Page 1

SERVICE MANUAL

AE-6B

CHASSIS

MODEL

KV-32FQ70B

KV-32FQ70E

COMMANDER DEST CHASSIS NO.

RM-938 FR SCC-Q83N-A

RM-938 ESP SCC-Q81Q-A

MODEL

KV-32FQ70K

KV-32FQ70U

COMMANDER DEST CHASSIS NO.

RM-938 OIRT SCC-Q82J-A

RM-938 UK SCC-Q84N-A

KV-32FQ70

- 1 -

RM-938

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Caution .................... 3

Specifications .................... 4

Connectors .................... 6

Self Diagnostic Software .................... 7

1. GENERAL

Switching On the TV and

Automatically Tuning .................... 8

Introducing and Using the Menu

System .................... 9

Menu Guide .................... 9

Teletext .................... 10

Fastext .................... 10

Remote Control Configuration

for VCR/DVD .................... 11

Specifications .................... 11

Troubleshooting .................... 12

2. DISASSEMBLY

2-1. Rear Cover Removal .................... 13

2-2. Speaker Box Removal .................... 13

2-3. Chassis Removal and Refitting .................... 13

2-4. Service Position .................... 14

2-5. G Board Removal .................... 14

2-6. D2 Board Removal .................... 14

2-7. D Board Removal .................... 14

2-8. M2 Board Removal .................... 15

2-9. Service Connector for M2 Board.................. 15

2-10. Wire Dressing .................... 15

2-11. Picture Tube Removal .................... 16

Bottom Plates .................... 17

5. DIAGRAMS

5-1. Block Diagrams (1) .................... 25

Block Diagrams (2) .................... 26

Block Diagrams (3) .................... 27

Block Diagrams (4) .................... 28

5-2. Circuit Board Location .................... 28

5-3. Schematic Diagrams and

Printed Wiring Boards .................... 28

* A Board Schematic .................... 29

* A Board PWB .................... 35

* F1 Board Schematic .................... 39

* F1 Board PWB .................... 40

* H1 Board Schematic .................... 39

* H1 Board PWB .................... 40

* VM Board Schematic .................... 39

* VM Board PWB .................... 40

* G Board Schematic .................... 41

* G Board PWB .................... 40

* C Board Schematic .................... 42

* C Board PWB .................... 43

* M2 Board Schematic .................... 44

* M2 Board PWB .................... 43

* D2 Board Schematic .................... 45

* D2 Board PWB .................... 43

* D Board Schematic .................... 47

* D Board PWB .................... 46

5-4. Semiconductors .................... 48

5-5. IC Blocks .................... 51

6. EXPLODED VIEWS

3. SET-UP ADJUSTMENTS

3-1. Beam Landing .................... 18

3-2. Convergence .................... 19

3-3. Focus Adjustment .................... 21

3-4. Screen (G2), White Balance .................... 21

4. CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments .................... 22

4-2. Test Mode 2 .................... 24

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT, AFTER REMOVAL OF THE

ANODE CAP.

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ON

6-1. Chassis .................... 53

6-2. Picture Tube .................... 54

7. ELECTRICAL PARTS LIST .................... 55

ATTENTION

APRES AVOIR DECONNECTE LE CAP DE’LANODE,

COURT-CIRCUITER L’ANODE DU TUBE CATHODIQUE ET

CELUI DE L’ANODE DU CAP AU CHASSIS METALLIQUE DE

L’APPAREIL, OU AU COUCHE DE CARBONE PEINTE SUR LE

TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION !!

AFIN D’EVITER TOUT RISQUE D’ELECTROCUTION

PROVENANT D’UN CHÁSSIS SOUS TENTION, UN

TRANSFORMATEUR D’ISOLEMENT DOIT ETRE UTILISÈ LORS

DE TOUT DÈPANNAGE LE CHÁSSIS DE CE RÈCEPTEUR EST

DIRECTMENT RACCORDÈ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á

LA SECURITÈ!!

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE SUR LES SCHÈMAS DE PRINCIPE, LES VUES

EXPLOSÈES ET LES LISTES DE PIECES SONT D’UNE IMPOR-

TANCE CRITIQUE POUR LA SÈCURITÈ DU FONCTIONNEMENT,

NE LES REMPLACER QUE PAR DES COMPSANTS SONY DONT

LE NUMÈRO DE PIÈCE EST INDIQUÈ DANS LE PRÈSENT

MANUEL OU DANS DES SUPPLÈMENTS PUBLIÈS PAR SONY.

- 2 -

Page 3

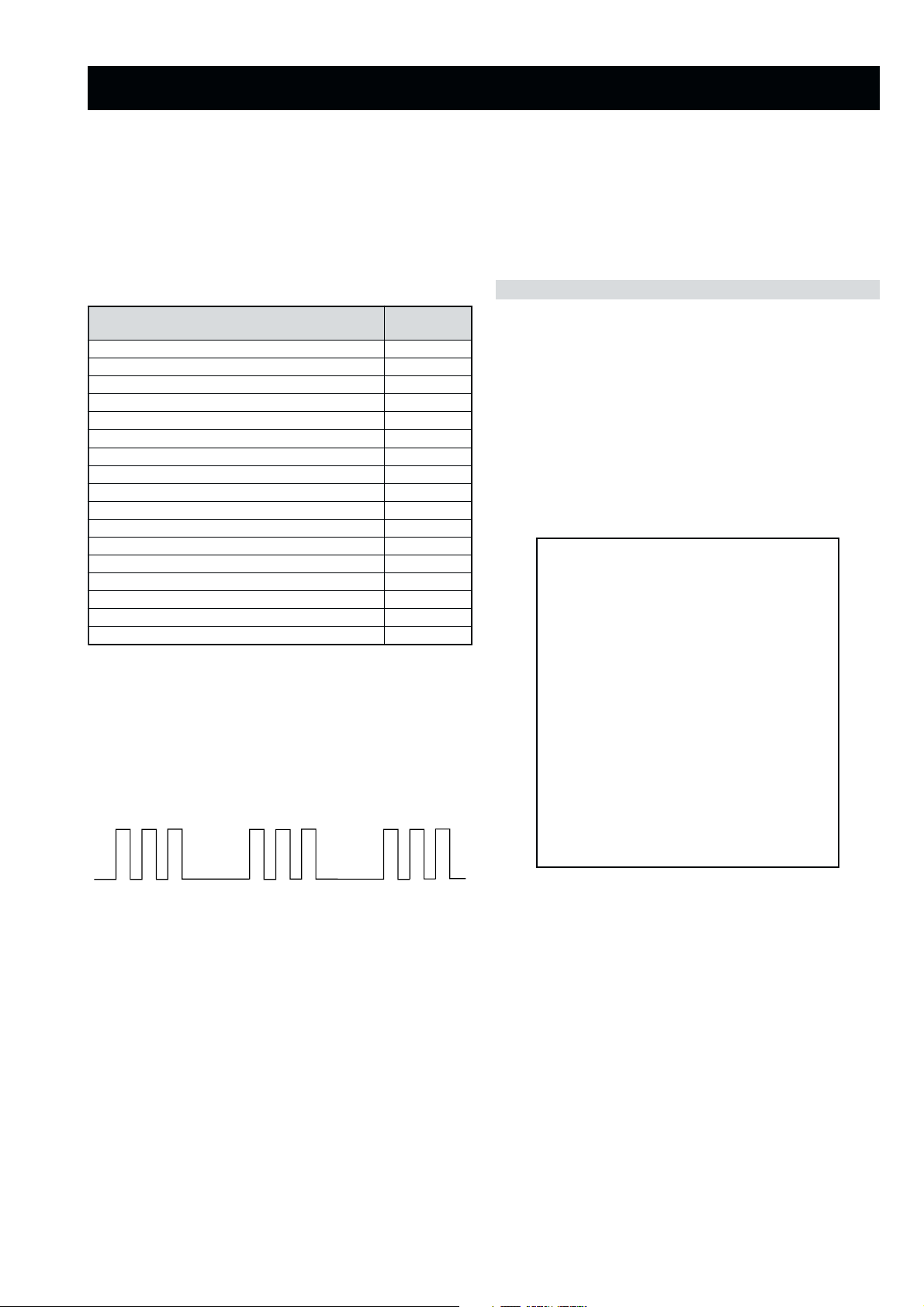

CAUTION

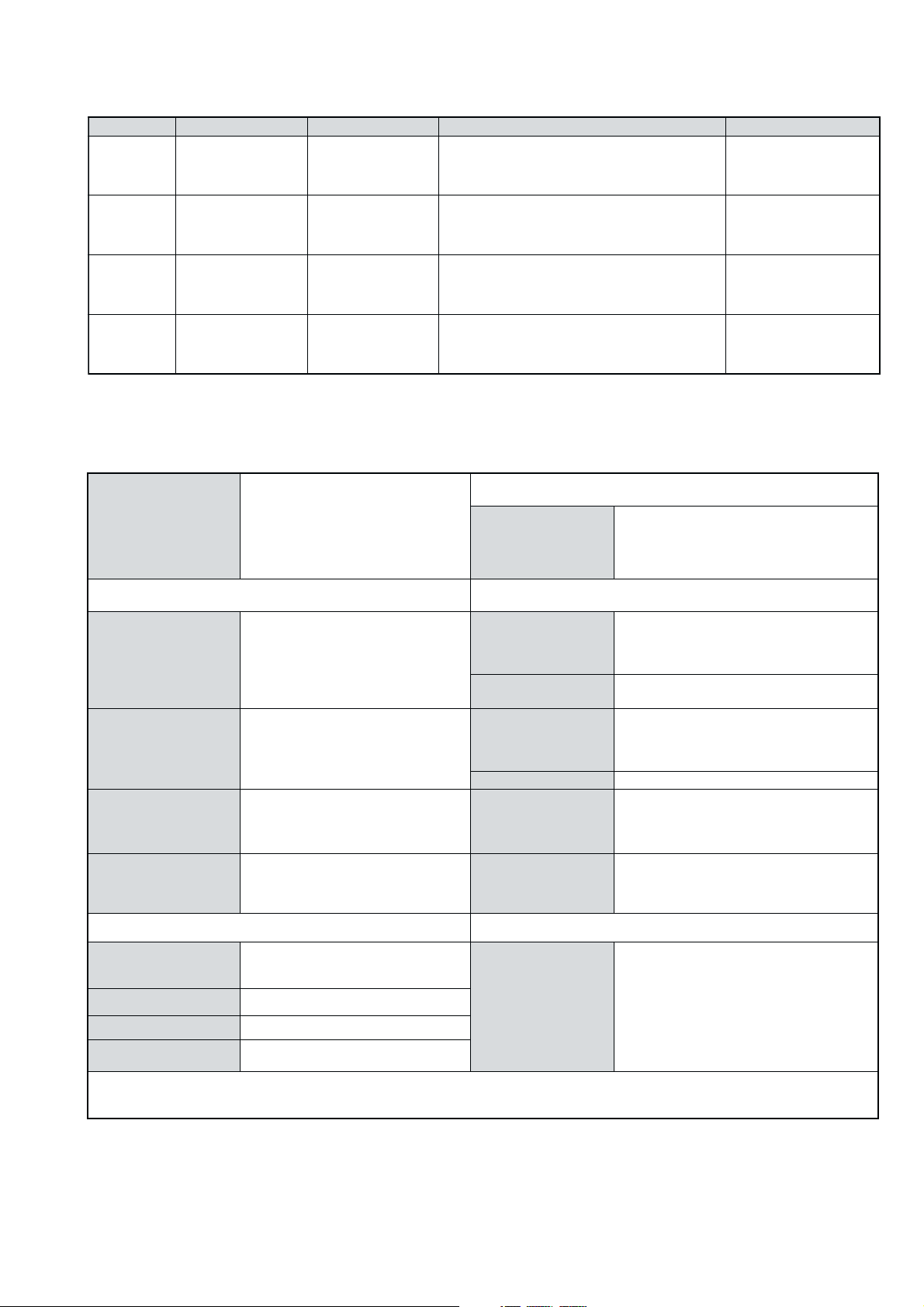

Lead Free Soldered Boards

The circuit boards listed below [Table 1] used in these models

may have been processed using Lead Free Solder. The boards are

identified by the LF logo located close to the board designation

e.g. F1, H1 etc [ see examples ]. The servicing of these boards

requires special precautions to be taken as outlined below.

Table 1

draoB noitcnuF

CtuOB,G,R

1F

1H

DEL

ybdnatS/SCRIS/esuF/hctiwSrewoP

dnaenohpdaeH/tupnIVAtnorF

sehctiwSlortnoC

example 1

example 2

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints. Lead Free Solder is

available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This

requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

- 3 -

Page 4

LEDOMMETI metsySnoisiveleT metsySoeretS egarevoClennahC metsySroloC

BL,I,K/D,H/G/B

EK/D,H/G/B

KK/D,H/G/B

UI

MACIN/NAMREG

oeretS

MACIN/NAMREG

oeretS

MACIN/NAMREG

oeretS

MACIN

oeretS

02S-10S:VTELBAC

14S-12S:REPYH

30S-10S,21R-1R,21E-2E:FHV

96R-12R,96E-12E:FHU

02S-10S:VTELBAC

14S-12S:REPYH

30S-10S,21R-1R,21E-2E:FHV

96R-12R,96E-12E:FHU

02S-10S:VTELBAC

14S-12S:REPYH

96B-12B:FHU

Q-B,01F-20F,30S-10S,21R-1R,21E-2E:FHV

96R-12R,96B-12B,96F-12F,96E-12E:FHU

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

MACES,LAP

85.3CSTN,34.4CSTN

)NIOEDIV(

nortinirTDFyalpsiDtalF

ebuTerutciP

)yllanogaid

]RAER[slanimreTtuptuO/tupnI snoitacificepSlareneG

rotcennocoruEnip-12:1

)dradnatsCELENEC(

rotcennocoruEnip-12:2

rotcennocoruEnip-12:3

skcaJonohP

slangiS

]EDIS[slanimreTtuptuO/tupnI lortnoCderarfnI:metsySlortnoCetomeR

.BGRrofstupnI

.slangis

.BGRrofstupnI

)tuOrotinoM(

)elbatceles(

)sehcni23(mc28xorppA

derusaemerutcipmc67xorppA(

.slangisoediVdnaoiduArofstupnI

oiduAdnaoediVVTfostuptuO

.slangisoediVdnaoiduArofstupnI

.slangisoiduAdnaoediVVTfostuptuO

.slangisoediVdnaoiduArofstupnI

.oediVSrofstupnI

.slangisoiduAdnaoediVVTfostuptuO

oiduArofelbairavsrotcennoCtuptuO

tuptuodnuoS

rekaepstfeLdnathgiR

refooWbuS

stnemeriuqeRrewoPV042-022

noitpmusnoCrewoPW031

snoisnemiDmm685x685x019xorppA

thgieWgk46xorppA

seirosseccAdeilppuS

serutaeFrehtO

)SMR(W01x2)rewoPcisuM(W02x2

)SMR(W51x1)rewoPcisuM(W03x1

)1(rednammoCetomeR839-MR

)2(yrettab6RdetangisedCEI

,noitcudeResioNotuA,RND,erutcipzH001

ybloDlautriV,EBB,kniltramS,txeteleT

kcajenohpdaeHkcajinimoerets

stupnioiduAskcajonohp

stupnioediVskcajonohp

tupnioediVSNIDnip4

- 4 -

stnemeriuqerrewoP

cdV3

noitangisedCEIseirettab2

)AAezis(6R

.ecitontuohtiwegnahcottcejbuserasnoitacificepsdnangiseD

Page 5

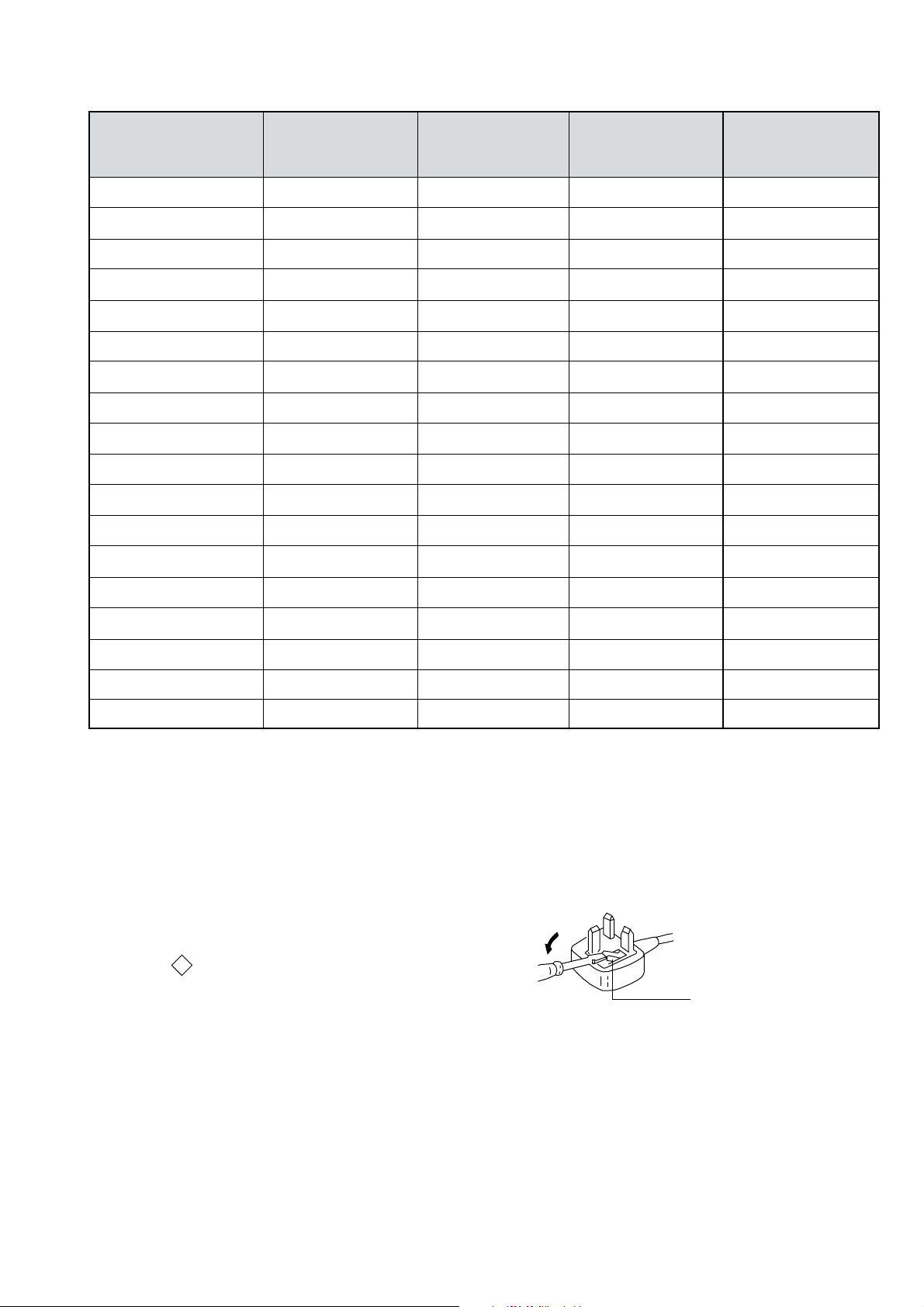

metI

How to replace the fuse.

