Sony MZ-E900 User Manual

MZ-E900

SERVICE MANUAL

Ver 1.1 2001.01

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation

SPECIFICATIONS

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: l = 790 nm

Emission duration: continuous

Laser output: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm from

the objective lens surface on the optical pick-up block with 7 mm

aperture.

Revolutions

Approx. 300 rpm to 2,700 rpm

Error correction

ACIRC (Advanced Cross Interleave Reed Solomon Code)

Sampling frequency

44.1 kHz

Coding

ATRAC (Adaptive TRansform Acoustic Coding)

ATRAC3: LP2

ATRAC3: LP4

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limits

Outputs

Headphones/earphones: stereo mini-jack, maximum output level 5

mW +5 mW, load impedance 16 ohms

Power requirements

Nickel metal hydride rechargeable battery

One NH-14WM(A) (supplied): 1.2V, 1,350 mAh (min)

One LR6 (size AA) battery (not supplied)

External power jack: Power rating 1.5V DC

US Model

Canadian Model

AEP Model

UK Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZE900-173

Optical Pick-up Mechanism Type LCX-4E

Battery operation time

Batteries Stereo(normal) LP2 Stereo LP4 Stereo

Ni-MH rechargeable 29 33 37

battery

NH-14WM (A)

LR6 (SG) Sony 42 49 58

alkaline dry battery

LR6 (SG) Sony 76 87 100

alkaline dry battery

and a Ni-MH rechargeable

rechargeable battery

1)

With a fully charged battery

2)

Measured in accordance with the EIAJ (Electronic Industries

Association of Japan) standard (using a Sony MDW-series Mini-disc).

3)

When using a Sony LR6 (SG) “STAMINA” alkaline dry battery

(produced in Japan).

Note

The battery life may be shorter depending on operating conditions, the

surrounding temperature, and the battery type.

Dimensions

Approx. 77.7 x 12.7 x 71.0 mm (w/h/d) (3 1/8 x 1/2 x 2 7/8 in.)

(not including projecting parts and controls)

Mass

Approx. 58g (2.0 oz) (the player only)

Supplied accessories

Headphones/earphones with a remote control (1)

Battery charger (1) (EXCEPT Korean MODEL)

Rechargeable battery (1)

Rechargeable battery carrying case (1) (Tourist MODEL)

Dry battery case (1)

Carrying pouch (1) (EXCEPT US MODEL)

AC plug adaptor (1) (E33, Tourist model)

Design and specifications are subject to change without notice.

1) 2)

1)

3)

3)

1)

Unit:Approx. hours

PORTABLE MINIDISC PLAYER

9-927-992-12

2001A0200-1

© 2001.1

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

MZ-E900

n

Ver 1.1 2001.01

SECTION 1

SERVICING NOTE

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE...................................................... 2

2. GENERAL

Location and Function of Controls .................................... 3

3. DISASSEMBLY

3-1. “Lid ASSY, Upper”, Holder ASSY ............................ 4

3-2. Mechanism Deck ........................................................ 4

3-3. Audio Board ................................................................ 5

3-4. Bracket (L) ASSY, Bracket (R) ASSY ....................... 5

3-5. Main Board, Bracket (L) ASSY, SW Board ............... 6

3-6. Optical Pick-up ASSY................................................ 6

4. TEST MODE.................................................................. 7

5. ELECTRICAL ADJUSTMENTS............................11

6. DIAGRAMS

6-1. Block Diagram.......................................................... 15

6-2. Printed Wiring Boards – Main Section (1/2) –......... 16

6-3. Printed Wiring Boards – Main Section (2/2) –......... 17

6-4. Schematic Diagram – Main Section (1/2) – ............. 18

6-5. Schematic Diagram – Main Section (2/2) – ............. 19

6-6. Printed Wiring Boards – Audio Section – ................ 20

6-7. Schematic Diagram – Audio Section –..................... 21

7. EXPLODED VIEWS

7-1. Front Section ............................................................ 25

