Sony MZ-E80 Service manual

MZ-E80

SERVICE MANUAL

Ver 1.1 2000. 05

With SUPPLEMENT-1

(9-927-132-82)

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

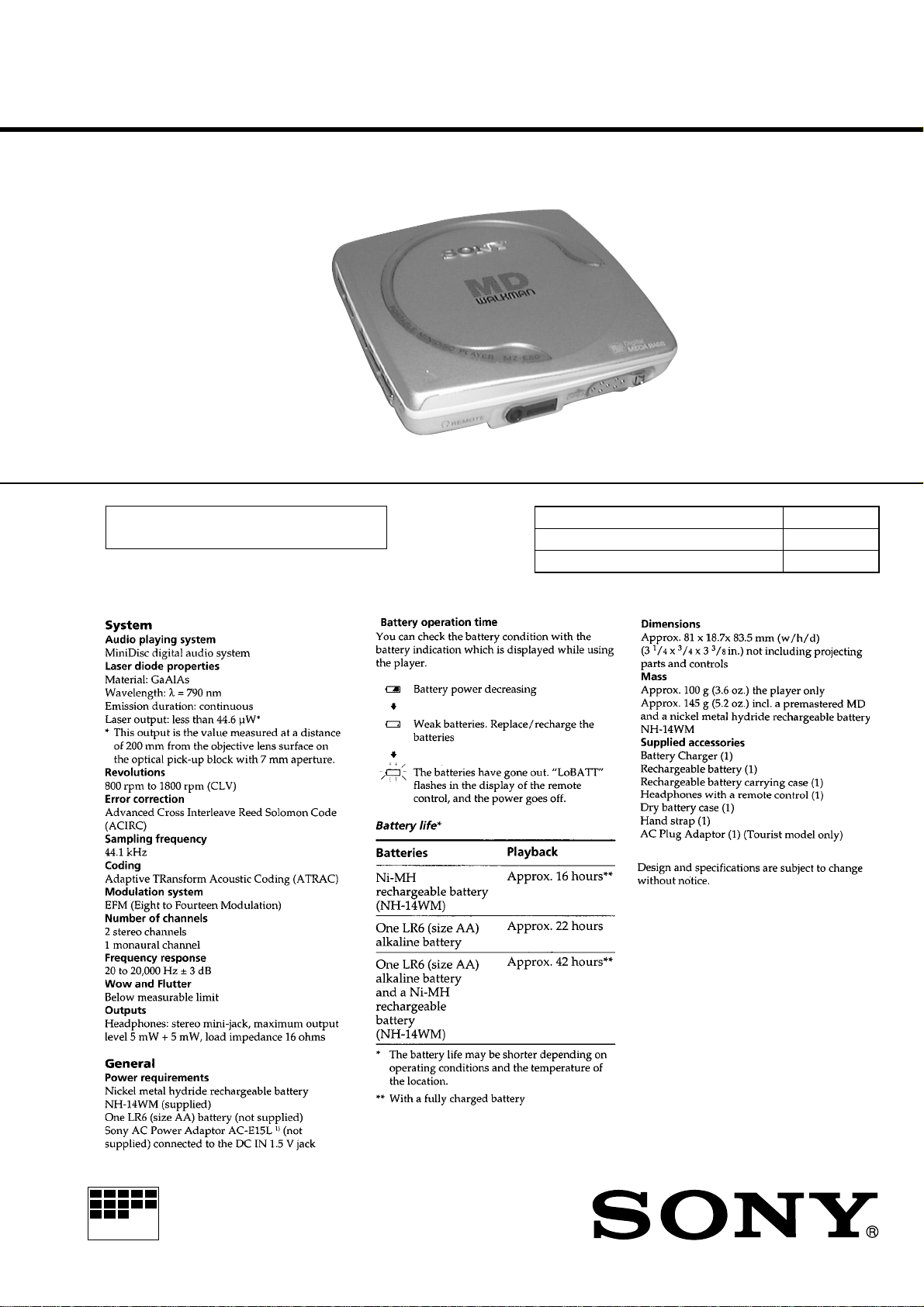

SPECIFICATIONS

E Model

Tourist Model

Photo: Silver

Model Name Using Similar Mechanism MZ-E55

Mechanism Type MT-MZE55-150

Optical Pick-Up Name ODX-1B

MICROFILM

PORTABLE MINIDISC PLAYER

SECTION 1

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 2

2. GENERAL ................................................................... 3

3. DISASSEMBLY ......................................................... 4

4. TEST MODE.............................................................. 6

5. ELECTRICAL ADJUSTMENTS......................... 10

6. DIAGRAMS

6-1. Block Diagram ................................................................ 11

6-2. Printed Wiring Boards .................................................... 16

6-3. Schematic Diagram ......................................................... 19

