Page 1

DEVICE CONTROL UNIT PACK

DCU-8000

DEVICE CONTROL UNIT

MKS-8700

HK-PSU03

MKS-8701

MKS-8702

INSTALLATION MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l'entretien. Afin de

réduire les risques de décharge électrique, d'incendie ou de blessure n'effectuer que les

réparations indiquées dans le mode d'emploi à moins d'être qualifié pour en effectuer d'autres.

Pour toute réparation faire appel à une personne compétente uniquement.

MKS-8700 Serial No. 10001 and Higher

HK-PSU03 Serial No. 10001 and Higher

MKS-8701 Serial No. 10001 and Higher

MKS-8702 Serial No. 10001 and Higher

DCU-8000 IM

Page 3

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the rear of

the unit 10 cm (4 inches) or more away from walls

in order to obtain proper exhaust and radiation of

heat.

When using a LAN cable:

For safety,do not connect to the connector for

peripheral device wiring that might have excessive

voltage.

DCU-8000 IM

1 (P)

Page 4

Page 5

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 3

Related manuals......................................................................................................... 3

Contents ..................................................................................................................... 3

1. Installation

1-1. Operating Environment ...............................................................................1-1

1-2. Power Supply .............................................................................................. 1-1

1-2-1. Power Specifications ..................................................................1-1

1-2-2. Recommended Power Cord ........................................................ 1-1

1-3. Installation Space (External dimensions) ................................................... 1-2

1-4. Installing the Options .................................................................................. 1-3

1-4-1. Installing the Plug-in Boards ...................................................... 1-4

1-4-2. Installing the Connector Board ..................................................1-5

1-4-3. Installing the HK-PSU03 ...........................................................1-6

1-5. Rack Mounting ............................................................................................ 1-7

1-6. Matching Connectors and Cables................................................................ 1-9

1-7. Input/Output Signals of Connectors .......................................................... 1-10

1-7-1. MKS-8700 ................................................................................1-10

1-7-2. MKS-8701 ................................................................................1-12

1-7-3. MKS-8702 ................................................................................1-15

1-8. Checks on Completion of Installation ....................................................... 1-16

1-8-1. Description of On-board Switches and LEDs ..........................1-16

1-9. System Connection.................................................................................... 1-22

DCU-8000 IM

2. Service Overview

2-1. Troubleshooting .......................................................................................... 2-1

2-2. Periodic Inspection and Maintenance ......................................................... 2-3

2-2-1. Cleaning .....................................................................................2-3

1

Page 6

Page 7

Purpose of this manual

Related manuals

Manual Structure

This manual is the installation manual of Device Control Unit Pack DCU-8000 and

the optional boards and units.

This manual is intended for use by trained system and service engineers, and

describes the information on installing the DCU-8000.

The following manuals are prepared for DCU-8000 and the optional boards and

units.

..

. Operation Manual (Supplied with DCU-8000)

..

This manual describes the application and operation of DCU-8000.

..

. System Setup Manual (Available on request)

..

This manual describes the information that is required to connect the MVS-8xxx/

MVE-8000/DCU-8000/CCP-8000 to the MVS-8000 system, and to start up the

system.

Contents

..

. Maintenance Manual (Available on request)

..

This manual describes the detailed service information.

If this manual is required, please contact your local Sony Sales Office/Service

Center.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

This manual is organized by following sections.

Section 1 Installation

This section describes the operating environment, power supply, installation space,

installation of optional boards and units, rack mounting, connectors, input and

output signals of connectors, checking upon completion of installation, and system

configuration.

DCU-8000 IM

Section 2 Service Overview

This section describes the troubleshooting and periodic inspection and maintenance.

