Sony MZE-75 Service manual

MZ-E75

SERVICE MANUAL

Ver 1.0 1999.09

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation

SPECIFICATIONS

System

Audio playing system

Minidisc digital audio system

Laser diode properties

Material : GaAlAs

Wavelength : λ =790nm

Emission duration : continuous

Laser output : less than 44.6 µW*

* This output is the value measured at a distance of 200 mm from the

objective lens surface on the optical pick-up block with 7mm aperture.

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon Code (ACIRC)

Sampling frequency

44.1kHz

Coding

Adaptive Transform Acoustic Coding (ATRAC)

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limit

Outputs

Headphones : stereo mini-jack, maximum output level 5mW+5mW,

load impedance 16 ohm

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZE75-167

Optical Pick-up Mechanism Type ODX-1B

General

Power requirements

Nickel metal hydride rechargeable battery NH-14WM (supplied)

One LR6 (size AA) alkaline battery (not supplied)

Sony AC Power Adaptor (not supplied) connected at the DC IN

1.5V jack

Battery operation time

Batteries Playback

Ni-MH Approx.

Rechargeable battery (NH-14WM) 16 hours

One LR6 (size AA) Approx.

Sony alkaline batteries 22 hours

One LR6 (size AA) and a Approx.

Ni-MH (NH-14WM) 42 hours

Dimensions

Approx. 86 x 16.3 x 75.4 mm (w/h/d)

not including projecting parts and controls

Mass

Approx. 98 g the player only

Approx. 141 g incl. a premastered MD and a nickel

metal hydride rechargeable battery NH-14WM (N)

Supplied accessories

Battery charger (1)

Rechargeable battery (1)

Rechargeable battery carrying case (1)

Headphones with a remote control (1)

Dry battery case (1)

Carrying pouch (1)

AC plug adaptor (Tourist model) (1)

Design and specifications are subject to change without notice.

MICROFILM

PORTABLE MINIDISC PLAYER

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE...................................................... 2

