Page 1

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-21SE43C

RM-Y155 E SCC-S55BA

BA-4D

CHASSIS

Trinitron

KV-20S90

RM-Y155

TRINITRON® COLOR TELEVISION

9-965-905-01

Page 2

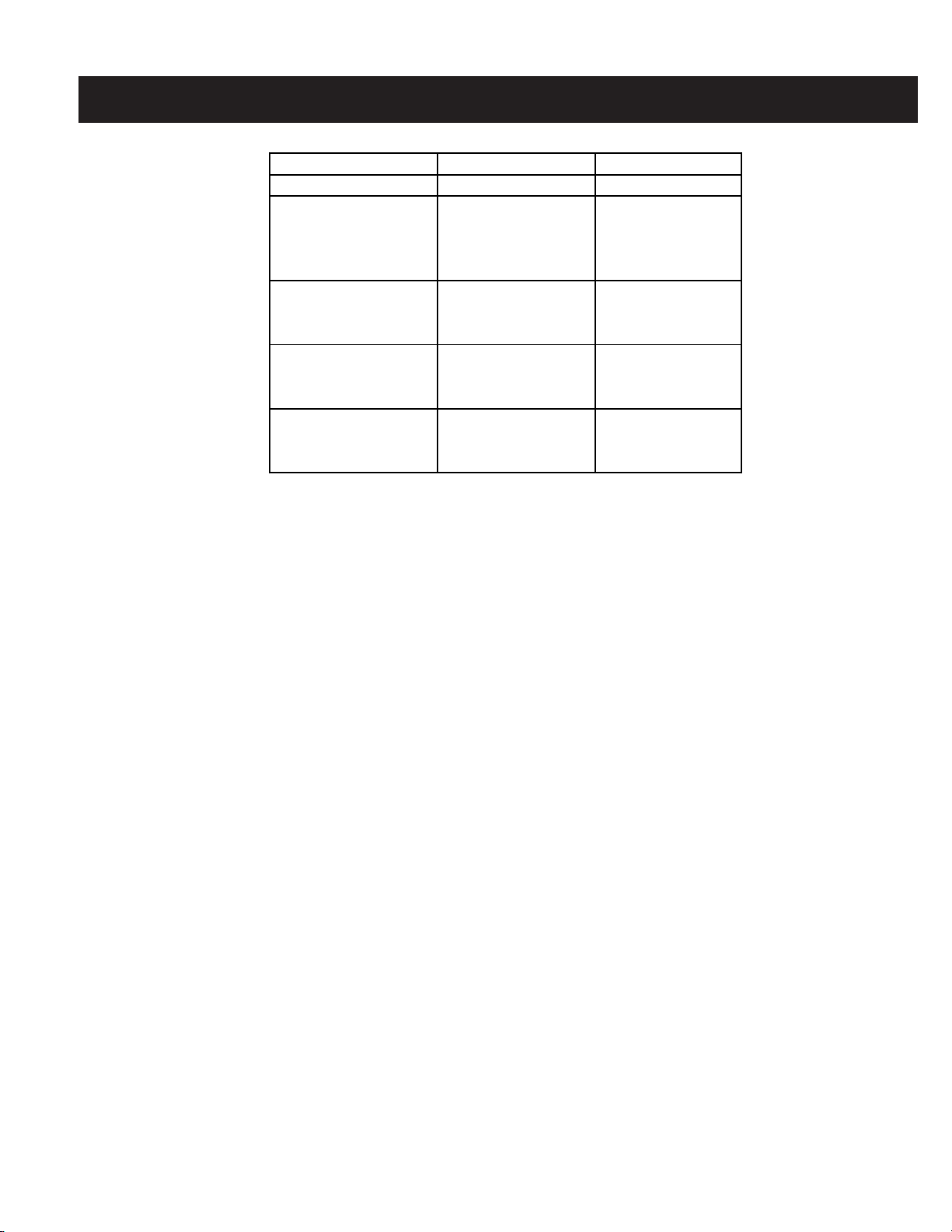

TABLE OF CONTENTS

SECTION TITLE PAG E

Specifi cations.......................................................................................................................................3

Warnings and Cautions........................................................................................................................4

Safety Check-out .................................................................................................................................5

Self-Diagnostic Function......................................................................................................................6

1. Disassembly

1-1. Rear Cover Removal.....................................................................................................................8

1-2. Chassis Assembly Removal..........................................................................................................8

1-3. Service Position ............................................................................................................................8

1-4. Picture Tube Removal...................................................................................................................9

Anode Cap Removal Procedure...................................................................................................9

2. Set-up Adjustments

2-1. Beam Landing...............................................................................................................................10

2-2. Convergence................................................................................................................................. 11

2-3. Focus ............................................................................................................................................12

2-4. Screen (G2) .................................................................................................................................. 12

2-5. Method of Setting the Service Adjustment Mode..........................................................................13

2-6. White Balance Adjustments .......................................................................................................... 13

3. Safety Related Adjustments

3-1.

3-2. B+ Voltage Confi rmation and Adjustment .....................................................................................14

4. Circuit Adjustments

4-1. Setting the Service Adjustment Mode...........................................................................................16

4-2. Memory Write Confi rmation Method .............................................................................................16

4-3. Remote Adjustment Buttons and Indicators .................................................................................16

Adjustment Items..........................................................................................................................17

4-4. A Board Adjustments....................................................................................................................18

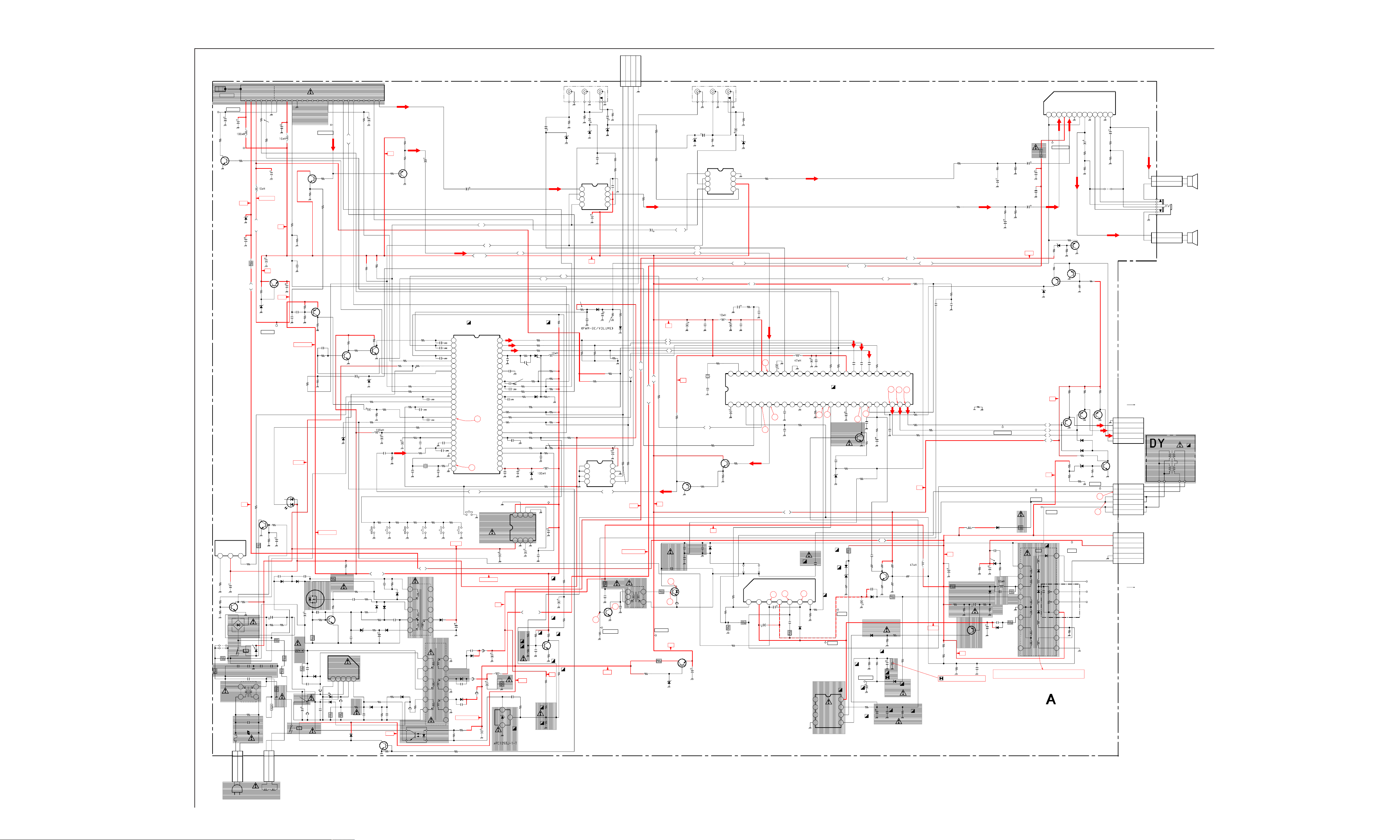

5. Diagrams

5-1. Circuit Boards Location.................................................................................................................21

5-2. Printed Wiring Board and Schematic Diagram Information ..........................................................21

5-3. Block Diagram and Schematics .................................................................................................... 22

Block Diagram ..............................................................................................................................22

A Board Schematic Diagram ........................................................................................................23

C Board Schematic Diagram........................................................................................................28

5-4. Semiconductors............................................................................................................................30

6. Exploded Views

6-1. Chassis.........................................................................................................................................31

7. Electrical Parts List ...................................................................................................................................... 32

X

R582 Confi rmation Method (Hold Down Confi rmation) and Readjustments........................... 14

KV-20S90 / 21SE43C

— 2 —

Page 3

SPECIFICATIONS

KV-21SE43C KV-20S90

Power requirements 220V 50Hz 120V 60Hz

Number of Inputs/Outputs

Audio Input

Speaker output (W) 4W x 2 3W x 2

Power Consumption (W)

In use (Max) 95W 90W

In Standby 1W 1W

Dimensions(W/H/D)

1)

Video

2)

22

22

mm 522 x 477 x 479 mm 522 x 477 x 479 mm

5

/

in 20

x 18 13/16 x 18 7/8 in. 20 5/8 x 18 13/16 x 18 7/8 in.