Open the fuse compartment with

a screwdriver blade and replace

the fuse.

FUSE

emaNledoM

bmoClaPFFOFFOFFOFFO

PIPFFOFFOFFOFFO

ytiroirPBGRNONONONO

xoBrefooWNONONONO

1tracSNONONONO

2tracSNONONONO

3tracSNONONONO

)4(niediSNONONONO

rotcejorPFFOFFOFFOFFO

G/BmroNNONONOFFO

ImroNNOFFOFFONO

K/DmroNNONONOFFO

SUAmroNFFOFFOFFOFFO

B07QF23-VK E07QF23-VK K07QF23-VK U07QF23-VK

LmroNNOFFOFFOFFO

TASmroNFFOFFOFFOFFO

MmroNFFOFFOFFOFFO

txeteleTNONONONO

oeretSmaciNNONONONO

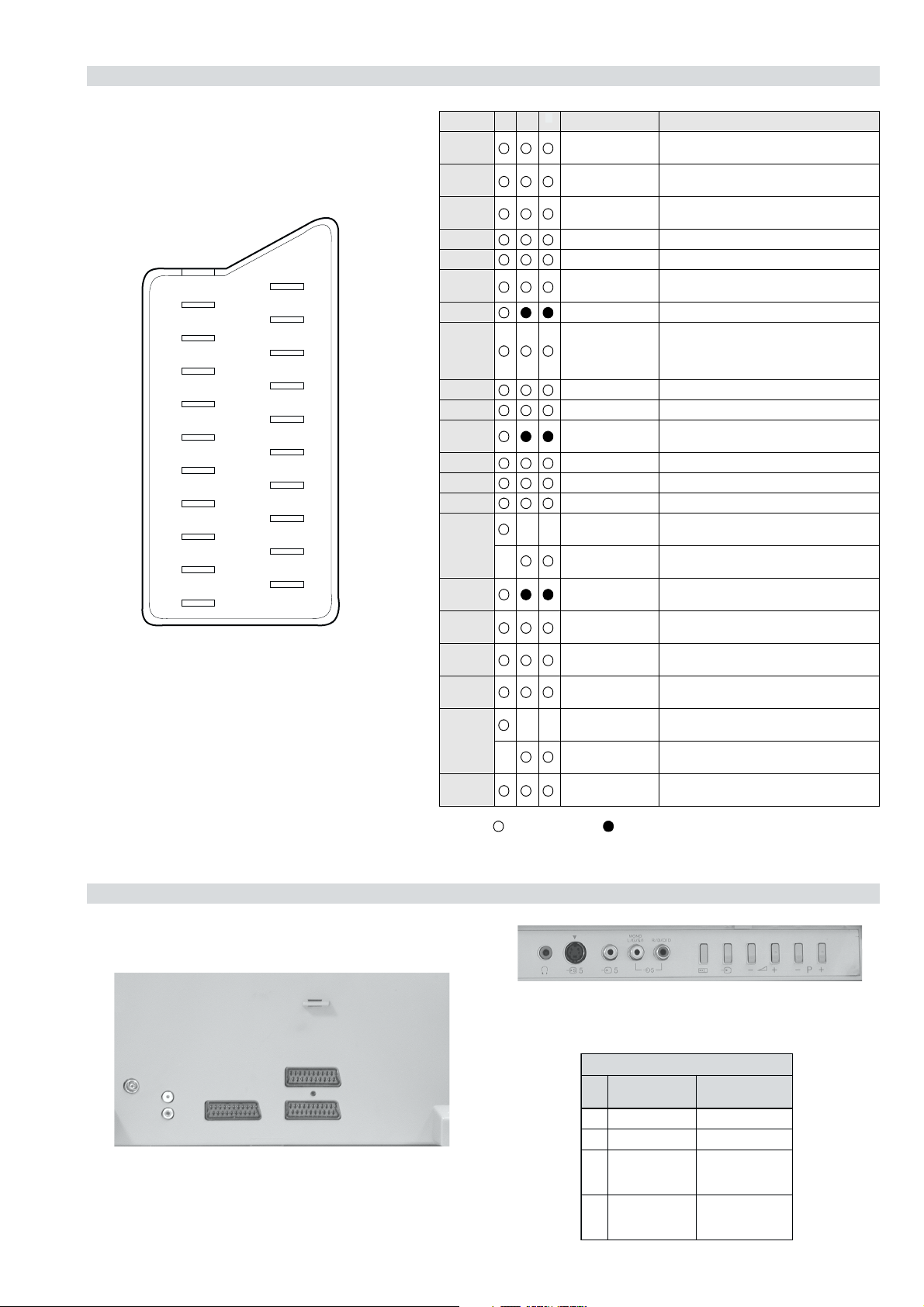

WARNING (UK Models only)

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of 5 AMP rating. Should the fuse need to be

replaced, use a 5 AMP FUSE approved by ASTA to BS 1362, ie one

that carries the

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT SUITABLE FOR THE OUTLET SOCKETS IN YOUR HOME, IT SHOULD

BE CUT OFF AND AN APPROPRIATE PLUG FITTED. THE PLUG

SEVERED FROM THE MAINS LEAD MUST BE DESTROYED AS A

PLUG WITH BARED WIRES IS DANGEROUS IF ENGAGED IN A

LIVE SOCKET.

ASA

T

mark.

When an alternative type of plug is used, it should be fitted with a

5 AMP FUSE, otherwise the circuit should be protected by a 5 AMP

FUSE at the distribution board.

- 5 -

Page 6

21 pin connector

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

8

6

4

2

Pin No 1 2 4 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blue)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 Open

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

12 Open

13 Ground (red)

14 Ground (blanking)

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

3

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

input)

(Ys signal)

output)

input)

_ _ Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

_ Video input

Y (S signal)

(plug, shield)

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

Connected Not Connected (open) * at 20Hz - 20kHz

Rear Connection Panel Front Connection Panel

S-Video

socket

niP

oN

1dnuorG-

2dnuorG-

3tupni)langisS(Y,mho57Bd3-/+V1

4tupni)langisS(CBd3-/+V3.0

langiS leveLlangiS

noitarugifnocniptekcosoediVS

V3.0.cnySevitisop

Bd01+3-

evitisop,mho57

.cnyS

- 6 -

Page 7

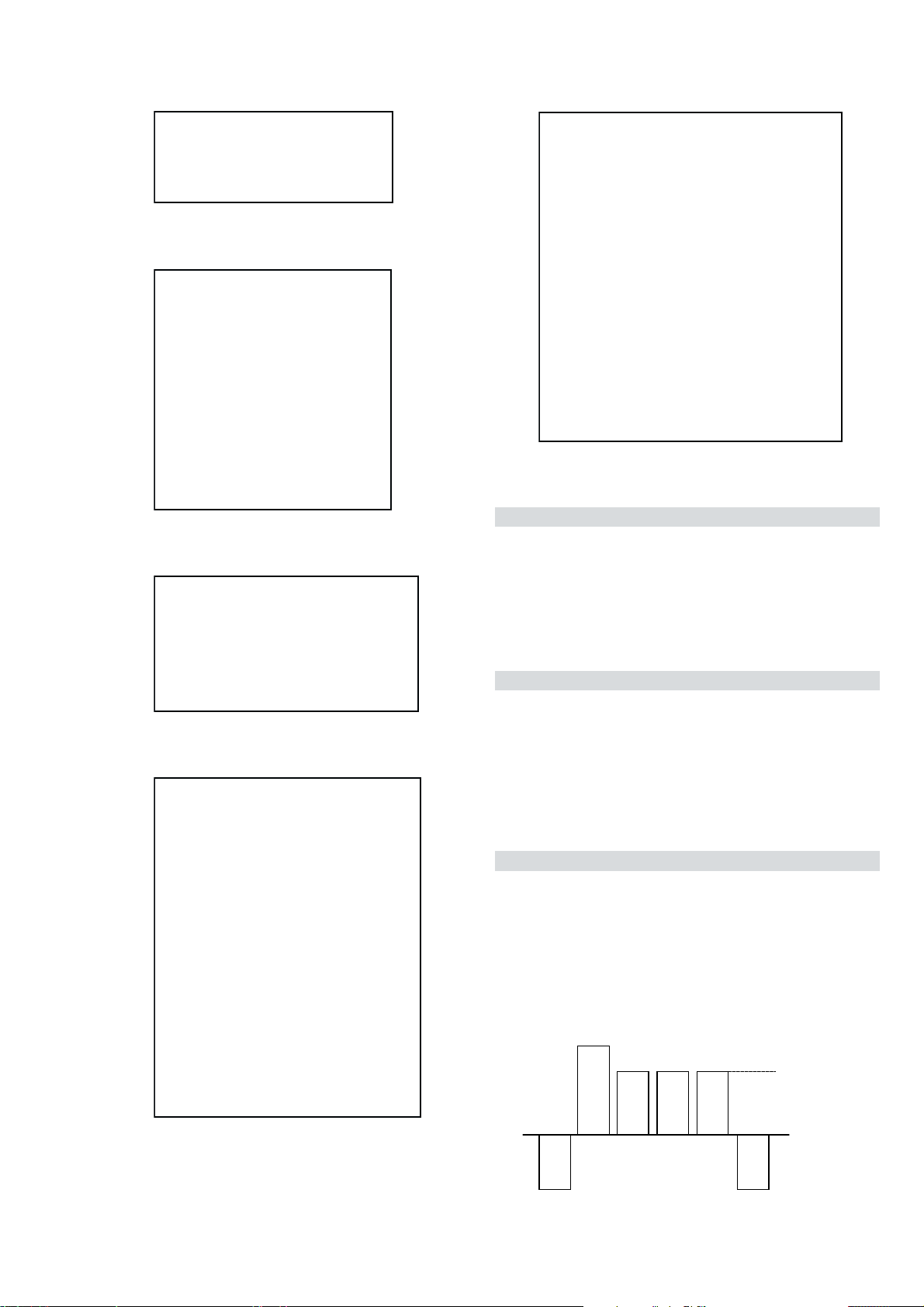

AE-6B SELF DIAGNOSTIC SOFTWARE

The identification of errors within the AE-6B chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted) See table 1, non fatal errors are reported using this

method.

Each time the software detects an error it is stored within the NVM. See Table 2.

Table 1

egasseMrorrE

rorreoN00

devreseR10

)noitcetorPtnerruCrevO(PCO20

noitcetorPegatloVrevO30

cnySlacitreVoN40

norewoptarorrERKI50

norewoptaegdelwonkcasubCIIonMVN70

noitcetorPlatnoziroH80

norewoptaegdelwonkcaonrenuT90

rorrErossecorPdnuoS01

devreseR11

rorrEetarnacS21

rorrECAD31

rorrEdnekcaB41

rorrEecnegrevnoCcimanyD51

rorrEPIP61

Flash Timing Example : e.g. error number 3

StBy LED

ON ON ON

OFF

OFF

norewoptawolsenilatadro/dnakcolcsubCII60

How to enter into Table 2

DEL

edoC

1. Turn on the main power switch of the TV set.

2. Program Remote Commander for Operation in Service

Mode. [See Page 22].

3. Press ‘VIDEO’ ‘VIDEO’ > ‘MENU’ on the Remote

Commander.

4. Using the Remote Commander, Scroll to the ‘Error Menu’

item using the down arrow key, then press the right arrow

key.

5. The following table will be displayed indicating the error

count.

Table 2

UNEMRORRE

20E

30E

40E

50E

60E

70E

80E

90E

01E

11E

21E

31E

41E

51E

61E

SRUOH

SETUNIM

PCO

PVO

CNYSV

RKI

CII

MVN

TORPH

RENUT

PDNUOS

ETARNACS

CAD

DNEKCAB

NOCNYD

PIP

EMITGNIKROW

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

41

7

Note: To clear the error count data press ‘80’ on the Remote

commander.

- 7 -

Page 8

7

GB

Language

English

Norge

Français

Italiano

Nederlands

Select Language: Confirm: OK

If picture slants, please

adjust picture rotation

Not necessary

Adjust now

Select: Confirm: OK

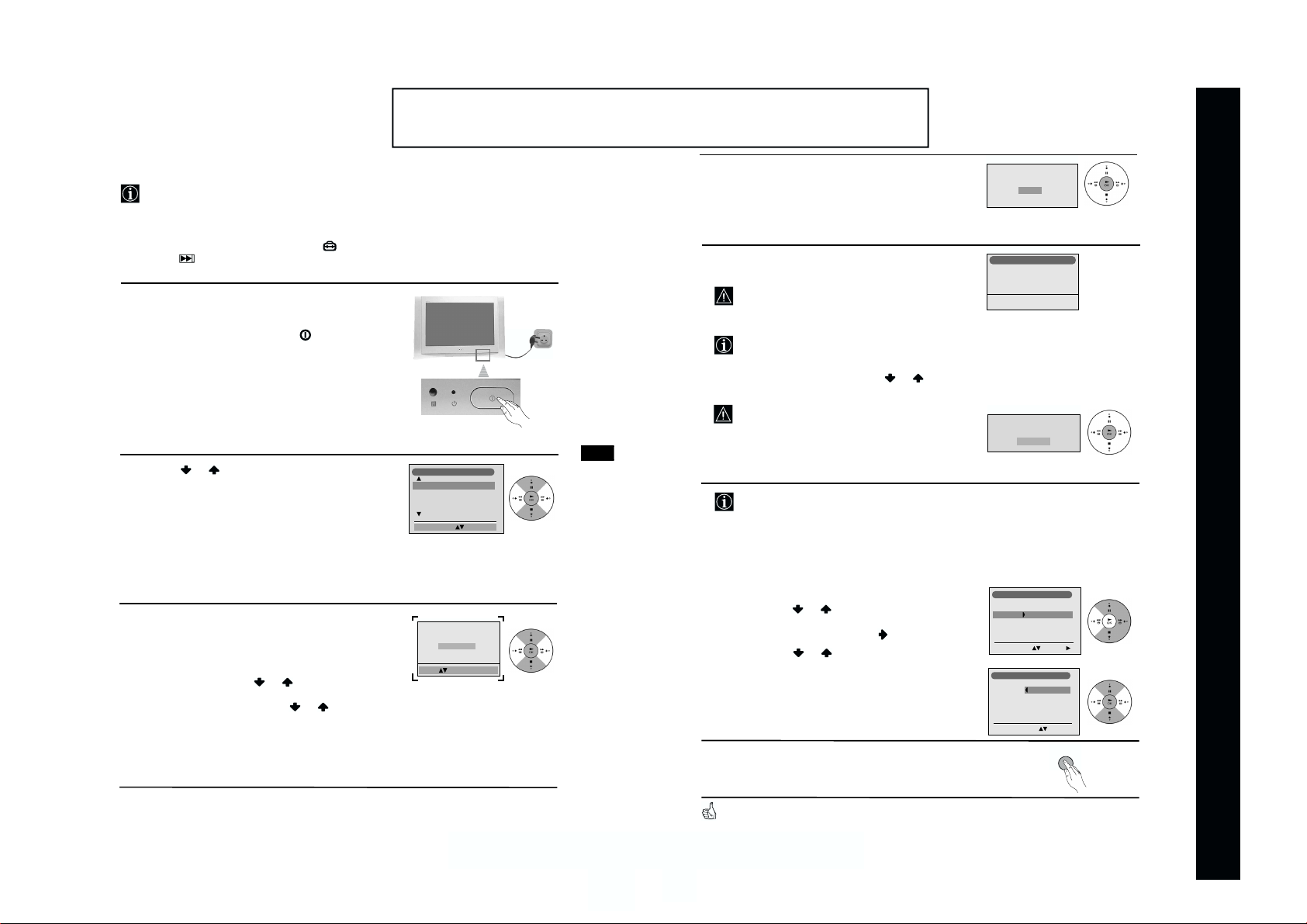

Switching On the TV and Automatically Tuning

The first time you switch on your TV, a sequence of menu screens appear on the TV

enabling you to: 1) choose the language of the menu screen, 2) adjust the picture slant,

3) search and store all available channels (TV Broadcast) and 4) change the order in which

the channels (TV Broadcast) appear on the screen.

