Sony MZE-300 Service manual

MZ-E300

SERVICE MANUAL

Ver 1.2 2001.12

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation

SPECIFICATIONS

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 790 nm

Emission duration: continuous

Laser output: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm from

the objective lens surface on the optical pick-up block with 7 mm

aperture.

Revolutions

Approx. 700 rpm to 1,500 rpm

Error correction

ACIRC (Advanced Cross Interleave Reed Solomon Code)

Sampling frequency

44.1 kHz

Coding

ATRAC (Adaptive TRansform Acoustic Coding)

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limits

Power requirements

One LR6 (size AA) battery (not supplied)

US Model

Canadian Model

AEP Model

E Model

Chinese Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZE300-176

Optical Pick-up Mechanism Type LCX-4E

Battery operation time

Battery life (EIAJ1))

Battery Playback

LR6 (SG) Sony Alkaline dry battery

1)

Measured in accordance with the EIAJ (Electronic Industries

Association of Japan) standard (using a Sony MDW-series Mini-disc).

2)

When using a Sony LR6 (SG) “STAMINA” alkaline dry battery

(produced in Japan).

Note

The effective battery life may be shorter than that indicated above,

depending on operating conditions, the surrounding temperature, and

the battery type.

Dimensions

Approx. 83.0 x 26.7 x 76.5 mm (w/h/d) (3 3/8 x 1 1/16 x 3 1/8 in.)

(not including projecting parts and controls)

Mass

Approx. 83.0 g (3.0 oz) (the player only)

Supplied accessories

Headphones/earphones (1)

Design and specifications are subject to change without notice.

2)

Approx. 33 hours

9-873-064-13

2001L0200-1

© 2001.12

PORTABLE MINIDISC PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

MZ-E300

TABLE OF CONTENTS

SECTION 1

SERVICING NOTE

Specifications ........................................................................... 1

1. SERVICING NOTE ...................................................... 2

2. GENERAL

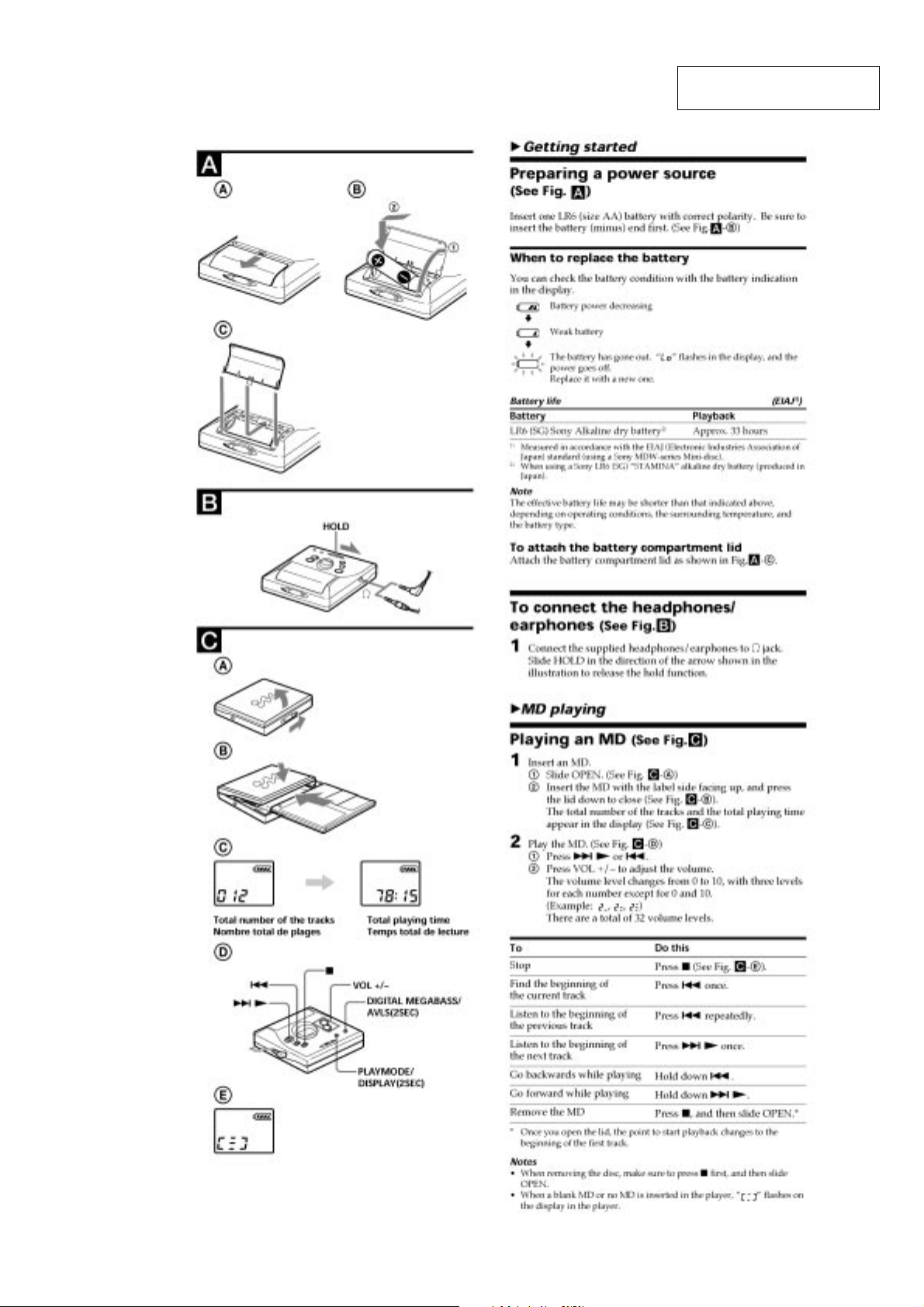

Preparing a Power Source .................................................. 3

To Connect the Headphones/Earphones ............................ 3

Playing an MD ................................................................... 3

