Page 1

SERVICE MANUAL

SPECIFICATIONS

SDM-P82

US Model

Canadian Model

LCD panel Panel type: a-Si TFT Active Matrix

Picture size: 18.1 inch

Input signal format RGB operating frequency*

Horizontal: 28 – 92 kHz

Vertical: 56 – 85 Hz

Resolution Horizontal: Max.1280 dots

Vertical: Max.1024 lines

Input signal levels Analog RGB video signal

0.7 Vp-p, 75 Ω, positive

SYNC signal

TTL level, 2.2 kΩ,

positive or negative

(Separate horizontal and vertical,

or composite sync)

0.3 Vp-p, 75Ω, negative

(Sync on green)

Digital RGB (DVI) signal: TMDS

(Single link)

Power requirements 100 – 240 V, 50 – 60 Hz,

Max. 1.2 A

Power consumption Max. 58 W

°

Operating temperature 5 – 35

C

Dimensions (width/height/depth)

Display (upright):

Approx. 404 × 406 × 201 mm

(16 × 16 × 8inches)

(with stand)

Approx. 404 × 332.6 × 86.2 mm

(16 × 13

(without stand)

Mass Approx. 7.6 kg (16 lb 12 oz) (with

stand)

Approx. 6.3 kg (13 lb 14 oz)

(without stand)

Plug & Play DDC2B

* Recommended horizontal and vertical timing condition

• Horizontal sync width duty should be more than 4.8% of total

horizontal time or 0.8 µs, whichever is larger.

• Horizontal blanking width should be more than 2.5 µsec.

• Vertical blanking width should be more than 450 µsec.

Design and specifications are subject to change without notice.

1

1

/

/2inches)

8

× 3

TFT LCD Color Computer Display

Page 2

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the connector shell, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC Leakage. Check leakage as described right.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson 250

and Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

SDM-P82(UC) 2

Page 3

WARNING!!

AVERTISSEMENT!!

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION ARE

IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION AUX COMPOSANTS RELATIFS À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET UNE

MARQUE ! SONT CRITIQUES POUR LA SÉCURITÉ. NE LES

REMPLACER QUE PAR UNE PIÈCE PORTANT LE NUMÉRO

SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

SDM-P82(UC) 3

Page 4

POWER SAVING FUNCTION

AUTOMATIC PICTURE QUALITY ADJUSTMENT

FUNCTION

(ANALOG RGB)

This monitor meets the power-saving guidelines set by VESA,

E

NERGYSTAR, and NUTEK. If the monitor is connected to a

computer or video graphics board that is DPMS (Display Power

Management Signaling) compliant, the monitor will

automatically reduce power consumption as shown below.

Power mode Power consumption (power)

indicator

normal

58 W (max.) green

operation

active off*

3 W (max.) orange

(deep sleep)**

(power) off 1 W red

main power off 0 W off

* When your computer enters the “active off” mode, the input signal is

cut andNOINPUT SIGNALappearsonthe screen. After 10 seconds,

the monitor enters the power saving mode.

** “Deep sleep” is a power saving mode defined by the Environmental

Protection Agency.

Note

ZZ...

If the (POWER SAVE) is set to OFF(page 16), the monitor does not

enter the power saving mode.

When the monitor receives an input signal, it

automatically adjusts the picture’s position and

sharpness(phase/pitch),and ensuresthata clear

picture appears on the screen.

The factory preset mode

When the monitor receives an input signal, it automatically

matches the signal to one of the factory preset modes stored in the

monitor’s memory to provide a high quality picture at the center

of the screen. If the input signal matches the factory preset mode,

the picture is appears on the screen automatically with the

appropriate default adjustment.

If input signals do not match one of the factory

preset modes

When the monitor receives an input signal, the automatic picture

quality adjustment function of this monitor is activated and

ensures that a clear picture always appears on the screen (within

the following monitor frequency ranges):

Horizontal frequency:28 – 92 kHz

Vertical frequency: 56 – 85Hz

Consequently, the first time the monitor receives input signals

that do not match one of the factory preset modes, the monitor

may take a longer time than normal for displaying the picture on

the screen. This adjustment data is automatically stored in

memory so that next time, the monitor will function in the same

way as when the monitor receives the signals that match one of

the factory preset modes.

If you adjust the phase, pitch, and pictures

position manually

For some input signals, the automatic picture quality adjustment

function of this monitor may not completely adjust the picture

position,phase,and pitch. Inthiscase, you can manuallyset these

adjustments (page 12). If you manually set these adjustments,

they are stored in memory as user modes and automatically

recalled whenever the monitor receives the same input signals.