8

Mass

kg

lbs

21.6 kg 21.6 kg

48 lbs 48 lbs

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

500 mVrms (100% modulation), Impedance: 47 kilohms

KV-20S90 / 21SE43C

Television system

American TV Standard/NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Picture tube

Flat Trinitron® tube

Visible screen size

20-inch picture measured diagonally

Actual screen size

21-inch measured diagonally

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

Remote Commander RM-Y155

Size AA (R6) batteries (2)

Telescopic Antenna (KV-21SE43C ONLY)

Optional Accessories

None

Design and specifi cations are subject to change without notice.

— 3 —

Page 4

KV-20S90 / 21SE43C

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT,

after removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 4 —

Page 5

SAFETY CHECK-OUT

KV-20S90 / 21SE43C

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage

as described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive VOMs

that are suitable. Nearly all battery-operated digital multimeters that

have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

Trouble Light

Ohmmeter

0.15 F

1.5 K Ω

AC Outlet Box

AC

Voltmeter

(0.75 V)

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 5 —

Cold-water Pipe

Page 6

KV-20S90 / 21SE43C

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on

+B overcurrent (OCP)*

Vertical Defl ection

Stopped

White Balance failure

(not balanced)

No. of times

STANDBY/ TIMER

lamp fl ashes

Does not light

2 times

4 times

5 times

Self-Diagnositc

Display/

Diagnostic Result

2:0 or 2:1

4:0 or 4:1

5:0 or 5:1

Probable Cause Location

• Power cord is not plugged in.

• Fuse is burned out (F601). (A Board)

• H.OUT (Q502) is shorted.(A Board)

• IC1751 (C Board) is shorted.

• +13V is not supplied. (A Board)

• IC541 is faulty. (A Board)

• Video OUT (Q392 to Q394) is faulty.

(A Board)

• IC301 is faulty. (A Board)

• Screen (G2) is improperly

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Has entered standby state after horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT Cathode current detection reference pulse

output is small.

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the

mircrocontroller is displayed on the screen.

**Refer to Screen (G2) Adjustments in Section 2-4. of this manual.

Display of Standby/Timer LED Flash Count

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

Standby/Timer LED

Diagnostic Item Flash Count*

+B Overcurrent 2 times

Vertical Defl ection Stopped 4 times

White Balance Failure 5 times

*One fl ash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

— 6 —

Page 7

KV-20S90 / 21SE43C

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up

past occurrences of failure on the screen for confi rmation.

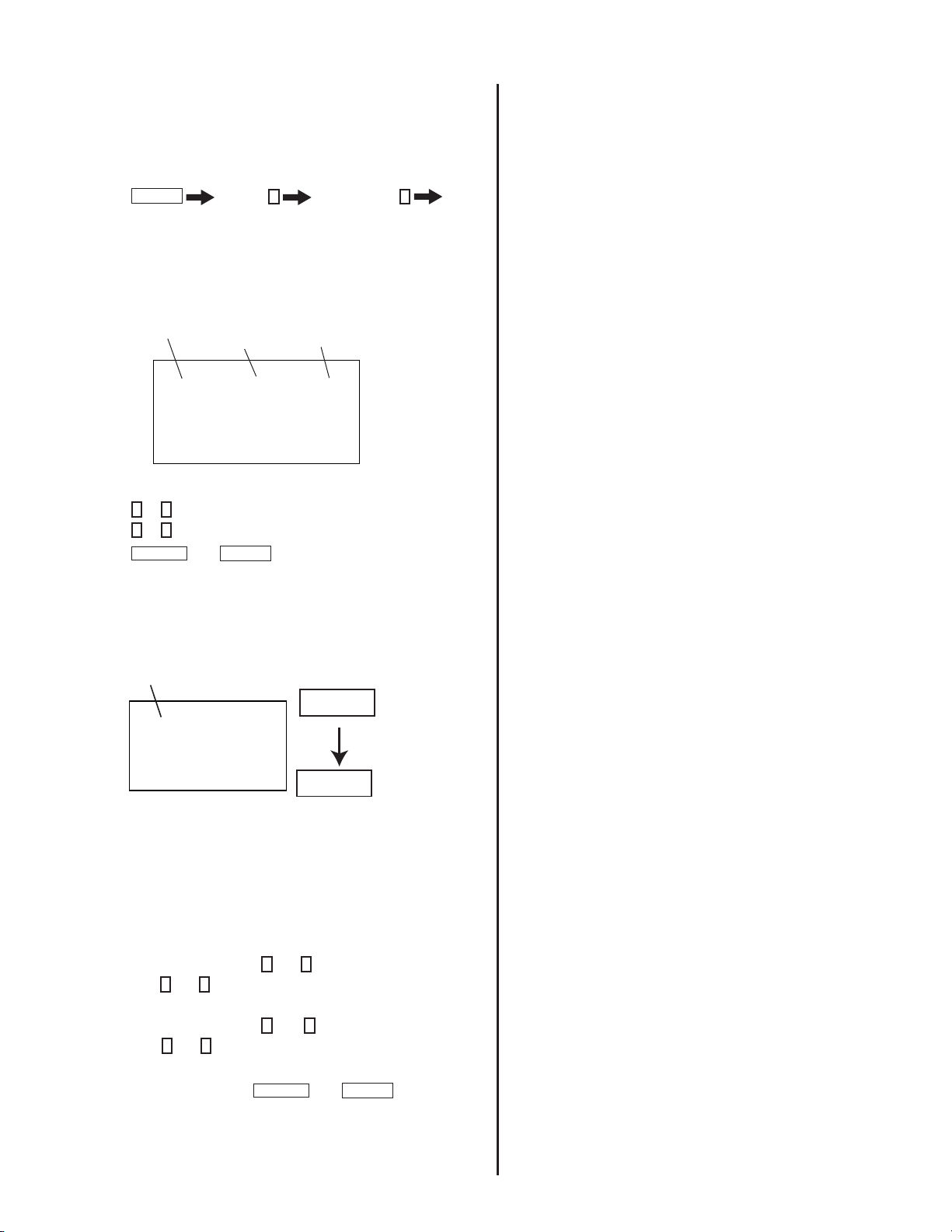

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display

Self-Diagnostic Screen Display

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Channel

SELF DIAGNOSTIC

2: 000

3: N/A

4: 000

5: 001

101: N/A

8

ENTER

5

Sound Volume - Power ON

Note that this differs from entering the Service Mode (Sound Volume

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

+

).

Self-Diagnostic Circuit

FROM

CRT

IC301

Y/CHROMA JUNGLE

21

IK IN

IC541

V. OUT

REF

IC001

SYSTEM

IO-BDAT

3

17

I-PROT

36

IC003

MEMORY

5

BDA

FROM

18

IC521

PIN 7

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (115V) line is detected by pin 18 of IC301. If the voltage of pin 18 of IC301 is less than 1V when V.SYNC is more

than seven verticals in a period, the unit will automatically turn off.

Vertical Defl ection Stopped

Occurs when an absence of the vertical defl ection pulse is detected by pin 17 of IC001. Power supply will shut down when waveform interval

exceeds 2 seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC301. TV will stay on, but there

will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

HP/PROTECT

SDA

35

37

IO-SDAT

O-LED

18

DISPLAY

— 7 —

Page 8

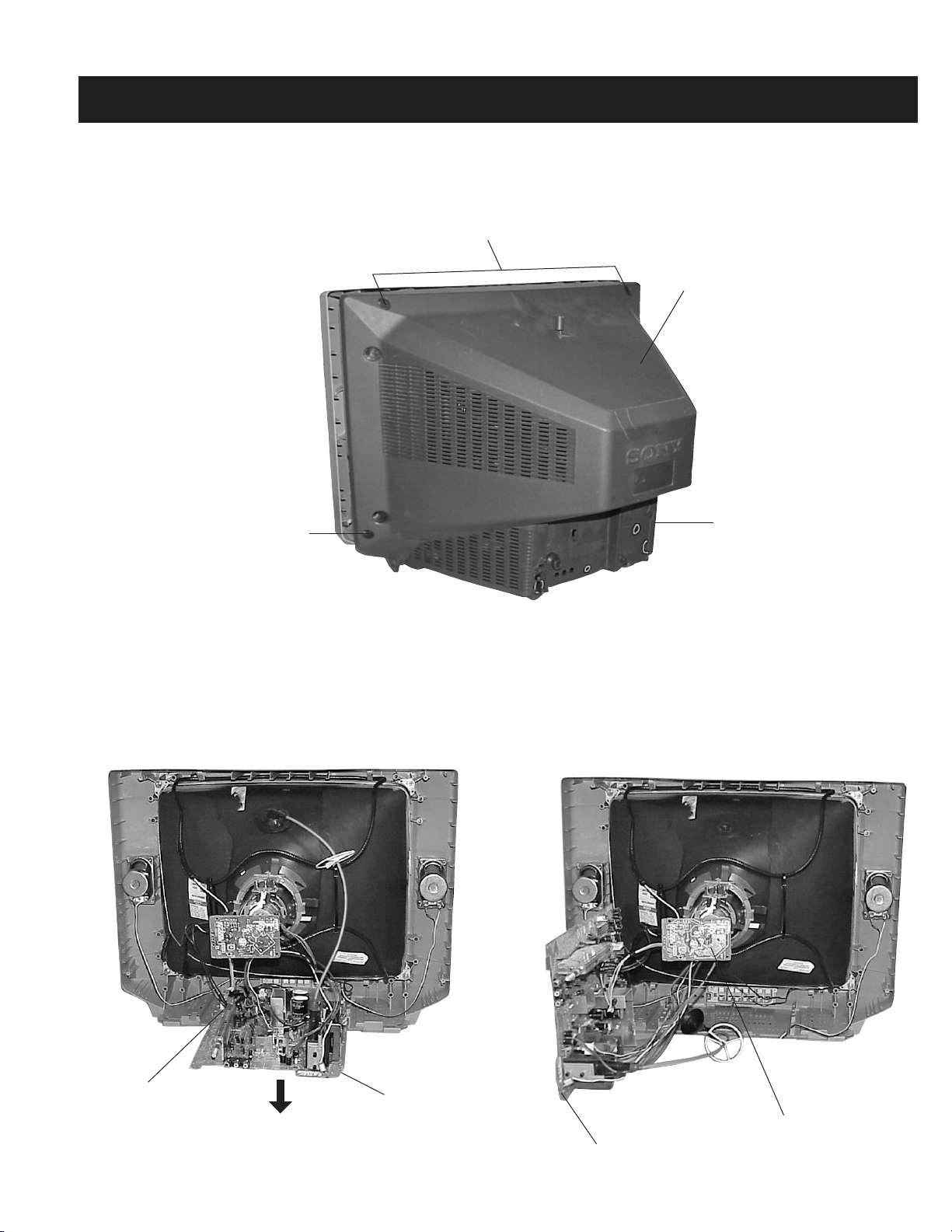

1-1. REAR COVER REMOVAL

KV-20S90 / 21SE43C

SECTION 1: DISASSEMBLY

2 Screws +BVTP 4x16

Rear Cover

Screw +BVTP 4x16

1-2. CHASSIS ASSEMBLY REMOVAL 1-3. SERVICE POSITION

Screw +BVTP 4x16

Claw

Chassis Assembly

C Board

A Board

— 8 —

Page 9

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

KV-20S90 / 21SE43C

Coated

Earth

Ground

Strap

1

10

5

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the defl ection yoke, neck

8

7

assembly, degaussing coils and CRT grounding strap.