3

Page 8

Page 9

Section 1

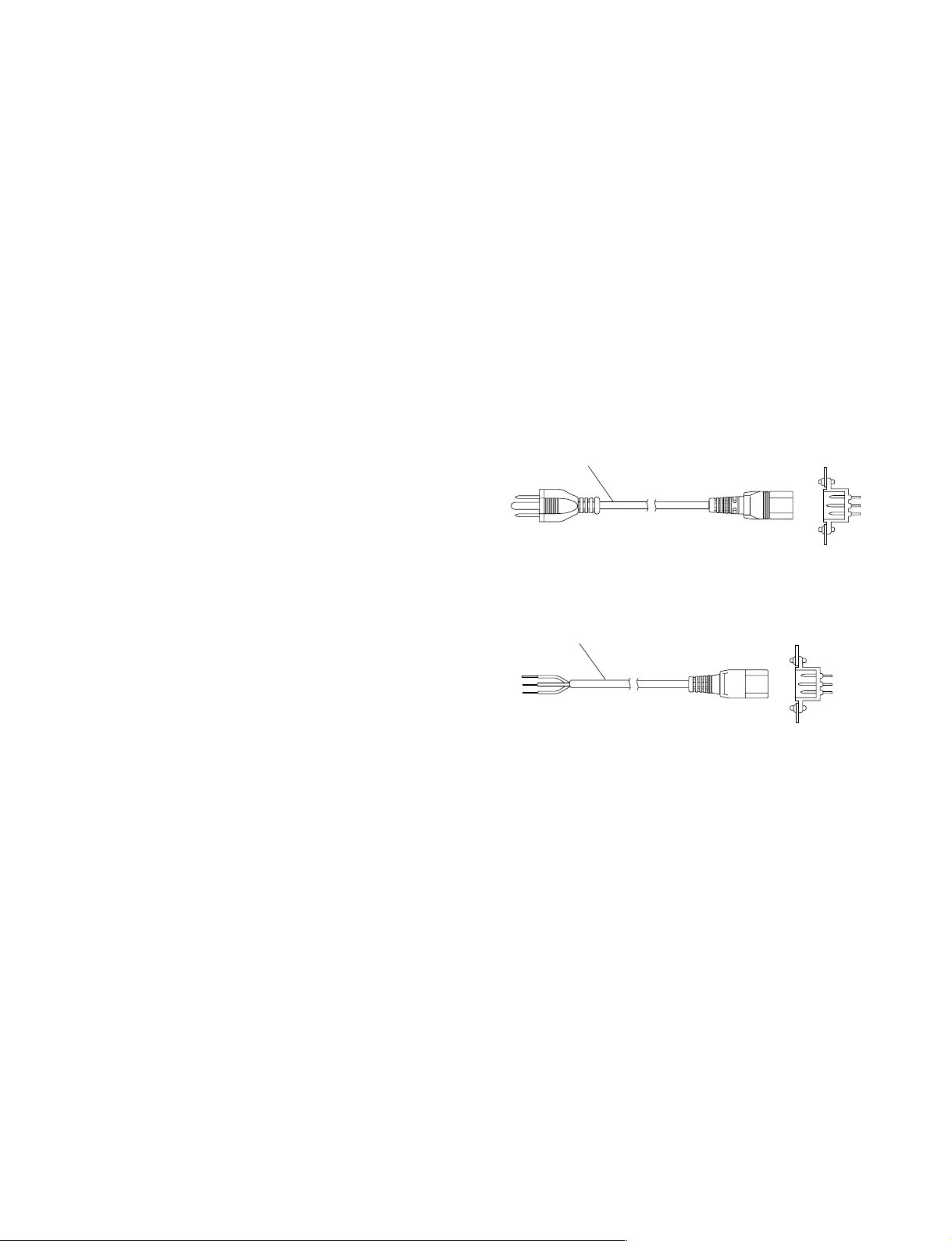

For customers in the U.S.A. and Canada

1 Power cord, 125 V 10 A (2.4 m) : ! 1-557-377-11

AC inlet

1

Installation

1-1. Operating Environment

Operating guaranteed temperature : +5 dC to +40 dC

Performance guaranteed temperature : +10 dC to +35 dC

Operating humidity : 10 % to 90 %

Storage temperature : _20 dC to +60 dC

Mass : Approx. 18 kg

(with all options

installed)

Prohibited locations for installation

. Areas where the unit will be exposed do direct sunlight

or any other strong lights.

. Dusty areas

. Areas is subject to vibration.

. Areas with strong electric or magnetic fields.

. Areas near heat sources.

. Areas subject to electrical noise.

. Areas subject to static electricity.

Ventilation

The inside of the DCU-8000 is cooled by a fan (both sides

on the rear).

The power supply can be damaged if the exhaust vent

(both sides on the rear) and air intake (front panel) are

blocked or the fan is stopped.

Therefore, leave a blank space of more than 10 cm in the

front and back of the DCU-8000.

1-2-2. Recommended Power Cord

w

. The power cord is not supplied with the DCU-8000.

Be sure to use the power cord that is applicable to places

in the area.

To avoid a fire or an electric shock, be sure to use the

designated power cord.

. Do not damage the power cord a otherwise fire or

electric shock may result.

For customers in the all Europian countories

1 Power cord, 250 V 10 A (2.4 m) : ! 1-782-929-21

1

AC inlet

1-2. Power Supply

1-2-1. Power Specifications

A switching regulator is used for the power supply of this

unit. A voltage within the range of 100 V to 240 V can be

used without changing the supply voltage.

Power requirements : AC 100 to 240 V ± 10 %

Power frequency : 50/60 Hz

Current consumption : Maximum 1.4 A

n

As the inrush current at turn-on is a maximum 20 A (at 100

V)/60 A (at 230 V), the capacity of the AC power must be

commensurate with this source load.

If the capacity of the AC power is not adequately large, the

AC power source breaker will operate or the unit will

abnormally operate.

DCU-8000 IM

1-1

Page 10

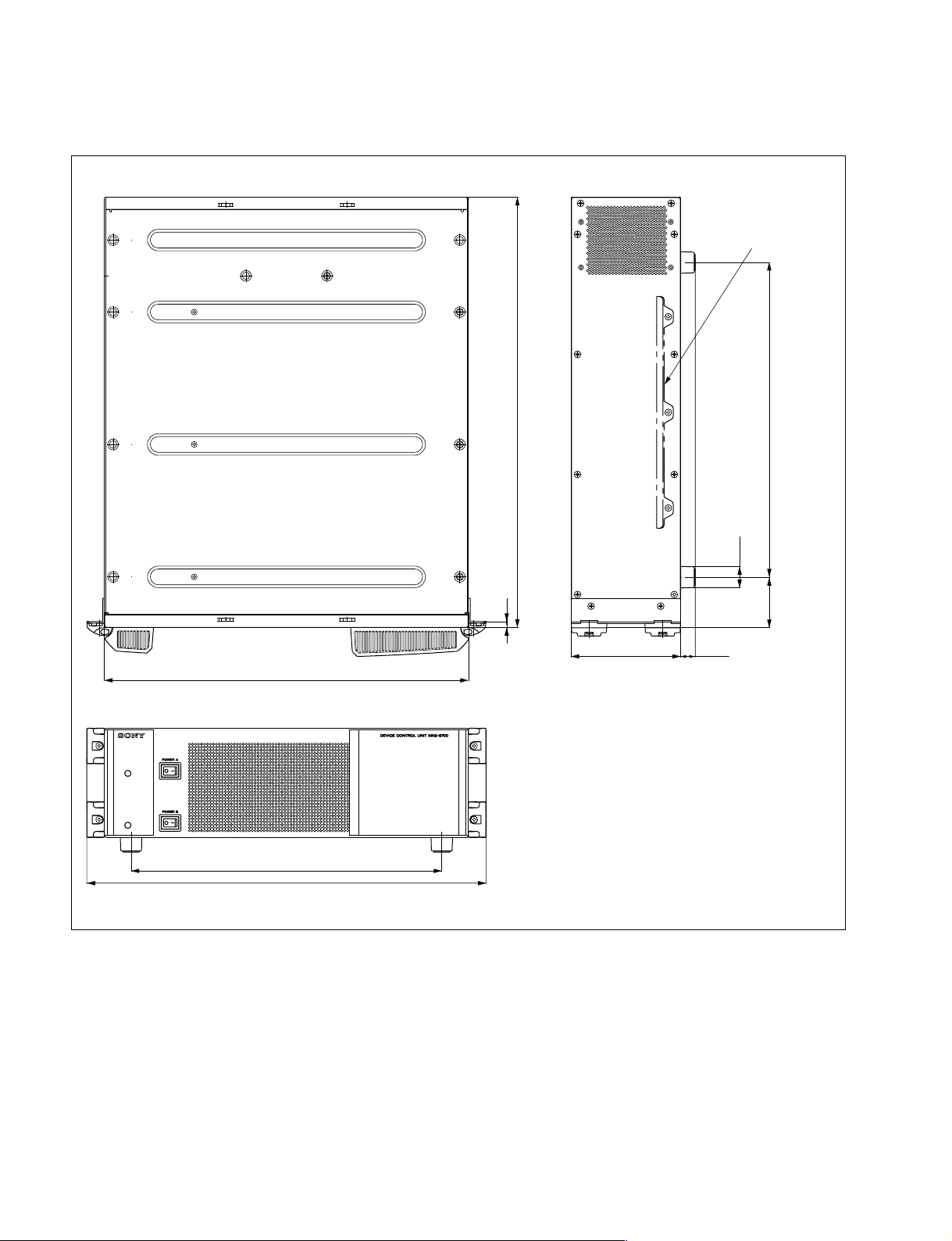

1-3. Installation Space (External dimensions)

1-3. Installation Space (External dimensions)

Rack mount metal

(supplied with RMM-10)

440

375

482

520

7

132.4

17.5

380

ø26

61

1-2

Unit : mm

DCU-8000 IM

Page 11

1-4. Installing the Options

The DCU-8000 is shipped from the factory with the necessary options (refer to the following table)

already installed in the MKS-8700, in accordance with the specified system configuration.

