Page 1

Page 2

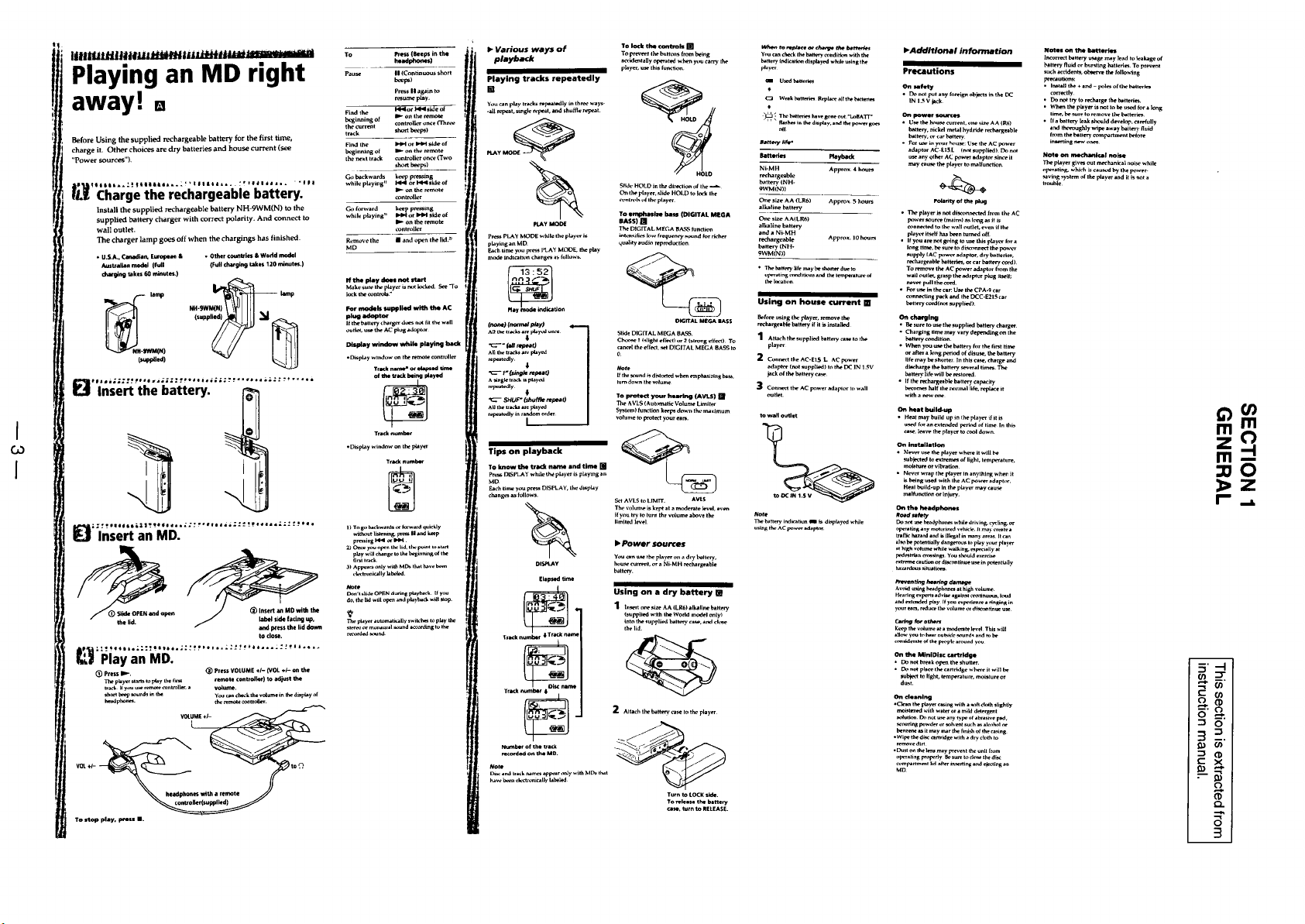

Page 3

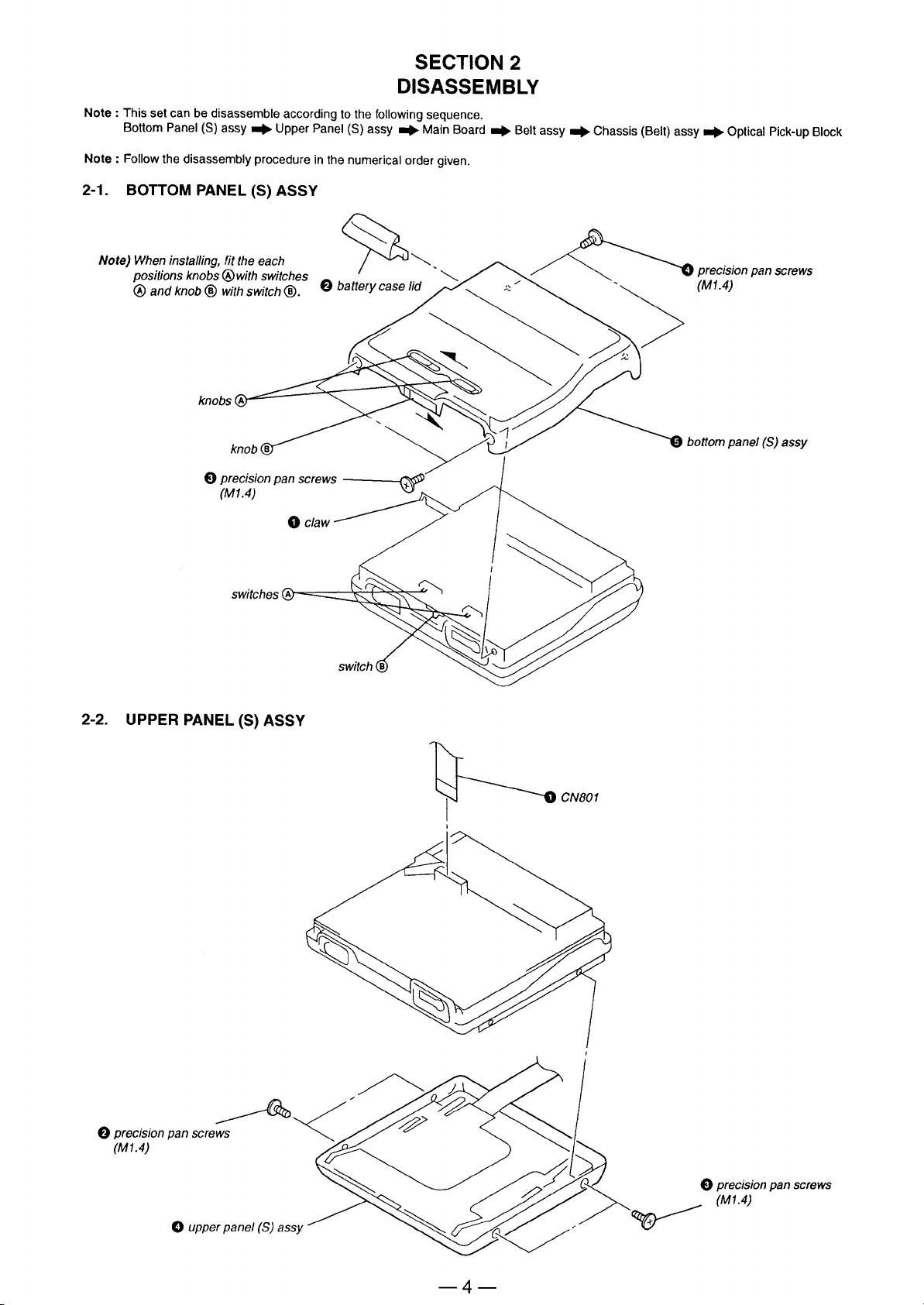

Page 4

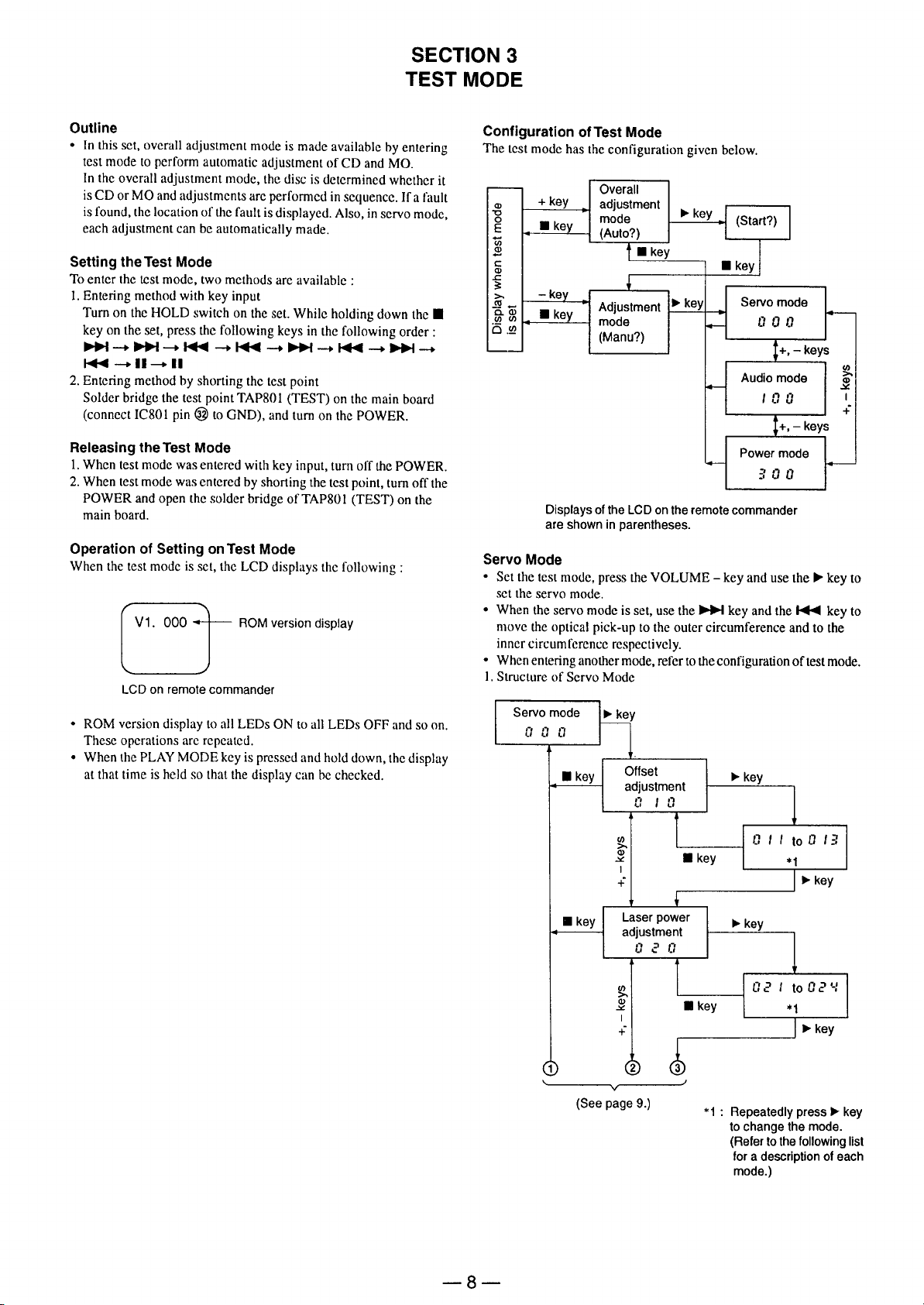

Page 5

Page 6

Page 7

Page 8

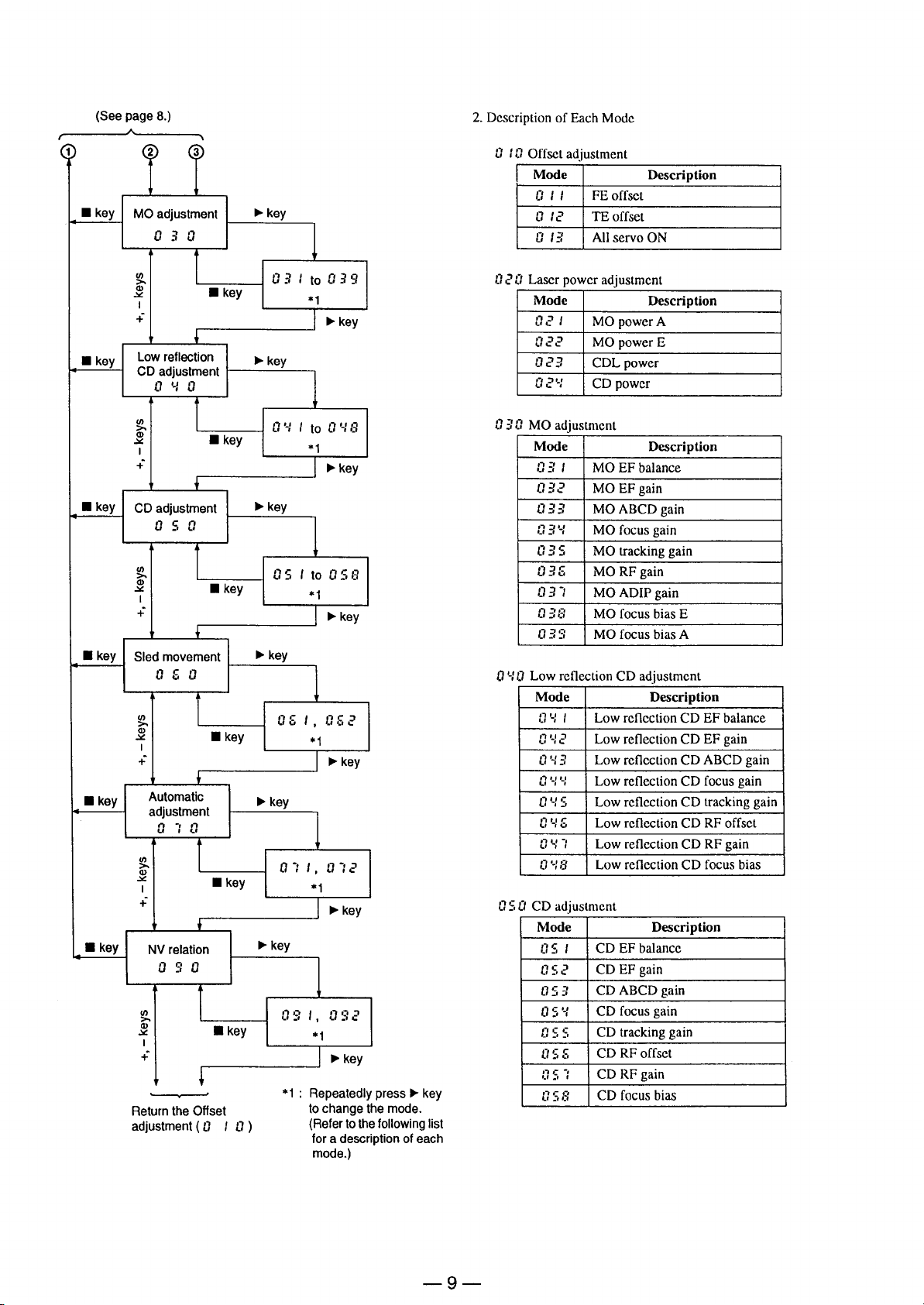

Page 9

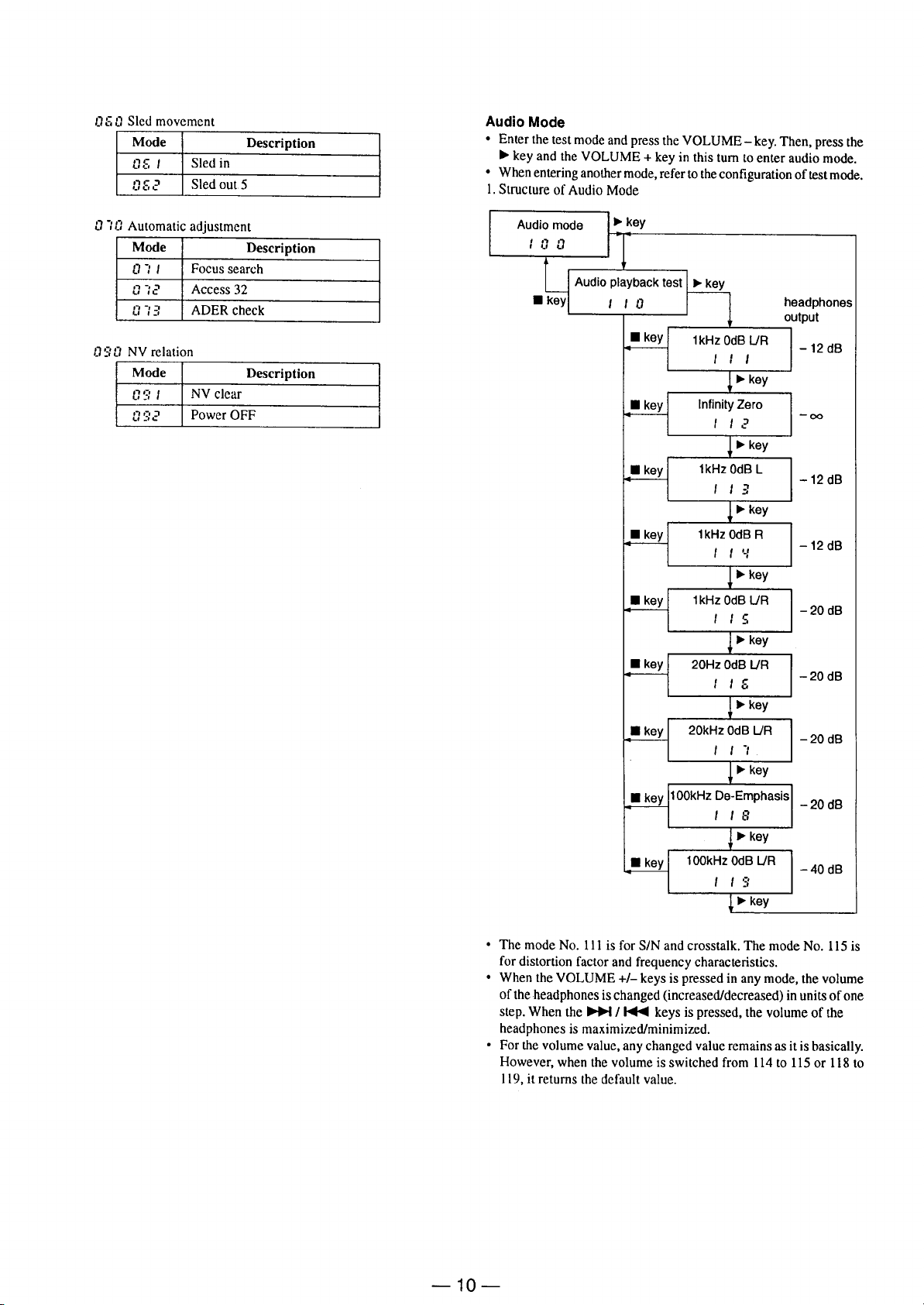

Page 10

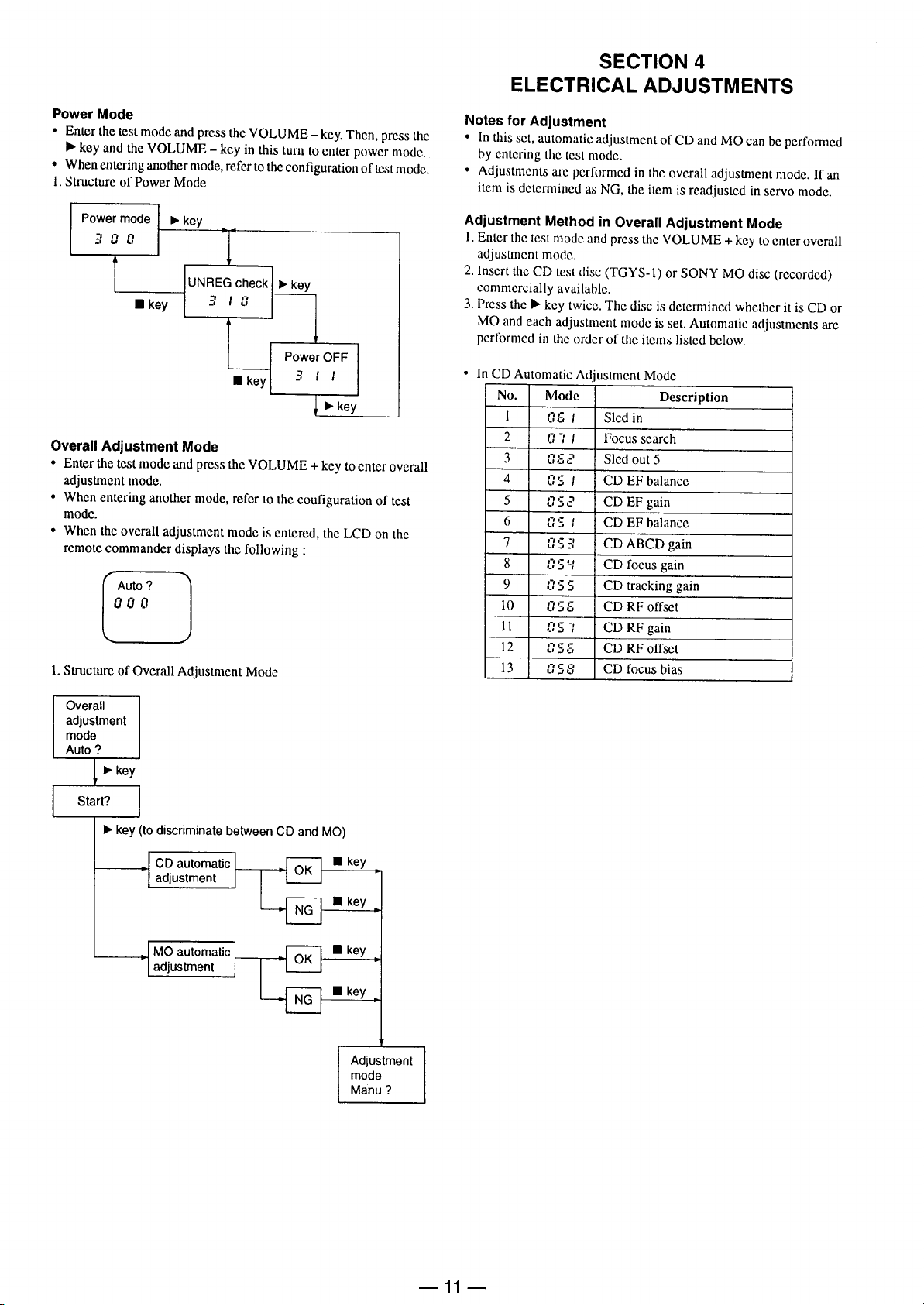

Page 11

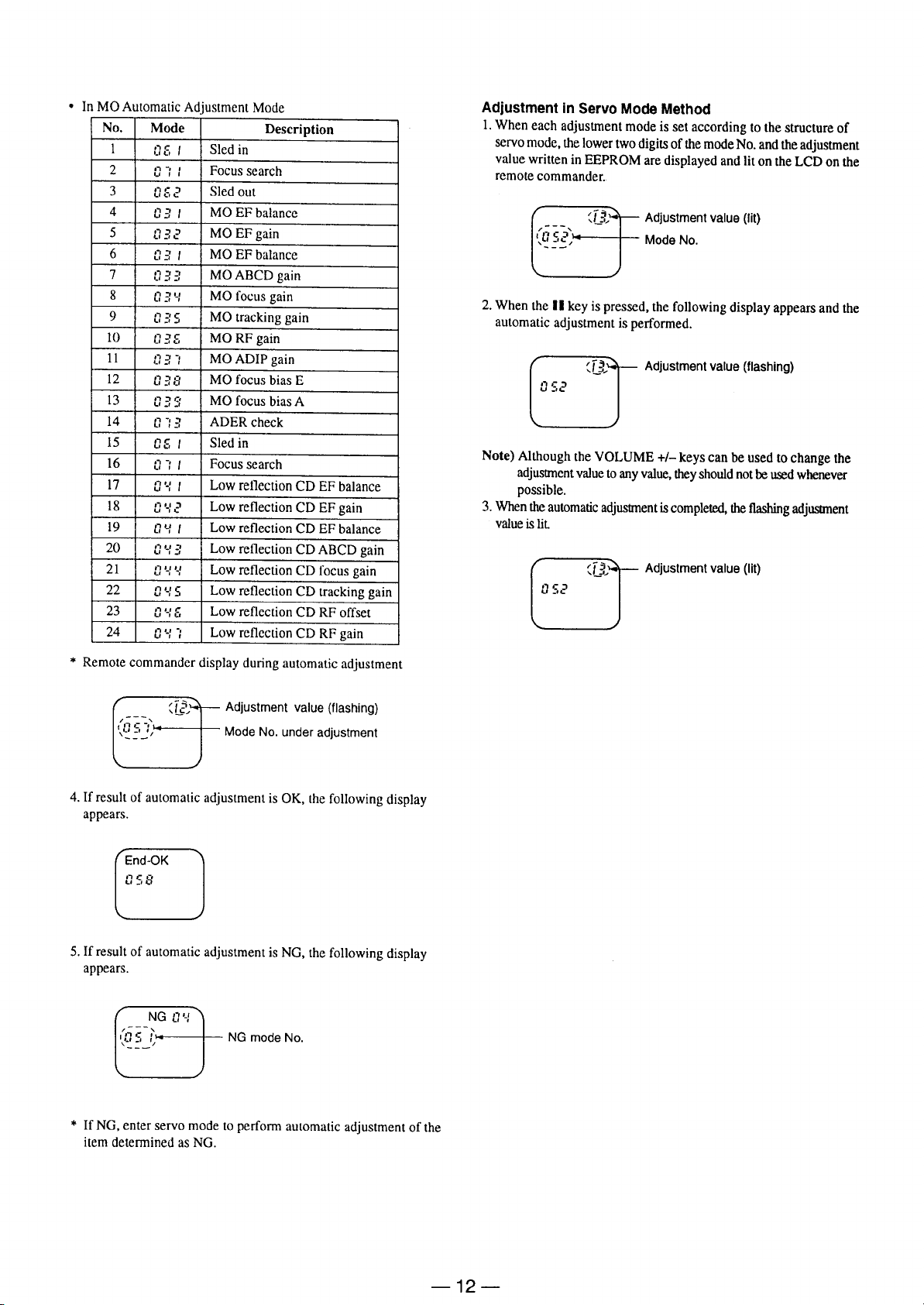

Page 12