6-4. IC Pin Function Description ........................................... 28

7. EXPLODED VIEWS ................................................ 35

8. ELECTRICAL PARTS LIST ............................... 37

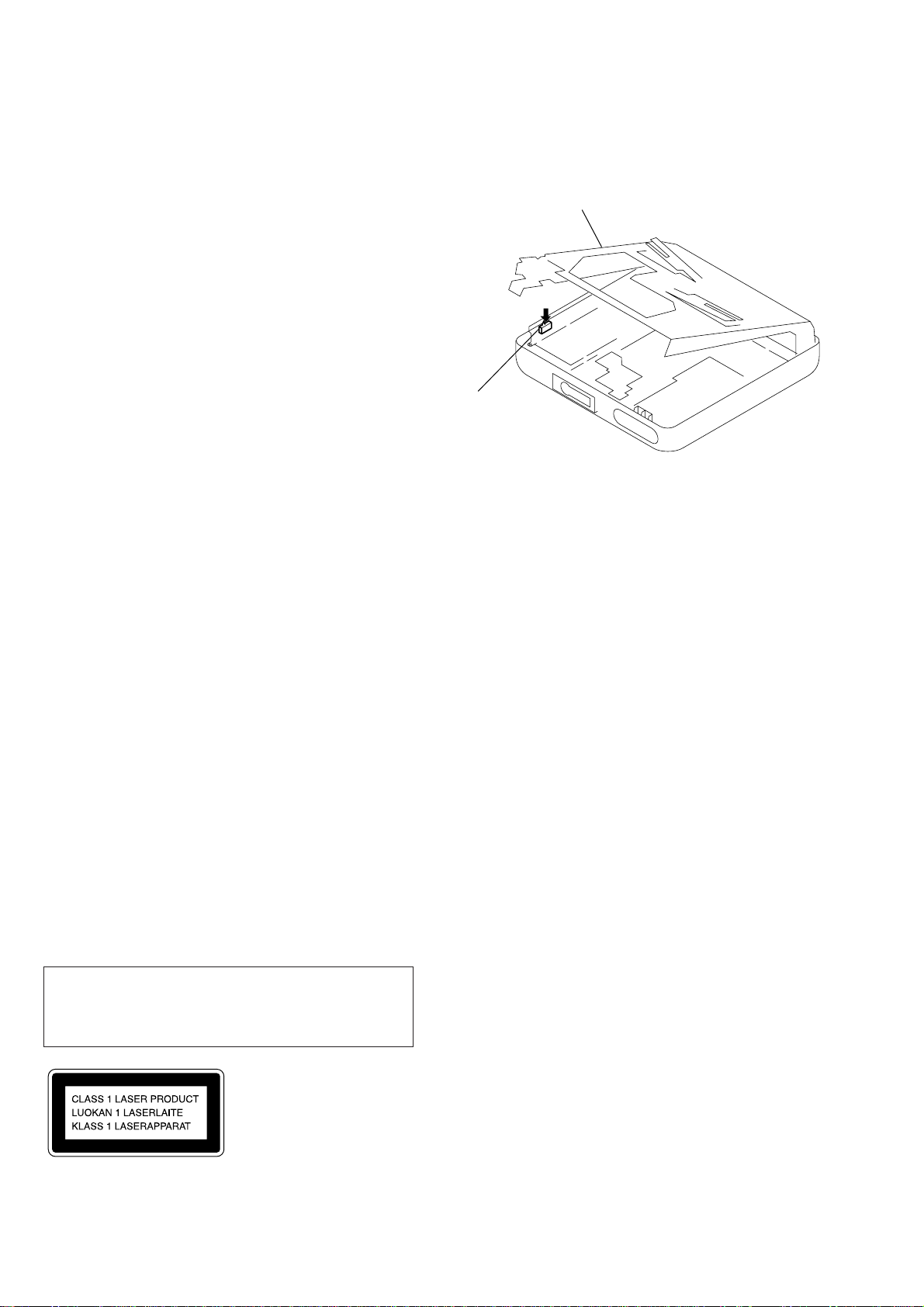

• Removing the mechanism deck causes this set to be disabled

during a repair with the power supplied to the set. Therefore,

lock convex portion of open/close detect switch (S801) during

a repair.

Mechanism deck section

Open/close detect

switch (S801)

• Replacement of CXD2663GA (IC601) used in this set requires

a special tool. Therefore, it cannot be replaced.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This MiniDisc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located

on the bottom exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

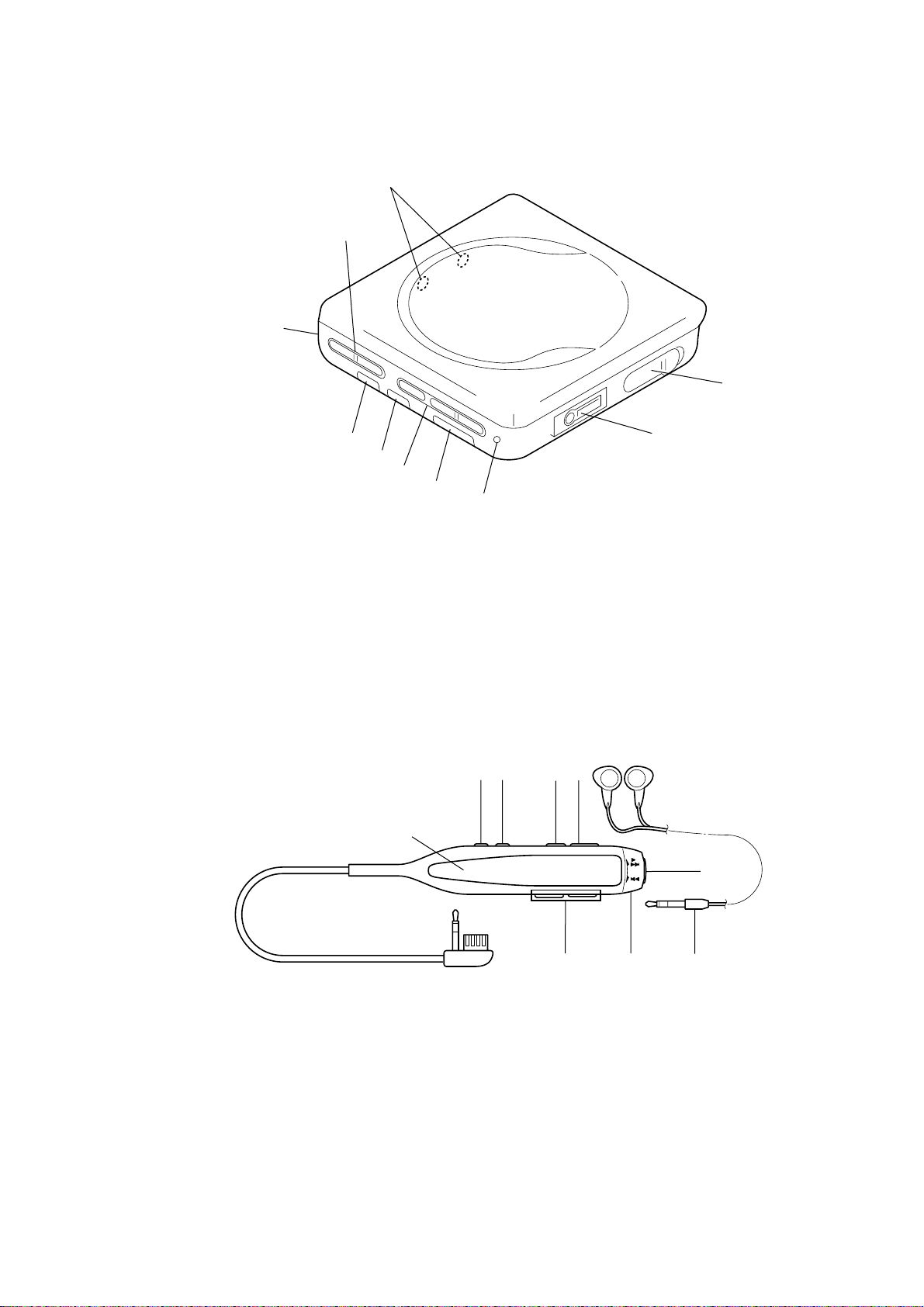

• LOCATION OF CONTROLS

– Main Unit –

5

SECTION 2

GENERAL

8

6

9

4

1 OPERATE indicator

2 HOLD switch

3 DIGITAL MEGABASS switch

4 AVLS switch

5 Battery cover

6 VOLUME +/– buttons

– Remote commander with headphone –

3

7

4

2

1

7 MD operate buttons

+/” ( FF • PLAY )