DCU-8000 Options

Model name Structure

Plug-in board Connector board

MKS-8701 Tally/GPI Output Board RC-90 board CN-2195 board

MKS-8702 Serial Interface Board IF-848 board CN-2194 board

HK-PSU03 Backup Power Supply Unit _

1-4. Installing the Options

DCU-8000 IM

1-3

Page 12

1-4. Installing the Options

1-4-1. Installing the Plug-in Boards

n

Be sure to turn off the POWER switch before starting

installation work.

If installation work is started with the POWER switch left

on, it may cause electrical shock or damage to printed

circuit boards.

Installation

1. Turn off the main power of the MKS-8700 and

disconnect the AC power cord from the wall outlet.

2. Loosen the four screws (with drop-safe) and remove

the front panel in the direction of the arrow.

Screws

(with drop-safe)

3. Remove the four screws (B3 x 5) and remove the

plug-in board loose-proof assembly.

B3 x 5

Plug-in board

loose-proof assembly

B3 x 5

4. While the eject levers are kept open as shown in the

illustration, insert the plug-in board into the board

guide rails.

Screws

(with drop-safe)

Eject levers

Plug-in board

Name of option Name of board

MKS-8701 RC-90 2, 3, 4, 5, 6

MKS-8702 IF-848 2, 3, 4, 5, 6

Slot on the front side

1-4

DCU-8000 IM

Page 13

1-4. Installing the Options

5. While closing the eject levers in the direction of arrow

1, push in the plug-in board.

11

Eject levers

Plug-in board

6. Attach the plug-in board loose-proof assembly and the

front panel by reversing the installation steps of 2, 3.

1-4-2. Installing the Connector Board

Installation

1. Remove the screw or the two installing screws from

the slot into which the connector board is going to be

installed. Then remove the blank panel or the

connector board.

B3 x 5

Blank panel

n

Store the removed blank panel in a safe place.

2. Insert the connector board horizontally level and

secure it with the two fixing screws.

DCU-8000 IM

Fixing screw

Connector board

Fixing screw

Name of option Name of board Slot on the rear side

MKS-8701 CN-2195 Install the board into the

slot in the rear that

corresponds to the RC-90

board that is inserted in

the slot in the front.

MKS-8702 CN-2194 Install the board into the

slot in the rear that

corresponds to the IF-848

board that is inserted in

the slot in the front.

1-5

Page 14

1-4. Installing the Options

1-4-3. Installing the HK-PSU03

The HK-PSU03 is used after it is installed in the MKS-

8700.

n

Be sure to turn off the POWER switch before starting

installation work.

If installation work is started with the POWER switch left

on, it may cause electrical shock or damage to printed

circuit boards.

Installation

1. Remove the front panel. (Refer to Section 1-4-1)

2. Loosen the two screws fixing the blank panel of the

slot to which you want to install the HK-PSU03.

Remove the blank panel.

B3 x 5

Blank panel

n

Store the removed blank panel in a safe location.

3. Install the HK-PSU03 firmly as far as it will go.

4. Secure the HK-PSU03 with the two screws.

B3 x 5

HK-PSU03

1-6

DCU-8000 IM

Page 15

1-5. Rack Mounting

1-5. Rack Mounting

The DCU-8000 installs in a 19-inch standard rack.

To mount the DCU-8000 in a rack, use the specified rack

mount kit and follow the procedure described below.

Specified rack mount kit : RMM-10

n

If a rack mount kit other than the specified one is used, the

unit may not correctly install in 19-inch standard rack.

Parts of the RMM-10

. Rack tools 2 pcs

. Right rack mount adaptor 1 pc

. Left rack mount adaptor 1 pc

. Rack tool attaching screws 6 pcs

(B4 x 6 : 7-682-560-09)

. Rack tool attaching screws 6 pcs

(B4 x 10 : 7-682-560-10)

1. Precautions for rack mounting

w

. To prevent the rack from falling or moving, fix the rack

on a flat and steady floor using bolts or others fixings.

If the rack falls due to the weight of the equipment, it

may cause death or injury.

. Be sure to use the specified rack mount kit.

If not, injury may result and the equipment may fall due

to insufficient strength.

. After rack mounting, be sure to tighten the screws on the

rack angle and fix the unit in the rack.

If the screws on the rack angle are not tightened, the unit

may slip from the rack and fall, causing injury.

c

When mounting the unit in the rack, note the following:

. Be sure to mount in the rack with two persons or more.

. Be careful not to catch your fingers or hands in the rack

mount rail or others.

. Mount in the rack in a stable position.

2. Rack mounting procedure

This section describes the rack mounting procedure using

the RMM-10 rack mount kit.

n

Tighten the screws to the following torque.

Tightening torque : 120 x 10_2 N.m {12.2 kgf.cm}

1. Attach the rack tool to the side of the equipment using

the specified six screws.

n

Use B4 x 6 screws.

Rack tools

B4 x 6

B4 x 6

Rack tools

2. Loosen the screws on the rear of the right and left

adaptors and adjust the length of the adaptor according

to the depth of the rack.

(The illustration below shows the left adaptor.)

Adaptor

n

If several units are mounted in a rack, it is recommended

that a ventilation fan is installed to prevent temperature rise

inside the rack.

DCU-8000 IM

Portion of

the rail

B4 x 6

n

Maximum depth of adaptor : 750 mm

Minimum depth of adaptor : 595 mm

1-7

Page 16

1-5. Rack Mounting

3. Attach the right and left adaptors to the rack completely using the specified six screws.

(The illustration below shows the left adaptor.)

B4 x 10

3U

31.75

31.75

B4 x 10

Unit : mm

4. Tighten the screws (B4 x 6 : two screws each on the

right and left) for adjusting the length of the adaptor

completely (the screws that were loosened in step 2).

5. Align the groove of the rack tool at the side of the

equipment with the rail, and slide the equipment to the

rear.

n

The rack tools are hooked on the rails as shown below.