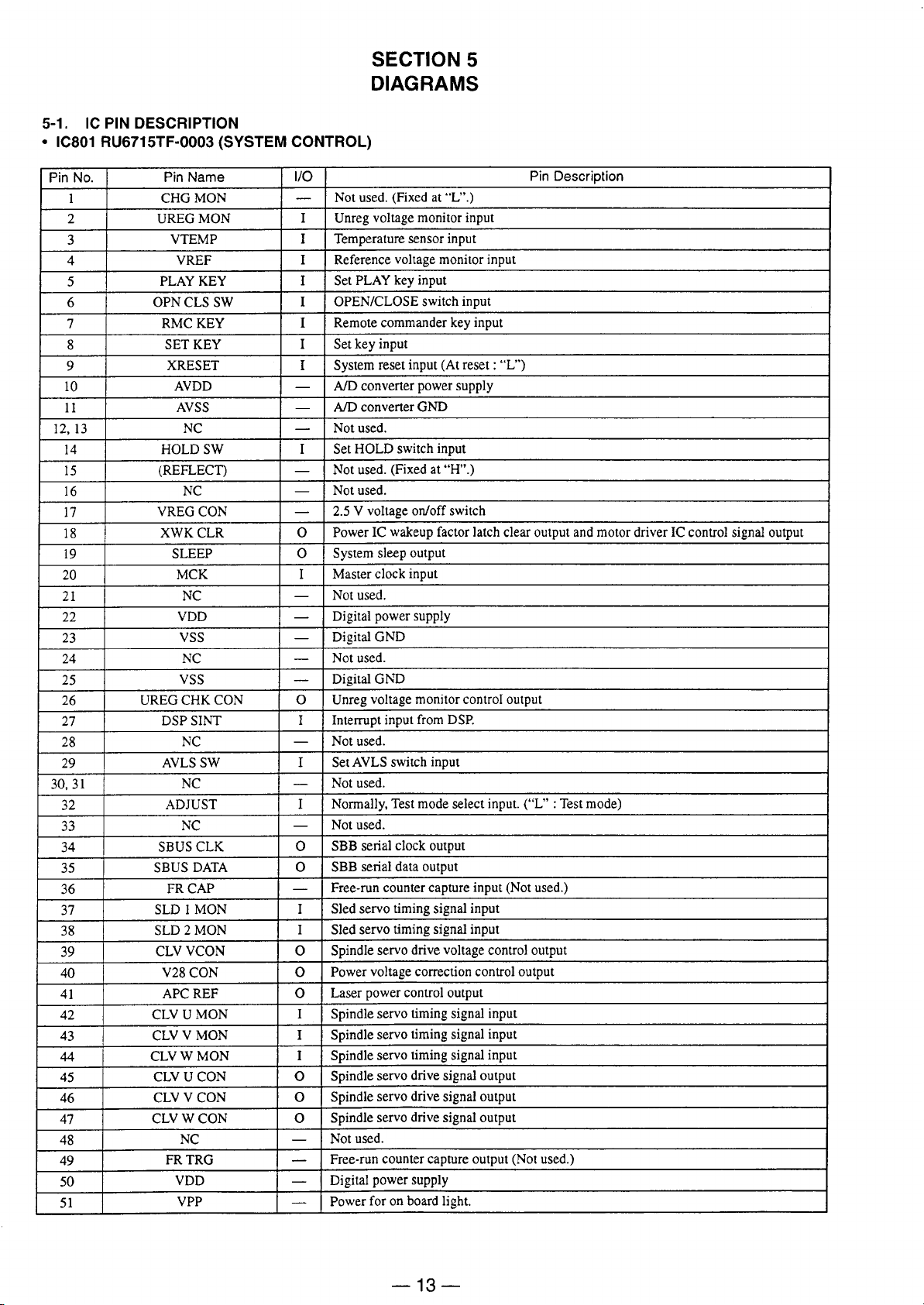

Page 13

Page 14

Page 15

Page 16

Page 17

NEW TECHNICAL THEORY

FOR SERVICING

MZ-E30

OPERATION MANUAL

— 1 —

PORTABLE MINI DISC PLAYER

Page 18

TABLE OF CONTENTS

Section Title Page

1. DIAGRAMS

1-1. BLOCK DIAGRAM ........................................................................................................................................ 3