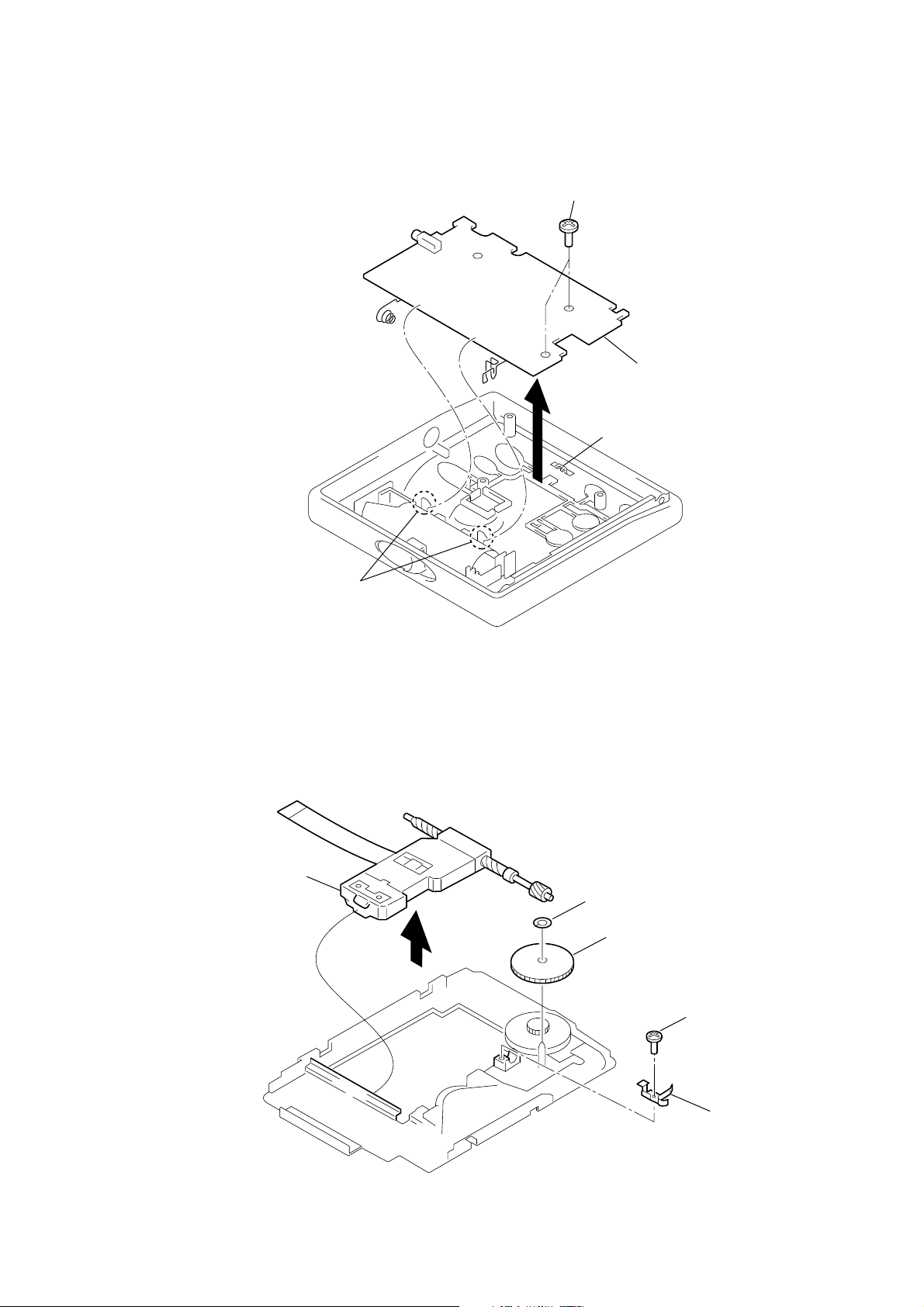

3. DISASSEMBLY

3-1. “Lid ASSY, Upper”, Holder ASSY ............................ 4

3-2. Mechanism Deck ........................................................ 4

3-3. Main Board ................................................................. 5

3-4. Optical Pick-up ASSY ................................................ 5

4. TEST MODE.................................................................. 6

5. DIAGRAMS

5-1. Explanation of IC Terminals ..................................... 13

5-2. Block Diagram .......................................................... 18

5-3. Printed Wiring Boards – Main Section (1/2) – ......... 19

5-4. Printed Wiring Boards – Main Section (2/2) – ......... 20

5-5. Schematic Diagram – Main Section (1/3) – ............. 21

5-6. Schematic Diagram – Main Section (2/3) – ............. 22

5-7. Schematic Diagram – Main Section (3/3) – ............. 23

6. EXPLODED VIEWS

6-1. Main Section ............................................................. 29

6-2. Mechanism Deck Section ......................................... 30

When repairing this device with the power on, if you remove the

main board, this device stops working.

In this case, you work without the device stopping by fastening

the hook of the Open/Close detection switch (S808).

Open/Close detection switch (S808)

Note on IC replacement

If using flux on replacing IC801 etc., clean it with alcohol or

equivalent, and after that, check carefully there are no dust or

rags in between pins.

Especially, be sure to check between pins 4 and 5.

7. ELECTRICAL PARTS LIST................................... 31

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

SECTION 2

GENERAL

MZ-E300

This section is extracted from

instruction manual.

