Sony Multiscan CPD-1604S, Multiscan CPD-1604SA Service Manual

SERVICE

MANUAL

REVISED

SPECIFICATIONS

US Model

Canadian Model

Chassis

No.

SCC-E72A-A

Multiscan

Picture tube

Viewable pixels

Scanning frequency

Video input signal

Sync input

Power requirements

Super

Fine Pitch T rinitron color tube

17-inch (16

90 degree deflection

Anti-glare dark screen

Phosphor P22

0.25

1024 x 768

Vertical sync signal frequency:

50Horizontal sync signal frequency:

28 - 57 kHz

Analog RGB positive

0.714 Vp-p1750 terminated

TIL

Composite sync is acceptable at Pin #

Sync on green

100-120 V AC, Max. 2.0

220-240 V AC, 1.0

V)

picture tube measured diagonally

mm

Aperture Grille Pitch

87 Hz

level. Polarity free.

is

acceptable.

A,

A,

50-60

50-60

Hz

Hz

Dimensions

.

I

p

300 rnrn

406 rnrn

'1

8.

Weight

Supplied accessory

Design and specification subject

430(H) x 406(W) x 437(0)

(17 x

16

-

-r

I

Approx. 20

Including the tilt-swivel

AC

power cord (1)

x 17'/4 inches)

E

E

0

M

".

E I

~T

I

kg

to

change without notice.

I

mm

300

~

io) III'

I;)

Ill'

I

rnrn

437mm

...dlll..

/

I

•••••

•••••

•••

MICROFILM

COLOR

COMPUTER

SONY:

MULTISCAN®

DISPLAY

CPD-1604S/1604SA

WARNING

To

prevent fire

to rain

or

Dangerously high voltage is present inside the unit. Do

not open the cabinet. Refer servicing to qualified

personnel only.

or

moisture.

shock hazard, do not expose the unit

NOTE:

This

limits for a

These

limits

interference

ment.

This

energy

and,

manual,

may

tion

of

this

interference

ence

at

his

'You

are

cautioned

approved in

ment."

equipment

Class

A digilal device,

are

designed

when

the

equipment

if notlnslalled

cause

harmful

equipment

in

which

own

expense.

that

this

manuaf

has

been

to

provide

equipment

generates,

and

used

interference

in a residential

case

the

user

any

changes

could

void

tested

pursuant

reasonable

is

operated

uses,

and

in

accordance

area

will

be

or

your

and

found

to

to

Part

15

protection

in a commercial

can

radiate

to

radio

communications.

is

likefy

to

required

modifications

authority

to

comply

of

the

radio

with

the

cause

to

correct

not

operate

with

FCC

against

environ·

frequency

instruction

harmful

the

expressly

this

equip-

the

Rules.

harmful

Opera-

interfer-

TABLE

Section

1. GENERAL

1-1.

Location

1-2.

Connections···································· .. ···· .. · ............... 5

1-3.

Use

of

the

1-4.

Timing Chart·························································· 7

2.

DISASSEMBLY

2-1.

Tilt

and

Cabinet Removal· ........................................ · 9

2-2.

DA(DC-l) board Removal ................ · .... · .................. 9

2-3. Chassis

and

2-4. D Board Removal .................................. · .. · ..............

2-5. Picture Tube Removal ..............................................

3.

SET-UP ADJUSTMENTS

3-1.

Beam

Landing ........ ·· ........ ·· ...... · ............................

3-2. Convergence···································· .. ······ .. ·········· ..

3-3. Focus Adjustment

3-4. White Balance ........................................ · ..............

3-5.

Bright Controllable Confirmation ...............................

Title

and

Function of Controls ...... · ........ ·.............. 4

Tilt-Swivel· ............ · ................ · .............. · 6

B Block Assembly Removal ................ · .... ·

..

· .... · .... · ............ ·· ........................ ·

10

11

11

·12

·13

16

·16

16

OF

CONTENTS

Section

4.

SEFETV RELATED ADJUSTMENT·

5.

CIRCUIT ADJUSTMENTS

5-1.

5-2. D

6.

DIAGRAMS

6-1.

6-2.

6-3.

7.

EXPLODED VIEWS·· ................................................

8.

ELECTRICAL PARTS LIST·· ..............

Title

...... " .....

DA(DC-

1)

Board Adjustment ................ ··· ......

and

DA(DC-J) Board Adjustments ..........................

··

...... ·

'"

Circuit Boards Location ............................................

Schematic Diagrams

and

Printed Wiring Boards ............

Frame Schmatic Diagram····································

DA(OC-1) Board .................... · ..............

D

,K

Board ........

B Board .... · ...... ·

··

............................................ ·

..

· ................ · ...... · .................... 44

Semiconductors .......... · .... · ........ · ..................

·· .. · .. ·· .. · 28

··

.... · .... ·

··

....................

..

'17

20

21

24

24

25

36

49

51

52

SAFETY·RELATED

COMPONENTS

&.

ON THE SCHEMATIC

VIEWS

AND

SAFE OPERATION. REPLACE THESE COMPONENTS

SONY PARTS WHOSE

WITH

SHOWN

AS

PUBLISHED

THAT

ARE

IDENTIFIED

CEDURES

REPLACED

IDENTIFIED

IN

IN

THIS

BY

CRITICAL

IN

THIS

WHENEVER

OR IMPROPER OPERATION IS SUSPECTED.

COMPONENT

THE PARTS

MANUAL

SONY.

TO SAFE OPERATION

MANUAL.

CRITICAL

WARNING

BY

SHADING

DIAGRAMS,

LIST

ARE

CRITICAL

PART

NUMBERS APPEAR

OR

IN

SUPPLEMENTS

CIRCUIT

ADJUSTMENTS

FOLLOW THESE PRO-

COMPONENTS ARE

!!

AND

MARK

EXPLODED

TO

ARE

ATTENTION

LES COMPOSANTS

PAR UNE

LES VUES EXPLOSEES

SONT

D'UNE

SECURITE

PLACER QUE PAR DES COMPOSANTS SONY

NUMERO DE PIECE EST

MANUEL

SONY. LES REGLAGES

TANCE

FONCTIONNEMENT

PRESENT

DE

CHAQUE

CRITIQUES,OU

MENT

EST SUSPECTE.

AUX

MARQUE

IMPORTANCE

DU

FONCTIONNEMENT.

OU

DANS

EST

CRITIQUE

MANUEL.

REMPLACEMENT

LORSQU'UN

COMPOSANTS

SECURITEII

IDENTIFIES

&SUR

DES SUPPLEMENTS PUBLIES PAR

DE

SONT

SUIVRE

PAR

LES SCHEMAS DE PRINCIPE,

ET

LES LISTES DE PIECES

CRITIQUE

INDIQUE

CIRCUIT

POUR

IDENTIFIES

CES PROCEDURES LORS

MAUVAIS

-2-

RELATIFS A LA

UNE

TRAME

POUR

NE LES REM-

DANS

LA

DE COMPOSANTS

DONT

LE

PRESENT

DONT

L'IMPOR-

SECURITE

DANS LE

FONCTIONNE-

ET

LA

LE

DU

CPD-1604S/1604SA

After

correcting

perform

the

2. Check

3.

