Page 1

MZ-E10

SERVICE MANUAL

Ver 1.0 2002.11

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation

SPECIFICATIONS

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 790 nm

Emission duration: continuous

Laser output: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm from the

objective lens surface on the optical pick-up block with 7 mm aperture.

Revolutions

Approx. 300 rpm to 2,700 rpm

Error correction

ACIRC (Advanced Cross Interleave Reed Solomon Code)

Sampling frequency

44.1 kHz

Coding

ATRAC (Adaptive TRansform Acoustic Coding)

ATRAC3: LP2/LP4

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Outputs

Headphones/earphones: dedicated headphone/ remote control jack,

output level 5 mW + 5 mW(US model) load impedance 16 ohms,

5 mW + 5 mW (Other models)

load impedance 16 ohms

Power requirements

Lithium-ion rechargeable battery (Built-in: LIP- 3WMB, 3.7 V,

340 mAh, Li-ion)

External power jack (for the battery charging stand): Power rating 6 V

DC

US Model

Canadian Model

AEP Model

UK Model

E Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZE10-184

Optical Pick-up Mechanism Type ABX-1ES

Battery life

Batteries SP Stereo LP2 LP4

Lithium-ion 23 33 40

built-in

rechargeable

battery

1)

Measured with the power save function on (see

“ Preserving battery power” ).

2)

Measured in accordance with the JEITA (Japan Electronics and

Information Technology Industries Association) standard (using a Sony

MDW-series Mini-disc).

3)

With a fully charged battery.

Note

The battery life may be shorter than that specified, depending on the

operating conditions,the temperature of the location.

Dimensions

Approx. 81.9 x 72.2 x 9.9 mm (w/h/d) ( 3 1/4 x 2 7/8 x 13/32 in.)

(not including projecting parts and controls)

Mass

Approx. 55 g (1.6 oz) (including the built-in rechargeable battery)

Supplied accessories

Headphones/earphones with a remote control (1)

Battery charging stand (1)

AC power adaptor (for the supplied battery charging stand) (1)

Headphone adaptor (1)

Carrying pouch (1)

Design and specifications are subject to change without notice.

1)

(Unit: Approx. hours) (JEITA2))

(normal) Stereo Stereo

3)

9-874-219-01

2002K0200-1

© 2002.11

PORTABLE MINIDISC PLAYER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

MZ-E10

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈSES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPÉMENTS

PUBLIÉS PAR SONY.

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE ...................................................... 3

2. GENERAL

Playing an MD ................................................................... 4

3. DISASSEMBLY

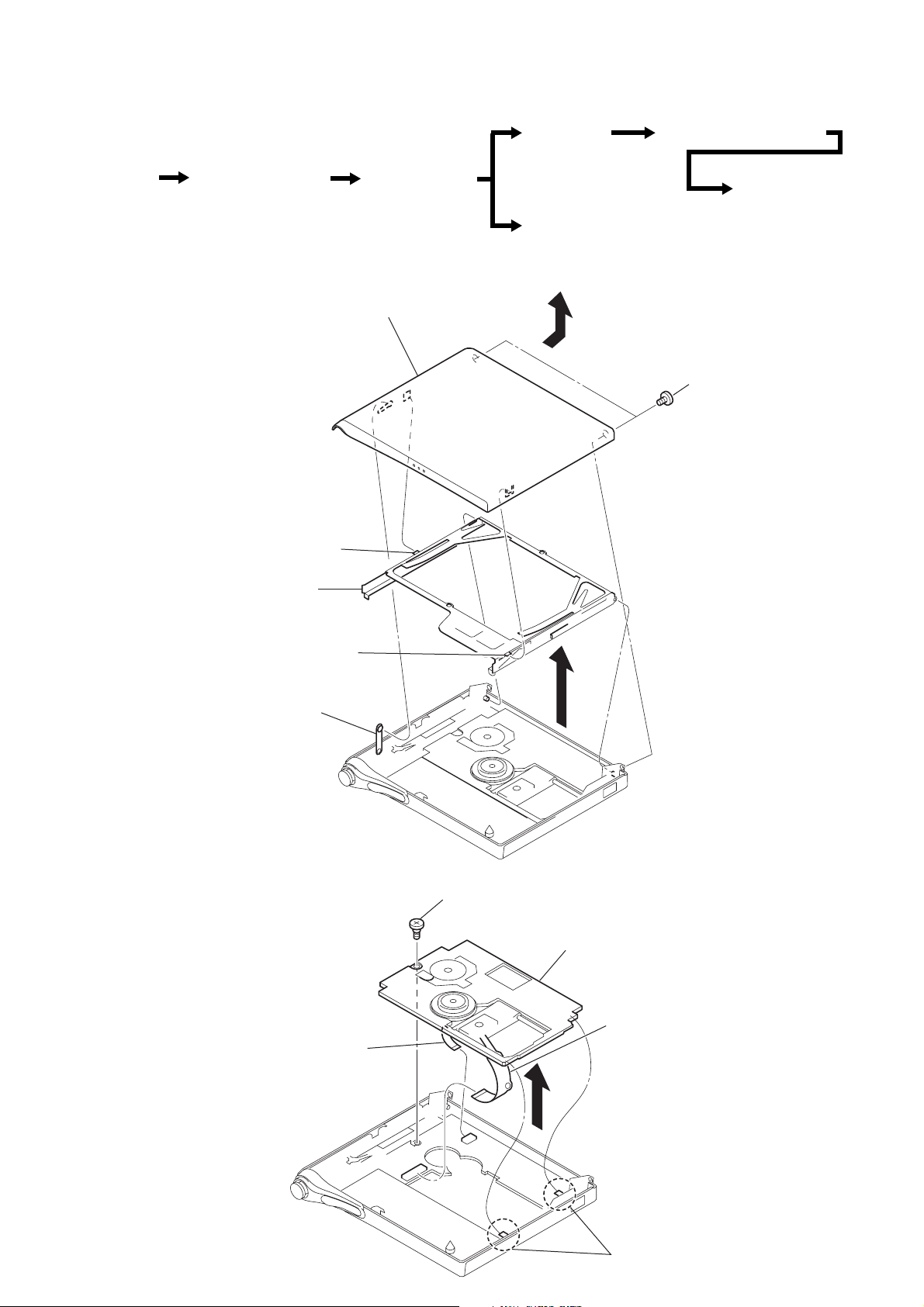

3-1. Panel assy (S), Upper ................................................. 5

3-2. Mechanism Deck (MT-MZE10-184) .......................... 5

3-3. Bracket assy ............................................................... 6

3-4. Power Board, Main Board .......................................... 6

3-5. Control Board ............................................................. 7

3-6. Optical Pick-up assy(ABX-1ES) ................................ 7

4. TEST MODE.................................................................. 8

5. ELECTRICAL ADJUSTMENTS ............................ 11

6. DIAGRAMS

6-1. Block Diagram .......................................................... 19

6-2. Printed Wiring Boards – Main Section (1/2) – ......... 20

6-3. Printed Wiring Boards – Main Section (2/2) – ......... 21

6-4. Schematic Diagram – Main Section (1/3) – ............. 22

6-5. Schematic Diagram – Main Section (2/3) – ............. 23

6-6. Schematic Diagram – Main Section (3/3) – ............. 24

6-7. IC Pin Function Descrintion ..................................... 26

6-8. IC Block Diagrams ................................................... 30

7. EXPLODED VIEWS

7-1. Main Section ............................................................. 33

7-2. Mechanism Deck Section (MT-MZE10-184) ........... 34

8. ELECTRICAL PARTS LIST................................... 35

r

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

* Replacement of SN761058ZQL (IC501) and LC896442-VH4-

16-E (IC601) used in this set requires a special tool.

2

Page 3

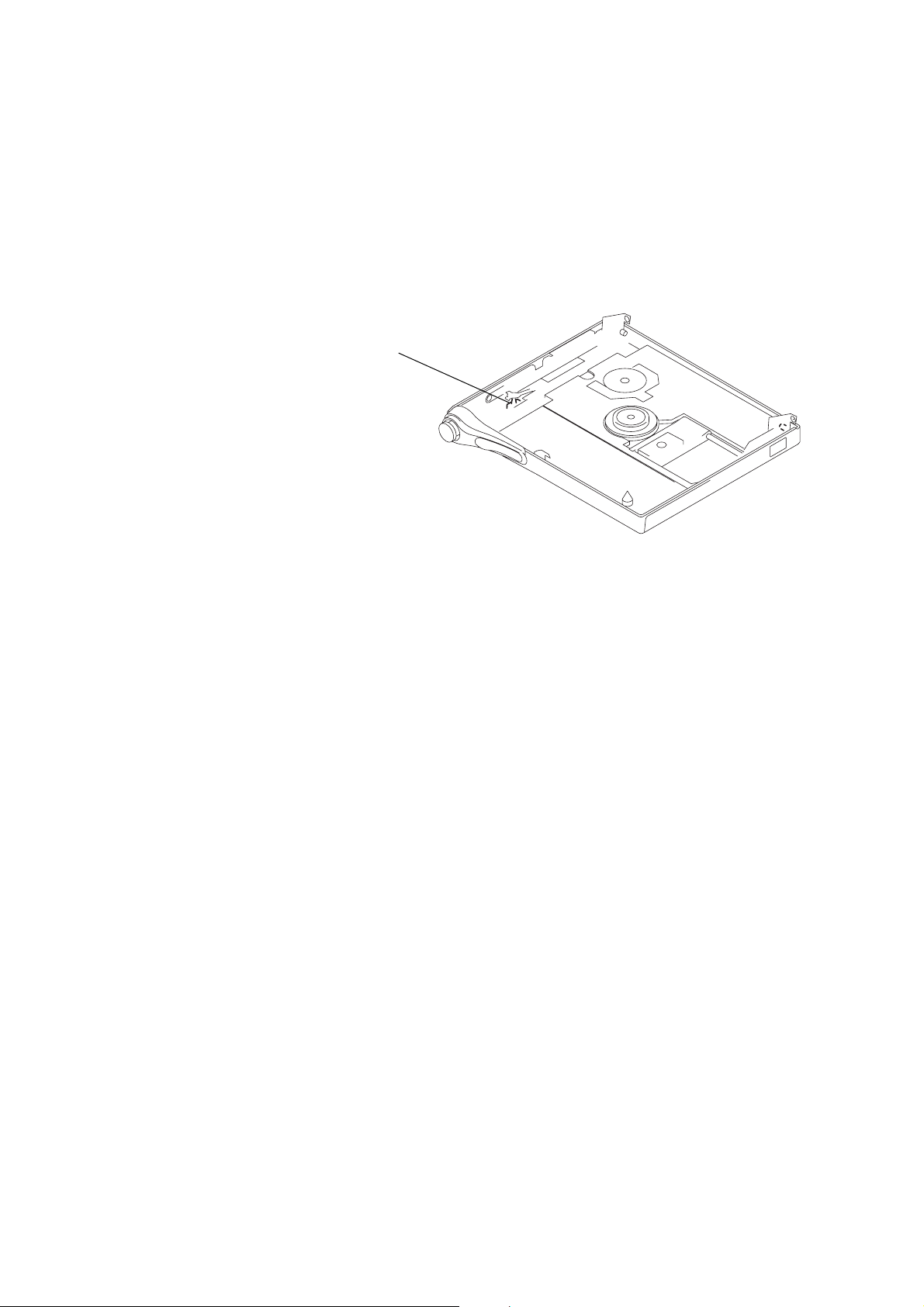

SECTION 1

SERVICING NOTE

When repairing this device with the power on, if you remove the main board, this device stops working.

In this case, you work without the device stopping by fastening the hook of the Open/Close detection switch (S803).

