Sony KV-AR34M81, KV-AR34N90 Service Manual

REVISION HISTORY

BG3R

CHASSIS

MODEL

KV-AR34M81

KV-AR34N90

NO. SUFFIX DATE SUPPL. / CORR DESCRIPTION

1 -01 2002/09 -- 1st. Issue

PART NO. : 9-872-340-01

SERVICE MANUAL BG3R

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-AR34M81 RM-995 ME SCC-U48V-A

KV-AR34N90 RM-996 Taiwan SCC-U54F-A

MODEL COMMANDER DEST. CHASSIS NO.

RM-995RM-996

TRINITRON

®

COLOR TV

KV-AR34M81/AR34N90

RM-995 RM-996

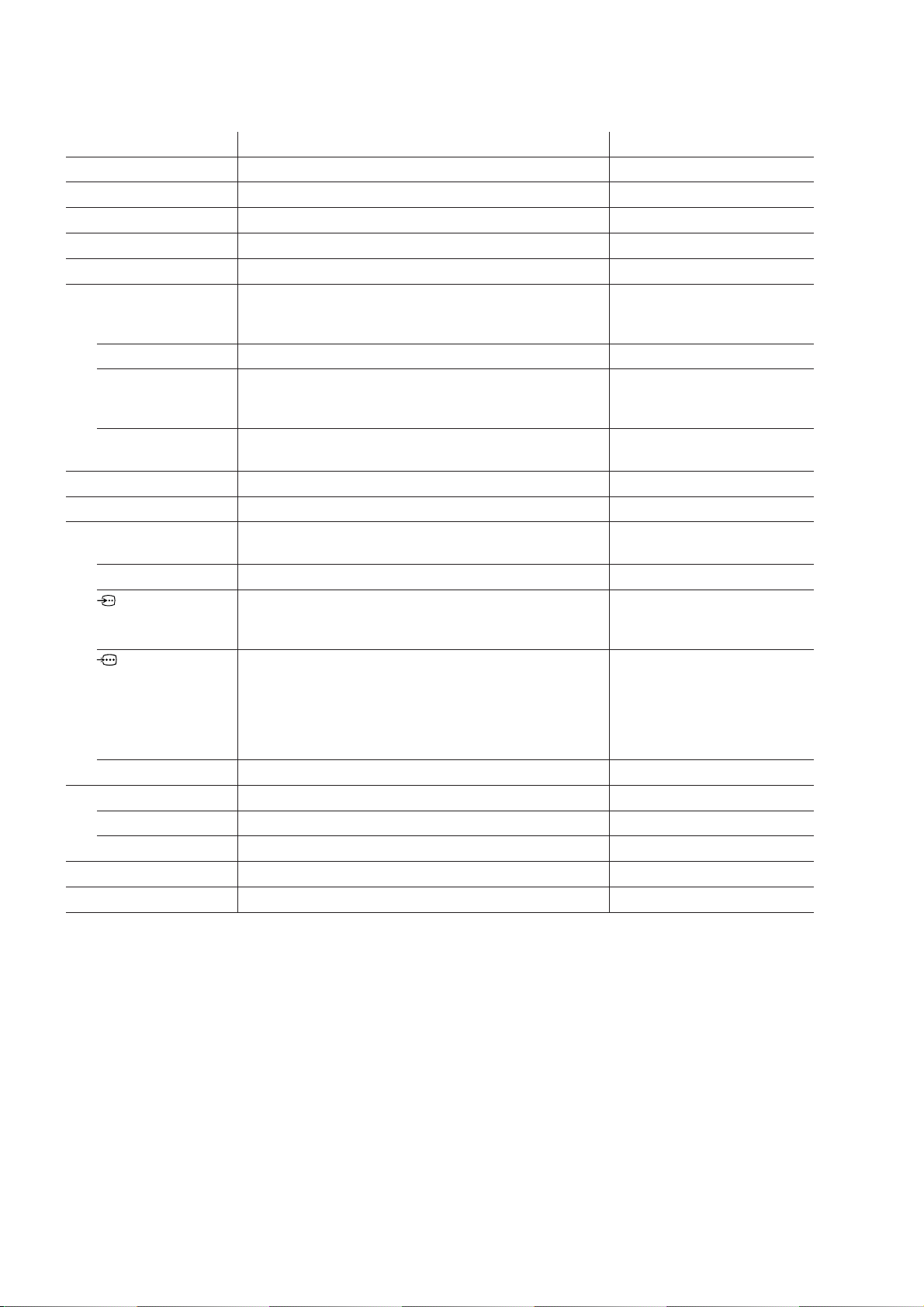

Power requirements 110-240 V AC, 50/60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system B/G, I, D/K, M

Color system PAL, PAL 60, SECAM, NTSC3.58, NTSC4.43

Teletext language English, Farsi (Persian), French

Channel coverage

B/G VHF: E2 to E12 / UHF: E21 to E69

I UHF: B21 to B68 / CATV: S01 to S03, S1 to S41

D/K VHF: C1 to C12, R1 to R12 /

M VHF: A2 to A13 / UHF: A14 to A79

˘(Antenna) 75-ohm external terminal

Audio output (Speaker) 8W + 8W

Number of terminal

DVideo Input: 4* Output: 1 * Three input lines available Phono jacks; 1 Vp-p, 75 ohms

≥ Audio Input: 4* Output: 1 * Three input lines available Phono jacks; 500 mVrms

(S Video) Input : 2 Y: 1 Vp-p, 75 ohms

(Component Input : 1 Phono jacks:

Video) Y: 1 Vp-p, 75 ohms

2 (Headphone) Output: 1 Stereo minijack

Picture tube 34

Tube size (cm) 86 Measured diagonally

Screen size (cm) 80 Measured diagonally

Dimension (w/h/d,mm) 896 × 686 × 569

Mass (kg) 79

SPECIFICATIONS

(KV-AR34M81)

CATV: S01 to S03, S1 to S41

UHF: C13 to C57, R21 to R60 /

CATV: S01 to S03, S1 to S41, Z1 to Z39

CATV: A-8 to A-2, A to W+4, W+6 to W+84

Note

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

sync negative

CB: 0.7 Vp-p, 75 ohms

R: 0.7 Vp-p, 75 ohms

C

Audio: 500mVrms

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

KV-AR34M81/AR34N90

RM-995 RM-996

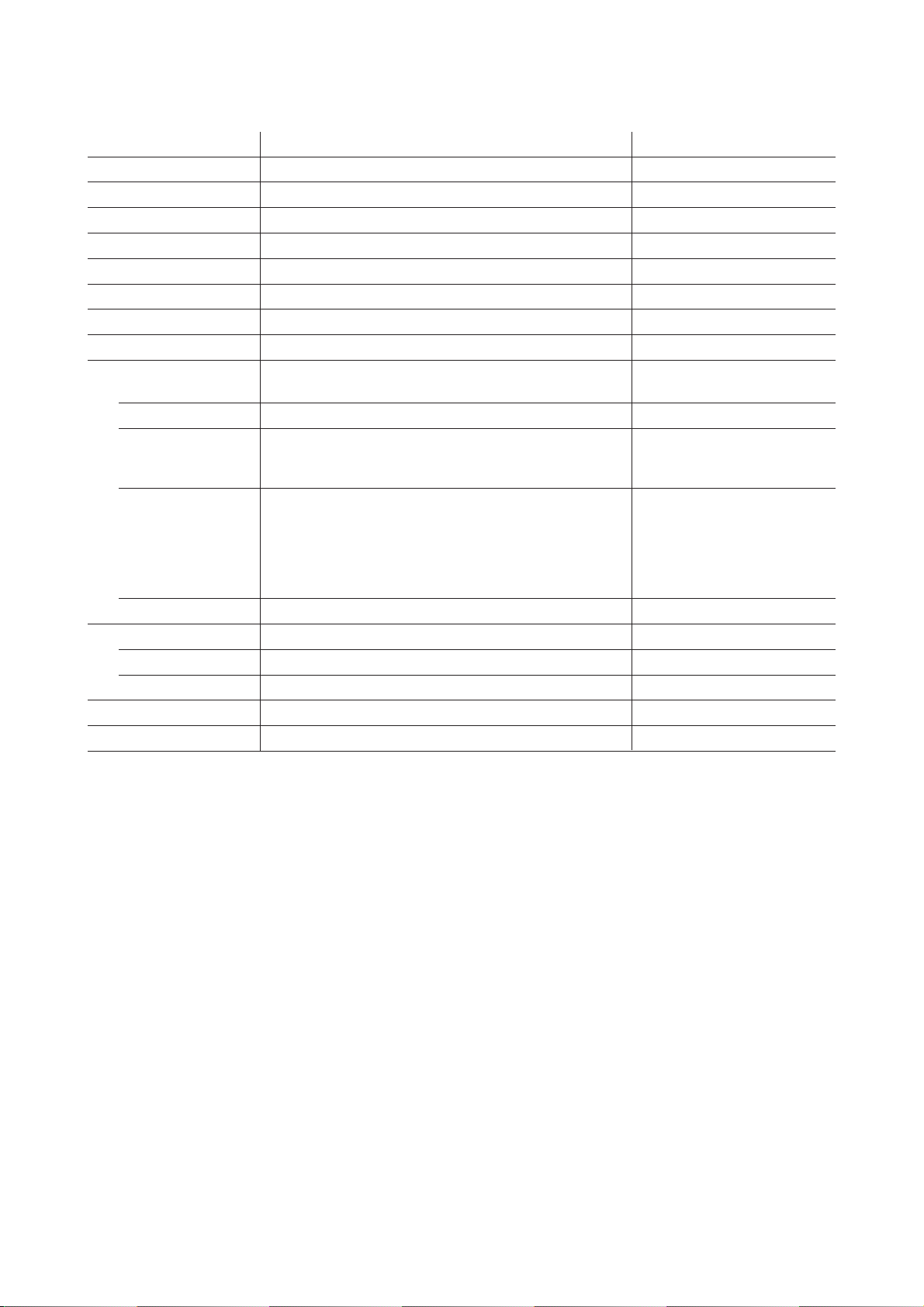

SPECIFICATIONS

(KV-AR34N90)

Note

Power requirements 110 V AC, 60 .Hz

Power consumption (W) Indicated on the rear of the TV

Television system M

Color system NTSC3.58, PAL*, PAL 60*, SECAM*, NTSC4.43* * AV IN only

Stereo/Bilingual System MTS

Channel coverage VHF : 2 to 13 / UHF : 14 to 69 / CATV : 1 to 125

˘(Antenna) 75-ohm external terminal

Audio output (Speaker) 8W + 8W

Number of terminal

Video Input: 4* Output: 1 * Three input lines available Phono jacks; 1 Vp-p, 75 ohms

Audio Input: 4* Output: 1 * Three input lines available Phono jacks; 500 mVrms

(S Video) Input : 2 Y: 1 Vp-p, 75 ohms

unbalanced, sync negative

C: 0.286 Vp-p, 75 ohms

Component Input : 1 Phono jacks:

Video (DVD) IN Y: 1 Vp-p, 75 ohms

sync negative

B: 0.7 Vp-p, 75 ohms

C

R: 0.7 Vp-p, 75 ohms

C

Audio: 500mVrms

2 (Headphone) Output: 1 Stereo minijack

Picture tube 34

Tube size 859 mm Measured diagonally

Screen size 803 mm Measured diagonally

Dimension (w/h/d,mm) 896 × 686 × 569

Mass (kg) 79 kg

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 3 –

KV-AR34M81/AR34N90

RM-995 RM-996

TABLE OF CONTENTS

Section Title Page

SELF DIAGNOSTIC FUNCTION ........................................ 5

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................... 8

1-2. Speaker Removal ........................................................ 8

1-3. Chassis Assy Removal ................................................ 8

1-4. F Board Removal ........................................................ 8

1-5. Service Position .......................................................... 8

1-6 HV Cap Block, PWB Holder and

DH Board Removal .................................................... 8

1-7. Terminal Bracket and J Board Removal .................... 9

1-8. D2 Board Removal ..................................................... 9

1-9. H1 and H2 Boards Removal ....................................... 9

1-10. B1 and V1 Boards Removal ....................................... 9

1-11. A and B10 Boards Removal ....................................... 9

1-12. Picture Tube Removal ............................................... 10

2. ADVANCE OPERATION

2-1. "RESET" Function .................................................... 11

3. SET-UP ADJUSTMENTS

3-1. Beam Landing ........................................................... 12

3-2. Convergence .............................................................. 13

3-3. Focus Adjustment ..................................................... 15

3-4. G2 (SCREEN) and White Balance Adjustment ....... 16

4. CIRCUIT ADJUSTMENTS

4-1. Adjustment With Commander .................................. 17

4-2. Adjustment Method .................................................. 17

4-3. Adjustment for Non Digital Texture Enhancer (DTE)

Model ........................................................................ 29

4-4. Adjustment for Digital Texture Enhancer (DTE)

Model ........................................................................ 29

4-5. Display Position Adjustment .................................... 30

4-6. Deflection Adjustment .............................................. 30

4-7. H-Trapezoid Adjustment .......................................... 31

4-8. A Board Adjustment After IC003 (MEMORY)