4. Look for

5. Look for parts

6. Check the line

7.

the

following

set

to

the

customer:

I.

Check

the

area

poorly-soldered

board

surface

the

wires are

resistors.

Check

ground

been

have replaced all

ticularly

previous repair.

and

obvious

to

the

ment.

Recommend

cord

Check

values specified. Make

are

if sets

"pinched"

that

straps,

replaced.

unauthorized

transistors,

recommend

signs

customer

to

the

the

accurate;

always

the

safety

of

your

connections.

for

solder

interboard

all

control

and

Be

absolutely

the

that

Point

their

which,

of

deterioration.

and

cord

the

replacement

customer.

B+

and

HV to see

be

suspicious

have low HV.

SAFETY

original service

checks

before

repair

for

unsoldered

Check

splashes

wiring

or

con

knobs,

mounting

insulators.

replacement

were

them

replacement.

though

recommend

for

sure

and

to

ensure

tact high-wa

shields,

hardware

certain

installed

out

to

the

functioning.

Point

their

cracks

and

of

any

they

your

of

your

(US

problem,

releasing

or

the

entire

c bridges.

that

no

ttage

covers,

have

that

you

parts,

par-

during

customer

show

them

out

replace-

abrasion.

such

line

are

at

the

instruments

HV

meter

CHECK-OUT

Model Only)

LEAKAGE TEST

The

earth

ground

exposed

not

exceed

current

methods.

I . A

Simpson

2. A

a

3. Measuring

meter.

analog

voltage scale.

SH-63Trd

is

suitable.

HOW TO

A

cover-plate

at

also

used as

by

measuring

water

zero

ohms.

connect a 60-100

lamp)

retaining

the

hot

normal

(See Fig.

AC leakage

and

from

metal

part

0.5 rnA

can

·be measured

commercial

229

manufacturers'

ments.

battery-operated

Precision

this

means

suitable.

multimeters

cold-water

earth

your

pipe

between

brilliance if

245

job.

of

a YOM

The

meters

(See Fig. A)

FIND

retaining

ground.

earth-ground,

the

with

If a

the

screw.

side

of

B)

the

are

Nearly all

A GOOD EARTH GROUND

pipe

an

Try

the

from

any

exposed

all

exposed

having a

(500

or

instructions

digital

voltage

"limit"·

must

The

examples

that

screw

resistance

ohmmeter.

cold-water

watts

hot

both

line,

the

return

microampers);

by

leakage

RCA WT-540A.

is

If

side

tester.

AC

milliammeter.

multimeter

drop

or

battery-operated

indication

have an

Simpson

of

battery

have a 2 V AC range are

guaranteed

on

most

the

retaining

verify

between

The

pipe is

trouble

of

the

slots,

if

the

lamp

screw

is

metal

metal

to

chassis,

anyone

such as

to

use

is

across a resistor

is

accurate

250

a passive YOM

operated

earth

AC

outlet

screw

that

it is at

it

reading

not

light

receptacle

necessary,

should

at

ground

part

to

parts

to

any

must

Leakage

of

three

the

Follow

these

suitable

and Sanwa

ground;

and

(not a neon

the

instru-

The

Data

for

AC volt-

0.75

V. so

low-

that

digital

the

boxes

is

to

ground

a cold-

should

accessible,

and

the

to

locate

Iigh

tat

potential.

by

be

be

is

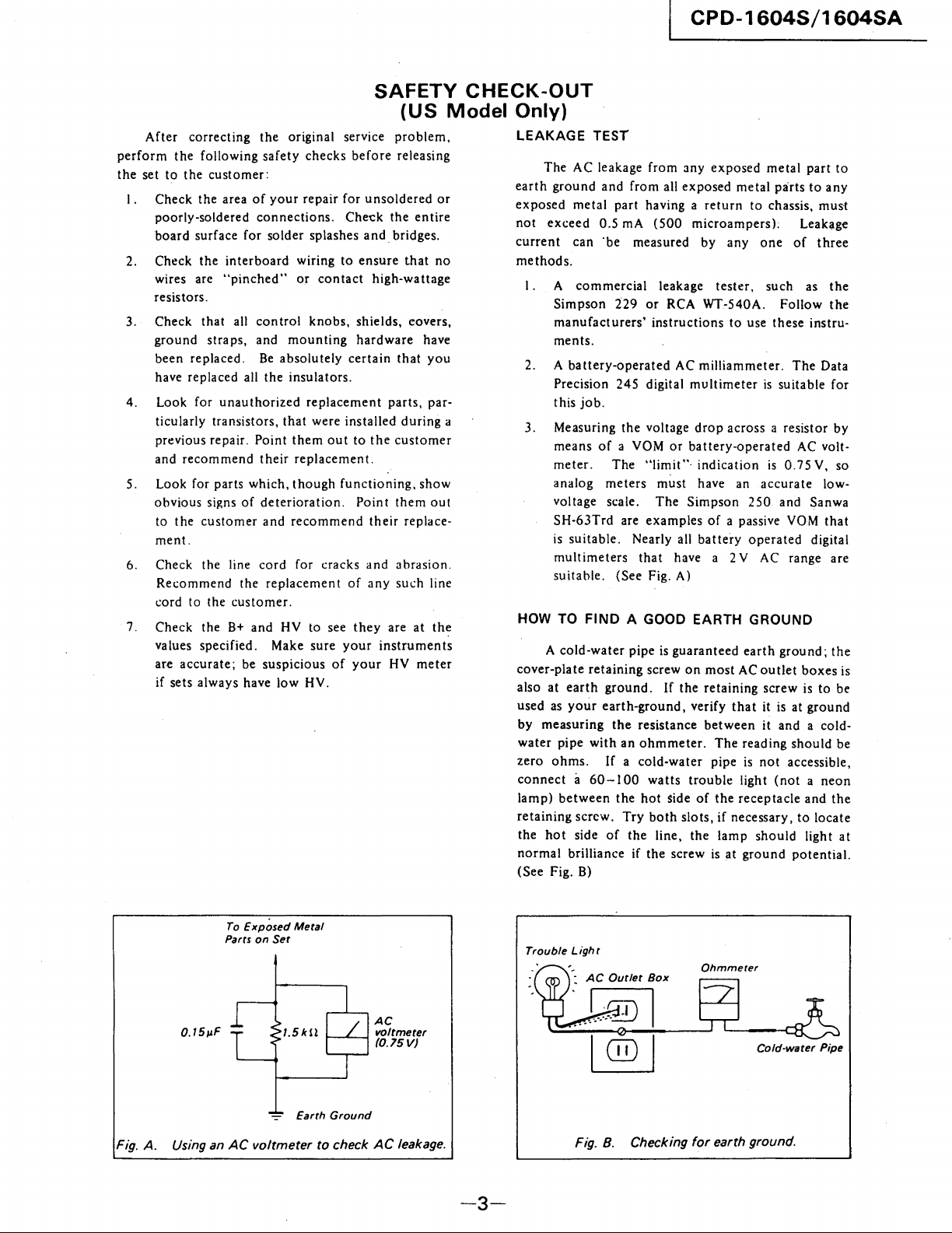

Fig. A. Using an

To

Parts

AC

Exposed

Metal

on

Set

-=-

Earth

voltmeter

Ground

to check

AC

voltmeter

(0.75

V)

AC

leakage.

