Page 1

SERVICE MANUAL

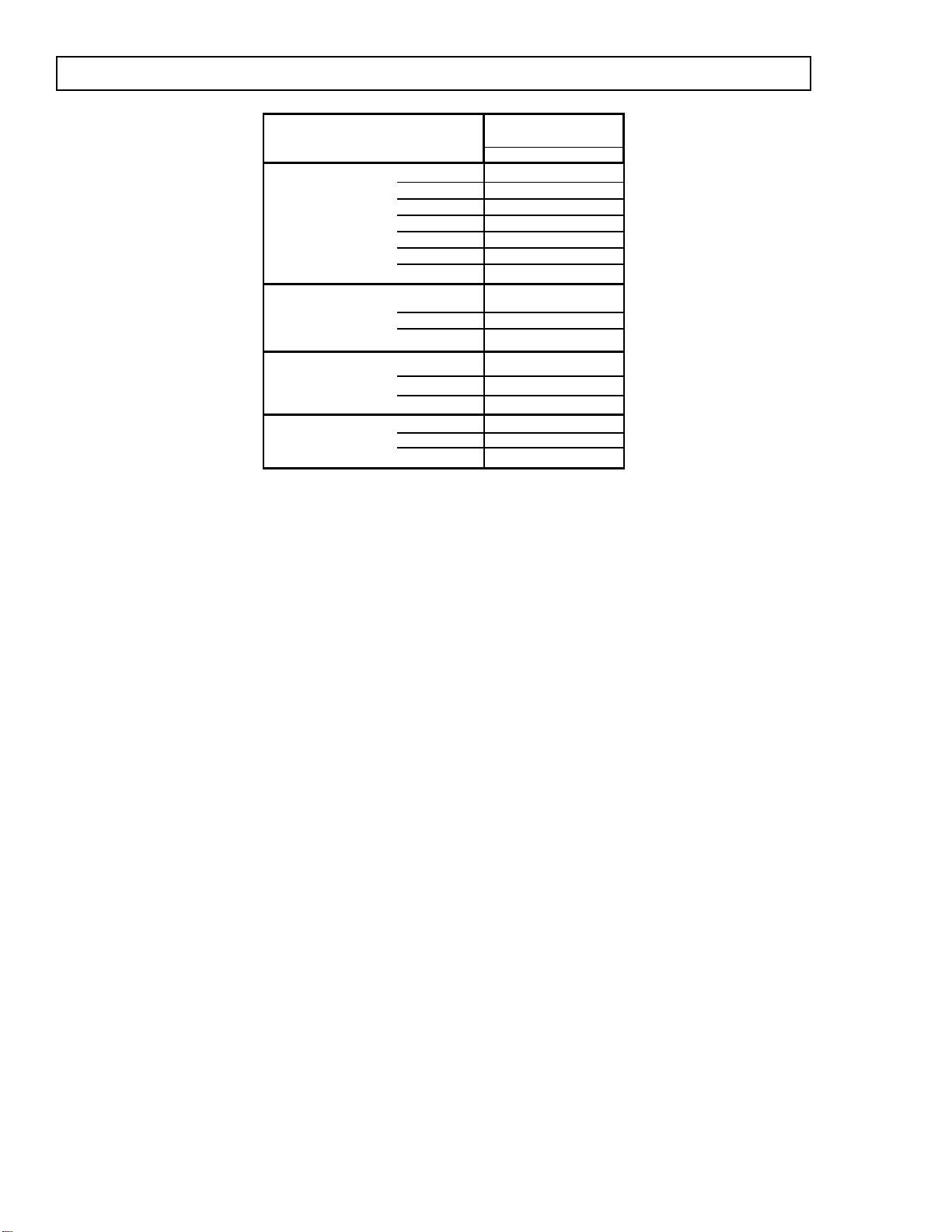

MODEL COMMANDER DEST CHASSIS NO.

BA-5 CHASSIS

KV -34FS12T

RM-Y168 TAIWAN SCC-S42B-A

RM-Y168KV-34FS12T

TRINITRON® COLOR TV

Page 2

KV-34FS12T

SPECIFICATIONS

Power requirements 110V, 60 Hz

Number of inputs/outputs

Speaker output(W) 5Wx2

Power Consumption(W)

Dimensions(W/H/D)

Mass

1) 1 Vp-p 75 ohms unbalanced, sync negative

2) Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) 500mVrms (100% modulation), impedance: 47kilohms

4) More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fix)

5) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR: Vp-p, 75 ohms

1)

Video

2)

S Video

3)

Audio

4)

Audio Out

5)

, PR

Y,P

B

In use(Max) 165W

In standby 5W

(mm)

(in)

(kg) 74 kg.

(lbs) 163 lbs. 2 oz.

KV-34FS12T

3

1

3

1

1

800 x 704 x 582 mm.

1/2

3/4

x 27

31

x 23 in.

Television system

American TV standard/NTSC

Channel coverage

VHF:2-13/UHF:14-69/CATV:1-125

Visible screen size

32” picture measured diagonally

Actual screen size

34” picture measured diagonally

Antenna

75 ohm external antenna terminal for VHF/UHF

Supplied accessories

Remote Commander RM-Y168

Size AA (R6) batteries (2)

Optional accessories

Connecting cables: VMC-810S/820S, VMC-720M,

YC-15V/30V , RK74A

U/V mixer EAC-66

TV Stand: SU27FD3

Design and specifications are subject to change without notice.

— 2 —

Page 3

KV-34FS12T

TABLE OF CONTENTS

Section Title Page

Warnings and Cautions ....................................................................................................................................... 4

Self-Diagnostic Function ...................................................................................................................................... 4

Safety Check-Out Instructions.............................................................................................................................. 7

1. GENERAL ........................................................................................................................................................... 8

2. DISASSEMBLY

2-1. Rear Cover Removal ............................................................................................................................... 14

2-2. Chassis Assembly Removal..................................................................................................................... 14

2-3. Service Position ...................................................................................................................................... 14

2-4. Picture Tube Removal............................................................................................................................. 15

3. SET-UP ADJUSTMENTS

3-1. Beam Landing......................................................................................................................................... 16

3-2. Convergence .......................................................................................................................................... 17

3-3. Focus...................................................................................................................................................... 18

3-4. Screen (G2) ............................................................................................................................................ 19

3-5. Method of Setting the Service Adjustment Mode..................................................................................... 19

3-6. White Balance Adjustments .................................................................................................................... 19

4. SAFETY RELATED ADJUSTMENTS

4-1.

4-2. B+ Volt age Confirmation and Adjustment................................................................................................ 20

5. CIRCUIT ADJUSTMENTS

5-1. Setting the Service Adjustment Mode...................................................................................................... 22

5-2. Memory Write Confirmation Method........................................................................................................ 22

5-3. Adjustment Buttons and Indicators.......................................................................................................... 22

5-4. MA Board Adjustments............................................................................................................................ 26

6. DIAGRAMS

6-1. Block Diagram......................................................................................................................................... 31

6-2. Circuit Board Location............................................................................................................................. 37

6-3. Printed Wiring Boards and Schematic Diagrams..................................................................................... 37

6-4. Semiconductors ...................................................................................................................................... 57

7. EXPLODED VIEW

7-1. Chassis ................................................................................................................................................... 58

R564 Confirmation Method (HV Hold-Down Confirmation) and Readjustments ................................. 20

• A Board .............................................................................................................................................. 38

• MA Board............................................................................................................................................ 45

• HX Board............................................................................................................................................ 49

• CA Board............................................................................................................................................ 51

• K Board .............................................................................................................................................. 52

• V A Board ............................................................................................................................................ 54

• D Board .............................................................................................................................................. 55

8. ELECTRICAL P ARTS LIST .............................................................................................................................. 59

— 3 —

Page 4

KV-34FS12T

WARNINGS AND CAUTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED

DURING ANY SERVICE TO AVOID POSSIBLE SHOCK

HAZARD, BECAUSE OF LIVE CHASSIS. THE CHASSIS

OF THIS RECEIVER IS DIRECTLY CONNECTED TO THE

AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS,

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERA TION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION!!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURT-CIRCUITER

L'ANODE DU TUBE CATHODIQUE ET CELUI DE L'ANODE DU CAP AU

CHASSIS METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE

PEINTE SUR LE TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT D'UN

CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR D'ISOLEMENT DOIT ETRE

UTILISÉ LORS DE TOUT DÉPANNAGE. LE CHÁSSIS DE CE RÉCEPTEUR EST

DIRECTEMENT RACCORDÉ À L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE MARQUE

SUR LES SCHEMAS DE PRINCIPE, LES VUES EXPLOSEES ET LES

LISTES DE PIECES SONT D'UNEIMPORTANCE CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST INDIQUE DANS

LE PRESENT MANUEL OU DANS DES SUPPLEMENTS PUBLIES P AR SONY.

LES REGLAGES DE CIRCUIT DONT L'IMPORT ANCE EST CRITIQUE POUR

LA SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS LE

PRESENT MANUEL. SUIVRE CES PROCEDURES LORS DE CHAQUE

REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU'UN

MAUVAIS FONTIONNEMENT SUSPECTE.

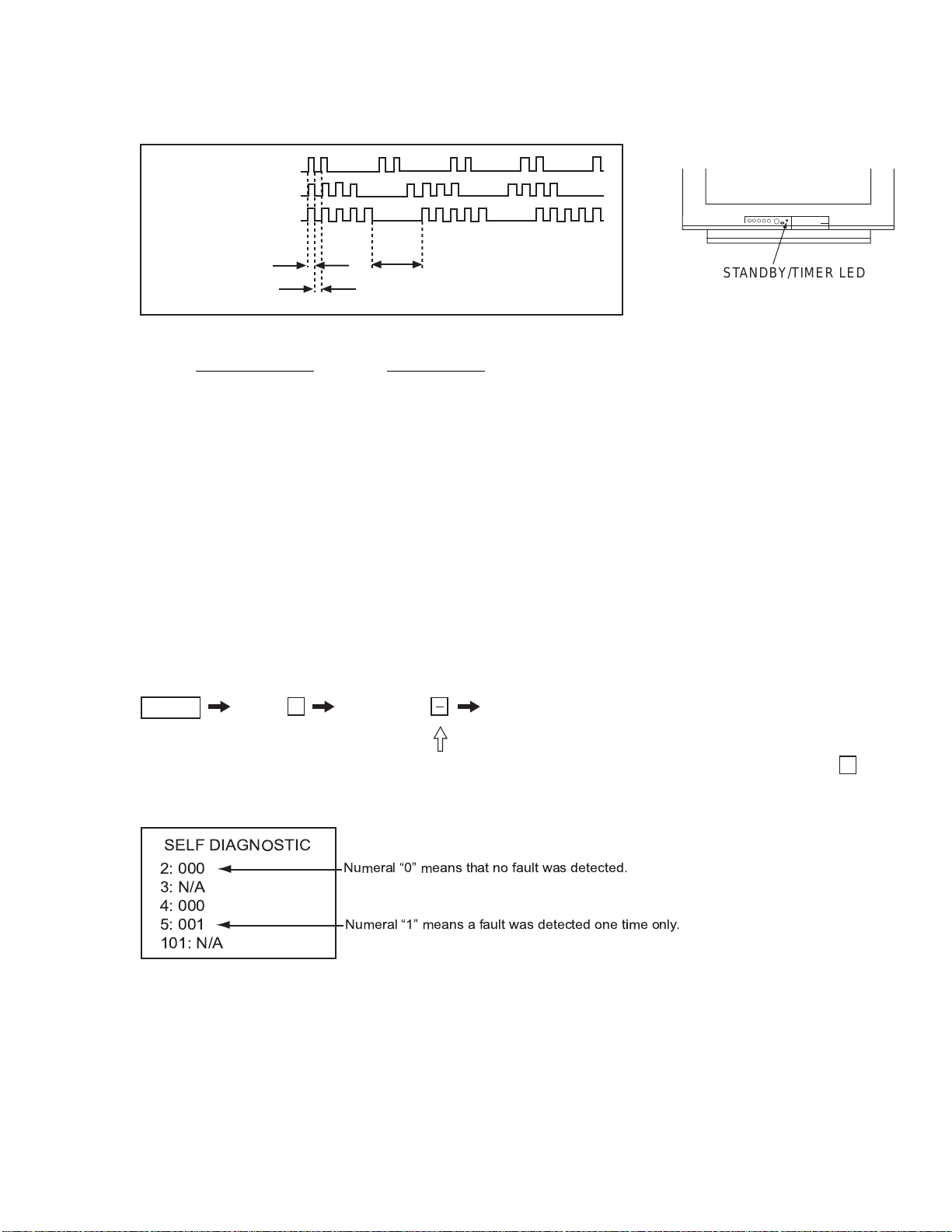

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the ST ANDBY/TIMER LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER LED flash

indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote

Commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will flash a set number of times to indicate the possible cause of the problem. If there is

more than one error, the LED will identify the first of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

— 4 —

Page 5

Display of Standby/Timer LED Flash Count

2 times

4 times

5 times

KV-34FS12T

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

STANDBY/TIMER LED

Diagnostic Item Flash Count*

+B overcurrent 2 times

I-Prot 4 times

IK 5 times

*One flash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from flashing.