2. FUNCTIONS AND FEATURES

2-1. Principal Features ............................................................................................................................................. 6

3. Difference in System Configurations by Generation

3-1. System Block Diagrams................................................................................................................................... 8

4. OUTLINE OF SYSTEM

4-1. Microprocessor Interface ................................................................................................................................. 11

4-2. Clock System.................................................................................................................................................... 14

5. POWER SUPPLY CIRCUIT

5-1. Outline of Power supply Circuit Operation .................................................................................................... 16

5-2. Operation in Wakeup (Startup) Mode ............................................................................................................. 20

5-3. Operation in the Sleep (Pause) Mode .............................................................................................................. 24

5-4. Detecting Decrease in Voltage ........................................................................................................................ 24

5-5. RESET Circuit.................................................................................................................................................. 26

6. SYSTEM CONTROL

6-1. Detection Switch .................................................................................................................................................. 27

6-2. Key Input Detection of Control Buttons ......................................................................................................... 28

6-3. Control of APC Circuit and Laser Power ....................................................................................................... 30

7. Playback Circuit

7-1. Outline of Playback Circuit ............................................................................................................................. 32

7-2. Playback Operations......................................................................................................................................... 32

7-3. Digital DBB and Mute Circuit ........................................................................................................................ 33

8. Servo Circuit

8-1. Outline of Servo Circuit ................................................................................................................................... 39

8-2. Intermittent Operations of Servo ........................................................................................... .......................... 40

8-3. Focus Search and Disc Discrimination ........................................................................................................... 40

8-4. Focus Servo Circuit.......................................................................................................................................... 42

8-5. Tracking Servo Circuit..................................................................................................................................... 46

8-6. Sled Servo Circuit ............................................................................................................................................ 46

8-7. Spindle Servo Circuit ....................................................................................................................................... 50

9. Operations of Mechanism ............................................................................................ 53

10. Appendix (Semiconductor Specifications)

10-1. RF AMP SN761050A ...................................................................................................................................... 54

10-2. DSP/Digital Servo µPD63730GC.................................................................................................................... 58

10-3. Servo Driver MPC17A55FTA ......................................................................................................................... 63

10-4. DC-DC Converter MPC1830VMEL ............................................................................................................... 71

— 2 —

Page 19

Page 20

Page 21

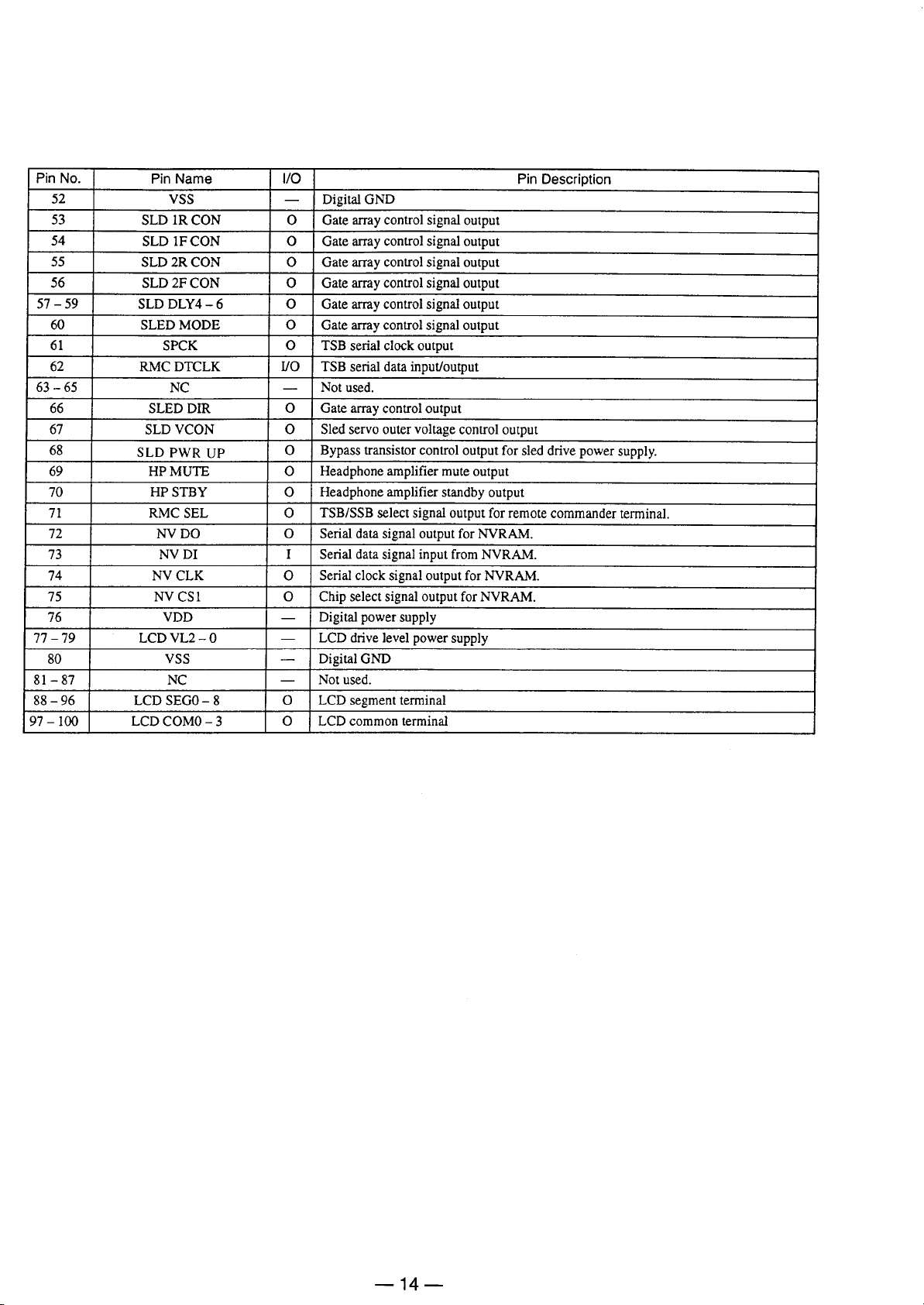

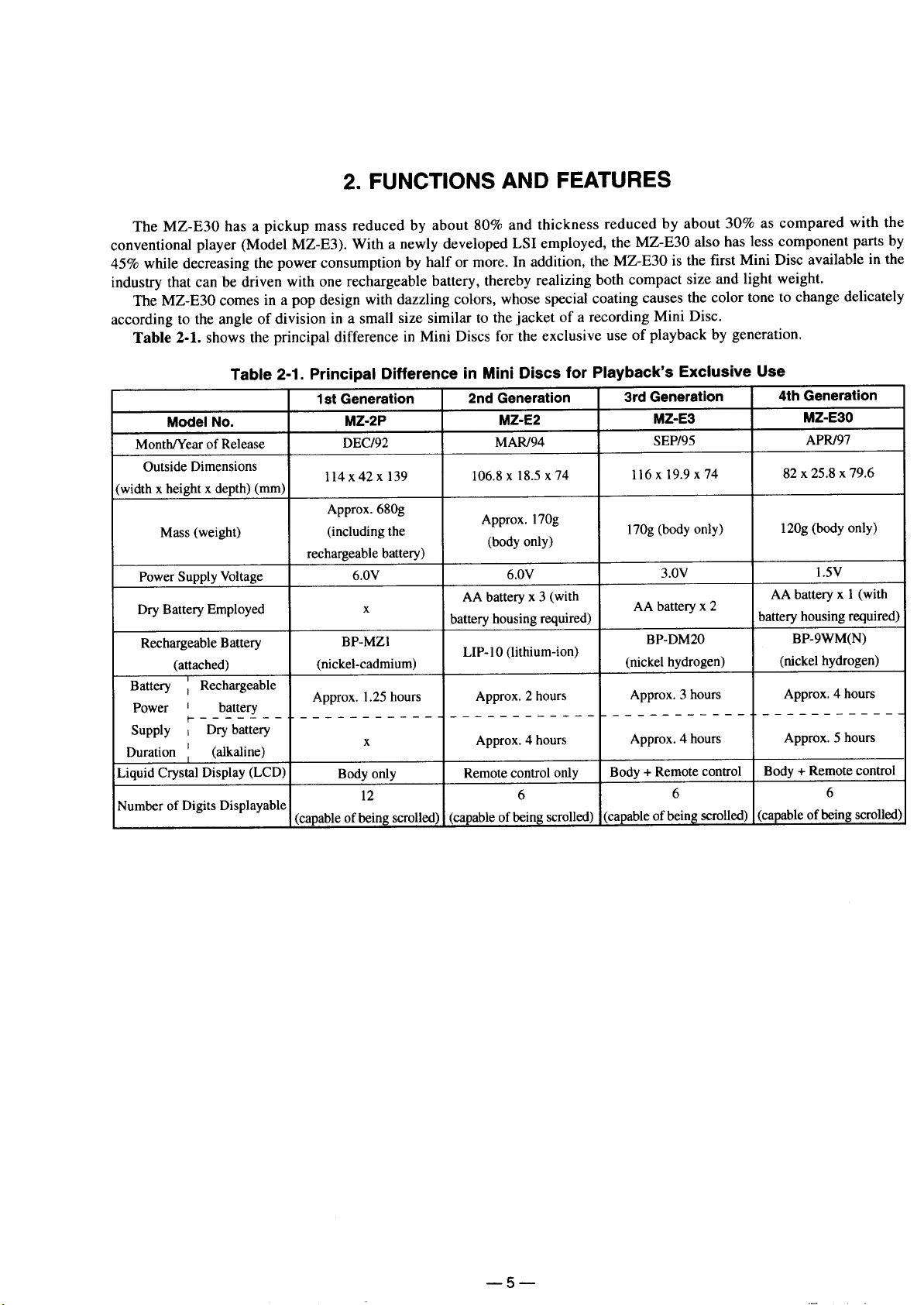

3. DIFFERENCE IN SYSTEM CONFIGURATIONS BY GENERATION

For a Mini Disc of playback type, each system is composed of such principal LSIs as shown in Table 3-1.. The difference

between the first and second generations lies in the L/Rch, two pieces of which have been employed in the ATRAC decoder

of the first generation and are intensified into a single LSI in the second generation. The third generation, moreover, has had

the principal LSIs intensified into three pieces except for the servo driver as shown in the table.

In the fourth generation, on the other hand, has been far larger sized and more highly integrated. As a result, the principal

circuit of a Mini Disc has been intensified into a single LSI while six LSIs, including the ATRAC decoder, were employed in

the first generation.

In the case of a playback type model heretofore available, a playback circuit and a decoder circuit have been employed while

jointly using the principal LSI with a recorder/playback unit. The MZ-E30, however, employs an newly developed LSI for the

exclusive use of playback, which has especially main functions, such as shock-proof, ATRAC decoding, EFM decoding and

ACIRC decoding.

The principal LSI in the fourth generation are outlined below.

µPD63730GC : DSSP (digital servo): EFM decoder, ACIR decoder, DRAM controller, ADIP decoder, and clock generator

circuit

MPC17A55FTA : Servo drive circuit, and step up/down power supply circuit

SN761050A : RF amplifier, and I-V amplifier with a gain adjustment switch

Table 3-1. Principal LSIs Employed in a Mini Disc for Playback

Applicable Model

Circuit Block

ATRAC Decoder

Shock-proof Memory Controller

EFM ACRIC Decoder

ADIP Demodulator

Servo Signal Processor

Servo Driver

RF Amplifier

1st Generation

MZ-2P

CXD2527R(2)

