SONY KV-BM14M40 Service Manual

REVISION HISTORY

BX1

CHASSIS

MODEL

KV-BM14M40

NO. SUFFIX DATE SUPPL. / CORR DESCRIPTION

1 -01 2003/12 -- 1st. Issue

PA RT NO. : 9-872-405-01

SERVICE MANUAL

BX1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-BM14M40 RM-W101 Vietnam SCC-V07C-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-W101

TRINITRON

®

COLOR TV

KV-BM14M40

RM-W101

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION.............................. 3

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................. 6

1-2. Speaker Removal ...................................................... 6

1-3. Chassis Assy Removal .............................................. 6

1-4. Service Position ........................................................ 6

1-5. Terminal Bracket Removal ....................................... 6

1-6. A Board Removal...................................................... 6

1-7. Picture Tube Removal ............................................... 7

2. SET-UP ADJUSTMENTS

2-1. Beam Landing ........................................................... 8

2-2. Convergence .............................................................. 9

2-3. Focus Adjustment.................................................... 11

2-4. G2 (SCREEN) Adjustments ................................... 11

2-5. White Balance Adjustment ..................................... 11

2-6. Sub Bright Adjustment ........................................... 11

3. CIRCUIT ADJUSTMENTS

3-1. Adjustment With Commander ................................ 12

3-2. Adjustment Method ................................................ 13

3-3. Picture Quality Adjustments ................................... 28

3-4. Deflection Adjustment ............................................ 28

3-5. Drive Adjustment .................................................... 29

3-6. Picture Distortion Adjustment ................................ 30

Section Title Page

4. DIAGRAMS

4-1. Block Diagram ........................................................ 31

4-2. Circuit Boards Location .......................................... 32

4-3. Schematic Diagram Information ............................ 32

4-3-1. A Board — Processor (Block A) ............... 33

4-3-2. A Board — Audio (Block B) ..................... 35

4-3-3. A Board — Power Supply (Block C) ........ 37

4-3-4. A Board — Deflection (Block D) .............. 39

4-3-5. A Board — Tuner (Block E) ...................... 41

4-3-6. A Board — Jack (Block F) ........................ 43

4-3-7. C Board ....................................................... 45

4-4. Voltage Measurement and Waveforms ................... 46

4-5. Printed Wiring Boards and Parts Location ............. 49

4-6. Semiconductors ....................................................... 52

5. EXPLODED VIEWS

5-1. Chassis..................................................................... 54

6. ELECTRICAL PARTS LIST.................................... 55

OPERATING INSTRUCTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-BM14M40

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self diagnostic function. If an error occurs, the STANDBY (1) indicator will

automatically begin to flash. A description of the self-diagnosis function is explained in the instruction manual. The

number of times the STANDBY (1) indicator flashes translates to a probable source of the problem. If an error

symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in

memory to reveal past problems and how often these problems occur.

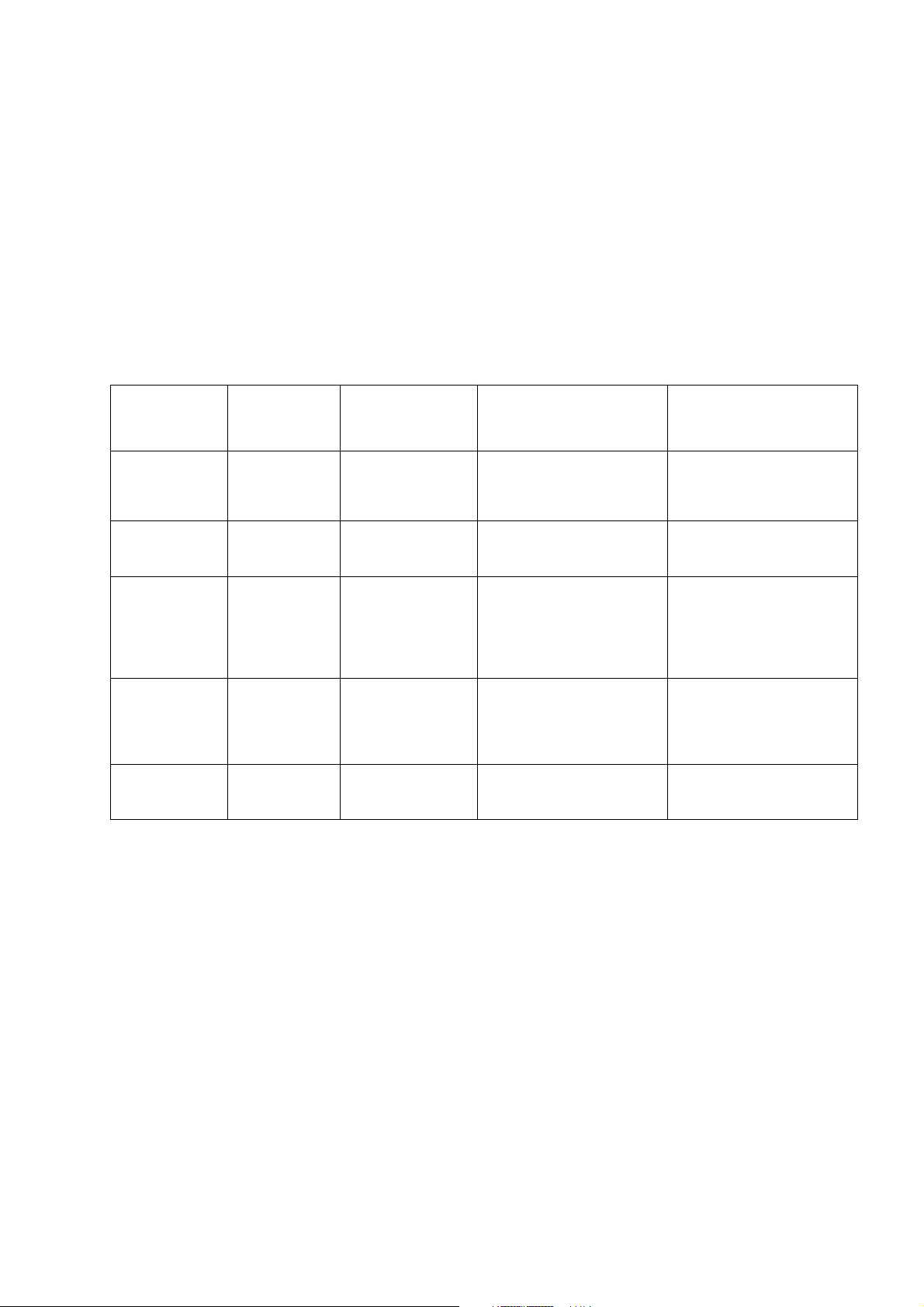

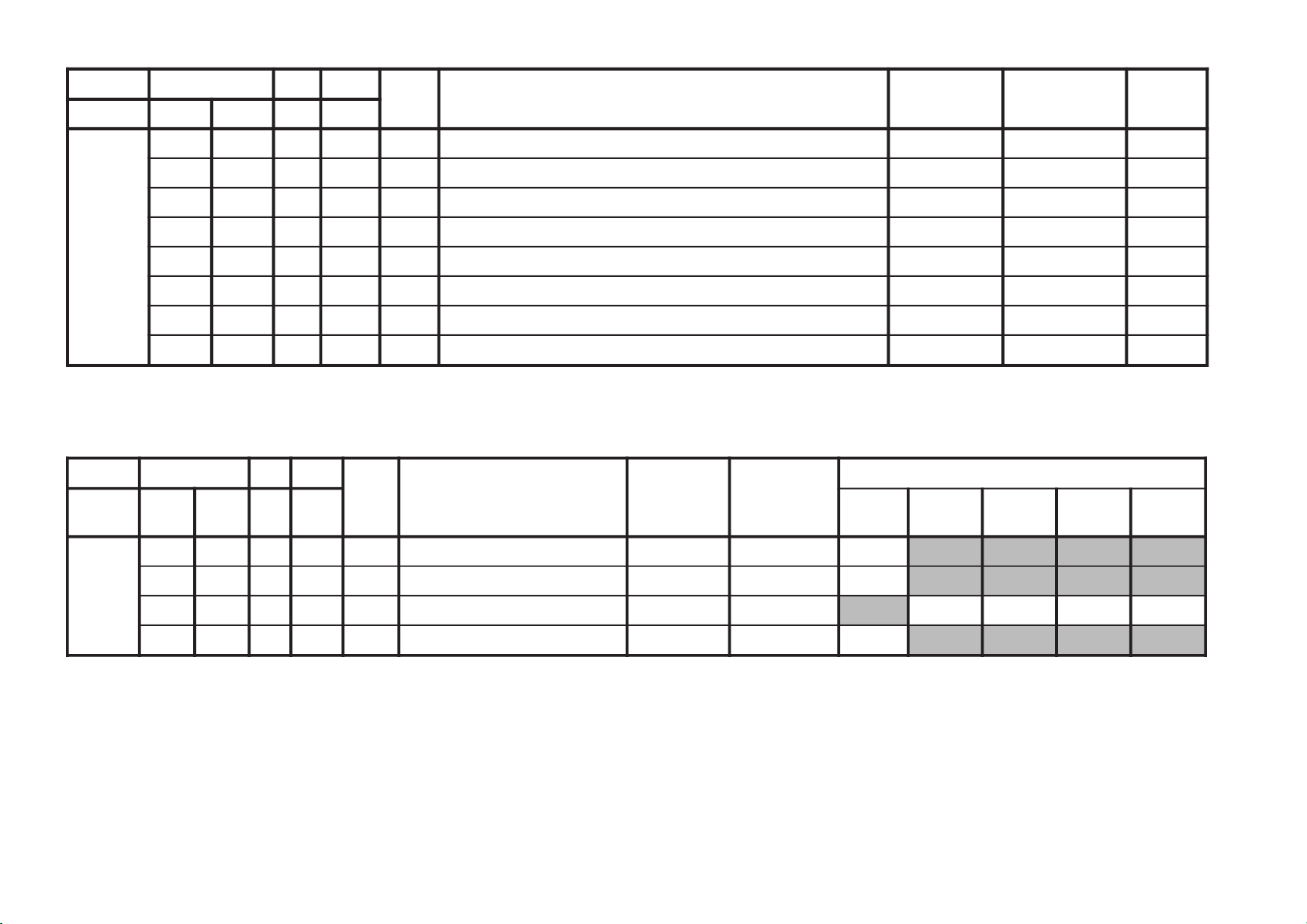

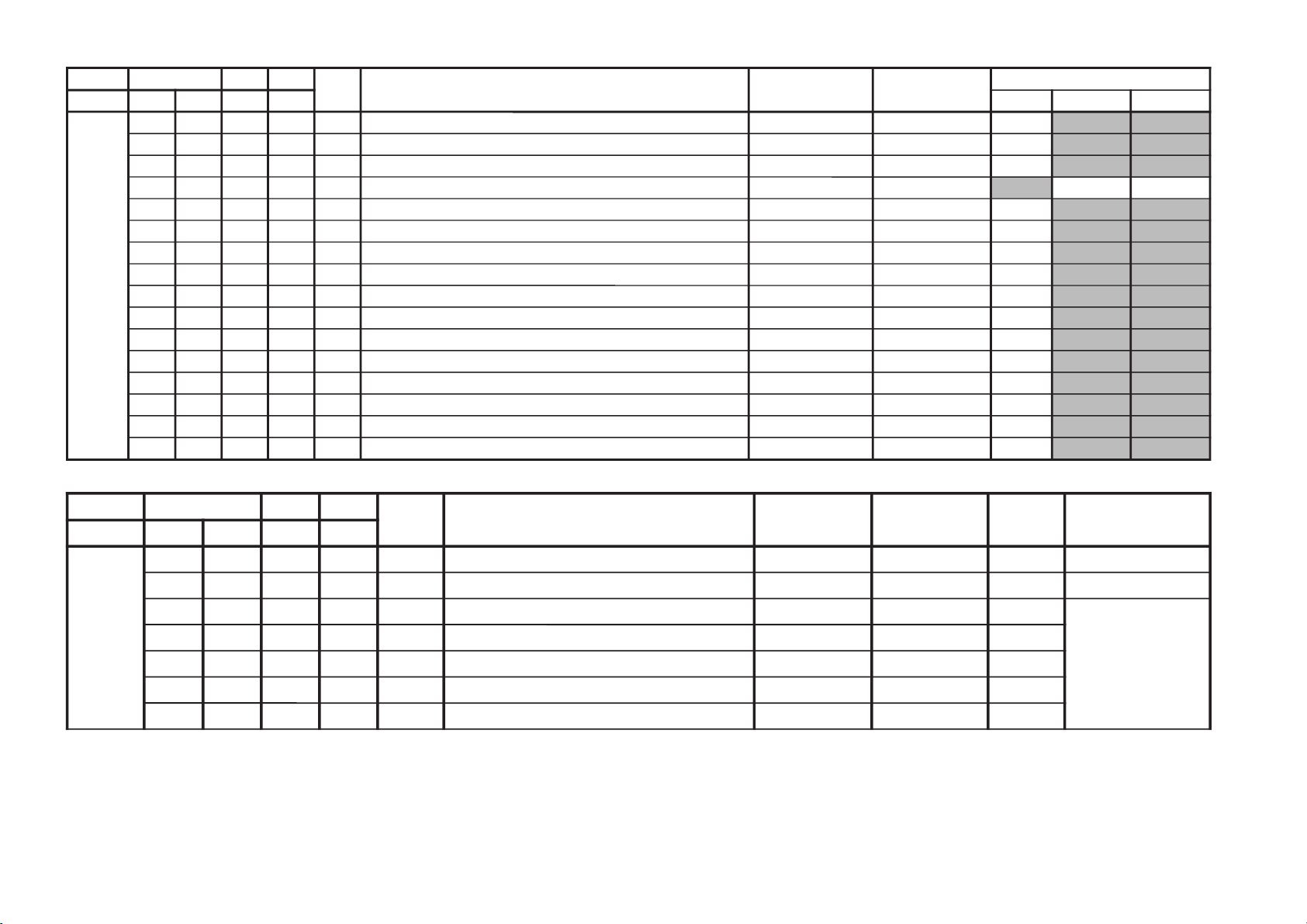

1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY (1) indicator will flash a set number of times to indicate the possible cause of

the problem. If there is more than one error, the indicator will identify the first of the problem areas.

Result for all of the following diagnosis items are displayed on screen. No error has occured if the screen displays a

"0".

