Sony NWE-5 Service manual

NW-E5

SERVICE MANUAL

Ver 1.0 2001.04

SPECIFICATIONS

Recording time

Approx. 90 min. (132kbps)

Approx. 120 min. (105kbps)

Approx. 180 min. (66kbps)

Sampling frequency response

44.1kHz

Recording format

ATRAC3

Frequency response

20 to 20,000 Hz (single signal measurement)

Output

Earphone: stereo mini-jack

Signal-to-noise ratio (S/N)

More than 80dB (excluding 66 kbps)

Dynamic range

More than 85dB (excluding 66 kbps)

Operating temperature

5˚C to 35˚C (-41˚F to 95˚F)

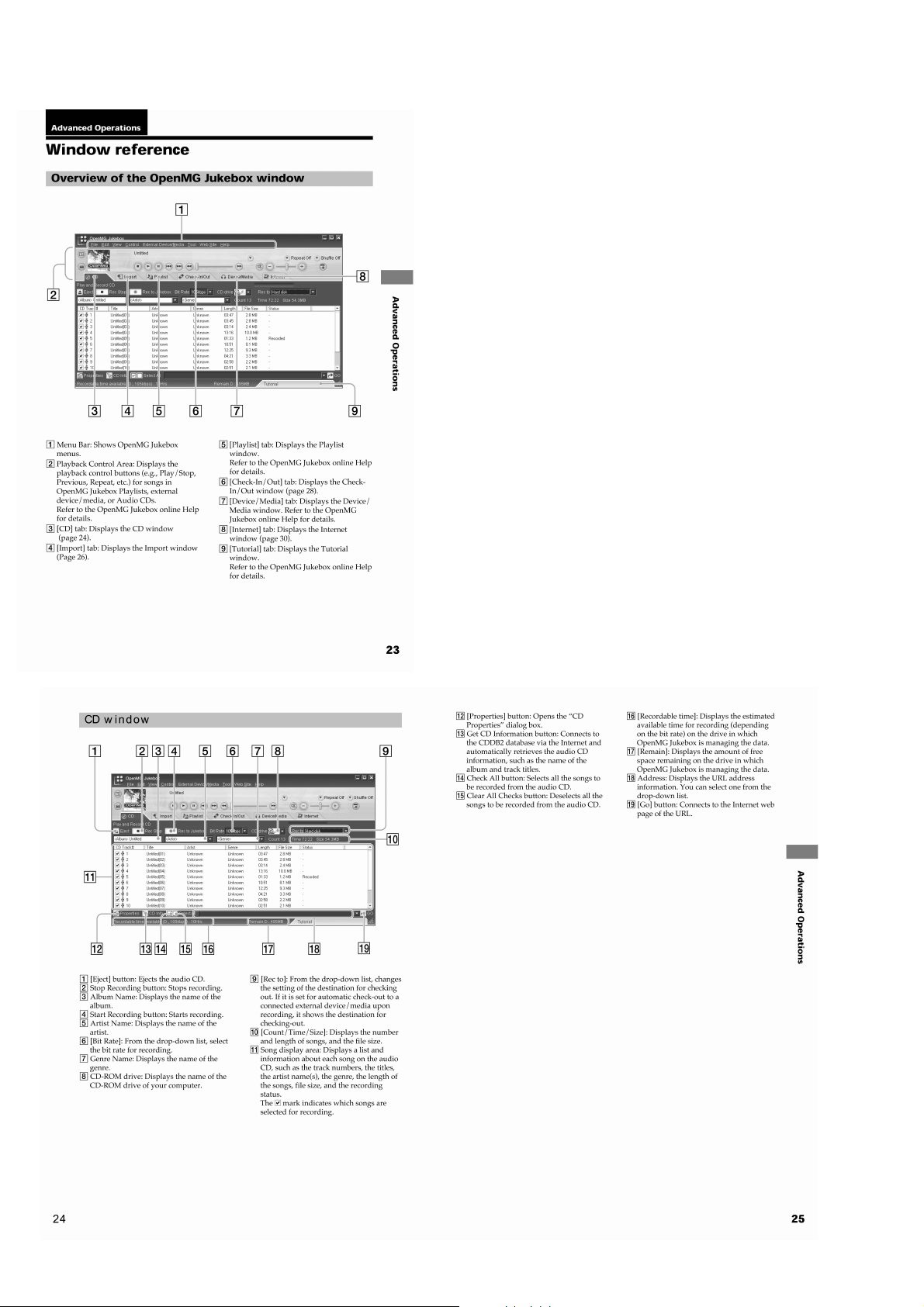

Power source

LR03 (Size AAA) alkaline battery

Battery life

Approx. 5 hours

Dimensions (approx.)