= (REW )

p (STOP)

8 External battery terminal (+/–)

9 OPEN switch

!º 2 REMOTE jack

5

6

7

8

0

9

3

1 Headphone

2 MD operate switch

”/+ (PLAY • FF)

= (REW)

3 VOL +/– buttons

4 Display window

5 DISPLAY button

6 PLAYMODE button

7 P (PAUSE) button

8 HOLD c switch

9 p (STOP) button

– 3 –

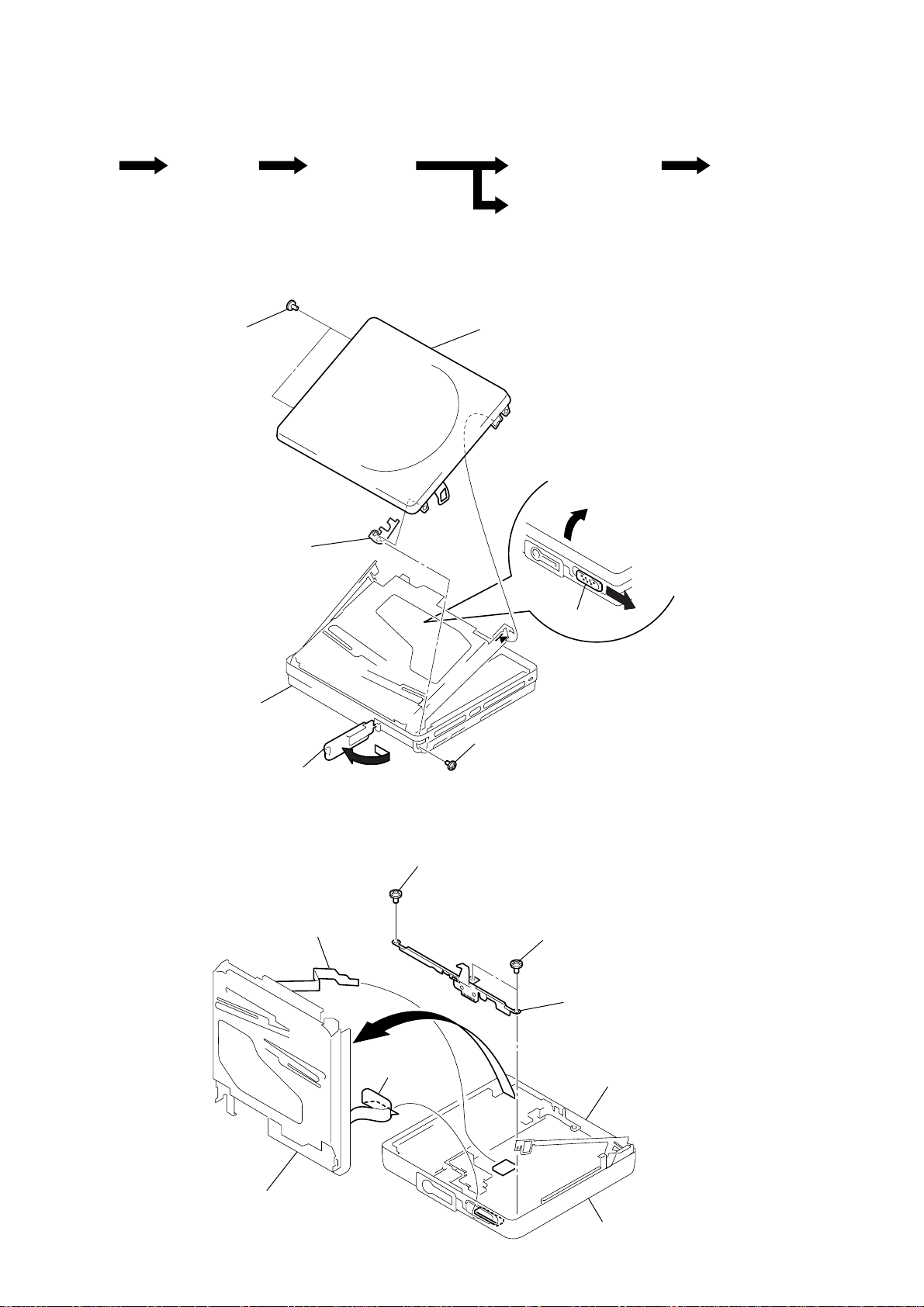

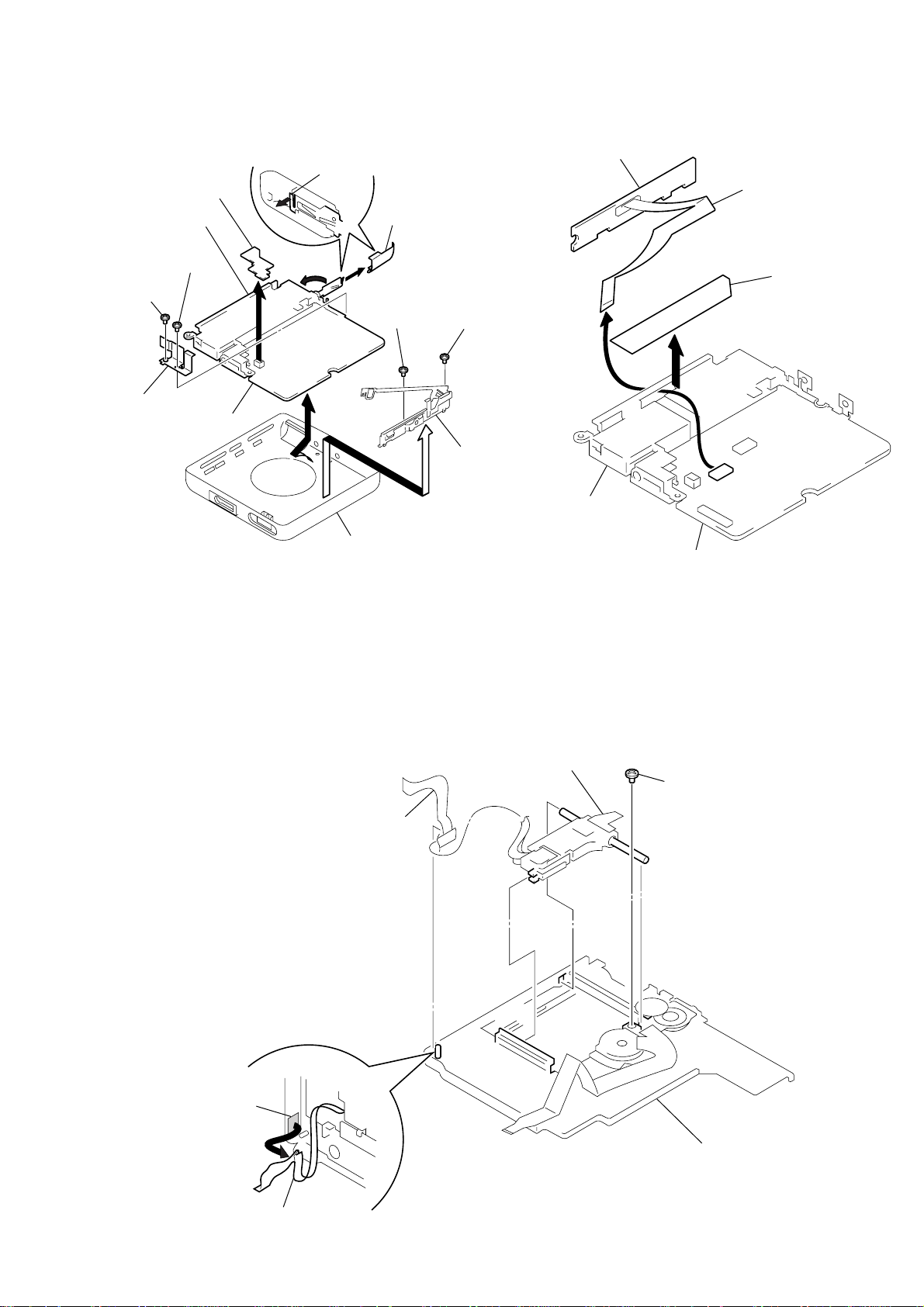

21

DISASSEMBLY

• This set can be disassembled in the order shown below.

SECTION 3

Set

Note: Follow the disassembly procedure in the numerical order given.

Upper lid assy

Mechanism deck

section

(MT-MZE55-150)

UPPER LID ASSY

5

two screws

(M1.4

×

1.6)

6

fulcrum plate (L)

assy

Optical pick-up section

7

upper lid assy

2

SW boardMain Board, Audio board

main section

3

lid

(battery case)

MECHANISM DECK SECTION (MT-MZE55-150)

3

flexible board

(CN551)

4

flexible board

(CN501)

1

screw

(B1.4

screw (M1.4 × 1.3)

4

×

3)

1

knob (open)

1

two screws

(B1.4

2

×

2.3)

Open slider assy

main board

5

mechanism deck section

main section

– 4 –

MAIN BOARD, AUDIO BOARD

y

9

audio board

*

1

battery case

4

screw

(B1.4

×

4

screw

(B1.4

5

×

bracket

2.3)

2.5)

8

main board

3

1

claw

2

lid (battery case)

6

screw

(1.4

×

2)

6

screw

(1.4

7

fulcrum plate

(R) assy

SW BOARD

3

×

3)

battery case

SW board

2

flexible board

*

2

1

caution label

*

1 Note: In removing the Audio board, raise the

connector section uprightly.

OPTICAL PICK-UP SECTION

bottom panel ass

2

flexible board

main board

*

2 Note: If the SW board or flexible board is removed,

the caution label (4-213-092-01) on the flexible board will be defaced or deformed, and

replace it with a new label.

4

optical pick-up

section

3

screw

(M1.4

×

2.5)