Open/Close detection switch (S803)

MZ-E10

3

Page 4

MZ-E10

4

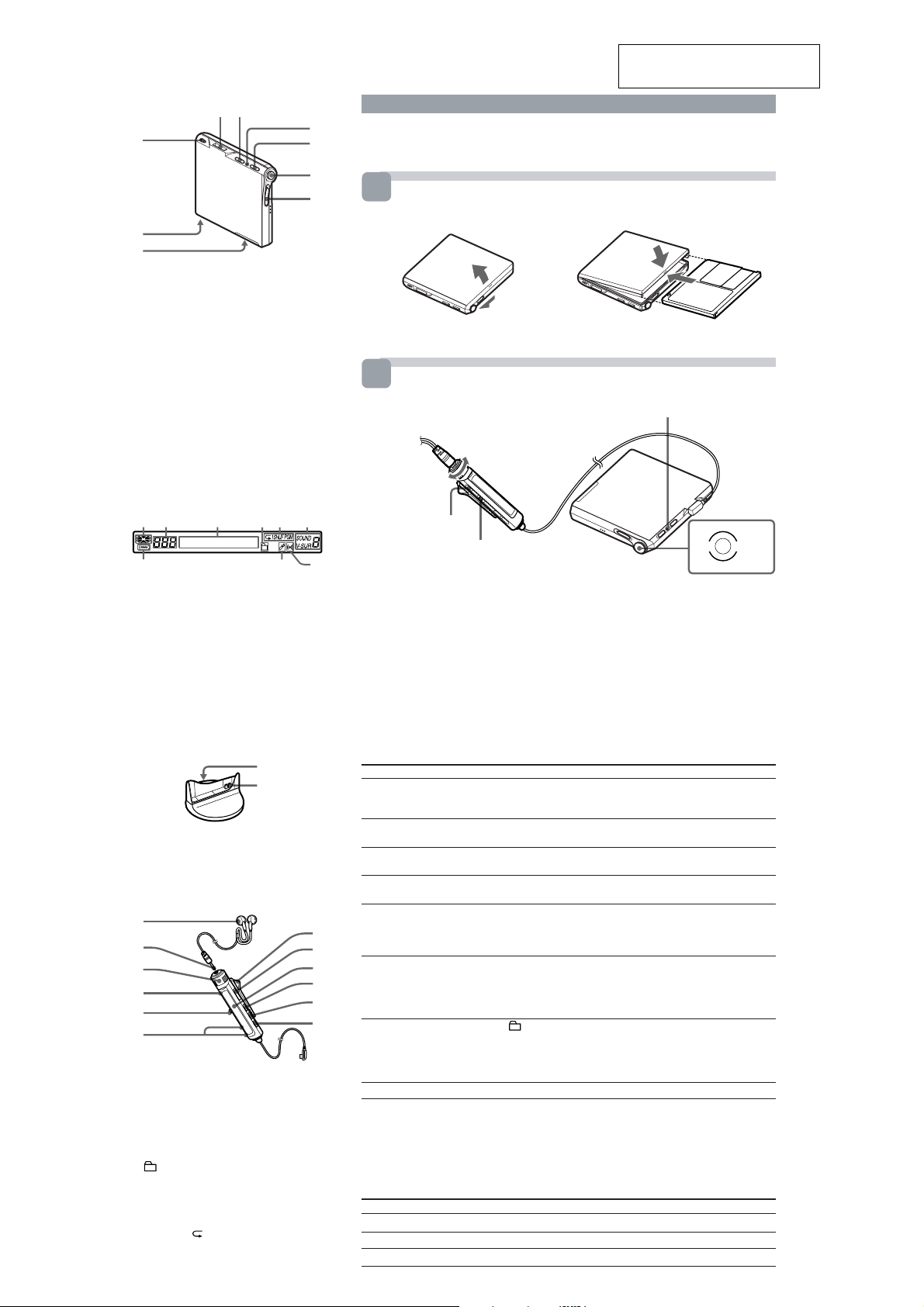

The Player

1 2

9

8

7

1 i (Headphones/earphones) jack

2 GROUP button

3 “3-color info-LED”

4 HOLD (Locking the control) switch

5 5-way control key ( .•

• x•VOL +, –)

6 OPEN switch

7 BUILT-IN BATTERY switch (at the

bottom)

8 Terminals for charging stand (at the

bottom)

9 Hand strap hole

Use the hole to attach your strap

*N has a tactile dot .

The display window of the remote

control

12 3456

7 9

1 Disc indication

2 Track number display

3 Character information display

4 Group play indication

5 Play mode indication

6 Virtual Surround/6-band equalizer

indications

7 Battery level indication

8 Bookmark indication

9 Alarm indication

The battery charging stand

> N

*

8

1

2

1 DC IN (6V jack) (at the bottom)

2 Terminals for charging

The headphones/earphones with a

remote control

A

B

C

D

5

F

1 Headphones/earphones

2 Stereo mini plug

3 Control VOL +, –

Turn to adjust the volume .

4 x (stop) button

5 Jog lever (.•u/ENT•>)

6 (Group) +, – button

7 Clip

8 HOLD switch

9 Display window

q; DISPLAY button

qa P MODE / (play mode/repeat) button

qs SOUND button

C

D

E

6

7

8

9

q;

qa

qs

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Playing an MD

1

Insert an MD.

1 Slide OPEN to open the lid. 2 Insert an MD. 3 Close the lid.

3

2

1

Insert an MD with the label side facing up, pushing the

MD to the direction of the arrow in the illustration.

2

Play an MD.

Bottom side of

VOL–

VOL+

x

Jog lever (.•u/ENT• >)

1 Press the jog lever ( u) on the remote control. (Press towards > N on

the player.)

A short beep sounds in the headphones/earphones. The LED lights up.

2 Turn the control towards VOL + or – on the remote control to adjust the

volume. (Press towards VOL + or – on the player. )

The volume indicator appears in the display, allowing you to check the

volume level.

To stop play, press

A long beep sounds in the headphones/earphones.

Playback starts from the point you last stopped playing. To start playback from the

beginning of the disc, press and hold the jog lever (u) for 2 seconds or more on the

remote control (Press and hold towards > N for 2 seconds or more on the player).

To

Pause

Cue to the current track

or the previous track

Cue to the next track

Go backwards or

forward while playing

Searching for a specific

position while viewing

a elapsed time

(Time search)

Searching for a specific

track while viewing

track numbers or

track names

(Index search)

Cue to the beginning of

every 10th track

(only during playback of

the disc with no group

settings1))

Remove the MD

1)

For more details, see “Using the group function.”

2)

Once you open the lid, the point to start play will change to the beginning of the first track (except

when the disc information has been stored in the personal disc memory).

About the “3-color info-LED”

The LED indicates the current operating mode, charging status, and battery condition. For

details about the charging status, see “Getting started.” For details about the battery condition,

see “When to recharge the built-in battery” on the back page.

LED color

Red

Green

Orange

Operating status

Playing a disc with no group settings

Playing a disc with group settings

Cueing to the another group (Group Skip)

x.

Do this (Beeps in the headphones/earphones)

Press the jog lever (u) on the remote control (continuous short

beeps).

Press the jog lever (u) again to resume play.

Slide the jog lever towards . on the remote control

(three short beeps). (Press towards . on the player. )

Slide the jog lever towards > on the remote control (two short

beeps). (Press towards > on the player.)

Slide and hold the jog lever towards . or > on the remote

control. (Press and hold towards . or > on the player. )

While the player is paused, slide and hold the jog lever towards

. or > on the remote control.

While the player is stopped, slide and hold the jog lever towards

. or > on the remote control.

Press + or – button.

Press x, and then slide OPEN2).

the player

“3-color info-LED”

VOL +

VOL –

5-way control key

x> N.

Page 5

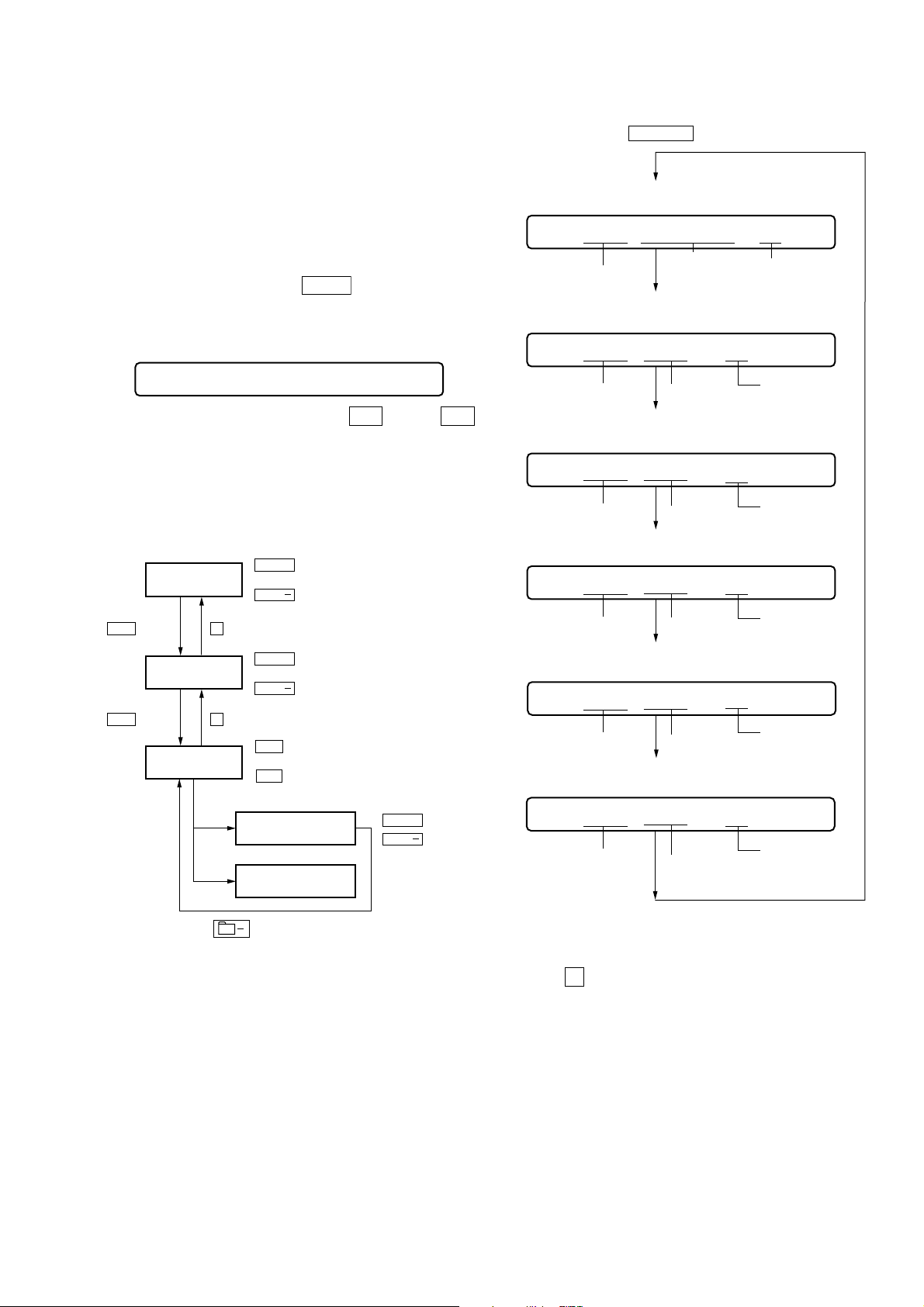

SECTION 3

)

d

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Bracket ASSY

MZ-E10

POWER board, MAIN board

Set

Note : Follow the disassembly procedure in the numerical order given.

Panel ASSY (S), upper

Mechsnism deck

(MT-MZE10-184)

3-1. PANEL ASSY (S), UPPER

7

Panel ASSY (S), upper

2

Claw

Holder ASSY

Optical pick-up ASSY

(ABX-1ES)

4

CONTROL board

1

Two screws (M1.4

3

Claw

5

Bracket ASSY

3-2. MECHANISM DECK (MT-MZE10-184)

5

Motor flexible board

(CN551)

1

Screw, step

6

6

Mechanism deck

(MT-MZE10-184)

4

OP flexible boar

(CN501)