SDM-P82(UC) 4

Page 5

TABLE OF CONTENTS

Section Title Page Section Title Page

1. DISASSEMBLY

1-1. Rear Cover and Cabinet Assy Removal ............... 1-1

1-2. I Board Removal .................................................. 1-2

1-3. G Board Removal ................................................ 1-3

1-4. A Board Removal ................................................ 1-4

1-5. LCD Unitl Removal.............................................. 1-5

1-6. LCD Panel Removal ............................................ 1-6

1-7. H Board Removal ................................................. 1-7

2. ADJUSTMENTS

2-1. Service Functions of Buttons in Front Panel ........ 2-1

2-2. Usea of Service Mode .......................................... 2-2

2-3. Functions of Service Mode .................................. 2-3

3. DIAGRAMS

3-1. Block Diagrams .................................................... 3-1

3-2. Circuit Boards Location ........................................ 3-2

3-3. Schematic Diagrams and Printed Wiring Boards.. 3-2

(1)Schematic Diagram

of A(a,b,c,d,e,f,g) Board............... 3-4

(2)Schematic Diagram of H Board. ...................... 3-12

(3)Schematic Diagram of I Board......................... 3-14

(4)Schematic Diagram of G Board. ...................... 3-16

4. EXPLODED VIEWS

4-1. Chassis ................................................................. 4-2

4-2. Packing Materials ................................................. 4-3

2-4. White Balance Adjustment .................................. 2-3

2-5. Action after Replacing

the LCD Panel and Board ..................................... 2-5

5. ELECTRICAL PARTS LIST ............................... 5-1

SDM-P82(UC) 5

Page 6

1-1. REAR COVER AND CABINET ASSY REMOVAL

SECTION 1

DISASSEMBLY

2 Rear cover

1 Connector cover

3 Two screws

(+PSW 4X8)

4 Cabinet assy

Protechtion sheet

3 Two screws

(+PSW 4X8)

SDM-P82(UC) 1-1

Page 7

1-2. I BOARD REMOVAL

3 Connector

CN03

3 Connector

CN04

2 Invertor shield

1 Screw

(+RK 3X6)

3 Connector

CN01

3 Connector

CN02

4 Screw

(+RK 3X6)

3 Connector

CN06

3 Connector

CN05

5 I Board

3 Connector

CN07

SDM-P82(UC) 1-2

Page 8

1-3. G BOARD REMOVAL

1 Two crews

(+RK 3X6)

2 Shield

3 Connector

CN203

4 Screw

(+RK 3X6)

5 G Board

3 Connector

CN102

3 Connector

CN101

SDM-P82(UC) 1-3

Page 9

1-4. A BOARD REMOVAL

3 Interface shield

5 Frexible cable

6 Four screws

(+PWH 3X6)

5 Connector

CN202

5 Connector

CN501

5 Connector

CN304

2 Three screws

(+PWH 3X6)

5 Connector

CN201

1 Screw

(+RK 3X6)

7 A board

4 Six connector screws

SDM-P82(UC) 1-4

Page 10

1-5. LCD UNIT REMOVAL

1 Flexible cable

2 Two screws

(+K 2X4)

3 LCD unit

2 Beznet assy

2 Two screws

(+K 2X4)

SDM-P82(UC) 1-5

Page 11

1-6. LCD PANEL REMOVAL

2 LCD panel

1 Two screws

(+PWH 3X6)

1 Two screws

(+PWH 3X6)

SDM-P82(UC) 1-6

Page 12

1-7. H BOARD REMOVAL

3 Connector

CN901

2 Flexible cable

1 Switch cover

3 H Board

SDM-P82(UC) 1-7

Page 13

SECTION 2

ADJUSTMENTS

2-1. Service Functions of Buttons in Front Panel

The following functions are available for servicing the set.

1. To display the model information

Press the MENU button for five seconds or more in the ordinary power-on state,

and the following information is displayed on the screen:

- Model name

- Serial number

- Manufactured year and week

This function is described in the instruction manual also.

2. To display ETI (Elapsed Time Indicator)

Press the OK button for five seconds or more in the ordinary power-on state, and

the cumulative power-on time excluding the power-off and power saving state is

displayed on the screen.

3. All mode recall

Press the POWER button with pressing the OK button in the power-off state, and

the user memory is completely cleared and the system is reset to the factory setting.

This reset is similar to RESET in the OSD menu, but differs from it in the

following:

- The NO SYNC AGING flag is cleared.

- LANGUAGE is set to ENGLIDH.

- INPUT is set to INPUT1: DVI-D.

5. To enter the service mode

Press the POWER button with pressing the UP (↑) and DOWN (↓)

buttons in the power-off state, and the system is set to the service mode. The service

mode will be explained later.

To exit from the service mode, turn off the power.

6. To copy EDID to the EEPROM and to clear ETI

Press the POWER button with pressing the UP (↑) and OK buttons in the

power-off state, and the data for the model information are copied to the EEPROM

for the internal microcontroller from EDID of INPUT2: HD15, and the model

information display is made correct.

When replacing the A board, this operation is required after writing EDID and at

the same time ETI is reset to 0.

7. To enter the ISP mode

Turn on the MAIN POWER switch with pressing the DOWN (↓) button in the

main-power-off state, and the system enters the ISP mode. The POWER LED goes

off, and both input LED's 1 and 2 light on, and the picture disappears, and any

button becomes invalid.

In the ISP mode, the internal software can be updated with an external personal

computer using a special fixture.

To cancel the ISP mode, turn off the MAIN POWER switch.

4. To set the NO SYNC AGING flag

Press the POWER button with pressing the UP (↑) button in the power-off

state, and the NO SYNC AGING flag is set. In this setting, when the input with no

input signal is selected, the system goes into the AGING MODE.

The NO SYNC AGING flag is held until it is cleared. To clear the NO SYNC

AGING flag, go into the service mode and then set the AGING MODE to OFF, or

execute the all mode recall.