2. GENERAL

Location and Function of Controls .................................... 3

3. DISASSEMBLY

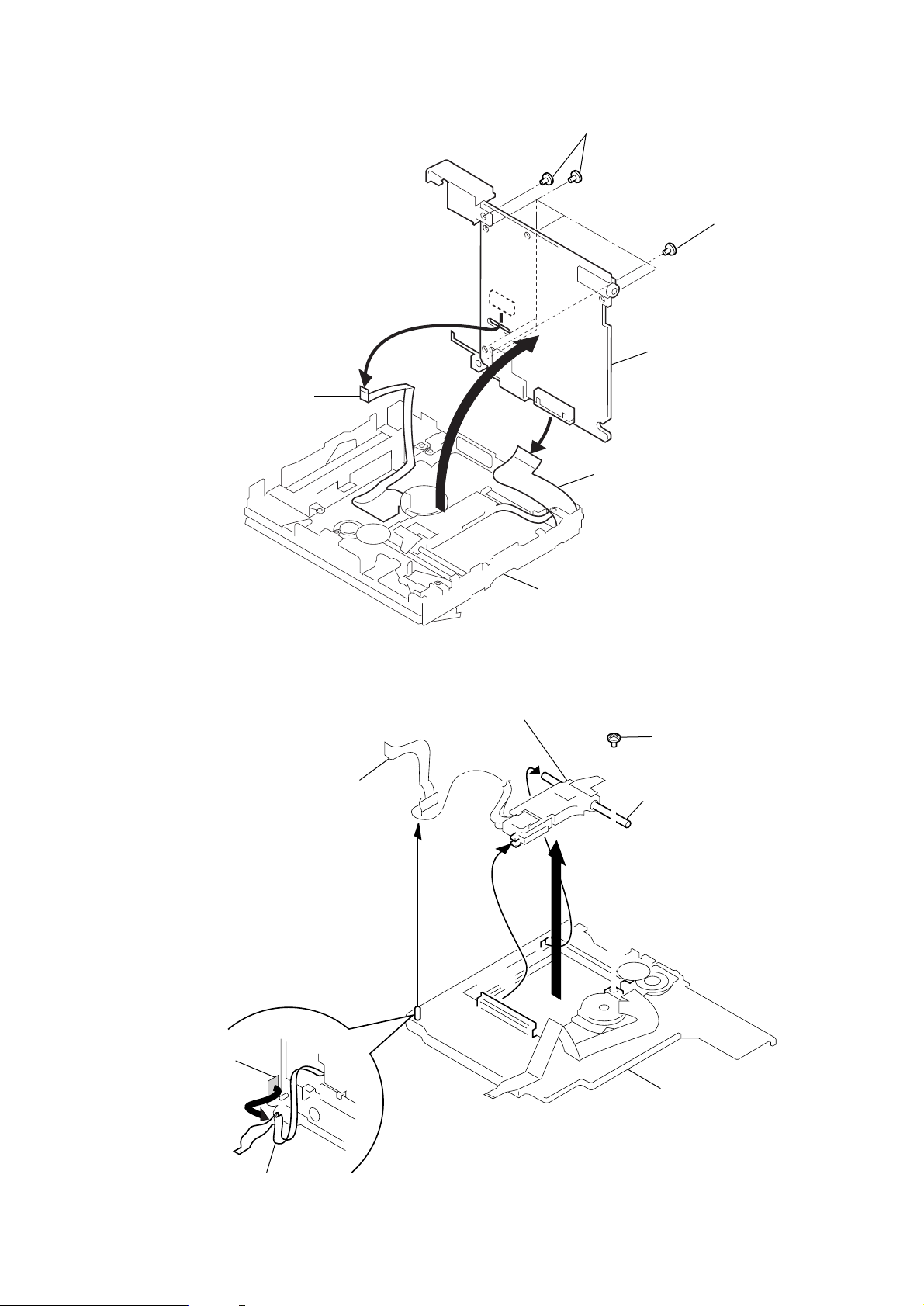

3-1. Upper Panel ASSY, “Panel ASSY, Bottom” ............... 4

3-2. Belt, Ornamental......................................................... 4

3-3. Main Board ................................................................. 5

3-4. Optical Pick-up Block ASSY ..................................... 5

4. TEST MODE.................................................................. 6

5. ELECTRICAL ADJUSTMENTS............................. 9

This Mini Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on the

bottom exterior.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

6. DIAGRAMS

6-1. Explanation of IC Terminals..................................... 10

6-2. Block Diagram.......................................................... 13

6-3. Printed Wiring Boards .............................................. 16

6-4. Schematic Diagram................................................... 19

7. EXPLODED VIEWS

7-1. Main Section............................................................. 26

7-2. Mechanism Deck Section ......................................... 27

8. ELECTRICAL PARTS LIST................................... 28

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHO WN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