81 x 32 x 14.6 mm (3 1/4 x 1 1/4 x 4 x 19/32 inches)

(w/h/d, projecting parts not included)

Mass (approx.)

45g (1.6 oz) (battery included)

Memory capacity

96MB (including the system software: 92.6MB available)

AEP Model

UK Model

Supplied accessories

LR03 (Size AAA) alkaline battery (1)

Earphones (1)

Headphones/earpones extension cord (1)

Dedicated USB cable (1)

Carrying pouch (1) (for other models)

CD-ROM (OpenMG Jukebox installation disc) (1)

NW-E3/E5 Operating Instructions (1)

OpenMG Jukebox Operating Instructions (1)

Design and specifications are subject to change without notice.

9-873-036-11

2001D0200-1

© 2001.4

NETWORK WALKMAN

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

NW-E5

TABLE OF CONTENTS

Specifications ............................................................................ 1

1. SERVICING NOTE ....................................................... 2

2. GENERAL ....................................................................... 3

3. DISASSEMBLY

3-1. Chassis ASSY, Case ASSY ......................................... 7

3-2. LID, Case .................................................................... 7

3-3. Main Board, Power Board .......................................... 7

3-4. LCD Unit .................................................................... 8

3-5. Button (Play/Stop), Holder (Knob,Spring),

Knob (FF/REV) .......................................................... 8

4. TEST MODE................................................................... 9

5. DIAGRAMS

5-1. Block Diagrams .........................................................11

5-2. Printed Wiring Boards (Main Section) ..................... 12

5-3. Schematic Diagram (Main Section (1/2)) ................. 13

5-4. Schematic Diagram (Main Section (2/2)) ................. 14

5-5. Printed Wiring Boards (Power Section) ................... 15

5-6. Schematic Diagram (Power Section) ........................ 16

6. EXPLODED VIEW

6-1. Main Section ............................................................. 21

6-2. Case Section ............................................................. 22

