Sony kv 29sl40 Service Manual

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

29SL45 / 29SL65 / 29SL65C/ 29XL40M / 29XL40P / 29XT11A

SELF-DIAGNOSTIC FUNCTION

SERVICE MANUAL

MODEL COMMANDER DEST. CHASSIS NO.

KV-27S40

KV-27S40

KV-27S45

KV-27S45

KV-27S65

KV-27S65

KV-29SL40

KV-29SL40A

KV-29SL40C

KV-29SL45

KV-29SL65

RM-Y165 US SCC-S01H-A

RM-Y165 CND SCC-S03E-A

RM-Y167 US SCC-S01J-A

RM-Y167 CND SCC-S03F-A

RM-Y167 US SCC-S01K-A

RM-Y167 CND SCC-S03G-A

RM-Y165 E SCC-S04X-A

RM-Y165 E SCC-S04S-A

RM-Y165 E SCC-S04U-A

RM-Y167 E SCC-S04Y-A

RM-Y167 E SCC-S06F-A

BA-4

CHASSIS

KV-29SL65C

KV-29XL40M

KV-29XL40P

KV-29XT11A

RM-Y167 E SCC-S04V-A

RM-Y165 MX SCC-S02D-A

RM-Y165 E SCC-S04R-A

RM-Y165 E SCC-S04T-A

KV-27S45

RM-Y167

TRINITRON® COLOR TV

— 1 —

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

g

g

)

y

(

)

)

(

(

y (

)

y

(

(

)

)

y

)

29SL45 / 29SL65 / 29SL65C/ 29XL40M / 29XL40P / 29XT11A

WARNINGS AND CAUTIONS

CAUTION!

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD,

OR CARBON PAINTED ON THE CRT, AFTER REMOVING

THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED

DURING ANY SERVICE TO AVOID POSSIBLE SHOCK

HAZARD, BECAUSE OF LIVE CHASSIS.THE CHASSIS OF

THIS RECEIVER IS DIRECTLY CONNECTED TO THE AC

POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERA TION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

SELF-DIAGNOSTIC FUNCTION

ATTENTION

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURT-CIRCUITER

L'ANODE DU TUBE CATHODIQUE ET CELUI DE L'ANODE DU CAP AU

CHASSIS METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE

PEINTE SUR LE TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT D'UN

CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR D'ISOLEMENT DOIT

ETRE UTILISÉ LORS DE TOUT DÉPANNAGE. LE CHÁSSIS DE CE

RÉCEPTEUR EST DIRECTEMENT RACCORDÉ À L'ALIMENTATION

SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE MARQUE

¡ SUR LES SCHEMAS DE PRINCIPE, LES VUES EXPLOSEES ET LES

LISTES DE PIECES SONT D'UNEIMPORTANCE CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT . NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST INDIQUE DANS

LE PRESENT MANUEL OU DANS DES SUPPLEMENTS PUBLIES PAR

SONY . LES REGLAGES DE CIRCUIT DONT L'IMPORT ANCE EST CRITIQUE

POUR LA SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS

LE PRESENT MANUEL. SUIVRE CES PROCEDURES LORS DE CHAQUE

REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU'UN

MAUVAIS FONTIONNEMENT SUSPECTE.

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically begin to

flash. The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER lamp

flash indicators is listed in the instruction manual for the user's knowledge and reference. If an error symptom cannot be reproduced, the

remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the ST ANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the problem. I f there

is more than one error, the lamp will identify the first of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occured if the the screen displays a "0" .

Diagnostic Item No. of times Self-diagnostic display/ Probable Cause Detected Symptoms

Description STANDBY/TIMER Dia

* Power does not turn on Does not li

* +B overcurrent

* Vertical deflection stopped 4 times 4:0 or 4:1 * +13V is not supplied.