3

2

Two claws

5

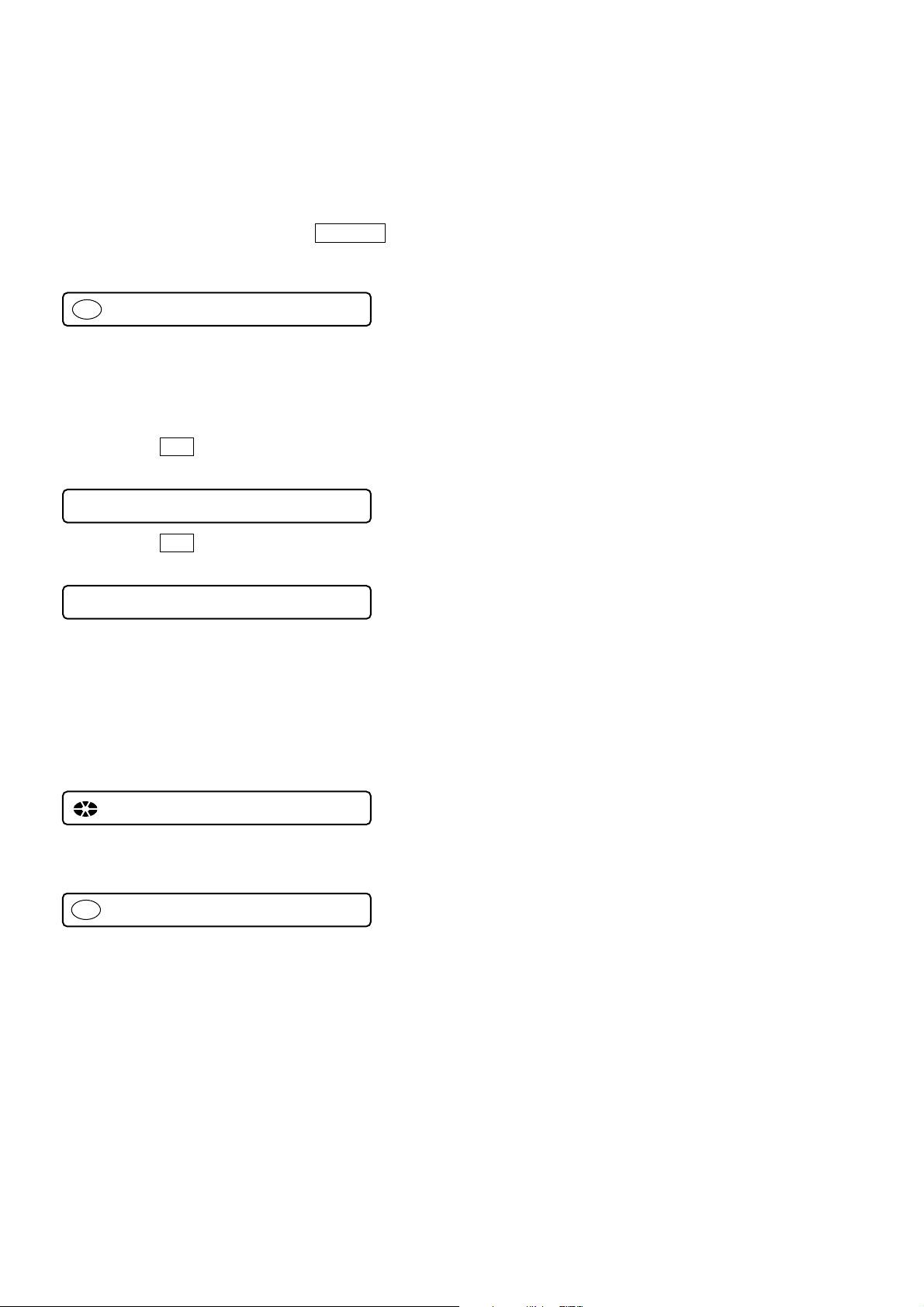

Page 6

MZ-E10

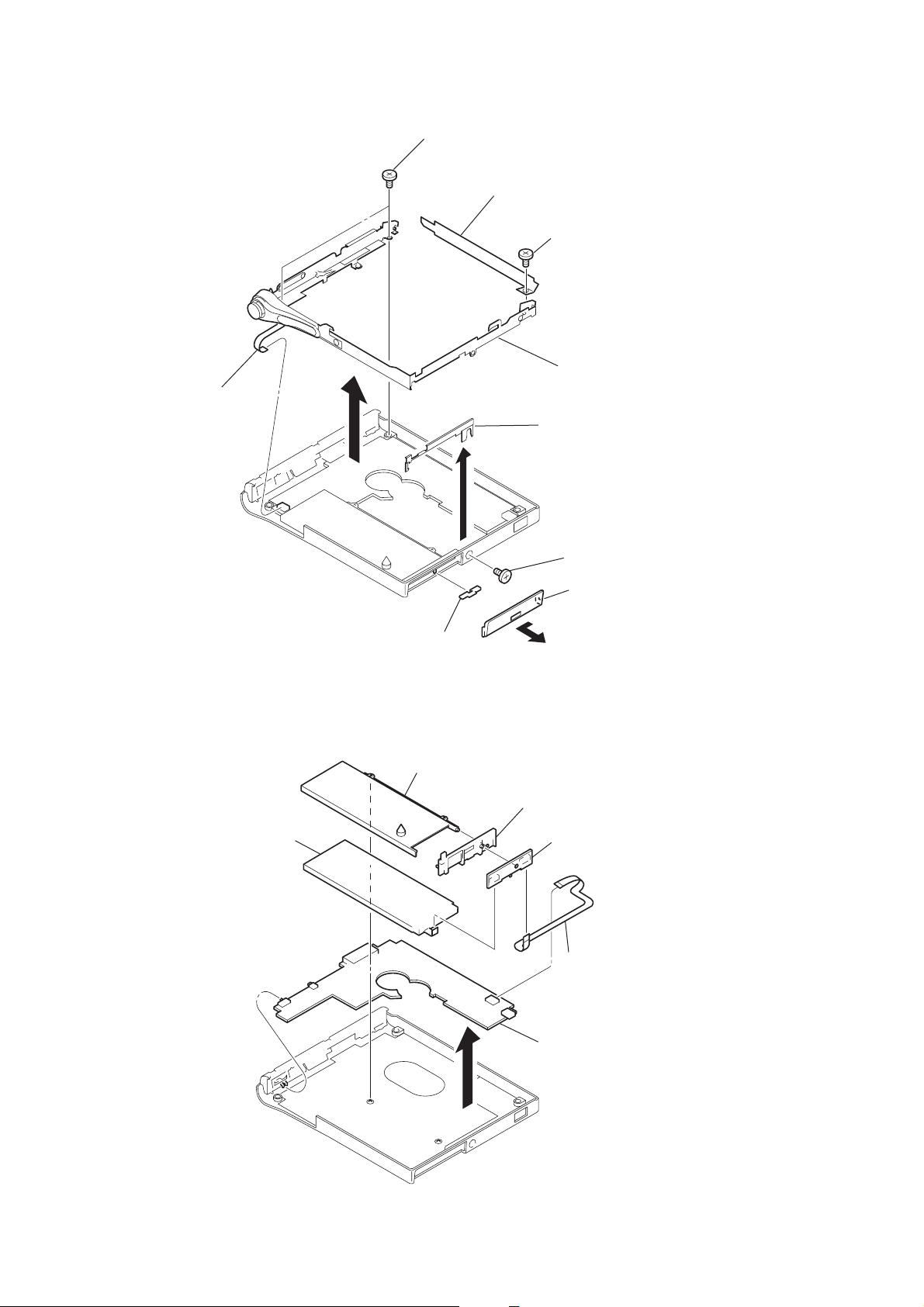

3-3. BRACKET ASSY

9

Switch flexible board

(CN801)

8

7

Two screws (M1.4)

Sheet (blind)

6

Screw (M1.4)

0

Bracket ASSY

2

Plate, retainer

3-4. POWER BOARD, MAIN BOARD

3

Battery, lithium ion storage

5

Konb (power)

1

Case, battery

1

Screw (M1.4)

4

Lid (DC), battery case

3

2

Retainer, battery

4

POWER board

5

Power relay flexible board

(CN952, CN953)

7

6

MAIN board ASSY

6

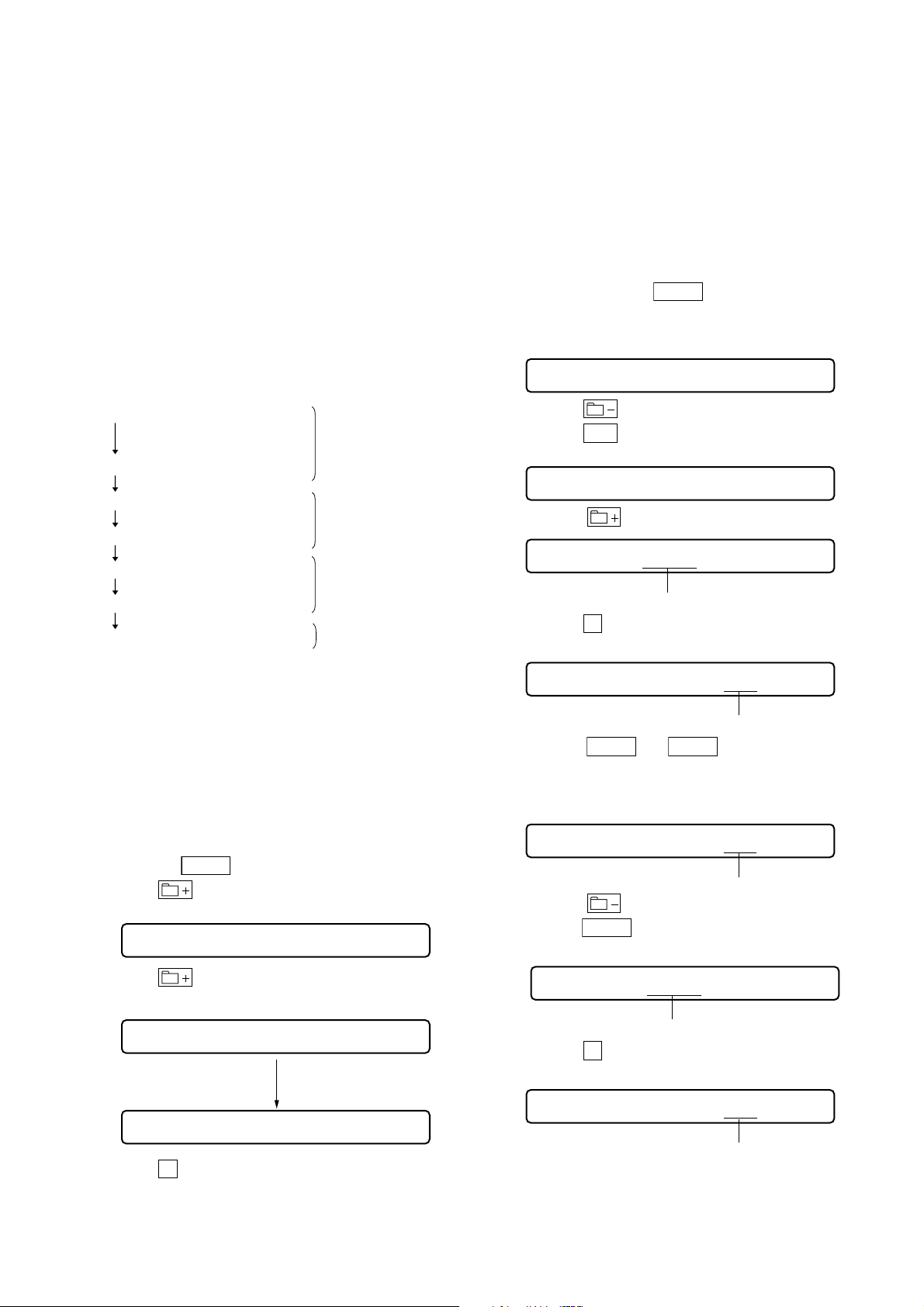

Page 7

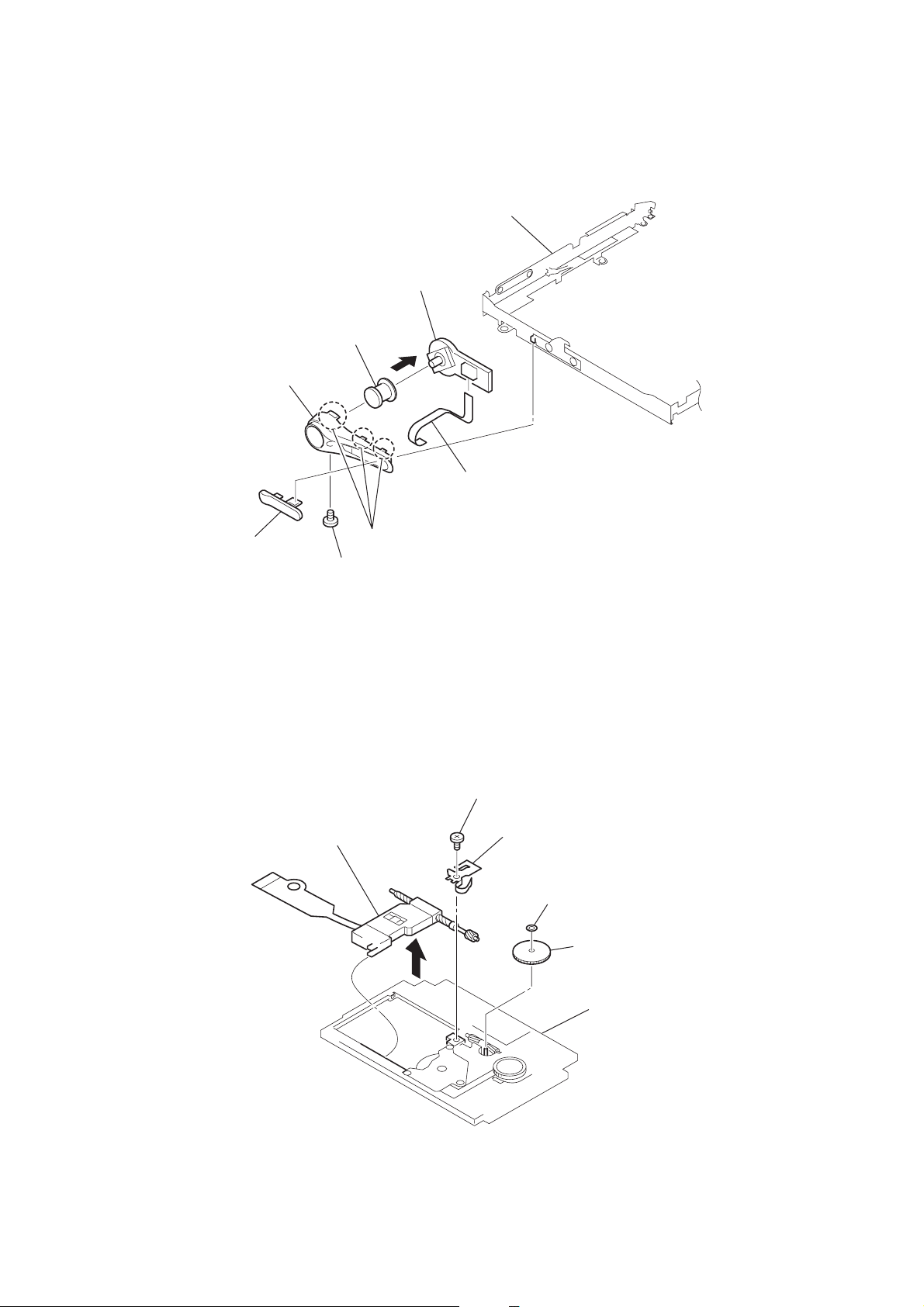

3-5. CONTROL BOARD

4

Cover (control)