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible

to bring up past occurrences of failure on the screen for confirmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display Channel

5

Sound volume

Power ON

Self-Diagnostic Screen Display

SELF DIAGNOSTIC

2: 000

Numeral 0 means that no fault was detected.

3: N/A

4: 000

5: 001

Numeral 1 means a fault was detected one time only.

101: N/A

Note that this differs from entering the service mode (sound volume

— 5 —

+

).

Page 6

KV-34FS12T

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs.

When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the

repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed,

as shown below:

8

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn of f the power switch on the Remote Commander or the main unit.

ENTERChannel

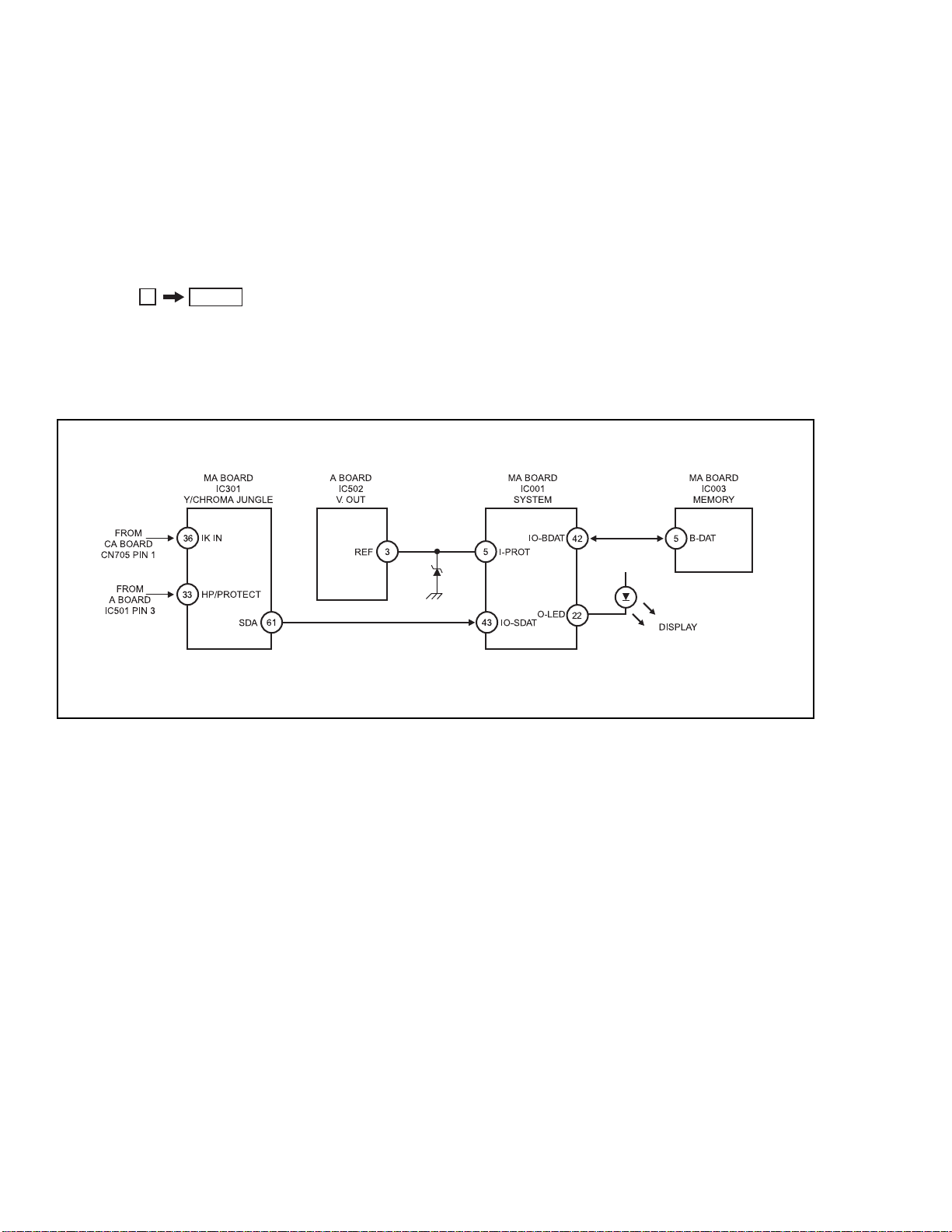

Self-Diagnostic Circuit

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135V) line is detected by pin 33 of IC301 (MA Board). If

the voltage of pin 33 of IC301 (MA Board) is less than 1V when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

I-Prot Occurs when an absence of the vertical deflection pulse is detected by pin 5 of IC001 (MA

Board). Power supply will shut down when waveform interval exceeds 2 seconds.

IK If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be

detected by IC301 (MA Board). TV will stay on, but there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

— 6 —

Page 7

SAFETY CHECK-OUT

KV-34FS12T

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps, and mounting hardware have been replaced.

Be absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair .

Point them out to the customer and recommend their

replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord

to the customer.

7. Check the B+ and HV to see if they are specified

values. Make sure your instruments are accurate;

be suspicious of your HV meter if sets always have

low HV .

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

Leakage Test

The AC leakage from any exposed metal p art to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed 0.5

mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester , such as the Simp son 229

or RCA WT-540A. Follow the manufacturers'

instructions to use these instructions.

2. A battery-operated AC milliammeter . The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means

of a VOM or battery-operated AC voltmeter. The “limit”

indication is 0.75 V , so analog meters must have an

accurate low voltage scale. The Simpson’s 250 and

Sanwa SH-63TRD are examples of passive VOMs that

are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable

(see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the coverplate retaining screw on most AC outlet boxes is also at earth

ground. If the retaining screw is to be used as your earth

ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The

reading should be zero ohms. If a cold-water pipe is not

accessible, connect a 60- to 100-watt trouble- light (not a

neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary , to locate the hot

side on the line; the lamp should light at normal brilliance if the

screw is at ground potential (see Figure B).

— 7 —

Trouble Light

AC Outlet Box

Figure B. Checking for earth ground.Figure A. Using an AC voltmeter to check AC leakage.

Ohmmeter

Cold-water Pipe

Page 8

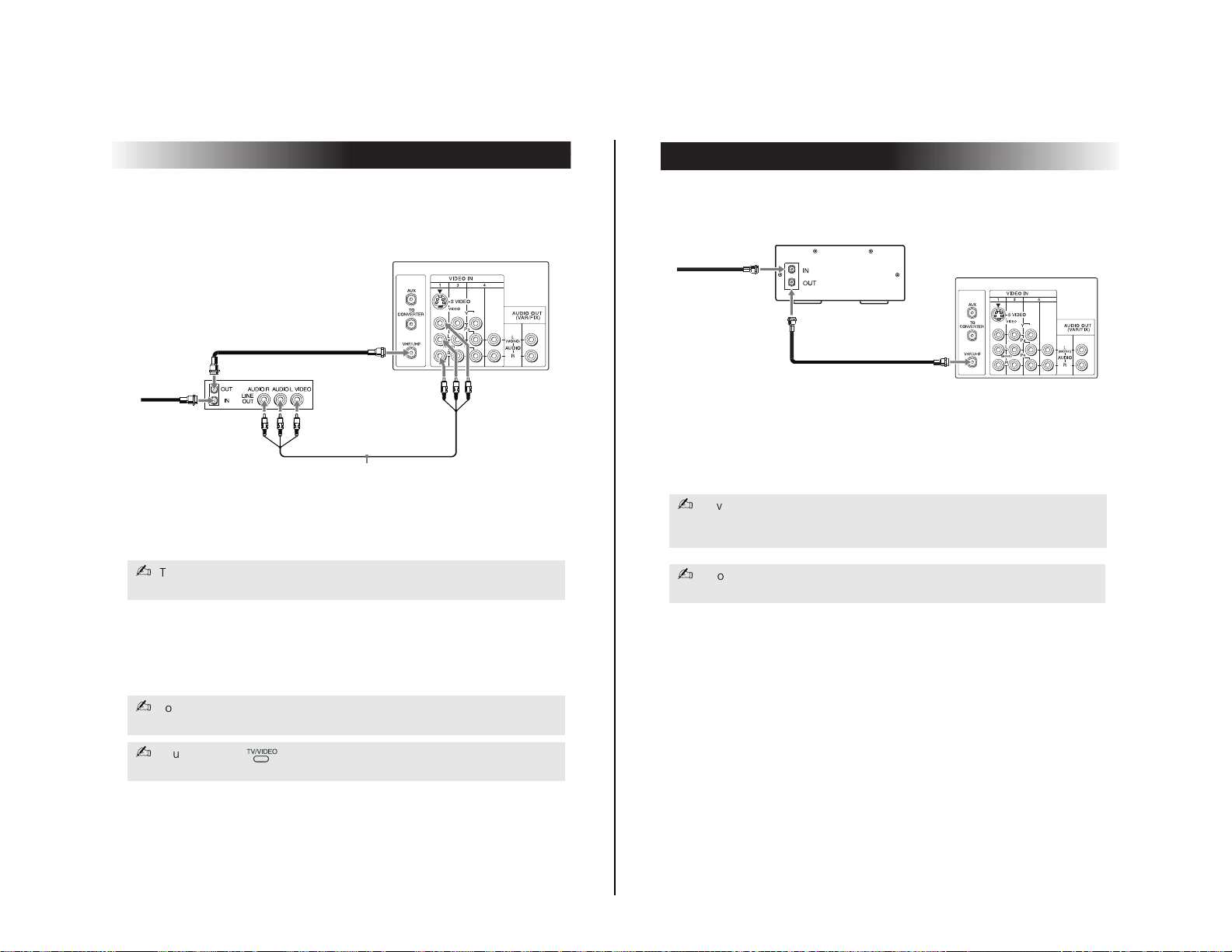

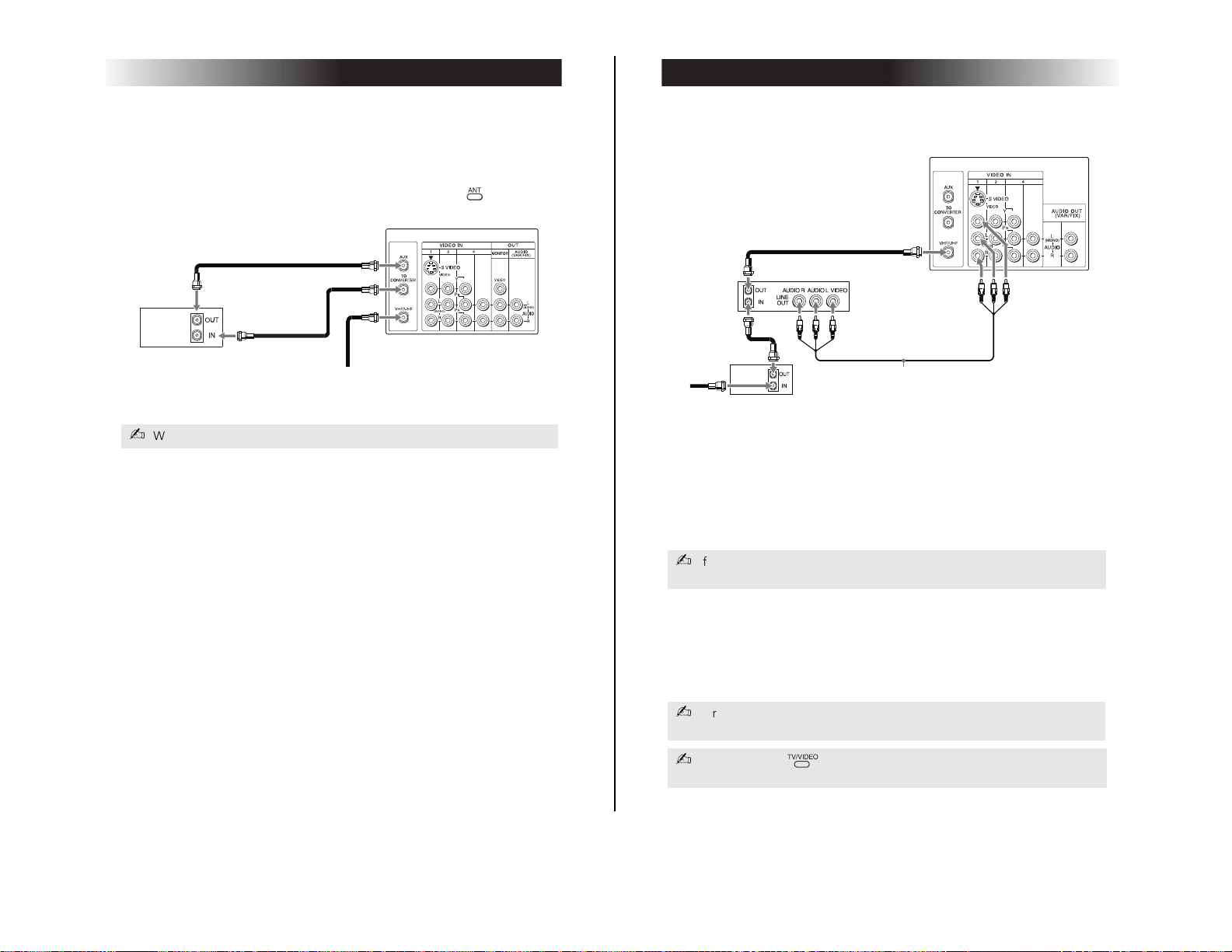

The instructions mentioned here are partial abstracts from the Operating Instruction Manual.