-3-

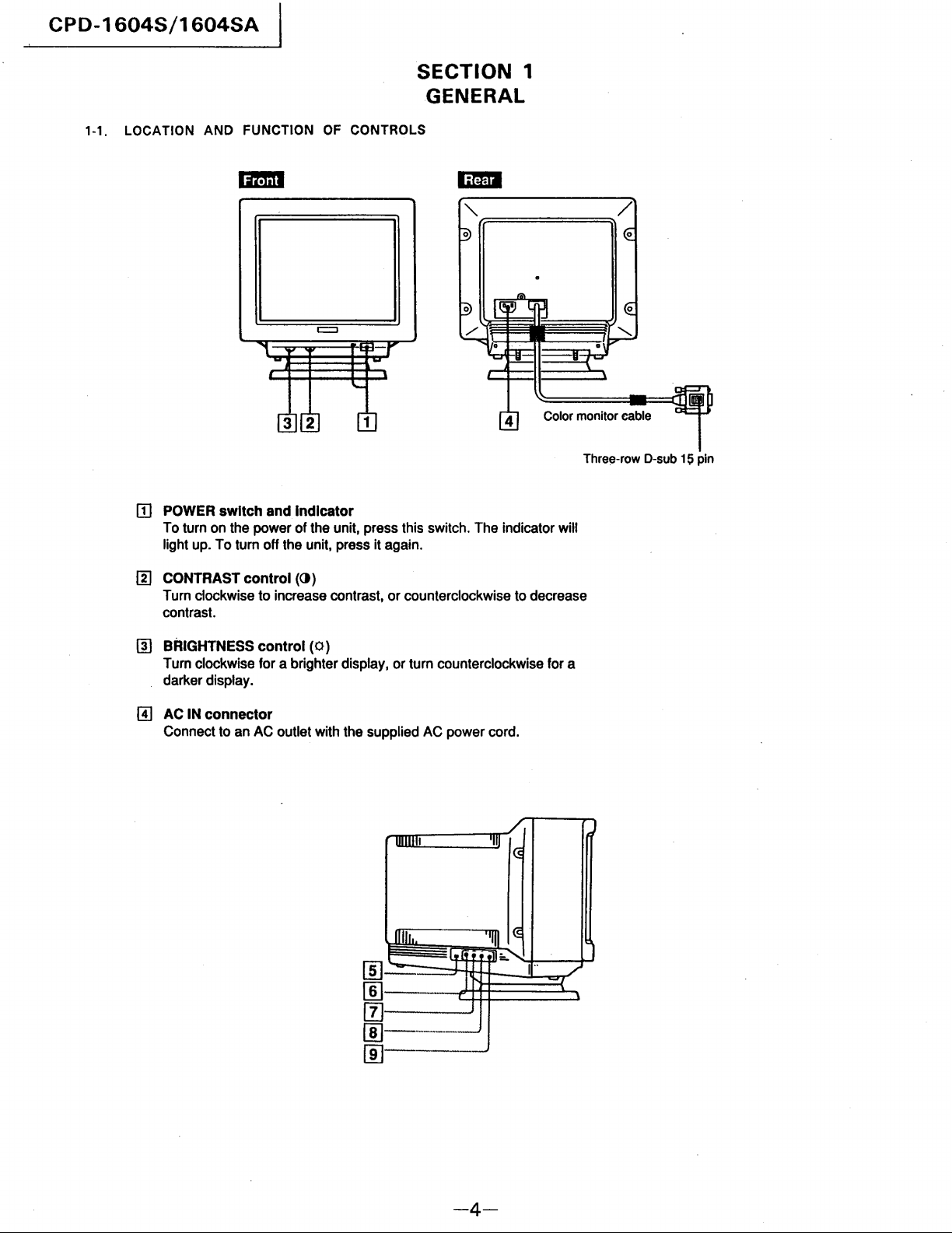

Trouble Ligh t

-:

AC

Fig. 8. Checking

Outlet

Box

Ohmmeter

for

earth ground.