6. Remove the front panel. (Refer to Section 1-4-1)

7. Fix the rack angle in the rack using the specified

screws.

Rack

Rack angle

B5 x 12

B5 x 12

Rack angle

8. Attach the front panel to the equipment.

1-8

Rack tool

Rail Rail

Rack tool

DCU-8000 IM

Page 17

1-6. Matching Connectors and Cables

Use the following connectors, cables or equivalents when connecting cables to the unit.

Model name Panel indication Connector name Matching connector and cable

Name Sony part No.

MKS-8700 TALLY/GPI IN 1-34, D-sub 37-pin, Female D-sub 37-pin, Male

35-68, 69-102 Connector 37-pin, Male 1-566-357-11

SERIAL TALLY1, 2 D-sub 9-pin, Female D-sub 9-pin, Male

PERIPH RJ-45 modular jack

REF IN BNC, 75 Z BNC, 75 Z_

MKS-8701 TALLY/GPI OUT 1-18, D-sub 37-pin, Female D-sub 37-pin, Male

19-36, 37-54 Connector 37-pin, Male 1-566-357-11

MKS-8702 REMOTE 1 to 6 D-sub 9-pin, Female D-sub 9-pin, Male

*1 : The following crimp contact is required for the plug.

AWG#18 to #22 : 1-566-493-21

AWG#22 to #24 : 1-564-774-11

AWG#24 to #30 : 1-564-775-11

*2 : Conforms to the IEEE 802.3 Ethernet 100BASE-TX standards.

Junction Shell 37-pin 1-563-378-11

Connector 9-pin, Male 1-560-651-00

Junction Shell 9-pin 1-561-749-00

*2

__

Belden 8281 coaxial cable

Junction Shell 37-pin 1-563-378-11

Connector 9-pin, Male 1-560-651-00

Junction Shell 9-pin 1-561-749-00

1-6. Matching Connectors and Cables

*1

*1

DCU-8000 IM

1-9

Page 18

1-7. Input/Output Signals of Connectors

1-7. Input/Output Signals of Connectors

The input/output signals of the connectors at the rear panel

are as follows.

n

<CONTROLLER> indicates a controlling device.

<DEVICE> indicates a controlled device.

1-7-1. MKS-8700

SERIAL TALLY 1, 2 : RS-422A (D-sub 9-pin, Female)

<CONTROLLER> to Tally Interface Unit (*1)

5

_ EXT VIEW _

Pin No. Signal Name Function

1 FG Frame ground

2RX_ Received data (_)

3TX+ Transmitted data (+)

4 GND Common ground

5 _ No Connection

6 GND Common ground

7RX+ Received data (+)

8TX_ Transmitted data (_)

9 _ No Connection

(*1) :

TALLY INTERFACE UNIT BKDS-6080 and others.

PERIPH :

Pin No. Signal Name Function

1TX+ Transmitted data (+)

2TX_ Transmitted data (_)

3RX+ Received data (+)

4 _ No Connection

5 _ No Connection

6RX_ Received data (_)

7 _ No Connection

8 _ No Connection

100BASE-TX, RJ-45 (8-pin)

1

_ EXT VIEW _

1

69

8

TALLY/GPI IN 1-34 : D-sub 37-pin, Female

INPUT x 34, TTL, 2 INPUT TTL/+12 V Switchable (*2)

119

2037

_EXT VIEW_

Pin No. Signal Name Function

1 TALLY/GPI IN 1 Tally/GPI inputs

2 TALLY/GPI IN 3

3 TALLY/GPI IN 5

4 TALLY/GPI IN 7

5 TALLY/GPI IN 9

6 TALLY/GPI IN 11

7 TALLY/GPI IN 13

8 TALLY/GPI IN 15

9 TALLY/GPI IN 17

10 TALLY/GPI IN 19

11 TALLY/GPI IN 21

12 TALLY/GPI IN 23

13 TALLY/GPI IN 25

14 TALLY/GPI IN 27

15 TALLY/GPI IN 29

16 TALLY/GPI IN 31

17 TALLY/GPI IN 33 (*2)

18 GND Ground

19 GND Ground

20 TALLY/GPI IN 2 Tally/GPI inputs

21 TALLY/GPI IN 4

22 TALLY/GPI IN 6

23 TALLY/GPI IN 8

24 TALLY/GPI IN 10

25 TALLY/GPI IN 12

26 TALLY/GPI IN 14

27 TALLY/GPI IN 16

28 TALLY/GPI IN 18

29 TALLY/GPI IN 20

30 TALLY/GPI IN 22

31 TALLY/GPI IN 24

32 TALLY/GPI IN 26

33 TALLY/GPI IN 28

34 TALLY/GPI IN 30

35 TALLY/GPI IN 32

36 TALLY/GPI IN 34 (*2)

37 GND Ground

1-10

DCU-8000 IM

Page 19

1-7. Input/Output Signals of Connectors

TALLY/GPI IN 35-68 : D-sub 37-pin, Female

INPUT x 34, TTL, 2 INPUT TTL/+12 V Switchable (*2)

119

2037

_EXT VIEW_

Pin No. Signal Name Function

1 TALLY/GPI IN 35 Tally/GPI inputs

2 TALLY/GPI IN 37

3 TALLY/GPI IN 39

4 TALLY/GPI IN 41

5 TALLY/GPI IN 43

6 TALLY/GPI IN 45

7 TALLY/GPI IN 47

8 TALLY/GPI IN 49

9 TALLY/GPI IN 51

10 TALLY/GPI IN 53

11 TALLY/GPI IN 55

12 TALLY/GPI IN 57

13 TALLY/GPI IN 59

14 TALLY/GPI IN 61

15 TALLY/GPI IN 63

16 TALLY/GPI IN 65

17 TALLY/GPI IN 67 (*2)

18 GND Ground

19 GND Ground

20 TALLY/GPI IN 36 Tally/GPI inputs

21 TALLY/GPI IN 38

22 TALLY/GPI IN 40

23 TALLY/GPI IN 42

24 TALLY/GPI IN 44

25 TALLY/GPI IN 46

26 TALLY/GPI IN 48

27 TALLY/GPI IN 50

28 TALLY/GPI IN 52

29 TALLY/GPI IN 54

30 TALLY/GPI IN 56

31 TALLY/GPI IN 58

32 TALLY/GPI IN 60

33 TALLY/GPI IN 62

34 TALLY/GPI IN 64

35 TALLY/GPI IN 66

36 TALLY/GPI IN 68 (*2)

37 GND Ground

TALLY/GPI IN 69-102 : D-sub 37-pin, Female

INPUT x 34, TTL, 2 INPUT TTL/+12 V Switchable (*2)