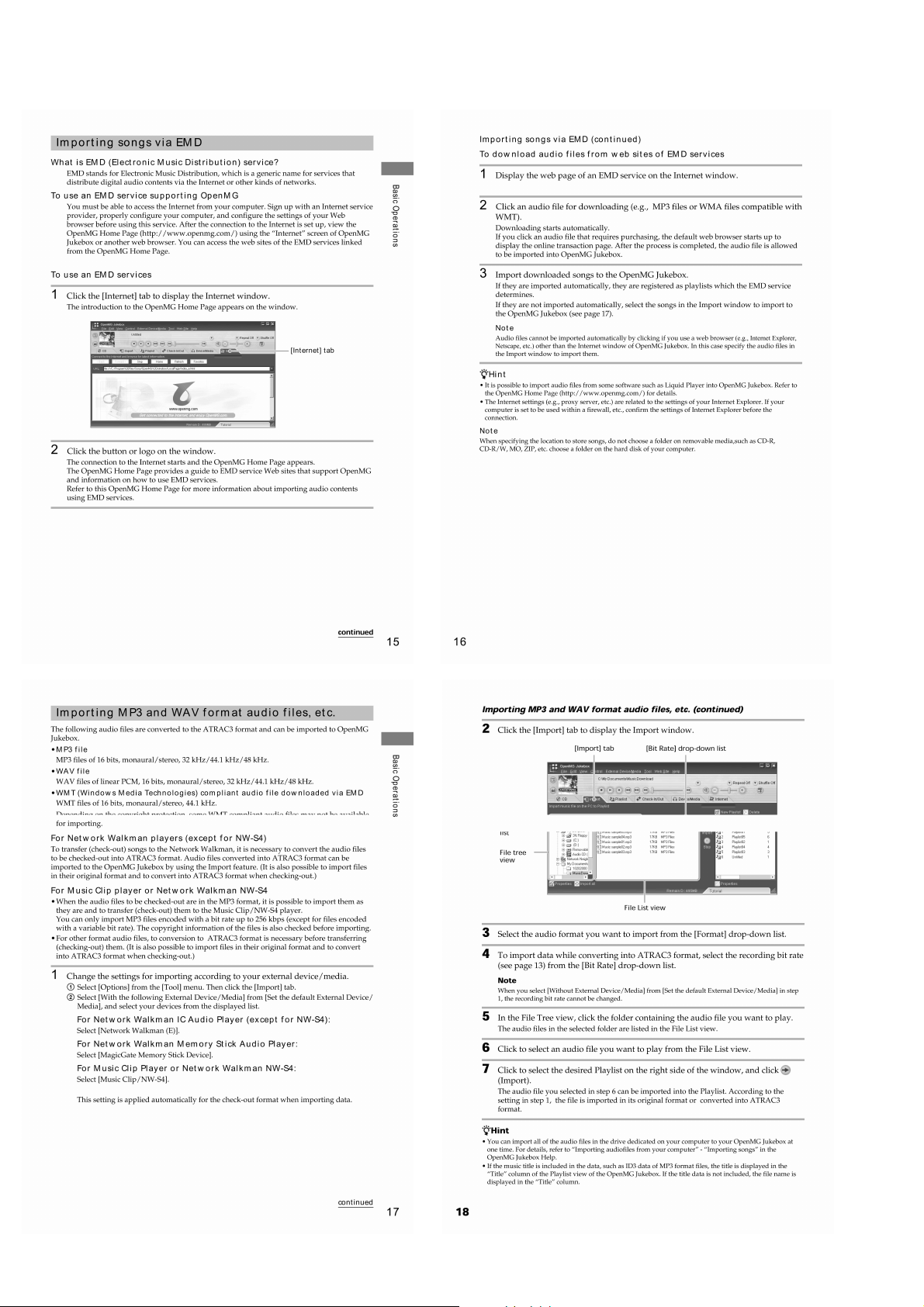

SECTION 1

SERVICING NOTE

r

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

7. ELECTRICAL PARTS LIST ................................... 23

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

• Replacement of CXD9534BGG (IC710) used in the set requires a special

tool.