Cold-water Pipe

CPD-1604S/1604SA

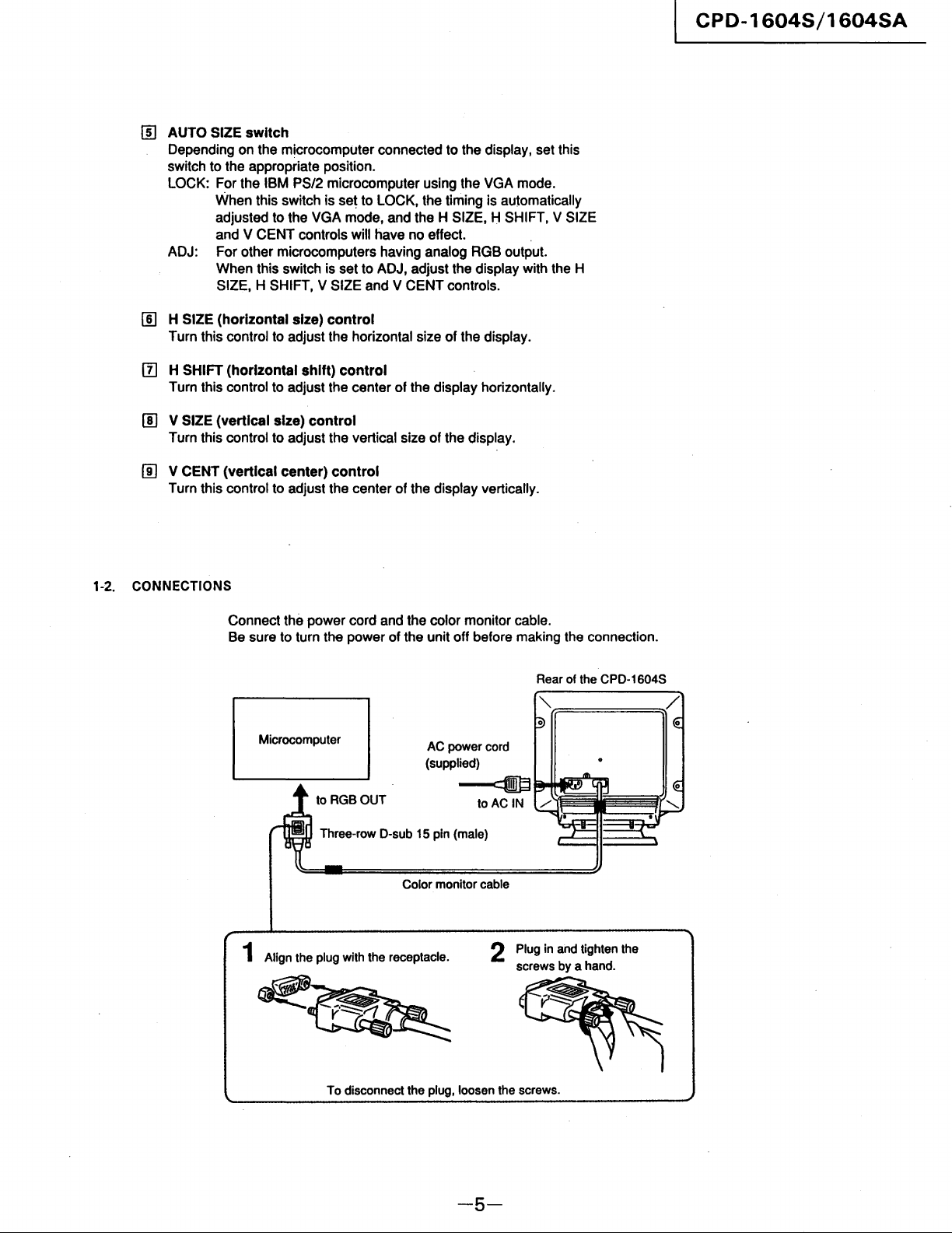

1-1. LOCATION AND FUNCTION

ITI

POWER

To turn on the power of the unit, press this switch. The indicator will

light up. To turn off the unit, press it again.

switch

and

Indicator

OF

=

CONTROLS

1

SECTION

GENERAL

"r,=====~/

1

Color monitor cable

Three-row D-sub 15 pin

rn

CONTRAST

Turn clockwise to increase contrast, or counterclockwise to decrease

contrast.

[!]

BRIGHTNESS

Turn clockwise for a brighter display, or turn counterclockwise for a

darker display.

GJ

AC

IN

Connect to an AC outlet with the supplied AC power cord.

control

control

connector

())

(0)

Willi!

..IJ.1&

'-

-~

'III

1<5

'ljlll~

.•

11

:.

i [ .. [

.........

I"

--"'--"---

-----------'

-4-

[!)

AUTO SIZE switch

Depending on the microcomputer connected to the display, set this

switch to the appropriate position.

LOCK: For the IBM PS/2 microcomputer using the VGA mode.

When this switch is set to LOCK, the timing is automatically

adjusted to the VGA mode, and the H SIZE, H SHIFT, V SIZE

and V CENT controls will have no effect.

ADJ: For other microcomputers having analog RGB output.

When this switch is set to ADJ, adjust the display with the H

SIZE, H SHIFT, V SIZE and V CENT controls.

[!]

H SIZE (horizontal size) control

Turn this control to adjust the horizontal size of the display.

[f]

H SHIFT (horizontal shift) control

Turn this control to adjust the center of the display horizontally.

[!]

V SIZE (vertical size) control

Turn this control to adjust the vertical size of the display.

Iil V CENT (vertical center) control

Turn this control to adjust the center of the display vertically.

CPD-1604S/1604SA

1-2. CONNECTIONS

Connect the power cord and the color monitor cable.

Be sure to turn the power of the unit off before making the connection.

Rear of the CPO-1604S

Microcomputer

to

RGBOUT

Three-row O-sub 15 pin (male)

1 Align the plug with the receptacle.

AC power cord

(supplied)

~

toAC

Color monitor cable

2 Plug in and tighten the

IN

screws by a hand.

To disconnect the

plug, loosen the screws.

-5-

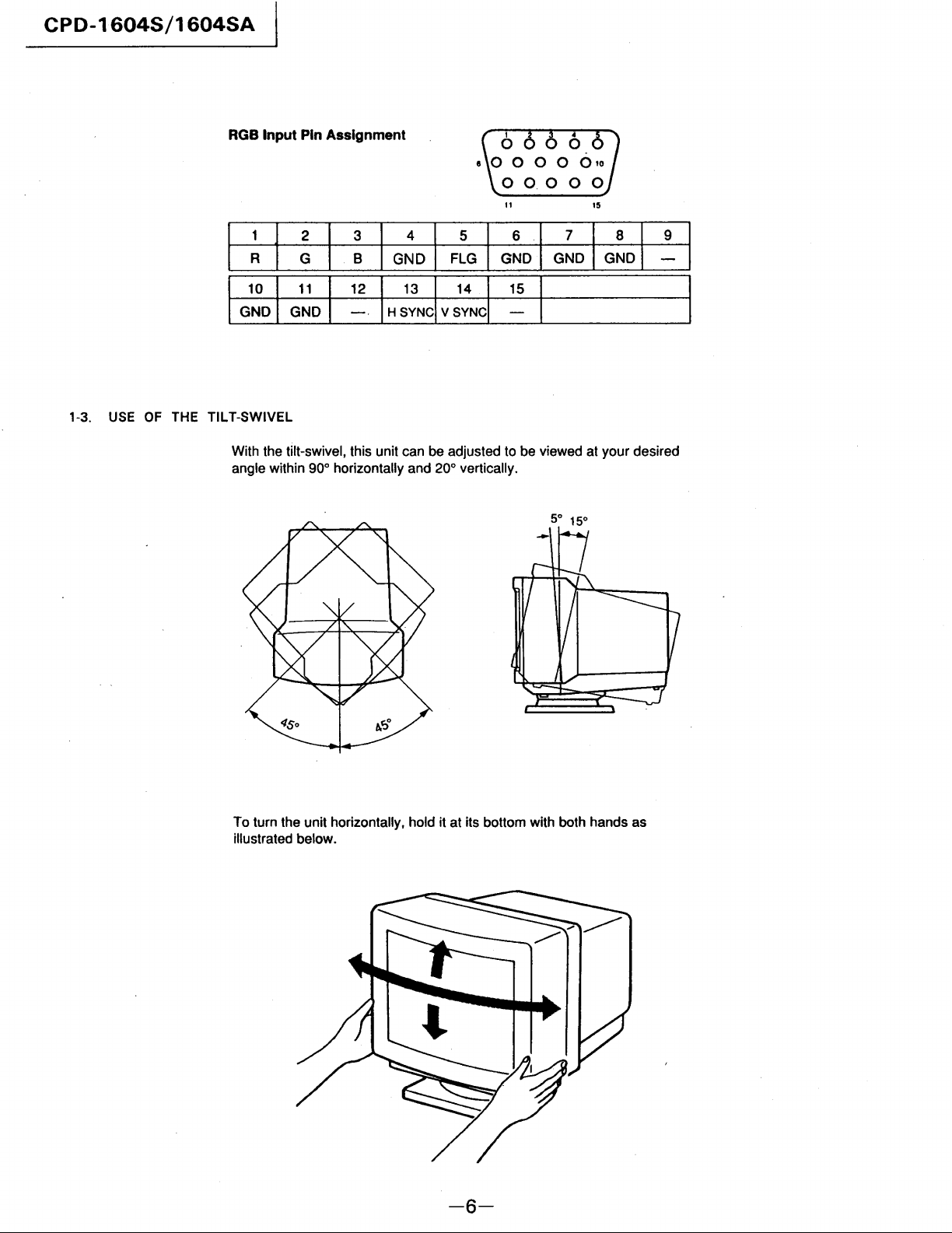

CPD-1604S/1604SA

RGB

Input

Pin Assignment

1-3.