CXD2526Q

CXD2525R

CXA1380N

CXA1602R

MPC1718PU

CXA1381R

2nd Generation

MZ-E2

CXD2531AR

CXD2526AR

CXD2525R

CXA1380N

CXA1602R

MPC1718PU

CXA1861R

3rd Generation

MZ-E3

MZ-E40

CXD2536R

CXD2535BR

MPC17A38VM

CXA1981AR

4th Generation

MZ-E30

µPD63730GC

MPC17A55FTA

SN761050A

— 7 —

Page 22

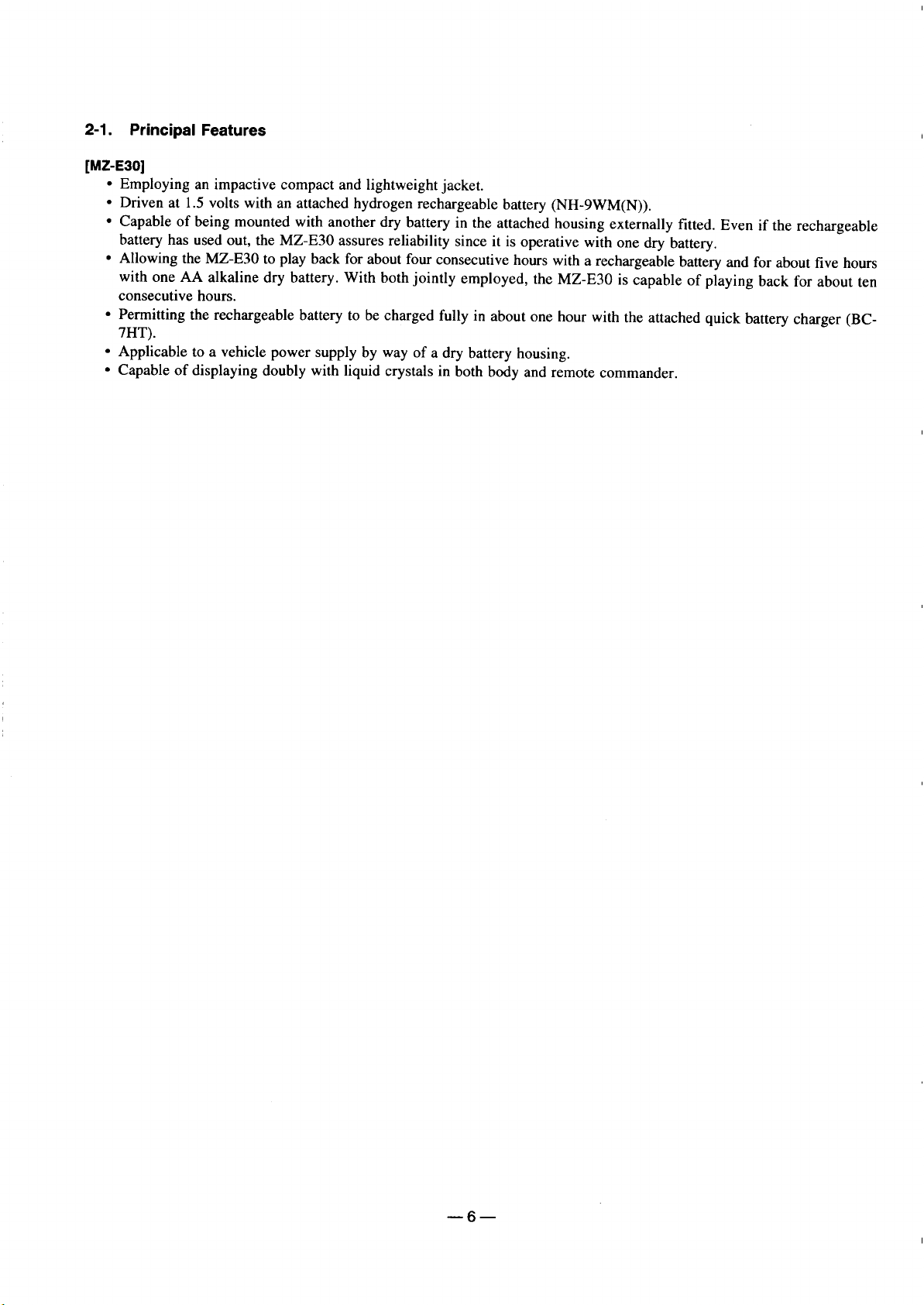

3-1. System Block Diagrams

The playback type Mini Discs belonging to the first thru 4th generations have their respective systems composed of the

blocks illustrated below.

(1) 1st Generation [MZ-2P]

4M DRAM

OPTICAL BLOCK

KMS-130

DRIVE

MPC1718

Fig. 3-1. First Generation Mini Disc System Block Diagram

(2) 2nd Generation [MZ-E2]

ADIP

CXA1380

RF AMP.

CXA1381

SERVO

CXA1602

EFM

ACIRC

CXD2525

SYSTEM CONTROLLER

CXD2526

4M DRAM

SHOCK

PROOF

ATRAC(L)

CXD2527

ATRAC(R)

CXD2527

D/A CONV.

AK4501

AUDIO

OUTPUT

OPTICAL BLOCK

KMS-200

DRIVE

MPC1718

ADIP

CXA1380

RF AMP.

CXA1381

SERVO

CXA1602

EFM

ACIRC

CXD2525

SYSTEM CONTROLLER

SHOCK

PROOF

CXD2526

ATRAC

CXD2531

D/A CONV.

Fig. 3-2. 2nd Generation Mini Disc System Block Diagram

— 8 —

SM5853

AUDIO

OUTPUT

Page 23

(3) 3rd Generation [MZ-E3/E40]

4M DRAM

OPTICAL BLOCK

KMS-201

DRIVE

MPC17A38

Fig. 3-3. 3rd Generation Mini Disc System Block Diagram

(4) 4th Generation [MZ-E30]

RF AMP.

CXA1981

EFM

ACIRC

&

DIGITAL

SERVO

CXD2535

SYSTEM CONTROLLER

CXD2536

4M DRAM

SHOCK

PROOF

&

ATRAC

D/A CONV.

CS4330

AUDIO

OUTPUT

OPTICAL BLOCK

ODX-01

DRIVE

MPC17A55

RF AMP.

SN761050

EFM,ACIRC

SHOCK PLOOF

ATRAC

DIGITAL SERVO

µPD63730

SYSTEM CONTROLLER

D/A CONV.

AK4314

AUDIO

OUTPUT

Fig. 3-4. 4th Generation Mini Disc System Block Diagram

— 9 —

Page 24

4. OUTLINE OF SYSTEM

IC602

4M DRAM

OPTICAL

PICK-UP

IC501

• ERROR AMP

• APC CIRCUIT

REMOTE CONTROLLER

UNIT

LCD

KEY

IC551(1/2)

SERVO DRIVER

POWER SUPPLY

1.5[V]

RF AMP

ERROR SIGNAL

CONTROL SIGNAL

IC901

CONVERTER

EFM SIGNAL

DC-DC

8[V]

2.8[V]

2.5[V]

IC601

DSP/DIGITAL SERVO

• ATRAC DECODER

• RAM CONTROLLER

• ACIRC DECODER

• EFM DEMODURATOR

• DIGITAL SERVO PROCESSOR

IC801

CONTROL

SYSTEM CONTROLLER

• CONTROL THE WHOLE SYSTEM

• LCD DRIVER

• CONTROL THE RF AMP. IC

• CONTROL THE DSP IC

LCD

SIGNAL

EEPROM

IC802

DA DATA

IC301

D/A CONVERTER

SERVO DRIVER

IC803

SLED MOTOR

CONTROL

IC551(2/2)

L/R

FOCUS

TRACKING

SPINDLE

SLED

IC302

H.P.

AMP

L/R

AUDIO OUTPUT

FOCUS/TRACKING

SERVO COIL

SPINDLE

M

MOTOR

SLED

M

MOTOR

Fig. 4-1. General System Block Diagram

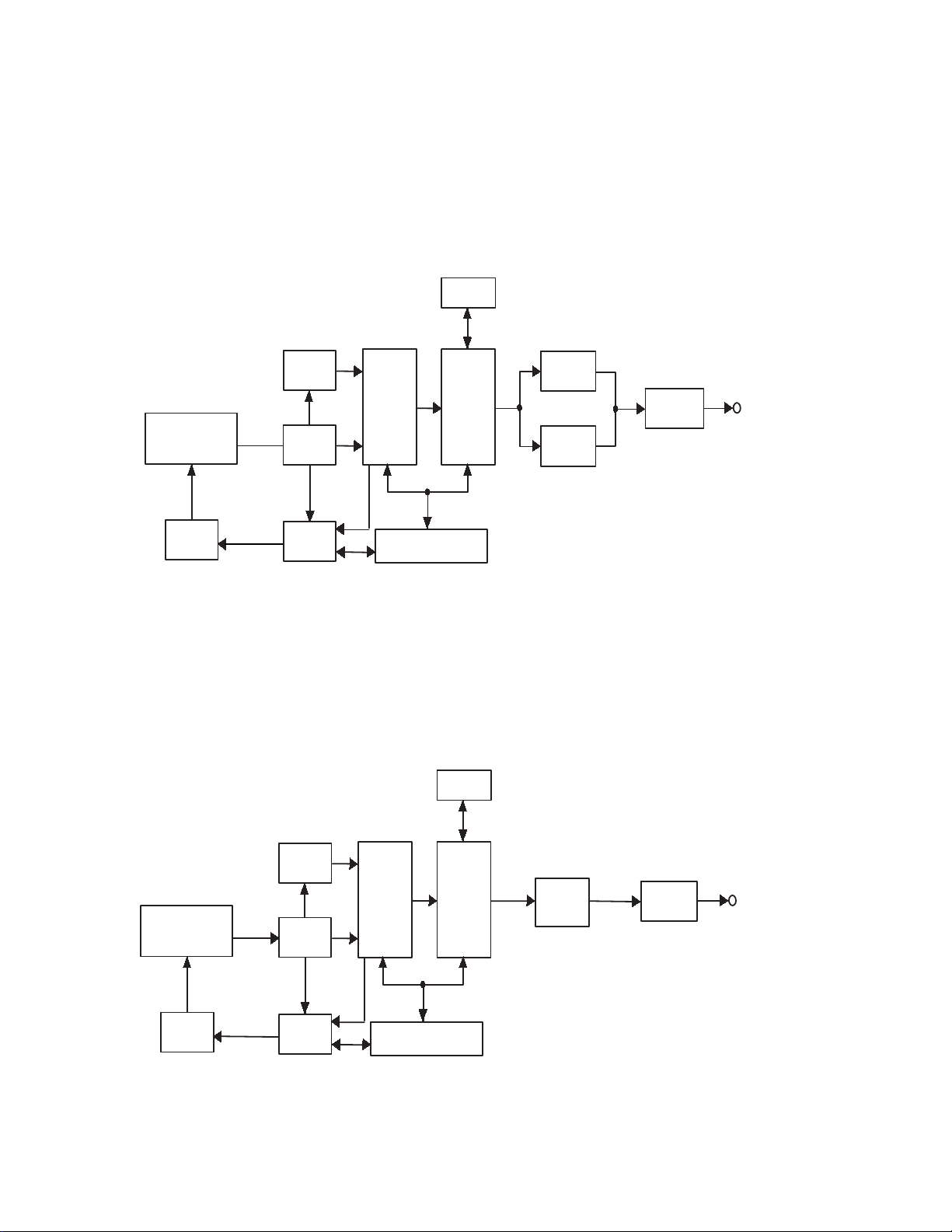

Fig. 4-1. is the general system block diagram. The MZ-E30 belonging to the fourth generation is generally composed of the

system controller (IC801) to control the system as a whole as illustrated in the figure. In addition, a digital signal processor and

a digital servo system are mainly composed of the DSP/digital servo LSI µPD63730GC (IC601) for playback.

Other main system components, moreover, include the servo driver (IC551) and RF amplifier (IC501), in which a power

supply circuit is also included.

The DSP/digital servo µPD63730GC for playback is provided with most of those functions which are required for a Mini

Disc to play back, such as ATRAC decoder, EFM decoder, ACIRC decoder, ADIP decoder, DRAM controller, etc. In

addition, it comprises the digital servo (DSSP) and clock generator circuits. Built in the RF amplifier, moreover, are such

circuits as the I-V converter amplifier capable of setting a gain, based on the serial data from the system controller, including

a servo error extractor circuit, an APC circuit and so on.

The D/A converter (IC301) is of the low-voltage 1-bit type, in which a digital de-emphasize function is built, in addition

to the digital filter applicable to 8-multiple oversampling and to a digital Dynamic Bass Boost (DBB). And the headphone

amplifier (IC302) employed in the next stage is of low-power consumption type in which a mute function is incorporated.

The system controller serves to control the RF amplifier and the power supply circuit while processing a digital signal and

controlling the digital servo, together with the DSP/digital servo. In addition, functions to detect a key-in and a remote control

signal, and to control and drive the LCD are also available. The memory (IC802) connected to the system controller is an EEP

ROM (nonvolatile memory) to store mainly servo-system data, such as a traverse supplementary value in the adjustment

(overall regulation) mode, a focus bias, etc. Stored in this memory are the sound volume data just before the power supply

enters the sleep mode, and the stop position address data to be used in the resume function. These data are transferred to each

circuit upon startup.

— 10 —

Page 25

4-1. Microprocessor Interface

IC501 RF AMP

IC601 DSP/DIGITAL SERVO

SSB I/F

21

SBUS

IC802 EEPROM

SSB I/F

22

SCK

4

3

2

1

SBUS CLOCK

SBUS DATA

DODINVDI

SK

NVCLK

CS

NVDO

NVCS

73

72

74

75

323133

CLK

SBUS

SBUS CLK

SBUS DATA

35

34

SINTDSP SINT

27

IC801

SYSTEM CONTROLLER

62

RMC DTCLK

Fig. 4-2. Outline of Microprocessor Interface

J301

REMOTE CONTROLLER

UNIT

4

3

2

1

RM-MZE50

LCD CONTROLLER

The MZ-E30 has a microprocessor interface outlined in Fig. 4-2.. As shown in the figure, the system controller (IC801) is

employed as the mainstay to control the system as a whole. Besides, the DSP/digital servo (IC601) and the EEP ROM (IC802)

are provided. Commands and data are, moreover, bilaterally given and taken to and from the remote commander. In addition,

data are unilaterally transmitted to the RF amplifier. Communications with the DSP/digital servo and RF amplifier, meanwhile,

are performed by way of a serial bus (SBUS). Given and taken between system controller and DSP/digital servo mainly as

described below, furthermore, are those serial data and serial commands which will be input and output to and from Pin #∞

(SBUS DATA) as timed with the serial clock output from Pin #¢ [SBUS CLK].

System Controller n DSP/digital servo (WRITE mode)

• Various function data in each digital servo (DSSP) and

• SERVO- and PLL-mode setting data, and electronic volume setting data

DSP/digital servo n System Controller (READ mode)

• Error data in each servo and

• SubQ/ADIP cluster and sector information

From the system controller to the RF amplifier, SBUS data are transferred similarly to the case of DSP/digital servo. And

the clock line is used to set a gain in the I-V converter amplifier and ADIP extractor circuits located inside the RF amplifier,

to adjust the balance of focus and tracking amplifiers, to amplify the RF, with pit or MO played back, and to select the servo

amplifier polarity.

— 11 —

Page 26

Between the system controller and the EEP ROM, a traverse supplementary value and a focus bias, both obtainable in the

adjustment mode as already referred to, including such data as an offset value of focus/tracking gain, are transferred to and

stored in the EEP ROM synchronously with the clock output from Pin &¢ [NV CLK] of the system controller.

In the conventional model, moreover, the sound volume setting data and the address data relating to the stop position applied

in the resume function are held in the RAM located in the interior of the system controller normally powered. In the MZ-E30,

however, the power will stop being supplied to the system controller if the stop mode should last for about 10 second (which

varies with an optical block position and/or with a mode) for the purpose of saving the energy. These data, therefore, are stored

in the EEP ROM similarly to the servo system data so that they will be read out onto the system controller upon startup and

transferred to each circuit.