SDM-P82(UC) 2-1

Page 14

2-2. Uses of Service Mode

1. Turn off the power with the POWER button in the front panel. The red POWER

LED lights on.

2. Press the POWER button in the front panel with pressing the UP (↑) and

DOWN (↓) buttons, and the system enters the service mode.

When no signal is input to the selected input terminal, the following functions are

disabled.

3. Press the MENU button, and the main menu is displayed. Then go to page 2 of the

main menu with the UP (↑) or DOWN (↓) button, then select the MAINTAIN icon

on the bottom line, and then press the OK button.

4. In this menu screen, the version number and released date of the internal software

can be checked.

5. The structure of the MAINTAIN menu is shown below.

MAINTAIN

CONFIGURATION

CHIPS

EXIT

COLOR TEMP

INITIAL EEPROM

CLEAR ETI TIME

EEPROM TEST

RGB RESET

EXIT

AGING MODE

REGISTERS VALUE

9300K

6500K

EXIT

ON

OFF

CONTROL REG

EXIT

SUB-BRIGHTNESS

R

G

B

SUB-CONTRAST

R

G

B

EXIT

000~1FF

The operation procedure is basically same as that of the ordinary user controls.

The function of each menu is explained in next section.

SDM-P82(UC) 2-2

Page 15

2-3. Functions of Service Mode

2-4. White Balance Adjustment

1. COLOR TEMP

This is used for the white balance adjustment at color temperature 9300 K and 6500

K. The adjustment requires to be done for every input (INPUT1: DVI-D, INPUT1:

HD15, or INPUT2: HD15) by switching the input. The adjustment data is stored into

the register for respective inputs.

2. INITIAL EEPROM

This sets the data of the EEPROM to the default data. This operation is not required

usually.

3. CLEAR ETI TIME

This resets the ETI (Elapsed Time Indicator) counter to 00000 H.

4. EEPROM TEST

This tests writing and reading of the EEPROM.

5. RGB RESET

This adjust the offset and gain of the input AD converter for the analog inputs

(INPUT1: HD15 and INPUT2:HD15). As these adjustments are common to both

inputs, perform them for either input. It is unnecessary for another input.

Execute the adjustments under the condition where the signal specified in "White

Balance Adjustment" is input.

6. AGING IN MODE

This sets and clears the NO SYNC AGING flag.

AGING MODE = ON: Sets the NO SYNC AGING flag.

AGING MODE = OFF: Clears the NO SYNC AGING flag.

When the NO SYNC AGING flag is set and the input with no input signal is

selected, the system goes into the AGING MODE. The NO SYNC AGING flag is

held until it is cleared. To clear the NO SYNC AGING flag, go into the service mode

and then set the AGINGN MODE to OFF, or execute the all mode recall.

1. Preparation

(1) Measurement point : Center of screen

(2) Measurement distance : 50 cm

(3) Measurement angle : 90°

(4) Color analyzer (Minolta CS-1000 or equivalent)

(5) Signal generator (Astro Design VG-828D or equivalent)

Be sure to calibrate the analog RGB output level with 75Ω termination.

2. Service mode setting

Enter the service mode referring to step 1 and 2 of Section 2-2.

3. Aging

Set the AGING MODE in the service mode to ON. Disconnect the signal input

terminal or select the input with no signal input, and the system goes into the

AGING MODE.

Execute aging for 30 minutes or more.

4. User control setting

Feed a signal to the selected input, and then execute reset in the menu screen. Then,

move the menu display position to avoid the measurement point. Or, set the

following for respective inputs.

BACKLIGHT (Brightness of backlight) = 100

CONTRAST = 70

BRIGHTNESS = 50

Menu display position = not center of screen (Avoid the measurement point.)

(The setting of the menu display position is common to respective inputs.)

ECO = OFF (The setting of ECO is common to respective inputs.)

Do not change the above setting until the white balance adjustment is completed.

7. CONTROL REG.

This can check the data of the internal registers. This operation is not required

usually.

SDM-P82(UC) 2-3

Page 16

5. Analog RGB white balance adjustment

(1) Feed the signal listed below to INPUT2: HD15, and then select INPUT2: HD15.

Then execute RGB RESET in the service mode menu.

Signal timing

Pattern

Input level

(6) Adjust the SUB-BRIGHTNESS: R, G, and B.

Specifications are listed below.

x

0.313 ± 0.003

y

0.329 ± 0.003 14 ± 0.7

Brightness (cd/m2)

VESA 1280 * 1024 / 60Hz

Gray scale

0.73 Vp-p

(2) Feed the signal listed below to INPUT2: HD15.

Signal timing

VESA 1280 * 1024 / 60Hz

Pattern

All gray

Pattern

30 IRE (0.21 Vp-p)

(3) Select COLOR TEMP → 9300K in the service mode menu, and set the data

listed below as initial data for adjustment.

SUB-BRIGHTNESS

R

30

G

30

B

30

SUB-CONTRAST

R

141

G

141

B

141

(4) Adjust SUB-BRIGHTNESS: R, G, and B. Specifications are listed below.

x

0.283 ± 0.003

y

0.298 ± 0.003 14 ± 0.7

Brightness (cd/m2)

(7) After adjusting (4) and (6), write down the value of SUB-CONTRAST

and SUB-BRIGHTNESS.