USE

I I

I

OF

THE TILT-SWIVEL

11

2 3

R

G~ol

With the tilt-swivel, this unit can be adjusted to be viewed at your desired

angle within 900 horizontally and 200 vertically.

G

G~O

8

12

I

4

GND

I H

~:Ncl

5

FLG

V

~:NCI

G:ol

15

15

G:O

I

G~O

9

I

To turn the unit horizontally, hold it at its bottom with both hands as

illustrated

below.

-6-

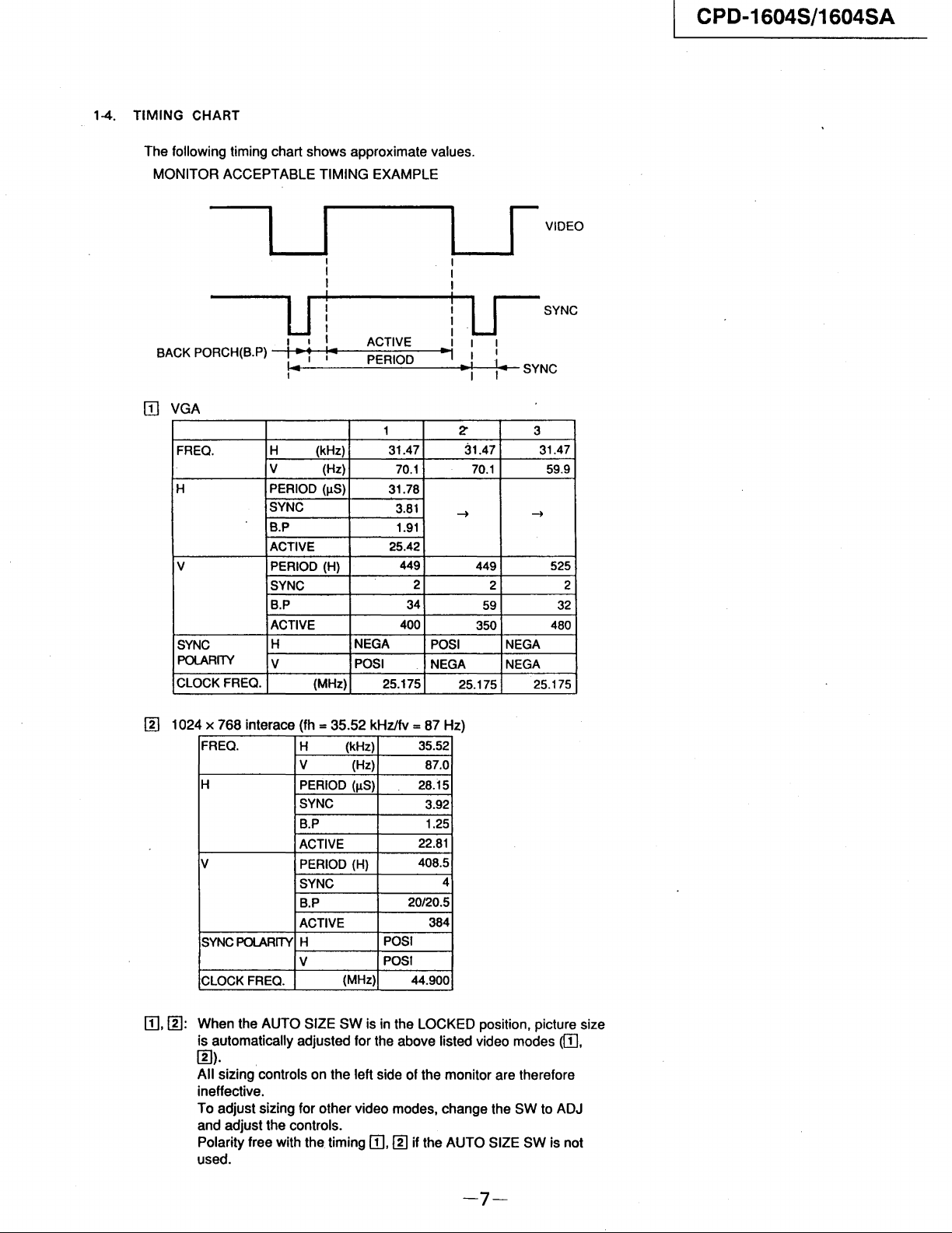

1-4.

TIMING

The

CHART

following timing chart

MONITOR

ACCEPTABLE

shows

approximate values.

TIMING

EXAMPLE

CPD-1604S/1604SA

BACK

PORCH(B.P) -1IIH

[TI

VGA

FREO.

H

V PERIOD

SYNC

POLARITY

CLOCK FREO.

a...._--II

I I

I I

I I

l I I

il

U

I I I ACTIVE I I I

..

·~1

-Ioo1"I---=:P:'::E:::R-:-:IO:'::D:---~·1

.-

I I I

1

H (kHz)

V (Hz)

PERIOD

SYNC

B.P

ACTIVE

SYNC

B.P

ACTIVE

H NEGA

V

(/.lS)

(H)

(MHz)

31.47 31.47

70.1 70.1

31.78

3.81

1.91

25.42

449

2

34

400

POSI

25.175

POSI

NEGA

r-

!.L-J

I I

~I

I.

2"

-+

449 525

2 2

59

350

25.175 25.175

VIDEO

SYNC

SYNC

3

31.47

59.9

-+

32

480

NEGA

NEGA

I]]

[TI,

1024 x

1]]:

768

interace (fh = 35.52 kHZ/fv =

FREO.

H

V

SYNC

POLARITY

CLOCK

FREO.

When

the

is

automatically

1]]).

All

sizing controls

ineffective.

To

adjust

and

adjust

Polarity

used.

free with the timing

H

V

PERIOD

SYNC

B.P

ACTIVE

PERIOD

SYNC

B.P

ACTIVE

H

V

AUTO

SIZE

adjusted

sizing for

the

controls.

87

Hz)

POSI

POSI

I]]

35.52

87.0

28.15

3.92

1.25

22.81

408.5

4

20/20.5

384

44.900

LOCKED

the

monitor

change

if the

AUTO

(kHz)

(Hz)

(IlS)

(H)

(MHz)

SW

is in the

for the above listed video modes

on

the

left side of

other

video modes.