Replacement .............................................................. 31

4-9. Picture Distortion Adjustment .................................. 32

Section Title Page

5. DIAGRAMS

5-1. Block Diagram .......................................................... 33

5-2. Circuit Board Location ............................................. 35

5-3. Schematic Diagram ................................................... 36

(1) C6 and J Boards Schematic Diagrams ............... 37

(2) A Board Schematic Diagram .............................. 39

(3) D2 Board Schematic Diagram ............................ 43

(4) H1 and F Boards Schematic Diagrams............... 45

(5) B10 Board Schematic Diagram .......................... 47

(6) V1 Board Schematic Diagram ............................ 49

(7) B1 Board Schematic Diagram ............................ 51

(8) DH Board Schematic Diagram ........................... 52

(9) H2 Board Schematic Diagram ............................ 53

(10) VM1 Board Schematic Diagram ...................... 54

5-4. Voltage List and Waveforms ..................................... 56

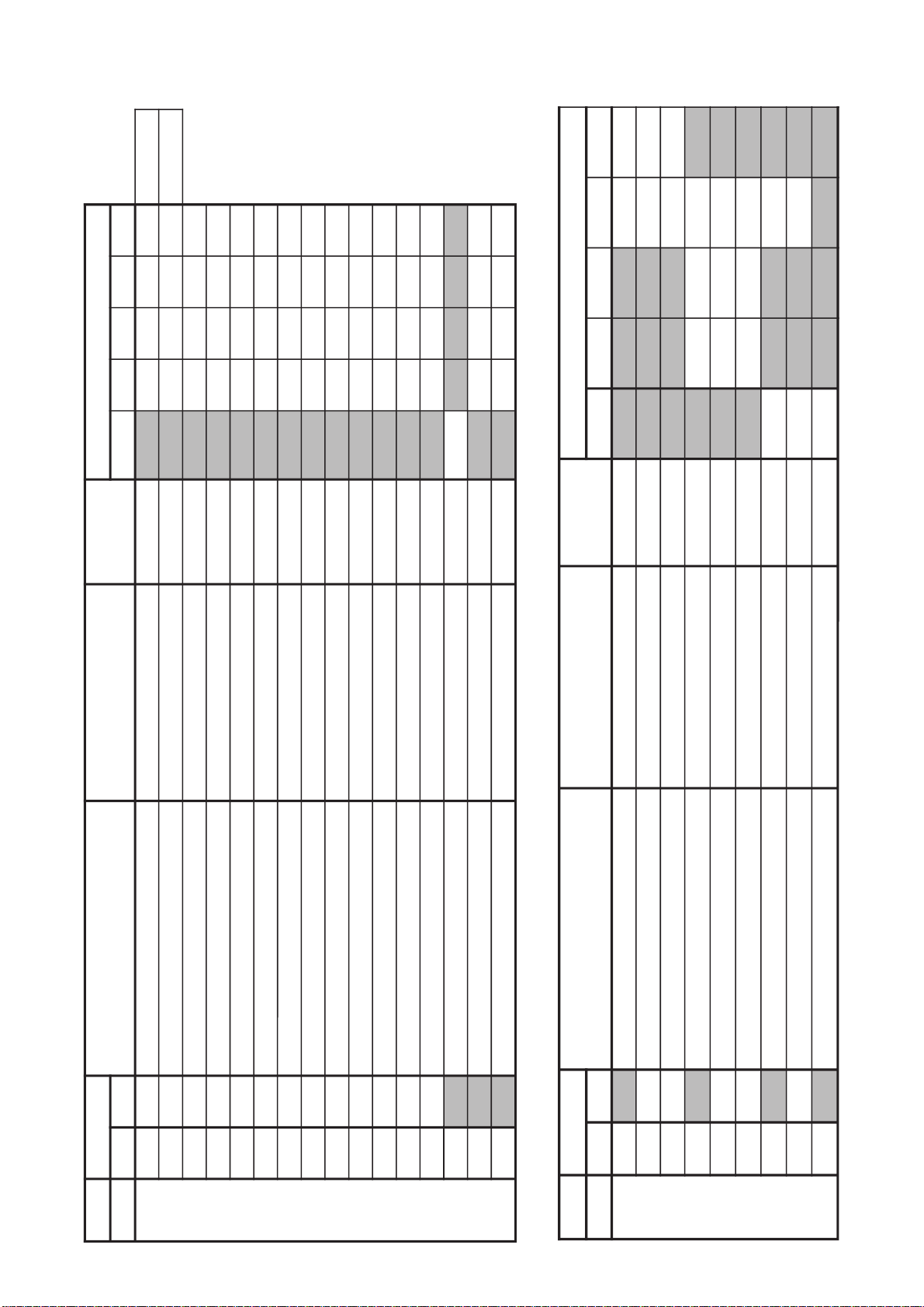

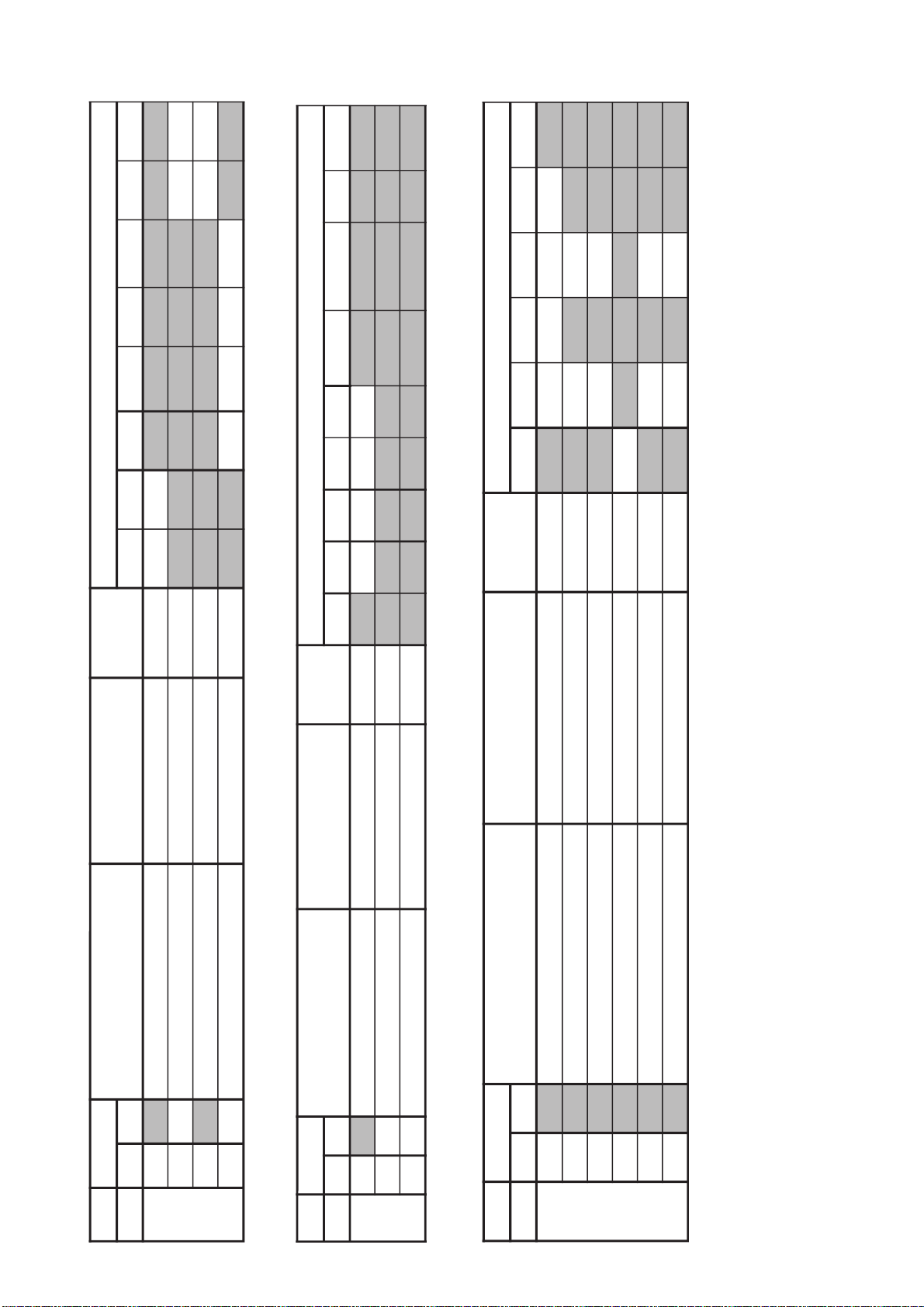

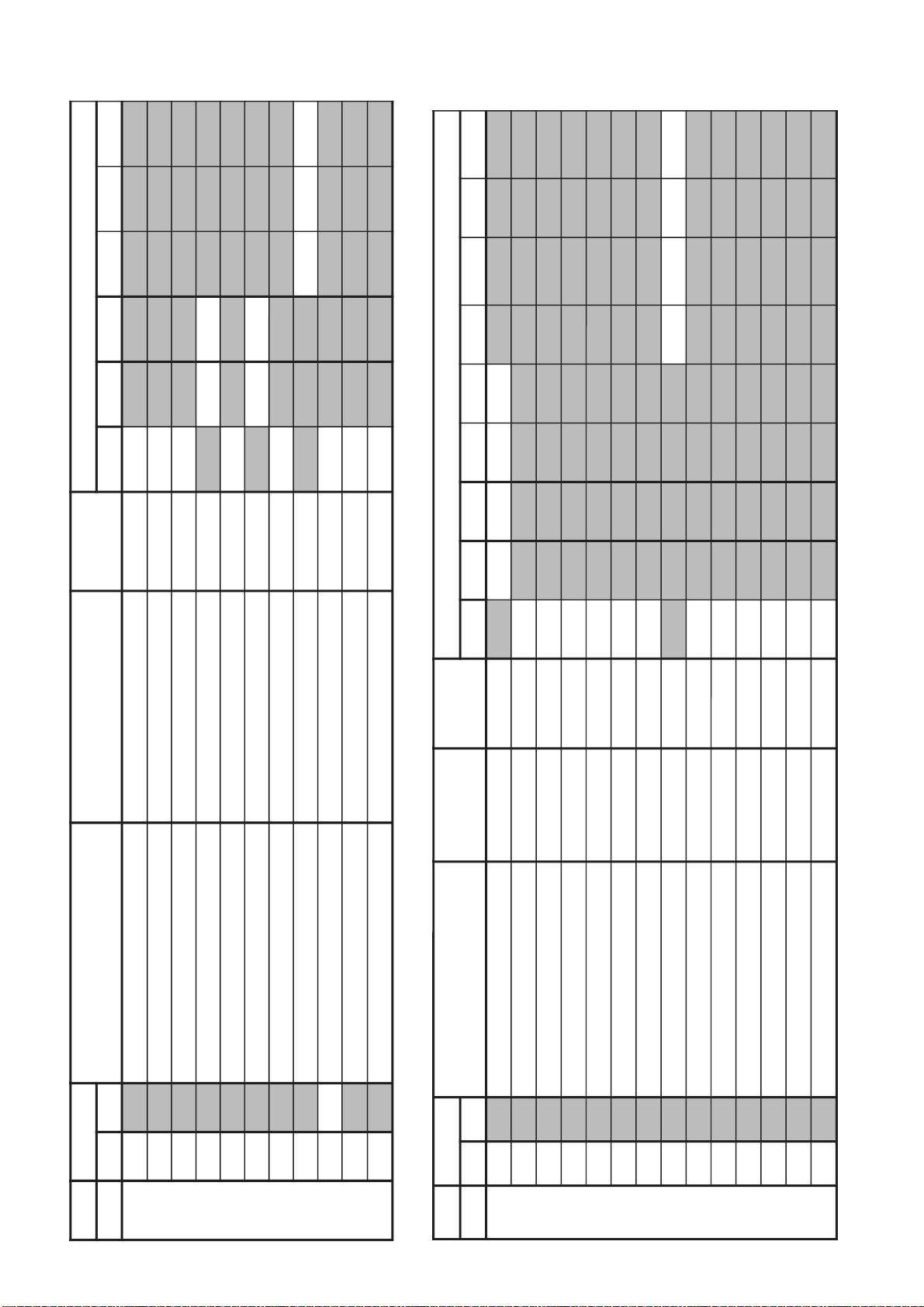

5-5. Printed Wiring Boards and Parts Location............... 61

5-6. Semiconductors ......................................................... 68

6. EXPLODED VIEWS

6-1. Speaker Bracket ........................................................ 70

6-2. Chassis ...................................................................... 71

6-3. Picture Tube .............................................................. 72

7. ELECTRICAL PARTS LIST ......................................... 73

OPERATING INSTRUCTIONS

– 4 –

KV-AR34M81/AR34N90

RM-995 RM-996

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot

be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

1. DIAGNOSTIC TEST INDICATORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP) or

overvoltage

(OVP)

• Vertical deflection

stopped

• Horizontal

deflection

overdrive

• White balance

failure (no

PICTURE)

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

5 times

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:001~255

004:001~255

at the same time

005:000 or

005:001~225

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out F4601

(F)

• H.OUT Q511 is shorted.

(A board)

• Q701, Q702, Q703 is

shorted (C6 board)

• -13V is not supplied.

(A board)

• IC 503 faulty (A board)

• G2 is improperly adjusted.

(Note 2)

• CRT problem.

• R(Q703), G(Q702) or

B(Q701) out is faulty

(C6 board)

• IC301 is faulty. (A board)

• No connection A board to

C6 board.

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Has entered standby state

after horizontal raster.

• Vertical deflection pulse is

stopped.

• Power line is shorted or

power supply is stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• Micro reset

Note 1: If a + B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to screen (G2) Adjustment in section 3-4 of this manual.

* R(Q703), G(Q702) or B(Q701) out is faulty (C6 board).

—

101:00 or

101:001~225

• Discharge CRT (C6 Board)

• Static discharge

• External noise

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

– 5 –

KV-AR34M81/AR34N90

RM-995 RM-996

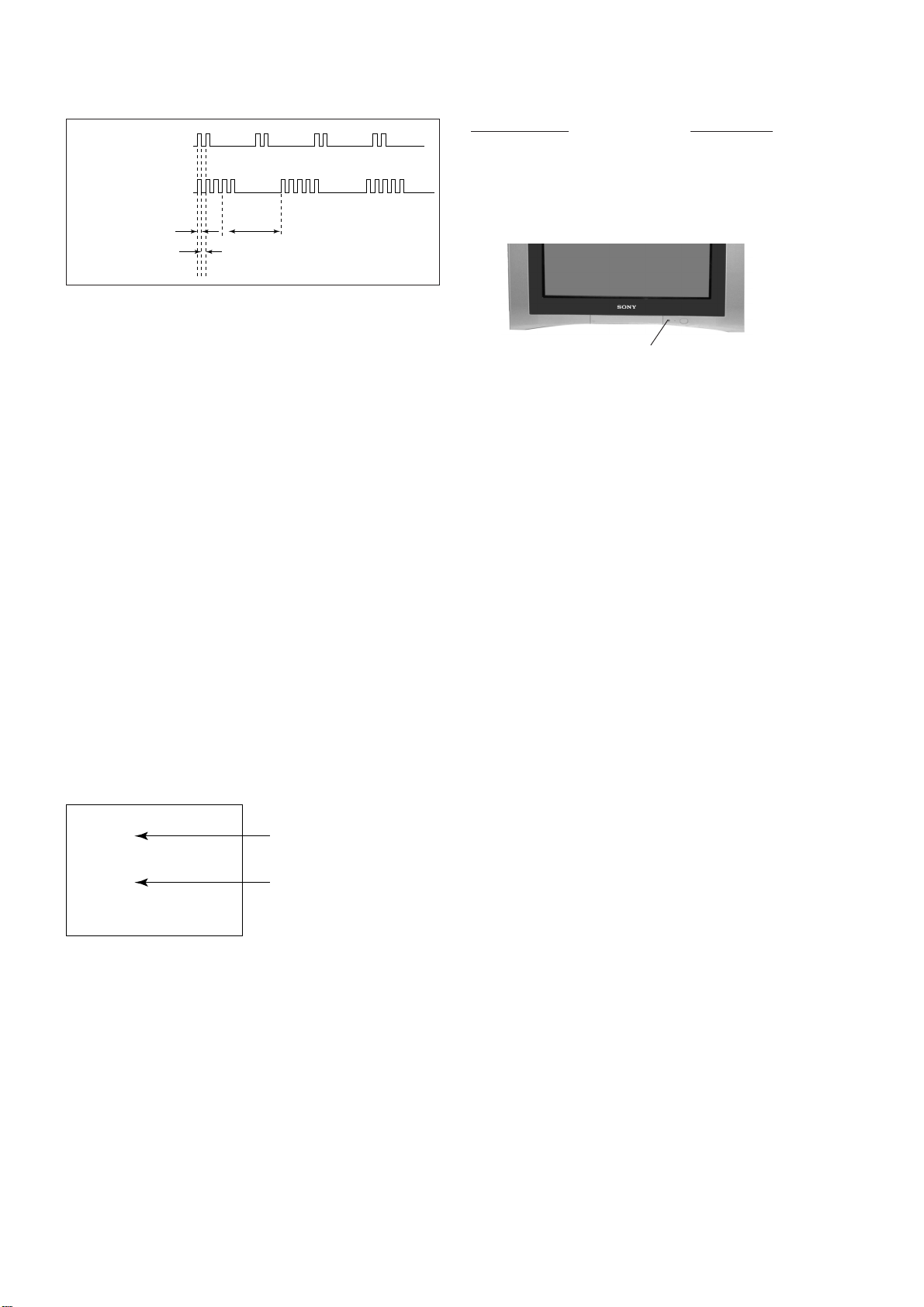

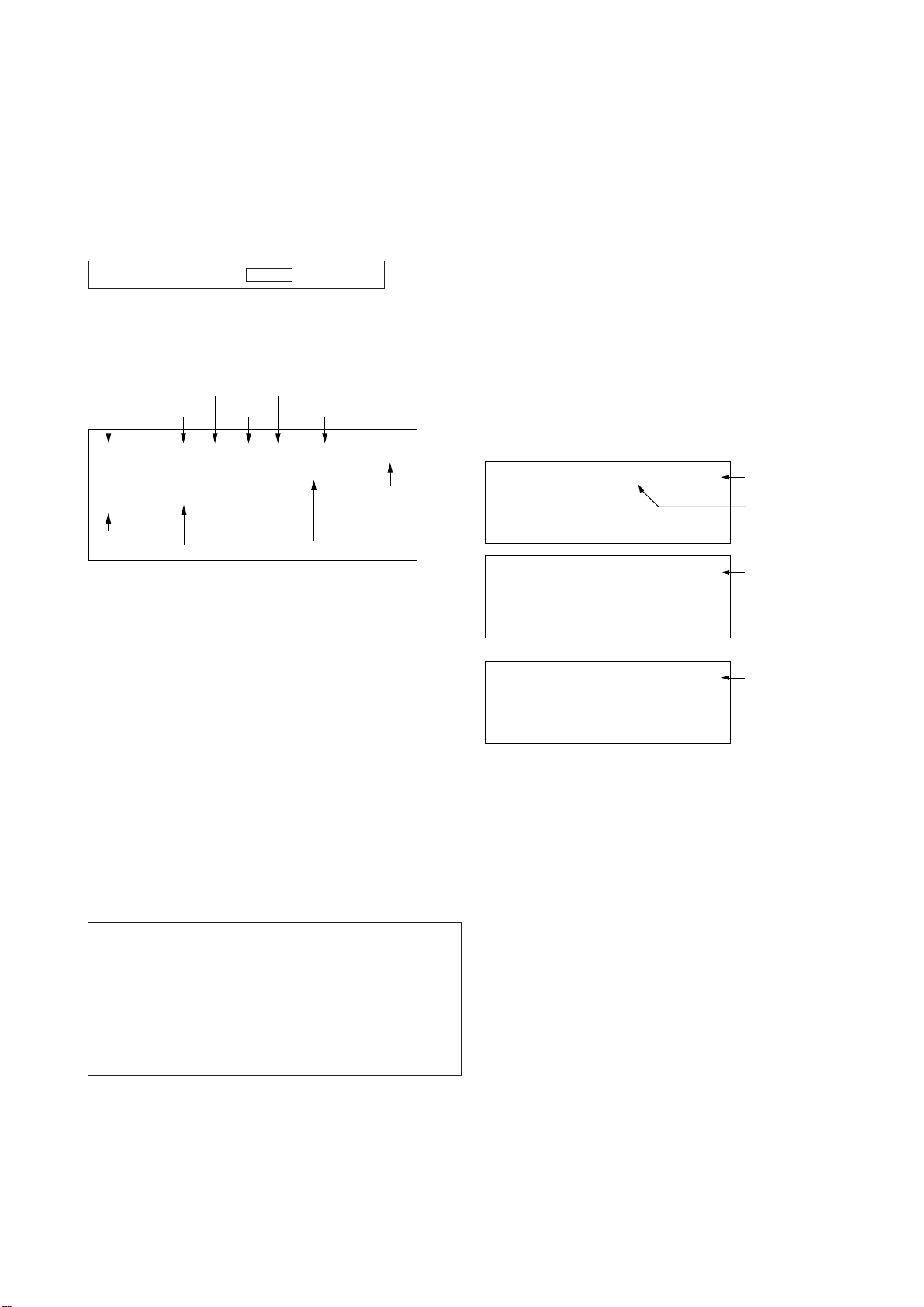

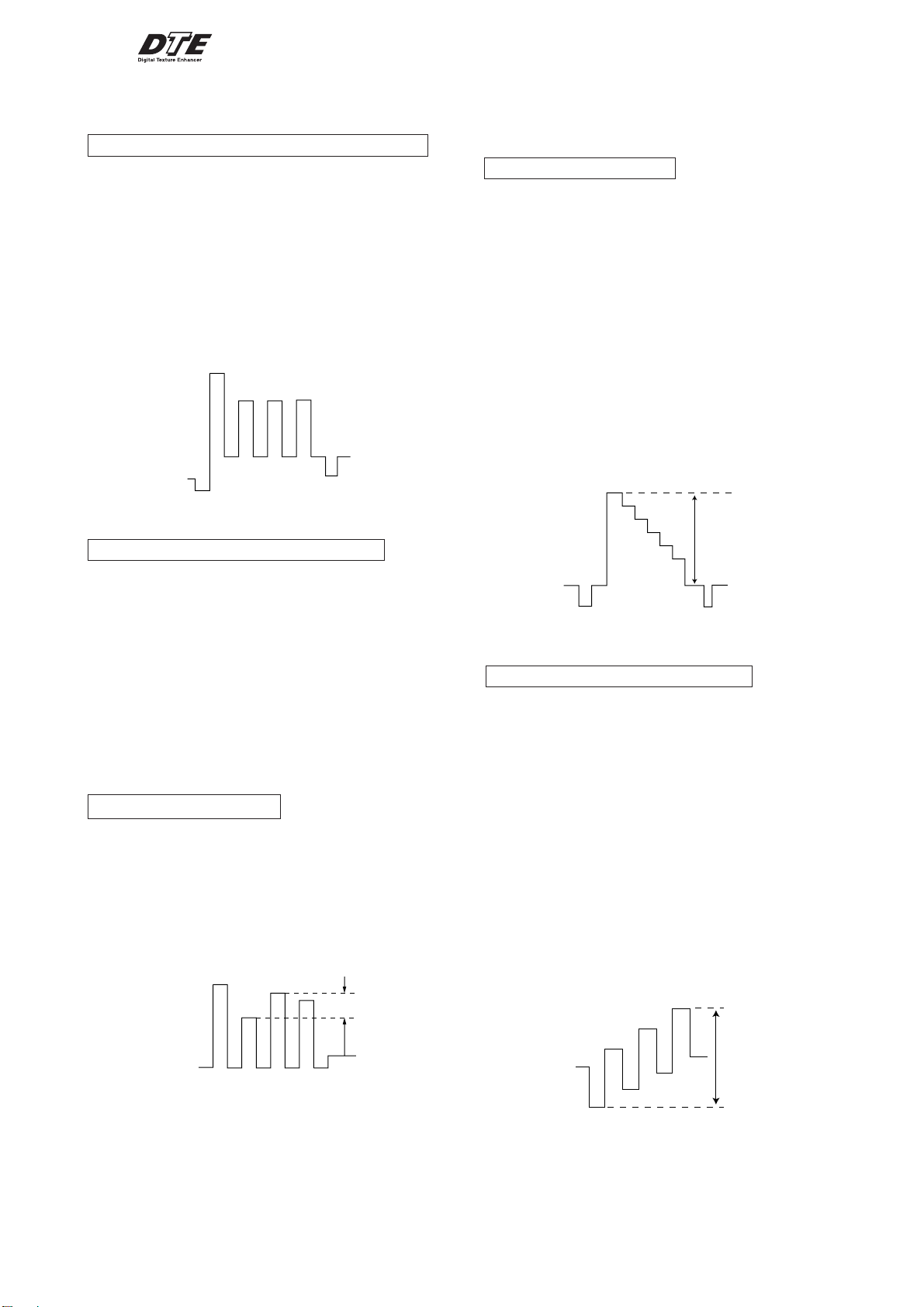

2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

+B overcurrent/overvoltage 2 times

Vertical deflection stopped

Diagnostic Item Flash Count*

5 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

White balance failure 5 times

* One flash count is not used for self-diagnostic.

