Sony KV-36FS76B Schematic

SERVICE MANUAL

AE-6A

CHASSIS

MODEL

KV-36FS76B

KV-36FS76E

COMMANDER DEST CHASSIS NO.

RM-938 FR SCC-Q83L-A

RM-938 ESP SCC-Q81N-A

MODEL

KV-36FS76U

COMMANDER DEST CHASSIS NO.

RM-938 UK SCC-Q84J-A

KV-36FS76

- 1 -

RM-938

TABLE OF CONTENTS

Section Title Page Section Title Page

Caution .................... 3

Specifications .................... 4

Connectors .................... 6

Self Diagnostic Software .................... 7

1. GENERAL

Automatically Tuning the TV .................... 10

Text .................... 10

Teletext Menu .................... 11

Multi Picture in Picture (Multi PIP) ............. 11

Picture and Picture (PAP) .................... 11

NexTView Electronic

Programme Guide (EPG) .................... 12

Using the TV menu system .................... 12

Remote Control of other equipment ............... 15

Specifications .................... 15

Troubleshooting .................... 15

2. DISASSEMBLY

2-1. Rear Cover Removal .................... 16

2-2. Speaker Disconnection .................... 16

2-3. Chassis Removal .................... 16

2-4. Service Position .................... 17

2-5. G Board Removal .................... 17

2-6. D2 Board Removal .................... 17

2-7. D1 Board Removal .................... 17

2-8. Wire Dressing 1 .................... 18

2-9. Wire Dressing 2 .................... 18

2-10. Wire Dressing 3 .................... 18

2-11. Wire Dressing 4 .................... 18

2-12. Picture Tube Removal .................... 19

Bottom Plates .................... 20

3. SET-UP ADJUSTMENTS

3-1. Beam Landing .................... 21

3-2. Convergence .................... 22

3-3. Focus Adjustment .................... 24

3-4. Screen (G2), White Balance .................... 24

4. CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments .................... 25

4-2. Volume Electrical Adjustments .................... 29

4-3. Test Mode 2 .................... 30

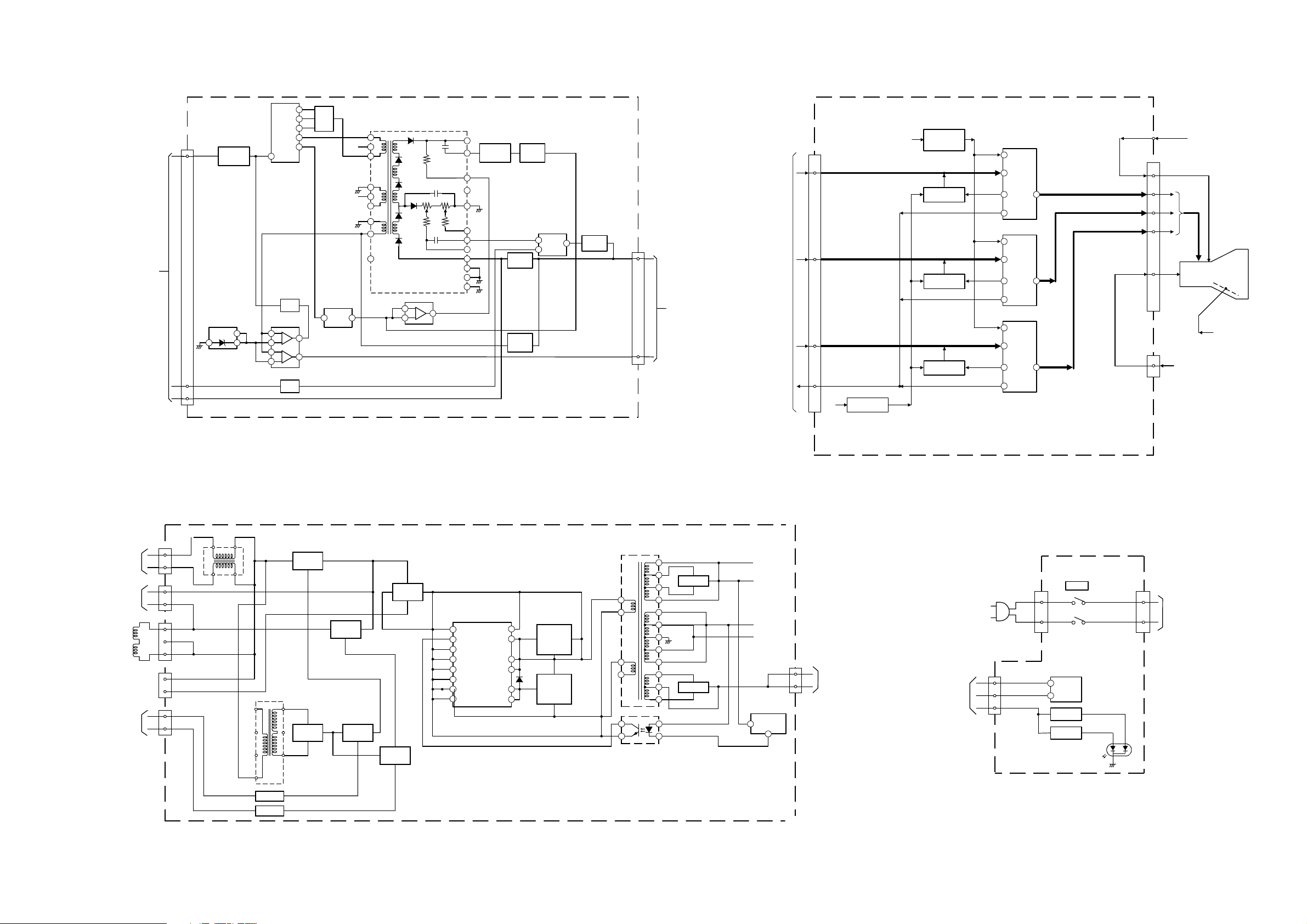

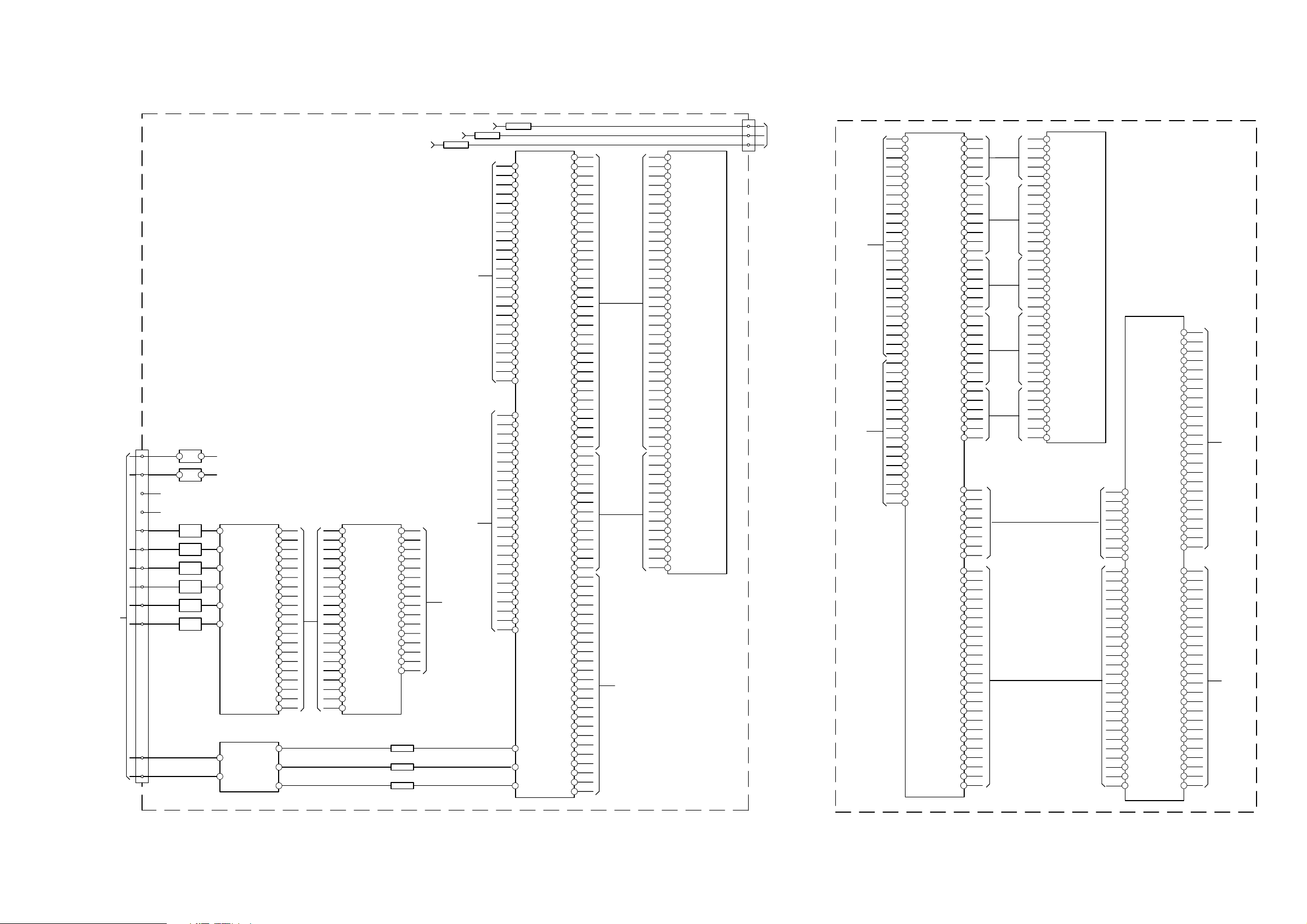

5. DIAGRAMS

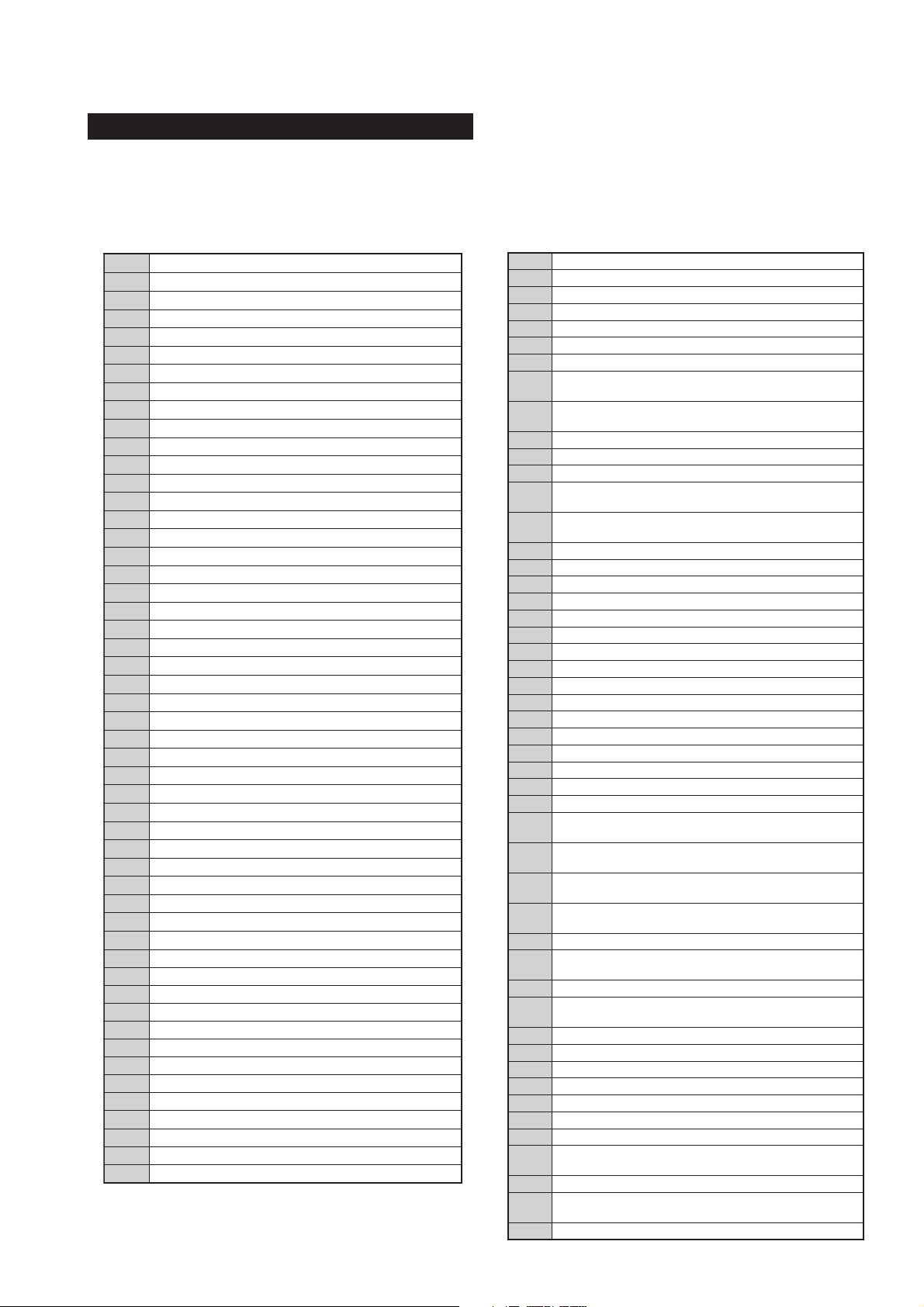

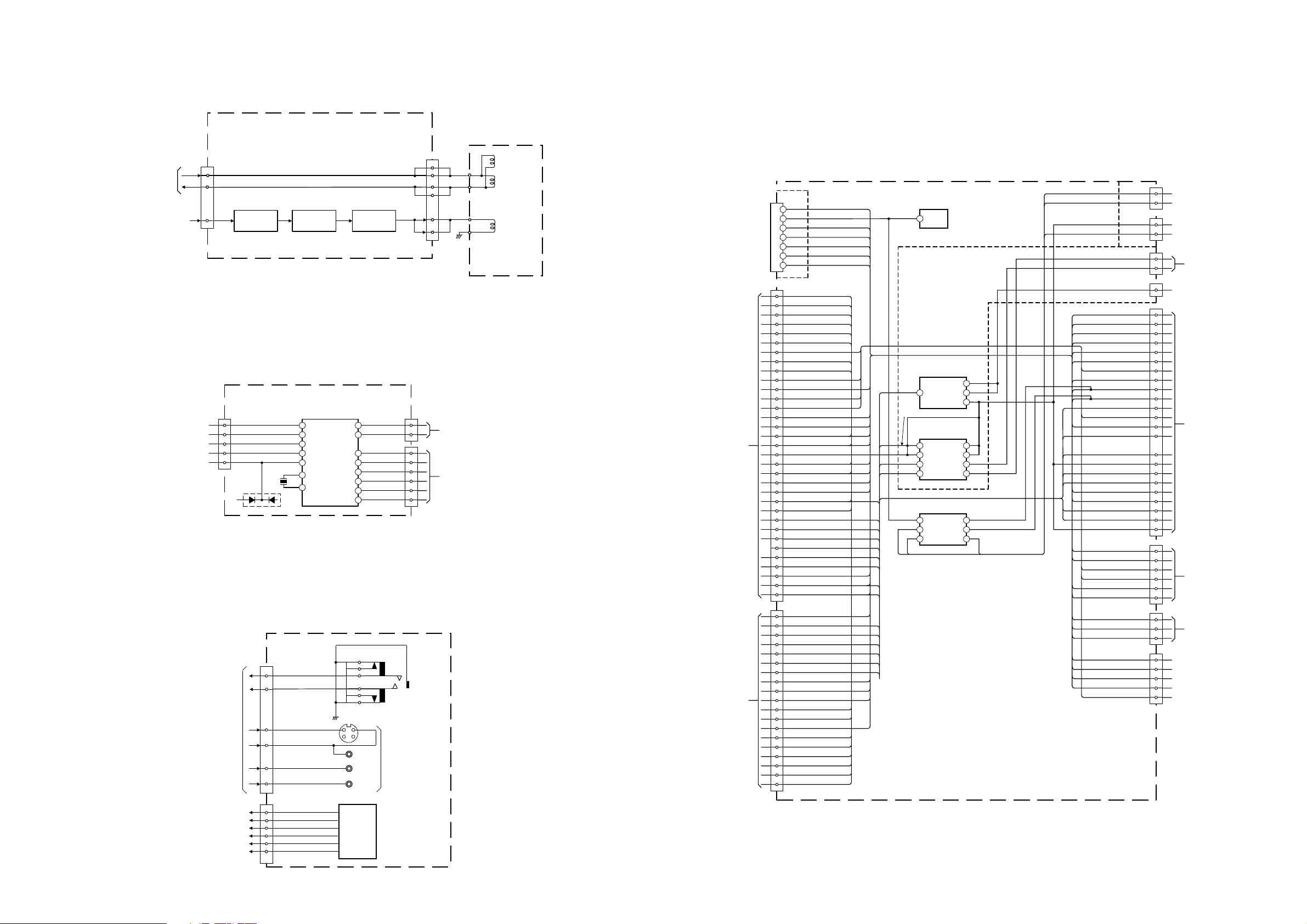

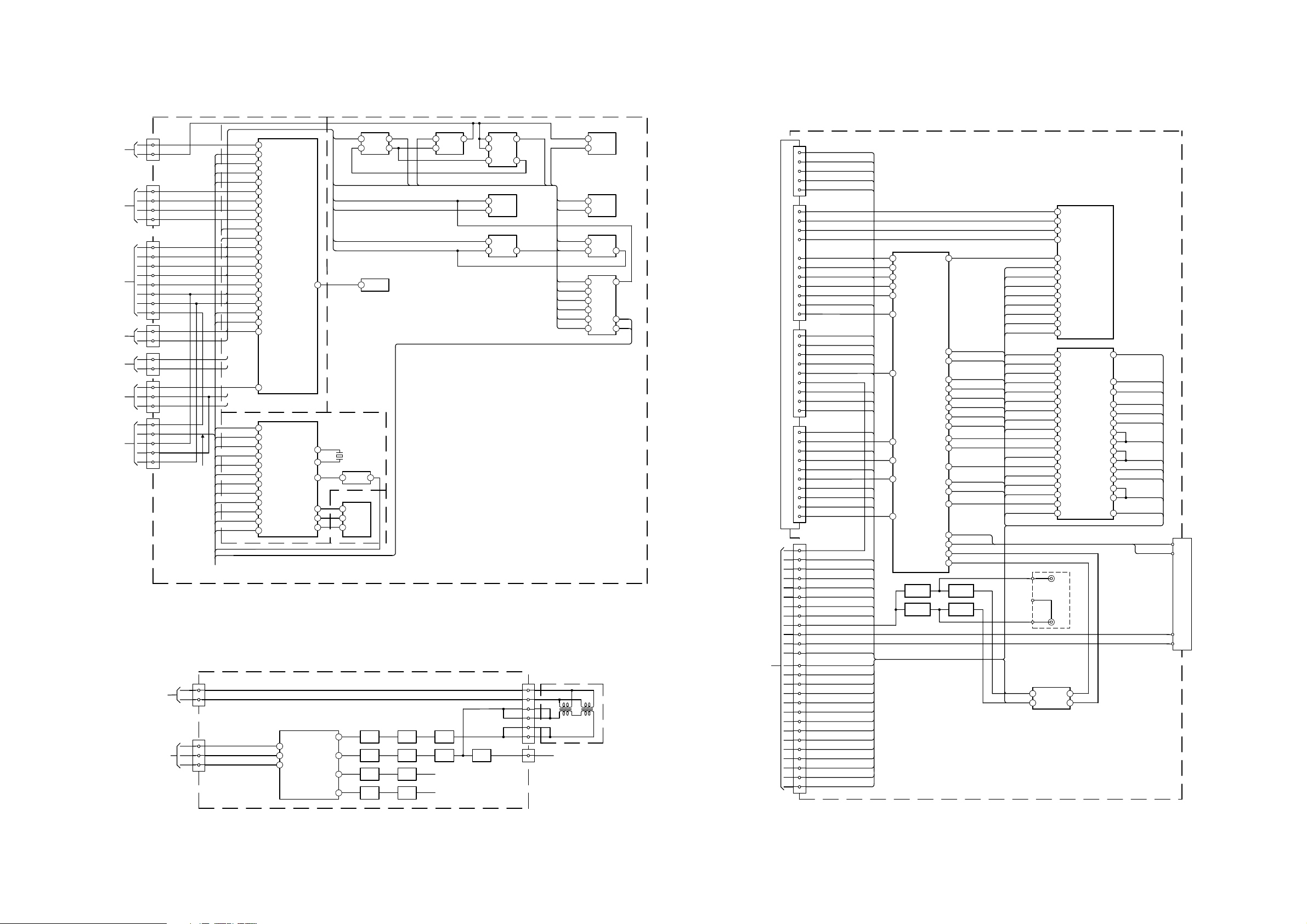

5-1. Block Diagrams (1) .................... 31

Block Diagrams (2) .................... 32

Block Diagrams (3) .................... 33

Block Diagrams (4) .................... 34

Block Diagrams (5) .................... 35

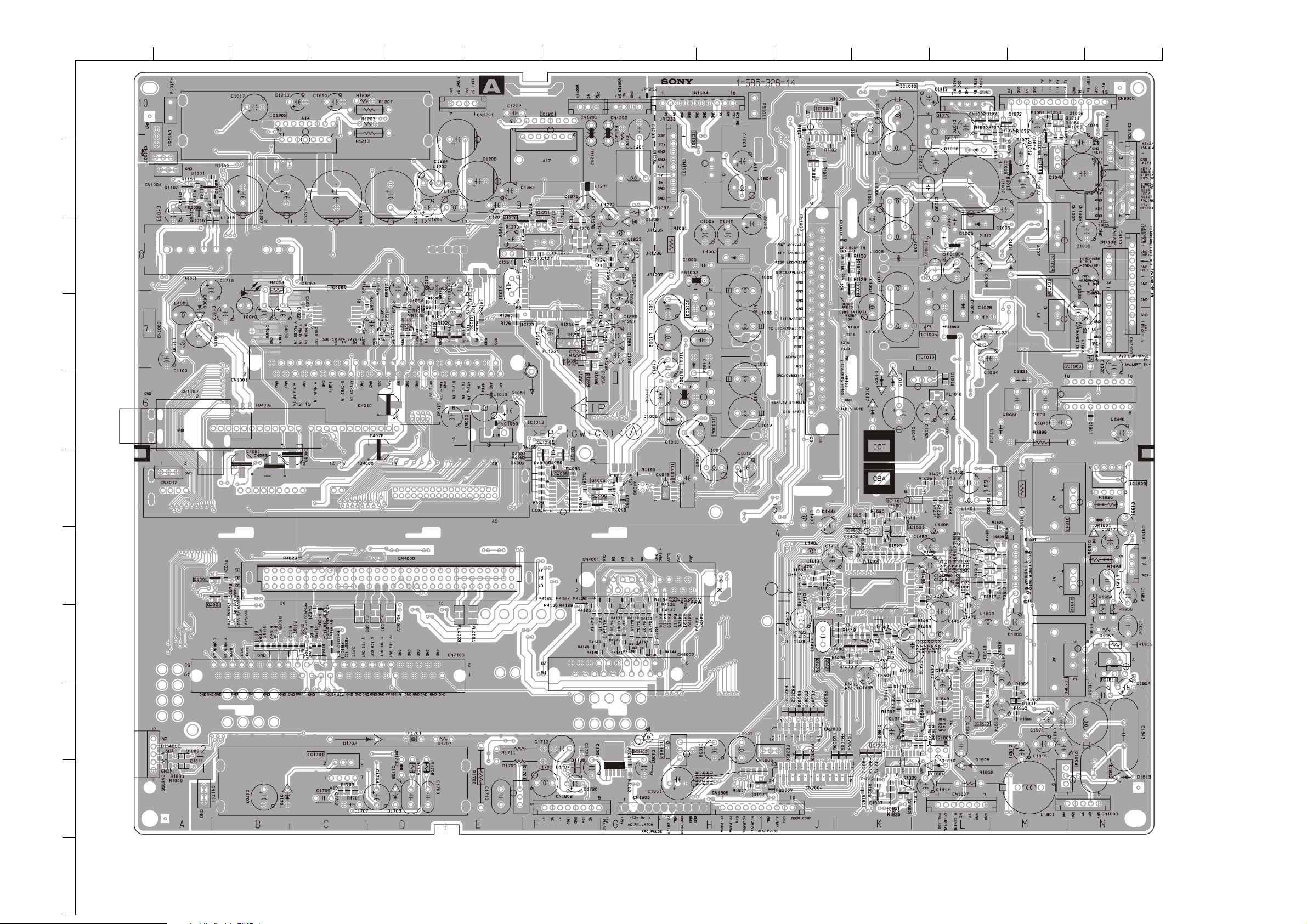

5-2. Circuit Board Location .................... 35

5-3. Schematic Diagrams and

Printed Wiring Boards .................... 35

* A Board Schematic .................... 39

* A Board PWB .................... 36

* J2 Board Schematic .................... 43

* J2 Board PWB .................... 45

* H Board Schematic .................... 44

* H Board PWB .................... 45

* H3 Board Schematic .................... 44

* H3 Board PWB .................... 45

* F4 Board Schematic .................... 44

* F4 Board PWB .................... 45

* C Board Schematic .................... 46

* C Board PWB .................... 47

* M2 Board Schematic .................... 48

* M2 Board PWB .................... 47

* D2 Board Schematic .................... 50

* D2 Board PWB .................... 49

* D1 Board Schematic .................... 51

* D1 Board PWB .................... 52

* G Board Schematic .................... 53

* G Board PWB .................... 54

* VM Board Schematic.................... 55

* VM Board PWB .................... 54

* B5 Board Schematic .................... 55

* B5 Board PWB .................... 62

5-4. Semiconductors .................... 63

5-5. IC Blocks .................... 66

6. EXPLODED VIEWS

6-1. Chassis .................... 69

6-2. Picture Tube .................... 70

7. ELECTRICAL PARTS LIST .................... 71

ATTENTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT, AFTER REMOVAL OF THE

ANODE CAP.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

CAUTION

WARNING !!

ON

APRES AVOIR DECONNECTE LE CAP DE’LANODE,

COURT-CIRCUITER L’ANODE DU TUBE CATHODIQUE ET

CELUI DE L’ANODE DU CAP AU CHASSIS METALLIQUE DE