7-2. Mechanism Deck Section ......................................... 26

8. ELECTRICAL PARTS LIST ................................... 27

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

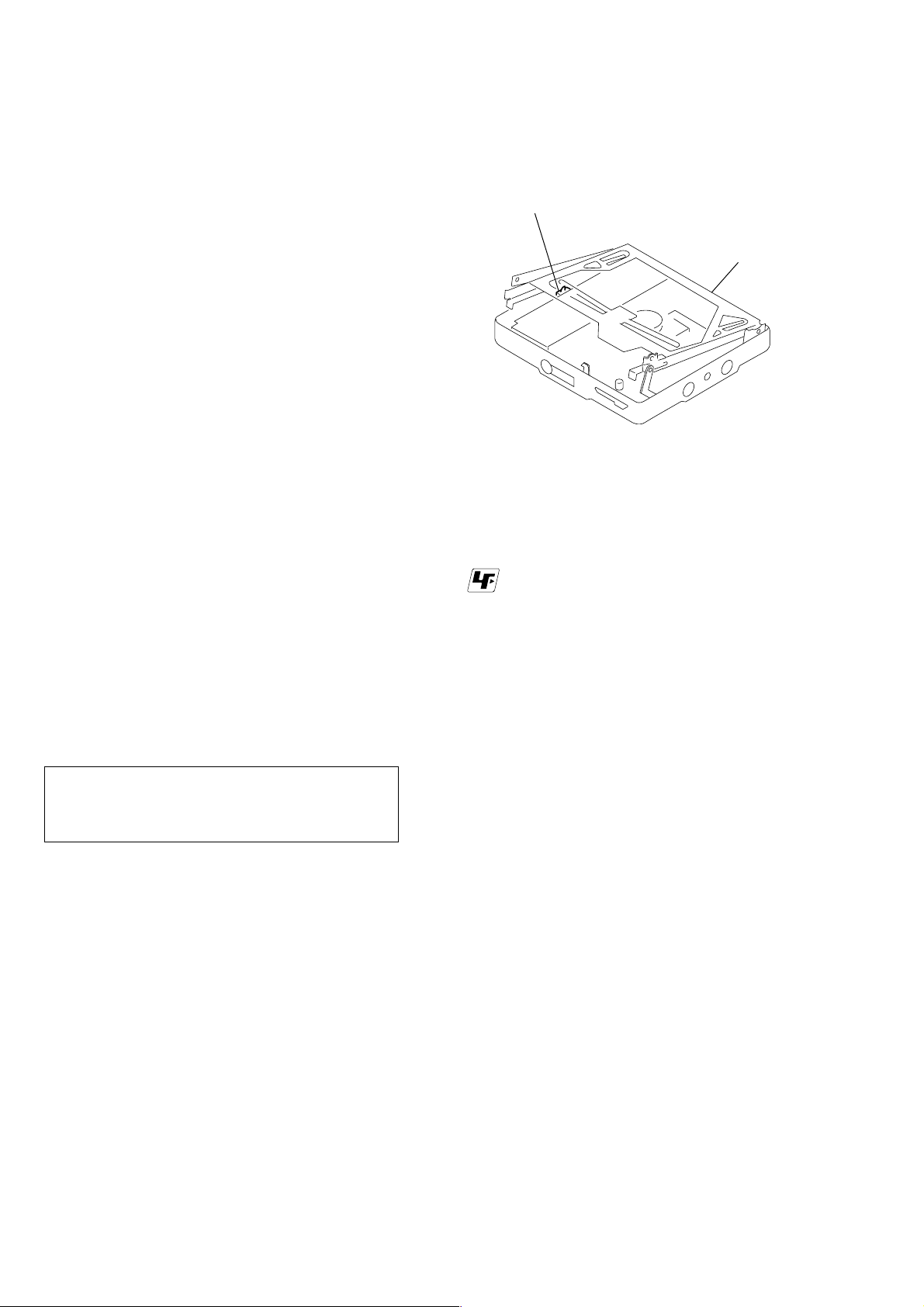

When repairing this device with the power on, if you remove the

main board, this device stops working.

In this case, you work without the device stopping by fastening

the hook of the Open/Close detection switch (S809).

Open/Close detection switch (S809)

Mechanism deck sectio

r

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

* Replacement of CXD2671-201GA (IC601) used in this set

requires a special tool.

