mm F1.4G)

3-5

Page 37

3-1-6. 1 GROUP, 2 GROUP AND 3 GROUP LENS BLOCK

DISASSEMBLY

(Ornamental Ring, See Page 3-1.)

G1 G2 G3

251

Ref. No. Part No. Description

251 2-684-879-01 G1

252 A-1191-451-A BLOCK, 1 GROUP LENS

253 2-684-759-01 FRAME, LARGE 2 GROUP MOVE

254 A-1191-452-A BLOCK, 2 GROUP LENS

255 2-684-813-01 TUBE, INNER

253 255

G4 G5

G6

257

G7 G8 G9 G10

258

256254252

256 A-1191-453-A BLOCK, 3 GROUP LENS

257 2-684-872-01 RETAINER, G10

258 2-684-871-01 G10

SAL35F14G (1.4/35G) (35mm F1.4G)

3-6

Page 38

3-1-7. SELECTION PARTS

Ref. No.60

These washers are provided for flange back adjustment.

Change the thickness (t) according to result of adjustment.

Part No. Description

2-684-123-01 WASHER (A), BACK ADJUSTMENT (t=0.05mm)

2-684-124-01 WASHER (B), BACK ADJUSTMENT (t=0.07mm)

2-684-125-01 WASHER (C), BACK ADJUSTMENT (t=0.1mm)

2-684-126-01 WASHER (D), BACK ADJUSTMENT (t=0.2mm)

2-684-127-01 WASHER (E), BACK ADJUSTMENT (t=0.5mm)

Ref. No.73

These washers are provided for coupler height adjustment.

Change the thickness (t) according to result of adjustment.

Part No. Description

2-684-057-01 WASHER (A) (t=0.05mm)

2-684-058-01 WASHER (B) (t=0.07mm)

2-684-059-01 WASHER (C) (t=0.1mm)

2-684-060-01 WASHER (D) (t=0.2mm)

2-684-061-01 WASHER (E) (t=0.5mm)

Ref. No.110

Select the type of part according to the operation load of the associated parts.

D1

D2

Part No. Description

2-684-750-01 ROLLER (A), GUIDE (D1=4.53mm, D2=4.03mm)

2-684-751-01 ROLLER (B), GUIDE (D1=4.53mm, D2=4.02mm)

2-684-752-01 ROLLER (C), GUIDE (D1=4.53mm, D2=4.01mm)

2-684-753-01 ROLLER (D), GUIDE (D1=4.52mm, D2=4.03mm)

2-684-754-01 ROLLER (E), GUIDE (D1=4.52mm, D2=4.02mm)

2-684-755-01 ROLLER (F), GUIDE (D1=4.52mm, D2=4.01mm)

2-684-756-01 ROLLER (G), GUIDE (D1=4.51mm, D2=4.03mm)

2-684-757-01 ROLLER (H), GUIDE (D1=4.51mm, D2=4.02mm)

2-684-758-01 ROLLER (I), GUIDE (D1=4.51mm, D2=4.01mm)

SAL35F14G (1.4/35G) (35mm F1.4G)

3-7

Page 39

3-2. SUPPLIED ACCESSORIES

Checking supplied accessories.

Lens Hood (SH0001)

2-687-324-01

Front Lens Cap

2-683-616-01

Other accessories

2-685-162-01 MANUAL, INSTRUCTION

(JAPANESE, ENGLISH, FRENCH, SPANISH)

2-685-162-11 MANUAL, INSTRUCTION

(GERMAN, DUTCH, SWEDISH, ITALIAN) (AEP)

2-685-162-21 MANUAL, INSTRUCTION (PORTUGUESE, RUSSIAN,

TRADITIONAL CHINESE, KOREAN) (AEP)

2-685-162-31 MANUAL, INSTRUCTION

(SIMPLIFIED CHINESE, ARABIC) (AEP, CH)

• Abbreviation

CH: chinese model

Rear Lens Cap

2-683-615-01 2-694-833-01

Carrying Case

SAL35F14G (1.4/35G) (35mm F1.4G)

3-8

Page 40

4. ADJUSTMENTS

Note: After the service repair, perform the adjustments referring to this section.

4-1. PREPARATIONS

4-1-1. List of Service Tools and Equipments

• Variable Transformer (Output voltage: AC 100 V) (Note 3)

• Camera DSLR-A100

• Compact Flash (CF) Card (For image saving)

• Screen (Art paper)

• Tape Measure

• Plane Mirror (For SLRs)

• Adhesive bond (B-10): J-6082-612-A

• Lens Adjustment Program (ActuatorChecker.exe)

• PC Card Setup File (InstaCal.exe)

• Color Calculator 2

Note: Color Calculator 2 and ActuatorChecker is downloadable from the ESI homepage.