L’APPAREIL, OU AU COUCHE DE CARBONE PEINTE SUR LE

TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION !!

AFIN D’EVITER TOUT RISQUE D’ELECTROCUTION

PROVENANT D’UN CHÁSSIS SOUS TENTION, UN

TRANSFORMATEUR D’ISOLEMENT DOIT ETRE UTILISÈ LORS

DE TOUT DÈPANNAGE LE CHÁSSIS DE CE RÈCEPTEUR EST

DIRECTMENT RACCORDÈ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á

LA SECURITÈ!!

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE SUR LES SCHÈMAS DE PRINCIPE, LES VUES

EXPLOSÈES ET LES LISTES DE PIECES SONT D’UNE IMPOR-

TANCE CRITIQUE POUR LA SÈCURITÈ DU FONCTIONNEMENT,

NE LES REMPLACER QUE PAR DES COMPSANTS SONY DONT

LE NUMÈRO DE PIÈCE EST INDIQUÈ DANS LE PRÈSENT

MANUEL OU DANS DES SUPPLÈMENTS PUBLIÈS PAR SONY.

- 2 -

CAUTION

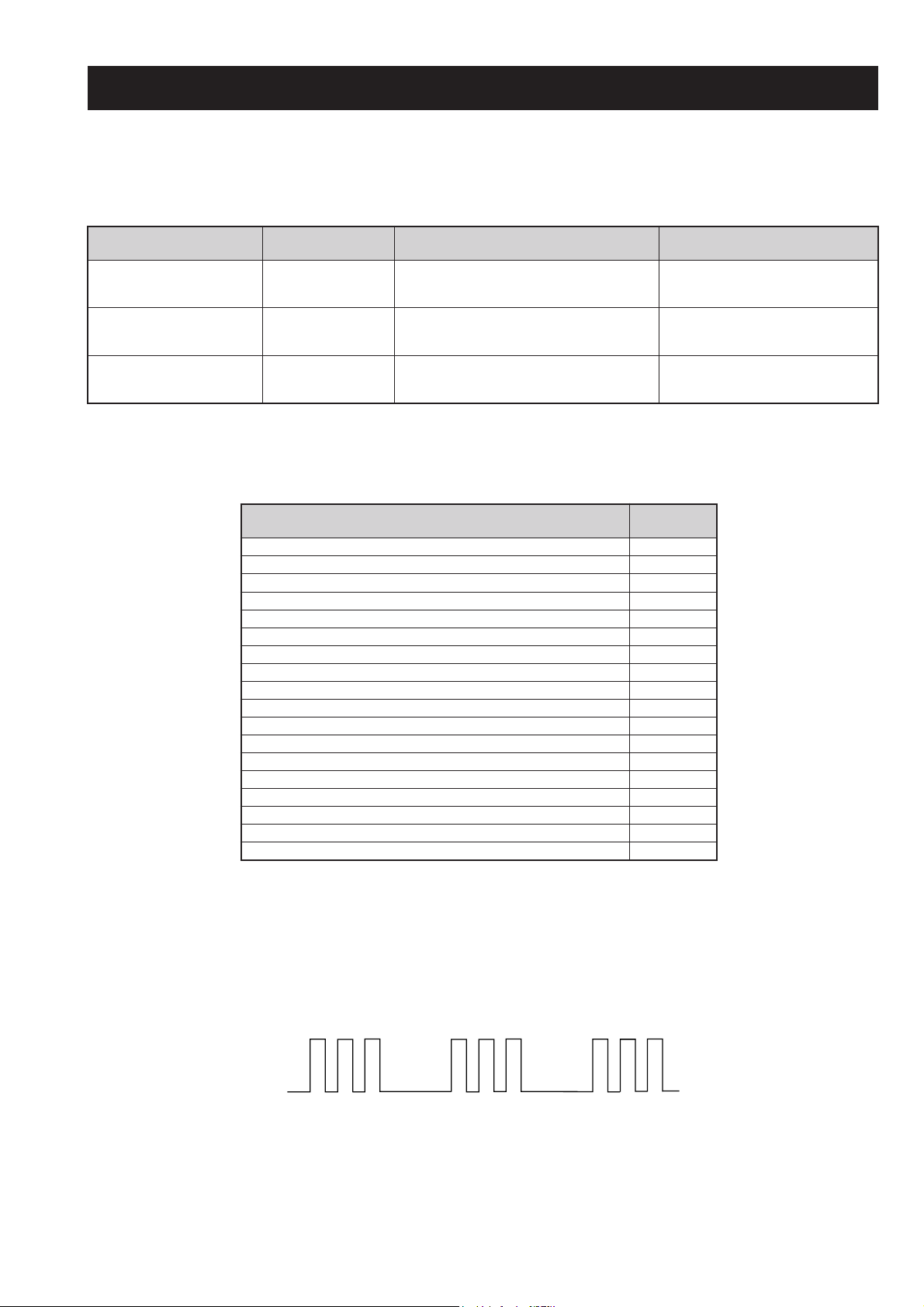

Lead Free Soldered Boards

The circuit boards listed below [Table 1] used in these models may

have been processed using Lead Free Solder. The boards are

identified by the LF logo located close to the board designation e.g.

F1, H1 etc [ see examples ]. The servicing of these boards requires

special precautions to be taken as outlined below.

Table 1

draoB noitcnuF

example 1

example 2

3HrossecorPkniLVA

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints. Lead Free Solder is

available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This requires

soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

- 3 -

LEDOMMETI metsySnoisiveleT metsySoeretS egarevoClennahC metsySroloC

BL,I,K/D,H/G/B

EH/G/B

MACIN/NAMREG

oeretS

MACIN/NAMREG

oeretS

02S-10S:VTELBAC

14S-12S:REPYH

30S-10S,21R-1R,21E-2E:FHV

96R-12R,96E-12E:FHU

02S-10S:VTELBAC

14S-12S:REPYH

Q-B,01F-20F,30S-10S,21R-1R,21E-2E:FHV

96R-12R,96B-12B,96F-12F,96E-12E:FHU

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

UI

ebuTerutciP

.)yllanogaid

]RAER[slanimreTtuptuO/tupnI snoitacificepSlareneG

rotcennocoruEnip-12:1

)dradnatsCELENEC(

rotcennocoruEnip-12:2

rotcennocoruEnip-12:3

rotcennocoruEnip-12:4

skcaJonohPoiduArofelbairavsrotcennoCtuptuO

]TNORF[slanimreTtuptuO/tupnI lortnoCderarfnI:metsySlortnoCetomeR

kcajenohpdaeHkcajinimoerets

stupnioiduAskcajonohp

stupnioediVskcajonohp

tupnioediVSNIDnip4

.BGRrofstupnI

.slangis

.BGRrofstupnI

)tuOrotinoM(

)elbatceles(

.slangiS

MACIN

oeretS

nortinirTDFyalpsiDtalF

)sehcni63(mc29xorppA

derusaemerutcipmc88xorppA(

.slangisoediVdnaoiduArofstupnI

oiduAdnaoediVVTfostuptuO

.slangisoediVdnaoiduArofstupnI

.slangisoiduAdnaoediVVTfostuptuO

.slangisoediVdnaoiduArofstupnI

.oediVSrofstupnI

.slangisoiduAdnaoediVVTfostuptuO

.slangisoediVdnaoiduArofstupnI

.oediVSrofstupnI

96B-12B:FHU

tuptuodnuoS

rekaepstfeLdnathgiR

refooWbuS

stnemeriuqeRrewoPV042-022

noitpmusnoCrewoPW661

snoisnemiDmm195x416x279xorppA

thgieWgk0.09xorppA

seirosseccAdeilppuS

serutaeFrehtO

.srenuT

cdV3

stnemeriuqerrewoP

)AAezis(6R

.ecitontuohtiwegnahcottcejbuserasnoitacificepsdnangiseD

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

)SMR(W01x2)rewoPcisuM(W02x2

)SMR(W51x1)rewoPcisuM(W03x1

)1(rednammoCetomeR839-MR

)2(yrettab6RdetangisedCEI

,erutciPdnaerutciPcimanyD,FCD,FMCRD

2,ybloDlautriV,noitcudeResioNotuA

noitangisedCEIseirettab2

- 4 -

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

metI

emaNledoM

PAPFFOFFOFFO

PIPFFOFFOFFO

ytiroirPBGRNONONO

xoBrefooWNONONO

1tracSNONONO

2tracSNONONO

)3(nitnorFNONONO

4tracSNONONO

rotcejorPFFOFFOFFO

G/BmroNNONOFFO

ImroNNOFFONO

K/DmroNNONOFFO

SUAmroNFFOFFOFFO

LmroNNOFFOFFO

TASmroNFFOFFOFFO

MmroNFFOFFOFFO

txeteleTNONONO

oeretSmaciNNONONO

B67SF63-VK E67SF63-VK U67SF63-VK

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of 5 AMP rating. Should the fuse need to be

replaced, use a 5 AMP FUSE approved by ASTA to BS 1362, ie one

that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD

BE CUT OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG

SEVERED FROM THE MAINS LEAD MUST BE DESTROYED AS A

PLUG WITH BARED WIRES IS DANGEROUS IF ENGAGED IN A

LIVE SOCKET.

When an alternative type of plug is used, it should be fitted with a

5 AMP FUSE, otherwise the circuit should be protected by a 5 AMP

FUSE at the distribution board.

ASA

mark.