3. Remove the C Board from the CRT.

6

3

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

2

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion and remove

9

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fi xing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the CRT

by the neck].

4

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or

carbon painted on the CRT.

c

b

a

Anode Button

Turn up one side of the rubber cap in

1

the direction indicated by arrow

a

.

Use your thumb to pull the rubber

2

cap fi rmly in the direction indicated

by arrow

.

b

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too hard.

A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

When one side of the rubber cap separates from

3

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow

.

c

— 9 —

Page 10

SECTION 2: SET-UP ADJUSTMENTS

KV-20S90 / 21SE43C

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: Standard

PICTURE CONTROL: Normal

BRIGHTNESS CONTROL: Normal

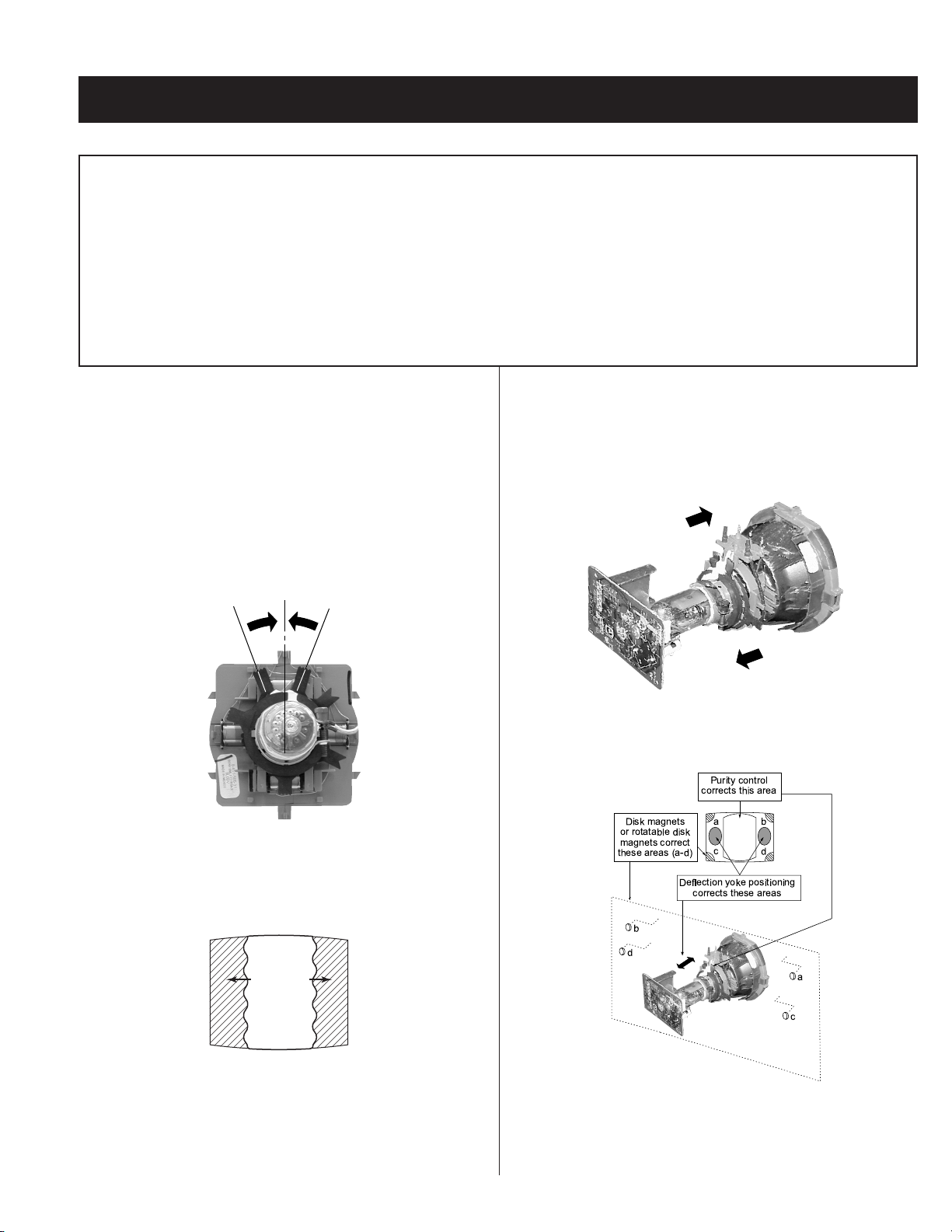

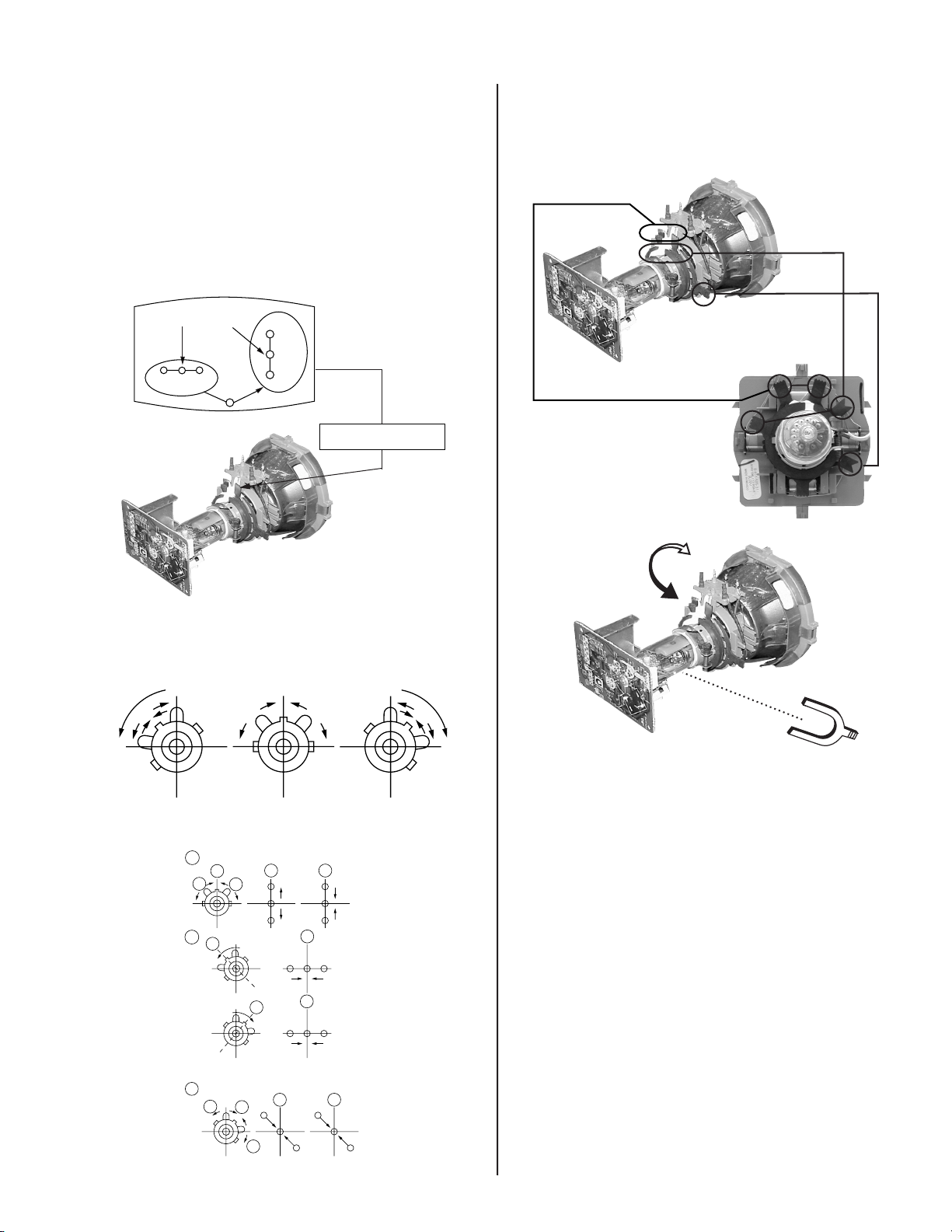

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Degauss the entire screen.

2. Feed in the white pattern signal.

ADJUSTMENT PROCEDURE

1. Input a raster signal with the pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk magnets.

3. Turn the raster signal of the pattern generator to green.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

— 10 —

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

Purity control

corrects this area

ba

cd

Deflection yoke positioning

corrects these areas

a

c

Page 11

KV-20S90 / 21SE43C

2-2. CONVERGENGE

Before starting convergence adjustments:

1 Perform FOCUS, VLIN and VSIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

VERTICAL STATIC CONVERGENCE

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen (Vertical movement adjust V.STAT RV701 to

converge).

Center dot

R G B

R

G

B

V.STAT magnet

If the blue dot does not converge with the red and green dots, peform

the following:

1. Move BMC magnet (a) to correct insuffi cient H.Static convergence.

2. Rotate BMC magnet (b) to correct insuffi cient V.Static convergence.

3. In either case, repeat Beam Landing Adjustment.

PURITY

V. S TAT

BMC MAGNET

2. Tilt the V. STAT magnet and adjust static convergence to open or close

the V. STAT magnet.