RM-W101

Diagnosis

Item

Description

Power does

not turn on

+B overcurrent

(OCP)*

V-Protect

IK (AKB)

Power supply

NG (+5V) for

Video Processor

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is

diagnosed first by the micro controller is displayed on the screen.

** Refer to Screen (G2) Adjustment in this manual.

No. of timer

STANDBY (1)

indicator flashes

Does not light

2 times

4 times

5 times

8 times

Self-Diagnostic

display/

Diagnosis result

–

2:0

or

2:1 ~ 255

4:0

or

4:1 ~ 255

5:0

or

5:1 ~ 255

8:0

or

8:1 ~ 255

Probable Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out (F600)

A board.

• H OUT (Q805) is shorted.

(A board)

IC751 is shorted. (C board)

•

• +13V is not supplied.

(A board)

• IC804 is faulty. (A board)

• Video OUT (IC1545) is

faulty. (A board)

• IC001 is faulty. (A board)

• Screen (G2) is improperly

adjusted.**

• IC604 faulty.

• IC602 faulty.

Detected

Symptoms

• Power does not turn on.

• No power is supplied on

TV.

• AC Power supply is faulty.

• Power does not turn on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is shorted.

• No raster is generated.

• CRT Cathode current

detection reference pulse

output is small.

• No power supply to CRT

ANODE.

• No RASTER is generated.

– 3 –

KV-BM14M40

RM-W101

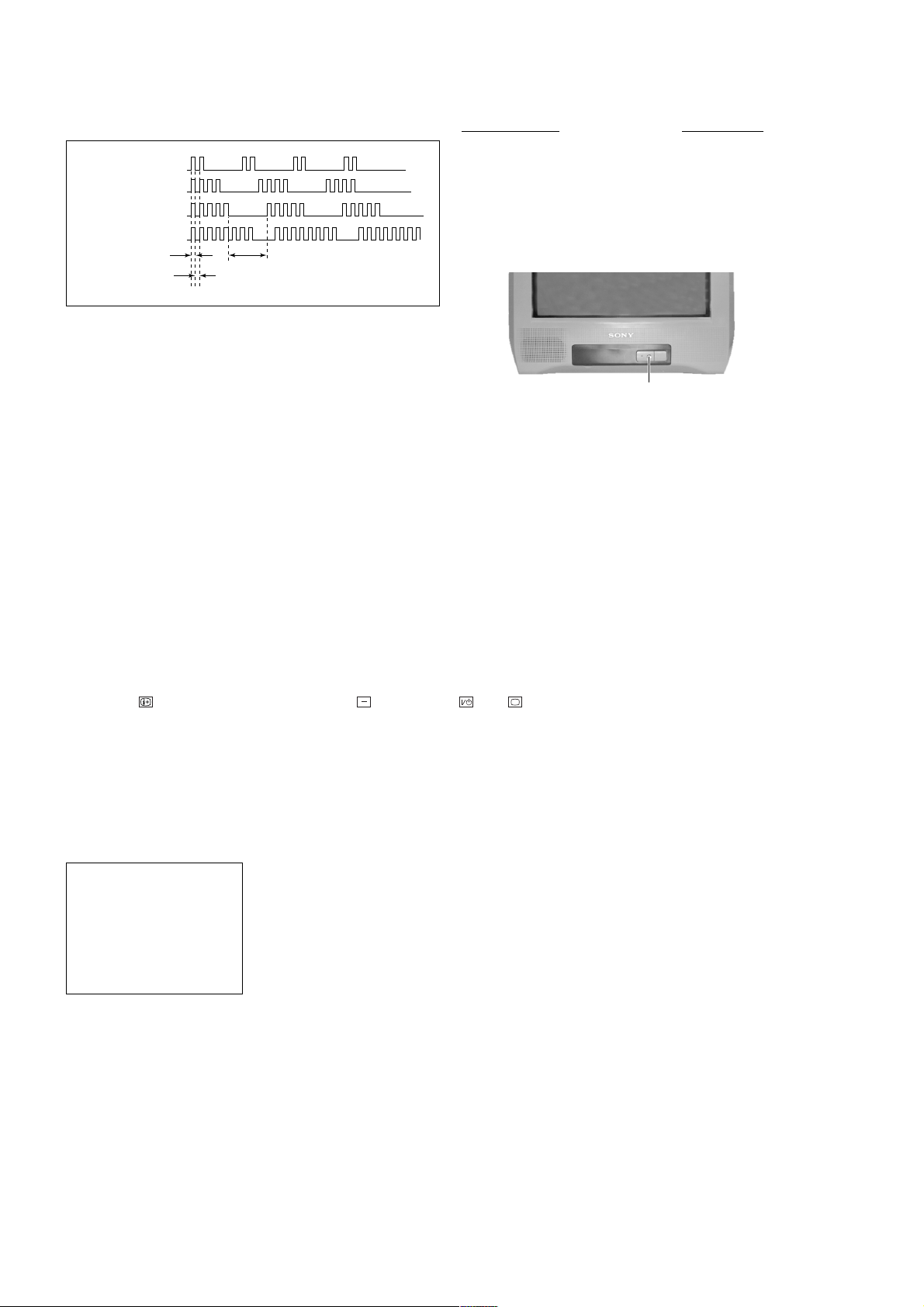

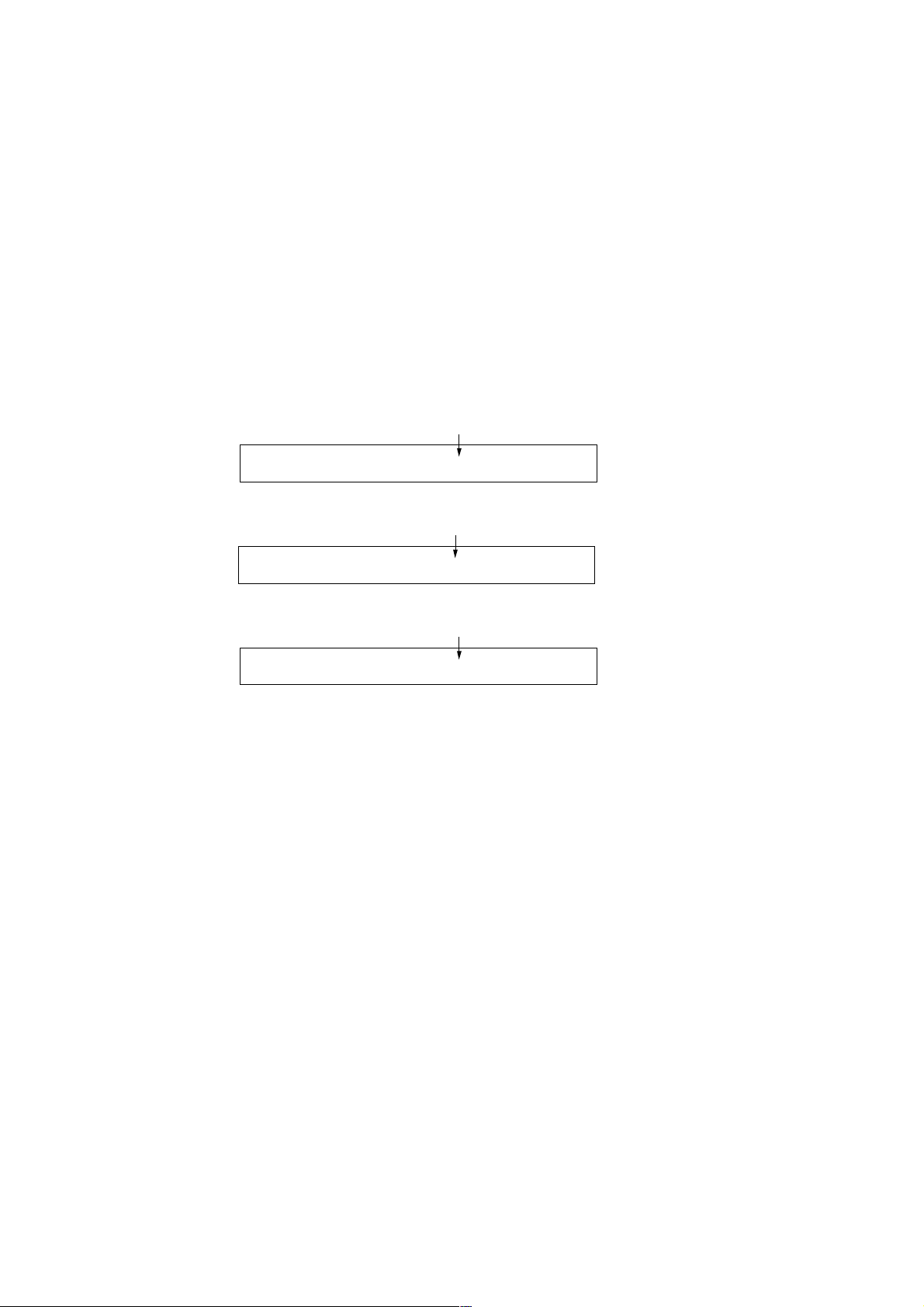

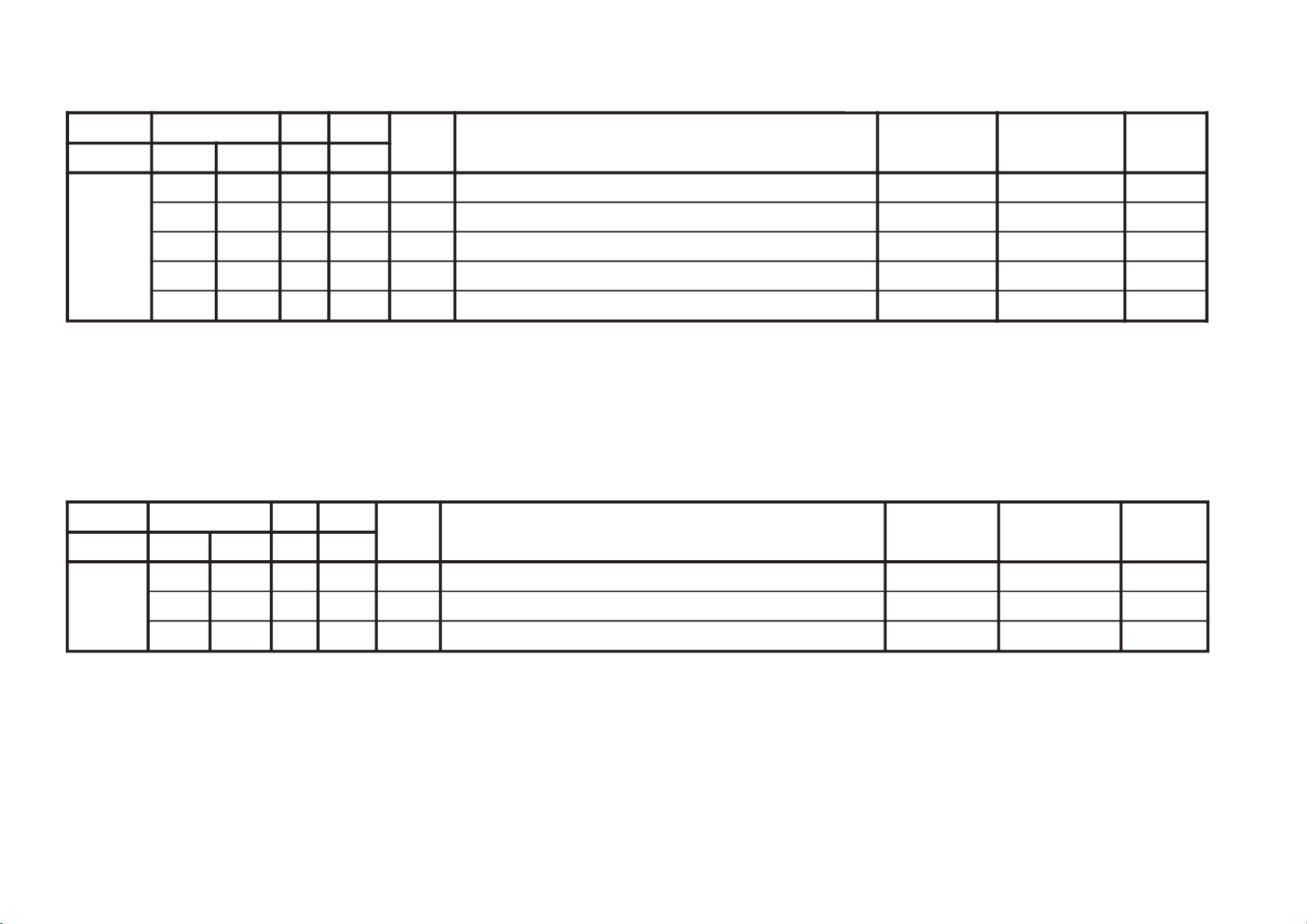

2. DISPLAY OF STANDBY (1) INDICATOR

FLASH COUNT

2 times

4 times

5 times

8 times

Lamp ON 300ms

Lamp OFF 300ms

Lamp OFF 3 sec.

Diagnostic Item Flash Count*

+B overcurrent 2 times

V-Protect 4 times

IK (AKB) 5 times

Power Supply NG (+5V) 8 times

for Video processor

* One flash count is not used for self-diagnosis.

STANDBY (1) indicator

3. STOPPING THE

STANDBY (1) INDICATOR FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY (1)

indicator from flashing.

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes off" that cannot be

confirmed, it is possible to bring up past occurrences of failure on the screen for confirmation.

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Display

/ Channel 5 / Volume / Power / TV

˘

Note that this differs from entering the service mode (volume [+]).

The following screen will be displayed indicating the error count.

SELF DIAGNOSTIC

2 : 0

3 : N/A

4 : 0

5 : 1

8 : 0

101 : N/A

Numeral "0" means that no fault was detected.

Numeral "1" means the number of a fault occurrence (1 ~ 255).

– 4 –

KV-BM14M40

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic

screen during repairs. When you have completed the repairs, clear the result display to "0".

Unless the result display is cleared to "0", the self-diagnosis function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to "0", press buttons on the remote commander subsequent as shown below when the

self-diagnostic screen is being displayed.

8 , -

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

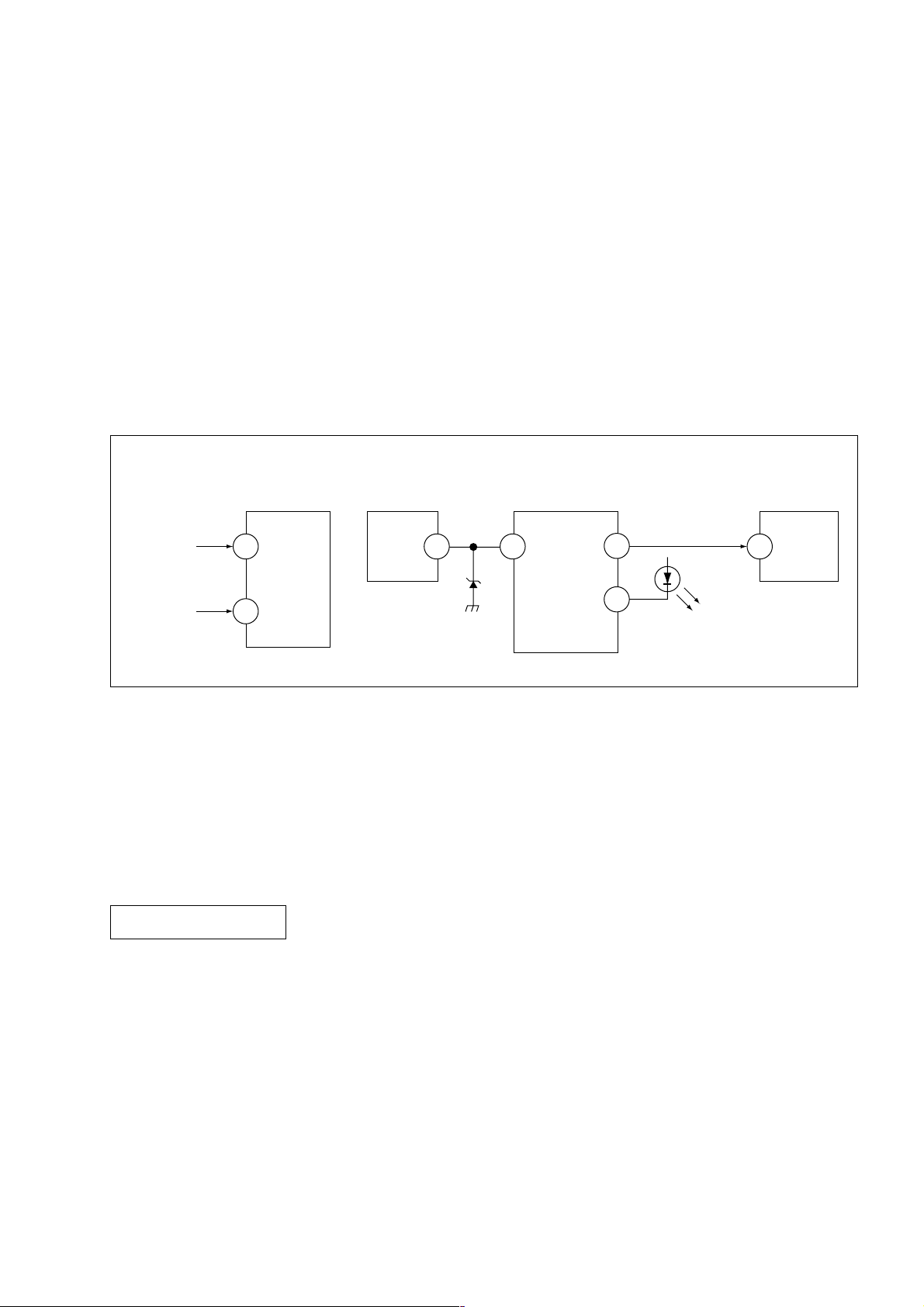

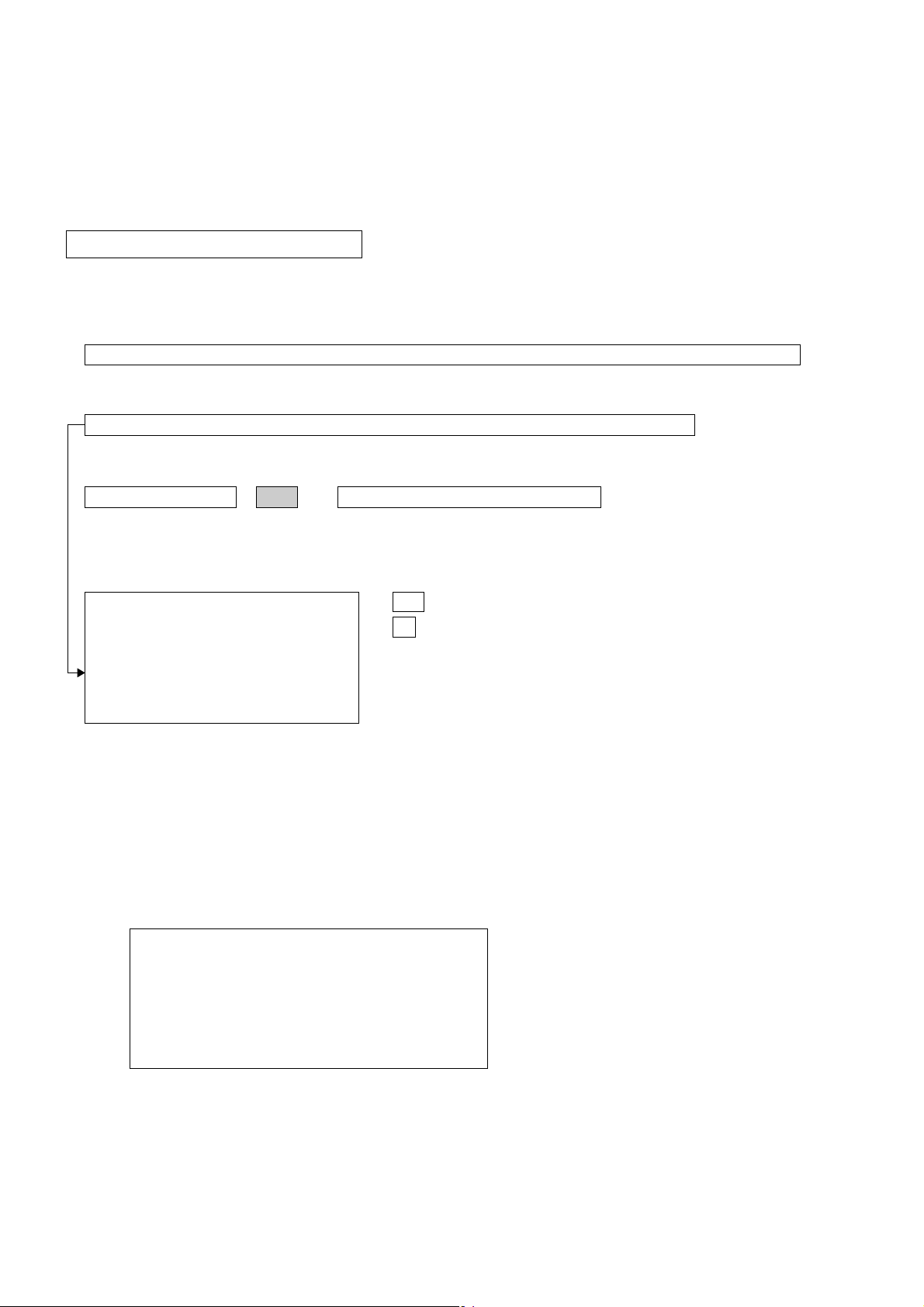

6. SELF-DIAGNOSTIC CIRCUIT

RM-W101

FROM

C BOARD

IC751 PIN 5

A BOARD

FROM

Q816

COLLECTOR

A BOARD

IC001

Y/CHROMA JUNGLE

IK

32

EHTO

A BOARD

IC804

V.OUT

F.B-PLS

A BOARD

IC001

SYSTEM

SDA1

3 1384

V.GUARD

RED LED

99

122

DISPLAY

A BOARD

IC003

MEMORY

5

SDA

[+B overcurrent $OCP%] Occurs when an overcurrent on the +B(135V) line is detected by pin 32 of IC001 (A board).

If the voltage of pin 32 of IC001 (A board) is more than 4V, the unit will automatically go

to standby.

[V-PROTECT] Occurs when an absence of the vertical deflection pulse is detected by pin 13 of IC001

(A board).

[IK $AKB%] If the RGB levels* do not balance within 15 sec after the power is turned on, this error will

be detected by IC001 (A board). TV will stay on, but there will be 5 times LED blinking.

POWER SUPPLY NG (+5V)

for VIDEO PROCESSOR

Occurs when IC001 internal HV protect detects an abnormal H-Pulse (frequency) due to

improper power supply to IC001. TV cuts off high voltage power of anode CRT. No picture

will be detected. eg: IC602, IC604 go faulty.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 5 –

KV-BM14M40

RM-W101

SECTION 1

DISASSEMBLY

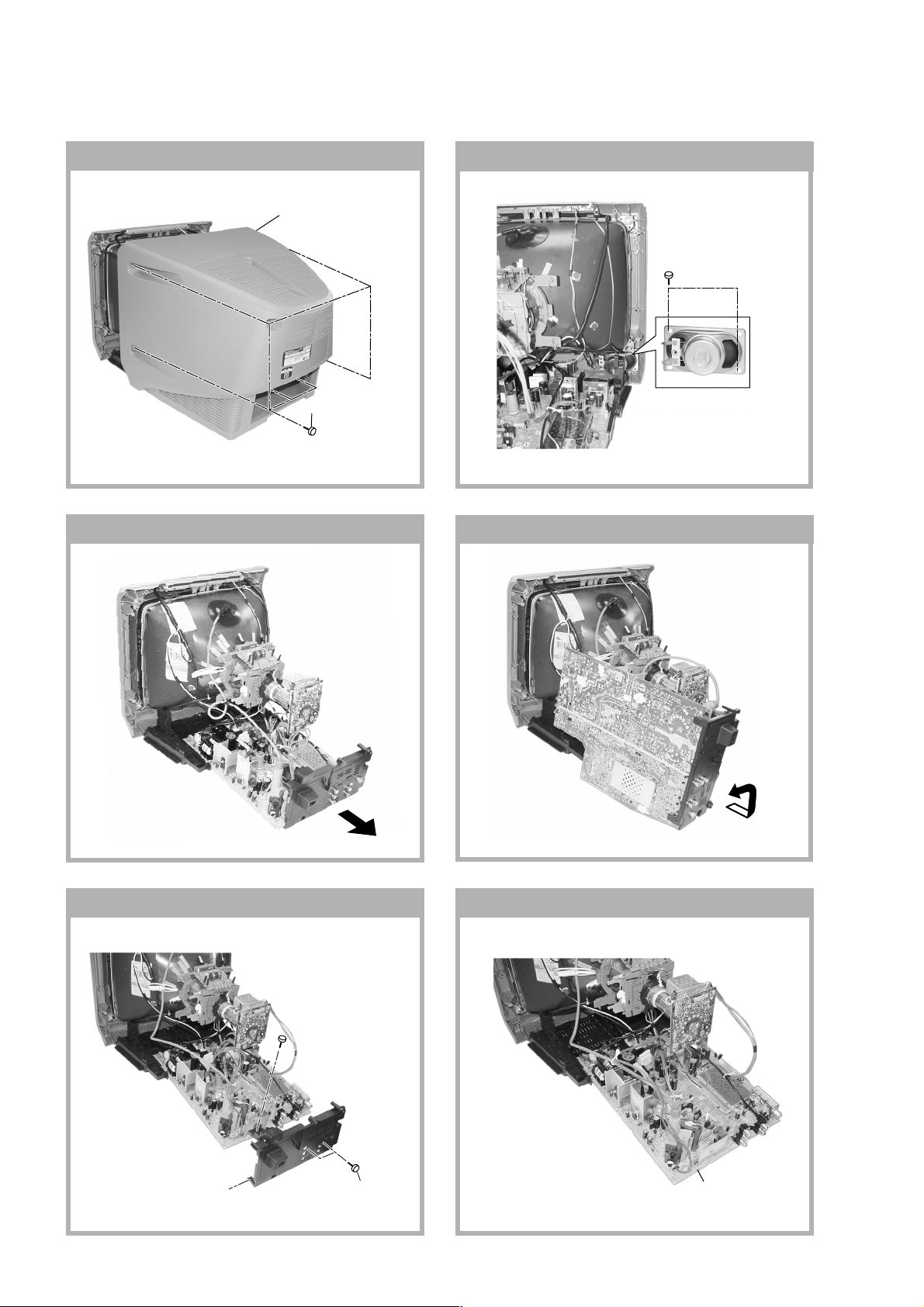

1-1. REAR COVER REMOVAL

1 Rear cover

2 Six screws

(+BVTP 4 × 16)

1-3. CHASSIS ASSY REMOVAL

1-2. SPEAKER REMOVAL

1 Two screw

(+BVTP 3 × 12)

1-4. SERVICE POSITION

1-5. TERMINAL BRACKET REMOVAL 1-6. A BOARD REMOVAL

2 One screw

(+BVTP 3 × 16)

1 Terminal

bracket

2 Two screw

(+BVTP 4 × 16)

– 6 –

1 A board

KV-BM14M40

c

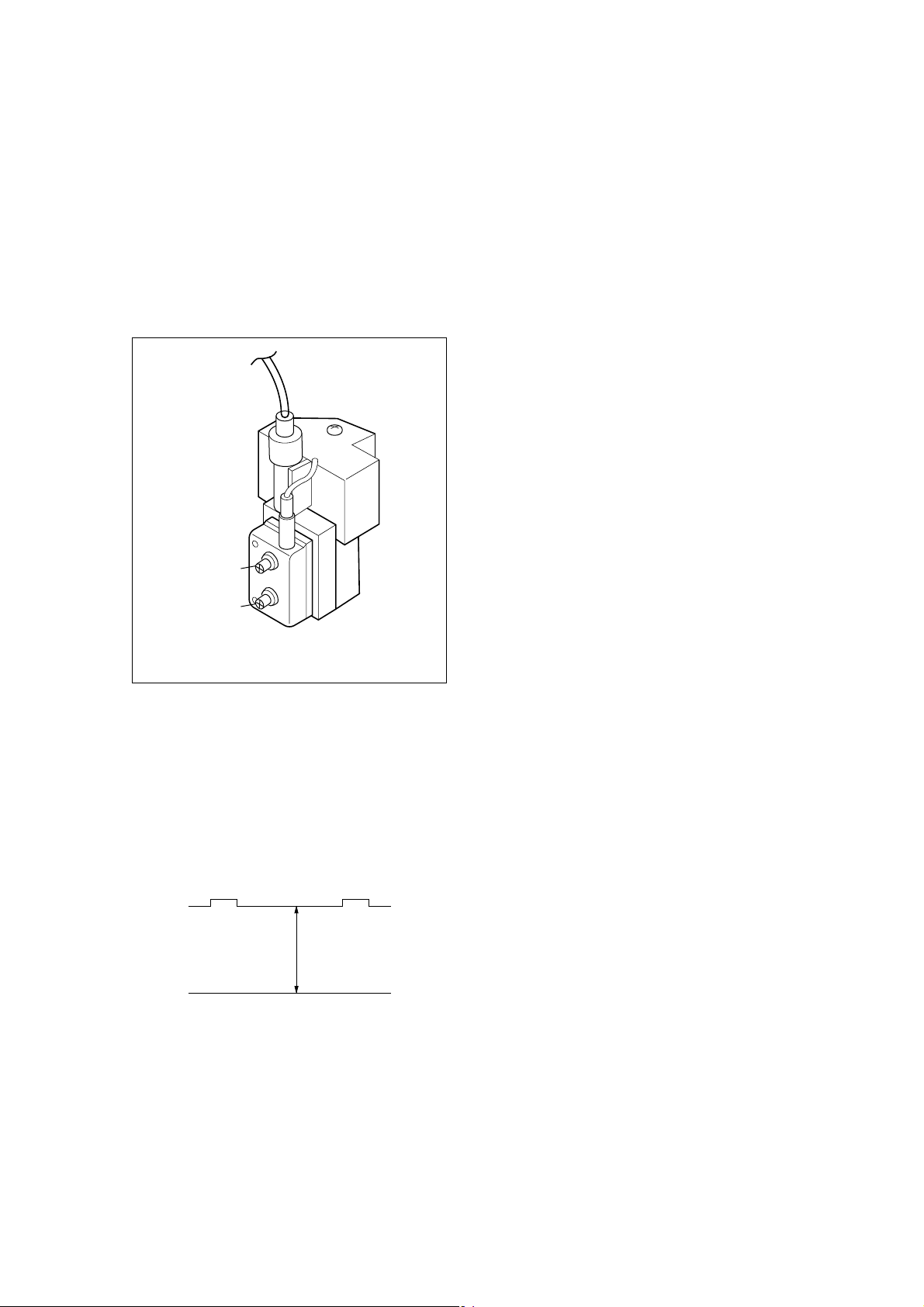

1-7. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Place the TV set with the CRT face down on a cushion jig.

2) Remove the rear cover.

3) Unplug all inder connecting leads from the Deflection Yoke, Degaussing Coil and CRT grounding strap.

qf Top switch Block

4 Anode Cap Removal

!£ Nut, Special, CRT (4)

RM-W101

qs Degaussing Coil

5 Earth Coating Assy

0 Support, CRT(2) Removal

qa Loosen the Deflection Yoke

fixing screw and remove

7 Loosen the Neck Assembly

fixing screw and removal

6 Spring Tension Removal

8 C Board Removal

9 Chassis Assy Removal

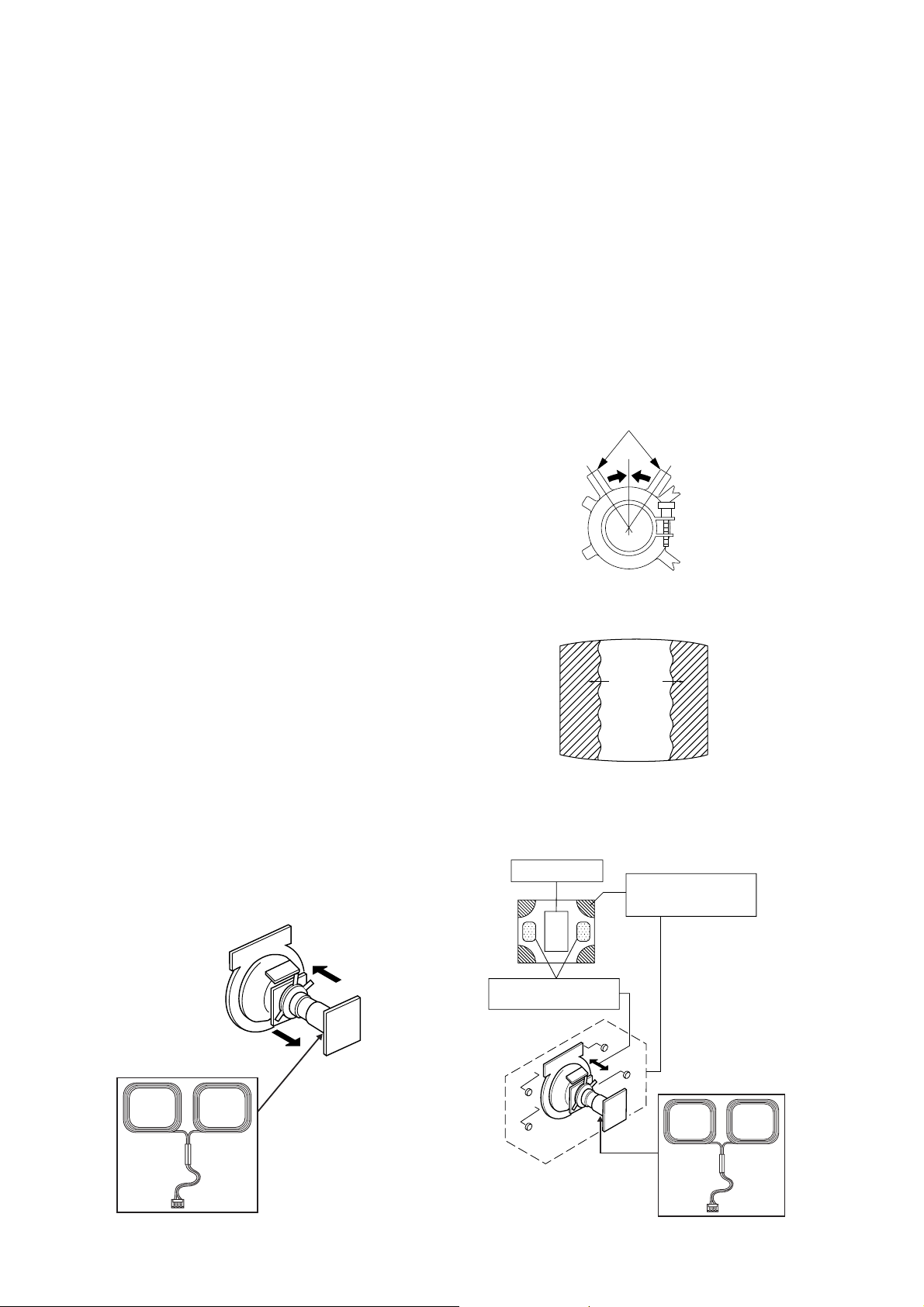

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow A.

b

b

2 Using a thumb pull up the rubber cap firmly in the di-

rection indicated by the arrow B.

3 When one side of the rubber cap is separated from

the anode button, the anode-cap can be removed by

anode button

turning up the rubber cap and pulling it up in the

direction of the arrow C.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 7 –

KV-BM14M40

Purity control

RM-W101

SECTION 2

SET-UP ADJUSTMENTS

• The following adjustments should be made when a

complete realignment is required or a new picture

tube is installed.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

Set the controls as follows unless otherwise noted:

VIDEO model ..................................................... Standard

PICTURE control .................................................. normal

BRIGHTNESS control .......................................... normal

4. Screen(G2)

5. White Balance

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

......................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on

the set's picture tube, face it east or west.

• Switch on the set's power and degauss with the

degausser.

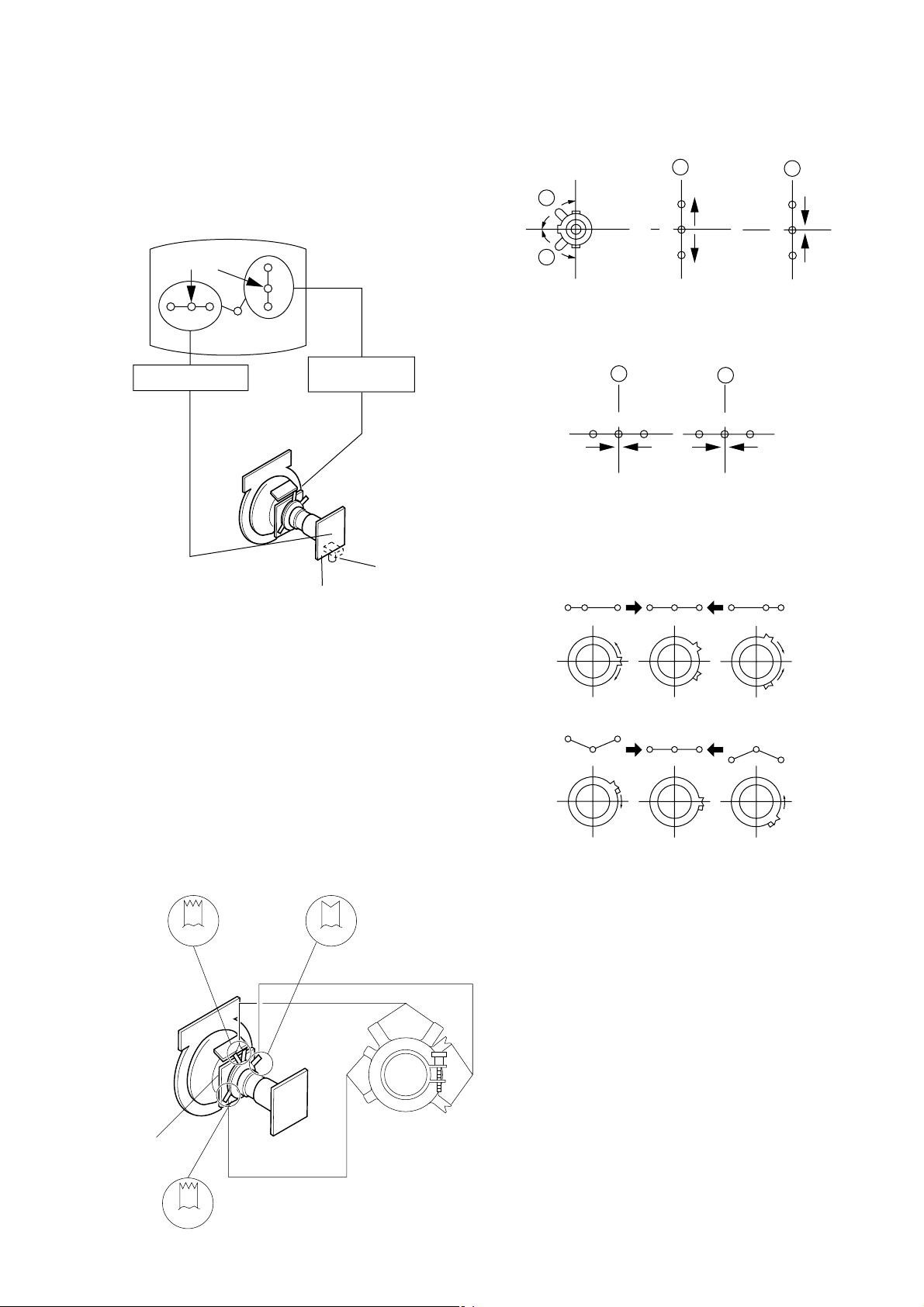

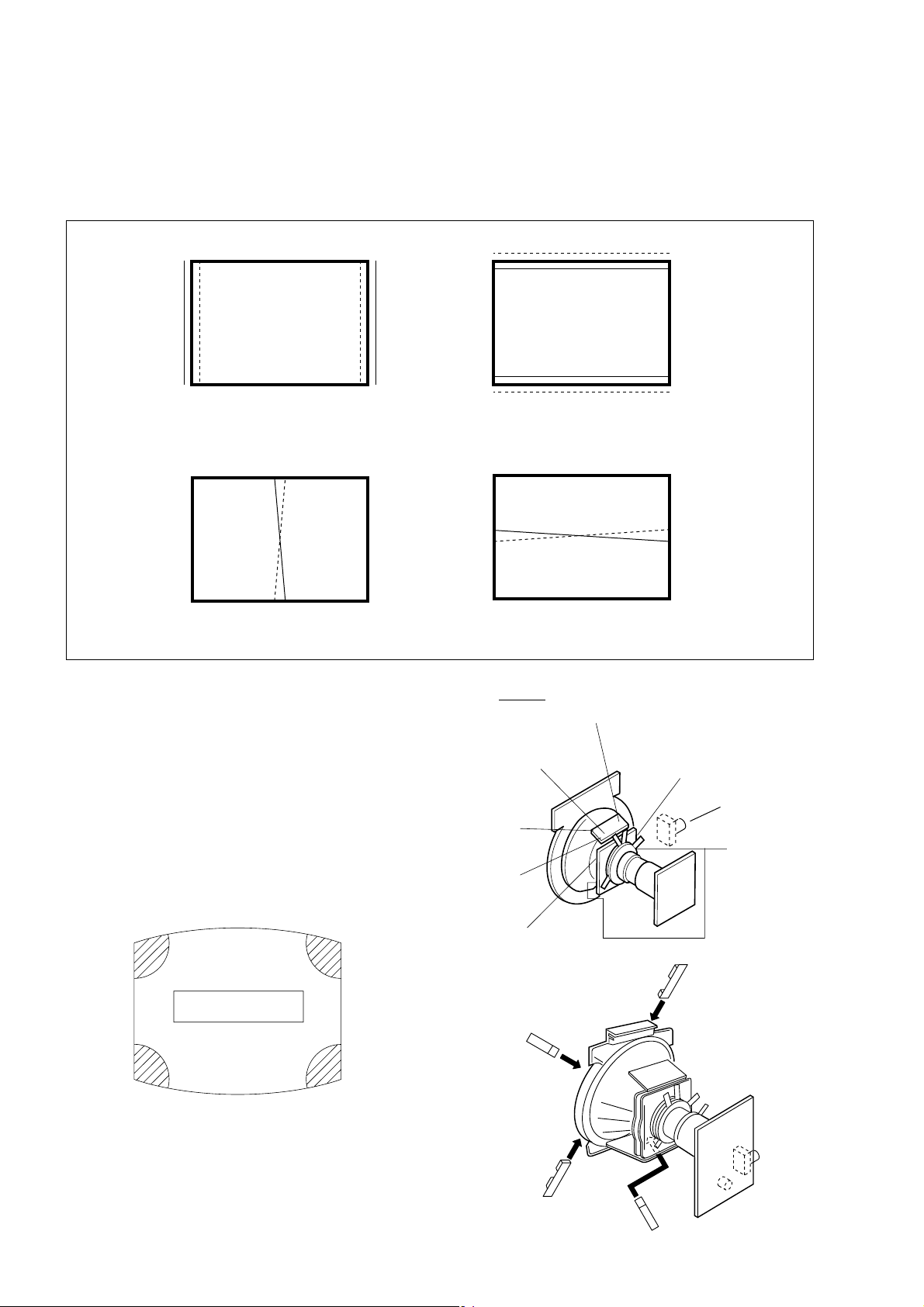

2-1. BEAM LANDING

Picture Mode: DYNAMIC

1. Input a white signal with the pattern generator.

Contrast

Brightness

}

normal

2. Set the pattern generator raster signal to a green

raster.

3. Move the deflection yoke to the rear and adjust with

purity control so that the green is at the center and

the blue and the red take up equally sized areas on

each side. (See Figures 2-1 through 2-4.)

4. Move the deflection yoke forward and adjust so that

the entire screen is green. (See Figure 2-1.)

5. Switch the raster signal to blue then to red and verify

the condition.

6. When the position of the deflection yoke has been

decided fasten the deflection yoke with the screws

and DY spacers.

7. If the beam does not land correctly in all the corners,

use a magnet to adjust it. (See Figure 2-4.)

Purity control

corrects this area.

b

Fig. 2-2

Blue

Red

Green

Fig. 2-3

Disk magnets or rotatable

disk magnets correct these

a

areas (a-d).

d

c

Deflection yoke positioning

corrects these areas.

b

c

a

d

Fig. 2-1 Fig. 2-4

– 8 –

KV-BM14M40

RM-W101

2-2. CONVERGENCE

• Before starting this adjustment, adjust the focus,

horizontal size and vertical size.

• Receive dot/hatch signal.

• Pic mode: Soft.

(1) Horizontal and Vertical Static Convergence

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

RV750

H. STAT

C Board

Operation of V.STAT magnet

If the V.Stat magnet is moved in the “A” and “B” arrows,

the red, green and blue dots moves as shown below.

A

B

A

B

G

R

B

B

G

R

Moved RV750 H.STAT.

the red, green and blue dots move as shown below.

A

RGGBB

B

R

4. BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or

aligned, then use the BMC magnet to adjust in the

manner described below.

RG B R G B R GB

1. (Moving vertically), adjust the V.STAT magnet so that

the red, green and blue dots are on top of each other

at the center of the screen.

2. (Moving horizontally), adjust the H.STAT control so

that the red, green and blue dots are on top of each

other at the center of the screen.

3. If the H.STAT variable resistor cannot bring the red,

green and blue dots together at the center of the

screen, adjust the horizontal convergence with the

H.STAT variable resistor and the V.STAT magnet in

the manner given below.

(In this case, the H.STAT variable resistor and the

V.STAT magnet influence each other, so be sure to

perform adjustments while tracking.)

BMCPurity

BMC (Hexapole)

Purity

RB

G

RG

GB

RB

DY pocket

V.STAT

V.STAT

– 9 –

KV-BM14M40

RM-W101

(2) Convergence Rough Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal

static convergence and the vertical static

convergence

B

R

B

R

TLH

RB

YCH

TLH Insert TLH Correction Plate to DY Pocket

(Left or Right)

YCH Insert YCH VOL on DY

TLV Rotate TLV VOL on DY

XCV Rotate XCV Adj core on DY

(3) Screen corner Convergence

1. Affix a Piece A (90), conv. correct corresponding to

the misconverged areas.

R

B

ON DY:

TLV

XCV

YCH

TLV

XCV

TLV

DY pocket

TLH Plate

XCV

ba

a-d : screen-corner

misconvergence

cd

– 10 –

DY pocket

a

d

Piece A (90), conv. correct

b

c

KV-BM14M40

RM-W101

2-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before the W/B

adjustment:

1. Receive digital monoscope pattern.

2. Set picture mode: DYNAMIC.

3. Adjust focus VR to obtain a just focus at the center of

the screen.

4. Change receiving signal to white pattern and blue

back.

5. Confirm MAGENTA RING is not noticeable. Incase

magenta ring is obvious, then adjust FOCUS VR to

balance magenta ring and FOCUS.

FOCUS

SCREEN

2-5. WHITE BALANCE ADJUSTMENT

1. Set to Service Mode (Refer Section 3-1:

ADJUSTMENTS WITH COMMANDER)

2. Input white raster signal.

3. Set Picture to <DYNAMIC mode>

4. Select RDRV (02) with 1 and 4 and fixed the value

to 25 with 3 and 6

5. Adjust WHBL GDRV (03) and BDRV (04) with 1 and

4 and adjust the data with 3 and 6 for best white

balance in Highlight condition.

6. Write into the memory by pressing [MUTING] then -.

7. Adjust WHBL BKOR (00) and BKOG (01) with 1 and

4 and adjust the level with 3 and 6 for best white

balance cut-off condition.

8. Write into memory by pressing [MUTING] then -.

9. US model need to apply only for colour temperature

in Neutral.

2-6. SUB BRIGHT ADJUSTMENT

1. Set to service mode.

2. Brightness set to 50%, Picture....Minimum

3. Select WHBL SBRT (10) with 1 and 4 and adjust

SBRT (10) data with 3 and 6 so that the third

stripe from right dimly lit.

4. Write into the memory by pressing [MUTING] then -.

5. GA models C/O: 20 IRE

S/G: 30 IRE

FLYBACK TRANSFORMER (T802-14")

FLYBACK TRANSFORMER (T801-21")

2-4. G2 (SCREEN) ADJUSTMENT

1. Set the PICTURE & BRIGHTNESS to STANDARD.

2. Put the Video input mode signal.

3. Connect R,G,B of the C board cathode to

oscilloscope.

4. Adjust Brightness to obtain the cathode value to

value below.

5. Adjust G2 (screen) on the FBT until picture shows

the point before cut off.

165 ± 2VDC

– 11 –

KV-BM14M40

RM-W101

SECTION 3

CIRCUIT ADJUSTMENTS

3-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the supplied remote commander RM-W101.

a. ENTERING SERVICE MODE

With the unit on standby

t [DISPLAY] t 5 t [VOL $+% ] t [POWER]

This operation sequence puts the unit into service mode.

This screen display is:

category in decimal item name in decimal NG service command frequency video input name

GEOM 006 HSIZ 031 x SERVICE 60 S VIDEO 1

release ID version in binary for factory color system (decimal?)

SUS01 0.69U 0001 1111 FF FF NTSC3 65535

111 11 11 1 7 11 FG xy 111 000000 000000

S : for Sony

A : Aiwa

U S : US/Latin/Taiwan

E U : Europe

G A : General Area

J P : Japan

item no. service data NVM field channel no./

software service data reserved power on time

Status Byte Status Byte

Flash DCXO #1 SSD #2 SSD

VDSP_C Flag

CO_LOCKED

VDSP

Detected Stereo Type (Direct Value from CZ_ Stereo_Mode)

111 Needed for Nicam DCXO aligment Purpose

xy Value of x = 0 - Unknown, 1 - BTSC, 2 - A2, 3 - NICAM,

4 - KOREAN, 5 - Japan, 6 - AV Stereo

Value of y = 0 - Mono, 1 - Stereo, 2 - Bilingual, 4 - SAP/Single

0 1 : serial no. of the M/P release

for each destination

b. METHOD OF CANCELLATION FROM SERVICE MODE

Set the standby condition (Press [POWER] button on the commander), then press [POWER] button again, hereupon it

becomes TV mode.

c. METHOD OF WRITE INTO MEMORY

1. Set to Service Mode.

2. Press 1 (UP) and 4 (DOWN), to select the adjustment item.

3. Change item by pressing 3, 6.

4. Press [MUTING] button to indicate WRITE on the screen.

5. Press - button to write into memory.

1, 4 Select the adjustment item.

r

3, 6 Raise/lower the data value.

r

[MUTING] Writes.

r

- Executes the writing.

d. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, pull out the plug from AC outlet, and then plug into AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confirm adjustments were made.

– 12 –

KV-BM14M40

e. OTHER FUNCTION VIA REMOTE COMMANDER

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

Display, - Service data initialization (Be sure not to use usually.)

2, 5 Select Device or Category

3-2. ADJUSTMENT METHOD

Item Number 000 HPOS

This explanation uses H POSITION as an example.

1. Select "000 HPOS" with the 1 and 4 buttons, or 2 and 5.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is IF for PAL reception.)

4. Write with the [MUTING] button. (The display changes to WRITE.)

5. Execute the writing with the - button. (The WRITE display will be changed to red color while excuting, and back to

SERVICE.)

Example on screen display :-

GREEN

GEOM 000 HPOS 039 SERVICE 50 VIDEO 1

RM-W101

Adjusted with [3] and [6] buttons.

GREEN

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

write with [MUTING].

RED

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

Write executed with [0].

The WRITE display

then returns to green

SERVICE

Use the same method for all Items. Use 1 and 4 to select the adjustment item, use 3 and 6 to adjust, write with

[MUTING], then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into memory together.

2. For adjustment items that have different standard data between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

– 13 –

KV-BM14M40

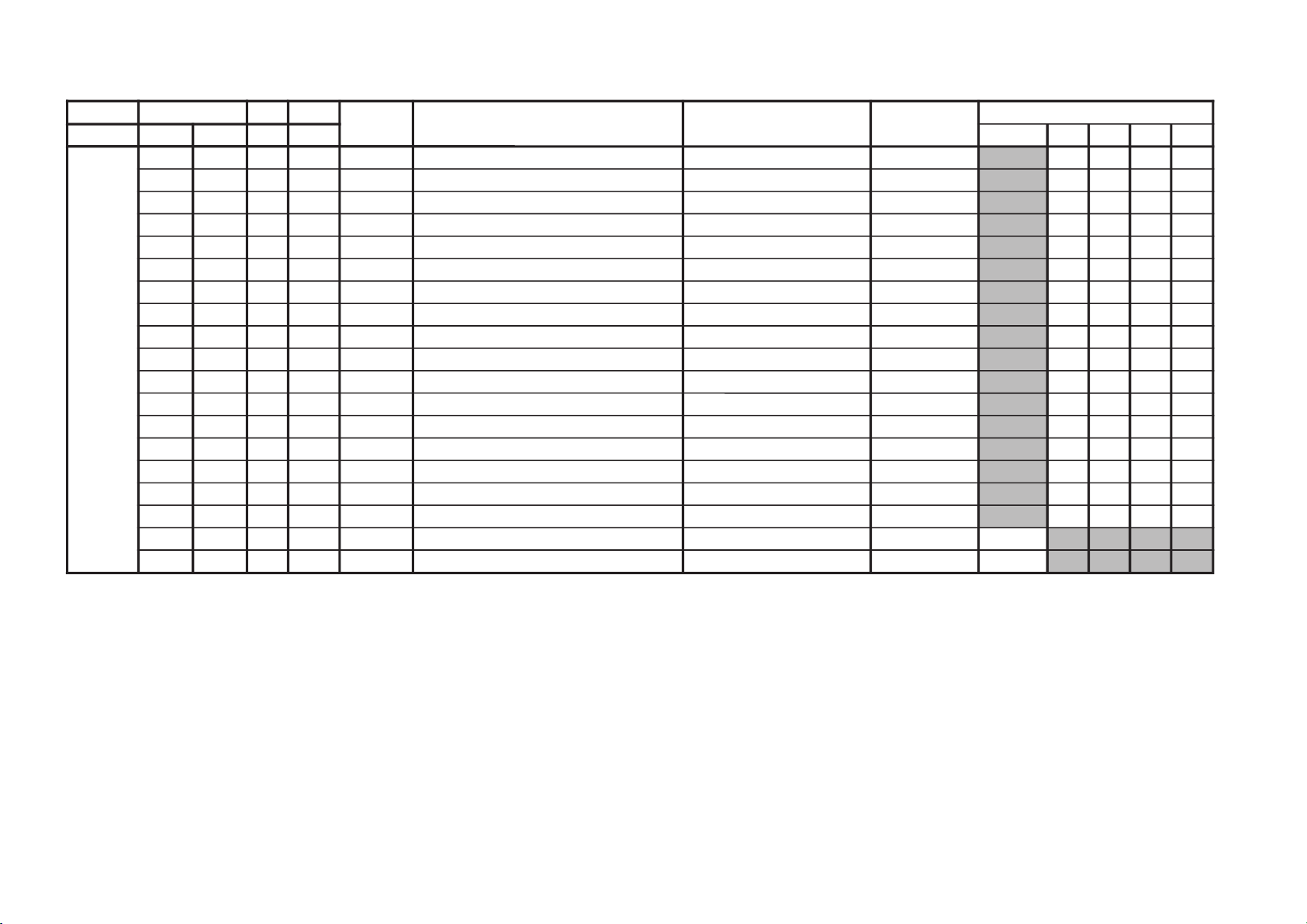

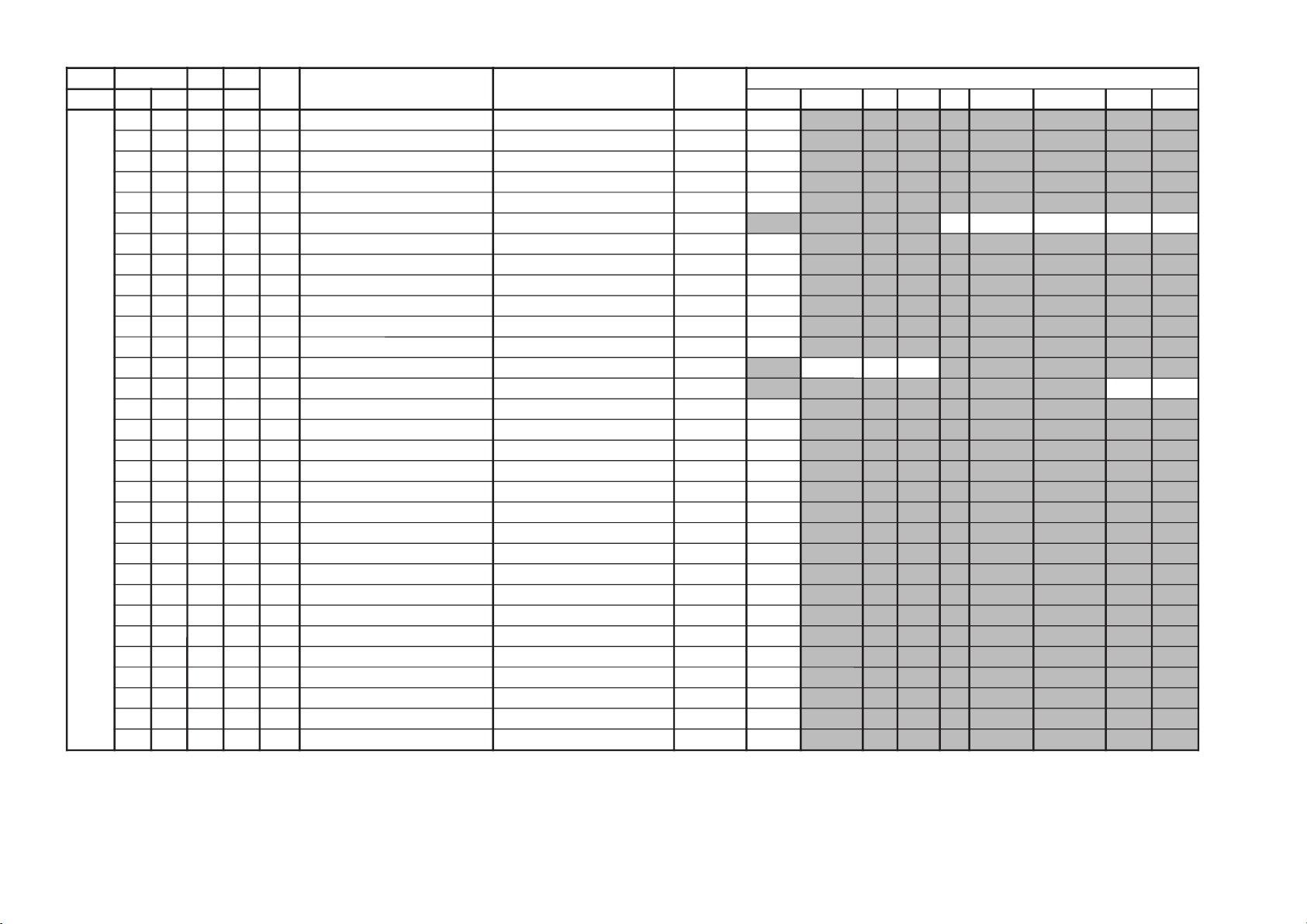

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoC050605w06w

MOEG000SOPH130360TSUJDA)SH(tfihSlatnoziroH )BGRNPJ+(06w/05w/06/05rossecorP-VT

24242424

100RAPH130360TSUJDAmargolellaraPlatnoziroH06w/05w/06/05)hA8(

13131313

200WOBH130360TSUJDAwoBlatnoziroH06w/05w/06/05

13131313

300NILV130360TSUJDAytiraeniLlacitreV06w/05w/06/05

13131313

400RCSV130360TSUJDAllorcSlacitreV06w/05w/06/05

13131313

500ZISH130360TSUJDA)WE(htdiWWE06w/05w/06/05

52525252

600WPWE130360TSUJDA)WP(htdiW/alobaraPWE )BGRNPJ+(06w/05w/06/05

13131313

700POCU710360TSUJDAalobaraPrenroCreppUWE06w/05w/06/05

13131313

800POCL710360TSUJDAalobaraPrenroCrewoLWE06w/05w/06/05

13131313

900ZTWE130360TSUJDAmuizeparTWE06w/05w/06/05

13131313

010PLSV130360TSUJDA)SV(epolSlacitreV06w/05w/06/05

13131313

110ZISV510360TSUJDAedutilpmAlacitreV06w/05w/06/05

51515151

210ROCS410360TSUJDA)CS(noitcerroC-S06w/05w/06/05

52525252

310SOPV130360TSUJDA)HSV(tfihSlacitreV06w/05w/06/05

13131313

410LBH000100XIFedoMgniknalBBGR06w/05w/06/05

10101010

510FBW700510XIF)FBW(gniknalBediWfognimiT06w/05w/06/05

70707070

610RBW700510XIF)RBW(gniknalBediWfognimiT06w/05w/06/05

01010101

710LBS000100XIFgniknalBecivreSenon00

810YPOC000100XIFaeraMVNzH06/05llaotatadOEGehtypoCenon00

Adjustment Item Tab le

– 14 –

RM-W101

– 15 –

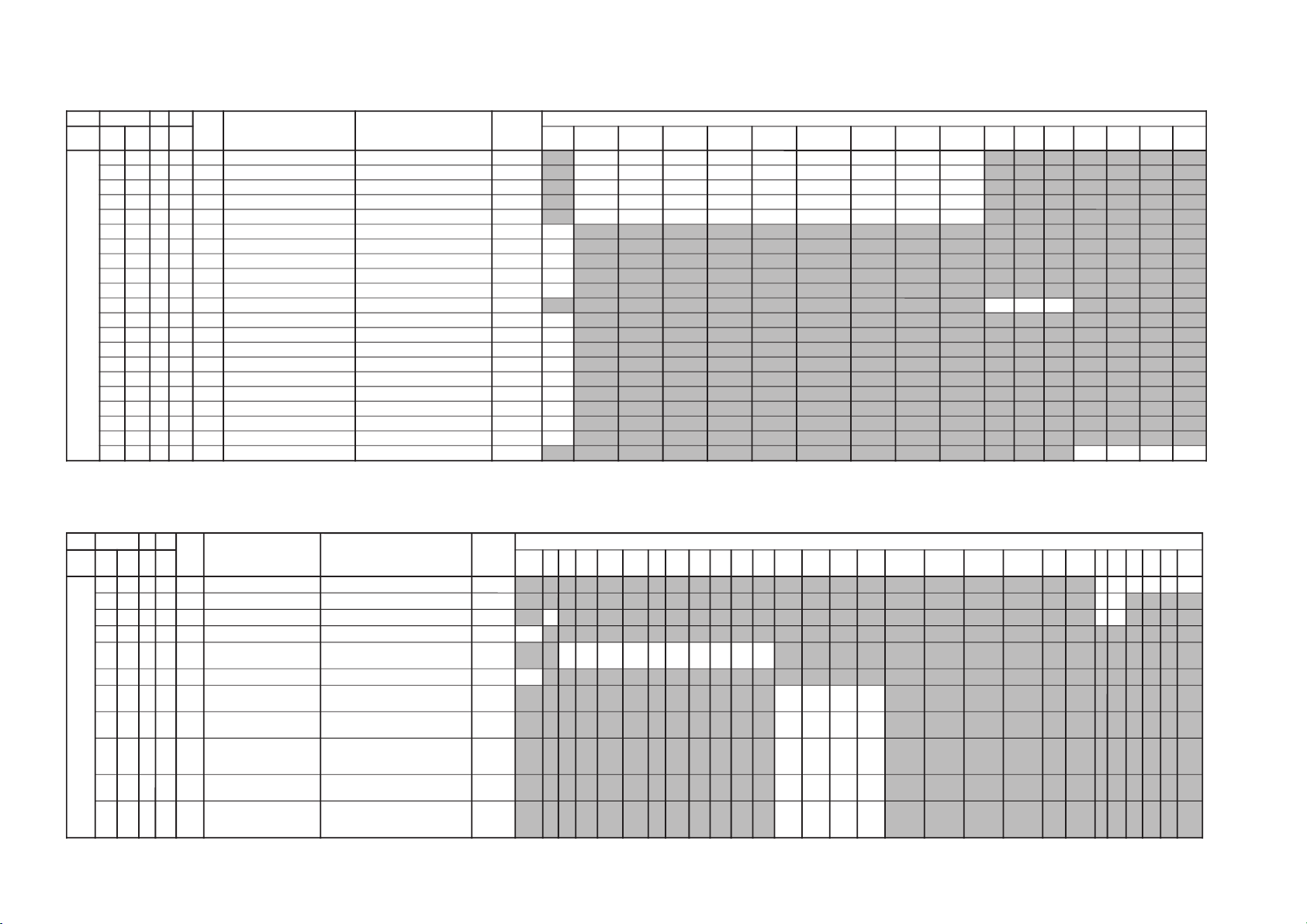

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCpmeTloC

)rehtoHGIH(

pmeTloC

)rehtoWOL(

pmeTloC

)rehtoMRON(

pmeTloC

)VUYHGIH(

pmeTloC

)VUYWOL(

pmeTloC

)VUYLAMRON(

pmeTloC

)BGRHGIH(

pmeTloC

)BGRWOL(

pmeTloC

)BGRMRON(

srehtOBGRVUYedomciP

0

edomciP

1

edomciP

2

edomciP

3

LBHW000ROKB130360TSUJDARtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetlocrossecorP-VT

131313131313131313

100GOKB130360TSUJDAGtesffOleveLkcalB )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc)hA8(

131313131313131313

200VRDR730360XIFRtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc)HA8(orP-VT

737373737373737373

300VRDG730360TSUJDAGtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

131313131313131313

400VRDB730360TSUJDABtnioPetihW )srehtO/BGR/VU(*)lamroN/WOL/HGIH(pmetloc

131313131313131313

500GPL000100XIFteserPniaGBGR enon10

600RGP130721XIF)RGP(RniaGteserP enon

**

700GGP130721XIF)GGP(GniaGteserP enon

**

800BGP130721XIF)BGP(BniaGteserP enon

**

900FONG000510XIFtesffOniaGteserP enonpoolCCC51

010TRBS130360TSUJDAssenthgirB-buS VUY/BGR/srehtO

131313

110ORBS000300XIF)ciPtnegilletnI(tesffOssenthgirB-buS enon00

210LGE000100XIFmetsySCCCnipooLniaGelbanE enon10

310LGS000300XIFmetsySCCCnitnerruChgiHfonoitceleS enon00

410BKA000100XIFnoitazilibatStnerruCkcalB enon00

510SBC000100XIFgnitimiLtnerruCmaeBfoecneuqeSlortnoC enon00

610BBGR000300XIFgniknalBBGR enon00

710GBLB000100XIFtuptuOneerG&eulBfogniknalB enon00

810BFO000100XIFeulBtesffOleveLkcalB enon10

910RBSN000510XIFtesffOssenthgirBdradnatSnoN enon50

020PBW000300XIF)woL:3,2,lamroN:1,hgiH:0(gnitteSpmeTroloC edoMerutciP

00102010

JVTytilanoitcnuF

.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCVUYlap05

)VT(

lap05

)oediV(

maces05

)VT(

maces05

)oediV(

VT06oediV06VUY05VUY06BGR05BGR06edomciP

0

edomciP

1

edomciP

2

edomciP

3

ocE*cimanyD

)npJ(dts

ocE*cimanyD

)npJ(hcum

ocE*dradnatS

)npJ(dts

ocE*dradnatS

)npJ(hcum

dtsocE

)npJ(

hcumocE

)npJ(

VToediVVT

ediW

oediV

ediW

MVA

)npJ(

ediWVA

)npJ(

JDAS000XAMP360360TSUJDAmumixaMerutciP )BGRNPJ+(>ediW/lamroN</)ediW/lamroN(*)oediV/VT( rossecorP-VT

737373730000

100EUHS700510TSUJDAeuH-buS oediV/VT

7070

200PHSS510360XIFssenprahS-buS )BGRNPJ+(VUY/oediV/VT

**

****

300OHSS000300XIF)ciPtnegilletnI(tesffOssenprahS-buS enon20

400LOCS130360TSUJDAroloC-buS /)oediv(maces05/)vt(maces05/)oediv(lap05/)vt(lap05

BGR06/BGR05/VUY06/VUY05/oediv06/VT06

13131313131313131313

500OOCS000300XIF)ciPtnegilletnI(tesffOroloC-buS enon20

600CIP130721XIF

;)dilavni(001>,)dilav(001-0:AG[lortnoCerutciP

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

0010856001

700LOC130721XIF

;)dilavni(001>,)dilav(001-0:AG[lortnoCroloC

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

65050405

800TRB130721XIF

,)dilav(001-0:AG[lortnoCssenthgirB

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

05050605

900EUH130721XIF

;)dilavni(001>,)dilav(001-0:AG[lortnoCeuH

])dilavni(6tiberongi;)dilav(36-0:srehtO

)ataDteseRresU=lanosreP:AG(ledoMerutciP

05050505

010PHS130721XIF

,)dilav(001-0:AG[lortnoCssenprahS

tiberongi;)dilav(36-0:srehtO;)dilavni(001>

])dilavni(6

)ataDteseRresU=lanosreP:AG(ledoMerutciP

06050505

Item remarks ** please refer to page 23

Item remarks ** please refer to page 23

KV-BM14M40

RM-W101

– 16 –

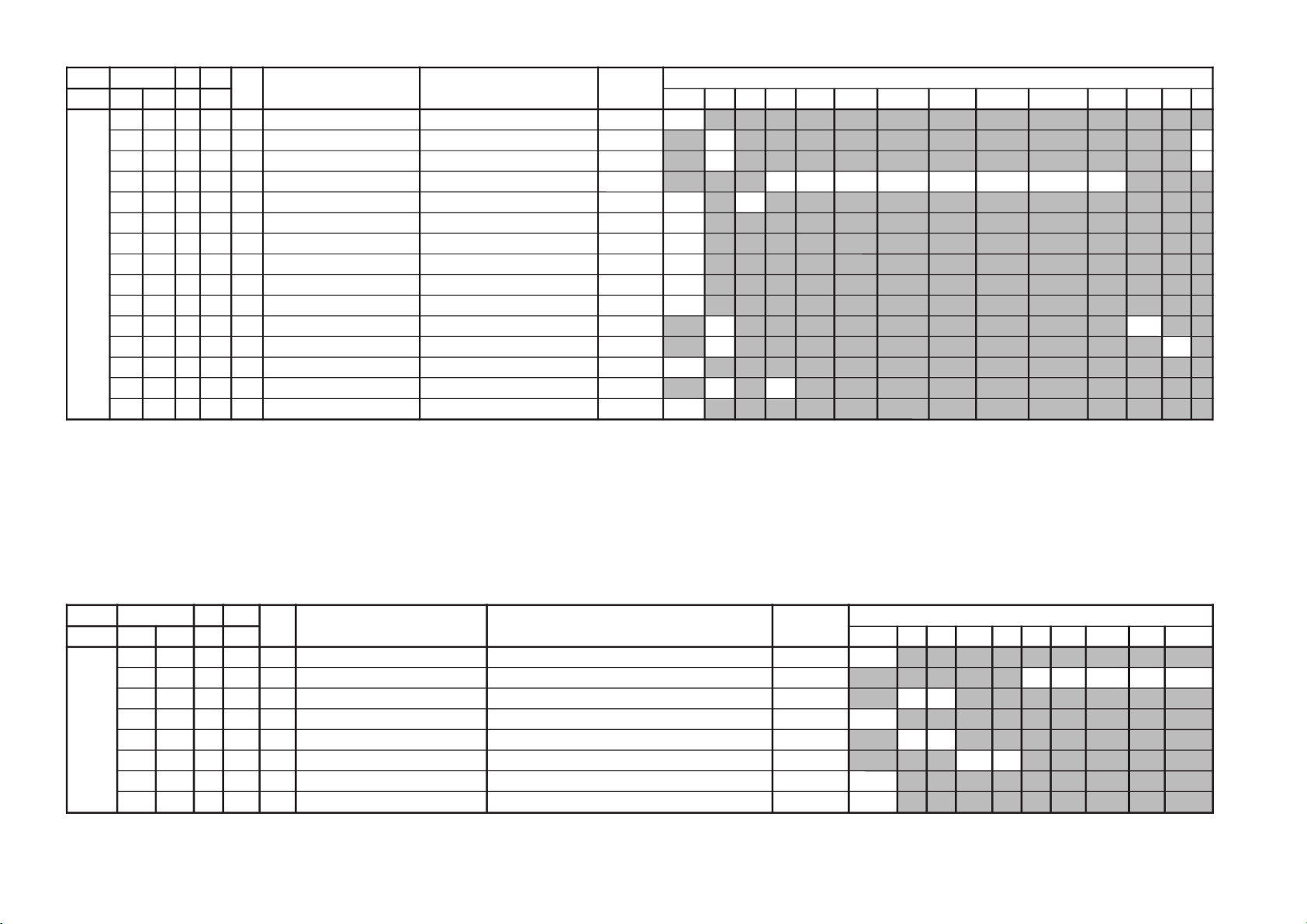

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoCsrehtOBGRVUY)VT(LAP)VT(CSTN)VT(MACES)oediV(LAP)oediV(CSTN)oediV(MACESTUPNI-SMACESCSTNVT

CY000QRFP000300XIFyaleDdnaycneuqerFretneCgnikaeP rossecorP-VT

**

100APR####300XIFtoohSrevO&erPoitaR rehto/VT

20

20

200OPR200300XIFskaePevitageN&evitisoPfooitaR rehto/VT

20

20

300YLDY210510XIFyaleD-Y TUPNI-S/VUY+)OEDIV/VT(*)MACES/CSTN/LAP(

****************

400TAMC000300XIFxirtaM)ASU/napaJ(CSTNroMACES-LAP )BGRNPJ(00

00

500LCA100100XIFgnitimiLroloCcitamotuA 10

600BC000100XIFycneuqerFretneCssapdnaBamorhC )xif0:oediV*(VThtiwylnodilav10

700OBS100300XIFtesffOkcalBMACES 00

800ESHC100300XIFytivitisneStnedICSTN/LAP 20

900OLC000100XIFretliF)lleB(ehcolCfoycneuqerFretneC 00

010PRTC000100XIFedoMparTamorhC srehto/MACES

00

10

110SPB000100XIFeniLyaleDdnab-esaBamorhCfossapyB srehto/CSTN

**

**

210OCF000100XIFnOroloCdecroF 00

310TNIT130360XIFlortnoCtniTdnaB-esaB srehto/VUY

13

13

410VUT000100XIFslangiSVUnolortnoCtniT 00

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoC0506srehtoVUYVToediVtxeteleTpi-VTlangisoN

CNYS000SYS000100XIFtupnICNYSYnonoitazinorhcnyS 00

100OF000300XIFtnatsnoCemiT1esahP )FR(langisoNrogninuTotuA/txeteleT/oediV/FFOPIVT/NOPIVT

3030100000

200DIV000100XIFedoMtnedIoediV 06/05

0000

300LSF000100XIFcnySlacitreVrofleveLgnicilSdecroF 00

400LSS000100XIFrotarapeScnySleveLgnicilS 06/05

0000

500DIVS100700XIFnoitacifitnedIoediVrofnoitceleSecruoS srehtO/VUY

0070

600FROF000300XIFycneuqerFdleiFdecroF 30

700KVM000100XIFgniyeKnoisiVorcaM 10

Item remarks ** please refer to page 23

KV-BM14M40

RM-W101

– 17 –

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD )sserddAevalS(nommoCVUYVToediV

WS0002VC000100XIFnoitceleSlangiStupnI2SBVC 00

100OVS100300XIF84@niPISBVC/OVS/OVFIfonoitcnuFVUY/oediV/VT

201010

200LFD000100XIFnoitcetorPhsalF 00

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD )deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCsrehtOBGReviLVT

)nyD(

VT

)srehtO(

oediV

)nyD(

oediV

)srehtO(

pmeTroloC

)HGIH(

pmeTroloC

)srehtO(

roloC

)WOL(pmeT

pmeTroloC

)LAMRON(

TCIP000LDAC700510XIFleveLevirDedohtaC 00

100AFC000300XIFedoMretliFbmoC

**

200COS200300XIFleveLgnippilCtfoS )hA8(00

300LWP100100XIFhctiwSgnitimiLetihWkaeP 10

400LTHW600510XIFgnitimiLetihWkaeP 00

500MAG100100XIFammaG 00

600STW100300XIFhctertSetihWdnalortnoCammaGsrehtO/eviL

10

10

700RFT000100XIFlangiSecnanimuLfooitaRrefsnarTCD )BGRNPJ+(srehtO/eviL

100010

800ROC300300XIFgniroC )srehto/anyD(*)oediV/VT(

00000000

900OROC000100XIF)ciPtnegilletnI(tesffOgniroC 00

010SKB300300XIFhctertSkcalBsrehto/BGR

2020

110SAA100100XIFhctertSkcalBehtffohctiwSotaerAkcalB 00

210KSD000100XIFlortnoCnikScimanyD 00

310SLB000100XIFhctertSeulB )SREHTO/HGIH(pmetloc

0000

410SLBN000100XIFtiucriChctertSeulBnoitarepO 00

510RRN000100XIFnoitcudeRdeRnoN )LAMRON/WOL/HGIH(pmetloc

10

1010

Item remarks ** please refer to page 23

KV-BM14M40

RM-W101

KV-BM14M40

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

FIV000DFIO630360XIFrotaludomeDFItesffO rossecorP-VT63

100TCGA130360XIFrevo-ekaTCGA )hA8(13

200MTS000100XIFedoMgninuThcraeS 10

300DG000100XIFlangiS1SBVCnoyaleDpuorG 00

400SCGA100300XIFdeepSCGAFI 10

500IFF000100XIFLLPFIretliFtsaF 00

600PMAO300300XIF)metsyS'L&Lylno(edutilpmAlangiStuptuOoediV 30

700IAV000100XIF)metsyS'L&Lylno(noitcerroCedutilpmAlangiStuptuOImetsyS 00

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD

)sserddAevalS(nommoCedomciP

0

edomciP

1

edomviP

2

edomciP

3

MV000DBGR300700XIFtuptuOMVottuptuOBGRfoyaleDenonrossecorP-VT20

100AMV300300XIFtuptuOMVfoedutilpmAenon)hA8(

**

200PAMV200300XIF)FFO:3,2,woL:1,hgiH:0(gnittesMVedoMerutciP

00102000

300OMMV300300XIFedoMMV 10

RM-W101

– 18 –

Item remarks ** please refer to page 23

– 19 –

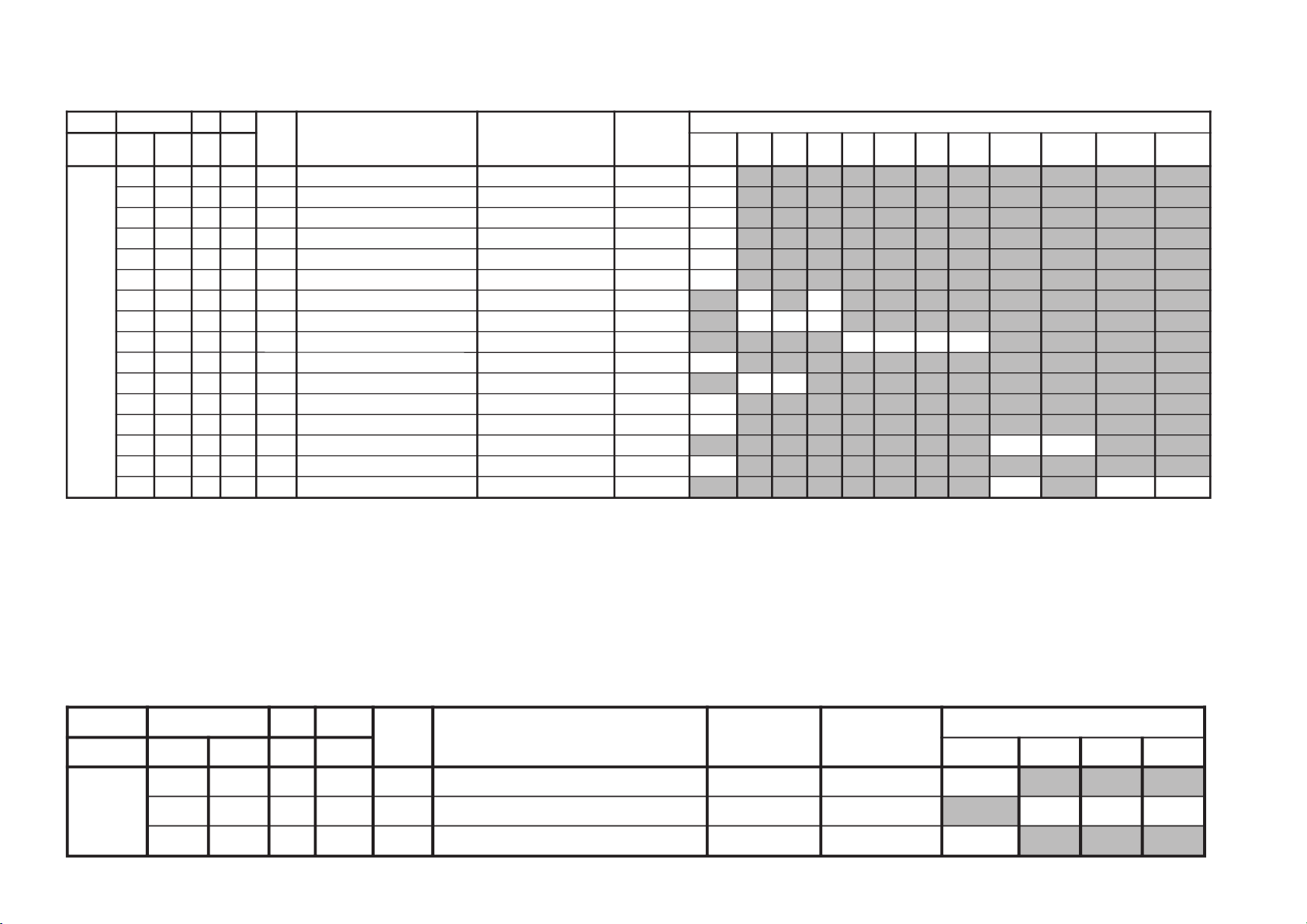

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

MEDS000SWMF000300XIFrotaludomeDMFrofnoitceleSwodniW rossecorP-VT20

100SSQ100100XIF)ledoMAGtpecxe(edoMreifilpmA)SSQ(dnuoStilpSisauQ )hA8(10

200BPB000100XIFretliFssapdnaBdnuoSfossapyB 00

300OLMA000100XIFdnuoSMAroflangiStuptuOoiduA 00

400CVPH000100XIFlortnoCemuloVenohPdaeH 00

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveDnommoC

yrogetaC.oNemaNceDceD )sserddAevalS(

TXT000VXT930360XIFspilihProfnoitisoPlacitreVtxeteleT redoceDtxeT93

100DHT500721XIFtfihSegdEevitcAcnus-HtxeteleT 50

200RBT400510XIFssenthgirBBGRtxeteleT 11

KV-BM14M40

RM-W101

KV-BM14M40

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD nommoC)oruE(L-VTVToediVffOWOW/SRSdnuorrusurToeretsIonomI

PSDS000MVA200700XIFedoMLVA DSS20

100VVA500510XIFleveLecnerefeRLVA )h0B(90

200LBB000510XIFruotnoCEBB

**

300HBB000510XIFssecorPEBB

**

400WLBB000510XIFtesffOruotnoCEBB

**

500FOVS000510XIFtesffOemuloVedoMtceffE/dnuorruS onomI/oeretsI/dnuorrusurT/)WOW/SRS(ffO

0070002000

600FOVI000700XIFtesffOevitisoPemuloVretsaM 60

700FOVE000700XIFtesffOevitageNemuloVretsaM 60

800DAL000130XIFtsujdAleveLredoceD 50

900MAL000130XIFtsujdAleveLonoM 50

010NAL000130XIFtsujdAleveLmaciN 71

110SAL000130XIFtsujdAleveLPAS 80

210AAL000130XIFtsujdAleveLCDA oediV/Lnon-VT/L-VTI)oruEnoN(oediV/vT

000000

310FES300700XIFtceffEoeretS/onoMelbidercnI onomI/oeretsI

5030

410L1A000552XIFtfeLemuloV1XUA 00

510R1A000552XIFthgiRemuloV1XUA 00

610SAB800510XIFtesffOssaBniaM

**

710ERT800510XIFtesffOelberTniaM

**

8101QE800510XIFtesffO)zH001(dnaBlennahCniaMrezilauqE

**

9102QE800510XIFtesffO)zH003(dnaBlennahCniaMrezilauqE

**

0203QE800510XIFtesffO)zH0001(dnaBlennahCniaMrezilauqE

**

1204QE800510XIFtesffO)zH0003(dnaBlennahCniaMrezilauqE

**

2205QE800510XIFtesffO)zH0008(dnaBlennahCniaMrezilauqE

**

320TCFB500700XIFlortnoCEBBdnaBUD,EBD

**

420NECS100510XIFlortnoCretneCD3SRS 40

520APSS000510XIFlortnoCecapSD3SRS 10

620WHBB000510XIFedomWOWnitesffossecorpEBB

**

720ERTS200700XIFedomdnuorrusroftesffOelberT

**

820THBB000510XIFedomVTnitesffOEBB 00

920AWD000000XIF???AWD 00

030ERTT200700XIFedoMVTnitesffOelberT 20

RM-W101

– 20 –

Item remarks ** please refer to page 23

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoC

yrogetaC.oNemaNceDceD

CEDS000UTPM300510XIF)CSTB(noitcetedtolipXPMrofdlohserhTreppU DSS20

100LTPM900510XIF)CSTB(noitcetedtolipXPMrofdlohserhTrewoL )h0B(50

200UTPS300510XIFnoitcetedreirracPASrofdlohserhTreppU 80

300LTPS600510XIFnoitcetedreirracPASrofdlohserhTrewoL 51

400HT1C000130XIF1CSfonoitcetedrofdlohserhTlamroN 00

500PA1C000130XIF1CSfonoitcetedrofdlohserhTmargorPotuA 00

600HTPS000130XIFPASfoetumotuarofdlohserhTesioN 00

700YHPS400510XIFPASfoetumotuarofezissiseretsyH 30

800HTMF000130XIFdradnats2AMFni2CSfoetumotuarofdlohserhTesioN 81

900YHMF400510XIFdradnats2AMFni2CSfoetumotuarofezissiseretsyH 70

010HTTB000130XIFreirracoeretsCSTBfoetumotuarofdlohserhTesioN 00

110YHTB400510XIFoeretsCSTBfoetumotuarofezissiseretsyH 30

210HTJE000130XIFreirracbusMFJAIEfoetumotuarofdlohserhTesioN 00

310YHJE400510XIFreirracbusMFJAIEfoetumotuarofezissiseretsyH 40

410YLNO000100XIFtuptuoCEDnoMACINdetalerylnoecudorpeR 00

510MAXE000100XIF)PEDD(LdradnatsnietumotuafoesacniecruoskcabllaF 00

610TMIN000100XIF)PEDD(etarrorretibnodnepednoitcnufetumotuaMACIN 00

710ELIN001552XIF)PEDD(timilrorrerewolMACIN 05

810EUIN002552XIF)PEDD(timilrorrereppuMACIN 002

910DMPE100300XIF)PEDD(gnimmargorPysaECEDMED 20

020SDTS910130XIFsedomSSSdnaDSArofdexelpitlumstiB 13

120AMVO100100XIFnoitpadanoitaludomrevoMF 00

220WBLF000300XIFhtdiwdnabretlifrotaludomedMA/MF 30

320DMDI000300XIFedomSSSnideepstnediMF 00

420LAPF000100XIFgnidocedCSTBrofycneuqefeniL 00

520TMVO100200XIFlanimonotevitalerdlohserhtlevelnoitaludomrevO 30

620IXCD000100XIFretrevnIlortnoCgnilacSOXCDMACIN

**

720GXCD000700XIFniaGlortnoCgnilacSOXCDMACIN

**

820LLCD110510XIF)L(timiLlortnoCgnilacSOXCDMACIN 00

920HLCD000130XIF)H(timiLlortnoCgnilacSOXCDMACIN

**

030UEDI100300XIFDTS2AnaeporuErofgnittesDOMDI 00

130RKDI100300XIFDTSMnaeroKrofgnittesDOMDI 00

230PJDI100300XIFDTSJAIErofgnittesDOMDI 10

– 21 –

Item remarks ** please refer to page 23

KV-BM14M40

RM-W101

KV-BM14M40

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

nommoCetoN

yrogetaC.oNemaNceDceD

BTPO000LLAI000100XIF)MVNnideziromemton(hctiwSetirWdradnatS 00

1001BPO000552XIF)detalermetsyS(1noitpO

****

2002BPO000552XIF)detalerlangiSoediV(2noitpO

****

kramerroF ****

noitpootreferesaelP

nosledomllaroftib

.72egapot52egap

3003BPO000552XIF)detalergnidoceDoeretS(3noitpO

****

4004BPO000552XIF)suoenallecsiM(4noitpO

****

5005BPO000552XIF)suoenallecsiM(5noitpO

****

6006BPO000552XIF)detaleregaugnaLDSO(6noitpO

****

JVTytilanoitcnuF.tinIegnaRATADnoitcnuFetoN&elbaTemaNeciveD

)sserddAevalS(

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaC.oNemaNceDceD nommoC0506

MTPO000THSA600700XIF)nim5*atad(remitffotuhsotuA 00

100BDSO000510XIFssenthgirbDSO h06orciM/RMM50

200HDSO500510XIFnoitisoPlatnoziroHDSO h06orciM/RMM50

300VDSO730360XIFnoitisoPlacitreVDSO 06/05h06orciM/RMM

3613

400ETUM000100XIF)delbane=1(hctiwSetuMlangiSoN 00

500LUFR510510XIF)hf0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSFR 40

600KLFR510510XIF)hf0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSFR 00

700LUVA510510XIF)hF0nehwelbasiD(dekcolnUretfaretnuoCegnahClangiSVA 40

800KLVA510510XIF)hF0nehwelbasiD(dekcoLretfaretnuoCegnahClangiSVA 00

900GNAL000300XIFnoitidnocgnippihsegaugnalDSO 00

010TXTH000100XIFwsrotarepescnyS )A8(rossecorP-VT00

110SSMC000100XIFwscnyS )A8(rossecorP-VT10

210OXCD060592XIFeulaVOXCD PSD/h06orciM/RFS95

310LBXE000510XIFesioNetihWetanimilEotremiTgniknalBdednetxE 70

410SYST000300XIF )ledoMAG(]K/D:3,M:2,I:1,G/B:0[teseRtseTtaMVNnisySVTeziromeM 00

510U0VT100100XIFlangistuohtiwetum:1,ffoetumsyawlA:0noitidnocetumtuOVT 00

RM-W101

– 22 –

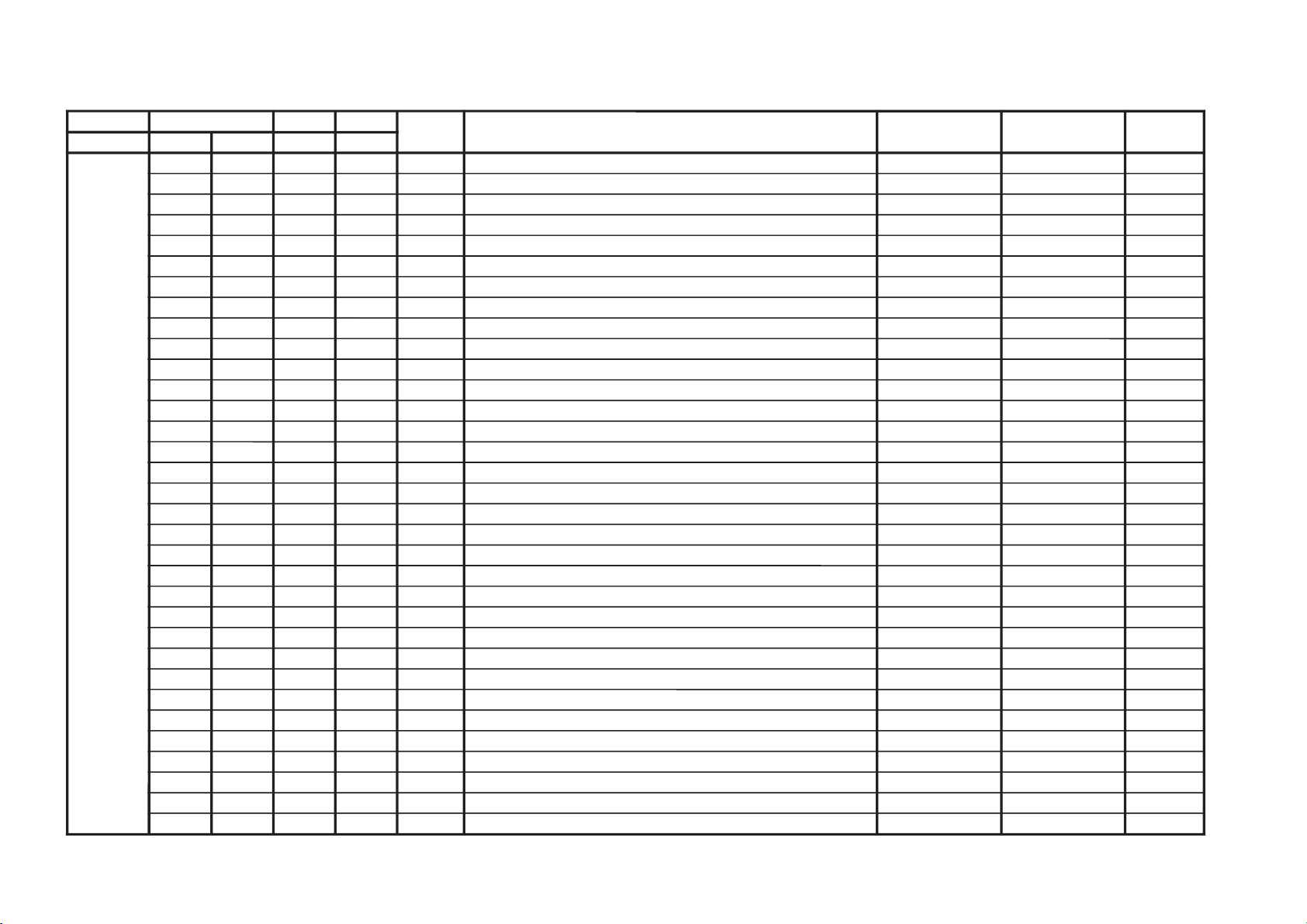

NOTE

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

• Note for Different Data Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively in the memory.

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

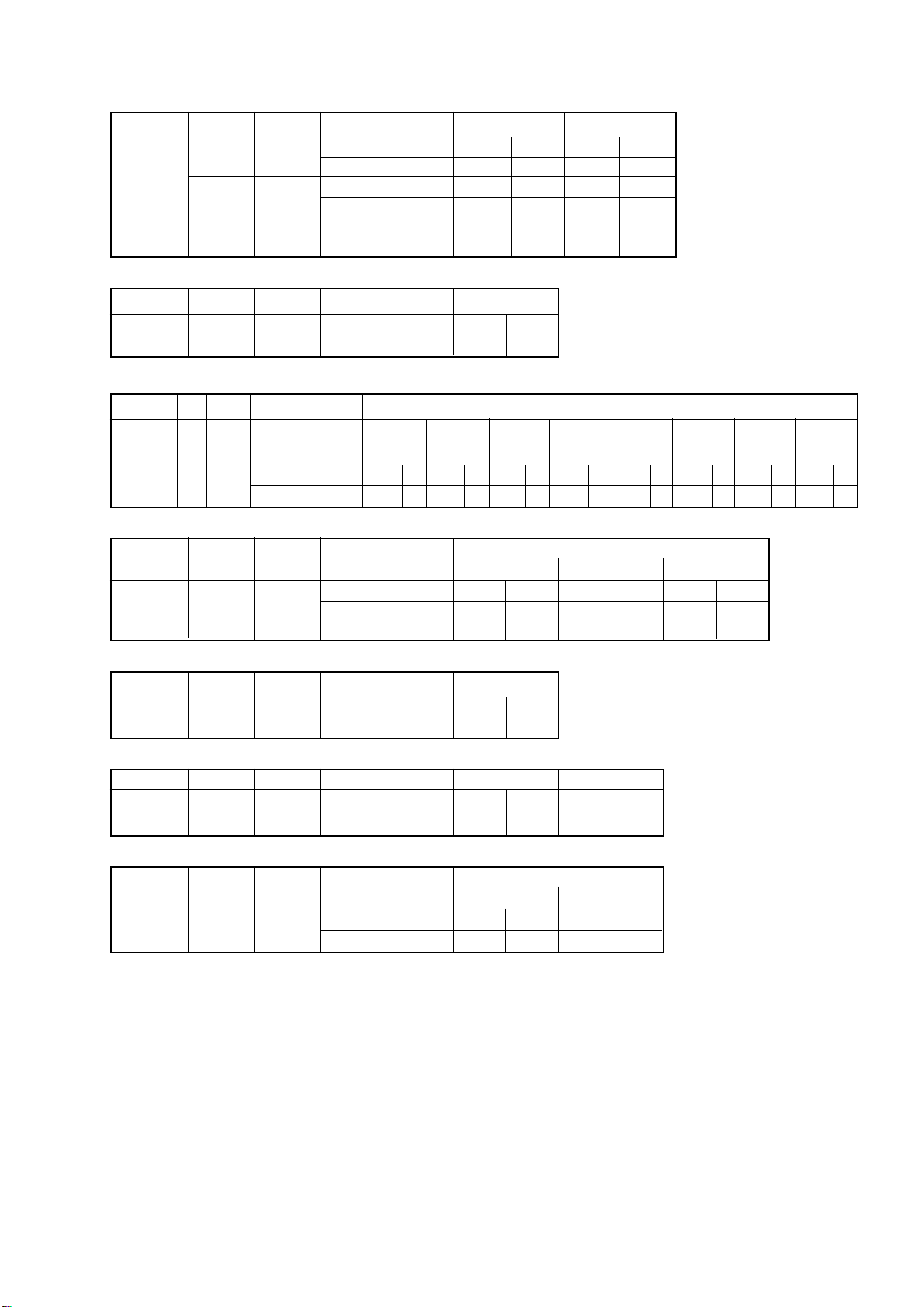

KV-BM14M40

Data variant depend on models

Category No Name Model Data (ES5.2D) Data (ES5.2~)

WHBL 006 PGR With VM A864 69 A864 50

Without VM A864 61 A864 45

007 PGG With VM A865 69 A865 50

Without VM A865 61 A865 45

008 PGB With VM A866 69 A866 50

Without VM A866 61 A866 45

Category No Name Model Data

VM 001 VMA With VM A87D 03

Without VM A87D 00

Category No Name Model Table

PAL NTSC SECAM PAL NTSC SECAM YUV S-Input

(TV) (TV) (TV) (VIDEO) (VIDEO) (VIDEO)

YC 003 YDLY Comb Model A851 08 A852 08 A853 08 A8D8 11 A8DC 09 A8DD 11 A8DE 09 A8DF 09

Non-Comb Model A851 02 A852 02 A853 10 A8D8 2 A8DC 2 A8DD 2 A8DE 09 A8DF 09

RM-W101

Category No Name Model Table

TV Video YUV

SADJ 002 SSHP

Category No Name Model Data

PICT 001 CFA Comb models A86D 00

Category No Name Model Data (ES5.2D) Data (ES7.2D)

YC 000 PFRQ Comb models A86D 01 A86D 00

Category No Name Model Table

YC 011 BPS Comb models AAF6 01 AAF5 00

21" Comb models

21"Non-Comb models &

All 14" models

Non-Comb models A86D 01

Non-Comb models A86D 00 A86D 00

Non-Comb models AAF6 00 AAF5 00

A859 35 A85A 35 A898 35

A859 35 A85A 38 A898 35

NTSC Others

– 23 –

Loading...

Loading...