However, if you need to change any of these settings at a later date, you can do that by

selecting the appropriate option in the (Set Up menu) or by pressing the Auto Start Up

Button on the TV set.

First Time Operation

1

Connect the TV plug to the mains socket (220-240V AC,

50Hz)

The first time that the TV set is connected, it is usually

turned on. If the TV is off, press the on/off button on

the TV set to turn on the TV.

The first time you switch on the TV, a Language menu

displays automatically on the TV screen.

2

Press the or button on the remote control to select

the language, then press the OK button to confirm your

selection. From now on all the menus will appear in the

selected language.

3

Because of the earth’s magnetism, the picture might slant.

The Picture Rotation menu allows you to correct the

picture slant if it is necessary.

a)

If it is not necessary, press OK to select Not necessary.

b)

If it is necessary, press or to select Adjust now,

then press OK and correct any slant of the picture

between –5 and +5 by pressing or . Finally press

OK to store.

continued...

8

Programme:

Channel:

Searching...

1

C 01

Auto Tuning

Do you want to start

automatic tuning?

Yes

No

No channel found

Please connect aerial

Confirm

First Time Operation

4

The Auto Tuning menu appears on the screen. Press the

OK button to select Yes.

5

The TV starts to automatically search and store all

available broadcast channels for you.

This procedure could take some minutes. Please be

patient and do not press any buttons, otherwise

automatic tuning will not be completed.

In some countries the TV Broadcaster installs the

channels automatically (ACI system). In this case,

the TV Broadcaster sends a menu in which you can

select your city by pressing the or button and

OK to store the channels.

If no channels were found during the auto tuning

process then a new menu appears automatically on

the screen asking you to connect the aerial. Please

connect the aerial (see page 6) and press OK. The

auto tuning process will start again.

6

After all available channels are captured and stored,

the Programme Sorting menu automatically appears

on the screen enabling you to change the order in

which the channels appear on the screen.

a)

If you wish to keep the broadcast channels in the

tuned order, go to step 7.

b)

If you wish to store the channels in a different order:

1 Press the or button to select the programme

number with the channel (TV Broadcast) you wish

to rearrange, then press the button.

2 Press the or button to select the new

programme number position for your selected

channel (TV Broadcast), then press OK.

3 Repeat steps b)1 and b)2 if you wish to change

the order of the other channels.

7

Press the MENU button to remove the menu from the

screen.

Your TV is now ready for use

Programme Sorting

Programme:

01 TVE2 41 TVE

02 TVE

03 ANT3

04 TELE5

05 C+

06 C44

Select new position Move: OK

MENU

Programme Sorting

Programme:

01 TVE2

02 TVE

03 ANT3

04 TELE5

05 C+

06 C44

Select Channel Confirm:

The operating instructions mentioned here are partial abstracts from the ‘Operating

Instruction Manual’. The page numbers of the ‘Operating Instruction Manual’ remain

as in the manual.

- 8 -

SECTION 1 GENERAL

Page 9

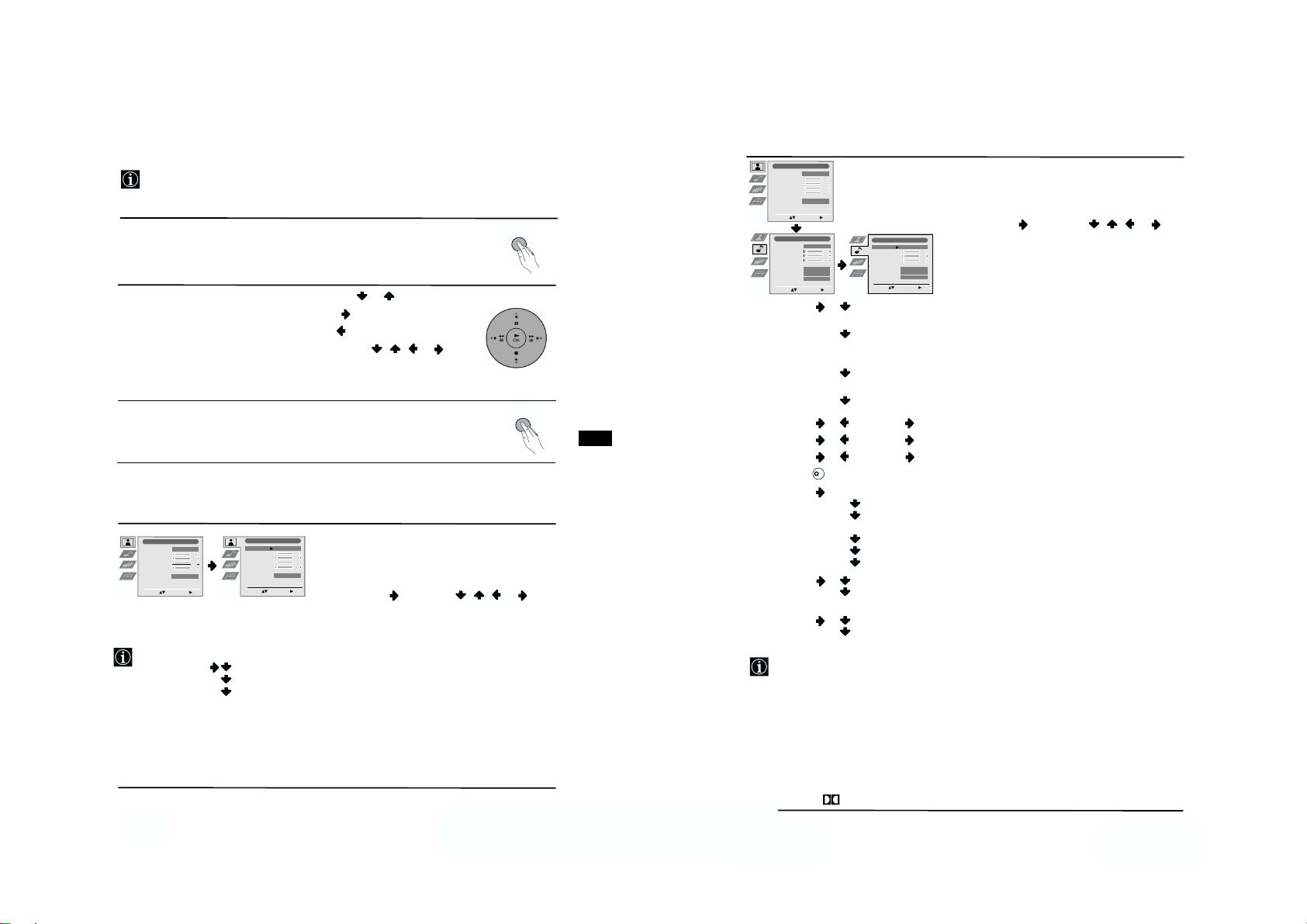

9

GB

Introducing and Using the Menu System

Your TV uses an on-screen menu system to guide you through the operations. Use the

following buttons on the Remote Control to operate the menu system:

1

Press the MENU button to switch the first level menu on.

2

• To highlight the desired menu or option, press or

.

• To enter the selected menu or option, press .

• To return to the last menu or option, press

.

• To alter the settings of your selected option, press / / or .

• To confirm and store your selection, press OK.

3

Press the MENU button to remove the menu from the screen.

continued...

Menu Guide

PICTURE ADJUSTMENT

The “Picture Adjustment” menu allows you to

alter the picture adjustments.

To do this: after selecting the item you want to

alter press , then press / / or

repeatedly to adjust it and finally press OK to

store the new adjustment.

Level 1 Level 2 Level 3 / Function

Picture Adjustment

Select: Enter Menu:

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Personal

AUTO

Picture Adjustment

Select: Enter:

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Personal

AUTO

• This menu also allows you to customise the picture mode based on the programme you are watching:

Picture Mode Live (for live broadcast programmes, DVD and Digital Set Top Box receivers).

Personal (for individual settings).

Movie (for films).

• Brightness, Colour and Sharpness can only be altered if “Personal” mode is selected.

•Hue is only available for NTSC colour signal (e.g: USA video tapes).

•Select Reset and press OK to reset the picture to the factory preset levels.

•The Noise Reduction option is set to AUTO to automatically reduce the picture noise visible in the

broadcast signal. To cancel this function, select “Off” instead of “AUTO”.

MENU

MENU

Menu System

10

Picture Adjustment

Select: Enter Menu:

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Personal

AUTO

Sound Adjustment

Select: Enter Menu:

Effect

Treble

Bass

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

Natural

Off

Stereo

On

Sound Adjustment

Select: Enter:

Effect

Treble

Bass

Balance

Reset

Dual Sound

Auto Volume

TV Speakers

Natural

Off

Stereo

On

SOUND ADJUSTMENT

The “Sound Adjustment” menu allows you to

alter the sound adjustments.

To do this: after selecting the item you want to

alter, press . Then press / / or

repeatedly to adjust it and finally press OK to

store the new adjustment.

Level 1 Level 2 Level 3 / Function

Effect Natural: Enhances clarity, detail and presence of sound by using

“BBE High Definition Sound system”

*

.

Dynamic: “BBE High Definition Sound system”

*

intensifies clarity

and presence of sound for better intelligibility

and musical realism.

Dolby

**

V: Dolby Virtual, simulates the sound effect of “Dolby

Surround Pro Logic”.

Off: Flat response.

Treble Less More

Bass Less More

Balance Left Right

Reset Resets the sound to the factory preset levels.

Dual Sound

•

For a stereo broadcast:

Mono.

Stereo.

•

For a bilingual broadcast:

Mono (for mono channel if available).

A (for channel 1).

B (for channel 2).

Auto Volume Off: volume level changes according to the broadcast signal.

On: volume level of the channels will stay the same, independent of

the broadcast signal (e.g. in the case of advertisements).

TV Speakers On: to listen to the TV from the set speakers.

Off: to listen to the TV from an external amplifier connected to the

audio outputs on the rear of the TV set.

• If you are listening to the TV through headphones, the “Effect” option will automatically be

switched to “Off”.

• If you select “Dolby Virtual” on the “Effect” option, the “Auto Volume” option will

automatically be switched to “Off” and vice versa.

*

The “BBE High Definition Sound system” is manufactured by Sony Corporation under license

from BBE Sound, Inc. It is covered by U.S. Patent No. 4,638,258 and No. 4,482,866. The word

“BBE” and BBE Symbol are trademarks of BBE Sound, Inc.

**

This TV has been designed to create the “Dolby Surround” sound effect by simulating the

sound of four speakers with two speakers, when the broadcast audio signal is Dolby Surround

encoded. The sound effect can also be improved by connecting a suitable external amplifier (for

details refer to “Connecting to external audio Equipment” on page 21).

**

Manufactured under license from Dolby Laboratories. “Dolby”, “Pro Logic” and the double-D

symbol are trademarks of Dolby Laboratories.

K

continued...

Menu System

- 9 -

Page 10

15

GB

continued...

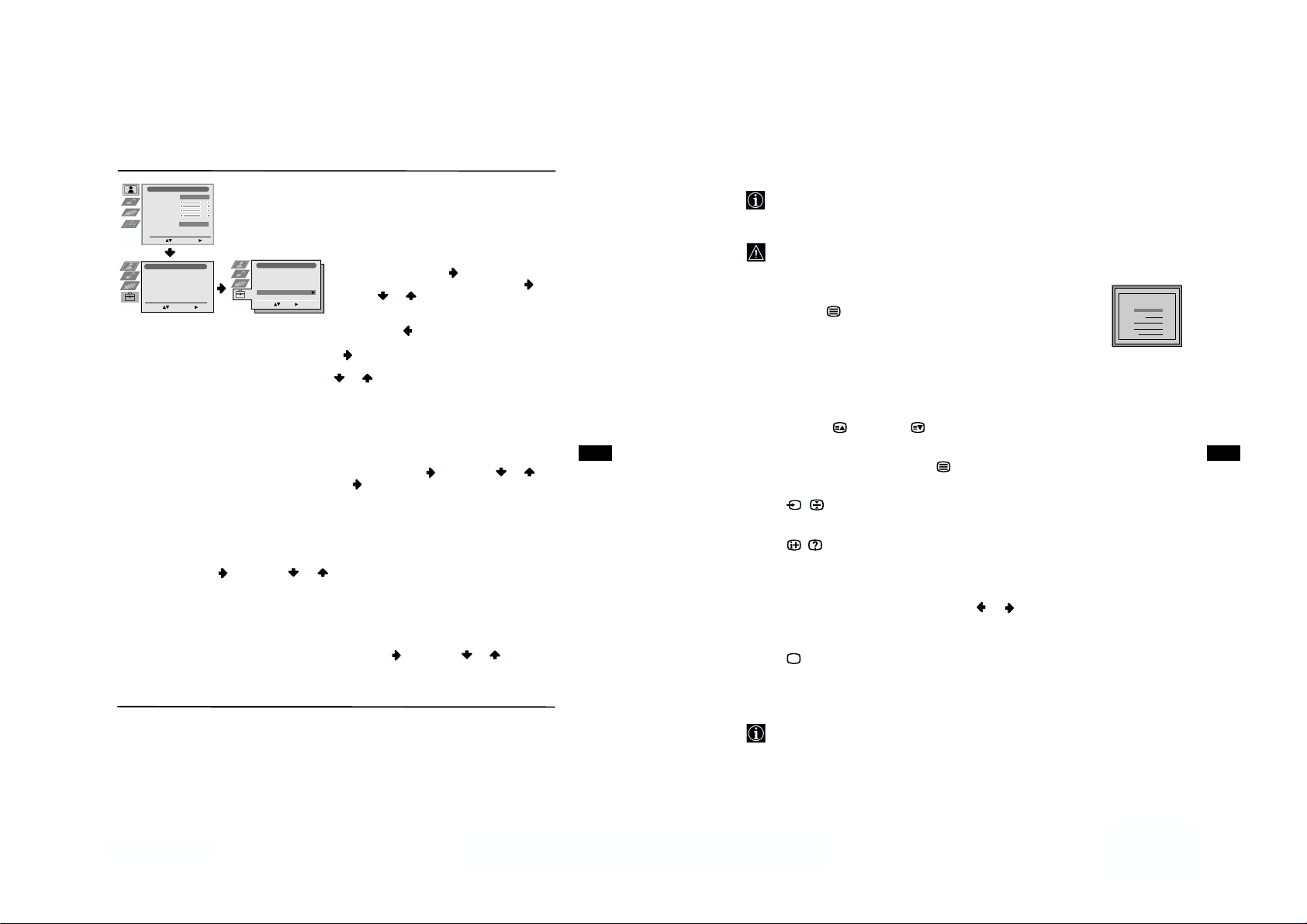

MANUAL PROGRAMME PRESET

The “Manual Programme Preset” option in the

“Set Up” menu allows you to:

a)

Preset channels or the VCR channel one by

one to the programme order of your choice.

To do this:

1 After selecting the ”Manual Programme

Preset” option, press then with

Programme option highlighted press .

Press or to select which programme

number you want to preset the channel on

(for VCR, select programme number “0”).

Then press .

2 After selecting the Channel option, press . Then press the number buttons to enter

directly the channel number of the TV Broadcast or the channel of the VCR signal. If you

do not know the channel number, press or to search for it. When you have tuned

the desired channel, press OK twice to store.

Repeat all the above steps to tune and store more channels.

b)

Label a channel using up to five characters.

To do this: Highlighting the Programme option, press the PROG +/- button to select the

programme number with the channel you wish to name. When the programme you want to

name appears on the screen, select the Label option and press . Next press o

r

to

select a letter, number or “-“ for a blank. Press to confirm this character. Select the other

four characters in the same way. After selecting all the characters, press OK twice to store.

c)

Fine tune the broadcast reception. Normally the automatic fine tuning (AFT) will give the

best possible picture, however you can manually fine tune the TV to obtain a better picture

reception in case the picture is distorted.

To do this: while watching the channel (TV Broadcast) you wish to fine tune, select the AFT

option and press . Next press

or to adjust the fine tuning between -15 and +15.

Finally press OK twice to store.

d)

Skip any unwanted programme numbers when they are selected with the PROG +/-

buttons.