(8) Feed the signal to INPUT1: HD15, and then select

INPUT1: HD15. Select COLOR TEMP → 9300K then 6500K in the service

mode menu, and enter the value written down in step (7) respectively.

6. Digital RGB white balance adjustment

(1) Feed the signal listed below to INPUT1: DVI-D.

Signal timing

VESA 1280 * 1024 / 60Hz

Pattern

All gray

Input level

30 IRE

(2) Select COLOR TEMP → 9300K in the service mode menu, and set the data

listed below as initial data for adjustment.

SUB-BRIGHTNESS

R

40

G

40

B

40

SUB-CONTRAST

R

130

G

130

B

130

(3) Adjust the SUB-BRIGHTNESS: R, G, and B. Specifications are listed below.

(5) Select COLOR TEMP → 6500K in the service mode menu, and set the data

listed below as initial data for adjustment.

SUB-BRIGHTNESS

R

30

G

30

B

30

SUB-CONTRAST

R

141

G

141

B

141

x

0.283 ± 0.003

y

0.298 ± 0.003 14 ± 0.7

Brightness (cd/m2)

SDM-P82(UC) 2-4

Page 17

(4) Select COLOR TEMP → 6500K in the service mode menu, and set the data

listed below as initial data for adjustment.

2-5. Action after Replacing the LCD Panel and Board

SUB-BRIGHTNESS

R

40

G

40

B

40

SUB-CONTRAST

R

130

G

130

B

130

(5) Adjust the SUB-BRIGHTNESS: R, G, and B. Specifications are listed below.

x

0.313 ± 0.003

y

0.329 ± 0.003 14 ± 0.7

Brightness (cd/m2)

7. Setting for shipping

Turn off the power with the POWER button in the front panel. Check that the red

POWER LED lights on, and then execute the all mode recall. (press the POWER

button with pressing the OK button in the power-off state)

1. After replacing the LCD panel

(1) White balance adjustment. (Refer to Section 2-4.)

(2) CLEAR ETI TIME. (Refer to Section 2-3 step 3.)

(3) Check of picture and sound.

2. After replacing the A board

(1) White balance adjustment. (Refer to Section 2-4.)

(2) EDID writing.

As the write protection is not applied in this unit, it is possible to write data

with an ordinary writing fixture.

It is required to be written for INPUT1: DVI-D, INPUT1: HD15, and

INPUT2: HD15 respectively.

Take care that the data for DVI-D and HD15 terminals are different

from each other.

(3) EDID copy to the EEPROM and ETI clear. (Refer to Section 2-1 step 6.)

Be sure to perform them after EDID writing. After executing, check

that the correct model information is displayed. (Refer to Section 2-1 step 1.)

(4) Operation check of buttons and LED's in the front panel, and Check of

picture and sound for respective inputs.

3. After replacing the I board

(1) White balance adjustment. (Refer to Section 2-4.)

(2) Check of picture and sound.

4. After replacing the G board

(1) Operation check of the MAIN POWER switch.

(2) Check of picture and sound.

5. After replacing the H board

(1) Operation check of buttons and LED's in the front panel.

SDM-P82(UC) 2-5

Page 18

3-1. BLOCK DIAGRAMS

SECTION 3

DIAGRAMS

CN602

CN603

CN601

A BOARD

(INTERFACE)

CN301

IC307

IC603

IC401

I BOARD

(INVERTER)

BOARD

IC502

CN501

IC503

IC503

IC504

IC505

IC302

IC303

IC305

IC304

IC201

IC601

CN802

CN803

IC802

IC301

IC801

H BOARD

(IKEY BOARD)

CN801

G BOARD

(POWER)

U BOARD

(EARPHONE)

SDM-P82(E) 3-1

Page 19

3-2. CIRCUIT BOARDS LOCATION

A Board

I Board

H Board

G Board

SDM-P82 (UC) 3-2

Page 20

3-3. SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

G

D

S

2

3

4

5

6

7

8

9

0

qa

qs

qf

qh

–

1

G

D

S

G

S

S

D

G

D

Ver.1.6

Transistor

(FET)

Transistor

Transistor

Discrete semiconductot

(Chip semiconductors that are not actually used are included.)

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Source

Source

Anode

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Common

Cathode

Cathode

Common

Cathode

Cathode

Common

Common

Common

Common

Cathode

Anode

Base

Emitter

Collector

Base

Emitter

Collector

Drain

Gate

Gate

Drain

Device Printed symbol Terminal name

Circuit

Terminal name of semiconductors in silk screen

printed circuit ( )

Anode

Anode

Anode Cathode

Anode Anode

Cathode

qd

Transistor

(FET)

Transistor

(FET)

qg

Emitter

Collector

Base

Transistor

Source

Gate

Drain

Cathode

Anode

Anode

Cathode

Anode

Anode

*

Note:

• All capacitors are in µF unless otherwise noted. (pF: µµF)

Capacitors without voltage indication are all 50 V.

• Indication of resistance, which does not have one for rating electrical

power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP : 1/10 W)

• All resistors are in ohms.

• : nonflammable resistor.

• : fusible resistor.

∆ : internal component.

•

• : panel designation, and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

• : earth-ground.

• : earth-chassis.

• When replacing the part in below table, be sure to perform the related

adjustment.

• All voltages are in V.

• Readings are taken with a 10 M digital multimeter.