4

Operating Instructions

Cable Box Connections

Some pay cable TV systems to use scrambled or encoded signals that

requireacableboxtoviewallchannels.

Cable Box

1

Connect the coaxial cable from your cable service to the IN jack on

your cable box.

2

Connect a coaxial cable (not supplied) from the OUT jack on your

cable box to the VHF/UHF jack on your TV.

Cable Box and Cable

For this set up, you can switch between scramble channels (through your

cable box), and normal (CATV) channels by using the button.

If you will be controlling all channel selection through your cable box, you

should consider using the Channel Fix feature, (see page 26).

If you are connecting a cable box through the AUX input and would like to

switch between the AUX and normal (CATV) input, you should consider using

the Channel Fix feature, (see page 26).

Your Sony remote control can be programmed to operate your cable box,

(see page 36).

When using PIP, you cannot view the AUX input in the window picture.

Cable

IN

OUT

(Rear of TV)

VHF/UHF

Cable Box

Cable Box

(Rear of TV)

AUX

OUT

IN

TO CONVERTER

(Signal)

VHF/UHF

75-ohm coaxial cable (not supplied)

CATV cable (unscrambled channels)

The page numbers shown reflect those of the Operating Instruction Manual.

Connecting Your TV

Read this chapter before s etting up your TV for the first time. This section

covers basic connections in addition to any optional equipment you may

be connecting.

KV-34FS12T

SECTION 1 GENERAL

— 8 —

Basic Connections

TV with indoor or outdoor antenna, or CATV cable

Depending on the cable available in your home, choose one of the

connections below:

If you are connecting to an indoor or outdoor antenna, you may need to

adjust the orientation of the antenna for best reception.

3

Page 9

Connecting Your TV

6

Operating Instructions

TV and Cable Box

1

Connect the coaxial cable from your cable service to the IN jack on

your cable box.

2

Connect a coaxial cable (not supplied) from the OUT jack on your

cable box to the VHF/UHF jack on the TV.

To view channels from your cable box, tune your TV to channel 3 or 4 (as set

on the rear panel of your cable box) and use the cable box’s remote control to

change channels.

If you will be controlling all channel selection through your cable box, you

should consider using the Channel Fix feature, (see page 26).

1

cable

2

Cable Box

Rear of TV

From

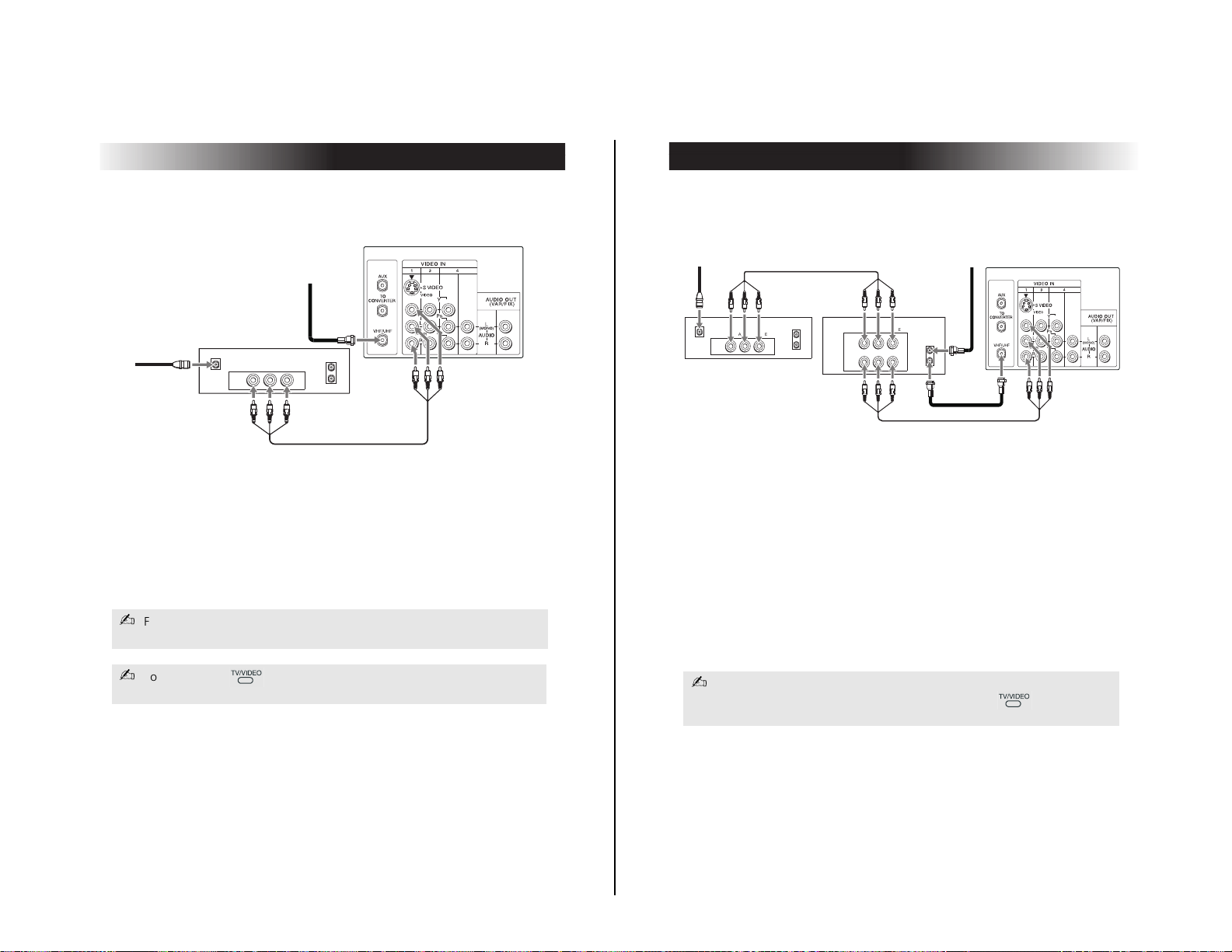

Connecting Additional Equipment

TV and VCR

1

From

cable/

antenna

— 9 —

1 Connect the coaxial cable from your TV antenna or cable service to

the IN jack on your VCR.

2 Connect a coaxial cable (not supplied) from the OUT jack on your

VCR to the VHF/UHF jack on the TV.

To watch video programs from your VCR, tune your TV to channel 3 or 4 (as

set on the rear of your VCR).

(Optional connection)

3 If your VCR is equipped with video outputs, you can get better

picture quality by connecting A/V cables (not supplied) from

AUDIO and VIDEO OUT on your VCR to AUDIO/VIDEO IN on

your TV.

For optimum picture quality, use S VIDEO instead of the yellow A/V cable.

S VIDEO does not provide sound, the audio cables must still be connected.

2

VCR

(Optional connection)

3

Rear of TV

You can use the button to switch between the VHF/UHF and VIDEO

inputs.

KV-34FS12T

5

Page 10

TV, Cable box, and Cable

8

Operating Instructions

TV, VCR, and Cable box

1

Connect the coaxial cable from your cable service to the IN jack on

your cable box.

2

Connect a coaxial cable (not supplied) from the OUT jack on your

cable box to the IN jack on your VCR.

3

Connect a coaxial cable (not supplied) from the OUT jack on your

VCR to the VHF/UHF jack on the TV.

(Optional connection)

4

If your VCR is equipped with video outputs, you can get better

picture quality by connecting A/V cables (not supplied) from

AUDIO and VIDEO OUT on your VCR to AUDIO/VIDEO IN on

your TV.

If you will be controlling all channel selection through your cable box, you

should consider using the Channel Fix feature, (see page 26).

For optimum picture quality, use S VIDEO instead of the yellow A/V cable.

S VIDEO does not provide sound, the audio cables must still be connected.

You can use the button to switch between the VHF/UHF and VIDEO

inputs.

3

Cable

4

(Optional connection)

Cable box

1

VCR

2

Rear of TV

KV-27FS16, KV-27FV16, KV-32FS16, KV-29FV16 only

For this set up, you can switch between scrambled channels (through

your cable box) and normal (CATV) channels by pressing .

Cable Box

KV-34FS12T

Connecting Your TV

Rear of TV (KV-27FV16 only)

— 10 —

When using PIP, the AUX input cannot be viewed in the window picture.

From

Cable

7

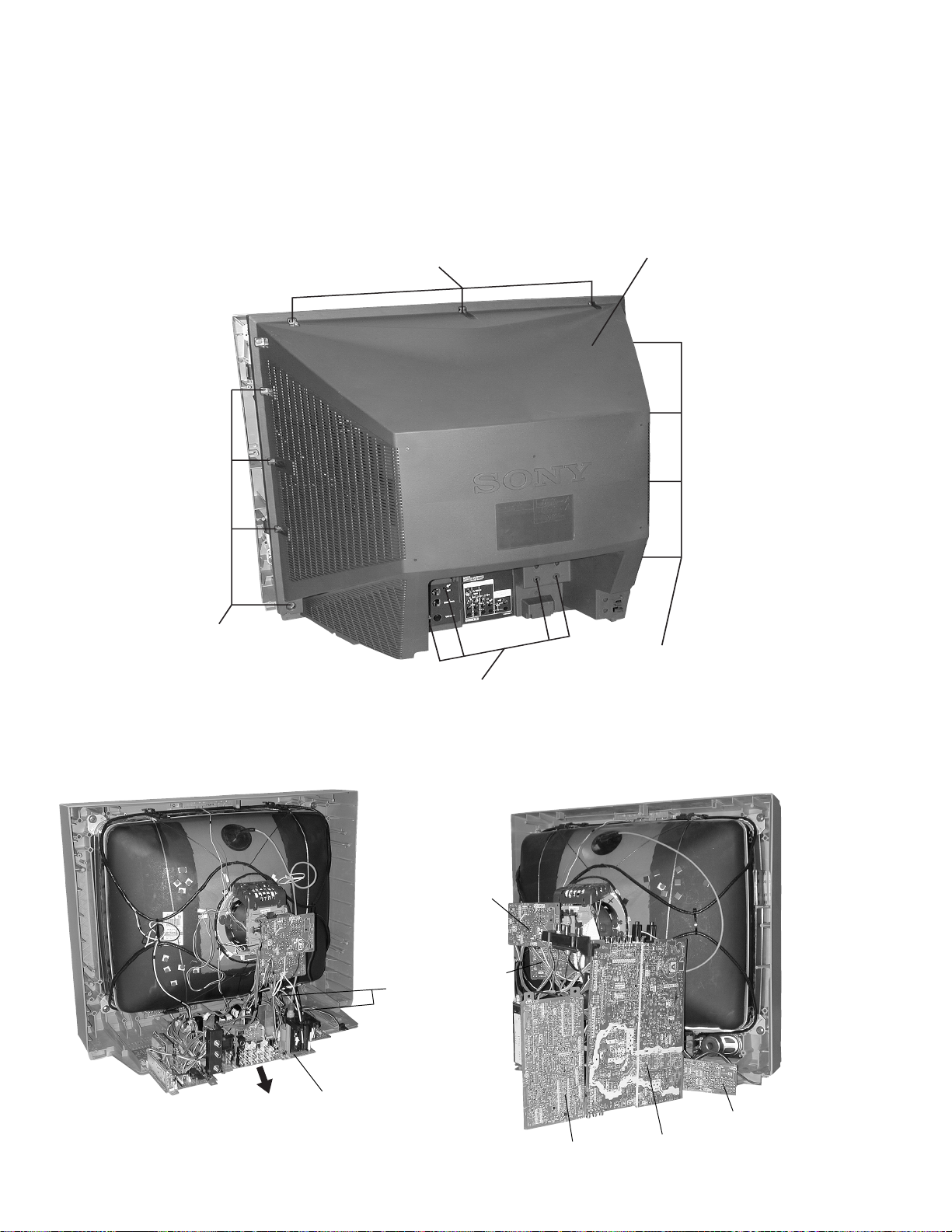

Page 11

Connecting Your TV

10

Operating Instructions

TV, Satellite Receiver, and VCR

1

Connect the cable from your satellite antenna to SATELLITE IN on

your satellite receiver.