7

CONTROL board

6

Button (control)

Bracket ASSY

5

Switch flexible board

(CN801)

MZ-E10

2

3

Knob (open)

1

3-6. OPTICAL PICK-UP ASSY (ABX-1ES)

6

Optical pick-up ASSY

(ABX-1ES)

Remove three claws

Screw (M1.4)

5

3

Screw, tapping

4

Spring, thrust detent

1

Washer (0.8-2.5)

2

Gear (SA)

Mechanism deck

(MT-MZE10-184)

7

Page 8

MZ-E10

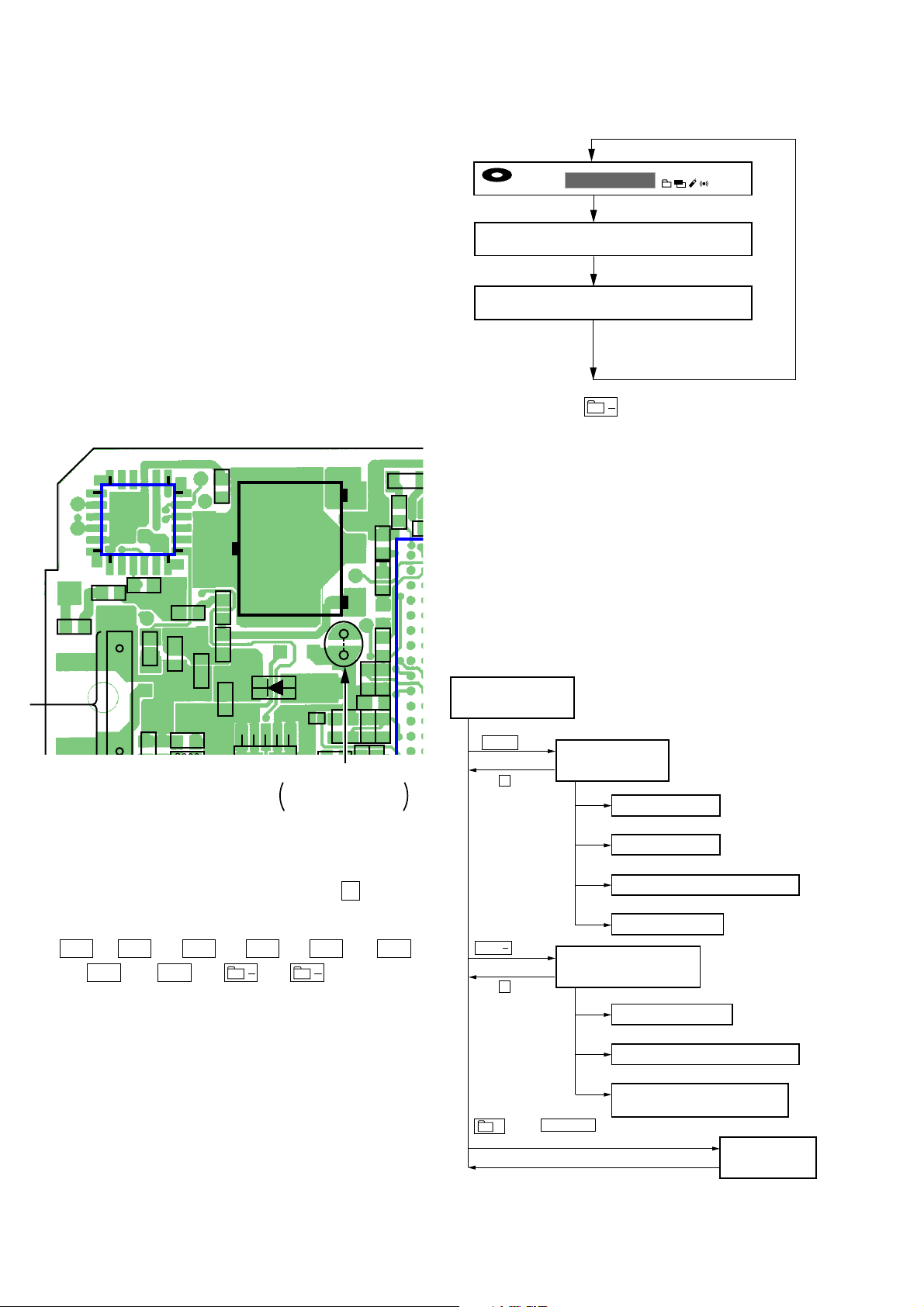

R

SECTION 4

TEST MODE

4-1. GENERAL

• When entered in the TEST MODE, this set provides the Overall

Adjustment mode which allows CD and MO discs to be automatically adjusted. In the Overall Adjustment mode, the system

discriminates between CD and MO discs, performs adjustments

in sequence automatically, and displays the faulty location if

any fault is found. In the Manual mode, selected adjustments

can be performed automatically.

• The attached remote control is used to operate the TEST MODE.

Unless otherwise specified in the text, the key means that on the

remote control.

4-2. SETTING THE TEST MODE

4-2-1. How to set the TEST MODE

To set the TEST MODE, two methods are available.

1 Solder bridge and short TAP602 (TEST) on the main board.

Then turn on the power.

MAIN BOARD (SIDE A)

12 7

13

6

C953

FB601

E

IC951

Q951

TAP602

(TEST)

D951

R604

51

TAP602

SHORT: TEST MODE

OPEN: NORMAL MODE

R623

C606

R620

C617C612C608

R607R622

C607

R621

R964

18

19 24

R965

1

C954

C957

C958

1

2

CN951

56

R959

C928

R958 R957

R961

R956

Remote control LCD

F

1SHUFPGM SOUND

u

000

V-SUR

All on

All off

001 V1.000

Microprocessor

version

display

• Press and hold down

key is being pressed.

4-2-3. How to release the TEST MODE

When method 1 was used:

Turn off the power and open the solder bridge on TAP602 on the

main board.

R627

Note: The solder should be removed clean. The remaining solder

may make a short with the chassis and other part.

When method 2 was used:

Turn off the power.

Note: If electrical adjustment (see page 11) has not been finished

completely, always start in the test mode.

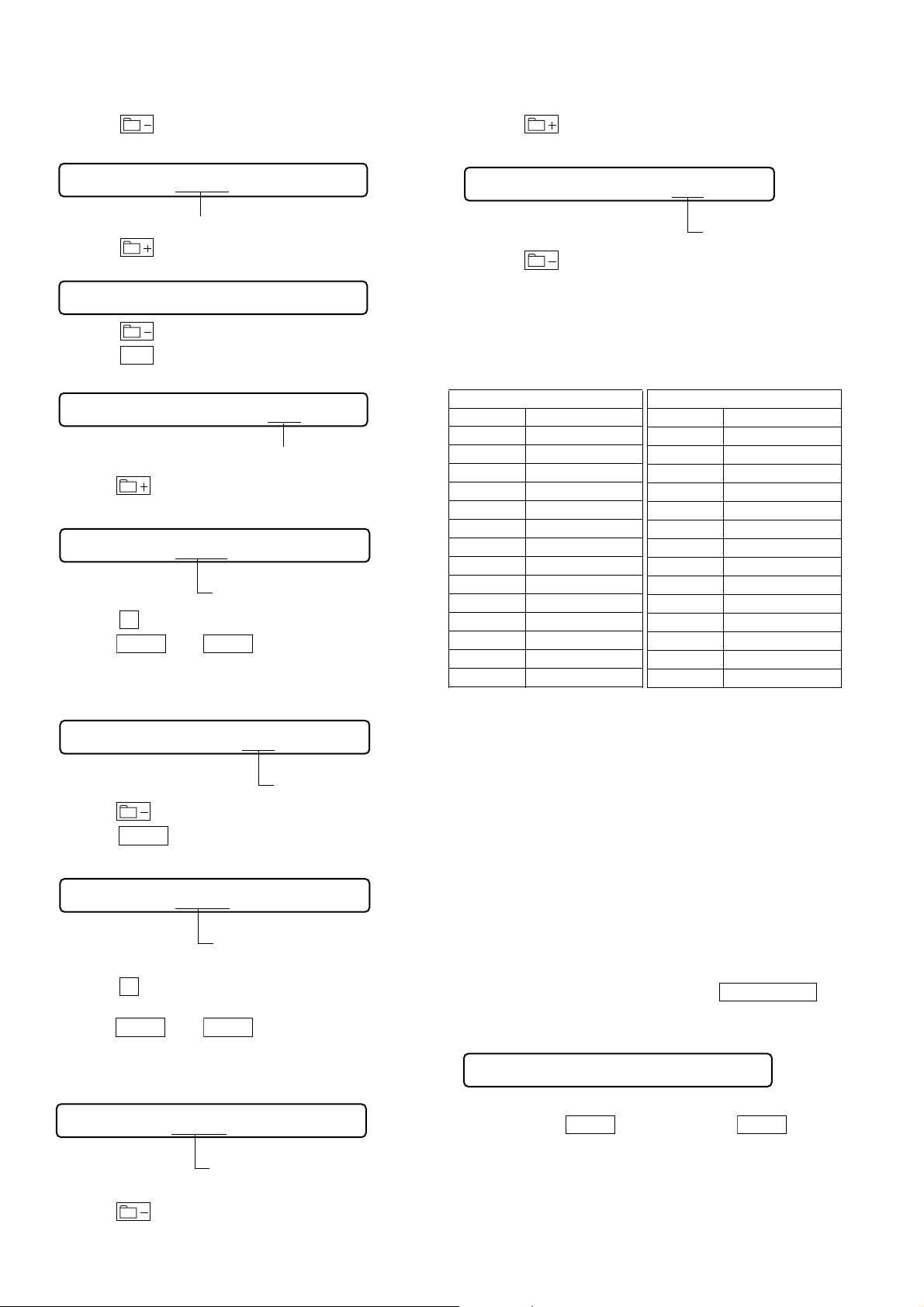

4-3. TEST MODE STRUCTURE

Test Mode

(Display Check Mode)

VOL + key

x

key

to hold the current display while the

Manual Mode

Servo Adjustment

8

2 In the normal mode, operate the keys on the set and those on the

remote control as specified below:

Turn on HOLD switch on the set. Holding down

x

(STOP)

key on the set, press the keys on the remote control in the

following sequence:

t

>

t

>

>

t

t

.

t t

.

t

.

t

>

t

.

4-2-2. Operations when the TEST MODE is set

When the TEST MODE is entered, the system switches to the display check mode within the TEST MODE. From this mode, the

other Test modes can be accessed.

When the TEST MODE is set, the LCD repeats a cycle of the following displays:

8

Audio Adjustment

Power Supply Voltage Adjustment

Charge Adjustment

key

VOL

Overall Adjustment Mode

x

key

CD/MO Adjustment

Power Supply Voltage Adjustment

NV Initialize

(Clear the Non-Volatile memory

+ key or DISPLAY key

(Press and hold down about for more than2 sec)

Terminate key checking or open

the top panel.