[TI.

position. picture size

([TI.

are therefore

the

SW

to ADJ

SIZE

SW

is not

-7-

CPD-1604S/1604SA

00

35 kHz non-interace (example)

x 600

800

FREQ.

H

V

CLOCKFREQ.

[!] 48 kHz non-interace (example)

1024

x 768

FREQ.

H

V

CLOCK FREQ.

H,

(kHz)

V

PERIOD (IlS)

SYNC

B.P

DISPLAY

PERIOD (H)

SYNC

B.P

ACTIVE

H (kHz)

V (Hz)

PERIOD (IlS)

SYNC

B.P

DISPLAY

PERIOD (H)

SYNC

B.P

ACTIVE

(Hz)

(MHz)

(MHz)

35.16

56.0

28.44

3.11

2.67

22.22

628

14

7

600

36.000

48.780

60.00

20.500

1.500

2.000

16.000

813

3

39

768

64.000

00,

[!]: SYNC POLARITY FREE

[!)

57 kHz non-interace

1024 x 768

FREQ.

H

V PERIOD

CLOCKFREQ.

H (kHz)

V (Hz)

PERIOD .(IlS)

SYNC

B.P

ACTIVE

(H)

SYNC

B.P

ACTIVE

(MHz)

56.476

70.069

17.707

1.813

1.920

13.653

806

6

29

768

75.000

-8-

CPD-1604S/1604SA

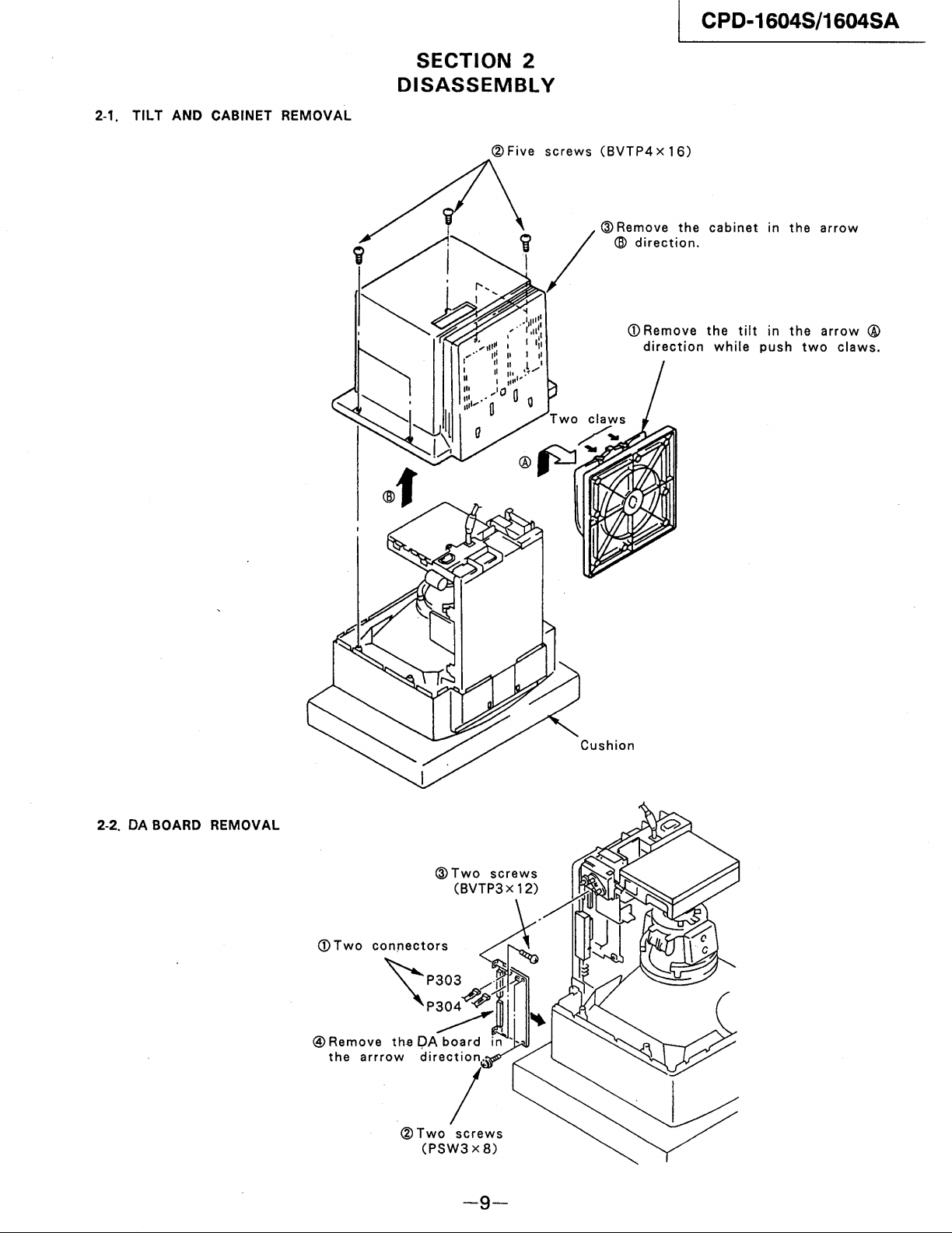

2-1.

TILT

AND

CABINET

REMOVAL

SECTION

2

DISASSEMBL

® Five

Y

screws

(BVTP4 x 16)

CD

Remove

direction

the

while

tilt

in

in

push

the

the

two

arrow

arrow

claws.

®

2-2.

DA

BOARD

REMOVAL

<DTwo

®Two

(PSW3 x 8)