2

Connect the coaxial cable from your cable or antenna to the

IN jack on your VCR.

3

Using a coaxial cable, connect the OUT jack on your VCR to the

VHF/UHFjackonyourTV.

4

Using A/V cables, connect AUDIO and VIDEO OUT on your

satellite receiver to AUDIO and VIDEO IN on your VCR.

5

Using A/V cables, connect AUDIO and VIDEO OUT on your VCR to

AUDIO and VIDEO IN on your TV.

To view from the satellite receiver or VCR, select the video input to which

your satellite receiver or VCR is connected by pressing on the remote

control.

AUDIO R AUDIO L VIDEO

VHF/UHF

OUT

IN

LINE OUT

LINE IN

VHF/UHF

OUT

IN

SATELLITE IN

AUDIO R AUDIO L VIDEO

LINE OUT

Satellite receiver

4

5

2

3

1

Rear of TV

VCR

Satellite

antenna

From

antenna

cable/

cable

TV and Satellite Receiver

Satellite receiver

SATELLITE IN

LINE OUT

AUDIO R AUDIO L VIDEO

3

Satellite

antenna

cable

1

2

From

cable/

antenna

VHF/UHF

IN

OUT

— 11 —

1

Connect the cable f rom your satellite antenna to SATELLITE IN on

your satellite receiver.

2

Connect the coaxial cable from your cable or antenna to the

VHF/UHFjackonyourTV.

3

Using A/V cables, connect AUDIO and VIDEO OUT on your

satellite receiver to AUDIO and VIDEO IN on your TV.

For optimum picture quality, use S VIDEO instead of the yellow A/V cable.

S VIDEO does not provide sound, the audio cables must still be connected.

You can use the button to switch between the VHF/UHF and satellite

receiver inputs.

Rear of TV

KV-34FS12T

9

Page 12

Using the Remote Control and

Using the Remote Control and Basic Functions

15

SLEEP Turns the TV off automatically in

approximately 15, 30, 45, 60, 90,

or 120 minutes. Cancel by

pressing until SLEEP OFF

appears.

MTS/SAP Cycles through the

Multi-channel TV Sound (MTS)

options: Stereo, Mono, and

Auto-SAP (Second Audio

Programming).

DISPLAY Press once to show current time,

(if set) and channel number.

Cycles through available Steady

Sound settings, (see page 23).

JUMP Alternates between the last two

channels selected with the

buttons.

GUIDE Brings up the custom guide of

your satellite receiver.

MENU Displays the on-screen menu.

Press again to exit the menu at

any time.

RESET Press to return to factory settings

while in an on-screen menu.

CODE SET Use to program your remote

control to operate connected

video equipment, (see page 36).

For information on Picture in Picture (PIP) operation buttons, see page 17.

If you lost your remote control, see page 40.

0 9

Basic Functions

This section shows you how to use the more advanced buttons on the

remote control and how to use the on-screen menus.

Using the Remote Control

KV-34FS12T

— 12 —

/

The remote control shown (RM-Y171) is for KV-27FV16. Your remote control

may not look like the one illustrated.

Button Description

POWER Press when you want to turn

FUNCTION Press when you want to control

MUTING Instantly turns off the sound.

SYSTEM

OFF

TV/VIDEO Cycles through available video

ANT Press to change the VHF/UHF

TV/VTR Press when you are finished

PICTURE

MODE

14

connectedequipmentonandoff.

connected equipment with your

remote control.

Press again or press to restore

sound.

Powers off all Sony equipment at

once, (may not work with older

equipment).

inputs.

input to the AUX input

(KV-27FS16, KV-27FV16,

KV-32FS16 only).

using a VCR and you want to

switch to the TV input. Your

VCR power will remain on.

Moves the cursor in the onscreen menus. Press the arrow

buttons to move the cursor. Press

the center button to select or

access an option.

Cycles through the available

Video Mode settings.

Page 13

Other Information

40

Operating Instructions

If, after reading these Operating Instructions, you have additional questions related to the use of your

Sony television, please call our Direct Response Center at 1-8 00-222-SONY (7669) (U.S. residents

only) or (416) 499-SONY (7669) (Can adian residents only).

Cannot receive

higher number

channels(UHF)

when using an

antenna

Make sure Cable is set to OFF in the Channel Setup

menu (page 25).

Perform Auto Program to add channels that are not

presently in the memory (page 16).

Cable stations

don’t seem to

work

Make sure Cable is set to ON in the Channel Setup

menu (page 25).

Perform Auto Program to add channels that are not

presently in the memory (page 16).

Remotecontrol

does not

operate

Batteries could be weak. Replace them (page 2).

Move the TV 3-4 feet away from fluorescent lights.

The TV needs

to be cleaned

Clean the TV with a soft dry cloth. Never use strong

solvents such as thinner or benzine, which might

damage the finish of the cabinet.

Lost password

for Parental

Control

In the password screen, enter the following master

password: 4357. After using the master password, you

must create a new password, it cannot be used to

unlock currently blocked channels.

You lost your

remote control

You can use the front A/V panel controls to acc e ss the

menu. Press to open the menu. Use the or

buttons on the front A/V panel instead of the

F or

buttons on the remote control. Use the button on

the front A/V panel instead of the

G, g

,and

buttons on the remote control. Press again when

the setting or adjustment is complete. Contact your

nearest S ony dealer to order a replacement.

Cannot access

other menus

whenusing the

Basic Menu

If you use the button to close the Basic menu, only

the Basic menu appears when you press again. To

have access to the other menus, use the button to

select Advance Menu (page 35).

F

F

Troubleshooting

If you are having a problem with your TV, try the suggestions below. If

the problem persists, contact your nearest Sony dea ler.

— 13 —

No picture, no

sound

Poor or no

picture, good

sound

Good picture,

no sound

No color

No signal

Dotted lines or

stripes

Double images

or ghosts

Make sure the power cord is plugged in.

If red light is flashing on the front of your TV for more

than a few minutes, disconnect and reconnect the

power cord to restore the TV. If the problem continues,

call your local service center.

Check the TV/VIDEO settings: when watching TV, set

to TV; when watching video equipment, set to VIDEO

(page 14).

Make sure the batteries have been inserted correctly

into the remote control (page 2).

Try another channel, it could be station trouble.

Adjust Picture in the Video menu (page 22).

Adjust Brightness in the Video menu (page 22).

Check the antenna and/or cable connections (page 3).

Press sothatMUTINGdisappearsfromthe

screen (page 14).

Check your Audio settings. Your TV may be set to

Auto-SAP (page 24).

Adjust Color in the Video menu (page 22).

Check the Cable setting in the Channel Setup menu

(page 25).

Check the antenna and/or cable connections (page 3).

Make sure the channel selected is currently

broadcasting.

Adjust the antenna.

Move the TV away from other electronic equipment.

Some electronic equipment can create electrical noise,

which can interfere with TV reception.

Check your outdoor antenna or call your cable service.

KV-34FS12T

39

Page 14

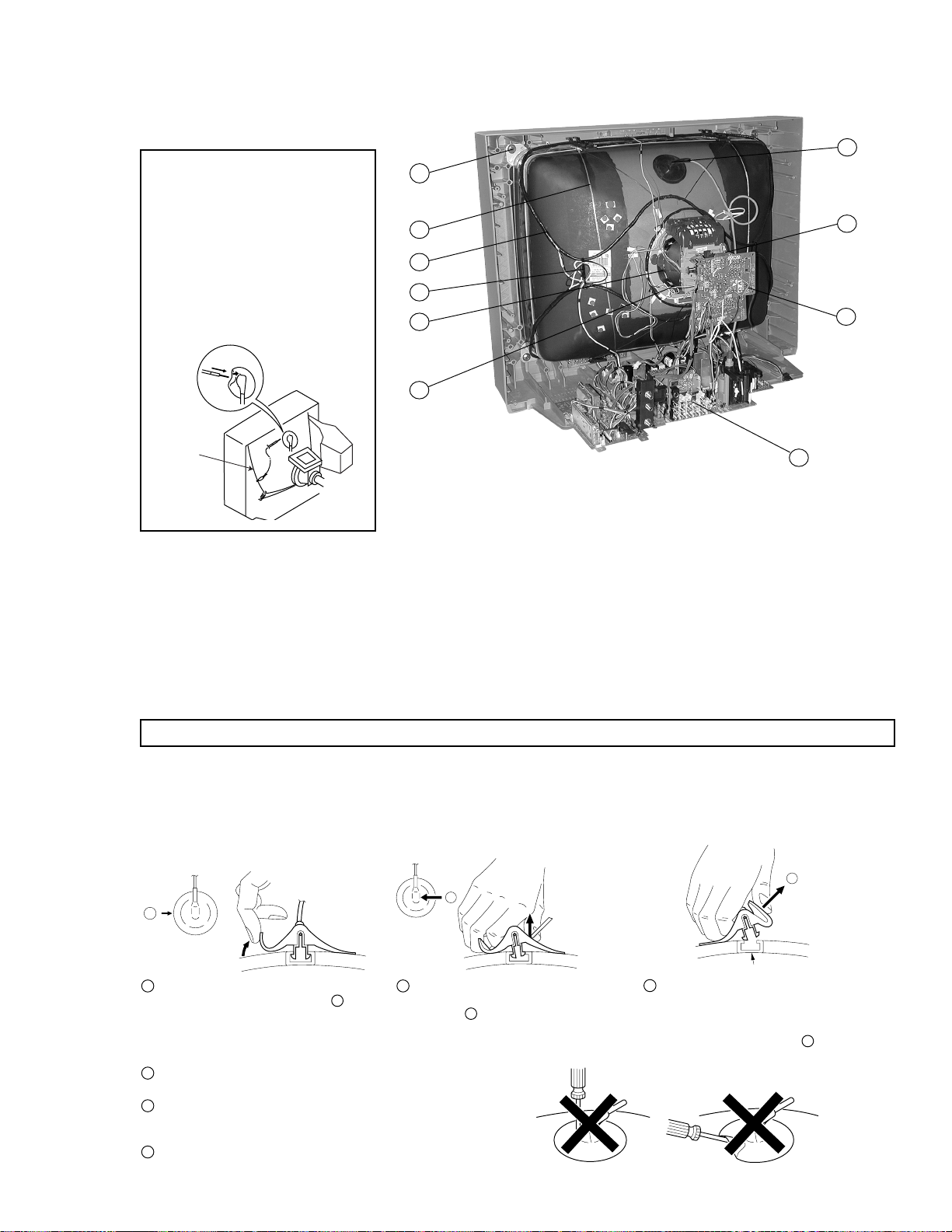

KV-34FS12T

2-1. REAR COVER REMOV AL

SECTION 2

DISASSEMBLY

4 Screws

(+BVTP 4x16)

4 Screws (+BVTP 4x16)

4 Screws (+BVTP 3x16)

Rear Cover

4 Screws

(+BVTP 4x16)

2-2. CHASSIS ASSEMBL Y REMOVAL

Chassis

Assembly

Claw

2-3. SERVICE POSITION

CA Board

VA Board

MA Board

D Board

A Board

— 14 —

Page 15

2-4. PICTURE TUBE REMOVAL

WARNING:

BEFORE REMOVING

THE ANODE CAP

High voltage remains in the CRT

even after the power is disconnected.

T o avoid electric shock, discharge

CRT before attempting to remove the

anode cap. Short between anode and

CRT coated earth ground strap.

Coated

Earth

Ground

Strap

10

KV-34FS12T

1

9

8

7

6

5

4

2

3

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the deflection yoke, neck

assembly, degaussing coils and CR T grounding strap.

3. Remove the CA Board from the CR T .

4. Remove the chassis assembly.

5. Loosen the neck assembly fixing screw and remove.

6. Loosen the deflection yoke fixing screw and remove.

7. Place the set with the CR T face down on a cushion and remove

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fixing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the

CRT by the neck].

ANODE CAP REMOV AL

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electrical shock, discharge the CRT before

NOTE: After removing the anode, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield,

attempting to remove the anode cap. Short between anode and coated earth ground strap of CRT.

or carbon painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

1

Turn up one side of the rubber cap in

the direction indicated by arrow

2

a

.

Use your thumb to pull the rubber

cap firmly in the direction indicated

by arrow

b

.

3

When one side of the rubber cap

separates from the anode button,

the anode cap can be removed by

turning the rubber cap and pulling

it in the direction of arrow

c

.

HOW TO HANDLE AN ANODE CAP

1

Do not use sharp objects which may cause damage to the

surface of the anode cap.

2

To avoid damaging the anode cap, do not squeeze the rubber

covering too hard. A material fitting called a shatter-hook terminal

is built into the rubber.