STANDBY/SLEEP lamp

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp

from flashing.

4. SELF-DIAGNOSTIC SCREEN DIPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it

is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screendisplay] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (mode volume [+]).

Self-Diagnosis screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

– 6 –

KV-AR34M81/AR34N90

RM-995 RM-996

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

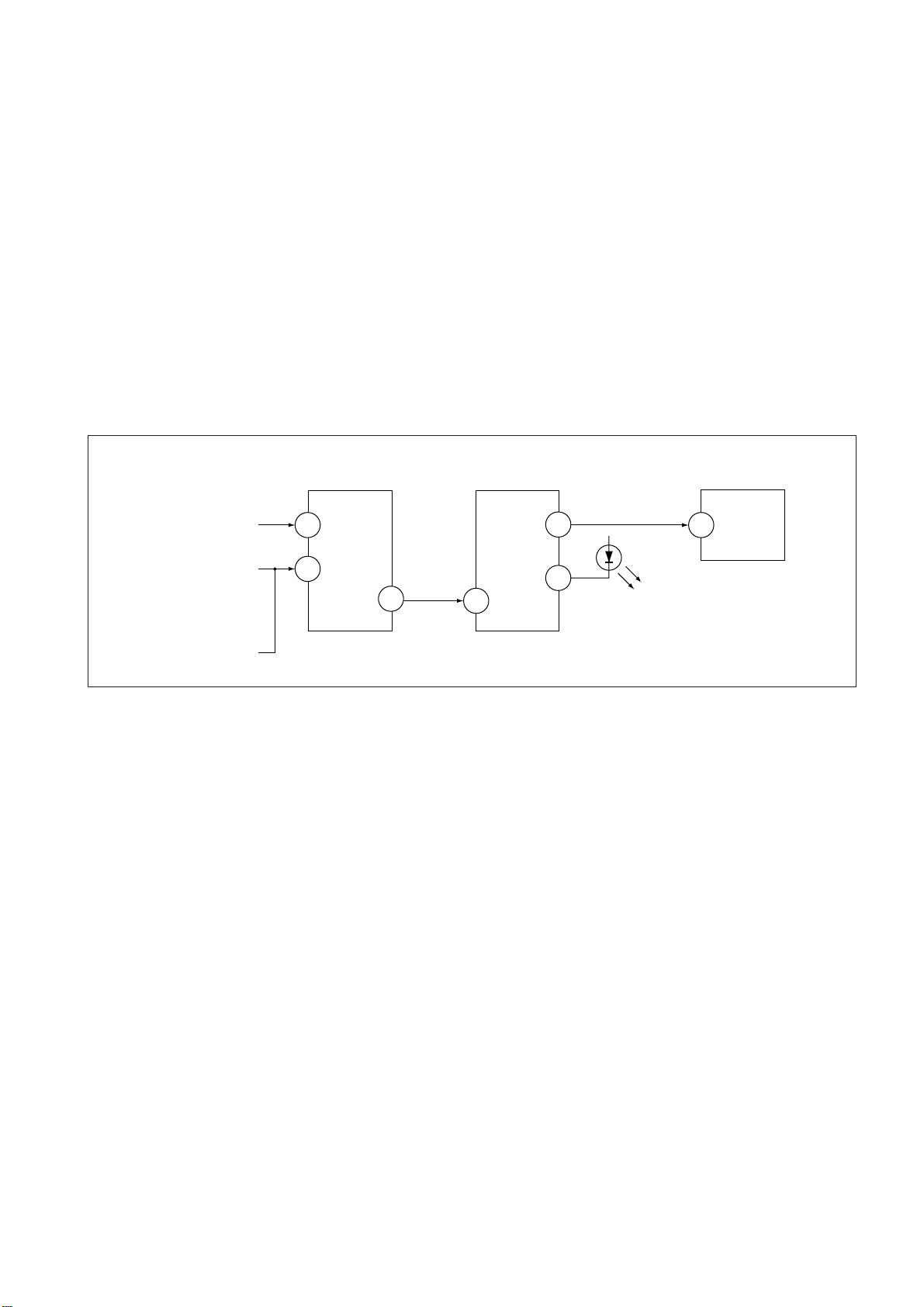

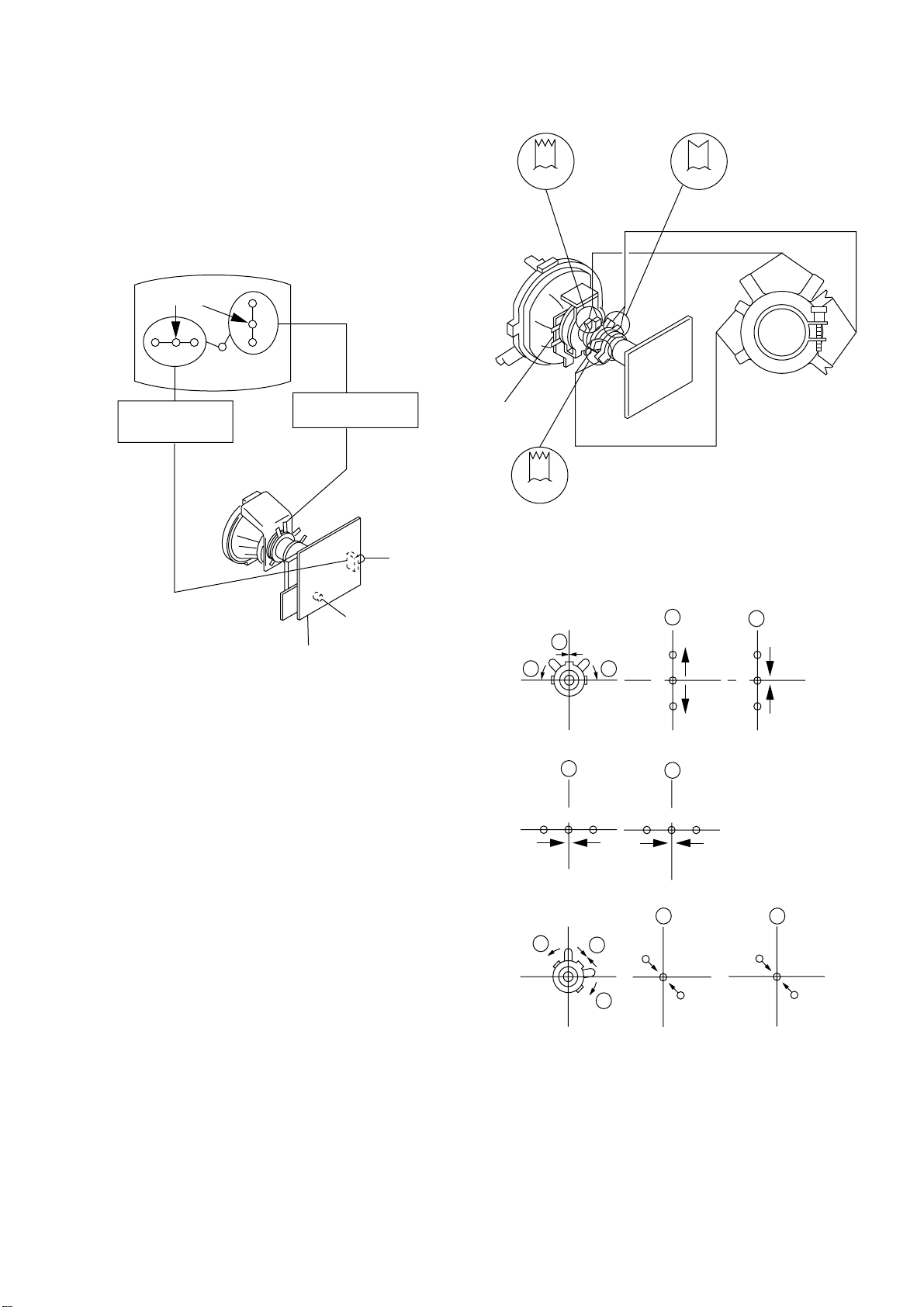

6. SELF-DIANOSTIC CIRCUIT

FROM

CRT

FROM

[+B] Q604 C6

[V] Q509/507

IC301

Y/CHROMA JUNGLE

IK-IN

MP/

18

PROTECT

35

SDA

IC001

SYSTEM

IO-8DAT B-DAT

O-LED

46

IO-SDAT

45

51

IC003

MEMORY

521

[+BovercurrentªOCPº] Occurs when an overcurrent on the +B(135) line is detected by Q604. If Q604 go to ON

and the voltage to pin 18 of IC301 should go down when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

[Verticaldeflectionstopped] Occurs when an absence of the vertical deflection pulse is detected by Q509 and IC001

shut down the power supply.

[Verticaldeflectionovercurrent] Occurs when an overcurrent on V drive line is detected by Q507. Power supply will be

shut down when detect this by IC001.

[Whitebalancefailure] If the RGB levels* do not balance or become low level within 5 seconds, this error will be

detected by IC301. TV will stay on, but there will be no picture.

* (Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

– 7 –

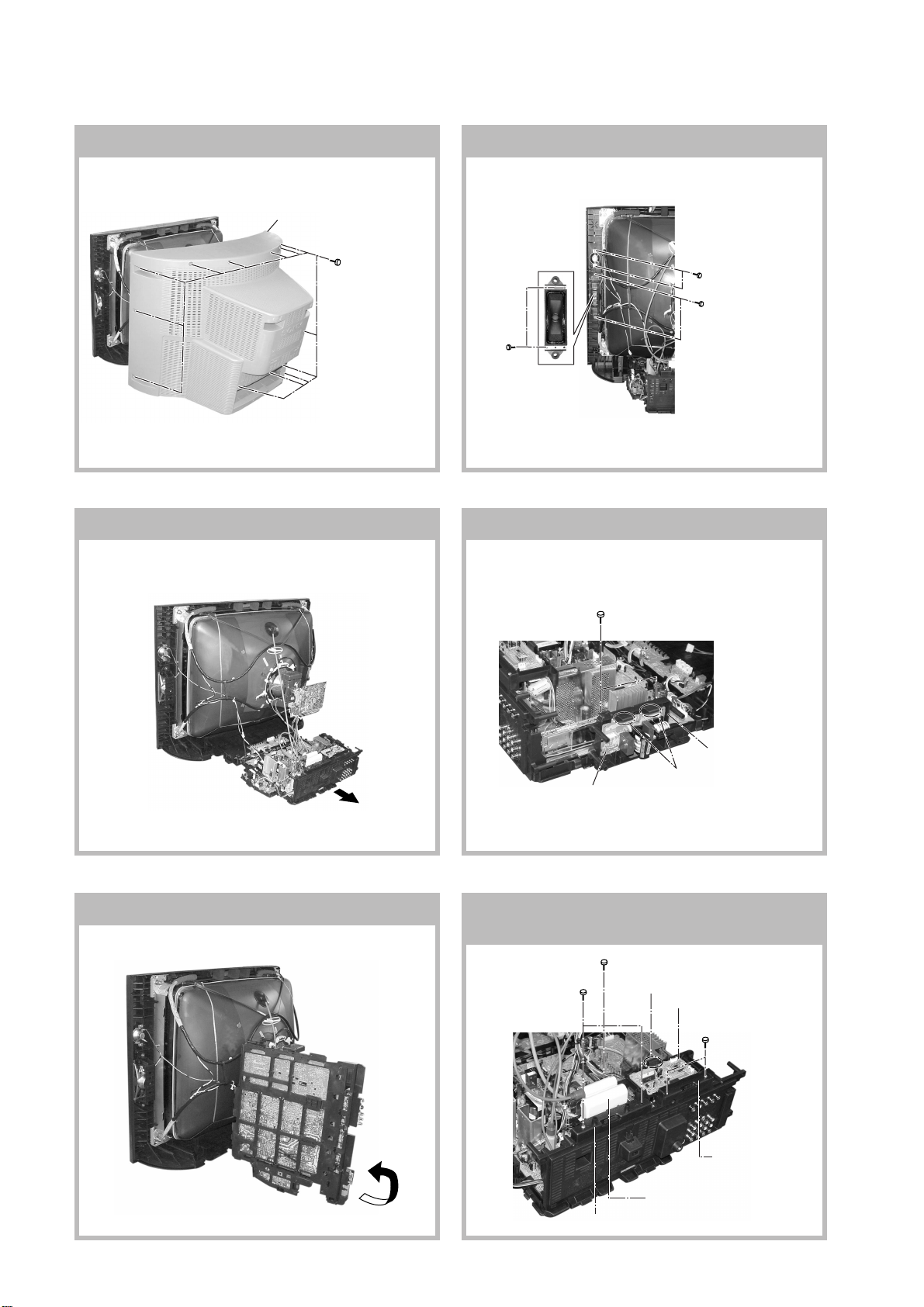

KV-AR34M81/AR34N90

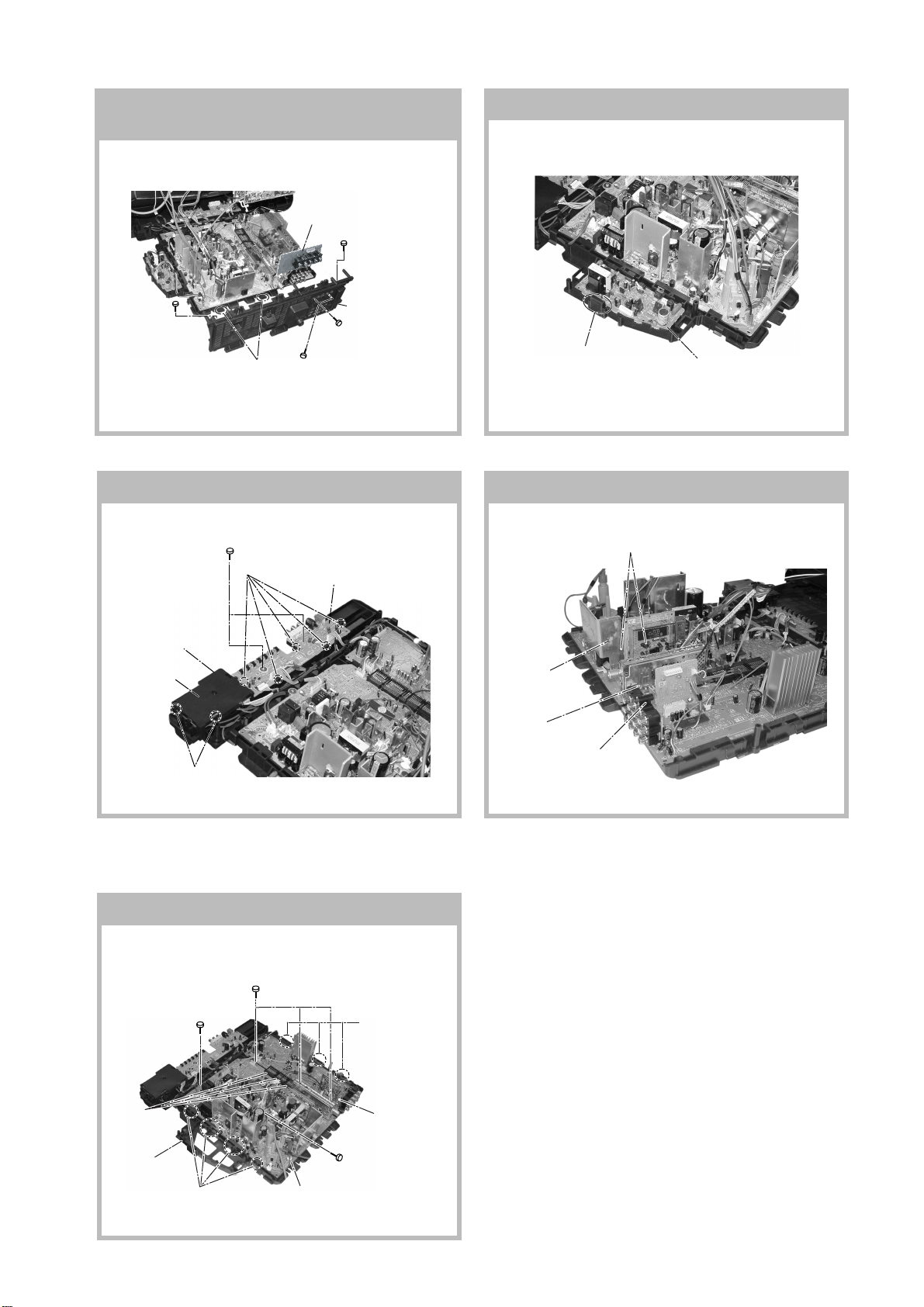

3 Two screws

(+BVTP 4 × 16)