When the V. STAT magnet is moved in the direction of arrow a and b,

red, green, and blue dots move as shown below:

1

a

b

2

a

a

b

B

G

R

b

b

B

G

R

a

RGB

b

BGR

b

BMC magnet

a

3

b

a

a

R

G

b

b

B

G

B

R

— 11 —

Page 12

KV-20S90 / 21SE43C

DYNAMIC CONVERGENCE ADJUSTMENT

Before performing this adjustment, perform Horizontal and Vertical Static

Convergence Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as

shown below:

BGR

RGB

BGR

R

G

B

RGB

RGB

B

G

R

B

B

G

R

BGR RGB

R

G

B

G

R

2-3. FOCUS

1. Adjust FOCUS control for best pictures.

Focus (FV)

Screen (G2)

2-4. SCREEN (G2)

1. Input a dot pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum and

COLOR control at normal.

3. Adjust SBRT, GCUT, BCUT in service mode with an oscilloscope as

shown below so that voltages on the red, green, and blue cathodes

are 170 ± 2 VDC.

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

SCREEN-CORNER CONVERGENCE

1. Affi x a permalloy assembly corresponding to the misconverged areas:

b

a

ba

a-d: screen-corner

misconvergence

cd

d

c

170 ± 2 VDC

GND

4. Observe the screen and adjust SCREEN (G2) VR to obtain the faintly

visible background of dot signal.

pedestal

— 12 —

Page 13

2-5. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. Standby mode (power off).

2. Press

Display

on the Remote Commander (press each button within a second).

Channel 5 Sound Volume + Power

SERVICE ADJUSTMENT MODE IN

1. The CRT displays the time being adjusted.

KV-20S90 / 21SE43C

Item

Data

0

to save into the memory.

2. Press

3. Press

4. Press

then

Display

Item

HSIZ

ENTER

Mode

SERVICE

1

or 4 on the Remote Commander to select the time.

3

or 6 on the Remote Commander to change the data.

MUTING

SERVICE ADJUSTMENT MODE MEMORY

Turn the set off then on to exit Service Adjustment Mode.

Mode

SERVICE

MUTING

WRITE

Green

ENTER

Red

2-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal.

2. Set to Service Adjustment Mode.

3. Set DCOL to “0”.

4. Set the PICTURE and BRIGHTNESS to minimum.

5. Adjust with SBRT if necessary.

6. Select GCUT and BCUT with

7. Adjust with

8. Set the PICTURE and BRIGHTNESS to maximum.

9. Select GDRV and BDRV with

10. Adjust with

11. Reset DCOL to “1”.

12. To write into memory, press

3

and 6 for the best white balance.

3

and 6 for the best white balance.

1

and 4 .

1

and 4.

MUTING

then

ENTER

.

— 13 —

Page 14

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-20S90 / 21SE43C

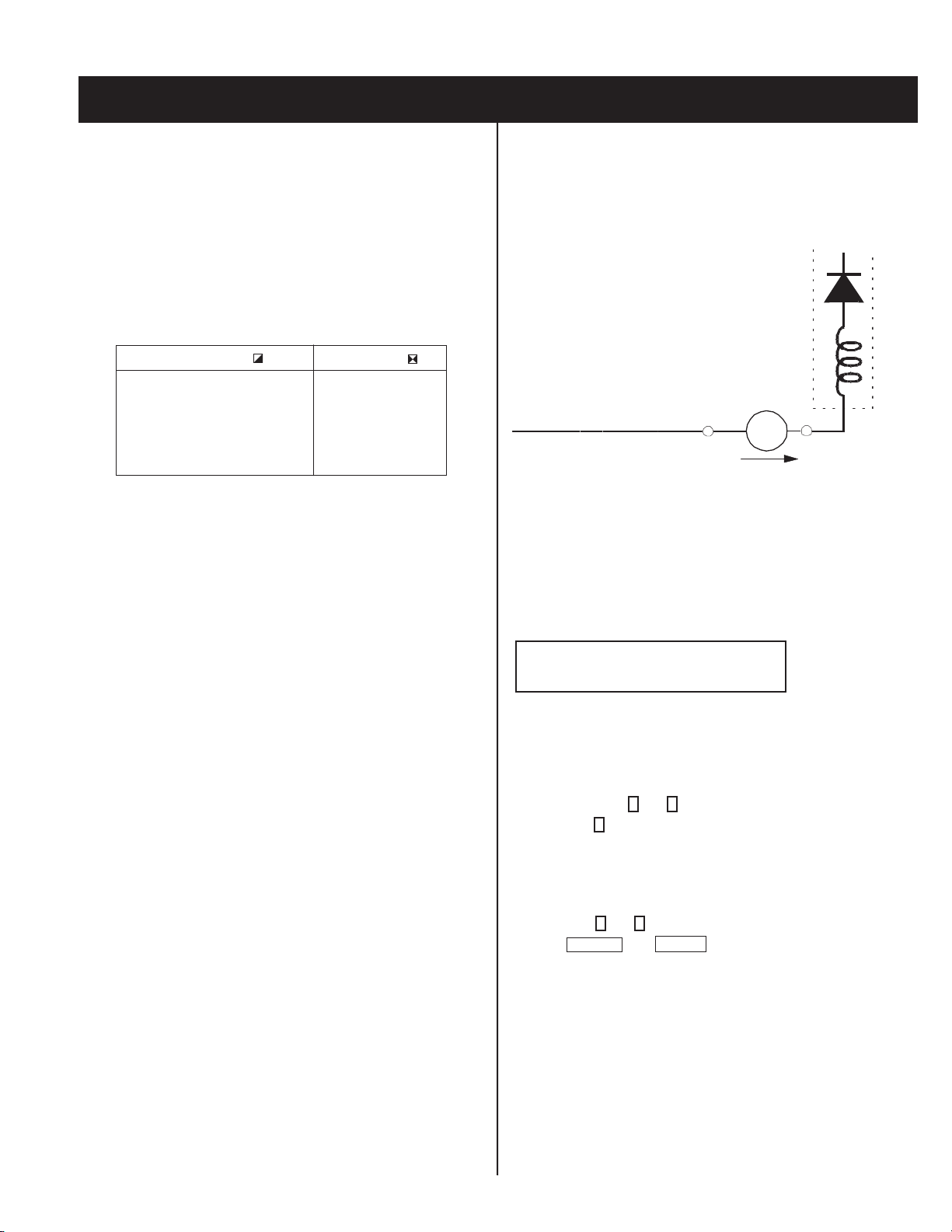

3-1. X R582 CONFIRMATION METHOD

(HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when replacing

the following components which are marked with

diagram:

Part Replaced ( )

DY, C511, C574, C575, D572,

D573, D574, R582, R583, R584,

R585, R586, R578, R625, R626,

R640, R635,T504, IC301, IC521,

IC602.............................A Board

Y

on the schematic

Adjustment ( )

HV HOLD-DOWN

R582

PREPARATION BEFORE CONFIRMATION

1. Turn the POWER switch ON. Input a white signal and set the

PICTURE and BRIGHTNESS controls to maximum.

2. Confi rm that the voltage between C574 (+) and ground is more than

99.8 VDC when set is operating normally with 120 +/- 2 VAC.

HOLD-DOWN OPERATION CONFIRMATION

1. Connect the current meter between Pin 11 of the FBT (T504) and

the PWB land where Pin 11 would normally attach (See Figure 1 on

the next page).

2. Input a dot signal and set PICTURE and BRIGHTNESS to minimum:

IABL = 95 + 100/-95µA.

3. Confi rm the voltage of A Board TP-600 is 117 ± 0.3 VDC.

4. Connect the digital voltmeter and the DC power supply via Diode

1SS119 to C574 (+) and ground (See Figure 1 on next page).

5. Increase the DC power voltage gradually until the picture blanks out.

6. Turn DC power source off immediately.

7. Read the digital voltmeter indication (standard: less than or equal to

127.3 VDC).

8. Input a white signal and set PICTURE and BRIGHTNESS to

maximum: (standard: less than or equal to 127.3 VDC).

9. Repeat steps 4 to 7.

HOLD-DOWN READJUSTMENT

If the setting indicated in Step 2 of Hold-Down Operation Confi rmation

cannot be met, readjustment should be performed by altering the

resistance value of R582 component marked with

X

.

T504

FBT

ampmeter

3.0 mA DC

range

ABL

+

-

A

IABL

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Note: The following adjustments should always be performed when

replacing the following components, which are marked with

schematic diagram on the A Board:

A BOARD: IC001,IC602, R030, R625, R626,

R632, R633, R635, R636, R637, R638, R639

1. Supply 130 +2.0 / -0.0V to the set with a variable auto transformer.

2. Input a dot signal.

3. Set the PICTURE and the BRIGHTNESS controls to minimum.

4. Set to Service Adjustment Mode.

5. Select PADJ with

6. Adjust with

7. Confi rm the voltage of A Board TP-600 is <125 VDC.

8. If step 7 is not satisfi ed, replace the components listed above, then

repeat the above steps.

9. Supply 130 +2.0 / -0.0V to the set with a variable auto transformer.

10. Adjust with

11. Press

MUTING

1

and 4 .

6

to the 0 level.

3

and 6 for 117.0 ± 0.3 VDC.

then

ENTER

to save into the memory.