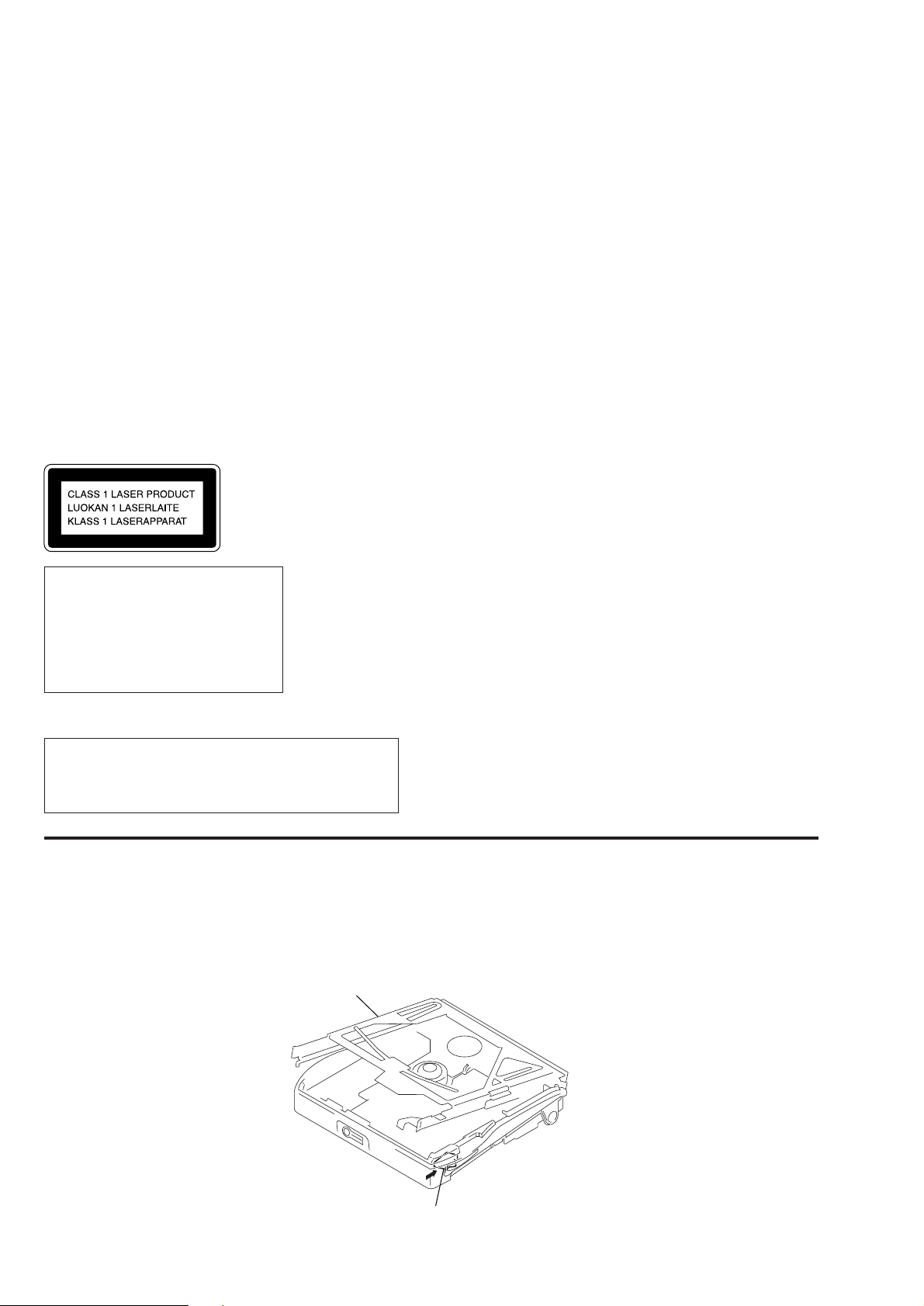

SECTION 1

SERVICING NOTE

When repairing this device with the power on, if you remove the main board, this device stops working.

In this case, you work without the device stopping by fastening the hook of the Open/Close detection switch (S801).

Mechanism deck section

* Replacement of CXD2661GA-2 (IC601) used

Open/Close detection switch (S801)

– 2 –

in this set requires a special tool. Therefore, it

cannot be replaced.