• Readings are taken with a color-bar signal input.

• Voltage variations may be noted due to normal production tolerances.

•

• Circled numbers are waveform references.

• : B + bus.

• : B – bus.

Note: The components identified by shading and

Note: Les composants identifiés par un tramé et

: Can not be measured.

*

mark ! are critical for safety. Replace only

with part number specified.

une marque ! sont critiques pour la

sécurité. Ne les remplacer que par une pièce

portant le numéro spécifié.

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-h. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

Circuit diagram division code

SDM-P82 (UC) 3-3

Page 21

(1) Schematic Diagrams of A (a, b, c, d, e, f, g) Board

A

B

C

D

1

ag 1

afg2

2

0

0

0.2

0

43

+12V

7.7

7.5

7.7

1.2

1.2

7.7

2.5

10.8

10.6

2.5

1.2

0

I/F

0

1.0

0.2

7.5

+12V

10.6

+5V REG

+5V REG

98765

+5V

+5V

10

11

12

TO

G BOARD

CN203

13

14

15

E

F

G

H

10.8

+3.3V REG

+3.3V

+3.3V REG +3.3V REG

+5V

+3.3V

+5V

+3.3V

A

-

a

+5V

+2.5V REG

+5V

+2.5V

af 3

(POWER)

B-SS3627<J..>-A..-P1

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

I

a b 1

Ref. No.

Circuit diagram division code

SDM-P82(UC) 3-4

Page 22

A

B

C

1

INPUT 1

DVI-D INPUT

(DIGITAL RGB)

2

ag 3

43

98765

10

11

12

bd 5

13

14

D

E

F

G

H

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

Circuit diagram division code

4.4

4.4

EEPROM

bc6

bg7

4.4

4.4

bc8

+5V

SW

4.4

4.9

4.9

4.4

4.9

4.8

0

bg 9

bg 10

A-b

(DVI AND DDC SWITCH IC)

B-SS3627<J..>-A..-P2

I

J

SDM-P82(UC) 3-5

Page 23

A

1

2

43

98765

10

11

12

13

14

15

B

C

D

E

INPUT 2

HD 15 INPUT

(ANALOG RGB)

c g 1 1

c g 1 2

b c 8

b c 6

+5V

4.4

4.4

EEPROM

c g 16

0.6

+5V

0

+5V

0

+5V SW

INPUT 1

HD 15 INPUT

F

(ANALOG RGB)

G

H

I

J

K

c g 1 3

c g 1 4

+5V

4.4

4.4

AT2XC02-10SC

EEPROM

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

Circuit diagram division code

c g 1 5

c d 1 9

c d 1 7

c g 1 8

ANALOG SW

A-c

(ANALOG)

B-SS3627<J..>-A..-P3

SDM-P82(UC) 3-6

Page 24

1

2

43

98765

10

11

12

13

14

15

A

B

C

D

E

+3.3V

+3.3V

+3.3V

+3.5V

cd19

df27

df26

df28

df29

df30

df31

df32

F

G

H

IC401

bd5

+2.5V

cd17

+2.5V

+3.3V

I

+2.5V

df20

dh21

dg22

dg23

dg24

dg25

GM5020

SCALER

de33

de34

de35

de36

de37

J

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

K

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

Circuit diagram division code

A

-

d

(SCALER)

B-SS3627<J..>-A..-P4

SDM-P82(UC) 3-7

Page 25

A

B

C

1

de34

2

43

+3.3V +3.3V +3.3V

98765

10

11

12

13

de33

14

15

D

E

G

1.2

1.2

1.2

1.2

1.2

1.3

1.2

1.1

1.7

1.6

0

0

1.3

3.3

de35

de36 de37

3.3

3.3

3.3

0

0

SDRAM SDRAM SDRAM

1.8

0.7

2.2

0.6

0.8

1.0

1.0

1.0

0.6

1.0

0.1

0.9

0.3

0.8

1.0

1.0

1.2

1.2

1.2

1.2

1.2

1.3

1.2

1.1

1.7

1.6

1.3

3.3

3.3

3.3

3.3

1.8

0.7

2.2

0.6

0.8

1.0

1.0

1.0

0.6

0

0

0

0

1.0

0.1

0.9

0.3

0.8

1.0

1.0

1.2

1.2

1.2

1.2

1.2

1.3

1.2

1.1

1.7

1.6

1.3

3.3

0

0

3.3

3.3

3.3

1.8

0.7

2.2

0.6

0.8

1.0

1.0

1.0

0.6

1.0

0.1

0.9

0.3

0.8

1.0

1.0

0

0

F

H

A

-

e

(SDRAM)

I

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

J

Circuit diagram division code

B-SS3627<J..>-A..-P5

SDM-P82(UC) 3-8

Page 26

A

1

2

43

98765

10

11

12

13

14

15

B

C

D

E

d f 3 0

a f 3

a f g 2

0

THC63LVDM83A

IC501

LVDS

3.8

0.7

+12V

0

0

+3.3V

d f 2 7

+5V

IC502

THC63LVDM83A

LVDS

1.3

1.3

1.2

1.3

1.2

1.2

1.3

1.3

1.3

1.2

TO LCD

1.2

1.2

1.1

1.3

1.2

1.3

1.3

1.1

1.2

1.2

1.3

+3.3V

f g 3 8

d f 2 0

F

G

H

d f 3 1

d f 3 2

d f 2 6

d f 2 8

d f 2 9

A

-

f

(LVDS)

I

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

J

a b 1

Ref. No.