Y

on the

— 14 —

Page 15

KV-20S90 / 21SE43C

4

D

2

0

6

5

T

5

AMMETER

3mA dc range

A

+

-

Pin 11

T504 FBT

TP600

DIGITAL

MULTIMETER

4

5

0

3

3

R

5

5

1

R

3

2

5

R

3

4

R

5

5

5

3

R

1

1

A

B

L

1

0

9

+

1

3

V

6

4

5

C

TP4

0

3

L O

U

T

5

6

C

T

P50

2

+

13V

4

TP4

0

0

0

2

J

R

O

U

T

4

0

5

T

8

7

6

-

1

C

N

2

5

3

V

ATE

R

H

E

R

4

T

P

5

0

180

V

6

2

0

5

2

5

R

5

4

7

5

R

7

6

R

5

5

1

C

9

9

1

R

5

H

1

Y

D

H

T

P

H

2

C

3

4

T

P

507

2

00V

V

MID

5

3

5

C

5

Q

L

5

0

3

1

1

7

7

2

5

R

E

B

1

7

5

4

5

4

R

4

5

R

5

7

1

5

9

L

5

1

5

R

+

Y

D

+

5

0

6

O

U

T

1

0

5

N

-

Y

D

H

-

Y

D

H

-

Y

D

V

+

Y

D

V

T

P

5

0

8

T

V

O

U

2

0

D

5

I

C

5

1

4

2

5

4

R

4

3

R

5

1

2

7

6

T

P

9

5

1

5

D

2

0

5

D

0

3

D

L

T

P

6

0

0

B

+

5

5

0

0

0

V

5

N

C

C

B

0

R

5

5

0

R

4

0

5

2

C

3

E

0

1

5

Q

1

1

C

5

1

R

3

0

C

0

4

5

C

1

8

0

C

5

5

2

3

+

-

9

4

R

1

6

R

2

R

2

8

0

3

0

2

J

R

2

8

3

2

8

7

7

D

R

5

5

1

5

8

D

R

5

0

8

5

C

X

R582

T

P50

1

-

1

3

V

8

5

7

4

5

D

5

7

C

I

C

5

2

1

5

4

D

4

2

5

C

R

5

8

3

3

7

4

C

5

1

5

DIGITAL

MULTIMETER

POWER

SUPPLY

C574

+

-

+

1SS119

-

Figure 1

— 15 —

Page 16

SECTION 4: CIRCUIT ADJUSTMENTS

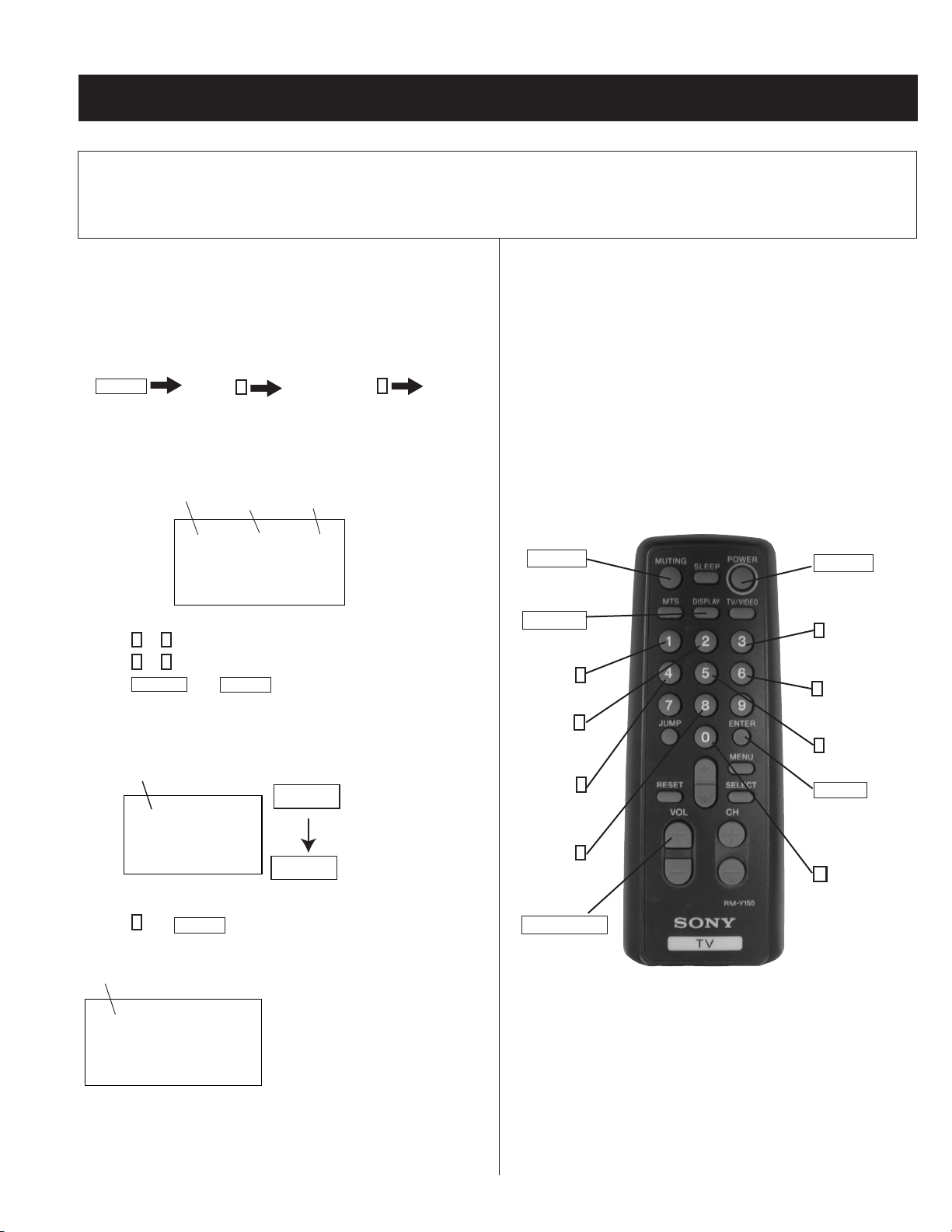

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y155) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

KV-20S90 / 21SE43C

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

Display

Channel 5 Sound Volumne + Power

SERVICE ADJUSTMENT MODE ON

1. The CRT displays the item being adjusted.

Item

Data

0

to write into memory.

2. Press

3. Press

4. Press

then

Display

Item

HSIZ

ENTER

Mode

SERVICE

1

or 4 on the Remote Commander to select the item.

3

or 6 on the Remote Commander to change the data.

MUTING

SERVICE ADJUSTMENT MODE MEMORY

Mode

1. Press

SERVICE

8

then

ENTER

MUTING

WRITE

ENTER

on the Remote Commander to initialize.

Green

Red

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace

the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

MUTING

(Enter into

memory)

DISPLAY

(Service Mode)

1

Disp. (Item up)

2

(Device Item Up)

4

Disp. (Item down)

8

(Initialize)

VOLUME (+)

(Service Mode)

POWER

(Service Mode)

3

Item (Data up)

6

Item (Data down)

5

(Device item down)

ENTER

(Enter into

memory)

0

(Remove from

memory)

Mode

SERVICE RESET

2. Turn set off then on to exit service adjustment mode.

Carry out Step 1 when adjusting

IDs 0-7 and when replacing and

adjusting IC003

RM-Y155

— 16 —

Page 17

ADJUSTMENT ITEMS (1 OF 2)

KV-20S90 / 21SE43C

DATA

Reg # ITEM FUNCTION

1 HSIZ Horizontal Amp. Adjustment 0-31 31 31

2 HPOS Horizontal Position Adjustment 0-31 21 20

3 VBOW Vertical Line Bowing Adj. 0-15 6 6

4 VANG Vertical line Bowing Slant Adj. 0-15 6 6

5 TRAP Horizontal Trapezoid Adj. 0-15 15 15

6 PAMP Horizontal PIN Distortion Adj. 0-31 31 31

7 CPIN SAME AS PAMP-SCRN TP/BTM 0-31 31 31

8 VSIZ Vertical Amp. Adjustment 0-31 43 37

9 VPOS Vertical Position Adj. 0-31 35 38

10 VLIN Vertical Linearity Adj. 0-15 7 7

11 SCOR Vertical Amount Adj. 0-15 7 7

12 VZOM Vertical Zooming 0,1 0 0

13 EHT Vertical High-Voltage Correction 0-15 15 4

14 ASP Aspect Ratio Control 0-63 47 47

15 SCRL 16:9 CRT Z Mode Trans. Scroll 0-31 31 31

16 HBLK RGB Out Width Control 0,1 1 1

17 LBLK Left Screen HBLK Control 0-15 15 15

18 RBLK RGT Screen HBLK Control 0-15 3 3

19 VUSN V Saw Waveform Compress 0,1 0 0

20 HDW Horizontal Drive Pulse Width 0,1 1 0

21 EWDC EW/ D.C. Adjustment 0,1 0 0

22 LVLN Lower Screen BTM Vertical Line Adj. 0-15 0 0

23 UVLN Upper Screen Top Vertical Line Adj. 0-15 0 0

24 RDRV R Output Drive Control 0-31 30 27

25 GDRV G Output Drive Control 0-31 24 22

26 BDRV B Output Drive Control 0-31 21 22

27 RCUT R Output Cutoff Control 0-15 10 9

28 GCUT G Output Cutoff Control 0-15 7 4

29 BCUT B Output Cutoff Control 0-15 7 4

30 DCOL Dynamic Color On/Off 0,1 0 0

31 SHUE Sub HUE 0-15 15 18

32 SCOL Sub Color 0-15 14 18

33 SBRT Sub BRIGHTNESS 0-15 7 10

34 RON R Output On/Off 0,1 1 1

35 GON G Output On/Off 0,1 1 1

36 BON B Output On/Off 0,1 1 1

37 AXPL Axis PAL 0,1 0 0

38 AXNT Axis NTSC 6.00 ± 0.8 0 0

39 CBPF Chroma BPF On/Off 0,1 1 1

40 CTRP Y TRAP FILTER On/Off 6.00 ± 0.9 0 1

41 COFF Color On/Off 0,1 0 0

42 KOFF Set Color Killer 6.00 ± 0.8 0 0

43 SSHP Sub SHARPNESS 0-15 9 6

44 SHPF SHARPNESS Circuit Fo 0,1 1 1 *

45 PREL Pre-Shoot / Over-Shoot Switching 0,1 1 1

46 Y-DC Axis NTSC 0,1 1 1

47 GAMM Chroma BPF On/Off 0,1 0 0

48 VTH Color On/Off 0,1 1 1

49 ABLM ABL Control Mode 0,1 1 1

50 YDEL Set Color Killer 0,1 7 7

51 NCOL Sub Sharpness 0-15 1 1

RANGE

INITIAL

DATA VIDEO

AVERAGE

* = TV/VIDEO = 0

DATA

— 17 —

Page 18

ADJUSTMENT ITEMS (2 OF 2)

KV-20S90 / 21SE43C

DATA

Reg # ITEM FUNCTION

52 FSC G Output On/Off 0,1 0 1

53 K-ID B Output On/Off 0,1 0 0

54 HOSC Horizontal VCO Oscillation Freq. 0-15 10 7

55 VSS Vertical Sync Slice Level 0,1 0 0

56 HSS Horizontal Sync Slice Level 0,1 0 0

57 HMSK HMASK On/Off 0,1 1 1

58 VTMS Select Signal VTIM Pin 0-3 0 0

59 CDMD Vertical Count Down Mode Switching 0-3 3 3 **

60 AFC AFC Loop Gain Switching 0-3 0 0 *

61 FIFR Field Frequency 0-3 3 3

62 SBAS Sub Bass 0-15 8 8

63 STRE Sub Treble 0-15 9 9

64 SBAL Sub Balance 0-15 13 13

65 DISP O.S.D Display Position 0-127 15 5

66 PADJ POWER ADJUSTMENT 0-63 51 42

67 HCHM H SYNCH SEP. LIMIT FOR TUNER 0-127 69 69

68 HCLM H SYNCH SEP. LIMIT FOR TUNER 0-127 16 16

69 HCHS H SYNCH SEP. LIMIT FOR VIDEO 0-127 69 69

70 HCLS H SYNCH SEP. LIMIT FOR VIDEO 0-127 16 16

71 ID0 0-255 SEE ID MAP

72 ID1 0-255 SEE ID MAP

73 ID2 0-255 SEE ID MAP

74 ID3 0-255 SEE ID MAP

75 ID4 0-255 SEE ID MAP

76 ID5 0-255 SEE ID MAP

77 ID6 0-255 SEE ID MAP

78 ID7 0-255 SEE ID MAP

RANGE

INITIAL

DATA VIDEO

AVERAGE

DATA

* = TV/VIDEO = 0

** = TV = 0, VIDEO = 1

Notes:

Mode

No. 1-78 show the order that each adjustment mode may be selected while in Service Mode.