1 Two screws

(+BVTP 4 × 16)

2 Two screws

(Washer Head) (+P4x16)

RM-995 RM-996

SECTION 1

DISASSEMBLY

1-1. REAR COVER REMOVAL

2 Rear cover

1 Thirteen screws

(+BVTP 4 × 16)

1-2. SPEAKER REMOVAL

1-3. CHASSIS ASSY REMOVAL 1-4. F BOARD REMOVAL

1-5. SERVICE POSITION

1 Two screws (+BVTP 3x12)

2 F Board bracket

4 F Board

3 Two hooks

1-6. HV CAP BLOCK, PWB HOLDER AND

DH BOARD REMOVAL

6 One screw

5 Two screws

(+BVTP 3x12)

(+BVTP 4x16)

4 One Hook

3 DH Board

(KV-AR34N90)

1Two screws

(+BVTP 3x12)

2 PWB holder

7 HV Cap block

8 Bracket HVC

– 8 –

KV-AR34M81/AR34N90

RM-995 RM-996

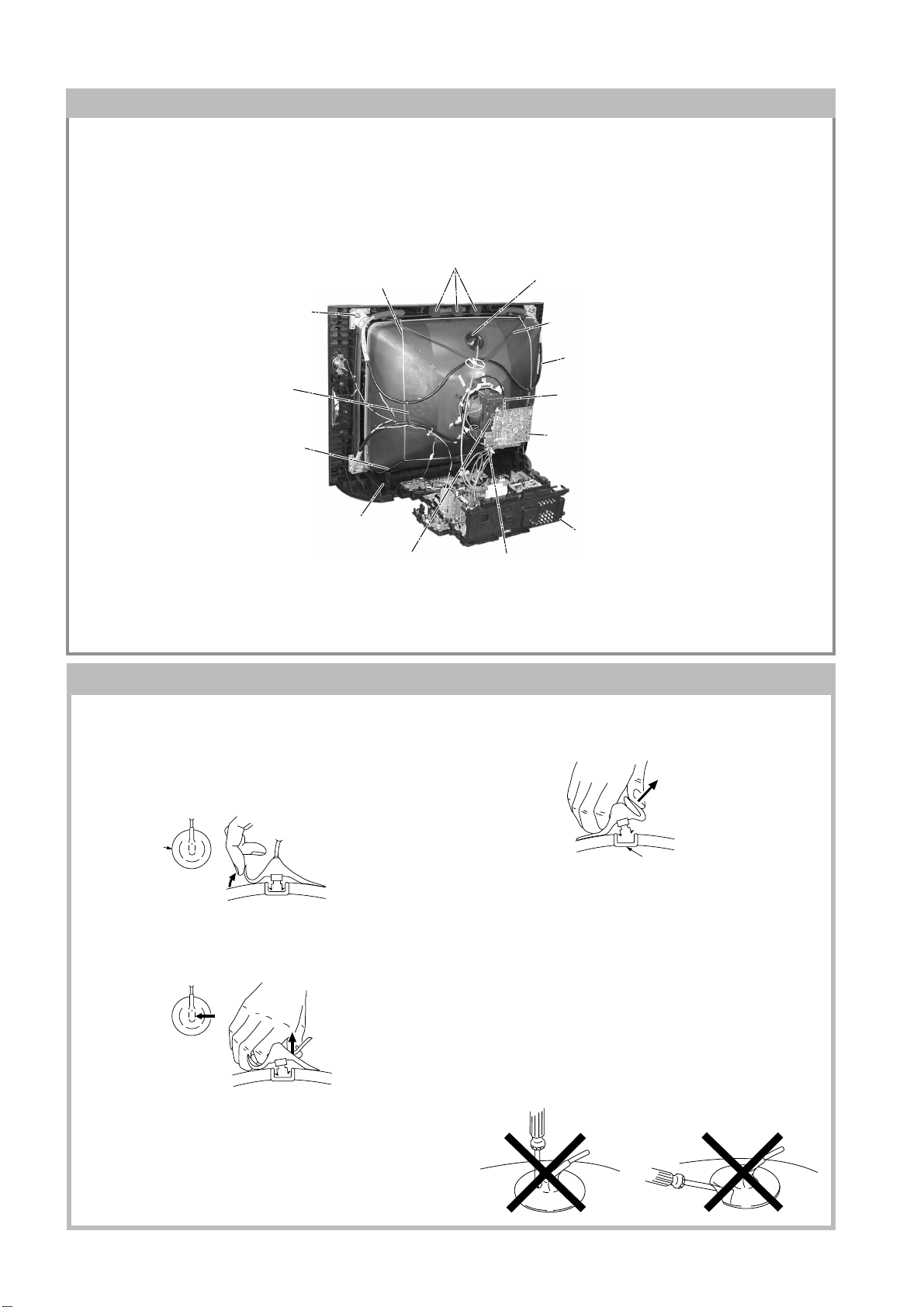

1-7. TERMINAL BRACKET AND J BOARD

REMOVAL

5 J Board

1 One screw

(+BVTP 3 × 12)

2 One screw

(+BVTP 3 × 12)

6 Two Hooks

3 One screw

(+BVTP 4 × 16)

7 Terminal bracket

4 Two screws

(+BVTP 3 × 12)

1-9. H1 AND H2 BOARDS REMOVAL

1 Two screws (Washer head)

(+BVTP 3 x12)

2 Five hooks

3 H1 Board

1-8. D2 BOARD REMOVAL

1 One Hooks

2 D2 Board

1-10. B1 AND V1 BOARDS REMOVAL

4 Two connectors

6 H2 Board

5 Cover, H

4 Two Hooks

1-11. A AND B10 BOARDS REMOVAL

2 Three screws (Washer head)

1 One screw

(Washer head)

(3 × 12)(+)(BVTP)

(3 × 12)(+) BVTP

7 Three hooks

2 V1 Board

(KV-AR34M81)

1 B1 Board

3 One connector

8 Three

connectors

9 D2 Board

6 Four hooks

4 A Board

5 B10 Board

3 One screw

(Washer head)

(3 × 12)(+)(BVTAP)

– 9 –

KV-AR34M81/AR34N90

c

RM-995 RM-996

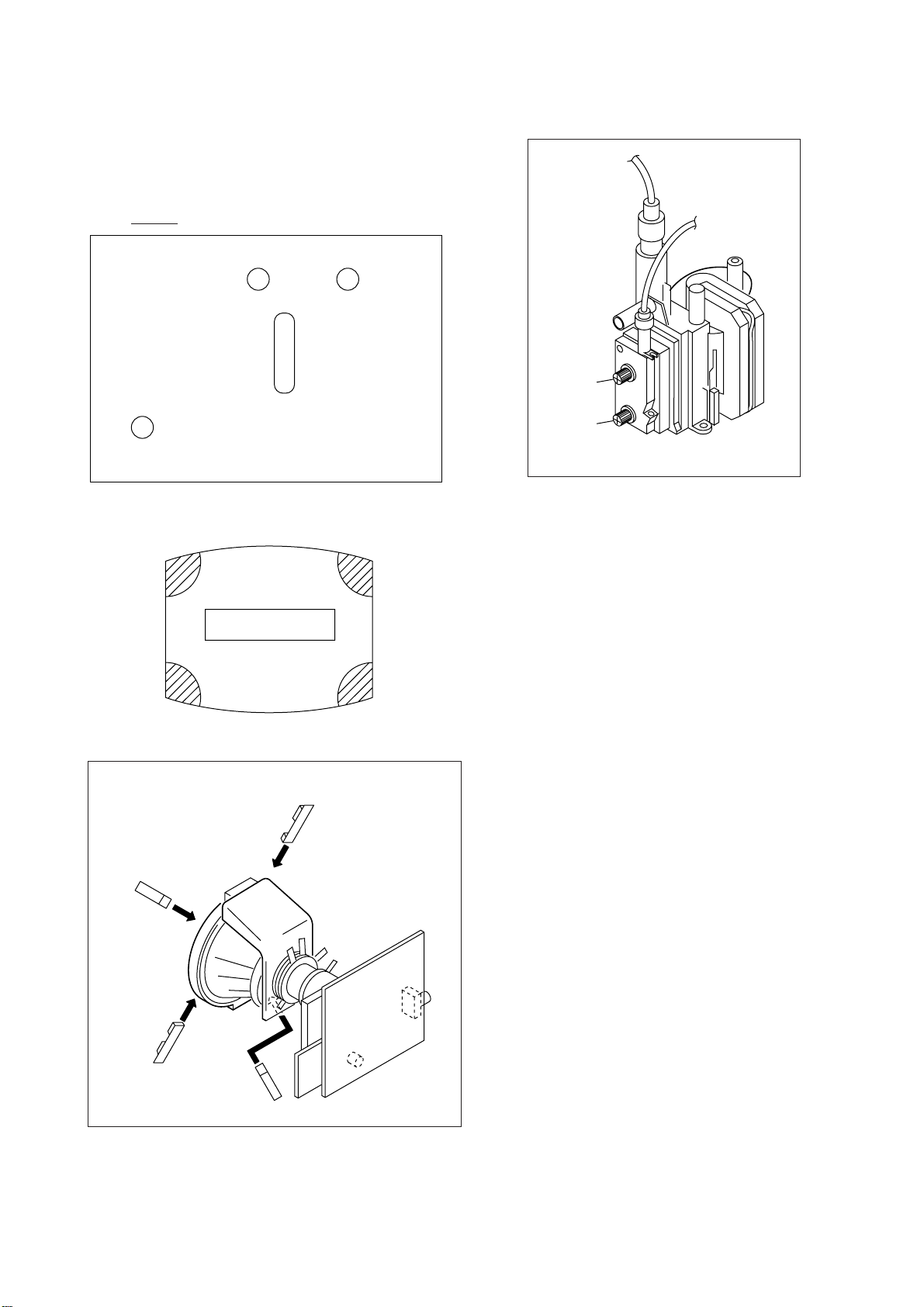

1-12. PICTURE TUBE REMOVAL

Note:

• Please make sure the TV set is not in standing position before removing necessary CRT support located on bottom

right and left.

1) Place the TV set with the CRT face down on a cushion jig.

2) Removal the rear cover.

3) Unplug all interconnecting leads from the Deflection yoke, Neck assy, Degaussing Coil and CRT grounding strap.

qs Earth Coating Assy

!∞ Block Center

4 Anode Cap Removal

!¶ Nut, Special, CRT (4)

!¢ Holder, DGC(2) Removal

qa Spring Tension(2) Removal

0 Support, CRT(2) Removal

8 Loosen the Deflection Yoke

fixing screw and remove

7 VM1 Board Removal

!£ Band, DGC Removal

!§ Degaussing Coil

6 Loosen the Neck Assembly

fixing screw and removal

5 C6 Board Removal

9 Chassis Assy Removal

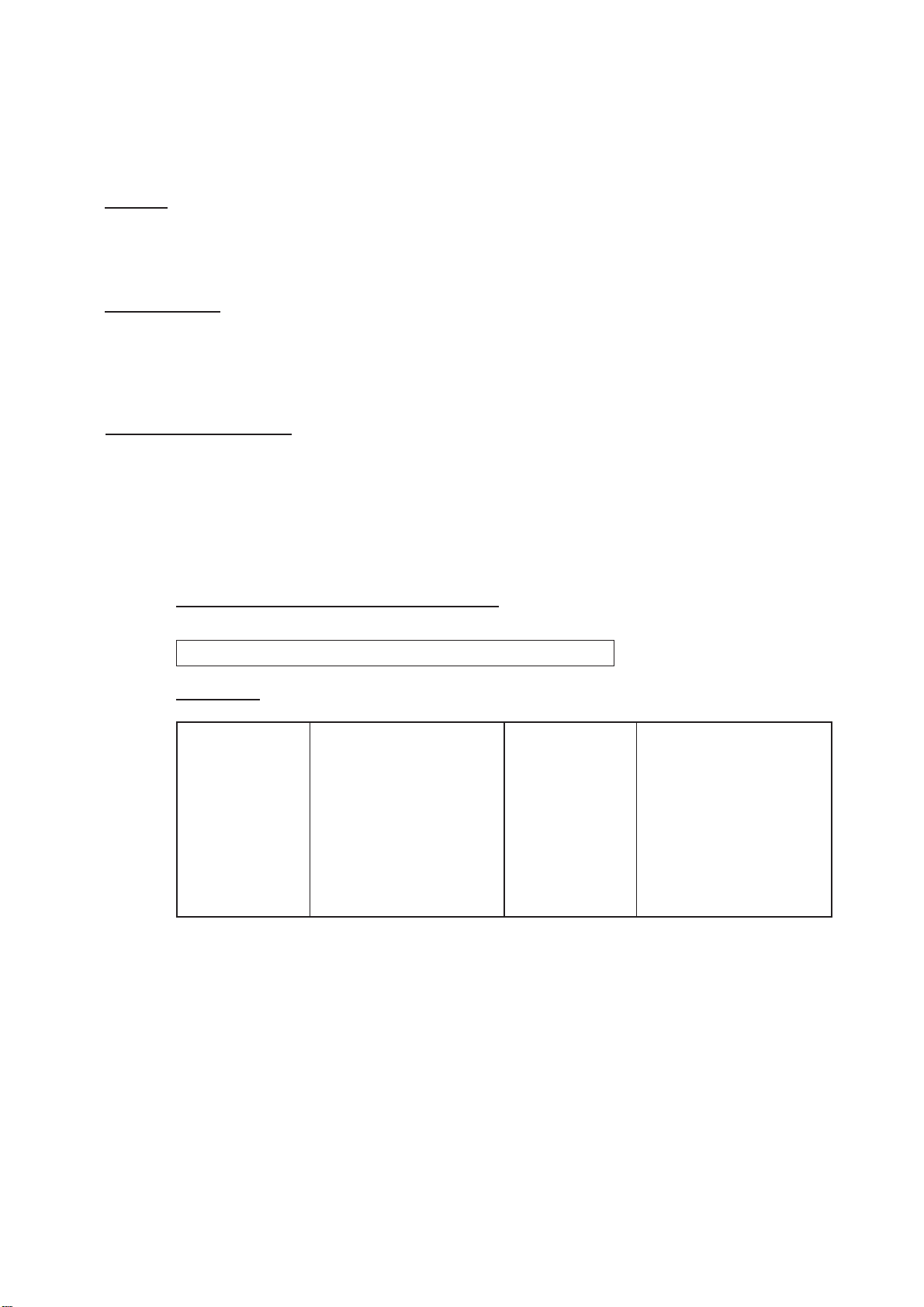

• REMOVAL OF ANODE-CAP

Note:

• After removing the anode, short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT

shield or carbon paint on the CRT.

• REMOVING PROCEDURES

a

a

1 Turn up one side of the rubber cap in the direction

indicated by the arrow a.

b

b

2 Using a thumb pull up the rubber cap firmly in the direc-

tion indicated by the arrow b.

anode button

3 When one side of the rubber cap is separated from the

anode button, the anode-cap can be removed by

turning up the rubber cap and pulling it up in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with

sharp shaped objects.

2 Do not press the rubber too hard so as not to

damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is

built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage

the rubber.

– 10 –

KV-AR34M81/AR34N90

RM-995 RM-996

SECTION 2

ADVANCE OPERATION

2-1. "RESET" FUNCTION

1. Purpose

If a customer faces some setting problem that cannot be solved, using the "RESET" function some items will

be reset to its original setting (shipment condition)

2. How to Operate

The way to access to the "RESET" Function:-

a) By pressing "MENU" button or "SELECT" button (for non-menu models) on the Front Key Input and

hold it down for 5 seconds.

3. Subsequent of Operation

Sequential to the resetting operation (either methods being used in No. 2), TV set would shut down once and

automatically turn on again. The power-off duration is expected to be about 500msec. An OSD message,

"RESET" tentatively will be displayed for 10 sec after IK status gets stable.

As a result, some items will be reset to an initial condition (shipment condition) wheareas some other remains

at the last selection by user.

Items that remains at the last selection by user

Channel No., PIC rotation, OSD Language, Skip

Reset Items

Video input RF

Volume 30

Picture mode DYNAMIC

DTE ON (Not used for this models)

Sound mode DYNAMIC

Surround mode OFF

Favourite CH mode AUTO (Not used for this models)

Multi Picture (PIP) OFF (Not used for this models)

PIP position Bottom Right

(Not used for this models)

OSD recall (Not used for this model)

Antenna sensitivity OFF (Not used for this models)

*= only when in RF mode

Antenna sensitivity OFF (Not used for this models)

Antenna sensitivity HIGH* (Not used for this models)

Stereo mode STEREO

Bilingual mode MAIN* (Not used for this models)

High-deviation mode AUTO (Not used for this models)

Child lock OFF*

Wide mode OFF

Game mode OFF (Not used for this models)

Sleep timer OFF

Wake-up timer OFF

Sound muting OFF

– 11 –

KV-AR34M81/AR34N90

RM-995 RM-996

SECTION 3

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Controls and switches should be set as follows unless otherwise noted:

PICTURE control ........................................................... normal

BRIGHTNESS control ................................................... normal

Note : Test Equipment Required.