Circuit diagram division code

B-SS3627<J..>A..-P6

SDM-P82(UC) 3-9

Page 27

A

1

2

43

98765

10

11

12

13

14

15

B

C

D

E

EEPROM

4.9

+5V

4.9

0.6

dg24

dg25

0.3

0.2

0.2

0.2

4.5

4.5

4.9

0

0

bg9

fg38

cg12

4.9

4.9

4.9

0

4.9

4.9

1.1

1.2

0

0.1

0.1

0

MCU

4.9

4.9

4.9

4.9

4.9

4.9

4.9

0

3.1

0

0

4.9

4.9

4.9

4.9

0.1

0

0

afg2

4.9

0

bg4

bg10

cg11

cg14

cg16

cg18

0.1

ag1

cg13

cg15

gh39

G

H

470

F

4.9

0

TO

H BOARD

CN901

5.6V

4.9

-9.0

0

-5.1

7.5

0

0

+5V

I / F

0

-9.0

0

4.9

4.8

4.8

0

4.8

0

dg22

gh40

bg7

0.5

0.5

10.9

3.0

3.3

4.9

dg23

5.2

4.9

TO

I BOARD

CN01

I

5.2

0

J

A-g

(MCU)

K

• Divided circuit diagram

One sheet of A board are circuit diagram is divided into eight sheets,

each having the code A-a to A-g. For example, the destination

ab1 on the code A-a sheet is connected to ab1 on the A-b sheet.

a b 1

Ref. No.

Circuit diagram division code

B-SS3627<J..> - A..-P7

SDM-P82(UC) 3-10

Page 28

A

1

2

34

A

B

C

[

MAIN CPU,SYSTEM IC,COLOR DEC,A/D CONV,3D COMB FILTER

— A BOARD —

]

A

B

1

2

34

<COMPONENT SIDE> <CONDUCTOR SIDE>

SDM-P82(UC) 3-11

Page 29

A

1 2 34

A

B

C

[

MAIN CPU,SYSTEM IC,COLOR DEC,A/D CONV,3D COMB FILTER

— A BOARD —

1 2 34

A

]

B

<COMPONENT SIDE> <CONDUCTOR SIDE>

SDM-P82(E) 3-12

Page 30

(2) Schematic Diagram of H Board

1

2

A

B

C

D

43

98765

10

H

(KEY)

B-SS3633<UC.>-H..

11

TO

A(g)BOARD

CN303

E

F

SDM-P82(UC) 3-12

Page 31

H

[

]

KEY

— H BOARD —

<COMPONENT SIDE>

<CONDUCTOR SIDE>

SDM-P82(UC) 3-13

Page 32

(3) Schematic Diagrams of I Board

A

B

C

D

E

F

G

1

5V

ICT53

5V

D06

BAS32

OP11

D04

BAS32

OP22

D05

BAS32

OP44

2

VIN

R41

2k

ICT54 ICT55

R42

1k

Q1

2N7002LTA

PDRV_C

VIN

R45

2k

ICT58

R46

1k

Q8

2N7002LTA

ICT60

PDRV_A

C23

0.1u

C24

0.1u

C25

0.1u

I

(INVERTOR)