* White balance failure 5 times 5:0 or 5:1 * Video OUT

not balanced

OCP

lamp flashes

ht * Power cord is not plugged in. * Power does not come on.

2 times 2:0 or 2:1 * H.OUT (Q502) is shorted. (A board

nostic result Location

* Fuse is burned out (F5050) (E Board

* IC1751 and Q1751 is shorted.

A board) * Has entered standby state after horizontal raster.

* IC 541 is fault

* IC301 is faulty. (A board

* G2 is improperl

A board

Q306 to 308) is faulty. (A board)* No raster is generated.

adjusted. (Note 2

* No power is suppled to the TV.

* AC power suppl

* Power does not come on.

C board)* Load on power line is shorted.

* Vertical deflection pulse is stopped.

* Power line is shorted or power suppl

* CRT cathode current detection reference pulse

output is small.

is faulty.

is stopped.

Note 1: If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

Note 2: Refer to Screen (G2) Adjustment in Section 3-4 of this manual.

— 4 —

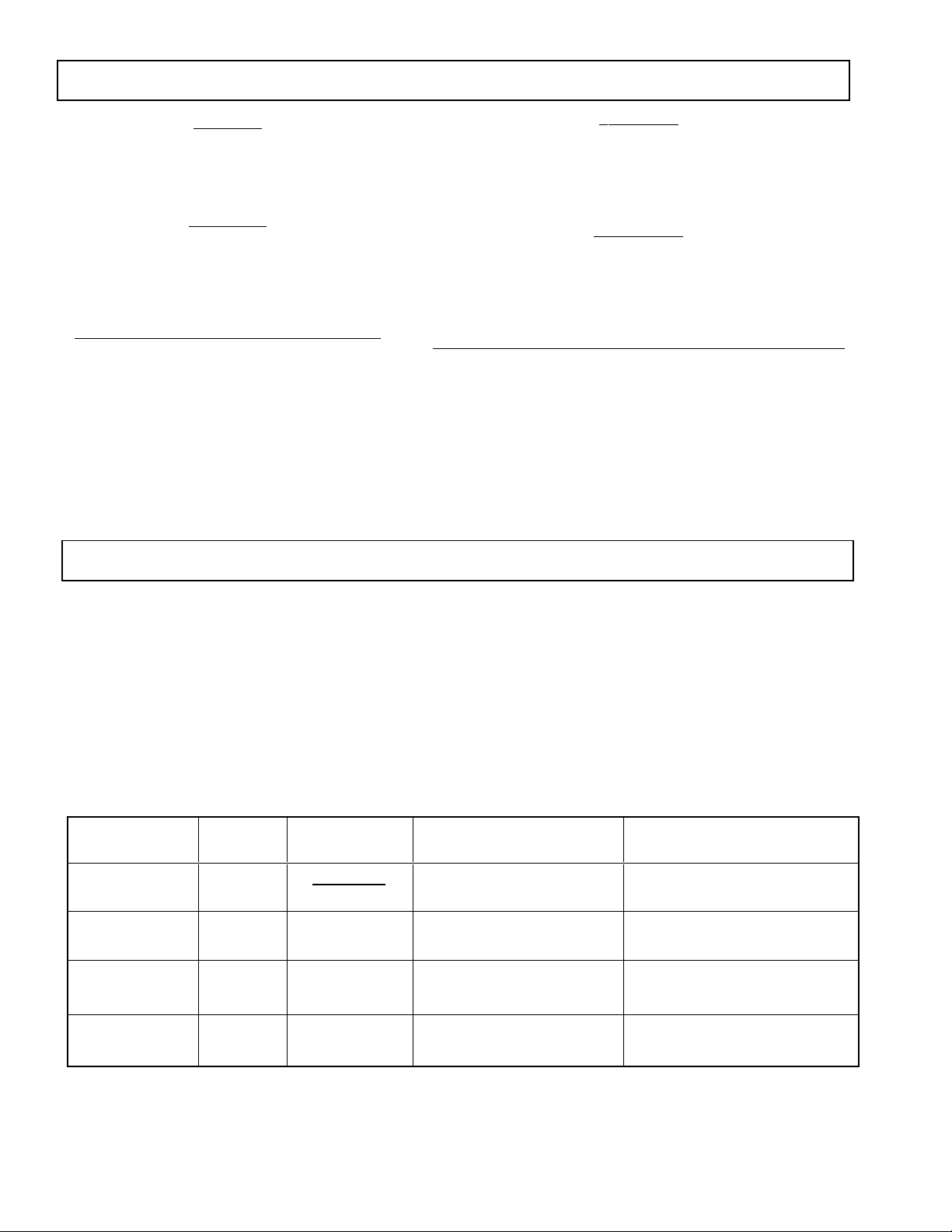

2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

4 times

5 times

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

29SL45 / 29SL65 / 29SL65C/ 29XL40M / 29XL40P / 29XT11A

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF

STANDBY/SLEEP lamp

3 sec.

Diagnostic Item Flash Count*

+B overcurrent 2 times

Vertical deflection stopped 4 times

White balance failure 5 times

* One flash count is not used for self-diagnostic.

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp from flashing.

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as "power sometimes shuts off" or "screen sometimes goes out" that cannot be confirmed, it is possible to bring up

past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Screen display

channel

5

Sound volume

–

Power ON

Note that this differs from entering the service mode (sound volume + ).

Self-Diagnostic screen display

SELF DIAGNOSTIC

2: 0 <-------------

Numeral "0" means that no fault has been detected.

3: N/A 0

4: 0

5: 1 <-------------

Numeral "1" means a fault has been detected one time only.

101: N/A 0

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When

you have completed the repairs, clear the result display to "0".

Unless the result display is cleared to "0", the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

[Clearing the result display]

To clear the result display to "0", press buttons on the remote commander sequentially as shown below when the diagnostic screen is being

displayed.