Between the system controller and the remote commander, on the other hand, such display information as characters, etc.

are transmitted by way of the remote jack (J301) to the LCD controller located inside the remote commander. Such

information, moreover, is transmitted from the controller inside the remote commander to the system controller since the

receiving data differ in transmission rate, etc. by type of remote control.

To transmit data, the clock timed with such data is also transmitted normally at a time. In the MZ-E30, however, clock

information, etc. are previously transmitted, based on which the controller in the interior of remote control has a function of

generating a clock. Only a single line for data, therefore, permits them to be received.

SBUS Data Transmission Timing

(1) Writing in DSP/digital servo or RF Amplifier from System Controller

To write in the DSP/digital servo or RF amplifier, each bit data are input synchronously with the falling edge of a serial

clock (SCK) as shown in Fig. 4-3.. As shown in the figure, the first three bits relate to the control, with Bit 1 “ST” standing

the for start bit, and Bit 2 “R/W” for the Read or Write mode.

Three types of information, command, address and data, are transferred from the system controller to the DSP/digital servo.

To identify them, Bit 3 “D/C” should be used.

Commands and data, moreover, have a configuration as shown in Fig. 4-4.. When the code of a device coincides with that

of a DSP/digital servo or of an RF amplifier, the device under the same code will receive the related command, thereby

performing subsequent data communications. The instruction code, meanwhile, is used to transfer a command, such as to reset

the hardware.

Fig. 4-3. Timing of Writing in DSP/digital servo or RF Amplifier from System Controller

Fig. 4-4. Command and Data Configurations

— 12 —

Page 27

(2) Reading onto System Controller from DSP/Digital Servo

To read from the DSP/digital servo, the information transferred to the system controller is limited to data only but free from

Bit 3 “D/C” as shown in Fig. 4-5.. The DSP/digital servo has an SBUS terminal employed as an output port only during the

bit period for which data are being output. In any other section, the DSP/digital servo has high impedance.

Fig. 4-5. Timing of Reading onto System Controller from DSP/digital servo

— 13 —

Page 28

4-2. Clock System

IC601

DSP/DIGITAL SERVO

(48fs)

MCK

IC803

SLED MOTOR

19

CONTROL

from RF AMP IC501

37

pin RF-OUT

EFM/ACIRC

DECODER

(96fs)

EFM

PLL

RF

3

ADC

(4fs)

RAM

CONTROLLER

TIMING

GENERATOR

48

25

XI

CLK CK176

28

IC901

DC-DC CONVERTER

IC301

D/A CONVERTER

(48fs)

BCK

41

LRCK

39

(fs)

(384fs)

LRCK

BCK

7

9

6

5 4

XTI

X301

(384fs)

XTO

NOTE : fs = 44.1[kHz]

CLKO

IC801

SYSTEM CONTROLLER

20

MCK

(384fs)

Fig. 4-6. Clock System Block Diagram

Fig. 4-6. shows a block diagram of the clock system.

For the master clock of both system controller (IC801) and DSP/digital servo (IC601), 384 fs (fs = 44.1kHz) available at

X301 connected between Pin 5 [XT1] and Pin 4 [XT0] in the D/A converter (IC301) is supplied from Pin 6 [CLK0].

The timing generator located in the interior of the DSP/digital servo divides a frequency of 384 fs input at Pin $• [X1] so

as to output 48 fs (bit clock) from Pin $¡ [BCK], fs (L/R clock) from Pin #ª [LRCK] and 4 fs from Pin @∞ [CK176].

Based on a frequency of 96 fs from the timing generator, the EFM PLL unit generates a PLL clock (PLCK) so as to

perform EFM demodulation in a subsequent stage of the EFM decoder.

A frequency of 48 fs (bit clock) supplied to Pin !ª [MCK] in the sled motor control (IC803) is used as the master clock for

the controller located inside. And the bit clock (BCK) and L/R clock (LRCK), both output to the D/A converter, are used as

the timing signal for the audio data output from the ATRAC block in the DSP/digital servo. (For details, refer to 7-2. Playback

Operations.)

A frequency of 4 fs, which is output from Pin @∞ [CK176] in the DSP/digital servo to Pin @• [CLK] in the DC-DC converter is

used as a switching signal to drive the STEP-UP circuit in the power supply unit. (For details, refer to 5-1. Outline of Power supply

Circuit Operations.)

— 14 —

Page 29

5. POWER SUPPLY CIRCUIT

Fig. 5-1. shows an outline of the power supply circuit employed in the MZ-E30, as shown in the figure, the power supply

voltages applied to the MZ-E30 may be divided, if roughly classified, into three: 1.5V, 2.8V and 2.5V lines. 2.8V (VC) is

obtained by raising the 1.5V voltage in the step up circuit (2) and supplied to principal circuits, such as D/A converter (IC301),

including system controller (IC801) and DSP/digital servo (IC601).

A voltage of 8V obtained in the step up circuit (1) and in the charge pump circuit, moreover, is supplied to the servo driver

(IC551) and 2.5V to the RF amplifier (IC501) and to the optical block.

To save the electric power, the MZ-E30 has the step up circuits stop operating according to the sleep signal which the

system controller will output if the STOP mode should last for about 10 seconds (which varies with an optical block position

and/or with a mode). As a result, the power will also stop being supplied to each component. To startup, on the other hand, a

wakeup circuit will start up when a operation button located in the remote commander or in the unit is pressed. This will cause

the step up circuit to start operating so that the power is supplied to each component. In addition, this power-saving feature

also interlocks with the ON/OFF operations of the disc door opening/closing detector switch. The power supply then enters the

wakeup (startup) or sleep (standby) mode immediately.

1.5[V]

IC901

CHARGE

PUMP

IC551

2.5[V]

REG

from

SYSTEM CONTROLLER (IC801)

8[V]

2.8[V](VC)

2.5[V]

1.5[V]

IC901

SW

IC901

STEP UP

CIRCUIT(1)

IC551

STEP UP

CIRCUIT(2)

DC-DC CONVERTER

SLEEP SIGNAL

Fig. 5-1. Outline of Power Supply Circuit

SERVO DRIVER(IC551)

HEADPHONE AMP(IC302)

SERVO DRIVER(IC551)

SYSTEM CONTROLLER(IC801)

DSP/DIGITAL SERVO(IC601)

D/A CONVERTER(IC301)

HEADPHONE AMP(IC302)

RF AMP(IC501)

OPTICAL BLOCK

RF AMP(IC501)

— 15 —

Page 30

5-1. Outline of Power supply Circuit Operation

Fig. 5-2. shows the power supply circuit block diagram and timing of waveforms in wakeup (startup) and sleep (standby)

modes.

Operating a key on the unit or in the remote commander connected to Pin #∞ [XWK1] thru Pin #™ [XWK4] in the DC-DC

converter (IC901) will cause the related input pin to become “L,” thereby causing the system control (wakeup/sleep control)

circuit inside to start up.

This will also cause the internal oscillator (OSC1) in the same IC, the step up circuit (1), and the charge pump circuit to start

operating. Subsequently, the internal

oscillator (OSC2) will also begin to operate. As a result, a switching PWM wave of about 200 kHz is output from Pin @™

[PWM1], and a switching power control mode signal from Pin @¡ [DI]. This will cause the step up circuit (2) inside the servo

driver (IC551) to start operating. In addition, the power switch (connected between Pins 4, 5 and 2, 3) will also turn on.

Thus, 2.8V (VC) will be supplied to each component.

At the same time, a voltage of 2.5V output from the 2.5V REG circuit in the interior is supplied from Pin ^¢ [VREG] to the

optical block and to the RF amplifier (IC501).

With 2.8V (VC) applied to Pin [10] [VC] in the DC-DC converter, a RESET signal 6 is sent from Pin 8 [XRST], thereby

causing each IC to start operating. The frequency of 176 kHz (4 fs : fs = 44.1 kHz) obtained, with a frequency of 384 fs

available at X301 divided by 96, enters Pin @• [CLK] from the DSP/digital servo (IC601). Thus, a switching operation continues so

that the step up circuits (1) and (2) will have their respective Drives OSC1 and OSC2 switched over to an external clock (4 fs).

If the voltage of 2.8V (VC) fluctuates, the saw-toothed generator (SAW) inside the DC-DC converter compares the sawtoothed wave obtained from the external clock (4 fs) with the VC input in Pin !º. The generator will control the duty ratio of

a PWM wave output from Pin @™, thereby controlling 2.8V (VC).

The latch clear signal 7, which is input from Pin !• [XWK CLR] in the system controller to Pin #¡ [FF CLR] in the DCDC converter, will have “L” input in either one of XWK1 thru 4 according to an FF (flip-flop) RESET signal inside the system

control in the DC-DC converter. All other input circuits are prohibited from being set until the latch clear signal has become

“H” after setting the FF.

To switch over to the sleep mode, on the other hand, the sleep signal 8 is output from Pin !ª [SLEEP] in the system controller

once the STOP mode has lasted for about 10 seconds (which vary with the optical block position and/or with a mode) or immediately

after the door has opened. This will cause the step up circuits (1) and (2) to stop operating while ceasing to supply the power to each

component.

— 16 —

Page 31

Page 32

Page 33

Page 34

5-4. Detecting Decrease in Voltage

Fig. 5-6. shows a block diagram of the battery voltage monitor circuit. When Pin @§ [UREG CHK CON] in the system controller

becomes to “H,” the VOLT CHECK (Q801) turns on. This will cause the voltage at both ends of the battery to be divided or halved

in the R801 and R802. And the voltage so halved is input to Pin 2 [UREG MON] in the system controller, thereby detecting a

decrease in voltage. A battery voltage of 0.8V or less will cause the MZ-E30 to be put into the STOP mode, with Message

“LoBATT” blinking on the remote commander display. In approximately 5 seconds, a sleep signal will be output from Pin !ª

[SLEEP] in the system controller so that the power supply circuit will stop operating. Upon wakeup, meanwhile, Pin @§ in the system

controller will change from “L” to “H” at the timing shown.

1

UREG MON

VC

VDD

22,50,76

2

from SERVO DRIVER IC551

, pin VB1

32

Q801

VOLT CHECK

R801

47k

1.5[V]

R802

1

2.8[V](VC)

2

UREG CHK CON

Q802

47k

2

UREG CHK CON

0

0

2.7[V]

8.5[ms]

SYSTEM CONTROLLER

26

IC801

19

SLEEP

Fig. 5-6. Battery Voltage Monitor Circuit

TO DC-DC CONVERTER IC901

30

pin SLEEP

— 25 —

Page 35

5-5. RESET Circuit

Fig. 5-7. shows the RESET circuit and the RESET signal timing. The 2.8V (VC) obtained in the step up power supply

circuit of the motor driver (IC551) enters the RESET circuit after being divided with a resistor inside via Pin 0 [VC] in the

DC-DC converter (IC901). In the RESET circuit, the capacitor connected to Pin 7 [CRST] outputs the RESET signal from

Pin 8 [XRST] to main ICs, such as system controller (IC801) and DSP/digital servo (IC601), at the delayed timing shown in

the figure.

2.8[V]

1

VC

from SERVO DRIVER IC551

, pin VB1

32

0

IC901

VC

10

DC-DC CONVERTER

RESET

1

7

GND

CRST

C903

XRST

8

SYSTEM CONTROLLER

1

2

RESET

0

2

XRESET

9

IC801

DSP/DIGITAL SERVO

RESET

30

IC601

6[ms]

2.7[V]

D/A CONVERTER

PD

3

IC301

RESET

24

IC501

RF AMP

PE

7

IC802

EEPROM

Fig. 5-7. RESET Circuit and RESET Signal Timing

— 26 —

Page 36

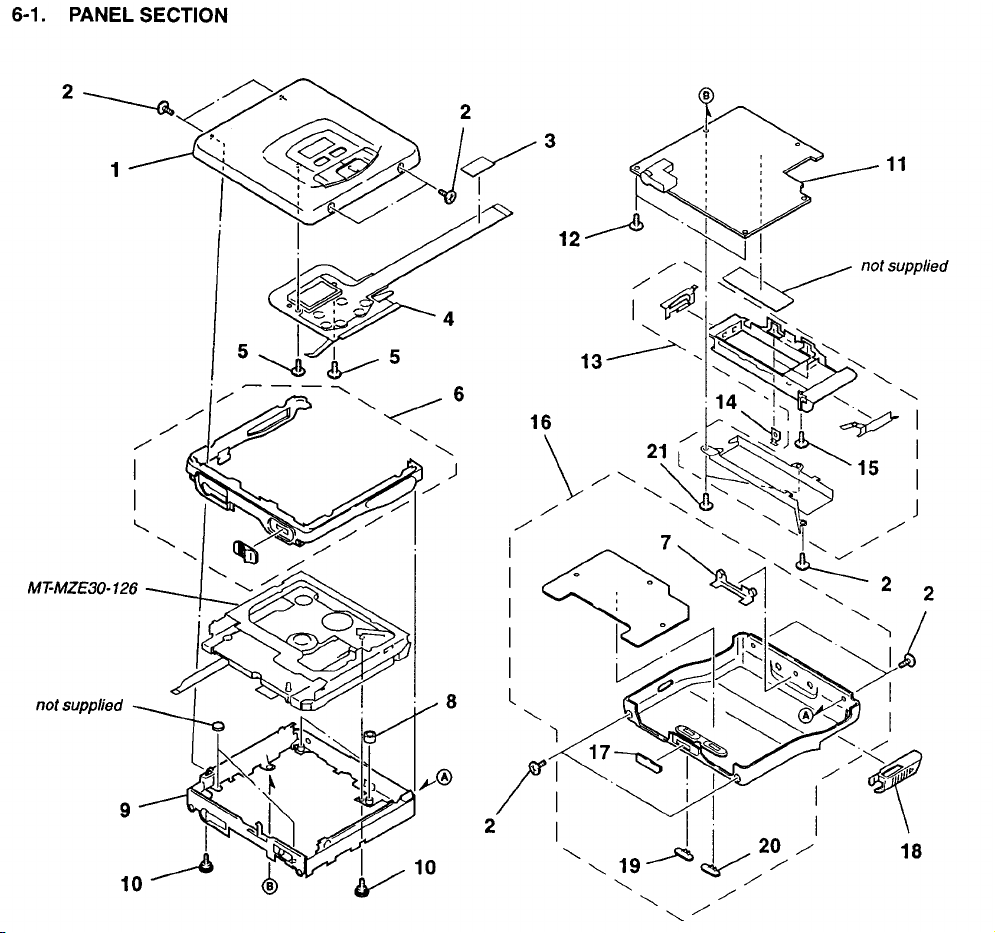

6. SYSTEM CONTROL

6-1. Detection Switch

Fig. 6-1. shows the detection switches connected to the system controller (IC801) and switch matrix for differentiating the

mode. This unit comes without the part enclosed in the dotted lines in (a) of the same figure which were provided with the

3rd generation unit, namely LIMITIN (detects the innermost circumference of the optical block), REFLECT (detects the

reflectivity rate of the disc), and the switches for differentiating and detecting the battery. Due to the omission of these parts,

focus search after disc replacement, etc. is performed at other than the innermost circumference in this unit. When the servo

turns ON, and data can be read from the disc, TOC accessing is performed based on the address.