Cushion

screws

-9-

CPD-1604S/1604SA

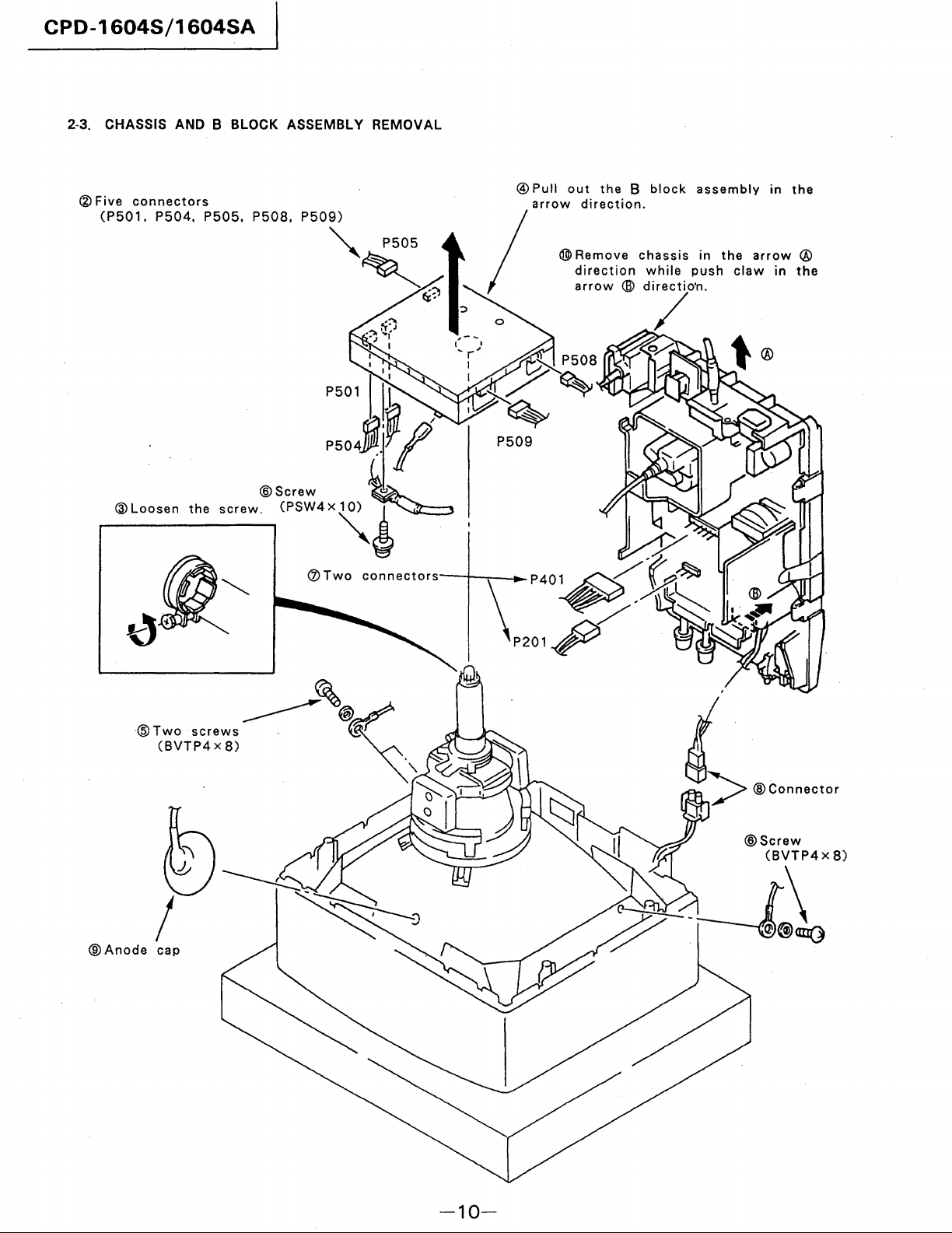

2-3. CHASSIS AND B BLOCK ASSEMBLY REMOVAL

®

Five

connectors

(P501,

P504.

P505.

P508.

®

Pull

out

arrow

/

the B block

direction.

®>

Remove

direction

arrow @ directio'n.

chassis

while

assembly

in

the

push

claw

in

arrow

in

the

@

the

/

®Anode

cap

-10-

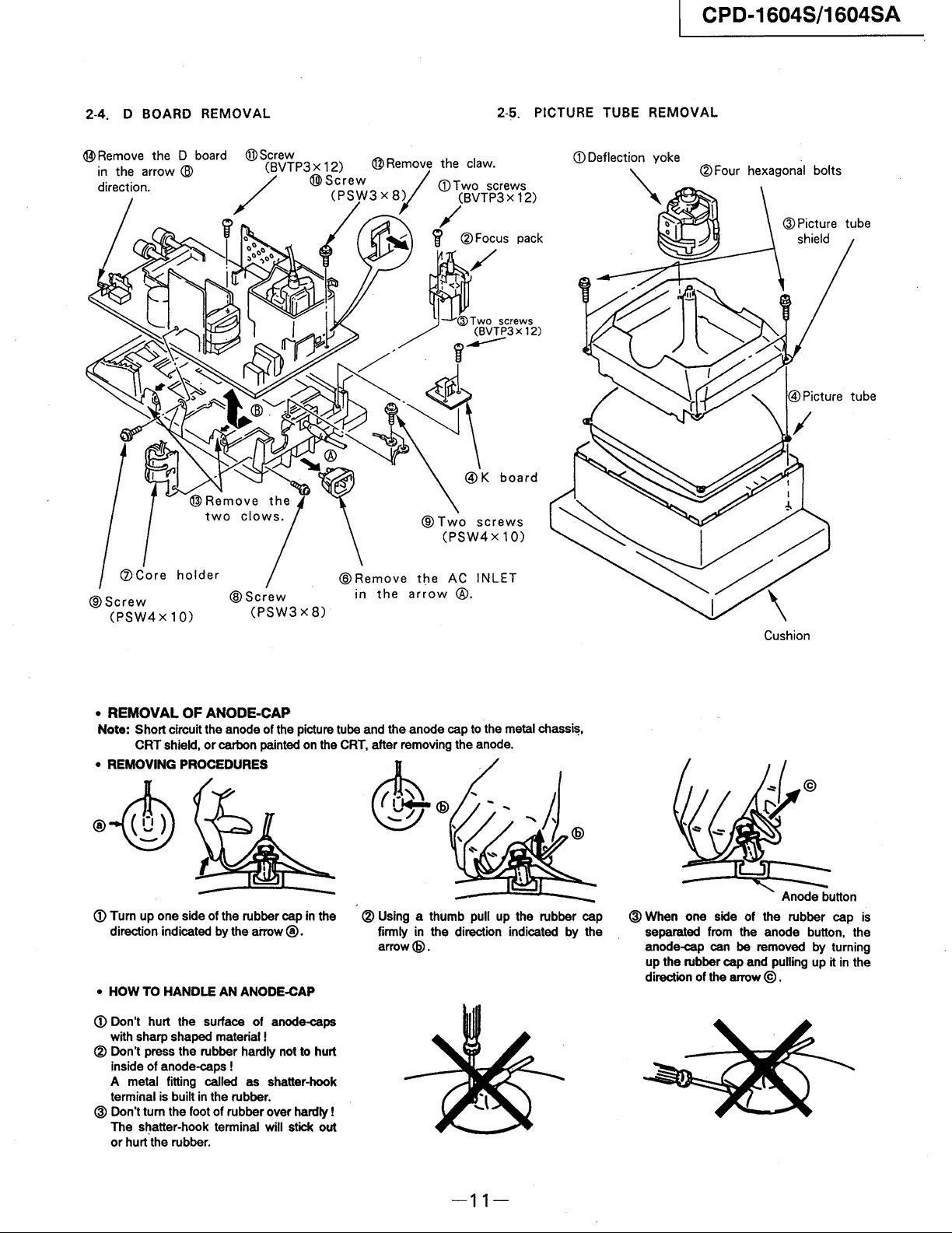

CPD-1604S/1604SA

2-4. D

BOARD

REMOVAL

®

Two

(PSW4x

2-5. PICTURE

pack

@K

board

screws

10)

TUBE

REMOVAL

hexagonal bolts

®

@Screw

Remove

in

the

the

arrow

(PSW4 x 10)

• REMOVAL OF ANODE-CAP

Note: Short circuit the anode of the picture tube and the anode cap

CRT shield,

• REMOVING PROCEDURES

CD

Turn up one side of the rubber cap

direction indicated

• HOW TO HANDLE AN ANODE-CAP

CD

Don't hurt the surface of anode-caps

with sharp shaped material!

or

carbon painted

by

the

aiTow

®.

on

in

the

CRT,

after removing the anode.

the

® Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow@.