1. Pattern Generator

2. Degausser

3. Oscilloscope

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

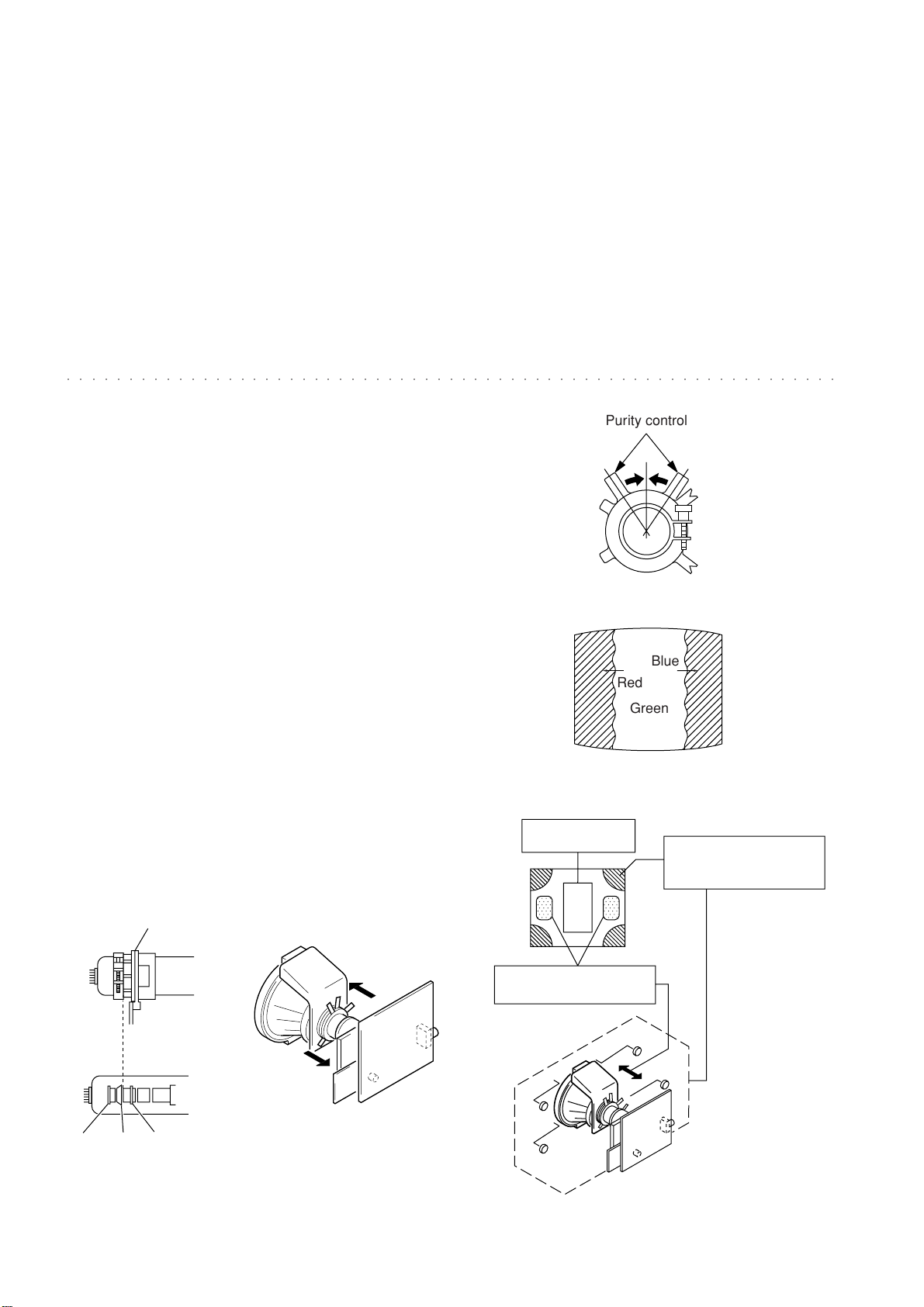

Preparation :

• In order to reduce the influence of geomagnetism on the set's

Purity control

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

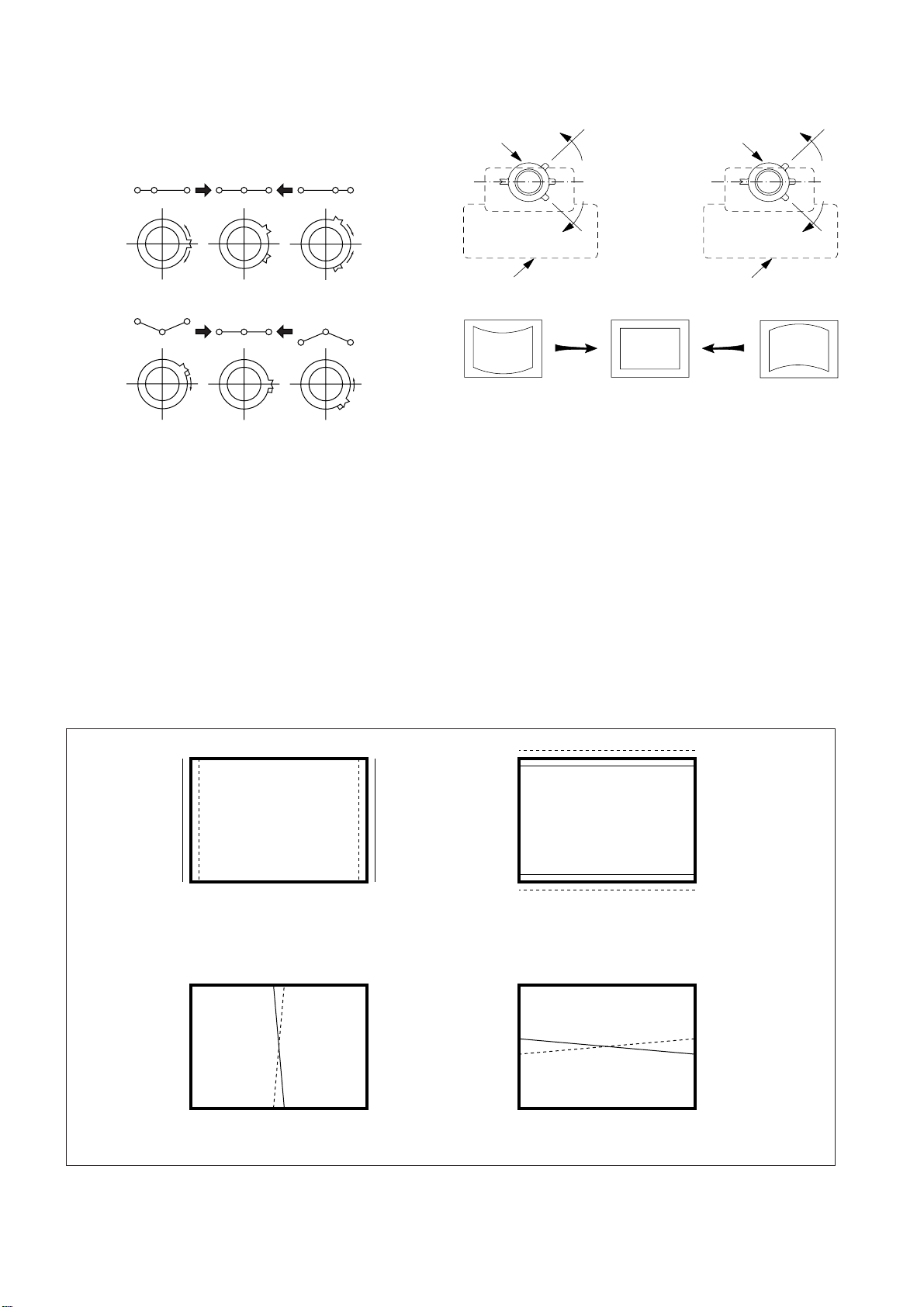

3-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig3-2.

}

normal

Fig. 3-3

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the

purity control so that the green is at the center and the blue

and the red take up equally sized areas on each side.

(See Figures 3-1 through 3-4.)

5. Move the deflection yoke forward and adjust so that the

Blue

Red

Green

entire screen is green. (See Figure 3-2.)

6. Switch the raster signal to blue, then to red and verify the

condition.

7. When the position of the deflection yoke has been decided,

Fig. 3-4

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 3-5.)

Purity control

corrects this area.

b

a

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Neck Assy

Behind the G3 edge

G2G1 G3

Fig. 3-1

Fig. 3-2

– 12 –

c

Deflection yoke positioning

corrects these areas.

a

d

d

Fig. 3-5

b

c

3-2. CONVERGENCE

Purity

BMC

BMC (Hexapole)

Purity

DY pocket

V.STAT

V.STAT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Receive dot/hatch signal.

• Pic mode: Personal (Pic 90%, Brightness 50%, Colour 50 %,

Hue 50%, Sharpness 50%).

(1) Horizontal and Vertical Static Convergence

KV-AR34M81/AR34N90

RM-995 RM-996

Center dot

R

GB

H. STAT VR

R

G

B

V. STST

Magnet

RV702

H. STAT

RV701

SCREEN (G2)

C6 Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center of

the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the red,

green and blue dots are on top of each other at the center of the

screen.

3. If the H.STAT variable resistor cannot bring the red, green and

blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform adjustments

while tracking.)

1 V. STAT

a

b b

2 H. STAT VR

a

RGGBB

3

a

B

G

R

b

R

a

b

B

G

R

b

– 13 –

b

a

R

b

G

B

B

G

R

KV-AR34M81/AR34N90

RM-995 RM-996

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned, then

use the BMC magnet to adjust in the manner described below.

Neck assy Neck assy

Blue

Red

GB

R

R

G

RGB R GB

B

GBRG

R

B

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to [MIN]

and [BRIGHTNESS] to [STANDARD] .

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

Red Blue

VM1 board VM1 board

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far. (Less than

8 mm)

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

RB

TLH TLV

RB

B

R

R

B

YCH XCV

– 14 –

KV-AR34M81/AR34N90

RM-995 RM-996

TLV Rotate TLV-2 VOL (29”, 34”) on DY

XCV Rotate XCV Adj core on DY

YCH Rotate YCH VOL on DY

TLH Insert TLH Correction Plate to DY Pocket

(Left or Right)

ON DY:

YCH

TLV1

XCV

TLV2

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

cd

3-3. FOCUS ADJUSTMENT

FOCUS adjustment should be completed before W/B adjustment.

Focus

Screen

FLYBACK TRANSFORMER (T503)

1. Receive digital monoscope pattern.

2. Set "Picture Mode" to "Standard".

3. Set S2801 to mechanical center position.

4. Adjust focus VR so that the center of the screen becomes just

focus.

5. Adjust S2801 when corner focus is unbalance is right and left.

6. Change the receiving signal to white pattern blue back.

7. Confirm Magenta ring is not noticable. Incase magneta ring is

obvious, reset S2801 to mechanical center position and then

adjust FOCUS VR to balance between MAGENTA RING and

FOCUS.

Fix a Permalloy assy corresponding to the misconverged

areas.

a

d

Permalloy assembly

b

c

– 15 –

KV-AR34M81/AR34N90

RM-995 RM-996

3-4. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C6 board cathode to the

oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the

value below.

5) Adjust G2 (screen) on the FBT until picture shows the point

before cut off.

Cathode setting voltage:

175 V ± 2 (VDC)

0 V

2. WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 4-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set the PICTURE to minimum.

4) Select WHB 04 "GCT" and WHB 05 "BCT" with [1] and [4],

and adjust the level with [3] and [6] for the best white

balance.

5) Set the PICTURE to maximum.

6) Select WHB 01 "GDR" and WHB 02 "BDR" with [1] and [4],

and adjust the level with [3] and [6] for the best white

balance.

7) Write into the memory by pressing [MUTING] then [0].

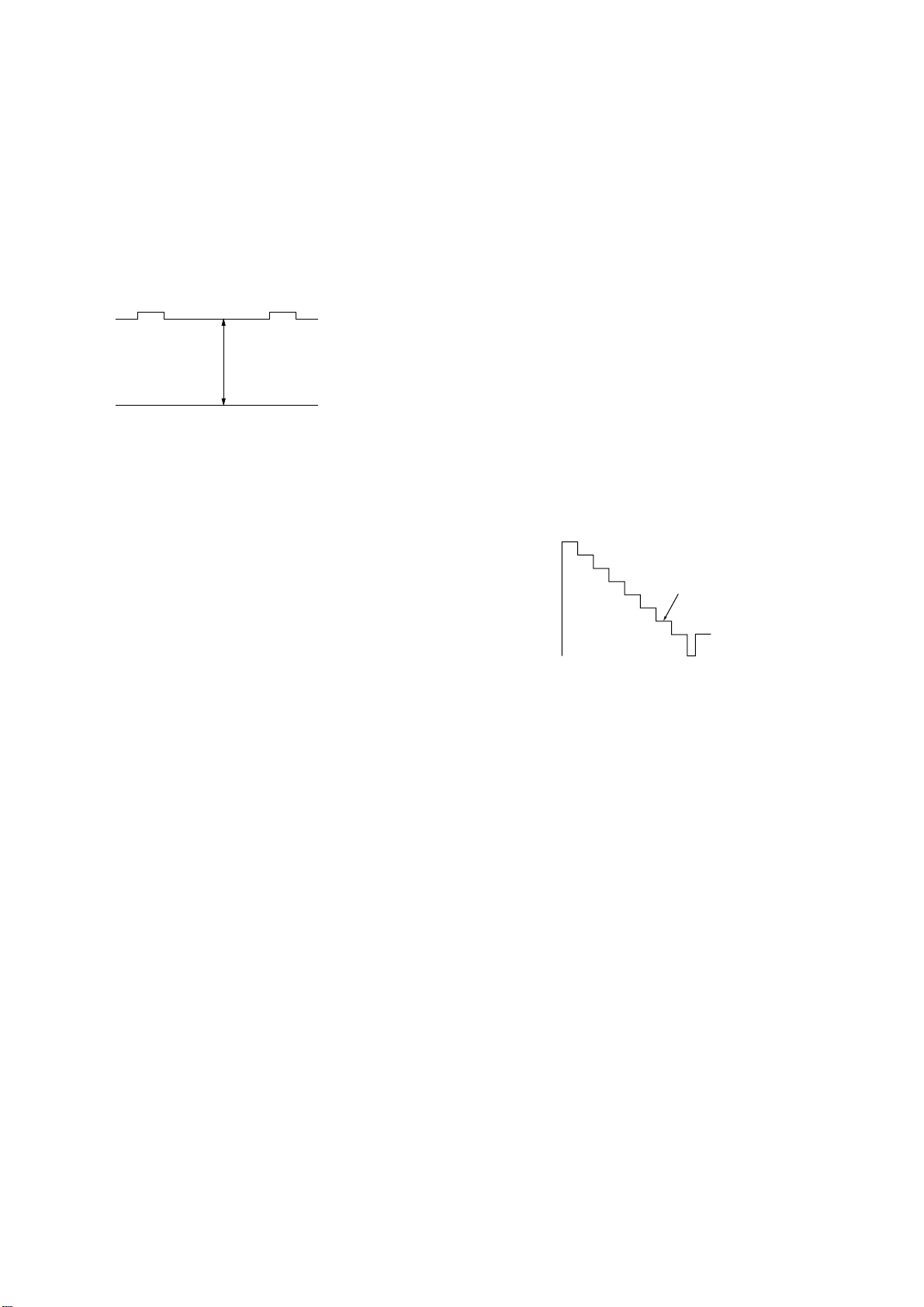

3. SUB BRIGHT ADJUSTMENT

1) Set to service mode.

2) Input a staircase signal of black to white from the pattern

generator.

3) BRIGHTNESS ....50%.

PICTURE ............MINIMUM

4) Select WHB 07 "SBR" with [1] and [4], and adjust WHB 07

"SBR" level with [3] and [6] so that the second stripe from the

right is dimly lit.

White

second from the right

Black

– 16 –

SECTION 4

CIRCUIT ADJUSTMENTS

KV-AR34M81/AR34N90

RM-995 RM-996

4-1. ADJUSTMENTS WITH COMMANDER

Service adjustments to this model can be performed using the

supplied Remote Commander RM-995 and RM-996.

a. ENTERING SERVICE MODE

With the unit on standby

n

[DISPLAY] n 5 n VOL (+) n [POWER]

This operation sequence puts the unit into service mode.

The screen display is :

Device

Name

GEO

605S

(KV-AR34M81)

604S

(KV-AR34N90)

Suffix No

(OEM Code)

Software version Total Power-On time (hours)

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press [POWER] button on the commander),

then press [POWER] button again, hereupon it becomes TV mode.

Item

Name

Item No

00

HPS 1C

1.1M

59 7F 000A

0.2N

Marking of new NVM

Data Mode

p

SERVICE

0

50

PAL,SECAM:50

NTSC :60

4-2. ADJUSTMENT METHOD

Item Number 00 of device GEO

This explanation uses H-Position as an example.

1. Select “GEO 00 HPS” with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is 1F for PAL

reception.)

4. Write with the [MUTING] button. (The display changes to

WRITE.)

5. Execute the writing with the - button. (The WRITE

display will be changed to red color while excuting, and

back to SERVICE.)

Example on screen display :-

GEO 00

605S

(KV-AR34M81)

604S

(KV-AR34N90)

GEO 00

605S

(KV-AR34M81)

604S

(KV-AR34N90)

1.1M

0.2N

1.1M

0.2N

Write with [MUTING]

1F SERVICE 50HPS

7F 0 000A59

1F 50HPS

WRITE

7F 0 000A59

GREEN

Adjusted with 3

and 6 buttons.

GREEN

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press [1] (UP) and [4] (DOWN), to select the adjustment.

4) Press [MUTING] button to indicate WRITE on the screen.

5) Press [0] button to write into memory.

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

plug into AC outlet again.

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were made.

1, 4 Select the adjustment item.

↓

3, 6 Raise/lower the data value.

↓

[MUTING] Writes.

↓

- Executes the writing.

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

5, - Service data initialization (Be sure not to use

usually.)

[MUTING], - Write 50Hz adjustment data to 60Hz, or vice

versa.

2, - Copy and write all data.

WRITE

605S

(KV-AR34M81)

604S

(KV-AR34N90)

Write executed with -

1F 50HPSGEO 00

7F 0 000A591.1M

0.2N

RED

The WRITE display

then the display

returns to green

SERVICE.

Use the same method for all Items. Use 1 and 4 to select the

adjustment item, use 3 and 6 to adjust, write with [MUTING],

then execute the write with -.

Note : 1. In [WRITE], the data for all items are written into

memory together.