3

Do not force turn the foot of the rubber cover. This may cause

the shatter-hook terminal to protrude and damage the rubber.

— 15 —

Page 16

KV-34FS12T

SECTION 3

SET -UP ADJUSTMENTS

The following adjustments should be made when

a complete realignment is required or when a new

picture tube is installed.

These adjustments should be performed with rated

power supply voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: ST ANDARD

PICTURE control: ................ Normal

BRIGHTNESS control: ........ Normal

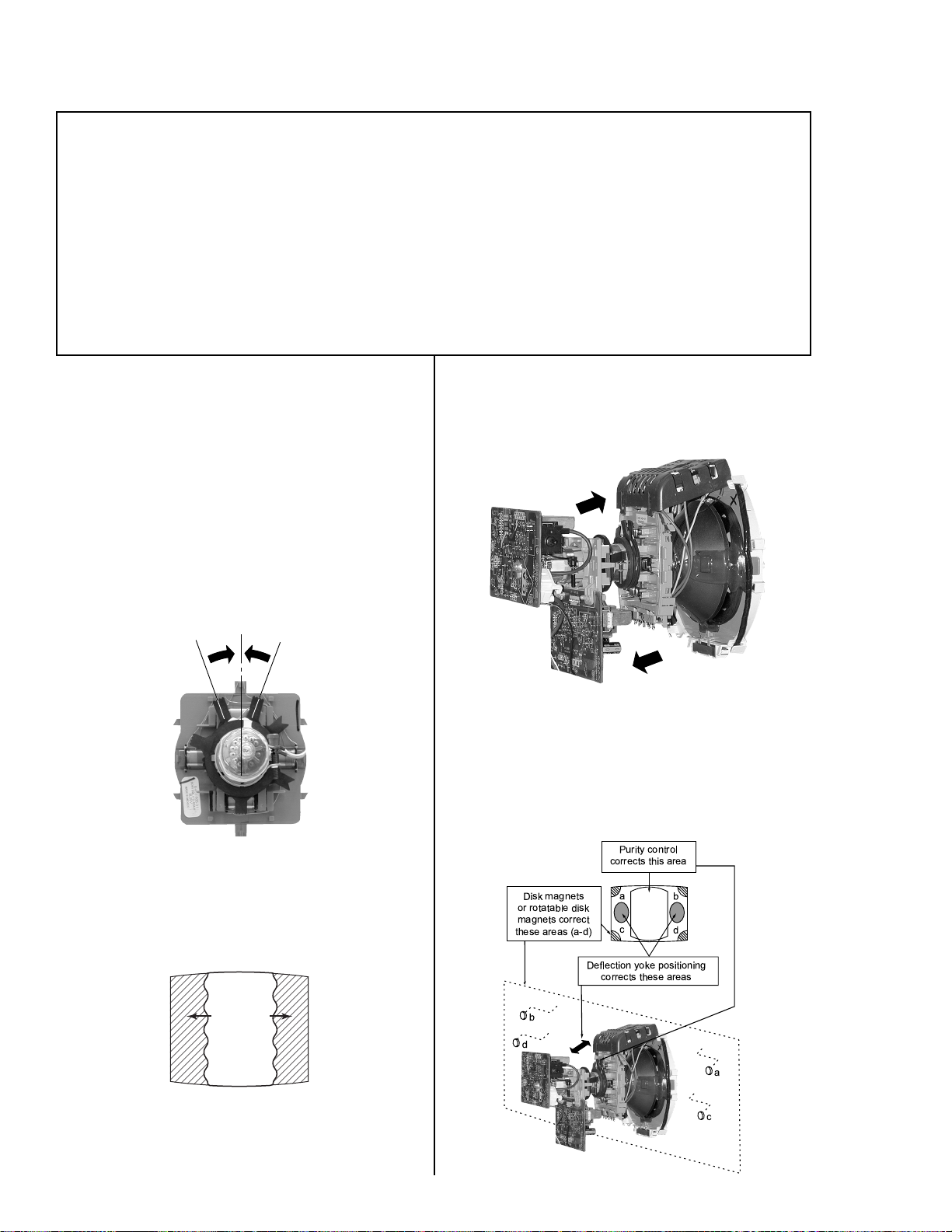

3-1. BEAM LANDING

Before beginning adjustment procedure:

1. Degauss the entire screen.

2. Feed in the white pattern signal.

Adjustment Procedure

1. Input a raster signal with the pattern generator .

2. Loosen the deflection yoke mounting screw and set the purity

control to the center as shown below.

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note: T est equipment required:

• Color Bar Pattern Generator

• Degausser

• DC Power Supply

• Digital Multimeter

5. Move the deflection yoke forward and adjust so that the entire

screen becomes green.

Purity Control

3. T urn the raster signal of the pattern generator to green.

4. Move the deflection yoke backward and adjust the purity

control so that green is in the center and red and blue are

at the sides evenly.

Blue Red

Green

6. Switch over the raster signal to red and blue and confirm

the condition.

7. When the position of the deflection yoke is determined,

tighten it with the deflection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk

magnets.

Purity control

corrects this area

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

cd

Deflection yoke positioning

corrects these areas

ba

a

— 16 —

c

Page 17

KV-34FS12T

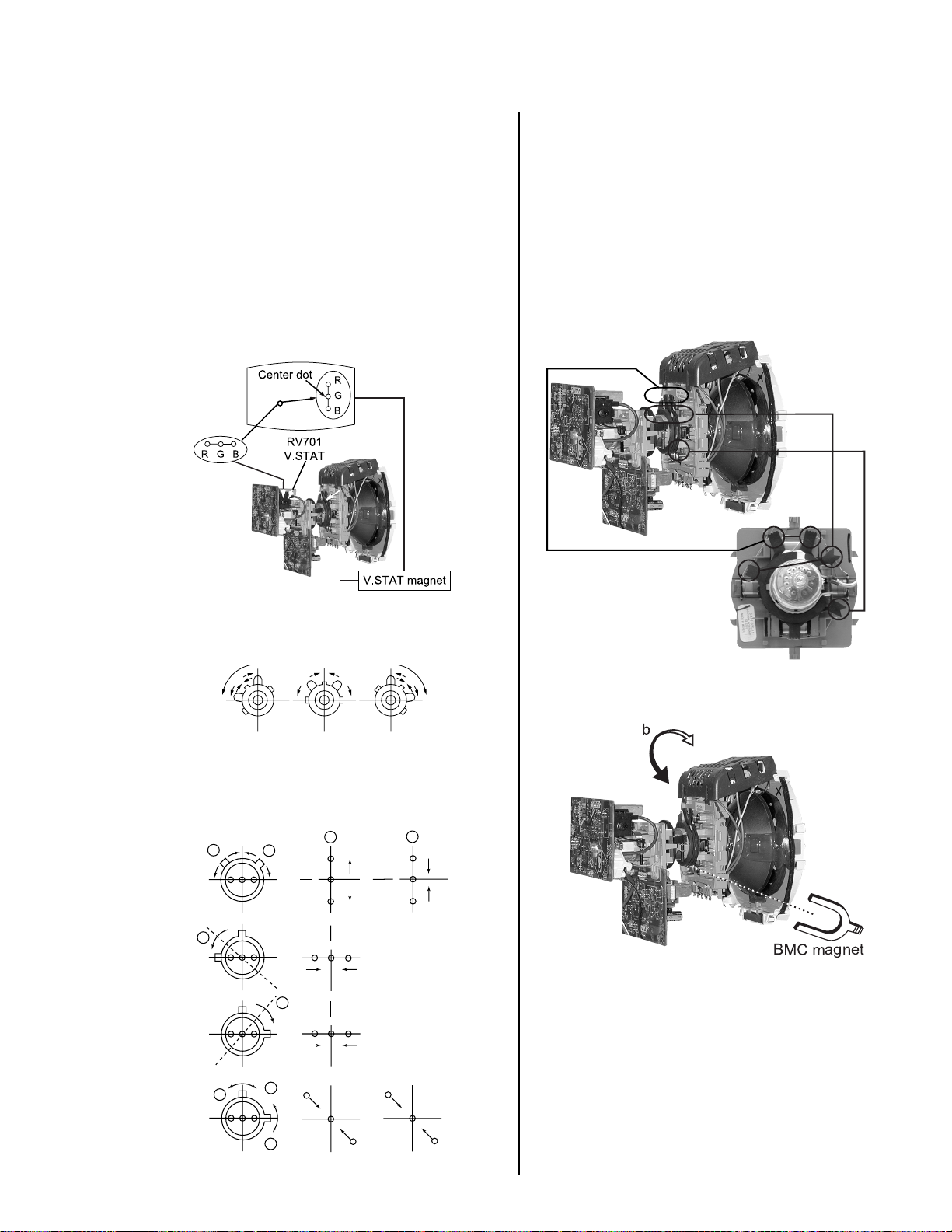

3-2. CONVERGENCE

Before starting convergence adjustments:

1. Perform FOCUS, V.LIN AND V .SIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

Vertical Static Convergence

1. Adjust V.STAT magnet to converge red, green and blue

dots in the center of the screen (Vertical movement adjust

V .STAT RV701 to converge).

Horizontal Static Convergence

If the blue dot does not converge with the red and green dots,

perform the following:

1. Move BMC magnet (a) to correct insufficient H. S tatic

convergence.

2. Rotate BMC magnet (b) to correct insufficient V. Static

convergence.

3. After adjusting the BMC magnet, repeat Beam Landing

Adjustment.

V.S TAT

BMC MAGNET

PURITY

2. T ilt the V.STAT magnet and adjust static convergence to open

or close the V.STA T magnet.

When the V.STA T magnet is moved in the direction of arrows

a and b, red, green, and blue dots move as shown below:

(1)

a

b

(2)

a

(3)

b

b

b

a

b

a

B

G

R

BGR

RGB

R

G

B

b

B

G

R

B

G

R

b

BMC magnet

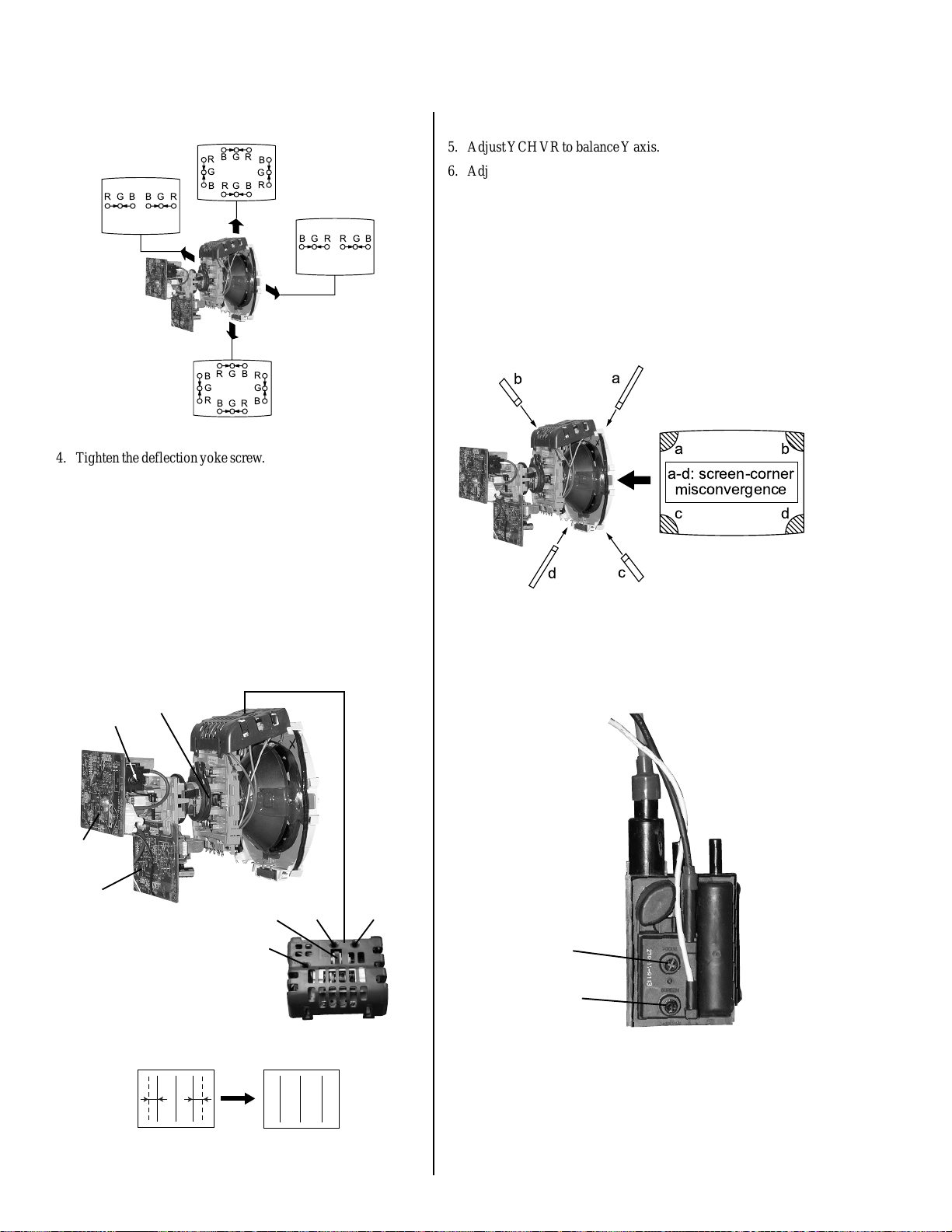

Dynamic Convergence Adjustment

Before performing this adjustment, perform Horizontal

and Vertical Static Convergence Adjustment.