adhesive sheet

1

flexible board

chassis assy

– 5 –

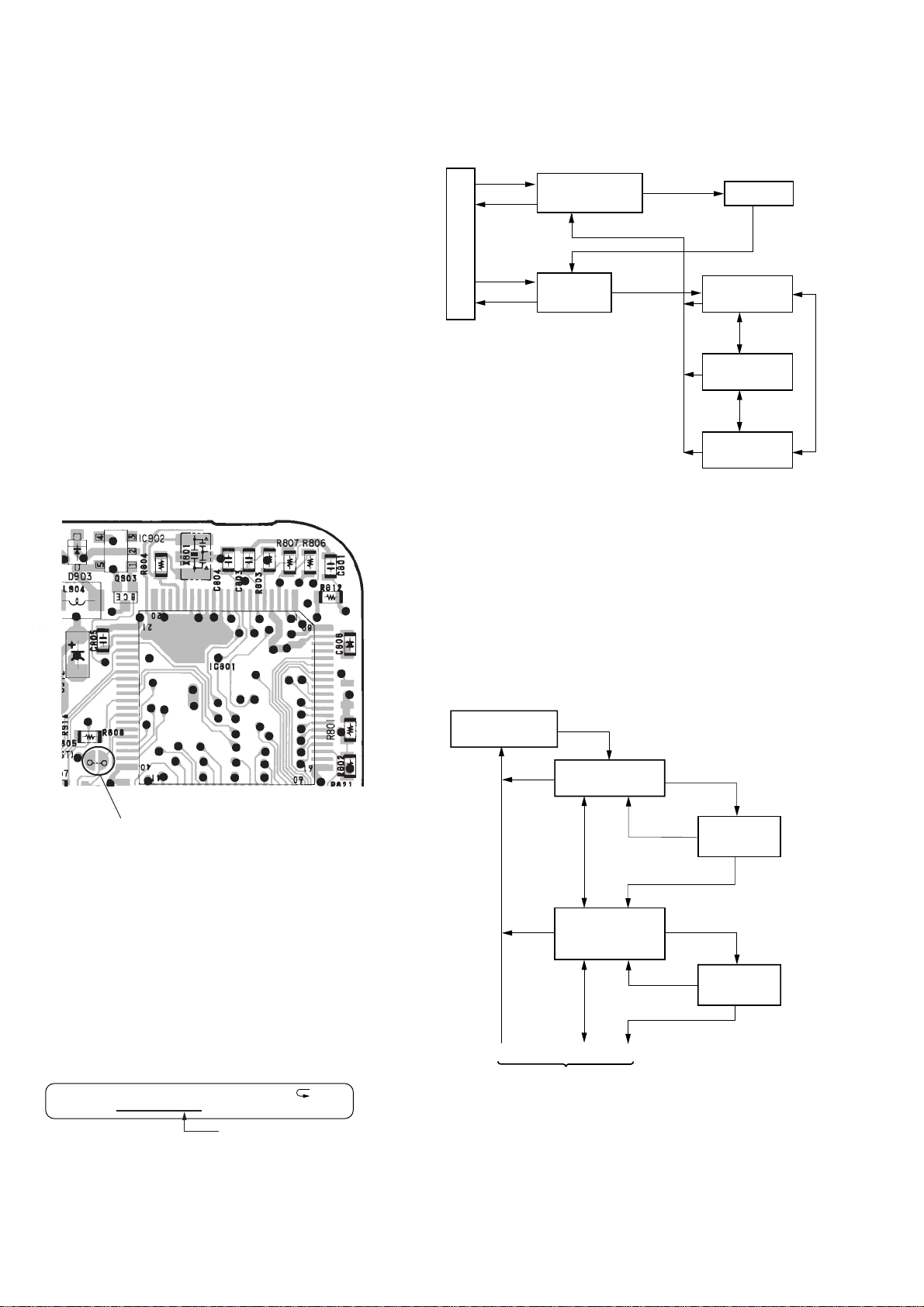

SECTION 4

TEST MODE

Outline

• In this set, overall adjustment mode is made available by entering test mode to perform automatic adjustment of CD and MO.

In the overall adjustment mode, the disc is determined whether

it is CD or MO and adjustments are performed in sequence. If a

fault is found, the location of the fault is displayed. Also, in

servo mode, each adjustment can be automatically made.

• Operation in the test mode is performed with the remote commander. A k ey ha ving no particular description in the te xt, indicates a remote commander key.

Setting the Test Mode

To enter the test mode, two methods are available :

1. Entering method with key input.

Turn on the HOLD switch on the set. While pressing the p

key on the set, press the following remote commander keys in

the following order :

”/+ n ”/+ n = n = n ”/+ n = n

”/+ n = n P n P

2. Entering method by shorting the test point

Solder bridge the test point TAP805 (TEST) on the MAIN

board (connect IC801 pin #£ to GND), and turn on the power.

– MAIN BOARD (Conductor side) –

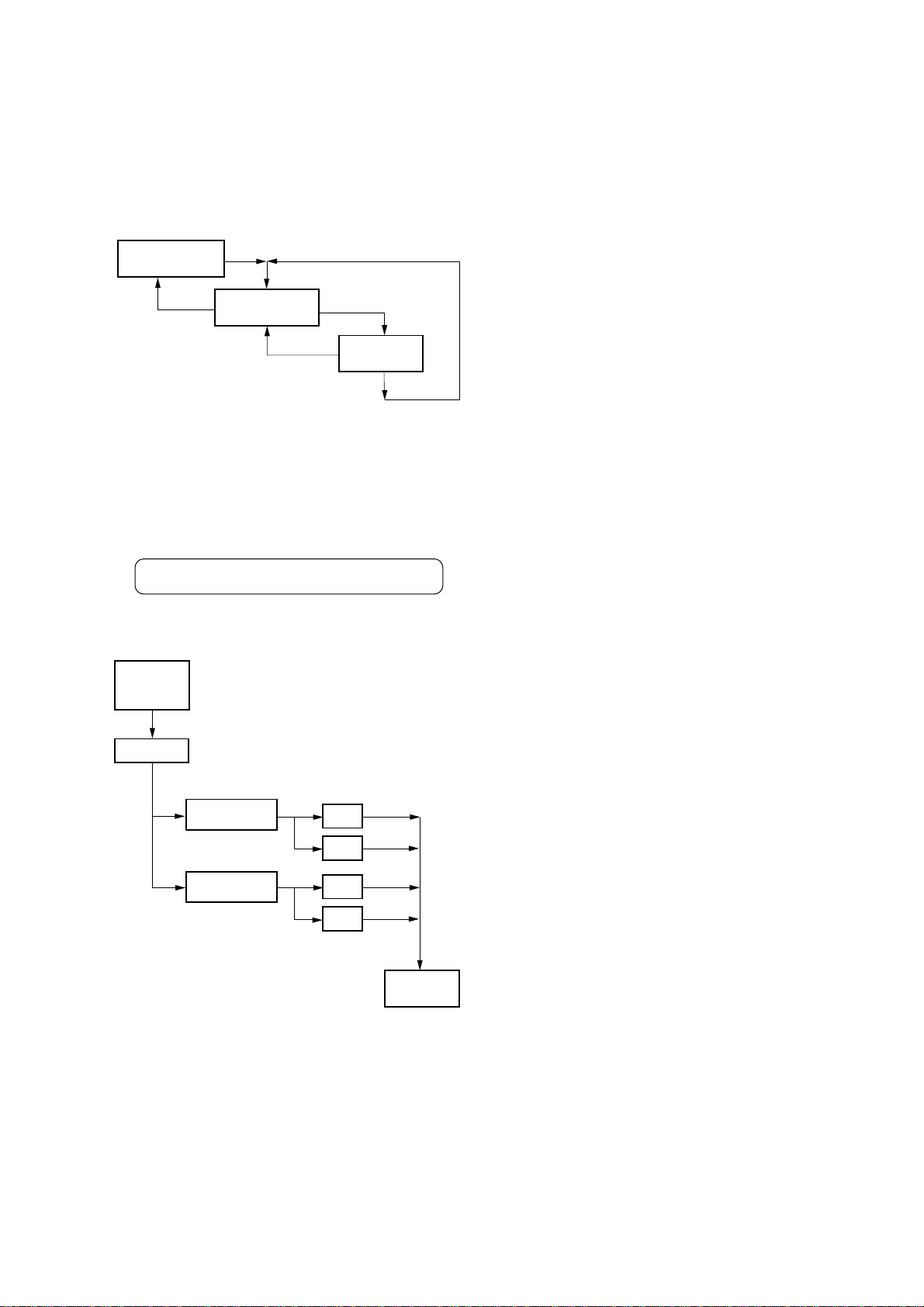

Configuration of Test Mode

The test mode has the configuration given below.

VOL

+ key

p

key

VOL

– key

p

key

is set

Display when test mode

Displays of the LCD on the remote commander

are shown in parenthesis.

Overall

adjustment

mode (044 Auto?)

p

key

Adjustment

mode

(044 Manu?)