2. For adjustment items that have different standard data

between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

– 17 –

KV-AR34M81/AR34N90

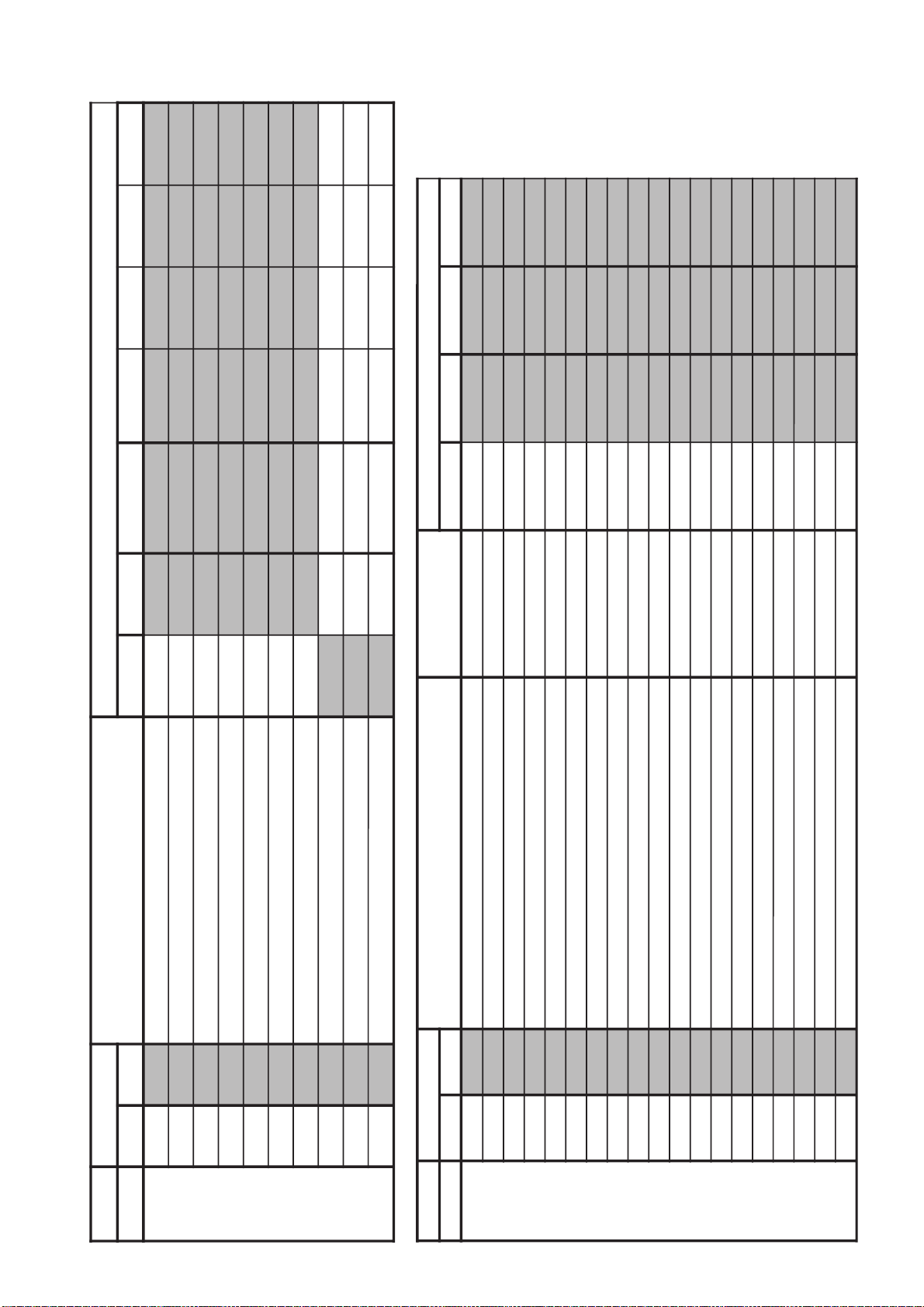

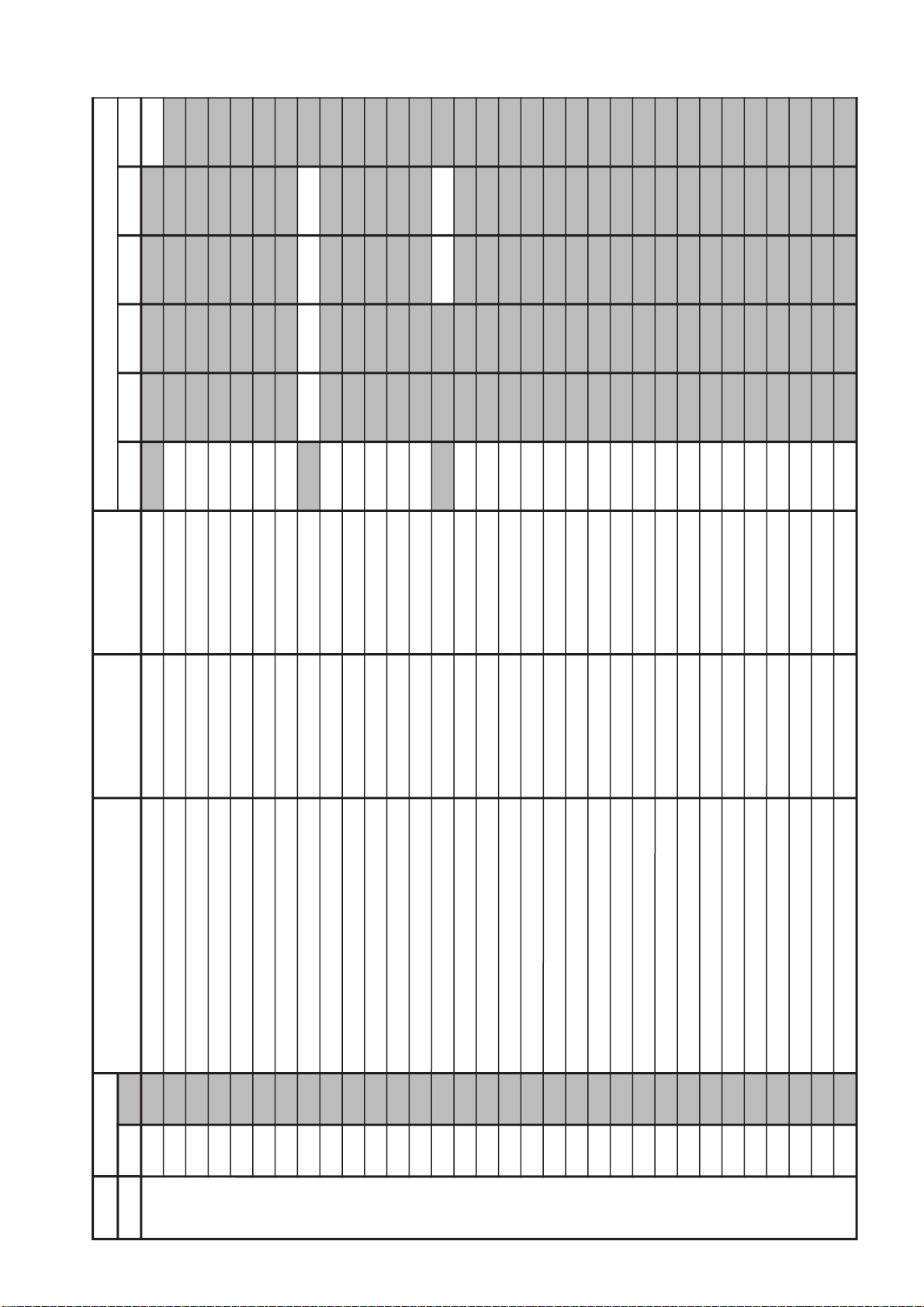

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCCN05CN06CV05CV06

OEG00SPHnoitisoPH )06/05(ediW/)06/05(lamroNS9512AXC

21A021A018M43RA-VK

00SPHnoitisoPH )06/05(ediW/)06/05(lamroN

E1E1E1E109N43RA-VK

10ZSHeziSH )06/05(ediW/)06/05(lamroN

52525252

20PAPpmAniP )06/05(ediW/)06/05(lamroN

F1F1F1F1

30TLTmuizeparT )06/05(ediW/)06/05(lamroN

70707070

40SPVnoitisoPV )06/05(ediW/)06/05(lamroN

F1F1F1F1

50ZSVeziSV )06/05(ediW/)06/05(lamroN

F0F07070

60OCSnoitcerroCS )06/05(ediW/)06/05(lamroN

70707070

70NLVytiraeniLV )06/05(ediW/)06/05(lamroN

70707070

80WOBwoBCFA )06/05(ediW/)06/05(lamroN

70707070

90LGAelgnACFA )06/05(ediW/)06/05(lamroN

70707070

A0NPUniPreppU )06/05(ediW/)06/05(lamroN

F1F1F1F1

B0NPLniPrewoL )06/05(ediW/)06/05(lamroN

F1F1F1F1

C0

LBHffo/nogniknalBH 10

D0

LBLgniknalBHtfeL )06/05(ediW/)06/05(lamroN

A0F0A0F0

E0

LBRgniknalBHthgiR )06/05(ediW/)06/05(lamroN

20202020

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCMACESsrehtOcimanyDsrehtO

BHW00

RDRevirDR srehto/CIMANYDS9512AXC

52A2

10RDGevirDG srehto/CIMANYD

5252

20RDBevirDB srehto/CIMANYD

5252

30

TCRffotuCR srehto/MACES

7070

40TCGffotuCG srehto/MACES

7070

50TCBffotuCB srehto/MACES

7070

60

NMBataDmuminiMssenthgirB 51

70RBSlortnoCssenthgirBbuS 52

80

BPA3#erutciPtnegilletnIrofhctiwSlortnoCthgirBbuS 30

RM-995 RM-996

Adjustment Item Table (Except KV-AR34M60)

– 18 –

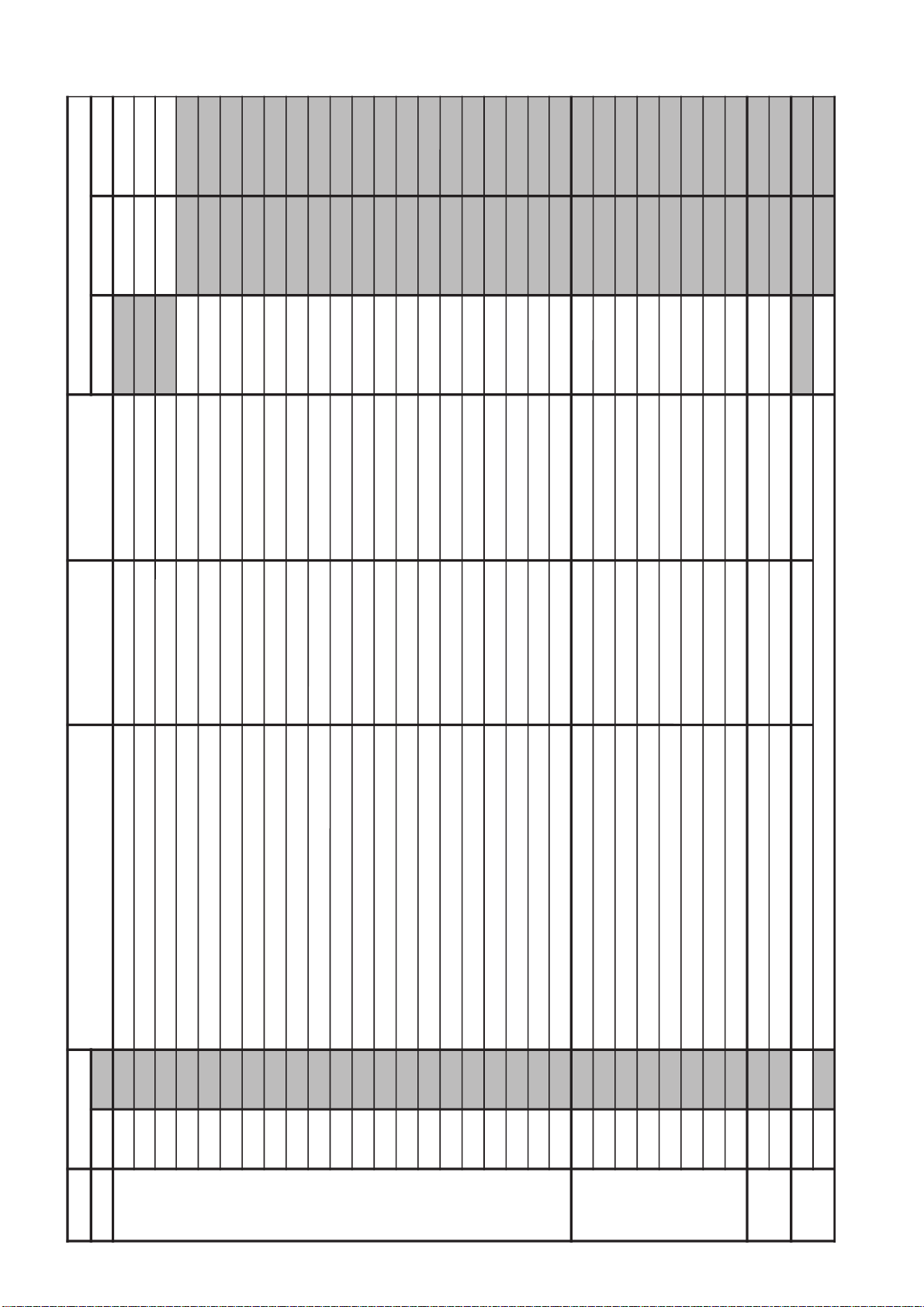

KV-AR34M81/AR34N90

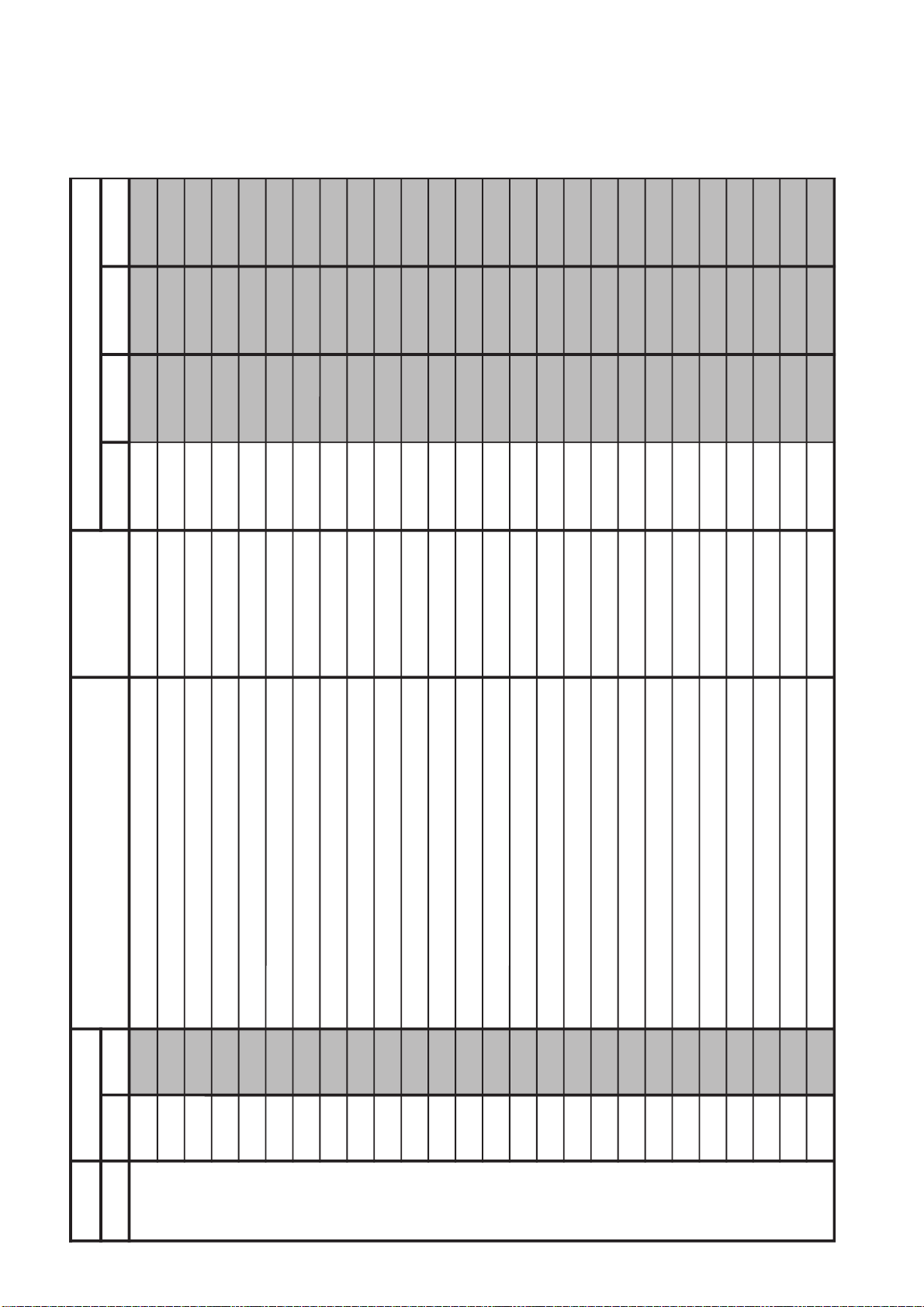

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN CNCVCNCSTNCNSREHTOCVCSTNCVSREHTOVToediV

JAS00 XMPataDmumixaMerutciP ediW/ediW-nonS9512AXC6313

10UHSlortnoCeuHbuS oediV/VT

7070

20

HSSlortnoCssenprahSbuS ediW/VT

4090

30LCSlortnoCroloCbuS )srehto/CSTN(EDIW/)srehto/CSTN(

321202E1

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCCN05CN06CV05CV06DTS-NONCSTNDTS-NONSREHTODTSCSTNDTSSREHTO

PV00

THEmpoCTHE )06/05(ediW/)06/05(lamroNS9512AXC

50505050

10AMG)edomDRADNATSnidetatapes(noitcerroCammaG )srehto/CSTN(.DTS/)srehto/CSTN(.DTS-NON

30

30

20

20

20GPA3#erutciPtnegilletnIrofhctiwSlortnoCammaG )srehto/CSTN(.DTS/)srehto/CSTN(.DTS-NON