ENTER

Channel

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

8

— 5 —

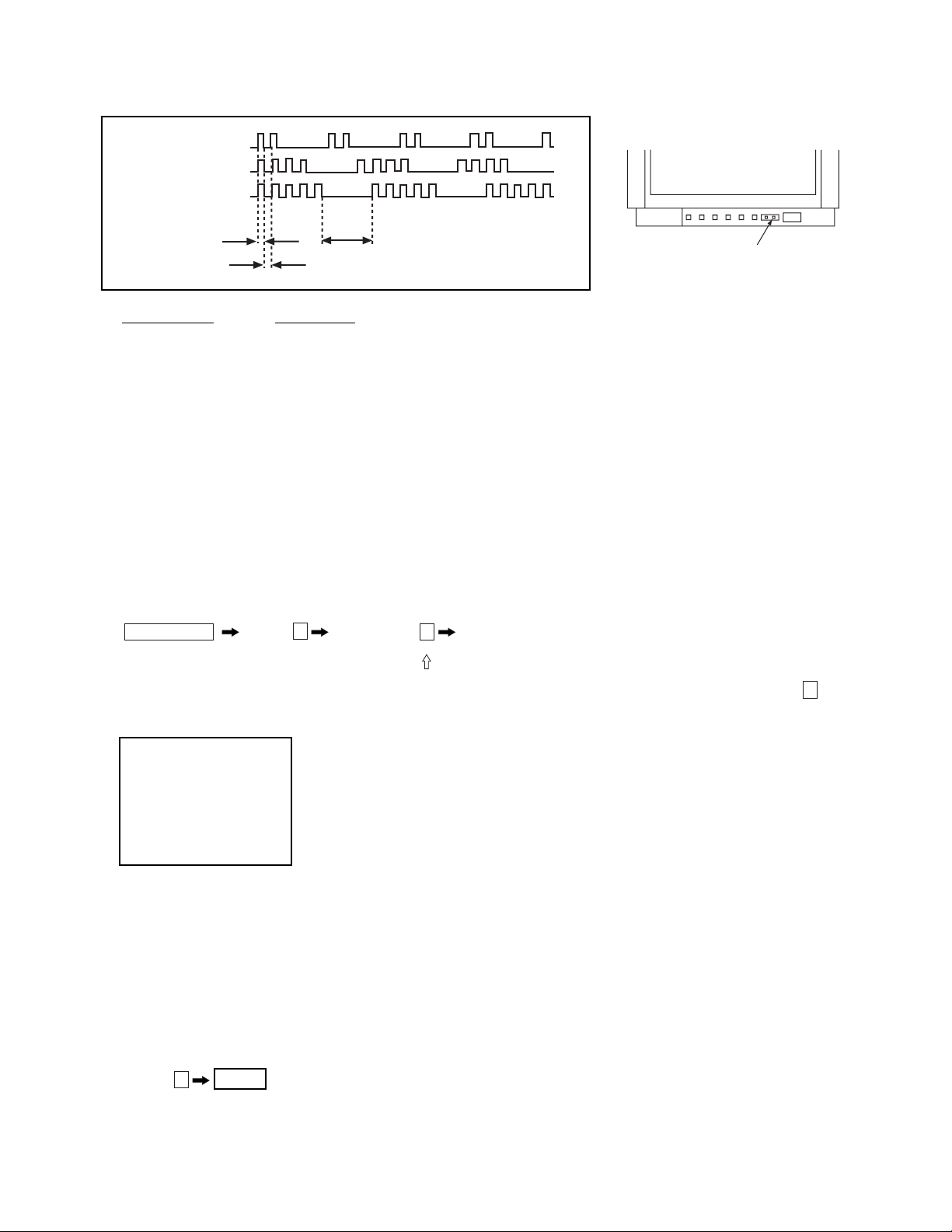

6. SELF-DIAGNOSTIC CIRCUIT

IC001

SYSTEM

17 I-PROT

37 SDAT

36 5

18

O-LED

MEMORY

B-DATIO-BDAT

FROM

CRT

FROM

IC521

PIN 7

IC301

Y/CHROMA JUNGLE

21

IK IN

18

HP/PROTECT

SDA

IC541

V.OUT

3

REF

35

+B overcurrent (OCP) Occurs when an overcurrent on the +B(115V) line is detected by pin 18 of IC301. If the

voltage to pin 18 of IC301 is less than 1V when V.SYNC is more than seven verticals in a

period, the unit will automatically turn off.

Vertical deflection stopped Occurs when an absence of the vertical deflection pulse is detected by pin 17 of IC001.

Power supply will shut down when waveform interval exceeds 2 seconds.

White balance failure If the RGB levels* do not balance within 2 seconds after the power is turned on, this error

will be detected by IC301. TV will stay on, but there will be no picture.

IC003

*(Refers to the RGB levels of the AKB detection Ref pulse that detects IK.)

— 6 —

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

29SL45 / 29SL65 / 29SL65C/29XL40M / 29XL40P / 29XT11A

SECTION 3

SET-UP ADJUSTMENTS

The following adjustments should be made when a

complete realignment is required or a new picture

tube is installed. These adjustments should be performed

with rated power supply voltage unless otherwise noted.