2

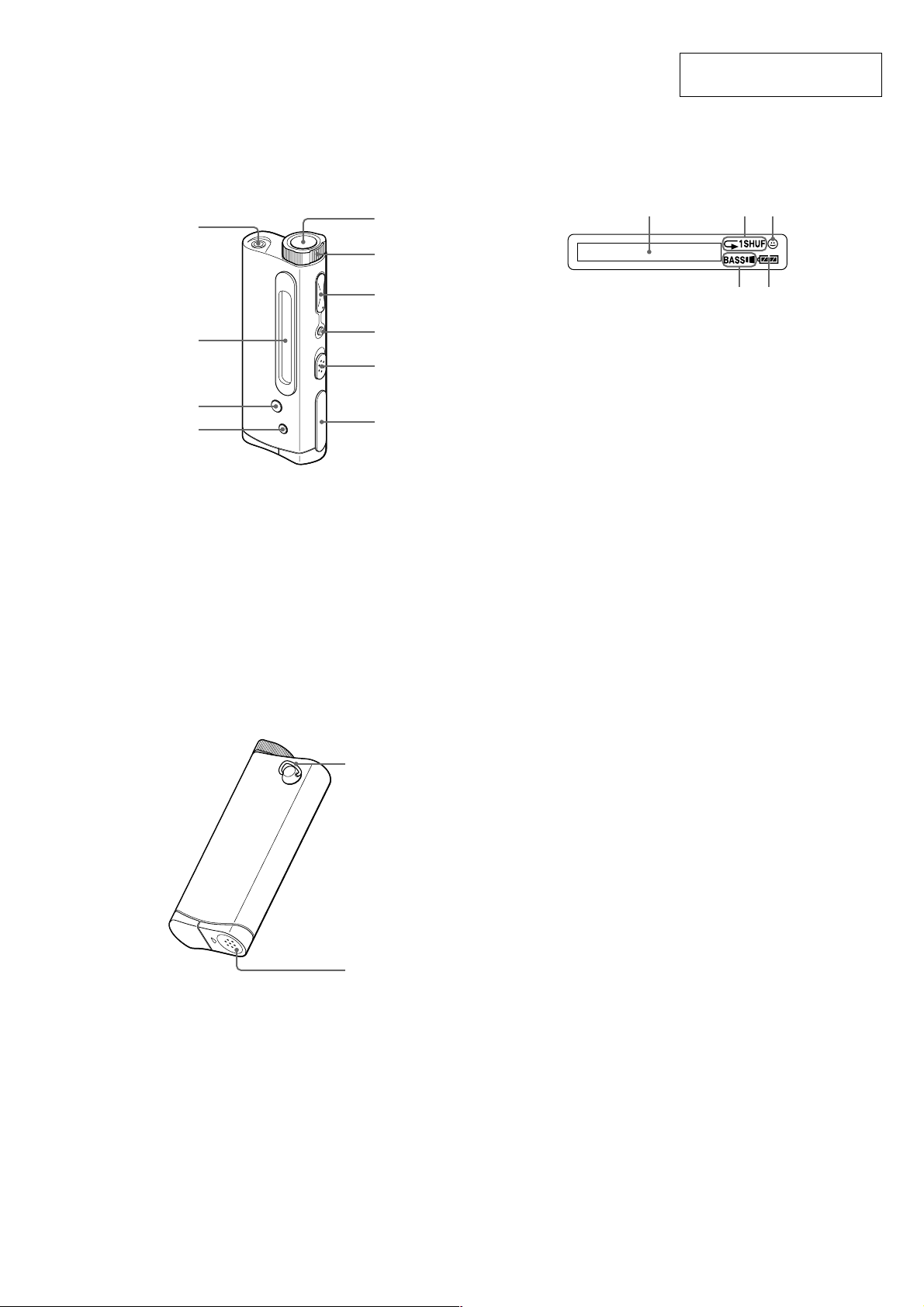

LOCATION AND FUNCTION OF CONTROLS

SECTION 2

GENERAL

NW-E5

This section is extracted from

instruction manual.

(front)

1

2

3

4

1 i (Headphones) jack

2 Display

3 PLAYMODE button

4 DISPLAY button

5 Bx (play/stop) button

6 Shuttle switch

7 VOLUME+/– button

8 MEGA BASS/AVLS button

9 HOLD switch

0 Dedicated USB jack

5

6

7

8

9

0

Display

1

1 Text/graphic information display

2 Play mode indication

3 AVLS indication

4 MEGA BASS indication

5 Battery remain indication

23

5

4

(rear)