”/+

”

/

+

key

(044 Start?)

p

key

key

Servo mode

0 0 0

VOL

+/– keys

Audio mode

1 0 0

VOL

+/– keys

Power mode

3 0 0

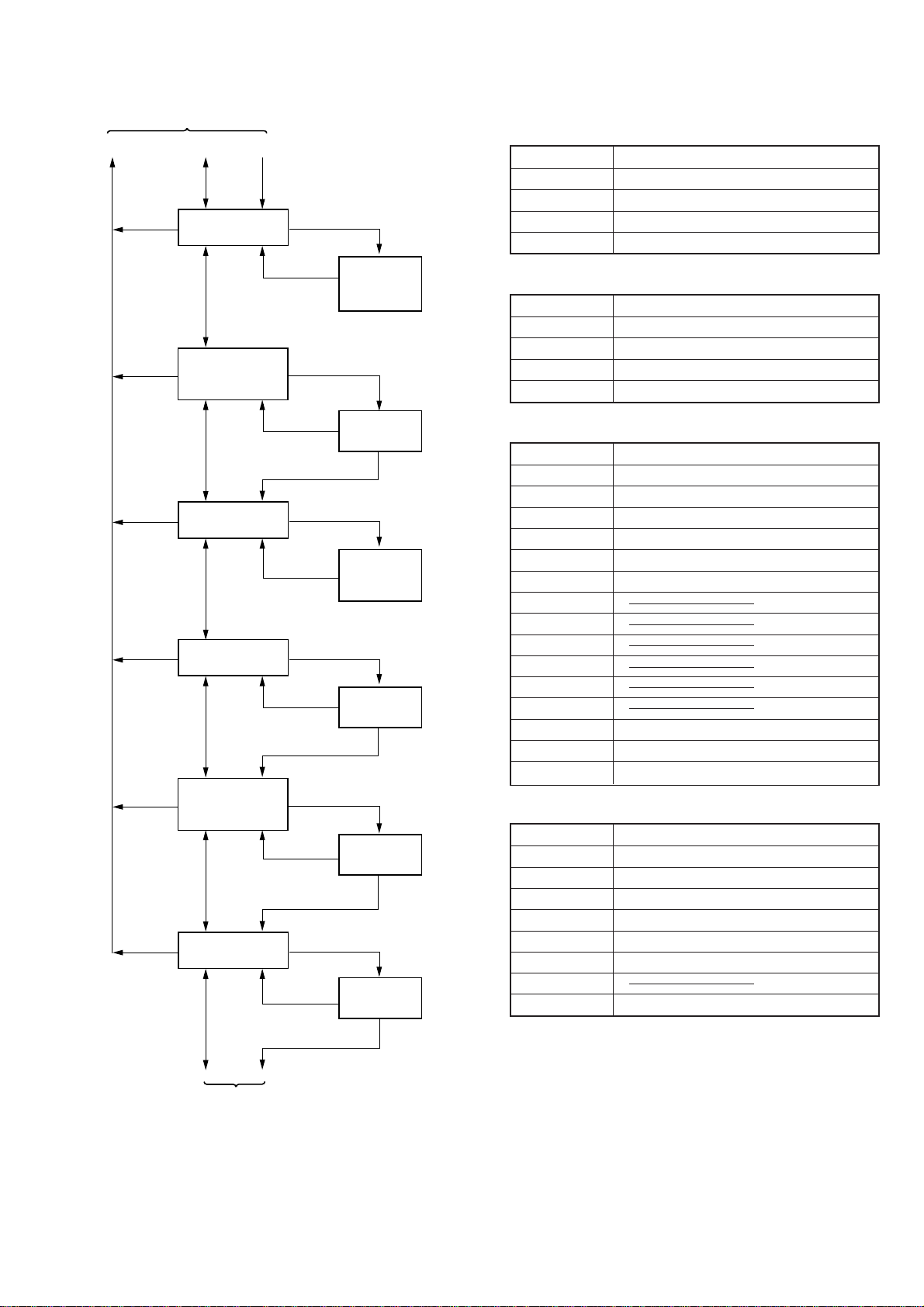

Servo Mode

• Set the test mode, press the VOL – key and use the ”/+ key

to set the servo mode.

• When the servo mode is set, use the +/” key and the =

key on the set to move the optical pick-up to the outer circumference and to the inner circumference respectively.

• When entering another mode, refer to the configuration of test

mode.

VOL +/– keys

1. Structure of Servo Mode

Servo mode

0 0 0

p

Test mode

Short : Test mode

()

Open: Normal mode

”/+

Offset adjustment

key

VOL

key

0 1 0

+/– keys

p

key

Releasing the Test Mode

A test mode releasing method varies depending on the test mode

setting method.

1. When test mode was entered with key input, turn off the power .

p

key

Laser power

adjustment

0 2 0

2. When test mode was entered by shorting the test point, turn

off the power and open the solder bridge of TAP805 (TEST

MODE) on the MAIN board.

VOL

+/– keys

p

Operation of Setting on Test Mode

When the test mode is set, the LCD displays the following :

100 V1. 000

ROM version display

LCD on remote commander

SHUF

• The cycle - the above ROM version display n All lit n All

1

(See page 7.)

23

*

1 Repeatedly press ”/+ key

to change the mode.

(Refer to the following list

for a description of each

mode.)

off - is repeated.

• When the PLAYMODE key is pressed and hold down, the dis-

play at that time is held so that display can be checked.

key

”/+

”/+

key

011

key

021

to

*

1

”/+

to

*

1

014

024

”/+

key

key

– 6 –

(See page 6.)

1

p

key

p

key

p

key

p

key

p

key

p

key

23

MO adjustment

0 3 0

p

VOL

+/– keys

Low reflection

CD adjustment

0 4 0

p

VOL

+/– keys

CD adjustment

0 5 0

p

VOL

+/– keys

Sled movement

0 6 0

p

VOL

+/– keys

Automatic

adjustment

0 7 0

p

VOL

+/– keys

NV relation

0 9 0

p

VOL

+/– keys

key

key

key

key

key

key

”/+

”/+

”/+

”/+

”/+

”/+

key

031

to

03a to 03f

*

1

key

041

to

1

*

key

to

051

05a to 05f

*

1

key

061

,

1

*

key

071

to

1

*

key

to

091

*

1

039

048

”/+

059

062

”/+

074

”/+

093

”/+

key

key

key

key

2. Description of Each Mode

010 Offset adjustment

Mode Description

011 VC offset, FE offset, ABCD offset

012 Not used

013 Not used

014 Not used

020 Laser power adjustment

Mode Description

021 MO power (GRV)

022 MO power (LPIT)

023 CD power (HPIT)

024 Not used

030 MO adjustment

Mode Description

031 MO EF balance

032 MO tracking offset

033 MO ABCD gain

034 MO focus gain

035 MO tracking gain

036 MO focus bias

037

038

039

(03a)

(03b)

(03c)

(03d) Not used

(03e) Not used

(03f) Not used

040 Lower reflection CD adjustment

Mode Description

041 Lower reflection CD EF balance

042 Lower reflection CD tracking offset

043 Lower reflection CD ABCD gain

044 Lower reflection CD focus gain

045 Lower reflection CD tracking gain

046 Lower reflection CD focus bias

047

048 Not used

Retern the Offset

adjustment (

0 1 0

*

1 : Repeatedly press ”/+ key

to change the mode.