Data Range shows the range of possible setting for each Adjustment Mode.

Initial Data shows the standard settings for each Adjustment Mode.

Function

SERVICE

ID0 25

Data

ID MAP

Model Destination ID-0 ID-1 ID-2 ID-3 ID-4 ID-5 ID-6 ID-7

KV-20S90 US 25 3 1 227 3100

KV-21SE43C E 17 3 1 195 115 1 0 0

4-4. A BOARD ADJUSTMENTS

H. FREQUENCY ADJUSTMENT

1. InputTV mode (RF) with no signal.

2. Set to Service Adjustment Mode.

3. Connect a frequency counter to base of Q501

(TP-500 H. DRIVE).

4. Check H. Frequency for 15735 ± 200 Hz.

5. Press

MUTING

then

ENTER

to save into the memory.

— 18 —

Page 19

V. FREQUENCY CHECK

1. Select video 1 with no signal input.

2. Set the conditions for a standard setting.

3. Connect the frequency counter to TP-508 or CN501 pin

connector and ground.

4. Check that V. Frequency shows 60 ± 4 Hz.

6

SUB CONTRAST ADJUSTMENT (RDRV)

(V DY+)

KV-20S90 / 21SE43C

DISPLAY POSITION ADJUSTMENT (DISP)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

3. Select DISP with

4. Adjust values of DISP with

5. Write to memory by pressing

6. Check to see if the text is displayed on the screen.

1

and 4 .

3

and 6 to adjust characters to the center.

MUTING

then

ENTER

.

1. Input a color-bar signal.

2. Set the red color on (1).

3. Set in Service Adjustment Mode.

4. Select the item DCOL level to 0.

5. Set the conditions as follows:

PICTURE: MAX

COLOR: MIN

BRIGHT: CENTER

R ON: ON (1)

G ON: OFF (0)

B ON: OFF (0)

Mode

SERVICE

6. Connect an oscilloscope probe to CN301 pin

ground .

1

7. Select RDRV with

8. Adjust the value of RDRV with

1.50 ± 0.05 Vpp.

and 4 .

Display

Item

RON

3

and 6 for

White

1.50 ± 0.05 Vpp

1: ON

0: OFF

26

2

(Red Out) and

Mode

SERVICE DISP 15

Display

Item

Item

Data

SUB BRIGHT ADJUSTMENT (SBRT)

1. Input a crosshatch signal.

2. Set to Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Select the SBRT item with

5. Adjust the values of SBRT with

crosshatch.

6. Press

MUTING

then

1

and 4 .

ENTER

3

and 6 to obtain a faintly visible

to save into the memory.

SUB HUE, SUB COLOR ADJUSTMENT (SHUE,

SCOL)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

3. Connect a probe to TP47B B-OUT (C Board).

4. Measure white V1 and blue V4.

4.1) Increase SCOL Register +1 setp.

Black

9. Reset the item DCOL to 1.

10. Press

11. Return the following back to normal after adjustment.

PICTURE: MAX

COLOR: CENTER

BRIGHT: CENTER

R ON: ON (1)

G ON: OFF (1)

B ON: OFF (1)

MUTING

then

ENTER

to save into the memory.

5. Press

— 19 —

STANDARD

|V4 - V1| = ± 0.2Vpp

|V3 - V2| = ± 0.2Vpp

MUTING

then

V1

ENTER

V2 V3

to save into the memory.

V4

Page 20

KV-20S90 / 21SE43C

V. SIZE ADJUSTMENT (VSIZ)

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VSIZ item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

1

and 4 for the best vertical center.

to save into the memory.

ENTER

V. CENTER ADJUSTMENT (VPOS)

1. Input a crosshatch signal.

2. Set to Service Adjustment Mode.

3. Select the VPOS item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

3

and 6 for the best vertical center.

ENTER

to save into the memory.

SERVICE ADJUSTMENT MODE MEMORY

1. Change the value of the DCOL item to 1.

ENTER

0

2. After completing all adjustments, press

Read From Memory

Mode

SERVICE READ

then

.

Green

0

Red

ENTER

H. CENTER ADJUSTMENT (HPOS)

Perform this adjustment after performing H. Frequency.

1. Input a crosshatch signal.

2. Set to Service Adjustment Mode.

3. Select the HPOS item with

4. Adjust the value of HPOS with

5. Press

MUTING

then

1

and 4 .

3

and 6 for the best horizontal center.

ENTER

to save into the memory.

V. LINEARITY (VLIN), V. CORRECTION

1. Input a crosshatch signal.

2. V.Correction is automatically adjusted from the circuit and should

satisfy the conditions below.

V LINEARITY (VLIN)

V CORRECTION

— 20 —

Page 21

5-1. CIRCUIT BOARDS LOCATION

SECTION 5: DIAGRAMS

Circled numbers are waveform references.

The components identifi ed by

been carefully factory-selected for each set in order to satisfy regulations

regarding X-ray radiation. Should replacement be necessary, replace

only with the value originally used.

KV-20S90 / 21SE43C

X

in this basic schematic diagram have

C Board

A Board

5-2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. K=1000, M=1000k

Indication of resistance, which does not have one for rating electrical

power, is as follows:

Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

: nonfl ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10M digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

All voltages are in V.

S : Measurement impossibillity.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

1

W and 1/

10

/

W

4

W in chip resistance.

8

When replacing components identifi ed by

Y

, make the necessary

adjustments as indicated. If the results do not meet the specifi ed value,

change the component identifi ed by

X

and repeat the adjustment until

the specifi ed value is achieved. (Refer to Safety Related Adjustments

on Page 14.)

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

Part Replaced ( )

DY, C511, C574, C575, D572,

D573, D574, R582, R583, R584,

R585, R586, R578, R625, R626,

R640, R635,T504, IC301, IC521,

IC602.............................A Board

Adjustment ( )

HV HOLD-DOWN

R582

REFERENCE INFORMATION

RESISTOR : RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL : LF-8L MICRO INDUCTOR

CAPACITOR : TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

Les composants identifi es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero specifi e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

!

sont critiques pour la

— 21 —

Page 22

5-3. BLOCK DIAGRAM AND SCHEMATICS

BA4D-905-BD

BLOCK DIAGRAM

KV-20S90 / 21SE43C

ANTENNA

BLOCK

FRONT A/V

(INPUT)

REAR A/V

(INPUT)

IN

DGC

DGC

AC

VIDEO OUT

VIDEO

AUDIO

VIDEO

AUDIO

J202

TU101

R OUT

L OUT

VCC 5V

VCC 30V

AFT OUT

J201

3P

3P

VCC 9V

CLOCK

RF AGC

CN402

1

AUDIO SWITCH

1

2

S1

3

V1-L

S2

4

5

+5V

+9V

MUTE

+30V

V2-L

DAT

AGC

Q252

V

L

TO V1-L

R

TO V1-R

V

L

TO V2-L

R

TO V2-R

5

IC003

VOLUME-

VOLUME+

CHANNEL-

CHANNEL+

TV/VIDEO

DEMO

POWER

DETECTOR

21

IC004

STAND-BY/TIMER

D002

B-DAT

6

B-CLK

S005

S004

S003

S002

S006

S007

S001

F601

NVM 1K BIT

MEMORY

CN203

B CLK

B DAT

B INT

STBY

+5V

CN601

2

1

CN602

2

1

+12V RY601

+9V +5V

7

34

I-AFT

O-AGC

TO S1

O-VO

10

11

O-V1

TO S2

38

O-BCLKN

36

IO-BDAT

31

I-BINTN

33

I-KEY

CLOSED CAPTION

CONTROL

TUNING SYSTEM

14

I-POWERN

12

I-RMCN

18

O-LED

O-DGC

39

37

IO-SDAT

IO-SCLKN

IC001

O-RELAY

613

T601

RELAY DRIVER

Q606,670

+7.5V RY602

5V REG

DGC RELAY

Q601

Q650

IC201

I-HSYNC

I-CVIN

O-OSDBLK

I-RESET

I-AVCC

O-MUTE

O-VOL

I-PROT

7

AUDIO SWITCH

1

2

S1

3

V1-R

S2

4

5

V2-R

7

IC202

B OUT

VIDEO

BUFFER

Q205

43

TV/C2

4

CVBS1/Y1

34

SCL

Y.CHROMA.JUNGLE

35

SDA

CVBS2/Y2

41

IC301

G OUT

R OUT

IK IN

VD-

5

PWM-DC/VOLUME

3

16

17

22

52

O-R

O-G

51

50

O-B

49

2

I-VPN

H.SYNC.

BUFFER

Q305,391

SEP.

Q001

Q203

BUFFER

SW

Q390

MONOUT

6

R2IN

32

G2IN

31

B2IN

30

29

YS2/YM

5

VTIM

VD+

ABL IN

AFCFIL

HD

HP/PROTECT

1

I-HP

30

19

4

O-ADJ

24

I-DSC

O-DSC

CF001

8MHZ

25

Q607

Q608

D601

AC RECT

R660

3 2

IC601

4

1

PIT

T604

1

3

4

5

6 8

T603

2

4

3

5

7

8910

3

PH600

PC123FY2

2

10

11

9

14

15

13

11

12

124

D636

7.5V RECT

D615

+B RECT

D616

AUDIO VCC

D617

12V RECT

+B

AUDIO VCC

12V

POWER

CONTROL

IC602

31

3

5

AUDIO OUT

IC401

1

7

24

23

22

+B

21

14

1

DRIVER-

7

DRIVER+

13

3

20

19

18

Q002,003

HP

SET 7.5V

STBY +5V

18

9V-REG

Q605

13

11

10

8

BUFFER

Q303

V.OUT

IC541

BUFFER

H DRIVE

BOOST

Q556

Q501

HP/PROT

Q300

H COMP

Q602

REF

36

6

REG.