J-1

J-2

Personal computer

(Note 1)

J-4 J-6J-5

AE master lens

J-6082-597-A

J-7

J-8

Flange back tester

J-6082-606-A

J-11

J-10

70

80

60

50

90

40

0

30

10

20

USB cord with

connector

1-833-062-11

1000 mm Collimator

110V: J-6082-604-A

240V: J-6082-604-B

(Note 2)

A-mount

attachment

J-6082-607-A

J-3

Luminance box

J-6082-581-A

Lens test projector

J-6082-605-A

(Note 3)

J-9

Flange back gauge

(43.50mm)

J-6082-608-A

Aberration

measuring cap

(SAL35F14G)

J-6082-641-A

SAL35F14G (1.4/35G) (35mm F1.4G)

Finished

Inspection

JIG

J-6082-645-A

(Note 4)

Fig.4-1-1

4-1

Page 41

Note 1: Personal Computer (PC)

(Color Calculator 2 installed)

OS: Windows XP

MEMORY: 40 M Byte or more recommended

Hard disk free area: 15 M Byte or more recommended

USB terminal: Standard equipment

Graphics: 32,000 colors or more recommended VGA monitor

Note 2: Attach the chart to the 1000 mm collimator as shown in Fig. 4-1-2.

Align the marks

Chart

1000 mm collimator

Fig.4-1-2

Note 3: Connect the variable transformer (Output voltage: AC 100 V) to the lens test projector.

Note 4: Finished Inspection JIG is AC 100 V only.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-2

Page 42

4-1-2. Lens Adjustment Program (ActuatorChecker)

The lens adjustment program is required for the following check/adjustment.

4-5. FOCUS-SHIFT CHECK/ADJUSTMENT (APERTURE)

4-6. LENS ROM CHECK

4-7. FOCUS BRUSH POSITION CHECK/ADJUSTMENT AND PATTERN CHECK

4-8. FOCUS HOLD BUTTON CHECK

4-9. Write dSB

Prepare/start the lens adjustment program with the following steps.

Equipment used

• Personal Computer

• Lens Adjustment Program (ActuatorChecker.exe)

• PC Card Setup File (InstaCal.exe)

Note 1: Lap top PC with PC card slot on which Windows XP runs

Note 2: Obtain the PC card setup file (InstaCal.exe) from the ESI homepage.

Note 3: Obtain the lens adjustment program (ActuatorChecker Ver. x.x.x.x.zip) from the ESI homepage.

1. Download of PC card setup file (InstaCal.exe)

1) Create the “MCC”folder in the C drive.

Fig.4-1-3

2) Download the file from Service Fixture and Software of ESI homepage, and save it in “C:\MCC”.

3) Double-click the downloaded file “InstaCal.exe”to extract it.

4) The window to specify the extract destination folder appears. Click [Browse...].

Fig.4-1-4

SAL35F14G (1.4/35G) (35mm F1.4G)

4-3

Page 43

5) Specify “C:\MCC” for the extract destination folder.

Fig.4-1-5

6) The window returns to the menu to specify the extract destination folder. Click [Unzip].

Fig.4-1-6

7) When the window below appears, click [OK].

Fig.4-1-7

8) Return to the menu to specify the extract destination folder. Then, click [Close] to close the window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-4

Page 44

2. Setup of PC Card

1) Double-click “InstaCal.exe” in “C:\MCC” folder to begin the installation.

Fig.4-1-8

2) The menu to begin the installation appears. Click [Next>].

Fig.4-1-9

3) Specify the install destination folder. As the default is used for it, click [Next>].

Fig.4-1-10

SAL35F14G (1.4/35G) (35mm F1.4G)

4-5

Page 45

4) The menu to tell that the wizard is ready to install appears. Click [Install].

Fig.4-1-11

5) The installation is completed. Click [Finish].

Note: To refer to the “readme” file, check the “Show the readme file” and click [Finish].

Fig.4-1-12

6) To make the configuration installed effective, the window to prompt the restart appears.

Click “Yes” to restart the PC.

Note: If a device is connected without restarting, the program may not work properly.

Fig.4-1-13

SAL35F14G (1.4/35G) (35mm F1.4G)

4-6

Page 46

7) After restarting the PC, insert the PC-CARD-DIO48 in the PC card slot.

8) The software installation window appears.

Click “Install the software automatically. (Recommended)”.

Fig.4-1-14

9) The software is detected and installed. When the window below appears, click [Finish] to terminate the installation.