2

SECTION 2

GENERAL

MZ-E900

Ver 1.1 2001.01

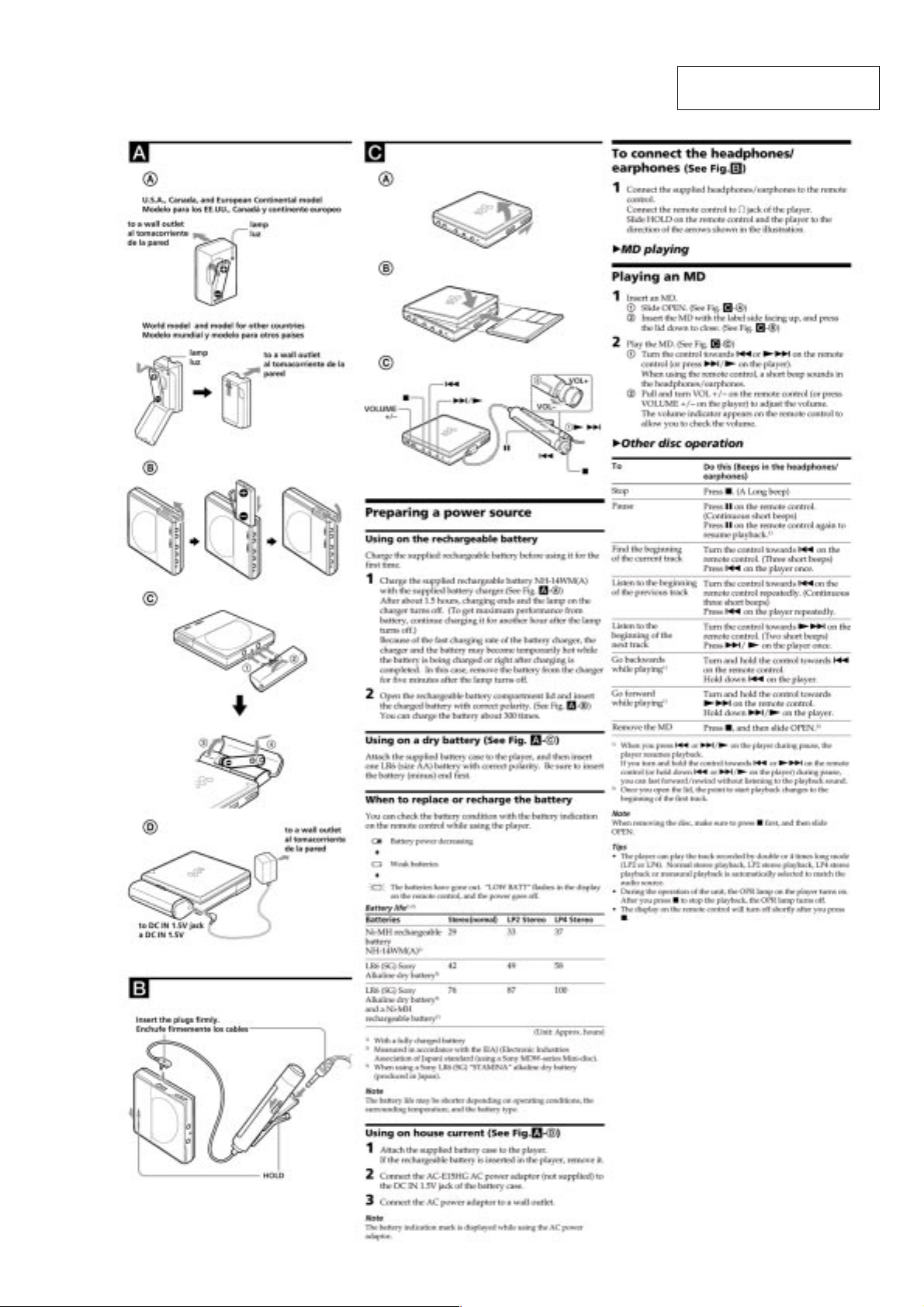

This section is extracted from

instruction manual.