To do this: Highlighting the Programme option, press the PROG +/- button to select the

programme number you want to skip. When the programme you want to skip

appears on the screen, select the Skip option and press . Next press or to select

Yes. Finally press OK twice to confirm and store.

To cancel this function afterwards, select “No” instead of “Yes” in the step above.

Level 1 Level 2 Level 3 / Function

Picture Adjustment

Select: Enter Menu:

Picture Mode

Contrast

Brightness

Colour

Sharpness

Reset

Noise Reduction

Personal

AUTO

Set Up

Auto Tuning

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Select:

Enter Menu:

Set Up

Auto Tuning

Programme Sorting

Select NexTView

AV Preset

Manual Set Up

Select:

Enter Menu:

Set Up

Language

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Select:

Enter Menu:

Enter:

Set Up

Select:

Language

Auto Tuning

Programme Sorting

Programme Labels

AV Preset

Manual Programme Preset

Detail Set Up

Menu System

17

GB

Teletext

Teletext is an information service transmitted by most TV stations. The index page of the

teletext service (usually page 100) gives you information on how to use the service. To

operate teletext, use the remote control buttons as indicated below.

Teletext errors may occur if you use a channel (TV Broadcast) with a weak signal.

To switch on Teletext :

After selecting the TV channel which carries the teletext service you wish

to view, press .

To select a Teletext page:

Input 3 digits for the page number, using the numbered buttons.

• If you make a mistake, retype the correct page number.

• If the counter on the screen continues searching, it is because the page is not available. If this is the

case, input another page number

To access the next or preceding page:

Press PROG + ( ) or PROG - ( ).

To superimpose teletext on to the TV:

Whilst you are viewing teletext, press . Press it again to cancel teletext mode.

To freeze a teletext page:

Press / . Press it again to cancel the freeze.

To reveal concealed information (e.g: answer to a quiz):

Press / . Press it again to conceal the information.

To select a sub page:

A teletext page may consist of several sub pages. In this case the page number that appears

on the upper left corner will change from white to green and one or more arrows will appear

next to the page number. Repeatedly press the or buttons on the remote control to

watch the desired sub page.

To Switch Off Teletext:

Press .

Fastext

Fastext service lets you access Teletext pages with one button push.

When you are in Teletext mode and Fastext is broadcast, a colour coded menu appears at

the bottom of the teletext page. Press the appropriate coloured button (red, green, yellow

or blue) to access the page corresponding to your menu choice.

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

TELETEXT

Index

Programme

News

Sport

Weather

25

153

101

98

Teletext

- 10 -

Page 11

22

Remote Control Configuration for VCR/DVD

In it’s default condition this remote control will operate the basic functions of this Sony TV, Sony

DVDs and most Sony VCRs. To control VCRs and DVDs of other manufacturers (and some Sony

VCR models), please complete the following steps:

Before you start, look up the 3 digit code for your brand of DVD or VCR from the list

below. On those brands that have more than one code, enter the first code number.

1

Press the Media Selector button on the remote control repeatedly until the

required green light (VCR or DVD) is lit.

If Media Selector is on TV position, code numbers will not be stored.

2

Before the green light goes out, press and hold the yellow button for

approximately 6 seconds until the green light starts flashing.

3

Whilst the green light is flashing, enter all three digits of the code for your

brand of VCR or DVD using the number buttons on the remote control.

If your selected code is entered correctly, all three green lights will be lit

momentarily.

4

Turn on your VCR or DVD and check that the main functions work.

• If your device is not working or some of the functions do not work

please check that you entered the correct code set or try the next code

listed against the brand.

• Your brand codes may be lost if weak batteries are not replaced within

a few minutes. To reset your brand of DVD or VCR please repeat the

above steps. A small label is added inside the battery door to allow you

to record your brand codes.

• Not all brands are covered and not all models of every brand may be

covered.

VCR Brand List DVD Brand List

Brand Code Brand Code

SONY (VHS) 301, 302, 303, 308, 309 SONY 001

SONY (BETA) 303, 307, 310 AIWA 021

SONY (DV) 304, 305, 306 DENON 018, 027, 020, 002

AIWA 325, 331, 351 GRUNDIG 009, 028, 023, 024, 016, 003

AKAI 326, 329, 330 HITACHI 025, 026, 015, 004

DAEWOO 342, 343 JVC 006, 017

GRUNDIG 358, 355, 360, 361, 320, 351 KENWOOD 008

HITACHI 327, 333, 334 LG 015, 014

JVC 314, 315, 322, 344, 352, 353, LOEWE 009, 028, 023, 024, 016, 003

354, 348, 349 MATSUI 013, 016

LG 332, 338 ONKYO 022

LOEWE 358, 355, 360, 361, 320, 351 PANASONIC 018, 027, 020, 002

MATSUI 356, 357 PHILIPS 009, 028, 023, 024, 016, 003

ORION 328 PIONEER 004

PANASONIC 321, 323 SAMSUNG 011, 014

PHILIPS 311, 312, 313, 316, 317, 318, SANYO 007

358, 359 SHARP 019, 027

SAMSUNG 339, 340, 341, 345 THOMSON 012

SANYO 335, 336 TOSHIBA 003

SHARP 324 YAMAHA 018, 027, 020, 002

THOMSON 319, 350

TOSHIBA 337

2

1

3

Additional Information

- 11 -

Specifications

TV system:

I

Colour system:

PAL

SECAM, NTSC 3.58, 4.43 (only

Video In)

Channel Coverage:

I: UHF B21-B69

Picture Tube:

Flat Display FD Trinitron

WIDE:

• KV-28FQ70U: 28” (approx.

71 cm mesaured diagonally).

• KV-32FQ70U: 32” (approx.

82 cm mesaured diagonally).

Rear Terminals

1/ 1

connector

(CENELEC standard)

including audio/video

input, RGB input, TV

audio/video output.

2/ 2

connector

(CENELEC standard)

including audio / video

input, RGB input, monitor

audio/video output.

3/3

(SMARTLINK)

connector

(CENELEC

standard) including

audio / video input, S video

input, selectable

audio / video output and

Smartlink interface.

audio outputs (Left/

Right) - phono jacks

21-pin scart

21-pin Scart

S

21-pin Scart

Front Terminals

S

4

S Video input – 4 pin

DIN

4

video input – phono

jack

4

audio input – phono

jacks

headphones jack

Sound Output:

2 x 20 W (music power)

2 x 10 W (RMS)

Woofer:

30 W (music power)

15 W (RMS)

Power Consumption:

• KV-28FQ70U: 125 W

• KV-32FQ70U: 130 W

Standby Power

Consumption:

0.3 W

Dimensions (w x h x d) :

• KV-28FQ70U: approx.

789 x 533 x 521 mm.

• KV-32FQ70U: approx.

910 x 586 x 586 mm.

Weight:

• KV-28FQ70U:

approx. 46.5 Kg.

• KV-32FQ70U:

approx. 64 Kg.

Design and specifications are subject to

change without notice.

Ecological Paper - Totally Chlorine Free

Accessories supplied:

1 Remote Control (RM-938)

2 Batteries (IEC designated,

AA size)

Other features:

• 100 Hz picture, Digital Plus.

• Teletext, Fastext, TOPtext

(250 page TEXT memory).

• Sleep Timer.

• SmartLink (direct link

between your TV set and a

compatible VCR. For more

information on SmartLink,

please refer to the

Instruction Manual of your

VCR).

• Dolby Virtual.

• BBE Digital.

• PIP.

• Auto Format.

• ACI (Auto Channel

Installation).

Additional Information

GB

23

Page 12

24

Troubleshooting

Here are some simple solutions to problems which may affect the picture and sound.

Problem

No picture (screen is dark)

and no sound.

Poor or no picture (screen is

dark), but good sound.

No picture or no menu

information from equipment

connected to the Scart

connector.

Good picture, no sound.

No colour on colour

programmes.

When you switch on the TV

the last channel you were

watching before switching

the TV off does not appear.

Distorted picture when

changing programmes or

selecting teletext.

Wrong characters appear

when viewing NexTView.

Solution

• Check the aerial connection.

• Plug the TV in and press the button on the front of the TV.

• If the standby indicator is on, press TV button on

the remote control.

• Using the menu system, select the “Picture Adjustment”

menu and select “Reset” to return to the factory settings (see

page 9).

• Check that the optional equipment is on and press the

button repeatedly on the remote control until the

correct input symbol is displayed on the screen (see page 21).

• Press the + button on the remote control.

• Check that “TV Speakers” is “On” in the “Sound Adjustment”

menu (see page 10).

• Check that headphones are not connected.

• Using the menu system, select the “Picture Adjustment”

menu and select “Reset” to return to factory settings (see

page 9).

• This is not a malfunction. Press the number buttons on the

remote control to select the desired channel.

• Turn off any equipment connected to the Scart connector on

the rear of the TV.

• Use the menu system to enter the “Language” menu (see page

13) and select the same language that NexTView is broadcast

in.

continued...

Additional Information

25

GB

If you continue to experience problems, have your TV serviced by qualified personnel.

Never open the casing yourself.

Problem

Picture slanted

Noisy picture when viewing

a TV channel.

Remote control does not

function.

The standby indicator on

the TV flashes.

Solution

• Using the menu system, select the “Picture Rotation” option

in the “Detail Set Up” menu to correct the picture slant (see

page 16).

• Using the menu system, select the “Manual Programme

Preset” menu and adjust Fine Tuning (AFT) to obtain better

picture reception (see page 15).

• Using the menu system, select the “Noise Reduction” option

in the “Picture Adjustment” menu and select “Auto” to

reduce the noise in the picture (see page 19).

• Check that the Media Selector on the remote control is set to

the device you are using (VCR, TV or DVD).

• If the remote control does not operate the VCR or DVD even

when the Media Selector has been set correctly. Enter the

necessary code set as explained in the “Remote Control

Configuration for VCR/DVD” chapter of this instruction

manual (see page 22).

• Replace the batteries.

• Contact your nearest Sony service centre.

Additional Information

- 12 -

Page 13

SECTION 2 DISASSEMBLY

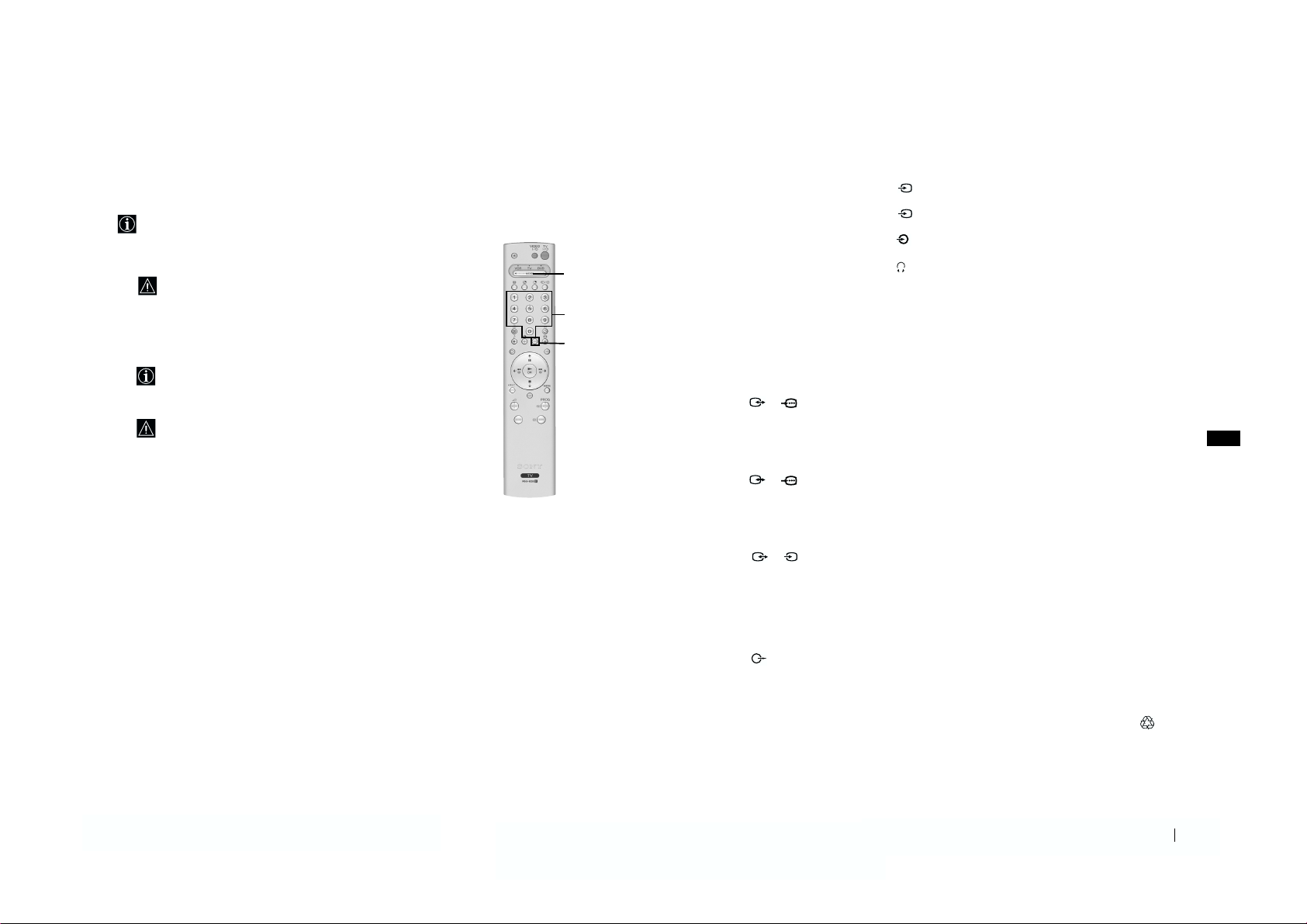

2-1. Rear Cover Removal

=>

=>

=>

=>

=>

=>

=>

Remove the rear cover fixing screws indicated and pull the

rear cover backwards away from the set.

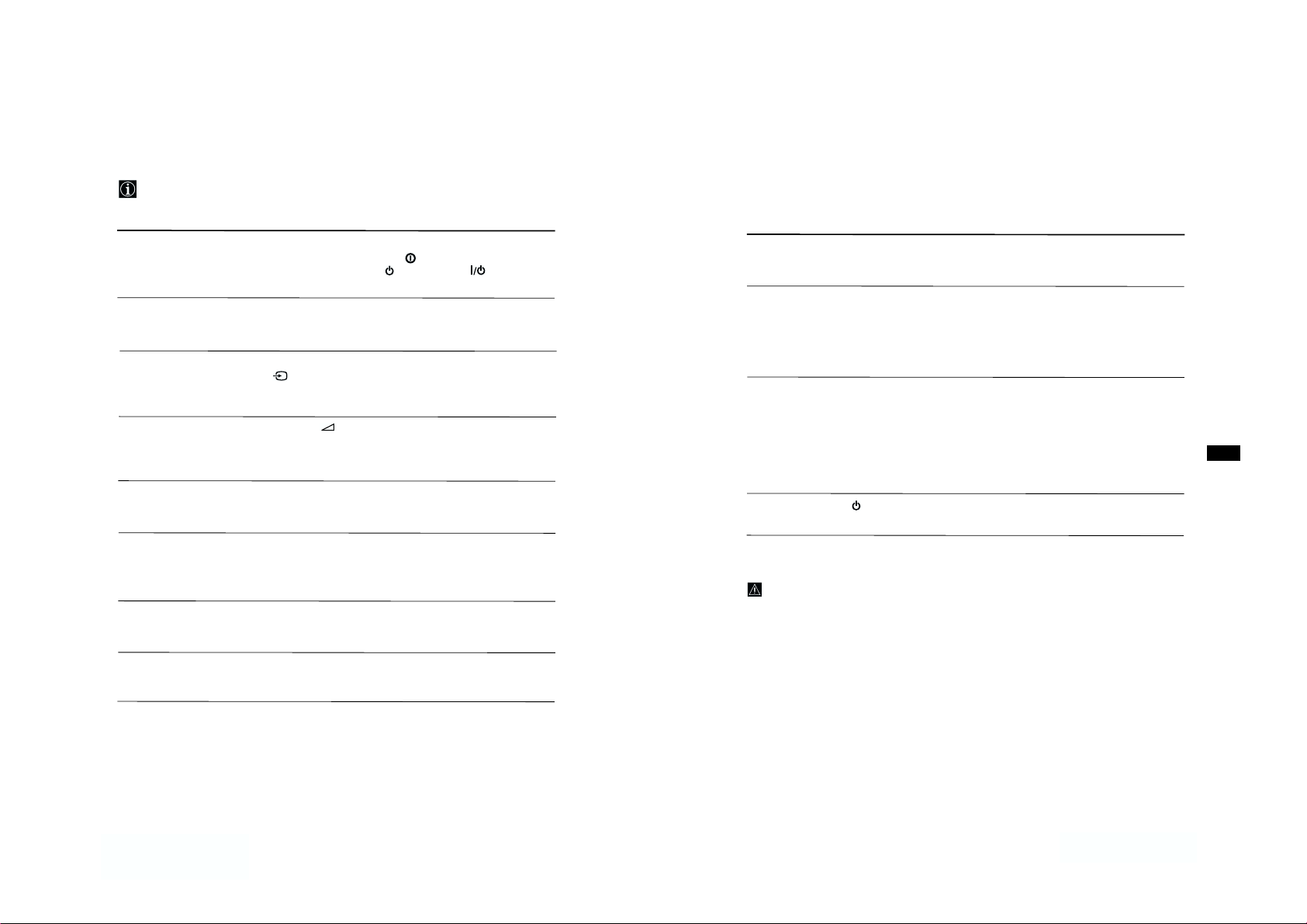

2-2. Speaker Box Removal

=>

=>

=>

=>

Screws

To remove the speaker box assembly remove the two screws

circled and unplug the speaker lead from connector CN2500

on the ‘A’ board. The assembly can then be lifted gently

away from its supporting arms.