Fig.4-1-15

SAL35F14G (1.4/35G) (35mm F1.4G)

4-7

Page 47

3. Confirmation of PC card setting

1) Select “All programs” - “MeasumentComputing” - “InstaCal” from the startup menu, and start up the software.

Note: Depending on the Windows setting, the window below may differ.

Fig.4-1-16

2) When “PC-CARD-DIO48” is detected, the window below appears. Confirm that the PC-CARD-DIO48” is checked.

Note: Depending on the slot inserted, the slot No. differs.

Fig.4-1-17

3) Confirm that “PC-CARD-DIO48” is recognized as “Board#0”.

Note: If not recognized as “Board#0”, the program does not work properly.

Fig.4-1-18

4) Click “File” - “Exit” to terminate “InstaCal”.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-8

Page 48

4. Startup of Lens Adjustment Program (ActuatorChecker.exe)

1) Download the file “ActuatorChecker VerX.X.X.X.zip” from Service Fixture and Software of ESI homepage, save and extract it.

2) Start up “ActuatorChecker.exe” from an arbitrary folder.

3) If “PC-CARD-DIO48” is properly installed, the window below appears.

Note: The version of “ActuatorCheker” might be updated.

Fig.4-1-19

SAL35F14G (1.4/35G) (35mm F1.4G)

4-9

Page 49

4-1-3. Connection of Finished Inspection JIG and Lens Adjustment Program

(ActuatorChecker.exe)

Note: Confirm “4-1-2. Lens Adjustment Program (ActuatorChecker)” has been completed before this procedure is executed.

Equipment

• Personal Computer

• USB cord with connector

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Connect equipment and checking lens as shown Fig.4-1-20.

Finished Inspection JIG

Lens

Fig.4-1-20

2. Turn on the finished inspection JIG.

3. Turn on the personal computer.

4. Start up “ActuatorChecker.exe” from an arbitrary folder, conform that start up program normally.

Note: Turn off the finished inspection jig after use.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-10

Page 50

4-1-4. Initial Setting of “ActuatorChecker”

1. Start up “ActuatorChecker.exe”.

Fig.4-1-21

2. Depending on the initial startup or setting made at the previous startup, the window differs.When the English window appears, click

the

[Set up] button.

Note: When any button is clicked, the Serial window appears. The window to enter the lens serial number appears.

Fig.4-1-22

SAL35F14G (1.4/35G) (35mm F1.4G)

4-11

Page 51

3. Set the following contents in the SETUP window.

• MODEL Model to be adjustment this time

• Language English

• State FINAL

• PROCESS SERVICE

4. Confirm that all of the items are set, and click [OK].

Fig.4-1-23

4-1-5. About Inspection Procedure of Lens Adjustment Program (ActuatorChecker)

The inspection method has the method of executing the method of inspecting the corresponding model as everything continues and the

inspection of each item one by one.

Click [START] from the start up window when you inspect the corresponding model as everything continues.

The procedure for executing the inspection of each item one by one has been described in this manual.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-12

Page 52

4-2. APERTURE DIAMETER CHECK/ADJUSTMENT

4-2-1. Aperture Diameter Check

Equipment

• Luminance Box

• Camera DSLR-A100

• AE Master Lens

• Compact Flash (CF) Card (For image saving)

• Personal Computer (PC)

(Color Calculator 2 installed)

1. Preparations

1) Install the CF card to the camera.

2) Set the equipments, camera and master lens as shown in Fig.4-2-1.

Luminance box

Luminance: EV11

Shoot the center of the luminance surface

Camera

ISO: 100

Exposure Mode: M

Shutter Speed: 1/125

Aperture: F5.6

Focus Mode: MF

Metering: Center weighted

Preset white balance: Tungsten

D-R: OFF

Master lens or checking lens

Focus: Infinity end

Fig.4-2-1

3) Shoot the images under the following conditions and save them.

Note: Shoot the center of the luminance surface three times with the master lens and checking lens.

Setting of Luminance box:

Luminance: EV11

Setting of Lens:

Focus: Infinity end

Setting of Camera:

ISO: 100

Exposure Mode: M

shutter Speed: 1/125

Aperture: F5.6

Focus Mode: MF

Metering: Center weighted

Preset white balance: Tungsten

D-R: OFF

SAL35F14G (1.4/35G) (35mm F1.4G)

4-13

Page 53

2. Checking of Image

Note: Check the image of both master lens and checking lens.

1) Start the Color Calculator 2.

Fig.4-2-2

2) Read the image from the file menu.

kk

k

kk

3) Set the Color Calculator 2 as follows.