T

- 5 -

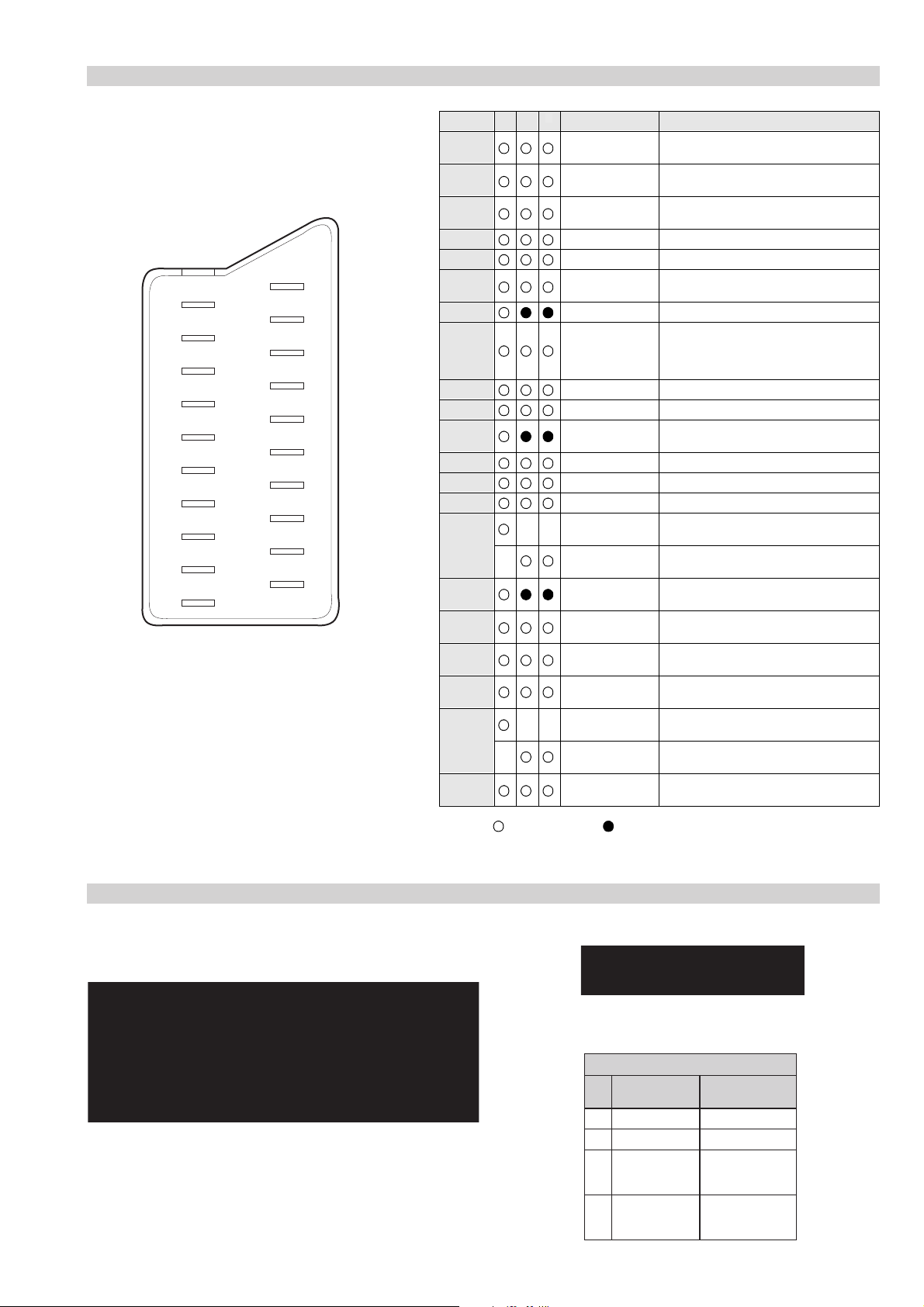

21 pin connector

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

8

6

4

2

Pin No 1 2 4 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blue)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 Open

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

13 Ground (red)

14 Ground (blanking)

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

3

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

input)

(Ys signal)

output)

input)

_ _ Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

_ Video input

Y (S signal)

(plug, shield)

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

Connected Not Connected (open) * at 20Hz - 20kHz

Rear Connection Panel Front Connection Panel

S-Video

socket

niP

oN

1dnuorG-

2dnuorG-

3tupni)langisS(Y,mho57Bd3-/+V1

4tupni)langisS(CBd3-/+V3.0

langiS leveLlangiS

noitarugifnocniptekcosoediVS

V3.0.cnySevitisop

Bd01+3-

evitisop,mho57

.cnyS

- 6 -

AE-6A SELF DIAGNOSTIC SOFTWARE

The identification of errors within the AE-6A chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted) See table 1., non fatal errors are reported using this

method.

metIcitsongaiD

noitpircseD

nonruttonseodrewoPthgiltonseoD

)PCO(tnerrucrevOB+semit2

deppotsnoitcelfeDlacitreVsemit4

ybdnatSsemitfooN

sehsalFDEL

.tiucricneposiesuF

egasseMrorrE

devreseR 10

)noitcetorPtnerruCrevO(PCO 20

)noitcetorPegatloVrevO(PVO 30

noitcetorPlacitreV 40

noitcetorPlatnoziroH 60

noitcetorPrekaepS 70

rorrEsuBC2I 80

MVN,23C42TS.B-2M 90

draoB-A 01

draoB5B 11

draoB2J 21

draoBH 31

draoBSM 41

redoceDruoloCniaM.B-5B 51

dnekcaB,Q0512AXC.B-A 61

.corPdnuoS,1143PSM.B-A 71

desutoN 23-81

esuacelbaborP

noitacoL

.nideggulptonsidrocrewoP

)draoB1D(.detrohssi)3018/2018Q(TUO.H

)draoB1D(.detrohssi)6018Q(TEFytiraeniL

)draoB1D(.detrohssiCIrewoP1088CI

)draoB1D(nepo7028RdeilppustonsiV51+

)draoB1D(nepo6028RdeilppustonsiV51-

)draoBA(detrohssi1071CI

)edoMnoitcudorPnidelbasid,s03retfastratskcehc(BKAelbatsnU 50

smotpmySdetceteD

noemoctonseodrewoP

VTehtotdeilppussirewopoN

ytluafsiylppusrewopCA

noemoctonseodrewoP

detrohssahenilrewopnodaoL

deppotssaheslupnoitcelfedlacitreV

detrohssahenilrewoP

DEL

edoC

Flash Timing Example : e.g. error number 3

StBy LED

ON ON ON

OFF

- 7 -

OFF

Error Detection Monitor

Device acknowledge is used to check IIC errors. Device acknowledge is checked by sending an IIC start sequence during CRT power on. Each

device is checked three times, if there is no acknowledge after each attempt, it will be regarded as an error.

There are three steps to check for errors.

1. IIC line 0

If all devices except the NVM have errors, IIC line 0 error is displayed.

2. Board check

If all devices mounted on one board have errors, board error is displayed.

3. Each device check

If IIC line error and board error are not detected then the device with the error is displayed.

The detected errors can be displayed as follows :

1. Error Monitor Menu.

2. Error Reader.

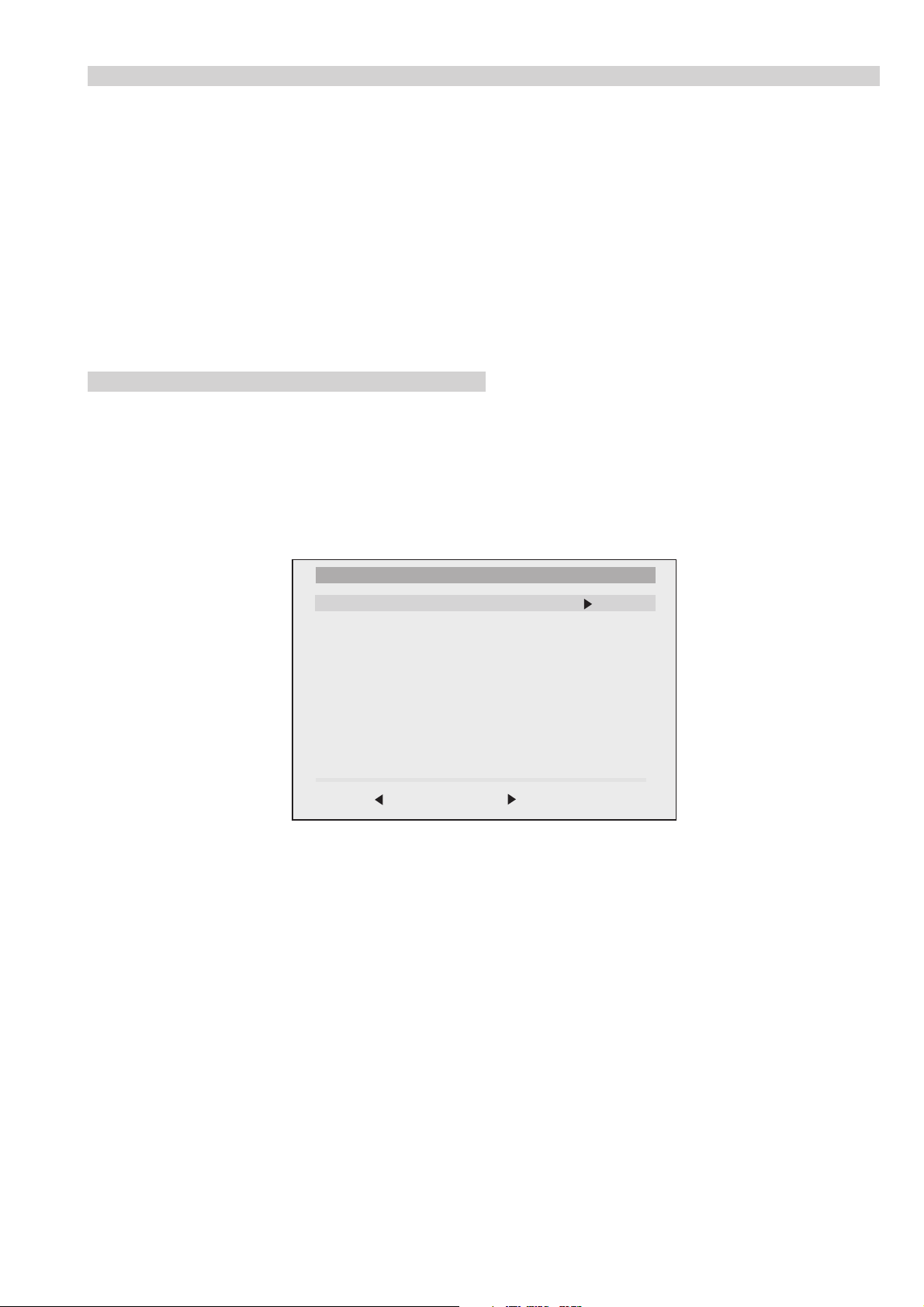

1. Error Monitor Menu

ERROR MONITOR

1. IGNORE ERRORS OFF ON OFF

Operating Time : 000167 h 45 min

Stored Errors :

1. A - B TU1350 Sub-Tuner

2. J - B TDA9320 Sub Col. Dec.

3. No Error Occured

4. No Error Occured

5. No Error Occured

Current Error :

A - B TU1350 Sub-Tuner

Last menu Enter item

- 8 -

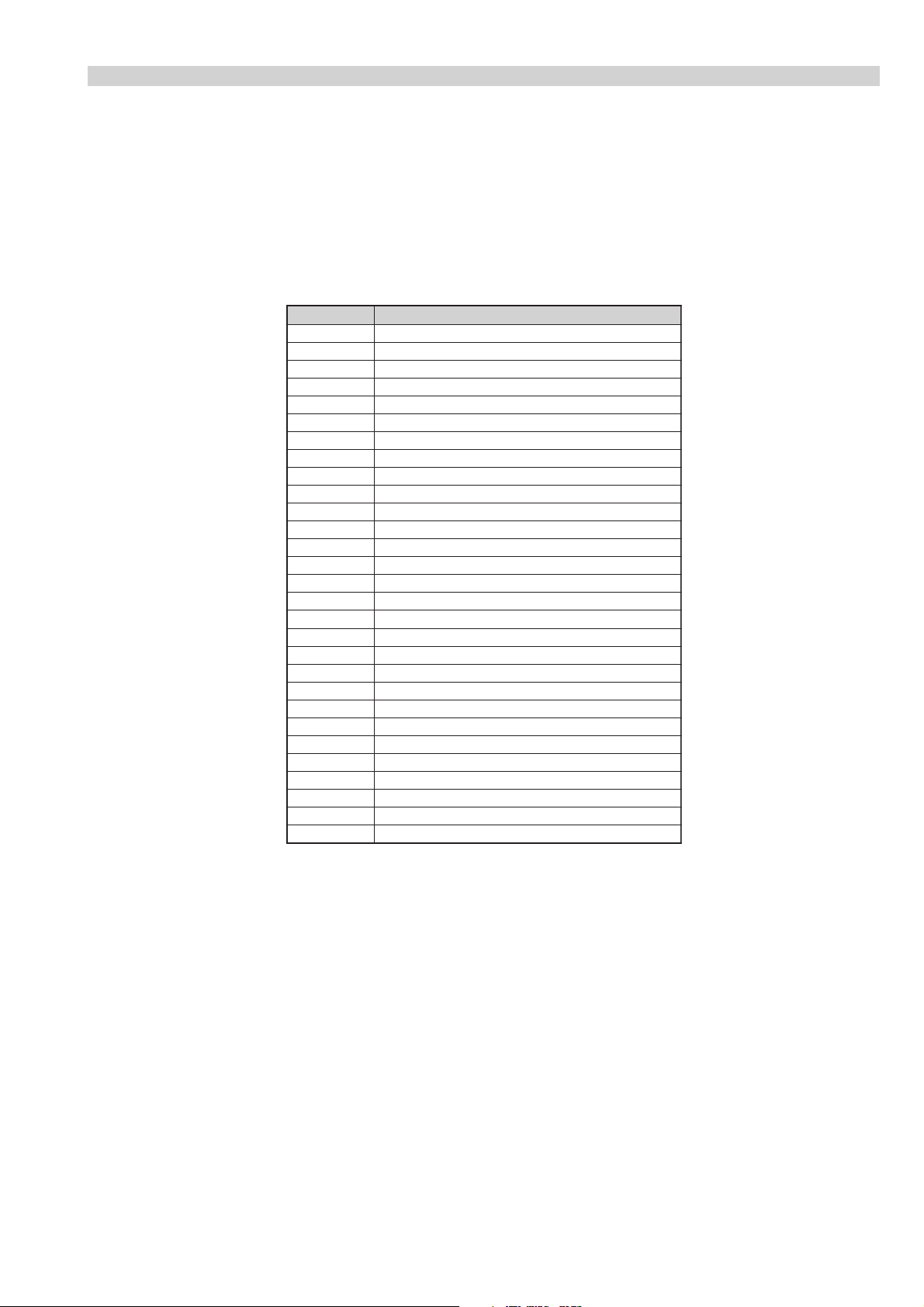

2. Error Reader Display

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display is

S-188-900-10. Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following

table.