qa

qs

qa Strap hole for attaching the strap

qs Battery compartment

3

NW-E5

4

NW-E5

5

NW-E5

6

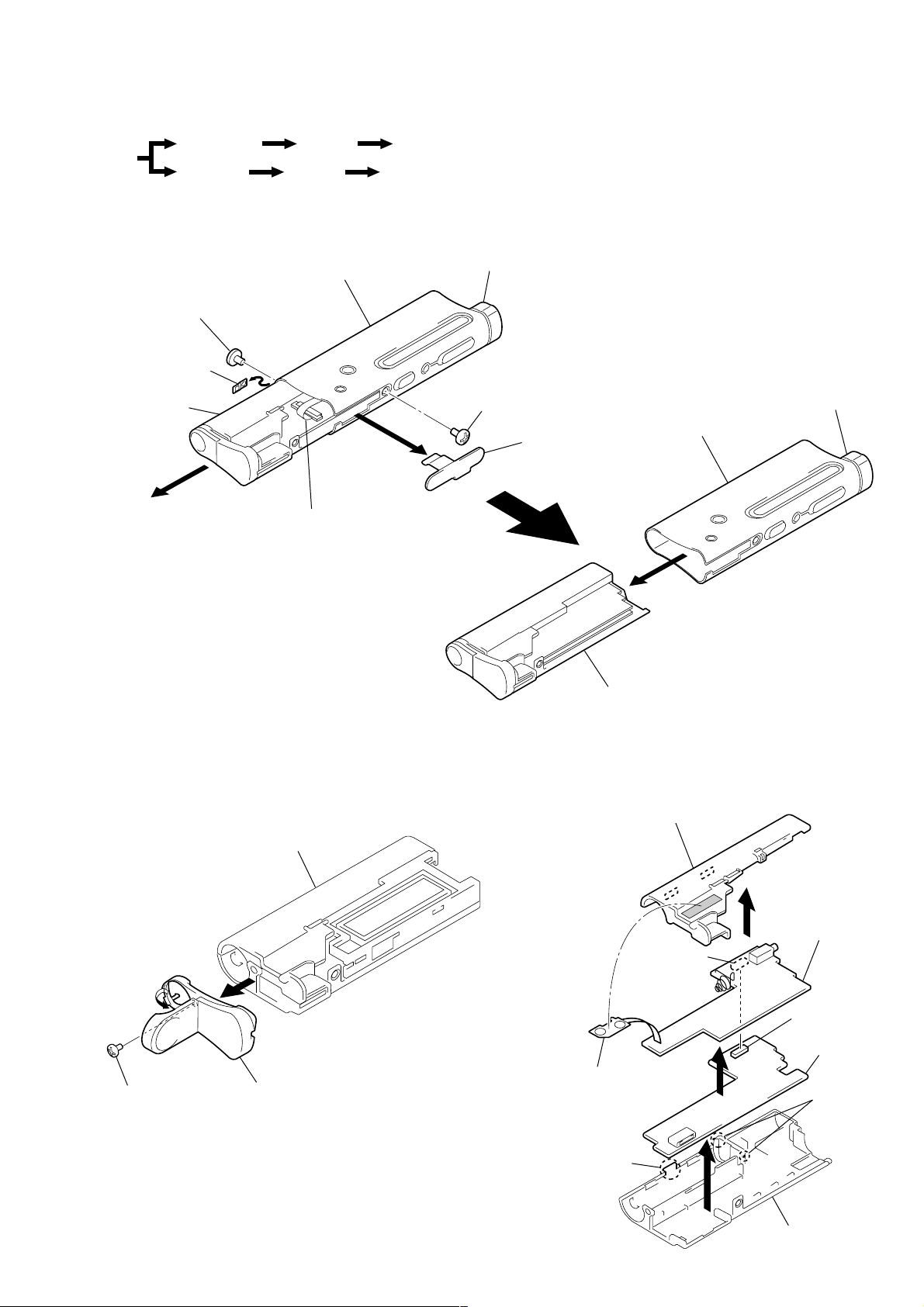

DISASSEMBLY

)

r

The equipment can be removed using the following procedure.

NW-E5

SECTION 3

Chassis ASSY

Lid, Case

Main board, Power board

Set

Case ASSY LCD unit Knob (PLAY/STOP), holder (knob, spring), knob (FF/REW)

Note : Follow the disassembly procedure in the numerical order given.

3-1. CHASSIS ASSY, CASE ASSY

Knob (FF/REW)

2

Screw (1.7x2.5)

1

Screw M1.4

5

Plate, lock

Chassis ASSY

4

Pull out Chassis

ASSY halfway.

Case ASSY

3

6

LCD flexible board

NOTE ON ATTACHING

On attaching Chassis ASSY, insert it straightly

without strength not to touch Knob (FF/REW).

With strength, sometimes Holder (knob,

spring) in Case ASSY is damaged.

Knob (FF/REW

Case ASSY

Lid, connector

7

3-2. LID, CASE

1

2

Screw B1.7x4

3

Chassis ASSY

Lid, case

Chassis ASSY

3-3. MAIN BOARD, POWER BOARD

Chassis (upper)

CN704

1

Mode switch flexible board

(Peel from Chassis (upper))

6

4

Power board

CN702

Main board

3

Claws

2

Claw

5

Chassis (lower)