(Refer to the following list

)

for a description of each

mode.)

– 7 –

050 CD adjustment

Mode Description

051 CD EF balance

052 CD tracking offset

053 CD ABCD gain

054 CD focus gain

055 CD tracking gain

056 CD focus bias

057

058

059

(05a)

(05b)

(05c)

(05d) Not used

(05e) Not used

(05f) Nor used

060 Sled movement

Mode Description

061 Sled in

062 Sled out

Audio Mode

• Enter the test mode and press the VOL – key. Then, press the

”/+ key and the V OL + k ey in this turn to enter audio mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Audio Mode

”/+

1 1 0

p

key

key

”/+

key

3 kHz Beep sound

1 1 1

”/+

key

Audio mode

1 0 0

p

key

Audio playback test

070 Automatic adjustment

Mode Description

071 Focus search

072 Access 32

073 Not used

074 Not used

090 NV relation

Mode Description

091 NV clear

092 Power OFF

093 Function code change

Note: The parenthesizal mode numbers in table are not displayed on the

LCD of remote commander.

– 8 –

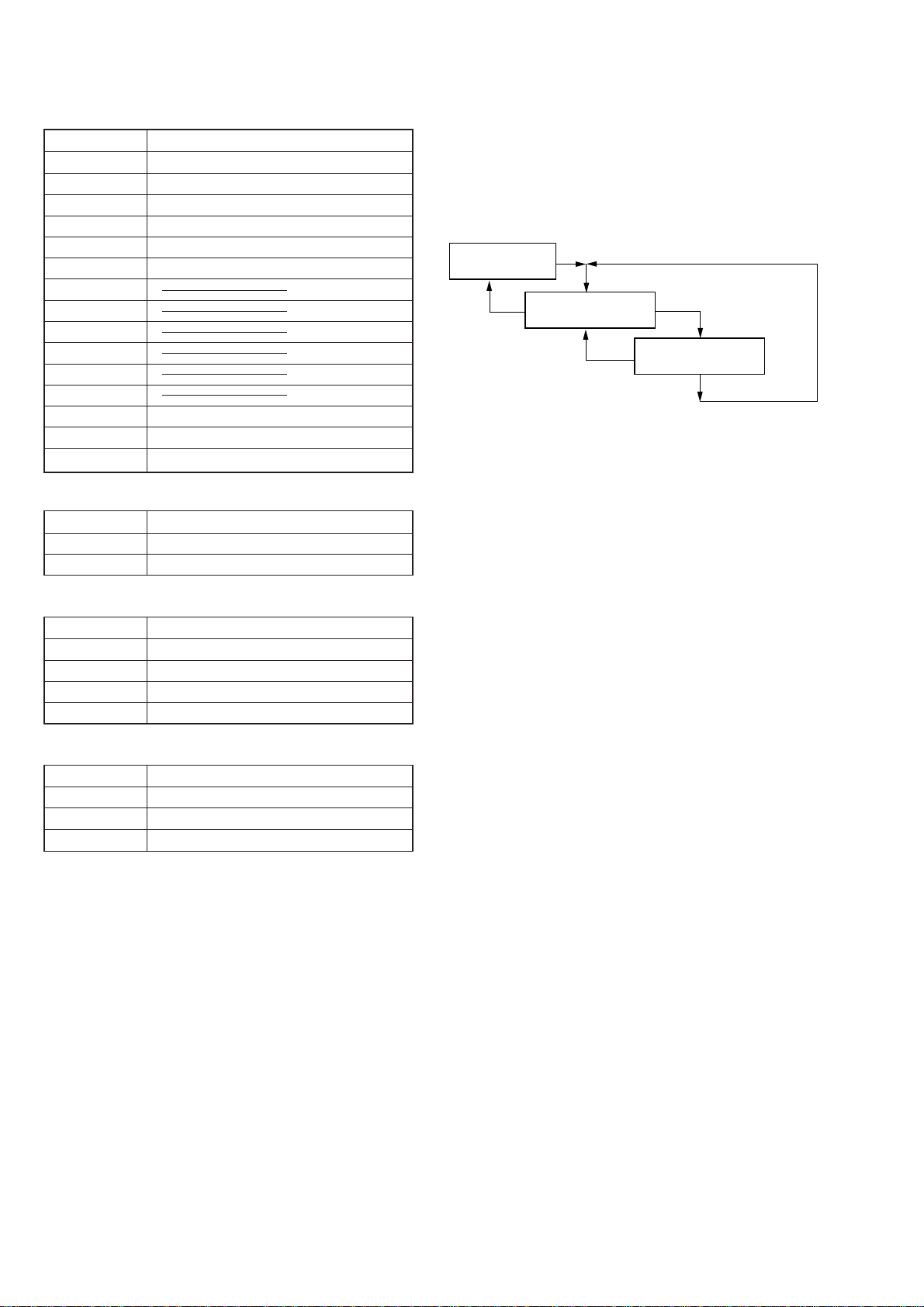

Power Mode

• Enter the test mode and press the VOL – ke y . Then, press the ”/

+ key and the VOL – key in this turn to enter power mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Power Mode

”/+

Power mode

3 0 0

p

key

key

UNREG check

31 0

p

key

”/+

Power OFF

key

3 1 1

”/+

key

Overall Adjustment Mode

• Enter the test mode and press the VOL + key to enter overall

adjustment mode.

• When entering another mode, refer to the configuration of test

mode.

• When the overall adjustment mode is entered, the LCD on the

remote commander display the following :

044 Auto?

1. Structure of Overall Adjustment Mode

Overall

adjustment

mode

Auto?

”/+

key

Start ?