edoCrorrE egasseMrorrE

h000deruccOrorrEoN

h1000C2I,rorrEsuB

h2001C2I,rorrEsuB

h3002C2I,rorrEsuB

h001draoB-A

h101.pxEtroP,5781AXC.B-A

h201renuT-niaM,xx06UT.B-A

h301FIniaM,6889ADT.B-A

h401dnekcaB,Q0512AXC.B-A

h501CAD,14188BM.B-A

h601.corPdnuoS,G1143PSM.B-A

h701.vnoC.anyD,0708AXC.B-A

h002draoB-5B

h102redoceDruoloCniaM.B-5B

h202redoceDruoloCbuS.B-5B

h302XDIM.B-5B

h402yarrAetaGamaronaP.B-5B

h502noitcudeResioN.giD.B-5B

h003draoB-H

h103kniLVA,8802DXC.B-H

h004draoB-J

h104hctiwSVA,5581AXC.B-2J

h204hctiwSVA,9412AXC.B-2J

h304renuT-buS,xx06UT.B-2J

h404FIbuS,6889ADT.B-2J

h005draoB-2M

h105MVN,23C42TS.B-2M

h006draoB-1SM

h106kcitSyromeM.B-1SM

- 9 -

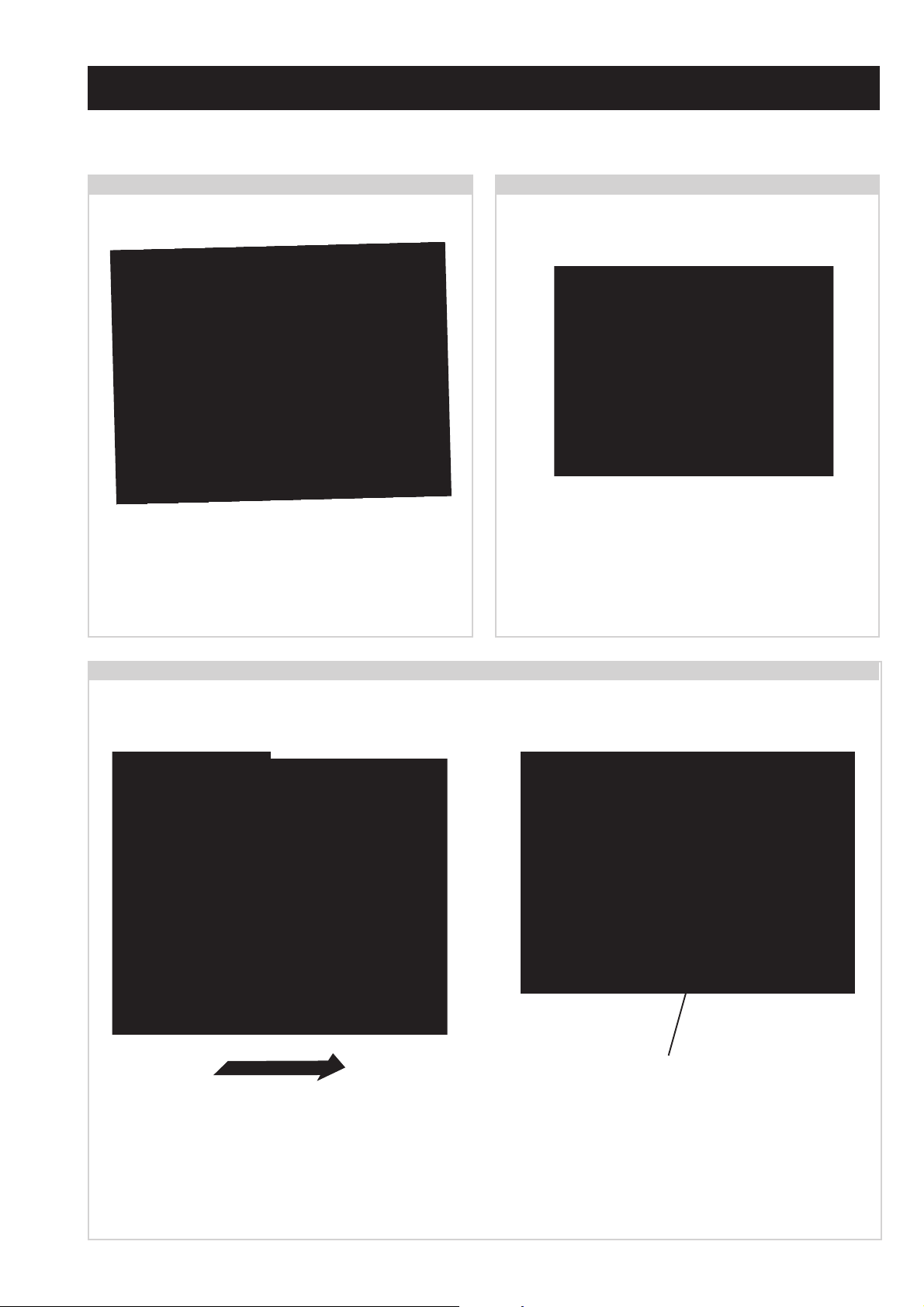

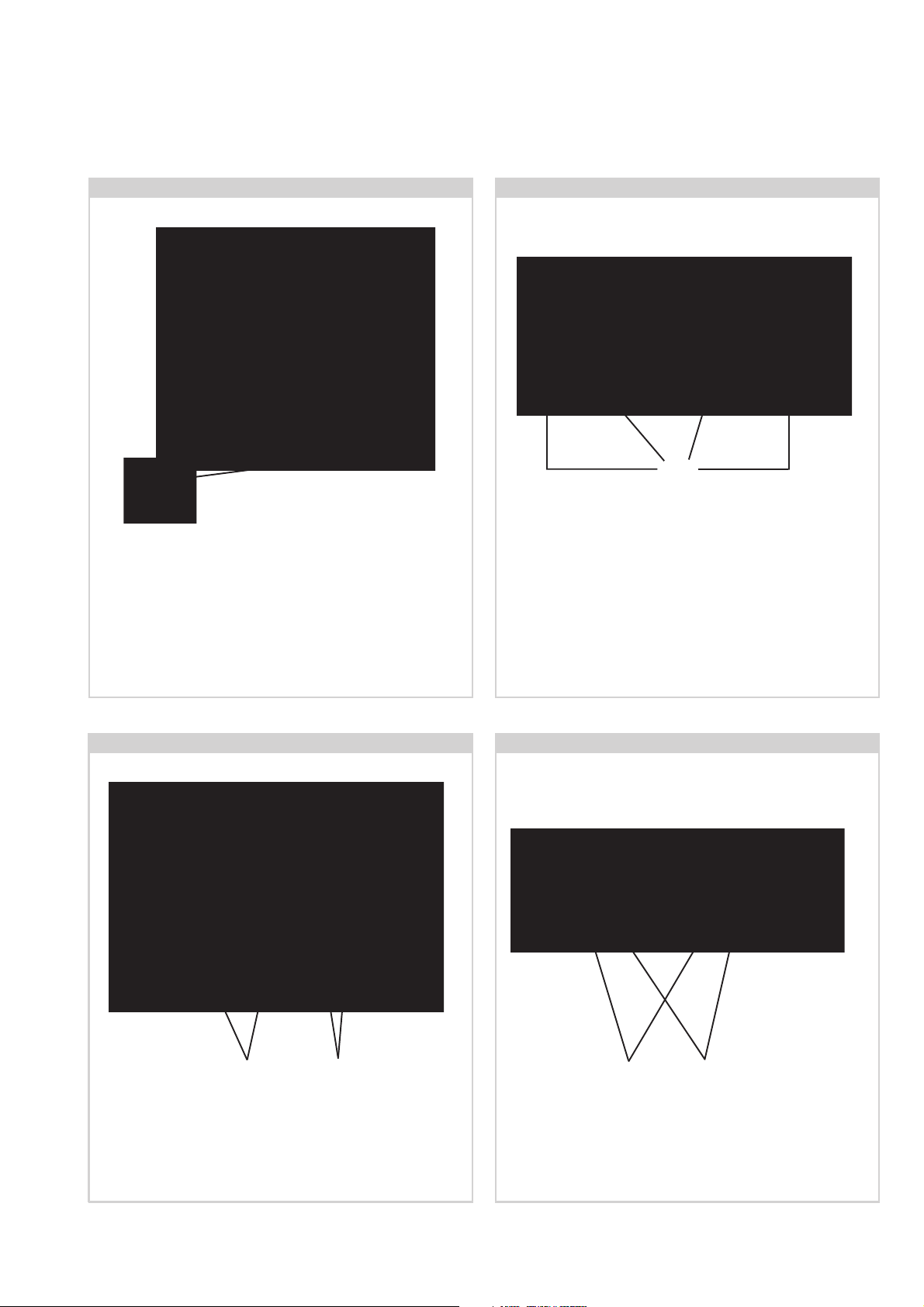

SECTION 2 DISASSEMBLY

2-1. Rear Cover Removal 2-2. Speaker Connector Disconnection

=>

=>

=>

=>

=>

Remove the rear cover fixing screws indicated. Take care

when removing the rear cover not to damage the speaker

cables [Disconnect the speaker connector] as speakers are

fitted inside the rear cover.

=>

=>

=>

<=

<=

<=

=>

=>

=>

Before completely removing the rear cover disconnect the

speaker connector which is located on the inside.

2-3. Chassis Removal and Refitting

To remove lift the main bracket rear slightly and slide the

chassis away from the beznet. Ensure that the interconnecting

leads are released from their purse locks to prevent damage

being caused.

When refitting the chassis ensure that the main bracket is

located in the beznet guide slots before sliding the chassis

forwards. Refit the inter-connecting leads in their respective

purse locks.

- 16 -

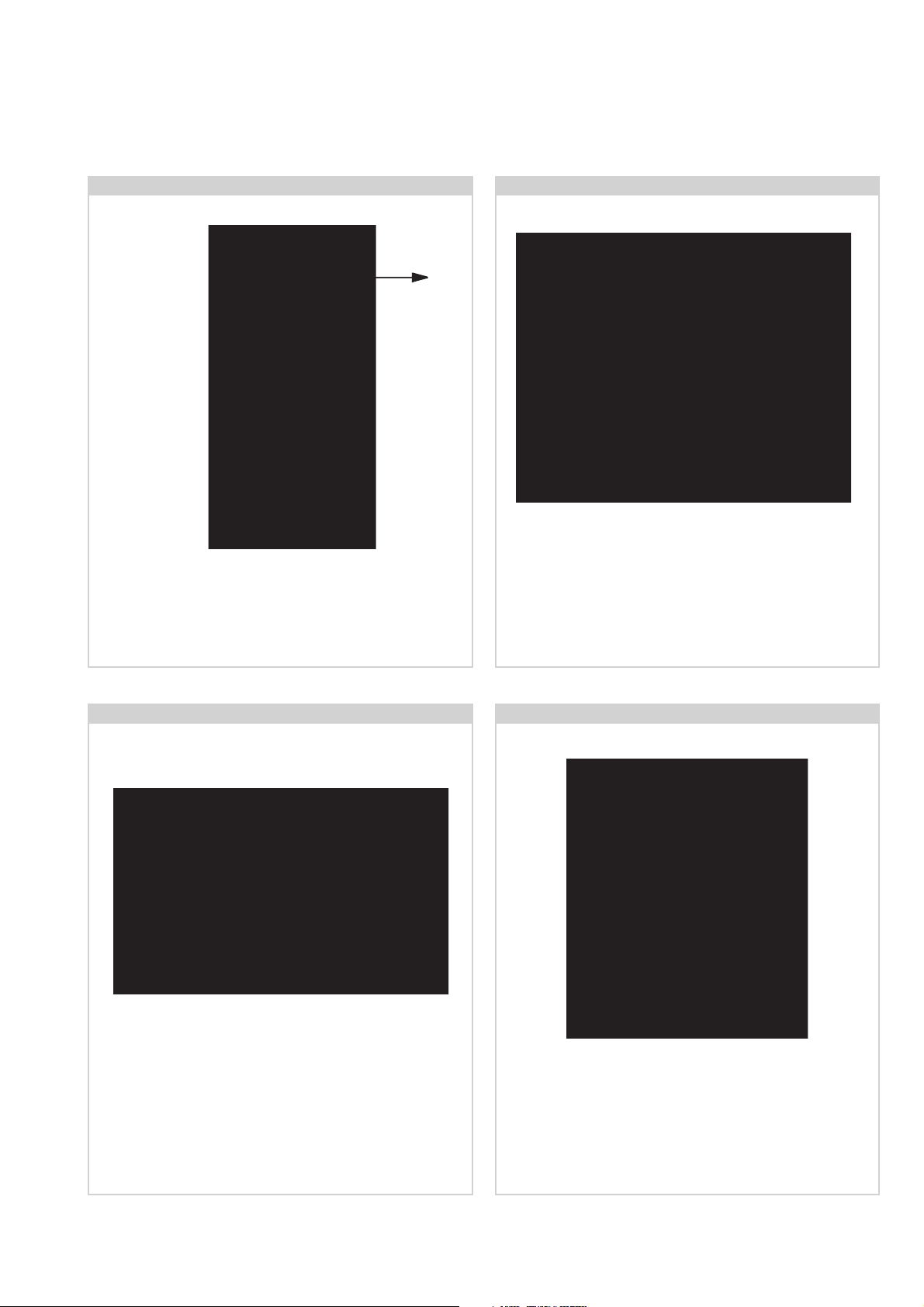

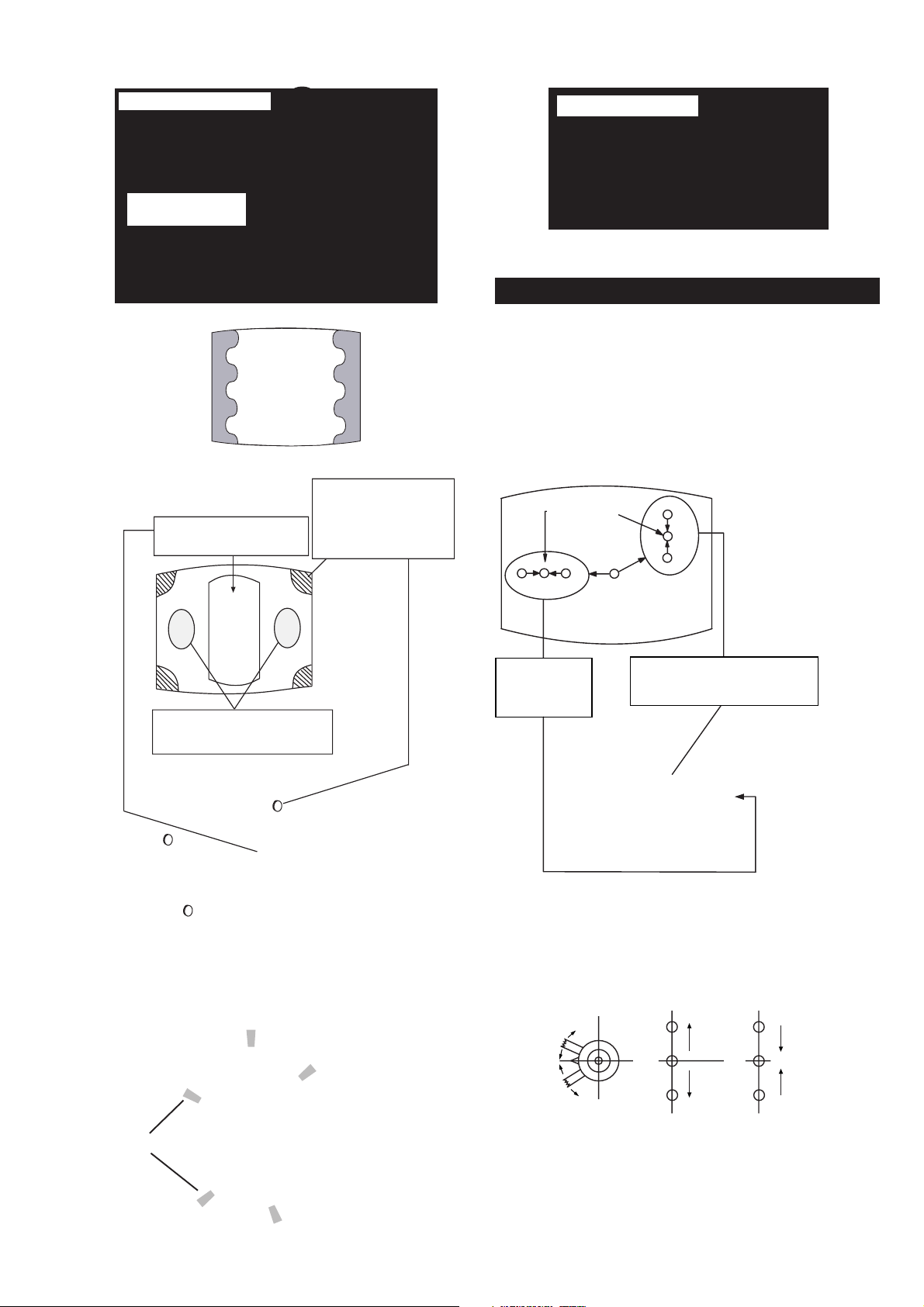

2-4. Service Position 2-5. G Board Removal

Screw

Clips

To place the chassis in the service position, remove the D2

bracket (see 2-7.) and locate on the beznet inside the set.

Insert the main bracket firmly into the T-slot located on the left

corner of the beznet as indicated (see inset). To gain access to

the underside of the boards follow the instructions on page 19.

[Removal and Replacement of the main bracket bottom plates].

2-6. D2 Board Removal

To remove the G Board first remove the PFC bracket by

removing the two fixing screws (one on each side of the

bracket) and lifting away from the G board.

Remove the screw from the centre of the G board, release

the clips circled and ease the board gently away from the

support bracket.

2-7. D1 Board Removal

Screws

Clips

To remove the D2 board remove the two screws circled,

release the clips circled and ease the board gently away from

the support bracket.

Screws Clips

To remove the D1 board first remove the D2 bracket by

removing the three screws from the bracket (one on opposite

side) and releasing the four clips (two on each side of the

bracket). The D1 board can then be removed using the

same method as the G board.

- 17 -

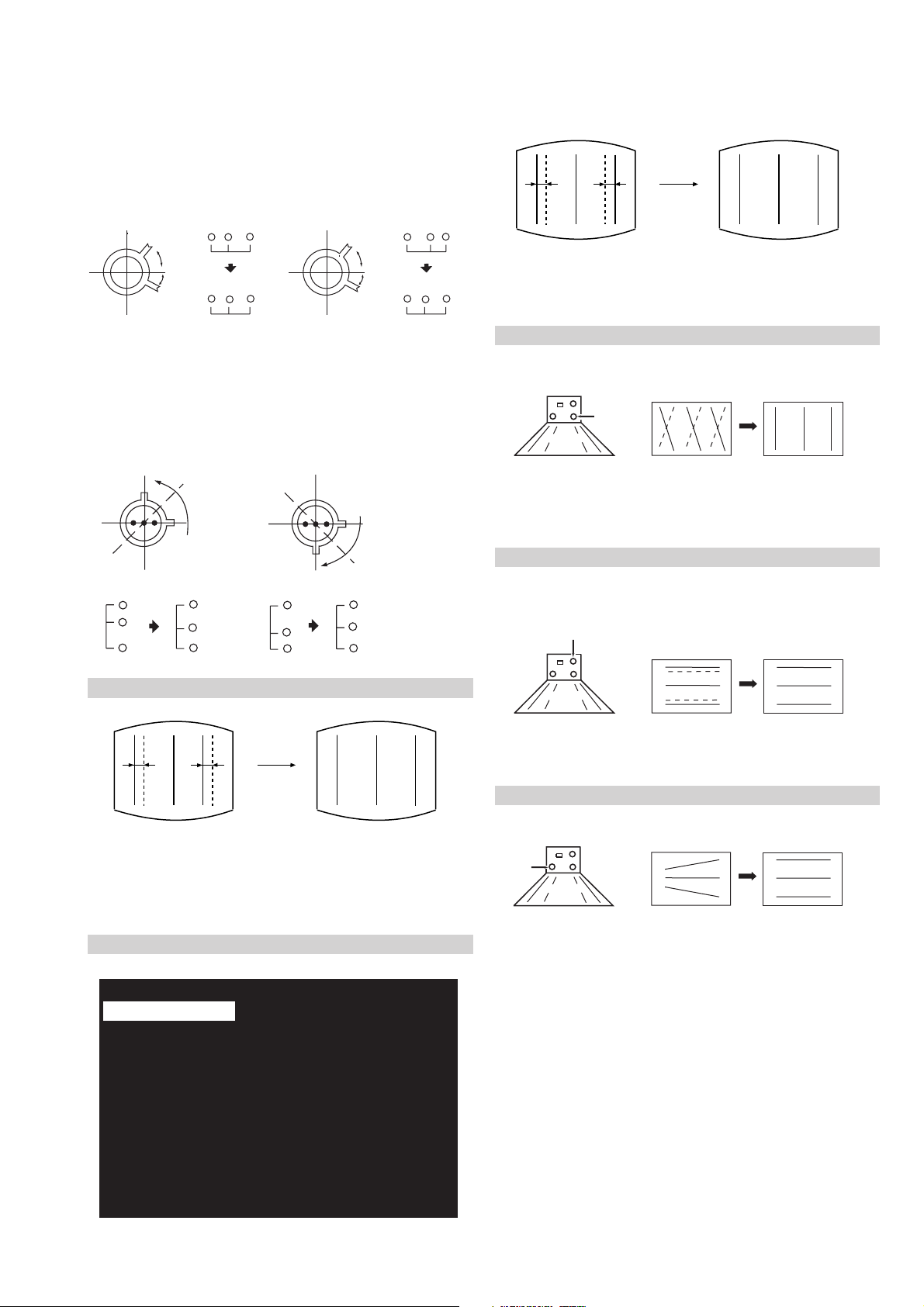

2-8. Wire Dressing 1

2-9. Wire Dressing 2

20mm

20mm

Ensure that wires do not touch heatsinks and high temperature

hotspots. All wires must be kept at a minimum distance of

20mm away from the EHT lead

2-10. Wire Dressing 3

The sheathed end of the ground connecting lead must be

plugged into the F3 board to avoid the possibility of the AC

mains power touching ground.