Moreover, the differentiation of the MO or playback only disc which was performed by the reflectance rate detection switch

is performed in this unit by alternately switching the internal gain and laser power settings of the RF amplifier during focus

search, and detecting at which of these settings the focus turns ON.

(Details of differentiation of the disc are provided in 8-3. Focus Search and Disc Differentiation.)

As this unit uses a single voltage and does not have a recharge function, it is not mounted with a switch for differentiating and

detecting the battery.

At the ON and OFF of the open/close switch (S801), the wakeup (startup) and sleep (standby) operations of the power supply

are controlled, and at the same time, clearing of the address data of the stop position used by the resume function is performed.

IC801

SYSTEM CONTROLLER

13

54

AVLS

14

OPEN/CLOSE

9

82

15

HOLD

INSL

REFLCT

AM3/NI

PLAY

KEY0

KEY1

55

57

49

SWITCH

MATRIX

PLAY

REMOTE CONTROLLER

UNIT

(SWITCH MATRIX)

HOLD

AVLS

OPEN/CLOSE

INLIMIT

REFLECT

AM3/NI DET

(a) Example of MZ-E3

IC801

SYSTEM CONTROLLER

14

29

6

HOLD SW

AVLS SW

OPN/CLS SW

PLAY

KEY

SET

KEY

RMC

KEY

5

8

7

SWITCH

MATRIX

PLAY

REMOTE CONTROLLER

UNIT

(SWITCH MATRIX)

S802

S805

S801

HOLD

AVLS

OPEN/CLOSE

(b) MZ-E30

Fig. 6-1. Detection Switch Connected to System Controller

— 27 —

Page 37

6-2. Key Input Detection of Operation Buttons

The operation buttons on the unit and remote commander are each composed of switch matrix by combining with the

dividing resistor. As shown in Fig. 6-1. (b), when a operation button on the unit or a operation button on the remote control

unit is pressed, the voltage corresponding to the mode determined by the dividing resistor is input to Pin 8 [SET KEY] or Pin

7 [REM KEY] of the system controller (IC801) respectively. The system controller differentiates the mode according to this

input voltage, and sets the corresponding mode. As no power is supplied to the system controller in the sleep (standby) mode,

it will differentiate the mode after a button is pressed and power is supplied.

(1) When operating using the unit

Fig. 6-2. shows the connection between the operation buttons on the unit and the system controller (IC801) while Table 6-

1. shows the voltage input to the key input Pin 8 [SET KEY] of the system controller when a operation button is pressed.

When power supply to each part starts after wake-up, 2.8V (VC) from Pin #§ [VSTB] is supplied to R808 (47 kΩ) via the

switch inside the DC-DC converter (IC901). When a operation button is pressed in this state, a dividing voltage determined by

R808 (47 kΩ) and the resistor corresponding to that operation button, is input to Pin 8 of the system controller. A separate

line from the switch matrix is incorporated only for the PLAY button and voltage is input separately to Pin 5 [PLAY KEY]

so that the PLAY mode is set even when the button has been pressed instantaneously.

Table 6-1. Key Input Voltage During Operations of

Unit (Reference Values)

2.8[V]

PLAY

STOP

VOL+

P-MODE

REW

FF

VOL-

VC

VC

IC901

DC-DC CONVERTER

10

IC801

SYSTEM CONTROLLER

5

8

R803

470k

36

VSTB

R808

47k

R809 2.2k

R810 4.7k

R811 6.8k

R812 15k

R813 33k

PLAY KEY

SET KEY

Operation Buttons of Unit

STOP

FF

REW

VOL +

VOL –

P-MODE

When nothing is pressed

Pin 8 of IC801

0V

0.15V

0.4V

0.6V

1.0V

1.5V

2.8V

Fig. 6-2 Key Input Circuit of Operation Buttons of Unit

— 28 —

Page 38

(2) When operating using the remote commander

Fig. 6-3. shows the connection between the operation buttons on the remote commander and the system controller (IC801)

while Table 6-2. shows the dividing voltage input to Pin 7 [RMC KEY] of the system controller when a remote commander

button is pressed.

When power supply to each part starts after wake-up, the two switches inside the DC-DC converter turn ON, and the

dividing voltage obtained by R905 (150 kΩ) and R838 (10 kΩ) is input to Pin 7 [RMC KEY] of the system controller. When

a remote commander button is pressed in this state, the matrix resistor corresponding to that button and a dividing voltage and

R905 are connected in parallel form, and the voltage shown in Table 6-2. is input to Pin 7 of the system controller.

Table 6-2. Key Input Voltage During Operations of

Remote Commander (Reference Values)

VC

IC901

DC-DC CONVERTER

2.8[V]

VC

10

36

VSTB

R905

150k

XWK3

33

R838

10k

HOLD

VOL+

VOL-

STOP

PAUSE

PLAY

REW

1k

1.5k

1.3k

2k

1.5k

2.6k

RMC KEY

IC801

SYSTEM CONTROLLER

7

Operation Buttons of

Remote Commander

VOL+

VOL–

STOP

PAUSE

PLAY (FF)

REW

When nothing is pressed

Pin 7 of IC801

1.4V

1.5V

1.65V

1.8V

2.0V

2.5V

0.2V

VRMC

2

1

GND

Fig. 6-3. Key Input Circuit of Remote Commander

— 29 —

Page 39

6-3. operation of APC Circuit and Laser Power

2.8[V](VC)

IC501

RF AMP

LD-VDD

16

R506

4.7

LD-SNS

15

(2.7[V])

Q501

LD-DRV

PD-IN

14

11

3

LD DRIVE

CN501

5

LD

8

2

ILCC

LDGND

-

+

SSB-I/F

+

IC801

PD-O

13

C506

LPF

R883

1

APCREF

41

(2fs)

C806

R504

PD-I

12

SYSTEM CONTROLLER

KGND

7

PD

PD

6

18

VTEMP

21

SBUS

22

SCK

IC801 SYSTEM CONTROLER

1

41

pin APCREF

2

Q501 COLLECTOR

IC501 RF AMP

3

11

pin PD-IN

35

34

SBUS CLK

SBUS DATA

APPROX.4.6[s]

APPROX.1.8[s]

0

0

0

ON ON

2.7[V]

2[V]

750[mV]

OFF

Fig. 6-4. APC Circuit and Waveform Timing

Fig. 6-4. shows the APC (Automatic LASER Power operation) circuit and main waveform timings. The APC circuit

controls the driving current of the laser so that the voltage supplied from outside becomes the same as the monitor diode

voltage. With functions such as PLAY where the laser diode emits light, Pin $¡ [APC REF] of the system controller (IC801)

outputs a 88.1 kHz (2 fs:fs=44.1 kHz) PWM waveform at the waveform timing (1) shown in the figure. In the LPF, the DC

APC REF signal is input to Pin !™ [PD-I] of the RF amplifier (IC501), passed through the two differential amplifiers inside,

output from Pin !¢ [LD-DRV], passed through the LD drive (Q501) to drive the laser diode inside the optical block.

Inside the monitor diode (PD), the photoelectric current corresponding to the amount of radiated laser light is converted to

voltage by the resistor connected between the monitor diode anode and GND, input to Pin !¡ [PD-IN], and fed back to the first

stage amplifier to control the laser power. A constant current circuit is composed by feeding back the voltage decreased by the

R506 resistor (4.7 Ω) connected to the emitter of the LD drive, so that the driving current does not change even when the

power supply voltage changes.

The ON/OFF of the laser driving current is controlled by the system controller via the serial bus (SBUS).

During normal playback, an approximately 1.8 seconds ON and 2.8 seconds OFF are repeated as shown by the timing in the

figure to save power.

— 30 —

Page 40

In models which can record, changes in the recording power of the disc according to the ambient temperature and internal

temperature of the unit are detected by the temperature sensor and compensated. The RF amplifier (IC501) has a function

which converts temperature into voltage and outputs it from Pin !• (VTEMP), but this function is not used in this unit intended

exclusively for playback.

As the optimum read power differs between the playback only disc and MO disc, the disc is differentiated by focus search

performed immediately after the unit is started. The duty ratio of the PWM wave output from Pin $¡ of the system controller

is controlled so that 0.6 mW power is obtained if the disc is a playback only disc, and 0.8 mW power is obtained if it is a MO

disc.

(Details of differentiation of disc are provided in 8-3. Focus Search and Disc Differentiation.)

— 31 —

Page 41

7. PLAYBACK CIRCUIT

7-1. Outline of Playback Circuit

Fig. 7-1. shows the structure of the playback circuit of the Mini Disc. The RF data read by the optical block is demodulated

by the EFM demodulator, and data errors are detected and corrected by the ACIRC decoder.

Since the Mini Disc data has the same structure as the CD-ROM, it is decoded in the CD-ROM decoder in the next step,

and the ATRAC data compressed to approximately 1/5 is stored in the shock proof memory (buffer RAM). Apart from the

ATRAC data, this memory also stores error information (C2PO) and TOC/UTOC information.

The ATRAC data is written in the memory intermittently, and read to the ATRAC decoder periodically. The compressed

data is expanded to 16-bit linear data by the ATRAC decoder, D/A converted by the D/A converter, and output as analog

signal.

MD

EFM

DEMODULATOR

ACIRC

DECODER

CD-ROM

DECODER

SHOCK PROOF

MEMORY

ATRAC

DECODER

D/A

CONVERTER

Fig. 7-1 Structure of Mini Disc (Playback Circuit)

7-2. Playback Operations

Fig. 7-2. shows the block diagram of the playback circuit and the waveform of the main parts.

The two RF signals (I and J signals) I-V converted inside the optical block are input respectively to Pins 6 (VI) and 7

(VJ) of the RF amplifier (IC501). The RF amplifier sets the gain and internal circuits according to the disc type (MO or CD)

using the serial data input form the system controller (IC801).

Disc discrimination and gain setting are performed together during focus search. (Details are provided in 8-3. Focus Search

and Disc Discrimination.)

Furthermore, the output of the RF amplifier (1) is switched according to the disc type written in the TOC. In the case of the

pit area of the playback only disc and MO disc, the additional signal of I and J is output, based on the Vref voltage (0.88V)

generated inside the RF amplifier, from Pin #¶ (RF-OUT) to the DSP/digital servo (IC601) via the RF amplifier (2) and EQ

(equalizer). In the case of the groove area (UTOC, program area) of the MO disc, the subtraction signal is output. (1)

The RF signal is converted to a 7-bit digital value at a sampling frequency of 4.23 MHz (96 fs:fs=44.1 kHz) by the

A/D converter inside the DSP/digital servo. In the EFM PLL circuit, clock extraction and generation are performed, and based

on the channel clock (4.23 MHz) obtained, EFM demodulation is performed in the next stage. In the ACIRC decoder, data

errors are detected and corrected, and the data is then written in the DRAM via the RAM controller. The accumulated data is

compressed to approximately 1/5 according to the transfer command from the system controller, and periodically sent to the

ATRAC decoder block. In the ATRAC decoder block, the compressed data is expanded, and the data is output continuously

to the D/A converter (IC301) from Rch and Lch alternately in synchronization with LRCK (L/R clock) and BCK (bit clock)

at the timing of the audio signal shown in the figure.(Refer to 2 to 4.)

— 32 —

Page 42

The D/A converter is also incorporated with a digital DBB (Dynamic Bass Boost) and eight times over sampling digital

filter. These perform boosting of low bands and data filtering respectively using digital signals. The D/A converter also has a

deemphasis function, which is controlled using the emphasis ON and OFF signals output from Pin #• (EMP) of the DSP/

digital servo. The D/A converted analog signal is output to the headphone amplifier (IC302) via the VOLUME DOWN circuit

(Q301), which attenuates the audio signal boosted when DBB is ON, from Pins !¶ and !§ (A OUT L, AOUT R).

When the VOL button connected to the system controller is operated to control volume, the volume data is sent to the

ATRAC decoder block of the DSP/digital servo (IC601) via the serial bus (SBUS) and the volume is controlled by digital

signal processing inside the block.

Likewise for the beep sound when the remote operation button is operated, the data is sent to the DSP/digital servo (IC601),

the beep signal is generated inside the DSP/digital servo and output to the headphone via the D/A converter and headphone

amplifier.

7-3. Digital DBB and Mute Circuit

Fig. 7-3. shows the digital DBB (Dynamic Bass Boost) and mute circuit.

The D/A converter (IC301) incorporates a digital DBB function which is switched ON/OFF using the DBB switch (S301)

connected to Pin !¡ (DBB0) and Pin !™ (DBB1).

Low bands are boosted using the digital signal.

When Pin !¡ is set to “H”, at the reference level (–12 dB), signal is boosted by about 3.5 dB for 100 Hz. When Pin !™ is set

to “H”, it is boosted by about 8.5 dB. When DBB is turned ON, Q301 connected between the D/A converter and headphone

amplifier (IC301) also is turned ON at the same time. As a result, R206 (15 kΩ) and R202 (6.8 kΩ) or R106 and R102 are

connected in parallel, and attenuate the volume boosted by the DBB to prevent clipping caused by the volume increasing and

excess input to headphone amplifier when the DBB is ON.

On the other hand, the headphone standby signal from Pin &º (HP STBY) or the mute signal from Pin ^ª (HP MUTE) of

the system controller is input to the headphone amplifier to turn the standby mode and mute. When the standby signal is set

to “H” or the mute signal is set to “L” as shown in the timing chart in the figure, the sound signal input from the D/A

converter is output from the headphone.

During wakeup, and immediately after the PLAY mode is set, the headphone is muted by the approximately 500 to 600 ms

mute signal output from the system controller to prevent the output of pop noise, etc.