® Don't press the rubber hardly not to hurt

inside of anode-caps!

A metal fitting called as shatter-hook

terminal is built

@ Don't turn the foot of rubber over hardly!

The shatter-hook terminal will stick out

or

hurt the rubber.

in

the rubber.

AC

®.

INLET

to

the metal

chassi~,

Cushion

Anode button

@ When one side of the rubber cap is

from

separated

anode-cap can be removed by turning

up the rubber cap and pulling up it

direction of the arrow

the anode button, the

in

@ .

the

-11-

CPD-1604S/1604SA

• The following adjustments should

a complete

tube is

•

These

power supply voltage unless ontherwise noted.

The control

unless otherwise noted:

CONTRAST control .........

BRIGHTNESS

realignment

installed.

adjustments

and

switch below should

control .......

is

should.

SET-UP ADJUSTMENT

be

made when

required

or a new picture

be

performed with rated

be

set

as

8096

5096

SECTION 3

follows

Perform the adjustments

3

-1.

Beam

landing

3 -

2.

Convergence

3-3.

Focus

3-4.

White

Balance

Note:

Test Equipment Required.

•

Signal

generator: VG807. VG809 ... etc

• Color Annalyzer

•

Degausser

in

order

(Astro

as

follows:

Design)

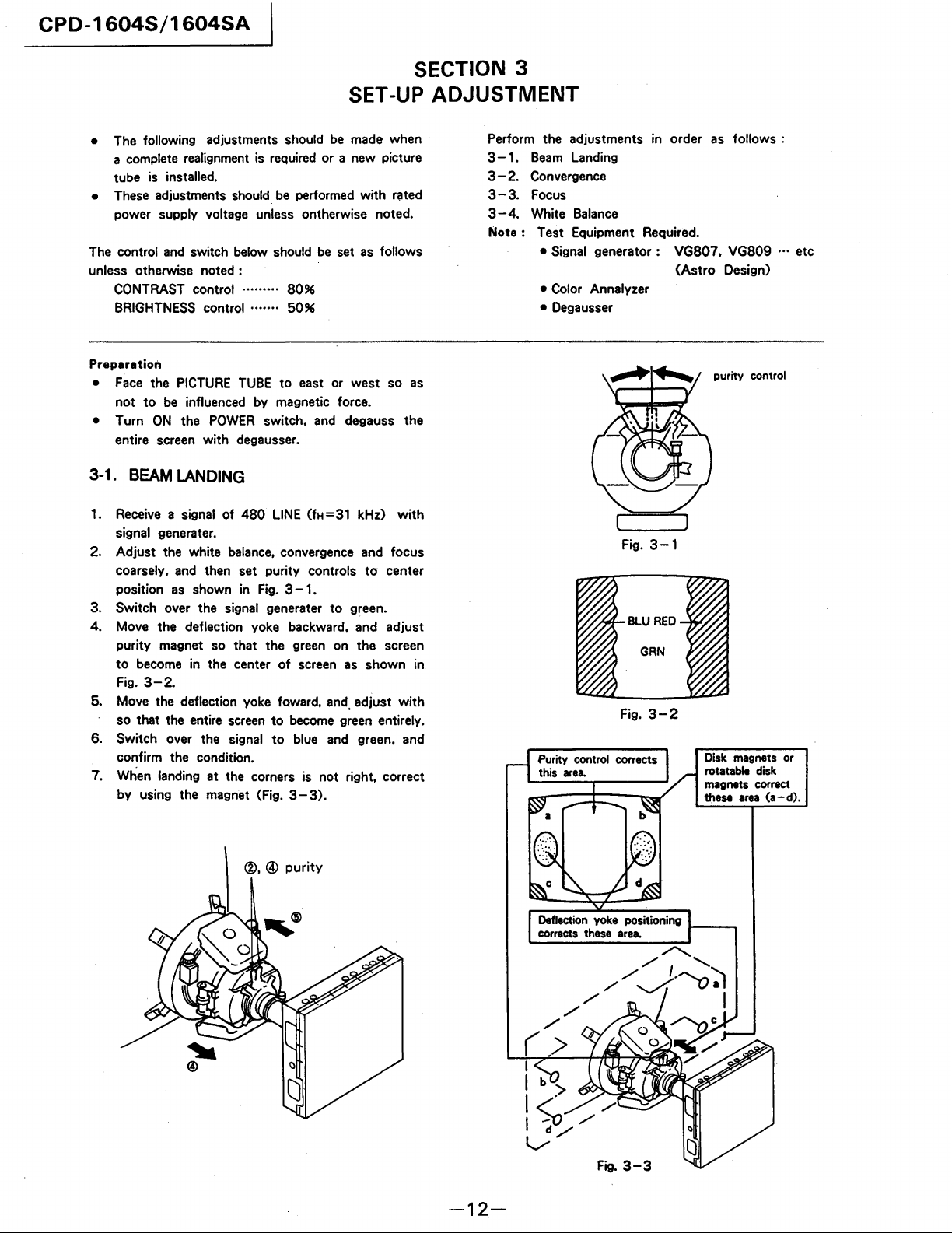

Preparation

•

Face

the

PICTURE

not

to

be

influenced by magnetic force.

• T urn

3-1.

1.

2. Adjust the white

3. Switch over the signal

4. Move the deflection yoke backward.

ON

the

entire screen with degausser.

BEAM

Receive

signal generater.

coarsely.

position

purity magnet

to

Fig.

a signal

as

become

3-2.

LANDING

and

in the center

5. Move the deflection yoke foward.

so that the entire

6. Switch over the signal

confirm the condition.

7. When landing at the corners is not right. correct

by using the magnet (Fig. 3 - 3).

TUBE

to

east or west so

POWER

then set purity controls

shown

so

of

480

balance.

in

that the

screen

switch.

LINE

convergence

Fig.

3 -

gene

rater

green

of

screen

to

become

to

blue

and

(fH=31 kHz)

1.

degauss the

with

and

focus

to

center

to

green.

and

adjust

on the screen

as

shown in

and.

adjust with

green

entirely.

and

green.

and

as

Fig.

Fig.

3-1

3-2

purity control

Disk

magnets

rotatable

magnets

these

disk

correct

area

or

(a-d).

-12-

Fig.

3-3

Loading...

Loading...