3

MZ-E900

d

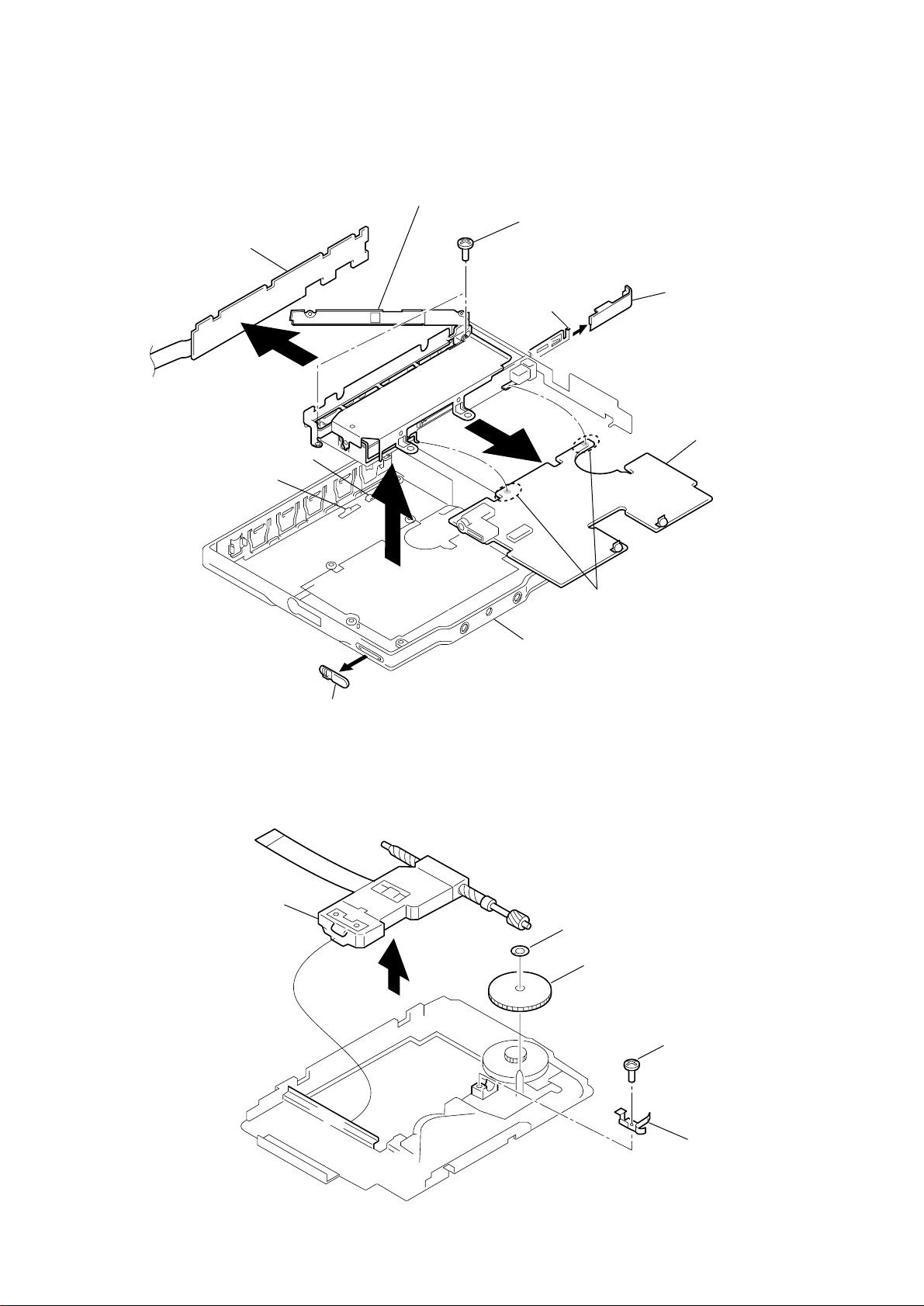

SECTION 3

DISASSEMBLY

r

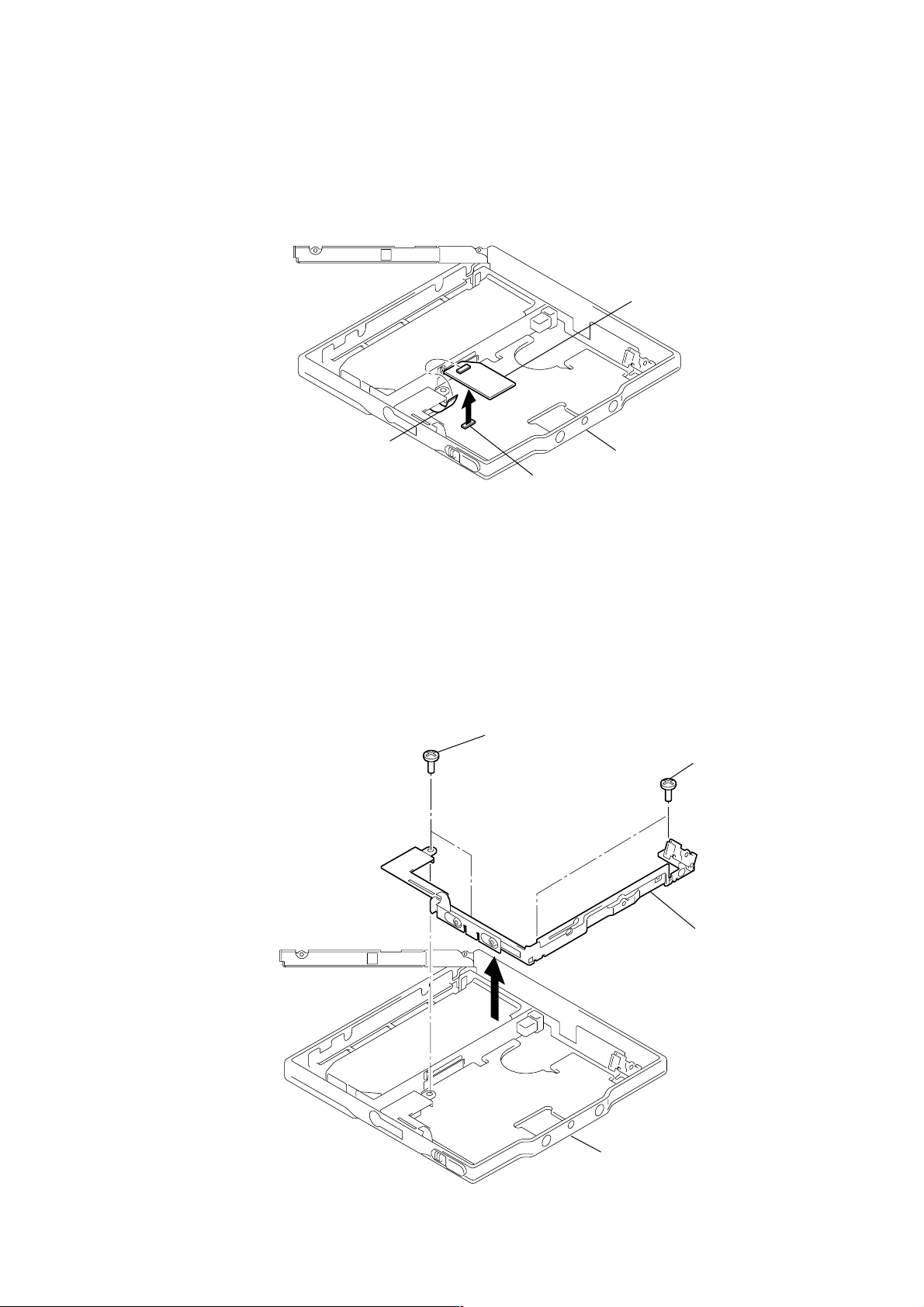

The equipment can be removed using the following procedure.

Set

“Lid ASSY , Upper”,

Holder ASSY

Mechanism deck

Note : Follow the disassembly procedure in the numerical order given.

3-1. “LID ASSY, UPPER”, HOLDER ASSY

1

Screws (MI 1.4)

3

Move it away

from projection

Audio board

Optical pick-up ASSY

Bracket (R) ASSY

Lid ASSY, upper

Holder ASSY

Main board,

Bracket (L) ASSY,

SW board

1

Screws (MI 1.4)

3-2. MECHANISM DECK

6

Motor flexible board

1

Screws (MD), step

2

2

4

Bracket (stop) ASSY

Panel, bottom

Mechanism deck

3

3

Move it away

from projection

7

OP flexible boar

5

Panel, bottom

4

Claw

4

3-3. AUDIO BOARD

)

1

Switch flexible board

MZ-E900

Ver 1.1 2001.01

Audio board

2

Panel, bottom

CN801

3-4. BRACKET (R) ASSY

2

Screws (MI 1.4)

3

1

Screws (MI 1.4

Bracket (R) ASSY

Panel, bottom

5

MZ-E900

t

3-5. MAIN BOARD, BRACKET (L) ASSY, SW BOARD

Note : On installation of bottom panel assy, adjust the position of both

two switches (S807, S808) and two knobs (AVLS, HOLD).