The controls and switch should be set as follows

unless otherwise noted:

PICTURE control ................. normal

BRIGHTNESS control ......... normal

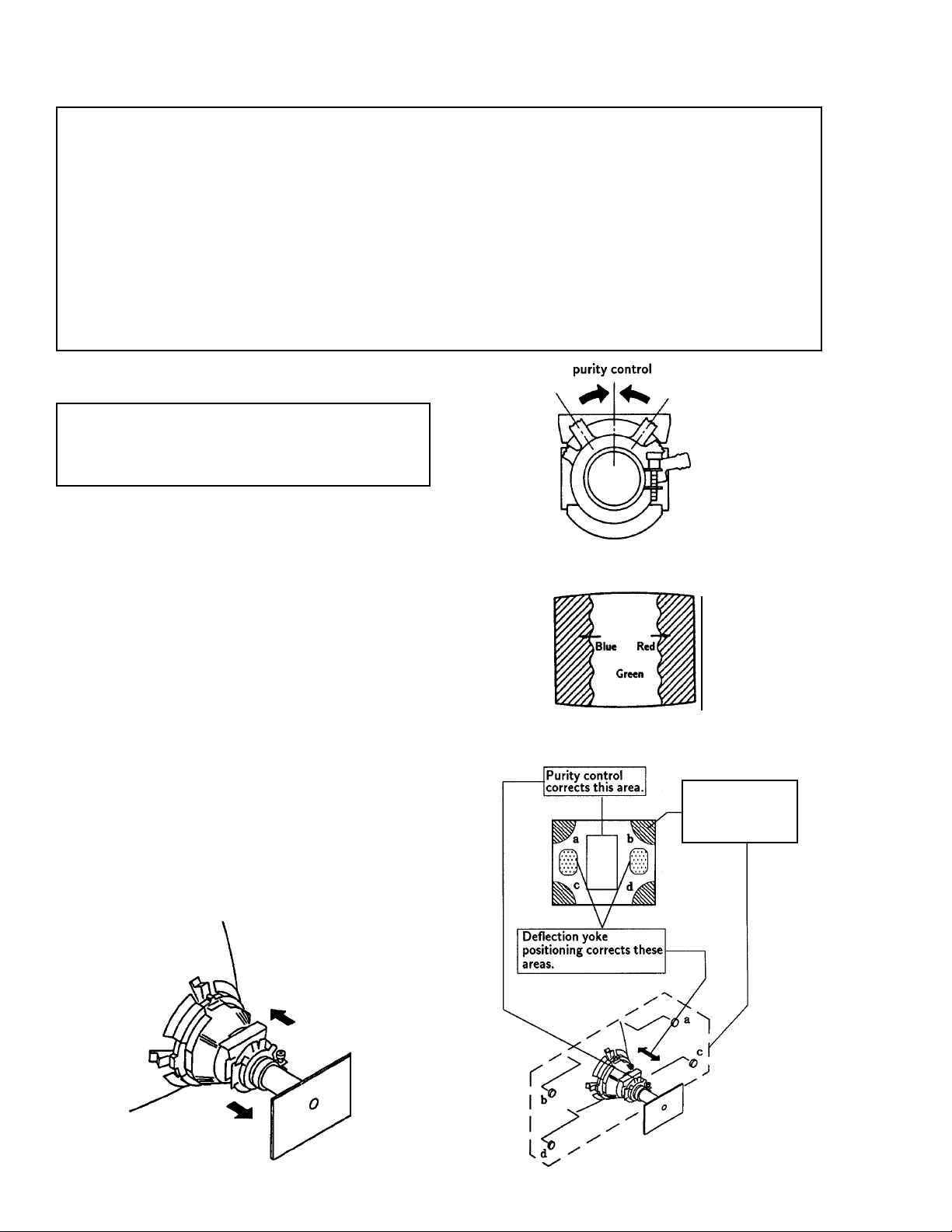

3-1. BEAM LANDING

Preparation:

• Feed in the white pattern signal.

• Before starting, degauss the entire screen.

1. Input a raster signal with the pattern generator.

2. Loosen the deflection yoke mounting screw, and set the

purity control to the center as shown in Fig.2.

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2) and White Balance

Note: Test Equipment Required

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

Fig. 2

3. Turn the raster signal of the pattern generator to

green.