2-11. Wire Dressing 4

Ensure the RF lead is dressed as shown circled above to avoid

obstructing the rear cover.

To avoid damage to the ground interconnecting leads from the

sharp edges of the heatsink they must be dressed as shown

above between the rear of the heatsink and the tuner.

- 18 -

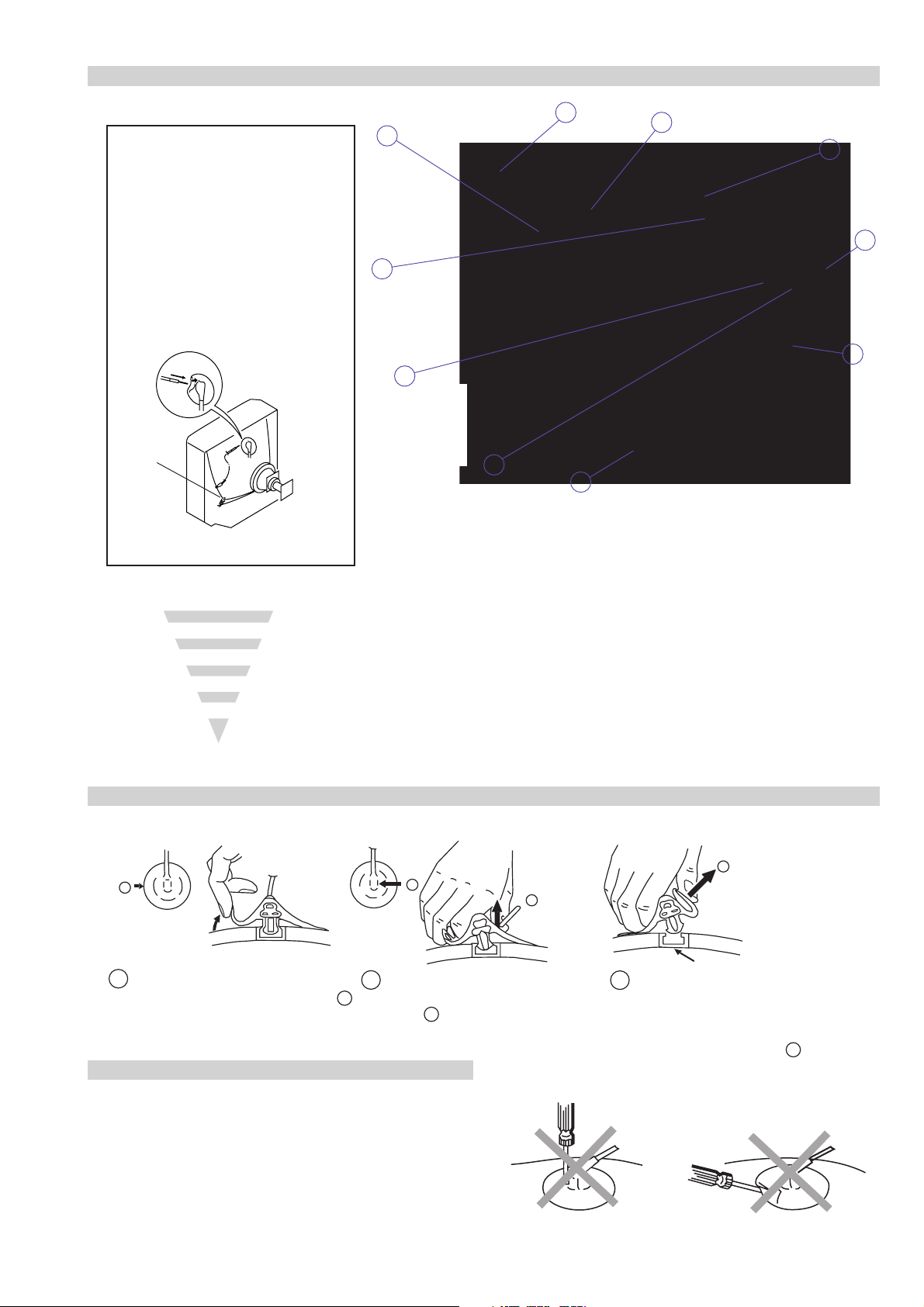

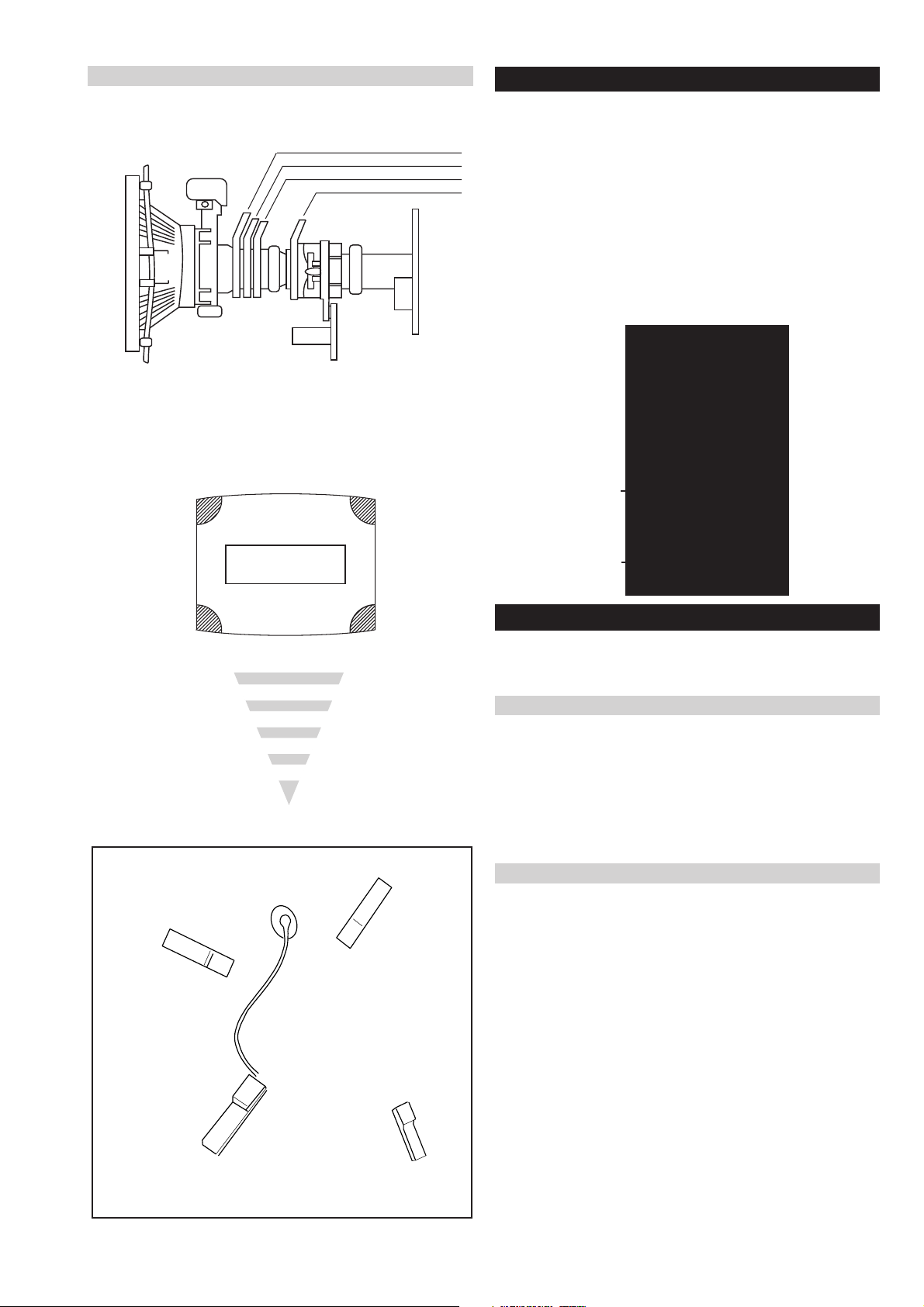

2-12. Picture Tube Removal

WARNING:

BEFORE REMOVING

THE ANODE CAP

High voltage remains in the CRT even

after the power is disconnected. To

avoid electric shock, discharge CRT

before attempting to remove the anode

cap. Short between anode and CRT

coated earth ground strap.

Coated Earth

Ground Strap

10

8

7

6

5

4

9

1

3

2

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the Deflection yoke, neck

assy, degaussing coils and CRT grounding strap.

3. Remove the C Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the Neck assembly fixing screw and remove.

6. Loosen the Deflection yoke fixing screw and remove.

7. Place the set with the CRT face down on a cushion and remove

the Degaussing Coil holders.

8. Remove the Degaussing Coils.

9. Remove the CRT grounding strap and spring tensioners.

10. Unscrew the four CRT fixing screws [ located on each CRT

corner ] and remove the CRT.

[Take care not to handle the CRT by the neck.]

Removal of the Anode-Cap

REMOVAL PROCEDURE.

a

1

Turn up one side of the rubber cap in

the direction indicated by the arrow a

b

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b

How to handle the Anode-Cap

1. To prevent damaging the surface of the anode-cap do not use

sharp materials.

2. Do not apply too great a pressure on the rubber, as this may cause

damage to the anode connector.

3. A metal fitting called a shatter hook terminal is fitted inside the

rubber cap.

4. Do not turn the rubber foot over excessively, this may cause

damage if the shatter hook sticks out.

c

b

Anode button

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling it up in

the direction of the arrow c

- 19 -

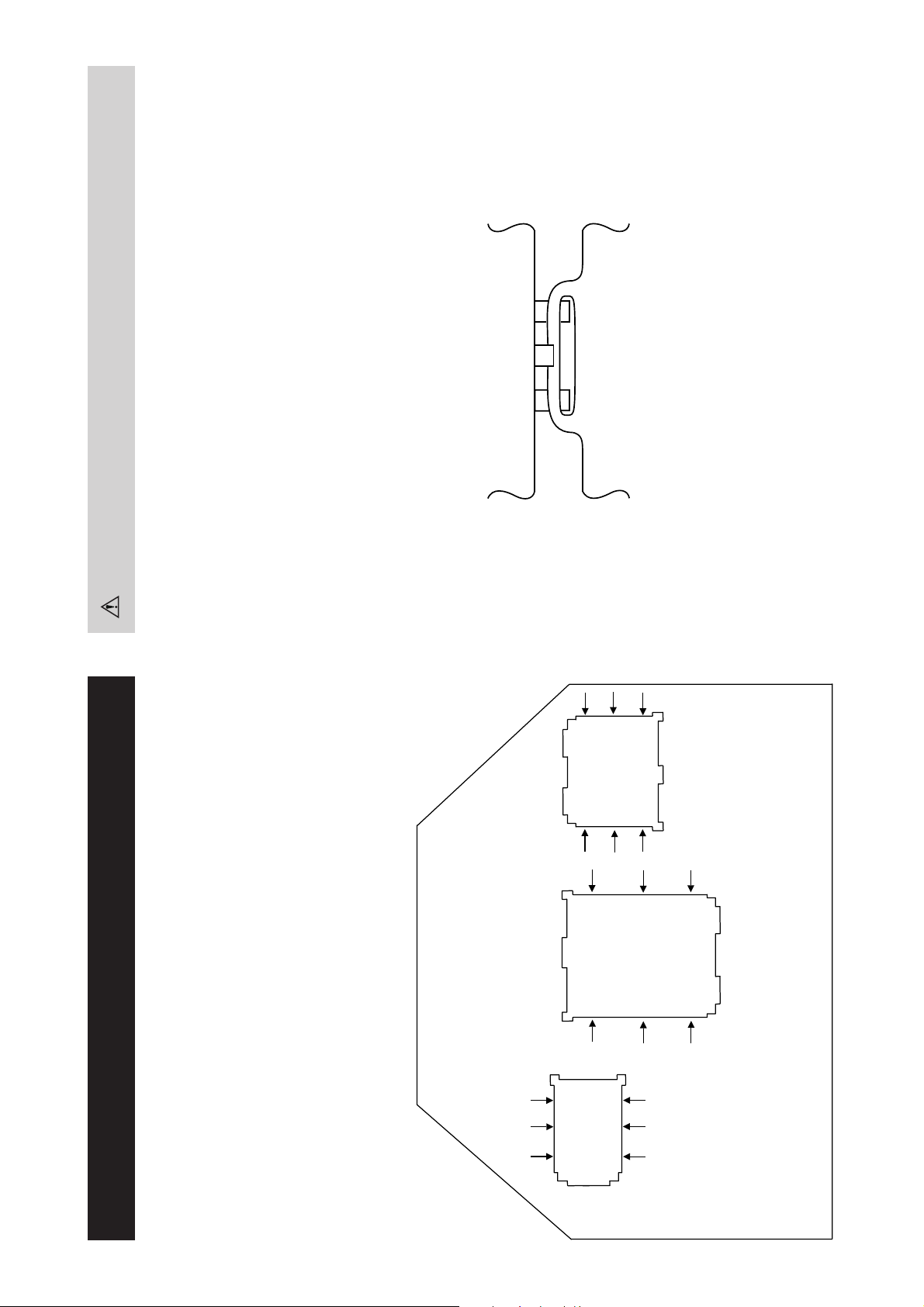

Catch

For safety reasons, on no account should the plates be removed

and not refitted after servicing.

Because the plates differ in size it is important that the correct plates are refitted in their original

location.

Please note that the plates need to be rotated 180 degrees from their cut position to allow the

(2) REFITTING THE PLATES

tabs to be fitted into their catch positions.

Ta b

REMOVAL AND REPLACEMENT OF THE MAIN-BRACKET

BOTTOM PLATES.

Only remove the necessary plate to gain access to the printed wiring board.

In the event of servicing being required to the solder side of the A, D1 or G printed wiring

boards, the bottom plates fitted to the main chassis bracket require to be removed.

This is performed by cutting the gates with a sharp wire cutter at the locations indicated by the

arrows.

(1) REMOVING THE PLATES

Note : There are 3 plates fitted to the main bracket and secured by 3 gates.

- 20 -

SECTION 3 SET-UP ADJUSTMENTS

Neck assy

G2

G1

+

Align the edge

of the neck assy on the

edge of the G3 grid closest

to the G2 grid.

G3

• When complete readjustment is necessary or a new picture tube

is installed, carry out the following adjustments.

• Unless there are specific instructions to the contrary, carry out

these adjustments with the rated power supply.

• Unless there are specific instructions to the contrary, set the

controls and switches to the following settings :

Contrast .................................. normal

Brightness .................................. normal

3-1. Beam Landing

Preparation :

1. In order to reduce the influence of geomagnetism on the set’s

picture tube, face it in an easterly or westerly direction.

2. Switch on the TV set’s power and degauss with a degausser.

(1) Adjustment of Correction Magnet for Y-Splitting Axis.

1. Input a crosshatch signal from the pattern generator.

2. Set the Picture control to minimum and confirm that the

Brightness control is set to normal.

3. Position the neck assembly as indicated in Fig.3-3.

4. Loosen the deflection yoke fixing screw.

5. Move the deflection yoke as far forward as is possible.

6. Adjust the upper and lower pin symmetrically by opening or

closing the Y-splitting axis correction magnets located on the

neck assembly. [See Fig 3-2]

7. Return the deflection yoke to its original position and re-tighten

its fixing screw.

Fig.3-1

Y-splitting axis correction magnet

Carry out the adjustments in the following order :

3-1. Beam Landing and Geometry.

3-2. Convergence.

3-3. Focus.

3-4. White Balance.

Note : Test equipment required.

1. Color bar/pattern generator.

2. Degausser.

3. Oscilloscope.

4. Digital multimeter.

(2) Landing and Geometry

Note : Before carrying out the following adjustments adjust the

magnets as indicated on page 22 [See Fig.3-4].

1. Input a crosshatch signal from the signal generator.

2. Rough-adjust the focus and horizontal convergence.

3. Switch from the crosshatch pattern to an all-red pattern.

4. Move the deflection yoke backwards and adjust with the purity

magnet so that the red is at the centre and it aligns

symmetrically [See Fig.3-5].

5. Move the deflection yoke forward to the point where the entire

screen just becomes red [Mark its position].

6. Move the deflection yoke further forward until the screen just

changes colour at the edges. [Mark its position].

7. Position the deflection yoke between the two marks indicated

above.

8. Input a crosshatch pattern from the pattern generator and rotate

the deflection yoke so that the horizontal lines are parallel with

the top and bottom of the screen.

9. When the position of the deflection yoke has been determined,

fasten it with its fixing screw.

10. Once dy rotation and swing left and right for h linearity is ok on

cross hatch pattern, insert dy wedges. [See Fig.3-6].

11. Switch the pattern generator to green then blue and confirm the

purity.

12. If the beam does not land correctly in all the corners of the

screen, use disk magnets to correct it. [Confirm the corner

landing forgreen and blue].

13. Re-check geometry for landing magnet effect. Adjust using

deflection menu. [TT Mode].

Fig.3-2

Caution :

High voltages are present on the Deflection yoke terminals - take care

when handling the Deflection yoke whilst carrying out adjustments.

Fig.3-3

- 21 -

Fig.3-4

B

G

R

B

G

R

Purity magnets

Align pips on

each magnet

Align both Purity

magnets to the vertical

position

Purity control magnets

3-2. Convergence

(1) Screen centre convergence [Static convergence]

Fig.3-5

GREEN

RED

BLUE

Disk magnets or

rotatable disk

Purity control corrects

this area

magnets correct

these areas (a-d)

ab

c

Deflection yoke positioning

corrects these areas

d

1. Input a dot pattern signal from the pattern generator.

2. Normalize the picture setting.

3. [Moving vertically], adjust the V.STAT magnet so that the

vertical red, green and blue dots coincide at the centre of the

screen.

Center dot

H.STAT

convergence

Vertical Static Magnet

V.STAT

control

RV5375 (H STAT)

H STAT Convergence

(on mount side)

Disk Magnets

Fig.3-6

5 Wedges

required

By opening or closing the V.STAT magnet, the red green and

blue dots move in the direction indicated below.

Note: Do not adjust the H.STAT by rotating the V.STAT

magnets as this can affect the focus setting.