”/+

key (to discriminate between CD and MO)

CD automatic

adjustment

MO automatic

adjustment

OK

NG

OK

NG

p

key

p

key

p

key

p

key

Adjustment

mode

Manu ?

– 9 –

SECTION 5

)

ELECTRICAL ADJUSTMENTS

Notes for Adjustment

• In this set, automatic adjustment of CD and MO can be performed by entering the test mode. (See page 6)

• Adjustments are performed in the overall adjustment mode. If

an item is determined as NG, the item is readjusted in servo

mode.

Adjustment Method in Overall Adjustment Mode

1. Enter the test mode and press the VOL + key to enter overall

adjustment mode.

2. Insert the CD test disc TDYS-1 (Parts No. 4-963-646-01) or

SONY MO disc (recorded) commercially available.

3. Press the ”/+ key . The disc is determined whether it is CD

or MO and each adjustment mode is set. Automatic adjustments are performed in the order of the items listed below.

• In CD Automatic adjustment Mode

No. Mode Description

1 061 Sled in

2 062 Sled out

3 071 Focus search

4 051 CD EF balance

5 053 CD ABCD gain

6 051 CD EF balance

7 052 CD tracking offset

8 054 CD focus gain

9 055 CD tracking gain

10 056 CD focus bias

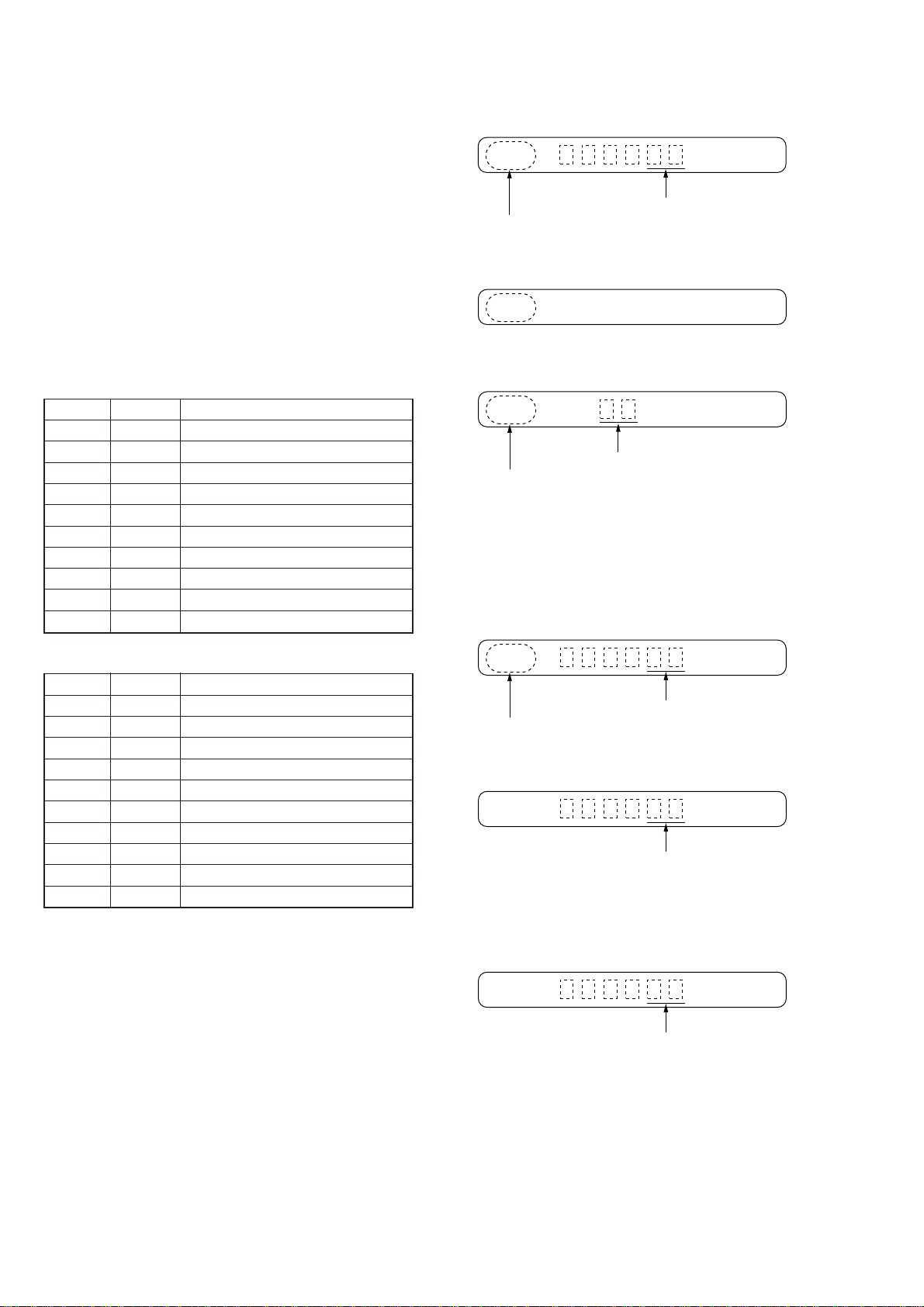

* Remote commander display during automatic adjustment

055

Adjustment value (flashing)

Mode No. under adjustment

4. If result of automatic adjustment is OK, the following display

appears.

056

5. If result of automatic adjustment is NG, the following display

appears.

052

NG mode No.

* If NG, enter servo mode to perform automatic adjustment of the

item determined as NG.

Adjustment in Servo Mode Method

1. When each adjustment mode is set according to the structure

of servo mode, the lower two digits of the mode No. and the

adjustment value written in EEPROM are displayed and lit on

the LCD on the remote commander. (See page 6)

End-OK

NG

Error code

• In MO Automatic adjustment Mode

No. Mode Description

1 061 Sled in

2 062 Sled out

3 071 Focus search

4 031 MO EF balance

5 033 MO ABCD gain

6 031 MO EF balance

7 032 MO tracking offset

8 034 MO focus gain

9 035 MO tracking gain

10 036 MO focus bias

052

Adjustment value (lit)

Mode No.

2. When the P key is pressed, the following display appears and

the automatic adjustment is performed.

052

Adjustment value (flashing)

Note: Although the VOL +/– keys can be used to change the adjust-

ment value to any value, they should not be used whenever

possible.

3. When the automatic adjustment is completed, the flashing adjustment value is lit.

052

Adjustment value (lit

– 10 –

Loading...

Loading...