4. Move the deflection yoke backward, and adjust with the

purity control so that green is in the center and red and

blue are at the sides evenly. (Fig.3)

5. Move the deflection yoke forward, and adjust so that the

entire screen becomes green. (Fig.1)

6. Switch over the raster signal to red and blue and confirm

the condition.

7. When the position of the deflection yoke is determined,

tighten it with the deflection yoke mounting screw.

8. When landing at the corner is not right, adjust by using

the disk magnets. (Fig.4)

Fig. 3

Disk magnets or

rotatable disk

magnets correct

these areas (a-d).

Fig. 1

Fig. 4

— 24 —

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

29SL45 / 29SL65 / 29SL65C/29XL40M / 29XL40P / 29XT11A

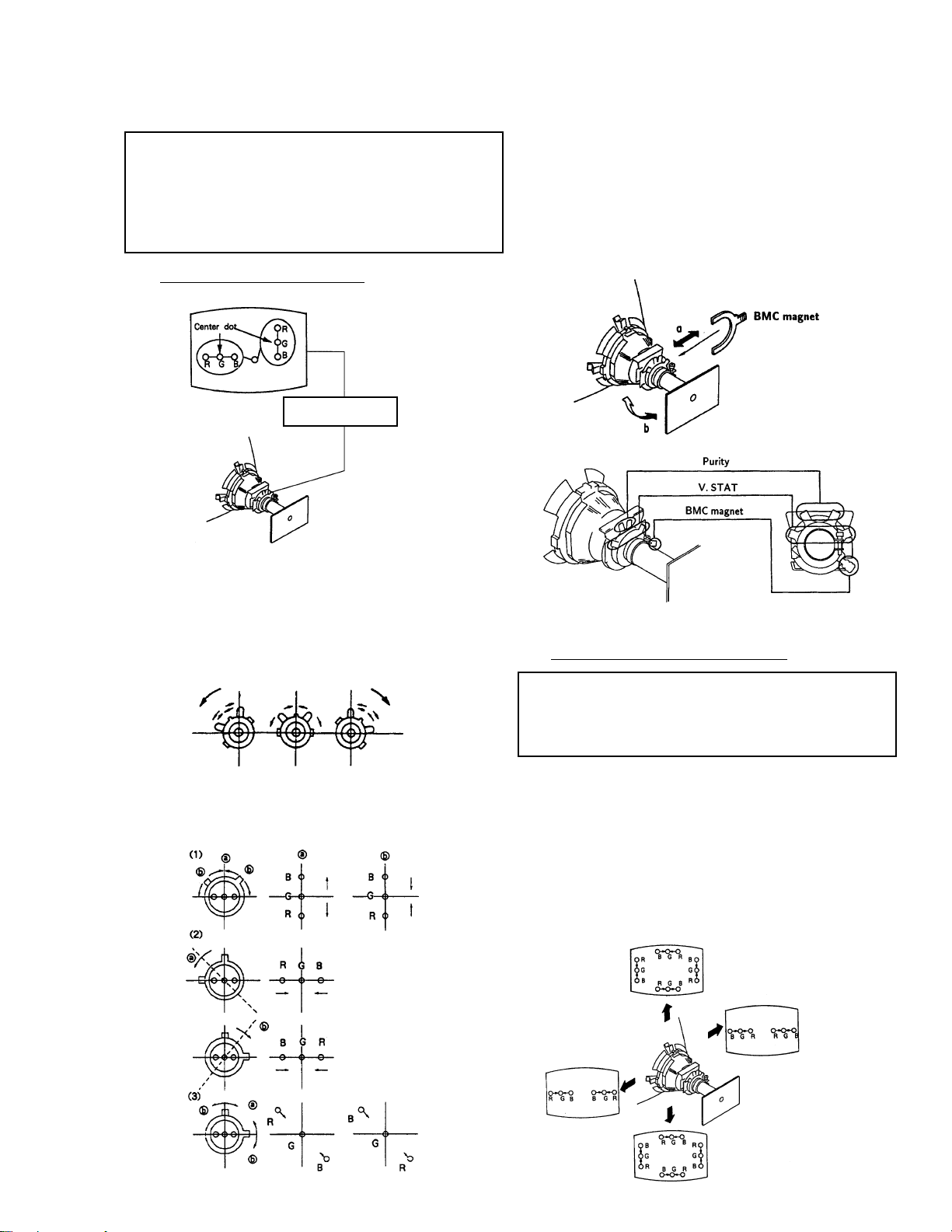

3-2. CONVERGENCE

Preparation:

• Before starting, perform FOCUS, V. LIN and V. SIZE

adjustments.

• Set BRIGHTNESS control to minimum.

• Feed in dot pattern.

(1) Vertical Static Convergence

V. STAT magnet

If the blue dot does not converge with red and green dots,

perform the following steps:

• Move BMC magnet (a) to correct insufficient H. Static

convergence.

• Rotate BMC magnet (b) to correct insufficient V. Static

convergence.

In either case, repeat Beam Landing Adjustment.

BMC magnet

Fig. 6

Fig. 5

1. Adjust V. STAT magnet to converge red, green and blue

dots in the center of the screen. (Vertical movement)

Tilt the V. STAT magnet and adjust static convergence

to open or close the V. STAT magnet.

2. When the V. ST AT magnet is moved in the direction of

arrow a and b, red, green, and blue dots move as

shown below:

Fig. 7

( 2 ) Dynamic Convergence Adjustment

Preparation:

• Before starting, perform Horizontal and Vertical

Static Convergence Adjustment.

1. Slightly loosen deflection yoke screw.

2. Remove deflection yoke spacers.

3. Move the deflection yoke for best convergence as shown

below. ( Fig. 8)

4. Tighten the deflection yoke screw.

5. Install the deflection yoke spacers.

— 25 —

Fig. 8

KV-27S40 / 27S45 / 27S65 / 29SL40 / 29SL40A / 29SL40C/

29SL45 / 29SL65 / 29SL65C/29XL40M / 29XL40P / 29XT11A

(3) Screen-corner Convergence

Fig. 9

Affix a permalloy assembly corresponding to the misconverged

areas:

3-3. FOCUS

1. Adjust FOCUS control for best picture.

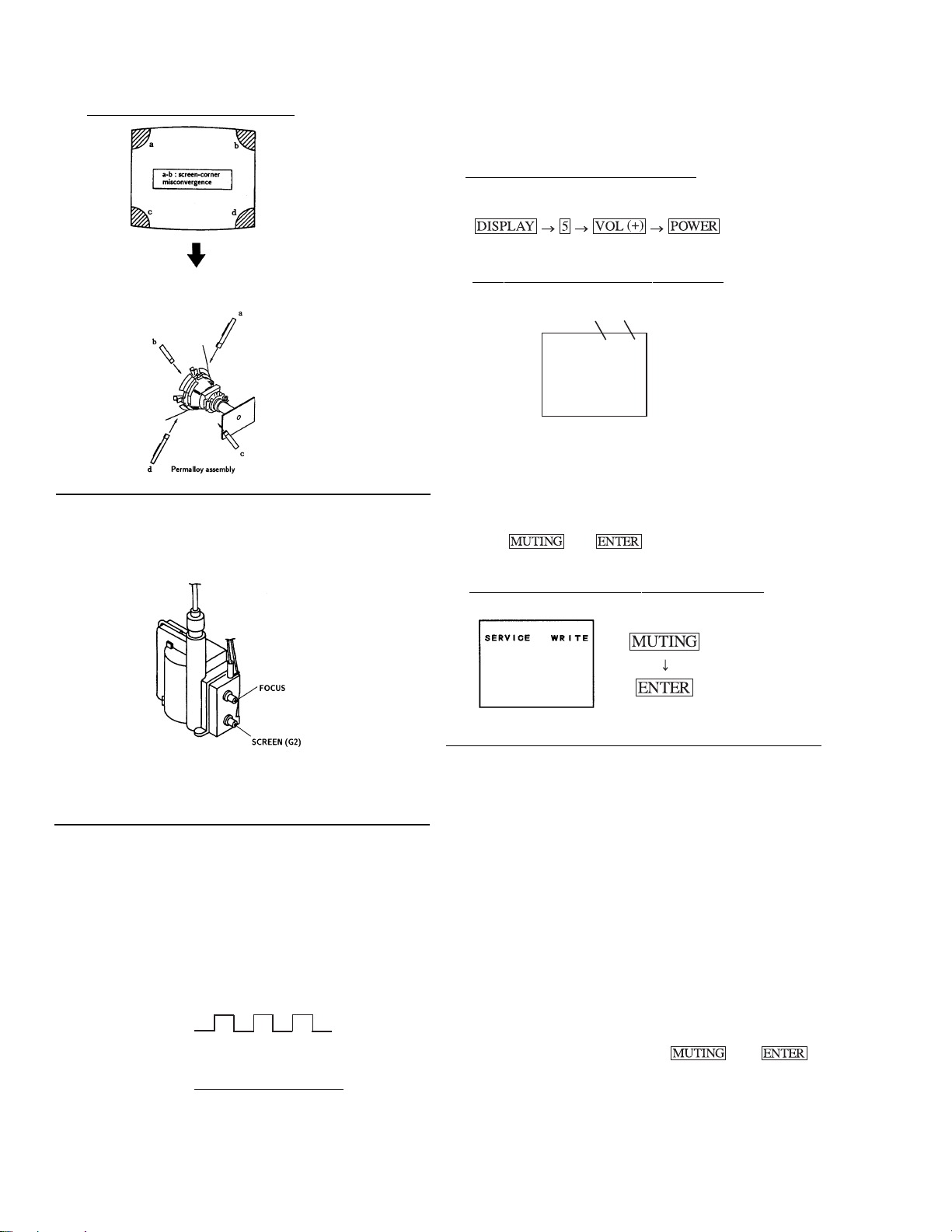

3-5. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE

(1) SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. on the

Remote Commander. (Press each button within a second.)

(2) SERVICE ADJUSTMENT MODE IN

Disp.

Item

(Item)

data

SERVICE AFC 0

3. The CRT displays the item being adjusted.

4. Press 1 or 4 on the Remote Commander to

select the item.

5. Press 3 or 6 on the Remote Commander to

change the data.

6. Press

then to write into memory.

Fig. 10

3-4. SCREEN (G2)

1. Input a dots pattern.

2. Set the PICTURE and BRIGHT controls at minimum

and COLOR control at normal.

3. Adjust SBRT, GCUT, BCUT in service mode with an

oscilloscope as shown in Fig. 11 so that voltages on the red,

green, and blue cathodes are 170Vdc.

N

NN

NN

Fig. 11

GND

170Vdc

170 V dc

NN

NN

N

4. Observe the screen and adjust SCREEN (G2) VR

to obtain the faintly visible background of dot signal.

N

NN

NN

pedestal

(3) SERVICE ADJUSTMENT MODE MEMORY

Green

Red

7. Turn set off and on to exit.

3-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal.

2. Set to Service adjustment Mode.

3. Set DCOL to "0"

4. Set the PICTURE and BRIGHT to minimum.

5. Adjust with SBRT if necessary.

6. Select GCUT and BCUT with 1 and 4 .

7. Adjust with 3 and 6 for the best white balance.

8. Set the PICTURE and BRIGHT to maximum.

9. Select GDRV and BDRV with 1 and 4 .

10. Adjust with 3 and 6 for the best white balance.

11. Reset DCOL to "1".

12. W rite into the memory by pressing

then .

— 26 —

Loading...

Loading...