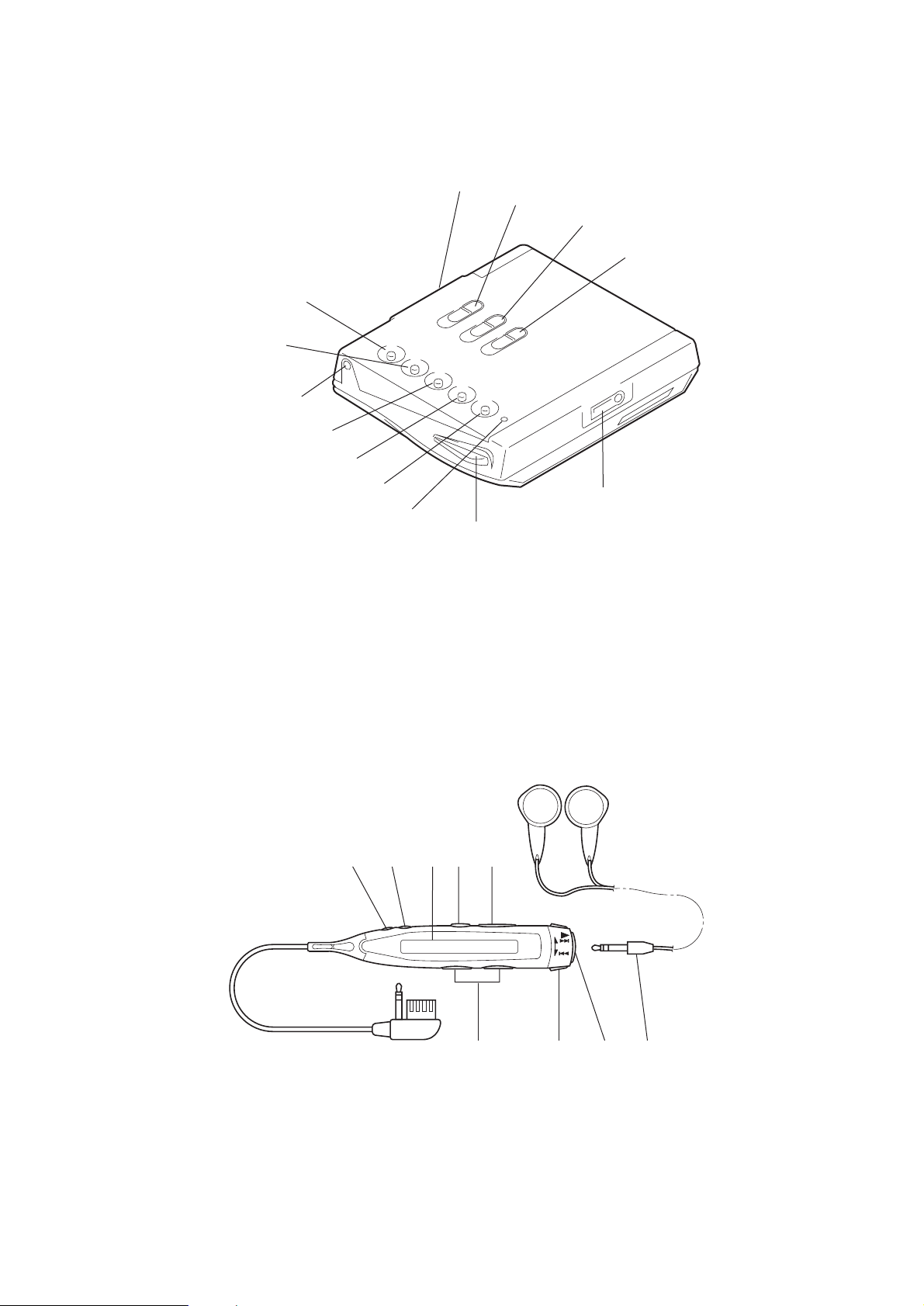

LOCATION AND FUNCTION OF CONTROLS

Main Unit

SECTION 2

GENERAL

9

8

7

6

5

4

1 i 1 jack

2 OPEN button

3 OPERATE indicator

4 > B button

5 . button

6 x button

7 i 2 jack

q;

qa`

qs

qd

1

3

2

8 VOLUME + button

9 VOLUME – button

q; External battery terminal (+/–)