7

NW-E5

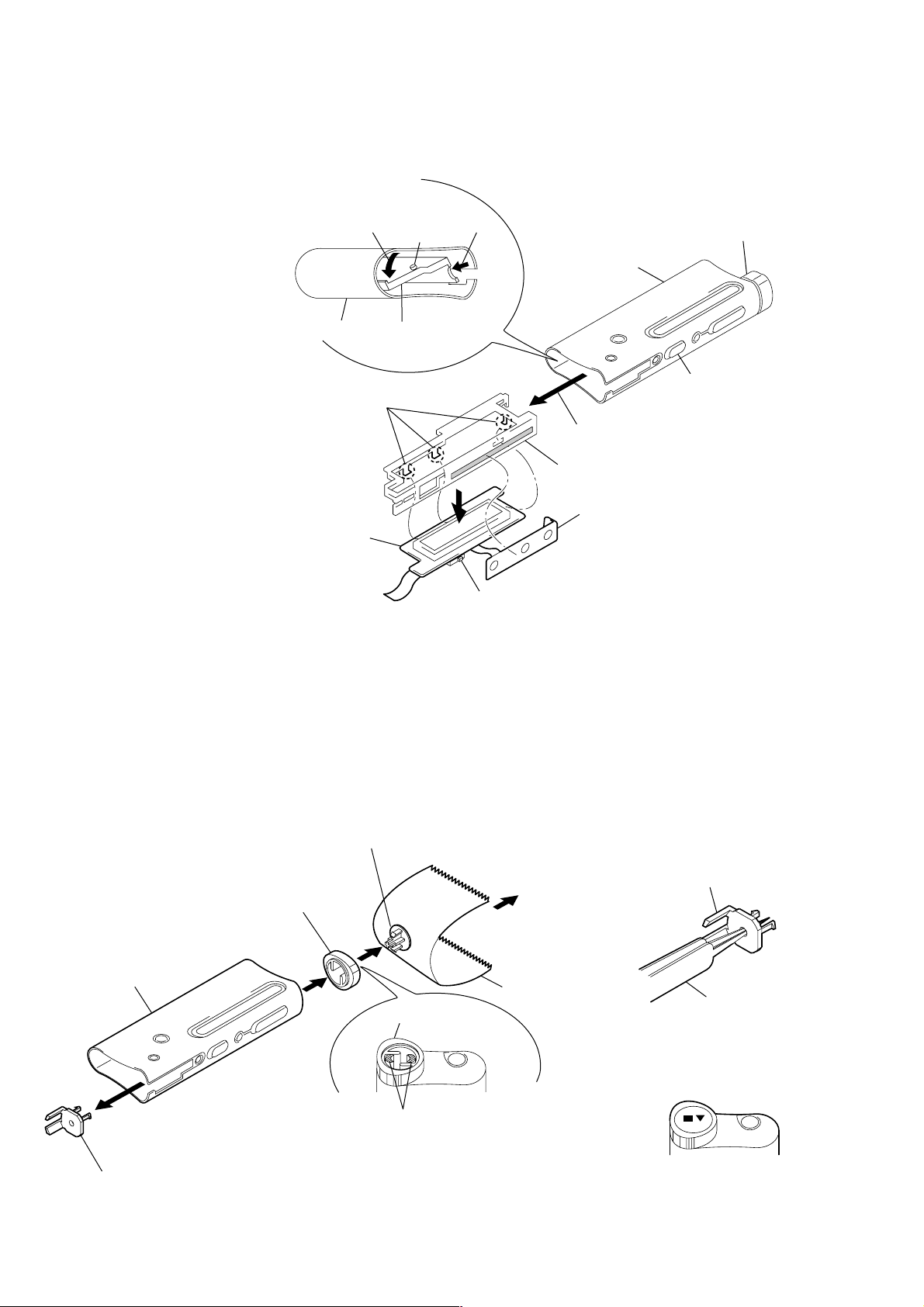

4

LCD flexible board

(Peel from “chassis, LCD”)

3

Pull out LCD chassis with tilting.

Chassis, LCD

Knob (HOLD)

Knob (FF/REW)

Case ASSY

Case ASSY Chassis, LCD

Projection

5

Claws

LCD unit

HOLD switch (S800)

12

6

)

3-4. LCD UNIT

NOTE ON ATTACHING

• On attaching LCD unit to Case ASSY, in

case of pressing Knob (FF/REW), it is hard

to attach it.

• Combine HOLD switch (S800) with Knob

(HOLD).

• Combine the projection on LCD chassis

with Case ASSY.

3-5. BUTTON (PLAY/STOP), HOLDER (KNOB, SPRING), KNOB (FF/REW)

1

Button (PLAY/STOP)

Put Gummed tape on surface, and pull it off.

4

Knob (FF/REW)

Case ASSY

3

Holder (knob, spring)

2

Press Holder (knob, spring) down with

picking its claws up both sides with tweezers.

Knob (FF/REW)

Gummed tape

NOTE ON ATTACHING

1. Insert Holder (knob, spring) from

the bottom side of Case ASSY

with tweezers.

Holder (knob, spring

Tweezers

2. Attach Knob (FF/REW) in with

pressing Holder (knob, spring).

3. Attach Button (PLAY/STOP) with

setting B x marked position.