Key Check Mode

Page 9

MZ-E10

011 AAAS 3F

address

mode number

mode number

mode number

mode number

mode number

adjusted value

adjusted value

adjusted value

adjusted value

adjusted value

011 OFFJ 3F

jitter value

011 000B 3F

block error value

011 000A 3F

ADIP error value

011 000F 3F

Focus drive voltage value

• Address & Adjusted Value Display

LCD display

011 Lrefpw 3F

Item title

mode number

adjusted value

• Item title Display

LCD display

• Jitter Value & Adjusted Value Display

LCD display

• Block Error Value & Adjusted Value Display

LCD display

• ADIP Error Value & Adjusted Value Display

LCD display

• Focus drive voltage value & Adjusted value

LCD display

4-4. MANUAL MODE

4-4-1. Outline of the function

The Manual mode is designed to perform adjustments and

operational checks on the set’s operation according to each

individual function.

The Manual mode is used to clear the memory before

performing automatic adjustments in the Overall Adjustment mode.

4-4-2. How to set the Manual mode

1. Set the TEST MODE and press

mode.

Remote control LCD display

000 Manual

2. During each test, press and hold down

key for a while to move the optical pickup on the sled outer or

inner perimeter.

3. Each test item is assigned with a three-digit item number. The

100th place is a major item, 10th place is a middle item, and unit

place is a minor item.

Note: Changes in adjustment item settings are written into the

non-volatile memory.

Change Major

>

>

key

Item

Change Middle

Item

Change Minor

Item

+

VOL

VOL

x

keykey

+

VOL

VOL

x

key

>

key : Unit place of mode number

increase

.

key : Unit place of mode number

decrease

Change Adjustment

Value

VOL +

key : 100th place of mode number

increase

key : 100th place of mode number

decrease

key : 10th place of mode number

increase

key : 10th place of mode number

decrease

key to set the Manual

key or

>

VOL

VOL

.

key : Up

+

key : Down

4. During each test mode, the display is changed from one to

another each time DISPLAY key is pressed.

Write Adjustment

Value

key : When adjusted value is changed :

Adjusted value is written.

When adjusted value is not changed :

That item is adjusted automatically.

Note: In the Power mode, the item title display is only displayed.

5. To terminate the Manual mode and return to the TEST MODE,

x

key.

press

4-5. OVERALL ADJUSTMENT MODE

4-5-1. Outline of the function

This mode is designed to adjust the servo system automatically by

going through all the adjustment items.

Usually, this mode is used to perform automatic adjustments when

servicing the set.

For further information, refer to section 5. ELECTRICAL ADJUSTMENTS. (See page 11)

9

Page 10

MZ-E10

4-6. KEY CHECK MODE

4-6-1. Outline of the function

This mode is used to check to make sure that each of the keys

(including the slide switch) on the set operates normally.

4-6-2. Setting the Key Check mode

1. Set the TEST MODE. Press and hold down

(for more than 2 sec) to set the Key Check mode.

LCD display

DISPLAY

key

000 XX

2. When each key on the set and on remote control is pressed, its

name is displayed on the LCD. (The operated position is displayed for 4 sec after the slide switch is operated. If any other

key is pressed during this display, the LCD switches to its name

display)

Example: When

LCD display

key on the set is pressed:

>

000 FF XX

Example: When

LCD display

key on the remote control is pressed:

>

000 rFF XX

XX: AD value of the remote control key (hexadecimal 00 to FF)

3. When all the keys on the set and on the remote control are considered as OK, the following displays are shown.

(The key pressed to enter the Key Check mode has been checked

even if it is not pressed in this mode)

Example: When the keys on the set are considered as OK:

LCD display

Example: When the keys on the remote control are considered

LCD display

SET OK XX

as OK:

4. When all the key have been checked or when the top panel is

opened during this checking, the system terminates the Key

Check mode and return to the TEST MODE.

Note: Slide switch can checked as OK by ON t OFF t ON

RMC OK XX

(or reverse) operation.

10

Page 11

SECTION 5

862 88C6 FF

This section (data) flashes.

862 88C7 FF

This section (data) flashes.

ELECTRICAL ADJUSTMENTS

MZ-E10

5-1. GENERAL

In this set, CD and MO discs can be automatically adjusted by setting the Overall Adjustment mode within the TEST MODE,

Before performing these automatic adjustments, it is necessary to

clear the memory, adjust the power charge and temperature in the

Manual mode.

5-2. NOTES FOR ADJUSTMENT

5-2-1. Jigs

• CD disc TDYS-1 (part code: 4-963-646-01)

• MO disc PTDM-1 (part code: J-2501-054-A) (recorded)

• Digital voltmeter

• Thermometer

5-2-2. Adjustment sequence

The adjustments should be always performed in the following

sequence:

1 NV Initialize

(Clear the Non-Volatile memory)

2 Power supply voltage adjustment

3 Charge adjustments

4 Temperature adjustment

5 Overall CD adjustments

6 Overall MO adjustments

7 RESUME clear

5-2-3. Power

In overall adjustment, the power is supplied from the internal battery (Li-Ion) and the charging stand simultaneously.

Turn S901 (BUILT-IN BATTERY) to ON.

Note: Be sure to place the set horizontally on the overall

adjustment.

Overall adjustment mode

Manual mode

Overall adjustment mode

Manual mode

5-3. NV Initialize

(Clear the Non-volatile memory)

5-3-1. How to NV Initialize

1. Set the Test mode.

2. Press the

3. Press

LCD display

000 Res OK?

kye and set the Overall adjustment.

VOL –

key on the remote control.

5-3-2. Changing Adjustment values

Adjustment settings are cleared when NV initialize is performed.

So right after performing NV initialize you must rewrite the correct

data according to the microcomputer version.

• Adjustment value change method 1

• Adjustment value change method 2

(Perform after the 7 charging adjustment)

5-3-3 Adjustment value change method 1

(when using Version 1.000)

1. In test mode press the

mode.

2. Set 861 as the item number.

LCD display

3. Press the key.

4. Press the

LCD display

5. Press the key, and set in Adjustment change mode.

861 VarB1k 00

>

862 VarWrt 00

VOL +

key and set 862 as the item number.

key and then switch to Manual

862 88C6 FF

This section (address) flashes.

6. Press the x key.

LCD display

7. Press the

flashing data section while referring to the adjustment data change

list.

LCD display

VOL +

and

VOL –

keys and set the value in the

862 88C6 3F

Data value.

8. Press the key. and the address section starts flashing.

9. Press the

LCD display

VOL +

key and set the next adjustment address.

4. Press key on the remote control again.

LCD display

000 Res ***

000 Reset

5. Press x key. to terminate the Manual mode and return to the

Overall adjustment mode.

Note: The power, charging and temperature adjustment settings are

not cleared during NV initialize.

862 88C7 FF

-

This section (address) flashes.

10.Press the x key.

LCD display

After initialize is completed.

11. Repeat the adjustments in items 6 - 9 and set up through address

88D3 while referring to the Adjustment Data Change List.

11

Page 12

MZ-E10

12.Press the key. (Address section starts flashing.)

LCD display

862 88D3 FC

This section (address) flashes.

13.Press the key to return to Manual mode.

LCD display

14.Press the key and write in the correction data.

15. Press the

LCD display

862 VarWrt 00

key and 862 as the item number.

>

862 VarWrt 01

Data value.

16.Press the key, and set in Adjustment change mode.

LCD display

862 88C6 FF

17. Press the x key . (FF section (data) flashes)

18.Press the

flashing data section while referring to the adjustment data change

list.

LCD display

VOL +

and

This section (address) flashes.

VOL –

key and set the value in the

862 88C6 07

Data value.

19.Press the key, and the address section starts flashing.

20.Press the

LCD display

VOL +

key and set the next adjustment address.

862 88C7 FF

This section (address) flashes.

21. Press the x key . (FF section (data) flashes)

LCD display

22.Press the

flashing data section while referring to the adjustment data change

list.

LCD display

VOL +

862 88C7 8D

and

VOL –

Data value.

key and set the value in the

24.Press the

LCD display

key to return to Manual mode.

862 VarWrt 01

Data value.

25.Press the key and write in the correction data.

26.Turn off the power.

Note: Always turn off the power after changing the adjustment set-

tings.

Adjustment Data Change List

If adjustment data is VarWrt is 00

Version 1.000

Address Adjustment Data

88C6 3F

88C7 03

88C8 D6

88C9 22

88CA C4

88CB 37

88CC C2

88CD 04

88CE E8

88CF 42

88D0 6E

88D1 FC

88D2 71

88D3 FC

5-4. POWER SUPPLY VOLTAGE ADJUSTMENTS

5-4-1. Adjustment sequence

The adjustments should be always performed in the following sequence:

1 LEG1 adjustment (item No.:741)

r

2 VC1 adjustment (item No.:742)

r

3 VC2 adjustment (item No.:743)

r

4 Class-D power supply adjustment (item No.:744)

5-4-2. REG1 adjustment method

1. Supply power (DC 6.0 volts) from the charging terminal CN951.

2. Set the Test mode.

3. Set the overall adjustment mode and press

key, item No. will change to 741.

LCD display

4. Connect a digital voltmeter to TP908 (REG1) on the main

board and adjust

(voltage down)key on the remote control.

741 Reg1 XX

VOL +

If adjustment data is VarWrt is 01

Version 1.000

Address Adjustment Data

88C6 07

88C7 8D

88C8 FF

88C9 FF

88CA FF

88CB FF

88CC FF

88CD FF

88CE FF

88CF FF

88D0 FF

88D1 FF

88D2 FF

88D3 FF

P.MODE/F

(voltage up) key and

VOL –

23.Press the key, and the address section starts flashing.

12

Page 13

MZ-E10

37

C

C

Adjustment value:1.05V

Standard value:1.04 to 1.055V

MAIN BOARD (SIDE A)

C202

TP908

(REG 1)

R911

12

C908C922

digital voltmeter

TP908

(REG1)

5. Press key to write the adjustment value, item No.will

change to 742.

5-4-3. VC1 adjustment method

1. Set the overall adjustment mode and set the item No. to 742.

LCD display

C910

R921

R908

C926

L904

C916

1-686-492-

3. Press key to write the adjustment value, item No. will

change to 743.

5-4-4. VC2 adjustment method

1. Set the overall adjustment mode and set the item No. to 743.

LCD display

2. Connect a digital voltmeter to TP907(VC2) on the main board

and adjust

(Voltage up) on the remote control.

Adjustment value:1.15V

Standard value:1.15 to 1.18V

MAIN BOARD (SIDE A)

743 Vc2 XX

VOL +

key (Voltage down) and

VOL –

key

TP907

C910

R921

R908

C926

L904

C916

1-686-492-

(VC2)

R91112

C908C922

digital voltmeter

TP907(VC2)

2. Connect a digital voltmeter to TP902 (VC1) on the main board

and adjust

(Voltage down) on the remote control.

Adjustment value:2.15V

Standard value:2.14 to 2.155V

2

digital voltmeter

742 Vc1 XX

key (Voltage up) and

MAIN BOARD (SIDE A)

TP902(VC1)

C908C922

R911

VOL +

C910

TP902

(VC1)

R921

R908

C916

VOL –

L904

key

C926

1-686-492-

3. Press key to write the adjustment value, item No. will

change to 744.

5-4-5. Class-D power supply adjustment method

1. Set the overall adjustment mode and set the item No. to 744.

LCD display

2. Connect a digital voltmeter to TP909 (Class-D) on the main

board and adjust

(Voltage down) on the remote control.

744 Cls D XX

VOL +

key (Voltage up) and

VOL –

key

13

Page 14

MZ-E10

D

D

D

Q

Q

Adjustment value:1.75V

Standard value:1.75 to 1.80V

MAIN BOARD (SIDE A)

C302

TP909

(CLASS-D)

C301 C104

14 8

IC301

digital voltmeter

3. Press key to write the adjustment value,

LCD display.

000 ADJ OK

17

TP909(CLASS-D)

C204 R317 R318

E

R818R819

HOLD

t

2. Set the manual mode, item No. will change to 754.

LCD display

3. Connect a digital voltmeter to TP962 on the main board and

adjust

key on the remote control.

Adjustment value:3.40V

Standard value:3.395 to 3.405V

MAIN BOARD (SIDE A)

754 ChgV L XX

VOL +

13

(voltage up) key and

12 7

6

C953

VOL –

(voltage down)

IC951

C958

1

C957

R959

R961

R957

TP962

R958

56

digital voltmeter

TP962

D95

R964

18

19 24

R965

C954

1

4. Press the x key and return to the test mode.

LCD display.

5-5. CHARGE ADJUSTMENTS

Note: Always remove the internal battery (Li-Ion) before making

charging adjustments.