2-3. Chassis Removal and Refitting

To remove lift the main bracket rear slightly and slide the

chassis away from the beznet. Ensure that the interconnecting

leads are released from their purse locks to prevent damage

being caused.

When refitting the chassis ensure that the main bracket is

located in the beznet guide slots before sliding the chassis

forwards. Refit the inter-connecting leads in their respective

purse locks.

- 13 -

Page 14

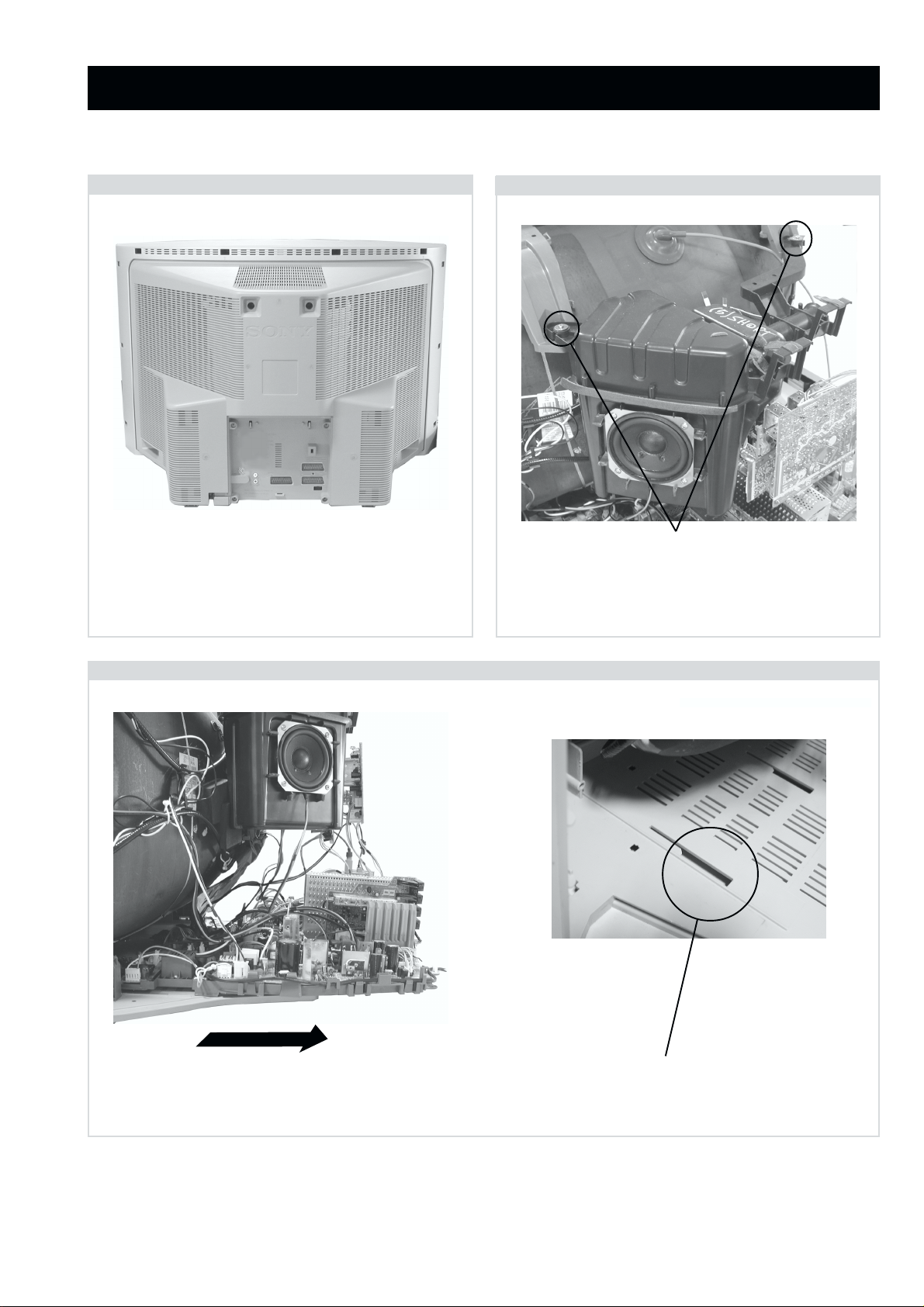

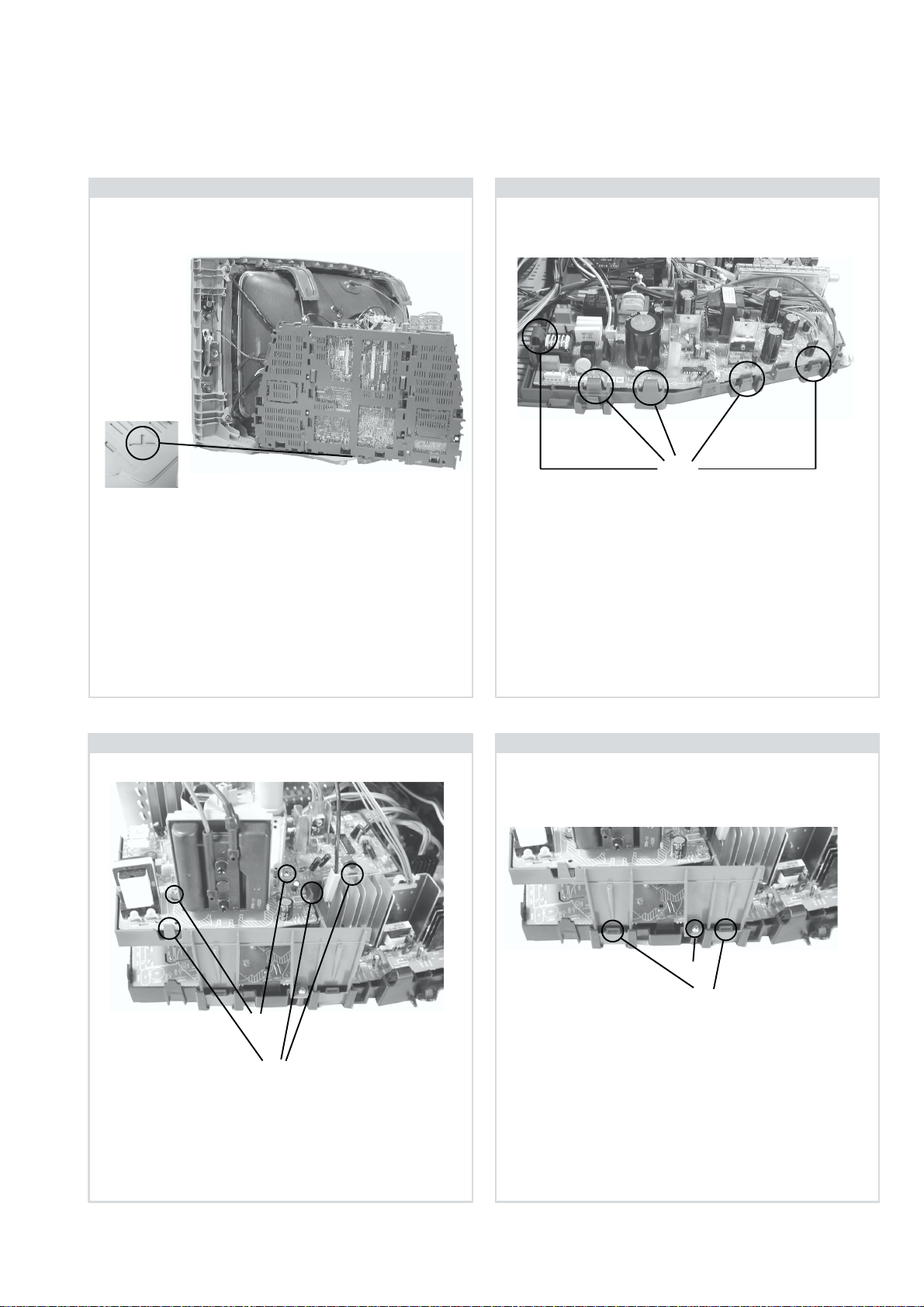

2-4. Service Position 2-5. G Board Removal

Clips

To place the chassis in the service position, remove the

speaker assembly box (see 2-2.) and insert the main bracket

firmly into the T-slot located on the left corner of the beznet

as indicated (see inset). To gain access to the underside of

the boards follow the instructions on page 17. [Removal

and Replacement of the main bracket bottom plates].

2-6. D2 Board Removal

To remove the G Board release the clips circled and ease the

board gently away from the support bracket.

2-7. D Board Removal

Screw

Screws

Clips

To remove the D2 board remove the two screws circled,

release the clips circled and ease the board gently away from

the support bracket.

Clips

To remove the D board first remove the D2 bracket by

removing the two screws (one on each side of the bracket)

and releasing the four clips (two on each side of the bracket).

The D board can then be removed using the same method as

the G board.

- 14 -

Page 15

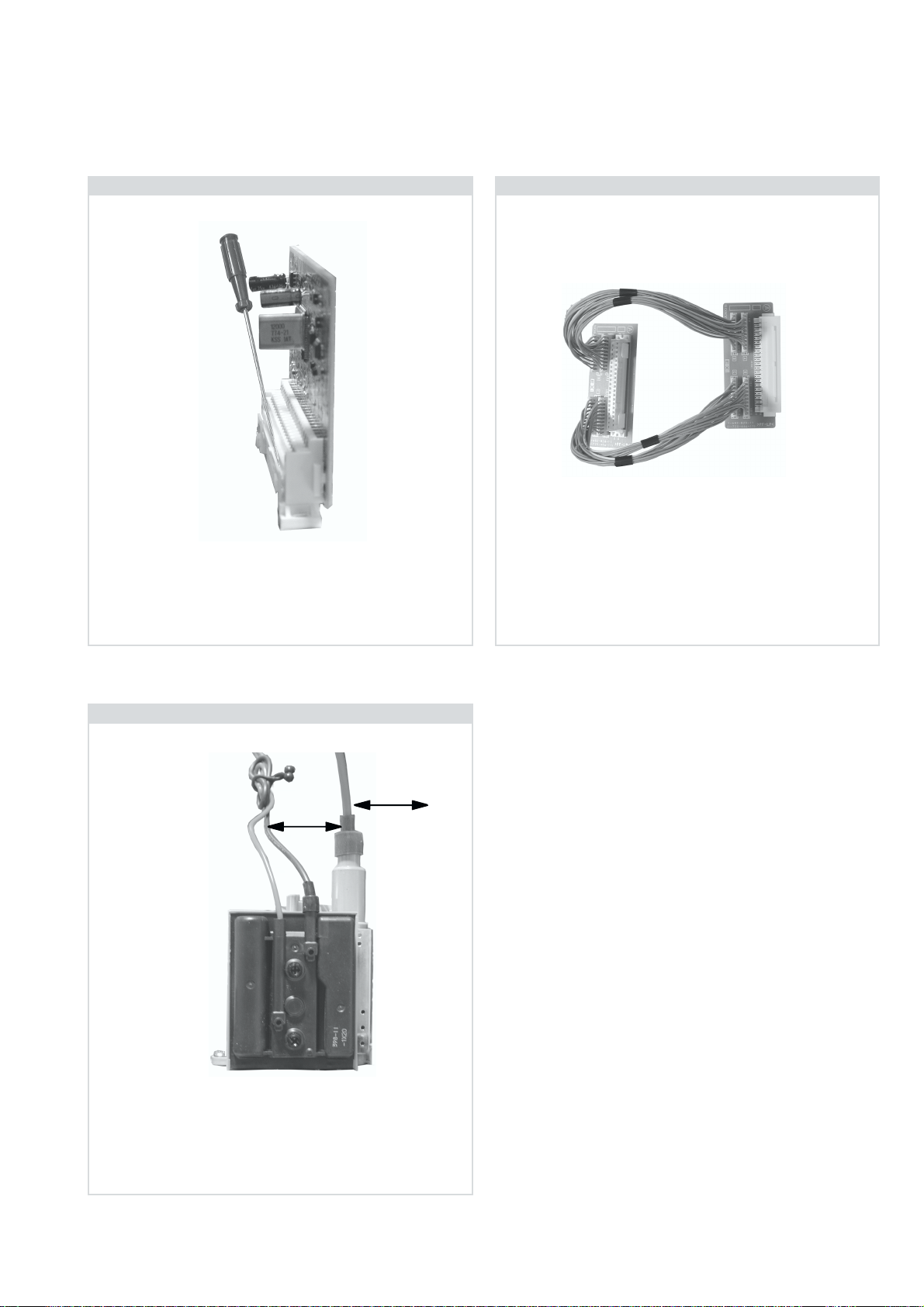

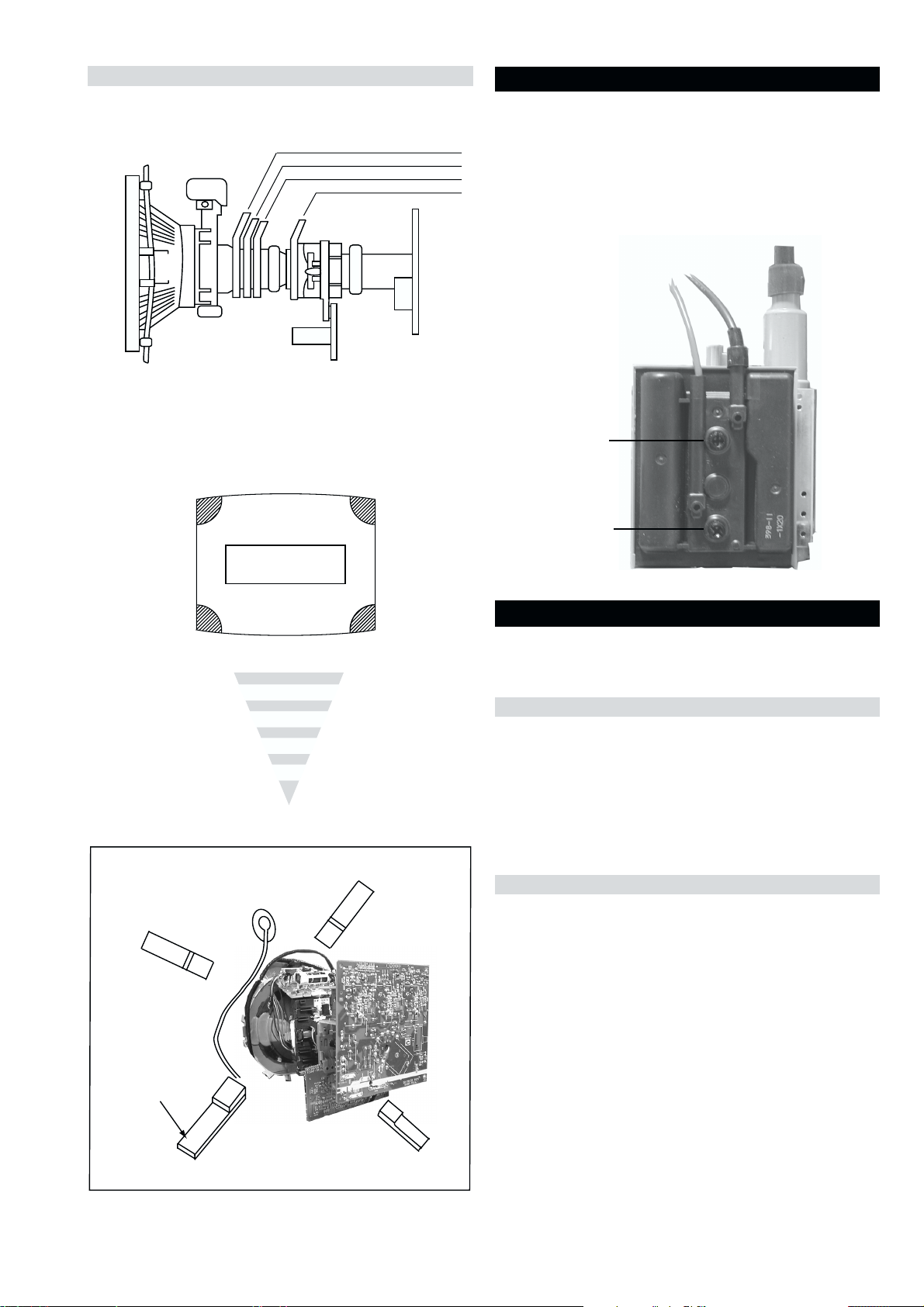

2-8. M2 Board Removal

To remove the M2 Board gently release the two clips with a

screwdriver and remove the board from its socket vertically.