IC002

SET +9V

STANDBY

V. BOOST

+5V

BUFFER

Q394

BUFFER

Q393

BUFFER

Q392

IK-BUFFER

Q301,302

V OUT

OUT

5

V DRIVE

+B

+13V

TP508

V MID

TP507

D502

H OUT

TP506

D502

T501

H OUT

Q502

SWITCH

D581

V.CONTROL HOLD

SWITCH

D507

7

H DRIVE

TP504

+180V

OCP

Q571

IC521

H-PROT

TP503

H-PROTECT

5

6

HOLD DOWN

REF.

D573

D574

TP501

-13V

TP502

+13V

+B

TUNING CONTROL, Y/C/J

POWER SUPPLY,DEFLECTION,

TUNER/IF,AUDIO,MTS

2

CN401

1

2

CN301

B

4

G

3

R

2

1

IK

CN501

6

5

4

3

2

1

+180V

RECT

D552

-13V

RECT

D561

+13V

RECT

D562

SP902

SPEAKER

HEADPHONE

CN1752

(L)

J400

SPEAKER

115V

SP901

(R)

CRT AMP

V DY(+)

4

3

2R

1IK

1

2

3

B IN

G IN

R IN

REFERENCE

IC1751

B OUT

G OUT

R OUT

VIP

RGB DRIVE

{

CRT DRIVE

B

G

DY ASSY

KB

9

KG

8

KR

7

IK

5

CN1754

1

}

HG2FV

20NX

PICTURE TUBE

HV

V DY(-)

H DY(-)

H DY(+)

T504

FBT

HV

1

4

2

7

8

9

FV

G2

ABL

11

HEATER

6

6

5

CN502

HV

FV

G2

— 22 —

Page 23

A BOARD SCHEMATIC DIAGRAM

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 |

A

C

T

G

U

A

O

T

U

F

F

O

R

I

C151

47

25V

:CI

L151

:CHIP

T

U

V

O

9

T

C

C

F

C

N

A

V

10 15

FSS BTF-WA412

—

B

—

C

—

TP100

STEREO

2SD601A

V

V

0

9

3

C

C

C

C

V

V

1

E

V

L

K

5

B

A

C

A

T

O

C

N

A

L

C

E

D

C

V

5

RF-AGC

C222

C150

10

470

:CI

16V

:CI

L150

R291

:CHIP

4.7k

TP101

Q252

AGC

R293

10k

30V

R150

100

:ZZ-CP

R151

100

:ZZ-CP

C160

100

16V

:CI

L160

:CHIP

SET-5V

D

—

E

—

F

—

D205

MTZJ-T-77-30D

:40

SET-5V

C226

4.7

160V

:CI

+B

MTZJ-T-77-5.6C

C653

47

25V

:CI

9V

Q650

2SD1292-T103

5V REG

R650

680

:RD

D650

:40

R253

15k

2W

:RS

TP602

SET-5V

R242

22k

9V

0.0047

C651

100

16V

:CI

2SB709A-QRS-TX

+5V

C006

0.047

C007

220p

CH

STBY+5V

G

—

H

—

I

7.5V

—

D002

J

—

K

—

L

—

M

—

N

—

O

—

TO AC

CONNECTOR

(5.0MM)

(5.0MM)

R659

JW690

JW691

1.8

10W

(5.0MM)

SBX3081-71

R060

JW

R643

4.7k

R682

4.7k

R652

*

CN601

2P

IC004

SIRCS

R043

+B

1k

:RD

2SD774-T-34

RELAY DRIVER

W

1

2

R671

2

5

7

6

R

123

R061

JW(5.0MM)

C004

47

25V

:CI

2.2k

R683

Q606

2SD1292-T103

PROTECT

D601

D3SB60F

D670

1SS133T-77

RY602

C638

4

0.47 125V

F601

*

1

C

A

4700pF

VDR601

C604 C605

C603

*

250V*250V

250V

1

23

R620

2.2M

1/2W

C601

*

TO

DGC

C602

4700pF

250V

T601

:LFT

2

C

A

LED UNIT

STAND-BY/TIMER

Q670

R670

2.2k

C633

47

1k

C643

0.0047 250V E

D631

ERC04-06S

D632

ERC04-06S

C646

C613

*

R698

R664

*

R672

5.6k

3W

R661

5.6k

3W

THP601

*

1

2

CN602

C

C

G

G

D

D

450V

*

R660

0.47

1/2W

R688

5.6k

3W

R658

** 125V

R651

*

C618

680p

1.5kV

C628

100

25V

2P

P

C

N

A

I

C

C

G

G

D

D

C

N

TU101

R391

1k

R243

33k

C243

H SYNCH SEP

R284

0

C644

0.0047

250V

10

RY601

2SD601A-QRS-TX

Q001

R077

100k

CHIP

R076

1M

E

S

C647

2SC3311A-QRSTA

C616

*

D609

*

C617

*

FB600 FB601

1.1UH 1.1UH

H

U

1

.

1

4

0

6

B

F

TP102

DET OUT

Q390

BUFFER

R075

10k

CHIP

C078

470p

R001

10k

CHIP

R280

:ZZ-CP

STBY+5V

2SK2845-LB102

CONVERTER

470p

R612

680

Q608

R616

6.8

1/2W

D615

p

0

7

4

0

2

6

C

2

T

U

O

T

E

D

R390

100

CHIP

R096

2.2k

CHIP

B

75

D001

MTZJ-T-77-5.1C

Q607

SW

D613

R655

0.22

2W

T

D

U

D

E

O

E

L

L

T

P

E

T

A

D

S

S

20 25

V

I

D

E

O

R078

1k

CHIP

:40

R073

3.3

R602

R617

680

C614

0.001

IC601

*

CONVERTER

FB602

1.1UH

R663

D602

1SS133T

1

2W

E

D

O

M

MAIN

R097

2SD601A

C200

4.7

C648

0.001

500V

MTZJ-T-77-6.2C

12345

R674

O

N

O

M

F

:ZZ-CP

10k

25V

:CG

R608

22M

1/2W

B

680

R101

10

10k

Q003

D

M

S

HP

1SS133T-77

D637

2SC3311A

E

T

U

M

C101

4.7

:CI

:ZZ-CP

Q002

2SD601A

HP

MTZJ-T-77-10B

R050

C005

R005

VOL-

:PU-Z

R609

2.2k

D634

R614

10k

C621

470p

Q601

SW

:1B

T

T

T

U

U

U

O

O

O

S

R

L

AUDIO

R252

470

:ZZ-CP

Q205

BUFFER

:ZZ-CP

:0B

R099

C017

:CI

VIDEO

R017

470k

820

:RD

:PU-Z

R008

220

:ZZ-CP

4.7k :RD

220 :RD

R072

0.0022 B:CC-CP

R013

1

R016

CH-

R251

470

:ZZ-CP

R009

C062

C014

R040

R038

CH:CC-CP

VIDEO

22k :RD

C047

220p

CH:CC-CP

2.2k

:RD

C228

R055

220

470p B:CC-CP

C028

470p B:CC-CP

R007

100 :ZZ-CP

220

0.1 25V B:CC-CP

C055

100p CHIP

470 :RD

1k :ZZ-CP

0.001 B:CC-CP

470 :RD

X001

15pF

CH:CC-CP

CH+:

PU-Z

10

:CI

CH:CC-CP

C060

C048

C019

560p CH:CC-CP

C091C092

15pF

R020R021 R022 R023

6.8k

:RD

TV/V

:PU-Z

C001

220p

:ZZ-CP

C232

1

:CI

V1

IC001

CONTROL

2

SET 9V

O-OSDBLK

0-ANTSW

0-BBE/MB

I-STEREN

0-HSYNCSW

IO-SCLKN

IO-BCLKN

IO-SDAT

1

IO-BDAT

0-MARKER

I-AFT2

I-BINTN

I-RESET

NJM78LR05BM-TE2

I-SSW

0-MONO

O-SAP

0-SRS2

O-SRS1

I-AFT

I-KEY

VO

O-YM

O-R

O-G

O-B

Vcc

IC002

STBY 5V

5

2

5

1

5

0

4

9

4

8

NC

4

7

4

6

4

5

4

4

4

3

4

2

4

1

4

0

3

9

3

8

3

7

3

6

3

5

3

4

3

3

3

2

3

1

3

0

2

9

2

8

2

7

C037

0.0022 B:CC-CP

C013

0.001

B:CHIP

R032

R046

R033

1000p B:CC-CP

VIDEO

M37273MF-255SP

TUNING SYSTEM

1

I-HP

2

I-VPN

3

O-VOL

4

O-ADJ

5

O-MUTE

6

O-RELAY

7

0-AGCMUTE

8

0-SPSW

9

O-CHBLK1

1

0

O-V0

1

1

O-V1

1

2

I-RMCN

1

3

O-DGC

1

4

I-POWERN

1

5

O-VMLV

1

6

I-HSYNC

1

7

I-PROT

1

8

O-LED

1

9

I-AVCC

2

0

I-HLF

2

1

I-VHOLD

2

2

I-CVIN

2

3

I-CNVSS

2

4

I-DSC

2

5

O-OSC

2

6

Vss

R031

680

S001

POWER

PU-Z

R090

10k

:RD

S007S006S002S005 S004 S003

DEMO

PU-Z

9V

2SB709A

R254

100

:ZZ-CP

R086

10k

:ZZ-CP

R085

10k

R092

1k

CHIP

D210

10k :RD

4.7k

R093

R074

10k

1

CHIP

220 CHIP

L003

:CHIP 220 :ZZ-CP

C046

47

25V

:CI

C020

0.1

:CQ

680

:RD

VOL+:

PU-Z

7.5V

C691

470

25V

:CI

1

3

4

5

6 8

R647

33

1/2W3.3k

FB609

0UH

PH600

PC123FY2

4

3

10k :RD

+B

T604

STBY+5V

2

10

11

D636

9

T603

*

2

4

3

5

7

8

1

2

C654

330

C611

0.001

2kV

14

15

13

11

S2L20UF

12

10

9

D617

R630

D616

S3L20UF4

C657

680p

500V

C641

680p

500V

AUDIO VCC

R634

1k

R648

2.2k

RU4AM-T3

B

2.2k :RD

D653

FB605

1.1UH

FB606

1.1UH

C632

1000

25V

+B

FB611

1.1UH

C634

100

160V

L200

JW(5mm)