5-5-1. Adjustment sequence

The adjustments should be always performed in the following sequence:

1 Current amplifier offset adjustment (item No.:751)

r

2 Change voltage (L) adjustment (item No.:754)

r

3 Change voltage (H) adjustment (item No.:755)

r

4 Current Amplifier (L) adjustment (item No.:752)

5-5-2. Current amplifier offset adjustment

1. The power supply of 3V is supplied to TP951 on the main board.

2. Set the Test mode.

3. Set the manualmode, item No.will change to 751.

LCD display

4. Press key to write the adjustment value.

5-5-3. Vc PWM Duty (L) adjustment method

1. Set the Test mode.

751 ChgIOf XX

4. Press key to write the adjustment value.

5-5-4. Charge voltage (H) adjustment method

1. Set the Manual mode and set the item No. to 755.

LCD display

2. Connect a digital voltmeter to TP962 on the main board and

adjust

(Voltage up) on the remote control.

Adjustment value:4.20V

Standard value:4.2 to 4.21V

MAIN BOARD (SIDE A)

755 ChgV H XX

VOL +

13

key (Voltage down) and

12 7

6

C953

VOL –

key

IC951

R964

18

19 24

R965

C954

1

C958

1

C957

R959

R961

R957

TP962

R958

56

digital voltmeter

TP962

D95

14

3. Press key to write the adjustment value.

Page 15

MZ-E10

5-5-5.Current Amplifier (L) adjustment method

1. Connect TP953 to TP959 on the main board.

2. Set the test mode.

3. Set the Manual mode and set the item No. to 752.

LCD display

4. Press key to write the adjustment value.

5-5-6. Adjustment value change method 2

(when using Version 1.000)

1. Set in Manual mode and then set item number 026.

LCD display

2. Press the key.

LCD display

752 ChgI L XX

026 NvWrt CC

026 8200 **

This section (address) flashes.

3. Press the key (100th place) and the

place) and set 828A in the flashing address section.

LCD display

VOL +

key (10th

4. Adjust with the remote control

that the temperature value is at room temperature.

Reset value: 19h = 25

Adjustment range: 80h to 7Fh = -128 C to +127

5. Press the key and write in the adjustment value.

VOL +

C

and

VOL –

C

5-7. OVERALL ADJUSTMENT MODE

5-7-1. Overall adjustment mode structure

TEST MODE

(Display Check Mode)

VOL — key

Overall Adjustment

Title Display(ASSY**)

>

key

x

key

x

key

x

key

.

key

key

>

key two times

CD overall

Adjustment

MO overall

Adjustment

NV Initialize

keys so

4. Press the x key.

LCD display

026 828A **

026 828A **

This section (data) flashes.

5. Press the

data section.

LCD display

6. Press the key.

7. Press the

LCD display

8. Press the key and write in the adjustment setting.

VOL +

026 828A 00

026 NvWrt CC

and

VOL –

key to return to Manual mode.

keys and set 00 in the flashing

5-6. TEMPERATURE ADJUSTMENT

[Temperature adjustment method]

1. Set in Test mode.

2. Set in Manual mode and set the item number 014.

LCD display

014 AdjTmp XX

Adjustment settingItem No.

3. Measure the temperature.

x

P.MODE/F key

Note: The overall adjustments should be always performed in the

sequence of CD t MO adjustments.

5-7-2. Total Adjust mode title display

Switching to Total Adjust Mode sets the following All Adjust mode

title display on the LCD.

LCD display

** : Left side is MO alignment information

5-7-3. Overall CD and MO adjustment method

1. Set the TEST MODE and press

Adjustment mode.

LCD display

000 Assy **

: Disk mark (outer) lights up when power adjustment is com-

plete.

Disk mark (inner) not used

F* : MO total alignment is complete

1* : Manual alignment (not part of total adjustment)

0* : Not adjusted

Right side is CD alignment information

F* : CD total alignment is complete

1* : Manual alignment (not part of total adjustment)

0* : Not adjusted

000 Assy11

Power Supply

Adjustment

VOL –

key

key to set the Overall

15

Page 16

MZ-E10

2. Insert CD disc in the set, and press . key to set the Overall

CD Adjustment mode.

Automatic adjustments are made.

LCD display

XXX: Item No. for which an adjustment is being executed.

3. If NG in the overall CD adjustments, return to Reset NV and

perform from the overall CD adjustment again.

LCD display

XXX: NG item No.

YY: adjusted valive.

4. If OK through the overall CD adjustments, then perform overall

MO adjustments.

LCD display

5. Insert MO disc in the set, and press

MO Adjustment mode. Automatic adjustments are made.

LCD display

XXX CD RUN

000 XXX NG YY

000 CD OK

>

key to set the Overall

3. Press the key.

LCD display

043 Res ***

After reset is completed

LCD display

043 Res C1r

5-7-5.Resume clear method

When the battery exchange was done.

1. Setting the testmode.

2. Set the Manual mode and set the item No.043(RESUME Clear).

LCD display

3. Press the

to 02.

4. Press the key.

LCD display

043 Resume 00

VOL +

key two times, and set the adjustment value

043 Res 02

043 Res ***

XXX: Item No. for which an adjustment is being executed.

6. If NG in the overall MO adjustments, return to NV initiale and

perform from the overall CD adjustments again.

LCD display

XXX: NG item No.

YY: adjusted valive.

7. If OK through the overall MO adjustments, press

return to the test mode.

LCD display

5-7-4.Resume clear method

When the battery exchange isn't being done.

1. Setting the testmode.

2. Set the Manual mode and set the item No.043(RESUME Clear).

LCD display

XXX MO RUN

000 XXX NG YY

000 MO OK

043 Resume 00

x

key to

After reset is completed

LCD display

043 Res C1r

5-7-6. Overall CD and MO adjustment items

1. Overall CD adjustment items

Item No. Contents

312 ALFA offsetadjustment

313 IJ offset adjustment

314 FE offset adjustment

320 Focus servo ON

324 TE offset adjustment

321 TE gain adjustment

328 TWPP gain adjustment

824 twpp-gain[H]+4 t twpp-gain[L]

324 TE offset adjustment

330 Tracking servo ON

336 ABCD gain adjustment

337 KF gain adjustment

338 RF gain adjustment

344 CD focus gain adjustment

345 CD tracking gain adjustment

521 CD two-axis sensitivity adjustment (inside)

522 CD two-axis sensitivity adjustment (outside)

16

Page 17

MZ-E10

2. Overall MO adjustment items

Item No. Contents

112 ALFA offset adjustment

113 IJ offset adjustment

114 FE offset adjustment

118AW DW OFFSET

224 TE offset adjustment

221 TE gain adjustment

224 TE offset adjustment

236 ABCD gain adjustment

237 KF gain adjustment

238 RF gain adjustment

244 Focus gain adjustment

245 Tracking gain adjustment

120 Focus servo ON

122 TE offset adjustment (TON)

121 TE gain adjustment

122 TE offset adjustment (TON)

123 TE offset adjustment (TEIN)

124 TE offset adjustment (TWPP)

130 Tracking servo ON

131 TE offset adjustment (TWPP/RF)

136 ABCD gain adjustment

137 KF gain adjustment

144 FCS gain adjustment

145 Tracking gain adjustment

139 BPF fo adjustment

134 TWPP gain adjustment

131 TE offset adjustment (TWPP/RF)

132 TE offset adjustment (TWPP/DSP)

138 RF gain adjustment

35 GOD offset correction.

5-8. REWEITING PATCH DATA AFTER REPLACING

THE NONVOLATILE MEMORY

Rewrite the program correction data after replacing the nonvolatile

memory.

5-8-1 Method for rewriting the corrected data

(when using Version 1.000)

1. Set in Test mode.

2. Set in Manual mode and enter the item number 022.

LCD display

022 PatClr CC

Data.

3. Press the key to reset the patch data.

(Writing is complete if the setting changes to DD.)

LCD display

5. Press the

LCD display

6. Press the key.

LCD display

VOL +

023 Patch 01

key and set the adjustment setting to 01.

022 PatClr CC

This section (address) flashes.

7. Press the x key.

(The data section flashes.)

8. Press the

data while referring to the patch data list.

9. Press the

10. Press the

address for adjustment.

LCD display

VOL +

and

VOL –

key and the address section flashes.

VOL +

keys and set the address value in the next

keys and set the adjustment

Data.

023 8922 00

This section (address) flashes.

11. Press the x key.

LCD display

023 8922 00

This section (data) flashes.

12. While referring to the patch data table repeat the data correction

write procedure from steps 8 through 11 until the address 899E

is set.

13. Press the

(The address value flashes.)

14. Press the

LCD display

15. Press the key.

LCD display

LCD display

key.

key to quit the patch data write mode.

023 Patch 01

023 Patch CC

After finished writing data.

LCD display

023 Patch DD

16. Turn off the power.

4. Press the

LCD display

022 PatClr DD

key and enter the item number 023.

>

023 Patch 00

17

Page 18

MZ-E10

Address Data

8921 02

8922 F7

8923 F4

8924 02

8925 06

8926 A9

8928 03

8929 2A

892A FD

892B 01

892C 12

892D 06

892E B3

8931 02

8932 15

8933 95

8934 02

8935 0A

8936 66

8938 02

8939 D1

893A B3

893B 02

893C 06

893D BD

8941 81

8942 B2

8943 81

8944 C3

8945 81

8946 E2

8947 E4

8948 90

8949 87

894A 75

894B F0

894C E5

894D 81

894E C3

8951 94

8952 04

8953 F8

8954 76

8955 19

8956 08

8957 76

8958 E9

8959 22

895A C0

895B E0

895C 12

895D 20

895E 7D

8961 8C

Varsion 1.000

Address Data

8962 DE

8963 03

8964 E5

8965 81

8966 C3

8967 94

8968 05

8969 F8

896A 76

896B 2E

896C 08

896D 76

896E FD

8971 D0

8972 E0

8973 B4

8974 02

8975 02

8976 D3

8977 22

8978 C3

8979 22

897A 6C

897B 05

897C 0A

897D 30

897E 1A

8981 02

8982 74

8983 FF

8984 F8

8985 D0

8986 E0

8987 D0

8988 E0

8989 D0

898A E0

898B 74

898C F8

898D C0

898E E0

8991 74

8992 B3

8993 C0

8994 E0

8995 74

8996 02

8997 C0

8998 E0

8999 E8

899A 02

899B 06

899C CF

899E 01

18

Page 19

6-1. BLOCK DIAGRAMS

Iy

Ix

Jx

Jy

Jx Jy

Jx

A

Ix Iy

Ix

B

a

cd

b

C

F

D

PD

LD-A

LD

LD-K

S0

S1

VCC

VCC

OPTICAL PICK-UP BLOCK

(ABX-1ES)