3

MZ-E300

SECTION 3

DISASSEMBLY

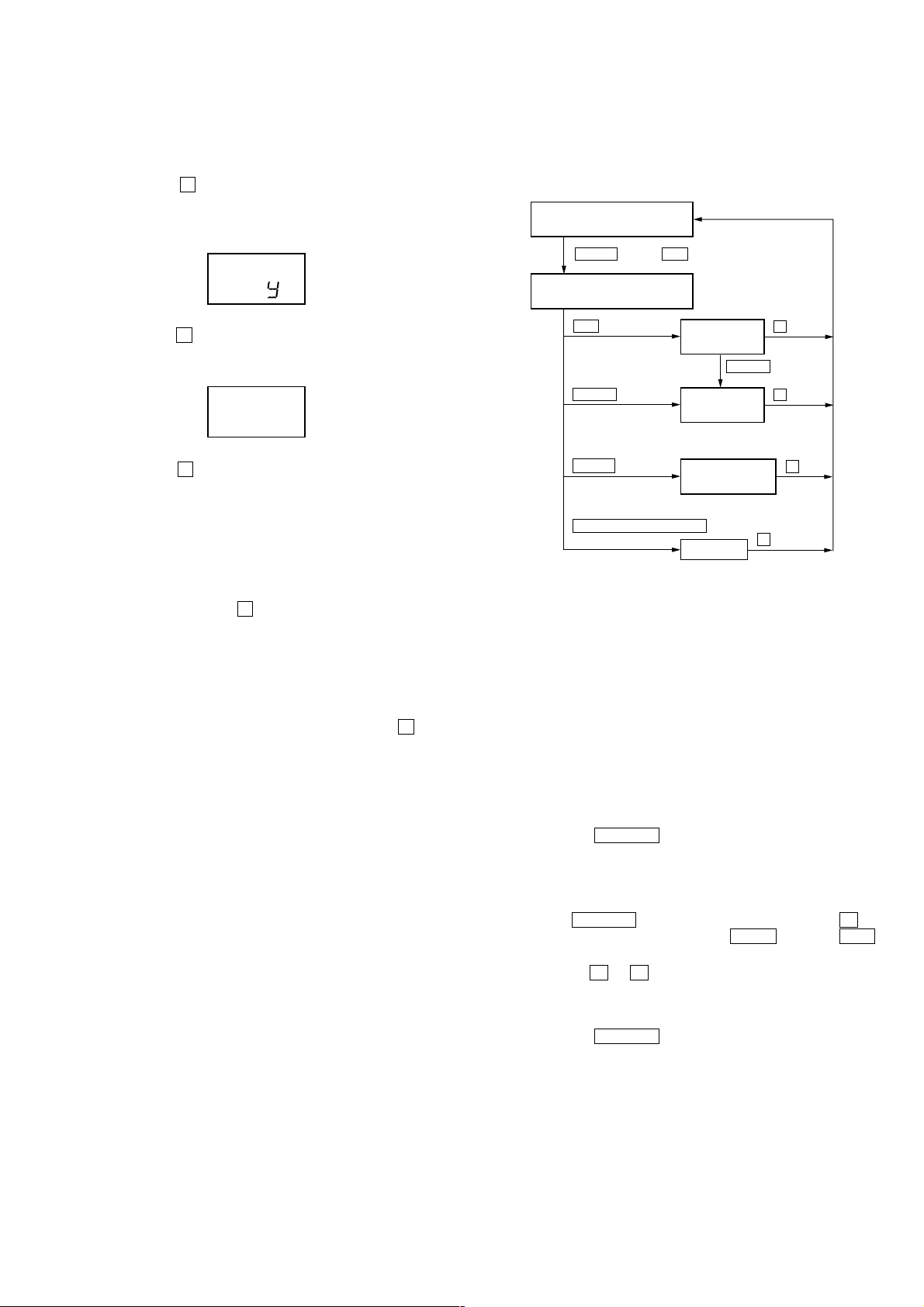

• The equipment can be removed using the following procedure.

Set

“Lid ASSY, Upper”,

Holder ASSY

Mechanism deck

Note : Follow the disassembly procedure in the numerical order given.

3-1. “LID ASSY, UPPER”, HOLDER ASSY

Note : Holder ASSY installation

1. Attach the holes on Holder ASSY to the projections on right and left sides.

2. Attach Spring (POP/L) as shown in the figure.

Holder ASSY

Main board

Optical pick-up ASSY

3

Lid ASSY , Upper

1

Screws (1.4),MI

2

Move it away

from projection

Reinforcement

Spring (POP/L)

