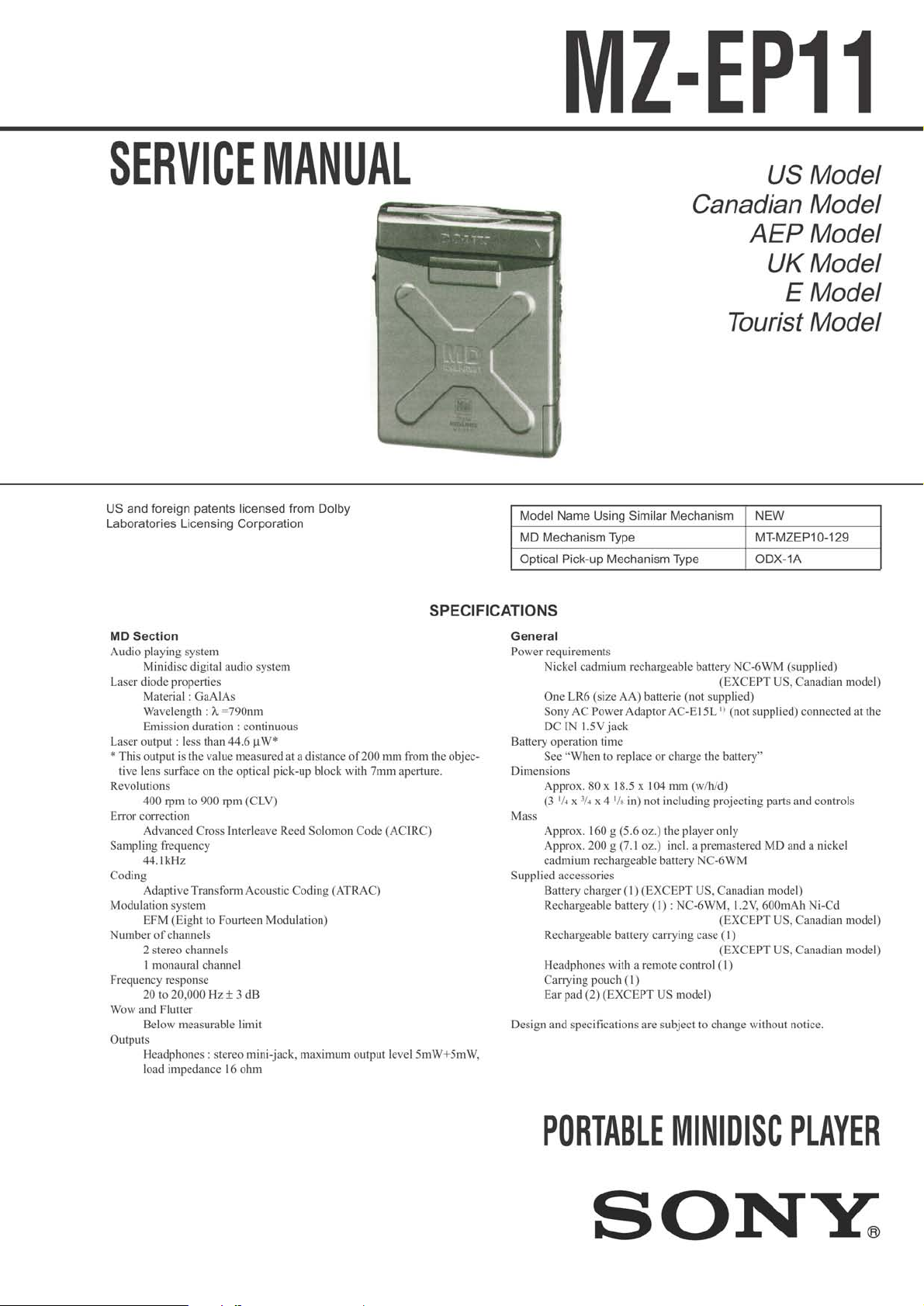

Page 1

Ver 1.2 2004. 03

9-923-222-14

2004C02-1

© 2004.03

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE.......................................................... 3

2. GENERAL

Location and Function of Controls .................................... 6

3. DISASSEMBLY ............................................................... 8

4. TEST MODE ...................................................................11

5. ELECTRICAL ADJUSTMENTS ................................. 14

6. DIAGRAMS

6-1. IC Pin Description .................................................... 16

6-2. Block Diagram.......................................................... 18

6-3. Printed Wiring Board................................................ 21

6-4. Schematic Diagram................................................... 25

7. EXPLODED VIEWS

7-1. Panel Section ............................................................ 32

7-2. Mechanism Deck Section (MT-MZEP10-129) ........ 33

Ver 1.1 1998.05

8. ELECTRICAL PARTS LIST ........................................ 34

This Mini Disc player is classified as a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT label is located on

the bottom exterior.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENT AL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT .

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

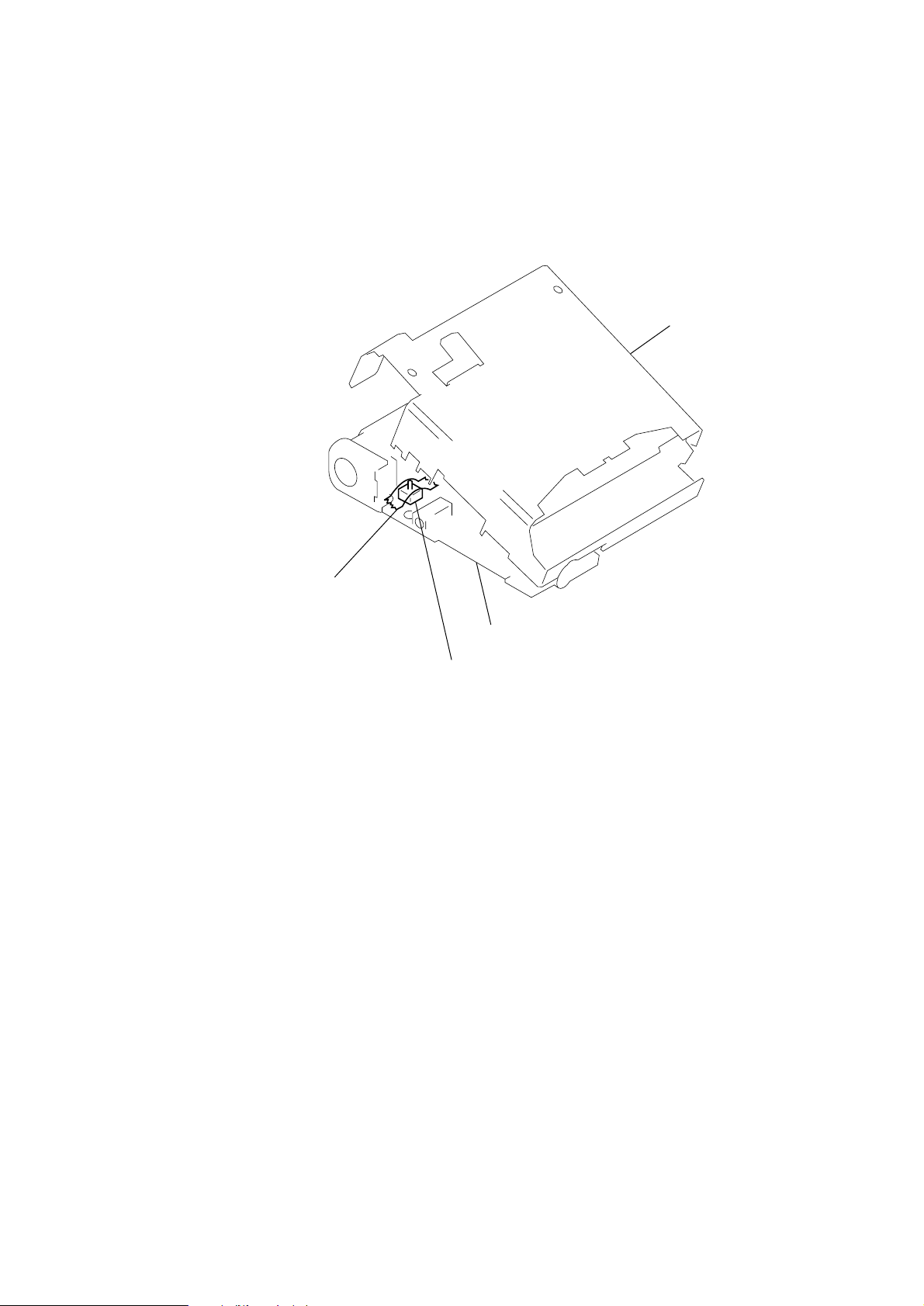

SECTION 1

y

SERVICING NOTE

When repairing this device with the power on, if you remove the main board, this device stops working.

In this case, you work without the device stopping by fastening the hook of the Open/Close detection switch (S801) with tape.

Chassis ass

Tape

Main board

Open/Close switch (S801)

– 3 –

Page 4

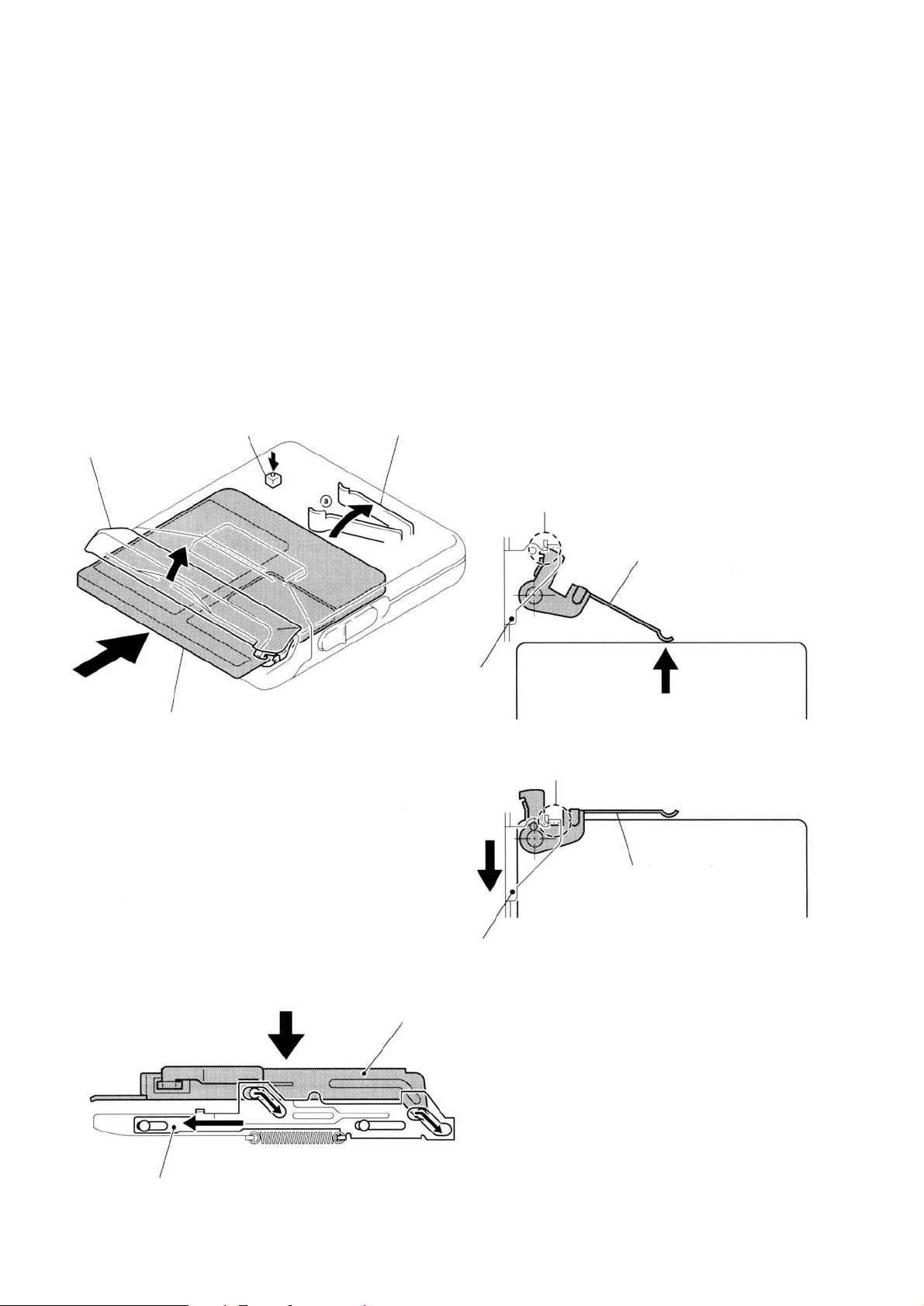

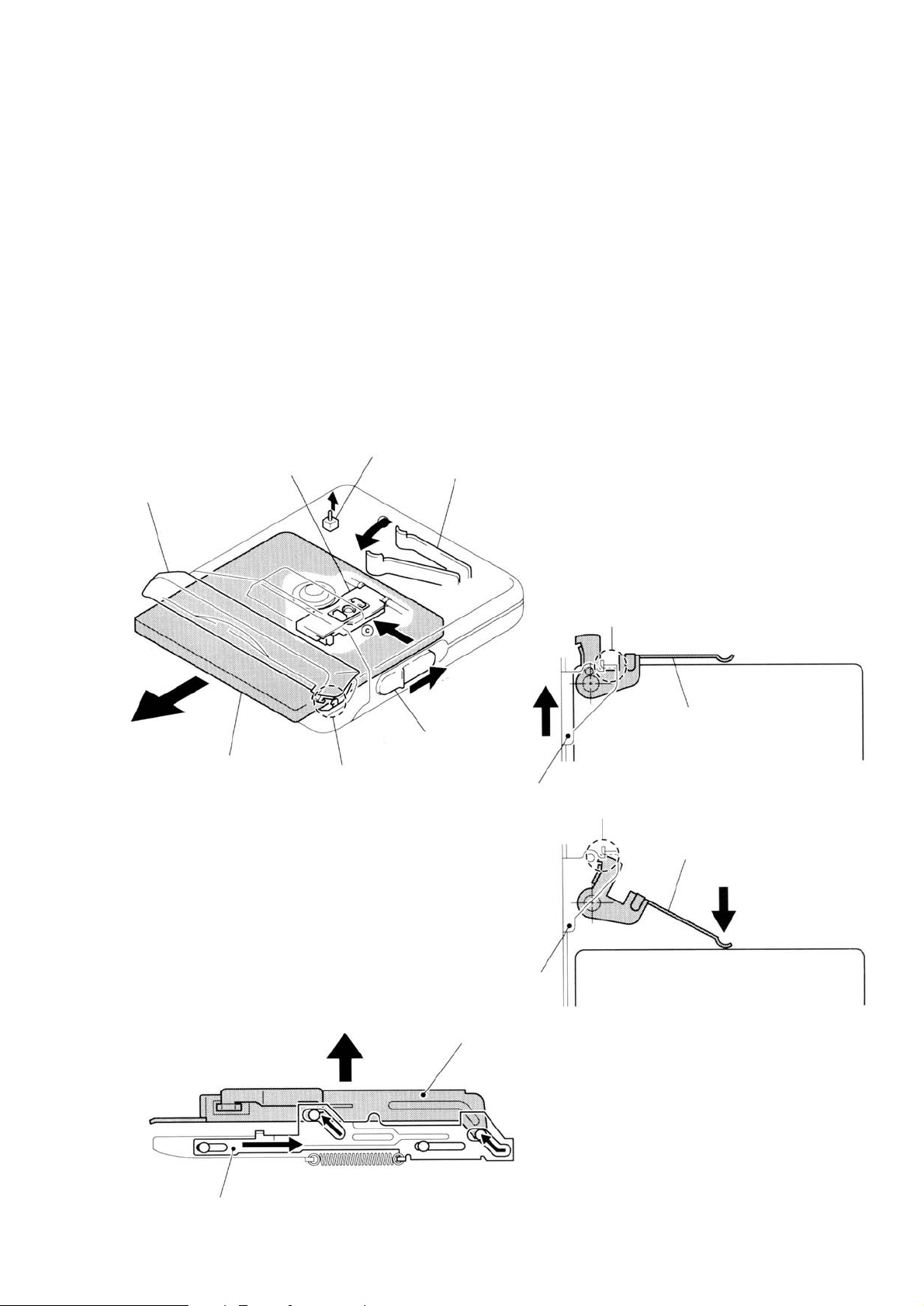

OPERATIONS OF MECHANISM (MZ-EP11)

When loading a disc

The disc shutter 1 opens when a disc is loaded. (Fig. 1)

≥

When a disc is loaded, the open lever 2 moves in arrow direction

a, and the holder assembly 3 lock is released. (Fig. 1 to 3)

≥

The slider 4 slides in arrow direction b, and the holder assembly

3 moves down to the chassis assembly (below). (Fig. 4)

≥

The OPEN/CLOSE SW (S801) is turned ON by the connection

lever linked. (Fig. 1)

≥

The wakeup mode is set and the power circuit starts operating.

Disc shutter

OPEN/CLOSE SW (S801)

1

Insert the Mini Disc

ON

(Fig. 1)

Open lever

Slider

2

b

4

Lock

Relesse

Open lever

Insert the Mini Disc

Open lever

2

2

(Fig. 2)

Slider

Descends to chassis side (below)

b

4

(Fig. 4)

Slider

Holder assembly

– 4 –

4

(Fig. 3)

3

Page 5

When removing the disc

When the open knob 1 is slid in arrow direction a, and the open

slider 2 lock is released, the disc shutter 3 opens. (Fig. 5)

≥

The slider 4 slides in arrow direction b, and the holder assembly

5 moves up to the upper panel (above). (Fig. 6, Fig. 8)

≥

The OPEN/CLOSE SW (S801) is turned OFF by the connection

lever linked. (Fig. 5)

≥

The optical pick-up block 6 moves to the inner circumference c.

(Fig. 5)

≥

The disc 7 is pushed by the open lever 8, and ejected out from

the holder assembly 5. (Fig. 7)

≥

The sleep mode is set and the power supply stops.

OPEN/CLOSE SW (S801)

Disc shutter

Optical pick-up block

3

6

Open lever

OFF

8

Disc is ejscted

Open knob

7

Open Slider

(Release)

2

(Fig. 5)

Moves up to the upper panel (above)

a

1

Slider

Slider

Holder assembly

b

5

4

4

Relesse

Lock

Open lever

Open lever

Disc is ejscted

8

8

(Fig. 6)

7

(Fig. 7)

Slider

4

b

(Fig. 8)

– 5 –

Page 6

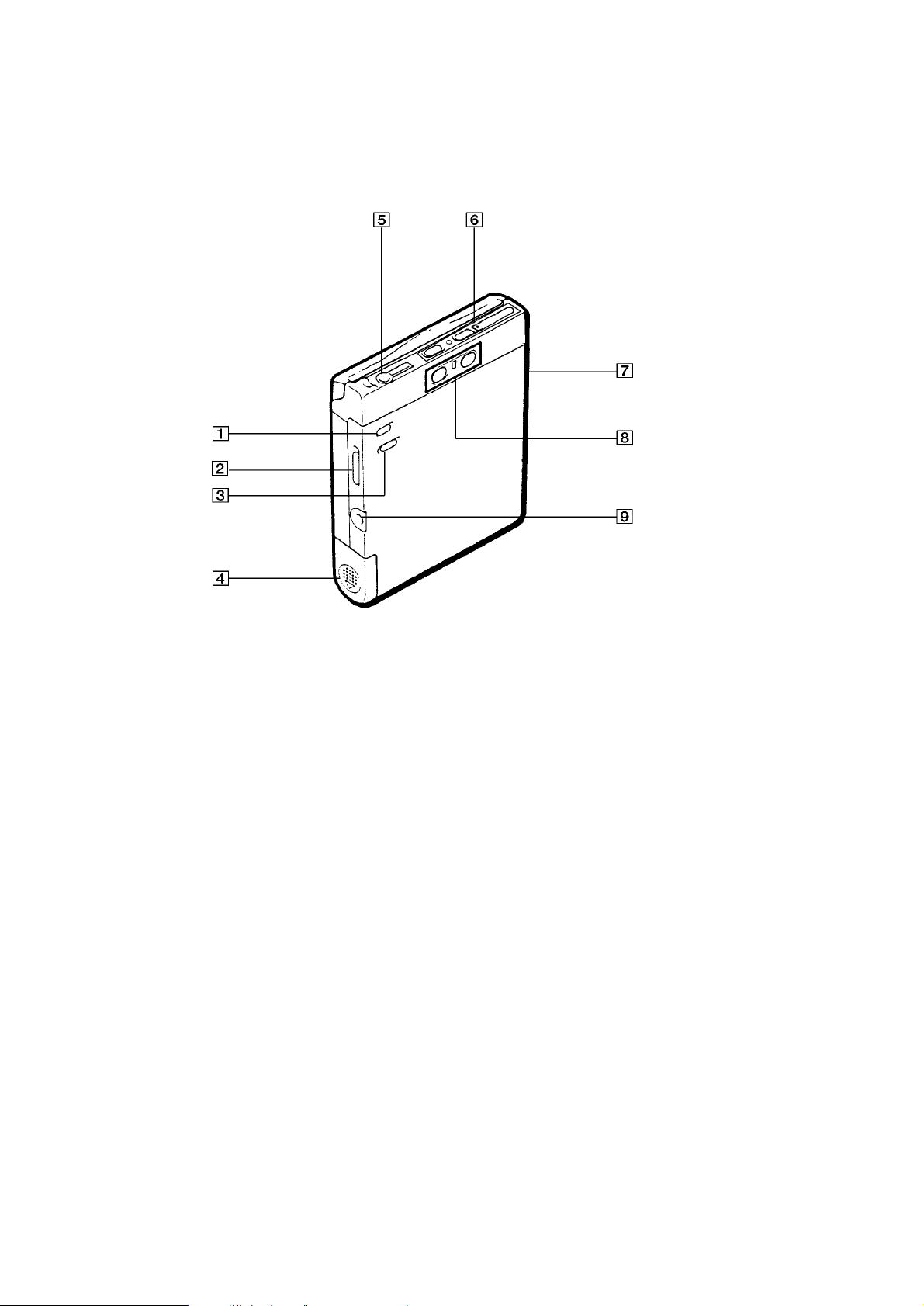

LOCATION AND FUNCTION OF CONTROLS

r

Main Unit

SECTION 2

GENERAL

1 AVLS switch

2 HOLD switch

3 DIGITAL MEGA BASS switch

4 Battery compartment

5 2 / REMOTE jack

6 MD operate buttons

( (play) button

=, +button

p button

7 EJECT knob

8 VOLUME +, – buttons

9 DC IN 1.5V jack

– 6 –

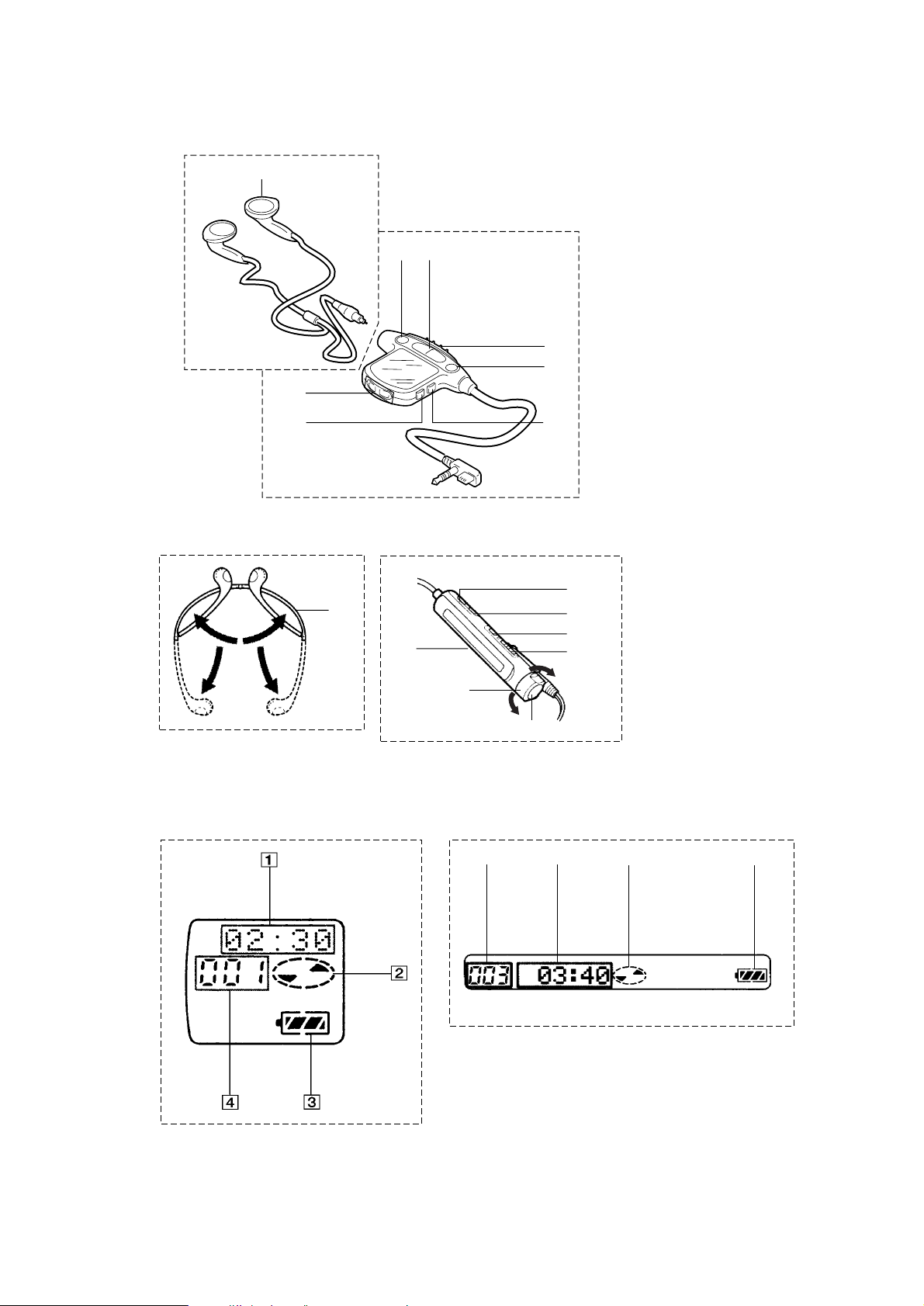

Page 7

Ver 1.1 1998.05

r

Headphones with Remote Control

Except US model

1

6

7

23

Tourist model

4

5

8

1 Headphones

2 P (pause) button

3 (/+, = buttons

4 HOLD switch

5 p (stop) button

6 VOL +, – buttons

7 DISPLAY button

8 PLAYMODE button

US model

r

Display windows (Remote Control)

Tourist model

1

Except T ourist model

6

3

Except Tourist model

4

5

1

7

8

2

4

1 Headphones

2 P (pause) button

3 (/+, = control

4 HOLD switch

5 p (stop) button

6 VOL +, – buttons

7 DISPLAY button

8 PLAYMODE button

23

1 Character display

2 Disc revolve indicator

3 Battery condition indicator

4 Track number display

– 7 –

Page 8

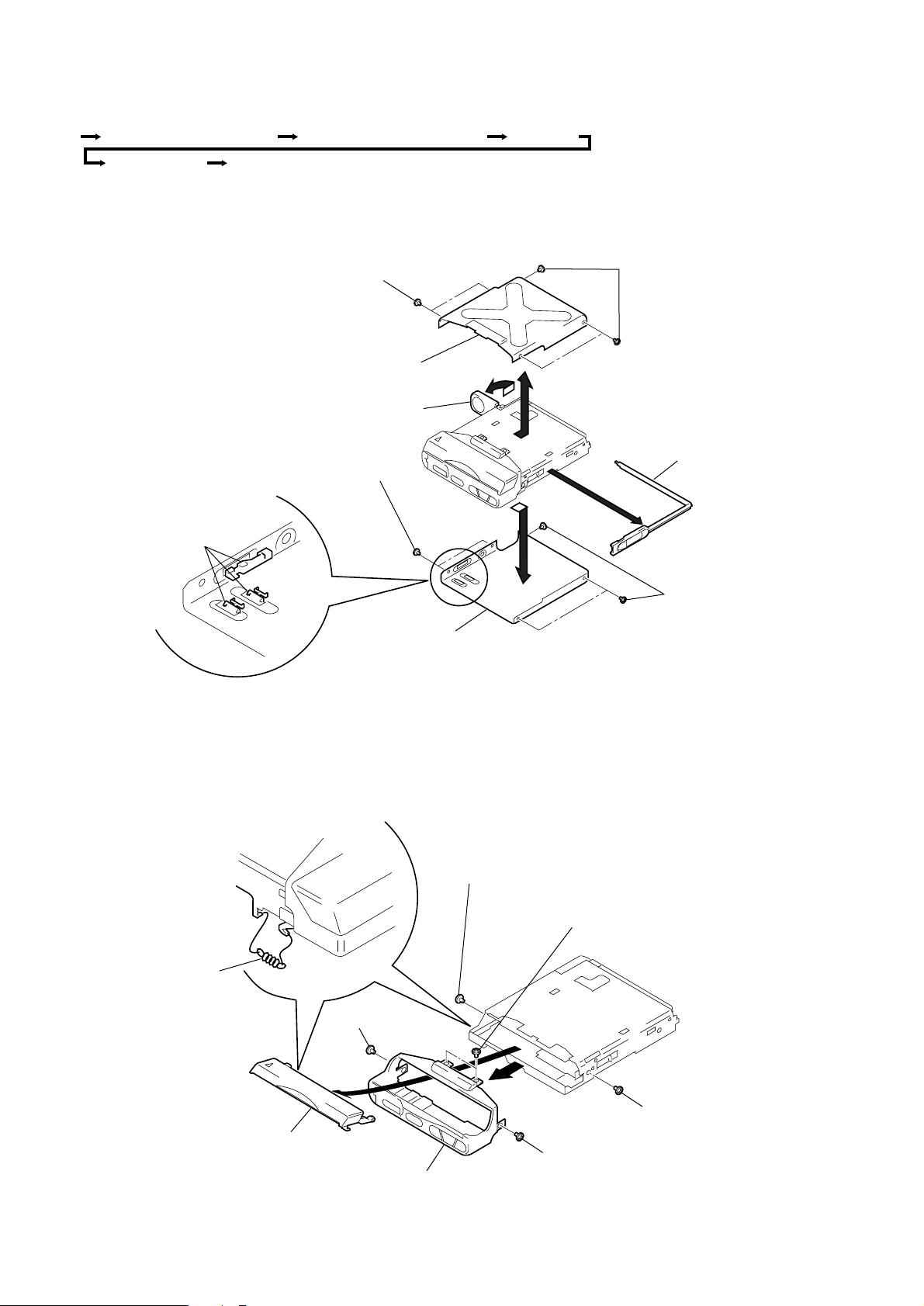

SECTION 3

)

)

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Set

Panel (X) upper, Bottom panel Plate (Control) assy, ornamental Main board

Mechanism deck

Optical pick-up

Note : Follow the disassembly procedure in the numerical order given.

3-1. PANEL (X) UPPER, BOTTOM PANEL REMOVAL

2

Screws

(M1.4 precision pan)

Panel (X) upper

Lid, battery case

5

Screws

(M1.4 precision pan)

* Caution during assembly

Align the MEGA BASS knob,

AVLS knob and the HOLD knob

position with the switch

on the Main board.

Bottom panel

1

4

6

3

Screws

(M1.4 precision pan)

7

Stripe (A) assy,

Ornamental

5

Screws

(M1.4 precision pan

3-2. PLATE (CONTROL) ASSY, ORNAMENTAL REMOVAL

1

Spring (Shutter),

Tension

4

Screw (step)

3

Shutter

Plate (Control) assy,

ornamental

2

Screw

(M1.4 precision pan)

5

Screws

(M1.4 precision pan)

6

4

Screw (step)

2

Screw

(M1.4 precision pan

– 8 –

Page 9

3-3. MAIN BOARD REMOVAL

r

)

2

Screws

(M1.4 toothed lock)

Main board

5

OP flexible board

(Main board CN501)

4

Switch unit

(Main board CN802)

1

Screw (1.7 tapping)

2

Screws

(M1.4 toothed lock)

3

Remove solder

3-4. MECHANISM DECK REMOVAL

6

7

CLV flexible board

(Main board CN551)

Mechanism deck

4

Damper

Battery flexible

board

3

Remove solde

1

Screws

(M1.4 precision pan

4

Dampers

5

Chassis (B) assy

3

Screws

(M1.4 precision pan)

– 9 –

Case, battery

2

Chassis assy

Page 10

3-5. OPTICAL PICK-UP REMOVAL

)

Optical Pick-up

2

1

Screw ( precision)

3-6. HOLDER ASSY REMOVAL

3

Holder assy

1

Washer (0.8–2.5

2

Spring (holder)

– 10 –

Chassis assy

Page 11

” key

” key

p key

p key

p key

p key

VOL

+ key

VOL

– key

(Start ?)

Overall

adjustment

mode (Auto?)

Adjustment

mode

(Manu ?)

Servo mode

0 0 0

Audio mode

1 0 0

Servo mode

3 0 0

+, – keys

+, – keys

+, – keys

Display when test mode

is set

Displays of the LCD on the remote commander

are shown in parentheses.

Ver 1.1 1998.05

SECTION 4

TEST MODE

Outline

• In this set, overall adjustment mode is made available by entering test mode to perform automatic adjustment of CD and MO.

In the overall adjustment mode, the disc is determined whether

it is CD or MO and adjustments are performed in sequence. If a

fault is found, the location of the fault is displayed. Also, in servo

mode, each adjustment can be automatically made.

Setting the Test Mode

To enter the test mode, two methods are available :

1. Entering method with key input.

Turn on the HOLD switch on the set. While holding down the p

key on the set, press the following remote commander keys in

the following order :

+ n + n = n = n + n = n + n

=n P n P

2. Entering method by shorting the test point

Solder bridge the test point TAP801 (TEST) on the main board

(connect IC801 pin #™ to GND), and turn on the POWER.

[MAIN BOARD] (Conductor side)

Test mode

Short : Test mode

( )

Open : Normal mode

Configuration of Test Mode

The test mode has the configuration given below.

Servo Mode

• Set the test mode, press the VOLUME – key and use the ( key

to set the servo mode.

• When the servo mode is set, use the + key and the = key

to move the optical pick-up to the outer circumference and to

the inner circumference respectively.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Servo Mode

Servo mode

0 0 0

” key

Releasing the Test Mode

1. When test mode was entered with key input, turn off the POWER.

2. When test mode was entered by shorting the test point, turn off

the POWER and open the solder bridge of TAP801 (TEST

MODE) on the main board.

Operation of Setting on Test Mode

When the test mode is set, the LCD displays the following :

• ROM version display to all LEDs ON to all LEDs OFF and so

on.

These operations are repeated.

• When the PLAY MODE key is pressed and hold down, the display at that time is held so that display can be checked.

V2. 00

LCD on remote commander

ROM version display

p key

p key

1

(See page 12.)

Offset adjustment

0 1 0

p key

+, – keys+, – keys

Laser power

adjustment

0 2 0

p key

23

*1 Repeatedly press ” key

” key

011 to 013

*1

” key

” key

021 to 024

*1

” key

to change the mode.

(Refer to the following list

for a description of each

mode.)

– 11 –

Page 12

Ver 1.1 1998.05

(See page 11.)

1

p key

p key

p key

23

MO adjustment

0 3 0

p key

+, – keys

Low reflection

CD adjustment

0 4 0

p key

+, – keys

CD adjustment

0 5 0

p key

+, – keys

” key

” key

” key

031 to 039

*1

” key

041 to 048

*1

” key

051 to 058

*1

” key

2. Description of Each Mode

010 Offset adjustment

Mode Description

011 FE offset

012 TE offset

013 All servo ON

020 Laser power adjustment

Mode Description

021 MO power A

022 MO power E

023 CDL power

024 CD power

030 MO adjustment

Mode Description

031 MO EF balance

032 MO EF gain

033 MO ABCD gain

034 MO focus gain

035 MO tracking gain

036 MO RF gain

037 MO ADIP gain

038 MO focus bias E

039 CD focus bias A

p key

p key

p key

Sled movement

0 6 0

p key

+, – keys

Automatic

adjustment

0 7 0

p key

+, – keys

NV relation

0 9 0

p key

+, – keys

Retern the Offset

adjustment (0 1 0)

” key

061 , 062

*1

” key

” key

071, 072,

073, 074

*1

” key

” key

091, 092,

093

*1

” key

*1 : Repeatedly press ” key

to change the mode.

(Refer to the following list

for a description of each

mode.)

040 Lower reflection CD adjustment

Mode Description

041 Lower reflection CD EF balance

042 Lower reflection CD EF gain

043 Lower reflection CD ABCD gain

044 Lower reflection CD focus gain

045 Lower reflection CD tracking gain

046 Lower reflection CD RF offset

047 Lower reflection CD RF gain

048 Lower reflection CD focus bias

050 CD adjustment

Mode Description

051 CD EF balance

052 CD EF gain

053 CD ABCD gain

054 CD focus gain

055 CD tracking gain

056 CD RF offset

057 CD RF gain

058 CD focus bias

– 12 –

Page 13

060 Seld movement

Audio mode

1 0 0

Audio playback test

1 1 0

1kHz 0dB L/R

1 1 1

Infinity Zero

1 1 2

–12dB

–

–12dB

–12dB

–20dB

–20dB

–20dB

–20dB

–40dB

1kHz 0dB L

1 1 3

1kHz 0dB R

1 1 4

1kHz 0dB L/R

1 1 5

20Hz 0dB L/R

1 1 6

20kHz 0dB L/R

1 1 7

100kHz De-Emphasis

1 1 8

100kHz 0dB L/R

1 1 9

headphones

output

p key

p key

” key

” key

” key

p key

” key

p key

” key

p key

” key

p key

” key

p key

” key

p key

” key

p key

” key

p key

” key

Mode Description

061 Seld in

062 Seld out 5

070 Automatic adjustment

Mode Description

071 Focus search

072 Access 32

073 ADER check

074 Tracking sensitivity adjust

090 NV relation

Mode Description

091 NV clear

092 Power OFF

093 Function code change

Audio Mode

• Enter the test mode and press the VOLUME – key. Then, press

the ( key and the VOLUME + key in this turn to enter audio

mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Audio Mode

• The mode No. 111 is for S/N and crosstalk. The mode No. 115 is

for distortion factor and frequency characteristics.

• When the VOLUME +/– keys is pressed in any mode, the volume of the headphones is changed (increased/decreased) in units

of one step. When the + / = keys is pressed, the volume of

the headphones is maximized/minimized.

• For the volume value, any changed value remains as it is basically.

However, when the volume is switched from 114 to 115 or 118

to 119, it returns the default value.

– 13 –

Page 14

SECTION 5

ELECTRICAL ADJUSTMENTS

Power Mode

• Enter the test mode and press the VOLUME – key. Then, press

the ( key and the VOLUME – key in this turn to enter power

mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Power Mode

Power mode

3 0 0

p key

” key

UNREG check

31 0

p key

” key

Power OFF

3 1 1

” key

Overall Adjustment Mode

• Enter the test mode and press the VOLUME + key to enter overall adjustment mode.

• When entering another mode, refer to the configuration of test

mode.

• When the overall adjustment mode is entered, the LCD on the

remote commander display the following :

Auto ?

000

1. Structure of Overall Adjustment Mode

Overall

adjustment

mode

Auto?

” key

Notes for Adjustment

• In this set, automatic adjustment of CD and MO can be performed by entering the test mode.

• Adjustments are performed in the overall adjustment mode. If

an item is determined as NG, the item is readjusted in servo

mode.

Adjustment Method in Overall Adjustment Mode

1. Enter the test mode and press the VOLUME + key to enter overall adjustment mode.

2. Insert the CD test disc (TGYS-1) or SONY MO disc (recorded)

commercially availble.

3. Press the ( key twice. The disc is determined whether it is CD

or MO and each adjustment mode is set. Automatic adjustments

are performed in the order of the items listed below.

• In CD Automatic adjustment Mode

No. Mode Description

1 061 Sled in

2 071 Focus search

3 062 Sled out 5

4 051 CD EF balance

5 052 CD EF gain

6 051 CD EF balance

7 053 CD ABCD gain

8 054 CD foucus gain

9 055 CD tracking gain

10 056 CD RF offset

11 057 CD RF gain

12 056 CD RF offset

13 058 CD Focus bias

Start ?

” key (to discriminate between CD and MO)

CD automatic

adjustment

MO automatic

adjustment

OK

NG

OK

NG

p key

p key

p key

p key

Adjustment

mode

Manu ?

– 14 –

Page 15

• In MO Automatic adjustment Mode

No. Mode Description

1 061 Sled in

2 071 Focus search

3 062 Sled out

4 031 MO EF balance

5 032 MO EF gain

6 031 MO EF balance

7 033 MO ABCD gain

8 034 MO focus gain

9 035 MO tracking gain

10 036 MO RF gain

11 037 MO ADIP gain

12 038 MO focus bias E

13 039 MO focus bias A

14 073 ADER check

15 061 Sled in

16 071 Focus search

17 041 Low reflection CD EF balance

18 042 Low reflection CD EF gain

19 041 Low reflection CD EF balance

20 043 Low reflection CD ABCD gain

21 044 Low reflection CD focus gain

22 045 Low reflection CD tracking gain

23 046 Low reflection CD RF offset

24 047 Low reflection CD RF gain

Adjustment in Servo Mode Method

1. When each adjustment mode is set according to the structure of

servo mode, the lower two digits of the mode No. and the adjustment value written in EEPROM are displayed and lit on the LCD

on the remote commander.

13

052

Adjustment value (lit)

Mode No.

2. When the P key is pressed, the following display appears and

the automatic adjustment is performed.

13

052

Note) Although the VOLUME +/– keys can be used to change the

Adjustment value (flashing)

adjustment value to any value, they should not be used whenever possible.

3. When the automatic adjustment is completed, the flashing adjustment value is lit.

13

052

Adjustment value (lit)

* Remote commander display during automatic adjustment

12

057

Adjustment value (flashing)

Mode No. under adjustment

4. If result of automatic adjustment is OK, the following display

appears.

End-OK

058

5. If result of automatic adjustment is NG, the following display

appears.

NG 04

051

NG mode No.

* If NG, enter servo mode to perform automatic adjustment of the

item determined as NG.

– 15 –

Page 16

SECTION 6

DIAGRAMS

6-1. IC PIN DESCRIPTION

IC801 RU6715MF-0004 (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 CHG MON – Not used (Fixed at “L” ).

2 UREG MON I Unreg voltage monitor input.

3 VTEMP I Temperature sensor input.

4 VREF I Reference voltage monitor input.

5 PLAY KEY I Set PLAY key input.

6 OPEN/CLS SW I OPEN/CLOSE switch input.

7 RMC KEY I Remote commander key input.

8 SET KEY I Set key input.

9 XRESET I Systen reset input (At reset : “L” ).

10 AVDD – A/D converter power supply.

11 AVSS – A/D converter GND.

12 TYPE 0 I (Fixed at “L” ).

13 TYPE 1 I (Fixed at “L” ).

14 HOLD SW I Set HOLD switch input.

15 MODEL I (Fixed at “L” ).

16 TYPE 2 I (Fixed at “L” ).

17 VREG CON O 2.5V voltage on/off switch.

18 XWK CLR O Power IC wakeup factor latch clear outpu and motor driver IC control signal outpt.

19 SLEEP O System sleep ouput.

20 MCK I Master clock input.

21 NC – Not used (Open).

22 VDD – Digital power supply.

23 VSS – Digital Ground.

24 NC – Not used (Open).

25 VSS – Digital Ground.

26 UREG CHK CON O Not used (Open).

27 DSP SINT I Interrupt input from DSP.

28 DBB OFF I DBB switch.

29 AVLS SW I Set AVLS switch input.

30 OPR LED O LED drive.

31 NC – Not used (Open).

32 ADJUST I “Normally, Test mode select input (“L” : Test mode)

33 NC – Not used (Open).

34 SBUS CLK O SBB serial clock output.

35 SBUS DATA O SBB serial data output.

36 FR CAP I Free-run counter capture input (Not used).

37 SLD 1 MON I Sled servo timing signal input.

38 SLD 2 MON I Sled servo timing signal input.

39 CLV VCON O Spindle servo drive voltage control output.

40 V28-CON O Power voltage correction control output.

41 APC REF O Laser power control output.

42 CLV U MON I Spindle servo timing signal input.

43 CLV V MON I Spindle servo timing signal input.

44 CLV W MON I Spindle servo timing signal input.

45 CL V U CON O Spindle servo drive signal output.

– 16 –

Page 17

Pin No. Pin Name I/O Pin Description

46 CLV V CON O Spindle servo drive signal output.

47 CLV W CON O Spindle servo drive signal output.

48 NC – Not used (Open).

49 FR TRG – Free-run counter capture output (Not used).

50 VDD – Digital power supply.

51 VPP – Power for on board light.

52 VSS – Digital ground.

53 SLD 1R CON O Gate array control signal output.

54 SLD 1F CON O Gate array control signal output.

55 SLD 2R CON O Gate array control signal output.

56 SLD 2F CON O Gate array control signal output.

57 SLD DLY4 O Gate array control signal output.

58 SLD DLY5 O Gate array control signal output.

59 SLD DLY6 O Gate array control signal output.

60 SLD MODE O Gate array control signal output.

61 SPCK – Not used (Open).

62 RMC DTCLK I/O TSB serial data input/output.

63 – 65 NC – Not used (Open).

66 SLD DIR O Gate array control output.

67 SLD VCON O Sled servo outer voltage control output.

68 SLD PWR-UP O Baypass transistor control output for sled drive power supply.

69 HP MUTE O Headphone amplifier mute output.

70 HP STBY O Headphone amplifier standby output.

71 RMC SEL O Not used (Open).

72 NV D0 O Serial data signal output for NVRAM.

73 NV D1 I Serial data signal input from NVRAM.

74 NV CLK O Serial clock signal output for NVRAM.

75 NV CS1 O Chip select signal output for NVRAM.

76 VDD – Digital power supply.

77 – 79 LCD VL2 – 0 I LCD drive level power supply (Ground).

80 VSS – Digital ground.

81 – 87 NC – Not used (Open).

88 – 96 LCD SEG0 – 8 – Not used (Open).

97 – 100 LCD COM0 – 3 – Not used (Open).

MZ-EP11

6-2. BLOCK DIAGRAM

– 17 – – 18 – – 20 –– 19 –

• Signal path.

J : PLAY

Page 18

Ver 1.2

Page 19

p

p

p

Ver 1.1 1998.05

MZ-EP11

6-4. SCHEMATIC DIAGRAM

r

Refer to page 29 for IC Block Diagrams.

r

WA VEFORMS

PLAY MODE

1

IC501 #¶ RF OUT

TIME/DIV : 20 nsec

2

VOLT/DIV : 0.1V AC

16.0 MHz

IC301 5 XT1

TIME/DIV : 50 nsec

3

VOL T/DIV : 0.5V AC

TIME/DIV : 0.5µ sec

VOLT/DIV : 0.5V

1.0 Vp-

0.4 Vp-

0.9 Vp-

59.8 msec

IC601 $• X1

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

Note: Note:

The components identi- Les composants identifiés

fied by mark ! or dotted par une marque ! sont criline with mark ! are cri- tiques pour la sécurité.

tical for safety. Ne les remplacer que par

Replace only with part une piéce portant le

number specified. numéro spécifié.

• U : B+ Line.

• Power voltage is dc 1.5V and fed with regulated dc power

supply from external power voltage jack. (J901)

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : PLAY

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

– 25 – – 26 – – 28 –– 27 –

J : PLA Y

4

W or less unless otherwise

Page 20

NOTE :

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

7-1. PANEL SECTION

SECTION 7

EXPLODED VIEWS

• The mechanical parts with no reference

number in the exploded views are not

supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

• Abbreviation

JE : Tourist

1

1

Ver 1.2

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

10

1

11

IC602 MSM51V4400-70TS-K

7

23

6

8

not

supplied

25

9

1

1

19

not supplied

12

20

13

1

14

1

15

22

18

1

16

1

23

5

24

21

not supplied

1

4

3

17

2

RAS

CAS

VDD

GND

4

23

9

A0

10

A1

11

A2

12

A3

14

A4

15

A5

16

A6

17

A7

18

A8

5

A9

13

26

TIMING

GENERATOR

COLUM

ADDRESS

BUFFERS

INTERNAL

ADDRESS

COUNTER

ROW

ADDRESS

BUFFERS

DECODERS

ON CHIP V

REFRESH

CONTROL CLOCK

ROW

DD

WORD

DRIVERS

COLUM

DECODERS

SENSE

AMPS

MEMORY

CELLS

TIMING

GENERATOR

WRITE

CLOCK

GENERATOR

I/O

SELECTOR

INPUT

BUFFERS

OUTPUT

BUFFERS

3

WE

22

OE

1

D0

2

D1

24

D2

25

D3

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 4-963-883-21 SCREW (M1.4), PRECISION PAN

15 4-993-389-01 SPRING (BATTERY), COMPRESSION

2 4-993-374-11 PANEL, BOTTOM

3 4-982-398-21 KNOB (BASS BOOST)

4 4-982-397-21 KNOB (AVLS)

5 4-986-207-21 KNOB (TUN)

16 1-666-783-11 FLEXIBLE BOARD

17 X-4948-818-1 STRIP (A) ASSY, ORNAMENTAL

18 A-3293-628-A MAIN BOARD, COMPLETE (JE)

18 A-3293-828-A MAIN BOARD, COMPLETE (EXCEPT JE)

6 X-4948-817-1 PLATE (CONTROL)ASSY,ORNAMENTAL

19 7-627-455-07 SCREW +K1.4X1.4, PRECISION

7 4-993-386-01 SPRING (SHUTTER), TENSION

8 4-993-384-01 SHUTTER

9 4-993-387-01 STRIP (B), ORNAMENTAL

10 4-993-413-01 PANEL (X), UPPER

20 4-963-883-41 SCREW (M1.4), PRECISION PAN

21 3-335-797-91 SCREW (M1.4), TOOTHED LOCK

22 4-984-017-11 SCREW (1.7), TAPPING

23 4-993-385-01 SCREW, STEP

11 4-993-392-02 LID, BATTERY CASE

24 3-338-625-11 SCREW (M1.4X1.6), WASHER HEAD

12 X-4948-821-1 TERMINAL BOARD ASSY, MINUS

13 4-993-415-01 CASE, BATTERY

25 3-350-775-01 SPACER

14 X-4948-820-1 TERMINAL BOARD ASSY, PLUS

– 31 – – 32 –– 29 – – 30 –

Page 21

Ver 1.1 1998.05

7-2. MECHANISM DECK SECTION

(MT-MZEP10-129)

59

62

51

58

not

supplied

61

M901

51

57

63

M902

51

56

not supplied

64

55

51

54

53

52

71

67

57

65

66

68

69

70

51

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 4-963-883-21 SCREW (M1.4), PRECISION PAN

52 X-4948-793-1 LEAD ASSY

53 4-982-555-01 GEAR (A)

54 4-965-893-01 WASHER, GEAR (A) STOPPER

55 4-982-563-01 SPRING, THRUST

56 1-666-784-11 FLEXIBLE BOARD (CLV)

57 4-993-388-01 DAMPER

58 1-475-297-11 SWITCH UNIT

* 59 X-4948-822-1 CHASSIS (B) ASSY, SET

61 3-338-645-41 WASHER (0.8-2.5)

62 X-4948-816-1 CHASSIS ASSY, SET

63 4-900-951-01 SPRING (HOLDER)

64 X-4948-792-1 HOLDER ASSY

* 65 X-4948-790-1 CHASSIS ASSY

66 4-993-253-01 SPRING (SLIDE), TENSION

67 4-993-252-01 SPRING (EJECT), TENSION

68 4-993-251-01 SHAFT, MAIN

! 69 X-4949-080-1 OPTICAL PICK-UP ASSY (ODX-1A)

70 4-982-561-11 SPRING, RACK

71 3-349-825-82 SCREW, PRECISION

M901 8-835-594-01 MOTOR, DC SSM-01C03A/J-S (SPINDLE)

M902 1-698-764-11 MOTOR, SLED (SLED)

Les composants identifiés par une

marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

– 33 –

Page 22

Ver 1.1 1998.05

SECTION 8

MAIN

NOTE :

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms

METAL : Metal-film resistor

METAL OXIDE :Metal oxide-film resistor

F : nonflammable

• Items marked “ * ”are not stocked since

they are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-3293-628-A MAIN BOARD, COMPLETE (JE)

A-3293-828-A MAIN BOARD, COMPLETE (EXCEPT JE)

*********************

* 4-993-391-01 RETAINER (DC)

< CAPACITOR >

C101 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C102 1-115-585-11 TANTAL. CHIP 220uF 20% 4V

C103 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C201 1-107-812-11 TANTAL. CHIP 4.7uF 20% 6.3V

C202 1-115-585-11 TANTAL. CHIP 220uF 20% 4V

C203 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C301 1-111-253-11 TANTAL. CHIP 100uF 20% 6.3V

C302 1-162-912-11 CERAMIC CHIP 7PF 0.5PF 50V

C303 1-162-912-11 CERAMIC CHIP 7PF 0.5PF 50V

C304 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C305 1-117-919-11 TANTAL. CHIP 10uF 6.3V

C307 1-117-919-11 TANTAL. CHIP 10uF 6.3V

C308 1-117-919-11 TANTAL. CHIP 10uF 6.3V

C309 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C311 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C312 1-113-600-11 TANTAL. CHIP 2.2uF 20% 6.3V

C314 1-104-929-11 TANTAL. CHIP 22uF 20% 6.3V

C315 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C316 1-109-888-11 TANTAL. CHIP 3.3uF 20% 6.3V

C317 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C319 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C320 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C322 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C324 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C327 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C328 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C329 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C501 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C502 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C503 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C504 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C505 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

C506 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C507 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C508 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C509 1-117-720-11 CERAMIC CHIP 4.7uF 10V

ELECTRICAL PARTS LIST

• SEMICONDUCTORS

In each case, u : µ , for example :

uA.... : µ A.... , uPA.... : µ PA....

uPB.... : µ PB.... , uPC.... : µ PC....

uPD.... : µ PD....

• CAPACIT ORS

uF : µ F

• COILS

uH : µ H

• Abbreviation

FR : French

JE : Tourist

C510 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C511 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C513 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C514 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C515 1-162-908-11 CERAMIC CHIP 3PF 0.25PF 50V

C516 1-162-910-11 CERAMIC CHIP 5PF 0.25PF 50V

C551 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C552 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C553 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C554 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C555 1-107-765-11 TANTAL. CHIP 3.3uF 20% 16V

C556 1-107-765-11 TANTAL. CHIP 3.3uF 20% 16V

C557 1-135-238-21 TANTAL. CHIP 6.8uF 20% 10V

C558 1-135-238-21 TANTAL. CHIP 6.8uF 20% 10V

C559 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C560 1-117-370-11 CERAMIC CHIP 10uF 10V

C561 1-117-370-11 CERAMIC CHIP 10uF 10V

C564 1-115-566-11 CERAMIC CHIP 4.7uF 10% 10V

C565 1-115-566-11 CERAMIC CHIP 4.7uF 10% 10V

C566 1-115-566-11 CERAMIC CHIP 4.7uF 10% 10V

C567 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C601 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C602 1-117-720-11 CERAMIC CHIP 4.7uF 10V

C604 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C605 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C606 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C607 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C608 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C610 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C611 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C802 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C803 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C805 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C806 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C807 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C808 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C809 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C811 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C812 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C813 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C901 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C902 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C903 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference number, please include the board.

– 34 –

Page 23

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C905 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

< COIL >

C906 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C907 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C908 1-107-765-11 TANTAL. CHIP 3.3uF 20% 16V

C909 1-117-920-11 TANTAL. CHIP 10uF 6.3V

C910 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C911 1-117-232-11 TANTALUM 22uF 20% 4V

C912 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C913 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C914 1-124-576-11 ELECT 220uF 20% 4V

C915 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C916 1-117-920-11 TANTAL. CHIP 10uF 6.3V

C917 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C918 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C919 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C920 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

< CONNECTOR >

CN501 1-573-360-21 CONNECTOR, FFC/FPC 20P

CN551 1-573-917-11 CONNECTOR, FFC/FPC (ZIF) 8P

CN802 1-778-711-11 CONNECTOR, FFC/FPC (ZIF) 5P

< DIODE >

D101 8-719-017-58 DIODE MA8068

D201 8-719-017-58 DIODE MA8068

D301 8-719-066-17 DIODE FTZ6.8E-T148

D303 8-719-017-58 DIODE MA8068

D304 8-719-017-58 DIODE MA8068

L301 1-414-754-11 INDUCTOR 10uH

L502 1-414-754-11 INDUCTOR 10uH

L551 1-412-031-11 INDUCTOR CHIP 47uH

L552 1-412-031-11 INDUCTOR CHIP 47uH

L553 1-414-400-11 INDUCTOR 22uH

L554 1-414-400-11 INDUCTOR 22uH

L555 1-412-031-11 INDUCTOR CHIP 47uH

L556 1-414-754-11 INDUCTOR 10uH

L601 1-414-754-11 INDUCTOR 10uH

L901 1-412-031-11 INDUCTOR CHIP 47uH

L902 1-411-804-21 COIL, CHOKE 10uH

L903 1-414-754-11 INDUCTOR 10uH

< TRANSISTOR >

Q501 8-729-922-10 TRANSISTOR 2SA1577-QR

Q551 8-729-904-87 TRANSISTOR 2SB1197K-R

Q552 8-729-929-12 TRANSISTOR DTC143ZE-TL

< RESISTOR >

R101 1-216-837-11 METAL CHIP 22K 5% 1/16W

R102 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R105 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R201 1-216-837-11 METAL CHIP 22K 5% 1/16W

R202 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R205 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R301 1-216-845-11 METAL CHIP 100K 5% 1/16W

R302 1-216-845-11 METAL CHIP 100K 5% 1/16W

D801 8-719-052-72 LED CL-220HR-C (OPERATE)

D901 8-719-421-27 DIODE MA728

D902 8-719-066-16 DIODE RB491D-T146

< FERRITE BEAD >

FB101 1-414-555-21 INDUCTOR, FERRITE BEAD

FB201 1-414-555-21 INDUCTOR, FERRITE BEAD

FB301 1-414-385-11 INDUCTOR, FERRITE BEAD

FB304 1-414-385-11 INDUCTOR, FERRITE BEAD

< IC >

IC301 8-759-432-15 IC AK4314-VF-E2

IC302 8-759-431-56 IC BA3577FS-E2

IC501 8-759-458-04 IC SN761050A

IC551 8-759-390-25 IC MPC17A55FTA

IC552 8-759-358-40 IC TLC372CPW-E20

IC601 8-759-433-60 IC UPD63730GC-9EU

IC602 8-759-334-38 IC MSM51V4400-70TS-K

IC801 8-759-476-17 IC RU6715MF-0004

IC802 8-759-449-23 IC AK93C55AV-L

IC803 8-759-441-35 IC BU12101-E2

IC901 8-759-457-81 IC MPC1830VMEL

< JACK >

J301 1-778-179-11 JACK (2 /REMOTE)

J901 1-779-080-11 JACK,DC(POLARITY UNIFIED TYPE)

(DC IN 1.5V)

R303 1-216-833-11 METAL CHIP 10K 5% 1/16W

R304 1-216-857-11 METAL CHIP 1M 5% 1/16W

R305 1-216-809-11 METAL CHIP 100 5% 1/16W

R307 1-216-809-11 METAL CHIP 100 5% 1/16W

R312 1-216-809-11 METAL CHIP 100 5% 1/16W

R313 1-216-809-11 METAL CHIP 100 5% 1/16W

R501 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R503 1-216-833-11 METAL CHIP 10K 5% 1/16W

R504 1-216-853-11 METAL CHIP 470K 5% 1/16W

R505 1-216-809-11 METAL CHIP 100 5% 1/16W

R506 1-216-793-11 METAL GLAZE 4.7 5% 1/16W

R507 1-216-849-11 METAL CHIP 220K 5% 1/16W

R508 1-216-841-11 METAL CHIP 47K 5% 1/16W

R509 1-216-864-11 METAL CHIP 0 5% 1/16W

R510 1-216-864-11 METAL CHIP 0 5% 1/16W

R511 1-216-817-11 METAL CHIP 470 5% 1/16W

R513 1-216-853-11 METAL CHIP 470K 5% 1/16W

R553 1-216-833-11 METAL CHIP 10K 5% 1/16W

R560 1-216-833-11 METAL CHIP 10K 5% 1/16W

R561 1-216-853-11 METAL CHIP 470K 5% 1/16W

R562 1-216-809-11 METAL CHIP 100 5% 1/16W

R601 1-216-864-11 METAL CHIP 0 5% 1/16W

R801 1-216-845-11 METAL CHIP 100K 5% 1/16W

R802 1-216-845-11 METAL CHIP 100K 5% 1/16W

R803 1-216-853-11 METAL CHIP 470K 5% 1/16W

R804 1-216-853-11 METAL CHIP 470K 5% 1/16W

R805 1-216-864-11 METAL CHIP 0 5% 1/16W

R808 1-216-841-11 METAL CHIP 47K 5% 1/16W

R809 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

– 35 –

Page 24

MZ-EP11

Ver 1.1 1998.05

MAIN

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

R810 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R811 1-216-831-11 METAL CHIP 6.8K 5% 1/16W

R812 1-216-835-11 METAL CHIP 15K 5% 1/16W

R813 1-216-809-11 METAL CHIP 100 5% 1/16W

R814 1-216-809-11 METAL CHIP 100 5% 1/16W

R815 1-216-853-11 METAL CHIP 470K 5% 1/16W

R818 1-216-853-11 METAL CHIP 470K 5% 1/16W

R820 1-216-845-11 METAL CHIP 100K 5% 1/16W

R823 1-216-857-11 METAL CHIP 1M 5% 1/16W

R825 1-216-825-11 METAL CHIP 2.2K 5% 1/16W

R831 1-216-853-11 METAL CHIP 470K 5% 1/16W

R833 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R835 1-216-853-11 METAL CHIP 470K 5% 1/16W

R836 1-216-853-11 METAL CHIP 470K 5% 1/16W

R838 1-218-871-11 METAL CHIP 10K 5% 1/16W

R901 1-216-863-11 METAL GLAZE 3.3M 5% 1/16W

R903 1-216-845-11 METAL CHIP 100K 5% 1/16W

R905 1-216-845-11 METAL CHIP 100K 5% 1/16W

R906 1-216-847-11 METAL CHIP 150K 5% 1/16W

R909 1-216-833-11 METAL CHIP 10K 5% 1/16W

R910 1-220-920-11 RES CHIP 0.47 1/2W

R911 1-216-809-11 METAL CHIP 100 5% 1/16W

R912 1-216-809-11 METAL CHIP 100 5% 1/16W

R914 1-216-864-11 METAL CHIP 0 5% 1/16W

< COMPOSITION CIRCUIT BLOCK >

RB551 1-236-904-11 NETWORK RESISTOR (CHIP) 1.0K

RB552 1-233-703-21 NETWORK RESISTOR (CHIP) 1M

< SWITCH >

S301 1-762-079-11 SWITCH, SLIDE (DIGITAL MEGA BASS)

S801 1-692-847-21 SWITCH, PUSH (1 KEY) (OPEN/CLOSE)

S802 1-762-078-11 SWITCH, SLIDE (C HOLD)

S803 1-771-053-21 SWITCH, KEY BOARD (VOL +)

S804 1-771-053-21 SWITCH, KEY BOARD (VOL –)

S805 1-762-078-11 SWITCH, SLIDE (AVLS)

! 1-528-252-21 BATTERY CHARGER (BC-7S) (UK)

! 1-528-580-21 BATTERY CHARGER (BC-7HT) (JE,E)

! 1-528-744-21 BATTERY CHARGER (BC-7DY) (AEP,FR)

! 1-569-007-11 ADAPTOR, CONVERSION 2P (JE,E)

1-528-543-22 BATTERY, NI-CD (NC-6WM) (AEP,UK,FR,E)

1-528-743-11 BATTERY, NICKEL HYDROGEN (JE)

3-008-521-01 CASE, BATTERY CHARGE

3-860-459-11 MANUAL, INSTRUCTION (ENGLISH,SPANISH)

3-860-459-21 MANUAL, INSTRUCTION (FRENCH,GERMAN)

3-860-459-31 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

3-860-459-41 MANUAL, INSTRUCTION (SPANISH,CHINESE)

3-860-459-51 MANUAL, INSTRUCTION(JAPANESE,

3-860-459-61 MANUAL, INSTRUCTION (GERMAN, DUTCH)

3-860-459-71 MANUAL, INSTRUCTION (SWEDISH,FINNISH)

3-860-459-81 MANUAL, INSTRUCTION (ITALIAN,

3-860-459-91 MANUAL, INSTRUCTION (ENGLISH) (US)

3-860-459-92 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

4-972-888-01 CASE, CARRYING

8-953-091-91 HEADPHONE MDR-E838MP//K SET (JE)

8-953-218-90 HEADPHONE MDR-E838SP//K SET

8-953-278-90 HEADPHONE MDR-A34SP SET (US)

X-3329-657-1 ATTACHMENT ASSY (EXCEPT US)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour

la sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

(EXCEPT US,Canadian)

CHINESE,KOREAN) (JE)

PORTUGUESE) (AEP)

(US, Canadian)

(EXCEPT US,JE)

(AEP,UK,FR,E)

(JE)

(JE)

(AEP, E)

(AEP, FR)

(AEP)

< VIBRATOR >

X301 1-767-124-11 VIBRATOR, CRYSTAL (16.9MHz)

************************************************************

MISCELLANEOUS

**************

16 1-666-783-11 FLEXIBLE BOARD

56 1-666-784-11 FLEXIBLE BOARD (CLV)

58 1-475-297-11 SWITCH UNIT

! 69 X-4949-080-1 OPTICAL PICK-UP ASSY (ODX-1A)

M901 8-835-594-01 MOTOR, DC SSM-01C03A/J-S (SPINDLE)

M902 1-698-764-11 MOTOR, SLED (SLED)

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

1-473-677-11 REMOTE CONTROL UNIT (RM-MZE50MP) (JE)

1-475-375-11 REMOTE CONTROL UNIT (RM-MZ35)

(EXCEPT JE)

– 36 –

Page 25

MZ-EP11

Printing Method for Large Sized Documents Such As Circuit Diagrams

Printing the page that exceeds A4-size two pages (or letter size) is possible by specifying the print

range. (Acrobat Reader Version 4.0 or later)

1. The enlarged print is made, if a smaller range than A4 size is specified and the A4 size is

selected as a print paper.

2. Almost real sized print is made, if the range is specified, meeting the print paper size.

3. The reduced print is made, if a larger range than the print paper size is specified.

Printing by Specifying a Range

In printing out the drawings such as a schematic diagram and a printed wiring board larger than

the printed paper size, they can be printed by specifying the range. (Acrobat Reader Version 4.0

or later)

1. Display the page to be printed.

2. From the File menu, select [Page Setup] and set the paper size.

3. From the Command bar, select [Graphic Select Tool].

(Keep pressing

4. Dragging the cursor, enclose the range on the page to be printed.

5. From the File menu, select [Print] and make sure that the [Selected Graphic] is already checked.

Also, if [Fit to page] is checked, the selected range is enlarged or reduced (and rotated as

necessary) meeting the paper size.

T

, select

)

@

@

!

!

6. To cancel the printed range, click an arbitrary position on the screen.

– 37 –

Page 26

MZ-EP11

REVISION HISTORY

Clicking the version allows you to jump to the revised page.

Also, clicking the version at the upper right on the revised page allows you to jump to the next revised

page.

Ver. Date Description of Revision

1.0 1997.07 New

1998.02 Addition of US, AEP, UK and E model.

1.1 1998.06 Addition of Canadian model.

1.2 2004.03 Addition of Diagrams for PDF data. (Page 21 to 24 and 29 to 31).

Loading...

Loading...