— 33 —

Page 43

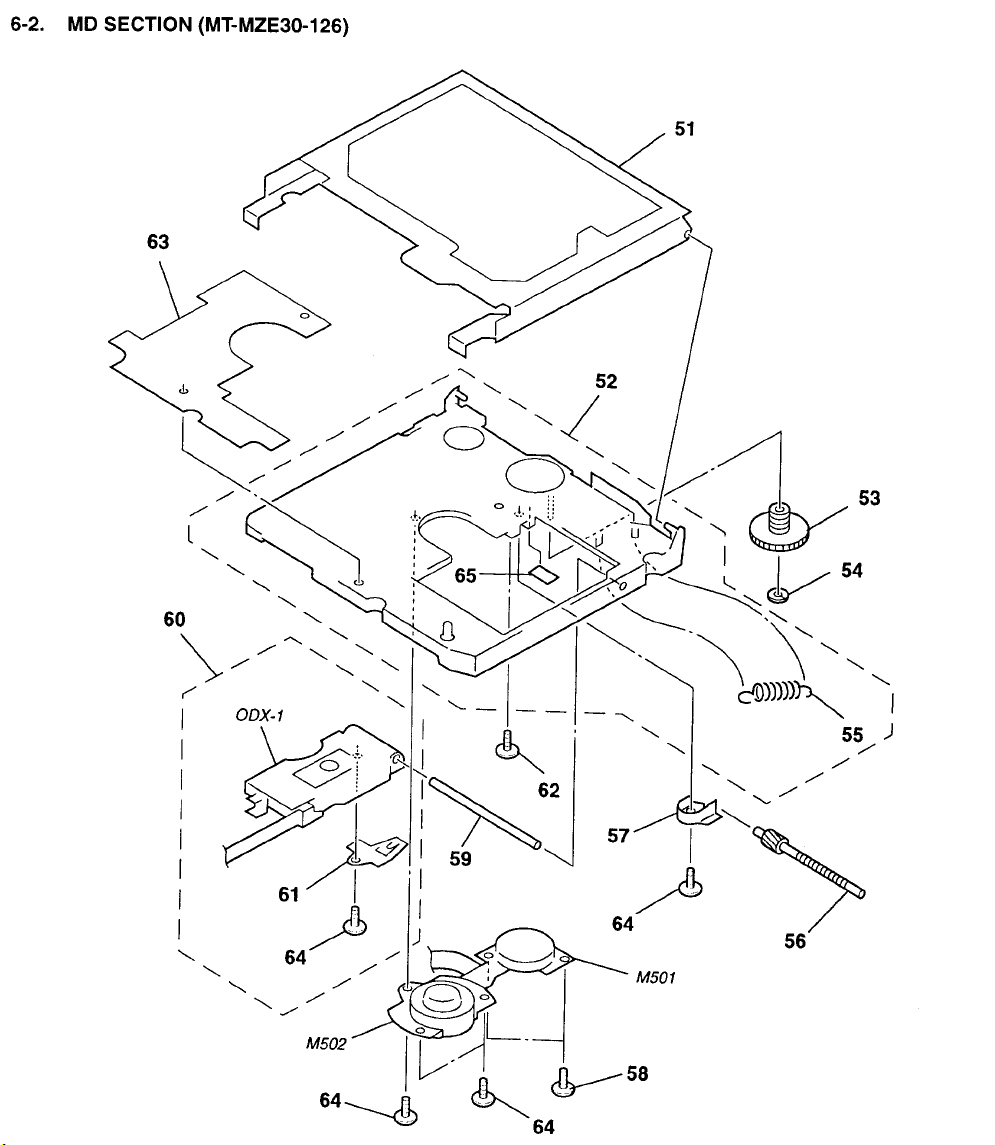

8. SERVO CIRCUIT

8-1. Outline of Servo Circuit

IC551(1/2)

SLED

MOTOR

SERVO DRIVER

FOCUS

TRACKING

IC551(2/2)

SERVO DRIVER

SPINDLE

SLED

M

M

FOCUS

COIL

TRACKING

COIL

SPINDLE

MOTOR

SLED

MOTOR

OPTICAL

PICK-UP

ODX-01

IC501

RF AMP

FE/TE

RF/ADIP

IC601

DSP/

DIGITAL SERVO

IC801

SYSTEM

CONTROLLER

IC802

EEP ROM

IC803

CONTROL

Fig. 8-1 Outline of Servo Circuit

As shown in Fig. 8-1., the servo circuit is composed of the RF amplifier (IC501), DSP/digital servo (IC601), system

controller (IC801), and the servo driver (IC551).

When a playback disc is played, the servo circuit operates in the same way as the CD player.

The focus and tracking servos A/D convert the error signals output from the RF amplifier inside the DSP/digital servo

(IC601), and perform servo calculation and correction. They then convert the signals to 2 fs (fs=44.1 kHz) PWM wave and

output them to drive the focus and tracking coil using the servo driver (IC551).

The spindle servo sends the measured period of the EFM frequency divided signal obtained from the RF signal using the DSP/

digital servo (IC601) to the system controller, generates the spindle error signal inside, and controls the rotation of the spindle

motor via the servo driver. The sled servo A/D converts the tracking error signal, sends the data to the system controller, and

generates the control signal of the sled motor control (IC803). The sled error signal is generated from this control signal in the

sled motor control (IC803) in the next stage, and used to control the rotation of the sled motor via the servo driver.

When the MO disc is played back, only the spindle servo in the servo circuit differs from when the playback only disc is

played back. In the case of the playback of the playback only disc, the measured period of the EFM frequency divided signal

obtained from the RF signal is used. In the case of the MO disc, that of the frequency divided signal obtained from the ADIP

signal recorded in the groove area is used.

In this unit, the digital servo composed of the RF amplifier (IC501), DSP/digital servo (IC601), and system controller

(IC801) controls focus, tracking, sled, and spindle. RF level adjustment and ABCD level adjustment are performed

automatically immediately after the unit is started by pressing the PLAY button so that the optimum values according to the

disc type (CD/MO) can be obtained by the digital servo.

The adjustment values of the servo such as focus/tracking gain, EF balance, focus bias, etc. stored in the non-volatile memory

(IC802, EEPROM) are sent to the servo circuit when the adjustment mode is started to optimize the servo. (Details of the

adjustment mode are provided in 4. Electrical Adjustments in the Service Manual.)

— 39 —

Page 44

8-2. Intermittent Operations of Servo

The focus servo and tracking servo of this unit turn ON and OFF repeatedly during normal playback and operate

intermittently.

To save power, they repeat 1.8 seconds of ON and 2.8 seconds of OFF as shown in the timing chart in Fig. 8-2. along with the

switching of the laser diode to ON/OFF. In the CLV servo, the control is different. When ON, as some time is required for the

servo to stabilize, the disc is rotated continuously in the rough servo mode even when the focus servo and tracking servo are

OFF. When the servo is ON, the focus servo sets the focus based on the focus voltage just before the servo is OFF to operate

the focus servo circuit.

Approx.

Approx.

1.8[s]

2.8[s]

FOCUS SERVO

TRACKING SERVO

ON

ON

OFF

OFF

OFF

ON

CLV SERVO

LOCK LOCK LOCK

LASER DIODE

ON

Fig. 8-2. Intermittent Operations of Servo

8-3. Focus Search and Disc Discrimination

ON

TRK-ON

A

ROUGH SERVO

B

ROUGH SERVO ROUGH SERVO

ON ONOFF OFF

ON

TRK-ON

AA

OFF

B

Y axis shows the focus drive voltage

The top is the disc.

Fig. 8-3. Focus Search (Previous Model)

Compared to the current CD discs, as the reflection rate of the MO disc is low (15 to 30%), the difference between the

pseudo reflected light on the disc surface (polycarbonate board surface of the side where signals are read) and the light

reflected from the MO media side is small, making it difficult for the IC to differentiate between the two. As a result, the FOK

signal sometimes becomes “H” according to the light reflected from the disc surface. Thus when the focus is turned ON, focus

is accidentally imposed on the disc surface. Focus search is therefore performed from near the disc (down search) unlike

current CDs to impose focus. (Part A of Fig. 8-3.)

— 40 —

Page 45

In 4th generation playback only players, improvements of the optical block enabled detection of the MO media to be

performed properly even when search was carried out from the far side of the disc as the disc surface deviated from the

focusing range.

As shown in Fig. 8-4., when search is performed from the side near the disc (down search), a disc with a high reflection rate

(CD) is set, when search is performed from the side far away from the disc (up search), a disc with a low reflection rate (MO)

is set, and MO/CD differentiation is performed together with focus search. After this, the focus on signal generated from the

focus OK signal is used to turn ON the focus and tracking servos.

The following shows the focus search process and disc differentiation method of the 4th generation playback only player.

Focus search process and disc differentiation

(1) After the power is turned ON, first high reflection rate gain of the RF amplifier and laser power of the high reflection rate

disc (CD) is set (0.6 mW), and focus search (from up to down) is started. (Part A of Fig. 8-4.)

(2) If this high reflection rate disc (CD) is loaded, focus is imposed. If a low reflection rate disc (MO) is loaded,

focus is not imposed and the the idling state is set. (Part A of Fig. 8-4.)

(3) Search is performed once, and if the disc is not detected (if idling is set), the RF amplifier sets the low reflection rate gain

again, sets the laser power of the low reflection rate disc (MO) (0.8 mW), and focus search (do wn to top) is performed. (Part

B of Fig. 8-4.)

(4) If focus is imposed here, the disc is determined to be a low reflection rate disc (MO), after which the tracking servo turns ON

and pit/groove differentiation is performed. This is performed by simultaneously switching the I+J (pit) and I-J (groove) of

the RF signal output from the RF amplifier (IC501) and E-F (pit) and F-E (groove) of the tracking error signal using the pit/

groove switching signal and detecting on which side the RF data is read.

(5) When the focus is not imposed (when the ABCD le vel does not reach a certain le vel), the abo ve operation is retried till eight

times.

(6) If focus is still not imposed after the retries, “NO DISC” is displayed.

* Disc differentiation is performed only once after the power is turned ON.

Immediately after the power turns ON, the offset data obtained in the adjustment mode and stored in the non-volatile

memory (IC802, EEPROM) is sent to the servo circuit to perform correction. To correct the offset generated due to

temperature characteristics, etc. of the optical block, fine adjustments of the focus offset and tracking offset are performed each

time the unit is started.

Standby

PON

Offset correction

CLV start

CLV

for

stabilization

Focus search start

ON

TRK-ON

Setting of high

reflection rate

(CD)

A

ON

TRK-ON

Setting of low

reflection rate

(MO)

B

AA

(When high

reflection rate)

“NO” DISC after 8 times of

no disc check continuously

B

(When low

reflection rate)

Y axis is focus drive voltage.

Top is disc

Fig. 8-4 Focus Search and Disc Differentiation (4th Generation Playback Only Player)

— 41 —

Page 46

8-4. Focus Servo Circuit

As shown in Fig. 8-5., the photoelectric current output from the optical block A to D detectors is input to the RF amplifier

(IC501), converted to voltage by the I-V amplifier inside, passed through the ABCD amplifier and F.E. (focus error) amplifier,

and the ABCD signal is output from Pin #∞ (ABCD) while the focus error signal is output from Pin #§ (FE) to the DSP/digital

servo (IC601). The A to D I-V amplifiers each have a gain switch for adjusting level. Using the serial data input from the

system controller (IC801) via the serial bus (SBUS), initial settings of the gain is performed together with ABCD level

adjustment according to the disc type each time PLAY, etc. to obtain the optimum output. To perform these, the system

controller reads the ABCD level data A/D converted from the DSP/digital servo (IC601) and control the gain switch so that the

data becomes the prescribed level.

The input of the DSP/digital servo (IC601) is incorporated with an A/D converter, which converts the ABCD signal and the

FE signal to 7-bit data at sampling frequencies of 22.05 kHz (fs/2) and 88.2 kHz (2 fs) respectively. The focus error signal is

then subject to servo calculation in the DSSP (digital servo signal processor) block, converted to the 88.2 kHz PWM wave, and

used to control the focus coil via the servo driver (IC551) and LPF (low pass filter).

In addition to the ABCD level adjustment mentioned earlier, the A/D converted ABCD signal data is also compared with the

reference level preset with the serial data from the system controller, and the FOK (focus OK) detection signal is output to the

system controller via the serial bus (SBUS).

The focus gain and focus bias adjustments are performed in the adjustment mode, the adjustment values are stored in the nonvolatile memory, the data is sent to the servo circuit via the serial bus (SBUS) at starting to set the focus gain and focus bias

adjustment data. In the case of focus bias, data on the bias amount during adjustment is sent to the DSSP block, added to the

focus error signal, and used to drive the focus coil.

— 42 —

Page 47

Page 48

Page 49

Page 50

Page 51

Internal Block Diagram

OFC-C1

OFC-C2

EQ-1

EQ-2

3941424644

EQ-3

VJ

EXT-IN

6

VI

7

10

IA

9

IB

3

IC

2

ID

1

IE

4

IF

27

i-v

conversion

i-v

conversion

i-v

conversion

i-v

conversion

i-v

conversion

i-v

conversion

RF

ABCD

Focus-Error

ADIP

FE and TE

DFCT

MIRROR

OFTRK

ADIP BPF

T-COUNT

37

26

25

34

35

38

36

29

31

30

32

33

28

FR-OUT

DFCT

OFTRK

OFTIN

ABCD

MIRR-VTH

FE

ADIP

BPFC0

BPFC1

REXT2

TE

T-COUNT

PD-IN

PD-I

PD-O

LD-SNS

LD-DRV

LD-VDD

SBUS

SCK

RESET

DVA1

19

11

12

13

15

14

16

21

22

24

17

APC

Remote control

Thermometer

Power supply

REXT1

18

VTEMP

8

A-VDD

43

A-VDD

20

D-VDD

47

VREF-OUT

46

VREF2-OUT

AGND

5

40

AGND

48

AGND

DGND

23

— 55 —

Page 52

Pin Assignment

MIRR-VTH

EQ-3

AGND

EQ-2

EQ-1

AVDD

OFC-C1

OFC-C2

VREF2-OUT

VREF-OUT

A-GND

48 47 46 45 44 43 42 41 40 39 38 37

RF-OUT

AGND

A-VDD

PD-IN

PD-I

ID

IC

VJ

1IE

2

3

4

IF

5

VI

6

SN761050A

7

8

9

IB

10

IA

11

12

13 14 15 16 17 18 19 20 21 22 23 24

PD-O

LD-DRV

LD-SNS

LD-VDD

DVA1

VTEMP

REXT1

DVDD

SBUS

SCK

DGND

RESET

36 FE

35

34

33

32

31

30

29

28

27

26

25

ABCD

OFTIN

TE

REXT2

BPFC0

BPFC1

ADIP

T-COUNT

EXT-IN

DFCT

OFTRK

— 56 —

Page 53

Pin Function

Pin No.

1

IE

2

ID

3

IC

4

IF

5

AGND

6

VI

7

VJ

8

A-VDD

9

IB

10

IA

11

PD-IN

12

PD-I

13

PD-O

14

LD-DRV

15

LD-SNS

16

LD-VDD

17

DV A1

18

VTEMP

19

REXT1

20

DVDD

21

SBUS

22

SCK

23

DGND

24

RESET

25

OFTRK

26

DFCT

27

EXT-IN

28

T-COUNT

29

ADIP

30

BPFC1

31

BPFC0

32

REXT2

33

TE

34

OFT-IN

35

ABCD

36

FE

37

RF-OUT

38

MIRR-VTH

39

EQ-3

40

AGND

41

EQ-2

42

EQ-1

43

AVDD

44

OFC-C1

45

OFC-C2

46

VREF2-OUT

47

VREF-OUT

48

AGND

Symbol

I/O

I

E current input

I

D current input

I

C current input

I

F current input

—

Analog GND

I

I voltage input

I

J voltage input

—

Analog Vdd

I

B current input

I

A current input

I

PD AMP non-inverted input

I

PD AMP inverted input

O

PD AMP output

O

LD-driver PNP-Tr base output

I

LD current detection input

I

LD power supply voltage detection input

I

Serial device code

O

Temperature gauge output

—

Temperature gauge current source setting resistor

—

Digital Vdd

I

Serial data input

I

Serial clock input

—

Digital GND

I

Reset input

O

Off track detection output

O

Defect detection output

I

External T-COUNT input

O

T-COUNT output

O

ADIP output

—

ADIP-BPF AC connecting capacitor

—

ADIP-BPF AC connecting capacitor

—

ADIP-BPF current source setting resistor

O

Tracking error output

I

Off track detection input

O

A+B+C+D output

O

Focus error output

O

RF output

I

Mirror comparator threshold setting

—

RF-amp phase shifter

—

Analog GND

—

RF-EQ external constant 2

—

RF-EQ external constant 1

—

Analog Vdd

—

DC canceler external capacitor 1

—

DC canceler external capacitor 1

O

Reference voltage output (GND reference 1.2V)

O

Reference voltage output (GND reference 1.2V)

—

Analog GND

Function

— 57 —

Page 54

10-2. DSP/Digital Servo µPD63730GC

DSP/digital servo for MD playback

• Built-in ATRAC decoder for playback

• Digital servo, EFM decoder, and ACIRC decoder functions

5175

76

100

50

uPD63730GC

26

251

— 58 —

Page 55

Internal Block Diagram

DRD 0-3

DRA 0-11

XWE

XWE2

XOE

XOE2

XCAS

XRAS

54

55

60

61

59

63

4

12

X BUSY

34

DREQ

XATWE

ATDT

16

AC-WDCK

S-DATA

8

DRM and peripheral-control

Address-generator

RD-DT-ECC

8

WRREQ etc.

EBA

12

ECC-DATA

8

EFM-DATA-A/B

16

AUDATA

40

8

AC-DATA

BCK

41

39

AC-BYCK

EFM

EMP

LRCK

38

ATRAC

Decoder

Sector

Decoder

AC-LRCK

AC-WDCK

ACIRC

Decoder

D-OUT

43

FLAG

ID0-3

SBR

SBW

SBA

8

SBD

8

SOREQ

2nd MSB

MCK-I/O

47

PMCK

25

44

Clock

Generator

SSB-Control

SubQ/ADIP

Decodeer

CK176

8

Monitor-I/O etc.

4

4

48

49

45

50

30

33

32

31

92

82

81

94

93

XI

XO

MCK/2

MCK

RESET

SINT

SCK

SBUS

TEST

M0CK

M00-3

M1CK

M10-3

ERFLAG

CRCF

FON

FOK

TFOUT

TROUT

FROUT

FFOUT

95

96

21

PLCK

22

23

24

11 12 13 4 6 5 1 3 2 7

DEFECT

T-COUNT

DSSP

OFTRK

TE

FE

FE

ABCD

TE

ABDC

EFM

VDD ADC

EFM

RF

ADC

RF

PLL

VREF

ADIP

ADIP

ADIP

PLL

89

EFM

88

PLCK

91

ADIP-DATA

ADPLCK

90

VSS

VDD

9

VRB

VRT

8

— 59 —

Page 56

Pin Configuration

VDD

DRA3

DRA2

DRA1

DRA0

DRA4

DRA5

DRA6

DRA7

DRA8

DRA10

DRA11

XRAS

DRA9

XOE2

XOE

XCAS

DRD2

DRD3

VSS

XWE2

XWE

DRD1

DRD0

51525354555657585960616263646566676869707172737475

VDD

VSS

MI0

MI1

MI2

MI3

MICK

MOCK

MO0

MO1

MO2

MO3

VDD

PLCK

EFM

ADPLCK

ADIP-DATA

TEST

CRCF

ERFLAG

FON

FOK

ID3

ID2

ID1

ID0

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VREF

VDD ADC

50 MCK

49

XO

48

XI

47

MCK-I/O

46

VSS

45

MCK/2

PMCK

44

43

DOUT

42

VSS

41

BCK

40

AUDATA

39

LRCK

38

CK176

EMP

37

VDD

36

35

34

XBUSY

33

SINT

32

SCK

31

SBUS

30

RESET

29

VDD

28

27

26

uPD63730GC

25242322212019181716151413121110987654321

FE

ABCD

TE

VRT

ADIP

VRB

VSS ADC

T-COUNT

DEFECT

OFTRK

VSS

TFOUT

TROUT

FROUT

FFOUT

RF

— 60 —

Page 57

Pin Function

Pin No.

1

VDD ADC

2

VREF

3

RF

4

FE

5

ABCD

6

TE

7

ADIP

8

VRT

9

VRB

10

VSS ADC

11

T -COUNT

12

DEFECT

13

OFTRK

14

VSS

15

16

17

18

19

20

21

TFOUT

22

TROUT

23

FROUT

24

FFOUT

25

CK176

26

27

28

29

VDD

30

RESET

31

SBUS

32

SCK

33

SINT

34

XBUSY

35

36

37

VDD

38

EMP

39

LRCK

40

AUDATA

41

BCK

42

VSS

43

DOUT

44

PMCK

45

MCK/2

46

VSS

47

MCK I/O

48

XI

49

XO

50

MCK

Symbol

I/O

—

Power supply for ADC block

I

Reference voltage input

I

RF signal input

I

Focus error input

I

ABCD (all quantity of light) signal input

I

Tracking error input

I

ADIP signal input

I

ADC high potential reference voltage for RF

I

ADC low potential reference voltage for other than RF

—

Ground for ADC block

I

Tracking count signal input

I

Defect signal input

I

Off track signal input

—

Ground

O

Tracking servo output (1)

O

Tracking servo output (2)

O

Focus servo output (1)

O

Focus servo output (2)

O

176.4 kHz (4 fs) output

—

Power supply

I

Reset input. Reset when “L”.

I/O

SBUS interface input/output

I

SBUS clock input

O

Interrupt signal output

O

DRAM access status

—

Power supply

O

Emphasis output for DAC. ON when ‘H”.

O

L/R clock output

O

Audio data output

O

Bit clock output

—

Ground

O

Digital output

O

1/4 divided output of MCK

O

1/2 divided output of MCK

—

Ground

I

Input/output direction switching of MCK. “L”:output, “H”:input.

I

Crystal oscillation input (384 fs=16.93 MHz)

O

Crystal oscillation output

I/O

Master clock input/output

Function

— 61 —

Page 58

Pin No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Symbol

VDD

DRD0

DRD1

XWE

XWE2

VSS

DRD3

DRD2

XCAS

XOE

XOE2

DRA9

XRAS

DRA11

DRA10

DRA8

DRA7

DRA6

DRA5

DRA4

DRA0

DRA1

DRA2

DRA3

VDD

VSS

M10

M11

M12

M13

MICK

MOCK

M00

M01

M02

M03

VDD

PLCK

EFM

ADPLCK

ADIP-DATA

TEST

CRCF

ERFLAG

FON

FOK

ID3

ID2

ID1

ID0

I/O

—

Power supply

I/O

DRAM data input/output

I/O

DRAM data input/output

O

DRAM write enable output

O

DRAM write enable output

—

Ground

I/O

DRAM data input/output

I/O

DRAM data input/output

O

DRAM-CAS output

O

DRAM output enable output

O

DRAM output enable output

O

DRAM address output

O

DRAM-RAS output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

O

DRAM address output

—

Power supply

—

Ground

I/O

Monitor input

I/O

Monitor input

I/O

Monitor input

I/O

Monitor input

O

Monitor in clock

O

Monitor out clock

O

Monitor output

O

Monitor output

O

Monitor output

O

Monitor output

—

Power supply

I/O

PLL clock input/output

I/O

PLL input/output

I/O

ADIP-PLL clock input/output

I/O

ADIP-PLL demodulation input/output

I

Test

O

CRC flag

O

Error flag

O

FON signal

O

FOK signal

I

SSB code setting input

I

SSB code setting input

I

SSB code setting input

I

SSB code setting input

Function

— 62 —

Page 59

10-3. Servo Driver MPC17A55FTA

MD/CD player motor driver, system power supply

54 54

55

36

MPC17A55FTA

72

1

18

19

— 63 —

Page 60

Internal Block Diagram

GND

GND

PO2

PI2

PI1

OE

D0

D1

PWM

VB

VB

VB1

VB1

VB2

L2H

DCC2

VPS2

31

30

29

PS

32

33

63

ROE

1

72

71

4

5

2

3

6

7

8

PO1

VPS1

28 27 36 35 34 37 68 70

VC

PWM

Control

VC

PWM

Control

VC

VC

VG

Slep-Up/Down

/Power SW

Decoder

VG

Power SW

Pre driver

VG

Slep-Up/Down

Pre driver

Pre driver

Pre driver

VG

VG

D0 or D1

BIAS

Control

3 Phese

Control

VC

int STB

int OE

VC

H-Bridge

Control

VC

HIU

VCVC

Pre driver

HIV

VG

HIW

VC

VC

Pre driver

VC

VC

VG

VG

VC

VG

VCVC

VG

69

GDN

20

VD1

24

VD2

21

Hou

23

Hov

25

How

26

GND

3P2

22

GND

3P1

19

IN

WO

18

17

VO

16

UO

58

RI1

57

FI1

56

RI2

55

FI2

52

VM2

53

FO2

51

RO2

50

H12

GND

54

GND

H2

48

VM1

L2L

VO

VO

L1

GND

DCC1

GND

DCC1

VREG CONT

VREG

RGDN

9

10

11

12

13

14

15

L1

VC

REN

65

64

66

VG

Slep-Up

Pre driver

VC

int STB

67 60 59 62 61

FI3

CLPF

RI3

FI4

RI4

H-Bridge

Control

VC

H-Bridge

Control

VC

H-Bridge

Control

Pre driver

VC

Pre driver

VC

Pre driver

49

FO1

47

RO1

46

H13

GND

VG

VG

44

VM3

43

FO3

45

RO3

42

GND

H34

40

VM4

39

FO4

41

RO4

38

GND

H4

— 64 —

Page 61

Pin Function

Pin No.

D0

1

VB1

2

VB1

3

VB

4

VB

5

VB2

6

L2H

7

GND DCC2

8

L2L

9

VO

10

VO

11

LI

12

GND DCC1

13

GND DCC1

14

L1

15

UO

16

VO

17

WO

18

IN

19

VD1

20

HOU

21

GND3P1

22

HOV

23

VD2

24

HOW

25

GND 3P2

26

VPS1

27

PO1

28

GND PS

29

PO2

30

VPS2

31

PI2

32

PI1

33

HIW

34

HIV

35

HIU

36

VC

37

GND H4

38

FO4

39

VM4

40

RO4

41

GND H34

42

FO3

43

VM3

44

RO3

45

Symbol

I/O

I

Operation mode setting

I

Power switch input 1

I

Power switch input 1

O

Power switch output

O

Power switch output

I

Power switch input 2

O

Step up/down converter PWM output

—

Step up/down converter GND

O

Step up/down converter fixed pulse output

O

DC/DC converter output

O

DC/DC converter output

O

Step up converter PWM output

—

Step up converter power GND

—

Step up converter power GND

O

Step up converter PWM output

O

U phase output of the phase detection comparator

O

V phase output of the phase detection comparator

O

W phase output of the phase detection comparator

I

Normal rotation input of the phase detection comparator

—

Three-phase driver power supply

O (I)

Three-phase driver U phase output and reverse rotation input of the phase detection comparator

—

Power GND for the three-phase driver

O (I)

Three-phase driver V phase output and reverse rotation input of the phase detection comparator

—

Power supply of the three-phase driver

O (I)

Three-phase driver W phase output and reverse rotation input of the phase detection comparator

—

Power GND for the three-phase driver

—

PWM driver 1 power supply

O

PWM driver 1 output

—

Power GND for PWM driver

O

PWM driver 2 output

—

PWM driver 2 power supply

I

PWM driver 2 control input

I

PWM driver 1 control input

I

Three-phase driver control input

I

Three-phase driver control input

I

Three-phase driver control input

—

Control circuit power supply

—

Power GND for the H bridge driver

O

H bridge driver 4 output

—

H bridge driver 4 power supply

O

H bridge driver 4 output

—

Power GND for the H bridge driver

O

H bridge driver 3 output

—

H bridge driver 3 power supply

O

H bridge driver 3 output

Function

— 65 —

Page 62

Pin No.

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

Symbol

GND H13

RO1

VM1

FO1

GND H12

RO2

VM2

FO2

GND H2

FI2

RI2

RI1

RI1

RI3

FI3

RI4

FI4

OE

VREG

VREG CONT

RGND

CLPF

VC

GND

VG

PWM

D1

I/O

_

Power GND for the H bridge driver

O

H bridge driver 1 output

_

H bridge driver 1 power supply

O

H bridge driver 1 output

_

Power GND for the H bridge driver

O

H bridge driver 2 output

_

H bridge driver 2 power supply

O

H bridge driver 2 output

_

Power GND for the H bridge driver

I

H bridge driver 2 control input

I

H bridge driver 2 control input

I

H bridge driver 1 control input

I

H bridge driver 1 control input

I

H bridge driver 3 control input

I

H bridge driver 3 control input

I

H bridge driver 4 control input

I

H bridge driver 4 control input

I

Driver output enable control input

O

Regulator circuit output

I

Regulator circuit output enable control input

_

Regulator circuit GND

Regulator circuit reference voltage filter

_

Control circuit power supply

_

Control circuit GND

_

Pre-driver circuit power supply

I

DC/DC PWM signal input

I

Operation mode setting

Function

— 66 —

Page 63

Outline of Operations

(1) Power Switch, DC/DC Block

VC

AM3

VCON

10uH

33uF

47uH

Li+

VB

PWM

VB1

VB1

VB2

L2H

GND

GNDDCC1

GND

D0

D1

VB

VB

DCC2

L2L

VO

VO

DCC1

VG

1

72