TRACKING

COIL

FOCUS

COIL

M902

M

SLED

MOTOR

M901

SPINDLE

MOTOR

M

MZ-E10

SECTION 6

DIAGRAMS

IC301

HEADPHONE AMP

RF AMP,FOCUS/TRACKING ERROR AMP

VREF

12

Iy

7

Ix

6

Jx

8

Jy

9

A

5

B

4

C

3

D

2

MON

13

VCC-2

14

LASER

16

DRIVER

1

SLDW

SLDV

SLDU

SLDN

CLVW

CLVV

CLVU

CLVN

TRK+

TRK-

FCS+

FCS-

L501

Q501

VCC-2

UNREG

15

S0

10

S1

11

20

17

18

19

VREF10

7

Iy

56

Ix

1

Jx

54

Jy

55

A

50

B

51

C

52

D

49

A-C

16

D-C

15

PD-NI

12

DVDD

AVCC

PD-O

14

VS2

43

OUT2F

44

OUT2R

45

VS1

18

OUT1F

17

OUT1R

16

SLVS

26

SWO

20

SVO

21

SUO

23

SLCOM

22

SPVS

35

WOUT

41

VOUT

40

UOUT

38

SPCOM

39

IC501

EFM

COMP

SERIAL

S-MONITOR

POWER

SUPPLY

IC551

PEAK

/BOTM

ADIP

I/F

VG1 S/S

LOGIC

VG1 S/S

LOGIC

VG1 S/S

LOGIC

VG1 S/S

LOGIC

RF AMP,

FOCUS

ERROR,

TRACKING

ERROR

TPP/WPP

APC

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

PRE

DRIVER

PRE

DRIVER

PRE

DRIVER

PRE

DRIVER

EFMO

RF OUT

PEAK

BOTM

ABCD

NPPO

ADIP IN

PD-NI

AFDG

RESET

SBUS

SCK

S MON

RFI

CLK

FE

TE

VC

NC

37

40

9

48

47

41

42

43

44

19

13

8

23

35

33

32

18

26

IN2F

IN2R

IN1F

IN1R

SLPWM

SLFG

ISEL1

VCC

VG1

SPBR

SPPWM

SPFG

CLK

110

D LPWM+

112

EFMIN

136

127

PEAK

BOTTOM

126

ABCD

125

FE

123

TE

124

LDREF

104

11

RFVCMON

139

ADIPW0

47

XRF RESET

SBUS DATA

160

21

SBUS CLK

14

RF TEMP MON

122

VC

24

AMICE CLK PWM

50

XSLPMIR OP

46

PDS1

DIGITAL SERVO SIGNAL PROCESSOR,

SHOCK PROOF MEMORY CONTROLLER,

16M BIT D-RAM, SYSTEM CONTROL

106

107

71

72

51

73

74

84

83

85

80

81

82

68

76

75

66

XIN

XOUT

TRPWMF

TRPWMR

XDISC DET

FOPWMF

FOPWMR

SLD2

SLD1

SLD3

SLPWMF

SLPWMR

SLD0

4M

SPPWMR

SPPWMF

FF

48

S/S

3

4

13

14

19

24

12

S1

8

S2

9

S3

10

7

6

5

47

42

37

16.9344MHz

VCC-1

VG

X601

IC601

DIGITAL SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

ATRAC ENCODER/DECODER

D/A CONVERTER

D RPWM+

F16M

D EN1

D EN2

D VO PWM

RMC KEY1

RMC DTCK

REC KEY

OPR LED R PWM

OPR LED O CTL

OPR LED G PWM

HOLD SW

SET KEY

OPEN CLS SW

XRESET

NV XCS

SI02 CLK

SI02 DO

SI02 DI

CHG MON

CHG PWM

CHG AMP SEL

CHG AD SEL

XCHGI LIMIT

CHG VI MON

UNREG MON

S104 DO

PWR STRB

S104 CLK

PWR CLK PWM

PWR SLEEP

PWR EFCLR

57

45

52

40

12

19

2

42

30

41

88

16

15

192

6

5

7

8

17

39

38

32

29

13

10

3

37

196

23

36

35

LED

DRIVER

Q802

TAP603

CHG MON

CHG CTL

CHG AMP SEL

CHG AD SEL

XCHGI LIMIT

CHG VI MON

S104 DO

PWR STRB

S104 CLK

176K

PWR SLEEP

PWR EFCLR

1

XCS

2

SK

3

DI

4

DO

VB

Q952

2

IN

IC952

OUT

VB DETECT

1

DIFFERENTIAL

(D CLASS AMP)

IN1

3 6

IN2

12

MCK

1

14

4

EN1

11

EN2

IC801

EEPROM

VCC-1

VCC-2

Q953

OUT1

OUT2

BEEP DRIVER

VDD0

Q901

9

7

•

8

(R)

(O)

(G)

S803

(OPEN/CLOSE)

CHG VI MON

CHG CTL

XCHG I LIMIT

CHG MON

CHG AMP SEL

CHG AD SEL

L901

RMC KEY1

SI04 DO

PWR STRB

SI04 CLK

176K

PWR SLEEP

PWR FFCLR

VCC-1 VG

Q904

Q301,302

BOOSTER

D801

D802

D803

S802

GROUP

55

MUTE ON

XRST2

27

LVB

7

VSTB

9

XWK3

3

VCO1

11

VCOUT

37

VCIN

38

VCI

10

VC1G

16

L1

13

L1

14

XWK1

5

XWK2

4

XWK4

2

SEQSEL

62

DATA

58

STRB

59

SCK

60

CLK

63

SLEEP

64

FFCLR

1

Q102,202

MUTE

IC302

REGULATOR

VI2DET

CHG_CTL

WK DET

I_CTL1

A/D

I_SEL

AD_SEL

V IN2

RESET

DRIVER

CONTROL

S804

HOLD

ON OFF

VOL+

SW

VC

SWITCH

CONTROL

VG

SETUP

1

3

N

REW/PB

CHAGER CONTROL

4

VOL-

S801

2

20

14

16

3

4

5

6

Q303

1

3

Q304

STOP

FF/PB

IC951

CHARGE

CONTROL

H

L

LVB

DRIVER

SERIES PASS

REGULATOR

SETUP

DRIVER

VB

VC

SETUP

DC/DC

CONVERTER

IC901

DC/DC CONVERTER

8,7

6,5

2,4

S801

VOL+

.

>

N

VOL-

12

VG

VI

24

IN1-

23

RF1

18

17

GND

VO

7

VBAT

8

IN2-

9

OUT2

10

BAT_SEL

11

HVB

8

VB

VB

26

REGO1

43

L2

44

VC2

42

36

VC2G

C1L

32

L2

34

35

L2

VG

23

LG

24

22

VG

L-CH

A-GND

R-CH

D-GND

RMC-KEY

RMC-DTCK

VCC-1

RMC-VDD

VG

Q951

D951

4

NC

Q903

D902

D904

L903

L903

3

1,2

5,6

S901

UNREG

VDD

Q902

VG

VGH

J301

i

FOR

STAND

CHARGER

LITHIUM-ION

RECHAGEABLE

BATTERY

1PC, 3.7v

BUILT-IN

BATTERY

ON

OFF

Li-ion

r

19 19

• Signal path.

F : Analog

J : Digital

Page 20

MZ-E10

6-2. PRINTED WIRING BOARDS – MAIN SECTION (1/2) –

z

See page 25 for Notes. : Uses unleaded solder.

C527

C513

L552

C911C907

L551

R911R912

C523

R513

C502

R563R561R562R564

R903

R916

R505

R901

TP908

(REG1)

R510

C506C526

R514

ECB

R902

8

C501

C906

C912

R516

C920

TP907

IC501

C503

Q501

C508

C509

C557

(VC2)

R511

*

C505

R504R904

R554

C959

C507

C519

E

1

2

R502

C536

C554

C555

C910

R952

3

4

C512

C511

BCE

C556

C551

R507

C921

Q904

Q304

C553

C916

R914

E

R204

R104

C552

C558

R921

R908

TP902

(VC1)

C525

R509

R506

L501

C510

R313

13

C804

C302

C301 C104

14 8

IC301

1

L101

L201

C310

IC952

R310

C520

C518

Q302

C515

R518

R803

R501

R802

C803

FB802

R951

D301

FB101

R102

C309 C311

R307

24 13

Q102

25

R551R552

R553

36

37 48

C202

L904

1-686-492-

9

CN801

TP909

(CLASS-D)

R317 R318

7

C204

C101C201

R315

C312

E

R311

C308

R309

R312

E

R306

4

E

IC302

C307

C306

R305

FB801

D851

R804

C852

C303C851

D101

D201

FB201

85

Q303

1

4

ECB

BCE

Q202

IC551

C926

11

(11)

E

Q301

R301

C304

R303

R302

C102

R818R819

Q802

FB803

R202

HOLD

E

E

C805

3

15

C305

12

1

t

HOLD

D803

D802

D801

S802

GROUP

(OPEN/CLOSE)

R304

1

J301

7

S804

ON

OFF

GROUP

S803

i

t

10

z

Semiconductor

Location

Ref. No. Location

B

D101 E-9

D201 E-9

D301 F-9

D801 B-9

D802 B-9

D803 B-9

D851 E-9

D902 G-6

D903 G-6

D904 G-7

D951 G-3

IC301 B-9

IC302 D-9

IC501 D-8

IC551 G-9

IC601 G-4

IC801 G-5

IC901 G-7

IC951 F-2

IC952 C-8

Q102 F-9

Q202 F-9

Q301 C-9

Q302 D-9

Q303 F-9

Q304 E-8

Q501 D-8

Q802 C-9

Q901 G-7

Q902 H-5

Q903 G-6

Q904 E-8

Q951 G-3

Q952 E-7

Q953 E-7

1

2

3 4 5 6 7

A

CONTROL BOARD (SIDE A)

CONTROL BOARD (SIDE B)

3

1

B

S801

VOL +

>

>

B

C

VOL –

CN802

R814 R813 R816

R812

R811

1-686-491-

R815

11

(11)

1-686-491-

11

(11)

C535

C534

C533

CN501

C532

POWER BOARD (SIDE A)

1

5

1-686-490-

1-686-490-

C622

R614

C618

R615

C621

CN954

1

4

C951

11

(11)

R801

IC801

11

(11)

L901

C801

8

5

C917

C601

OPTICAL

PICK-UP

BLOCK

ABX–1ES

Q953

M901

SPINDLE

MOTOR

M902

SLED

MOTOR

R602

R955

C903

D

G

Q902

DDS

Q903

C929

D903

L903

D902

R915

R905

R906

C915 C905C913

R919R909R918

32

C925

C904

16

17

33

DD

G

C909

L902

C902

S

1

2

M

3

4

5

6

M

7

8

D904

C924

IC901

BCEBCE

Q952

R953

G

S

Q901

D

C923C901

1

64

49

48

R917

CN551

8

1

C952 C908C922

1

5

D

POWER BOARD (SIDE B)

CN953

t

ON OFF

S901

BUILT–IN BATTERY

LITHIUM–ION

RECHARGEABLE

BATTERY

LIP–3WMB

1PC,3.7V 340mAh

Li–ion

1

2

4

5

E

F

G

FOR

STAND CHARGER

H

MAIN BOARD (SIDE A)

12 7

C954

CN951

C958

C956

C957

R959

TP953TP951

C928

C960

C955

6

C953

1

TAP602

TEST MODE

R958 R957

D951

R961

R956

CN952

TP959

R964

13

18

19 24

R965

IC951

1

2

Q951

51

C626

R618

R617

R601

C604

R623

E

R620

C606

C628

C603

R603R967

C607

R621

C605

C617C612C608

R607R622

R628

R817

FB601

R627

X601

R605R606

R611

C613

R608

C611C609

IC601

R610

C616

C619

C610

R609

C614

C620

R613

*

20

20

Page 21

6-3. PRINTED WIRING BOARDS – MAIN SECTION (2/2) –

1

2

3 4 5 6 7

MAIN BOARD (SIDE B)

A

B

MZ-E10

z

See page 25 for Notes. : Uses unleaded solder.

8

9

C

D

E

F

G

H

1-686-492-

11

(11)

21 21

Page 22

MZ-E10

6-4. SCHEMATIzC DIAGRAM – MAIN SECTION (1/3) –

D801

R819

470

R818

2.2

TLRE1008A

D802

TLOE1008A

D803

TLGE1008A

C607

0.1

R817

220

Q802

XP4214-TXE

LED DRIVE

D EN2

R627

D CLK

C605

0.1

FG

4M

TRPW

TRPW

FOPW

FOPW

SPPW

SPPW

SLPW

SLPW

SLD0

SLD1

SLD2

SLD3

S804

HOLD

OFF

M

MR

M

MR

M

M

MF

M

0

F

F

F

R

R

FB601

TAP602

ON

XSLP MTR OP

XDISC DET

D EN2

SMON0

SMON1

ON2

SM

SMON3

F16M

D7

M

D6

M

D5

M

D4

M

VCC2

D3VCC2

M

MECNT0(OPEN:M

ECNT1

M

FG

D2

M

4M

MD1

D0

M

MF

TRPW

R

M

TRPW

F

M

FOPW

R

M

FOPW

MF

SPPW

R

M

SPPW

VSS

VCC2

VDD

F

M

SLPW

R

M

SLPW

SLD0

SLD1

SLD2

SLD3

(LOCAL CHK 3)

VSS

HOLD SW

D15

M

D14

M

XADJUST

XPATCH

D13

M

TYPE3

D12

M

TYPE2

VSS

D11

M

D10

M

D9

M

MD8

T1YPE

TYPE0

D EN1

PD S1

XRF RESET

PD S1

XSLP MTR OP

ASK/L:FLASH)

LDREF

VSS

C604

0.1

0.047

C628

0.1

C603

VSS

VDD

D EN1

MSON4

XRF RESET

(LOCAL CHK 3)

XIN

XOUT

VDD

D VO PWM

22k

R628

D VO PWM

OPR LED R PWM

OPR LED G PWM

D LPWM+

D LPWM-

DPVSS

D801-803

GROUP

z

See page 25 for Notes.

CHG PWM

PWR STRB

PWR FFCLR

CHG AMP SEL

2.2k

R603

CHG PWM

CHG AMP SEL

D RPWM+

D RPWM-

PWR SLEEP

PWR STRB

PWR FFCLR

PWR SLEEP

VVDD

DVPP

D CPWM

VSS

VPDD

CHG I LIMIT

CHG AD SEL

VCC2

CHG AD SEL

(LOCAL CHK1)

OPR LED O CTL

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO SIGNAL PROCESSOR,

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF M

ATRAC ENCODER/DECODER,

D/A CONVERTER,16M BIT D-RAM

AUX

AVDD1

AVSS1

VVSS

176K

AMICE CLK PWM

DSP INTB

DSP WRQB

DRV FG INT

CHG I LIMIT

DRV SLED1 INT

AMICE CLK PWM

*

IC601

LC896442-VH4-16-E

EMORY CONTROLLER,

SYSTEM CONTROL

CSP(Chip Size Package)

VC

FE

TE

ABCD

BOTTOM

PEAK

z

See page 26 for IC Pin Function Description.