- 22 -

4. Correction for HMC [Horizontal mis-convergence] and VMC

+

+

+

YCH VR

Deflection Yoke

+

+

+

TLV VR

Deflection Yoke

[Vertical mis-convergence] by using the BMC [Hexapole]

magnet.

a). HMC correction by BMC [Hexapole] magnet and movement of

the electron beam.

HMC correction(A) HMC correction(B)

A < B

RG B

A > B

RGB

HTIL correction can be performed by adding a THL correction

assembly to the Deflection yoke.

A = B

A B

RG B

A B

A = B

A B

RG B

A B

b). VMC correction by BMC [Hexapole] magnet and movement of

the electron beam.

VMC correction(A) VMC correction(B)

C < D

C

D

C = D C > D C = D

R

G

B

R

C

G

D

B

C

D

R

G

B

R

C

G

D

B

HAMP Adjustment

YCH Adjustment

TLV Adjustment

Adjust the HAMP using HAMPL and HAMPR registers in the

Dynamic Convergence section of the service menu.

HTIL Adjustment

THL Correction assy

H-TRAP Adjustment

+

+

HTRAP VR

+

Deflection Yoke

The H-TRAP should not be adjusted unless absolutely necessary as it

affects the TLV settings.

- 23 -

Layout of each control

Purity magnet

BMC (Hexaploe) magnet

V STAT convergence magnet

Y-splitting axis correction magnet

Note : If you are unable to adjust the corner convergence properly,

this can be corrected with the use of permalloy magnets.

a

b

3-3. Focus Adjustment

1. Receive a cross hatch pattern from a video generator.

2. Adjust the focus control located on the flyback transformer to

the best level at the centre of the screen.

3. Check left and right x-axis vertical line thickness and adjust to

make them as thin as possible.

4. Considering x-axis and centre, adjust to make uniform.

5. If no cross hatch signal is possible, follow the next three steps.

6. Receive a television broadcast signal.

7. Normalize the picture setting.

8. Adjust the focus control located on the flyback transformer to

obtain the best focus at the centre of the screen.

Bring only the centre area of the screen into focus, the magentaring appears on the screen. In this case, adjust the focus to

optimize the screen uniformly.

Focus

a-d: screen-corner

convergence defect

c

Install the permalloy assembly

for the area that needs correcting.

b

Permalloy Assy

X-4387-214-1.

d

Convergence adjustment with permalloy

Screen

d

3-4. Screen (G2), White Balance

[Adjustment in the service mode using the remote

commander]

G2 adjustment

1. Input a dot signal from the pattern generator.

2. Set the Picture, Brightness and Colour to minimum.

3. Apply 165V DC from an external power supply to the R, G

and B cathodes of the CRT.

4. Whilst watching the picture, adjust the G2 control [SCREEN]

located on the flyback transformer to the point just before the

flyback return lines disappear.

a

White balance adjustment for TV mode

1. Input an all-white signal from the pattern generator.

2. Program the Remote Commander for operation in Service Mode.

[See Page 25].

3. Enter into the ‘Service Mode’ by pressing ‘VIDEO’ button twice

and ‘MENU’ on the Service Commander.

4. Select ‘Device Register Setting’ from the on screen menu display

and press ‘Right Arrow’.

5. Select ‘Backend’ from the on screen menu display and press

‘Right Arrow’.

6. Set the ‘Contrast’ to MAX.

7. Set the ‘R-Drive’ to 45.

8. Adjust the ‘G-Drive’ and the ‘B-Drive’ so that the white

balance becomes optimum.

9. Press the ‘OK’ button to write the data for each item.

10. Set the ‘Contrast’ to MIN.

11. Set the ‘R-Cutoff’ to 35.

c

12. Adjust the ‘G-Cutoff’, and the ‘B-Cutoff’ with the left and

right buttons on the remote commander so that the white

balance becomes optimum.

13. Press the ‘OK’ button to write the data for each item.

- 24 -

SECTION 4 CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments

Service adjustments to this model can be performed using the

supplied remote Commander RM-938.

Programming the Remote Commander for Operation in Service Mode

1. Press the VCR/TV/DVD button until the

TV LED lights.

2. Press and hold the yellow button for

approx. 5 seconds until the TV LED

flashes quickly.

3. Press 99999. All three LED’s should light.

The remote commander is now set to Service Mode.

4. To return the remote commander to normal operation mode

repeat steps 1. and 2. then press 00000. All three LED’s

should light.

The remote commander is now set to normal mode.

Setting the TV into Service Mode

1. Program the remote commander for operation in Service

Mode as described above.

2. Turn on the TV main power switch.

3. Press the video standby button on the remote

commander twice.

‘TT ’ will appear in the upper right corner of the screen.

Other status information will also be displayed.

Initialising Menu

gnisilaitinI

gnitteSledoM

gnitteSnoitanitseD

gnitteScisaB

gnitteSerutaeF

:tceleS:unemtxeN

Model Setting

The menu contains a list with all the available models of this software

to set up the TV set in an easy way. The selection of a model is setting

data for its features and hardware resources which cannot be detected

by the automatic power on H/W detection as well as a special model

byte to get an unique model identification for models which cannot be

differed by features and hardware resources (e.g. KV-29FQ76 and

KV-32FQ80)

Before data is set, the user will be asked if he really wants to set a

new model. If the user agrees, automatically the destination setting

menu is shown.

gnitteSledoM

67QF92-VK

67QF92-VK

08QF63-VK

67SF63-VK

eseR

t

4. Press ‘MENU’ on the remote commander twice to obtain the

following menu on the screen.

71095V,200201rpA,A6EAecivreS

gnisilaitinI

seciveDteseR

gnirotinoM

gnitteSretsigeReciveD

.tnemtsujdAlaicepS

:uneMtxeN:tceleS

5. Move to the corresponding adjustment item using the

up or down arrow buttons on the Remote Commander.

6. Press the right arrow button to enter into the required menu item.

7. Press the ‘Menu’ button on the Remote Commander to quit the

Service Mode when all adjustments have been completed.

Note :

· After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON.

· Certain menu items are only available in production mode.

KCALBytimrofnoCoN=

NEERGledoMelbitapmoC=

DERatadllarofytimrofnoC=

Table.4-1

Indication of Model Compatibility.

Black:

If any data does not match to specific model, the model name is

displayed in black.

Green:

All data which is checked by model setting menu concurs to model

except model byte.

Red:

All data which is checked by model setting menu concurs to model

including model byte.

Note:

After selecting a model, it may be necessary to reset some devices to

get the correct data. (Treble/Bass Offset of Sound, deflection

adjustments, ...)

- 25 -

Basic Setting

noitcelfeD.txE

oNrcseDfeDniMxaMataD

1esahPFD5810552581

2esahPPQD5210552521

3raeniLdiM5310552531

4raeniLH0010552021

5pmacaPQD0510552231

6lvlcdPQD8410552621

7"63tneCH0055208

X-diM

oNrcseDfeDniMxaMataD

1SOPHM061-610

2SOPHS08-80

3LESSYD1031

4YALEDSYD7077

5DOMCNYSDNOFFONONO

6prahStxeTFFOFFONOFFO

7LLP.txEFFOFFONOFFO

8retliFHFFOFFONOFFO

hctiwSoediV/oiduA

gnittescisaB

oNrcseDniMxaMataD

1G/B.sySFFONONO

2K/D.sySFFONONO

3L.sySFFONOFFO

4)KU(I.sySFFONOFFO

5)LRI(I.sySFFONOFFO

6noitpo.taNTXT143

7TRC9:61FFONOFFO

8refoow-buSFFONONO

9yb-dnatsotuAFFONONO

01retlif-bmoCFFONONO

11tedCYotuAFFONONO

21tedbmocotuAFFONONO

31elbaliavA2VAFFONONO

41elbaliavA3VAFFONONO

51elbaliavA4VAFFONONO

61elbaliavA5VAFFONONO

71epaTMACESFFONOFFO

81etuMdnuoS1VAFFONONO

Table.4-2

Feature Setting

gnitteserutaeF

oNrcseDniMxaMataD

1PAPFFONONO

2TAPFFONONO

3XEDNIFFONONO

4txeTeleTFFONONO

5GPEFFONONO

6beWeleTFFONOFFO

Table.4-3

oNrcseDfeDniMxaMataD

11TUOVC0090

22TUOVC2090

3LRTC0OLFFOFFONOFFO

4LRTC1OLFFOFFONOFFO

51TUOCY2072

62TUOCY0070

7WSDCZFFOFFONOFFO

8ETUM3TUOAFFOFFONOFFO

91TUOA3073

012TUOA1071

11LEDPUORG6101361

213TUOA3073

31CLOV3TUOA4074

41FLOV3TUOA4074

51R/L3TUOA0030

61WS1DGNOFFONONO

71WS2DGNOFFONONO

811CNYS1011

912CNYS1011

021TNOCS3233

121OEDIV4034

221OIDUA0030

322TNOCS2232

422OEDIV4034

522OIDUA0030

623TNOCS2232

723OEDIV0030

823OIDUA1031

Table.4-5

Device Register Setting

dnekcaB

noitcelfeD

noitcelfeDtxE

ecnegrevnoCcimanyD

1redoceDruoloC

2redoceDruoloC

hctiwSoediV/oiduA

X-diM

X-diMLLPlanretxE

dnuoS

RNlatigiD

Table.4-4

Table.4-6

Table.4-7

- 26 -

1redoceDruoloC

)tnoc(1redoceDruoloC

oNrcseDfeDniMxaMataD

753EDOMDCFFOFFONOFFO

85SOPSH50515

95DNLRHTNFFOFFONOFFO

06VELECILS00130

16AERAPUFFOFFONOFFO

26NIHTPUFFOFFONOFFO

36J941XFFOFFONOFFO

46CTSMDFFOFFONOFFO

56TSNIFFOFFONOFFO

66LVLRPUNOFFONONO

76LVLSFOFFOFFONOFFO

86TSFOLSFFOFFONOFFO

9634MORF2032

07EDIWMORF2032

17SELTITRF2032

27LFPLNOFFONONO

37TESERWAFFOFFONOFFO

471EPOLSOTD005520

572EPOLSOTD005520

673EPOLSOTD005520

77CNACPUTES00510

87TNIV70517

97HPPLCTXE00360

08TUOTSETFFOFFONOFFO

18METSYSLOC80518

28EDOMBGR2032

38LESSYFFOFFONOFFO

48TEDNFFOFFONOFFO

58ECNAHNEV4074

68RNPFFOFFONOFFO

78QERFV0030

88BMOCNFFOFFONOFFO

98WSOTUAFFOFFONOFFO

09PARTMACESFFOFFONOFFO

19EDOMLLEBFFOFFONOFFO

29LIKMACES1031

39SOPDI2032

49DIWDINOFFONONO

59SYSLOC-EFFOFFONOFFO

69TUPNI-EFFOFFONOFFO

79KCOLH-EFFOFFONOFFO

89QERFV-ENOFFONONO

99SSW-EFFOFFONOFFO

001TESERTNIFFOFFONOFFO

101WS2CRS0030

201WSBMOC0030

301WSBGRFFOFFONOFFO

401KLBMACES1031

501LVLHNEV1031

601YLDCMCSFFOFFONOFFO

701DIMCSFFOFFONOFFO

801PDAMCSNOFFONONO

901EMITLLIKFFOFFONOFFO

011LVLLLIK2032

111SOPNK5075

211DIWDK70517

oNrcseDfeDniMxaMataD

1LESKLC0030

2KLCSYSNOFFONONO

3KLCPSD3033

4LEDFFOFFONOFFO

5LLPFFOFFONOFFO

6KLCFER1031

7LESDA0030

8NOPLCDFFOFFONOFFO

9FFOPLCFFOFFONOFFO

01LESBMOCFFOFFONOFFO

11FFOWAFFOFFONOFFO

21EDOMSYS00510

31MROFGIS210 5121

41VELPILC0030

51RNY0030

61RNC0030

71EDOMKLB2032

81VELY2010552201

91VELC8010552801

02VELDSO0030

12SERDSOFFOFFONOFFO

22ROCPHS0030

322PUF1031

42JDAYLDCY60516

52DEPA0030

62NARTCD0030

72PHSBUS90519

82QEY3073

92OFPHSNOFFONONO

03KTADPA0030

13DLHDPA0030

23AERADPA0030

33SIHDPA0030

43CTRTCD0030

53CTPLCD0030

63SOPPLC70517

73QEC0030

83FPBC0030

93PARTFIDCFFOFFONOFFO

04CTPESSFFOFFONOFFO

14BMOCTNI0030

24EUHBUS70517

34NILRGPLC0030

44GPADAPLCFFOFFONOFFO

54ECILSSH0030

64ECILSSV1031

74CTPITS1031

84FPLCNYSNOFFONONO

94LIFCNYSFFOFFONOFFO

05NIAGCFA1031

15NIAGWOL1031

25PUDPSCFANOFFONONO

35OCWOLNOFFONONO

45OCHGIH0030

551EDOMDC0030

652EDOMDCFFOFFONOFFO

Table.4-8

Table.4-9

- 27 -

2redoceDruoloC

dnekcaB

oNrcseDfeDniMxaMataD

1no-RNOFFONONO

2no-GNOFFONONO

3no-BNOFFONONO

4loc-D0030

5wS-bWFFOFFONOFFO

6L-ammaGFFOFFONOFFO

7tsartnoC0403604

8mottoB-KLB3033

9euH8203662

01sixA-ruoloC1031

11ruoloC1303613

21leveL-ITC2032

31ssenthgirB5203652

41lbA-S0030

51ssenprahS5203652

61leveL-ITL0030

71evirD-R5303653

81timiLP0030

91evirD-G1403614

02edoM-LBA0030

12evirD-B1403614

22edoM-ITC0030

32thgirBbuS60366

42ammaG1031

52ffotuC-R1303613

62edoM-ITL1031

72ffotuC-G7203672

82leveL-CIPD1031

92ffotuC-B1303613

03narT-CD1031

13tnoC-buS80518

23lvL-2BGRL80518

33lbA-P5105151

43HT-LBA00510

53P.ffO-BC2303645

63P.ffO-RC9203611

73S.ffO-BC4503636

83S.ffO-RC103636

93W-gnigAFFOFFONOFFO

04B-gnigAFFOFFONOFFO

14metsyS1031

24tesffo-Y70517

34leveL-MV1031

44OF.prahSNOFFONONO

54ffO-DCFFOFFONOFFO

64DC.prahS2032

74IF.prahS0030

84revO/erP2032

94roC-MV0030

05OF-MV2032

15timiL-MV3033

25yaleD-MV2032

35ruoloCbuS08-80

oNrcseDfeDniMxaMataD

1TNIT1303613

2WGN/PFFOFFONOFFO

3DIN/PFFOFFONOFFO

4RUOLOCBUS70517

5RTNOCBUS80518

6OFPRAHS1031

7QEPRAHS2032

8NIAGPRAHS80518

9.VELTUO-Y5403683

01TNIOPSB0030

11.VELTUO-C8303683

21TSERCD0030

31OFFPB1031

41QFPB1031

51WSRETLIFFFOFFONOFFO

61WSPART-C0010

71PARTD-SNOFFONONO

81FPLNOFFONONO

91LD-Y40014

02BMOC-NNOFFONONO

12LESOEDIV00510

22LESBGR0030

32ENOTFLAHFFOFFONOFFO

421.FFOrC70517

521.FFObC70517

622.FFOrC70517

722.FFObC70517

82QERFDCV3073

92EDOMDCV1031

03SNESCFA1031

13MVMFFOFFONOFFO

23JDAY-RS60516

33JDAY-BS40514

43FPH/LLEB2032

53OFLLEBFFOFFONOFFO

63PGS2032

73DISFFOFFONOFFO

83BNE1BGRFFOFFONOFFO

93HP-SH0010

04WSotuA1011

14DI-C1011

24HP-PV0010

34OITARN/S3033

Table.4-10

oNrcseDfeDniMxaMataD

1elbaTRN0070

21ccL00360

32ccL00360

43ccL00360

5leS_miLVU0070

Table.4-11

RNlatigiD

Table.4-12

- 28 -

Deflection System Adjustment

4-2. Volume Electrical Adjustments

1. Enter into the service mode and select ‘Deflection’ from the

menu. The ‘Deflection’ adjustment menu will be displayed.

2. Select and adjust each item to obtain the optimum image.

noitcelfeD

oNrcseDfeDniMxaMataD

1eziS-H4303643

2noitisoP-H5203663

3eziS-V1303615

4noitisoP-V1303682

5pmA-niP8103661

6niPC-pU7303614

7niPC-oL7303604

8woB-CFA1303672

9elgnA-CFA1303682

01esahP-niP8203652

11niL-V70518

21rroC-S805121

311-noitatoR1031

412-noitatoR5105151

51parT-H510 131

61raeniLH0010552021

71pmA-raP-CH8303663

81pmA-raP-PM90517

91sixAniPpU2033

02sixAniPoL2033

12niaGniPpU1033

22niaGniPoL1032

32miT-bkA510 1351

42ffO-KLBNOFFONOFFO

52ffO-BKAFFOFFONOFFO

62klB-pU40510

72klB-oL90510

82nO-VNOFFONONO

92cD-wEFFOFFONOFFO

03loP-cUFFOFFONOFFO

13wS-klbVNOFFONOFFO

23esahP-cnyS0030

33edoM-CFA2032

43wS-tsRFFOFFONOFFO

53klB-tfeL2503625

63esahP-plC3033

73klB-thgiR0303603

83etaG-plCFFOFFONOFFO

93klbHNOFFONONO

04tcepsA-V7403674

14wS-mooZFFOFFONOFFO

24wS-pmJFFOFFONOFFO

34llorcS-V1303613

44qerF-V2032

54nilV-pU00510

64nilV-oL00510

74pmoC-V00516

84pmoC-H00510

94cD-1waSV70517

05pmoC-niP7074

15pmA-1waSV00130

25pmoC-CFA0070

35cD-raP-PM3105151

45cD-raP-CH3603613

55wS-psAFFOFFONOFFO

65WS-vrDVFFOFFONOFFO

75ahP-raP-CH1303613

Table.4-13

Sub Colour Adjustment

1. Input a PAL colour bar signal.

2. Connect an oscilloscope to CN5400 pin 5 located on the C

Board.