Measured value display (Display menu): RGB+L*a*b*

Measuring method (Display menu): Center Single Area

Fig.4-2-4

Color space (Edit menu): sRGB

Fig.4-2-5

Area size for calculate (Edit menu →Option): 256×256 Pixels

Fig.4-2-3

Fig.4-2-6

SAL35F14G (1.4/35G) (35mm F1.4G)

4-14

Page 54

4) Click the calculate button to measure the image.

5) After measuring, check the “G” values.

Average “G” value of the three images shoot with master lens: (a)

Average “G” value of the three images shoot with checking lens: (b)

Calculate button

Check the “G” value

Fig.4-2-7

3. Checking Method

1) Calculate aperture error using the following formula, and check that the aperture error is within the specification.

Aperture error = Average “G” value of master lens (a) - Average “G” value of checking lens (b)

Specification

Aperture error = 0 ±12

2) When the aperture error is out of specification, perform “4-2-2. Aperture Diameter Adjustment”.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-15

Page 55

4-2-2. Aperture Diameter Adjustment

Equipment

• Luminance Box

• Camera DSLR-A100

• AE Master Lens

• Compact Flash (CF) Card (For image saving)

• Personal Computer (PC)

(Color Calculator 2 installed)

• Adhesive bond (B-10)

1. Preparations

1) Disassemble up to the group lens block.

2) Assemble the lens mount (including the preset ring).

Lens Mount

Fixed Tube Block

Fig.4-2-8

3) Remove the adhesive bond fixing the iris retainer tube (SP).

Apply bond(B-10) (3 areas)

Iris Retainer Tube

Bond

Bond

Iris Retainer Tube SP

Fig.4-2-9

SAL35F14G (1.4/35G) (35mm F1.4G)

4-16

Page 56

2. Adjusting Method

1) Move the preset ring and fix it at the fully opened position.

Set the preset ring at the open aperture position.

Preset lever

Fig.4-2-10

2) Adjust by rotating the iris retainer ring so that the blades of iris are just hidden within the inner diameter of iris retainer ring.

Diaphragm blades are hidden into the

edge completely.

Fig.4-2-11

3) After adjustment, apply the adhesive bond (B-10) to portions shown in Fig.4-2-9.

4) Assemble the lens in the state of near completion. Perform “4-2-1. Confirmation of iris diameter”.

Note: Repeat “4-2-2. Adjustment of iris diameter” and “4-2-1. Confirmation of iris diameter” until the iris tolerance meets the specifica-

tion.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-17

Page 57

Ver 1.1 2007.02

4-3. PROJECTIVE RESOLVING POWER CHECK

Equipment

• Lens Test Projector and Variable Transformer (Output voltage: AC 100 V)

Note: Connect the variable transformer (Output voltage: AC 100 V) to the lens test projector.

• A-mount Attachment

• Screen (Art paper)

• Tape Measure

• Plane Mirror (For SLRs)

1. Preparations

Note: Check the projective resolving power of the checking lens at the following focal-length and distance.

Focal-length Distance (m)

f (mm)

35 1.4

Table 4-3-1

1) Perform the following steps (1) to (3), and incorporate the internal lenses of the lens test projector according to the checking focal-

length.

(1) Open the lid of the lens test projector.

(2) Pull up and turn the fixed levers on the right and left sides of the lens test projector.

(3) Remove or insert the lens.

Note: Be sure to have the right position and direction of the lens.

Incorporate of the lenses

according to the checking focal-length (f).

Fixed lever

Lid

Lens

Fixed lever

Heat-absorbing filter

Filament Filament

f=18 to 35 mm

ChartChart

f=100 to 200 mm

ChartChart

Lens test projector

SAL35F14G (1.4/35G) (35mm F1.4G)

Fig.4-3-1

4-18

f=35 to 100 mm

Filament Filament

f=200 to 300 mm

Page 58

2) Attach the checking lens to the lens test projector, and set the equipments as shown in Fig.4-3-2.

3) Turn the fan switch of the lens test projector to ON, then turn the lamp switch to ON.

Screen

A-mount attachment

Checking lens

Chart

Fan switch

Plane mirror

Lens test projector

Distance

F L

Lamp switch

Fig.4-3-2

4) Turn the focus ring of the checking lens until the chart image projected on the screen is the sharpest at the center (y’=0).

5) Set the plane mirror to the center of the projected image (y’= 0), and adjust the projector position so that the mirror reflects the light

to the center of the lens.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-19

Page 59

Ver 1.1 2007.02

2. Checking Method

1) Turn the focus ring of the checking lens until the chart image projected on the screen is the sharpest at the center (y’=0).

2) Read the number of the smallest pitched lines at the center (y’= 0).