1. Slightly loosen deflection yoke screw .

2. Remove deflection yoke spacers.

3. Move the deflection yoke for best convergence

as shown on the following page.

— 17 —

Page 18

KV-34FS12T

RGB

BGR

R

G

B

B

G

R

BGR

RGB

RGB

G

B

R

B

G

R

R

G

B

BGR RGB

4. Adjust XCV core to balance X axis.

5. Adjust YCH VR to balance Y axis.

6. Adjust vertical red and blue convergence with V.TIL T

(TLV VR).

Note: Perform adjustments 3-6 while tracking items 1 and 2.

Screen-Corner Convergence

1. Affix a permalloy assembly corresponding to the

misconverged areas.

b

a

4. Tighten the deflection yoke screw.

5. Install the deflection yoke spacers.

TLH Plate Adjustment

1. Input crosshatch pattern.

2. Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

3. Adjust the Horizontal Convergence of red and blue dots

by tilting the TLH plate on the deflection yoke.

RV701

V.STAT

CA

Board

VA

Board

TLH Plate

XCV

YCH

TLV

a-d: screen-corner

d

c

3-3. FOCUS

1. Adjust FOCUS control for best picture.

ba

misconvergence

cd

B R R B

(R)(B) (B)(R)

TLH+

TLH-

(TLV)

Focus (FV)

Screen (G2)

— 18 —

Page 19

KV-34FS12T

r

3-4. SCREEN (G2)

1. Input a dots pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum

and COLOR control at normal.

3. Adjust SBR T , GCUT, BCUT in service mode with an

oscilloscope as shown below so that voltages on the red,

green, and blue cathodes are 170 ± 2.0 VDC.

4. Observe the screen and adjust SCREEN (G2) VR in FBT

to obtain the faintly visible background of dot signal.

3-5. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE

Service Mode Procedure

1. Standby mode (power off).

3-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal with burst.

2. Set to Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Adjust with SBR T if necessary .

5. Select GCUT and BCUT with

6. Adjust with

and for the best white balance.

7. Set PICTURE and BRIGHTNESS to maximum.

8. Select GDRV and BDR V with

9. Adjust with

and for the best white balance.

10. To write into memory, press

and .

and .

then .

2. Press

Display Channel

5

Sound volume Powe

+

on the Remote Commander (press each button within a

second).

Service Adjustment Mode In

1. The CR T displays the item being adjusted.

2. Press or on the Remote Commander to select the item.

3. Press

or on the Remote Commander to change the

data.

4. Press

then to save into the memory.

Service Adjustment Mode Memory

Turn set off then on to exit service adjustment mode.

Category

Mode

service defl hsiz 16

Signal

ntsc

Type

vchp 00000000 00000000

Display

Item

write

Item

Data

— 19 —

Page 20

KV-34FS12T

SECTION 4

SAFETY RELATED ADJUSTMENTS

4-1.

R564 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when

replacing the following components which are marked with

on

the schematic diagram:

Part Replaced ( ) Adjustment ( )

DY, T505, CRT, IC501, C507,

C520, C505, C509, C515, T504,

T503, C551, L510, C546, C537,

C547, D517, D518, D519, R560,

R561, R562, R563, R565, R566,

R567, R525........................A Board

IC301.............................MA Board

HV HOLD-DOWN

(R564)

Preparation Before Confirmation

1. Using a Variac, apply AC input voltage: 120 ± 2 VAC.

2. T urn the POWER switch ON.

3. Input a white signal and set the PICTURE and

BRIGHTNESS controls to maximum.

4. Confirm that the voltage between C546 (+) or TP503

and ground is more than 23.0 VDC.

Hold-Down Operation Confirmation

1. Connect the current meter between Pin 1 1 of the FBT

(T505) and the PWB land where Pin 11 would normally

attach (See Figure 1 on the next page.)

2. Input a dot signal and set PICTURE and BRIGHTNESS

to minimum: IABL = 2175 + 100/- 325 µA.

3. Confirm the voltage of A Board TP-600 is 135 ± 1.5 VDC.

4. Connect the digital voltmeter and the DC power supply

via diode 1SS119 to C546 (+) and ground (See Figure 1

on the next page.)

5. Increase the DC power voltage gradually until the picture

blanks out.

6. T urn DC power source off immediately .

7. Read the digital voltmeter indication

(standard < 27.24 + 0.0/- 0.1 VDC) .

8. Input a white signal and set PICTURE and BRIGHTNESS to

maximum: IABL = 2175 + 100/- 325 µA .

9. Repeat Steps 4 to 7.

Hold-Down Readjustment

If the setting indicated in Step 2 of Hold-Down Operation

Confirmation cannot be met, readjustment should be performed by

altering the resistance value of R564 component marked with

T505

FBT

ammeter

3.0 mA DC

range

ABL

+

A

IABL

-

.

4-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Note: The following adjustments should always be performed

when replacing the following components, which are marked with

on the schematic diagram on the A Board.

A BOARD: IC601, PH601

1. Using a Variac, apply AC input voltage: 130 + 2.0/-0.0 V AC.

2. Input a monoscope pattern.

3. Set the PICTURE and BRIGHTNESS controls to minimum.

4. Confirm that the voltage of A Board TP-600 is <136.5 VDC.

5. If Step 3 is not satisfied, replace the components listed above,

then repeat Steps 1–3.

— 20 —

Page 21

11119

+

+

+

+

18

1818

9

5

6

C

9

5

6

C

9

5

6

9

5

C

6

C

R601

R601

R601R601

R615

R615

R615R615

D616

D616

D616D616

1

6

0

B

1

F

0

6

B

F

1

6

0

B

1

F

0

6

B

F

C624

C624

C624C624

H.DRIVE

H.DRIVE

H.DRIVEH.DRIVE

CN511

CN511

C611

C611

CN511CN511

C611C611

C654

C654

C654C654

CN506

CN506

CN506CN506

1111

1111

CN515

CN515

CN515CN515

+B

+B

+B+B

R515

R515

R515R515

C536

C536

C536C536

D521

D521

D521D521

4444

1111

5555

7777

R503

R503

R503R503

R516

R516

R516R516

C503

C503

C503C503

C554

C554

C554C554

R502

R502

R502R502

R547

R547R547

9

99

10

1018

1010

5

6

R

5

6

R

9

9

5

6

R

5

6

R

9

9

L602

L602

L602L602

C629

C629

C629C629

H.PULSE

H.PULSE

H.PULSEH.PULSE

FB503

FB503

FB503FB503

R507

R507

R507R507

T503

T503

T503T503

T502

T502

T502T502

Q501

Q501

Q501Q501

C504

C504

C504C504

R547

KV-34FS12T

POWER

SUPPLY

DIGITAL

MUL TIMETER

+

–

1SS119

+

–

R564

C546

R438

R438

R449

R449

R454

R454

R454R454

JR503

JR503

JR503JR503

R445

R445

R445R445

Q411

Q411

Q411Q411

D620

D620

D620D620

C524

C524

C524C524

R506

R506

R506R506

D506

D506

C510

C510

C510C510

L502

L502

T504

T504

T504T504

L509

L509

L509L509

C513

C513

C513C513

R504

R504

R504R504

L502L502

L505

L505

L505L505

C517

C517

C517C517

E

E

E

E

R505

R505

R505R505

C555

C555

C555C555

2

0

5

Q

2

0

5

Q

2

0

2

5

0

Q

5

Q

O

-

H

O

-

H

T

U

T

U

O

-

O

H

-

H

T

U

T

U

C505

C505

C505C505

C515

C515

C515C515

R553

R553

R553R553

D506D506

C550

C550

C550C550

C511

C511

C511C511

L501

L501

L501L501

B

B

B

B

B

B

B

B

C

C

C

C

C509

C509

C509C509

L510

L510

L510L510

R568

R568

R568R568

R449R449

C448

C448

C448C448

R450

R450

R450R450

R567

R567

R567R567

R565

R565

R565R565

IC501

IC501

IC501IC501

R522

R522

R522R522

R525

R525

R525R525

Q503

Q503

Q503Q503

R447

R447

R447R447

D507

D507

D507D507

FB502

FB502

FB502FB502

8888

1111

R527

R527

R541

R541

R541R541

R514

R514

R514R514

R527R527

B

B

E

E

BB

E

E

E

E

E

E

C525

C525

C525C525

5555

4444

3333

2222

1111

5

1

N

0

C

1

5

0

N

C

5

1

N

0

C

1

5

0

N

C

R546

R546

R546R546

R533

R533

R533R533

R534

R534

C551

C551

R534R534

C551C551

R438R438

C530

C530

C530C530

R529

R529

R529R529

5555

R573

R573

R573R573

R531

R531

R531R531

4444

C541

C541

C541C541

D510

D510

D510D510

6

6

66

R539

R539

R539R539

R518

R518

R518R518

7

7

77

R540

R540

R540R540

C543

C543

C543C543

C519

C519

C519C519

R537

R537

R537R537

D511

D511

D511D511

C552

C552

C552C552

R403

R403

R403R403

R563

R563

R563R563

C546

C546

C546C546

H.PROT

H.PROT

H.PROTH.PROT

C542

C542

C542C542

6

6

2

2

6

6

22

4

4

44

2

2

22

C518

C518

C518C518

IC502

IC502

IC502IC502

1

1

11

TH501

TH501

TH501TH501

R543

R543

R543R543

6

6

6

6

200V

200V

200V200V

6666

V DY -

V DY V DY -V DY -

V DY +

V DY +

V DY +V DY +

H DY -

H DY H DY -H DY -

H DY -

H DY H DY -H DY -

H DY +

H DY +

H DY +H DY +

H DY +

H DY +

H DY +H DY +

R545

R545

R545R545

L507

L507

L507L507

R225

R225

R225R225

D235

D235

D235D235

D234

D234

D234D234

C213

C213

C213C213

R218

R218

R218R218

R407

R407

R407R407

-13V

-13V

-13V-13V

HEATER

HEATER

HEATERHEATER

C211

C211

C211C211

Q205

Q205

Q205Q205

1

1

1

1

CN502

CN502

CN502CN502

Q206

Q206

Q206Q206

C523

C523

C523C523

R532

R532

R532R532

Q201

Q201

Q201Q201

D236

D236D236

D232

D232

D232D232

R232

R232R232

R511

R511

R511R511

R561

R561

R561R561

T505

FBT

135V

135V

135V135V

ABL11

R226

R226

R226R226

R227

R227

D236

R231R232

R231R231

D233

D233

D233D233

D514

D514D514

T505

T505

T505T505

R227R227

R231

D520

D520

D520D520

D518

D518

D518D518

D517

D517

D517D517

D514

C532

C532

C532C532

R558

R558

R558R558

R559

R559

JR502

JR502

JR502JR502

R559R559

R557

R557

R557R557

Q505

Q505

Q505Q505

R554

R554

R554R554

D516

D516

D516D516

R555

R555

R555R555

R535

R535

R535R535

JUMPER-ID

JUMPER-ID

JUMPER-IDJUMPER-ID

R801

R801

R801R801

R803

R803

R803R803

R804

R804

R804R804

CN504

CN504

CN504CN504

TP600

AMMETER

3mA dc range

A

+

–

Figure 1

— 21 —

Page 22

KV-34FS12T

r

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y168) to perform the circuit adjustments in this section.

NOTE: T est Equipment Required:

• Pattern generator

• Frequency counter

• Digital multimeter

• Audio oscillator

SECTION 5

CIRCUIT ADJUSTMENTS

5-1. SETTING THE SERVICE ADJUSTMENT MODE

1. Standby mode (power off).

2. Press

Display Channel

5

Sound volume Powe

+

on the Remote Commander (press each button within a

second).

Service Adjustment Mode On

1. The CR T displays the item being adjusted.

2. Press or on the Remote Commander to select an item.

3. Press

4. Press

or on the Remote Commander to change the data.

then to save into the memory.

Service Adjustment Mode Memory

Display

Mode

Category

Item

Item

Data

5-2. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, remove the power plug from the AC outlet,

then plug it in again.