3. Enter into the ‘Service Mode’.

4. Choose ‘Backend’ from the menu.

5. Adjust ‘Sub Colour’ data so that the right sides of the waveform

are of equal height.

Same Level

B-Out Waveform

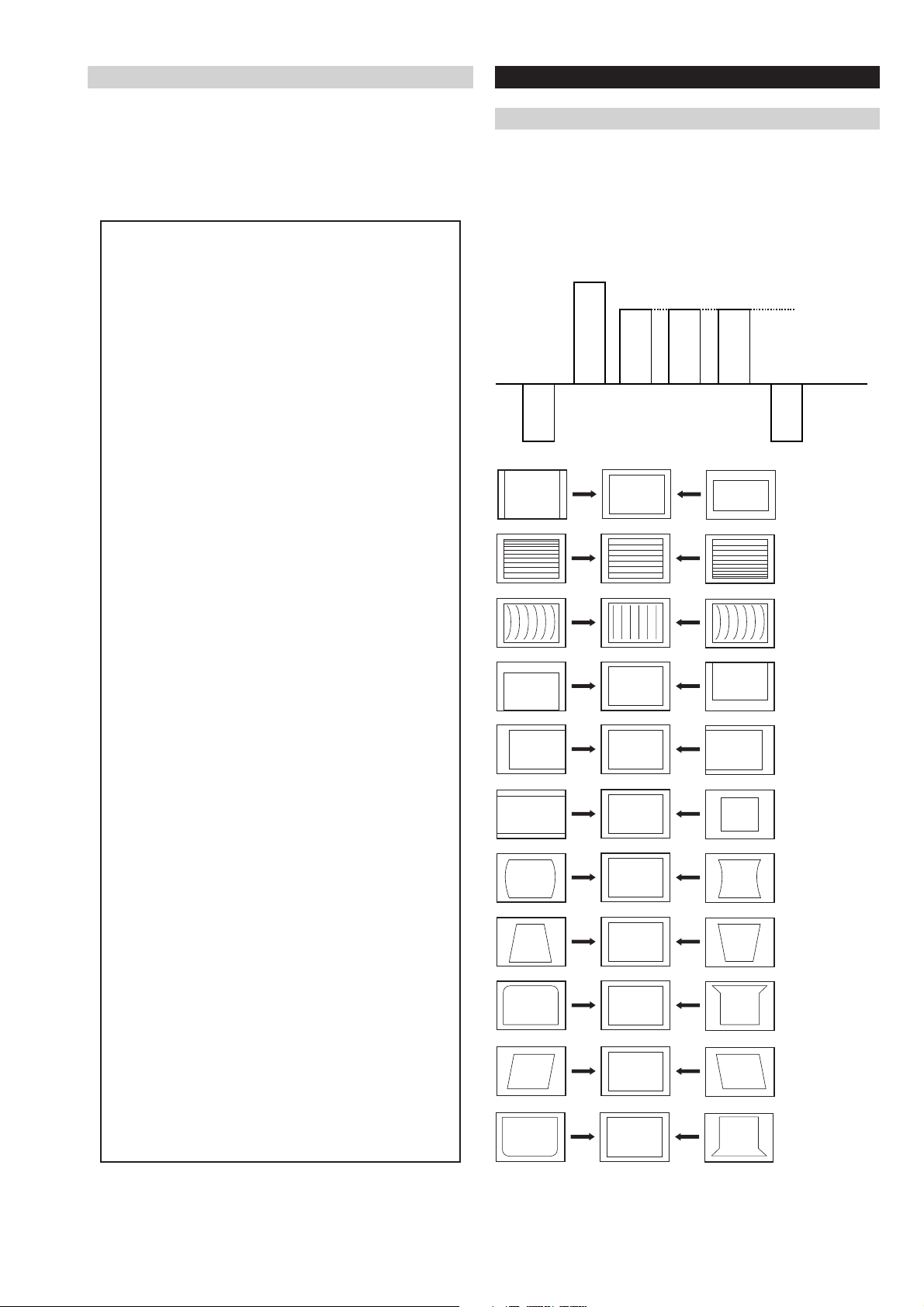

V SIZE

V LIN

AFC V BOW

V POS

H POS

H SIZE

H PIN CUSH

H TILT

H UP COR

AFC V ANGLE

H LOWER COR

- 29 -

4-3. TEST MODE 2:

15

ffo/noyblodlautriV

25

ffo/noetumDSO

35

MVNnisecivresGPEteseR

45

kcehcxednI

55

ylnoesuerawtfoslanretnI

65

tsujdaesahpsucoF

75

tsujdalevelCDsucoF

85

ecivresnoMVNlanretxeotMVNlanretniypoC

rotcennoc

95

lanretniotrotcennocecivresnoMVNlanretxeypoC

MVN

06

noitcAoN

16

tsetkniltramS

26

)elggot(dnabesabmorfoiduaLmetsyS

36

erutcipehtotniMORmorfatadtesererutcipehtypoC

MVNfonoitacolteser

46

ehtotniMVNmorfataderutcipjdalautcaehtypoC

MVNfonoitacoltesererutcip

56

srorreteseR

66

)elggot(srorreerongI

76

)yrevoceRAMMElaunaM(VTDIrofdevreseR

86

noitcaoN

96

teserDIlanosreP

07

noitcaoN

17

LAPecroF

27

LAPecrofnU

37

noitcaoN

47

noitcaoN

57

tsujdaniPCU/pmAniP

67

tsujdaparT/niPCL

77

stesffonoitcelfedteseR

87

tfelecnalaB

97

thgirecnalaB

08

noitcaoN

18

ylno-ffO/nOyalpsidREBlatigiD(VTDIrofdevreseR

)edomlatigidni

28

niylno-ffO/nOedomrotinomVA(VTDIrofdevreseR

)edomlatigid

38

niylno-elggotK8&k2,K8,K2(VTDIrofdevreseR

)edomlatigid

48

niylno-tluafedMVNlatigidteS(VTDIrofdevreseR

)edomlatigid

58

VTDIrofdevreseR

68

gnittesledomlatigiD(VTDIrofdevreseR

)edomlatigidniylno-elggot)D2EF/D6EA(

78

tsetsyeklacoL

88

raelc(noitidnocgnippihslatigiD(VTDIrofdevreseR

)edomlatigidniylno-)esabatadenut

98

VTDIrofdevreseR

09

noitcaoN

19

edom9:41

29

edomtramS

39

edom9:61

49

edommooZ

59

edom3:4

69

-)tolsIC/renut(hctiwshtapST(VTDIrofdevreseR

)edomlatigidniylno

79

)edomlatigidniylno-edomITC(VTDIrofdevreseR

89

yrevocerAMMEotuA(VTDIrofdevreseR

)elbasid/elbane

99

rotinomrorreyalpsiD

Is available by pressing the ‘TEST’ button twice, OSD ‘TT’ appears. The functions described below are available by selecting the two numbers.

To release the ‘Test mode 2’, press 0 twice, press the TV button or switch the TV set into Stand-by mode. Pressing the two Local Control

buttons (+ and -) during power ON will also switch into ‘TT’ mode or from standby mode press OSD, 5, volume plus, TV.

In ‘TT’ mode, it is possible to remove the Menu from the screen by pressing the Speaker Off button once. Pressing the Speaker OFF button a

second time will cause the Menu to reappear. The function is kept even when the menu is not displayed on screen !!.

00

10

20

30

40

50

60

70

80

90

01

11

21

31

41

51

61

71

81

91

02

12

22

32

42

52

62

72

82

92

03

13

23

33

43

53

63

73

83001CRDottesedomCRD

9305CRDottesedomCRD

04noitcaoN

14MVNesilaitinieR

243tsujdayrtemoeG

34dnuosAlauD

44dnuosBlauD

54dnuosonoM

64dnuosoeretS

74

84nigriv-nonsaMVNteS

94nigrivsaMVNteS

05noitcAoN

ffoedom'TT'

mumixamerutciP

muminimerutciP

%03otemuloVenohpdaeh/rekaepsteS

%05otemuloVenohpdaeh/rekaepsteS

%56otemuloVenohpdaeh/rekaepsteS

%08otemuloVenohpdaeh/rekaepsteS

edomgniegA

noitidnoCgnippihS

noitcaoN

noitcaoN

tnemtsujdaerutcipbuS

tnemtsujdaruolocbuS

tnemtsujdassenthgirbbuS

noitcaoN

%05levelerutciP

rotinomnoitcudorP

noitcaoN

noitcnufcitamotuanoitatorerutciP

elbasid/elbaneedomnoitcudorP

noitcaoN

sutatsVTyalpsid,E,D,AnoitanitseD

sutatsVTyalpsid,itluM,BnoitanitseD

sutatsVTyalpsid,E,D,AnoitanitseD

sutatsVTyalpsid,UnoitanitseD

sutatsVTyalpsid,E,D,AnoitanitseD

sutatsVTyalpsid,itluM,BnoitanitseD

sutatsVTyalpsid,KnoitanitseD

sutatsVTyalpsid,RnoitanitseD

1tnemtsujdayrtemoeG

noitcaoN

elbasid/elbaneybdnatsotuA

2tnemtsujdayrtemoeG

noitcaoN

tsetedomneercS

sutatsVT,9:61>-<3:4TRC

noitaludomyticoleV

noitcaoN

noitcaoN

- 30 -

5-1. BLOCK DIA GRAMS (1)

TO

A BOARD

CN1803

VM ( )

VELOCITY MODULATION

CN5602

4

Q.P -

5

Q.P +

VM IN

1

CN302 IC300

VM AMP

Q5400,5401

AV LINK PROCESSOR

H ( )

1

SCL_3.3

SDA_3.3

3

AV_INT

5

RESET

6

AV-LINK

7

X300

3.3V

D302

CN907

1

3

TO A BOARD

CN1701

5

7

9

11

VM BUFFER

Q5402,5403,

5404,5405

23

SCL

24

SDA

22

INT

6

RESET

21 14

AV-LINK

28

OSC_OUT

29

OSC_IN

HEADPHONE R OUT

HEADPHONE L OUT

AV4 CHROMA IN

AV3 LUMINANCE IN

AV4 LEFT IN

AV4 RIGHT IN

SIRCS

RESP LED

VOL+

VOL-

RESET

BUTTON

AV-IN

PROG+

PROG-

4 3

2 1

Q5406,5407

20

17

15

11

10

9

8

Y/C

VIDEO

L

R

VM OUT

SIRCS

RESET -BUTTON

PROG+

PROG-

CN900

VOL+

VOL-

AV-IN

Q.P -

Q.P +

1

2

3

4

7

8

CN301

3

4RESP LED

CN300

1

2

3

4

5

6

J900

HEADPHONE

CN5444

TO

F4 BOARD

CN2161

TO

TOP CONTROLLER

QP-

QP+

VM

NECK

ASSY

TO

J2 BOARD

TO

B5 BOARD

CN4472

TU1001

CN1001

CN7109

ANALOGUE

TUNER

3

FBLK

5

V-PULSE

6

H-PULSE

7

MAIN-Y

9

MAIN-U

10

MAIN-V

11

CV-TEXT

13

SUB-C

14

SUB-Y

17

AV4.C

18

ATV-CV OUT

19

AV4.Y

21

AV-LINK

23

SDA

24

SCL

25

SDA1

26

SCL1

31

HP-MUTE

33

HP-R

34

HP-L

35

AV4-R

36

AV4-L

39

DTV-R

40

DTV-L

41

TV-R

42

TV-L

43

ATV-R

44

ATV-L

45

MAIN-R

46

MAIN-L

48

AGC MON

49

QSS

50

AM

1

MS-SHUT-DOWN

11

VP100 IN

12

HP100 IN

14

Y100

16

U100

18

V100

20

DPIC

22

RESET 100

23

SCL

24

SDA

31

VPSUBOUT/Y-SUB

34

VSUBOUT/C-SUB

36

USUBOUT/INT-COL

38

YSUBOUT/FB

42

MAIN-Y

44

MAIN-U

46

MAIN-V

48

V-PULSE

50

H-PULSE

AGC

SCL

SDA

FM/AM

QSS

VIDEO

VIDEO

AGC

AGC

VSYNC100

HSYNC100

SUB-Y

SUB-C

INT-COL

FBLK

TO

SHEET

CN2000

OCP

12

OVP

MAIN RY

DGCRY

LEFT SP

RIGHT SP

DISABLE

HM(1)

HM(2)

INT-COL

HM(3)

AV-LINK

HM(4)

SCL0

SDA0

VIDEO

TXTBLKBLK-MB

TXTB

STBY

TXTG

TXTR

SCL-DIG

SDA-DIG

VP100

HP100

SDA

DISABLE

HM(1)

HM(2)

HM(4)

HM(3)

AV LINK

13

CN1602

1

2

CN1201

1

TO SPEAKERS

3

CN1202

1

TO SUB WOOFER

CN1000

1

4

5

6

7

8

9

10

11

13

15

17

19

21

23

24

25

27

29

31

33

35

39

CN1701

1

3

5

7

9

11

CN1999

SCL

2

3

4

CN1706

1

3

5

6

7

TO

M2 BOARD

CN100

TO

H3 BOARD

CN907

TO

SERVICE

CP1100

1

SWATT

AUDIO

IC1201

AUDIO AMPLIFIER

WOOFER

1

WOOFER

AC-RY-LATCH

RIGHT

LEFT

OVP

2

OUTPUT

9 3

INPUT

BOOT

10

STBY/MUTE

IC1202

AUDIO AMPLIFIER

LEFT AND RIGHT

11

MUTE

6

MUTE

13

IN S+

8

IN C+

I/O EXPANDER

6

ATTN

1

0V PROT

4

DG CRY

A 1/2 ( )

IC1008

INTERFACE

STBY

STBY

OUT S

OUT C

PROT

14

9

1

3

15

SCL

14

SDA

OCP

10

AUDIO DECODER AND AMPLIFIER, VERTICAL DEFLECTION,

PICTURE ROTATION, DYNAMIC CONVERGENCE

SCL-TV

SDA-TV

CV TEXT

B-MB

G-MB

R-MB

SCL1

SDA1

VSYNC

HSYNC

HP-R

HP-L

AV4.C

AV4-Y AV3 LUMINANCE IN

AV4-L AV4 LEFT IN

AV4-R AV4 RIGHT IN

WOOFER SP

MS-SHUT-DOWN

SCL

SDA

AUDIO RESET

RESET 100

AUDIO MUTE

HEADPHONE RIGHT OUT

HEADPHONE LEFT OUT

AV4 CHRONA IN

VOL-

1

2

VOL+

3

PRESET

VIDEO

4

5

PROG -

6

PROG +

S900

S901

S902

S903

S904

S905

H3

FRONT AV INPUT,

HEADPHONE

(

)

- 31 -

5-1. BLOCK DIA GRAMS (2)

J2 ( )

AV4

5

3

TO

A BOARD

3

11

25

26

31

33

34

46

45

19

36

10

9

7

42

41

14

18

CN3600

AV4-C-IN

TU3800

SUB TUNER

AV3L

AVFC

CVBS-TV-SUB

5

3

5

3

3

5

6

13

24

23

17

35

21

AV1

AV3

AV2

F-BLK-OUT

32

36

25

29

18

60

20

35

5

62

30

24

23

11

13

45

9

41

40

49

54

34

26

33

27

55

43

28

19

58

SWITCH

Q2302

SWITCH

Q2303

SWITCH

Q2300

SWITCH

Q2301

1

3

R OUT6L-IN

7

L OUT R-IN

HP-R-OUT

RGBSEL

5

2

15

4

3

6

7

8

14

13

12

11

10

IC3500

IC3400

48

16

18

47

45

17

46

44

5

32

22

2

20

19

13

14

7

9

4

42

40

39

37

33

29

23

3

1

26

25

6

12

11

CVBS-to-2149

J2300

L

R

STU-LR

SCL-DIG

SDA-DIG

VIDEO

FM/AM

SCL

SDA

HP-L-OUT

IC2300

HP OUT

V-IN-1-B

V-IN-1-G

V-IN-1-R

BLK-1

SEL

V-IN-2-B

V-IN-2-G

V-IN-2-R

BLK-2

BLK-OUT

V-OUT-B

V-OUT-G

V-OUT-R

BLUE IN

GREEN IN

RED IN

BLANKING

AV3ROUT

AV3LOUT

AV3C

AV3Y

AV3VOUT

AV4R

AV4L

AV4C

AVFL

AV3OUT

AVFY

AV4R-IN

L-to-1855

R-to-1855

AV4Y

AV3R

AV3MODE R-FRONT

R-SEL-OUTPUT

L-SEL-OUTPUT

C-AV

Y-AV3

CVBS-SEL-(AV3)

R-AV4

L-AV4

C-AV4

R-to-2149

L-to-2149-P26

L-FRONT

R-to-2149-P33

C-SUB

SCL

SDA

CVBS-from-2149

Y-FRONT

L-from-2149

R-from-2149

C-to-2149

Y-to-2149

L-to-2149

CVBS-to-2149

Y-AV4

CVBS-AV4

R-AV3

L-AV3

AV4MODE-1

AV4MODE-2

C-FRONT

LDO

CVBS-TV-SUB

IC3300

MAIN AUDIO/VIDEO SWITCH

STU-LR

Y-MAIN

C-MAIN

CVBS-TEXT

CVBS-SUB

L-TO-2149

SUB-TUNER

L-AV1

R-HP-VAR-OUTPUT

MAIN-TV

R-AV1

L-MAIN-TV

MODE 1

SUB-TV-(MOND)

CVBS-AV1

L-HP-VAR-OUTPUT

Y-MAIN-OUTPUT

C-MAIN-OUTPUT

MODE 3

Y-OUTPUT-TEXT

CVBS-SUB-OUTPUT

L-to-1855

R-to-1855

C-to-2149

Y-to-2149

R-from-1855-P32

L-from-1855-P22

R-from-1855-P20

L-from-1855-P33

CVBS-from-1855

CVBS-to-1855

R-AV2

L-AV2

MODE 2

Y-AV2

RIGHT IN(4) AV4R

LEFT IN(4) AV4L

MODE(4) AV4MODE

C IN(2) AV4C

Y IN AV4Y

BLUE IN

GREEN IN

RED IN

BLANKING

RIGHT OUT(1)