qa DIGITAL SOUND PRESET switch

qs AVLS switch

qd HOLD switch

Headphones with Remote Control

1 Headphones

2 x button

3 B >/. button

4 VOL +/– button

5 DISPLAY button

5

6

7

98

4

3 2 1

6 PLAYMODE button

7 DISPLAY window

8 X button

9 HOLD . switch

– 3 –

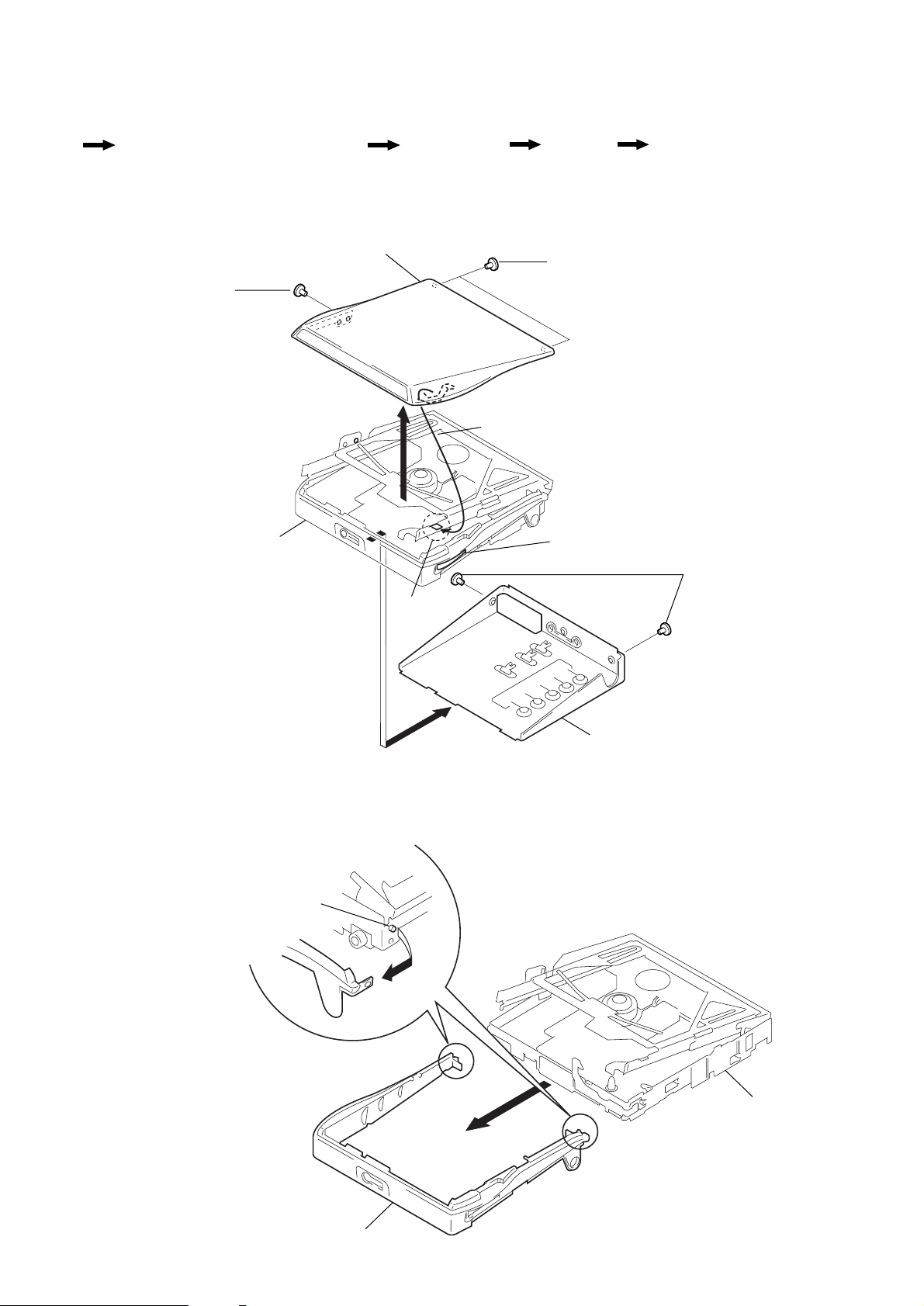

DISASSEMBLY

)

t

r

The equipment can be removed using the following procedure.

SECTION 3

set Upper panel ASSY, “Panel ASSY, bottom” Belt, Ornamental

Note : Follow the disassembly procedure in the numerical order given.

3-1. UPPER PANEL ASSY, “PANEL ASSY, BOTTOM”

Upper panel ASSY

3

Screw (1.7)

5

Main unit

4

Claw

Main board

1

Screws (1.4)

2

Press the OPEN button

Optical pick-up block ASSY

6

Screws (1.4

3-2. BELT, ORNAMENTAL

1

Move it away

from projection

Claw

7

Panel ASSY, bottom

Belt, ornamental

– 4 –

2

Main uni

3-3. MAIN BOARD

1

Screws (M1.4 toothed lock)

Main board

2

Screw (HP), step

3

CLV fexble board

3-4. OPTICAL PICK-UP BLOCK ASSY

OP flexible board

4

Optical pick-up block ASSY

4

Main unit

5

OP flexble board

3

Shaft (Main)

Screw (M1.4) precision pan

Double sided

adhesive tape

OP flexible board

Note :Put the OP flexible board to a correct

5

6

2

Chissis ASSY

1

position of c hassis ASSY .

– 5 –

SECTION 4

R818

R

SP806

4

5

S

8

V

T

T

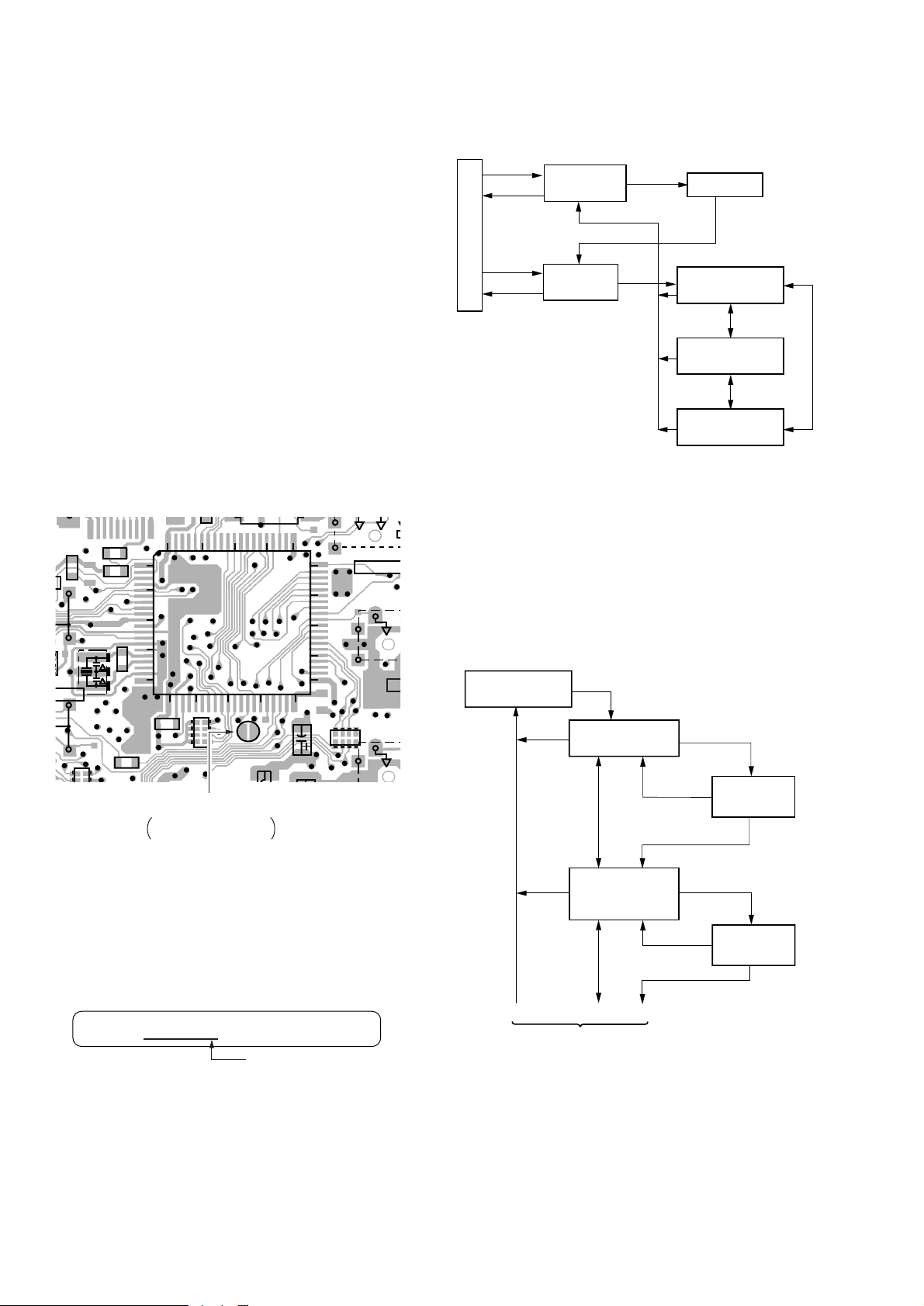

TEST MODE

Outline

• In this set, overall adjustment mode is made available by entering test mode to perform automatic adjustment of CD and MO.

In the overall adjustment mode, the disc is determined whether

it is CD or MO and adjustments are performed in sequence. If a

fault is found, the location of the fault is displayed. Also, in servo

mode, each adjustment can be automatically made.

• Operation in the test mode is performed with the Remote Commander. A key having no particular description in the text, indicates a Remote Commander key .

Setting the Test Mode

T o enter the test mode, two methods are available :

1. Entering method with key input.

Turn on the HOLD switch on the set. While holding down the x

key on the set, press the following remote commander keys in

the following order :

B/> t B/> t . t . t B/> t .t

B/> t . t X t X

2. Entering method by shorting the test point

Solder bridge the test point TAP805 (TEST) on the main board

(connect IC801 pin ed to GND), and turn on the POWER.

[MAIN BOARD] (SIDE B)

TP8061

61

356540

TP852

3

C565

SP805

07

UME+

R807

X801

SP804

52

R802

R801

R808

10

15

R804

20

70

75

1

5

IC801

RB801

30

TAP805

(TEST)

218025

C805

Test mode

Short : Test mode

Open : Normal mode

Releasing the Test Mode

1. When test mode was entered with key input, turn off the POWER.

2. When test mode was entered by shorting the test point, turn off

the POWER and open the solder bridge of TAP805 (TEST

MODE) on the main board.

Operation of Setting on Test Mode

When the test mode is set, the LCD displays the following :

F

100V1. 000

LCD on remote commander

ROM version display

• The cycle - the above ROM version display t All lit t All off

- is repeated.

(The ROM version is constantly displayed.)

• When the PLAY MODE key is pressed and hold down, the display at that time is held so that display can be checked.

60

55

TP811

50

45

41

RB802

SHUF

DIGITAL S

2

LIMIT

Configuration of Test Mode

The test mode has the configuration given below.

VOL

+ key

x key

Overall

adjustment

mode (Auto?)

VOL

– key

x key

Display when test mode

is set

Adjustment

mode

(Manu ?)

Displays of the LCD on the remote commander

are shown in parentheses.

x key

B/>

key

B/>

key

(044 Start ?)

x key

Servo mode

0 0 0

Audio mode

1 0 0

Power mode

3 0 0

+, – keys

+, – keys

VOL +, – keys

Servo Mode

• Set the test mode, press the VOLUME – key and use the B/>

key to set the servo mode.

• When the servo mode is set, use the B/> key and the .

key to move the optical pick-up to the outer circumference and

to the inner circumference respectively.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Servo Mode

S

A

Servo mode

0 0 0

x key

x key

1

B/> key

Offset adjustment

0 1 0

VOL

+, – keys

Laser power

adjustment

VOL

+, – keys

23

(See page 7.)

B/> key

011 to 013

x key

*1

B/> key

0 2 0

021 to 023

x key

*1

*1 Repeatedly press B/> key

to change the mode.

(Refer to the following list for

a description of each mode.)

B/>

key

B/>

key

– 6 –

(See page 6.)

1

x key

x key

x key

x key

23

MO adjustment

0 3 0

VOL

+, – keys

Low reflection

CD adjustment

0 4 0

VOL

+, – keys

CD adjustment

0 5 0

VOL

+, – keys

Sled movement

0 6 0

x key

x key

x key

B/> key

031 to 039,

03a to 03c

B/> key

041 to 047

B/> key

051 to 059,

B/> key

*1

B/> key

*1

B/> key

05a to 05c

*1

B/> key

2. Description of Each Mode

010 Offset adjustment

Mode Description

011 VC offset, FE offset, ABCD offset

012 Not used

013 Not used

020 Laser power adjustment

Mode Description

021 MO power (GRV)

022 MO power (LPIT)

023 CD power (HPIT)

030 MO adjustment

Mode Description

031 MO EF balance

032 MO EF gain

033 MO ABCD gain

034 MO focus gain

035 MO tracking gain

036 MO RF gain

037 ––––––––––––

038 ––––––––––––

039 ––––––––––––

(03a) ––––––––––––

(03b) ––––––––––––

(03c) ––––––––––––

x key

x key

VOL

+, – keys

Automatic

adjustment

0 7 0

VOL

+, – keys

NV relation

0 9 0

VOL

+, – keys

Retern the Offset

adjustment (0 1 0)

x key

x key

x key

061 , 062

*1

B/> key

B/> key

071 to 074

*1

B/> key

B/> key

091 to 094

*1

B/> key

*1 : Repeatedly press B/> key

to change the mode.

(Refer to the following list

for a description of each

mode.)