5

3-2. MECHANISM DECK

5 Motor flexible board

7 Screws, tapping (1.7)

Holder ASSY

4

Move it away

from projection

1 Screw (MD), step

2

Case ASSY

Mechanism deck

6 OP flexible board

4

Move it away

from projection

4

Reinforcement

Case ASSY

8

3 Claw

4

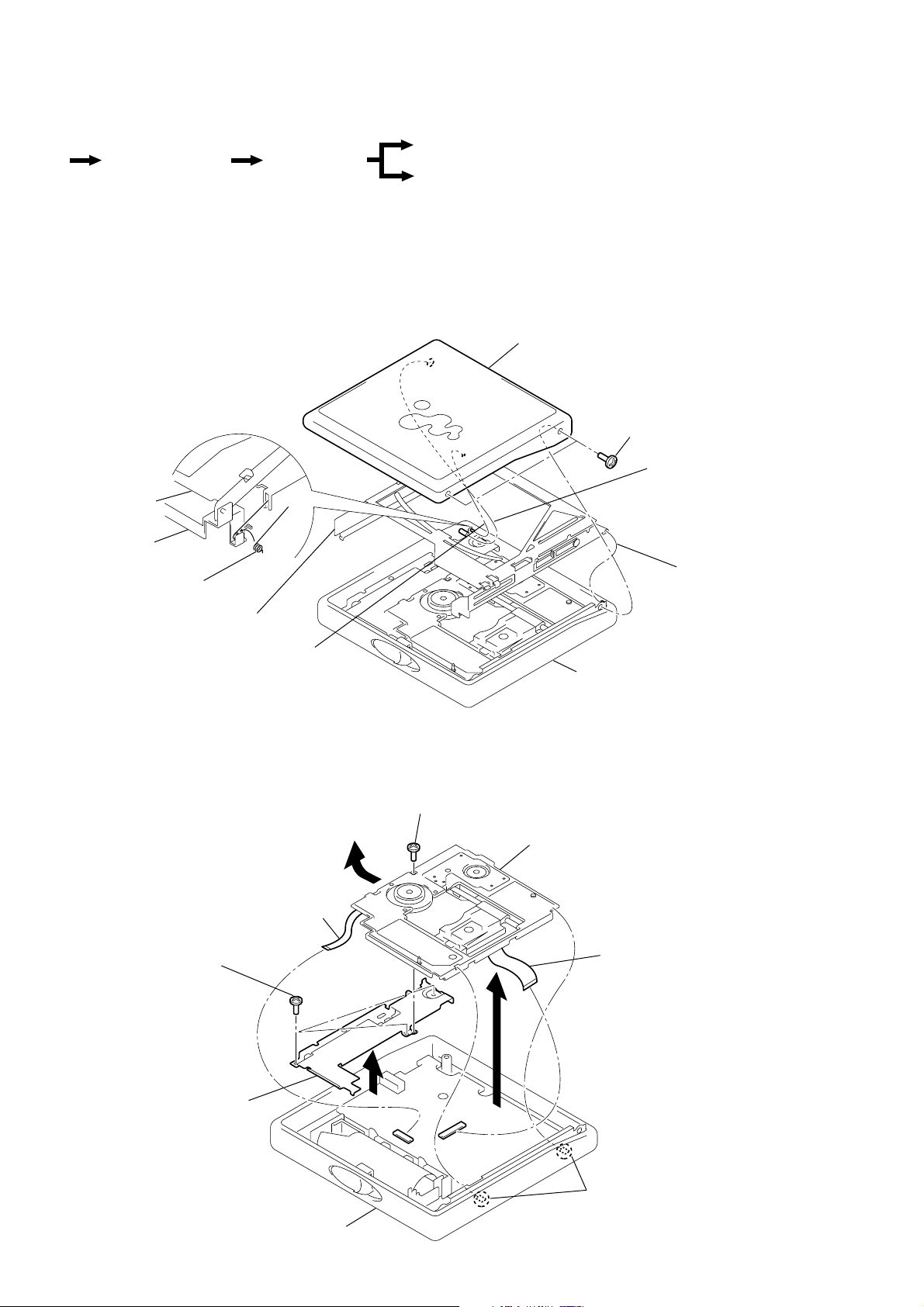

3-3. MAIN BOARD

d

t

Note : On installation of main board, adjust the position of

both switch (S809) and knob (HOLD).

MZ-E300

1 Screws, tapping (1.7)

Main boar

3-4. OPTICAL PICK-UP ASSY

Optical pick-up ASSY

(LCX-4E)

2 Claw

3

Knob (HOLD)

1

Washer

2

Gear (SA)

5

3

Screw (MI 1.4)

4

Spring, thrust deten

5

MZ-E300

8

0

IC501

SECTION 4

TEST MODE

4-1. GENERAL

• When entered in the TEST MODE, this set provides the Overall

Adjustment mode which allows CD and MO discs to be automatically adjusted. In the Overall Adjustment mode, performs

adjustments in sequence automatically, and displays the faulty

location if any fault is found. In the Manual mode, selected adjustments can be performed automatically.

• Operations in the Overall Adjustment mode can be performed

either via the main unit, or the keys of a remote control unit.

Note that this device does not include a remote control unit.

Therefore, since no connection terminals for a remote control

are provided either, a connection device must be used in order

to allow a suitable remote control unit to be connected.

Connection

Following parts are required

Remote commander: RM-MZ2N (1-418-493-71)

After RM-MZE1 applicable to 2.4V

(Not applicable to remote commanders

before RM-MZE1).

Jack: 7 poles jack for phones/remote commander (1-793-288-61)

JACK: 1-793-288-61

R_KEY

R_DATA

R_VDD

R_GND

Lead wires: 4 leads

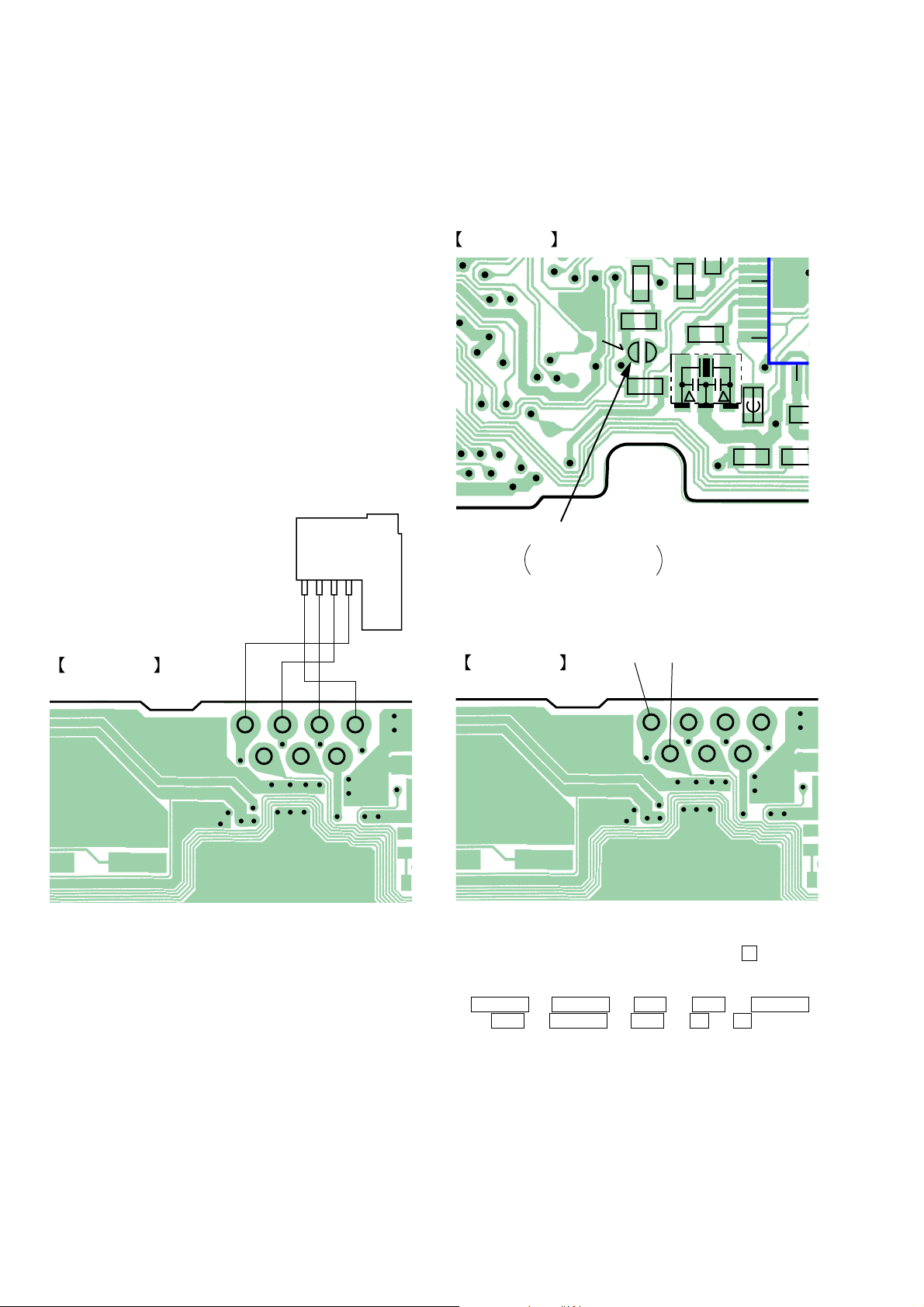

4-2. SETTING THE TEST MODE

4-2-1. How to set the TEST MODE

To set the TEST MODE, three methods are available.