Bracket (L) ASSY

SW board

8

Knob (HOLD)

Knob (AVLS)

4

Screw (MI 1.4)

1

Claw

7

2

Lid, battery case

Main board

3-6. OPTICAL PICK-UP ASSY

Optical pick-up ASSY

(LCX-4E)

3

Knob (open)

5

5

Panel, bottom

1

Washer

2

6

Remove solder

Gear (SA)

3

Screw (MI 1.4)

4

Spring, thrust deten

6

SECTION 4

888

u

008 V1.000

F

1SHUFF PGM

SOUND 1 2 BASS 1 2

All on

All off

Microprocessor

version

display

TEST MODE

MZ-E900

4-1. GENERAL

• When entered in the TEST MODE, this set provides the Overall

Adjustment mode which allows CD and MO discs to be automatically adjusted. In the Overall Adjustment mode, the system

discriminates between CD and MO discs, performs adjustments

in sequence automatically, and displays the faulty location if

any fault is found. In the Manual mode, selected adjustments

can be performed automatically.

• The attached remote control is used to operate the TEST MODE.

Unless otherwise specified in the text, the key means that on the

remote control.

4-2. SETTING THE TEST MODE

4-2-1. How to set the TEST MODE

To set the TEST MODE, two methods are available.

1 Solder bridge and short TAP601 (TEST) on the main board.

Then turn on the power.

MAIN BOARD (SIDE A)

R607

TAP601

SHORT: TEST MODE

OPEN: NORMAL MODE

TP921

R617

C613 C605

R911

C606

C610

C802

C810

Remote control LCD

• Press and hold down X to hold the current display while the

key is being pressed.

4-2-3. How to release the TEST MODE

When method 1 was used:

Turn off the power and open the solder bridge on TAP601 on the

main board.

Note: The solder should be removed clean. The remaining solder

may make a short with the chassis and other part.

When method 2 was used:

Turn off the power.

Note: If electrical adjustment (see page 11) has not been finished

completely, always start in the test mode. (The set cannot

start in normal mode)

2 In the normal mode, operate the keys on the set and those on the

4-2-2. Operations when the TEST MODE is set

When the TEST MODE is entered, the system switches to the display check mode within the TEST MODE. From this mode, the

other Test modes can be accessed.

When the TEST MODE is set, the LCD repeats a cycle of the following displays:

TAP601

OPEN : Normal mode

SHORT : Test mode

remote control as specified below:

Turn on HOLD switch on the set. Holding down x (STOP)

key on the set, press the keys on the remote control in the

following sequence:

> N t > N t . t . t > N

t . t > N t . t X t X

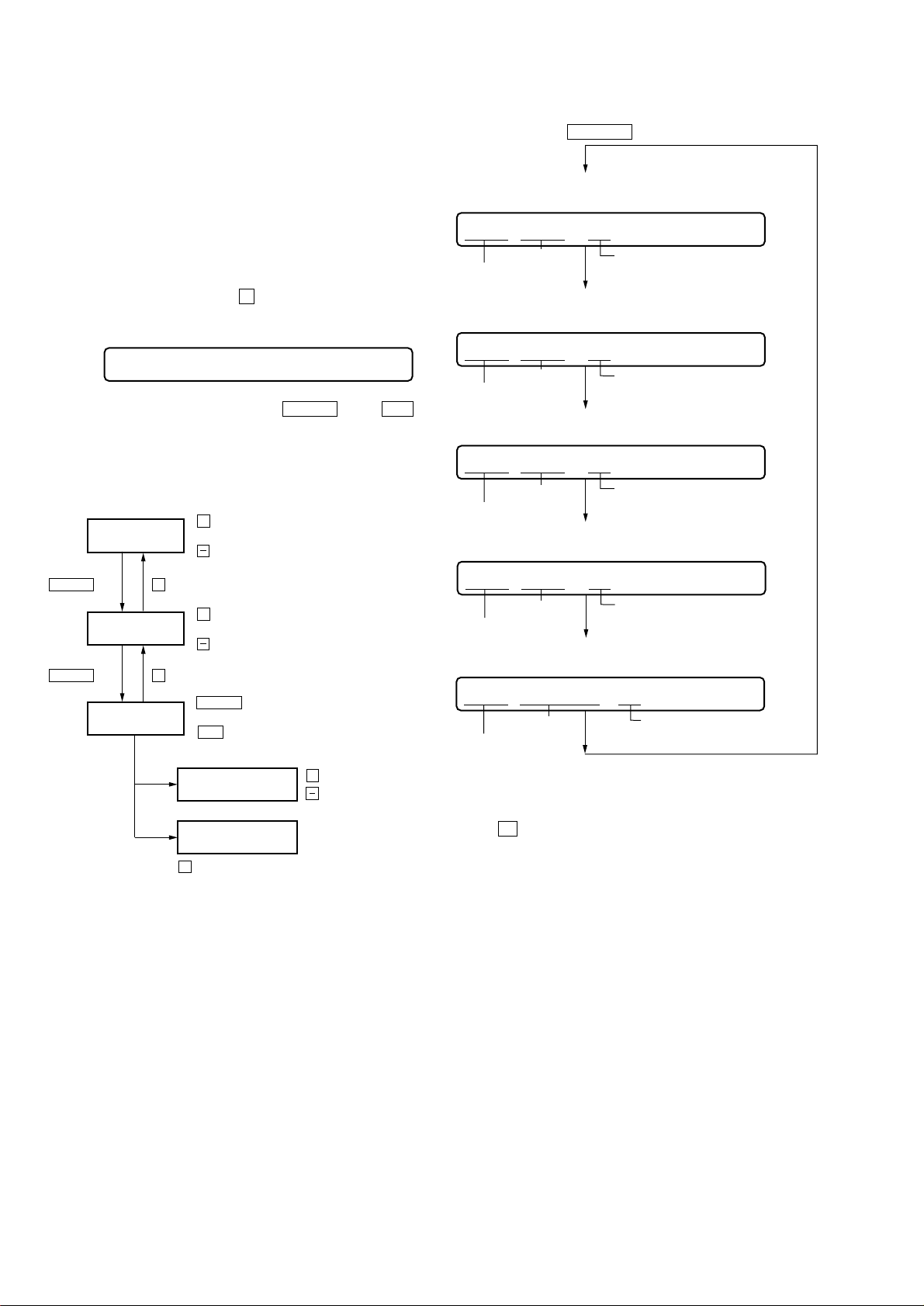

4-3. TEST MODE STRUCTURE

Test Mode

(Display Check Mode)

+

key

Manual Mode

x

key

+

key

key

.

or

key

Overall Adjustment Mode

x

key

DISPLAY key

x

key

>B

key

x

key

DISPLAY key

(Press and hold down about 3 sec)

Terminate key checking or open

the top panel.

Self-diagnostic Display Mode

Sound Skip Check Result Display Mode

Servo Mode

Audio Mode

Power Mode

OP Alignment Mode

Key Check Mode

7

MZ-E900

011 C68S01

adress

mode number

adjusted value

011 OFFJ01

jitter value

mode number

adjusted value

011 063B01

block error value

mode number

adjusted value

011 059A01

ADIP error value

mode number

adjusted value

011 LrefPw 0 1

item title

mode number

adjusted value

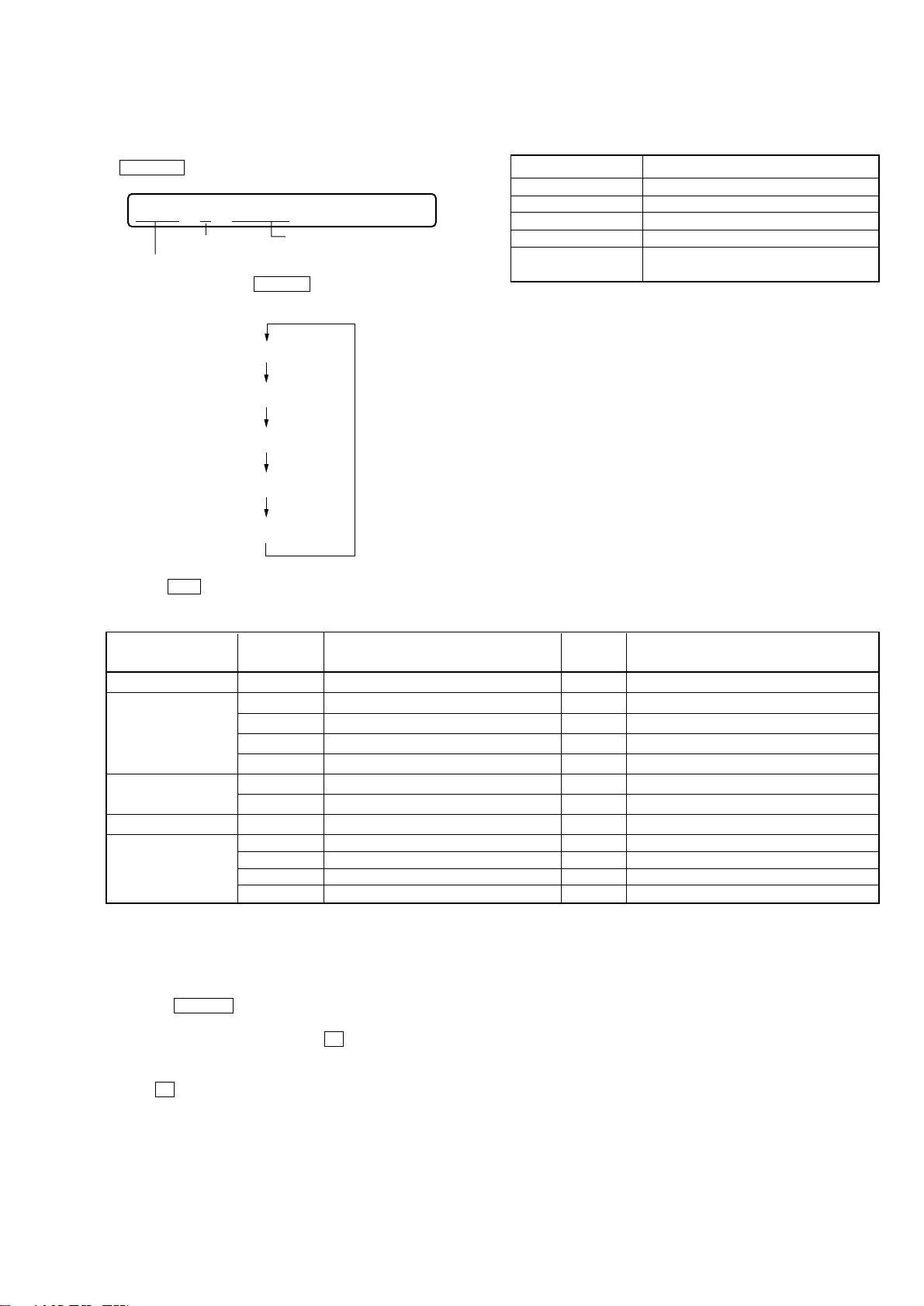

4-4. MANUAL MODE

4-4-1. Outline of the function

The Manual mode is designed to perform adjustments and

operational checks on the set’s operation according to each

individual function.