The number represents for lines per mm.

Saggital (S)

Meridional (M)

Fig.4-3-3

3) Turn the mount rotation ring of lens test projector until the projected image at a certain peripheral point (y’= 15) on the screen

appears the most unsharp.

Read the number of the smallest pitched lines (both saggital and meridional: 3 lines) at the peripheral point.

Note: When reading the number of the smallest pitched lines, be careful of the spurious resolution.

Spurious resolution is the reversed image of 2 or 4 lines which appears on screen when focus is beyond maximum revolving

power.

Do not confuse spurious resolution for the smallest pitched lines.

Correct resolution Spurious resolution

Fig.4-3-4

4) Check that the all readings (y’= 0, saggital (S) and meridional (M) at y’= 15) is within the specification of the Table 4-3-2.

Specification

Number of the smallest pitched lines

Distance (m) Center (y’= 0) Peripheral (y’= 15)

1.4 125 or greater 50 or greater 40 or greater

(Lines per mm) (Lines per mm)

SM

Table 4-3-2

5) After the checking is completed, turn the lamp switch of the lens test projector to OFF and cool the inside of the lens test projector,

then turn the fan switch to OFF.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-20

Page 60

4-4. FLANGE BACK (f’F) CHECK/ADJUSTMENT

4-4-1. Flange Back (f’F) Check

Equipment

• 1000 mm Collimator

• Flange Back Tester

• A-mount Attachment

• Flange Back Gauge (43.50mm)

1. Preparations

1) Set the equipments as shown in the Fig.4-4-1.

flange back gauge (43.50mm)

A-mount attachment

Objective lens (10x)

Dial Gauge (Min. scale: 0.01 mm)

Eyepiece ring

Eyepiece lens (7x)

Scale ring

Fig.4-4-1

2)

Looking through the eyepiece lens, turn the eyepiece ring of the flange back tester so that cross line or scale in the view is the sharpest.

3) Attach the flange back gauge (43.50mm) securely to the A-mount attachment and hold them together.

4) Turn the focusing knob of the flange back tester so that fine scratches on the flange back gauge (43.50mm) is the sharpest.

Note: Turn the knob in the direction of the arrow of Fig.4-4-2 for correct reading.

Always turn the knob in the arrow

direction for correct reading.

Focusing knob

5) Turn the scale ring of the dial gauge until the long pointer indicates “0”.

Note: This position is the flange back (f’F) = 43.5 mm.

Memorize the position of short-pointer.

SAL35F14G (1.4/35G) (35mm F1.4G)

Focus on fine lines on the surface.

Fig.4-4-2

4-21

Page 61

2. Frange Back (f’F) Check

1) Attach the checking lens to the flange back tester, and set the 1000 mm collimator.

Checking lens

1000 mm collimator

Fig.4-4-3

2) Set the focus ring of the checking lens to infinity end position while looking through the microscope, and align the optical axis to the

center of the chart image accurately.

3) Turn the focusing knob of the tester until the chart image is the sharpest (red and green color areas are equal on the chart *).

*: Position in which the color of collimator chart changes from green into red and come into focus.

Also check the optical axis aligns with the chart center. (Refer to Fig.4-4-4.)

Note: Figure shows example. The cause depends on individual lens.

Optical Alignment

Best alignment

Incorrect aligned

e.g. As the focusing knob is turned, the chart may appear blurry as illustrated.

The cause depends on individual lens.

Fig.4-4-4

Optical Axis Adjustment

1) Turn the G10, or do the adjustment of looseness. After align the axis.

2) Apply the adhesive bond (B-10) to the G10 retainer.

Note: Tolerance: 0.02 mm or less

3. Checking Method

1) Calculate the flange back (f’F) of the checking lens using the following formula, and check that the specification of the Table 4-4-1 is

satisfied.

Flange back (f’F) of the checking lens = (SR flange back gauge) + (Number of short-pointer revolution) + (Reading of long-pointer)

Specification

Focal-length f’F (mm)

f (mm) (Infinity position)

35 44.58 to 44.60

Table 4-4-1

2) When the flange back (f’F) of the checking lens is out of specification of the Table 4-4-1, perform “4-4-2. Flange Back (f’F)

Adjustment”.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-22

Page 62

4-4-2. Over Infinity (Infinity End) Flange Back (f’F) Adjustment

Equipment

• 1000 mm Collimator

• Flange Back Tester

• A-mount Attachment

• Flange Back Gauge (43.50mm)

• Adhesive bond (B-10)

Adjusting Method

1) Perform “4-4-1. Confirmation of flange-back (f’F)” and confirm that the flange-back value (f’F) of lens does not meet the specifica-

tion in Table 4-4-1.