2. T urn the power switch ON and set to service mode.

3. Call the adjusted items again to confirm they were adjusted.

5-3. ADJUSTMENT BUTTONS AND INDICATORS

MUTING

1

4

POWER

DISPLAY

3

5

6

ENTER

service defl hsiz 16

Signal

ntsc

Type

vchp 00000000 00000000

write

1. Press then on the Remote Commander to

initialize.

Display

Category

Mode

service defl hsiz 16

Signal

ntsc

Type

vchp 00000000 00000000

Item

write

Item

Data

Carry out Step 1 when adjusting

IDs 0–6 and when replacing

and adjusting IC003.

2. Turn set of f then on to exit Service Adjustment Mode.

8

VOLUME

RM-Y168

— 22 —

Page 23

Adjustment Items

KV-34FS12T

Reg # ITEM FUNCTION RANGE

1 HSIZ Horizontal Size Adjustment 0-63 18 22

2 HPOS Horizontal Position Adjustment 0-63 13 22

3 VBOW Vertical Line Bowing Adj. 0-15 9 9

4 VANG Vertical Line Bowing Slant Adj. 0-15 3 7

5 VTRP TRAPEZIUM 0-31 18 17

6 HTRP Horiz. Trapezoid 0-15 6 2

7 TROT Tilt Correction 0-63 31 31

8 PAMP Horizontal PIN distortion Adj. 0-63 27 27

9 UPIN Upper PIN Distortion Adj. 0-63 41 38

10 LPIN Lower PIN Distortion Adj. 0-63 39 35

11 VSIZ Vertical Size Adjustment 0-63 51 51

12 VPOS Vertical Position Adj. 0-63 42 39

13 VLIN Vertical lineality Adj. 0-15 5 4

14 SCOR Vertical "S" Correction Adjustment 0-15 8 8

15 VZOM 16:9 CRT Z Mode on/off 0-1 0 0

16 EHT Vertical High-Voltage Compensation 0-15 5 5

17 ASP Aspect Ratio control 0-63 47 47

18 SCRL 16:9 CRT Z Mode Trans. Scroll 0-63 31 31

19 HBLK Horizontal Blanking on/off 0-1 1 1

20 LBLK Left Blanking Adjustment 0-15 13 13

21 RBLK Rigth Blanking Adjustment 0-15 8 8

22 HDW Horizontal Drive Pulse Width 1 1

23 EWDC "Parabola" EW, D.C. Adjustment 0-1 0 0

24 LVLN Lower Screen BTM Vertical Line Adj. 0-15 0 0

25 UVLN Upper Screen BTM Vertical Line Adj. 0-15 0 0

26 INTL INTERLACE 0-3 0 0

27 G2SW 0-1 0 0

28 G2LV 0-7 0 0

29 HOSC Horizontal VCO Oscillation Freq. 0-15 12 7

30 VSS Vertical Sync Slice Level 0-1 0 0

31 HSS Horizontal Sync Slice Level 0-1 0 0

32 HMSK For Macro Vision 0-1 0 0

33 VTMS Select Signal VTIM Pin 0-3 0 0

34 CDMD Vertical Count Down Mode Switching 0-3 3 0 3

35 AFC AFC Loop Gain Switching 0-3 0 0

36 FIFR Field Frequency 0-3 3 3

37 VBLK VBLKW 0-3 0 0

38 REFP REFP 0-1 0 0

39 JPSW JUMPSW 0-1 MENU 0

40 RDRV R Output Drive control 0-63 41 40

41 GDRV G Output Drive control 0-63 25 42

42 BDRV B Output Drive control 0-63 25 31

43 RCUT R Output Cutoff control 0-15 31 31

44 GCUT G Output Cutoff control 0-15 15 12

45 BCUT B Output Cutoff control 0-15 12 15

46 SCON SUB CONT 0-15 8 11

47 SHUE Sub HUE adjustment 0-31 16 16

48 SCOL Sub COLOR adjustment 0-31 18

49 SBRT Sub BRIGHTNESS adjustment 0-31 16 16

50 CHUE SUB HUE (Except YUV 0-31 7 6

51 CCOL SUB COLOR (Except YUV) 0-31 4

52 UOFS YUV U OFFSET 0-15 7 7

53 VOFS YUV V OFFSET 0-15 7 7

54 RON R Output on/off 0-1 1 1

55 GON G Output on/off 0-1 1 1

56 BON B Output on/off 0-1 1 1

57 AXPL Axis PAL 0-1 0 0

58 AXNT Axis NTSC 0-1 1 1

59 CBPF Chroma BPF on/off 0-1 1 1

60 CTRP Y TRAP FILTER on/off 0-1 1 1

61 COFF Color On/off 0-1 0 0

62 KOFF Set Color Killer 0-1 0 0

63 SSHP Sub SHARPNESS 0-15 5 5

64 SHPF SHARPNESS Circuit Fo 0-3 Palette 2

65 PREL Pre-Shoot/ Over-Shoot 0- 1 1 0

66 Y-DC DC transmition Ratio Switching 0-3 Palette 2

67 GAMM Gamma Correction 0-3 Palette 2

68 ABLM ABL Mode Switch 0-1 1 1

69 VTH ABL CD VHT Switching 0-1 1 1

70 YDEL Y Delay Time Control 0-15 7 7

71 NCOL No Color ID 0-1 1 1

72 FSC FSC Out on/off 0-1 1 1

73 K-ID Killer ID Control on/off 0-1 0 0

74 GDOF 0-31 3 3

75 BDOF 0-31 16 16

76 GCOF 0-31 16 16

77 BCOF 0-31 7 7

78 SYSC Color System 0-7 4 4

79 VENH Vertical Enhancement 0-7 Palette 3

FIX

DATA VIDEO NTSC RF

AVERAGE

DATA

— 23 —

Page 24

KV-34FS12T

Reg # ITEM FUNCTION RANGE

FIX

DATA VIDEO NTSC RF

A

DATA

80 PDSO PDS OFF 0-1 0 0

81 CK CK 0-1 0 0

82 VNL VNL 0-15 3 3

83 HPK HPK 0-1 0 0

84 HPKO HPK OFF 0-1 Palette 0

85 CORE CORE 0-3 2 1

86 TRAP TRAP 0-1 1 1

87 CHTR CH TRAP 0-1 0 0

88 CBPF CBPF 0-1 1 1

89 ENHO ENHOFF 0-1 0 0

90 NMRD NMRD 0-3 0 0

91 YAPS YAPS 0-3 3 3

92 CLKS CLKS 0-3 0 0

93 NSTD NSTDS 0-3 0 0

94 MSS MSS 0-3 0 0

95 KILS KILS 0-3 1 1

96 ADIN ADIN 0-1 0 0

97 EXCS EXCSS 0-3 1 1

98 CPP CPP 0-3 2 2

99 HDP HDP 0-7 4 4

100 CDL CDL 0-7 4 4

101 DYCR DYCOR 0-15 2 2

102 DYGN DYGAIN 0-15 10 10

103 DCCR DCCOR 0-15 3 3

104 DCGN DCGAIN 0-15 6 6

105 YNRL YNRLIM 0-3 1 1

106 CNRL CNRLIM 0-3 1 1

107 WSC WSC 0-3 1 1

108 VTRH VTRH 0-3 1 1

109 VTRR VTRR 0-3 1 1

110 LDSR LDSR 0-3 2 2

111 VAPG VAPGAIN 0-7 3 3

112 VAPI VAPINV 0-31 6 6

113 TEST TEST 0-1 0 0

114 YPFT YPFT 0-3 3 3

115 YPFG YPFG 0-15 7 7

116 CC3N CC3N 0-1 0 0

117 SELD SELD 0-1 1 1

118 D2GN D2GAIN 0-7 4 5

119 YHCR YHCOR 0-3 0 0

120 YPFC YPFCOR 0-1 0 0

121 SHT SHT 0-3 0 0

122 MVT MVT 0-1 0 0

123 OTT OTT 0-1 0 0

124 CL2D CL2D 0-1 1 1

125 CLKG CLKGGT 0-1 0 0

126 HPLL HPLLFS 0-1 1 1

127 BPLL BPLLFS 0-1 0 0

128 FSCF FSCFG 0-1 0 0

129 PLLS PLLS 0-1 1 1

130 KILR KILR 0-15 3 3

131 HSSL HSSL 0-15 12 12

132 VSSL VSSL 0-15 8 8

133 BGPS BGPS 0-15 4 4

134 BGPW BGPW 0-15 10 10

135 ADCK ADCLKS 0-3 3 3

136 NDSW NSDSW 0-1 1 1

137 PFRN FREE_RUN 0-1 0 0

138 PRVS RVS 0-1 0 0

139 PCON CONTRAST 0-127 45 45

140 PUCO U-DAC 0-127 10 16

141 PVCO V-DAC 0-127 18 24

142 PHUE 0-31 15 15

143 PKIL KILLER 0.1 0 0

144 PSEP EXT_SC_SEL 0-3 2 2

145 PHIM 0-1 0 0

146 PSUB 0-1 0 0

147 PBGS BG_START 0-63 14 14

148 PDL0 0-15 6 6

149 PDL1 0-15 13 13

150 PBRT Y_OFFSET 0-31 25 25

151 PVP1 0 0

152 PUP1 0 0

153 PVP2 0 0

154 PUP2 0 0

155 PVP3 0 0

156 PUP3 0 0

157 PACS SET_ACC 0-1 1 1

158 PSDL SYNC_DELAY 0-3 0 0

VERAGE

— 24 —

Page 25

KV-34FS12T

Reg # ITEM FUNCTION RANGE

159 PDCO 0-3 0 0

160 PCGA C_GAIN 0-1 1 1

161 PAAF 0-1 0 0

162 PSU2 0-1 0 0

163 PCVF 0-1 0 0

164 PBIT BITSEL 0-1 0 0

165 PAFC AFCBITSEL 0-1 0 0

166 PACC ACC_LEVEL 0-63 22 22

167 PBUR BURST_CLK 0-1 0 0

168 PEVE EVENUPRA 0-1 0 0

169 PINW INV_WFF 0-1 0 0

170 PINR INV_REF 0-1 0 0

171 PREF RFF_FIX 0-1 0 0

172 PARE AUTO_REF 0-1 1 1

173 PAVE AVERAGE 0-1 0 0

174 PFRA FREE_RUN_ADJ 0-15 0 0

175 PPAL SUB_PALM_JUDGE 0-255 0 0

176 PHPO 0-31 9 6

177 PVPO 0-31 22 22

178 PHTI HT 0-15 5 9

179 PHAJ ADJ 0-15 1 1

180 PBGY BGY 0-15 0 0

181 PCRO CROSS_SEL 0-1 0 0

182 PPAR PALRY 0-63 2 2

183 PHPF HPFOFF 0-1 0 0

184 PFSC FSC_OUTPUT 0-1 0 0

185 PVCH SET_VCHIP 0-1 0 0

186 PVON VCHIP_ONLY 0-1 1 1

187 PVLN LINE_NUM 0-31 17 17

188 PVSB STB_DLY 0-255 64 64

189 PVLV L_LEVEL 0-255 130 130

190 SBAL Sub Balance 0-15 5 5

191 SBAS Sub Bass 0-7 0 0

192 STRE Sub Trebble 0-7 3 3

193 BBEL BBE Low 0-15 0 0

194 BBEH BBE High 0-15 0 0

195 BBE BBE 0-1 0 0

196 AUX SRS, Simulated 0-3 0 0

197 DISP O.S.D Display position 0-130 20 34

198 HCLW Horizontal Count Lower limit 0-255 16 16 16

199 HCHG Horizontal Count High limit 0-255 64 64 64

200 ID0 0-255 9

201 ID1 0-255 31

202 ID2 0-255 207

203 ID3 0-255 130

204 ID4 0-255 137

205 ID5 0-255 19

206 ID6 0-255 0

FIX

DATA VIDEO NTSC RF

AVERAGE

DATA

Notes:

No. 1–206 show the order that each adjustment mode may be selected

while in service mode. Data Range shows the range of possible

settings for each adjustment mode. Initial Data shows the standard

settings for each adjustment mode.

— 25 —

Function

Mode

service id’s id5 19

Signal

Type

ntsc

Chip

M37280MK-00SP VERB.O

Version

ID

Number

00010011

Data

Page 26

KV-34FS12T

service micro disp 48

ntsc

vchp

Category

Display

Item

Mode

Item

Data

Signal

Type

8(0) 8(0)

5-4. MA BOARD ADJUSTMENTS

H. Frequency (Free Run) Check

1. Input a TV mode (RF) with no signal.

2. Connect a frequency counter to base of Q501

(TP-500 H. DRIVE) on the A Board.

3. Check H. Frequency for 15735 ± 200 Hz

V. Frequency (Free Run) Check

1. Select video 1 with no signal input.

2. Set the conditions for a standard setting.

3. Connect the frequency counter to TP-508 (V OUT) or

CN501pin

(V DY+) and ground on the A Board .