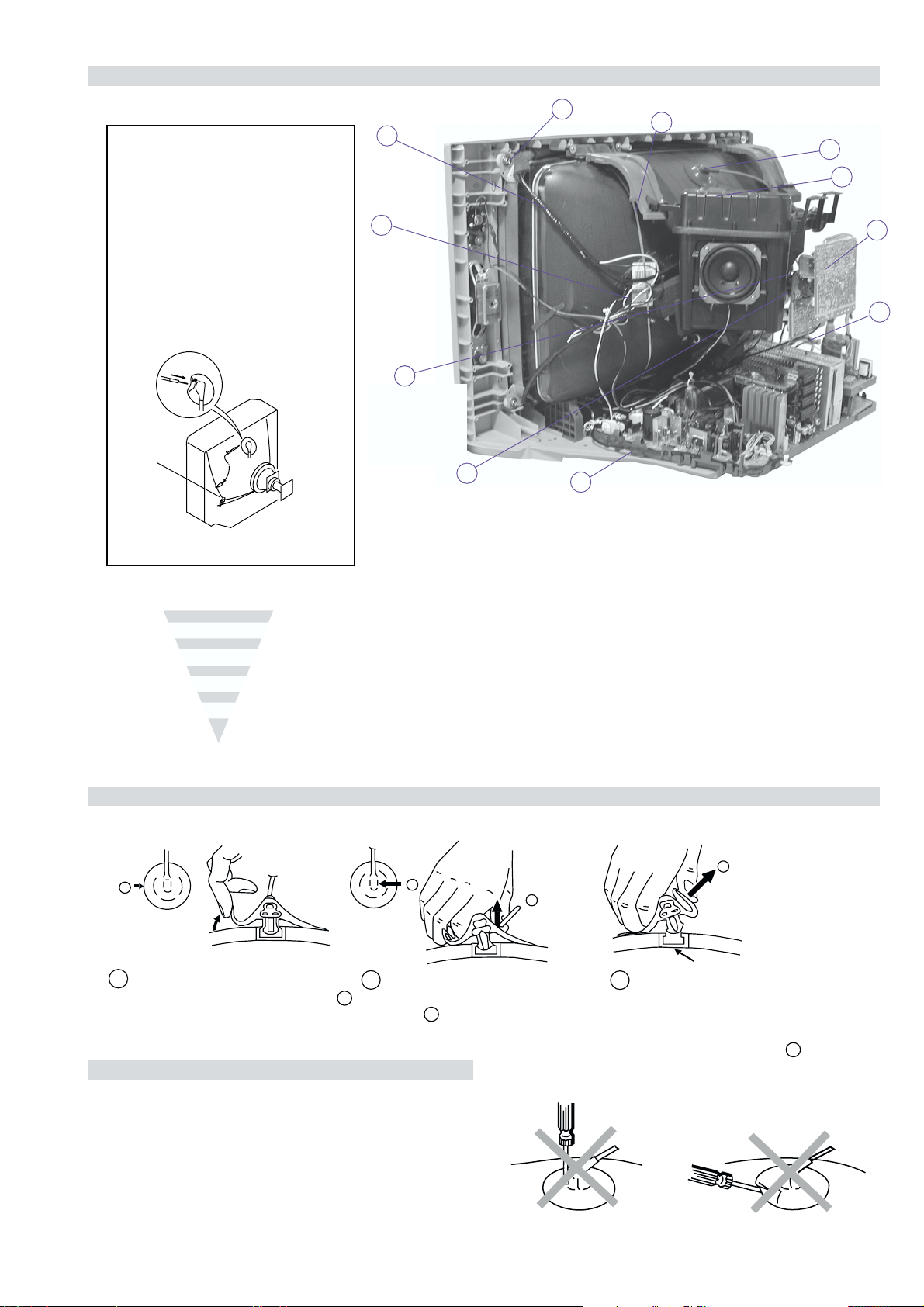

2-9. Service Connector for M2 Board

To A

From M2

Board

Extender Board Assembly A-1642-293-A

Board

If the M2 Board needs to be removed for testing when the

chassis is placed in its service position, it would be necessary

to use an extender board and extension cable as indicated

above.

The Extender board and extension cable are available as a

service part by ordering the part number as indicated.

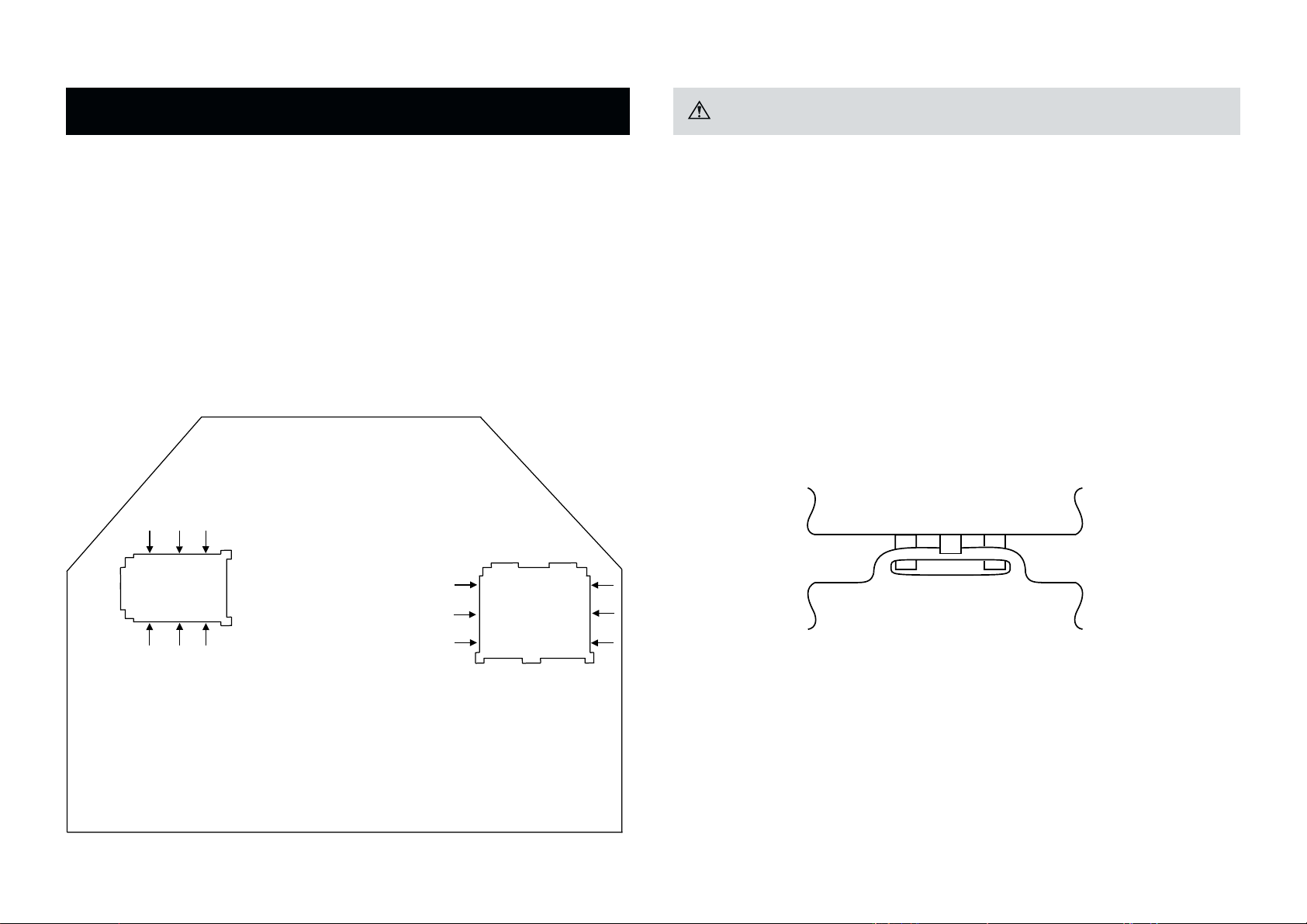

2-10. Wire Dressing

20mm

20mm

Ensure that wires do not touch heatsinks and high temperature

hotspots. All wires must be kept at a minimum distance of

20mm away from the EHT lead

- 15 -

Page 16

2-11. Picture Tube Removal

WARNING:

BEFORE REMOVING

THE ANODE CAP

High voltage remains in the CRT even

after the power is disconnected. To

avoid electric shock, discharge CRT

before attempting to remove the anode

cap. Short between anode and CRT

coated earth ground strap.

Coated Earth

Ground Strap

11

9

8

7

6

5

10

2

1

4

3

1. Remove Speaker Box assembly.

2. Discharge the anode of the CRT and remove the anode cap.

3. Unplug all interconnecting leads from the Deflection yoke, neck

assy, degaussing coils and CRT grounding strap.

4. Remove the C Board from the CRT.

5. Remove the chassis assembly.

6. Loosen the Neck assembly fixing screw and remove.

7. Loosen the Deflection yoke fixing screw and remove.

8. Place the set with the CRT face down on a cushion and remove

the Degaussing Coil holders.

9. Remove the Degaussing Coils.

10. Remove the CRT grounding strap and spring tensioners.

11. Unscrew the four CRT fixing screws [ located on each CRT

corner ] and remove the CRT.

[Take care not to handle the CRT by the neck.]

Removal of the Anode-Cap

REMOVAL PROCEDURE.

a

1

Turn up one side of the rubber cap in

the direction indicated by the arrow a

b

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b

How to handle the Anode-Cap

1. To prevent damaging the surface of the anode-cap do not use

sharp materials.

2. Do not apply too great a pressure on the rubber, as this may cause

damage to the anode connector.

3. A metal fitting called a shatter hook terminal is fitted inside the

rubber cap.

4. Do not turn the rubber foot over excessively, this may cause

damage if the shatter hook sticks out.

c

b

Anode button

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling it up in

the direction of the arrow c

- 16 -

Page 17

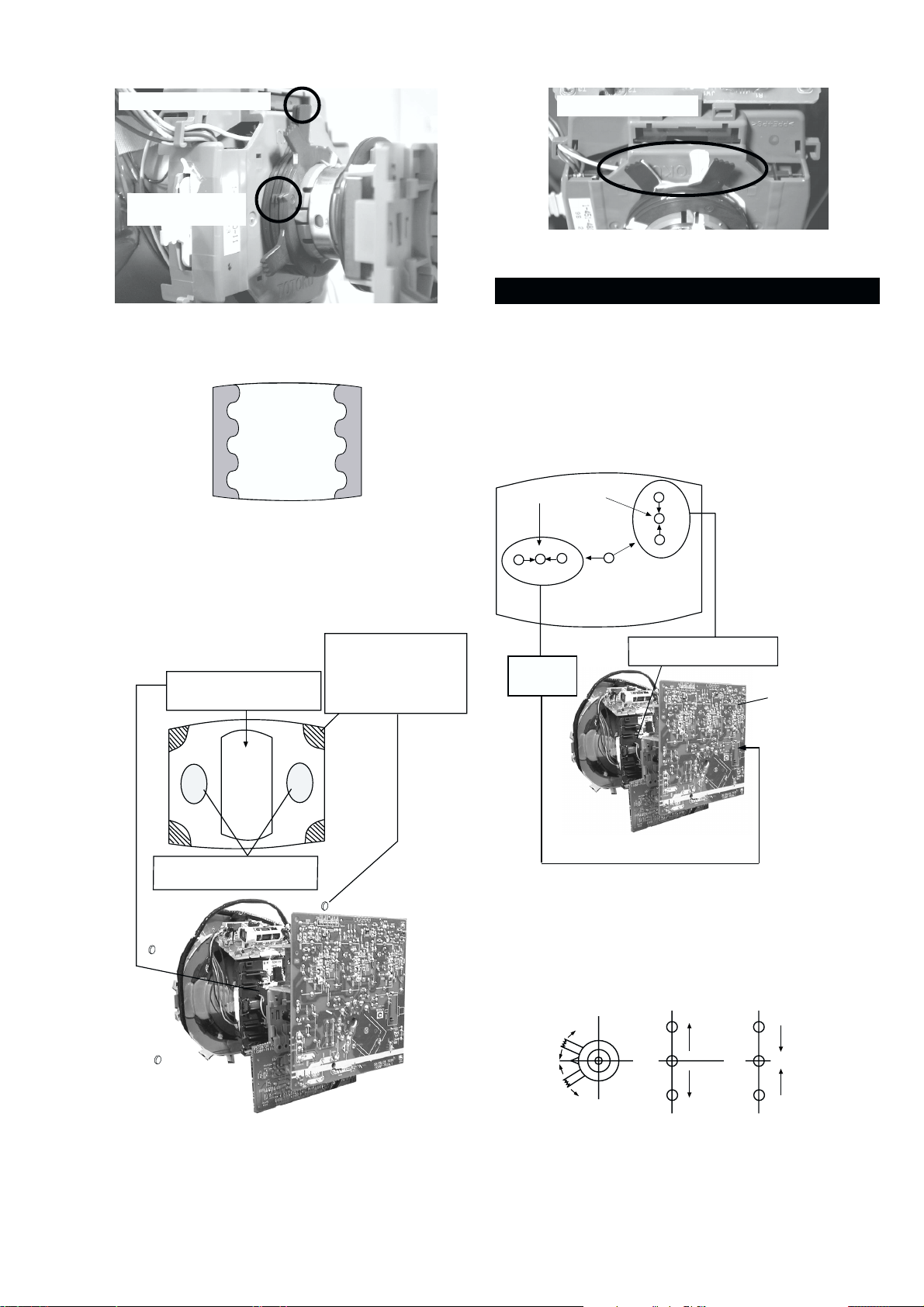

REMOVAL AND REPLACEMENT OF THE MAIN-BRACKET

BOTTOM PLATES.

For safety reasons, on no account should the plates be removed

and not refitted after servicing.

(1) REMOVING THE PLATES

In the event of servicing being required to the solder side of the printed wiring boards, the

bottom plates fitted to the main chassis bracket require to be removed. This is performed by

cutting the gates with a sharp wire cutter at the locations indicated by the arrows.

Note : There are 2 plates fitted to the main bracket. Only remove the necessary plate to gain

access to the printed wiring board.

- 17 -

(2) REFITTING THE PLATES

Because the plates differ in size it is important that the correct plates are refitted in their original

location.

Please note that the plates need to be rotated 180 degrees from their cut position to allow the

tabs to be fitted into their catch positions.

Catch

Ta b

Page 18

SECTION 3 SET-UP ADJUSTMENTS

• When complete readjustment is necessary or a new picture tube

is installed, carry out the following adjustments.

• Unless there are specific instructions to the contrary, carry out

these adjustments with the rated power supply.

• Unless there are specific instructions to the contrary, set the

controls and switches to the following settings :

Contrast .................................. normal

Brightness .................................. normal

3-1. Beam Landing

Preparation :

1. In order to reduce the influence of geomagnetism on the set’s

picture tube, face it in an easterly or westerly direction.

2. Switch on the TV set’s power and degauss with a degausser.

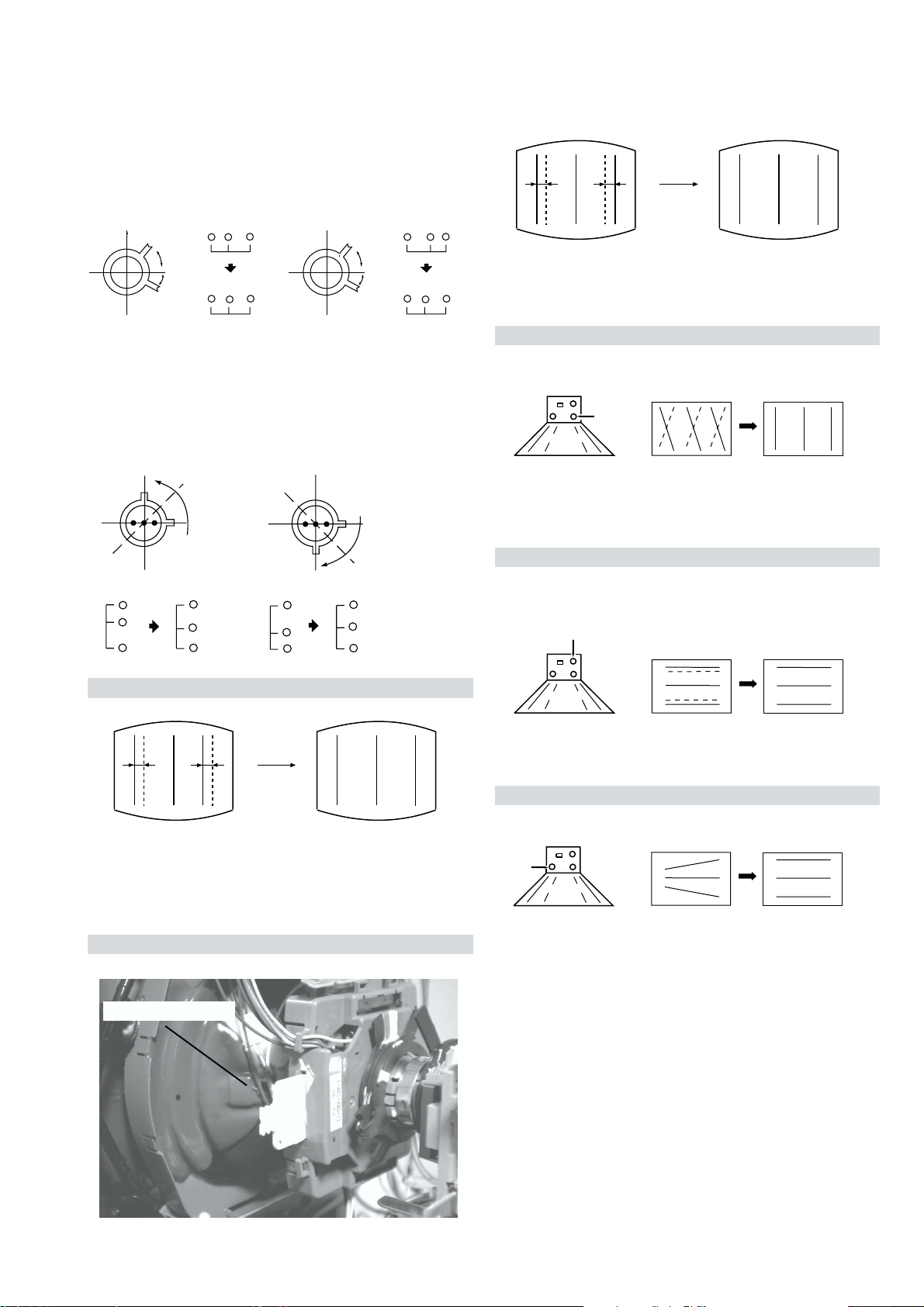

(1) Adjustment of Correction Magnet for Y-Splitting Axis.