2) Adjust the lens focus to the infinite.

3) Observing the microscope, adjust the focus by turning the knob of flange-back measuring equipment.

4) Calculate the shift amount by formula below.

Shift Amount (x) = f’F (measured value) at infinite - 44.59mm

x: Shift amount to be adjusted by backwasher

5) Depending on the result in step 4), adjust the thickness of backwasher. (Refer to Table 4-4-2.)

Note: Measure the thickness of backwasher with micrometer or calipers.

• When the shift amount (x) is the positive (+) value: Increase the thickness of backwasher by a value of x.

• When the shift amount (x) is the negative (-) value: Decrease the thickness of backwasher by a value of x.

6) Build in the backwasher and perform “4-4-1. Confirmation of flange-back (f’F)” again.

Specification

Focal-length f’F (mm)

f(mm) (Infinity position)

35 44.58 to 44.60

Table 4-4-2

7) When the flange back (f’F) is out of specification of the Table 4-4-2, repeat steps 2) to 6) again.

Part No. Description

2-684-123-01 WASHER (A), BACK ADJUSTMENT (t=0.05mm)

2-684-124-01 WASHER (B), BACK ADJUSTMENT (t=0.07mm)

2-684-125-01 WASHER (C), BACK ADJUSTMENT (t=0.1mm)

2-684-126-01 WASHER (D), BACK ADJUSTMENT (t=0.2mm)

2-684-127-01 WASHER (E), BACK ADJUSTMENT (t=0.5mm)

SAL35F14G (1.4/35G) (35mm F1.4G)

4-23

Page 63

4-5. FOCUS-SHIFT CHECK/ADJUSTMENT (APERTURE (AMOUNT OF SPHERICAL

ABERRATION))

This section describes the check/adjustment of focus-shift amount resulting change of focal-length by aperture setting.

Equipment

• 1000 mm Collimator

• Flange Back Tester

• A-mount Attachment

• Flange Back Gauge (43.50mm)

• Aberration measuring cap 55mm (SAL35F14G)

1. Preparations

1) Perform “1. Preparations” of “4-4-1. Flange Back (f’F) Check”.

2) Set the checking lens focus to the infinite.

2. Checking Method

1) Set the lens aperture to the open aperture position, and measure the flange back (f’F).

2) Set the aberration measuring cap 55mm (F8 equivalent) on the tip of lens as shown in the Fig.4-5-1, then measure the flange back

(f’F).

Aberration measuring cap 55mm (SAL35F14G)

Fig.4-5-1

3) Calculate amount of focus-shift using the following formula, and check that the specification is satisfied.

Note: The focus-shift amount of the checking lens is difference between the flange back (f’F) of open aperture and flange back

(f’F) reading (using aberration measuring cap 55mm).

Focus-shift = flange back (f’F) of open aperture reading - Flange back (f’F) reading (using aberration measuring cap 55mm)

Specification

Focus-shift (mm) = 0 to +0.15

4) Perform the “4-9. WRITE dSB”.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-24

Page 64

4-6. LENS ROM CHECK

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Click [ROM Data].

Fig.4-6-1

2) The Serial window appears. Input the lens serial number.

Note: When [OK] is clicked without inputting the serial number, the date executed is displayed on the completion window of each

item.

Fig.4-6-2

SAL35F14G (1.4/35G) (35mm F1.4G)

4-25

Page 65

3) The message “Move FOCUS to Infinity position. Then push [ENTER].” is displayed on the pop-up window.

Set the focus to the infinity position and press down the ENTER key.

Fig.4-6-3

4) When “OK” is displayed on the pop-up window, press the ENTER key to return to the initial window.

Fig.4-6-4

3. In case of error display in the ROM Data

1) When the error display and the NG display appear to the pop up window, press the ENTER key to return to the initial window, and

perform “2. Checking Method” again.

Fig.4-6-5

Fig.4-6-6

2) Although the lens is positioned at the infinity position, if the “NG” appears, confirm or perform the following.

• 4-7-1. FOCUS BRUSH POSITION CHECK(Search Focus Adjustment Point)

• Cleaning of flexible pattern or the brush.

• Replaceing the brush.

• Replaceing the main flexible unit.

3) Perform “2. Checking Method” again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-26

Page 66

4-7. FOCUS BRUSH POSITION CHECK/ADJUSTMENT

4-7-1. Focus Brush Position Check (Search Focus Adjustment Point)

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Set the focus position to infinity position.

2) Remove the beam leather, confirm that can see the brush base plate.

3) Loosen two screws fixing the brush base plate.