Usually, no adjustments are made in this mode.

However, the Manual mode is used to clear the memory before

performing automatic adjustments in the Overall Adjustment mode.

4-4-2. How to set the Manual mode

1. Set the TEST MODE and press + key to set the Manual mode.

Remote control LCD display

000 Manual

2. During each test, press and hold down > N key or .

key for a while to move the optical pickup on the sled outer or

inner perimeter.

3. Each test item is assigned with a three-digit item number. The

100th place is a major item, 10th place is a middle item, and unit

place is a minor item.

+

key : 100th place of mode number

increase

key : 100th place of mode number

decrease

keykey

> N

Change Major

Item

x

4. During each test mode, the display is changed from one to

another each time DISPLAY key is pressed.

• Address & Adjusted Value Display

LCD display

• Jitter Value & Adjusted Value Display

LCD display

• Block Error Value & Adjusted Value Display

LCD display

• ADIP Error Value & Adjusted Value Display

LCD display

Change Middle

Item

key

> N

Change Minor

Item

+

key : 10th place of mode number

increase

key : 10th place of mode number

x

decrease

key

key : Unit place of mode number

> N

increase

.

key : Unit place of mode number

decrease

Change Adjustment

Value

Write Adjustment

Value

X

key : When adjusted value is changed :

Adjusted value is written.

When adjusted value is not changed :

That item is adjusted automatically.

+

key : Up

key : Down

• Item Title Display

LCD display

Note: In the Power mode, the item title display is only displayed.

5. To terminate the Manual mode and return to the TEST MODE,

press x key.

4-5. OVERALL ADJUSTMENT MODE

4-5-1. Outline of the function

This mode is designed to adjust the servo system automatically by

going through all the adjustment items.

Usually, this mode is used to perform automatic adjustments when

servicing the set.

For further information, refer to section 5. ELECTRICAL ADJUST MENTS. (See page 11)

4-6. SELF-DIAGNOSTIC DISPLAY MODE

4-6-1. Outline of the function

The Self-diagnostic system is used in this set. If an error occurs

during playback, this system detects the fault through the

microprocessor’s mechanism and power control blocks and stores

the cause in EEPROM in a history format.

This history, which can be viewed in the TEST MODE, provides

the means of locating the fault in troubleshooting.

8

4-6-2. Self-diagnostic mode

1. Set the TEST MODE.

2. With all the LCD display segments blinking on the set, press

DISPLAY key and the Self-diagnostic mode is entered.

001 1 Adrs

History code

Error display code

3. Hereinafter, each time > N key is pressed, the reference

information display changes as follows:

0XX 1 # # # #

0XX N # # # #

0XX N1 # # # #

Simplified contents

• Contents of the history codes

History code number

1 The first error that occurred.

N The last error that occurred.

N-1 The first error from the last one.

N-2 The second error from the last one.

R

T otal recording time ( – – – – is displayed

for MZ-E900)

MZ-E900

Contents

0XX N2 # # # #

0XX R

• Press . key to go back to the previous display.

• Description of the error display codes

Contents of fault Display code Meaning of code

No error 00 No error – – – – No error

Servo system error

TOC error

Power system error 22 LOWBATT LBat Instantaneous interruption detected.

Offset error

– – – –

Simplified

contents

01 Access target address illegally specified Adrs An attempt to access an abnormal address.

02 HIGH TEMP T emp HIGH TEMP

03 FOCUS ERROR Fcus Focus off-center.

04 SPINDLE ERROR Spdl Abnormal rotation of disc

11 TOC ERROR TOC

12 READ DATA ERROR Data

31 OFFSET ERROR Ofst Offset error

32 FE_ABCD_OFFSET_ERR ABCD FE ABCD Offset error

33 TE_ABCD_OFFSET_ERR TE TE ABCD Offset error

34 X1_TE_OFFSET_ERR X1TE X1 TE ABCD Offset error

Description

4-6-3. Clearing the error display code

After servicing, reset the error display code.

1. Set the TEST MODE.

2. Press the DISPLAY key on the remote control activates the selfdiagnosis display mode.

3. To reset the error display code press X key on the remote control when the code is displayed.(except for R - - - - display)

(All the data on the 1st, N, N-1 and N-2 will be reset)

4. Press X key on the remote control again.

9

MZ-E900

4-7. Sound Skip Check Result Display Mode

This set can display and check the error count occurring during

play.

• Setting method of Sound Skip Check Result Display Mode

1. Setting the test mode.

2. Press the > N key activates the sound skip check result

display mode where the LCD displays as shown below.

LCD display

000 P**P##

Total of play system

error count

Total of record system error count

3. When > N key is pressed, the total of error count is displayed on the LCD, and each time the > N key is pressed,

the error count descents one by one as shown below. Also, when

. key is pressed, the error count ascends by one.