119

2037

_EXT VIEW_

Pin No. Signal Name Function

1 TALLY/GPI IN 69 Tally/GPI inputs

2 TALLY/GPI IN 71

3 TALLY/GPI IN 73

4 TALLY/GPI IN 75

5 TALLY/GPI IN 77

6 TALLY/GPI IN 79

7 TALLY/GPI IN 81

8 TALLY/GPI IN 83

9 TALLY/GPI IN 85

10 TALLY/GPI IN 87

11 TALLY/GPI IN 89

12 TALLY/GPI IN 91

13 TALLY/GPI IN 93

14 TALLY/GPI IN 95

15 TALLY/GPI IN 97

16 TALLY/GPI IN 99

17 TALLY/GPI IN 101 (*2)

18 GND Ground

19 GND Ground

20 TALLY/GPI IN 70 Tally/GPI inputs

21 TALLY/GPI IN 72

22 TALLY/GPI IN 74

23 TALLY/GPI IN 76

24 TALLY/GPI IN 78

25 TALLY/GPI IN 80

26 TALLY/GPI IN 82

27 TALLY/GPI IN 84

28 TALLY/GPI IN 86

29 TALLY/GPI IN 88

30 TALLY/GPI IN 90

31 TALLY/GPI IN 92

32 TALLY/GPI IN 94

33 TALLY/GPI IN 96

34 TALLY/GPI IN 98

35 TALLY/GPI IN 100

36 TALLY/GPI IN 102 (*2)

37 GND Ground

DCU-8000 IM

1-11

Page 20

1-7. Input/Output Signals of Connectors

1-7-2. MKS-8701

TALLY/GPI OUT 1-18 : D-sub 37-pin, Female

OUTPUT x 18, relay contacts 30 V 0.1 A (*3)

119

2037

_EXT VIEW_

Pin No. Signal Name Function

1 TALLY/GPI OUT 1A Tally/GPI outputs

2 TALLY/GPI OUT 2A

3 TALLY/GPI OUT 3A

4 TALLY/GPI OUT 4A

5 TALLY/GPI OUT 5A

6 TALLY/GPI OUT 6A

7 TALLY/GPI OUT 7A

8 TALLY/GPI OUT 8A

9 TALLY/GPI OUT 9A

10 TALLY/GPI OUT 10A

11 TALLY/GPI OUT 11A

12 TALLY/GPI OUT 12A

13 TALLY/GPI OUT 13A

14 TALLY/GPI OUT 14A

15 TALLY/GPI OUT 15A

16 TALLY/GPI OUT 16A

17 TALLY/GPI OUT 17A

18 TALLY/GPI OUT 18A

19 GND Ground

20 TALLY/GPI OUT 1B Tally/GPI outputs

21 TALLY/GPI OUT 2B

22 TALLY/GPI OUT 3B

23 TALLY/GPI OUT 4B

24 TALLY/GPI OUT 5B

25 TALLY/GPI OUT 6B

26 TALLY/GPI OUT 7B

27 TALLY/GPI OUT 8B

28 TALLY/GPI OUT 9B

29 TALLY/GPI OUT 10B

Pin No. Signal Name Function

30 TALLY/GPI OUT 11B Tally/GPI outputs

31 TALLY/GPI OUT 12B

32 TALLY/GPI OUT 13B

33 TALLY/GPI OUT 14B

34 TALLY/GPI OUT 15B

35 TALLY/GPI OUT 16B

36 TALLY/GPI OUT 17B

37 TALLY/GPI OUT 18B

(*3)

n

A and B of the same number constitute a pair of relay

contacts.

<Relay>

TALLY/GPI OUT xB

TALLY/GPI OUT xA

1-12

DCU-8000 IM

Page 21

TALLY/GPI OUT 19-36 : D-sub 37-pin, Female

OUTPUT x 18, relay contacts 30 V 0.1 A (*3)

119

2037

_EXT VIEW_

1-7. Input/Output Signals of Connectors

Pin No. Signal Name Function

1 TALLY/GPI OUT 19A Tally/GPI outputs

2 TALLY/GPI OUT 20A

3 TALLY/GPI OUT 21A

4 TALLY/GPI OUT 22A

5 TALLY/GPI OUT 23A

6 TALLY/GPI OUT 24A

7 TALLY/GPI OUT 25A

8 TALLY/GPI OUT 26A

9 TALLY/GPI OUT 27A

10 TALLY/GPI OUT 28A

11 TALLY/GPI OUT 29A

12 TALLY/GPI OUT 30A

13 TALLY/GPI OUT 31A

14 TALLY/GPI OUT 32A

15 TALLY/GPI OUT 33A

16 TALLY/GPI OUT 34A

17 TALLY/GPI OUT 35A

18 TALLY/GPI OUT 36A

19 GND Ground

20 TALLY/GPI OUT 19B Tally/GPI outputs

21 TALLY/GPI OUT 20B

22 TALLY/GPI OUT 21B

23 TALLY/GPI OUT 22B

24 TALLY/GPI OUT 23B

25 TALLY/GPI OUT 24B

26 TALLY/GPI OUT 25B

27 TALLY/GPI OUT 26B

28 TALLY/GPI OUT 27B

29 TALLY/GPI OUT 28B

Pin No. Signal Name Function

30 TALLY/GPI OUT 29B Tally/GPI outputs

31 TALLY/GPI OUT 30B

32 TALLY/GPI OUT 31B

33 TALLY/GPI OUT 32B

34 TALLY/GPI OUT 33B

35 TALLY/GPI OUT 34B

36 TALLY/GPI OUT 35B

37 TALLY/GPI OUT 36B

(*3)

n

A and B of the same number constitute a pair of relay

contacts.