8

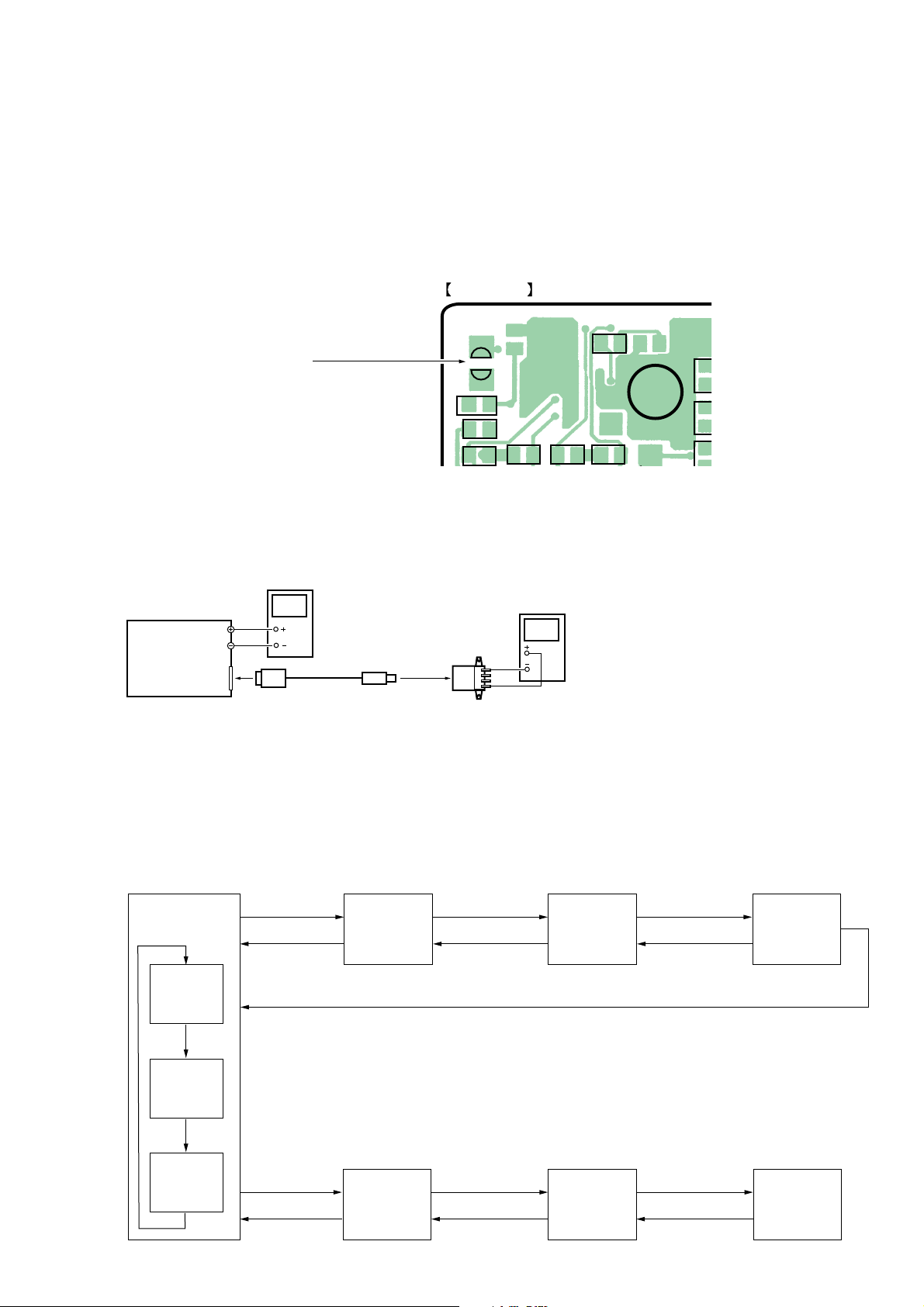

SECTION 4

)