RIGHT IN(1)

LEFT OUT(1)

LEFT IN(1)

MODE(1)

VIDEO OUT(1)

VIDEO IN(1)

RIGHT OUT(3)

RIGHT IN(3)

LEFT OUT(3)

LEFT IN(3)

MODE(3)

AV LINK

C IN(1)

VIDEO OUT

VIDEO IN(3)

RIGHT OUT(2) RMONIT-OUT

RIGHT IN(2)

LEFT OUT(2) LMONIT-O UT

LEFT IN(2)

BLUE IN

MODE(2)

GREEN IN

RED IN

BLANKING

VIDEO(2) AV2V

AV-LINK

MAIN-R-OUT

MAIN-L-OUT

AV4R-IN

HP-L-OUT

HP-R-OUT

ATV-CV-IN/GNG

SUB-Y CVBS-SUB

HP-MUTE

SCL-DIG

SDA-DIG

CVBS-TEXT

B-OUT

G-OUT

R-OUT

MAIN-TV-R-IN

MAIN-TV-L-IN

AV4-L-IN

AV4-Y-IN

SDA

SCL

SUB-C

MAIN-C-OUT

MAIN-Y-OUT

CN1001

RMONIT-OUT

LMONIT-OUT

AV1TVOUT

AVFL

AVFY

AVFC

C-MAIN

Y-MAIN

AV3Y

AV3YOUT

AV3ROUT

AV3L

AV3LOUT

AV3R

AV1TVOUT

MAIN-TV-L-IN

MAIN-TV-R-IN

AV SCART, I/O

SWITCHING AND SOCKETS

TO

VM BOARD

CN5602

TO

C BOARD

CN5400

TO

D1 BOARD

CN8500

TO ROT COIL

TO CY

TO

D1 BOARD

CN8616

TO

D2 BOARD

CN6801

CN1803

1

VM

4

QP-

CN1804

1

R-OUT

3

G-OUT

5

B-OUT

8

IK

CN1805

1

DF-PARA

2

MP-PARA

3

E/W

4

HC-PARA

5

H-DRIVE

6

AFC-PULSE

7

ABL

8

XRAY

CN1901

1

ROT-

3

ROT+

CN1902

1

CY+

3

CY-

CN1807

1

PRE-RGB

2

DF-DRIVE

3

H-CENTRE

CN1903

4

H-PROT

5

HDP-OVP

6

AFC-PULSE

7

DF-DRIVE

8

ABL

TO

A BOARD

CN1802

T0

A BOARD

CN1805

AC-RY-LATCH

CN8612

CN8500

2

3

5

TO

SHEET 1

MP-PARA

EW

H-DRIVE

14

VM-OUT

DPIC

12

DPDT-OFF

Y100

20

Y-IN

U100

21

CB-IN

V100

22

CR-IN

64

R-OUT

63

G-OUT

62

B-OUT

58

42

28

46

45

47

43

40

39

56

25

26

51

60

IK-IN

VS-IN

HS-IN

DF-PARA

MP-PARA

EW-DRV

HC-PARA

H-DRV

HP-IN

APL-IN

SDA

SCL

VSAW1

PRE-RGB

VSYNC100

HSYNC100

BACK END BLOCK RESPONSIBILITY

2

SCL

3

TV-R

TV-L

ATV-R

ATV-L

DTV-L

DTV-R

MAIN-L

MAIN-R

AM

SDA

POWER ON

21

RESET

33

SC2-OUT-R

34

SC2-OUT-L

36

SC1-OUT-R

37

SC1-OUT-L

53

SC2-IN-L

54

SC2-IN-R

56

SC1-IN-L

57

SC1-IN-R

60

MONO IN (AM)

AUDIO RESET

IC1402

VPROT

DF-DRIVE

35

XTAL OUT

XTAL IN

IF IN

72

71

69

30 3

28

27

AUDIO

FL1270

4 1

IC1270

OUTPUT AMP

5

7

IC1231

SUBWOOFER OUT

SPEAKER OUT L

SPEAKER OUT R

IC8801

29

18

8

1

HD1 OUT

MP.PARA

EW

HD1N

HD2 OUT

LIN OUT

MP OUT

28

14

16

IC1801

7 5

3 6

VERTICAL

IC1701

1

QSS

BUFFER

Q8010

Q8011

BUFFER

Q8014

Q8015

BUFFER

Q8507

Q8508

BUFFER

Q8503

Q8504

DFPHASE

DQP-

AC-AMP

IC1804

2 1

3

AFC-PULSE

HC-PARA

DF-PARA

ABL

IC1808

7 5

1

DQP-PHASE

26

IC1811

7

4

IC1806

14

6

5 2

DQP-DC-LEVEL

ROTROT+

CY+

CY-

H-CENTRE

DQP-AC-AMP

DQP-DC-LEV

DF-PHASE

DQP-PHASE

MP-PARA

AUDIO DECODER AND AMPLIFIER, VERTICAL DEFLECTION,

A 2/2 ( )

PICTURE ROTATION, DYNAMIC CONVERGENCE

DY

ASSY

6

V+

5

V-

4

H-

3

HDT

T8100

HDT

T8101

LINEARITY

Q8106

INNER

PIN

Q8105

UPPER

H OUT

Q8102

LOWER

H OUT

Q8103

+B

+B

D1 ( )

T8202

HDT

HORIZONTAL

DEFLECTION

2

H+

1

TO

CN8614

5HEATER

C BOARD

CN5634

IC1811

4

1

IC1950

ROTATION (N/S)

2

4

IC1809

6

3

IC1803

10

8

12

3

7

9

4

21

20

H-LINEAR

SDA

SCL

- 32 -

5-1. BLOCK DIA GRAMS (3)

2

4

SWITCH

Q2161

STBY 5V

TO H BOARD

CN301

CN2161

RESP LED

SWITCH

Q2160

OUT

IC2160

GR

1

5

POWER

S2650

CN2652CN2650

2

1

F4( )

POWER SWITCH, SIRCS

RECEIVER AND STAND-

BY LED INDICATOR

TO

G BOARD

CN6001

D2172

VCC

3

SIRCS

AC IN

AC IN

AC OUT

AC OUT

CN6801

1/2

6

TO

A BOARD

CN1903

7

8

AFC

PULSE

2 3

DF DRIVE

ABL

AFC PULSE

DETECT

Q6802, Q6803

IC6807

12

VG(L)

VG(H)

1

V SENSE

IC6800

BUFFER

Q6803

1

3

2

5

6

IC6801

Q8909

Q6804,

15

VS

Q6805

16

9

2

F/B

CATHODE

IC6803

1

7

9

8

200V

7

5

10

200V

6

4

3

11

43

REF

T6800

POWER ON SWITCH

HV

HV

OVERSHOOT

17

PROJECT

Q6816, Q6817

13

15

14

G2

16

FV

1

18

19

12

IC6802

7

5

6

SS RESET

Q6814,

Q6813

6

DYNAMIC

3

FOCUS

T8901

1

ABL

PROTECT

Q6807

UNDER

VOLTAGE

PROTECT

Q6808

D2 ( )

DYNAMIC

FOCUS

Q8918

HPROT

HOP OV

DYNAMIC PICTURE

STABILISING CIRCUIT

CN6801

2/2

4

5

TO

A BOARD

CN1903

TO A BOARD

CN1804

CN5400

R

1

G

3

B

5

IK

8

VOLTAGE DET

+12V

Q5375, 5376

+12V

Q5350

STANBY SW

Q5300

STANBY SW

Q5325

STANBY SW

Q5351

IC5300

VIDEO OUT (RED)

1

VB

3

VI

9

VDF

VO

5

IK

IC5325

VIDEO OUT (GREEN)

1

VB

3

VI

9

VDF

VO

5

IK

IC5350

VIDEO OUT (BLUE)

1

VB

3

VI

9

VDF

VO

5

IK

8

8

8

FV

G4

R

10

G

9

B

8

H1

5

H1

5

J5375

CN5634

TO D2 BOARD

FV (T6800)

PICTURE TUBE

HV

TO D1 BOARD

CN8614

TO D2 BOARD

HV (T6800)

TO F4 BOARD

CN2652

FOR CHECK

TO A BOARD

CN1602

CN6001

CN6002

CN6003

CN6004

CN6008

R, G, B OUT

C (

)

T6003

4

AC IN

1

5

AC IN

CHECK

1

2

CHECK

1

DGC

DGC

2

3

DGC

1

PFC

3

PFC

MAIN RY

1

2

DGC RY

3

2

1

T6101

1

2

3

4

RELAY

RY6001

MAIN RECT

D6001

RELAY

RY6002

7

8

RECT

D6102

9

RELAY

SWITCH

Q6103

RELAY

SWITCH

Q6101

MAIN BRIDGE

1

V SENSE

2

F/B

3

CT

4RT

TIMER

6

7

SS

8

VC 1

9

OCP

IC6001

RECTIFIER

VG (L)

18

VD

16

VG

15

VS

14

VB

12

VC 2

10

D6004

MOSFET

TRANSISTOR

USED BY

SWITCHING

CIRCUIT Q6006

MOSFET

TRANSISTOR

USED BY

SWITCHING

CIRCUIT Q6007

T6002

10

11

RECT

D6010

12

6

8

7

9

13

14

15

16

17

18

1

RECT

2

D6016

3

PH6001

4

3

1

2

+200V

+135V

+11V

+6V

CN6006

AU (+)

5

TO A BOARD

AU (+)

6

CN2000

IC6003

1

2

Q6104

Q6105

G ( )

- 33 -

POWER

SUPPLY

DB09

DQ3

DQ2

DQ1

DQ0

ADDR11

DQ7

DQ6

DQ5

DQ4

XCAS

XRAS

153

152

154

150

151

139

138

136

137

135

133

129

134

128

149

148

140

147

126

125

127

124

123

192

193

195

196

194

199

201

202

200

203

122

189

191

190

DQ11

DQ10

DQ9

DQ8

ADDR9

ADDR0

DQ15

DQ14

DQ13

DQ12

ADDR2

ADDR1

204

205

206

10

11

9

14

13

19

20

36

35

46

48

49

47

25

15

16

18

17

27

28

26

29

30

39

40

42

41

31

32

38

37

7

8

TO

SHEET 1/2 (B)

TO

SHEET 1/2 (A)

DB08

DB07

DB06

DB05

DB04

DB03

DB02

DR09

DR08

DR07

DR06

DR05

DR04

DR03

DR02

DY09

DY08

DY07

DY06

DY05

DY04

DY03

DY02

DIC00

DIC01

DIC02

DIC03

DIC04

DIC05

DIC06

DIC07

DIY00

DIY01

DIY02

DIY03

DIY04

DIY05

DIY06

DIY07

XWE

DOM

XCS

ADDR10

ADDR3

ADDR8

ADDR7

ADDR6

ADDR5

ADDR4

17

15

16

18

14

6

5

2

3

19

21

22

20

23

12

11

8

9

49

48

24

46

45

32

31

29

28

30

27

43

42

39

40

DQ(3)

DQ(2)

DQ(1)

DQ(0)

ADDR(11)

DQ(7)

DQ(6)

DQ(5)

DQ(4)

XCAS

XRAS

DQ11

DQ10

DQ9

DQ8

ADDR9

ADDR(0)

DQ15

DQ14

DQ13

DQ12

ADDR(2)

ADDR(1)

XWE

DOM

XCS

ADDR(10)

ADDR(3)

ADDR8

ADDR7

ADDR6

ADDR5

ADDR4

DQ(3)

DQ(2)

DQ(1)

DQ(0)

ADDR(11)

DQ(7)

DQ(6)

DQ(5)

DQ(4)

XCAS

XRAS

DQ11

DQ10

DQ9

DQ8

ADDR9

ADDR(0)

DQ15

DQ14

DQ13

DQ12

ADDR(2)

ADDR(1)

XWE

DOM

XCS

ADDR(10)

ADDR(3)

ADDR8

ADDR7

ADDR6

ADDR5

ADDR4

DQ3

DQ2

DQ1

DQ0

ADDR11

DQ7

DQ6

DQ5

DQ4

CAS

RAS

DQ11

DQ10

DQ9

DQ8

ADDR9

ADDR0

DQ15

DQ14

DQ13

DQ12

ADDR2

ADDR1

WE

LDGM

CS

ADDR10

ADDR3

ADDR8

ADDR7

ADDR6

ADDR5

ADDR4

IC4203

IC4201

B5 (2/2)

( )

PICTURE DECODER, DRC,

DIGITAL NOISE REDUCTION

IOPORT7

IOPORT6

7

8

6

11

11

132

131

129

130

128

124

123

125

122

12

135

133

134

120

119

121

118

116

111

110

109

115

114

112

113

4

5

TO

SHEET 1/2 (C)

DRCCBIN0

IP7

IC4304

IOPORT5

IOPORT4

IOPORT3

IOPORT2

IOPORT1

IOPORT0

IP6

IP5

IP4

IP3

IP2

IP1

IP0

57

58

59

69

80

93

81

60

IP7

IP6

IP5

IP4

IP3

IP2

IP1

IP0

FV

FH

PXI

FFSW

GAME

SO

S1

VSTILL1

DB03

DB04

DB05

DB06

DB07

DB02

150

151

153

152

154

134

135

133

136

147

149

148

138

139

137

140

122

127

128

129

123

124

126

125

DB08

DB09

DSB(3)

DSB(4)

DSB(5)

DSB(6)

DSB(7)

DSB(2)

DSR(4)

DSR(2)

DSR(3)

DSB(8)

DSB(9)

DR03

DR04

DR05

DR06

DR07

DR02

DR08

DR09

DY03

DY04

DY05

DY06

DY07

DY02

DY08

DY09

DSR(5)

DSR(6)

DSR(7)

DSR(8)

DSR(9)

DSY(4)

DSY(2)

DSY(3)

DSY(5)

DSY(6)

DSY(7)

DSY(8)

DSY(9)

DSB(3)

DSB(4)

DSB(5)

DSB(6)

DSB(7)

DSB(2)

DSR(4)

DSR(2)

DSR(3)

DSB(8)

DSB(9)

DSR(5)

DSR(6)

DSR(7)

DSR(8)

DSR(9)

DSY(4)

DSY(2)

DSY(3)

DSY(5)

DSY(6)

DSY(7)

DSY(8)

DSY(9)

DRCCBIN1

DRCCBIN2

DRCCBIN3

DRCCBIN4

DRCCBIN5

DRCCBIN6

DRCCBIN7

DRCCRIN0

DRCCRIN1

DRCCRIN2

DRCCRIN3

DRCCRIN4

DRCCRIN5

DRCCRIN6

DRCCRIN7

DRCCYIN0

DRCCYIN1

DRCCYIN2

DRCCYIN3

DRCCYIN4

DRCCYIN5

DRCCYIN6

DRCCYIN7

48

49

51

50

52

56

57

53

58

44

47

46

60

61

59

62

63

69

70

71

64

65

68

67

DSPCRIN0

DSPCRIN1

DSPCRIN2

DSPCRIN3

DSPCRIN4

DSPCRIN5

DSPCRIN6

DSPCRIN7

DSPCBIN0

DSPCBIN1

DSPCBIN2

DSPCBIN3

DSPCBIN4

DSPCBIN5

DSPCBIN6

DSPCBIN7

DSPCYIN0

DSPCYIN1

DSPCYIN2

DSPCYIN3

DSPCYIN4

DSPCYIN5

DSPCYIN6

DSPCYIN7

RP(1)

RP(2)

RP(3)

RP(4)

RP(5)

RP(0)

BP(2)

BP(0)

RP(6)

RP(7)

BP(3)

BP(4)

BP(5)

BP(6)

BP(7)

GP(2)

GP(0)

GP(3)

GP(4)

GP(5)

GP(6)

GP(7)

BP(1)

GP(1)

TO

SHEET 1/2 (D)

99

98

96

97

95

93

92

94

89

104

100

103

87

86

88

85

82

76

75

74

80

79

77

78

DY(5)

DY(7)

DY(4)

DY(3)

DY(2)

DY(1)

DY(0)

DY(6)

DRCCYOUT0

DRCCYOUT1

DRCCYOUT2

DRCCYOUT3

DRCCYOUT4

DRCCYOUT5

DRCCYOUT6

DRCCYOUT7

DRCCROUT0

DR(5)

DR(7)

DR(4)

DR(3)

DR(2)

DR(1)

DR(0)

DR(6)

DRCCROUT1

DRCCROUT2

DRCCROUT3

DRCCROUT4

DRCCROUT5

DRCCROUT6

DRCCROUT7

DB(5)

DB(7)

DB(4)

DB(3)

DB(2)

DB(1)

DB(0)

DB(6)

DRCCBOUT1

DRCCBOUT2

DRCCBOUT3

DRCCBOUT4

DRCCBOUT5

DRCCBOUT6

DRCCBOUT7

DRCCBOUT0

5-1. BLOCK DIAGRAMS (4)

A BOARD

CN7109

CN4472(1/2)

TO

11

12

23

24

38

42

44

46

48

50

31

34

VP100 OUT

HP100 OUT

SCL

SDA

FBIN

BIN

GIN

RIN

CV/Y MAIN IN

C MAIN IN

SUB CVBS

C SUB IN

IC4403

VP-100

442

OUT

HP-100

OUT

IC4402

BUFFER

Q3119

BUFFER

Q3116

BUFFER

Q3110

BUFFER

Q3120

BUFFER

Q3108

BUFFER

Q3106

2

CN4472(2/2)

14

IC4602

Y 100 OUT

U 100 OUT

V 100 OUT

16

18

AMP Q4903

PDACY

AMP Q4904

PDACU

AMP Q4905

PDACV

RP(0)

71

DSPCR0

RP(1)

70

DSPCR1

RP(2)

69

DSPCR2

RP(3)

68

DSPCR3

RP(4)

65

DSPCR4

RP(5)

64

DSPCR5

RP(6)

63

DSPCR6

RP(7)

62

DSPCR7

35

AIN6

29

AIN4

24

AIN3

32

AIN5

16

AIN2

12

AIN1

IC4602

IC3100

CLKO

COUT2

COUT3

COUT4

COUT5

COUT6

COUT7

COUT8

COUT9

YOUT2

YOUT3

YOUT4

YOUT5

YOUT6

YOUT7

YOUT8

YOUT9

LIEN

VSO

HSO

154