1 Solder bridge and short BP801 (TEST) on the main board.

Then turn on the power.

MAIN BOARD (SIDE A)

TP809

TP816

BP801

(TEST)

TP808

C806

R907

R830

C

C810

R803

X801

15

20

FB801

C805

BP801

OPEN : Normal mode

SHORT : Test mode

21

C8

R82

MAIN BOARD

(SIDE A)

4321

12 34

TP803

TP804

TP805

TP802

TP806

TP951

TP801

2 Using a pair of tweezers or similar tool short-circuit TP804 and

TP805 on the main board and turn on the power.

MAIN BOARD

TP804 TP805

(SIDE A)

TP803

TP802

TP804

TP805

TP806

3 In the normal mode, operate the keys on the set and those on the

remote control as specified below:

Turn on HOLD switch on the set. Holding down x (STOP)

key on the set, press the keys on the remote control in the

following sequence:

> N t > N t . t . t > N

t . t > N t . t X t X

TP801

TP951

6

MZ-E300

Ver 1.2 2001.12

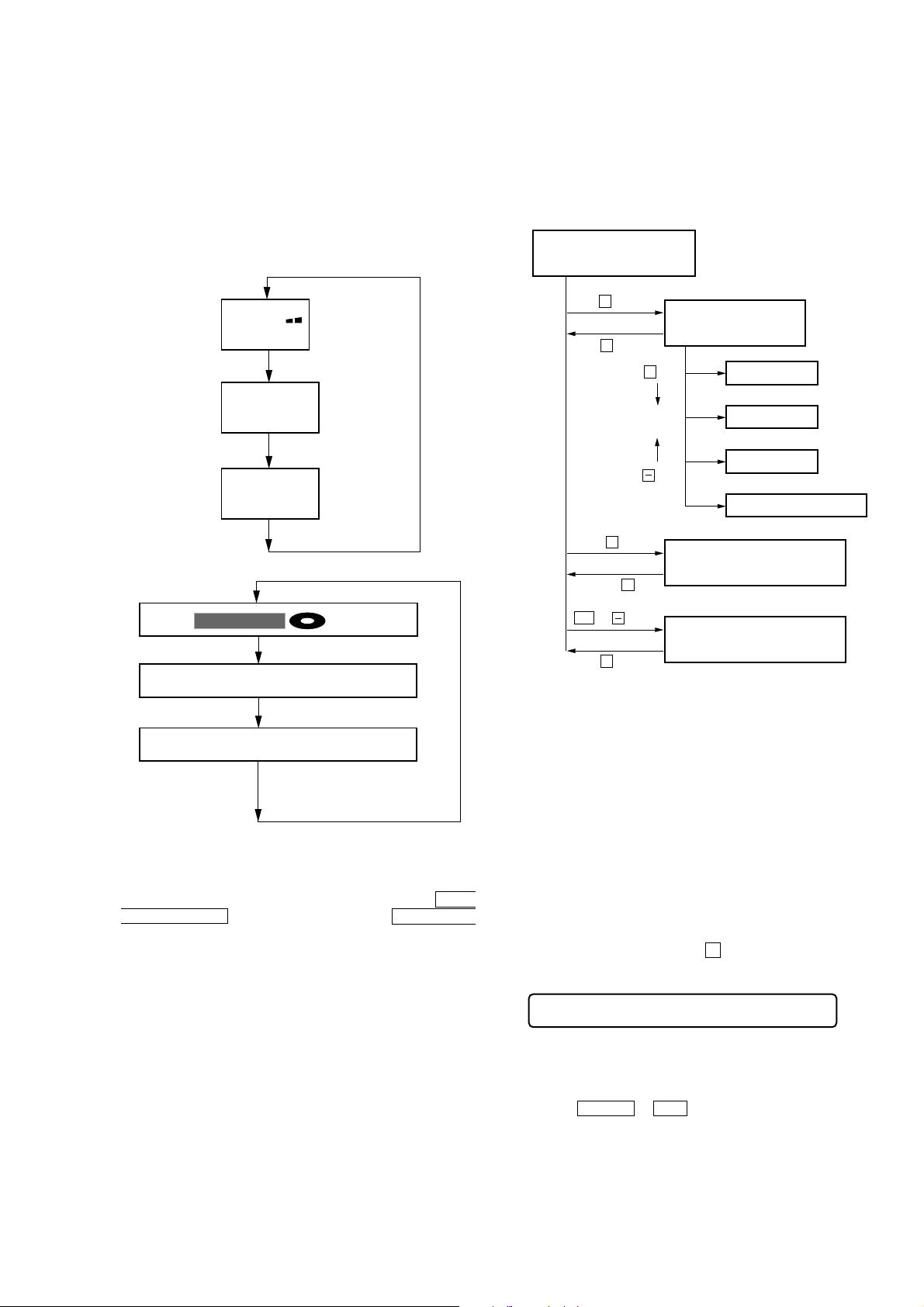

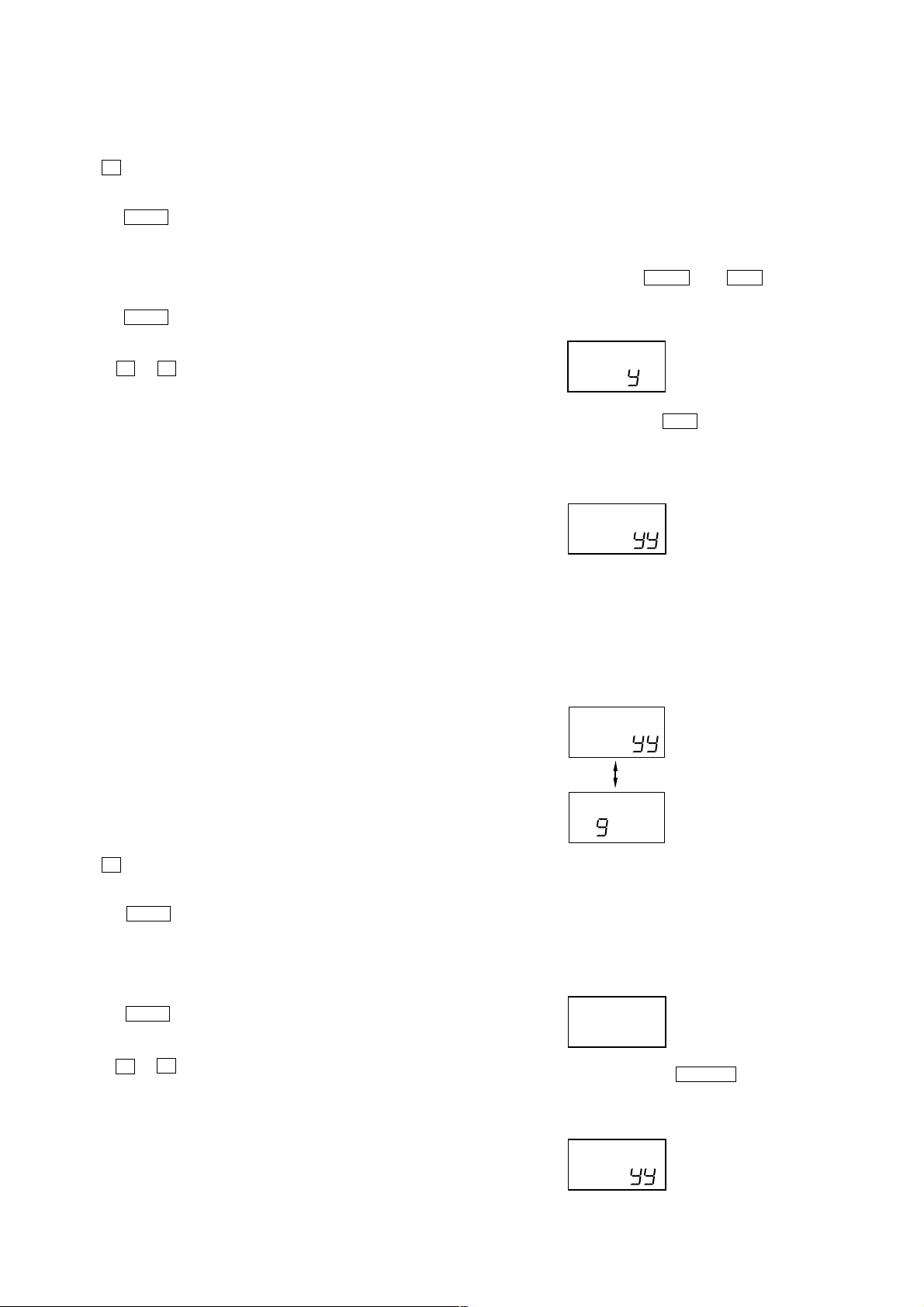

4-2-2. Operations when the TEST MODE is set

When the TEST MODE is entered, the system switches to the display check mode within the TEST MODE. From this mode, the

other Test modes can be accessed.

When the TEST MODE is set, the LCD repeats a cycle of the following displays:

Main unit LCD

F

1SHUFF

AVLS BASS

888:88

130

u

All on

All off

Microprocessor

version

display

Remote control LCD

4-3. TEST MODE STRUCTURE

* Manual mode operation can only be performed via the remote

control unit.

Use the connection tool to connect the remote control unit. The

display of the main unit shows “Adj”.

Test Mode

(Display Check Mode)

+

key

Manual Mode

x

key

Press and hold

x

down

key

x

(Remote control only)

+

key

key

Display segment check mode

keyRelease

Servo Mode

Audio Mode

Power Mode

OP Alignment Mode

(Main unit only)

888

1SHUFF PGM

SOUND 1 2 BASS 1 2

u

All on

All off

F

008 V1.300

Microprocessor

version

display

The remote control display varies with the type of

remote control unit used.

(Example shown: RM-MC10L)

• The current display is retained as long as either the PLAY

MODE/DISPLAY key on the main unit or the PLAY MODE

key on the remote control unit is pressed and held.

4-2-3. How to release the TEST MODE

When method 1 was used:

Turn off the power and open the solder bridge on BP801 on the

main board.

Note: The solder should be removed clean. The remaining solder

may make a short with the chassis and other part.

When method 2 or 3 was used:

Turn off the power.

Note: If electrical adjustment (see page 8) has not been finished

completely, always start in the test mode. (The set cannot

start in normal mode)

.