1. Input a crosshatch signal from the pattern generator.

2. Set the Picture control to minimum and confirm that the

Brightness control is set to normal.

3. Position the neck assembly as indicated in Fig.3-2.

4. Loosen the deflection yoke fixing screw.

5. Move the deflection yoke as far forward as is possible.

6. Adjust the upper and lower pin symmetrically by opening or

closing the Y-splitting axis correction magnets located on the

neck assembly. [See Fig 3-3]

7. Return the deflection yoke to its original position and re-tighten

its fixing screw.

Fig.3-1

Y-splitting axis correction magnet

Carry out the adjustments in the following order :

3-1. Beam Landing.

3-2. Convergence.

3-3. Focus.

3-4. White Balance.

Note : Test equipment required.

1. Color bar/pattern generator.

2. Degausser.

3. Oscilloscope.

4. Digital multimeter.

(2) Landing

Note : Before carrying out the following adjustments adjust the

magnets as indicated [See Fig.3-4].

1. Input a crosshatch signal from the signal generator.

2. Rough-adjust the focus and horizontal convergence.

3. Switch from the crosshatch pattern to an all-red pattern.

4. Move the deflection yoke backwards and adjust with the purity

magnet so that the red is at the centre and it aligns

symmetrically [See Fig.3-5].

5. Move the deflection yoke forward to the point where the entire

screen just becomes red [Mark its position].

6. Move the deflection yoke further forward until the screen just

changes colour at the edges. [Mark its position]

7. Position the deflection yoke between the two marks indicated

above.

8. Input a crosshatch pattern from the pattern generator and rotate

the deflection yoke so that the horizontal lines are parallel with

the top and bottom of the screen.

9. When the position of the deflection yoke has been determined,

fasten it with its fixing screw.

10. Switch the pattern generator to green then blue and confirm the

purity.

11. If the beam does not land correctly in all the corners of the

screen, use disk magnets to correct it. [Confirm the corner

landing forgreen and blue]

Caution :

High voltages are present on the Deflection yoke terminals - take care

when handling the Deflection yoke whilst carrying out

adjustments.

- 18 -

Fig.3-2

Fig.3-3

G1

G2

+

G3

Neck assy

Align the edge

of the neck assy with

the edge of the G2 grid

on the G3 side.

Page 19

B

G

R

B

G

R

Fig.3-4

Purity magnets

Align pips on

each magnet

GREEN

RED

Align both Purity

magnets to the vertical

position

BLUE

Purity control magnets

3-2. Convergence

(1) Screen centre convergence [Static convergence]

1. Input a dot pattern signal from the pattern generator.

2. Normalize the picture setting.

3. [Moving vertically], adjust the V.STAT magnet so that the

vertical red, green and blue dots coincide at the centre of the

screen.

Fig.3-5

Purity control corrects

this area

a

cd

b

Deflection yoke positioning

corrects these areas

Disk magnets or

rotatable disk

magnets correct

these areas (a-d)

Center dot

R

G

B

H STAT

convergence

control

R

G

B

V.STAT Vertical Static Magnet

C Board

RV7375 (H STAT)

H STAT Convergence

(on mount side)

Disk Magnets

By opening or closing the V.STAT magnet, the red green and

blue dots move in the direction indicated below.

Note: Do not adjust the H.STAT by rotating the V.STAT

magnets as this can affect the focus setting.

- 19 -

Page 20

4. Correction for HMC [Horizontal mis-convergence] and VMC

+

+

+

YCH VR

Deflection Yoke

+

+

+

TLV VR

Deflection Yoke

[Vertical mis-convergence] by using the BMC [Hexapole]

magnet.

a). HMC correction by BMC [Hexapole] magnet and movement of

the electron beam.

HMC correction(A) HMC correction(B)

A < B

RG B

A > B

RGB

HTIL correction can be performed by adding a THL correction

assembly to the Deflection yoke.

A = B

RG B

A = B

RG B

b). VMC correction by BMC [Hexapole] magnet and movement of

the electron beam.

VMC correction(A) VMC correction(B)

C < D

C

D

C = D C > D C = D

R

G

B

R

C

G

D

B

R

G

B

R

G

B

HAMP Adjustment

YCH Adjustment

TLV Adjustment

Adjust the HAMP using HAMPL and HAMPR registers in the

Dynamic Convergence section of the service menu.

HTIL Adjustment

THL Correction assy

H-TRAP Adjustment

+

+

HTRAP VR

+

Deflection Yoke

The H-TRAP should not be adjusted unless absolutely necessary as it

affects the TLV settings.

- 20 -

Page 21

Layout of each control

Purity magnet

BMC (Hexaploe) magnet

V STAT convergence magnet

Y-splitting axis correction magnet

3-3. Focus Adjustment

1. Receive a television broadcast signal.

2. Normalize the picture setting.

3. Adjust the focus control located on the flyback transformer to

obtain the best focus at the centre of the screen.

Bring only the centre area of the screen into focus, the magentaring appears on the screen. In this case, adjust the focus to

optimize the screen uniformly.

Note : If you are unable to adjust the corner convergence properly,

this can be corrected with the use of permalloy magnets.

a

a-d: screen-corner

convergence defect

c

Install the permalloy assembly

for the area that needs correcting.

b

d

a

b

Permalloy Assy

X-4387-214-1

c

d

Convergence adjustment with permalloy

Focus

Screen

3-4. Screen (G2), White Balance

[Adjustment in the service mode using the remote

commander]

G2 adjustment

1. Input a dot signal from the pattern generator.

2. Set the Picture, Brightness and Colour to minimum.

3. Apply 165V DC from an external power supply to the R, G

and B cathodes of the CRT.

4. Whilst watching the picture, adjust the G2 control [SCREEN]

located on the flyback transformer to the point just before the

flyback return lines disappear.

White balance adjustment for TV mode

1. Input an all-white signal from the pattern generator.

2. Program the Remote Commander for operation in Service Mode.

[ See Page 22 ].

3. Enter into the ‘Service Mode’ by pressing ‘VIDEO’ button twice

and ‘MENU’ on the Service Commander.

4. Select ‘Service’ from the on screen menu display and press

‘Right Arrow’.

5. The ‘Service’ menu will appear on the screen.[See Page 23]

6. Set the ‘Contrast’ to MAX.

7. Set the ‘R-Drive’ to 50.

8. Adjust the ‘G-Drive’ and the ‘B-Drive’ so that the white

balance becomes optimum.

9. Press the ‘OK’ button to write the data for each item.

10. Set the ‘Contrast’ to MIN.

11. Set the ‘R-Cutoff’ to 29.

12. Adjust the ‘G-Cutoff’, and the ‘B-Cutoff’ with the left and

right buttons on the remote commander so that the white

balance becomes optimum.

13. Press the ‘OK’ button to write the data for each item.

- 21 -

Page 22

4-1. Electrical Adjustments

SECTION 4 CIRCUIT ADJUSTMENTS

Service adjustments to this model can be performed using the

supplied remote Commander RM-938.

Programming the Remote Commander for

Operation in Service Mode

1. Press the VCR/TV/DVD button until the

TV LED lights.

2. Press and hold the yellow button for

approx. 5 seconds until the TV LED

flashes quickly.

3. Press 99999. All three LED’s should light.

The remote commander is now set to Service Mode.

4. To return the remote commander to normal operation mode

repeat steps 1. and 2. then press 00000. All three LED’s

should light.

The remote commander is now set to normal mode.

Setting the TV into Service Mode

1. Program the remote commander for operation in Service

Mode as described above.

YRTEMOEG

HTLBA

EDOMLBA

LBAP

EZISV

NOITISOPV

PMOCV

NILV

NOITCERROCS

EZISH

PMANIP

NIPRENROCPU

NIPM

NIPRENROCOL

MUIZEPART

NOITISOPH

WOBCFA

ELGNACFA

KLBTFEL

KLBTHGIR

TCEPSAV

1MITBKA

2MITBKA

RKI

GNH

GNV

)3,0(

)3,0(

)3,0(

)3,0(

)3,0(

)1,0(

0

0

)51,0(

)36,0(

)36,0(

)51,0(

)51,0(

)36,0(

)36,0(

)36,0(

)36,0(

)51,0(

)36,0(

)51,0(

)51,0(

)36,0(

)36,0(

)36,0(

51

53

33

1

7

7

44

23

92

2

92

2

04

8

9

43

71

74

2

0

1

0

0

2. Turn on the TV main power switch.

3. Press the video standby button on the remote

commander twice.

‘TT ’ will appear in the upper right corner of the screen.

Other status information will also be displayed.

4. Press ‘MENU’ on the remote commander to obtain the

following menu on the screen.

yrtemoeG

amaronaP

ecivreS

etarnacS

CAD

PiP

dnuoS

tsujdaFI

uneMrorrE

)2002naJ(12.2vediWB6EA

h61h20atadyrotcaF

G1143PSM:eciveDPSM

5. Move to the corresponding adjustment item using the

up or down arrow buttons on the Remote Commander.

6. Press the right arrow button to enter into the required menu item.

7. Press the ‘Menu’ button on the Remote Commander to quit the

Service Mode when all adjustments have been completed.

AMARONAP

HHTDIWROH

LHTDIWROH

HSOPROH

LSOPROH

HPILPPAN

LPILPPAN

HCSOPCSH

LCSOPCSH

LEDNALB

NELNALB

LOPNALB

H1GESH

L1GESH

H2GESH

L2GESH

H3GESH

L3GESH

H4GESH

L4GESH

HOCNIH

LOCNIH

H1CNIH

L1CNIH

H2CNIH

L2CNIH

H3CNIH

L3CNIH

H4CNIH

L4CNIH

)7,0(

)7,0(

)7,0(

)1,0(

)7,0(

)7,0(

)7,0(

)7,0(

)1,0(

)1,0(

)1,0(

)1,0(

)1,0(

1

)552,0(

)552,0(

)721,0(

)51,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

071

0

51

1

26

8

151

31

702

0

0

69

0

291

0

422

1

46

0

04

0

02

0

0

1

632

1

612

·

Note :

· After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON.

- 22 -

Page 23

TSUJDAFI

UNEMRORRE

etumotuA

niaGoiduA

gnitaGL

ECIVRES

LOCBUS

EUHBUS

PRAHSBUS

THGIRBBUS

TNOCBUS

EVIRD-R

EVIRD-G

EVIRD-B

FFOTUCR

FFOTUCG

FFOTUCB

TXTrB

DSOrB

)36,0(

)36,0(

)36,0(

)36,0(

)51,0(

)36,0(

)36,0(

)36,0(

)36,0(

)36,0(

)36,0(

)51,0(

)51,0(

1

0

0

jdA

13

03

31

21

05

jdA

jdA

82

42

64

7

01

20E

30E

40E

50E

60E

70E

80E

90E

01E

11E

21E

31E

41E

51E

61E

EMITGNIKROW

SRUOH

SETUNIM

PCO

PVO

CNYSV

RKI

CII

MVN

TORPH

RENUT

PDNUOS

ETARNACS

CAD

DNEKCAB

NOCNYD

PIP

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

)552,0(

0

41

7

Sub Brightness Adjustment

1. Input a Monoscope pattern.

2. Program the Remote Commander for operation in Service Mode.

CAD

[ See Page 22 ].

3. Press ‘VIDEO’ ‘VIDEO’ 13 on the Remote Commander.

GIFNOC

TNOCNIPM

NILH

PARTH

LIOC.TOR

HPSUCOHP

)552,0(

)552,0(

)552,0(

)552,0(

)552,0(

00000000

69

38

721

031

09

4. Adjust the ‘Sub-Brightness’ data so that there is barely a

difference between the 0 IRE and 10 IRE signal levels.

Sub Contrast Adjustment

1. Input a video signal that contains a small 100% white area on a

black background.

2. Connect an digital voltmeter to Pin 10 of J7376 [C Board].

3. Program the Remote Commander for operation in Service Mode.

DNUOS

N-M

D-M

S-M

M-S

M-D

M-N

EBB

1B

2B

3B

4B

5B

LWS

FWS

DACMACIN

rorrEMACIN

oeretS

)115,0(

)1-,821-(

)721+,0+(

)721+,0+(

)1-,821-(

)3201,0(

)86+,0+(

)69+,69-(

)69+,69-(

)69+,69-(

)69+,69-(

)69+,69-(

)0+,821-(

)04+,5+(

)7402,0(

)721+,821-(

002

02-

02+

01+

01-

694

82+

0+

0+

0+

0+

0+

0+

03+

10001

0

0+

[ See Page 22 ].

4. Adjust the Sub-Contrast [ Using ‘VIDEO’ ‘VIDEO’ ‘11’ ] to

obtain a voltage of 105 +/- 5V.

Sub Colour Adjustment

1. Receive a PAL colour bar signal.

2. Connect an oscilloscope to Pin 6 of CN7001 [A Board].

3. Program the Remote Commander for operation in Service Mode.

[ See Page 22 ].

4. Adjust the ‘Sub Colour’ [ Using ‘VIDEO’ ‘VIDEO’ ‘12’ ] so

that the Cyan, Magenta and Blue colour bars are of equal levels

as indicated below.

Same Level

sutatS0110000000

B-Out Waveform

- 23 -

Page 24

Deflection System Adjustment

72

RKEDAnoitanitseD

82

RKEDAnoitanitseD

13

elbasiD/elbanEffotuhSotuA

63

tsetNO/FFO)MV(noitaludoMyticoleV

14

MVNesilaitini-eR

34

dnuosAlauDtceleS

44

dnuosBlauDtceleS

54

dnuosonoMtceleS

64

dnuosoeretStceleS

84

nigrivnonsaMVNteS

94

nigrivsaMVNteS

35

elbasiD/elbanEnoitaludomrevOMF

55

)SPLA/YNOS(noitcelesrenuT

95

stracS2roPIP+stracS3ledoMtceleS

86

)melborpN(erusaemretnuoc62XelbasiD/elbanE

37

)47.6/5.6(metsys2K/DnotiewZelbanE

47

)47.5/5.6(metsys3K/DnotiewZelbanE

87

thgirllufecnalaB

97

tfelllufecnalaB

78

tsetsyeklacoL

99

unememiTgnikroWdnarorrEyalpsiD

00

ffoedom'TT'

10

mumixamerutciP

20

muminimerutciP

30

%53otemuloVenohpdaeh/rekaepsteS

40

%05otemuloVenohpdaeh/rekaepsteS

50

%56otemuloVenohpdaeh/rekaepsteS

60

%08otemuloVenohpdaeh/rekaepsteS

70

edomgniegA

80

noitidnoCgnippihS

11

tnemtsujdaerutcipbuS

21

tnemtsujdaruolocbuS

31

tnemtsujdassenthgirBbuS

41

tnemtsujdanoitisoPHtxeT

51

tseTlioCnoitatoR

61

%05levelerutciP

91

elbasiD/elbanEedoMyrotcaF

12

RKEDAnoitanitseD

22

LBnoitanitseD

32

RKEDAnoitanitseD

42

UnoitanitseD

52

RKEDAnoitanitseD

62

LBnoitanitseD

4-2. TEST MODE 2:

1. Program the Remote Commander for operation in Service Mode.

[ See Page 22 ] and enter into the ‘Geometry’ service menu.