040 Lower reflection CD adjustment

Mode Description

041 Lower reflection CD EF balance

042 Lower reflection CD tracking offset

043 Lower reflection CD ABCD gain

044 Lower reflection CD focus gain

045 Lower reflection CD tracking gain

046 Lower reflection CD focus bias

047 ––––––––––––

050 CD adjustment

Mode Description

051 CD EF balance

052 CD tracking offset

053 CD ABCD gain

054 CD focus gain

055 CD tracking gain

056 CD focus bias

057 ––––––––––––

058 ––––––––––––

059 ––––––––––––

(05a) ––––––––––––

(05b) ––––––––––––

(05c) ––––––––––––

– 7 –

060 Sled movement

Mode Description

061 Sled in

062 Sled out

070 Automatic adjustment

Mode Description

071 Focus search

072 Access 32

090 NV relation

Mode Description

091 NV clear

092 Power OFF

093 Function code change

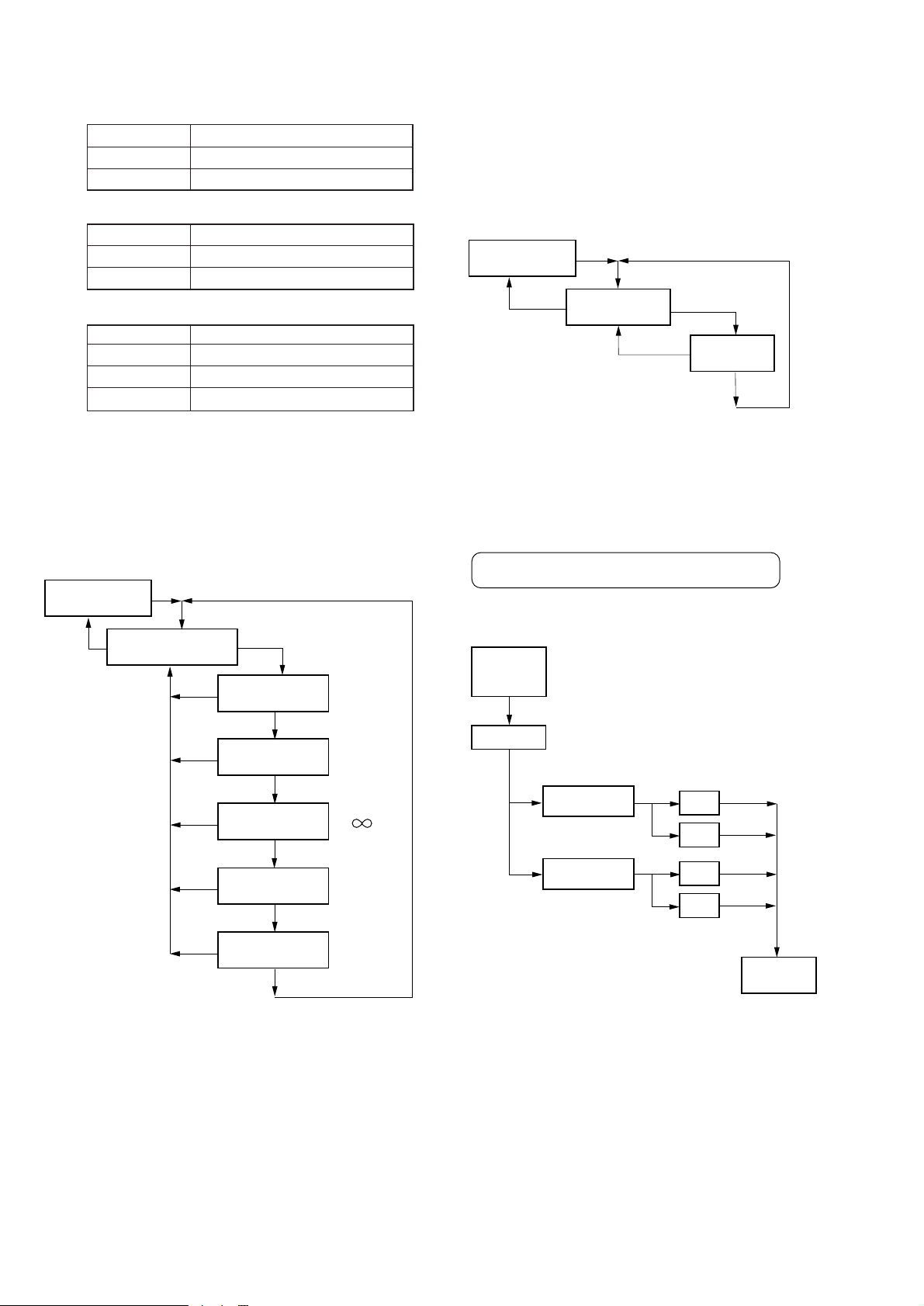

Audio Mode

• Enter the test mode and press the VOL – key. Then, press the B/

> key and the VOL + key in this turn to enter audio mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Audio Mode

Power Mode

• Enter the test mode and press the VOL – key. Then, press the B/

> key and the VOLUME – key in this turn to enter power

mode.

• When entering another mode, refer to the configuration of test

mode.

1. Structure of Power Mode

Power mode

3 0 0

x key

B/> key

UNREG check

31 0

x key

B/> key

Power OFF

3 1 1

B/>

key

Overall Adjustment Mode

• Enter the test mode and press the VOL + key to enter overall

adjustment mode.

• When entering another mode, refer to the configuration of test

mode.

• When the overall adjustment mode is entered, the LCD on the

remote commander display the following :

Audio mode

1 0 0

x key

B/> key

Audio playback test

1 1 0

x key

x key

x key

x key

x key

B/> key

Beep sound

1 1 1

B/> key

1kHz 0dB L/R

1 1 2

B/> key

Infinity Zero

1 1 3

B/> key

1kHz 0dB L

1 1 4

B/> key

1kHz 0dB R

1 1 5

B/> key

headphones

output

–12dB

–

–12dB

–12dB

• When the > B/. keys is pressed, the volume of the main

unit is maximized/minimized.

040 Auto?

1. Structure of Overall Adjustment Mode

Overall

adjustment

mode

Auto?

B/> key

Start ?

B/> key (to discriminate between CD and MO)

CD automatic

adjustment

MO automatic

adjustment

OK

NG

OK

NG

x key

x key

x key

x key

Adjustment

mode

Manu ?

– 8 –

Loading...

Loading...