00

00

00

00

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCMACESCSTNLAPDVDTXET

PV30

LDYyaleDY DVD/CSTN/MACES/LAP

90806080

40

TSSnoitisoPtratSDIMACES CSTN&LAP-DECROF/OTUTA&MACES

10

10

50

PSSnoitisoPpotSDIMACES CSTN&LAP-DECROF/OTUTA&MACES

10

10

60

MLRtimiLBGR 00

70

VLSleveLDIMACES CSTN&LAP-DECROF/OTUTA&MACES

20

20

80

FBSOfLLEBMACES CSTN&LAP-DECROF/OTUTA&MACES

22

22

RM-995 RM-996

– 19 –

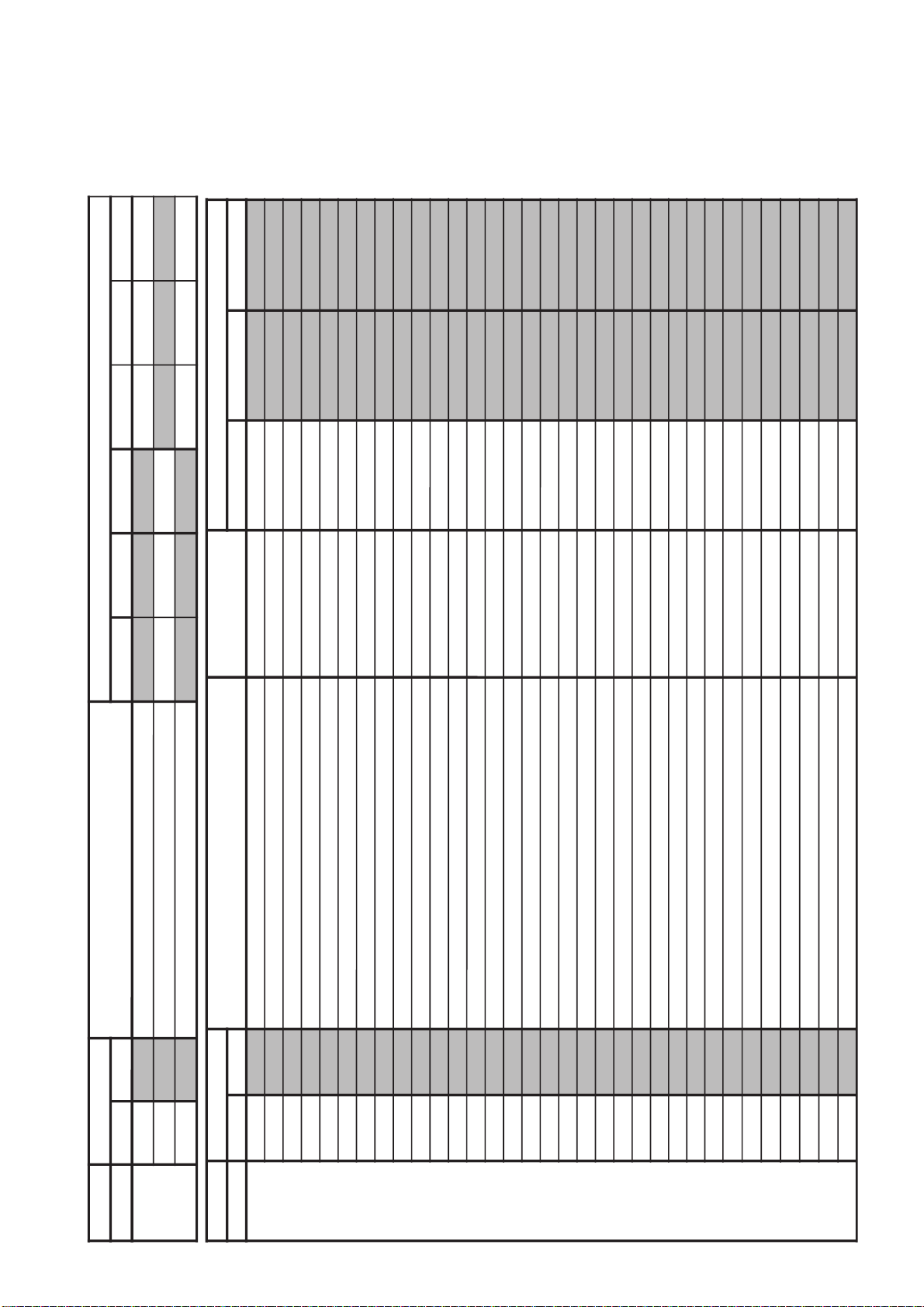

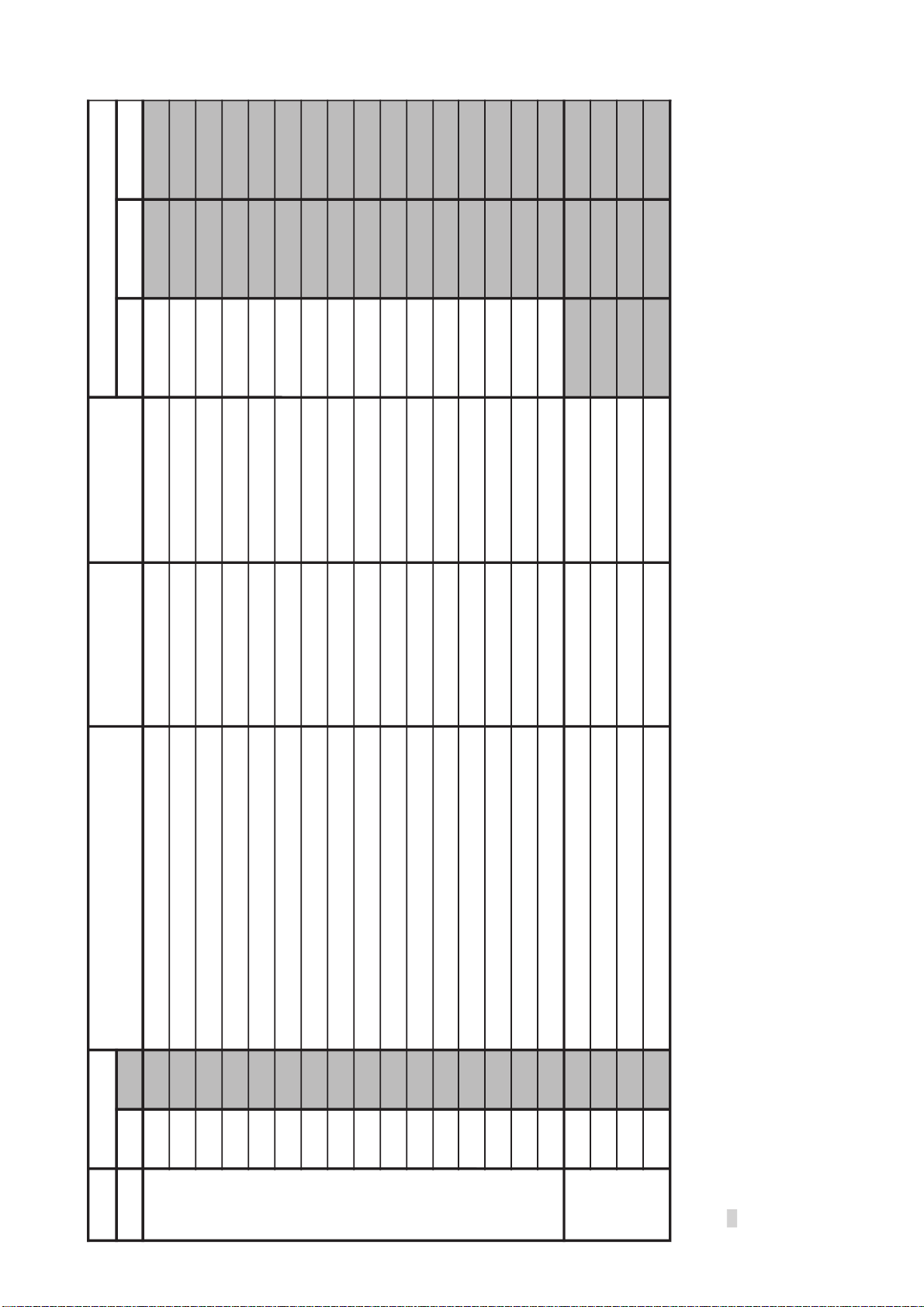

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCCSTNsrehtOVToediVTXET

PV90

CYDffo/noroloCcimanyD 10

A0

LBA)edomDRADNATStpecxe(gnihctiwSedoMLBA DRADNATStpecxe10

B0

HTVgnihctiwShtVnoitceteDLBA 10

C0

0FSssenprahSrofgnihctiwSOF srehto/CSTN

1010

D0

XCDgnihctiwSoitaR.snarTCD 10

E0

THShctiwSoitartoohsrevO/-erP srehto/CSTN

1010

F0

WDHhctiwShtdiWesluPevirDH 00

01

CFAlortnoCniaGCFA txeT/oediV/VT

100010

11SOHnoitallicsOH 70

21

SSH.peScnySHfoleveLecilS 00

31

SSV.peScnySVfoleveLecilS 00

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCCN05CN06CV05CV06CNCSTNCNSREHTOCVCSTNCVSREHTO

PV41

SMHno/ffom/CnoisiVorcaM S9512AXC

10101010

51

VUYLESY 00

61

VDClangisonrednuFRdnaoediVrofedomDC 10

71

NORNOR 10

81

NOGNOG 10

91

NOBNOB 10

A1

NOPNOP 10

B1

NXAWSSIXA

10101010

C1

LSRLESBGR 00

D1

WBVWKLBV 00

E1

PFRPFER 00

F1

CMVleveLMV 00

02

FBCretliFssapdnaBamorhC 10

12

OTCffOparTamorhC 10

RM-995 RM-996

– 20 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuF

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaNnommoCcimanyDamarD/dradnatStfoS/eniF-iHwsbanyDwsbamarDwsbtfoS

2PA00

SBBgnitteSleveLtsooBssaB30

10

BCBlortnoCssaBbuSroftcelestuctsooB00

20

SBSgnitteSleveLssaBbuS00

30

TCBlortnoCelberTbuSroftcelestuctsooB00

40

STSgnitteSleveLelberTbuS00

50

LGAgnitteSleveLCGA00

60

WSBhctiwSFFO/NOtsooBssaB00

70

SABlortnoCedomdnuosssaB

113030113030

80

ERTlortnoCedomdnuoselberT

414120414120

90

EBBlortnoCedomdnuoSEBB

98C60098C600

GVTytilanoitcnuF

noitcnuFemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCMACESCSTNLAP

PSM00

TSWdlohserhToeretSG/W05143PSM51

10

TBWdlohserhTlaugniliBG/W CE

20

LLWdlohserhTlaruanoMG/W 50

30

CAWtnuoCtnemeergAG/W 10

40

LDWyaleDhcraeSG/W 03

50

LDNyaleDhcraeSMACIN 02

60

LDSyaleDdaeRsutatsoeretS 01

70

CGAtnatsnoC/otuAhctiwSCGA 10

80

LERedoMtnatsnoCtaniaGCGA 82

90

MRCffo/nognitumreirraC 00

A0

OCAffo/notuokcolCoiduA 10

B0

PFmetsysM-nonrofelacserPMF B1

C0

MPFmetsysMrofelacserPMF 23

D0

HFVEDHrofelacserPMF 63

E0

MHFMdnaVEDHrofelacserPMF 56

F0

PGWelacserPG/W C1

01

PINelacserPMACIN F7

11

RREdlohserhThctiwsMFotuA 05

21

RREh0ff7oth0007niagrekaepSduoL D6

RM-995 RM-996

– 21 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoCMACESCSTNLAP

PIP00

ORPelbanEedoMnacSevieergorP05143PSM00

10

DERedoMelbuoDdaeR 00

20

IEFtceleSdleiF 00

30

SPHnoitisoPerutciPlatnoziroH 33

40

SPVnoitisoPerutciPlacitreV B1

50

PFHgninoitisoPeniFlatnoziroH 80

60

PFVgninoitisoPeniFlacitreV 00

70

SIDdradnatsyalpsiD 00

80

SOHmooZlatnoziroH 00

90

SEVnoitcudeResioNeluPcnySlacitreV 00

A0

SPFdradnatStneraPecroF 00

B0

MZHmooZlatnoziroH 00

C0

PSVnoitcudeResioNeluPcnySlacitreV 10

D0

LDVyaleDesluPcnySlacitreV 00

E0

HRFlatnoziroHhtdiWemarF 50

F0

VWFlacitreVhtdiWemarF 20

01

DRVnoitcudeR 00

11

KBVgniknalBlacitreV 00

21

YLDyaleDtceleS 10

31

RCPnoitcerroCnoitisoP 00

41

MGAedoMCGA 30

51

CGAeulaVlortnoCniaGcitamotuA 90

61

NVCtceleSSBVC 00

71

DPCnoitaruDGNIPMALC 10

81

TPCtratsesluPGNIPMALC 10

91

MULtesffoecnanimuL 00

RM-995 RM-996

– 22 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuF

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaNMACESCSTNLAPVToediVDVD

PIPA1

LLPtnatsnoCemiTLLPtresnI

0000

B1

DCYyaleDC/Y808080

80

C1

RSNIIPtesnirofnoitcudeResioN

2000

GVTytilanoitcnuF

noitcnuFetoN&elbaT

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN nommoC0506

PIPD1

PSLdeepSnoitacifitnedIdradnatS 00

E1

LIKdlohserhTrelliKroloC 20

F1

PGBnoitisoPetaGtsruB 10

02

CESleveLnoitacifitnedIMACES 10

12

MEDnoitceleswsahpmeeD 10

22

AMChtiwdnaBamorhC 00

32

CFIretliFnoitasnepmoCFI 20

42

EUHeuH 00

52

ACStnemtsujdAreirracbuSroloC 60

62

NOCtnemtsujdAtsartnoC 00

72

RLBlennahCdeRleveLgniknalB 00

82

TRBtnemtsujdAssenthgirB 30

92

GLBlennahCneerGleveLgniknalB 00

A2

RIBlennahCdeRnoisrevnIgniknalB 00

B2

BIBlennahCeulBnoisrevnIgniknalB 00

C2

BLBlennahCeulBleveLgniknalB 00

D2

TNIlavretnIhserfeR 00

E2

RKPlennahCdeRleveLkaeP 58

F2

GKPlennahCneerGleveLkaeP 58

03

BKPlennahCeulBleveLkaeP 58

13

YRFYroloCemarF 90

23

TUOtamroFtuptuO 10

33

URFYroloCemarF 00

43

VRFVroloCemarF 00

53

TAStnemtsujdAnoitarutaSroloC 90

63

KDYtnemtsujdAkaePY 30

73

OCYelbanEgniroCY 10

83

LAPleveLDILAP 30

93

VOPlacitreVtesffOnoitisoP 00

A3

HOPlatnoziroHtesffOnoitisoP 00

B3

HSVknirhSlacitreV 00

C3

HSHknirhSH 00

D3

LPChtgneLesluPGNIPMALC 10

RM-995 RM-996

– 23 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN NOMMOCTUPNI-SVTOEDIV

TCY00UHStnemtsujdAeuHbuSQA3612AXC

E0

21

10

GNPhtdiWetaGCSTN/LAP 10

20

INPWSytivitisneSCSTN/LAP 00

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoNemaN NOMMOCVT05OEDIV05DVD05VT06OEDIV06DVD06

TCY30

LCSlortnoCroloCbuSoediV/VT*06/05QA3612AXC

50

70

50

70

40

TCSlortnoCtsartnoCbuSoediV/VT*06-05

50

80

50

80

50

0FSgnignahCycneuqerFretneCssenprahS 20

60

QEScitsiretcarahCrezilauqEssenprahS 00

70

GHSlortnoCniaGssenprahSDVD/oediV/VT*06/05

7080A06080A0

80LOYlortnoCleveLtuptuo-Y 12

90

PSBgnignahCtnioPtratShtcertSkcalB 00

RM-995 RM-996

– 24 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoN

emaN NOMMOCTUPNI-SVTOEDIVDVDSREHTO

TCYA0

LOClortnoCleveLtuptuOrC/bC QA3612AXC

72 E1

B0

RCDtnemtsujdAoitaRnoitarotseRCD 00

C0

0FBtnemtsujdA0FFQT/FPB 10

D0

QFBtnemtsujdAQFQT/FPB 20

E0

WSFhctiwSFQT/FPB 10

F0

TDShctiwSparTelbuoDMACES 10

01

FPLhctiwSFPLrC/bC/Y 10

11

LDYtnemtsujdAemiTLD-YDVD/tupni-S/oediV/VT

50605050

21

TMChctiwSetuMtuptuOrC/bC 00

31

10B)etuorniam(tnemtsujdA1tesffObC 70

41

1ORtnemtsujdA1tesffOrC 70

51

FDChctiwSycneuqerFnwoDtnuoCV langisonrofzH05decrof00

61

MDChctiwSegduJnwoDtnuoCV 00

71

CFAhctiwSytivitisneSCFADVD/oediV)/VT(

0000

81

MVMksaMCFA+ksaMnoisivorcaM 10

91

YRStnemtsujdAkcalBY-RMACES 70

A1

YBStnemtsujdAkcalBY-BMACES 10

B1

LEBgnihctiwSFPH/LLEBMACES 20

C1

FLBtnemtsujdA0fLLEB 00

D1

IVShctiwSDI-VMACES 00

E1

PGStnemtsujdAnoitisoPetaGMACES 00

F1

DIShctiwSytivitisneSMACESMACEStpecxe10

02

HIShctiwSnoitibihnIMACES 00

12

PTSsulpLAProfputeSleveLkcalBY 00

22

WSAWSedoMtceleSoediVotuA 10

32

HSWnoitcuderesionrofpetSniaGssenprahS 00

42

OCWnoitcuderesionrofpetSleveLtuptuOrC/bC 00

52

2BC)tupni2rCbCY(tnemtsujbatesffo2bC 70

62

2RC)tupni2rCbCY(tnemtsujbatesffo2rC 70

72

HPHhctiwsesahptuptuOSH 00

82

HPVesahptuptuoPVrofhctiwS 00

92

MCNBMOCCSTN 00

RM-995 RM-996

– 25 –

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoN

emaN NOMMOCCSTNSREHTO

ET00

0RNRNsrehtO/CSTNETD

1010

10

0CTgniroCETsrehtO/CSTN

5050

20

0GTniaGETsrehtO/CSTN

5050

30

HTSssapybET:1ssapybETdecroF 00

40

FOC)215(FFO:1FFOtnenopmoCroloC 00

50

FOYFFO:1FFOtnenopmoCecnanimuL 00

60

RJV2PS:32PS:21PS:1NO:0lortnocrettijV 00

70

FOTFFOET:1FFOET 00

80

FODFFORNtoD:1FFORNtoD 00

90

FOFFFOFPL:1FFOFPLET 10

A0

HTCFFO:1FFOETroloC 00

B0

LSPnoitceleSretemaraPET 20

C0

PLCleveLpmalCtupnI 80

D0

2LCleveLpmalCtuptuO 80

E0

1AL)etihW,+(niaGdnepedleveL 00

F0

2AL)kcalB,+(niaGdnepedleveL 10

01

3AL)etihW,-(niaGdnepedleveL F0

11

4AL)kcalB,-(niaGdnepedleveL 10

21

WRCoitarnoitasnepmocC/YET 40

31

DCYtnemtsujdayaledtuptuoC/YET 40

41

OSOtesffossenprahsffO 00

RN00

OMD)edoMomeD=1(FFO/NOedoMomeDRN ETD00

10

VHTnoitceridlacitrevrofleveldlohserhTesioNfotesffO 30

20

HHTnoitceridlatnozirohrofleveldlohserhTlevelfotesffO 11

30

LLBleveLkcalBrofnoitcetedleveLfotesffO 70

40

TSCleveLroloCrofnoitcetedleveLfotesffO 70

50

CHTdlohserhTnoitceteDegdEfotesffO 90

60

FRN0=knaRsyawla0RN 00

70

GID)nIlatigiD=1(nIlatigiDronID/A 00

TXT00

HXTnoitisoPlatnoziroHtxeteleT 1625AAS00

10

VXTnoitisoPlacitreVtxeteleT 00

MPO00HSOnoitisoPHDSO 790057PXC

F0

10

MOC ]ETD[)enoN:3,D3:2,itluM:1,enoN:0(/]ETD-NON[)D3:3,itluM:2,CSTN:1,enoN:0(noitceleSbmoC 20