ICT56

Q10

BC817-25

R04

10

Q11

BC807-25

Q16

BC817-25

R15

10

Q17

BC807-25

R28

1M

R29

1M

R30

1M

ICT57

ICT59

P_C

P_A

R50

100k

2N7002LTA

2N7002LTA

2N7002LTA

43

CN01

7PIN

VCC

VCC

TO

A (g) BOARD

CN202

5V

FB

Q24

2N7002LTA

Q25

GND

GND

GND

OFF

ADJ

D01

BAS32

OP1

D02

BAS32

OP2

D03

BAS32

OP4

Q26

Q27

D11

1SS355

D12

PBC

1SS355

D13

1SS355

F01

2A

D

63V

1

ICT19

2

3

4

6

5

7

ICT38

UDZSTE-175.6B

ICT51

C21

0.1u

ICT50

C22

0.1u

ICT52

C03

0.1u

YST-A186490

1

VP11

2

5

VP22

FB11

FB22

ZD01

R05

1M

R06

1M

R07

1M

T06

VIN

+

ICT39

20

19

18

17

16

14

13

12

ICT29

ICT28

ICT31

NDRV_B

PDRV_A

PDRV_C

NDRV_D

ICT23

ICT22

R18

R17

30k

ICT26

NDRV_B

NDRV_D

C12

220p

J01

C13 0.01u

C15

0.1u

ICT21

ICT27

20

R43

20

R21 62k

C14

ICT20

ICT33

R12

47k

5V

0.01u

ICT42

ICT34

R09

22

ICT40

R10

10k

ENA

C04

C05

1u

FB

C06

0.01u

R39

33k

D21

100

10k

Q06

BC817-25

R11

100k

R08

R03

ICT43

Q02

2N7002LTA

Q03

2N7002LTA

ICT48

Q04

2N7002LTA

ICT44

R14

681k

D07

C08

1u

0

ICT37

C10 0.1u

ICT35

C09 1u

C38

0.0015u

R13

27k

ICT45

IC01

OZ9601S

1

2

3

4

5

6 15

2.5V

7

8

9

10 11

ICT46

ICT49

C11

Q05

2N7002LTA

R01

C07

CN07

2PIN

ICT13

ICT63

CY06

1SS226

22p

674

1

D19

2

B

ICT65

R35

560

OP44

ICT64

R36

390

R16

51k

D

F02

2A

63V

0.01u

C

+

C36

220u

R19

1M

PBC

R20

15k

D08

1SS355

ICT8

C40

IC04

10u

8958

1

N_B

P_A

VP11

IC05

8958

1

N_D

P_C

ICT66

C33

220u

35v

N_B

N_D

D09

1SS355

D10

1SS355

T04

YST-A186490

1

2

4

5

VP22VP11

ICT16

T05

YST-A186490

1

2

4

5

VP1

VP2

FB1

FB2

N_B

P_A

N_D

P_C

7

6

7

6

98765

ICT18

ICT25

1

ICT24

1

ICT17

T03

YST-A186490

1

2

4

5

ICT15

ICT36

ICT41

8958

IC03

8958

CY04

CY05

IC02

C19

333p

22p

ICT1

VP1

7

6

ICT14

22p

10

T01

YST-A186490

ICT3

1

7

2

CY01

6

4

5

VP2VP1

C39

10u

ICT2

T02

YST-A186490

ICT6

1

7

2

6

4

5

CY03

ICT11

22p

D16

B

1SS226

R26

560

OP4

R27

ICT12

390

D20

B

1SS226

ICT47

D17

B

1SS226

R31

560

OP11 FB11

ICT30

ICT32

D18

B

1SS226

R33

560

OP22 FB22

ICT68

ICT9

22p

D14

B

1SS226

R22

560

OP1 FB1

ICT4

CY02

22p

D15

B

1SS226

R24

560

OP2 FB2

ICT7

ICT10

R32

390

ICT67

R34

390

ICT5

11

CN02

2PIN

1

TO LCD BACK LIGHT

2

R23

390

CN03

2PIN

1

TO LCD BACK LIGHT

2

R25

390

CN04

2PIN

1

TO LCD BACK LIGHT

2

CN05

2PIN

1

TO LCD BACK LIGHT

2

CN06

2PIN

1

TO LCD BACK LIGHT

2

12

13

H

B-SS3627<J..> - I..

SDM-P82(UC) 3-14

Page 33

I

[

INVERTER

— I BOARD —

]

<COMPONENT SIDE>

<CONDUCTOR SIDE>

SDM-P82(UC) 3-15

Page 34

(4) Schematic Diagrams of G Board

A

B

C

D

1

AC IN

100V

50/60Hz

2

43

98765

10

11

+5V

12

13

TO

A (a) BOARD

CN201

14

15

E

F

G

H

G(POWER)

I

B-SS3633<UC.> - G..

J

SDM-P82(UC) 3-16

Page 35

G

[

POWER SUPPLY

—G BOARD —

]

<COMPONENT SIDE>

<CONDUCTOR SIDE>

SDM-P82(UC) 3-17

Page 36

• Items with no part number and no

description are not stocked because they

are seldom required for routine service.

• The construction parts of an assembled

part are indicated with a collation number

in the remark column.

• Items marked " * " are not stocked since

they are seldom required for routine

service. Some delay should be anticipated

when ordering these items.

The components identified ! marked are

critical for safety.

Replace only with the part number specified.

Les composants identifiés par la marque !

sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

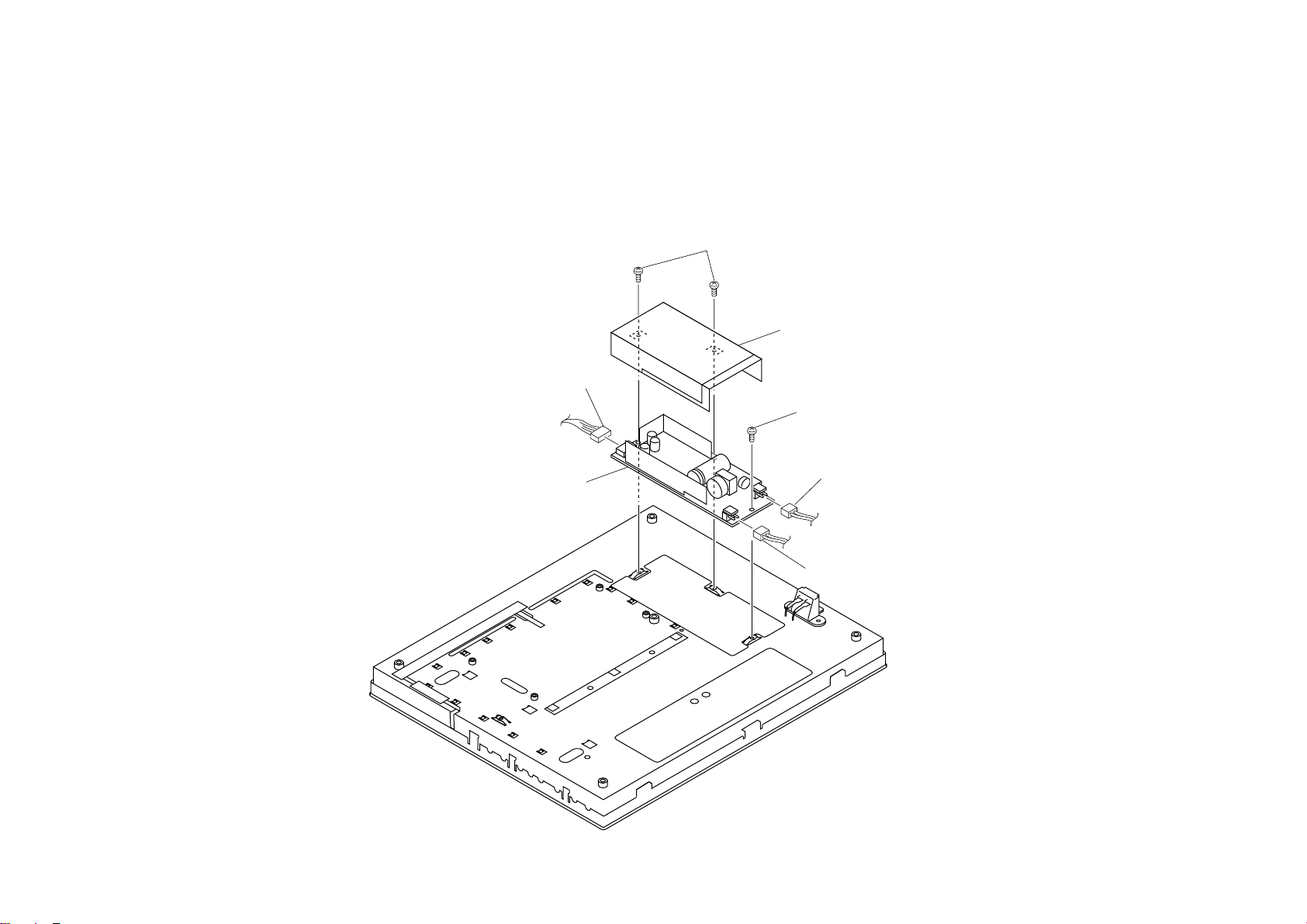

SECTION 4

EXPLODED VIEWS

SDM-P82(UC) 4-1

Page 37

4-1. CHASSIS

4

1

+K 2.6X4

+RK 3X6

+PWH

3X6

REF.NO. PART NO. DESCRIPTION REMARK

1 X-4040-765-1 BEZEL ASSY

2 3-704-176-51 EMBLEM (NO.6), SONY

3 1-761-645-11 H BOARD, MOUNT

4 1-804-967-11 PANEL, LCD (LM181E05)

5 1-761-646-11 I BOARD, MOUNT

6 1-761-615-11 G BOARD, MOUNT

7 1-761-644-11 A BOARD, MOUNT

8 X-4040-766-1 STAND ASSY 9

9 4-090-701-01 ARM (REAR)

10 4-090-715-01 COVER, REAR

+RK 3X6

7

+PWH

3X6

+RK 3X6

+PWH 3X6

6

11 4-090-704-01 COVER CABLE

12 X-4040-764-1 CABINET ASSY 13

13 4-089-923-01 COVER, MINI DIN

+RK 3X6

+PWH 3X6

+RK

3X6

5

+P 3X6

+P 3X4

8

9

+K 2.6X4

+PSW 4X8

13

10

11

+PSW 4X8

+PSW 4X8

3

2

12

SDM-P82(UC) 4-2

Page 38

4-2. PACKING MATERIALS

555657 58 59

54

53

61

52

REF.NO. PART NO. DESCRIPTION REMARK

51 * 4-090-725-01 INDIVIDUAL CARTON

52 * 4-090-727-11 CUSHION (LOWER)

53 * 4-378-262-21 BAG, PROTECTION

54 * 4-090-726-01 CUSHION (UPPER)

55 1-765-718-11 CORD SET, POWER

56 1-796-496-11 DISC, CD-ROM

57 1-824-596-11 CABLE, D-SUB

58 1-824-598-11 CABLE, DVI-D

59 4-090-729-11 MANUAL INSTRUCTION

60 *4-091-820-01 PAPER SHEET (BOTTOM)

61 * 4-091-819-01 PAPER SHEET (BACK)

60

51

SDM-P82(UC) 4-3

Page 39

NOTE:

The components identified ! marked are

critical for safety.

Replace only with the part number specified.

SECTION 5

ELECTRICAL PARTS LIST

• All variable and adjustable resistors have

characteristic curve B, unless otherwise

noted.

Les composants identifiés par la marque !

sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

When indicating parts by reference

number, please include the board name.

• Items marked " * " are not stocked since

they are seldom required for routine

service. Some delay should be anticipated

when ordering these items.

RESISTORS

• All resistors are in ohms

• F : nonflammable

SDM-P82(UC) 5-1

Page 40

No. # Board Type ! /*Ref.No. Part No. Descrption Remarks-1 Remarks-2 Difference

1 G DIODE D130 8-719-510-51 DIODE SB60B

SDM-P82(UC) 5-2

Page 41

9-978-738-01

Sony EMCS Corporation

Ichinomiya TEC

English

200HL08-Data

Made in Japan

2002. 8

SDM-P82(UC) 41

Loading...

Loading...