or

key

Overall Adjustment Mode

x

key

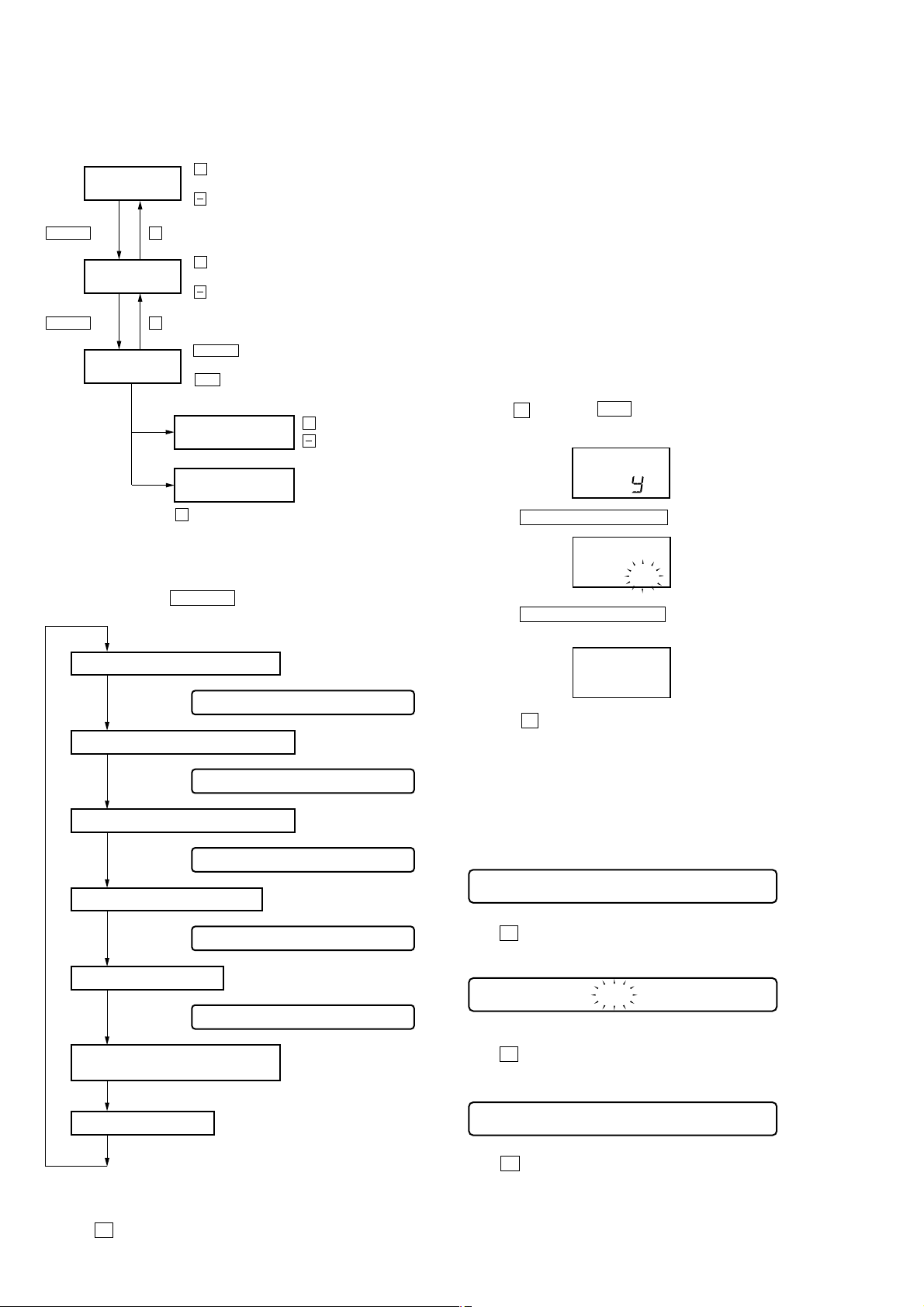

4-4. MANUAL MODE

4-4-1. Outline of the function

The Manual mode is designed to perform adjustments and

operational checks on the set’s operation according to each

individual function.

Usually, no adjustments are made in this mode.

However, the Manual mode is used to clear the memory before

performing automatic adjustments in the Overall Adjustment mode.

* Manual mode operation can only be performed via the remote

control unit.

Use the connection tool to connect the remote control unit. The

display of the main unit shows “Adj”.

4-4-2. How to set the Manual mode

1. Set the TEST MODE and press + key to set the Manual mode.

Remote control LCD display

000 AAAS CC

2. When the test mode display shows “100”, “200”, “300”, “500”,

“600”, “700”, “800”, or “900”, the optical pickup can be moved

inside and outside of the SLED perimeter by continuously pressing the ( > N or . keys on the main unit.

7

MZ-E300

3. Each test item is assigned with a three-digit item number. The

100th place is a major item, 10th place is a middle item, and unit

place is a minor item.

+

key : 100th place of mode number

increase

key : 100th place of mode number

decrease

keykey

+

key : 10th place of mode number

increase

key : 10th place of mode number

decrease

key

key : Unit place of mode number

> N

increase

.

key : Unit place of mode number

decrease

+

Change Adjustment

Value

Write Adjustment

Value

X

key : When adjusted value is changed :

Adjusted value is written.

When adjusted value is not changed :

That item is adjusted automatically.

key : Up

key : Down

> N

> N

Change Major

Item

x

Change Middle

Item

key

Change Minor

Item

x

4. During each test mode, the display is changed from one to

another each time DISPLAY key is pressed (Remote control

only).

4-5. OVERALL ADJUSTMENT MODE

4-5-1. Outline of the function

This mode is designed to adjust the servo system automatically by

going through all the adjustment items.

Usually, this mode is used to perform automatic adjustments when

servicing the set.

4-6. NV RESET

Power: Connect the battery terminals to a stable DC 1.5V power

supply, or insert fresh batteries (size “AA”, IEC “LR6”).

Two different methods apply for NV reset, depending on whether

the main unit or a remote control unit is used.

NV reset via main unit

1. Enter test mode.

2. Use the – key or the . key to set the device to Overall

Adjustment mode.

ASS

3. Press the PLAY MODE/DISPLAY key. “CL” starts to flash.

AdJ

4. Press the PLA Y MODE/DISPLAY key once more. “CL” stops

flashing and remains lit, thus concluding NV reset.

cL

Address Value & Adjustment Value

LCD display

011 XXXSXX

Block Error Value & Adjustment Value

LCD display

011 XX BXX

ADIP Error Value & Adjustment Value

LCD display

011 XX AXX

* Functions are displayed,

Jitter Value & Adjustment Value

LCD display

but cannot be used via

this unit.

011 XXXJXX

Power Adjustment Value

LCD display

731 XX VXX

After the voltage indicator appears,

press the DISPLAY key twice.

AdJ

cL

5. Press the x key to return to test mode.

NV reset via remote control

1. Set the TEST MODE.

2. Set the Manual mode and set the item No. 021, Reset NV.

LCD display

021 AAAS CC

3. Press X key on the remote control.

LCD display

021 AAAS CC

Flash CC

4. Press X key on the remote control again.

LCD display

Memory Monitor Mode

XXX: Each Value

XX: Adjustment Value

for Item number

Note: In the Power mode, the item title display is only displayed.

5. To terminate the Manual mode and return to the TEST MODE,

press x key.

8

021 AAAS CC

5. Press x key to terminate the Manual mode and return to the

TEST MODE.

MZ-E300

4-6-1. Electrical offset adjustment method

Note: Doing adjustment by the state that a disc does not enter.

1. Confirm the power voltage is 1.5V.

2. Set to the test mode.

3. Press the – key of main unit activates the overall adjustment

mode.

Main unit LCD display

ASS

4. Press the + key.

Main unit LCD display

035:

5. Press the + key once more. Adjustment is complete when the

adjustment value appears in the “XX” position.