SBUS CLK

RMC DTCK

SBUS DATA

SBUS CLK

SBUS DATA

(RMC SPCK)

PWR CLK PWM

AVDD1

VCVSS

ISET

FR

CHG MON

R623

10k

0.022

0.1

C626

C601

AVDD

CHG MON

RMC DTCK

VCVDD

PDO

JITTREC

SMON

SET KEY

OPEN CLS SW

47k

R602

SET KEY

OPEN CLS SW

RF TEMP MON

HFL

EFMIN

SLCISET

CHG VI MON

CHG VI MON

SLCO

RMC KEY1

RF VCMON

10k

R620

RMC KEY1

RF VCMON

ADIPWO

VCC2

SIO2 DI

SIO2 DO

R621

100k

R622

10k

AVSS

SIO2 DI

UNREG MON

VSS

DATA0

DATA1

NV XCS

NV XCS

SIO2 DO

XD MUTE

SIO4 DO

DATA3

DATA2

SIO2 CLK

(SIO4 DI)

SIO2 CLK

MWEB

DATA5

DATA4

SIO4 DO

XD MUTE

SIO4 CLK

DATA7

DATA6

R617

220k

RASB

M

AD0

M

MAD1

MAD2

AD3

M

VSS

VDD

XRESET

TEST3

TEST2

TEST1

TEST0

DEDATA

VCC2

DECLK

DEFECT

PCK

ADR17

VSS

ADR16

ADR15

ADR14

ADR13

ADR12

ADR11

AD4

M

VCC2

VSS

MAD5

VDD

ADR10

ADR9

AD6

M

ADR8

AD7

M

ADR7

ADR6

AD8

M

MAD9

OEB

M

CASB

M

ADR5

ADR4

ADR3

ADR2

ADR1

ADR0

FCEB

FOEB

FWEB

R618

470k

C606

0.1

SIO4 CLK

XRESET

K1

XW

SET KEY

OPEN CLS SW

R801

1M

R601

220k

C804

470p

S802

GROUP

S803

(OPEN/CLOSE)

C805

0.01

TAP603

C801

0.1

VCC

XBUSY

XCS

SK

SIO2 DO

SIO2 CLK

NV XCS

RST

DI

VSTB

UNREG

BUS

GND

DO

SIO2 DI

IC801

AK6417AL-L

EEPROM

CN801

3P

OPR GND

DGND

VCC

AGND

VDD

GND

XW

SET KEY

CN802

3P

K1

R811

2.2k

R812

2.2k

R813

4.7k

R814

4.7k

R816

R815

10k

10k

S801

VOL+

VOL-

R605

R606

0

X601

16.9344M

1M

R607

2.2k

Hz

LDREF

C608

0.047

C613

0.047

D RPWM+

D LPWM+

R608

4.7k

C609

0.1

C610

0.1

C611

1000p

R611

C616

2.2k

HFL

R613

4.7k

R614

EFMIN

C618

0.1

C621

470

10k

R615

0.047

C622

ADIPWO

470p

C619

22

0.1

22

C612

0.1

SMON

FE

0.1

0.1

C614

TE

ABCD

BOTTOM

PEAK

4.7k

R610

10k

R609

0.1

C617

4700p

C620

Page 23

6-5. SCHEMATIzC DIAGRAM – MAIN SECTION (2/3) –

R562

R564

10

47

R561

C534

22p

L551

µH

47

TRK+

FCSFCS+

TRK-

L552

22

µH

22

ON

M

VREF

PD S1

JY

JX

IY

IX

A

B

C

D

TR OP

XSLP M

C535

22p

CN501

20P

RF VDD

20

R563

15

22

10

5

1

C533

C532

22p

22p

z

See page 25 for Notes.

VREF

RF VCM

EFM

C510

10

6.3V

L501

10

µH

M

R501

10k

C536

0.047

Q501

2SA1577-T106-QR

LASER DRIVER

ON

R504

C501

C502

IN

1

MZ-E10

A

B

C

IY

JY

IX

PS

EQ

AGND

OFC C1

OFC C2

VREF10

VC

RFO

VREF09

AVCC2

PD NI

PD I

PD O

C512

C513

4700p

JX

IY

JY

JX

RF AM

D

A

AGND

IX

10p

10p

C505

0.1

ON

R502

1k

C507

C511

10

4V

C506

R505

100k

0.1

4700p

2200p

C508

2200p

R516

LDREF

C503

2.2k

4700p

D

PEAK

BOTTOM

C

B

A

D

AVCC

CSP(Chip Size Package)

SMON

SMON

PEAK

*

IC501

SN761058ZQL

P,TRACKING/FOCUS

P

ERROR AM

ADIP IN

WPP LPF

AGND

AGND

ADFG

C515

ADIPWO

C527

0.1

BOTM

TON C

OFTRX

CLK

CCSL2

CDN

0.022

AMICE CLK PWM

TE

R514

TE

NPPO

ABCD

ASSY

EFM

DGND

RESET

VGIN

SBUS

CPOUT

DVCC

CN

CPGND

HFL

CIG

SCK

0

FE

RFI

CP

TP511

O

C526

0.1

R510

10k

C518

0.047

R513

C523

0.01

R518

R509

0

R511

10k

0

R506

0

R507

0

0

ABCD

XRF RESET

SBUS DATA

SBUS CLK

FE

C525

0.01

C520

1

C519

1

C509

0.1

VG1

BUS

UNREG

902

M

SLED

OTOR

M

901

M

SPINDLE

OTOR

M

CN551

8P

8

1

SLDN

SLDU

SLDV

SLDW

CLVW

CLVV

CLVU

CLVN

R551

100k

C553

C554

R552

C555

C556

LITHIUM

RECHARGEABLE

BATTERY

LIP-3W

1PC,3.7V 340m

Li-ion

0.47

470p

10k

0.22

2200p

-ION

M

FCS-

SLD1

SLDN

SLDU

SUO

C552

0.1

C558

1000p

+B

CN954

5P

+B

GND

GND

B

Ah

SLFG

SLCOM

SLGND

SLVS

SLPD

SLVCO

AX

SLM

CXA8125ER-TBM

GND

VG2

SPVCO

SPFIL

SPCIN

SPVS

SPGND

BUILT-IN BATTERY

SPFG

FG

S901

ON

TRACKING/FOCUS

SPCOM

UOUT

CLVN

CLVU

OFF

SLD2

SLDV

SLDW

SVO

SWO

SLPWM

IC551

COIL DRIVE,

SPINDLE/SLED

OTOR DRIVE

M

SPPWM

WOUT

VOUT

CLVV

CLVW

SPPWMF

VS1

VS2

FCS+

OUT1L

OUT2F

TRK+

OUT1R

-E

OUT2R

TRK-

FOPWMF

FOPWMR

IN1R

PGND1

SPM

PGND2

SPBR

SPPWMR

XSLP MTR OP

CN953

IN1F

SEL1

SEL2

IN2R

IN2F

SPPD

S/S

5P

CLK

VCC

VG1

S3

S2

S1

AX

SLD3

SLD0

R

M

SLPW

F

M

SLPW

4M

R

M

TRPW

F

M

TRPW

FOR STAND CHARGER

+B

+B

R CTL

PW

GND

GND

R554

4.7M

CN951

2P

CN952

5P

R553

47k

C557

2.2

C551

0.1

R959

Q951

FZT968TA

ITCH

SW

R958

10k

C957

0.1

C960

M

CHG PW

1

C928

0.1

R967

2.2k

0.1

R961

2.2

CHG VI MON

TP959

R964

100

R965

220

C954

4700p

C956

0.1

R957

C955

10

100

D951

FT1J3

GND

CHG CTL

T

PW

DT

W

IN1

VI

C958

1

RF1

PGND

SC901582EPR2

CHARE CONTROL

CAP C LIM

VI2DET

XRESET

R955

1M

C953

0.1

CHG I LIMIT

I CTL1

I CTL2

IC951

A/D

I SEL

CHG MON

CHG AMP SEL

WK DET

PWR WAKE

BAT SEL

VI2

AD SEL

CHG AD SEL

VG

OUT2

IN2-

VBAT

VO

Q903

HAT1043M

SW

C929

0.1

ITCH

0.022

-EL

C951

47

10V

R956

C952

10V

R952

47k

VIN

VOUT

NC

GND

22

Q952

UN9113J

SW

C959

0.1

R953

47k

IC952

XC61CN3002NR

VB DETECT

ITCH

XW

Q953

2SC4738F

DIFFERENTIAL

VCC

AGND

DGND

K1

OPR GND

23 23

Page 24

MZ-E10

6-6. SCHEMATIzC DIAGRAM – MAIN SECTION (3/3) –

XD MUTE

RMC DTCK

RMC KEY1

MUTE ON

D EN2

D LPWM+

NJU8713V-TE2

HEADPHONE AMP

(D CLASS AMP)

0.1

LMV301MGX/NOPB

OPR GND

VCC

AGND

DGND

C312

10p

D CLK

D RPWM+

D EN1

R317

D VO PWM

1M

C201

0.22

R315

R302

22k

R303

10k

47

L201

100µH

C204

C202

220

2.5V

C305

4.7

10V

R304

2.2k

z

See page 25 for Notes.

MCK

VSS

IN1

EN1

VSSO

OUT1

VDDO

IN+

GND

IN-

R301

C304

0.047

IC301

IC302

REG

10k

VCC

OUT

BEEP

VDD

EN2

VSSO

OUT2

VDDO

IN2

C302

6.3V

R318

C104

0.1

C310

220

4V

47

R305

10k

C306

0.47

1M

100µH

R306

100

C307

1

R312

22k

L101

R310

0

UMX1N

C301

0.1

C101

0.22

Q301

R307

C102

220

2.5V

R311

1k

R309

Q301,302

BOOSTER

47k

10

C308

BUS

UNREG

RF VDD

22

4V

Q302

UMT1N

C309

0.1

C311

0.47

UN9113J-(TX).SO

R313

1k

R104

2.2k

Q102

2SC5585TL

MUTE

R908

10k

XRESET

Q304

INVERTER

R204

Q202

2SC5585TL

MUTE

C909

4.7

16V

C907

0.01

C910

0.1

C915

470p

C926

6.3V

2.2k

L904

10µH

22

C904

470p

R802

NTHD5904T1

R915

0

C921

1

C906

1000p

220

R918

220k

1M

Q303

MUTE

R914

0

D903

MA116

R905

C905

0.01

L902

µH

R919

1M

C913

0.047

R909

1k

MMBF0202PLT1

R921

R202

4.7k

R904

220k

Q904

XP4313-(TX).SO

SWITCH

MA116

R906

1k

1M

D902

MA729-TX

0.01

C911

0.01

C912

Q902

SWITCH

0

D904

FB101

0

FB201

R102

4.7k

C803

470p

0

C924

R917

220k

1

C925

0.1

FB801

FB802

R803

100

R804

100

Q901

XP152A12COMR

SWITCH

RF1

INM1

DTC1

CRST1

XRST1

C1L

VG

LG

PGND3

VB

XRST2

CRST2

DTC2

INM2

RF2

VC2G

L903

µH

150

C916

1

MAZZ068H01S0

C903

22

6.3V

150

L1

VC1G

PGND1

PGND2

L2

L2

L901

µH

L1

VO2

C917

D851

6.3V

47

C908

VO1

VCO1

SC901580EPR2

CONVERTER

VCO2

VCIN

22

6.3V

FB803

6.3V

22

C902

VC1

IC901

DC-DC

REGO3

0.1

C901

VSTB

REGI3

C922

HVB

REGO2

22

4V

10k

R903

LVB

VC2

C851

0.1

XWK1

XWK1

VRMC

REGI1

REGC1

R912

10k

RMC KEY1

OPEN CLS SW

XWK2

XWK3

REGC1

REGC2

R911

100k

D201

MAZS027008SO

PWR FFCLR

R901

470k

XWK4

FFCLR

SLEEP

CLK

SEQSEL

WDT

SCK

STRB

DATA

HPI2

HPI1

MUTEON

GND

VHP1

HP1

PGND

HP2

VHP2

VREF

REGC3

C920

0.1

R902

220k

R916

470k

D301

MAZS027008SO

D101

MAZS027008SO

VG1

VSTB

TAP901

PWR SLEEP

SIO4 CLK

PWR STRB

SIO4 DO

MUTE ON

C303

0.1

176K

C852

0.1

C923

R951

7

RVDD

RDTCK

RKEY

RGND

J301

L-CH

A-GND

R-CH

1

1

0

VDD

24

(CHASSIS)