RM-995 RM-996

– 26 –

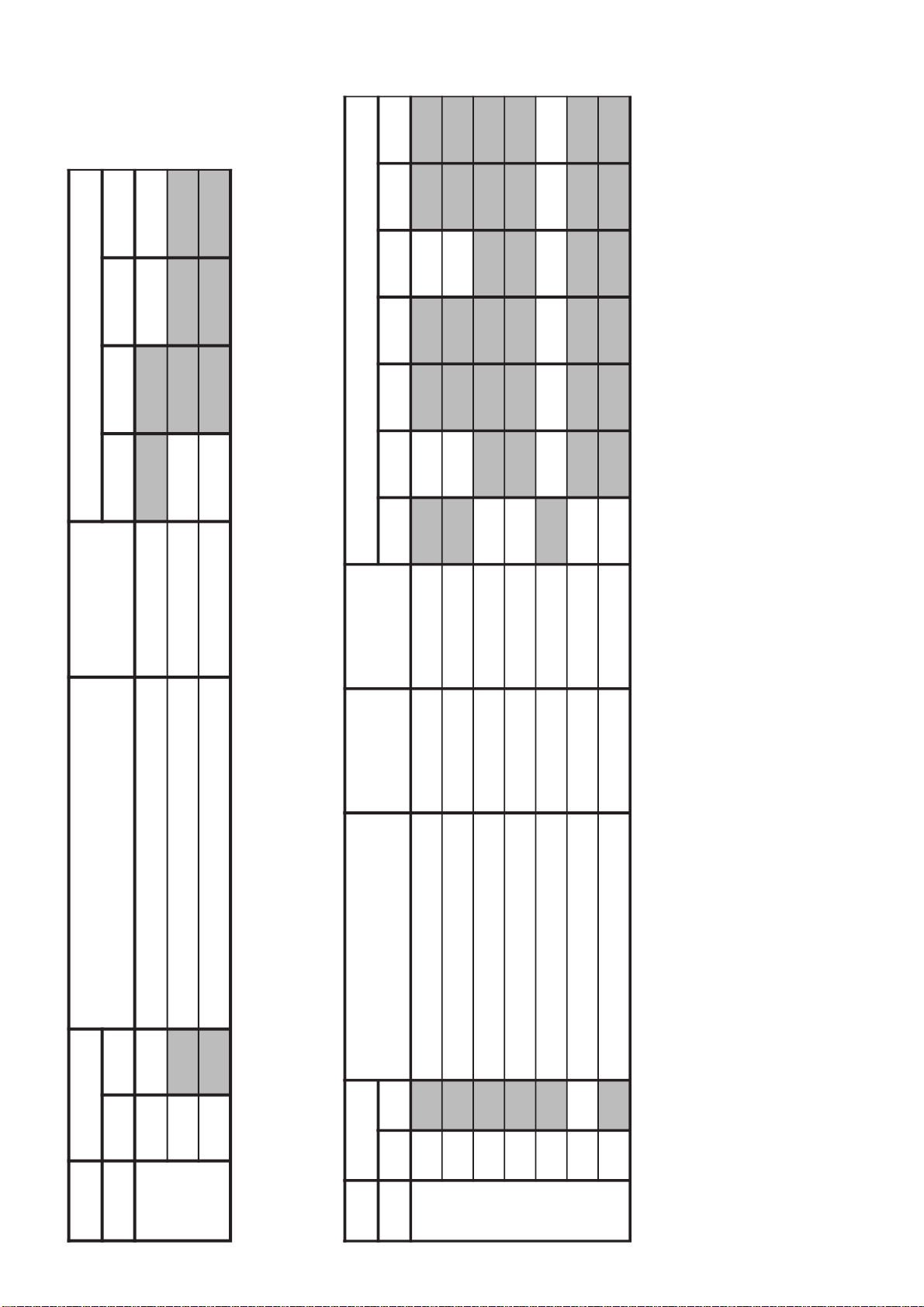

KV-AR34M81/AR34N90

GVTytilanoitcnuF

noitcnuFetoN&elbaTemaNeciveD

)deliateD(eulaVlaitinI/sserddAMVN

yrogetaCoN

emaN NOMMOCCSTNsrehtO

MPO20

CPAhctiwSCPA 790057PXC10

30

YSTotuAtasySVT 00

40

TUMetuMlangiSoN 10

50

MFAhctiwsMFotuA 10

60

BFRlortnoCFPB-C 00

70

OVTtesffoelgnA-VottliT 30

80

LBDnoitcnuFkcabeulBelbasiD 00

90

OSS)x8:3,x6:2,x4:1,ffO:0(noitpOhcraeSdeepS 10

A0

HCSnoitidnoCgnippihSrofnoitceleSHCylnosledoMCSTN70

B0

ACSnoitidnocgnippihsrofnoitcelesriA/elbaCylnosledoMCSTN10

C0

ROPTCYmorFnoitcetceDteseRnOrewoP 00

D0

CRNISCIProfretnuoCteD-N F1

E0

CURdekcolnUretfaretnuocegnahclangiSFR F0

F0

CLRdekcoLretfaretnuocegnahclangiSFR F0

01

PYBISCIPssapyB 00

11

LBPgniknalBFFO/NOISCIP 00

BPO00

1PO)SEGAPDEIFICEPSees(1stiBlanoitpOstiB-noitpO

10

2PO)SEGAPDEIFICEPSees(2stiBlanoitpO

20

3PO)SEGAPDEIFICEPSees(3stiBlanoitpO

30

4PO)SEGAPDEIFICEPSees(4stiBlanoitpO

RM-995 RM-996

shaded items are fixed data.

NOTE

•

In case of a device replacement, adjustment by rewriting the data value is necessary for some items.

• Standard data listed on the Adjustment Item Table are reference values, therefore it may be different for each model and for each mode.

• Note for Different Data Those are the standard data values written on the microprocessor. Therefore, the data values of the modes and stored respectively in the memory.

– 27 –

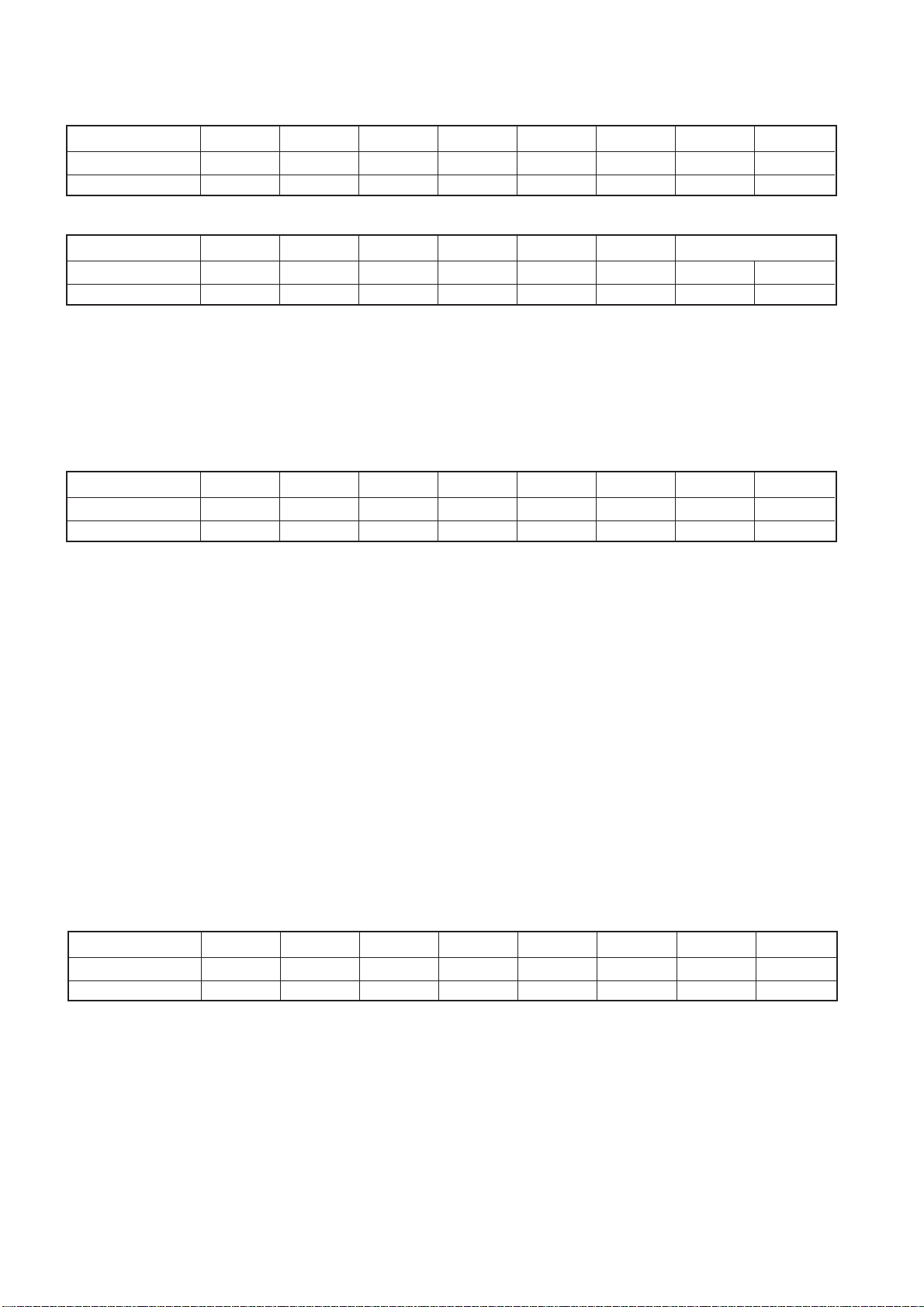

KV-AR34M81/AR34N90

RM-995 RM-996

ITEM INFORMATION

No. OPB0 OP1

Item

KV-AR34M81

KV-AR34N90

No. OPB1 OP2

Item

KV-AR34M81

KV-AR34N90

AV Input 00 = no AV Input 01 = 1 AV Input

DVD Input Effective only when "AV Input" is set to 3 AV Input

PIP 4 PIP 4 0 = disabled, 1 = enabled

No. OPB2 OP3

Item

KV-AR34M81

KV-AR34N90

XTAL 4.43

1

1

TOP

0

0

Initial Menu

1

1

XTAL 3.58

1

1

NICAM

0

0

AP2

1

1

SECAM

1

1

HDEV

0

0

2nd. Lang

1

1

Thai Bil

0

0

B/G

1

0

PIP4

0

0

10 = 2 AV Input 11 = 3 AV Input

Auto PIC

1

1

A-TVsys

0

0

US ST

0

1

I

1

0

DVD Input

1

1

DTE

0

0

D/K

1

0

AV Input

1

1

Forced 50/60

0

0

M

1

1

1

1

Colour SW*

2

1

1

Initial Menu Initial Men Setup 0 = disabled, 1 = enabled

AP2 Auto Processor Selection 0 = AP, 1 = AP2.

Auto PIC

*3

A-TVsys Auto TV System in Auto Program0 = disabled, 1 = enabled

*

US ST

DTE DTE Model Selection 0 = Non DTE, 1 = DTE

Forced 50/60 Forced to 50/60 Hz during no signal condition 0=60Hz, 1=50Hz

Color SW

Note:*1 - For XA21/XH29 Models Only

No. OPB3 *OP4

*2

- For XA34/29/25 Models Only

*3

- For PNC3, the enables are from service item APG and APB.

Item

KV-AR34M81

KV-AR34N90

*2

PNC2

0

1

Korean ST

0

0

Auto Picture Improvement 0 = off PNC1/PNC2

1 = activate PNC1/PNC2

USA Stereo 0 = disabled, 1 = enabled

Color Data Selection in Dynamic Mode 0 = 65 (No PIP), 1 = 57 (PIP)

Vid NTSC3.58

0

0

Wide

1

1

Video3

0

0

Chinese(Multi mdl)

1

0

Arabic/C.Chinese

Thai/Korean

1

1

1

0

APPLICABLE TO XS ONLY - Sub Language Selection (Bit 0 - Bit 2)

Korean Stereo* Korean Stereo 0 = disabled, 1 = enabled

2

PNC2*

Enable switch of PNC2 0 = disable, 1 = enable

Video NTSC3.58* Video Color System 0 = Multi System, 1 = Single System (NTSC3.58)

Wide Enable wide mode 0 = disable, 1 = enable

Note : *APPLICABLE FOR NTSC MODELS ONLY

– 28 –

KV-AR34M81/AR34N90

VY

RM-995 RM-996

4-3. ADJUSTMENT FOR NON DIGITAL TEXTURE

ENHANCER (DTE) MODEL

SUB COLOR ADJUSTMENT (KV-AR25/AR29)

1. Select Video.

2. Input PAL Color Bar

3. Set to following condition PICTURE 100%, BRIGHTNESS

50%, Color 50%.

4. Connect an oscilloscope to pin 1 (BOUT) of CN305, A Board.

5. Set the service mode and select SAJ 3 ‘SCL’ with 1 and 4 of

the commander then adjust the VB2=VB3=VB4 3 and 6.

6. Press

7. Input NTSC Color Bar to set and repeat items (3 to 7).

8. Select "WIDE" mode, write the "SAME DATA- 3 STEPS" for

[MUTING] → - of the commander to write the data.

both PAL and NTSC Color Bar input.

VB1

VB2 VB3

VB2 = VB3 = VB4

VB2 = VB3 = VB4 (Difference is within 70mV)

VB4

4-4. ADJUSTMENT FOR DIGITAL TEXTURE

ENHANCER (DTE) MODEL

(not used for this models)

Y LEVEL ADJUSTMENT

1. Select Video.

2. Input PAL Color Bar to TV set (white reference 100%).

3. Set the following condition:

DTE : ON

Picture Mode : Dynamic

4. Connect an oscilloscope to pin 1 (CV/Y in) of CN106, A

Board.

5. Set to Service Mode and YCT 08 ‘YOL’ with 1 and 4 of the

commander then adjust to VY within spec with 3 and 6.

6. Then press

7. Select RF.

8. Repeat item 2 to 4.

9. Set to Service Mode and YCT 04 ‘SCT’ with 1 and 4 of the

commander then adjust to VY within spec with 3 to 6.

10. Copy SCT data to NTSC (RF).

[MUTING] → - to write the data.

SCT Setting (Video Mode) : 07h (NTSC & PAL)

SUB COLOR ADJUSTMENT (KV-AR34)

1. Select Video.

2. Input PAL Color Bar

3. Set to following condition PICTURE 100%, BRIGHTNESS

50%, Color 50%.

4. Connect an oscilloscope to pin 1 (BOUT) of CN305, A Board.

5. Set the service mode and select SAJ 3 ‘SCL’ with 1 and 4 of

the commander then adjust the VB2=VB3=VB4 3 and 6.

6. Press

[MUTING] → - of the commander to write the data.

7. Add 6 steps and save the data.

8. Input NTSC Color Bar to TV set and repeat items 3 to 7.

9. Select "WIDE" mode, write the "SAME DATA- 3 STEPS" for

both PAL and NTSC Color Bar input.

SUB HUE ADJUSTMENT

1. Select Video 1.

2. Input a NTSC 3.58 color-bar, video into Video 1.

3. Set the following condition:

PICTURE 100%, BRIGHTNESS 50%, COLOR 50%

4. Connect an oscilloscope to pin 1 (B OUT) of CN305, A board.

5. Select SAJ 1 "SHU" with 1 and 4 of the commander by

setting to Service Mode and adjust to VB1=VB2=VB3=VB4

with 3 and 6.

VB1

VB2

VB3

VB4

± 110mV

SPEC: VY : 1.2 Vpp ± 0.05m Vpp

SUB COLOR (YCT) ADJUSTMENT

1. Select Video.

2. Input NTSC Color Bar.

3. Set the following condition:

DTE : ON

Picture Mode : Dynamic

NTSC 75% Color Bar

4. Connect an oscilloscope to pin 2 (B-Y in) of CN303, A Board.

5. Set to Service Mode and YCT 0A ‘COL’ with 1 and 4 of the

commander then adjust to VB within spec with 3 and 6.

6. Then press

7. Select RF.

8. Repeat item no 2 to 4.

9. Set to Service Mode and YCT 03 ‘COL’ with 1 and 4 of the

commander then adjust the waveform within spec with 3 and

6.

10. Then press

11. Input PAL Color Bar (75%) and repeat item no 8 to 10.

[MUTING] → - to write the data.

[MUTING] → - to write the data.

VB1 = VB2 = VB3 = VB4

The highest level of VB1,VB2,VB3,VB4 must be aligned at

the same line. Ideal difference level between VB2 and VB3

should be within ± 110mV.

6. Press [MUTING] → - of the commander to write the data.

7. Adjust SAJ 1 "SHU" as step 3 to 6 when receiving TV mode.

VB

SPEC :

VIDEO : VB = 0.931 Vpp ± 50 mVpp

RF : VB = 0.931 Vpp ± 50 mVpp

– 29 –

Loading...

Loading...