<Relay>

TALLY/GPI OUT xB

TALLY/GPI OUT xA

DCU-8000 IM

1-13

Page 22

1-7. Input/Output Signals of Connectors

TALLY/GPI OUT 37-54 : D-sub 37-pin, Female

OUTPUT x 18, relay contacts 30 V 0.1 A (*3)

119

2037

_EXT VIEW_

Pin No. Signal Name Function

1 TALLY/GPI OUT 37A Tally/GPI outputs

2 TALLY/GPI OUT 38A

3 TALLY/GPI OUT 39A

4 TALLY/GPI OUT 40A

5 TALLY/GPI OUT 41A

6 TALLY/GPI OUT 42A

7 TALLY/GPI OUT 43A

8 TALLY/GPI OUT 44A

9 TALLY/GPI OUT 45A

10 TALLY/GPI OUT 46A

11 TALLY/GPI OUT 47A

12 TALLY/GPI OUT 48A

13 TALLY/GPI OUT 49A

14 TALLY/GPI OUT 50A

15 TALLY/GPI OUT 51A

16 TALLY/GPI OUT 52A

17 TALLY/GPI OUT 53A

18 TALLY/GPI OUT 54A

19 GND Ground

20 TALLY/GPI OUT 37B Tally/GPI outputs

21 TALLY/GPI OUT 38B

22 TALLY/GPI OUT 39B

23 TALLY/GPI OUT 40B

24 TALLY/GPI OUT 41B

25 TALLY/GPI OUT 42B

26 TALLY/GPI OUT 43B

27 TALLY/GPI OUT 44B

28 TALLY/GPI OUT 45B

29 TALLY/GPI OUT 46B

Pin No. Signal Name Function

30 TALLY/GPI OUT 47B Tally/GPI outputs

31 TALLY/GPI OUT 48B

32 TALLY/GPI OUT 49B

33 TALLY/GPI OUT 50B

34 TALLY/GPI OUT 51B

35 TALLY/GPI OUT 52B

36 TALLY/GPI OUT 53B

37 TALLY/GPI OUT 54B

(*3)

n

A and B of the same number constitute a pair of relay

contacts.

<Relay>

TALLY/GPI OUT xB

TALLY/GPI OUT xA

1-14

DCU-8000 IM

Page 23

1-7-3. MKS-8702

REMOTE1 to 6 : RS-422A (D-sub 9-pin, Female)

<CONTROLLER> to External Device

1-7. Input/Output Signals of Connectors

5

_ EXT VIEW _

Pin No. Signal Name Function

1 FG Frame ground

2RX_ Received data (_)

3TX+ Transmitted data (+)

4 GND Common ground

5 _ No Connection

6 GND Common ground

7RX+ Received data (+)

8TX_ Transmitted data (_)

9 _ No Connection

1

69

DCU-8000 IM

1-15

Page 24

1-8. Checks on Completion of Installation

1-8. Checks on Completion of Installation

1-8-1. Description of On-board Switches and LEDs

n

The number shown in parentheses ( ) indicates the address on the circuit board.

1. CA-47 board

123456789101112131415

M

L

K

J

H

G

F

E

D

C

B

A

12345

F

E

D

C

B

A

DI2

DI3

CPU-DK

Module

DI6

DI7

DI8

SW1

SW2

DI4

DI1

CN803

ND752

ND751

D759

D758

D757

D756

D755

D754

E751

S751

S753

S752

CN752

D760

S755

S754

TP755

S506

S505

S504

S503

S502

S501

CN802

D763

D762

D761

D751

D765

D766

D767

<LEDs>

D751 (H-15) : REF-OK status LED

REF IN signal presence/absence status indication.

Not lit when the REF signal is not input.

Lit when the REF signal is input via the REF IN connector.

1-16

A side/Component side

D754 (D-15) : LAN status LED

LAN (IC151/CA-47 board) status indication.

Flashes while communication with the main panel is in

progress.

D755 (D-15) : 100

LAN (IC151/CA-47 board) status indication

Lit while communication with the main panel is in

progress at 100 Mb/s.

DCU-8000 IM

Page 25

1-8. Checks on Completion of Installation

D756 (H-15) : Main CPU status LED

Main CPU status indication. Used only for production in

the assembly factory.

D757 (H-15) : Main CPU status LED

Main CPU status indication. Used only for production in

the assembly factory.

D758 (J-15) : Main CPU status LED

Main CPU status indication. Used only for production in

the assembly factory.

D759 (J-15) : Main CPU status LED

Main CPU status indication. Used only for production in

the assembly factory.

D760 (G-15) : RESET

Lit at reset.

D761 (H-15) : SIO0

Serial I/F (IC402/CA-47 board) status indication.

Not lit : During normal operation

Lit : When the system does not start up correctly

Flashing : When the memory has an abnormality

ND752 (K-15) : Main CPU status LED

Main CPU status indication.

<Switches>

S501 (K-15) : Tally/GPI IN MODE 33

Selects either TTL level or +12 V for Tally/GPI IN 33

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication :

TTL level

S502 (K-15) : Tally/GPI IN MODE 34

Selects either TTL level or +12 V for Tally/GPI IN 34

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication

: TTL level

S503 (K-15) : Tally/GPI IN MODE 67

Selects either TTL level or +12 V for Tally/GPI IN 67

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication

: TTL level

S504 (K-15) : Tally/GPI IN MODE 68

Selects either TTL level or +12 V for Tally/GPI IN 68

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication

: TTL level

D762 (J-15) : CH0

Flashes while communication with the equipment that is

connected by the serial I/F (IC402/CA-47 board) is in

progress.

D763 (J-15) : CH1

Flashes while communication with the equipment that is

connected by the serial I/F (IC402/CA-47 board) is in

progress.

D765 (D-15) :

++

+3.3 V

++

+3.3 V power supply status indication.

Lit when the +3.3 V power is supplied.

D766 (D-15) :

++

+5 V

++

+5 V power supply status indication.

Lit when the +5 V power is supplied.

D767 (D-15) :

++

+12 V

++

+12 V power supply status indication.

If this LED does not light on, the fuse may have blown.

Lit when the +12 V power is supplied.

ND751 (J-15) : Main CPU status LED

Main CPU status indication.

S505 (L-15) : Tally/GPI IN MODE 101

Selects either TTL level or +12 V for Tally/GPI IN 101

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication

: TTL level

S506 (L-15) : Tally/GPI IN MODE 102

Selects either TTL level or +12 V for Tally/GPI IN 102

The “V” position of the circuit board indication : 12 V

The “N” position of the circuit board indication :

TTL

level

S751 (H-15) : Modes setting switch for the main

CPU

Reserved for future expansion. Used only for production in

the assembly factory. Default setting when shipped from

the factory is all OFF.

S752 (G-15) : System reset switch

Reset switch for the entire DCU-8000.

S753 (G-15) : Monitor setting switch for the main

CPU

Reset switch that is used during maintenance of the main

CPU from the TERMINAL pin.

DCU-8000 IM

1-17

Page 26

1-8. Checks on Completion of Installation

S754 (D-15) : Group ID setting switch for LAN

Sets the network group ID.

This switch is used to set the PERIPH terminal.

Refer to System Setup Manual for details.

S755 (E-15) : Unit ID setting switch for LAN

Sets the unit ID within a network.

This switch is used to set the PERIPH terminal.

Refer to System Setup Manual for details.

<Connectors>

CN752 (F-15) : TERMINAL pin

This pin is connected to the main CPU control terminal

and used during maintenance.

Used only for production in the assembly factory.

CN802 (J-15) : ISP common connector

Used only for production in the assembly factory. Used for

program writing into the JTAG device with ISP.

CN803 (K-15) : JTAG2

Used only for production in the assembly factory.

<TEST terminals>

DI6 (F-3) (green) : STATUS3 status LED

Used for maintenance purpose. Only the STATUS1 LED is

lit in normal operation.

DI7 (F-3) (green) : STATUS2 status LED

Used for maintenance purpose. Only the STATUS1 LED is

lit in normal operation.

DI8 (F-4) (green) : STATUS1 status LED

Used for maintenance purpose. Only the STATUS1 LED is

lit in normal operation.

<Switches on the CPU-DK module> (G-5)

SW1 (E-5) : RESET switch

Pressing this switch resets the CPU-DK module.

n

In some machines in which the CPU-DK module is

installed, the system reset may be activated.

SW2 (C-5) : MODE switch

8-pin DIP switch

Used only for production in the assembly factory.

All switches are set to OFF for normal operation.

Default setting when shipped from the factory is all OFF.

E751 (C-15) : GND pin

Used as GND when measuring of the each check

terminals.

TP755 (C-15) :

++

+12 V check terminal

++

+12 V measuring terminal.

<LEDs on the CPU DK module> (G-5)

DI1 (green) (B-5) : CD (Card Detect) status LED

Lit when the CPU-DK module is inserted correctly to the

parent board.

DI2 (green) (F-3) : RUN status LED

Lit when the CPU-DK module starts operating.

DI3 (F-3) (green) : STATUS4 status LED

Used for maintenance purpose. Only the STATUS1 LED is

lit in normal operation.

DI4 (green) (B-5) :

++

+3.3 V

++

Indicates the status of the VCC (CORE) and VCC (I/O)

power supplied to the CPU-DK module.

Lit while the specified powers are turned on.

1-18

DCU-8000 IM

Page 27

2. IF-848 board

123456789101112131415

M

L

K

J

H

G

DI4

SW1

CPU-DK

Module

E

SW2

D

C

DI8

DI7

DI6

DI3

DI2

12345

F

DI1

B

1-8. Checks on Completion of Installation

CN802

CN803

A

D865

D864

D863

D862

D861

D860

D851

D852

D853

D854

D855

D856

D857

D858

D859

F

E

D

C

B

A

<LEDs>

D851 (J-15) : CH5

Flashes while communication with the equipment that is

connected by the serial I/F (IC402/IF-848 board) is in

progress.

D852 (H-15) : CH4

Flashes while communication with the equipment that is

connected by the serial I/F (IC402/IF-848 board) is in

progress.

D853 (H-15) : SIO2

Serial I/F (IC402/IF-848 board) status indication.

Not lit : During normal operation

Lit : When the system does not start up correctly

Flashing : When the memory has an abnormality

CN852

ND852

ND851

D866

S851

D867

D868

D869

D870

S853

S852

D871

D872

D873

A side/Component side

D854 (H-15) : CH3

Flashes while communication with the equipment that is

connected by the serial I/F (IC302/IF-848 board) is in

progress.

D855 (H-15) : CH2

Flashes while the communication with the equipment that

is connected by the serial I/F (IC302/IF-848 board) is in

progress.

D856 (H-15) : SIO1

Serial I/F (IC302/IF-848 board) status indication.

Not lit : During normal operation

Lit : When the system does not start up correctly

Flashing : When the memory has an abnormality

DCU-8000 IM

1-19

Page 28

1-8. Checks on Completion of Installation

D857 (H-15) : CH1

Flashes while communication with the equipment that is

connected by the serial I/F (IC202/IF-848 board) is in

progress.

D858 (G-15) : CH0

Flashes while communication with the equipment that is

connected by the serial I/F (IC202/IF-848 board) is in

progress.

D859 (G-15) : SIO0

Serial I/F (IC202/IF-848 board) status indication.

Not lit : During normal operation

Lit : When the system does not start up correctly

Flashing : When the memory has an abnormality

D860 (G-15) : ST1

Not used at present.

D861 (H-15) : ST2

Not used at present.

D862 (H-15) : ST3

Not used at present.

D863 (H-15) : ST4

Not used at present.

D864 (H-15) : ST5

Not used at present.

D865 (J-15) : ST6

Not used at present.

D866 (C-15) : RESET

Lit at reset.

D867 (E-15) : IF CPU status LED

IF CPU status indication.

Used only for production in the assembly factory.

D868 (E-15) : IF CPU status LED

IF CPU status indication.

Used only for production in the assembly factory.

D869 (E-15) : IF CPU status LED

IF CPU status indication.

Used only for production in the assembly factory.

D870 (E-15) : IF CPU status LED

IF CPU status indication.

Used only for production in the assembly factory.

D871 (C-15) :

++

+5 V

++

+5 V power supply status indication.

Lit when the +5 V power is supplied.

D872 (C-15) :

++

+3.3 V

++

+3.3 V power supply status indication.

Lit when the +3.3 V power is supplied.

D873 (C-15) :

++

+12 V

++

+12 V power supply status indication.

If this LED does not light on, the fuse may have blown.

Lit when the +12 V power is supplied.

ND851 (E-15) : IF CPU status LED

IF CPU status indication.

ND852 (F-15) : IF CPU status LED

IF CPU status indication.

<Switches>

S851 (D-15) : Modes setting switch for the IF CPU

Reserved for future expansion. Used only for production

in the assembly factory. Default setting when shipped from

the factory is all OFF.

S852 (D-15) : IF CPU RESET switch

Reset switch for the entire IF-848 board.

S853 (D-15) : Monitor reset switch for the IF CPU

Reset switch that is used during maintenance of the IF

CPU from the TERMINAL.

<Connectors>

CN802 (J-15) : ISP common connector

Used only for production in the assembly factory. Used for

program writing into the JTAG device with ISP.

CN803 (J-14) : JTAG2

Used only for production in the assembly factory.

CN852 (F-15) : TERMINAL pin

This pin is connected to the CPU control terminal and used

during maintenance. Used only for production in the

assembly factory.

<LEDs on the CPU-DK module> (K-5)

Refer to <LEDs on the CPU-DK module> of “1. CA-47

board”.

<Switches on the CPU-DK module> (K-5)

Refer to <Switches on the CPU-DK module> of “1. CA-47

board”.

1-20

DCU-8000 IM

Page 29

3. RC-90 board

ABC D E F GHJ

1

2

3

1-8. Checks on Completion of Installation

4

D104

D103

D102

<LEDs>

D102 (B-4) :

++

+5 V

++

+5 V power supply status indication.

Lit while +5 V power is supplied.

D103 (B-4) :

++

+3.3 V

++

+3.3 V power supply status indication.

Lit when the +3.3 V power is supplied.

D104 (B-4) :

++

+12 V

++

+12 V power supply status indication.

Lit when the +12 V power is supplied.

If this LED does not light, the fuse may have blown.

A side/Component side

DCU-8000 IM

1-21

Page 30

1-9. System Connection

1-9. System Connection

Configure the MVS-8000 series system connection referring to the connection example as shown below.

Connection example

Reference video signal (*2)

Ethernet switch

Reference video

signal (*2)

(*1)

Ethernet switch

DATA CTRL REMOTE 1

(*1)

CTRL

REMOTE

Reference video

signal (*2)

BKS-R series

HDS-X series

Device Control Unit Pack DCU-8000

CTRL

EDITORDATA LAN

Editing Control System

BVE-9100

DATA

DME Processor Pack

MVE-8000

PERIPH

System Control Unit

MKS-8010

PERIPH

Reference video

signal (*2)

VTR DDR

Switcher Processor Pack

MVS-8400/8300/8200

Audio mixer

Crossover cable

BNC cable

(*1) : Connect each LAN (CTRL, DATA) to the separate Ethernet switches respectively.

However, a single Ethernet switch can be used for connecting each LAN.

For information about Ethernet switches that can be used in an MVS system, contact your local Sony Sales Office/Service Center.

For detailed information about setting up the Ethernet switch, refer to the documentation supplied with the switch.

(*2) : Terminate the system with the 75 Z terminators supplied. The 75 Z terminators are supplied with the equipment.

1-22

DCU-8000 IM

Page 31

Section 2

Service Overview

2-1. Troubleshooting

The main power cannot be turned on. (Indicator does not light green.)

Flow1

The main power of the DCU-8000 cannot be turned on.

(Indicator does not light green.)

YES

Is the POWER switch of the DCU -8000 turned ON?

YES

Is the power cord of the DCU -8000 connected correctly?

YES

Is the power supply unit probably defective.

Cannot read the Tally/GPI input correctly.

Flow2

Cannot read the Tally/GPI input correctly.

YES

Is the DCU-8000 connector (Tally/GPI IN) connected

to the cable of the destination equipment?

YES

Is the reference signal that matches the format of

your system input?

YES

Is the Tally/GPI Input on the center control panel set

correctly?

YES

NO

Set it to ON.

NO

Connect it correctly.

NO

Connect the cable.

Connect the correct reference signal

NO

to input.

NO

Set it.

The CA-47 board or the CN-2193 board of the

MKS-8700 is probably defective.

DCU-8000 IM

2-1

Page 32

2-1. Troubleshooting

Tally/GPI Output does not work correctly.

Flow3

The Tally/GPI Output does not work correctly.

(The Tally lamp is not lit.)

YES

Is the MKS-8700 connector (Tally/GPI IN) connected

to the cable of the destination equipment (display unit)?

YES

Is the reference signal that matches the format of your

system input?

YES

Is the Tally/GPI Input on the center control panel set

correctly?

YES

The CA-47 board of the MKS-8700, or the RC-90 board

or the CN-2193 board of the MKS-8701 that is inserted in

the corresponding slot of the MKS-8700 is probably

defective.

NO

Connect the cable.

Connect the right reference signal to

NO

input.

NO

Set it.

The device that is connected to Remote does not work correctly.

Flow4

The device that is connected to the Remote does not

work correctly.

YES

Is the cable connected between the Remote connector of

the MKS-8702 and the device?

YES

NO

Connect the cable.

Is the controllable device connected?

YES

Is the reference signal that matches the format of your

system input?

YES

Is the center control panel side already set?

YES

The CA-47 board of the MKS-8700, or the IF-848 board

or the CN-2194 board of the MKS-8702 that is inserted in

the corresponding slot of the MKS-8700 is probably

defective.

NO

Connect the controllable device.

Connect the connect reference

NO

signal to input.

NO

Set it.

2-2

DCU-8000 IM

Page 33

2-2. Periodic Inspection and Maintenance

2-2.

Periodic Inspection and Maintenance

2-2-1. Cleaning

1. Front panel

The filter on the rear of the front panel can easily accumulate the dust. Be sure to remove dust by cleaning as follows.

1. Remove the front panel. (Refer to Section 1-4-1.)

2. Remove the dust accumulated on the filter with a

vacuum cleaner.

n

Cleaning the filter by washing in water is recommended when there is a heavy accumulation of dust.

Be sure to dry the filter completely after it has been

washed is cleaned by water.

Front panl

Filter

2. Fan

The inside of the DCU-8000 is cooled by a fan (both sides

on the rear).

If dust has accumulated in the intake of the fan, air is

prevented from flowing smoothly and this may result in a

temperature rise inside the machine. This may have an

adverse effect on performance and life of the machine.

Cleaning of the fan every month is recommended.

Contact your local Sony Sales Office/Service Center for

information on cleaning the fan.

Fans

DCU-8000 IM

2-3

Page 34

Page 35

The material contained in this manual consists of

information that is the property of Sony Corporation.

Sony Corporation expressly prohibits the duplication of

any portion of this manual or the use thereof for any

purpose other than the operation or maintenance of the

equipment described in this manual without the express

written permission of Sony Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony Corporation.

Sony Corporation interdit formellement la copie de

quelque partie que ce soit de ce manuel ou son emploi

pour tout autre but que des opérations ou entretiens de

l’équipement à moins d’une permission écrite de Sony

Corporation.

Das in dieser Anleitung enthaltene Material besteht aus

Informationen, die Eigentum der Sony Corporation sind.

Die Sony Corporation untersagt ausdrücklich die

Vervielfältigung jeglicher Teile dieser Anleitung oder den

Gebrauch derselben für irgendeinen anderen Zweck als

die Bedienung oder Wartung der in dieser Anleitung

beschriebenen Ausrüstung ohne ausdrückliche

schriftliche Erlaubnis der Sony Corporation.

DCU-8000 IM

Page 36

DCU-8000 (SY) E

3-206-023-01 (1)

Printed in Japan

Sony Corporation 2001. 10 16

B&P Company ©2001

Loading...

Loading...