TEST MODE

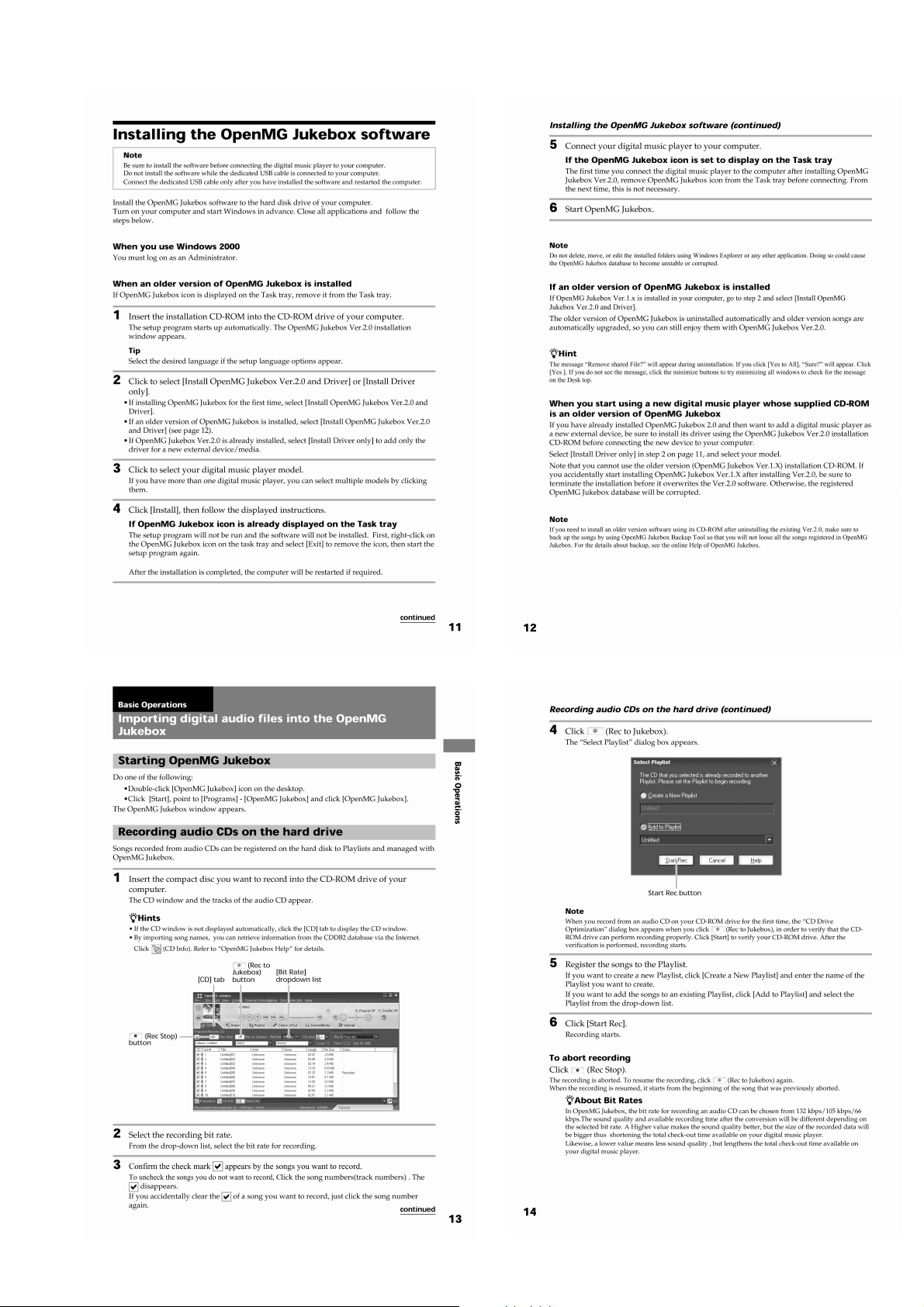

Setting the Test Mode

To enter the test mode, two methods are available :

1. Entering method with key input.

Turn the HOLD switch to ON. While holding down the Bx key, press the following keys in the following order :

VOLUME + t VOLUME – t VOLUME – t VOLUME + t VOLUME – t MEGA BASS t MEGA BASS t DISPLAY

Note : Push each key for less than 3 seconds.

2. Entering method by shorting the test point.

Solder brige the test point SL701 (TEST) on the main board and turn on the power.

MAIN BOARD (SIDE A)

NW-E5

Test mode

Short : Test mode

( )

Open : Normal mode

SL701

(TEST)

R806

JC704

R702

R812

R811

R810

Releasing the TEST mode

1. When test mode was entered with key input, turn off the power supply.

2. When test mode was entered by shorting the test point, turn off the power supply and open the solder brige of SL701 (TEST) on the main

board.

Connection

regulated

Set

Battery terminal

CN701

(USB Connector)

DC power supply

Connecting cable

supplied with the set

USB Connector

(1-784-009-11 or 1-779-676-11

regulated

DC power supply

4

1

TP3

R813

P701

805 R804 R814

Configuration of Test Mode

The test mode has the configuration given below.

Bx : Play/stop key

(+) : VOLUME + key

(–) : VOLUME – key

LCD

Check

Bx

Ver. /

destination

display

Bx

All display

lit

Bx

All display

off

Bx

(+)

(–)

Supply 0.9V DC to battery

terminal and press (–) key.

(–)

Flash memory

bad block

Low voltage

check

check

(+)

(–)

Supply 1.24V DC to battery

terminal and 7V DC to USB

connector and press (+) key.

(–)

Destination

setting

High DC

detection

check

(+)

(–)

Supply 1.24V DC to battery

terminal and 4V DC to USB

connector and press (+) key.

(–)

Contrast

adjustment

Low DC

detection

check

(+)

9

Loading...

Loading...