4. Check that V. Frequency shows 60 ± 4 Hz.

Drive (RDRV)

1. Input a color-bar signal and set the level to 75%.

2. In Standard mode, set PICTURE to maximum and COLOR

to minimum.

3. Activate the Service Adjustment Mode.

4. Set both GON and BON items. Using

the following values. Leave RON set to “1”.

Category

Mode

service video rdrv 26

Signal

Type

ntsc

vchp

R ON: ON (1)

G ON: O F F (0)

B ON: O F F (0)

5. Connect an oscilloscope probe to CA Board, J701 Pin 12

(KR) (Red Out) .

6. Select RDRV with

and .

7. Adjust the value of RDRV with

92.5 ± 3 VDC.

and ; set each to

Item

8(0) 8(0)

Item

Data

Display

and for

Display Position Adjustment (DISP)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

3. Select DISP with

4. Adjust values of DISP with

and .

and to adjust characters

to the center.

5. W rite to memory by pressing

then .

6. Check to see if the text is displayed on the screen.

Sub Bright Adjustment (SBRT)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Select the SBR T item with

5. Adjust the values of SBRT with

and .

and to obtain a faintly

visible crosshatch.

6. Press

then to save into the memory.

Sub Hue, Sub Color Adjustment (CHUE, CCOL)

1. Input a color-bar signal.

2. Activate the Service Adjustment Mode.

3. Connect an oscilloscope probe to CA Board, CN705

.

Pin

4. Select the CHUE and CCOL item with

5. While showing the CHUE item, adjust the waveform with

and until the second and third bars show the same level

(V2 = V3 < 0.1 Vp-p).

6. While showing the CCOL item, adjust the waveform with

and until the first and fourth bars show the same level

(V1 = V4 < 0.1 Vp-p).

V2 V3

V1

and .

V4

8. Reset GON and BON values to “1”.

9. Reset Picture and Color to normal values:

10.Press

R ON: ON (1)

G ON: ON (1)

B ON: ON (1)

PICTURE: MAX

COLOR: CENTER

then to save into the memory.

7. Press then to save into the memory.

V. Size Adjustment (VSIZ)

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VSIZ item with

4. Adjust value of VPOS with and for the best vertical

center.

5. Press

then to save into the memory.

— 26 —

and .

Page 27

V. Center Adjustment (VPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VPOS item with

4. Adjust value of VPOS with

and .

and for the best vertical

center.

5. Press

then to save into the memory.

H. Center Adjustment (HPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the HPOS item with

4. Adjust the value of HPOS with

horizontal center.

5. Press

then to save into the memory.

and .

and for the best

KV-34FS12T

V LINEARITY (VLIN)

V CORRECTION (SCOR)

PIN AMP (PAMP)

HORIZONT AL TRAPEZOID (HTRP)

V. Angle (VANG), V. Bow (VBOW), Upper pin

(UPIN) and Low Pin (LPIN) Adjustments

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VANG , VBOW, UPIN, and LPIN with

4. Adjust with

5. Press

V ANGLE (VANG)

and for the best picture.

then to save into the memory.

and .

H. Size Adjustment (HSIZ)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

3. Select HSIZ with

4. Adjust with

5. Press

and .

and for the best horizontal size.

then to save into the memory.

V. Linearity (VLIN), V. Correction (SCOR),

Pin Amp (PAMP), and Horizontal Trapezoid

(HTRP) Adjustments

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VLIN, SCOR, PAMP, and HTRP with with

4. Adjust with

5. Press

and for the best horizontal size.

then to save into the memory.

and .

V BOW (VBOW)

UPPER PIN (UPIN)

LOW PIN (LPIN)

Service Adjustment Mode Memory

1. Change the value of the DCOL item to “1”.

2. After completing all adjustments, press

Read From Memory

Mode

Category

service defl vbow 7

Signal

Type

ntsc

vchp

Display

Item

00000000 00000000

then .

Item

Data

Green

Red

ENTER

0

— 27 —

Page 28

KV-34FS12T

NOTES:

— 28 —

Page 29

NOTES:

KV-34FS12T

— 29 —

Page 30

KV-34FS12T

NOTES:

— 30 —

Page 31

BA5-889-BD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

1

2

3

4

5

1

3

2

4

6

1

2

1

2

3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

3

4

7

8

9

1

0

1

2

3

4

5

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

1

2

3

4

12

34

V

L

R

S

1

2

3

4

1

2

3

4

5

7

8

9

10

11

12

14

15

16

17

13

18

1

2

4

3

1

2

3

4

5

6

1

2

3

4

5

1

2

3

1

2

3

1

2

3

4

5

6

7

8

1

2

3

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

CN460

J201

CN406

T604

D626

C636

PH600

T505

CN501

T603

T501

T504

CN506

CN2005

CN2006

CN2007

CN2008

CN4001 CN2003

T503

CN901

CN902

CN904

CN301

CN450

CN402

CN602

CN603

CN604

CN801

CN800CN515

D605

VDR601

F601

T602

RY601

RY602

D622

R645

D2001

CN2001

S-VIDEO

4P

SRT

:STAND BY

PHOTOCOUPLER

FBT

D4SB60L-F

AC RECT

DGC RELAY

RELAY

AC POWER

D4SB60L-F

AC RECT

10k

VIDEO

MAIN1

ST LED I-STEREN

SAP LED I-SAP

MODE O-SAP

F MONO O-MONO

GND

MAIN2

AFT OUT AFT

RF AGC

AGC MUTE

AGC

Q101

9V

30V

5V

L OUT

DE-EM OUT

R OUT

MUTE

VOL-CTRL

Q410

C

Y

TV-L

TV-R

FRONT A/V

VIDEO

AUDIO

L

R

V2-L

V2-R

CLOCK

DATA

V1-R

V1-L

YUV-R

YUV-L

AUDIO

L

R

GND

9V

OUT-R

OUT-L

SPK R+

SPK R-

SPK L+

SPK L-

GND

GND

V1

VM

9V

E

NC

+B

VM

1

3

4

5

6 8

9

STANDBY CIRCUIT

D623

Q606

PROTECT

Q605

CONVERTER

SWITCH

Q608

STBY DRIVE

Q607

RELAY DRIVE

Q604

RELAY

DGC

DGC

DGC

DGC DRIVER

Q609

DGC

D

VIN

S

OCP/FB

+B

FV

G2

ABL

H

5

6

9

8

7

2

4

1

0

0

11

DF

HV

H OUT

Q502

H DRIVE

Q501

HD

HP

IN+1

EW

IN-1

PIN DRIVE

PIN OUT

Q504

Q503

O

U

T

1

I-HLDWN

OUT2

SW

Q506,507

IN+2

VD+

D

R

I

V

E

+

OUT

GND

I-PROT

REF

STBY 7.5V

VD-

D

R

I

V

E

-

ABL

DET-OUT

CONVERTER

IC601

5V REG

IC604

9V REG

IC603

ERROR AMP

IC602

IC501

V HOLD

CNTRL

V OUT

IC502

IR DETECT

IC2001

SPR

SPL

+

+

AC IN

TU101

MON-L

MON-R

VAR/FIX-R

VAR/FIX-L

H

E

A

T

E

R

6

SPSW

MONITOR

V3

9V

30V

5V

SET5V

SET9V

30V

9V

9V

+B

STBY 7.5V

CN502

V3-L

V3-R

PIP-L

IR(SENSOR)

POWER-SW

LED-TIMER

GND

V DY+

V DY-

H DY-

H DY-

H DY+

H DY+

YCBCR AUDIO

INPUT

VOL-CTRL

Q411

+B

VC1

VC2

IN2

IN1

OUT1+

OUT3-

OUT4+

OUT2-

AUDIO AMP

IC401

NC

VIDEO

AUDIO

L

R

J202

J203

REAR A/V

SET9V SET9V

J205

AUDIO

L

RJ402

REAR VAR/FIX

POWER-SW

GND

KEY-SW

SWITCHES

FUNCTION

POWER-SW

GND

KEY-SW

S2008

S2007

TP507

TP508

TP 506

AMP

VELOCITY

MODULATION

Q903

Q904

VM OUT

Q905

Q906

VM DRIVE

Q901

Q902

VM

9V

E

NC

+B

9V

VM

VM

E

E

QP+

QP+

QP-

QP-

VM

VM

E

E

QP+

QP-

QP-

QP+

DQP DRIVE

V

M

O

D

V

M

O

D

9

V

D

R

I

V

E

Q

P

D

R

I

V

E

Q808

QP H OUT

Q807

QP QP VM

VM

200V

AUDIO

Y-TO-YUV

CR

CB

GND

V DY(+)

V DY(-)

H DY(-)

H DY(+)

Y

PB

PR

J206

Y,PR,PB

INPUT

INPUT

INPUT

TV-L

TV-R

V2-L

V2-R

V1-R

V1-L

YUV-R

YUV-L

GND

9V

OUT-R

OUT-L

OUT-B

OUT-A

IN5

IN5A

IN2

IN2A

IN1

IN1A

IN3A

IN3

MON-L

MON-R

VAR/FIX-R

VAR/FIX-L

9V

V3-L

V3-R

LINEA

LINEB

IN4A

IN4

MUTE

NC

MUTE

Q430,431

BUFFER

Q432,433

AUDIO

PROCESSOR

IC404

SCL

SDA

GND

SCL

SDA

DGC

DGC

DGC

NC

OCP

Q505

SW

Q603

Q601,602

9V

V MOD

V MOD

9V DRIVE

QP DRIVE

135V

NC

GND

GND

HP

VD+

+B

9V

Q812 IC803

IC802

DF-COMP

HP HP

Q811

Q801

Q803,804 Q802

IC801

Q805,806

Q810 Q809

QP DRIVE

SW BUFFER

BUFFER

SW BUFFER

V MOD

V MOD

9V

135V

NC

GND

GND

HP

VD+

+B

9V

CN802

11

DFDF

CN504

LOW B LOW B5V 9V

LOW B

AUDIO

LOW B

VCC

+B

RECT

+B

RECT

LOW B

RECT

AUDIO

OUTPUT

(POWER SUPPLY)

(DEFLECTION)

(TUNER/IF)

(AUDIO)

(MTS)

(AUDIO PROCESSOR)

( )

(CONVERGENCE)

(KEY)

MUTE

NC

Y1

C1

SDAT

SET9V

30V

SET5V

SCL

STBY

+5V

V2(VIDEO2)

STBY +5V

KEY-SW

MENU-SW

KV-34FS12T

SECTION 6 DIAGRAMS

6.1 BLOCK DIAGRAM

A

B

C

D

E

F

G

H

— 32 —

— 33 —— 31 —

Page 32

KV-34FS12T

MEMORY

STBY+7.5V STBY+5V

IC003

B

CN309

DAT

GND

CLK

B-CLK

CN002

FOR JIG

B-DAT

B-INT

GND

SPSW

VM

STBY 7.5V

C

CN003

I-PROT

RELAY

MUTE

GND

O-MON0

O-SAP

D

CN004

I-SAP

I-STEREN

MAIN 1

MAIN 2

AFT

AGC MUTE

3

2

1

1

2

3

4

9

8

7

STBY 7.5V

6

GND

5

4

DGC

3

HP

2

1

9

8

7

6

5

4

3

2

1

BUFFER

Q001

IO-BCLKN

IO-BDAT

I-BINT

Q002 Q006

I-PROT

O-DGC

O-RELAY

O-MUTE

O-MONO

O-SAP

I-SAP

I-STEREN

I-AFT

O-AGCMUTE

I-RESET

I-HSYNC

I-BSC

O-OSC

I-SDAT

O-YM YS2/YM

O-OSDBLCK

O-R

O-G

O-B

STBY+5V REG

HSYNCH SEPBUFFER

X1001

IC002

RESET

Q365,082

DIG COMB

FILTER

IC302

T

T

N

I

A

N

A

L

C

S

U

U

I

D

O

O

K

S

Y

C

C

(TUNING CONTROL)

(Y/C/J)

CN302

CVBS4IN

VM OUT

Q375

HP

VM

HP PROTECTI-HP

SDA

SCLO-SCLN

DVD-YIN

DVDCR-IN

DVDCB-IN

1

Y-TO-YUV

2

CR

3

CB

4

GND

A

Y/C JUNGLE

R2IN

IC301

G2IN

B2IN

CONTROL

TUNING SYSTEM

IC001

SET9V SET9V

I-HLDWN

HD

GND

E

CN005

ABL

EW

VD+

VD-

MONITOR

V3

PIP-L

SDAT

SCL

F

CN006

SET5V

30V

SET9V

V1

GND

Y1

C1

LED

POWER-SW

IR(SENSOR)

G

CN001

MENU-SW

KEY-SW

STBY +5V

V2(VIDEO2)

GND

10

9

8

7