2. Select and adjust each item in order to obtain the optimum image.

V SIZE

V LIN

AFC BOW

V POSITION

H POSITION

H SIZE

PIN AMP

Test Mode 2 is available by rogramming the Remote Commander for

operation in Service Mode [ As shown on Page 22 ] then pressing the

‘VIDEO’ button twice, OSD ‘TT’ appears. The functions described

below are available by selecting the two numbers. To release the ‘Test

mode 2’, press 00, 10, 20 ... or switch the TV set into Stand-by

mode.

TRAPEZIUM

UP CORNER PIN

AFC ANGLE

LO CORNER PIN

YRTEMOEG

HTLBA

EDOMLBA

LBAP

EZISV

RKI

NOITISOPV

PMOCV

NILV

EZISH

PMANIP

NIPM

WOBCFA

KLBTFEL

1MITBKA

2MITBKA

NOITCERROCS

NIPRENROCPU

NIPRENROCOL

MUIZEPART

NOITISOPH

ELGNACFA

KLBTHGIR

TCEPSAV

GNH

GNV

)3,0(

)3,0(

)3,0(

)3,0(

)3,0(

)1,0(

0

0

)51,0(

)36,0(

)36,0(

)51,0(

)51,0(

)36,0(

)36,0(

)36,0(

)36,0(

)51,0(

)36,0(

)51,0(

)51,0(

)36,0(

)36,0(

)36,0(

51

53

33

1

7

7

44

23

92

2

92

2

04

8

9

43

71

74

2

0

1

0

0

- 24 -

Page 25

VM

5

4

1

CN7442

QP (+)

QP (-)

4

7

8

2

3

VM

VM

1

QP (+)

QP (+)

QP (-)

QP (-)

VM ( )

VELOCITY

MODULATION

CN7444

QP-

QP+

VM

NECK ASSY

TO A BOARD (1/2)

CN7000

VM AMPLIFIER

BUFFER

Q7408, Q7409

VM AMPLIFIER

BUFFER

Q7400, Q7401

BUFFER

Q7402

BUFFER

Q7404

VM AMPLIFIER

BUFFER

Q7405

VM AMPLIFIER

BUFFER

Q7403

VM AMPLIFIER

OUTPUT

Q7406

VM AMPLIFIER

OUTPUT

Q7407

5-1. BLOCK DIAGRAMS (1)

POWER

CN6400

AC

IN

1

2

S6400

STB +5V

IC0981

RPM7240-H5F

F1 ( )

OUT

POWER SWITCH,

FUSE, SIRCS AND

STAND-BY LED

SIRCS

LED

1

5

2

1

CN6401

CN0981

TO G BOARD

CN6001

TO A BOARD (1/2)

CN0103

CN6202

5

6

1

2

3

6

7

11

15

19

20

1

2

3

6

19

20

1

4

6

9

LED

2

1

SIRCS

TO A BOARD

R OUT

L OUT

AU(+)

AU(+)

SCL

SDA

FM/AM

QSS

VIDEO

RIGHT OUT

RIGHT IN

LEFT OUT

LEFT IN

BLUE IN 1

GREEN IN 1

RED IN 1

VIDEO OUT 1

VIDEO IN 1

RIGHT OUT

RIGHT IN

LEFT OUT

LEFT IN

BLUE IN 2

GREEN IN 2

RED IN 2

VIDEO OUT 2

VIDEO IN 2

RIGHT OUT

RIGHT IN

LEFT OUT

LEFT IN

VIDEO OUT 2

V/Y IN 3

KEY

Y/CVBS FRONT

LEFT

RIGHT

SHEET 2

PROTECTOR

PS2501

AUDIO VCC

SCL

SDA

HEADPHONE

AMPLIFIER

IC2001

5

3

1

7

60

MONO IN (AM)

67

IF INI

SCL

2

SDA

3

36

SC1 OUT R

57 SC1 IN R

SC1 OUT L

37

SC1 IN L

56

71

XTAL IN

72

XTAL OUT

33

SC2 OUT R

54

SC2 IN R

SC2 OUT L

34

SC2 IN L

53

51

SC3 IN R

SC3 IN L

50

48

FR IN R

47

FR IN L

AUDIO PROCESSOR

IC2000

SPEAKER OUT R

SPEAKER OUT L

SUBWOOFER OUT

27

28

30

RIGHT

LEFT

WOOFER

FS 100

B TXT

G TXT

R TXT

Y IN 100

U IN 100

V IN 100

H SYNC

V SYNC

PIP Y

PIP CB

PIP CR

AUDIO AMPLIFIER

5IN R

1

IN L

IN W

6

MUTE W

9

10

MUTE

BACKEND: DEFLECTION -

RGB PROCESSOR

33

YSYM 2

34

B2 IN

G2 IN

35

R2 IN

36

52

Y1 IN

53

CB1 IN

54

CR1 IN

HS IN

59

VS IN

60

56

Y2 IN

57

CB2 IN

58

CR2 IN

IC2500

IC7002

OUT R

OUT L

WOOFER MUTE

OUT W

R OUT

G OUT

B OUT

DF PARA

EXTRA PARA

EW OUT

HD OUT

HP IN

X RAY IN

VDP OUT

VDN OUT

VPROT

12

14

10

3

30

28

26

64

63

1

17

18

20

5

6

16

45VM OUT

DF PARA

MP PARA

E/W

H DRIVE

AFC PULSE

X RAY

PART OF

V PROT

Q5400

Q5401

OP. AMP IC5104

DAC IC5103

V OUT IC5400

1

7

ROT -

1

ROT+

4

DF PHOCUS PHASE

3

M PIN CONT

7

OP. AMP IC5301

A 1/2 ( )

COMPARATOR IC5302

5

6

36

IC5300

LM358N

68+12V

VIDEO AND AUDIO PROCESSORS,

AUDIO OUTPUT, VERTICAL DEFLECTION

7

BUFFER

Q5305, Q5306

WOOFER MUTE

DF DRIVE

M PIN CONT

H CENTRE

DF PARA

MP PARA

H DRIVE

AFC PULSE

NC/X RAY

AFC PULSE

DF DRIVE

GND

TO G BOARD

CN6006

TU1000

CN1000

CN1001 (1/2)

CN1001 (2/2)

CN2000

TO H1 BOARD

CN2909

CN0103

TO F1 BOARD

CN0981

J2000

R OUT

L OUT

ROT-

ROT+

X RAY

R IN

L IN

E/W

ABL

ABL

QP(-)

QP(+)

CN2501

4

R

1

L

3

5

2

6

1

1WOOFER

1

3

2

4

3

R-

1

R+

2

G-

3

G+

4

B-

5

B+

6

1

2

3

5

6

7

8

3

5

6

7

1VM

4

5

CN2502

CN2500

CN5100

CN5002

CN7001

CN5801

CN5802

CN7000

TO

SPEAKERS

TO H1 BOARD

CN2910

TO

SUBWOOFER

TO

ROTATION

COIL

TO D BOARD

CN8810

TO C BOARD

CN7301

TO D BOARD

CN8620

TO D2 BOARD

CN6801

TO VM BOARD

CN7442

- 25 -

Page 26

5-1. BLOCK DIAGRAMS (2)

DYNAMIC

FOCUS

T8901

D2 ( )

14

G2

16

FV

1

18

19

12

15

13

HV

17

8

9

7

10

5

6

4

3

11

HV OVERSHOOT

PROJECT

Q6816, Q6817

SS RESET

Q6814,

Q6813

ABL

PROTECT

Q6807

6

1

3

DYNAMIC

FOCUS

Q8918

5

7

6

UNDER VOLTAGE

PROTECT

Q6808

43

200V

1

3

2

7

5

6

1

2 3

BUFFER

Q6803

16

12

1

9

15

2

200V

Q6804,

Q6805

Q8909

AFC

PULSE

DETECT

Q6801,

Q6802

AFC PULSE

TO A BOARD (1/2)

CN5802

CN6801

1/2

V SENSE

F/B

VG(H)

VS

VG(L)

IC6800

DF DRIVE

ABL

8

7

6

IC6801

IC6807

IC6803

CATHODE

REF

IC6802

T6800

4

5

HOP OVP

HPROT

CN6801

2/2

TO A BOARD (1/2)

CN5802

DYNAMIC PICTURE

STABILISING CIRCUIT

1

RY SIGNAL

CN6804

TO M2 BOARD

CN0003

Y IN 100

BLK 100

H SYNC

V SYNC

BLK 1

BLK 2

RED IN 1

GREEN IN 1

BLUE IN 1

RED IN 2

GREEN IN 2

BLUE IN 2

VIDEO RF

V IN 1

100Hz BUFFER

Y SCAN RATE

BACKEND

Q3300

SCAN RATE CONVERTER,

COLOUR DECODER AND I/O

VIDEO SWITCH

IC3200

2 AY OUT 100

8

17

23

37

38

39

40

41

46

47

48

52

53

NC

H OUT 100

V OUT 100

FBL 1

FBL 2

R IN 1

G IN 1

B IN 1

R IN 2

G IN 2

B IN 2

CVBS 1

CVBS 2

AU OUT 100

AY OUT 100

CVBS OUT 1

CVBS OUT 2

CVBS OUT 3

X OUT

CVBS 7

CVBS 6

CVBS 5

CVBS 4

CVBS 3

X IN

79

76

70

69

63

62

61

58

Y/CVBS FRONT

57

56

55

54

CVBS PIP

C FRONT

C IN 3

V/Y IN 3

V IN 2

6dB AMPLIFIER

FOR THE

SELECTABLE

OUTPUT CVBS

(3RD SCART)

Q3202

6dB AMPLIFIER

FOR THE

SELECTABLE

OUTPUT CVBS

(3RD SCART)

Q3200

6dB AMPLIFIER

FOR THE

MONITOR

OUTPUT CVBS

(2ND SCART)

Q3204

6dB AMPLIFIER

FOR THE

MONITOR

OUTPUT CVBS

(2ND SCART)

Q3201

100Hz BUFFER

U SCAN RATE

BACKEND

Q3302

100Hz BUFFER

U SCAN RATE

BACKEND

Q3301

+3.3V

V OUT 3

V OUT 2

V IN 100

U IN 100

VIDEO RF

H SYNC

V SYNC

CVBS TXT

12 C ADAPTOR

COINCIDENCE

DETECTOR

Q1005

5V - 3.3V

Q3500

OVP

PART OF

OVERVOLTAGE

PROTECTION

Q5816

TO A BOARD

SHEET 1

GROUP DELAY

COINCIDENCE

RESET AUDIO

AUDIO MUTE

LINE MUTE

TXT VIDEO

12C DISABLE

SDA

SIRCS

AGC

MODE 3

OVP

OCP

MAIN RY

DGC RY

B TEXT

G TEXT

R TEXT

FS 100

MODE 1

AV LINK

MODE 2

H SYNC

V SYNC

KEY

IC7300

VIDEO OUT (RED)

1

VB

3

VO

VI

5

IK

IC7325

VIDEO OUT (GREEN)

1

VB

VO

3

VI

5

IK

IC7350

VIDEO OUT (BLUE)

1

VB

3

VO

VI

5

IK

J7376

R

HEATER

)

10

G

9

B

8

13

5

CN7300

5

PICTURE TUBE

HV

TO D BOARD

CN8614

TO D BOARD

HV (T8800)

8

8

8

RV7375

G2

R, G, B OUT

C (

CN7001

CN7301

1

R-

R+

2

3

G-

4

G+

5

B-

6

B+

9

IK

STANBY SW

Q7355

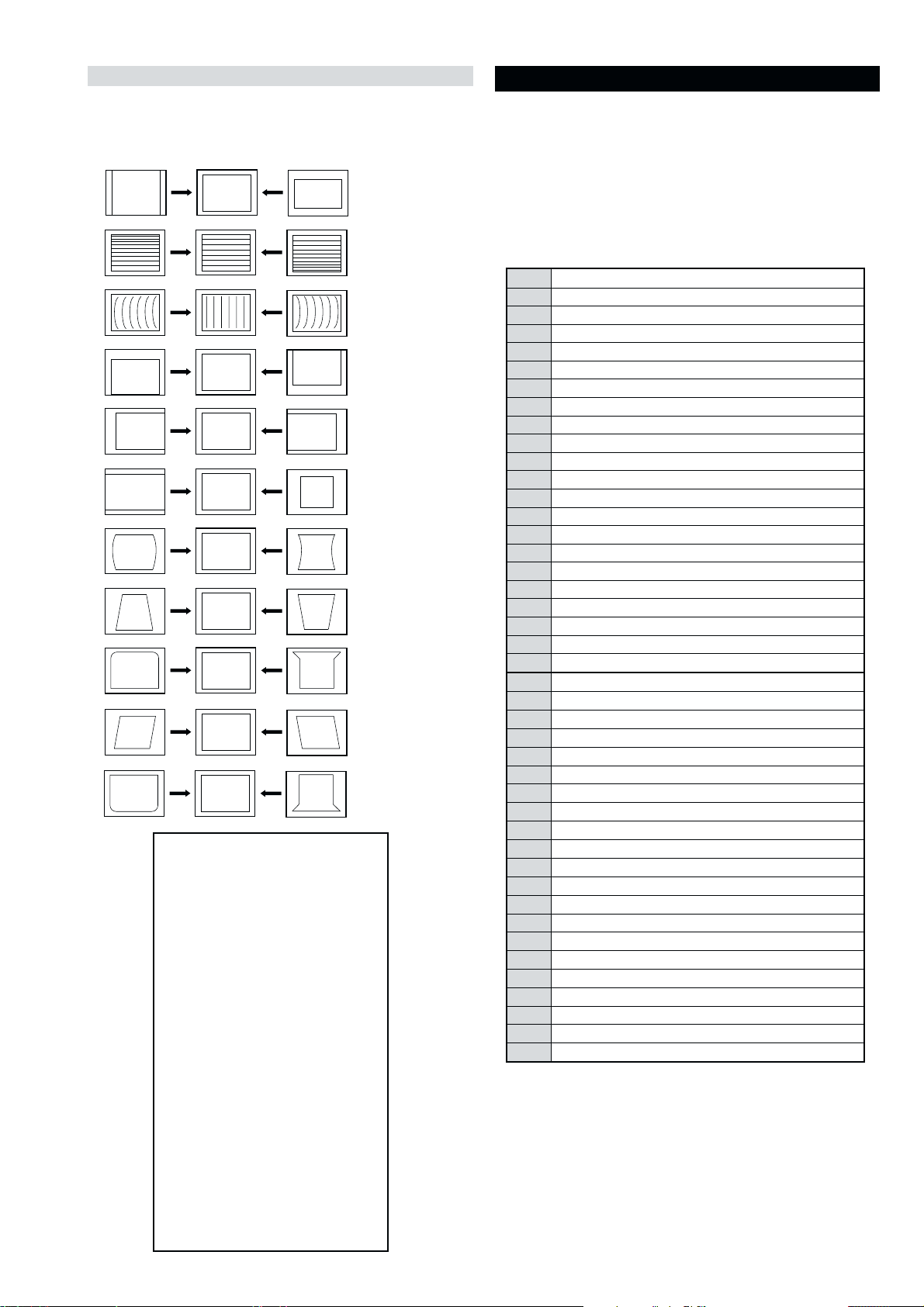

STANBY SW

Q7352

STANBY SW

+12V

VOLTAGE DET

Q7354, 7350

Q7353

CN6200

1

TO G BOARD

CN0101

CN6008

TO M2 BOARD

CN0001

TO A BOARD (1/2)

2

SCL

8

9

LED

24

10

40

6

25

11

23

15

13

14

20

19

22

18

36

12

35

5

34

37

17

16

21

39

7

VIDEO AND AUDIO PROCESSORS,

A 2/2 ( )

AUDIO OUTPUT, VERTICAL DEFLECTION

CN2502

TO A BOARD (1/2)

CN2910

WOOFER MUTE

R OUT

R IN

L IN

CN2909

AUDIO L

AUDIO R

TO A BOARD (1/2)

CN2000

Y/CVBS

C

1

2

3

5

6L OUT

6

9

1

4

2

H1( )

S0900 - S0905

FRONT AV INPUT,

HEADPHONE AND

CONTROL SWITCHES

12 C ADAPTOR

5V - 3.3V

Q3501

CN2900

L

R

VIDEO

1

Y/C

3

4

2

J2901

HEADPHONES

SERVICE CONNECTOR

2

SCL

3

SDA

4

CS

5

AGC

CN0102

- 26 -

Page 27

5-1. BLOCK DIAGRAMS (3)

TO A BOARD (1/2)

CN5002

TO A BOARD (1/2)

CN5801

CN8810

CN8620

1

V STAT

3

H CENTRE

4

M PIN CONT

2

MP PARA

3

E/W

4

H LIN

5

H DRIVE

6

AFC PULSE

7

ABL

8

X RAY PROTECT

Q8136,8137

Q8100,8102

COMPARATOR IC8100

1

2

+

3

4

COMPARATOR IC8101

1

2

-

+

3

4

COMPARATOR IC8103

1

2

3

4

8

VCC

7

6

+

5

8

VCC

7

6 6

+

5

+

Q8201,

8202,8118

VCC

8

7

6

+

5

+8

1

+8

HD1

OP. AMP IC8102

1

2

+

3

4

D8819

T8801

T8802

CN8611

V +

6

5

V -

4

H -

H -

3

H +

2

H +

1

Q8807

3