4-6-2. Display segment check mode

1. Enter test mode. Display continuously alternates between the

following three conditions: entire LCD is lit, entire LCD is extinguished, version info is shown, and so on.

2. Press and hold the x key on the main unit to enter display

segment check mode.

* Should segments not be displayed correctly at this point, a short-

circuited COM terminal and/or SEG terminal on the microprocessor chip (IC801) are possible causes.

3. Display returns to condition “1” as soon as the x key is released.

XX

4-7. OVERALL ADJUSTMENT MODE

4-7-1. Overall adjustment mode structure

TEST MODE

(Display Check Mode)

key

.

CD overall

Adjustment

MO overall

Adjustment

Electrical offset

Adjustment key

NV reset

> N

x

key

key

x

key

x

key

x

key

VOL – key or key

Overall Adjustment

Title Display(ASSY**)

.

key

> N

VOL + key

PLAY MODE/DISPLAY key

Perform overall adjustments according to the following procedures

(procedures may differ depending on the microprocessor chip

version used).

For Ver. 1.10, if it is no good in the overall adjustment, please

repeat the overall adjustment several times.

Microprocessor Version 1.10

1 Clear NV.

2 Electric offset adjustment.

3 Rewriting of RAM 633h

1. switch to manual mode No. 100.

2. Press the DISPLAY key on the remote control unit 6 times

consecutively to enter RAM mode.

3. Change the RAM address to 633h.

Use the following keys on the remote control unit to change

the digits of the RAM address:

“The DISPLAY key for the first digit (hundreds), the x key

for the second digit (tens) and the >B key or the .

key for the third digits (units).”

4. Use the + and – keys on the remote control unit to set the

adjustment value of No.633h to 03h and press once the pause

key on the remote control unit to write this value to NV.

“(If NV is cleared, the value is 00h.)

5. Press the DISPLAY key once more to change the display

to “address and adjustment value display”.

6. Switch to the overall adjustment.

4 CD overall adjustment * (Not to turn off the power between the

items 3 and 4 .)

9

MZ-E300

XXX:

n

Ver 1.1 2001.03

5 Rewriting of the adjustment value.

1.After CD overall adjustment, switch to manual mode No. 321

in the condition the disc is in.

2.Press – key on the remote control unit to set 1 step down the

adjustment value of No. 321, and press the pause key on the

remote control unit to write this value to NV.

3.Press the >B key on the remote control unit to switch to

manual mode No. 323.

4.Press the pause key on the remote control unit to set to the

automatic adjustment.

During adjusting automatically, the adjustment value turns on

and off, so wait for the time the adjustment value is on.

5.Press the >B key on the remote control unit to switch to

manual mode No. 345.

6.Note down the current adjustment value of No. 345 (value X).

Use the + and – keys on the remote control unit to set the

adjustment value of No. 345 to the value (Y) determined by

the formula below, and press the pause key on the remote

control unit to write this value to NV.

Formula: X x 1.18 = Y

* Since X and Y are 2’sC, attention must be paid to codes.

And the maximum value of Y must be 7Fh. (Never set it to

the negative value.)

Example: Since X = 2Bh, Y = 2Bh x 1.18 = 33h

6 Change the disc to MO overall adjustment disc (GA1 disc).

Switch to manual mode No.114.

Press the pause key on the remotecontrol unit to set to the

automatic adjustment.

After adjustment, pull out the battery from the set to turn off

the power.

Then insert the battery again.

7 MO overall adjustment.

5 Change the disc to MO overall adjustment disc (GA1 disc).

Switch to manual mode No.114.

Press the pause key on the remotecontrol unit to set to the

automatic adjustment.

After adjustment, pull out the battery from the set to turn off

the power.

Then insert the battery again.

6 MO overall adjustment.

4-7-2. Overall CD and MO adjustment method

1. Set the TEST MODE and press VOL – key or . key to set

the Overall Adjustment mode.

Main unit LCD display

ASS

2. Insert CD disc in the set, and press . key to set the Overall

CD Adjustment mode.

Automatic adjustments are made.

Main unit LCD display

XXX:

XXX: Item No. for which an adjustment is being executed.

YY: Adjustment Value

3. If NG in the overall CD adjustments, return to Reset NV and

perform from the electrical offset adjustment again.

Microprocessor Version 1.20 and higher

1 Clear NV.

2 Electric offset adjustment.

3 CD overall adjustment.

4 Rewriting of the adjustment value.

1.After CD overall adjustment, switch to manual mode No. 321

in the condition the disc is in.

2.Press – key on the remote control unit to set 1 step down the

adjustment value of No. 321, and press the pause key on the

remote control unit to write this value to NV.

3.Press the >B key on the remote control unit to switch to

manual mode No. 323.

4.Press the pause key on the remote control unit to set to the

automatic adjustment.

During adjusting automatically, the adjustment value turns on

and off, so wait for the time the adjustment value is on.

5.Press the >B key on the remote control unit to switch to

manual mode No. 345.

6.Note down the current adjustment value of No. 345 (value X).

Use the + and – keys on the remote control unit to set the

adjustment value of No. 345 to the value (Y) determined by

the formula below, and press the pause key on the remote

control unit to write this value to NV.

Formula: X x 1.18 = Y

* Since X and Y are 2’sC, attention must be paid to codes.

And the maximum value of Y must be 7Fh. (Never set it to

the negative value.)

Example: Since X = 2Bh, Y = 2Bh x 1.18 = 33h

The NG item and “ng” alternately flash on the main unit LCD

display.

XXX: NG item No.

YY: Adjustment Value

4. If OK through the overall CD adjustments, then perform overall

MO adjustments.

Main unit LCD display

End:cd

5. Insert MO disc in the set, and press > N key to set the

Overall MO Adjustment mode. Automatic adjustments are made.

Main unit LCD display

XXX:

XXX: Item No. for which an adjustment is being executed.

YY: Adjustment Value

10

6. If NG in the overall MO adjustments, return to Reset NV and

perform the adjustment again.

The NG item and “ng” alternately flash on the main unit LCD

display.

XXX:

n

XXX: NG item No.

YY : Adjustment Value

7. If OK through the overall MO adjustments, press x key to

return to the TEST MODE and terminate the Overall Adjustment mode.

Main unit LCD display

MZ-E300

11

Loading...

Loading...