Screw Screw Brush Base Plate

Fig.4-7-1

4) Click the [Search Focus Adj Point].

Fig.4-7-2

SAL35F14G (1.4/35G) (35mm F1.4G)

4-27

Page 67

5) The message “If Focus-Adjustment-Point is found, Buzzer sounds”. is displayed on the pop-up window.

Search the position where the sound beeps by turning the lens to the infinity position.

Fig.4-7-3

6) At the position where the sound beeps, tighten two screws loosened, apply the adhesive bond (B-10) to the screws.

7) Perform “4-7-2. Focus Brush Position Check” and “4-7-3. Focus Brush Pattern Check”

3. In case of error display in the Search Focus Adjustment Point

1) When the error display and the NG display appear to the pop-up window, press the ENTER key to return to the initial window, and

perform “2. Checking Method”again.

Fig.4-7-4

Fig.4-7-5

2) If the “NG” appears again, thought cause communication error of the finished inspection JIG and checking lens, confirm or perform

the following.

• Improper connection of connector.

• Improper of BL contact.

• Disconnection of mirror box fixture.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-28

Page 68

4-7-2. Focus Brush Position Check (Focus Adjustment Point)

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Click the [Focus Adjustment Point].

Fig.4-7-6

2) The Serial window appears. Input the lens serial number.

Note: When [OK] is clicked without inputting the serial number, the date executed is displayed on the completion window of each

item.

Fig.4-7-7

3) The message “Move FOCUS to Near position. Then push [ENTER].” is displayed on the pop-up window.

Set the focus to the near position and press down the ENTER key.

Fig.4-7-8

SAL35F14G (1.4/35G) (35mm F1.4G)

4-29

Page 69

4) When the Near position check finishes normally, the message “Move FOCUS to Infinity position. Then push [ENTER].” is displayed

on the pop-up window.

Set the focus to the infinity position and press down the ENTER key.

Fig.4-7-9

5) When the infinity position check finishes normally, “OK” is displayed on the pop-up window, and press the ENTER key to return to

the initial window.

Fig.4-7-10

3. In case of error display in the Focus Adjustment Point

1) When the error display and the NG display appear to the pop up window, press the ENTER key to return to the initial window, and

perform “2. Checking Method”again.

• In case of error at the near position in the Focus Adjustment Point

Fig.4-7-11

Fig.4-7-12

• In case of error at the infinity position in the Focus Adjustment Point

Fig.4-7-13

Fig.4-7-14

2) Although the lens is positioned at the near position or the infinity position, if “NG” appears, confirm or perform the following.

• 4-7-1. Focus Brush Position Check (Search Focus Adjustment Point)

• Cleaning of flexible pattern or the brush.

• Replaceing the brush.

3) Perform “2. Checking Method”again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-30

Page 70

4-7-3. Focus Brush Pattern Check(Focus Brush Pattern)

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Click the [Focus Pattern].

Fig.4-7-15

2) The Serial window appears. Input the lens serial number.

Note: When [OK] is clicked without inputting the serial number, the date executed is displayed on the completion window of each

item.

Fig.4-7-16

3) The message “Move FOCUS to Near position. Then push [ENTER].” is displayed on the pop-up window.

Set the focus to the near position and press down the ENTER key.

Fig.4-7-17

SAL35F14G (1.4/35G) (35mm F1.4G)

4-31

Page 71

4) When the Near position check finishes normally, the message “Move FOCUS to Infinity position at about 5sec.” is displayed on the

pop-up window.

Set the focus to the infinity position and press down the ENTER key.

Fig.4-7-18

5) When the infinity position check finishes normally, “OK” is displayed on the pop-up window, and press the ENTER key to return to

the initial window.

Fig.4-7-19

3. In case of error display in the Focus Pattern (near position)

1) When the error display and the NG display appear to the pop-up window, press the ENTER key to return to the initial window, and

perform “2. Checking Method”again.

Fig.4-7-20

Fig.4-7-21

2) Although the lens is positioned at the near position, if “NG” appears, confirm or perform the following.

• 4-7-1. Focus Brush Position Check (Search Focus Adjustment Point)

• Cleaning of flexible pattern or the brush.

• Replaceing the brush.

• Rotating operation error of the focus ring (rotation speed is not suitable at a regulated speed.).

3) Perform “2. Checking Method”again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-32

Page 72

4. In case of error display in the Focus Pattern (infinity position)

1) When the error display and the NG display appear to the pop-up window, perform the work with caution so that setting the lens to the

infinity position can be done in more than 5 seconds and no more than 20 seconds.

• When the focus pattern error

Fig.4-7-22

Fig.4-7-23

• When the lens does not reach the infinity end infinity position seconds.