C631

2200

R662

16V

0.47

3

2

IC602

ERROR AMP

:HD

SYBY+5

C645

0.01

R603

250V

470k

D633

ERA22-08TP3

D635

1SS133T-77

R611

C650

47k

0.001

1k

R610

D638

C656

D1N20R-TA

22

R644

1.2k

R657

D603

R656

1.5k

D614

C622

0.001

12V

R631

R

G

B

R028

C050

100p

CH:CC-CP

220p CH

C011

CH:CC-CP

R011

C074

100p CH:CC-CP

220 :ZZ-CP

220 :ZZ-CP

220 :RD

C065

T

U

P

T

U

O

T

U

P

N

I

1 2 3 4

C623

0.01

1

TV

1k CHIP

CH:CC-CP

C072

220p

R051

220 :CHIP

220 :CHIP

10k

R091

R044

R003

R018

100 :ZZ-CP

MTZJ-T-77-5.6C

C038

470

25V

:CI

R056

C

T

/

E

N

S

E

R

C

/

D

N

C

C690

0.47

AUDIO VCC

R640

47k

R635

10k

12V

R623

10k

C204

10

25V

5.6k :RD

R025

5.6k :RD

R026

R027

5.6k :RD

1SS133T-77 :4A

C027

220p

R010

220

D004

220 :ZZ-CP

1k :RD

R048

R054

D038

:40

4.7k :RD

5678

D

N

G

C692

C

/

N

:CI

R639

47k

C630

0.01

FRONT A/V

HP

L001

D003

1SS133T-77

R004

R045

R047

47k :ZZ-CP

10k :ZZ-CP

C034

0.022

B:CC-CP

L002

TP001

47

25V

:CI

C693

0.47

:CQ

B

J202

3P

MTZJ-T-77-10B

AUDIO

R030

10k

:RD

R070

4.7k

R241

4.7k

R071

4.7k

10k

4.7k

4.7k

R049

:CHIP

C626

0.47

:CI

R637

10k

R636

4.7k

+B

R679

470

R626

100k

:RN

R625

2.2k

:RN

KV-20S90 / 21SE43C

CN203

4P

:ZZZ

E

B INT

B DAT

B CLK

V

L

L

D203

:40

NJM2521M-TE1

L-SWITCH

1

TV-L

2

V1-L

3

4

B:CC-CP

IC201

S1

S2

0.001

:HT

C203

C205

1

C234

10

R

C206

1

MTZJ-T-77-10B

C236

0.01

CHIP

GND

L-OUT

V+

V2-L

V

R205

470k

R204

75

:CHIP

MTZJ-T-77-10B

D209

:40

4

R206

470k

D204

ESD

R295

0

CHIP

R289

0

CHIP

8

7

6

5

9V

VP

R400

22k

CHIP

R089

680

:ZZ-CP

R019

4.7k

:RD

D403

C077

100p

CH:CC-CP

R087

:ZZ-CP

R057

R058

IC003

M24C08-MN6T(A)

MEMORY

AO

1

A1

2

A2

3

VSS

4

1SS133 :4A

680

4.7k :ZZ-CP

4.7k :ZZ-CP

B-CLK

B-DAT

R433

C418

12k

10

R432

12k

D434

1SS133

R088

680

:ZZ-CP

C039

10

:CI

8

VDD

7

6

5

R066

220

:ZZ-CP

VIDEOVIDEO

AUDIO VCC

R633

33k

:RN

Q501

2SC3209LK-TP

H DRIVE

R632

10k

Q602

2SD601A

BUFFER

R638

22k

:1B

R502

4.7k

3W

C502

0.015

200V

:CA

14

C504

470p

500V

TP500

H.DRIVE

B:CC

13

R501

2.2k

:RD

12V

<FOR JIG>

1

3

2

J201

3P

REAR A/V

R294

0

CHIP

R288

0

CHIP

R298

100

AUDIO

C233

1

V

2

1

SDA

R065

220

:ZZ-CP

12V

T501

:HDT

3

2

1

9V

C

C

V

O

I

D

U

A

9V

6

R504

(7.5MM)

4

TP601

SET+9V

R002

10k

:RD

JW

9V

R

G

VIDEO

C505

2000pF

1.2kV

MTZJ-T-77-10B

B

C509

330p

C508

0.015

200V

:CA

16

15

TV R

D201

C312

1000

R324

4.7k

:RD

2kV

:CC

0.45UH

:40

25V

FB501

9V

2SD2624

H OUT

:E

Q305

2SB709A

BUFFER

:0B

3900pF

1.2kV

Q502

9V

R641

R649

4.7

470

3W

:RD

:RS

D611

MTZJ-T-77-10B

:40

V

V

C201

:CI

V2

TV

HP

C311

0.01

B:CC-CP

X301

:SV

C301

18p

CH:CC-CP

R394

100

C507

Q605

2SD2137-OP-TA

9V REG

:1D

C629

100

25V

:CI

A

L

1

NJM2521M-TE1

1

TV-R

2

S1

3

V1-R

S2

4

VP

R255

100 :ZZ-CP

Q391

2SD601A

BUFFER

:1B

R393

1k

:ZZ-CP

+B

ERC06-15S

R

R202

470k

:CHIP

C202

1

MTZJ-T-77-10B

:ZZ-CP

R201

470k

IC200

R-SWITCH

8

GND

7

R-OUT

6

V+

V2-R

5

VOL 5V

9V

C320

0.47

R319

10k

:ZZ-CP

C375

0.1

25V

F:CC-CP

1

2

3

L

L

L

A

A

A

T

T

T

X

X

X

N

I

D

L

E

1

B

P

A

A

C

1 2 3 4 5 6 7 8 9

R392

100

:ZZ-CP

0 :RT

L302

:CHIP

C376

47

25V

:CI

R301

C303

10

:CI

D501

JW510 JW511

(12.5MM) (12.5MM)

E

V

I

R

D

1 2 3 4 5 6 7

R546

470

2W

:RS

R549

R544

4.7

2W

:RS

R548

4.7k

:RD

R543

10k

:RD

10k :ZZ-CP

1

Y

/

1

S

B

V

C

VIDEO

D202

ESD

L

I

F

C

P

A

+

C

C

V

R297

100

C321

470pF

V

I

D

E

O

C319

3

2

C

C

V

T

U

M

O

I

N

T

O

V

M

4

F

E

R

C541

220

:CI

C542

47

:CI

4.7

:CI

2

L

2

C

I

Y

/

F

/

V

L

2

T

B

S

A

B

V

C

P

C

M

B

A

M

L

O

C

C

Y

C305

0.1

25V

5

B:CC-CP

C306

0.1

25V

B:CC-CP

9V

IC541

AN5522 V OUT :HN

-

18

17

C

C

V

R547

2.2

:RD

AUDIO

AUDIO VCC

HP

R

1

C

C

V

G

E

R

C308

10

:CI

G

P

C

C

C

7

8

:

1

1

B

3

3

C

C

1

0

.

0

N

N

I

I

2

2

T

R

G

C

E

T

O

R

P

P

/

C

P

S

H

9

8

R311

JW (5MM)

C556

0.0022

R568

1M

Q556

2SD601A-QRS-TX

BUFFER

C561

220p 500V B:CC

C562

470

RGP15GPKG23

25V

:CI

1SS133T-77

R584

10k

:ZZ-CP

TP503

H.PROT

R585

33k

B

P

C

P

-

C

C

-

C

C

6

:

C

1

B

:

3

B

C

R316

1

100

0

1

.

0

:ZZ-CP

0

.

0

N

N

M

I

I

Y

2

1

/

B

R

2

S

Y

L

I

F

N

C

I

D

F

K

A

H

I

C309

0.01

CHIP

R307

4.7k

:CHIP

C310

1

R310

:CI

1k

:ZZ-CP

+B

B

R566

15k

R567

4.7k

D561

:4G

D581

:4A

R577

18k

R583

100k

:ZZ-CP

C573

4.7

:CI

C574

4.7

EGP20DPKG23

160V

:CI

C577

0.47

:CI

P

P

C

C

-

-

Z

Z

Z

Z

:

W

S

V

U

Y

Y.CHROMA.JUNGLE

+

D

V

7

1SS133T-77

TEMP CORR

3

7

5

D

0

0

1

0

3

3

R

A

D

S

IC301

CXA2133BS

D

M

V

V

2SD601A-QRS-TX

HP PROTECT

B:CC-CP

UDZ-TE-17-5.1B

D572

:4A

B

2

N

.

W

8

R579

0

O

-

4

D

7

620

:

7

D

:ZZ-CP

-

L

T

O

H

J

Z

T

M

:

0

0

1

1

3

3

R

L

C

S

Q300

:1B

C313

0.01

R318

10k

D320

R578

56k

2W

L301

:CHIP

2

D

N

G

Y

B

1

M

D

O

N

C

G

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

R304

10k :ZZ-CP

T

S

O

O

OUT

B

C373

C374

0.1 25V

470

16V

:CI

N

N

N

I

I

I

Y

Y

Y

E

-

-

B

R

E

E

F

E

W

R

E

I

R306

10k

6

:RN-CP

C511

0.33

250V

+

E

V

19

I

R

D

TP501

IC521

V HOLD OUT

-13V

+13V

:HA

+VCC

8

OUT2

7

IN-2

6

IN+2

5

R541

R542

4.7k

10k

:ZZ-CP

:RD

C543

0.22

:CQ

D541

GP08DPKG23

:4A

TP502

NJM4558M-TE2

OUT1

1

IN-1

2

IN+1

3

-VCC

4

10

0.001

R561

R582

:CHIP

T

U

O

R

C314

CHIP

1

1W

R576

100k

68k

D574

B:CC-CP

+

2

-

-

1

IC401

TDA7057AQ/N2

AUDIO AMP

R230

10k

:CHIP

R234

3.3k

:CHIP

C214

0.22

R231

10k :CHIP

R235

AUDIO

3.3k

:CHIP

C215

0.22

:CI

12V

VOL 5V

R356

2.2k

:ZZ-CP

252627282930313233343536373839404142434445464748

1

N

N

S

I

I

Y

1

1

G

B

12

11

T

T

U

U

O

O

G

B

R312

GB

220

:ZZ-CP

R315

220 :RD

R314

220 :RD

R313