000 P**R00

000 EIB **

000 Stat**

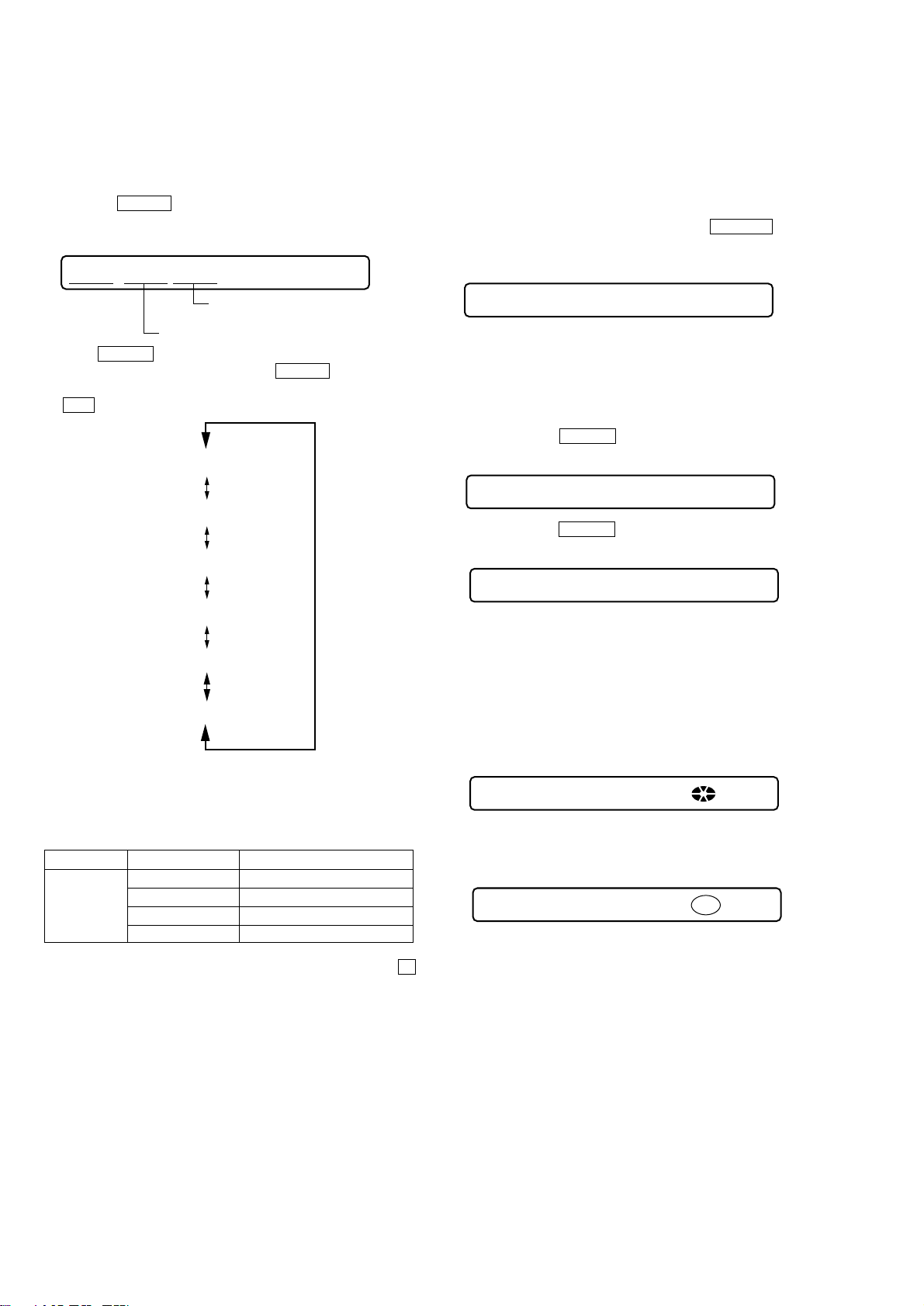

4-8. KEY CHECK MODE

4-8-1. Outline of the function

This mode is used to check to make sure that each of the keys

(including the slide switch) on the set operates normally.

4-8-2. Setting the Key Check mode

1. Set the TEST MODE. Press and hold down DISPLAY key (for

more than 3 sec) to set the Key Check mode.

LCD display

000 0F

2. When each key on the set and on remote control is pressed, its

name is displayed on the LCD. (The operated position is displayed for 4 sec after the slide switch is operated. If any other

key is pressed during this display, the LCD switches to its name

display)

Example: When > N key on the set is pressed:

LCD display

000 FF 0F

Example: When > N key on the remote control is pressed:

LCD display

000 rPLAY XX

000 Adrs**

000 BEmp**

000 ######

P**R00 : Total of play system error and record system error count

** : Sound skip check items counter (hexadecimal)

##### : 6-digit address (hexadecimal) where a sound skipped

Error code

Cause of error Description of error

Playback EIB Sound error correction error

Stat Decorder status error

Adrs Cannot access the address

BEmp Buffer becomes empty

4. Quit the sound skip check result display mode, and press the x

key to return to the test mode. (display check mode)

XX: AD value of the remote control key (hexadecimal 00 to FF)

3. When all the keys on the set and on the remote control are considered as OK, the following displays are shown for 2 sec.

(The key pressed to enter the Key Check mode has been checked

even if it is not pressed in this mode)

Example: When the keys on the set are considered as OK:

LCD display

888 SET OK OF

Example: When the keys on the remote control are considered

as OK:

LCD display

888 RMC OK OX

4. When all the key have been checked or when the top panel is

opened during this checking, the system terminates the Key

Check mode and return to the TEST MODE.

10

Loading...

Loading...