Fig.4-7-24

2) Perform “2. Checking Method”again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-33

Page 73

4-8. FOCUS HOLD BUTTON CHECK (FOCUS HOLD BUTTON)

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Click the [Focus Hold Button].

Fig.4-8-1

2) The Serial window appears. Input the lens serial number.

Note: When [OK] is clicked without inputting the serial number, the date executed is displayed on the completion window of each

item.

Fig.4-8-2

3) The message “Push [FOCUS HOLD] button once softly.” is displayed on the pop-up window.

Press the focus hold button.

Fig.4-8-3

4) When the focus hold button check finishes normally, “OK” is displayed on the pop-up window.

Fig.4-8-4

SAL35F14G (1.4/35G) (35mm F1.4G)

4-34

Page 74

3. In case of error display in the Focus Hold Button

1) When the Focus Hold Button cannot be pressed within a certain period of time or the button is defective, the window below appears.

Fig.4-8-5

2) In case of error caused by time-out of key pressing, perform the work with caution so as to press the focus hold button within a

certain period of time.

3) Although the button is pressed within a certain period of time, if the error occurs, replace parts relating to the focus hold button.

(Refer to “2-1-5. G ORNAMENTAL RING BLOCK AND FOCUS HOLD BUTTON BASE”)

4) Perform “2. Checking Method”again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-35

Page 75

4-9. WRITE dSB

Equipment

• Personal Computer

• Finished Inspection JIG

• Lens Adjustment Program (ActuatorChecker.exe)

1. Preparations

1) Connected to equipment with checking lens. (Refer to Section 4-1-3.)

2) Start up of “ActuatorChecker.exe”.

3) Click [Set up], and perform the initial setting. (Refer to Section 4-1-4.)

2. Checking Method

1) Click the [Write dSB].

Fig.4-9-1

2) The Serial window appears. Input the lens serial number.

Note:

3) The “Select dsb” window appears.

4) Being based on the image point shift amount calculated by “4-5. FOCUS-SHIFT CHECK/ADJUSTMENT (APERTURE (AMOUNT

OF SPHERICAL ABERRATION))”, select the button.

5) When the Write dSB finishes normally, “OK” appears on the pop-up window.

When

Fig.4-9-2

[OK]

is clicked without inputting the serial number, the date executed is displayed on the completion window of each item.

Fig.4-9-3

SAL35F14G (1.4/35G) (35mm F1.4G)

Fig.4-9-4

4-36

Page 76

3. In case of error in the Write dSB

1) When the error display and the NG display appear to the pop-up window, press the ENTER key to return to the initial window.

Fig.4-9-5

Fig.4-9-6

2) If the “NG” appears again, confirm or perform the following.

• Replaceing the main flexible unit.

• Connected state of equipment (Improper connection of BL error.).

3) Perform “2. Checking Method”again, repeat the inspection until “OK” appears on the pop-up window.

SAL35F14G (1.4/35G) (35mm F1.4G)

4-37

Page 77

[Description of main button functions on toolbar of the Adobe Acrobat Reader Ver5.0 (for Windows)]

Toolbar

Printing a text

1. Click the Print button .

2. Specify a printer, print range, number of copies, and other options, and then click [OK].

Application of printing:

To set a range to be printed within a page, select the graphic

selection tool

be printed, and then click the Print button.

and drag on the page to enclose a range to

Finding a text

1. Click the Find button .

2. Enter a character string to be found into a text box, and click

the [Find]. (Specify the find options as necessary)

Application to the Service Manual:

To execute “find” from current page toward the previous pages,

select the check box “Find Backward” and then click the

“Find”.

3. Open the find dialog box again, and click the [Find Again] and

you can find the matched character strings displayed next.

(Character strings entered previously are displayed as they are

in the text box.)

Reversing the screens displayed once

•To reverse the previous screens (operation) one by one, click

the .

•To advance the reversed screens (operation) one by one, click

the .

Application to the Service Manual:

This function allows you to go and back between circuit diagram and printed circuit board diagram, and accordingly it

will be convenient for the voltage check.

Moving with link

1. Select either palm tool , zoom tool , text selection tool

, or graphic selection tool .

2. Place the pointer in the position in a text where the link exists

(such as a button on cover and the table of contents page, or

blue characters on the removal flowchart page or drawing page),

and the pointer will change to the forefinger form

3. Then, click the link. (You will go to the link destination.)

.

Moving with bookmark:

Click an item (text) on the bookmark pallet, and you can move

to the link destination. Also, clicking

hidden items.

(To go back to original state, click )

can display the

Application to the Service Manual: